Page 1

INSTRUCTION MANUAL

NSW Schools / TAFE - MB1250

Magnetic Panbrake (240V)

1300 x 1.6mm

K8303

Page 1

Instruction Manual for MB1250 (K8303)

01/12/2015

Page 2

# S5251 EB625 4/6/08

Page 2

Instruction Manual for MB1250 (K8303)

01/12/2015

# S5291 EB1000

# S5291 EB1250

ELECTRABRAKE

Electromagnetic sheetmetal bending machines

User Manual on the

EB 0625/1000/1250

Page 3

PAGE 1

Page 3

Instruction Manual for MB1250 (K8303)

01/12/2015

INTRODUCTION

ELECTRABRAKE machines use an electromagnet, rather than mechanical clamping. The

machine consists of a long electromagnet with a steel clamp bar located above it. The sheet

metal is clamped between the two surfaces by an electromagnet capable of clamping with a force

range of between 3 - 12 Tons. Rotating the bending beam then forms the bend. The sheet is bent

around the front edge of the clamp-bar.

Using the machine is simple, slide the sheet in under the clamp-bar; press the start-button to

initiate clamping; pull the handle to form the bend to the desired angle; and then return the handle

to automatically release the clamping force. The folded sheet can now be removed or

repositioned ready for another bend.

The special centre less compound hinges are distributed along the length of the bendi ng beam

allowing bending loads close to where they are generated.

The combined effect of the magnetic clamping with the special center less hinges means that the

ELECTRABRAKE is a very compact, space saving, machine with a very high strength-to-weight

ratio.

ELECTRABRAKE EB0625 EB1000 & EB1250

The ELECTRABRAKE EB0625, EB1000 & EB1250 are highly versatile sheet metal folding

machines used to bend mild steel and aluminium sheet metal. Thicknesses of up to 1.6 mm thick

can be folded across the full length of these machines. These multi-purpose machines bend

sheet metal of lengths 625mm, 1000mm and 1250mm respectively.

The ELECTRABRAKE magnetic clamping system replaces the bulky clamping structure used in

conventional folding machines. The small compact clamp bar does not hinder or obstruct the

work piece. Automatic electromagnetic clamping and unclamping, means faster operation. These

machines have much greater versatility than conventional sheet metal benders. The machines

are ideal for use in the sheet metal industry, air-conditioning and building industries.

An electrical interlock is offered to enhance Operator Safety. This operation ensures that a safe

pre-clamping force must be applied before full-clamping can be engaged.

ACCESSORIES

Adjustable backstops, storage tray and a complete set of short-length clamp-bars are included

as Standard Accessories.

A narrow clamp bar, a slotted clamp bar for forming shallow boxes more quickly and a power

shear with guide for straight distortion-free cutting of up to 1.6 mm thick is all available as

Optional Extra Accessories. A further optional extra is a foot switch which is available for

theEB1250 unit only.

A Full 12 month Warranty is offered that covers faulty materials and workmanship.

Page 4

ASSEMBLY

Page 4

Instruction Manual for MB1250 (K8303)

01/12/2015

HOW TO ASSEMBLE YOUR ELECTRABRAKE

Note: The machine is supplied upside down for assembly purposes.

1. Remove all parts from the crate with the exception of ELECTRABRAKE magnet body

assembly.

2. Find the 6mm Allen Key and fasteners supplied.

3. Use slings provided to remove the magnet body from the crate. Rest the body on wooden

blocks supplied.

4. Attach the feet to column

by using the M10 x 16 button-head screws provided. Point the

pair of feet forwards ensuring that the safety tape is facing forwards. Ensure that the

joining seam on the column faces to the backwards.

5. On Models EB0625 and EB1000, fasten foot plate under front feet using M10 by 16 caphead screws with washers. Alignment is easier if foot mounting is not tightened until the

foot plate is fitted. The rear feet cap head screws can be adjusted to level the machine.

A foot plate is not supplied with the EB1250 machine. The machine is bolted directly to

the floor at the front feet.

6. Place the ELECTRABRAKE magnet body on the stand securing it with M8 x 16 cap head

screws. This would be best if lifted with a lifting facility or some assistance. On Models

EB0625 and EB1000 ensure that connector and wires are g uided down the column as

the magnet body is lowered on to the stand.

7. On Models EB0625 and EB1000, connect the electromagnet to the electrical unit by

removing the rear access panel and plug the three pin connectors together. Refit access

panel.

8. On Model EB0625 using the M6 pan head screws and nuts, join the two halves of the

tray. Using M8 x 12 cap head screws attach tray to rear of machine. Fit rubber mat inside

tray. Attach backstop slides to the sides of tray. On Model EB1000 and EB1250, use two

M8 x 16 cap head screws to attach the two back stop bars. Slide the stop collars onto

each back stop bar. Fit rubber mat.

9. Using M8 x16 cap head screws attach the handle (s) to the bending beam. Before

attaching the handle on Models EB0625 and EB1000, slide it through the angle

indicating ring. On Model EB1250, slide stop collar to the top of the handle and tighten.

Fit the handle with angle scale to the right side.

10. On Model EB 1250 rotate the bending beam to 180 °. Slide angle indicator unit on to

right handle. Attach the two arms to the indicator spindle at the anchor block. To ensure

correct operation, securely fasten screws to switch mechanism.

11. Use solvent i.e. turpentine to remove the clear protective coating from the top of the unit

and from the clamp bar.

12. Place the clamp bar on the magnet body.

13. To obtain excellent results follow the operating instructions.

Page 2

Page 5

Page 3

Page 5

Instruction Manual for MB1250 (K8303)

01/12/2015

OPERATING PROCEDURES

GENERAL CAUTIONARY IMPORTANT WARNINGS

Electrabrake machines are designed for ONE operator only, which includes the inserting of the

sheet metal and operating the switches.

See specifications for clamping strength – please note that the force is several tonnes. All units

are fitted with a two-handed interlocking system to prevent hands being accidentally trapped

when clamping.

Safety procedures:

1. Safe pre-clamping is engaged

2. Full clamping is activated

3. Lower clamp bar to 5mm of the bed

4. Magnet will disengage

STANDARD BENDING

Preparation: Switch on power. Check that the clamp bar is correctly positioned.

♦ Set the machine to suit the sheet metal thickness by rotating the 2 adjuster pins situated

on top of the clamp bar. Check the clearance by lifting the bending beam at 90 deg. and

examine the gap. To achieve and perfect bend, set a fractionally larger gap than the

thickness of the sheet metal between the edge of the clamp bar and the face of the

bending beam.

♦ Place sheet metal under clamp bar – the backstop can be used if needed.

♦ To apply pre-claming force use start button or the foot-switch to activate the magnet.

♦ To activate the micro-switch for full clamping, pull one of the bending handles with your

free hand. Release footswitch or start button.

♦ Pull on both handles and begin bending until the angle required is achieved. The right

handle has a angle scale, which graduates continuously. To allow for spring ba ck of the

sheet metal, bend a few degrees more than the angle that is required.

♦ The electrical circuit of the machine releases a reverse pulse as soon as the bending

beam starts its journey to the home position, allowing the clamp bar to release

immediately.

CAUTION

Do not insert small items under the clamp bar – a minimum lip bend of 15mm is required

except when bending very lightweight soft metal.

Page 6

Page 6

Instruction Manual for MB1250 (K8303)

01/12/2015

Page 4

To get the best performance do not clamp longer than is necessary due to the magnet having

less clamping force when heated.

HOW TO USE THE BACKSTOPS

Make use of the backstops when handling volume bends that are all the same size. Set the

backstops to the depth required.

Backstops can be used with a bar (not supplied) laid against them, making a long surface to

use as a reference.

Use a strip of sheet metal of the same thickness as the work piece if a backstop is required

under the clamp bar.

Page 7

Page 7

Instruction Manual for MB1250 (K8303)

01/12/2015

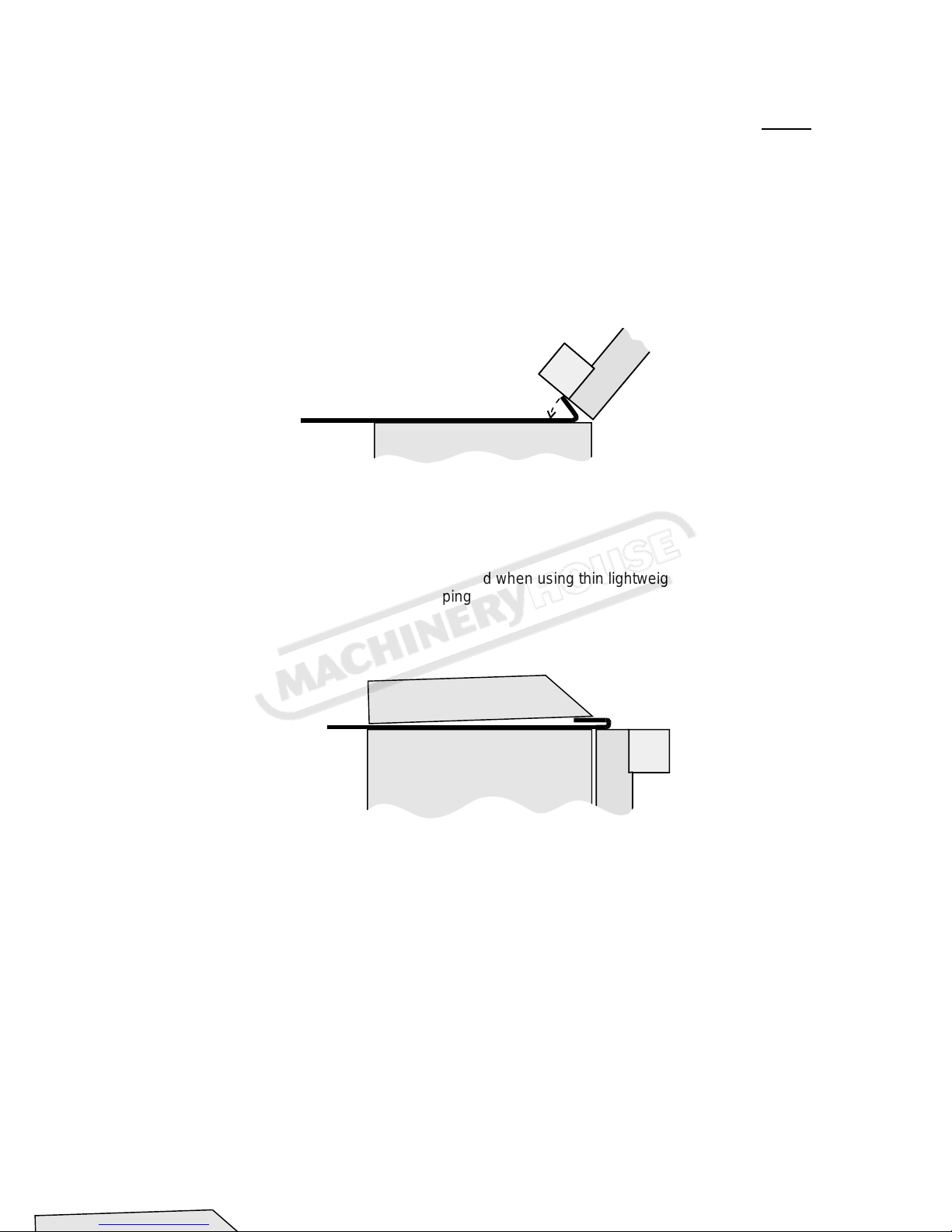

HOW TO FOLD A LIP

Folding the lip will depend on the sheet metal thickness and the length and width.

Lightweight sheet metal up to 0.8mm.

1. Carry out instruction for standard bending and continue to bend as far as possible.

2. Take away the clamp bar, leave the sheet metal on the machine and move 10mm

backwards, bring over the bending beam and compress the lip. No clamping is

required. Thick sheet metal is not suitable for this application.

3. Further flattening can be accomplished when using thin lightweight material by

following up with magnetic clamping

Page 5

Page 8

HOW TO MAKE A ROLLED EDGE

Page 8

Instruction Manual for MB1250 (K8303)

01/12/2015

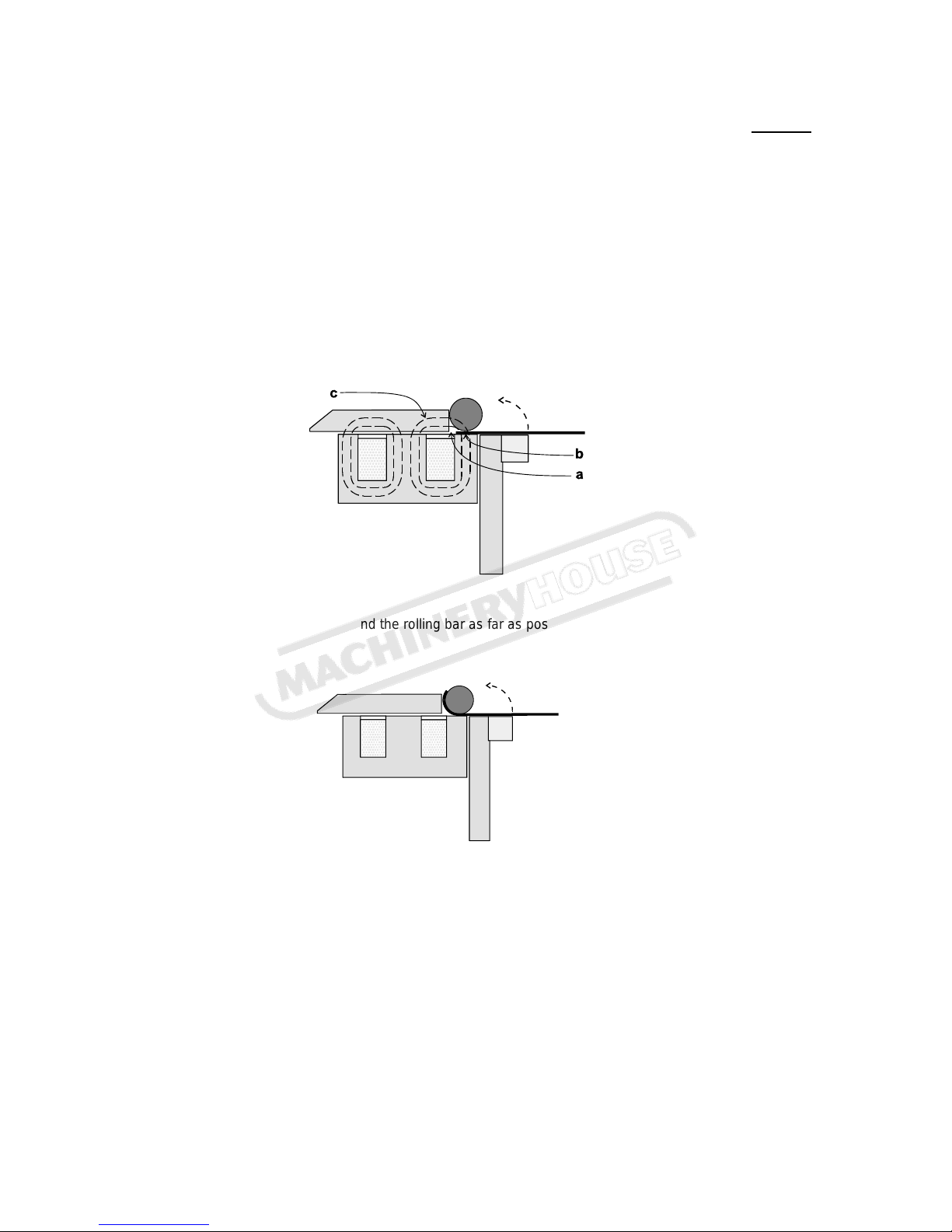

Wrap sheet metal around a round steel bar or pipe.

1. Position sheet metal clamp bar and round pipe/bar as indicated on drawing.

i) To avoid weak clamping make sure that the clamp bar does not overlap the

machines front pole (A).

ii) Ensure that the rolling pipe is resting on the front pole of the machine (B). It

must not sit on the aluminium surface of the machine.

iii) The clamp bar provides a magnetic pathway (C) for the rolling bar.

2. Wrap the sheet metal around the rolling bar as far as possible –

3. Repeat step 2 until rolled edge is formed to required diameter.

Page 6

Page 9

Page 7

Page 9

Instruction Manual for MB1250 (K8303)

01/12/2015

HOW TO FORM A TEST PIECE

To learn how to work the Electrabrake with confidence it is recommended that test pieces are

made.

Use a piece of 0.8 mm thick x 320 x 200mm aluminium or mild steel sheet. Mark sheet as per

drawing

8

200

180°

Bend 1

45

95

117

190

90° reverse bend (mark this line on the

Bend 2

reverse side of the sheet)

Bend 3

90°

Bend 4 90°

90°

Bend 5

Form a lip on the edge of the sheet metal (see: How to form a lip)

Turn sheet metal over and insert under the clamp bar with the folded lip end toward you. Tilt

clamp bar and line up bend marked 2. Bend to 90 degrees as shown in drawing below.

335

This section to be rolled around Ø25mm

round bar

Turn sheet metal over and continue with steps marked 3, 4 and 5 bent to 90 degrees.

Roll the remaining piece around a 25 mm diameter round bar (see How to make a rolled edg e)

See drawing below for completed job.

Page 10

Page 8

Page 10

Instruction Manual for MB1250 (K8303)

01/12/2015

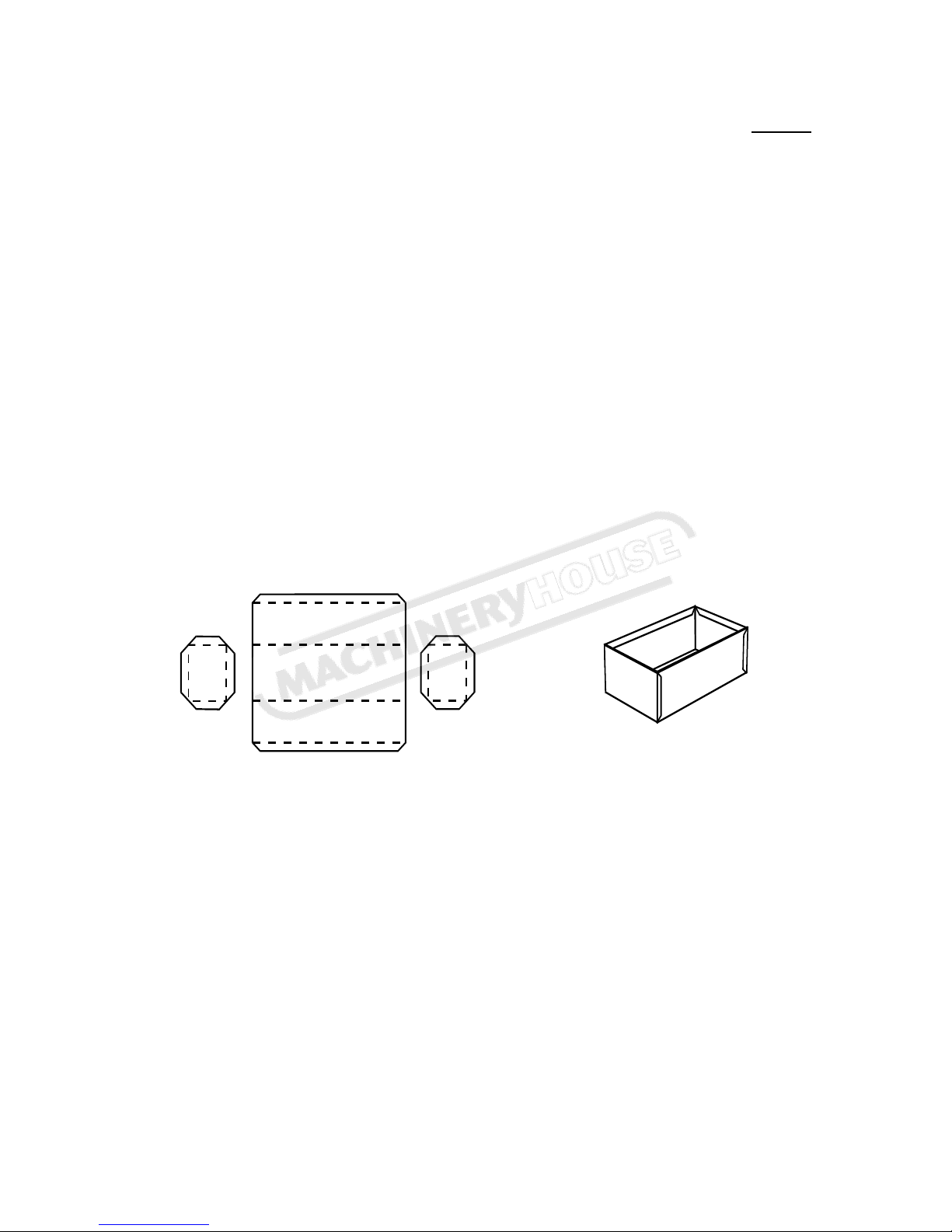

HOW TO MAKE A BOX USING SHORT CLAMP BARS

For ease of folding, make use of the short clamp bars which are able to be attached to each

other. Electrabrake is designed to assist you in the manufacture of a vast variety of box shapes.

BASIC BOXES

Use the long bar clamp to make the first two bends. Choose and insert one or two of the short

clamp bars as indicated on drawing.

Select the largest clamp piece for bends up to 70mm and for longer lengths use several clamp

pieces to fit the required length.

Clamp pieces can be plugged together for repeat bending when making a single unit. A slotted

clamp bar must be used for boxes or trays with shallow sides. Refer to HOW TO MAKE TRAYS.

LIPPED BOXES

1. Use the set of standard short clamp bars to make rectangular lipped boxes i.e. 98mm.

2. Choose the short clamp bar with at least a lip-width shorter than that of the box (Two or

three may be necessary – depending on length). Make folds 5, 6, 7 and 8. Take care to

guide the corner tabs on inside or outside of the box.

Page 11

Page 11

Instruction Manual for MB1250 (K8303)

01/12/2015

BOXES WITH INDIVIDUAL ENDS

Advantages:

Material saving

No corner notching

Cut without a guillotine

Fold with the regular full length clamp bar.

Disadvantages:

Extra folds to be carried out

Extra corners to join

The finished product shows more joins

Use the full length clamp bar for all folding.

1. Set up sheet metal as per drawing below.

2. Form four folds in the sheet metal as shown on drawing.

3. For folds on side panels, as per drawing, use the narrow flange of the end piece of the

clamp bar

4. Join the box

Page 9

Page 12

Page 10

Page 12

Instruction Manual for MB1250 (K8303)

01/12/2015

FLANGED BOXES WITH PLAIN CORNERS

To make plain cornered boxes, the length and width should not exceed the clamp bar width of

98mm. Outside flanges are also used when making top hat sections.

1. Mark up sheet metal as per drawing below.

2. Use the full length clamp bar and fold sections marked 1, 2, 3 & 4.

3. Form fold 5 by inserting the flange under clamp bar follow by folding 6.

4. Using slotted clamp bar form folds 3, 4, 7 and 8.

Page 13

Page 11

Page 13

Instruction Manual for MB1250 (K8303)

01/12/2015

FLANGED BOX WITH CORNER TABS

Important Note: Folds must be formed in the correct sequence using one piece of sheet metal. It

is suggested the deep boxes are manufactured with separate end pieces.

1. Mark up sheet metal as be drawing below

2. Form all tab folds to 90deg. marked A at the one end of the full length clamp bar by

inserting the tab under the clamp bar.

3. Use the same end of the clamp bar and fold B to 45deg. Insert the side of the box instead

of the bottom under the clamp bar.

4. Form the flange fold C to 90deg, at the other end of the clamp bar.

5. Complete folds B to 90deg. By using suitable short clamp bars.

6. Complete the box by joining the corners.

Page 14

Page 12

Page 14

Instruction Manual for MB1250 (K8303)

01/12/2015

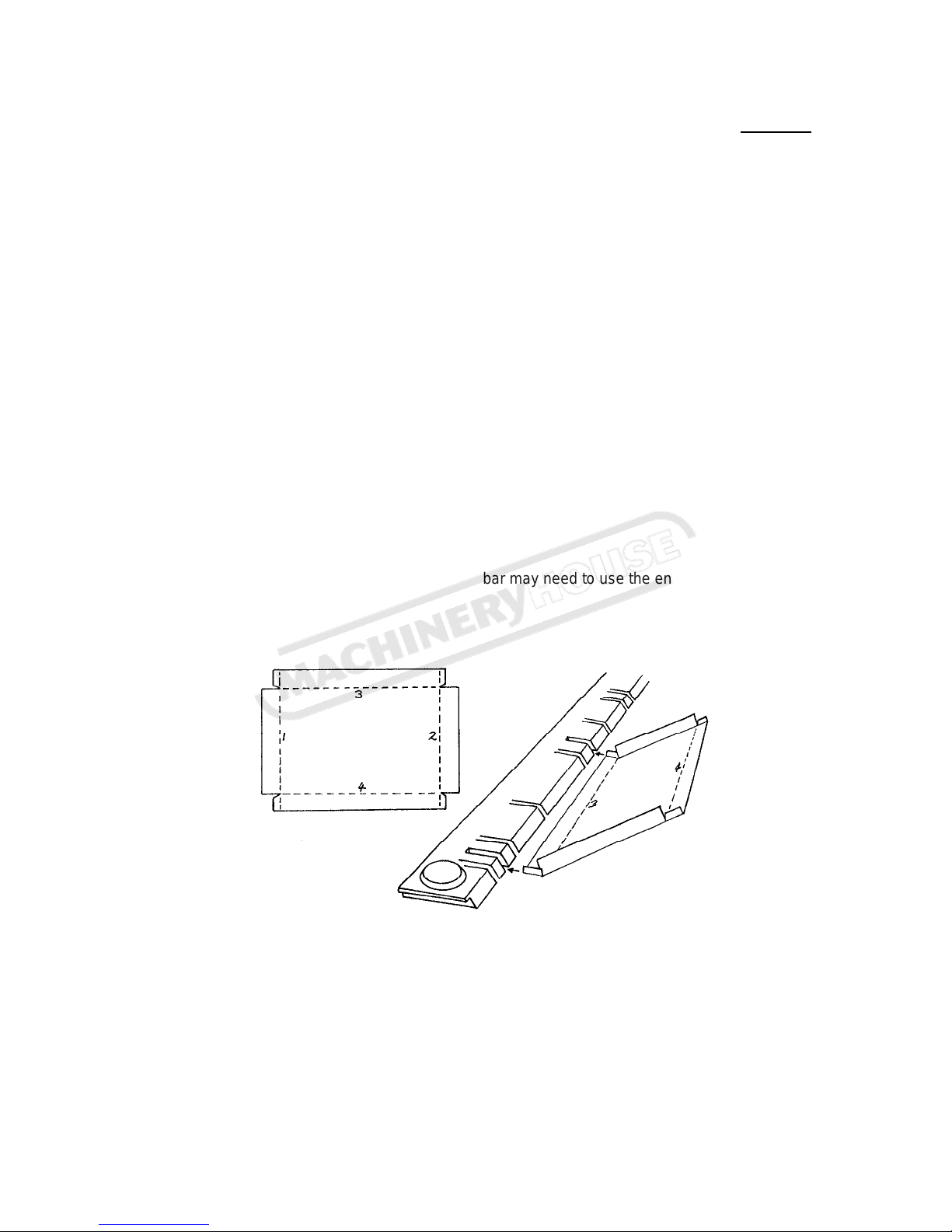

HOW TO USE A SLOTTED CLAMPBAR

FORMING TRAYS

The slotted clamp bar is perfect for manufacturing shallow trays and pans.

Advantages:

The Bending edges are aligned automatically to the front edge of the magnet body. The clamp

bar automatically lifts to facilitate insertion and removal of the sheet metal whereas with the short

set each section must be lifted individually.

The slotted clamp bar folds shallow trays, however trays of unlimited depth and complex shapes

can be manufactured with a short clamp bar.

The pitch of the slots has been calculated to enable the folding of various sizes of trays.

Specification sheet indicate shortest and longest tray sizes that can be accommodated by the

slotted clamp bar

To fold shallow tray

1. First fold two opposite sides and the corner tabs by using the slotted clamp bar – ignore

the slots they will have no effect on the finished folds.

2. Select two slots to fold the remaining two sides. Line up the left side of the tray with the

left slot and check if there is a slot for the right side. Slide the tray along the left and try

the next slot until a suitable slot is found. The edge of the tray should be under the clamp

bar and between the two chosen slots.

3. To complete, fold the remaining sides.

Note: Trays that are almost as long as the clamp bar may need to use the end of the clamp bar

in lieu of a slot.

Page 15

Page 13

Page 15

Instruction Manual for MB1250 (K8303)

01/12/2015

HOW TO CHECK THE ACCURACY OF YOUR MACHINE

Critical aspects of Electrabrake are that working surfaces of the bending beam, the bending edge

clamp bar are straight and that both of these surfaces are parallel. This can be checked with a

precision straight edge.

How to check using the machine.

Swing bending beam up to 90deg. and hold or lock it in position with a back stop clamp collar at

the back of the angle slide on the handle. Check the gap between the working surface of the

bending beam and the edge of the clamp bar. Set the gap at 1mm on each side by using the

clamp bar adjusters. A feeler gauge or scrap piece of metal can be used.

The gap must be the same along the edge of the clamp bar. Variations can be wi thin +/-0.2mm.

the gap must not exceed 1.2mm and be less than 0.8mm. Should the adjustors not be the same

at each end, they will have to be reset – see Maintenance page 14.

Notes

The straightness of the elevated clamp bar is not important as this is flattened out in magnetic

clamping when in use.

The gap between the magnet body and bending beam is about 2 to 3mm. This does not affect the

bending accuracy.

Electrabrake produces folds on thinner gauges and non-ferrous metals such as aluminium,

however, check the specification for heavier gauges.

To fill in unused portion under the clamp bar, make use of scrap pieces of sheet metal to create

uniformity of the bends in thicker gauges.

Page 16

Page 14

Page 16

Instruction Manual for MB1250 (K8303)

01/12/2015

MAINTENANCE

ADJUSTERS

The adjuster rings on top of the clamp bar control the thickness of the sheet metal between the

bending beam and its edge.

Use these marks as a reference for repeat setting of the clamp bar. The bending gap will be

approx. 1mm if adjuster rings are both set so that the single pop mark is uppermost.

HINGE LUBRICATION

Grease all hinges once per month.

WORKING SURFACES

Bare working surface may become rusty or tarnished. Recondition by filling off and clean up

surfaces with emery paper. Use an anti-rust spray.

Page 17

Page 15

Page 17

Instruction Manual for MB1250 (K8303)

01/12/2015

TROUBLE SHOOTING

Prior to ordering a replacement electrical unit from the manufacturer please

check the following:

♦ If the machine does not operate at all, check the pilot light in the ON/OFF switch.

♦ If the machine is hot and power is available, leave the machine to cool and try again.

♦ Do not pull the handle prior to starting – the start button must be pressed first.

♦ If the bending beam is moved prior pressing the start button begin again and make sure

the handle is pushed fully back.

♦ Should the problem continue, the micro switch actuator may need to be adjusted.

♦ To check if the start button is faulty, try to start the machine with the foot switch.(if

provided)

♦ Check the connector and magnet at the electrical module.

♦ If the clamp bar snaps down on the release of the start button, this indicates that the 15

microfarad capacitor needs to be replaced.

♦ Should the machine cause blown fuses or trip your circuit breakers, it is likely that the

bridge rectifier is blown.

Full clamping not operating

If you are not achieving a full clamp, the angle micro switch may not be fully actuated.

How to check that the angle micro switch is being fully actuated.

♦ The micro switch can be found on the electrical panel located at the end of the square

brass section. The brass section is attached to the angle indicating mechanism.

♦ To access the electrical panel, the rear cover must be removed.

♦ When the bending beam is lifted this rotates the brass section which in turn depresses

the micro switch. You should be able to hear the micro switch click on and off.

♦ Failing this, adjust the clutching force. This can be done by ensuring that the two M8 cap

head screws at either end of the actuator shaft are secured.

♦ This adjustment should ensure that the actuator rotates and clutches however, if you are

still unable to hear the click, the micro switch may need adjusting.

♦ The actuator can be adjusted by loosening the screw that secures it, making the

adjustment, followed by re-tightening the screw.

Page 18

♦ If the micro switch does not click on and off after you have made the above adjustments

Page 18

Instruction Manual for MB1250 (K8303)

01/12/2015

and rotated the bending beam to the maximum stops, then the switch may be fused and

would need to be replaced. Call or email your distributor or Electrabrake.

Clamp bar not being released

♦ This is caused by the failure of the reverse pulse de-magnetising circuit.

♦ Check for sticky contacts on the relay and clean.

♦ The 6.8 power resistor or diodes could be faulty which will have to be replaced.

Problems with the bending of heavy gauge sheet metal.

♦ Ensure that sheet metal thickness is within the specifications of the machine.

♦ It may occur if narrow lips are being bent over the full length of the machine, please note

that the machine is not equipped to do this.

♦ Should the work piece not be level (i.e. have a welded seam or a joint) it may not be

possible to bend the work piece. Ensure that all spaces under the clamp bar are filled

with flat pieces of scrap metal.

Page 16

Page 19

CIRCUIT DIAGRAMS

Page 19

Instruction Manual for MB1250 (K8303)

01/12/2015

Page 17

Voltage Tests

AC DC

Reference point Any BLUE

wire

Test point

LIGHT-

Clamping

A B C D E

240

V ac

25

V ac

Condition

FULL-

Clamping

240

V ac

240

V ac

Condition

Any BLACK wire

+25

V dc

+215

V dc

+25

V dc

+215

V dc

-300

V dc

-340

V dc

Page 20

Page 18

Page 20

Instruction Manual for MB1250 (K8303)

01/12/2015

SPECIFICATION SHEET

Model EB0625 EB1000 EB1250 EB2000 EB2500 EB3200

Weight of Machine

Nominal Capacity (length x

thickness)

Clamping Force Tons

Electricity Supply

Duty Cycle %

Protection

Foot Switch

Bending-edge Length mm

Distance between Lifters mm

U-Channel bends, minimum

spacing

Closed channel, minimum

internal

Z-reverse bends, minimum

spacing

Kg 72 110 150 270 315 380

mm

0625

x1.6

1000 x

1.6

1250 x

1.6

2000 x

1.6

2500 x

1.6

3200 x

1.2

3 4.5 6 9 12 10

1 phase, 220/240vac, 10A 1 phase, 220/240vac, 15A

30

°C Thermal cut-out 70°C

No Optional Standard

670 1050 1300 2090 2590 3290

630 1010 1260 2028 2528 3228

mm

mm

mm

35** / 16* 36** / 18*

16*** 19*** 45***

99 x 27*** 114 x 22***

114 x

45***

Thickness Capacities, full length (material thickness can increase depending on the length of

bend)

…Mild steel mm 1.6** / 1.2*

…Aluminum (medium-

hard)

…Copper, Zinc, Brass

(medium-hard)

mm 1.6** / 1.2*

mm 1.6** / 1.2*

…Stainless steel mm 1.0** / 0.9*

1.2** /

1.0*

1.2** /

1.0*

1.2** /

1.0*

0.9** /

0.8*

*** with standard full length clamp bar **with bending beam extension bar *extension bar

removed

Bending dimensions.

19mm

19mm (min)

Unlimited

- 98mm (min) Standard Clampbar

- 49mm (min) Narrow Clampbar

19mm (min)

Refer to Ch art

Page 21

Page 21

Instruction Manual for MB1250 (K8303)

01/12/2015

DIMENSIONAL SPECIFICATIONS

Page 19

Page 22

Page 22

Instruction Manual for MB1250 (K8303)

01/12/2015

INSPECTION SHEET

SERIAL NUMBER: ________________________

DATE: ___________________________________

MODEL: _________________________________

CONNECTIONS

g - Measure the resist

Earthin

CLAMPBAR

Check the bending-edge for Straightness (max deviation = 0.25 mm)

Height of lift (with lifting balls in grove) (min 3 mm) ......................... _______ mm

Are lifting balls able to be compressed flush with surface? ............. YES/NO

With the bending beam at 90° and adjusters set at position 1 (one)

is the bending-edge 1 mm from and parallel

With the bending beam at 90°, can the clamp bar be adjusted

forward to touch

BENDING TEST

(Maximum specifications bend to 90°, at minimum supply voltage.)

Thickness of test piece .............. _____ mm Length of Bend _____ mm

Lip Width .................................. _____ mm Radius of Bend _____ mm

Uniformity of bend angle (maximum deviation = 2°) ....................... _____ deg

LABELS

Check for clar

Name Plate with serial number. . Clamp bar Warning ........

Electrical warnings ..................... Switch labelling ..............

Main ID label ..............................

Safety Tape on front legs ...........

FINISH

Free from rust, blemishes etc and machine is clean. ......................

ELECTRICAL INSOLATION

Test insolation from coil to magnet body .........................................

MIN/MAX SUPPLY VOLTAGE TESTS

At 260v: Pre-clamp.... ________ full-clamp.... _______ release…. _______

At 200v: Pre-clamp.... ________ full-c

Pre-clamp.... ________ full-clamp.... _______ release…. _______

INTERLOCK SEQUENCE

ith powe

W

Check that machine does NOT activate ........................................

ANGLE SCALE

Reading at edge of Indicator when bending beam is set

to 90° with an engineer's square. (Min 89°, max 91°) .................... ______ deg

the bending beam and adjusted back by 2 mm? .. YES/NO

ity, adhesion to machi

r on, pull HANDLE, then press START button.

ance from mains plug earth pin to magnet body _______ ohm

to the magnet-edge? . YES/NO

ne and proper alignment.

lamp… _______ release…. _______

_______ mm

Page 20

Page 23

Page 21

Page 23

Instruction Manual for MB1250 (K8303)

01/12/2015

MAGNET BODY

Straightness of top surface, along the length of machine

(Tolerance = ± 0.5 mm) ……….. ............................ ______ mm

Flatness of top surface, across the width of machines

(Tolerance = ± 0.1 mm) …………… ....................... ______ mm

FULL CLAMPING ACTIVATION DISTANCE

Distanc

measured at bottom of bending beam. (4 mm to 6 mm) ................ ______ mm

Reverse motion to switch-off machine. Measure back

from 90°. (Should be within the range 15° +

BENDING BEAM

Straightness of work

Alignment of extension bar (max deviation = ± 0.25 mm) ............... ______ mm

[Note: Test straightness with precision straight-edge.]

HINGES

Check for lubrication on shafts ... and sector blocks...........

Check that hinges rotate through 180° freely and smoothly ............

Check hinge pins do not rotate . and are “loctited” ...........

Have the retaining screw nuts been locked? ................................... YES/NO

e of movement of Bending Beam to a

ing surface (Tolerance = ± 0.25 mm) .............. ______ mm

ctivate full-clamping,

5°) ............................. ______ deg

SIGNATURES

Assembled & Tested .................. _____________________________________

Q. A. Inspection ......................... _____________________________________

Page 24

Page 22

Page 24

Instruction Manual for MB1250 (K8303)

01/12/2015

WARRANTY

Thank you for purchasing an Electrabrake Electromagnetic Sheet Metal Folding Machine. The

manufacturer warrants this Electrabrake folding machine to be free from defects in materials

and/or workmanship for a period of 12 months.

Our obligation under this Warranty is limited to repairing or replacing faulty parts or material s and

does not extend to consequential loss or damage arising from the use of the machine.

This Warranty does not cover faults that are due to misuse, abuse, negligence, accident or

caused during transportation. Also excluded are faults arising from unauthorised repair use not

according to instructions, and normal wear and tear.

Returns under Warranty must be freight-prepaid and, if the Warranty Registration has not been

previously returned, must be accompanied by proof of the purchase date.

The Warranty does not cover the costs of any repairs done by an unauthorised contractor of

these contractors unless prior arrangements have been made

Please fill in for your own reference:

Model _________ Serial No. __________ Date Purchased ___________

Dealer's Name and Address: ________________________________

________________________________

________________________________

________________________________

Before returning your machine for repair under warranty, please contact the Manufacturer to

discuss the most efficient means of transport and packaging and whether the whole or only a part

of the machine needs to be returned to the factory.

To establish proof of purchase date, please return the Warranty Registration on the following

page.

Page 25

Page 23

Page 25

Instruction Manual for MB1250 (K8303)

01/12/2015

WARRANTY REGISTRATION

Model No. ____________________ Serial No. ____________________

Date Purchased _______________

Dealer’s Name & Address:

_____________________________________

_____________________________________

_____________________________________

Customer's Name & Address:

_____________________________________

_____________________________________

_____________________________________

_____________________________________

After completing, please post this form to:

Electrabrake, PO Box 13043, Witfield, Gauteng 1467 South

Africa.

Fax (011) 823 3439

Page 26

ELECTRABRAKE EB 0625,EB 1000, EB 1250 PACKING LIST

Page 26

Instruction Manual for MB1250 (K8303)

01/12/2015

1. Main Electrabrake Assembly (with bending-beam Extension Bar fitted)

2. Main Full-length Clamp Bar

3. 1x Column

4. 4x Feet (2left &2right)

5. 2 x Handles (1 plain, 1 with angle scale) forEB 1250. 1x handle with angle

scale for EB0625&EB1000

6. 2x Backstop Bars for EB 1000&EB 1250

7. Angle Indicator Assembly

8. Tray + rubber mat

9. Fasteners, in packet with list. (including Stop Collars, 1 Allen key)

10. Clamp bar

11. Clamp bar 600mm (EB 1000&EB 1250)

12. Set of 6 Short Clamp bars

13. User Manual

Loading...

Loading...