ElectraStream BEL 130, BEL 150, BETP 215, 200, 300 User Manual

...

heating products

User and Installation ManualUser and Installation Manual

User and Installation Manual

User and Installation ManualUser and Installation Manual

Single and Twin Coil Models

For owners, installers and service engineers

27/02/13

A complete cost effective solution for Hot and Cold water supply and Electric Central

Heating with water filled radiators, suitable for Self-contained Flats, Small Dwellings,

Offices, Home Offices and Granny Annexes.

9 kW (30,000 Btu) - for Heating and Hot Water

TT

win Coil Cylinder option available for SOLAR enerwin Coil Cylinder option available for SOLAR ener

T

win Coil Cylinder option available for SOLAR ener

TT

win Coil Cylinder option available for SOLAR enerwin Coil Cylinder option available for SOLAR ener

gygy

gy

gygy

..

.

..

1

Important Health and Safety Information for Installers and Service Engineers

Health and Safety at Work Act 1974

Consumer Protection Act 1987

COSHH Regulations 1988

The following information is given as a requirement of the

above legislation.

Great care is taken by GAH (HEATING PRODUCTS) LIMITED

to ensure that Electrastream systems are designed and

manufactured to meet general safety requirements when

properly used and installed as recommended in this manual.

It is the responsibility of Users and Engineers to ensure that

adequate protective clothing and glasses are worn when

working with the Electrastream system.

SEALS AND INSULATIONSEALS AND INSULATION

SEALS AND INSULATION

SEALS AND INSULATIONSEALS AND INSULATION

Insulation and sealing materials are used in the construction

of the Electrastream cylinders. Units are sealed and when

used in the manner for which they are intended the insulating

and sealing materials do not present any known hazard.

However always observe the following recommendations:-

1. Avoid inhalation of fibres or dust, wear face mask.

2. Avoid eye contamination by fibres or dust - wear eye

protection.

3. As far as possible avoid any skin contact with Fibreglass

Insulation, Glass Rope, Mineral Wool, Insulation Pads and

Ceramic Fibre.

HEALHEAL

HEAL

HEALHEAL

OTHER MATERIALSOTHER MATERIALS

OTHER MATERIALS

OTHER MATERIALSOTHER MATERIALS

SEALANTS, ADHESIVES AND PAINTS

Sealants, Adhesives and Paints are used in the construction of

the Electrastream components. When used in the manner for

which they are intended they do not present any known hazard.

ELECTRICELECTRIC

ELECTRIC

ELECTRICELECTRIC

The Cylinder Tri-Core Heater, Pump, Thermostats and Contactor

Box all have electrical supply of 230V (enough to endanger

life).

Always isolate before connection, adjustment, servicing and

repair.

When the Tri-Core Heater cover is removed high power live

electrical terminals are exposed.

ISOLATE THE TRI-CORE HEATER BEFORE REMOVING ITS

COVER.

Earth protection - Earth Continuity Conductors must be fitted

and must comply with IEE Wiring Regulations.

GAH (HEATING PRODUCTS) LIMITED will not accept

responsibility for any damage or personal injury caused

by not giving due consideration to the above safety

recommendations.

TH & SAFETYTH & SAFETY

TH & SAFETY

TH & SAFETYTH & SAFETY

In pursuance of a policy of constant development, GAH (HEATING PRODUCTS) LIMITED

reserve the right to change Electrastream parts or design without notice, therefore

certain details included in this manual may not be correct at the time of printing. Any

modification and improvements detailed in this manual does not commit GAH to update

any system previously supplied.

Manual Part No. ...................MAN1019

Manual Ref ..........................ES02

Issue ...................................13

Date ....................................25/02/13

PP

atent application 01514800.2atent application 01514800.2

P

atent application 01514800.2

PP

atent application 01514800.2atent application 01514800.2

©©

2010 GAH (HEATING PRODUCTS) L 2010 GAH (HEATING PRODUCTS) L

©

2010 GAH (HEATING PRODUCTS) L

2010 GAH (HEATING PRODUCTS) L 2010 GAH (HEATING PRODUCTS) L

©©

ElectrastrElectrastr

eam is a Team is a T

Electrastr

eam is a T

ElectrastrElectrastr

eam is a Team is a T

HTS REF GAH ELECTRASTREAM 25/02/13

Manual by Harber Technical Services Tel/Fax 01263 515444

E-mail:info@harbertech.co.uk www.harbertech.co.uk

2

rademark of GAH (HEATING PRODUCTS) Lrademark of GAH (HEATING PRODUCTS) L

rademark of GAH (HEATING PRODUCTS) L

rademark of GAH (HEATING PRODUCTS) Lrademark of GAH (HEATING PRODUCTS) L

TD.TD.

TD.

TD.TD.

TD.TD.

TD.

TD.TD.

GAH (Heating PrGAH (Heating Pr

GAH (Heating Pr

GAH (Heating PrGAH (Heating Pr

oducts) Ltd.oducts) Ltd.

oducts) Ltd.

oducts) Ltd.oducts) Ltd.

Building 846

Bentwaters Parks

Rendlesham

Woodbridge

Suffolk IP12 2TW

TT

el:el:

01394 42116001394 421160

T

el:

01394 421160

TT

el:el:

01394 42116001394 421160

Fax:Fax:

01394 42117001394 421170

Fax:

01394 421170

Fax:Fax:

01394 42117001394 421170

email: mail@gah.co.uk

www.gah.co.uk

CONTENTSCONTENTS

CONTENTS

CONTENTSCONTENTS

ImporImpor

tant Informationtant Information

Impor

tant Information

ImporImpor

tant Informationtant Information

Section 1 IntrSection 1 Intr

Section 1 Intr

Section 1 IntrSection 1 Intr

1-1 Introduction ---------------------------------------------- 5

1-2 System Layout ------------------------------------------- 8

1-3 Parts Supplied------------------------------------------- 11

1-4 The Electrastream System ------------------------------- 12

1-5 Tri Core Heater Operation -------------------------------- 13

oductionoduction

oduction

oductionoduction

----------------------------------------------------------------------------------

----------------------------------------- 4

----------------------------------------------------------------------------------

1 INTRODUCTION1 INTRODUCTION

1 INTRODUCTION

1 INTRODUCTION1 INTRODUCTION

2 OPERA2 OPERA

2 OPERA

2 OPERA2 OPERA

CONTENTSCONTENTS

CONTENTS

CONTENTSCONTENTS

TOR CONTROLSTOR CONTROLS

TOR CONTROLS

TOR CONTROLSTOR CONTROLS

Section 2 Operator ContrSection 2 Operator Contr

Section 2 Operator Contr

Section 2 Operator ContrSection 2 Operator Contr

2-1 System Control ------------------------------------------ 14

2-2 Electrastream Control Unit------------------------------- 16

2-3 Shut Off Valves ------------------------------------------ 20

2-4 Temperature & Pressure Relief Discharge ---------------- 22

2-5 Thermostatic Mixing Valve ------------------------------ 22

2-6 Servicing ------------------------------------------------ 22

Section 3 TSection 3 T

Section 3 T

Section 3 TSection 3 T

3-1 Specifications ------------------------------------------- 23

3-2 Dimensions --------------------------------------------- 25

3-3 Wiring --------------------------------------------------- 29

Section 4 InstallationSection 4 Installation

Section 4 Installation

Section 4 InstallationSection 4 Installation

4-1 Building Control ----------------------------------------- 31

4-2 Electrical ------------------------------------------------ 31

4-3 Hot Water System --------------------------------------- 33

4-4 Heating System ----------------------------------------- 37

4-5 Expansion Discharge ------------------------------------ 40

4-6 System Pressure ---------------------------------------- 43

4-7 Electrastream Connections - ---------------------------- 44

echnical Informationechnical Information

echnical Information

echnical Informationechnical Information

olsols

ols

olsols

3 TECHNICAL INFORMA3 TECHNICAL INFORMA

3 TECHNICAL INFORMA

3 TECHNICAL INFORMA3 TECHNICAL INFORMA

4 INST4 INST

4 INST

4 INST4 INST

5 COMMISSIONING5 COMMISSIONING

5 COMMISSIONING

5 COMMISSIONING5 COMMISSIONING

ALLAALLA

ALLA

ALLAALLA

6 SERVICING6 SERVICING

6 SERVICING

6 SERVICING6 SERVICING

TIONTION

TION

TIONTION

TIONTION

TION

TIONTION

Section 5 CommissioningSection 5 Commissioning

Section 5 Commissioning

Section 5 CommissioningSection 5 Commissioning

5-1 Commissioning ----------------------------------------- 47

Section 6 ServicingSection 6 Servicing

Section 6 Servicing

Section 6 ServicingSection 6 Servicing

6-1 Routine Service ----------------------------------------- 50

Section 7 Fault FindingSection 7 Fault Finding

Section 7 Fault Finding

Section 7 Fault FindingSection 7 Fault Finding

7-1 Fault Finding -------------------------------------------- 52

Health & SafetyHealth & Safety

Health & Safety

Health & SafetyHealth & Safety

------------------------------------------------------------

------------------------------ Inside Front Cover

------------------------------------------------------------

7 F7 F

AULAUL

7 F

AUL

7 F7 F

AULAUL

HEALHEAL

TH & SAFETYTH & SAFETY

HEAL

TH & SAFETY

HEALHEAL

TH & SAFETYTH & SAFETY

T FINDINGT FINDING

T FINDING

T FINDINGT FINDING

IMPORTANT

BEFORE STARTING THE INSTALLATION OF THE ELECTRASTREAM CHECK ALL COMPONENTS HAVE

BEEN DELIVERED AND ARE IN SATISFACTORY CONDITION - Refer to 1-3 .

3

IMPORTIMPORT

IMPORT

IMPORTIMPORT

IMPORTANT INFORMATION

ANT INFORMAANT INFORMA

ANT INFORMA

ANT INFORMAANT INFORMA

TIONTION

TION

TIONTION

BEFORE STARBEFORE STAR

BEFORE STAR

BEFORE STARBEFORE STAR

IN SATISFACTORY CONDITION - RIN SATISFACTORY CONDITION - R

IN SATISFACTORY CONDITION - R

IN SATISFACTORY CONDITION - RIN SATISFACTORY CONDITION - R

TING THE INSTALLATION OF THE ELECTRASTREAM CHECK ALL COMPONENTS HAVE BEEN DELIVERED AND ARETING THE INSTALLATION OF THE ELECTRASTREAM CHECK ALL COMPONENTS HAVE BEEN DELIVERED AND ARE

TING THE INSTALLATION OF THE ELECTRASTREAM CHECK ALL COMPONENTS HAVE BEEN DELIVERED AND ARE

TING THE INSTALLATION OF THE ELECTRASTREAM CHECK ALL COMPONENTS HAVE BEEN DELIVERED AND ARETING THE INSTALLATION OF THE ELECTRASTREAM CHECK ALL COMPONENTS HAVE BEEN DELIVERED AND ARE

efer to 1-3.efer to 1-3.

efer to 1-3.

efer to 1-3.efer to 1-3.

Delivery

Standard Electrastream systems will be delivered wrapped on single pallet with cylinder together with box containing control box

and loose components.

Pre-Plumbed Electrastream systems will be delivered wrapped on single pallet with cylinder, control box and all components fully

assembled.

Pack should be lifted using suitable sized pallet truck or fork lift truck.

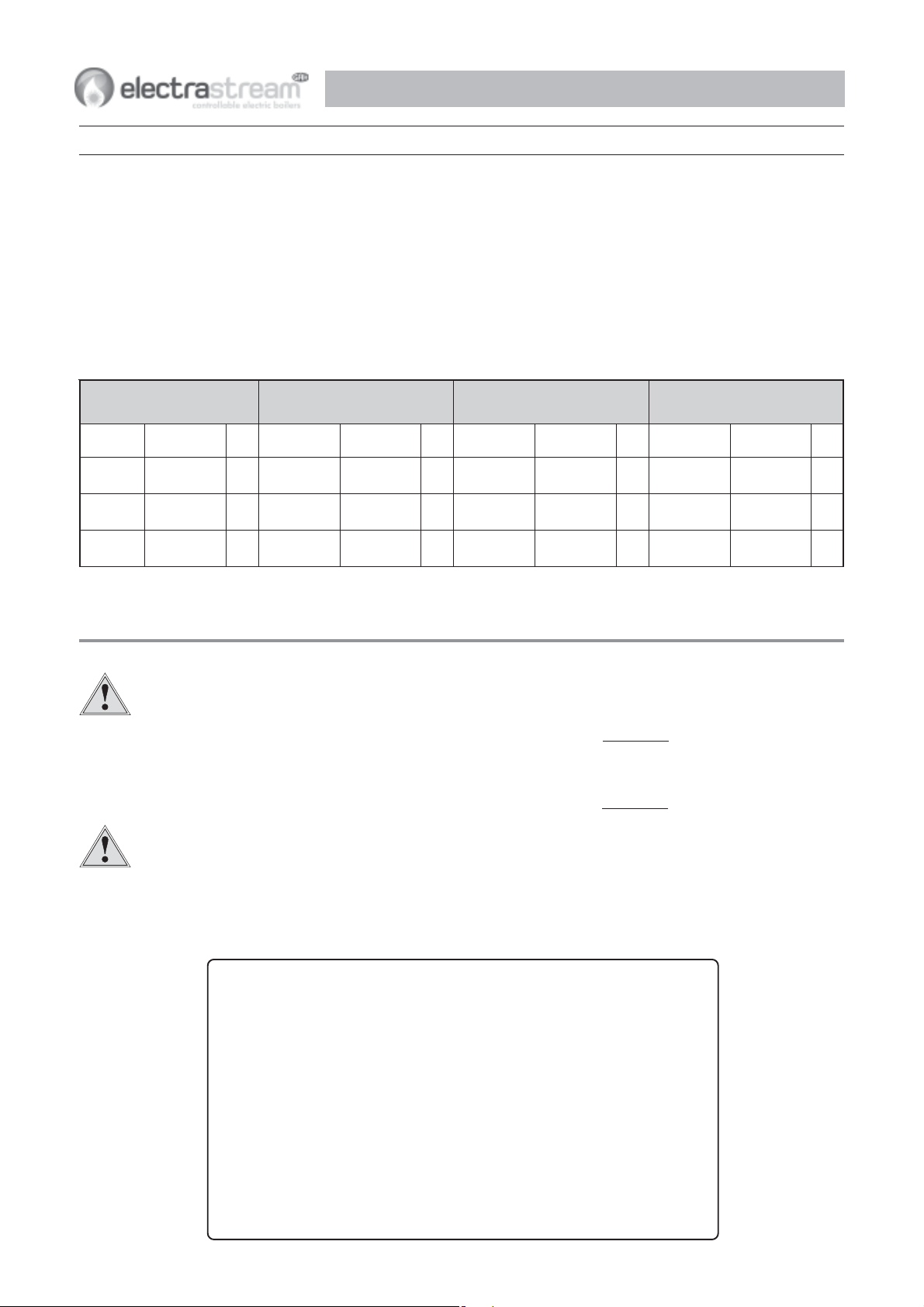

WEIGHTS OF PACKED CYLINDERS and COMPONENTS

ledoMthgiewkcaP

031LEB

051LEB

smetsySlioCelgniS

✓

gk55

gk06

ledoMthgiewkcaP

031PEB

051PEB

R521PEB

lioCelgniS

smetsySdebmulP-erP

✓

gk17

ledoMthgiewkcaP

512PTEB

gk67003gk05

gk77

lioCniwT

smetsySdebmulP-erP

✓

ledoMthgiewkcaP

gk771002gk53

'P'sulP

rotalumuccA

Storage

Prior to installation the cylinder and box should remain on its pallet with wrapping intact and stored upright. The cylinder and

components must be stored safely in a dry, frost free environment and protected from accidental damage.

✓

WARNING TO THE USERWARNING TO THE USER

WARNING TO THE USER

WARNING TO THE USERWARNING TO THE USER

DO NOT rDO NOT r

DO NOT r

DO NOT rDO NOT r

In the event of hot water/steam being emitted at the discharIn the event of hot water/steam being emitted at the dischar

In the event of hot water/steam being emitted at the dischar

In the event of hot water/steam being emitted at the discharIn the event of hot water/steam being emitted at the dischar

Fault Finding section 7.Fault Finding section 7.

Fault Finding section 7.

Fault Finding section 7.Fault Finding section 7.

If the ElectrastrIf the Electrastr

If the Electrastr

If the ElectrastrIf the Electrastr

This installation is subject to Building RThis installation is subject to Building R

This installation is subject to Building R

This installation is subject to Building RThis installation is subject to Building R

Use only manufacturUse only manufactur

Use only manufactur

Use only manufacturUse only manufactur

The following Information must be prThe following Information must be pr

The following Information must be pr

The following Information must be prThe following Information must be pr

emove or adjust any component paremove or adjust any component par

emove or adjust any component par

emove or adjust any component paremove or adjust any component par

eam system develops a fault or is not operating as expected: contact the eam system develops a fault or is not operating as expected: contact the

eam system develops a fault or is not operating as expected: contact the

eam system develops a fault or is not operating as expected: contact the eam system develops a fault or is not operating as expected: contact the

IMPORIMPOR

TANT TO THE INSTALLERTANT TO THE INSTALLER

IMPOR

TANT TO THE INSTALLER

IMPORIMPOR

TANT TO THE INSTALLERTANT TO THE INSTALLER

er’s rer’s r

ecommended recommended r

er’s r

ecommended r

er’s rer’s r

ecommended recommended r

ovided:-ovided:-

ovided:-

ovided:-ovided:-

INSTALLED BY:-

Name ............................................................................................................

Address .........................................................................................................

Tel. ................................................................................................................

Completion Date ...........................................................................................

ELECTRICS BY:-

Name ............................................................................................................

t of the unvented water heater: contact the t of the unvented water heater: contact the

t of the unvented water heater: contact the

t of the unvented water heater: contact the t of the unvented water heater: contact the

egulation Appregulation Appr

egulation Appr

egulation Appregulation Appr

eplacement pareplacement par

eplacement par

eplacement pareplacement par

oval, notifoval, notif

oval, notif

oval, notifoval, notif

ts.ts.

ts.

ts.ts.

INSTALLERINSTALLER

INSTALLER

INSTALLERINSTALLER

ge pipe or tundish, switch the system Off and contact installer - rge pipe or tundish, switch the system Off and contact installer - r

ge pipe or tundish, switch the system Off and contact installer - r

ge pipe or tundish, switch the system Off and contact installer - rge pipe or tundish, switch the system Off and contact installer - r

INSTALLERINSTALLER

INSTALLER

INSTALLERINSTALLER

y the Ly the L

ocal Authority of intention to install.ocal Authority of intention to install.

y the L

ocal Authority of intention to install.

y the Ly the L

ocal Authority of intention to install.ocal Authority of intention to install.

..

.

..

..

.

..

efer toefer to

efer to

efer toefer to

Address .........................................................................................................

Tel. ................................................................................................................

Completion Date ...........................................................................................

4

1-1 Introduction

GAH ElectrastrGAH Electrastr

GAH Electrastr

GAH ElectrastrGAH Electrastr

eam Systems aream Systems ar

eam Systems ar

eam Systems aream Systems ar

e pre pr

otected pending patent applications.otected pending patent applications.

e pr

otected pending patent applications.

e pre pr

otected pending patent applications.otected pending patent applications.

INTRODUCTION 1INTRODUCTION 1

INTRODUCTION 1

INTRODUCTION 1INTRODUCTION 1

11

1

11

ElectrastrElectrastr

Electrastr

ElectrastrElectrastr

This Handbook has been compiled to assist in the Installation and Operation of GAH (HEATING PRODUCTS) LIMITEDThis Handbook has been compiled to assist in the Installation and Operation of GAH (HEATING PRODUCTS) LIMITED

This Handbook has been compiled to assist in the Installation and Operation of GAH (HEATING PRODUCTS) LIMITED

This Handbook has been compiled to assist in the Installation and Operation of GAH (HEATING PRODUCTS) LIMITEDThis Handbook has been compiled to assist in the Installation and Operation of GAH (HEATING PRODUCTS) LIMITED

ElectrastrElectrastr

Electrastr

ElectrastrElectrastr

© 2009 GAH (HEATING PRODUCTS) LIMITED© 2009 GAH (HEATING PRODUCTS) LIMITED

© 2009 GAH (HEATING PRODUCTS) LIMITED

© 2009 GAH (HEATING PRODUCTS) LIMITED© 2009 GAH (HEATING PRODUCTS) LIMITED

Notified Body NB 0558Notified Body NB 0558

Notified Body NB 0558

Notified Body NB 0558Notified Body NB 0558

After installation the Installer of the system should give full operating instructions to the householder for the ElectrastrAfter installation the Installer of the system should give full operating instructions to the householder for the Electrastr

After installation the Installer of the system should give full operating instructions to the householder for the Electrastr

After installation the Installer of the system should give full operating instructions to the householder for the ElectrastrAfter installation the Installer of the system should give full operating instructions to the householder for the Electrastr

System. This User and Installation Manual must be left for the end userSystem. This User and Installation Manual must be left for the end user

System. This User and Installation Manual must be left for the end user

System. This User and Installation Manual must be left for the end userSystem. This User and Installation Manual must be left for the end user

eam is a Team is a T

eam is a T

eam is a Team is a T

eam domestic hot water and heating system.eam domestic hot water and heating system.

eam domestic hot water and heating system.

eam domestic hot water and heating system.eam domestic hot water and heating system.

rademark of GAH (HEATING PRODUCTS) Lrademark of GAH (HEATING PRODUCTS) L

rademark of GAH (HEATING PRODUCTS) L

rademark of GAH (HEATING PRODUCTS) Lrademark of GAH (HEATING PRODUCTS) L

1-1.1 The Electrastream System

The Electrastream system by GAH (Heating Products) Ltd. has been developed as a cost

effective solution for domestic hot and cold water and electric central heating with water

filled radiators.

Electrastream is a 9kW - 30,000 Btu system suitable for flats, small dwellings, offices,

home offices and granny annexes.

1-1.2 Electrastream Options Available

Consult GAH (Heating Products) Ltd.

1-1.3 Basic Principles

ELECTRASTREAM

Water in the unvented cylinder is heated by the high powered titanium electric tri-core

heater. Hot water is drawn from the cylinder and mixed with cold water by a thermostatic

mixing valve; this ensures safer lower temperatures at the hot water outlets.

The hot water within the unvented indirect cylinder also heats the water for the heating

system via the indirect coil within the cylinder. The circulating pump for the heating

system is controlled by a thermostat and programmable timer with override so that heat

is available on demand, providing there is a supply of hot water.

TD.TD.

TD.

TD.TD.

..

.

..

eameam

eam

eameam

ELECTRASTREAM PRE-PIPED

Operationally the same as the Electrastream but supplied pre-piped and assembled onto

a mounting frame.

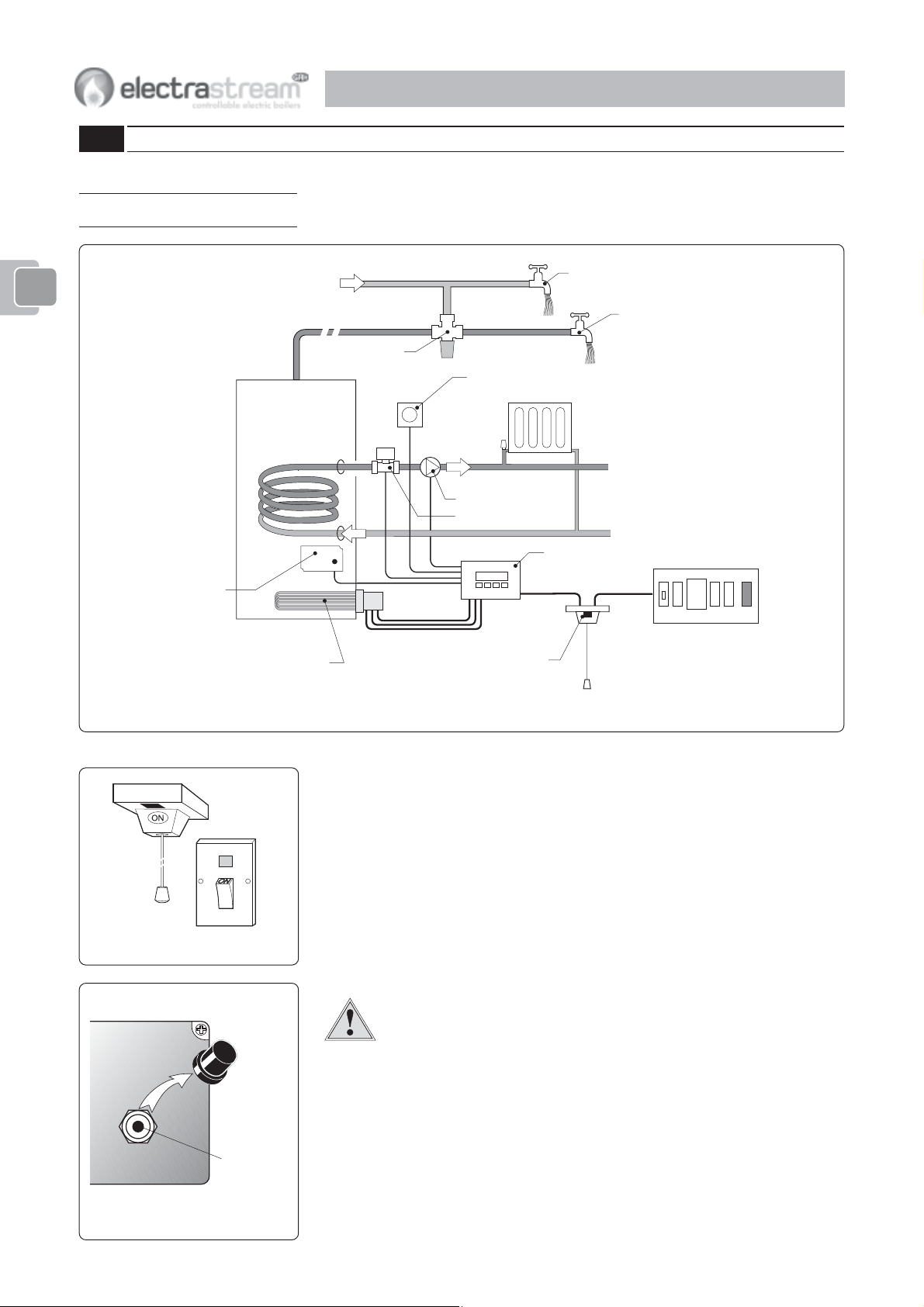

Electrastream

Control

Unit

Unvented

Indirect

Cylinder

Pump

Incoming

Water Main

Tri-core Heater

Thermostatic

Mixing Valve

Fig. 1-1a Electrastream

5

INTRODUCTION 1INTRODUCTION 1

INTRODUCTION 1

INTRODUCTION 1INTRODUCTION 1

11

1

11

ELECTRASTREAM TWIN COIL

Operationally the same as the Electrastream but supplied with a twin coil cylinder which

enables the Electrastream to be used in conjunction with alternative energy systems e.g.

Solar.

Electrastream

Control

Solar Collectors

Solar

Control

Unvented

Indirect

Cylinder

Electrastream

Coil

Tri-core

Heater

Primary Coil

for alternative

energy

Incoming

Water Main

Fig. 1-1b Electrastream Twin Coil - typical solar arrangement

Unit

Pump

Thermostatic

Mixing Valve

ELECTRASTREAM PLUS

Unvented

Indirect

Cylinder

Incoming

Water Main

Accumulator

Cold water storage

Electrastream

Control

Unit

Pump

Tri-core

Heater

Fig. 1-1c Electrastream Plus

Thermostatic

Mixing Valve

The Electrastream Plus system is supplied with a cold water storage accumulator.

The accumulator has an internally controlled butyl diaphragm, incoming cold water is

stored within this diaphragm at mains pressure. The air space between the diaphragm

and the accumulator case is pressurised, this balances the supply and maintains

pressure to the unvented hot water cylinder and cold outlets. When hot and cold water

outlets are turned on, the stored water from the accumulator supplements water from the

incoming main, this results in consistent pressure and flow to all taps, showers and baths

even when outlets are used simultaneously. Pressure will be sustained for as long as the

accumulator is holding sufficient volume of water.

ELECTRASTREAM PLUS PRE-PIPED

Operationally the same as the Electrastream Plus but supplied pre-piped and assembled

onto a mounting frame, the cold storage accumulator is supplied separately.

6

Note

For components supplied with system refer

to page 9.

Note

Further options are available consult GAH

(Heating Products) Ltd.

INTRODUCTION 1INTRODUCTION 1

INTRODUCTION 1

INTRODUCTION 1INTRODUCTION 1

1-1.4 Electrastream System Features

ELECTRASTREAM AND ELECTRASTREAM TWIN COIL

1. Only water and electric services required.

2. No gas or oil - no Boiler.

3. Central heating with conventional water filled radiators.

4. Heat on demand 24 hours a day.

5. Can be timed for economy tariff.

6. Far more flexible heating control than storage radiators.

7. Hot water to taps and shower from unvented cylinder.

8. Hot water to outlets temperature controlled by thermostatic mixing valve.

9. Mains pressure to hot and cold outlets.

10. All plumbing, water storage and controls are within the dwelling - no header tank.

11. Low maintenance cost, no CORGI Landlord Certificate required.

12. 9kW titanium tri-core heater (combined 3 x 3kW).

13. Tri-core heater will still work should one or two of its three elements fail.

14. Stainless Steel Unvented Cylinder with 25 years guarantee.

11

1

11

ELECTRASTREAM TWIN COIL

1. Cylinder with primary coil for alternative energy source typically solar and ground

source.

ELECTRASTREAM PLUS ONLY

1. Balanced hot and cold supply to taps.

2. All taps and showers at maximum system pressure.

3. Pressure maintained for both hot and cold taps even when other taps are open

(subject to volume used).

noitpOledoMedoCrednilyC

maertsartcelE031LEB

depip-erPmaertsartcelE521PEB

maertsartcelE

maertsartcelE051LEB

depip-erPmaertsartcelE051PEB

lioCniwTmaertsartcelEdepip-erPmaertsartcelE512PTEBliocniwtertil512

ertil031

ertil051

sulP rotalumuccA

031LEBmaertsartcelEP031LEB

ertil031

031PEBdepip-erPmaertsartcelEP031PEB

sulPmaertsartcelE

051LEBmaertsartcelEP051LEB

ertil051

051PEBdepip-erPmaertsartcelEP051PEB

sulPlioCniwTmaertsartcelE512PTEBdepip-erPmaertsartcelEP012PTEBliocniwtertil512

002ledoM

ertil071

7

INTRODUCTION 1INTRODUCTION 1

INTRODUCTION 1

INTRODUCTION 1INTRODUCTION 1

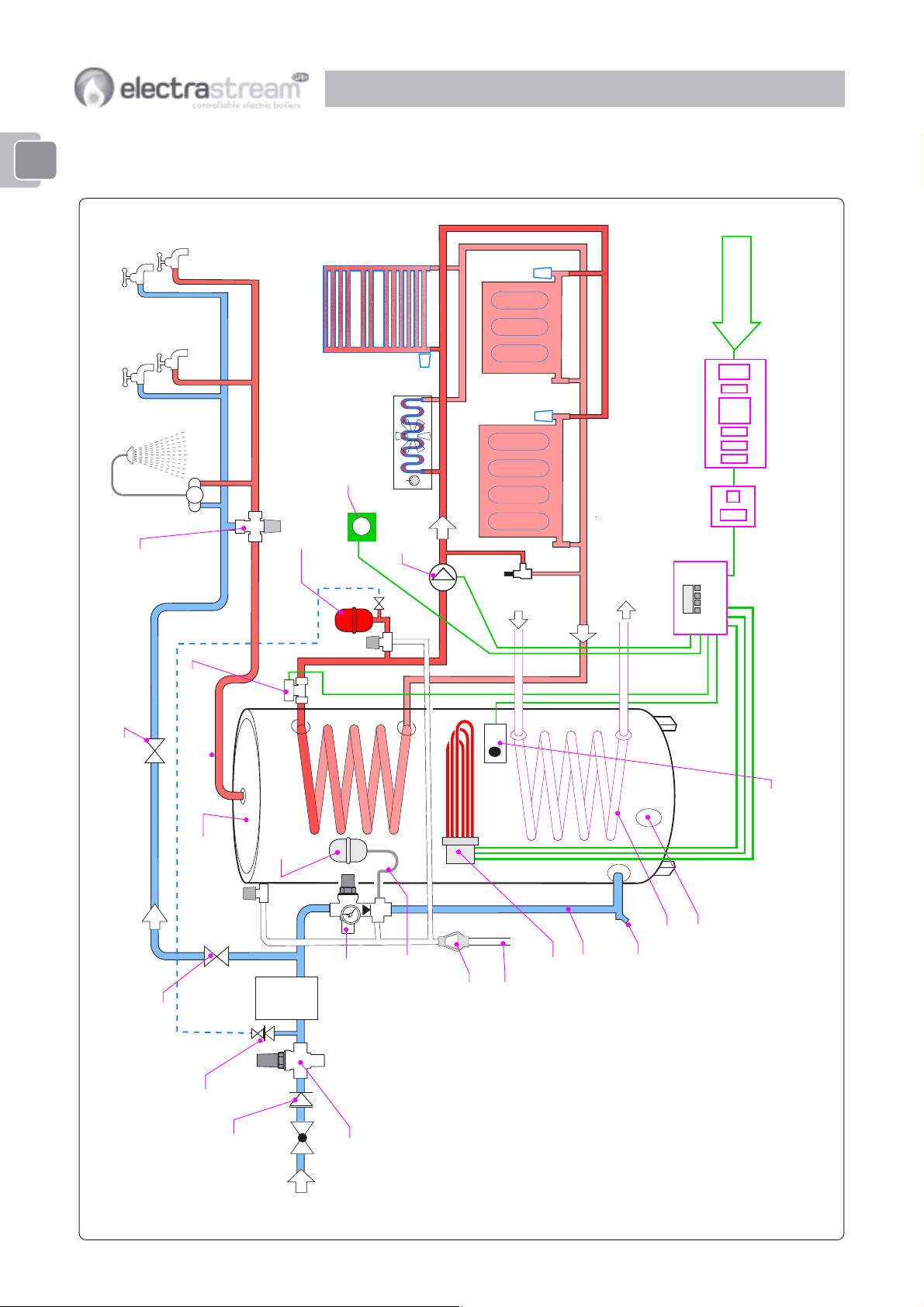

1-2 System Layout

11

1

11

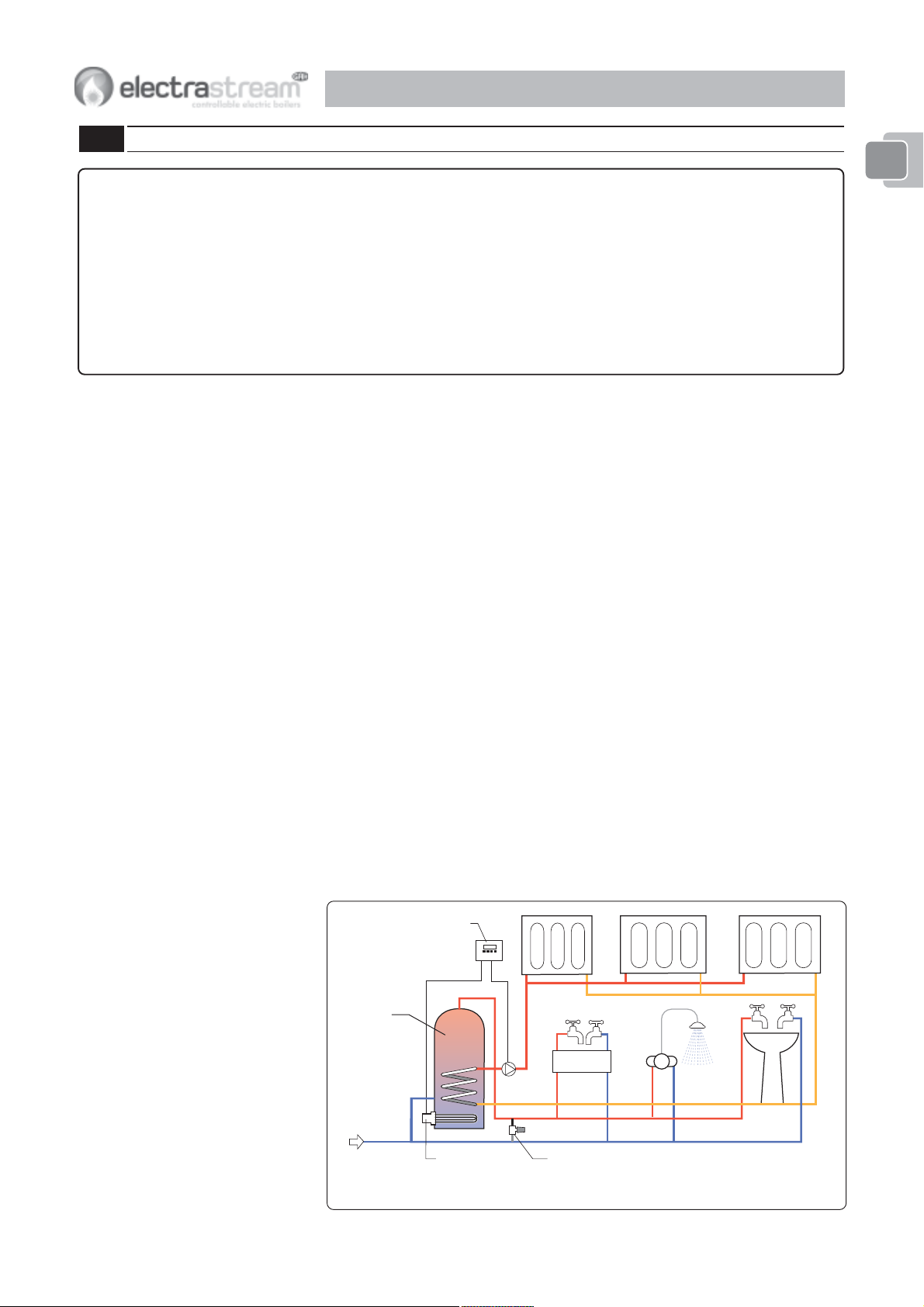

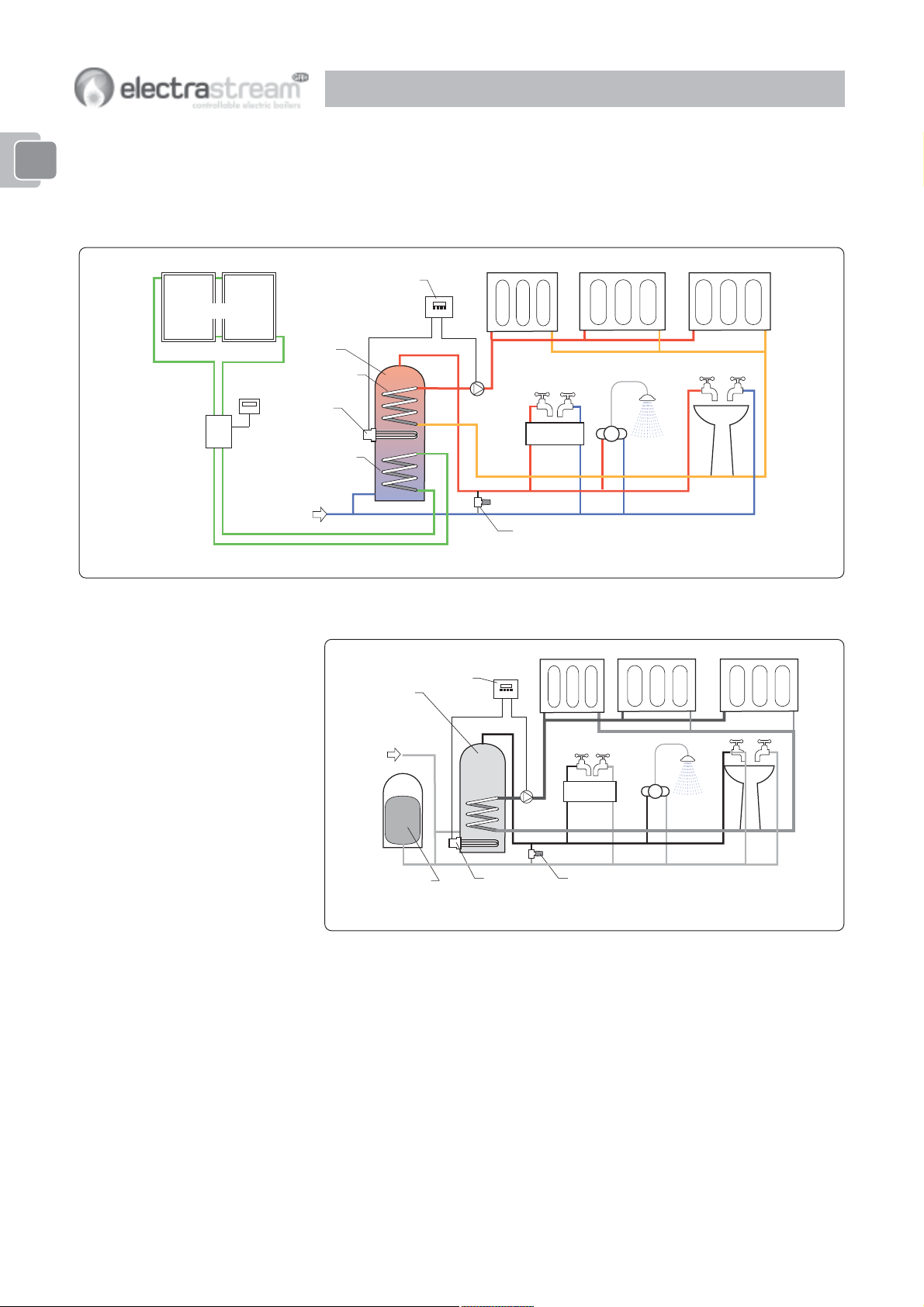

1-2.1 Electrastream

Economy Tariff

22mm

3Thermostatic Mixing Valve -

limits temperature of hot water to taps

Thermostatic

Shower

Hot supply to taps

Towel Rail

Shower Room

3Heating Expansion Vessel 8l

No valves to be fitted between PRV

and Expansion Vessel

3Hot Water

Expansion

Kitchen

Kick Space Heater

Room Thermostat

3Pump

& valves

Vessel

3Motorised

Valve

3PRV

3

28mm

FLOW 22mm

Bypass

RCD

Consumer Unit with RCD

2 Pole

Isolator

Control Unit

3Electrastream

RETURN 22mm

3

28mm

3Isolating Valve

Balanced cold supply to taps

3Isolating Valve

3TPRV

Single Check Valve

3Heating System Fill 15mm

22mm Incoming

Cylinder

3Unvented

22mm

Water

(option)

Softener

mains supply

3Cylinder Temperature Sensor

& Thermal Cut Out

PRV

15mm

15mm

3Tundish

3Combination Valve

3.5 Bar Pressure

Reducing Valve

3

Drain 15mm

Discharge

No valves to be fitted between

Cylinder and PRV

Fig. 1-2a Typical Schematic Installation - Electrastream

3Tri-core Heater Combined 3 x 3kW

8

a

r

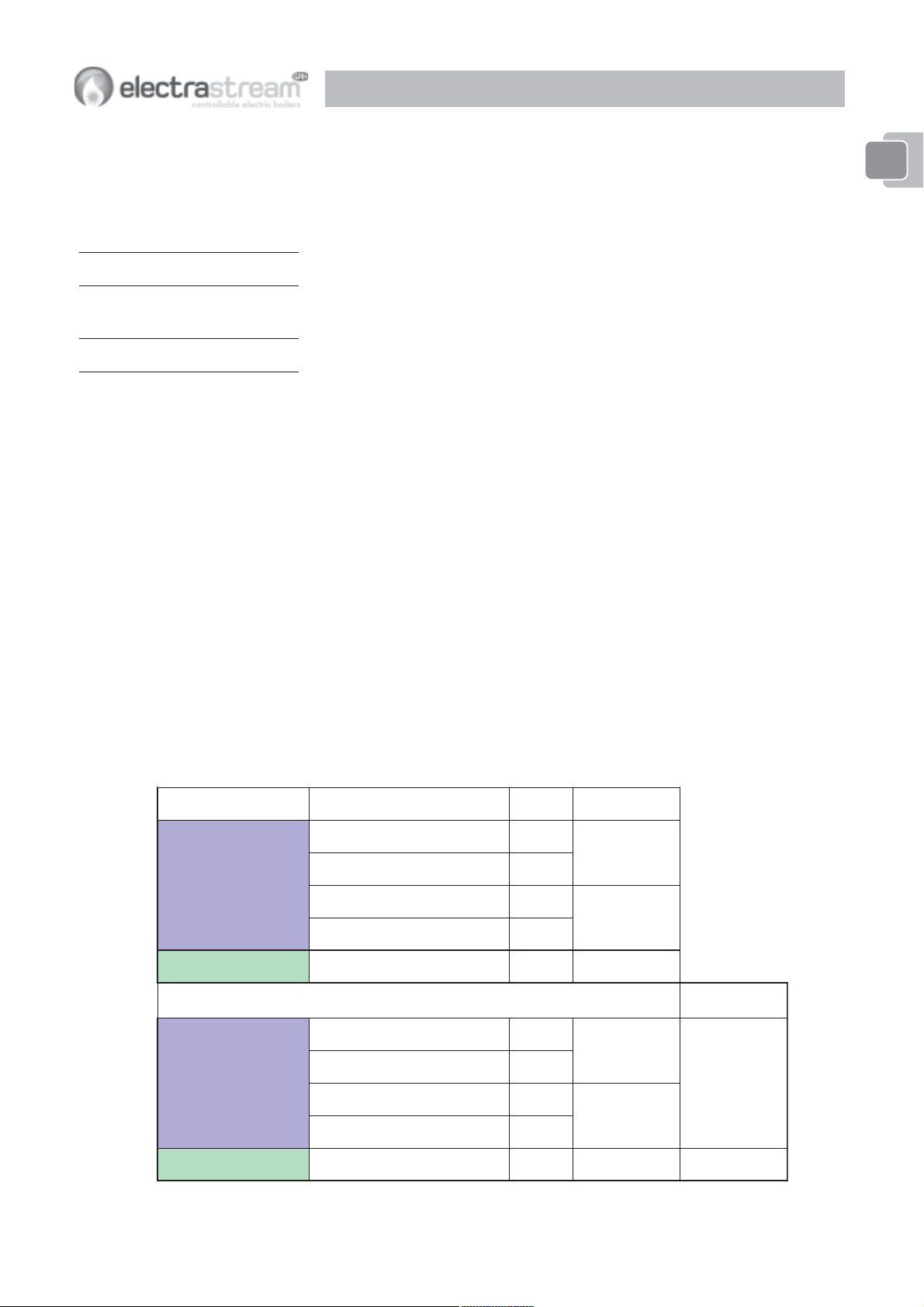

1-2.2 Electrastream Plus

INTRODUCTION 1INTRODUCTION 1

INTRODUCTION 1

INTRODUCTION 1INTRODUCTION 1

11

1

11

Hot supply to t

Thermostatic

Shower

✓Thermostatic Mixing Valve -

limits temperature of hot water to taps

Towel Rail

Shower Room

Room Thermostat

✓Heating Expansion Vessel 8l

No valves to be fitted between PRV

and Expansion Vessel

Vessel

Expansion

✓Hot Water

Kitchen

Kick Space Heater

FLOW 22mm

✓Pump

& valves

✓PRV

✓

28mm

✓Motorised

Valve

Bypass

✓

RETURN 22mm

28mm

Control Unit

✓Electrastream

Economy Ta

RCD

Consumer Unit with RCD

2 Pole

Isolator

Cylinder

✓Unvented

✓Isolating Valve

✓

✓ Isolating Valve

✓TPRV

22mm

Water

(option)

Softener

Balanced cold supply to taps

mains supply

22mm Incoming

Single Check Valve

✓Heating System Fill 15mm

PRV

15mm

✓Combination

Valve

Accumulator

✓

3.5 Bar Pressure

Reducing Valve

✓Tundish

✓

Discharge

Cold water storage

Drain 15mm

22mm

✓Cylinder Temperature Sensor

& Thermal Cut Out

Fig. 1-2b Typical Schematic Installation - Electrastream Plus 130 & 150

✓Tri-core Heater Combined 3 x 3kW

✓ Isolating Valve

9

INTRODUCTION 1INTRODUCTION 1

INTRODUCTION 1

INTRODUCTION 1INTRODUCTION 1

11

1

11

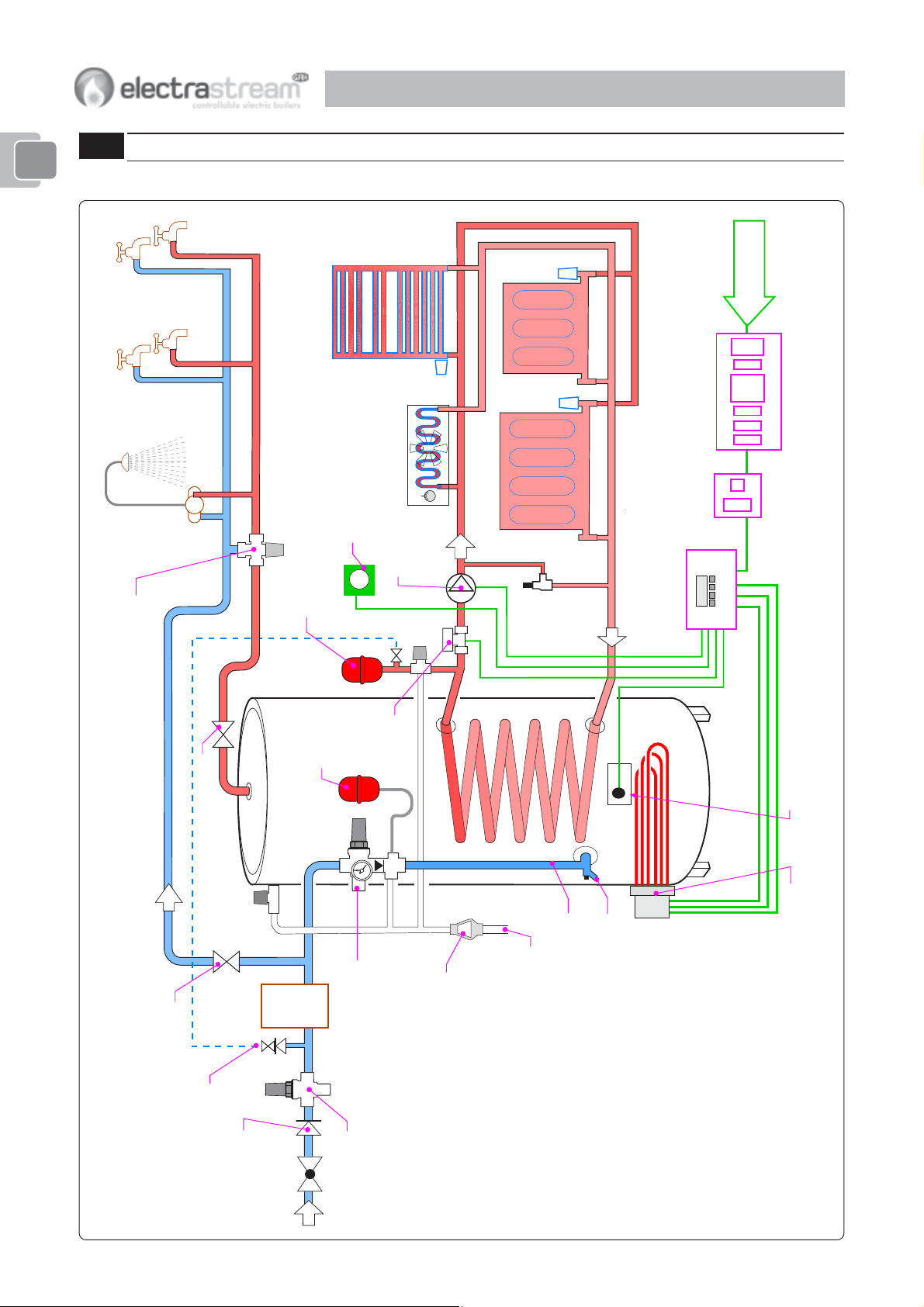

1-2.3 Twin Coil

3Thermostatic Mixing Valve -

limits temperature of hot water to taps

3Motorised

Thermostatic

Shower

Valve

Towel Rail

Shower Room

Hot supply to taps

3Heating Expansion Vessel 8l

No valves to be fitted between PRV

and Expansion Vessel

3

28mm

Kitchen

Room Thermostat

Kick Space Heater

3Pump

3PRV

& valves

3

28mm

FLOW 22mm

Bypass

source Flow

Alternative heat

source Return

Alternative heat

RETURN 22mm

3Electrastream

Control Unit

Economy Tariff

RCD

Consumer Unit with RCD

2 Pole

Isolator

10

3 Full Bore Isolating Valve

Cylinder

3Twin Coil Unvented

Balanced cold supply to taps

3Isolating Valve

3Heating System Fill 15mm

3TPRV

Single Check Valve

22mm

22 mm

Vessel

3HW Expansion

22mm

Water

(option)

Softener

Incoming

mains supply

3Combination Valve

3.5 Bar Pressure

Reducing Valve (option)

15mm

3

Fig. 1-2c Typical Schematic Installation - Electrastream Twin Coil 215, 255 & 305

PRV

Discharge

3Tundish

No valves to be fitted between PRV

and Expansion Vessel

22mm

Drain 15mm

No valves to be fitted between

Cylinder and PRV

3Tri-core Heater Combined 3 x 3kw

Primary Coil

Lower Immersion Heater

Tapping Blanked

3Cylinder Temperature Sensor & Thermal Cut Out

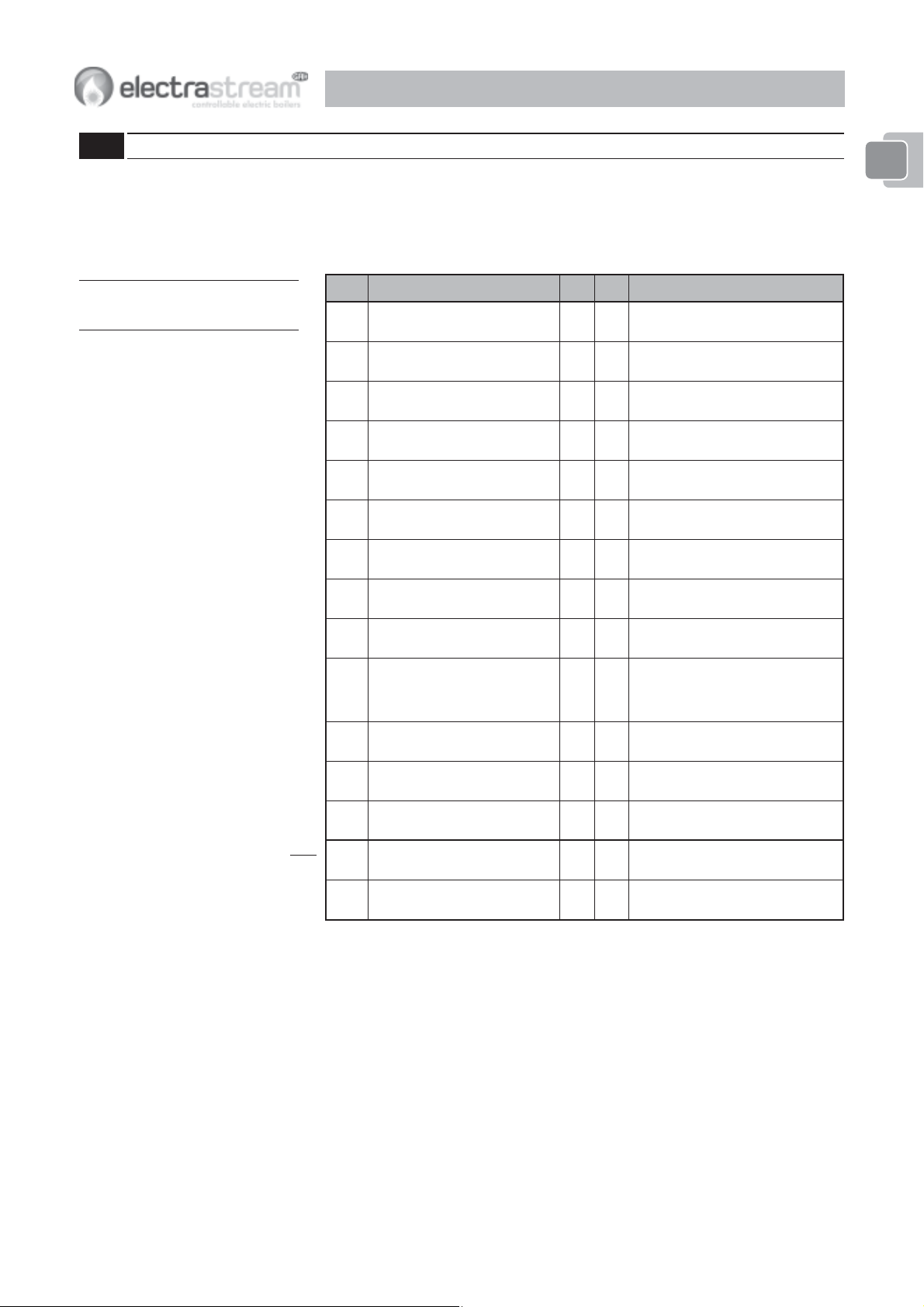

1-3 Parts Supplied

Note

On Electrastream Pre-piped units,

components are supplied already

assembled.

INTRODUCTION 1INTRODUCTION 1

INTRODUCTION 1

INTRODUCTION 1INTRODUCTION 1

Standard Electrastream systems will be delivered wrapped on single pallet with cylinder

together with box containing control box, expansion vessels and loose components.

Pre-Plumbed Electrastream systems will be delivered wrapped on single pallet with

cylinder, control box, expansion vessels and all components fully assembled.

metI traP .ytQ

1

lortnoCmaertsartcelE1

✓

setoN

rosneserutarepmetrednilycw/C

11

1

11

2

3

4

5

retaeHeroc-irTWk91

pmuPgnitalucriCHAG1

sevlaVgnitalosIpmuP2

6

7

8

evlaVnoitanibmoC1

9

01

11

21

evlaVdesirotoM1

tiKsgnittiF+rednilyCdetnevnU1

muinatiT

mm22

evlaVgnixiMcitatsomrehT1

tiK&lesseVnoisnapxEl8WHD1

xoBtatsomrehTrednilyC1

ssarBPSB"¾xmm22relpuoCIM4

evlaVreveLeroBlluFmm222

troP2

metsysdetcelesrofdeziS

Wk3x3denibmoC

esahPelgniSV032

morfretawtohhtiwretawdlocsdnelB

.spatrofrednilyc

,eguaGerusserP,pooLgnilliFw/C-etihW

partSdnatekcarB&VRPT

.)evlaVgnicudeRerusserP(VRPsedulcnI

.tatsedirrevolaunamw/C

nIdloCrednilyC-1

tuOtoHrednilyC-1

wolFgnitaeHrednilyC-1

nruteRgnitaeHrednilyC-1

spaTotylppuSdloC-1

spaTotylppuStoH-1

Electrastream Plus only

31

41

tiK&lesseV

rotalumuccA1

51

noisnapxEl8metsySgnitaeH

evlaVreveLeroBlluFmm221

1

partSdnatekcarB&VRPT

evlaVffOtuhSrotalumuccA

,eguaGerusserP,pooLgnilliFw/C-deR

l003rol002ledoMegarotSretaWdloC

11

INTRODUCTION 1 INTRODUCTION 1

INTRODUCTION 1

INTRODUCTION 1 INTRODUCTION 1

1-4 The Electrastream System

11

1

11

1-4.1 Hot & Cold Water Supply

Refer to fig. 1-2a for Electrastream.

Refer to fig. 1-2b for Electrastream Twin Coil

The incoming mains water supply is connected to the combination valve which is

Note

All installations must comply with relevant

regulations - refer to section 4-1.

assembled to the unvented indirect hot water cylinder. The combination valve has an

integral check valve. A single check valve is supplied, this is only required to be fitted if

back syphonage is possible from any item fitted prior to the combination valve.

Provision should also be provided in the cold supply for:-

1. Heating system fill.

2. Drinking water.

3. Water softener (when applicable).

4. Outside tap (when applicable).

The combination valve limits the incoming pressure to 3.5 Bar, it has an integral nonreturn valve and pressure relief valve (PRV).

Supply to the hot outlets is taken from the cylinder and mixed with cold water by the

thermostatic mixing valve, this ensures that a safer lower temperature hot water is

available at outlets.

Note

The alternative heat source must be

configured correctly to be used with the

GAH Electrastream system.

Note

The final fill of the heating system should

include the correct percentage of suitable

scale/corrosion inhibitor.

Cold supply to all outlets is taken direct from the main supply. If the mains pressure is

high (over 3.5 Bar) a 3.5 Bar pressure reducing valve is recommended.

1-4.2 Twin Coil - Alternative Heat Source

Twin Coil Cylinders have two coils, the upper coil is connected to the Electrastream

heating system. The Electrastream high powered titanium electric tri-core heater is

positioned about halfway up the cylinder so that it is only used to heat the water in the

upper part of the cylinder.

The lower coil is heated by the chosen alternative heat source (e.g. solar), this will heat

the water in the whole cylinder when ‘energy’ is available resulting in optimum efficiency.

1-4.3 System Control

The Electrastream system is controlled by a purpose designed Electrastream Control

Unit, this controls the hot water and heating ON/OFF times together with the heating

pump and valve. The control also has a dedicated programme that ensures efficient use

of electricity by selecting how many of the three immersion heater elements are required

to meet the current demand for heating or hot water.

1-4.4 Heating System

The heating system is for water filled radiators on a standard ‘sealed system’. The water

for the heating is heated by being pumped through the indirect coil of the cylinder. A

room thermostat and the Electrastream Control Unit’s programmable timers control the

circulating pump and motorised valve.

12

1-4.5 Electric System

The unvented cylinder is heated by a 240V, 9kW (combined 3 x 3kW) titanium tri-core

heater. This is controlled by the cylinder temperature sensor and the Electrastream

Control Unit.

Electrastream is designed to make full use of economy tariff electricity supplies and the

wiring must be arranged to make full use of this.

GAH offer a range of quality Water

Softeners, for information contact

GAH (HEATING PRODUCTS) LTD.

Note

When a water softener is fitted, the takeoffs for heating system fill, drinking water

and outside tap (when applicable), must

be positioned before the water softener.

INTRODUCTION 1INTRODUCTION 1

INTRODUCTION 1

INTRODUCTION 1INTRODUCTION 1

1-4.6 Output

The tri-core heater provides 9kW (30,000 Btu) for heating and hot water.

1-4.7 Scale Protection

IMPORTANT All installations should have a scale protection device fitted

and in areas known to have hard water, a water softening device is

strongly recommended. The cylinder is not guaranteed against damage

caused by scale. Higher water temperatures of 65°C and above can

cause excessive scale.

GAH recommend and promote the use of scale prevention devices and water softeners in

areas that are known to have hard water. Installed correctly they prolong the life of

equipment and help prevent limescale formation in the pipework. Water softeners

provide the advantages of soft water, as well as preventing scale build up on taps and

shower heads.

Water softeners and any mains fed system must be of adequate capacity and should be

installed with suitably sized hoses to prevent any possibility of flow reduction.

1-4.8 Frost Protection

When planning the installation location of both the accumulator and the unvented

cylinder, consideration must be given to the risk of frost and the use of frost protection.

The design of the accumulator gives it a degree of frost protection enabling it to be

located within the dwelling, loft space or garage without further protection.

The cylinder can also be installed within the dwelling or loft space without further

protection.

Cylinders or accumulators must have frost protection when they are installed where low

temperatures could be a potential problem. Cylinders can be protected by a frost

thermostat.

To comply with Building Regulations, all necessary pipework must be suitably lagged.

11

1

11

1-5 Tri-core Heater Operation

Note

Refer to 2-2.2 for display settings.

IMPORTANT

On twin coil cylinders the

Electrastream tri-core heater must

be fitted to the upper immersion

heater tapping.

1-4.9 Handling and Storage

The Electrastream system will be delivered fully wrapped and palleted.

Lift the package carefully using a safe and suitable lifting method.

Keep the packaging intact and store in a secure dry and weatherproof area prior to

installation.

The three elements of the tri-core heater are switched on and off by the Electrasteam

Control Unit. They have a staggered switch on sequence that prevents sudden high load

on the power supply.

The control unit also limits the use of the elements for efficiency.

When the hot water within the cylinder is within 2° of the set (8) Target 65°C, only one

element will be on.

When the hot water within the cylinder is between 2° and 4°C below the set (8) Target

65°C, then two elements will be on.

When the hot water within the cylinder is below 6°C of the set (8) Target 65°C, then all

three elements will be on.

13

2-1 System Control

OPERAOPERA

OPERA

OPERAOPERA

TOR CONTROLS 2TOR CONTROLS 2

TOR CONTROLS 2

TOR CONTROLS 2TOR CONTROLS 2

Note

On twin coil systems the alternative heat

source supplements the electric.

22

2

22

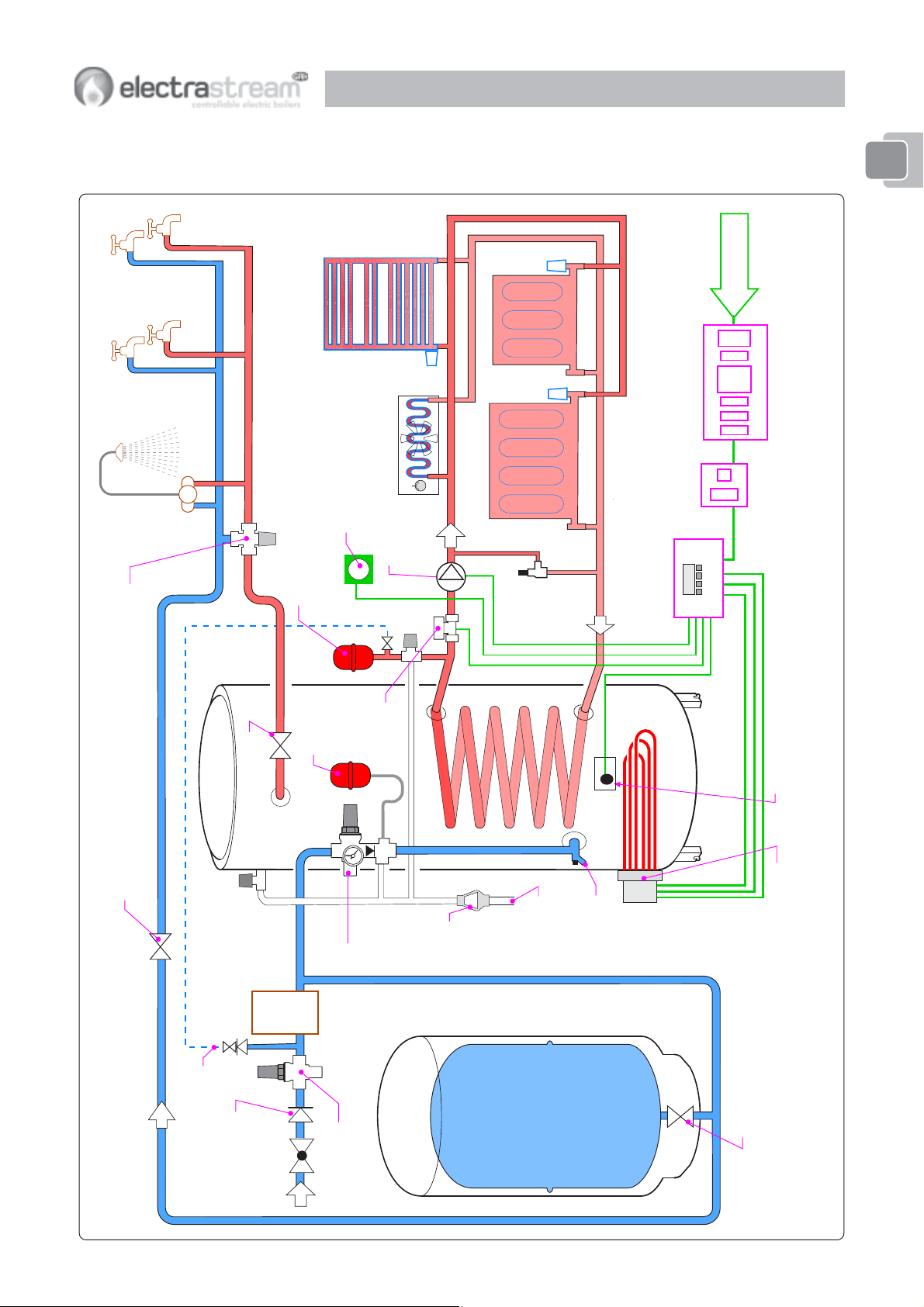

UNVENTED CYLINDER

CYLINDER

TEMPERATURE SENSOR

& THERMAL CUT-OUT

The heating and hot water system is all electric. The hot water for the taps (outlets) and

radiators is heated by the tri-core heater in the cylinder.

The system will have the following controls.

1

THERMOSTAIC

MIXING VALVE

ROOM THERMOSTAT

PUMP

MOTORISED VALVE

COLD WATER OUTLETS

ELECTRASTREAM

CONTROL UNIT

HOT WATER OUTLETS

CONSUMER UNIT

RC

TRI-CORE HEATER

Fig. 2-1b Isolating Switch

MANUAL RESET

BUTTON

Fig. 2-1c Thermal Cut-Out Thermostat

ISOLATING SWITCH

Fig. 2-1a Schematic of Typical Controls

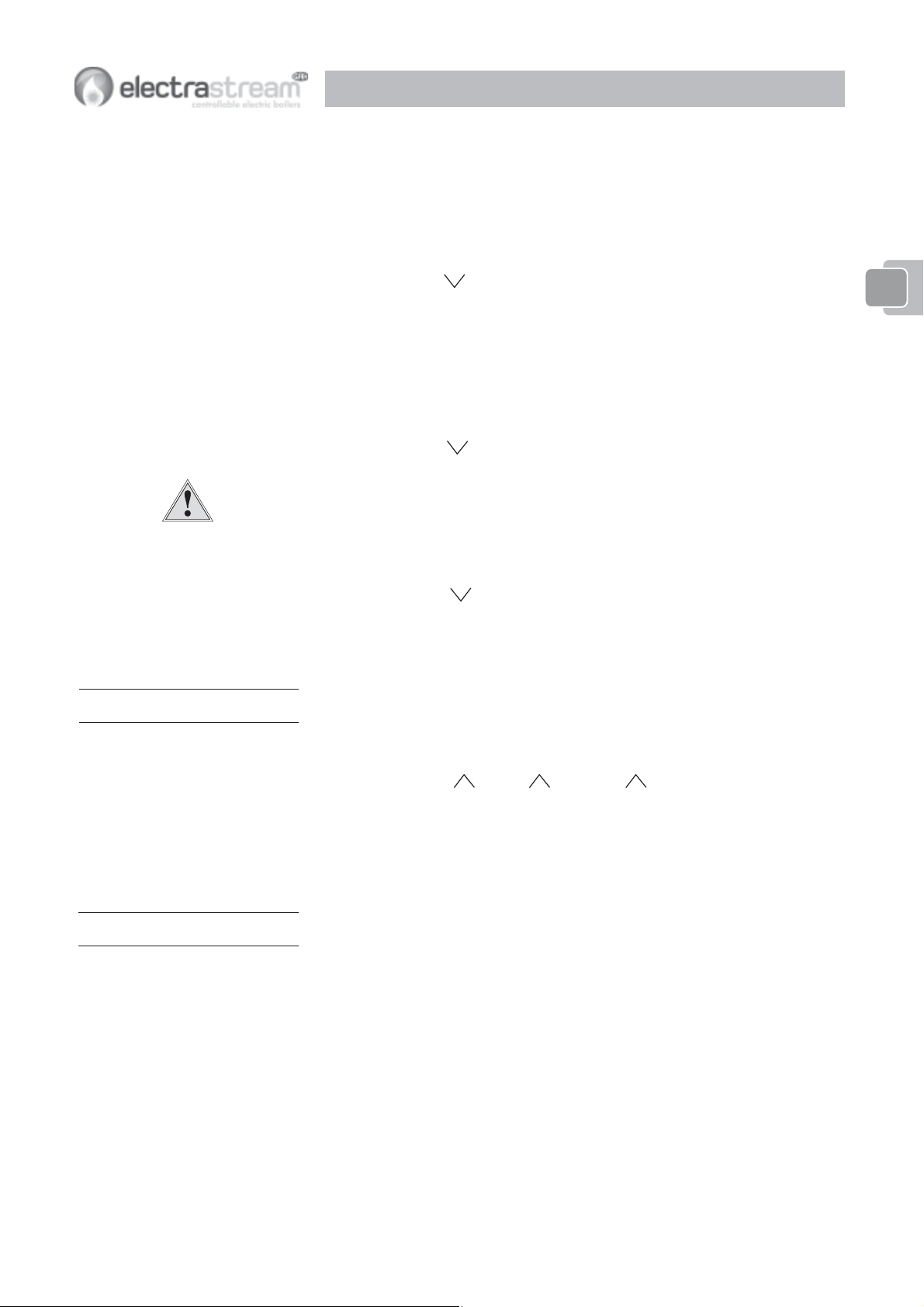

2-1.1 Isolating Switch

The system will have a double pole isolating switch with neon and mechanical indicators.

This could be a pull cord or wall mounted type.

When the switch is ON (neon on) the system is operational.

When the switch is OFF (neon off) no hot water or heating will be available.

It is advised to turn the switch off when hot water and heating are not required, i.e.

holidays etc.

2-1.2 Electrastream Tri-core Heater

WARNING Unlike immersion heaters, the Electrastream tri-core heater

does not have an internal thermostat, therefore the cover should not need

to be removed.

When the cover is removed live electrical terminals are exposed.

ISOLATE THE TRI-CORE HEATER BEFORE REMOVING ITS COVER.

2-1.3 Over Temperature Cut-Out Thermostat

In the Electrastream temperature sensor box on the cylinder is the over temperature cutout thermostat. This prevents the water within the cylinder from overheating.

The over temperature cut-out thermostat is a manual reset type, this means it has a small

button that pops up when the thermostat has been tripped by overheating.

To reset the system after overheating, switch heating and hot water OFF, allow time for

the water to cool, or run off some hot water, then remove the cap and press the button.

14

OPERAOPERA

OPERA

OPERAOPERA

If the over temperature cut-out trips more than once, switch off the Electrastream

isolating switch and contact your installer.

2-1.4 Heating Motorised Valve

When the room thermostat is calling for heat and the Electrastream control unit is set for

heat ON, the heating motorised valve will open allowing water to the radiators.

TOR CONTROLS 2TOR CONTROLS 2

TOR CONTROLS 2

TOR CONTROLS 2TOR CONTROLS 2

IMPORTANT

When a programmable room

thermostat is used it should only be

set to call for heat when ‘Economy

Tariff’ is available.

Note

Refer to 2-2 for the Electrastream Control

Unit display and settings.

Display icon ‘Valve

2-1.5 Pump

The heating circulating pump is controlled by the Electrastream Control Unit in response

to the room thermostat.

The pump has 3 speeds, it is normally set to speed 2 (II). Consult the Electrastream

installer before changing this setting - see 4-4.3.

Display icon ‘Pump

2-1.6 Room Thermostat

The room thermostat controls the heat within the property.

When the room thermostat is calling for heat and the Electrastream control unit is set for

heat ON, the heating circulating pump will run, pumping water through the radiators.

Display icon ‘Therm ’ indicates the room thermostat is calling for heat.

2-1.7 Tri-core Heater Elements

The three elements heat the water in the cylinder when the Electrastream control unit is

programmed for a heat cycle. The elements are switched On and Off by the

Electrastream control unit in response to the temperature within the cylinder as detected

by the temperature sensor.

The elements have a staggered On sequence to prevent sudden loads - see 1-5.

’ indicates the valve is open.

’ indicates the pump is ON.

22

2

22

Note

Testing the RCD will not cause loss of the

Electrastream Control Unit settings.

Display icons ‘Heat 1 , Heat 2 , and Heat 3 indicate that the elements are

heating.

If either of the Heat icons are displaying an exclamation mark

an element - see 2-2.3.

2-1.8 Residual Current Device (RCD)

The Electrastream system will be protected by a Residual Current Device, this will

automatically switch Off the electric supply if an earth fault develops.

The RCD must be tested at least every three months, this is done by pressing the RCD

‘Test’ or ‘T’ button, this should switch the supply Off. Reset RCD to On after test.

If the RCD appears not to be working correctly contact your installer or a qualified

electrician.

2-1.9 Alternative Heat Source Controls

For twin coil systems the alternative heat source will have its own controls - refer to

manufacturers instructions.

The alternative heat source would normally be a cost effective method of heating the

cylinder and should be used and controlled for optimum performance thus reducing

heating costs.

‘!’ ‘!’

‘!’ this indicates a fault with

‘!’ ‘!’

15

OPERAOPERA

OPERA

OPERAOPERA

TOR CONTROLS 2TOR CONTROLS 2

TOR CONTROLS 2

TOR CONTROLS 2TOR CONTROLS 2

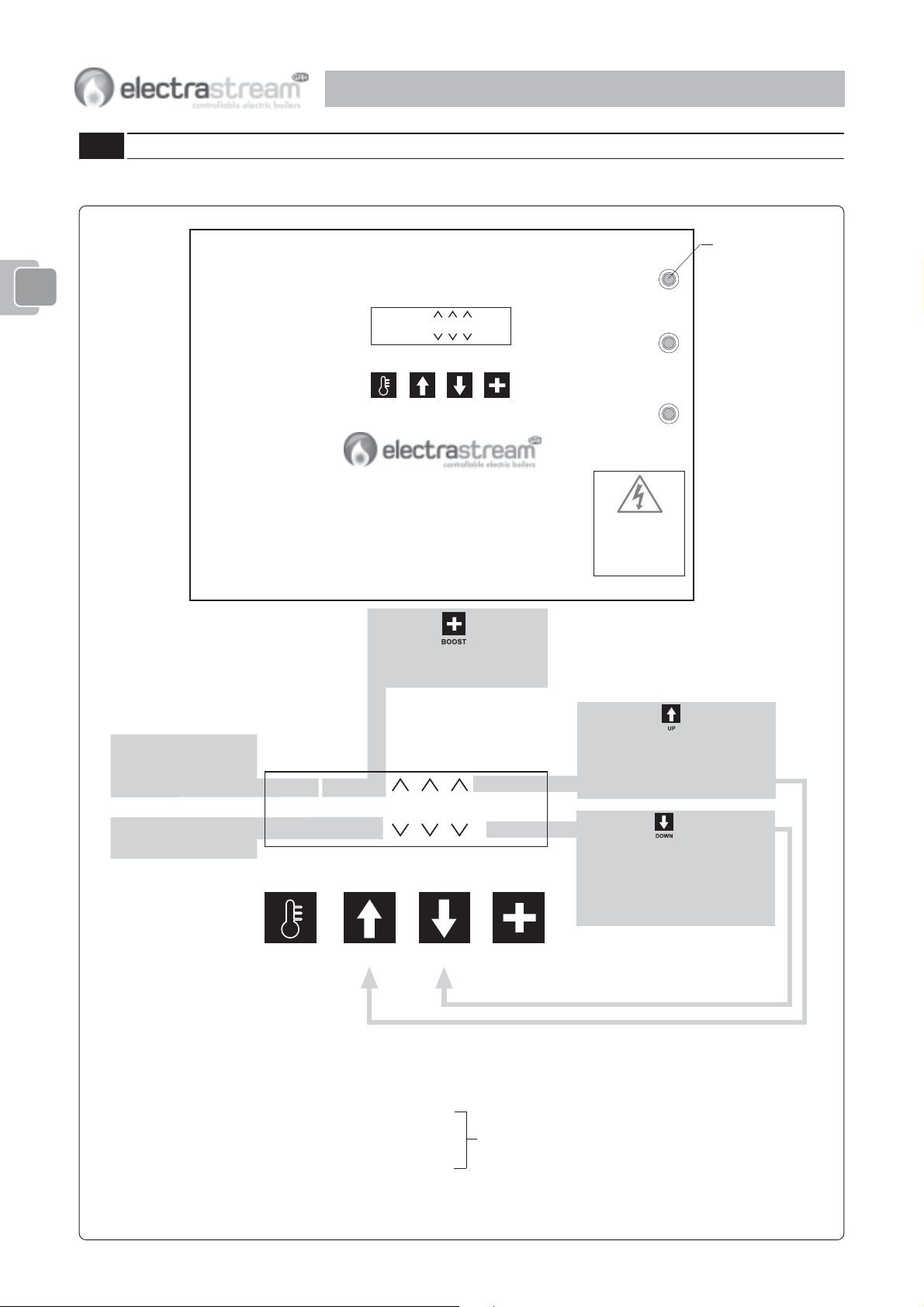

2-2 Electrastream Control Unit

2-2.1 Control Unit Display - Normal Screen

RESETTABLE THERMAL TRIPS

11

1

22

2

22

WATER TEMP

24°c Boost

Day hh:mm

HEAT 1

VALVE

HEAT 2

PUMP

HEAT 3

Auto/On/Off

THERM

MODE

HOT WATER

Auto/Off

HEATING

MODE

11

22

2

22

For display settings see 2-2.2

For error displays see 2-2.3

Displays actual water

temperature in cylinder

Set by (8) Target °c

Displays current Day

and Time (24 hr clock)

SET UP DOWN BOOST

ELECTRASTREAM

CONTROL

GAH HEATING PRODUCTS Ltd. 01394 421160

Toggled by

Boost displayed - Heating

On until next set OFF time

WATER TEMP

24°c Boost

HEAT 1

HEAT 2

HEAT 3

Auto/On/Off

Day hh:mm

THERM

PUMP

VALV E

MODE

HOT WATER

Auto/Off

HEATING

MODE

33

3

33

CAUTION

HIGH VOLTAGE!

DO NOT REMOVE ANY

COVERS (INCLUDING

ROOM THERMOSTAT)

BEFORE ISOLATING

THIS UNIT

Toggled by

Auto Timed

On Hot Water permanently ON

Off Hot Water permanently OFF

Toggled by

Auto Timed

Not available when HOT WATER MODE is Off

Off Heating Permanently OFF

Notes:- Select to turn heating off.

For Heating On use Boost.

16

SET DOWN BOOST

HEAT 1 Indicates Element 1 is ON HEAT 1

HEAT 2 Indicates Element 2 is ON HEAT 2

HEAT 3 Indicates Element 3 is ON HEAT 3

VALVE Indicates Heating Valve is OPEN

PUMP Indicates Heating Pump is ON

THERM Indicates Room Stat is calling for heat

>

>>

>>

>

>>

>>

>

>>

>>

>>

>>

>

>>

>>

>

>>

>>

>

UP

! !

! Indicates heater element has failed - see 2-2.4

! !

! !

! Indicates heater element has failed - see 2-2.4

! !

! !

! Indicates heater element has failed - see 2-2.4

! !

Heating on

TEST 1......5 Indicates heater test is being performed after midnight, this may take up to 30 minutes

Fig. 2-2a Electrastream Control Unit - Normal Screen

NORMAL SCREEN

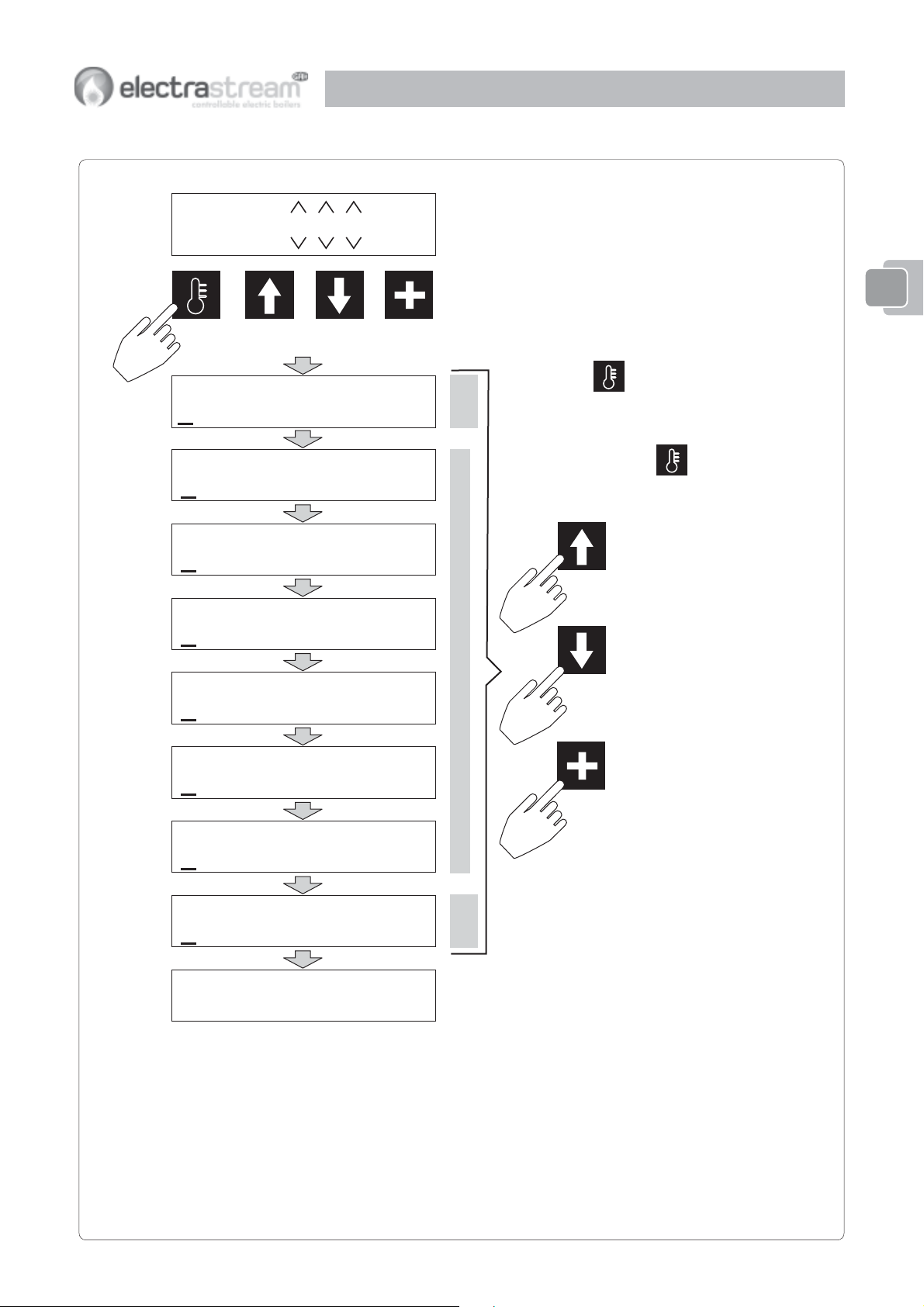

2-2.2 Display Time Settings

OPERAOPERA

OPERA

OPERAOPERA

TOR CONTROLS 2TOR CONTROLS 2

TOR CONTROLS 2

TOR CONTROLS 2TOR CONTROLS 2

24°c Boost

Day hh:mm

SET DOWN BOOST

UP

Auto/On/Off

Auto/Off

(1) Time

Day hh:mm

(2) Start 1

hh:mm

(3) Stop 1

hh:mm

(4) Start 2

hh:mm

22

2

22

When

DATE

TIME &

displayed for 10 seconds, display then reverts

back to normal screen

Repeat pressing

settings.

UP

SET is pressed, time settings are

SET to index through

Use to increment time up

Use to increment time down

(5) Stop 2

hh:mm

(6) Start 3

hh:mm

HEATING & HOT WATER

(7) Stop 3

hh:mm

(8) Target

65 °C

Hrs Run = 0000.1

0000.0 0000.0

Notes:All times are given in 24 hour clock.

Maximum cylinder temperature setting (Target °C) is 70°C.

TEMP.

WATER

Display only. Indicates the total hours that each tri-core

heater element has been in operation. (For service

engineers information only.)

DOWN

Use to select hours (hh:) or

minutes (:mm)

BOOST

For error displays see 2-2.3

Fig. 2-2b Electrastream Control Unit - Display Settings

17

Loading...

Loading...