AUTOTRIP

RCD TESTER

USER MANUAL

Safety information and explanation of symbols used

Caution read this manual for important safety information

The AUTOTRIP must only be used by suitably trained or competant

persons.

Before using the AUTOTRIP please read and fully understand these instructions paying

particular attention to the safety warnings. Do not use this tester in a manner other than

that described in this booklet.

Check the instrument case and test leads for damage before each use. If any

damage is noticed the unit should be withdrawn from service and returned to

place of purchase for repair.

The battery cover must be fitted and secure before using the instrument.

Always verify the continuity of the protective earthing conductors and

equipotential bonds before carrying out RCD testing.

Do not operate the meter around explosive gas, vapor, or dust.

Do not apply more than the rated voltage, (300V) as marked on the meter,

between terminals or between any terminal and earth ground.

The AUTOTRIP is rated at 300V Category III.

Exposed metal work in the installation should not be touched during testing.

Ensure when handling test probes and crocodile clips that fingers are always

behind the protective guards.

Do not change ranges by turning the rotary knob while a test is in progress.

Please note the polarity LED indicator is not able to determine N-PE supply

reversal.

Always perform a relevant risk assesment before testing and concider any

critical equipment and loads that maybe connected on the circuit under test

which will be turned off by tripping the RCD.

Symbols marked on the equipment

Caution refer to instruction manual and accompaning notes

Double Insulation

Equipment complies with current EU directives

ACMA mark

Batteries

Do not switch the instrument on or use it with the battery cover removed.

When installing batteries observe correct polarity do not mix old and new

batteries.

Dispose of used batteries in accordance with local regulations.

Never incinerate batteries.

For safety reasons the tester is shipped without batteries fitted.

To install or replace batteries

Replace batteries as soon as the low battery indication appears.

Switch the instrument off and disconnect from any electrical circuits.

Remove test leads.

Remove the small crosshead screw on the back of the instrument that retains

the battery cover and fit four Alkaline batteries type AA / LR6 in accordance with

the polarity shown.

Replace the battery cover and ensure it is secure before use.

The batteries should not be left in the instrument if it will not be used for an

extended period.

Overheating

Repetitive testing may generate heat within the instrument. If this occurs the hot

symbol is displayed and the instrument should be left to cool down before further

testing.

Maintenance

To clean the tester wipe with a damp cloth with a mild soap solution taking care

not to allow water ingress into the input terminals. Do not use solvents and do

not immerse. Allow the tester to fully dry before use.

Features of the AUTOTRIP

The AUTOTRIP is packed with design features that maximize both convenience and

safety. These include:

Large LCD display

To give the clearest results the AUTOTRIP uses a large auto-backlit LCD which

makes reading the test results easy even when used in poorly lit areas.

Auto shut down

To preserve battery life when not in use the AUTOTRIP incorporates an Auto-Off

function that powers the unit down after three minutes of inactivity. To resume

use after an Auto shut down a single press of any of the function buttons will

power up the unit.

Battery check

The battery charge condition is indicated on the LCD display.

For simplicity the tester is powered by just four conventional AA (LR6) alkaline

batteries.

Easy to locate

The test lead inputs are located on the top of the case allowing the tester to

stand vertically or be laid flat.

Hands Free

Most of the test functions can utilise the Hands-Free mode in which the tester

is primed to automatically start the test as soon as the probes are connected to

a circuit, thereby leaving your hands free to hold the test probes.

Socket wiring check

To protect both the user and the instrument against harm caused by accidental

connection to an incorrectly wired supply the tester will automatically check the

polarity upon connection to a live supply. If the wiring has been incorrectly

connected testing will be inhibited an alarm will sound along with a flashing red LED.

Please note the polarity LED indicator is not able to determine N-PE supply reversal.

Pass Fail Result

In addition to displaying the time taken for the RCD to trip the AUTOTRIP will also

indicate whether it has passed or failed the RCD requirements.

Auto Type II RCD Testing

To reduce the testing time the AUTOTRIP has two automatic test functions

which allows the operator to set the auto test sequence to run, resetting the RCD at the

distribution board during auto test cycle then returning to the instrument to recall the

results.

Quick Auto(2 Tests): 30mA x1 at 00 & 1800

Full Auto(6 Tests): 30mA x½, x1,x 5 at 0

0

& 1800

Audible tones

A simple selection of audible tones is used to supplement the visual display.

These help the user by providing intuitive feedback during testing. In addition

to warning about dangerous or unstable supply conditions they provide a very

quick confirmation that the measurement process is taking place and, upon

completion of the test, a warning if the results are likely to be regarded as a

failure.

The meaning of the tone for each individual function is covered in the table below.

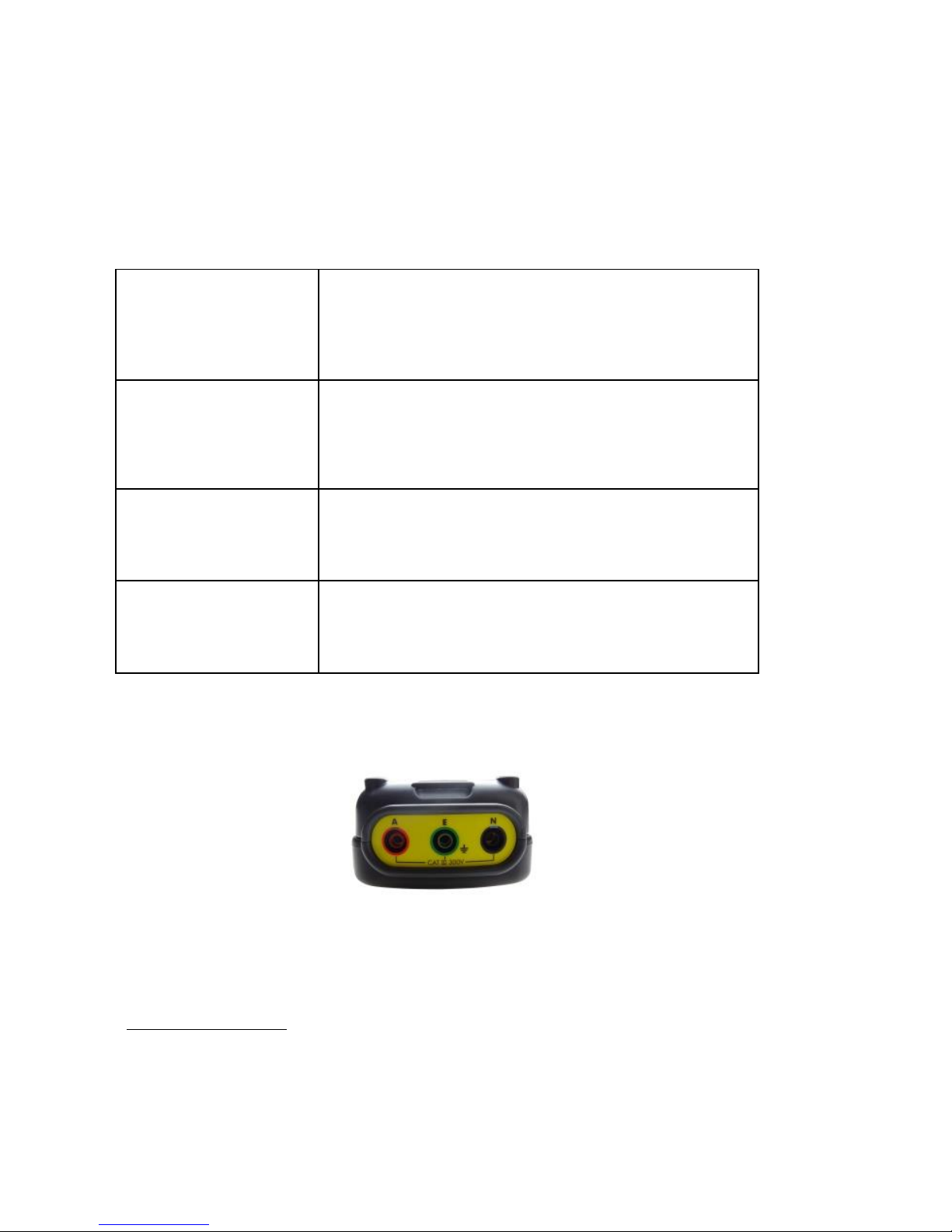

Test lead inputs

The test lead input terminals are Red Active terminal (marked A) the Black Neutral

terminal (marked N) and the Green Earth terminal (marked E).

Test lead configuration

The AUTOTRIP can be used with 2 different types of connecting lead.

1 Ref: TL-3P Mains lead; 3 x 4mm plugs to a 10A plug

Optional Accessory

2 Ref: TL-RGB 3-Pole distribution board test lead set; that can be fitted

with either prod tips or crocodile clips as required. The 3 colour coded prods/crocodile

clips of the test lead should be connected to the corresponding Line, Neutral

and Earth terminals.

The leads are an integral part of the tester set-up and should accompany the

tester when being returned for re-calibration or service.

Warning

A continuous 2 tone

alarm

An unsuitable supply configuration such as a

mains supply with incorrect polarity or having the

leads connected wrongly will be accompanied by

the Red Voltage/Polarity warning LED flashing

Wait-Test in progress

A steady beeping

sound

Emitted whilst a measurement is in progress. The

same tone is sounded when used in Hands Free

mode to indicate that continual measurement is

being made

Test completed

A single beep

Sounded upon completion of a measurement to

indicate that the result is being displayed

Alert

A short 2 tone alarm

Sounded when a test returns a result that is likely

to be regarded as a failure e.g.30mA RCD

trip time test gives a result of greater than 300ms

Overview of the switches and LCD display

The Primary display of the large LCD shows the result of the test being conducted. At

the same time a secondary display area shows supporting information e.g. Pass/Fail.

Mains supply wiring and voltage test

When first connected to a mains supply the AUTOTRIP will automatically conduct a

safety test to ensure that the Live, Neutral and Earth conductors are all

connected correctly and that the supply voltage is in the acceptable range

(195-253V). Please note the polarity LED indicator is not able to determine N-PE supply

reversal.

If all is well the VOLTAGE/POLARITY warning LED will light Green and the

supply voltage will be displayed in the primary display area.

In the event of a problem with either the mains voltage supply or reversed

connections the VOLTAGE/POLARITY warning LED will light Red, a warning

tone will be sounded and testing will be inhibited.

Battery Condition

Indication

Manual Select Test

Button

x ½, x1, x5 or Ramp

Select RCD Rating

10mA, 30mA, 100mA

Type AC

Start Test Button

Select RCD 100mA

Type ACS

Hands Free Function

Rotary Selector

LCD Backlit Display

Result Recall Button

Quick Auto & Full Auto

Tests

30mA Type II (AC)

Mains Polarity Check

Voltage Present Indication

RCD TEST FUNCTIONS

The AUTOTRIP will test Type I (10mA) & Type II (30mA) RCD

standard (AC) types across the full range of tests required and also RCD (S) type

100mA rated RCD’s.

Test Requirements

Each (AC) type RCD should be tested to ensure that it operates with a maximum

disconnection time indicated in the table when a fault at its rated current is introduced

for both the 00 & 1800 cycle. This is referred to as the x1 test.

Table referenced to 3.7.2.2 AS/NZS 3017:2007, always verify this complies with any

changes to the legislation or guidelines.

Recommended Additional Tests for 30mA RCD’s

It is not prone to ‘nuisance’ tripping and does not trip when a fault of half its rated current

is introduced. This is referred to as the x½ test.

In the case of an RCD rated at 30mA it should operate with a maximum disconnection

time of 40ms when a fault of five times itsrated current is introduced. This is referred to

as the x5 test.

For the reasons explained below all of the above tests have to be conducted at both 0°

and 180°.

100mA (S) Type

Type S: Selective or time delayed RCD's are used in applications where RCDs have

been connected in series to achieve discrimination between upstream and

downstream devices.

Residual Tripping

Current

Tripping Time

100mA Type S

Minimum 130ms

100mA Type S

Maximum 500ms

Sinusoidal Polarity (the 0° or 180° test)

RCD’s often operate with different reaction times depending upon whether the

fault is introduced during the positive or negative half cycle of the AC waveform.

Therefore to accurately determine the maximum response time of an RCD it is

necessary to test it twice at each given fault current, firstly with the fault introduced

during the positive half cycle 0° and secondly during the negative half cycle180°.

Residual Tripping

Current

Maximum Tripping

Time

10mA

40mS

30mA or Other

300mS

The AUTOTRIP takes care of this for you by alternating the start point of

consecutive tests at any given setting. If for example you have selected a test

at the rated trip current (x1) of a 30mA RCD, the first press of the test button

will apply a 30mA fault current starting on the positive half cycle (0°)

and display the result. A further press of the test button will carry out another

test at the same current but starting on the negative half cycle (180°).

RCD Test Procedure

Although fully protected against over voltage to 440V this tester should only be

used on a 240V AC supply.

Connect the 4mm plugs of the chosen test lead to the corresponding L, N & E

terminals of the AUTOTRIP and connect the other end to the socket or circuit

terminals under test.

If using the distribution board test lead set (TL-RGB) observe the correct polarity

by connecting the Red probe to the Live conductor, Black to Neutral and Green

to Earth.

Select the type and rating of the RCD to be tested with the rotary function

selector switch. (10mA, 30mA,100mA Type AC or 100mA Type S)

When first connected to a mains supply the AUTOTRIP will automatically conduct a

safety test to ensure that the Live, Neutral and Earth conductors are all

connected correctly and that the supply voltage is in the acceptable range

(195-253V).

If all is well the VOLTAGE/POLARITY warning LED will light Green and the

supply voltage will be displayed in the primary display area.

In the event of a problem with either the mains voltage supply or reversed

connections the VOLTAGE/POLARITY warning LED will light Red, a warning

tone will be sounded and testing will be inhibited.Do not proceed.

User Selected Manual Tests

x½

The recommended order of tests is firstly at x½ the rated current followed by a

x1 test at the rated current and finally, for 30mA RCD’s only x5 the rated current.

The default test parameter for the selected current

multiplier x½ is 0° for the phase polarity this

will be automatically selected for the first test. This will

be displayed on the LCD display along with the

Line-Neutral voltage.

Press the test button and a test will be conducted at the

selected settings. If successful and the RCD has failed

to trip a single beep will sound and the main display

will be similar to figure 5.

Displaying 1st test result of x ½ test 0° (figure 5)

The main display shows that the fault current was applied for over 2000

milliseconds (2 seconds) without tripping the RCD. The secondary display

confirms that this passes the requirements.

In the event of the RCD failing the test and tripping at half the

rated current the main display will show the trip time and the secondary display

will show ‘FAIL’. A short 2 tone alert will also sound.

After displaying the result for a few seconds the tester

will switch to the 180°phase polarity setting in readiness

for the next test. (Figure 6)

Changed polarity displaying line voltage ready for 2nd test x ½ test 180° (figure 6)

When both tests have been conducted at the x½ setting press the multiplier

button to change the test current to the x1 setting.

x1

Press the test button to conduct a test at the x1 setting at 0°. The result will be

shown as a pass if a 30mA RCD trips within 300ms. After displaying the result for a few

seconds the tester will switch to the 180° phase polarity setting in readiness for

the second test at the x1 current setting.

x5

If the 30mA setting has been selected a x5 current option will be available by

using the multiplier button. This option is not available for other

ratings.

Ramp Test

The AUTOTRIP also includes a diagnostic Ramp test feature. In this mode rather

than applying a steady fault current and measuring the time taken for the RCD

to trip, the AUTOTRIP gradually increases the fault current and identifies the level of

leakage at which the RCD trips.

This is particularly useful in diagnostic testing of circuits where nuisance

tripping is a problem and helps to identify the difference between an over

sensitive RCD and excessive leakage from poor insulation or equipment with

high leakage.

Use the rotary switch to select the rating of the RCD.

Press the multiplier button until the ramp symbol is displayed.

Press the test button to start the test. The fault current applied will increment in

3mA steps until the RCD trips.

If nuisance tripping on a circuit is a problem this function can be used to retest

the RCD with other appliances systematically connected and removed.

For example a 30mA RCD may trip at 12mA on ramp test with an appliance

connected and then at 27mA with the appliance removed. You will know that

the appliance is leaking approximately 15mA.

Automatic Tests

30mA Quick Auto Test

Turn the rotary selector to the ‘30mA QUICK AUTO’ setting, press the test button

and the tester will conduct 2 tests: (30mA x1 test at both the 00 and 1800 half cycle).

All that is required is to remain at the switchboard and reset the RCD after it trips.

Upon completion of the auto test routine the results for each setting can be

recalled by using the RECALL button to cycle through the routine.

The AUTOTRIP will also indicate whether it has passed or failed the RCD requirements.

30mA Full Auto Test

Turn the rotary selector to the ‘30mA Full AUTO’ setting, press the test button and the

tester will conduct 6 tests: (30mA x½, x1,x5 at both the 00 and 1800 half cycle)

All that is required is to remain at the switchboard and reset the RCD each time it trips.

Upon completion of the auto test routine the results for each setting can be recalled by

using the RECALL button to cycle through the routine.

AUTOTRIP will also indicate whether it has passed or failed the RCD requirements.

Hands Free Testing

The hands free feature can be used where repeat testing is required. To enable

hands free simply press the Hands Free button once.

The ‘HANDSFREE’ annunciator will appear flashing on the LCD and will coniine to do

so until cancelled by a further press of the Hands Free button or by changing the

selector switch.

When the HANDSFREE annunciator is flashing all you need to do is connect the test

lead to a mains supply and the test will be automatically carried out.

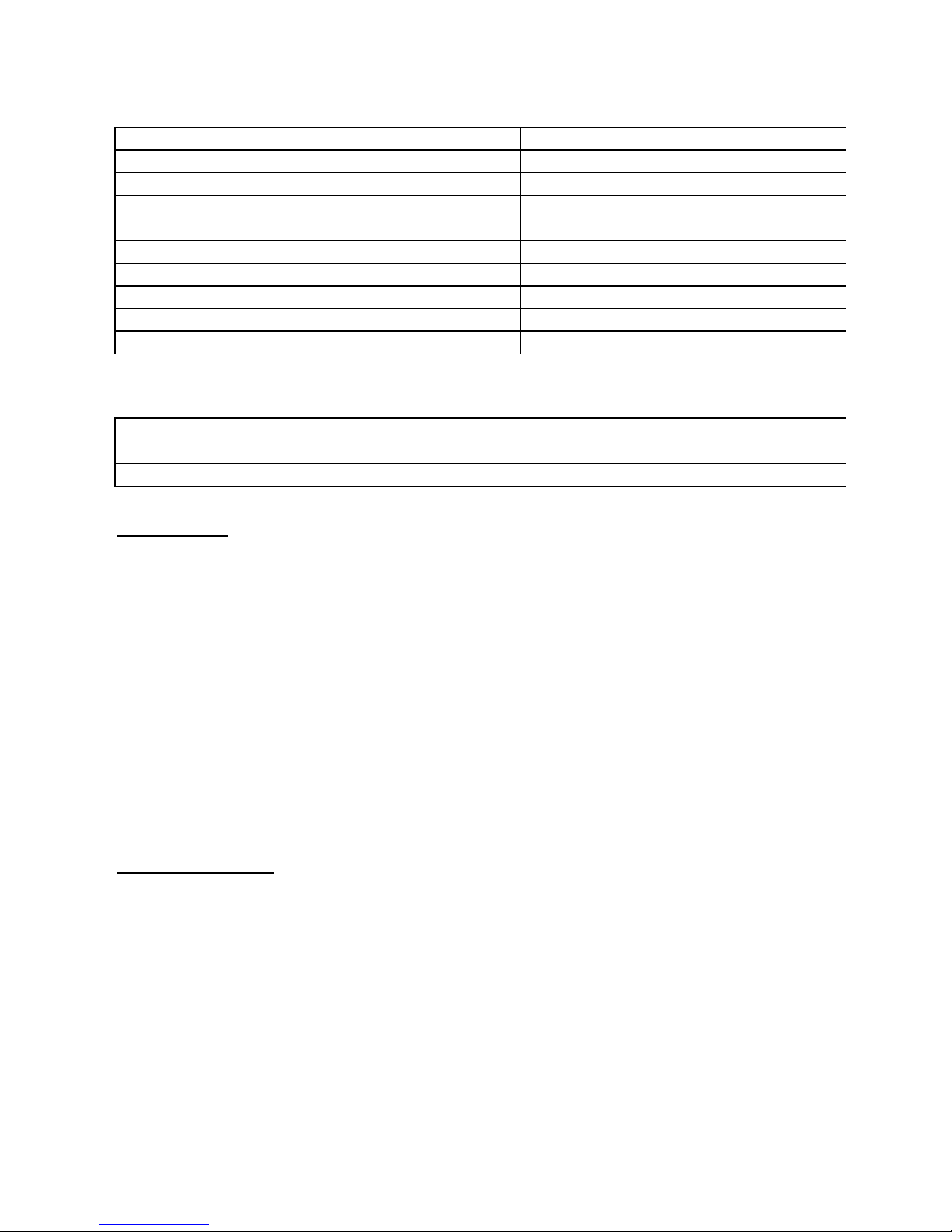

Specifications and tolerances

RCD TEST TOLERANCES

Supply Voltage Range

195 to 253V AC 50-60Hz

Nominal Currents

10mA,30mA,100mA

Test Current Accuracy x 1/2

+0% - 10%

Test Current Accuracy x 1

+10% -0%

Test Current Accuracy x 5 (30mA only)

+/- 5%

Test Current Accuracy Ramp

+/- 5% of rated IN

Trip Time Accuracy to 1.999s

+/- (1% +1ms)

Fault / Touch Voltage

50V

Over Voltage Protection

440V

RCD Trip Time

Measurement Range

5ms – 1999ms

Operating Range Per EN61557

38ms – 1999ms

Standards

To meet 300V CATIII

The AUTOTRIP complies fully with the requirements of EN61010 and complies with

the sections of EN61557, Electrical Safety in Low Voltage Systems up to 1000V AC

and 1500V DC as listed below.

BS EN 61010-2-030:2010 (Safety)

BS EN 61326-2-2:2013 (EMC)

BS EN 61557-1:2007 (General performance)

BS EN 61557-6:2007 (RCD performance)

Environmental

Operating Temperature Range 0C to 40C

Storage Temperature Range -10C to 60C

Operating Humidity 80% @ 31C to 50% @40C

For repair and calibration please contact place of purchase.

Electrical Factory Outlet Pty Ltd

PO Box 701, Rochedale South, QLD 4123

PH +61 7 3411 0303

E-mail: sales@electricalfactory.com.au

www.electricalfactory.com.au

Loading...

Loading...