Page 1

EB2500

Magnetic Panbrake (240V)

2500 x 1.6mm

INSTRUCTION MANUAL

S5321

1

Instruction Manual for EB2500 (S5321)

24/8/2012

Page 2

2

C O N T E N T S

2

Instruction Manual for EB2500 (S5321)

24/8/2012

Page number

Introduction 3

Risk assessment 4 – 6

Pace maker warning 7

Assembling the EB0625, EB1000 8

Assembling the EB1250 9

Assembling the EB2000, EB2500, EB3200 10

Operating procedures for the EB2000, EB2500 and EB3200 11

General cautionary important warnings 11

Safety procedures: 11

Standard bending 11

How to use the backstops 12

How to fold a lip 12

How to make a rolled edge 13

How to form a test piece 14

Basic boxes 15

Lipped boxes 15

Boxes with individual ends 16

Flanged boxes with plain corners 16

Flanged box with corner tabs 17

How to use a slotted clamp bar 18

Forming trays 18

How to check the accuracy of your machine 19

How to check using th

Maintenance 20

Adjusters 20

Hinge lubrication 20

Working surfaces 20

Trouble shooting 20

Full clamping not operating 21

Clamp bar not being released 21

Problems with the bending of heavy gauge sheet metal. 22

EB 625 and EB1000 panel 23

EB 2000 EB3200 Wire panel 24

EB-0625 EB1250 Circuit diagram 25

EB 2000, EB2500 and EB3200 circuit diagram 26

Specification sheet 27

Dimensional specifications EB625 28

Dimensional specifications EB1000 28

Dimensional specifications EB1250 29

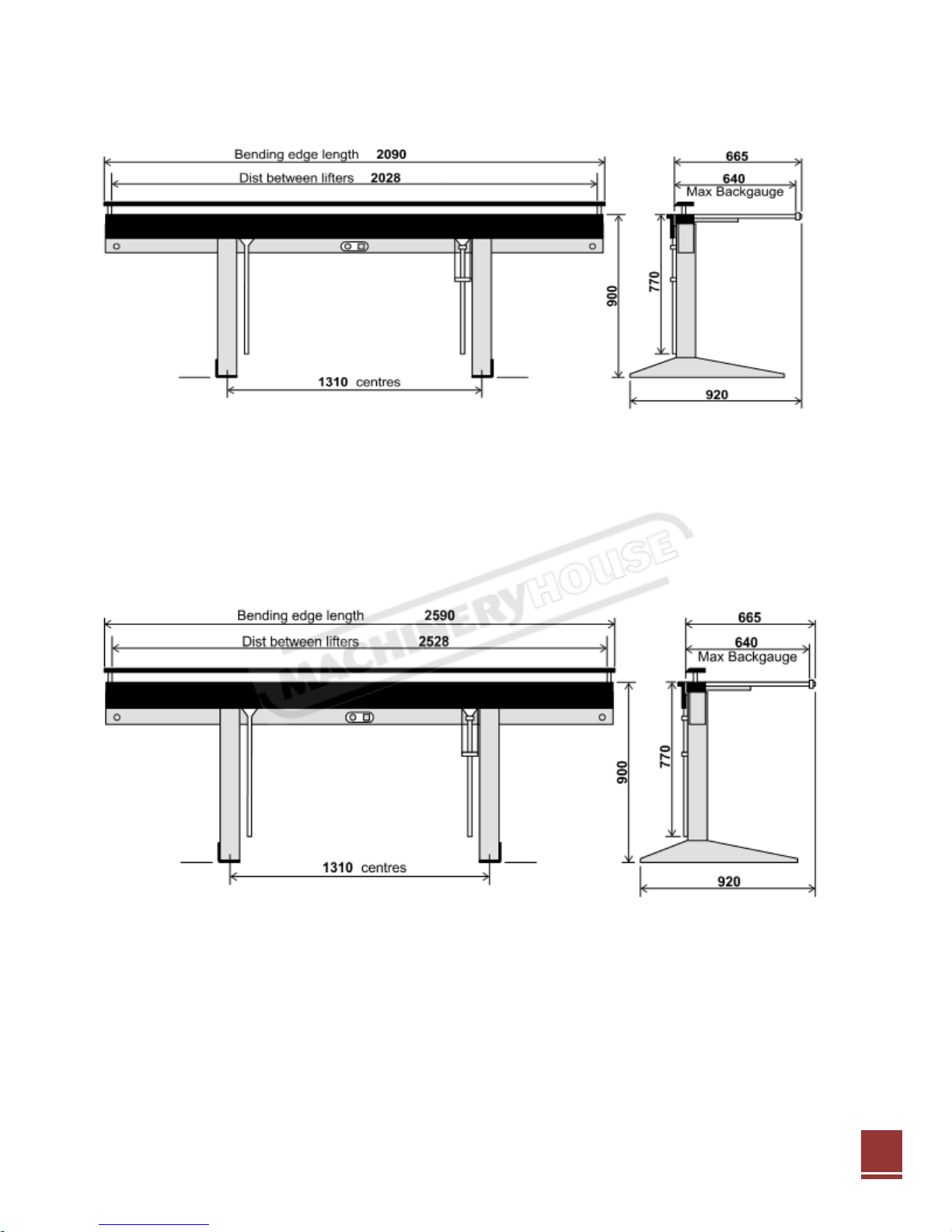

Dimensional specifications EB2000 30

Dimensional specifications EB2500 30

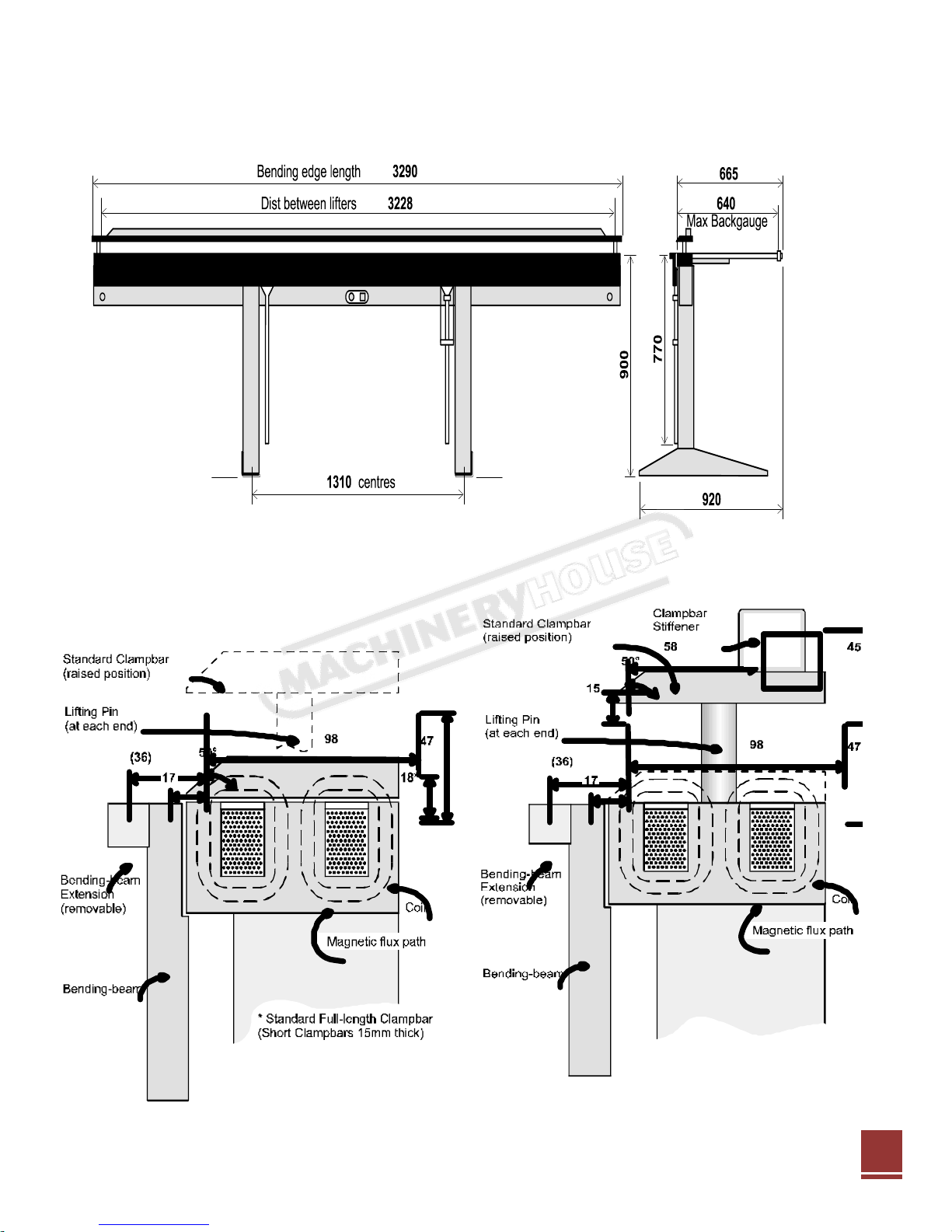

Dimensional specifications EB3200 31

Warranty 32

Warranty registration 33

ANEXURE 1

Basic Safety Precautions and Procedures: 34-35

FRAME ASSEMBLY AND PARTS LIST EB2000, EB2500, EB3200 36-37

e machine. 19

Packing Lists for EB 625 – EB 3200 38-43

Page 3

3

3

Instruction Manual for EB2500 (S5321)

24/8/2012

INTRODUCTION

ELECTRABRAKE machines use an electromagnet, rather than a mechanical, clamping system.

The machine consists of a long electromagnet with a steel clamp bar located above it. The sheet

metal is clamped between the two by an electromagnet capable of clamping with a force range of

between 3 - 10 Tons. Rotating the bending beam then forms the bend. The sheet is bent around

the front edge of the clamp-bar.

Using the machine is simple, slide the sheet in under the clamp-bar; press the start-button to

initiate clamping; lift the handle to form the bend to the desired angle; and then return the handle to

automatically release the clamping force. The folded sheet can now be removed or repositioned

ready for another bend.

The special centre less compound hinges, are distributed along the length of the bending beam

allowing bending loads close to where they are generated.

The combined effect of the magnetic clamping with the special centre less hinges means that the

ELECTRABRAKE is a very compact, space saving, machine with a very high strength-to-weight

ratio.

ELECTRABRAKE EB625, EB1000, EB1250, EB 2000, EB 2500 & EB3200

The ELECTRABRAKE EB625, EB1000, EB1250, EB2000, EB2500 & EB3200 are highly versatile

sheet metal folding machines used to bend mild steel and aluminium sheet metal. Thicknesses of

up to 1.2 mm thick can be folded on the EB3200, across the full length of the machine. The

EB625, EB1000, EB1250, EB2000 and EB2500 machines fold material of up 1.6mm thickness.

These multi-purpose machines bend sheet metal of lengths 625mm, 1000mm, 1250mm, 2000mm,

2500mm and 3200mm respectively.

The ELECTRABRAKE magnetic clamping system replaces the bulky clamping structure used in

conventional folding machines. The small compact clamp bar does not hinder or obstruct the work

piece. Automatic electromagnetic clamping and unclamping, means faster operation. These

machines have a much greater versatility than conventional sheet metal benders. The machines

are ideal for use in industry, air-conditioning and building industries.

For the EB-2000, EB2500 and EB3200 an electrical interlock is offered to enhance Operator

Safety. This operation ensures that a safe pre-clamping force must be applied before fullclamping can be engaged.

ACCESSORIES

Adjustable backstops, storage tray and a complete set of short-length clamp-bars are included as

Standard Accessories.

A foot switch is supplied as a standard accessory on the EB2000, EB2500 and EB3200 only. On

the EB1250 the foot switch is an optional extra.

A narrow clamp bar, a slotted clamp bar for forming shallow boxes more quickly and a power

shear with guide for straight distortion-free cutting of up to 1.6 mm thick is all available as Optional

Extra Accessories.

A Full 12 month warranty is offered that covers faulty materials and workmanship.

Page 4

4

4

Instruction Manual for EB2500 (S5321)

24/8/2012

Page 5

5

5

Instruction Manual for EB2500 (S5321)

24/8/2012

Page 6

6

6

Instruction Manual for EB2500 (S5321)

24/8/2012

Page 7

7

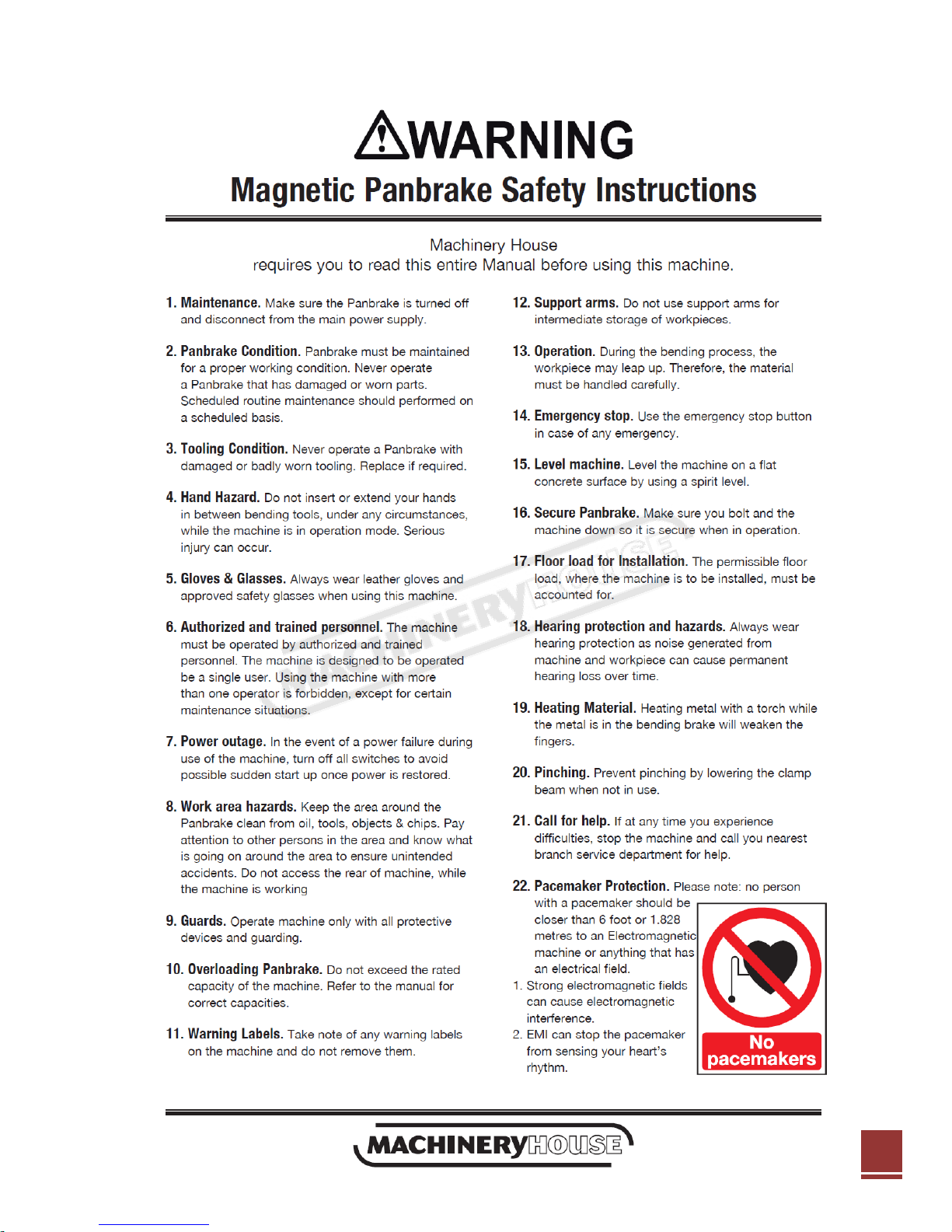

PACEMAKER PROTECTION

7

Instruction Manual for EB2500 (S5321)

24/8/2012

SAFETY PRECAUTIONS

Please note: no person with a pacemak

er should be closer than 6 FOOT OR 1.828 METRES to

an Electramagnetic machine or anything that has an electrical field.

1. Strong electromagnetic fields can cause electromagnetic interference.

2. EMI can stop the pacemaker from sensing your heart’s rhythm.

Page 8

8

8

Instruction Manual for EB2500 (S5321)

24/8/2012

ASSEMBLY

HOW TO ASSEMBLE YOUR ELECTRABRAKE

The EB625, EB1000

Note: The machine is supplied upside down for assembly purposes.

1. Remove all parts from the crate with the exception of ELECTRABRAKE magnet body

assembly.

2. Use the 6mm Allen Key and the screws supplied.

3. Place packing between the body and the crate.

4. Attach the feet to the column using the eight M10 x 16 button-head screws provided. Note

that the seam on the column is at the back and the two feet with the yellow and black safety

tape are the front feet.

5. Fasten the foot plate under the front feet using the M10 x 16 cap-head screws with washers.

Alignment is easier if the foot mounting is not tightened until the foot plate is fitted. The rear

feet cap head screws can be adjusted to level the machine.

6. Place the stand on its feet in a safe area so that the magnet body can be fastened to the

stand.

7. Place the magnet body on the stand securing it with two M8 x 16 cap head screws. This

would be best of you used a lifting device or got some assistance. Ensure that the magnet

wires are guided down the column as the magnet body is lowered onto the stand.

8. Remove the rear access cover to gain access to the electrical unit. By removing the four pan

head screws. Connect the adjoining matching plug leads from the magnetic coil and PC

board. Refit the rear access cover.

9. On the EB625 the tray is in two halves. First join the two halves of the tray using the two M6

pan head screws and nuts. Now using two M8 x 12 cap head screws attach the tray to the

back of the magnet body. Place the rubber mat in the tray. Attach the back stop slides to the

side of the tray.

10. On the EB1000 use four M8 x 12 cap head screws to attach the two back stop bars to the

back of the magnet body

11. On the EB1000 use three M8 x 12 cap head screws to attach the tray to the back of the

magnet body between the two back stop bars. Place the rubber mat in the tray.

12. Open the bending beam to gain access to the back of the bending beam so that you can

attach the handle.

13. Slide the handle through the angle indicating ring. Now using two M8 x 16 cap-head screws

to attach the handle to the bending beam.

14. Use solvent i.e. turpentine or methylated spirits to remove the clear protective coating from

the top of the unit and the clamp bar.

15. Place the clamp bar on the magnet body.

16. To obtain excellent results follow the operating instructions.

Page 9

9

9

Instruction Manual for EB2500 (S5321)

24/8/2012

ASSEMBLY

HOW TO ASSEMBLE YOUR ELECTRABRAKE

The EB1250

Note: The machine is supplied upside down for assembly purposes.

1. Remove all parts from the crate with the exception of ELECTRABRAKE magnet body

assembly.

2. Find the 6mm Allen Key and the screws supplied.

3. Lift the magnet body up from the crate. Place a plank between the body and the crate.

4. Attach the feet to the column using the eight M10 x 16 button-head screws provided. Note

that the seam on the column is at the back and the two feet with the yellow and black safety

tape are the front feet.

5. The rear feet cap head screws can be adjusted to level the machine.

6. Place the stand on its feet in a safe area so that the magnet body can be fastened to the

stand.

7. Place the magnet body on the stand securing it with two M8 x 16 cap head screws. This

would be best of you used a lifting device or got some assistance.

8. Use four M8 x 12 cap head screws to attach the two back stop bars to the back of the

magnet body

9. Use three M8 x 12 cap head screws to attach the tray to the back of the magnet body

between the two back stop bars. Place the rubber mat in the tray.

10. Open the bending beam to gain access to the back of the bending beam so that you can

attach the handle.

11. Use two M8 x 20 cap-head screws per handle to attach the handles to the bending beam.

12. The handle with the angle scale is attached on the left hand side of the bending beam.

Attach the other handle on the right hand side.

13. Slide the angle indicator unit onto the left handle. Attach the 2 arms to the indicator spindle.

To ensure correct operation securely fasten the screws to the switching mechanism.

14. Use the two M12 x 60 masonry bolts supplied to secure the Electrabrake machine to the

floor. Adjust the head levelling screws in the rear of each foot until the machine is stable and

level.

15. Use solvent i.e. turpentine or methylated spirits to remove the clear protective coating from

the top of the unit and the clamp bar.

16. Place the clamp bar on the magnet body.

17. To obtain excellent results follow the operating instructions.

Page 10

10

10

Instruction Manual for EB2500 (S5321)

24/8/2012

ASSEMBLY

HOW TO ASSEMBLE YOUR ELECTRABRAKE

The EB2000, EB2500, EB3200

Note: The machine is supplied upside down for assembly purposes.

1. Remove all parts from the crate with the exception of ELECTRABRAKE magnet body

assembly.

2. Find the 6mm Allen Key and the screws supplied.

3. Lift the magnet body up from the crate. Place a plank between the body and the crate.

4. Attach the columns to the magnet body by using four M8 x 16 cap-head screws per column.

Open-out the bending beam to gain access to insert the screws.

5. NB Check that the right and left columns are in the correct position with the foot mounting

holes facing to the outside.

6. Attach the feet to respective columns with the adjusting screws pointing backwards using

four M10 x 16 button-head screws per foot.

7. Place the machine the right way up. Assistance is required on the large units.

8. Use four M8 x 16 cap-head screws to attach shelf to the columns. Place the rubber mat in

the shelf.

9. Use three M8 x 12 cap-head screws to attach the tray to the magnet body. Place the rubber

mat in the tray.

10. Use two M8 x 12 screws per backstop to attach the four backstop bars to the back of the

magnet body.

11. Use one M8 x 20 cap-head screw with lock nut per lifter handle to attach lifter handles to the

back of the shaft located at the outside of the columns.

12. Open the bending beam to gain access to the back of the bending beam so that you can

attach the handles

13. Use two M8 x 20 cap-head screws per handle to attach the handles to the bending beam.

14. The handle with the angle scale is attached to the right of the bending beam. Attach the

other handle on the left hand side.

15. Slide the angle indicator unit onto the right handle. Attach the 2 arms to the indicator spindle.

To ensure correct operation securely fasten the screws to the switching mechanism.

16. Use the two M12 x 60 masonry bolts supplied to secure the Electrabrake machine to the

floor. Adjust the head levelling screws in the rear of each foot until the machine is stable and

level.

17. Use solvent i.e. turpentine or methylated spirits to remove the clear protective coating from

the top of the unit and the clamp bar.

18. Place the clamp bar on the magnet body. To engage the heads of the lifter pins push lifter

handle back and then pull the handle forward.

19. To obtain excellent results follow the operating instructions.

Page 11

11

OPERATING PROCEDURES

11

Instruction Manual for EB2500 (S5321)

24/8/2012

GENERAL CAUTIONARY IMPORTANT WARNINGS

Electrabrake machines are designed for ONE operator only, which includes the inserting the sheet

metal and operating the switches.

See specifications for clamping strength – please note that the force is several tonnes. All units are

fitted with a two-handed interlocking system to prevent hands being accidentally trapped when

clamping.

Safety procedures:

1. Safe pre-clamping is engaged

2. Full clamping is activated

3. Lower clamp bar to 5mm of the bed

4. Magnet will engage

STANDARD BENDING

Preparation: Switch on power. Check that the clamp bar is correctly positioned and that locating

pins are in place at each end of the clamp bar.

For bigger models EB-2000, EB-2500 and EB-3200

Should lifting pins be locked – locate handles below the machine, push hard back and release

forward to lift the clamp bar slightly.

Set the machine to suit the sheet metal thickness by rotating the 2 screws situated on the

back edge of the clamp bar. Check the clearance by lifting the bending beam at 90 deg. and

examine the gap. To achieve and perfect bend, set a fractionally larger gap, than the depth

of the sheet metal, between the edge of the clamp bar and the face of the bending beam.

Place sheet metal under clamp bar – the backstop can be used if needed.

Lift handles or push down the clamp bar onto the sheet metal. The machine will not turn ON

until the clamp bar is within 5mm above the surface bed due to the interlock. The interlock

can be operated by locking down the lifting system if the clamp bar is unable to be lowered

to 5mm. This can occur when sheet metal is buckled.

To apply pre-claming force use the foot-switch or depress and hold any of the green start

buttons.

To activate the micro-switch for full clamping, pull one of the bending handles with your free

hand. Release footswitch or start button.

Pull on both handles and begin bending till the angle required is achieved. Assistance will be

necessary when carrying out heavy duty bending. The right handle has a beam angle, which

graduates continuously. To allow for spring back of the sheet metal, bend a few degrees

more than the angle that is required.

The electrical circuit of the machine releases a reverse pulse at the OFF stage allowing the

clamp bar to release immediately.

Page 12

12

To release the sheet metal, flick the material upwards, which will lift the clamp bar to make

12

Instruction Manual for EB2500 (S5321)

24/8/2012

ready for the next bend. It may be necessary to lift the clamp bar by using one of the lifting

handles.

CAUTION

Do not insert small items under the clamp bar – a minimum bend of 15mm is essential except

when bending very lightweight soft metal. This will prevent damage to the clamp bar.

To get the best performance do not clamp longer than is necessary due to the magnet having

less clamping force when heated.

HOW TO USE THE BACKSTOPS

Make use of the backstops when handling volume bends that are all the same size. Set the

backstops at the size required.

Backstops can be used with a bar (not supplied) laid against them, making a long surface to

use as a reference. The extension pies from the bending beam could be used.

Use a strip of sheet metal of the same thickness as the work piece if a backstop is required

under the clamp bar.

HOW TO FOLD A LIP

Folding the lip will depend on the sheet metal thickness and the length and width.

Lightweight sheet metal up to 0.8mm.

1. Carry out instruction for standard bending and continue to bend as far as possible. Move

the angle stop collar up to the top of the handle, and tighten the Allen head screw to

keep it there.

2. Take away the clamp bar, leave the sheet metal on the machine and move 10mm

backwards, bring over the bending beam and compress the lip. No clamping is required.

Thick sheet metal is not suitable for this application.

3. Further flattening can be accomplished when using thin lightweight material by following

up with magnetic clamping

Page 13

13

13

Instruction Manual for EB2500 (S5321)

24/8/2012

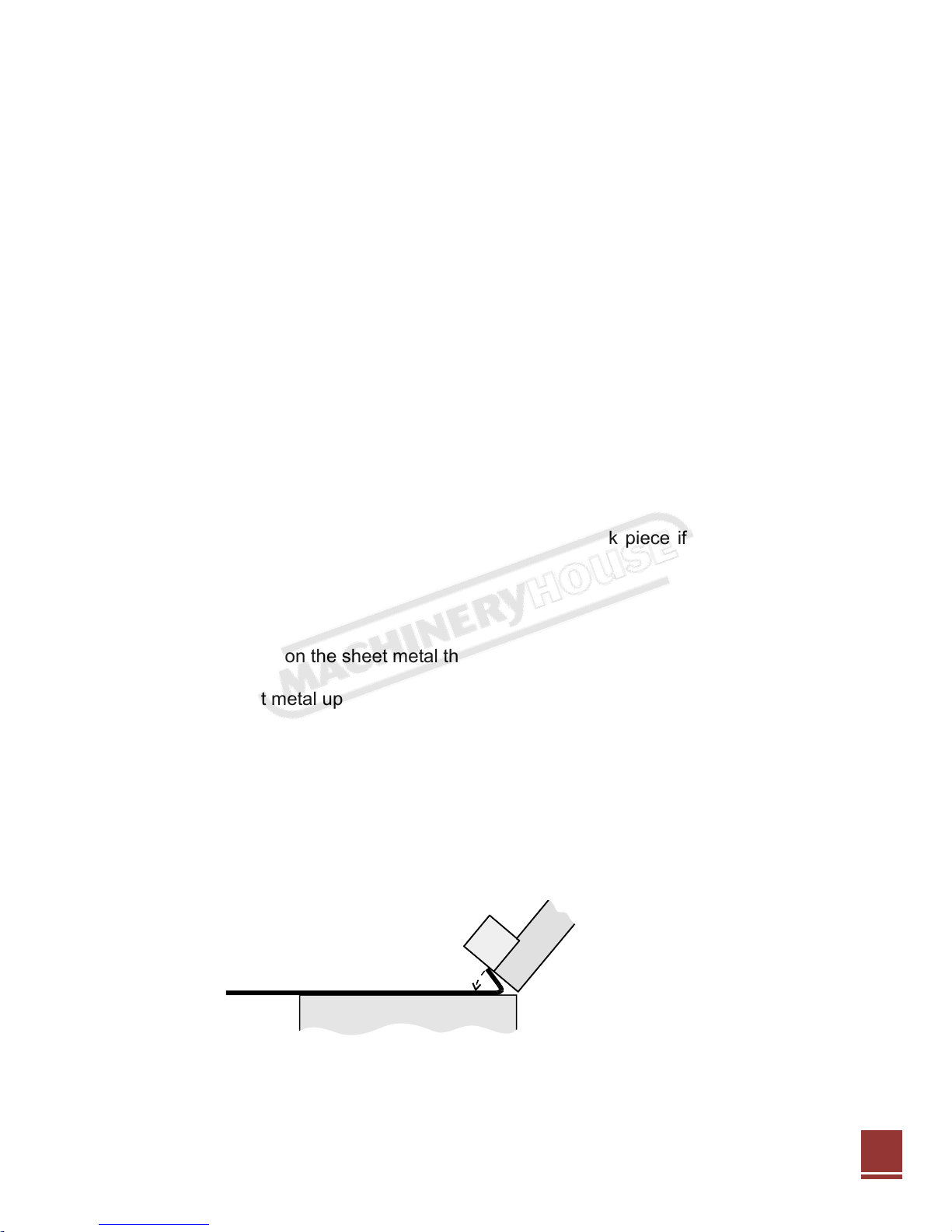

HOW TO MAKE A ROLLED EDGE

Wrap sheet metal around a round steel bar or pipe.

1. Position sheet metal clamp bar and round pipe/bar as indicated on drawing.

i) To avoid weak clamping make sure that the clamp bar does not overlap the

machines front pole (A).

ii) Ensure that the rolling pipe is resting on the front pole of the machine (B). It must

not sit on the aluminium surface of the machine.

iii) The clamp bar provides a magnetic pathway © for the rolling bar.

Folding round a pipe

2. Wrap the sheet metal around the rolling bar as far as possible –

Page 14

14

3. Repeat step 2 until rolled edge to requirement.

200

8

45

95

117

190

335

Bend 2

Bend 4 90°

Bend 3 90°

Bend 1 180°

This section to be rolled around Ø25mm

round bar

90° reverse bend (mark this line on the

reverse side of the sheet)

Bend 5 90°

14

Instruction Manual for EB2500 (S5321)

24/8/2012

HOW TO FORM A TEST PIECE

To learn how to work the Electrabrake with confidence it is recommended that test pieces are

made.

Use a piece of 0.8 mm thick x 320 x 200mm aluminium or mild steel sheet. Mark sheet as per

drawing

Form a lip on the edge of the sheet metal (see ‘How to form a Lip)

Turn sheet metal over and insert under the clamp bar with the folded lip end toward you. Tilt clamp

bar and line up bend marked 2. Bend to 90 degrees as shown in drawing below.

Turn sheet metal over and continue with steps marked 3, 4 and 5 bent to 90 degrees.

Roll the remaining piece around a 25 mm diameter round bar (see How to make a rolled edge) See

drawing below for completed job.

Page 15

15

For ease of folding, make use of the short clamp bars to the shape folds into each other.

15

Instruction Manual for EB2500 (S5321)

24/8/2012

Electrabrake is designed to assist you in the manufacture of a vast variety of box shapes.

BASIC BOXES

Use the long bar clamp to make the first two bends. Choose and insert one or two of the short

clamp bars as indicated on drawing.

Fitting the short clamp bar

Select the largest clamp piece for bends up to 70mm and for longer lengths use several clamp

pieces to fit the required length.

Clamp pieces can be plugged together for repeat bending when making a single unit. A slotted

clamp bar must be used for boxes or trays with shallow sides. Refer to HOW TO

MAKE TRAYS.

LIPPED BOXES

1. Use the set of standard short clamp bars to make rectangular lipped boxes i.e. 98mm.

2. Choose the short clamp bar with at least a lip-width shorter than that of the box (Two or

three may be necessary – depending on length). Make folds 5, 6, 7 and 8. Take care to

guide the corner tabs on inside or outside of the box.

Page 16

16

16

Instruction Manual for EB2500 (S5321)

24/8/2012

BOXES WITH INDIVIDUAL ENDS

Advantages:

Material saving

No corner notching

Cut without a guillotine

Fold with the regular full length clamp bar.

Disadvantages:

Extra folds to be carried out

Extra corners to join

The finished product shows more joins

Use the full length clamp bar for all folding.

1. Set up sheet metal as per drawing below

2. Form four folds in the sheet metal as shown on drawing.

3. For folds on side panels, as per drawing, use the narrow flange of the end piece of the

clamp bar

4. Join the box

FLANGED BOXES WITH PLAIN CORNERS

To make plain cornered boxes, the length and width should not exceed the clamp bar width of

98mm. Outside flanges are also used when making top hat sections.

1. Mark up sheet metal as per drawing below.

2. Use the full length clamp bar and fold sections marked 1, 2, 3 & 4.

3. Form fold 5 by inserting the flange under clamp bar follow by folding 6.

Page 17

17

4. Using slotted clamp bar form folds 3, 4, 7 and 8.

17

Instruction Manual for EB2500 (S5321)

24/8/2012

FLANGED BOX WITH CORNER TABS

Important Note: Folds must be formed in the correct sequence using one piece of sheet metal. It is

suggested the deep boxes are manufactured with separate end pieces.

1. Mark up sheet metal as be drawing below

2. Form all tab folds to 90deg. marked A at the one end of the full length clamp bar by inserting

the tab under the clamp bar.

3. Use the same end of the clamp bar and fold B to 45deg. by inserting the side of the box

instead of the bottom of the box under the clamp bar.

4. Form the flange fold C to 90deg. at the other end of the clamp bar.

5. Complete folds B to 90deg. By using suitable short clamp bars.

6. Complete the box by joining the corners.

Page 18

18

18

Instruction Manual for EB2500 (S5321)

24/8/2012

HOW TO USE A SLOTTED CLAMPBAR

FORMING TRAYS

The slotted clamp bar is perfect for manufacturing shallow trays and pans.

Advantages:

The Bending edges are aligned automatically to the front edge of the magnet body. The clamp bar

automatically lifts to facilitate insertion and removal of the sheet metal whereas with the short set

each section must be lifted individually.

The slotted clamp bar folds shallow trays, however trays of unlimited depth and complex shapes

can be manufactured with a short clamp bar.

The pitch of the slots has been calculated to enable the folding of various sizes of trays.

Specification sheet indicate shortest and longest tray sizes that can be accommodated by the

slotted clamp bar

To fold shallow tray

1. First fold two opposite sides and the corner tabs by using the slotted clamp bar – ignore the

slots they will have no effect on the finished folds.

2. Select two slots to fold the remaining two sides. Line up the left side of the tray with the left

slot and check if there is a slot for the right side. Slide the tray along the left and try the next

slot until a suitable slot is found. The edge of the tray should be under the clamp bar and

between the two chosen slots.

3. To complete, fold the remaining sides.

Note: Trays that are almost as long as the clamp bar may need to use the end of the clamp bar in

lieu of a slot.

Page 19

19

19

Instruction Manual for EB2500 (S5321)

24/8/2012

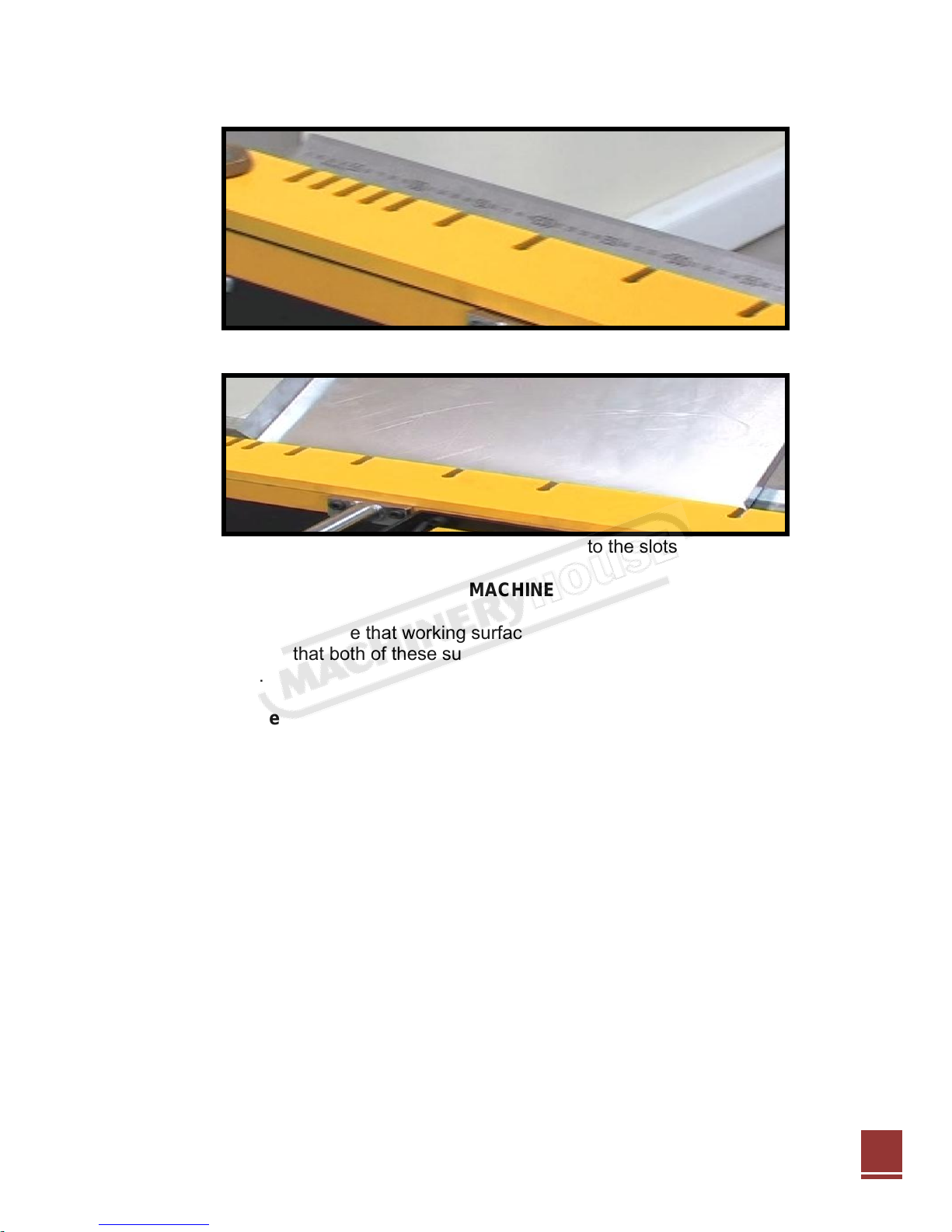

Measuring the slotted clamp bar

Folding a tray note that the folded sides fit into the slots

HOW TO CHECK THE ACCURACY OF YOUR MACHINE

Critical aspects of Electrabrake are that working surfaces of the bending beam, the bending edge

clamp bar are straight and that both of these surfaces are parallel. This can be checked with a

precision straight edge.

How to check using the machine.

Swing bending beam up to 90deg. and hold or lock it in position with a back stop clamp collar at

the back of the angle slide on the handle. Check the gap between the working surface of the

bending beam and the edge of the clamp bar. Set the gap at 1mm on each side by using the clamp

bar adjusters. A feeler gauge or scrap piece of metal can be used.

The gap must be the same along the edge of the clamp bar. Variations can be within +/-0.2mm.

The gap must not exceed 1.2mm and be less than 0.8mm. Should the adjustors not be the same at

each end, they will have to be reset – see Maintenance page 16.

Notes

The straightness of the elevated clamp bar is not important as this is flattened out in magnetic

clamping when in use.

The gap between the magnet body and bending beam is about 2 to 3mm. This does not affect the

bending accuracy.

Page 20

20

Electrabrake produces folds on thinner gauges and non-ferrous metals such as aluminium,

20

Instruction Manual for EB2500 (S5321)

24/8/2012

however, check the specification for heavier gauges.

To fill in unused portion under the clamp bar, make use of scrap pieces of sheet metal to create

uniformity of the bends in thicker gauges.

MAINTENANCE

ADJUSTERS

The adjuster screws at the end of the clamp bar control the thickness of the sheet metal between

the bending beam and its edge.

The heads for the screws are divided into 3 by centre pop marks. Use these marks as a reference

for repeat setting of the clamp bar. The bending gap will be approx. 1mm if adjuster screws are

both set so that the single pop mark is uppermost.

Adjuster set to 1mm

HINGE LUBRICATION

Grease all hinges once per month .

Hinge

WORKING SURFACES

Bare working surface may become rusty or tarnished. Recondition by filling off and clean up

surfaces with emery paper. Use an anti-rust spray.

TROUBLE SHOOTING

Prior to ordering a replacement electrical unit from the manufacturer please check the

following:

If the machine does not operate at all, check the pilot light in the ON/OFF switch.

If the machine is hot and power is available, leave the machine to cool and try again.

Do not pull the handle prior to starting – the start button must be pressed first.

If the bending beam is moved prior pressing the start button begin again and make sure the

handle is pushed fully back.

Page 21

21

Should the problem continue the micro switch actuator may need to be adjusted?

21

Instruction Manual for EB2500 (S5321)

24/8/2012

To check if the start button is faulty, try to start the machine with the foot switch.

Check the connector and magnet at the electrical module.

If the clamp bar snaps down on the release of the start button, this indicates that the 15

microfarad capacitor needs to be replaced.

Should the machine cause blown fuses or trip your circuit breakers, it is likely that the bridge

rectifier is blown.

Full clamping not operating

If you are not achieving a full clamp, the angle micro switch may not be fully actuated.

How to check that the angle micro switch is being fully actuated.

The micro switch can be found on the electrical panel located at the end of the square brass

section. The brass section is attached to the angle indicating mechanism.

To access the electrical panel, the rear cover must be removed.

When the bending beam is lifted this rotates the brass section which in turn depresses the

micro switch. You should be able to hear the micro switch click on and off.

Failing this, adjust the clutching force. This can be done by ensuring that the two M8 cap

head screws at either end of the actuator shaft are secured.

This adjustment should ensure that the actuator rotates and clutches however, if you are still

unable to hear the click, the micro switch may need adjusting.

The actuator can be adjusted by loosening the screw that secures it, making the adjustment,

followed by re-tightening the screw.

If the micro switch does not click on and off after you have made the above adjustments and

rotated the bending beam to the maximum stops, then the switch may be fused and would

need to be replaced. Call or email your distributor or Electrabrake.

Clamp bar not being released

This is caused by the failure of the reverse pulse de-magnetising circuit.

Check for sticky contacts on the relay and clean.

The 6.8 power resistor or diodes could faulty which will have to be replaced.

Page 22

22

Problems with the bending of heavy gauge sheet metal.

22

Instruction Manual for EB2500 (S5321)

24/8/2012

Ensure that sheet metal thickness is within the specifications of the machine.

It may occur if narrow lips are being bent over the full length of the machine, please note

that the machine is not equipped to do this.

Should the work piece not be level (i.e. have a welded seam or a joint) it may not be

possible to bend the work piece. Ensure that all spaces under the clamp bar are filled with

flat pieces of scrap metal.

Page 23

23

23

Instruction Manual for EB2500 (S5321)

24/8/2012

EB0625 AND EB1000 PANEL

Page 24

24

24

Instruction Manual for EB2500 (S5321)

24/8/2012

EB 2000 TO 3200 WIRE PANEL

Page 25

25

25

Instruction Manual for EB2500 (S5321)

24/8/2012

EB 0625 1250 CIRCUIT

Page 26

26

26

Instruction Manual for EB2500 (S5321)

24/8/2012

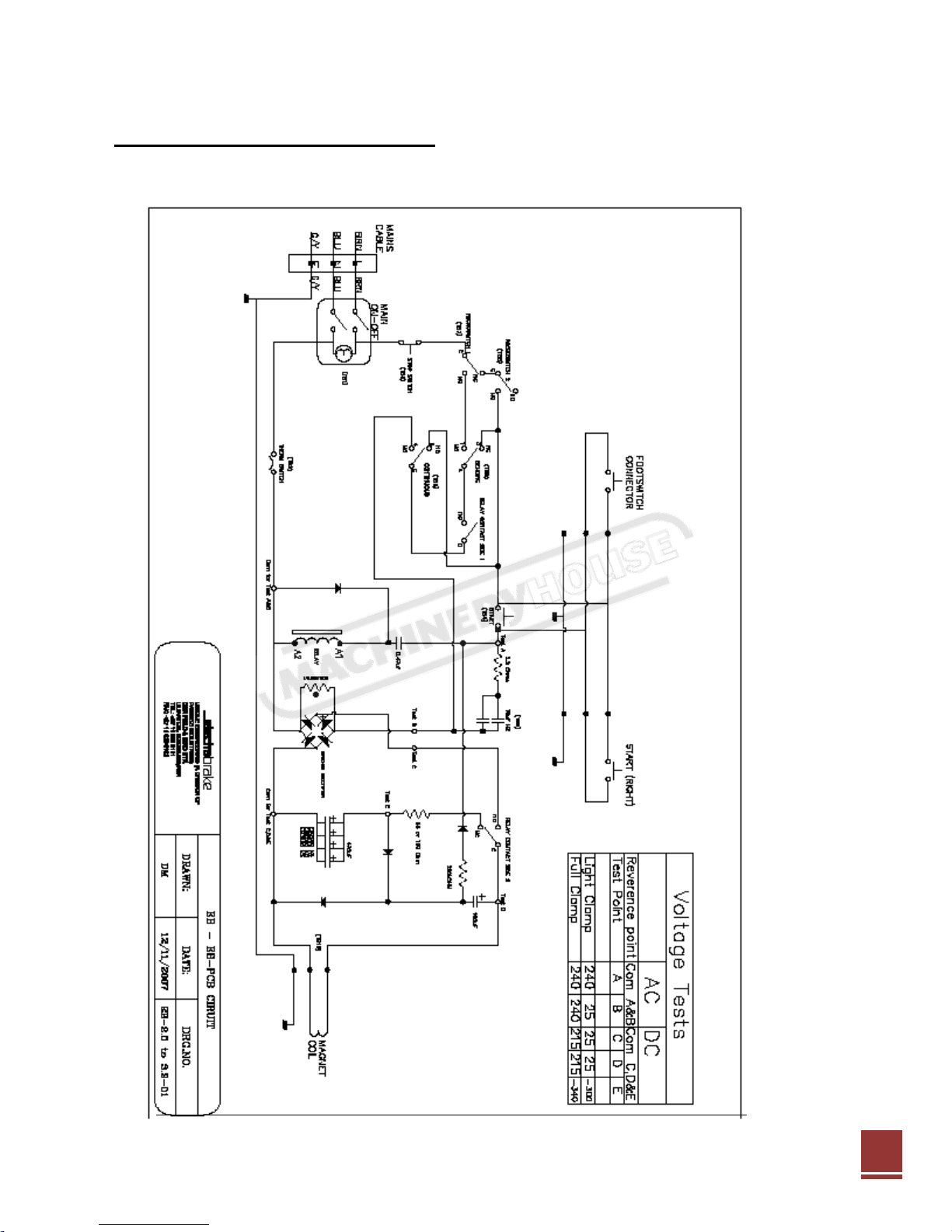

EB 2000-EB3200 CIRCUIT DIAGRAM

Page 27

27

SPECIFICATION SHEET

Model

EB0625

EB1000

EB1250

EB2000

EB2500

EB3200

Weight of Machine

Kg

72

110

150

270

315

380

Nominal Capacity (length

x thickness)

mm

0625

x1.6

1000 x

1.6

1250 x

1.6

2000 x

1.6

2500 x

1.6

3200 x

1.2

Clamping Force

Tons 3 4.5 6 9

12

10

Electricity Supply

1 phase, 220/240vac, 10A

1 phase, 220/240vac, 16A

Duty Cycle

%

30

Protection

°C

Thermal cut-out 70°/80°C

Foot Switch

No

Standard

Bending-edge Length

mm

670

1050

1300

2090

2590

3290

Distance between Lifters

mm

630

1010

1260

2028

2528

3228

U-Channel bends,

minimum spacing

mm

16***

19***

45***

Closed channel, minimum

internal

mm

99 x 27***

114 x 22***

114 x

45***

Z-reverse bends, minimum

spacing

mm

35** / 16*

36** / 18*

Thickness Capacities, full length (material thickness can increase depending on the length of bend)

…Mild steel

mm

1.6** / 1.2*

1.2** /

1.0*

…Aluminium (medium-

hard)

mm

1.6** / 1.2*

1.2** /

1.0*

…Copper, Zinc, Brass

(medium-hard)

mm

1.6** / 1.2*

1.2** /

1.0*

…Stainless steel

mm

1.0** / 0.9*

0.9** /

0.8*

*** with standard full length clamp bar **with bending beam extension bar *extension bar

removed

Refer to Chart

19mm

19mm (min)

- 98mm (min) Standard Clampbar

- 49mm (min) Narrow Clampbar

19mm (min)

Unlimited

27

Instruction Manual for EB2500 (S5321)

24/8/2012

Bending dimensions.

Page 28

28

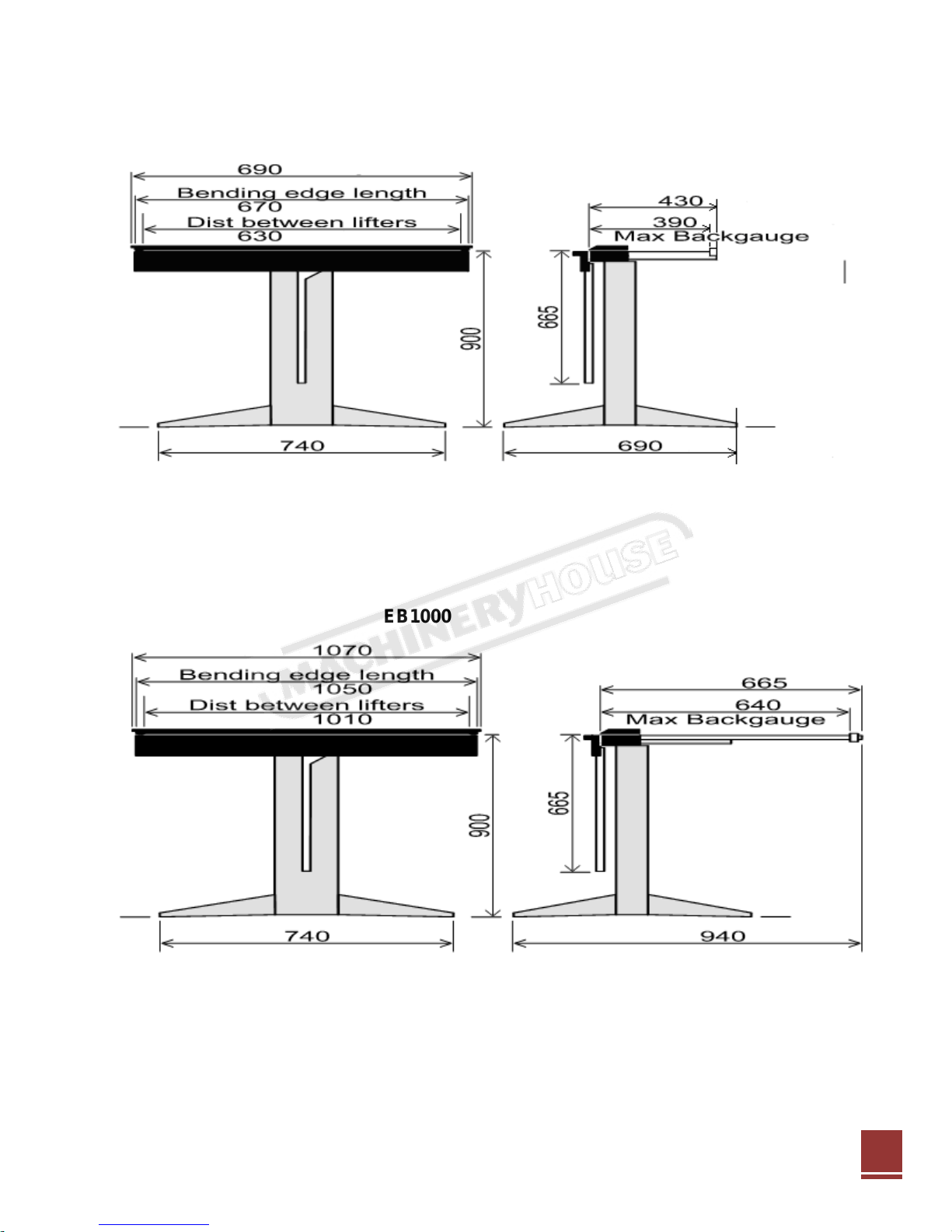

DIMENSIONAL SPECIFICATIONS EB625

28

Instruction Manual for EB2500 (S5321)

24/8/2012

DIMENSIONAL SPECIFICATIONS EB1000

Page 29

29

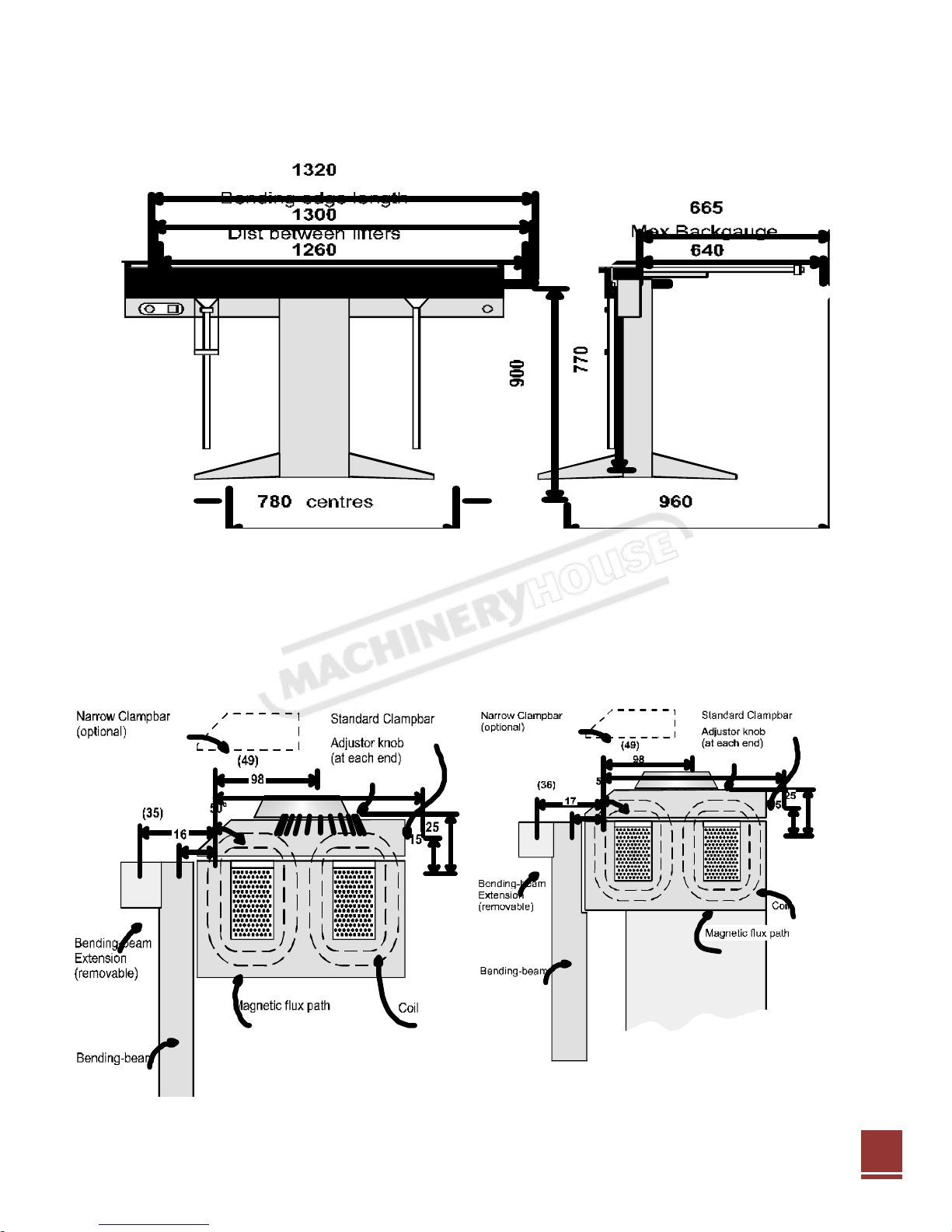

DIMENSIONAL SPECIFICATIONS EB1250

29

Instruction Manual for EB2500 (S5321)

24/8/2012

Page 30

30

DIMENSIONAL SPECIFICATIONS EB2000

30

Instruction Manual for EB2500 (S5321)

24/8/2012

DIMENSIONAL SPECIFICATIONS EB2500

Page 31

31

DIMENSIONAL SPECIFICATIONS EB3200

31

Instruction Manual for EB2500 (S5321)

24/8/2012

Page 32

34

ANNEXURE 1

32

Instruction Manual for EB2500 (S5321)

24/8/2012

Basic Safety Precautions and Procedures:

Safety is all about preventing accidents. Personal injury typically occurs because safety precautions are

either not learned, or they are not practiced. The following information is intended to assist you with some

basic safety procedures and precautions to help ensure your safety when operating and servicing your

ELECTRABRAKE machine.

If you cannot operate basic tools, you should not attempt to maintain or repair your ELECTRABRAKE

machine. Contact the Manufacturer or Sales Agent if any repair or maintenance procedure is not

understood.

Keep a first aid kit near by. Be aware of and know how to use the contents of the first aid kit. It is also a

good idea to have a fire extinguisher handy just in case of an emergency.

SAFETY PROCEDURES:

Individual, electrical, machines, and operating safety precautions are relatively similar for all of the major

categories. Make sure to pay close attention to any and all safety cautions and warnings posted on the

appliance being operated or serviced. Understanding and adhering to these safety tips can greatly reduce

the risk of personal injury.

Individual Safety Precautions:

Protecting yourself from injury and harm is absolutely imperative. We strongly suggest that before you begin

to install, operate, maintain or service your ELECTRABRAKE machine that you strictly adhere to each of the

following:

Always wear gloves. A sharp edge on a machine or work peace can hurt and/or cut your hands.

Ensure gloves are worn at all times as the magnet body will become hot and can cause minor burns.

Ensure that your machine is adheres to the assembly instructions.

Be sure to wear safety boots. You can cause serious injury to unprotected feet by dropping any heavy

tools or work peaces.

Refrain from wearing loose clothing. Loose clothes can get caught in an operating machine.

Remember to remove any jewellery when operating or servicing your machine.

If you have long hair, keep it tied back.

Wear safety glasses to guard your eyes from any dust or flying debris.

Make sure you use the correct tools and that they are clean and in good condition.

Keep your work area well lit.

Use extreme caution when handling access panels, or any other parts that could have sharp edges.

Abstain from putting your hands into any section of the machine that you have not visually inspected

for jagged edges or sharp screws.

Inspect your work area to make sure it is clean and free of water or oil spills.

Ask for help if you need to move a heavy object.

Lift heavy tooling or work peaces with your leg muscles, not your back muscles.

MOVING ELECTRABRAKE BENDING MACHINE:

Moving bending machine into position. Use lifting brackets attached to Electrabrake columns.

Page 33

35

33

Instruction Manual for EB2500 (S5321)

24/8/2012

Electrical Safety Precautions:

Before beginning any machine repair, make sure you know where and how to turn off the electricity to the

appliance. Know the locations of any plugs, fuses, circuit breakers, and cartridge fuses in your home or

workshop. Be sure to label them.

If in servicing your appliance, a voltage test is required, reconnect the power supply only for the duration of

the voltage test. Disconnect the power immediately following the test. When conducting a voltage test, make

sure that no other conductive parts come into contact with any exposed current-carrying metal parts.

When you replace any parts, or are putting the machine back together, always reinstall the wires to the

correct terminals as per the wiring diagram. Inspect the wires closely to make sure they are not crossing any

sharp areas, are pinched in any way, caught between panels, or in between any moving parts that can

cause an electrical malfunction.

It is also important to keep these safety tips in mind:

Make sure that your machine has its own grounded electrical circuit.

Never use an extension cord to plug in your appliance.

Ensure the electricity has been turned off before servicing the machine.

Do not remove the ground wire from a three-prong power cord, or any other ground wires from the

machine.

Do not perform any alterations to any machine switches, components, or features.

Before repairing the machine, replace any damaged, pinched, or frayed wires.

Make sure all electrical connections within the unit are correctly and securely connected.

Moisture Protection Ordinary. This Product is not suitable for out door use.

Shock Protection Class 1.

This apparatus should always be earthed.

Machine Safety Precautions:

Always call a machine repair technician if you doubt the safety of your machine.

When replacing any part that is not working correctly or that may have blown, use only replacement parts of

the same size specifications and capacity as your original part. Consult a machine repair technician if you

have any questions or concerns.

Operating Safety Precautions:

Once you have repaired your machine, do not operate it again until it has been properly reinstalled

according to the manual's use and care instructions, and according to the manufacturer's instructions.

Also, follow these additional safety tips to prevent injuries:

Do not permit children to play on or operate your machine.

Do not permit persons who are unfamiliar with the proper operation of your machine to operate it.

Use your machine only to complete the tasks they were designed to complete.

Page 34

36

34

Instruction Manual for EB2500 (S5321)

24/8/2012

FRAME ASSEMBLY AND PARTS LIST EB2000, EB2500, EB3200

Page 35

37

35

Instruction Manual for EB2500 (S5321)

24/8/2012

Page 36

38

PART NUMBERS

DESCRIPTION

QTY

CHECKED

EB-119

SAFETY CABLE ASSY

2

EB0625-TEST PIECE

625 BENDER – TEST PIECE

1

EB-097

BASIC ASSEMBLY 650

1

EB-101

STAND ASSEMBLY 650/10

1 EB-059

HANDLE 650/1000

1

EB-054

BEAM EXTENSION 650

1

EB-057

SWITCH ACTUATOR LIGHT

1

EB-058

ANGLE ROD 1

EB-052/L

TRAY LEFT 650 COMP

1

EB-052/R

TRAY RIGHT 650 COMP

1

EB-052-01

625 TRAY STOP CLAMP

2 EB-102 (DECALS)

EB0625 630X65 BLK/RD ON

1

EB-053

RUBBER MAT 650

1

EB-250 RULER

EB0625 ALUMINIUM RULER

1

EB-ELEC-650/PCB

EB 650 ELECTRICAL UNIT

1 EB-012

STOP COLLAR 1

EB-110/D

FUSE 3 VARIANT (10A) WA

1

EB-089

CLAMP BAR 625 ASSY

1

EB-020

CLAMP BARS (SHORT SET)

1 ELEC476

CRIMP TERMINAL PINS 29

2

EB-111-BACK

STICKER FOR ELECTRABRAKE

1

EB-110-FRONT

STICKER FOR ELECTRABRAKE

1

EB-112-LEFT

STICKER FOR ELECTRABRAKE

1 EB-113-RIGHT

STICKER FOR ELECTRABRAKE

1

ELEC474

SOCKET HOUSING 3 PIN 29

1

FW-M10 EG

M10X1.2 FLAT WASHER GAL

4

FW-M6 EG

M6X1.2 FLAT WASHER GAL

3 P/O-WAS-8MM

8MM PUSH ON FIX WASHER

1

PAN-M6X10

M6X10 POZI PAN HEAD SCREW

3

SW-M6 EG

M6 SPRING WASHERS GALV

3 A/KEY-M6

M6 ALLEN KEY LONG SERIES

1

EB-650-CRATE

880X270X270 WOODEN CRATE

1

CAP-M8X12 HT

M8X12 SOCK HEAD SCREW

5

FW-M8 EG

M8X1.2 FLAT WASHER GALV

3

CAP-M8X20

M8X20 SOCKET HEAD CAP S

3

36

Instruction Manual for EB2500 (S5321)

24/8/2012

PACKING LIST FOR EB0625

MACHINE SERIAL NUMBER_______________________________

Page 37

39

PART NUMBERS

DESCRIPTION

QTY

CHECKED

EB1000-TEST PIECE

1000 BENDING TEST PIECE

1

EB-119

SAFETY CABLE ASSY

2 EB-098

BASIC ASSEMBLY 1000

1

EB-101

STAND ASSEMBLY 650/1000

1 EB-059

HANDLE 650/1000

1

EB-062

BENDING BEAM EXTENSION

1 EB-057

SWITCH ACTUATOR LIGHT

1

EB-058

ANGLE ROD 1

EB-016

LARGE TRAY 1

EB-017

RUBBER MAT

1

EB-015

BACK STOP BAR – ASSY

2 EB-012

STOP COLLAR

3

EB-103 (DECALS)

EB1000 1010X65 BLK/RD C

1 EB-090

CLAMP BAR 1000 ASSY

1

EB-019

CLAMP BAR 600 LONG

1

EB-020

CLAMP BARS (SHORT SET)

1 EB-ELEC-1000/PCB

1000 ELECTRICAL UNIT WI

1

ELEC474

SOCKET HOUSING 3 PIN 29

1 ELEC476

CRIMP TERMINAL PINS 29

2

FW-M8 EG

M8X1.2 FLAT WASHER GAL

3 P/O-WAS-8MM

8MM PUSH ON FIX WASHER

1

EB-1000-CRATE

1170X270X270 WOODEN CRATE

1

EB-110-FRONT

STICKER FOR ELECTRABRAKE

1 EB-111-BACK

STICKER FOR ELECTRABRAKE

1

EB-112-LEFT

STICKER FOR ELECTRABRAKE

1 EB-113-RIGHT

STICKER FOR ELECTRABRAKE

1

EB-250-RULER

EB0625 ALUMINIUM RULER

1 A/KEY-M6

M6 ALLEN KEY LONG SERIES

1

CAP-M8X12 HT

M8X12 SOCKET HEAD SCREW

7 CAP-M8X16

M8X16 SOCKET HEAD CAP SCREW

2

CAP-M8X20

M8X20 SOCKET HEAD CAP SCREW

4

CAP-M8X25 HT

M8X25 CAP SCREWS HT

4 EB-110/D

FUSE 3 VARIANT (10A) WA

1

37

Instruction Manual for EB2500 (S5321)

24/8/2012

PACKING LIST FOR EB1000 ELECTRABRAKE BENDING MACHINE

MACHINE SERIAL NUMBER_______________________________

Page 38

40

PACKING LIST FOR EB1250 ELECTRABRAKE BENDING MACHINE

PART NUMBERS

DESCRIPTION

QTY

CHECKED

EB-119

SAFETY CABLE ASSY

2

EB1250-TEST PIECE

1250 BENDER TEST PIECE

1

EB-099

BASIC ASSEMBLY 1250

1

EB-100

STAND ASSEMBLY 1250

1

EB-010

HANDLE REINFORCED

1

EB-011

HANDLE REINFORCED & GROOVED

1

EB-012

STOP COLLAR 3

EB-015

BACK STOP BAR – ASSY

2 EB-016

LARGE TRAY 1

EB-017

RUBBER MAT 1

EB-038

B/BEAM EXTENSION 1250

1 EB-046

INDICATOR ANCHOR

1 EB-039

COVER 1250 R/HAND

1

EB-044

COVER 1250 L/HAND

1

EB-047

ACCESS PANEL 1250

1

EB-048

COLUMN BLOCK 1250

1

EB-006

COVER END PLATE

2

EB-002

INDICATOR ASSEMBLY H.D.

1

EB-104 (DECALS)

1260X95 EB1250 BLK/RED

1

EB-110-FRONT

STICKER FOR ELECTRABRAKE

1

EB-111

START LABEL 1

EB-111-BACK

STICKER FOR ELECTRABRAKE

1 EB-112-LEFT

STICKER FOR ELECTRABRAKE

1 EB-113-RIGHT

STICKER FOR ELECTRABRAKE

1 EB-225 RULER

EB1250 ALUMINIUM RULER

1 EB-019

CLAMP BAR 600 LONG

1

EB-020

CLAMP BARS (SHORT SET)

1

EB-ELEC-1250/PCB

1250 ELECTRICAL UNIT WI

1

EB-HAR 1250/S

1250 HARNESS – SHORT

1

EB-HARNESS 1250

1250-ELECTRICAL HARNESS

1

ELEC474

SOCKET HOUSING 3 PIN 29

1

ELEC476

CRIMP TERMINAL PINS 29

2

EB-091

CLAMP BAR 1250 ASSY

1

EB-1250-CRATE

1400X300X300 WOODEN CRA

1 CAP-M8X30 EG

M8X30 CAP SCREWS GALV

4 PAN-M6X10

M6X10 POZI PAN HEAD SCR

13

R/BOLT-M12X60

M12X60 RAWL BOLT

2 A/KEY-M6

M6 ALLEN KEY LONG SERIES

1 CAP-M8X12 HT

M8X12 SOCK HEAD SCREW

7

CAP-M8X16

M8X16 SOCKET HEAD CAP S

8

CAP-M8X25 HT

M8X25 CAP SCREWS HT

7

EB-110/D

FUSE 3 VARIANT (10A) WA

2

PAN-M10X16

10X16 POZI S/T PAN HEAD

6

38

Instruction Manual for EB2500 (S5321)

24/8/2012

MACHINE SERIAL NUMBER_______________________________

Page 39

41

PACKING LIST FOR EB2000 ELECTRABRAKE BENDING MACHINE

PART NUMBERS

DESCRIPTION

QTY

CHECKED

EB2000-TEST PIECE

2000 BENDER – TEST PIECE

1

EB-119

SAFETY CABLE ASSY

2

EB-096

BASIC ASSEMBLY 2000

1

EB-001

STAND ASSY 1

EB-002

INDICATOR ASSEMBLY H.D.

1 EB-066

BEAM EXTENSION 2000 UNP

1 EB-095

LIFTER MECHANISM 2000

1 EB-011

HANDLE REINFORCED & GROOVED

1 EB-012

STOP COLLAR 5

EB-015

BACK STOP BAR – ASSY

4

EB-016

LARGE TRAY 1

EB-017

RUBBER MAT 1

EB-006

COVER END PLATE

2

EB-007

COLUMN BLOCK

2

EB-008

COVER CENTRAL

1

EB-009

ACCESS PANEL 1

EB-068

COVER LEFT 2000

1

EB-069

COVER RIGHT 2000

1 EB-010

HANDLE REINFORCED

1 EB-225 RULER

EB1250 ALUMINIUM RULER

1 EB-105 (DECALS)

EB2000 2040X95 BLK/RED

1 EB-110-FRONT

STICKER FOR ELECTRABRAKE

1 EB-110/B

FUSE 3 VARIANT (20A) WA

1

EB-111

START LABEL 2

EB-111-BACK

STICKER FOR ELECTRABRAKE

1

EB-112-LEFT

STICKER FOR ELECTRABRAKE

1

EB-113-RIGHT

STICKER FOR ELECTRABRAKE

1

EB-079

CLAMP BAR FULL LENGTH

1

EB-019

CLAMP BAR 600 LONG

1

EB-083

FOOT SWITCH ASSY

1

EB-020

CLAMP BARS (SHORT SET)

1 EB-021

CLAMP BAR 1160

1 EB-ELEC-2.0/PCB

2MT ELECTRICAL UNIT

1 EB-HAR 1250/S

1250 HARNESS – SHORT

1 EB-HARNESS 2000

2000 ELECTRICAL HARNESS

1 ELEC474

SOCKET HOUSING 3 PIN 29

1

EB-2000-CRATE

2165X295X250 WOODEN CRATE

1

ELEC476

CRIMP TERMINAL PINS 29

2

PAN-M6X10

M6X10 POZI PAN HEAD SCR

24

R/BOLT-M12X60

M12X60 RAWL BOLT

2

A/KEY-M6

M6 ALLEN KEY LONG SERIES

1

CAP-M8X12 HT

M8X12 SOCKET HEAD SCREW

44

CAP-M8X16

M8X16 SOCKET HEAD CAP SCREW

44

CAP-M8X20

M8X20 SOCKET HEAD CAP SCREW

20 CAP-M8X30 EG

M8X30 CAP SCREWS GALV

8 PAN-M10X16

10X16 POZI S/T PAN HEAD

6

39

Instruction Manual for EB2500 (S5321)

24/8/2012

MACHINE SERIAL NUMBER_______________________________

Page 40

42

PACKING LIST FOR EB2500 ELECTRABRAKE BENDING MACHINE

PART NUMBERS

DESCRIPTION

QTY

CHECKED

EB-119

SAFETY CABLE ASSY

2 EB2500-TEST PIECE

2500 BENDER – TEST PIECE

1 EB-003

BASIC ASSEMBLY 2500

1 EB-001

STAND ASSY 1

EB-002

INDICATOR ASSEMBLY H.D

1 EB-014

B-BEAM EXTENSION 2500

1

EB-010

HANDLE REINFORCED

1

EB-011

HANDLE REINFORCED & GROOVED

1

EB-012

STOP COLLAR 5

EB-015

BACK STOP BAR – ASSY

4

EB-016

LARGE TRAY 1

EB-017

RUBBER MAT 1

EB-006

COVER END PLATE

2

EB-007

COLUMN BLOCK

2 EB-004

LIFTER MECHANISM 2500E

1 EB-008

COVER CENTRAL

1 EB-009

ACCESS PANEL 1

EB-022-01

2500 COVER L/H

1 EB-022-02

2500 COVER R/H

1

EB-106 (DECALS)

EB2500 2540X95 BLK / RED

1

EB-110-FRONT

STICKER FOR ELECTRABRAKE

1

EB-110/B

FUSE 3 VARIANT (20A) WA

1

EB-111

START LABEL 2

EB-111-BACK

STICKER FOR ELECTRABRAKE

1

EB-112-LEFT

STICKER FOR ELECTRABRAKE

1 EB-113-RIGHT

STICKER FOR ELECTRABRAKE

1 EB-225 RULER

EB1250 ALUMINIUM RULER

1 EB-018

CLAMP BAR (FULL LENGTH)

1 EB-019

CLAMP BAR 600 LONG

1 EB-020

CLAMP BAR (SHORT SET)

1 EB-021

CLAMP BAR 1160

1 EB-083

FOOT SWITCH ASSY

1

EB-ELEC-2.5/PCB

2.5MT ELECTRICAL UNIT

1

EB-HAR 1250/S

1250 HARNESS – SHORT

1

EB-HARNESS 2.5

2.5 ELECTRICAL HARNESS

1

ELEC474

SOCKET HOUSING 3 PIN 29

1

ELEC476

CRIMP TERMINAL PINS 29

2

PAN-M10X16

10X16 POZI S/T PAN HEAD

6 PAN-M6X10

M6X10 POZI PAN HEAD SCR

24

R/BOLT-M12X60

M12X60 RAWL BOLT

2 A/KEY-M6

M6 ALLEN KEY LONG SERIES

1 CAP-M8X12 HT

M8X12 SOCK HEAD SCREW

11 CAP-M8X16

M8X16 SOCKET HEAD CAP S

8

CAP-M8X25 HT

M8X25 CAP SCREWS HT

16

CAP-M8X30 EG

M8X30 CAP SCREWS GALV

8

EB-2500-CRATE

2665X295X250 WOODEN CRATE

1

40

Instruction Manual for EB2500 (S5321)

24/8/2012

MACHINE SERIAL NUMBER_______________________________

Page 41

43

PACKING LIST FOR EB3200 ELECTRABRAKE BENDING MACHINE

PART NUMBERS

DESCRIPTION

QTY

CHECKED

EB-119

SAFETY CABLE ASSY

2

EB3200-TEST PIECE

3200 BENDER – TEST PIECE

1

EB-024

BASIC ASSEMBLY 3200

1

EB-001

STAND ASSY 1

EB-002

INDICATOR ASSEMBLY H.D.

1 EB-025

BENDING BEAM EXTENSION

1 EB-028

LIFTER MECHANISM – 3200

1 EB-010

HANDLE REINFORCED

1 EB-011

HANDLE REINFORCED (GROOVED)

1

EB-012

STOP COLLAR 5

EB-015

BACK STOP BAR – ASSY

4

EB-016

LARGE TRAY 1

EB-017

RUBBER MAT 1

EB-006

COVER END PLATE

2

EB-007

COLUMN BLOCK

2

EB-008

COVER CENTRAL

1

EB-009

ACCESS PANEL 1

EB-023-01

3200 COVER PLATE R/H

1 EB-023-02

3200 COVER L/H

1 EB-107 (DECALS)

EB3200 3240X95 BLK/RD C

1 EB-110-FRONT

STICKER FOR ELECTRABRAKE

1 EB-110/B

FUSE 3 VARIANT (20A) WA

1

EB-111

START LABEL 2

EB-111-BACK

STICKER FOR ELECTRABRAKE

1

EB-112-LEFT

STICKER FOR ELECTRABRAKE

1

EB-113-RIGHT

STICKER FOR ELECTRABRAKE

1

EB-225-RULER

EB1250 ALUMINIUM RULER

1

EB-026

CLAMPBAR FULL LENGTH

1

EB-019

CLAMPBAR 600 LONG

1

EB-020

CLAMPBARS (SHORT SET)

1 EB-021

CLAMPBAR 1160

1 EB-083

FOOT SWITCH ASSY

1 EB-118

SUPPORT LEG ASSEMBLY

2 EB-3200-CRATE

3365X295X250 WOODEN CRATE

1 EB-ELEC-3.2/PCB

3.2MT ELECTRICAL UNIT

1

EB-HAR 1250/S

1250 HARNESS – SHORT

1

EB-HARNESS 3.2

3.2 ELECTRICAL HARNESS

1

ELEC474

SOCKET HOUSING 3 PIN 29

1

ELEC476

CRIMP TERMINAL PINS 29

1

PAN-M10X16

10X16 POZI S/T PAN HEAD

6

PAN-M6X10

M6X10 POZI PAN HEAD SCR

24

R/BOLT-M12X60

M12X60 RAWL BOLT

2

A/KEY-M6

M6 ALLEN KEY LONG SERIES

1 CAP-M8X12

M8X12 SOCKET HEAD CAP S

1 CAP-M8X16

M8X16 SOCKET HEAD CAP S

15 CAP-M8X25 HT

M8X25 CAP SCREWS HT

15

41

Instruction Manual for EB2500 (S5321)

24/8/2012

MACHINE SERIAL NUMBER_______________________________

Loading...

Loading...