Electrex KILO, KILO M Instructions Manual

ELECTREX S.r.l. via Claudia, 96 - 41096 Savignano s/P (MO) - Italy - Tel. +39.59.796372 Fax. +39.59.796378

SUBJECT TO CHANGE WITHOUT NOTICE 02/2004

KILO

KILO M

1 TERMS OF WARRANTY

The warranty is valid 3 years starting from the manufacturing date, as evidenced on the receipt

of the calibration certificate, for the period indicated on the package.

The warranty covers the free repair or substitution of equipment parts which are recognized as

faulty due to manufacturing defects.

The warranty does not cover those parts which result defective due to negligent or improper use,

incorrect installation or maintenance, operation by unauthorized personnel, damage during

transportation, or which in any case do not indicate manufacturing defects of the equipment. Also

excluded from the warranty are technical interventions regarding the installation of the equipment.

Also excluded from the warranty are technical interventions regarding the installation of the

equipment to the electrical system.

The manufacturer declines any responsability for eventual injury or damage to persons, animals

or things as result of failure to follow the instructions in the Instructions Manual or caused by

improper use of the equipment.

The warranty covers equipment returned ex works. The expenses of transport as well as the relative

risks of same, both to and from the place of repair, will be the sole responsability of the User.

This warranty expires after the date of purchase and any assistance required after said date

including spare parts, labor, transport of personnel and materials will be charged to the User

basated on the tariffs in force for Technical Assistance Service at the time of such requested service.

In any case the substitution of the equipment as well as the extension of the warranty after such

breakdown is excluded.

The packaging of each instrument bears a "CE" mark of conformity.

2 SAFETY

This instrument was manufactured and tested in compliance with class 2 IEC EN61010 and VDE

411 standards, in accordance with group C VDE 0110 standards for operating voltages up to 500

VACrms. Quality and accuracy are guaranteed by an ISO9000 certified production structure

which utilizes the latest surface mounting techniques, therefore the instrument left the factory in

perfect condition regarding technical safety.

In order to maintain this condition and to ensure safe operation, the user must comply with the

indications and markings contained in the following instructions:

When the instrument is received, before beginning installation, check that it is still intact and no

damage was incurred during transport.

Before mounting, ensure that the operating voltage and mains voltage set are the same, and then

proceed with installation.

The instrument unit is double insulated and does not require an earth connection. The power supply

must be connected to phase and neutral as shown in the relevant diagram.

A 50 mA T type HBC fuse should be installed in the power supply circuit to the instrument.

The power supply must be connected before the measurement circuit.

Before any maintenace and/or repairs, whenever the instmrument must be opened, it must be

disconnected from all power sources.

The instrument’s capacitors may still be charged even after it has been disconnected from all

power sources.

Maintenance and/or repairs must be carried out only by qualified, authorized personnel.

If there is ever the suspicion that safe use is no longer possible, the instrument must be taken out

of service and precautions taken against accidental use.

Operation is no longer safe when:

- There is clealy visible damage.

- The instrument no longer functions.

- After lengthy storage in unfavorable conditions.

- After serious damage incurred during transport.

2.1 OPERATOR SAFETY

Read these pages carefully before installing and utilising the instrument

The instrument described in this user manual is intended for use by properly trained staff only.

Maintenace and/or repairs must be carried out only by authorized personnel.

For proper, safe use of the instrument and for maintenace and/or repair, it is essential that the

persons instructed to carry out these procedures follow normal safety precautions.

2.2 SYMBOLS

READ THE INSTRUCTIONS

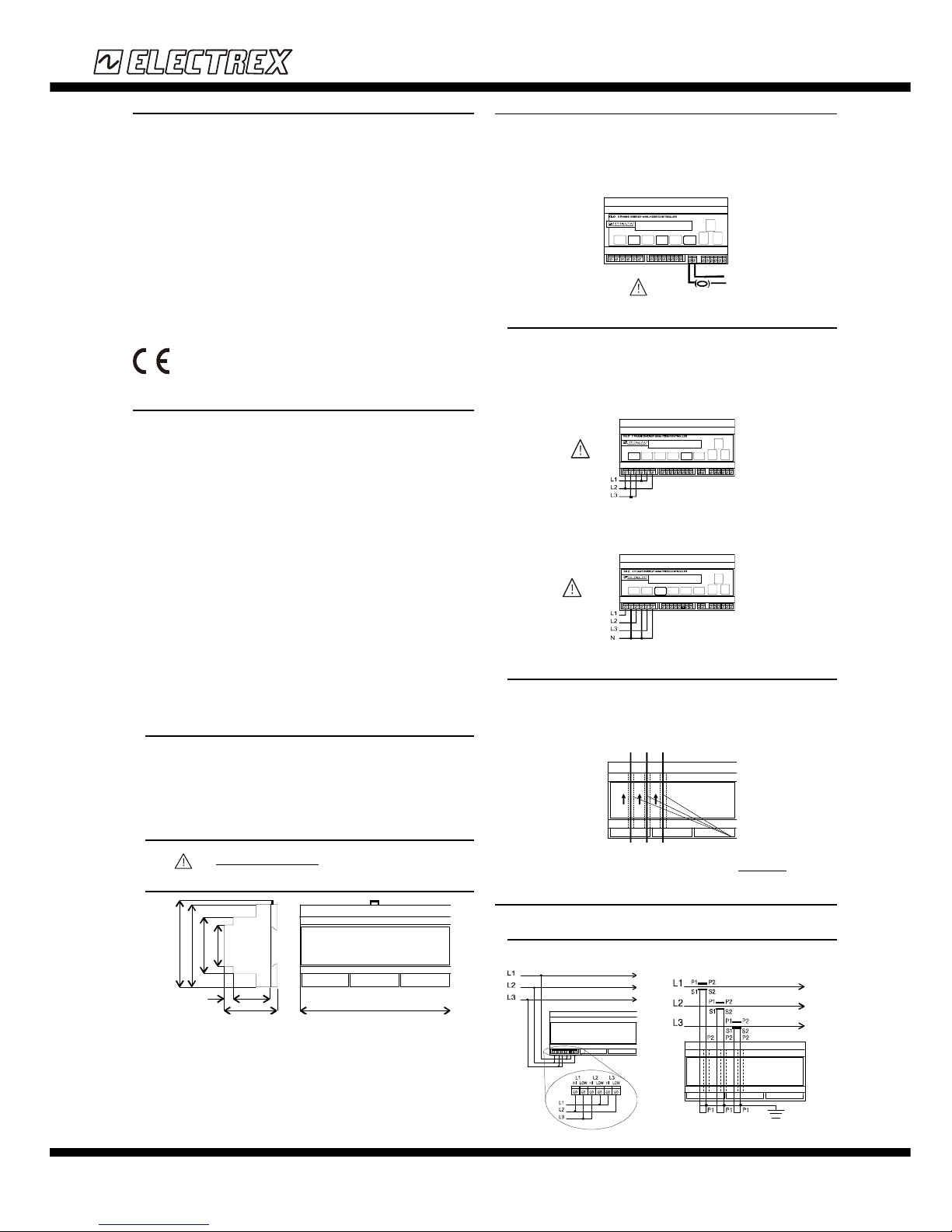

2.3 DIMENSIONS AND TECNICAL CHARACTERISTICS

• Inputs:

Voltage: 500V 20 to 800 Hz

Current: 5 A 20 to 800 Hz

• Power Supply:

200÷240 VAC ± 10% 50/60 Hz

100÷120 VAC ± 10% 50/60 Hz

(on request)

• Temperature Range: -10°C to +60°C

• Storage Temperature: -25°C to +80°C

200 ÷ 240 VAC

50 mAT

Max 500 VAC

Fase-Fase

Max 500 VAC

Fase-Neutro

Fig. 1

Fig. 2

Fig. 3

Fig. 4

P1 P1 P1

Wire passages

3 POWER SUPPLY

The instrument must have a power supply with voltage ranging from 200 ÷ 240 VAC 50/60 Hz

(100 ÷ 120 VAC 50/60 Hz is also available on request) using max. cable gauge 4 mm2 and

attached to the power supply terminals (see Fig.1).

The instrument’s power supply does not need an earth connection.

The instrument requires the installation of an external 50 mA type HBC fuse in the power supply

circuit.

3.1 VOLTAGE MEASUREMENT CONNECTIONS

For the voltage measurement connection use wires with max gauge 4mm2. Insert the wires in

the screw terminals for the voltage measurement connection.

3.1.1 3 wires delta connection (? )

The diagram in Fig.2 indicate how to connect the terminals to the phases on unbalanced threephase systems without neutral (DELTA).

3.1.2 4 wires STAR CONNECTION (Y )

The diagrams in Fig. 3 indicate how to connect the terminals to the phases on unbalanced threephase systems with neutral (STAR).

The detailed wiring diagrams to the network are given in chapter 3.

3.2 CURRENT MEASUREMENT CONNECTIONS

The instrument is equipped with three wire passages through which the current wires must be

passed without having to interrupt them. Insert the wires as indicated in Fig.4 (instructions as

to how to insert the current wire are also found on the instrument’s label in correspondence with

the wire passages). The P1 and P2 indications identify the correct direction of the current.

Wires with max. 7 mm external diameter are permitted.

Advanced Function: If the instrument has been programmed for Cogeneration functioning, it

is absolutely essential that the sense (orientation) of the current direction be observed.

4 WIRING DIAGRAMS

4.1 CONNECTION ON UNBALANCED THREE-PHASE 3 WIRE DELTA

NETWORKS (?)

Voltage Signal Connection

Corrent Signal Connection

Fig. 5

Fig. 6

English

Instructions

9

5

90

62

41

10

58

45

157,5

ELECTREX S.r.l. via Claudia, 96 - 41096 Savignano s/P (MO) - Italy - Tel. +39.59.796372 Fax. +39.59.796378

SUBJECT TO CHANGE WITHOUT NOTICE 02/2004

KILO

KILO M

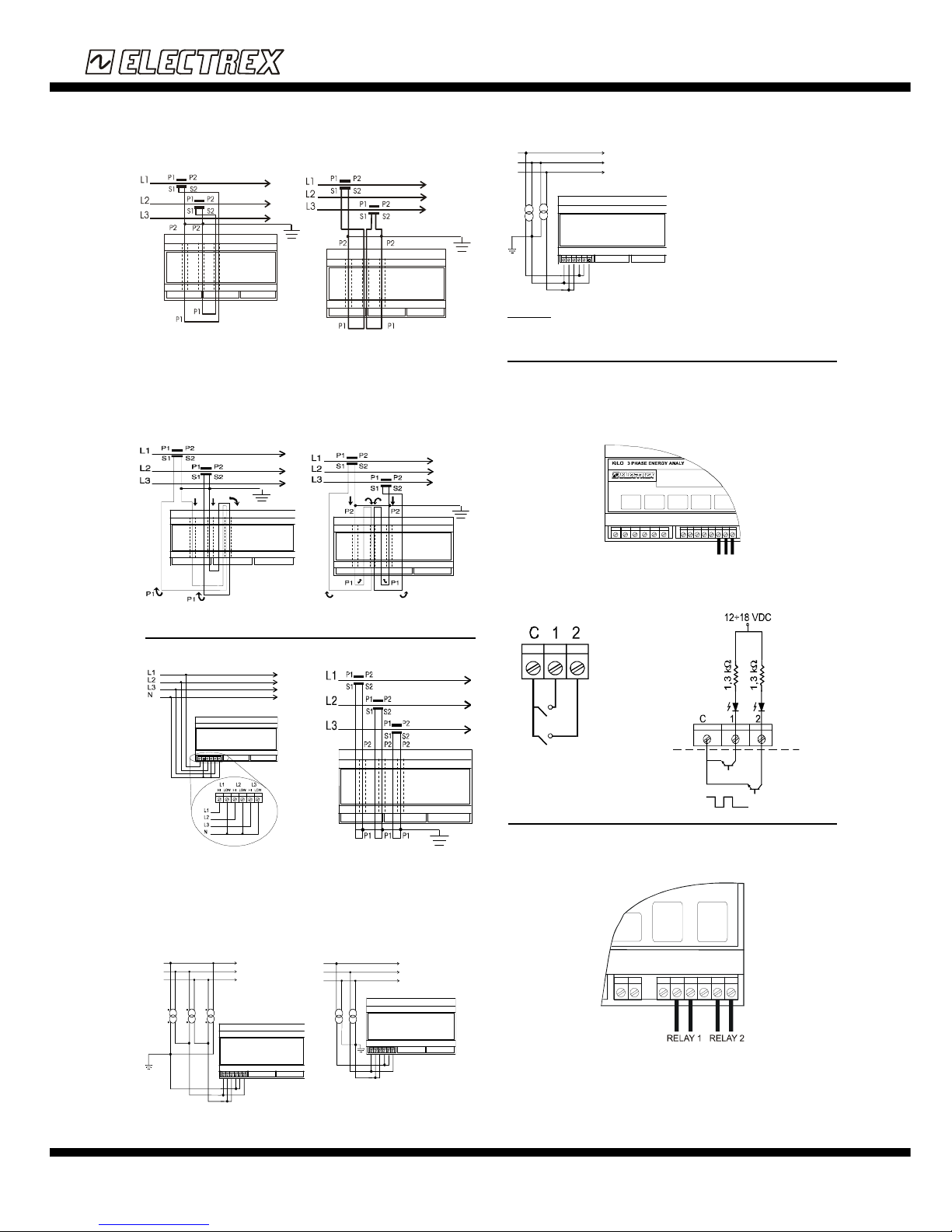

Fig. 10

Fig. 9

Fig. 12

Fig. 11

Fig. 13

Fig. 14

C 1 2

C = Common

1 = Meter 1

2 = Meter 2

Min Pulse 5 mSec.

INSTRUMENT

INTERIOR

INSTRUMENT

ESTERIOR

Connection to voltage-free

contacts

Connection to open-collector transistor

4.4 ALARMS CONNECTION

There are two alarms which drive two relays, the terminals are internally connected to

noramlly open voltage free contacts of an opto-mos (solid state relay) rating 250 VDC, 100mA.

Use cables with max. gauge 4 mm2 for the terminal connections (see Fig. 15).

C = Common

NO = Normally Open

C NO C NO

Fig. 15

Fig. 7-1

Fig. 7-2

Fig. 8-1

Fig. 8-2

Current signal connection

with 2 CTs (L1 and L2)

Current signal connection

with 2 CTs (L1 and L3)

Connection of 2 CTs in Cogeneration mode

The drawing in Fig. 6 indicates how to make the current connections with 3 CTs. The Fig. 71 and 7-2 indicate how to connect current signal using 2 CTs (Phase L1 and L2 or Phase L1

and L3).

CAUTION: In case of connection of 2 CTs it is absolutely essential to respect the sense

(orientation) of the CTs current output as indicated in the drawings (Fig. 7-1 and 7-2).

Advanced Functions: If the instrument has been programmed for Cogeneration mode,

connection of the CTs must be carried out as indicated in the drawings in Fig.10-1 and Fig.102 located on the next page.

4.2 CONNECTION ON UNBALANCED THREE-PHASE 4 WIRE NETWORKS

The drawing in Fig.10 indicates how to make the current connections with 3 CTs.

4.2.1 HIGH VOLTAGE THREE PHASE WIRES DELTA NETWROK WITH CT's

AND VT's

L

1

L3

L2

L1

L2

L3

L

1

L3

L2

L1

L2

L3

L

1

L3

L2

L1

L2

L3

WARNING: In Fig. 12 and 13 any one of the delta vertices may be earthed.

For the connection of CTs in medium or high voltage networks, follow the same procedure

described for low voltage connections.

4.3 CONNECTION OF THE AUXILIARY METERS

The instrument has two digital inputs to which two external meters can be connected (for

example, a water meter and a gas meter).

The digital inputs are optoisolated and internally power supplied (12 ÷ 18 VDC 1,3 KOhm)

and can count pulses with a maximum frequency of 100 Hz.

The connection must be carried out using cables with max. gauge 4 mm2 to be inserted in the

terminals indicated below in Fig.14.

Voltage signal connection with 3 VTs Voltage signal connection with 2 VTs

Voltage signal connection with 2 VTs

English

Instructions

Voltage signal connection

Current signal connection

Loading...

Loading...