Page 1

TRIO DELTA 5.2

CONTENTS

Indoor Units Outdoor Units

DELTA 22

DELTA 25

DELTA 35

TRIO Delta 5.2 DCI

SM TRIO52 1-E.1 GB

REFRIGERANT

R410A HEAT PUMP

OCTOBER – 2008

Page 2

LIST OF EFFECTIVE PAGES

CONTENTS

LIST OF EFFECTIVE PAGES

Note: Changes in the pages are indicated by a “Revision#” in the footer of each effected page

(when none indicates no changes in the relevant page). All pages in the following list represent

effected/ non effected pages divided by chapters.

Dates of issue for original and changed pages are:

Original ....... 0 ........ May 2006

Total number of pages in this publication is 56 consisting of the following:

Page

No.

Title ....................... 1

A ........................... 1

i ............................. 1

1-1 ........................ 1

2-1 - 2-4 ................ 1

3-1 ........................ 1

4-1 - 4-2 ................ 1

5-1 - 5-6 ................ 1

6-1 - 6-6 ................ 1

7-1 ........................ 1

8-1 ........................ 1

9-1 ........................ 1

10-1 ...................... 1

11-1-11-15 ............. 1

12-1-12-6 .............. 1

13-1-13-2 .............. 1

Appendix -A ...........1

Revision

No. #

Page

No.

Revision

No. #

Page

No.

Revision

No. #

• Zero in this column indicates an original page.

*Due to constant improvements please note that the data on this service manual can be modified

with out notice.

**Photos are not contractual

A

SM TRIO52 1- E.1 GB

Page 3

TABLE OF CONTENTS

Table of Contents

1. INTRODUCTION ...................................................................................................1-1

2. PRODUCT DATA SHEET ......................................................................................2-1

3. RATING CONDITIONS ..........................................................................................3-1

4. OUTLINE DIMENSIONS .......................................................................................4-1

5. PERFORMANCE DATA .......................................................................................5-1

6. PRESSURE CURVES ...........................................................................................6-1

7. ELECTRICAL DATA ..............................................................................................7-1

8. WIRING DIAGRAMS .............................................................................................8-1

9. REFRIGERATION DIAGRAMS .............................................................................9-1

10. TUBING CONNECTIONS ......................................................................................10-1

11. CONTROL SYSTEM .............................................................................................11-1

12. TROUBLESHOOTING ..........................................................................................12-1

13. EXPLODED VIEWS AND SPARE PARTS LISTS .................................................13-1

14. APPENDIX A .........................................................................................................14-1

SM TRIO52 1- E.1 GB

i

Page 4

1. INTRODUCTION

CONTENTS

1.1 General

The new Trio 5.2 Delta DCI Outdoor Unit is a high efficiency multi split inverter unit,

supporting Indoor Units capacity range of - 2.2, 2.5 and 3.5 Kw.

1.2 Main Features

• DC Inverter

• R410A

• High COP (A class energy rating)

• Pre-Charged

• Base heater connection.

• Heating operation at outdoor temperature down to -150C.

• 10 LED’s, shows both indoor and outdoor diagnostics.

• Variable Speed DC Inverter outdoor fan.

• M2L diagnostics softwear cable Port ( for PC).

• Low noise level

INTRODUCTION

1.3 Tubing Connections

Flare type interconnecting tubing to be produced on site.

For further details please refer to APPENDIX A on this manual, and to the relevant indoor

service Manual,

1.4 Inbox Documentation

Each indoor unit is supplied with its own installation and operation manuals.

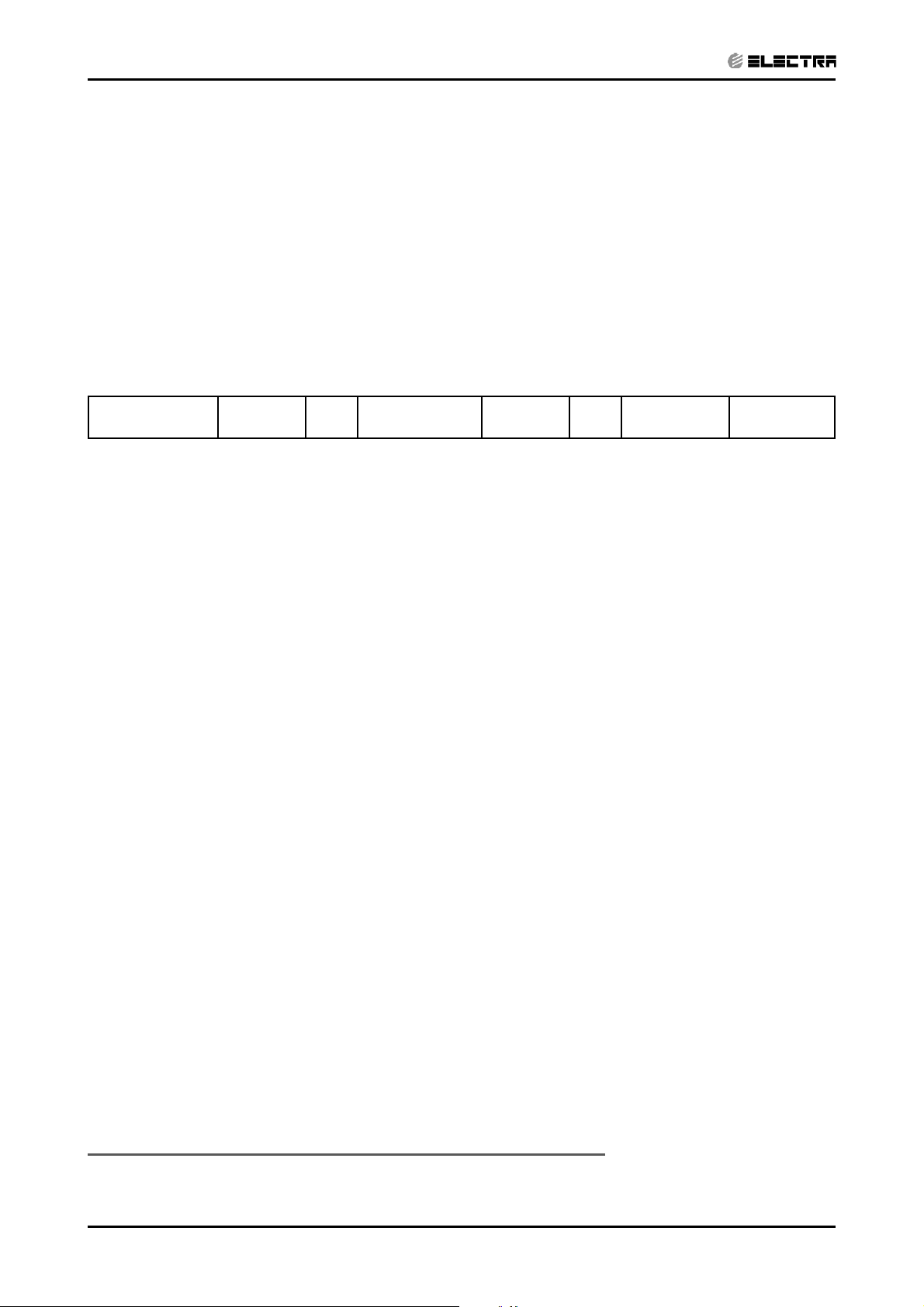

1.5 Matching Table

1.5.1 R410A

OUTDOOR UNITS

MODEL REFRIGERANT DELTA 22 DCI DELTA 25 DCI DELTA 35 DCI

INDOOR UNITS

SM TRIO52 1- E.1 GB

Trio 5.2 Delta DCI R410A

√√ √

1-1

Page 5

PRODUCT DATA SHEET

CONTENTS

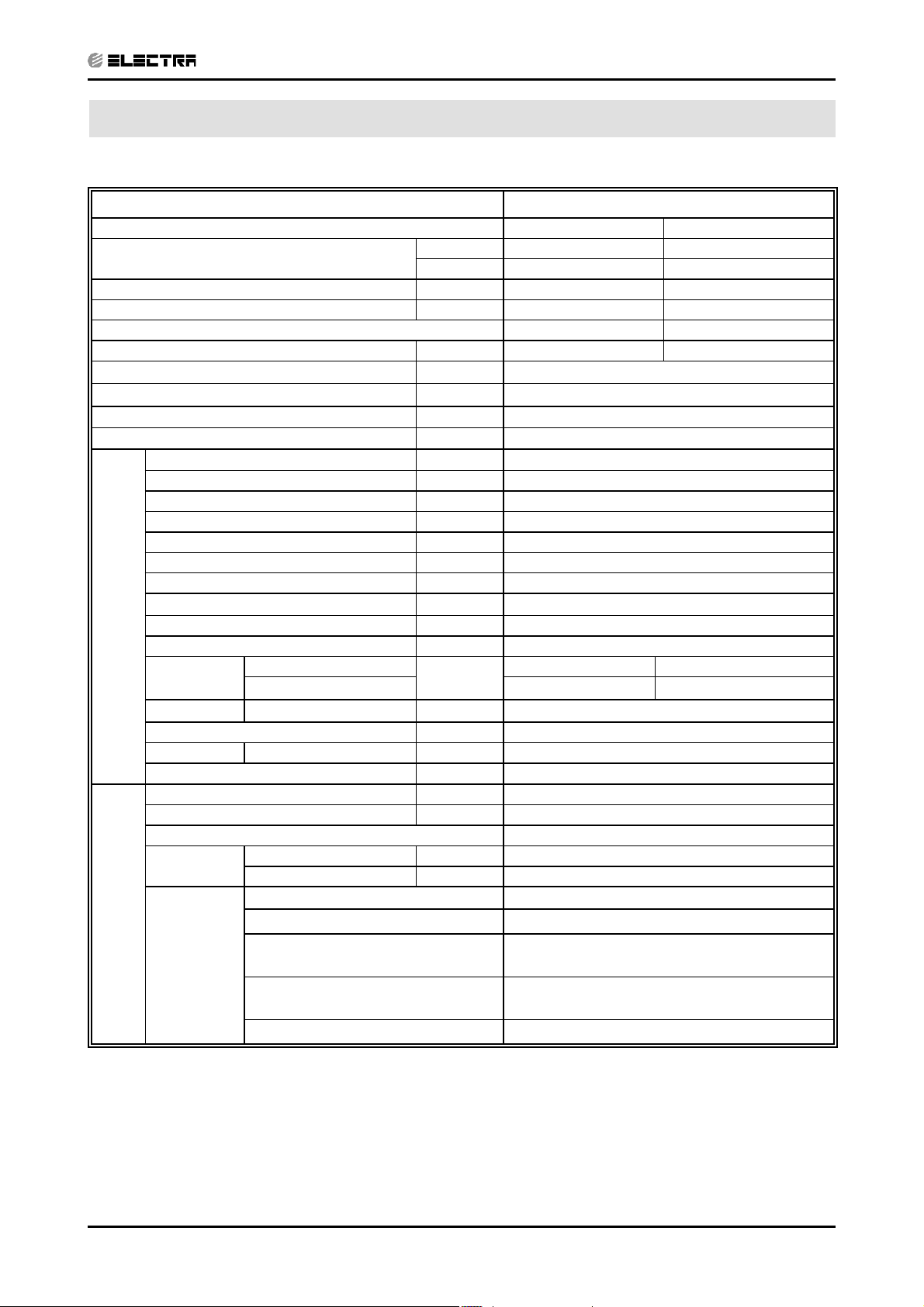

2. PRODUCT DATA SHEET

2.1 Outdoor Unit TRIO 5.2 Delta Specifications.

Model TRIO Delta 5.2kw DCI R410A

Operation Mode Cooling Heating

Capacity

Total Input W 1550(450~2150) 1800(450~1900)

E.E.R (Cooling) / C.O.P (Heating) W/W 3.35 3.67

Energy efficienty class A A

Running Current

Starting Current A 10.5

Inrush Current A 35.0

Power Supply V/Ph/Hz Single Phase / 50Hz / 230V

Dehumidification L/h 1.7

Refrigerant control Electronic expansion valve

Compressor type Scroll DC Inverter

Model Panasonic 5CS130XCC03

Starter type --Protection device Outdoor SW control

Heat exchanger Hydrophilic flat fin, Grooved tube coil

Fan x No. Propeller x 1

Airflow m

Motor output W 70

Defrost method Reverse cycle

OUTDOOR UNIT

Noise level

Dimensions W*H*D mm 846*690*302

Weight Kg 48

Package W*H*D mm 990X770X430

Unit stacking # 3

Refrigerant Charge Kg R410A

Charge (7.5m connection tube) g 1850

Fresh Air NO

Tube size

O.D.

Connection

TUBING

method

between the

indoor and

outdoor units

(3)

(4)

Indoor & outdoor Flared

Height difference between indoor units Max.5m

Height difference between indoor &

outdoor

Tubing length

Additional charge No need

Pressure

Power 63 67

Liquid mm 6.35

Suction mm 9.5

Btu/hr 17747(2389~22184) 22525(3413~29914)

W 5200 (1000~6500) 6600(1000~7300

A6.7 7.8

3

/hr 2860

dB(A)

Standard 7.5m Max. 25m for one unit and 35m for

50 56

Max.5m

total

SM TRIO52 1- E.1 GB

2-1

Page 6

PRODUCT DATA SHEET

CONTENTS

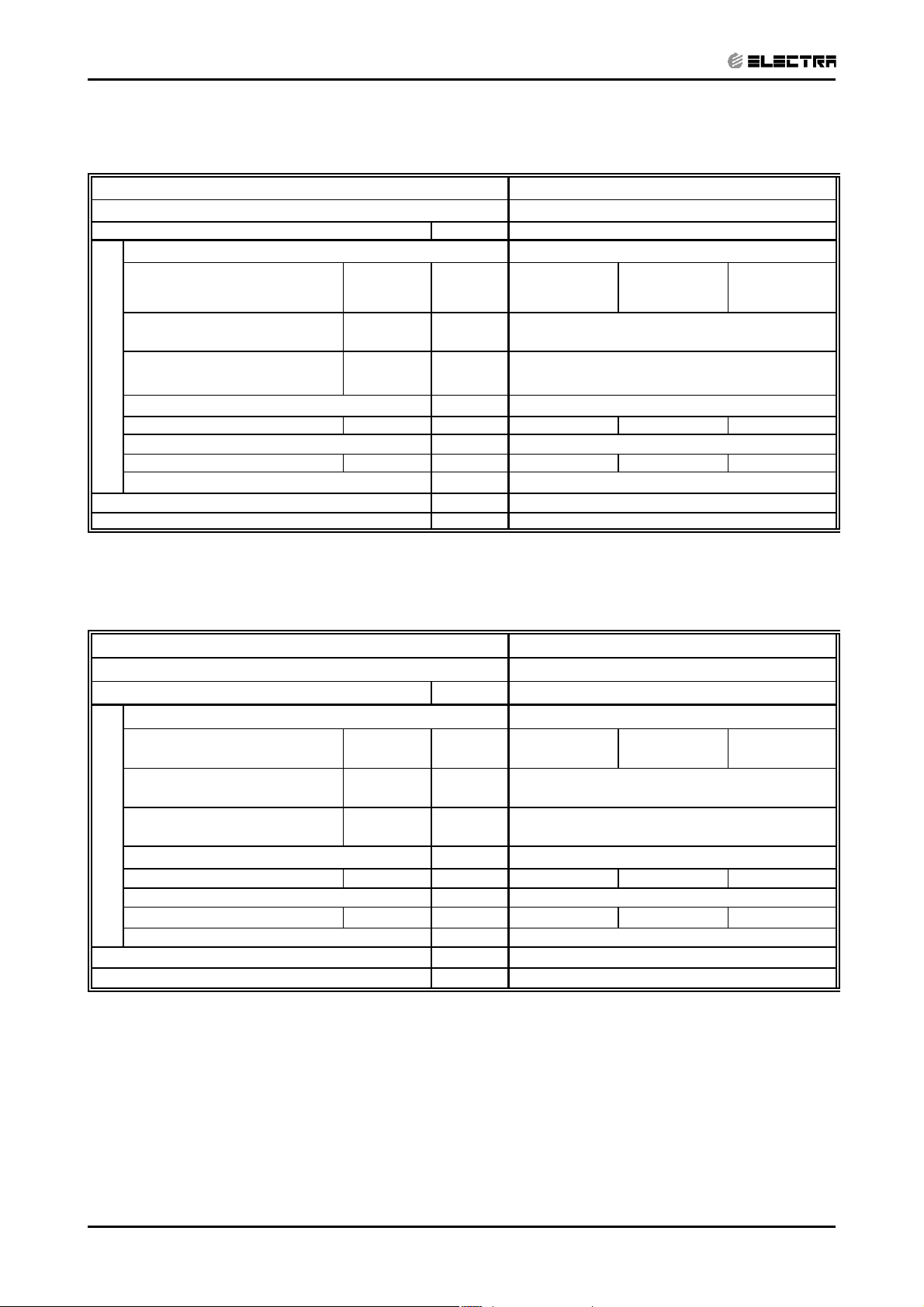

2.2 Indoor Units Data

2.2.1 DELTA 22 DCI Specifications

Model Indoor Unit / Type DELTA 22 DCI / Wall Mounted

Installation Method FLARE

Power Supply V/Ph/Hz 220-240 / 1/ 50

Fan Type & Quantity Crossflow *1

(2)

Airflow

Cooling / Heating

Sound Power Level

Cooling / Heating

Sound Pressure Level

Cooling / Heating

INDOOR

(3)

(4)

H/M/L m

L - H dB (A) 49/46/43

L - H dB (A) 36/33/30

Condensate Drain Tube I.D. mm 16

Dimensions W/H/D mm 680 250 185

Weight kg 7

Package Dimensions W/H/D mm 740 320 265

Stacking Height Units 9 LEVELS

Heating Elements kW N/A

Moisture Removal L/hr 1

3

/hr 400 350 300

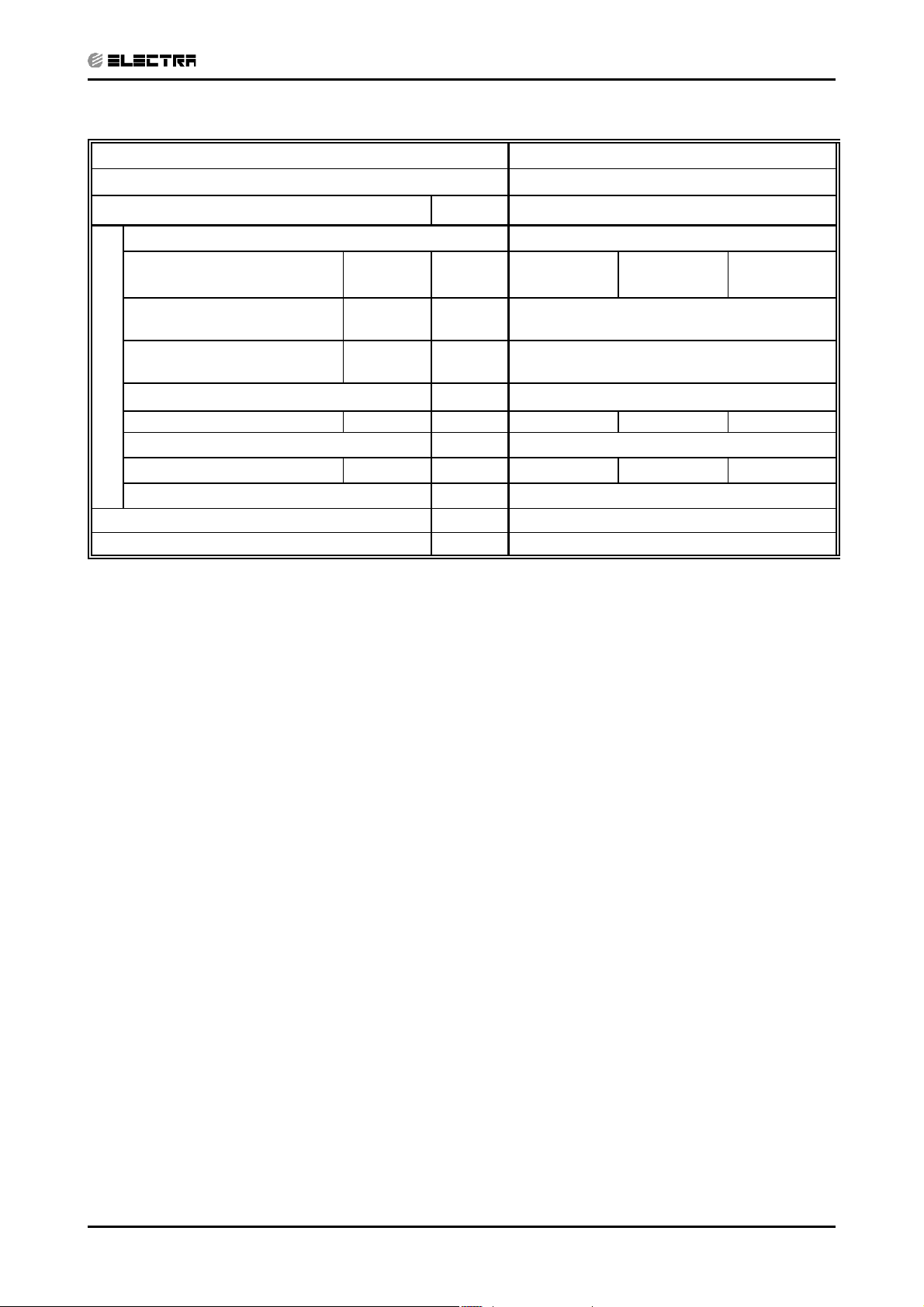

2.2.2 DELTA 25 DCI Specifications

Model Indoor Unit / Type DELTA 25 DCI / Wall Mounted

Installation Method FLARE

Power Supply V/Ph/Hz 220-240 / 1/ 50

Fan Type & Quantity Crossflow *1

(2)

Airflow

Cooling / Heating

Sound Power Level

(3)

Cooling / Heating

Sound Pressure Level

Cooling / Heating

INDOOR

Condensate Drain Tube I.D. mm 16

(4)

H/M/L m

L - H dB (A) 52/48/45

L - H dB (A) 39/35/32

Dimensions W/H/D mm 680 250 185

Weight kg 7

Package Dimensions W/H/D mm 740 320 260

Stacking Height Units 9 LEVELS

Heating Elements kW N/A

Moisture Removal L/hr 1.0

(1) Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units) and EN14511.

(2) Airflow in ducted units; at nominal external static pressure.

(3) Sound power in ducted units is measured at air discharge.

(4) Sound pressure level measured at 1 meter distance from unit.

3

/hr 420 350 270

2-2

SM TRIO52 1- E.1 GB

Page 7

PRODUCT DATA SHEET

CONTENTS

2.2.3 DELTA 35 DCI Specifications

Model Indoor Unit / Type DELTA 35 DCI / Wall Mounted

Installation Method FLARE

Power Supply V/Ph/Hz 220-240 / 1/ 50

Fan Type & Quantity Crossflow *1

(2)

Airflow

Cooling / Heating

Sound Power Level

(3)

Cooling / Heating

(4)

Sound Pressure Level

Cooling / Heating

INDOOR

Condensate Drain Tube I.D. mm 16

H/M/L m

L - H dB (A) 56/46/42

L - H dB (A) 39/33/29

Dimensions W/H/D mm 840 250 185

Weight kg 8.0

Package Dimensions W/H/D mm 930 320 265

Stacking Height Units 9 LEVELS

Heating Elements kW N/A

Moisture Removal L/hr 1.5

3

/hr 550 450 350

(1) Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units) and EN14511.

(2) Airflow in ducted units; at nominal external static pressure.

(3) Sound power in ducted units is measured at air discharge.

(4) Sound pressure level measured at 1 meter distance from unit.

SM TRIO52 1- E.1 GB

2-3

Page 8

PRODUCT DATA SHEET

CONTENTS

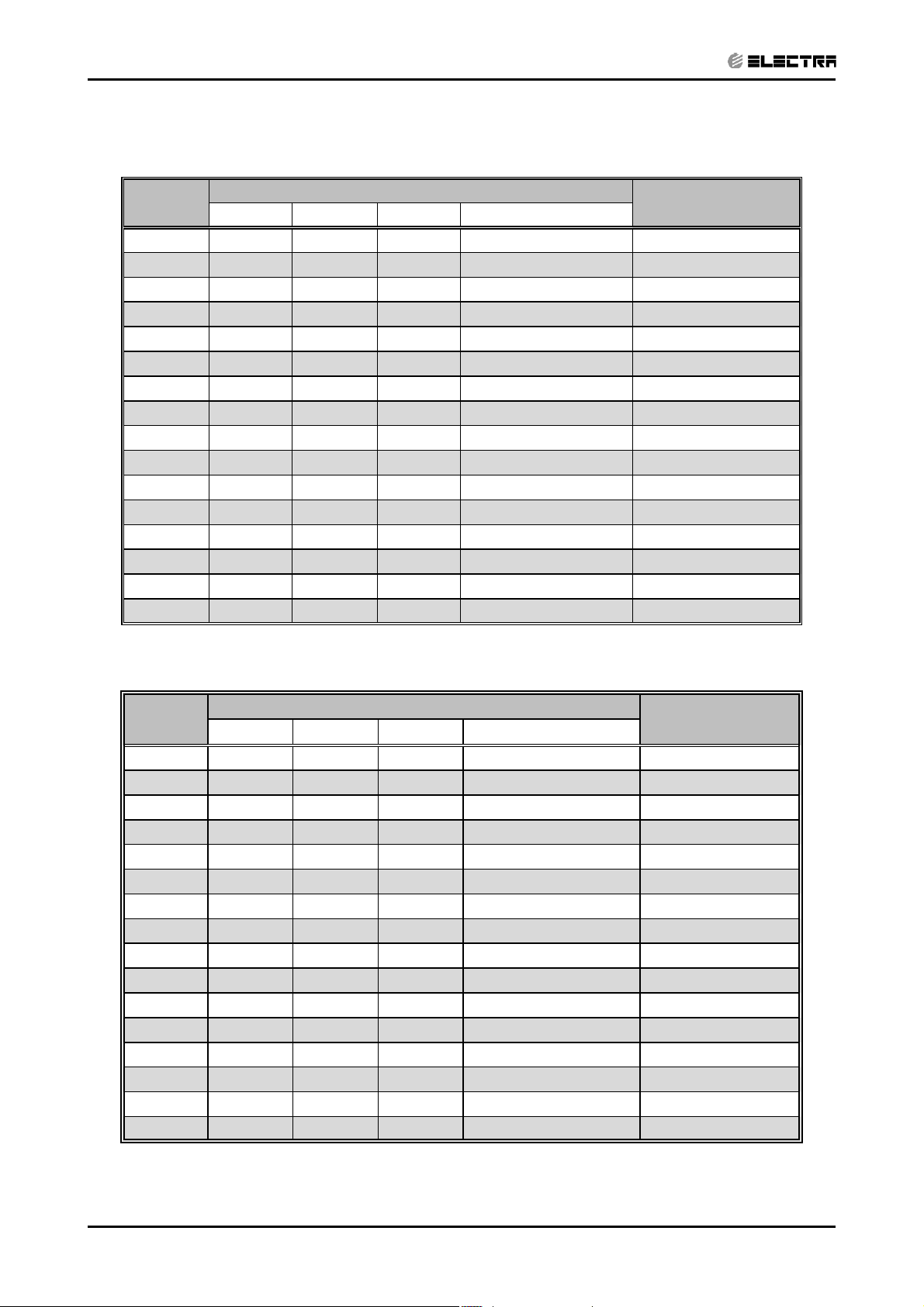

2.3 Indoor Units Combinations

2.3.1 Cooling

Model

22 2200 - - 2200(1050-2600) 645(450-750)

25 2500 - - 2500(1100-3500) 740(510-1040)

35 3500 - - 3500(1200-4200) 1020(510-1250)

22+22 2000 2000 - 4000(1400-5100) 1170(520-1500)

22+25 2000 2150 - 4150(1450-5200) 1220(530-1530)

22+35 2000 3000 - 5000(1720-6200) 1450(610-1910)

25+25 2150 2150 - 4300(1710-6200) 1250(610-1910)

25+35 2150 3000 - 5150(1710-6280) 1510(600-1930)

35+35 3000 3000 - 6000(1800-6400) 1720(635-2110)

22+22+22 1700 1700 1700 5100(1860-6420) 1500(636-2000)

22+22+25 1700 1700 1730 5130(1870-6420) 1510(636-2000)

22+22+35 1700 1700 2600 6000(1870-6450) 1720(635-2110)

22+25+25 1700 1730 1730 5160(1870-6450) 1500(635-2110)

22+25+35 1700 1730 2600 6030(1880-6450) 1730(640-2115)

25+25+25 1730 1730 1740 5200(1860-6440) 1550(640-2020)

25+25+35 1730 1730 2600 6060(1880-6500) 1740(640-2130)

ABCTotal Capacity

Cooling Capacity [W]

Total Power[W]

2.3.2 Heating

Model

ABC Total Capacity

22 2600 - - 2600(1200-3000) 708(450-800)

25 3000 - - 3000(1200-3500) 795(450-920)

35 4200 - - 4200(1200-4500) 1080(510-1160)

22+22 2500 2500 - 5000(1600-6000) 1280(460-1560)

22+25 2500 2650 - 5150(1600-6150) 1300(460-1560)

22+35 2500 3350 - 5850(2000-7100) 1420(510-1920)

25+25 2650 2650 - 5300(1800-6500) 1350(480-1600)

25+35 2650 3350 - 6000(2000-7100) 1450(510-1920)

35+35 3350 3350 - 6700(2100-7150) 1700(515-1930)

22+22+22 2100 2100 2100 6300(2100-7220) 1665(525-1980)

22+22+25 2100 2100 2200 6400(2100-7250) 1670(525-1980)

22+22+35 2100 2100 3020 7220(2120-7260) 1870(530-2000)

22+25+25 2100 2200 2200 6500(2120-7260) 1680(635-2000)

22+25+35 2100 2200 3020 7320(2130-7560) 1660(640-2105)

25+25+25 2200 2200 2200 6600(2120-7260) 1800(640-2000)

25+25+35 2200 2200 3020 7420(2200-7600) 1910(640-2110)

Heating Capacity [W]

Total Power[W]

2-4

SM TRIO52 1- E.1 GB

Page 9

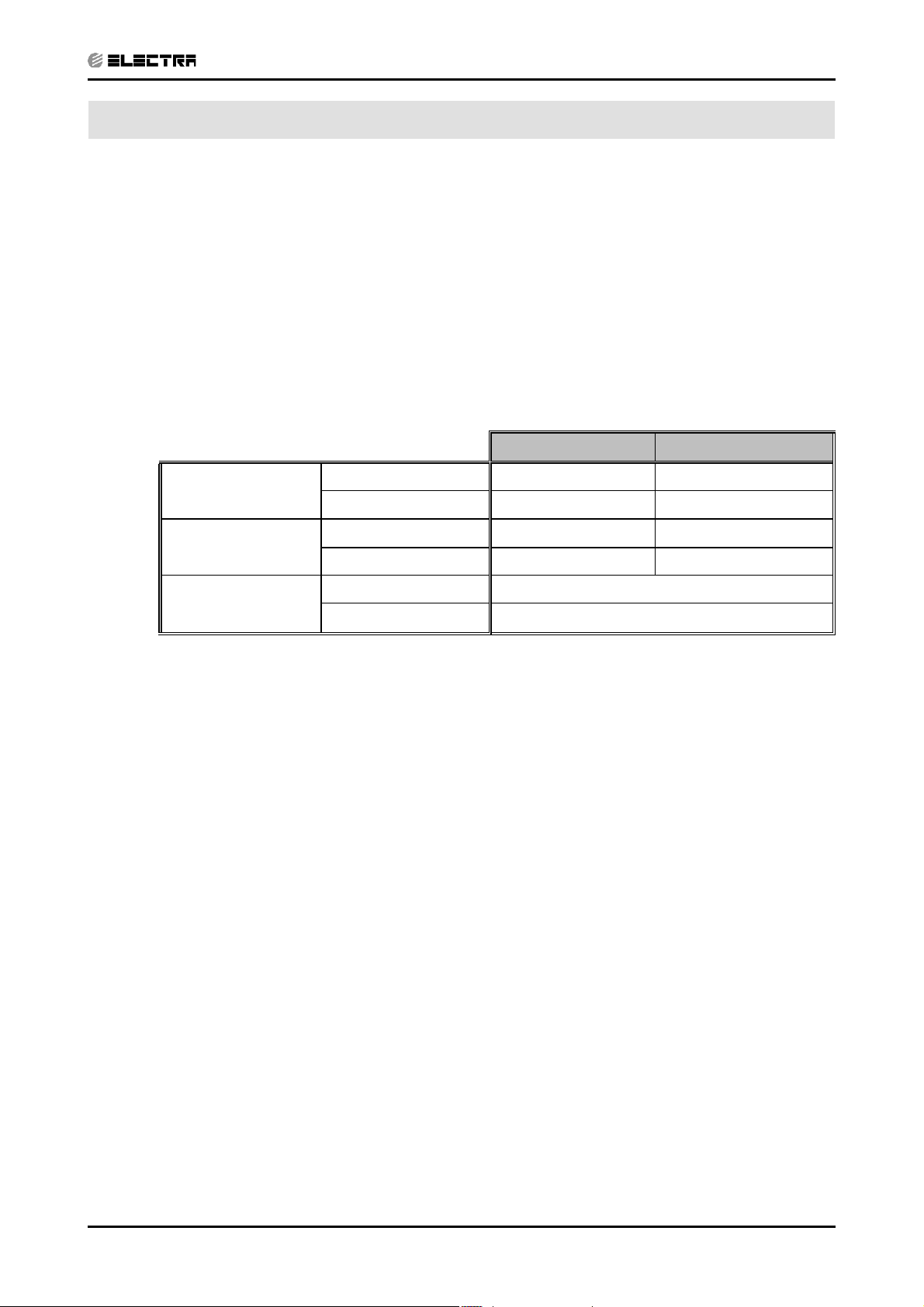

3. RATING CONDITIONS

CONTENTS

Standard conditions in accordance with ISO 5151, ISO 13253 (for ducted units)

and EN 14511.

Cooling:

Indoor: 27oC DB 19oC WB

Outdoor: 35 oC DB

Heating:

Indoor: 20oC DB

Outdoor: 7oC DB 6oC WB

3.1 Operating Limits

Upper limit 32

Cooling

Lower limit 21

Upper limit 27

Heating

Lower limit 10oC DB -15oC DB -16oC WB

RATING CONDITIONS

Indoor Outdoor

o

C DB 23oC WB 46oC DB

o

C DB 15oC WB 10oC DB

o

C DB 24oC DB 18oC WB

Voltage

1PH 198 – 264 V

3PH N/A

SM TRIO52 1- E.1 GB

3-1

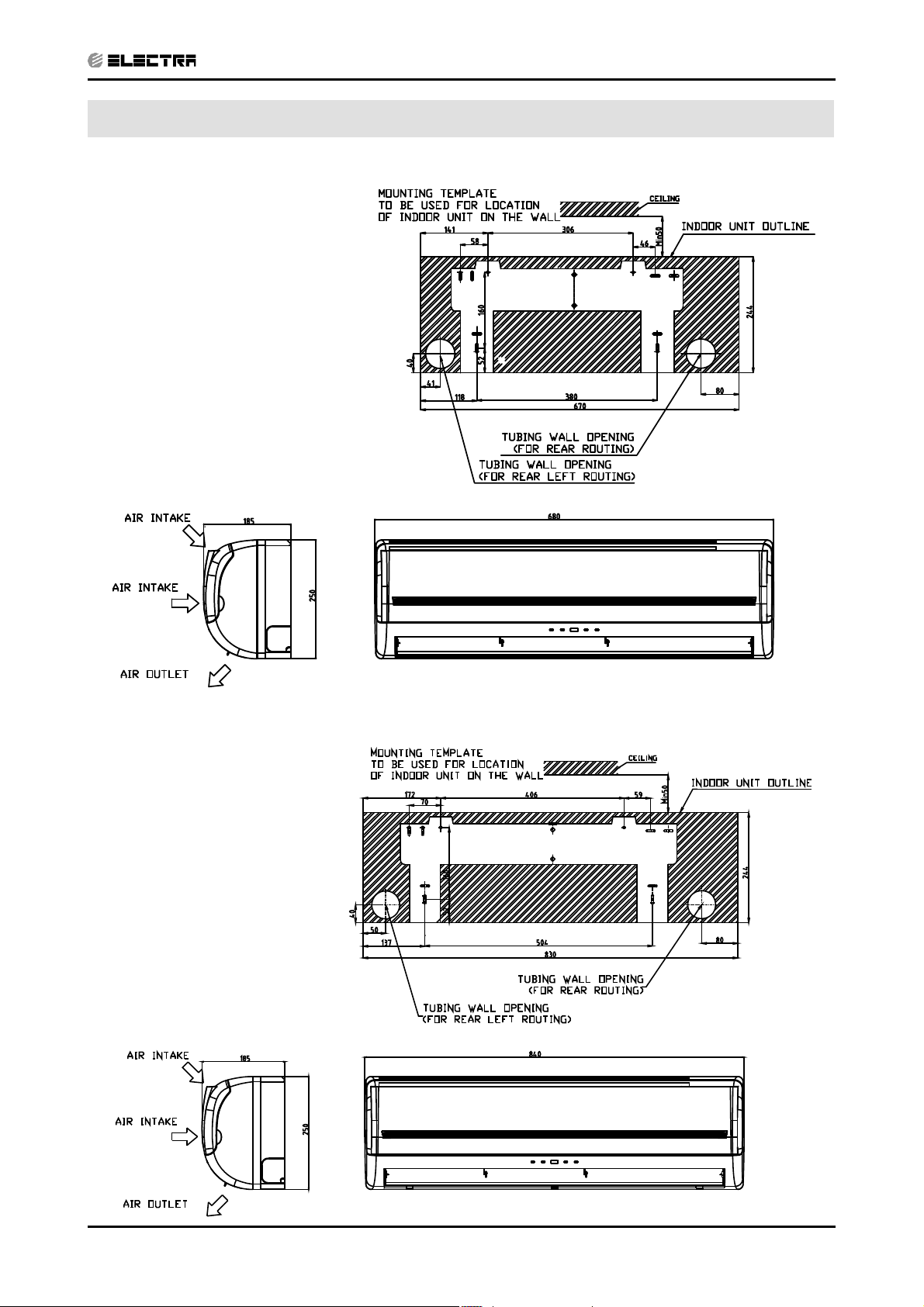

Page 10

4. OUTLINE DIMENSIONS

CONTENTS

4.1 Indoor Unit: DELTA 22 / 25 DCI

OUTLINE DIMENSIONS

4.2

Indoor Unit: DELTA 35 DCI

SM TRIO52 1- E.1 GB

4-1

Page 11

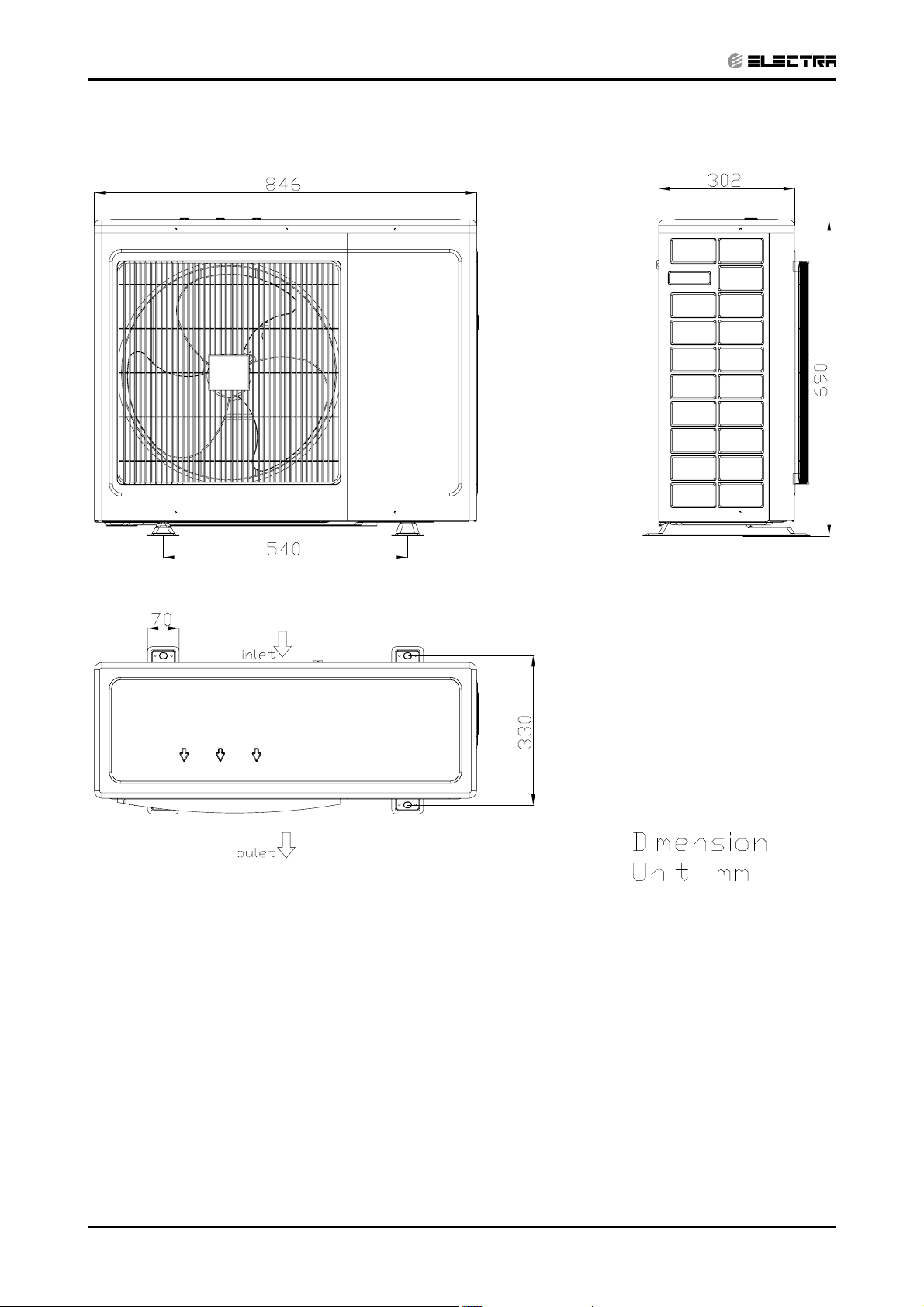

OUTLINE DIMENSIONS

CONTENTS

4.3 Outdoor Unit: Trio Delta 5.2 DCI

4-2

SM TRIO52 1- E.1 GB

Page 12

5. PERFORMANCE DATA

CONTENTS

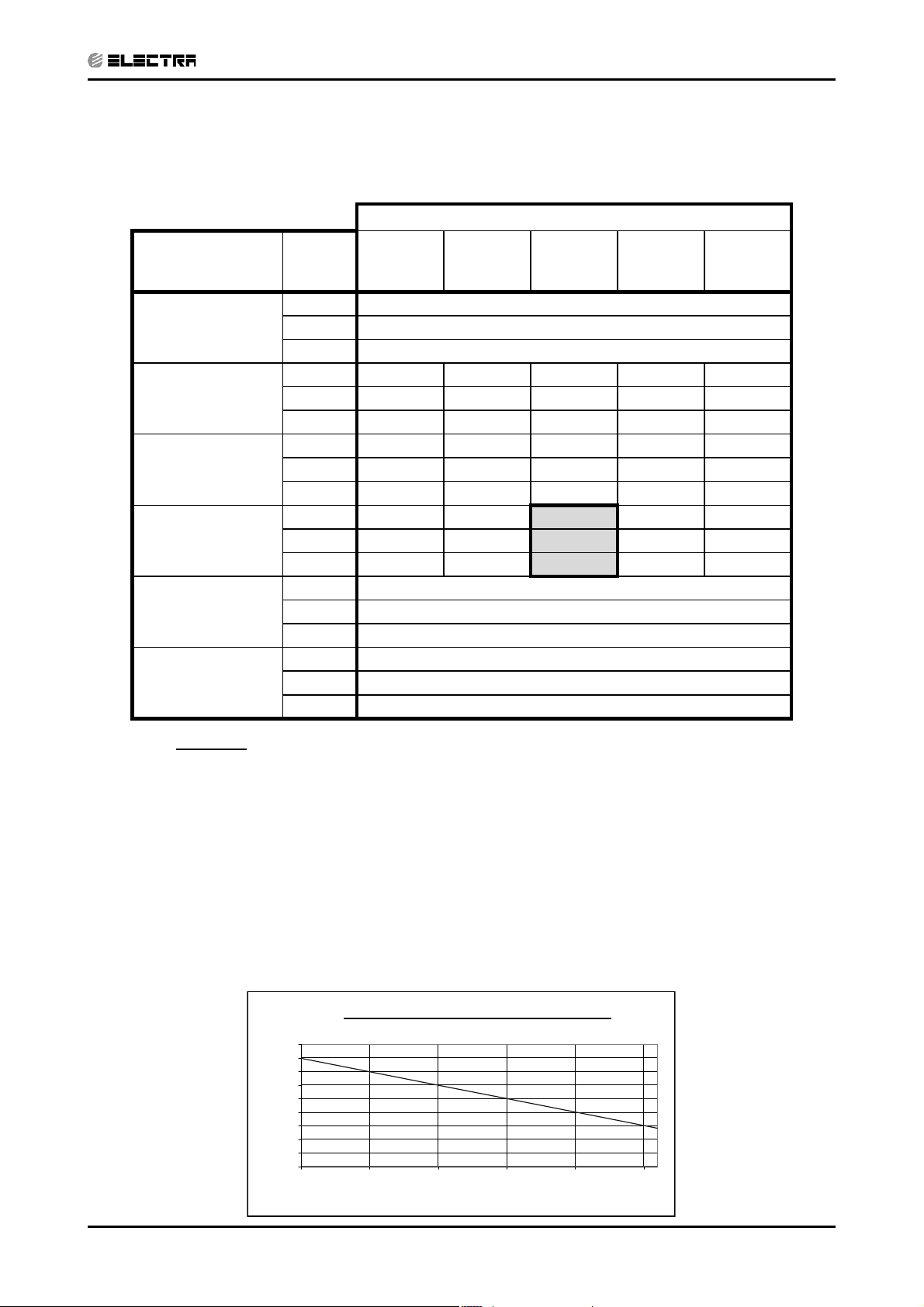

5.1 TRIO DELTA 25+25+25

5.1.1 Cooling Capacity (kW) - Run Mode

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB/WB TEMPERATURE [C0]

PERFORMANCE DATA

OD COIL ENTERING AIR

DB TEMPERATURE [C0]

-10 - 20

(protection range)

25

30

35

40(Protection Range)

46(Protection Range)

DATA 22/15 24/17 27/19 29/21 32/23

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

PI 25 - 50 % of nominal

TC 5.58 5.90 6.23 6.56 6.88

SC 4.84 4.95 5.07 5.19 5.30

PI 1.22 1.24 1.27 1.29 1.32

TC 5.06 5.39 5.71 6.04 6.37

SC 4.59 4.71 4.82 4.94 5.05

PI 1.36 1.38 1.41 1.43 1.46

TC 4.55 4.87 5.20 5.53 5.85

SC 4.35 4.46 4.58 4.69 4.81

PI 1.50 1.52 1.55 1.58 1.60

TC 80%-92% of nominal

SC 80%-92% of nominal

PI 80%-92% of nominal

TC 70%-85% of nominal

SC 70%-85% of nominal

PI 90%-100% of nominal

LEGEND

TC – Total Cooling Capacity, kW

PI – Power Input, kW

o

WB – Wet Bulb Temp., (

C)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

SC – Sensible Capacity, kW

5.1.2 Capacity Correction Factors

Cooling Capacity Ratio Vs. Outdoor Temperature

1.40

1.30

1.20

1.10

1.00

0.90

0.80

Capacity Ratio

0.70

0.60

0.50

20 25 30 35 40 45

Outdoor Temperature [deg C]

SM TRIO52 1- E.1 GB

5-1

Page 13

PERFORMANCE DATA

CONTENTS

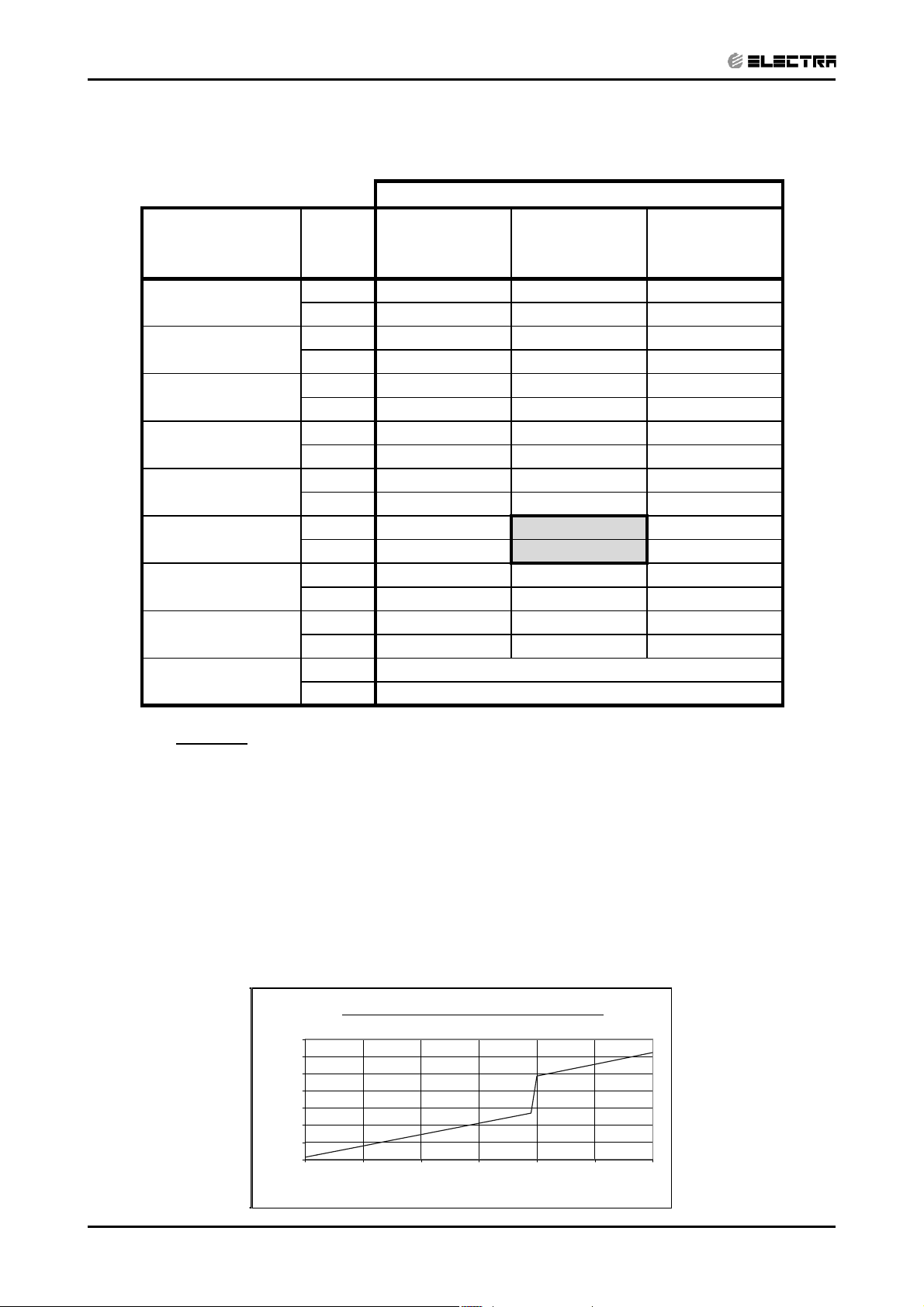

5.1.3 Heating Capacity (kW) - Run Mode

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [C0]

OD COIL ENTERING

AIR DB/WB

TEMPERATURE [C0]

DATA 15 20 25

-15/-16

-10/-12

-7/-8

-1/-2

2/1

7/6

10/9

15/12

TC 3.52 3.30 3.08

PI 1.15 1.32 1.48

TC 4.21 3.99 3.78

PI 1.33 1.49 1.66

TC 4.73 4.52 4.30

PI 1.46 1.62 1.79

TC 5.00 4.78 4.56

PI 1.52 1.69 1.86

TC 5.17 4.95 4.73

PI 1.57 1.73 1.90

TC 6.82 6.60 6.38

PI 1.63 1.80 1.97

TC 7.09 6.87 6.65

PI 1.71 1.88 2.04

TC 7.36 7.14 6.92

PI 1.79 1.95 2.12

15-24 TC 85 - 105 % of nominal

(Protection Range) PI 80 - 120 % of nominal

LEGEND

TC – Total Heating Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OU – Outdoor

5.1.4 Capacity Correction Factors

Heating Capacity Ratio Vs. Outdoor Temperature

1.20

1.10

1.00

0.90

0.80

0.70

Capacity Ratio

0.60

0.50

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [deg C]

5-2

SM TRIO52 1- E.1 GB

Page 14

5.2 Delta Trio 25+25+35

CONTENTS

5.2.1 Cooling Capacity (kW) - Run Mode

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB/WB TEMPERATURE [C0]

OD COIL

ENTERING AIR DB

TEMPERATURE [C0]

-10 - 20

(protection range)

25

30

35

40(Protection Range)

46(Protection Range)

DATA 22/15 24/17 27/19 29/21 32/23

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

PI 25 - 50 % of nominal

TC 6.50 6.88 7.26 7.64 8.02

SC 5.64 5.77 5.91 6.04 6.18

PI 1.37 1.40 1.42 1.45 1.48

TC 5.90 6.28 6.66 7.04 7.42

SC 5.35 5.49 5.62 5.76 5.89

PI 1.53 1.55 1.58 1.61 1.64

TC 5.30 5.68 6.06 6.44 6.82

SC 5.06 5.20 5.33 5.47 5.60

PI 1.68 1.71 1.74 1.77 1.80

TC 80%-92% of nominal

SC 80%-92% of nominal

PI 80%-92% of nominal

TC 70%-85% of nominal

SC 70%-85% of nominal

PI 90%-100% of nominal

PERFORMANCE DATA

LEGEND

TC – Total Cooling Capacity, kW

PI – Power Input, kW

o

WB – Wet Bulb Temp., (

C)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

SC – Sensible Capacity, kW

5.2.2 Capacity Correction Factors

Cooling Capacity Ratio Vs. Outdoor Temperature

1.40

1.30

1.20

1.10

1.00

0.90

0.80

Capacity Ratio

0.70

0.60

0.50

20 25 30 35 40 45

Outdoor Temperature [deg C]

SM TRIO52 1- E.1 GB

5-3

Page 15

PERFORMANCE DATA

CONTENTS

5.2.3 Heating Capacity (kW) - Run Mode

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [C0]

OD COIL ENTERING

AIR DB/WB

TEMPERATURE [C

DATA 15 20 25

0

]

-15/-16

-10/-12

-7/-8

-1/-2

2/1

7/6

10/9

15/12

TC 3.95 3.71 3.46

PI 1.22 1.40 1.57

TC 4.74 4.49 4.25

PI 1.41 1.58 1.76

TC 5.32 5.08 4.83

PI 1.55 1.72 1.90

TC 5.62 5.37 5.13

PI 1.62 1.79 1.97

TC 5.81 5.57 5.32

PI 1.66 1.84 2.02

TC 7.66 7.42 7.18

PI 1.73 1.91 2.09

TC 7.97 7.73 7.48

PI 1.82 1.99 2.17

TC 8.27 8.03 7.79

PI 1.90 2.07 2.25

15-24 TC 85 - 105 % of nominal

(Protection Range) PI 80 - 120 % of nominal

LEGEND

TC – Total Heating Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OU – Outdoor

5.2.4 Capacity Correction Factors

Heating Capacity Ratio Vs. Outdoor Temperature

1.20

1.10

1.00

0.90

0.80

0.70

Capacity Ratio

0.60

0.50

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [deg C]

5-4

SM TRIO52 1- E.1 GB

Page 16

5.3 Delta Trio 35+35

CONTENTS

5.3.1 Cooling Capacity (kW) - Run Mode

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB/WB TEMPERATURE [C0]

OD COIL

ENTERING AIR DB

TEMPERATURE [C0]

-10 - 20

(protection range)

25

30

35

40(Protection Range)

46(Protection Range)

DATA 22/15 24/17 27/19 29/21 32/23

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

PI 25 - 50 % of nominal

TC 6.44 6.81 7.19 7.56 7.94

SC 5.58 5.72 5.85 5.98 6.12

PI 1.35 1.38 1.41 1.43 1.46

TC 5.84 6.22 6.59 6.97 7.35

SC 5.30 5.43 5.57 5.70 5.83

PI 1.51 1.54 1.56 1.59 1.62

TC 5.25 5.62 6.00 6.38 6.75

SC 5.01 5.15 5.28 5.41 5.55

PI 1.66 1.69 1.72 1.75 1.78

TC 80%-92% of nominal

SC 80%-92% of nominal

PI 80%-92% of nominal

TC 70%-85% of nominal

SC 70%-85% of nominal

PI 90%-100% of nominal

PERFORMANCE DATA

LEGEND

TC – Total Cooling Capacity, kW

PI – Power Input, kW

o

WB – Wet Bulb Temp., (

DB – Dry Bulb Temp., (

o

C)

C)

ID – Indoor

OD – Outdoor

SC – Sensible Capacity, kW

5.3.2 Capacity Correction Factors

Cooling Capacity Ratio Vs. Outdoor Temperature

1.40

1.30

1.20

1.10

1.00

0.90

0.80

0.70

Capacity Ratio

0.60

0.50

20 25 30 35 40 45

Outdoor Temperature [deg C]

SM TRIO52 1- E.1 GB

5-5

Page 17

PERFORMANCE DATA

CONTENTS

5.3.3 Heating Capacity (kW) - Run Mode)

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [C0]

OD COIL ENTERING

AIR DB/WB

TEMPERATURE [C0]

DATA 15 20 25

-15/-16

-10/-12

-7/-8

-1/-2

2/1

7/6

10/9

15/12

TC 3.57 3.35 3.13

PI 1.09 1.24 1.40

TC 4.28 4.05 3.83

PI 1.25 1.41 1.57

TC 4.81 4.59 4.36

PI 1.38 1.53 1.69

TC 5.07 4.85 4.63

PI 1.44 1.60 1.75

TC 5.25 5.03 4.81

PI 1.48 1.64 1.79

TC 6.92 6.70 6.48

PI 1.54 1.70 1.86

TC 7.20 6.98 6.75

PI 1.62 1.77 1.93

TC 7.47 7.25 7.03

PI 1.69 1.84 2.00

15-24 TC 85 - 105 % of nominal

(Protection Range) PI 80 - 120 % of nominal

LEGEND

TC – Total Heating Capacity, kW

PI – Power Input, kW

o

WB – Wet Bulb Temp., (

DB – Dry Bulb Temp., (

o

C)

C)

ID – Indoor

OU – Outdoor

5.3.4 Capacity Correction Factors

Heating Capacity Ratio Vs. Outdoor Temperature

1.20

1.10

1.00

0.90

0.80

0.70

Capacity Ration

0.60

0.50

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [deg C]

5-6

SM TRIO52 1- E.1 GB

Page 18

PERFORMANCE DATA

CONTENTS

5.4 Capacity Correction Factor Due to Tubing Length

(OneWay)

5.4.1 Delta 22 / 25 / 35 DCI

5.4.2 Cooling

Capacity Ratio Vs.Tubing Length - Cooling

1.01

1.00

0.99

0.98

0.97

0.96

0.95

Capacity Ratio

0.94

0.93

0.92

4 6 8 10 12 14 16 18 20 22 24 26 28 30

Tubing Lenght [m]

5.4.3 Heating

1.01

1.00

0.99

0.98

0.97

0.96

0.95

Capacity Ratio

0.94

0.93

0.92

Capacity Ratio Vs.Tubing Length - Cooling

4 6 8 1012141618202224262830

Tubing Lenght [m]

SM TRIO52 1- E.1 GB

5-7

Page 19

6. PRESSURE CURVES

p

p

CONTENTS

6.1 Model: Trio Delta 25+25+25

6.1.1 Cooling – Test Mode

Suction Pressure VS.Outdoor Temp'.

1400

PRESSURE CURVES

1300

1200

1100

1000

900

800

Suction Pressure [kPa]

700

10 15 20 25 30 35 40 45

Discharge Pressure VS. Outdoor Temp'.

3750

3500

3250

3000

2750

2500

2250

2000

1750

Discharge Pressure [kPa]

1500

10 15 20 25 30 35 40 45

Outdoor DB Temperature [ºC]

Indoor DB/WB

'.

Tem

22/15

24/17

27/19

29/21

32/23

Indoor DB/WB

Tem

'.

22/15

24/17

27/19

29/21

32/23

SM TRIO52 1- E.1 GB

Outdoor DB Temperature[ºC]

6-1

Page 20

PRESSURE CURVES

CONTENTS

6.1.2 Heating – Test Mode

Suction Pressure VS.Outdoor Temp'.

1100

Suction Pressure [kPa]

1000

900

800

700

600

500

400

-15 -10 -5 0 5 10 15

Outdoor WB Temperature[ºC]

Discharge Pressure VS. Outdoor Temp'.

3250

3000

2750

2500

2250

Indoor DB

Temp'.

15

20

25

Indoor DB

Temp'.

15

20

2000

1750

DischargePressure[kPa]

1500

25

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [ºC]

6-2

SM TRIO52 1- E.1 GB

Page 21

6.2 Model: Trio Delta 25+25+35

p

p

CONTENTS

6.2.1 Cooling - Test Mode

Suction Pressure VS.Outdoor Temp'.

PRESSURE CURVES

Suction Pressure [kPa]

Discharge Pressure [kPa]

1300

1200

1100

1000

900

800

700

10 15 20 25 30 35 40 45

Outdoor DB Temperature [ºC]

Discharge Pressure VS. Outdoor Temp'.

4000

3750

3500

3250

3000

2750

2500

2250

2000

1750

1500

10 15 20 25 30 35 40 45

Indoor DB/WB

Tem

'.

22/15

24/17

27/19

29/21

32/23

Indoor DB/WB

Tem

'.

22/15

24/17

27/19

29/21

32/23

SM TRIO52 1- E.1 GB

Outdoor DB Temperature[ºC]

6-3

Page 22

PRESSURE CURVES

CONTENTS

6.2.2 Heating – Test Mode

Suction Pressure VS.Outdoor Temp'.

1100

1000

900

800

700

Indoor DB

Temp'.

15

20

600

500

400

Suction Pressure [kPa]

300

-15 -10 -5 0 5 10 15

25

Outdoor WB Temperature[ºC]

Discharge Pressure VS. Outdoor Temp'.

3150

2900

2650

2400

2150

1900

1650

Discharge Pressure[kPa]

1400

-15 -10 -5 0 5 10 15

Indoor DB

Temp'.

15

20

25

6-4

Outdoor W B Temperature [ºC]

SM TRIO52 1- E.1 GB

Page 23

6.3 Model: Trio Delta 35+35

p

p

CONTENTS

6.3.1 Cooling - Test Mode

Suction Pressure VS.Outdoor Temp'.

1200

1100

1000

900

800

Suction Pressure [kPa]

700

10 15 20 25 30 35 40 45

PRESSURE CURVES

Indoor DB/WB

'.

Tem

22/15

24/17

27/19

29/21

32/23

Suction Pressure VS.Outdoor Temp'.

4000

3750

3500

3250

3000

2750

2500

2250

2000

1750

Discharge Pressure [kPa]

1500

10 15 20 25 30 35 40 45

Outdoor DB Temperature[ºC]

Outdoor DB Temperature [ºC]

Indoor DB/WB

'.

Tem

22/15

24/17

27/19

29/21

32/23

SM TRIO52 1- E.1 GB

6-5

Page 24

PRESSURE CURVES

CONTENTS

6.3.2 Heating – Test Mode

Suction Pressure VS.Outdoor Temp'.

1100

1000

Note: all temperatures are in C0.

900

800

700

600

500

400

Suction Pressure [kPa]

300

-15 -10 -5 0 5 10 15

Discharge Pressure VS. Outdoor Temp'.

3750

3500

3250

3000

2750

2500

2250

2000

1750

Discharge Pressure [kPa]

1500

-15 -10 -5 0 5 10 15

Indoor DB

Temp'.

15

20

25

Outdoor WB Temperature[ºC]

Indoor DB

Temp'.

15

20

25

6-6

Outdoor WB Temperature[ºC]

SM TRIO52 1- E.1 GB

Page 25

ELECTRICAL DATA

CONTENTS

7. ELECTRICAL DATA

7.1 Single Phase Units

MODEL TRIO 5.2 kW DELTA

Power Supply 1 PH, 220-240 VAC, 50Hz

Connected to Delta 22, 25 and 35

Maximum Current 9.4 A

Inrush Current* 35 A

Starting Current** 10.5 A

Circuit breaker 20 A

Power supply wiring - No. x cross section, mm

Interconnecting cable - No. x cross section, mm

Note:

* Inrush current is the current when power is up. (charging the DC capacitors at outdoor unit

controller).

** Starting current is the current when starting the compressor

2

2

3 X 2.5

4 X 1.5

NOTE

Power wiring cord should comply with local lows and electrical regulations

requirements.

SM TRIO52 1- E.1 GB

7-1

Page 26

8. WIRING DIAGRAMS

CONTENTS

8.1 TRIO 5.2 DELTA DCI

WIRING DIAGRAMS

SM TRIO52 1- E.1 GB

8-1

Page 27

9. REFRIGERATION DIAGRAMS

CONTENTS

9.1 Heat Pump Models

9.1.1 TRIO 5.2 DELTA => Cooling & Heating Mode

REFRIGERATION DIAGRAMS

SM TRIO52 1- E.1 GB

9-1

Page 28

10. TUBING CONNECTIONS

CONTENTS

TUBING CONNECTIONS

TUBE (Inch)

¼” ⅜” ½” ⅝” ¾”

TORQUE (Nm)

Flare Nuts 11-13 40-45 60-65 70-75 80-85

Valve Cap 13-20 13-20 18-25 18-25 40-50

Service Port Cap 11-13 11-13 11-13 11-13 11-13

1. Valve Protection Cap-end

2. Refrigerant Valve Port (use Allen wrench to open/close)

3. Valve Protection Cap

4. Refrigerant Valve

5. Service Port Cap

6. Flare Nut

7. Unit Back Side

8. Copper Tube

When the outdoor unit is installed above the indoor unit an oil trap is required every 5m along the suction

line at the lowest point of the riser. Incase the indoor unit is installed above the outdoor, no trap is

required.

SM TRIO52 1- E.1 GB

10-1

Page 29

11. CONTROL SYSTEM

CONTENTS

11. CONTROL SYSTEM

11.1 General Functions and Operating Rules

The DCI software is fully parametric.

All the model dependent parameters are shown in Blue color and with Italic style

The parameters values are given in the last section of this control logic chapter of the

service manual.

11.2 System Operation Concept

The control function is divided into indoor, MSMP and main outdoor unit controllers. MSMP

is a specific PCB in outdoor unit which serves as a bridge between all indoor units and

outdoor unit. It communicates with the outdoor unit as one indoor unit and communicates

with each indoor unit as one outdoor unit. Each indoor unit will send the request to MSMP

for cooling/heating capacity supply. MSMP will deal with all the requests from indoor units

and send an integral capacity request to outdoor unit. The outdoor unit will supply the

required capacity unless it enters into a protection mode avoiding it from supplying the

requested capacity.

The capacity request is transferred via indoor, MSMP and outdoor communication, and is

represented by a parameter called ‘NLOAD’. NLOAD is an integer number with values

between 0 and 127, and it represents the total heat or cool load felt by all the indoor units.

CONTROL SYSTEM

[parameter].

11.3 Compressor Frequency Control

11.3.1 NLOAD setting

The NLOAD setting is done by each indoor unit controller, based on a PI control scheme.

MSMP will deal with request from each unit and send a synthetical NLOAD to the outdoor unit.

The actual NLOAD to be sent to the outdoor unit controller is based on the calculated LOAD from

MSMP and the power shedding function.

NLOAD limits as a function of indoor fan speed:

Indoor Fan Speed Maximum NLOAD Cooling Maximum NLOAD Heating

Max NLOADIF1C

Max NLOADIF2C

Max NLOADIF3C

Max NLOADIF4C

Max NLOADIF5C

n

1

ODUNomCode

127

127

127

127

127

CodeNLOADCalcIDU

ii

127,min

Low

Medium

High

Turbo

Auto

Outdoor unit NLOAD calculation by MSMP:

NLOADODU

i

NLOAD limits as a function of power shedding:

Mode Power Shedding OFF Power Shedding ON

Cool No limit Nominal Cooling

Heat No limit Nominal Heating

SM TRIO52 1- E.1 GB

11-1

Page 30

CONTROL SYSTEM

CONTENTS

11.3.2 Target Frequency Setting

The compressor target frequency is a function of the NLOAD number sent from MSMP and

the outdoor air temperature.

Basic Target Frequency Setting

NLOAD Target Frequency

127

10 < NLOAD < 127 Interpolated value between minimum and maximum frequency

10

0 Compressor is stopped

Target frequency limits as a function of outdoor air temperature (OAT):

OAT Range Cool mode limits Heat mode limits

OAT < 6 No limit

6 OAT < 15

15 OAT < 24

24 OAT No limit

MaxFreqAsOATC

:

Maximum frequency

Minimum frequency

MaxFreqAsOAT1H

MaxFreqAsOAT2H

11.3.3 Frequency Changes Control

Frequency change rate is 1 Hz/sec.

11.3.4

Frequency

Step 3

Step 2

Step 1

1

Minute

1

Minute

Min 10 Minutes

11.3.5 Minimum On and Off Time

3 minutes.

Time

11-2

SM TRIO52 1- E.1 GB

Page 31

CONTROL SYSTEM

CONTENTS

11.4 Indoor Fan Control

10 Indoor fan speeds are determined for each model. 5 speeds for cooling/dry/fan modes

and 5 speeds for heating mode.

When user sets the indoor fan speed to a fixed speed (Low/ Medium/ High), unit will operate

constantly at set speed.

When Auto Fan is selected, indoor unit controller can operate in all speeds. The actual

speed is set according to the cool/heat load.

11.4.1 Turbo Speed

The Turbo speed is activated during the first 30 minutes of unit operation when auto fan

speed is selected and under the following conditions:

Difference between set point and actual room temperature is bigger then 3 degrees.

Room temperature > 22 for cooling, or < 25 for heating.

11.5 Heating Element Control

Heating element can be started if LOAD > 0.8 * Maximum NLOAD AND Indoor Coil

temperature < 45.

The heating element will be stopped when LOAD < 0.5 * Maximum NLOAD OR if Indoor Coil

temperature > 50.

11.6 Outdoor Fan Control

7 outdoor fan speeds are determined for each model. 3 speeds for cooling and dry modes,

and 3 speeds for heating mode, and a very low speed.

Outdoor fan speed is a function of compressor frequency and outdoor air temperature

(OAT).

4 routines for fan control are determined. The control routine selection depends on operation

mode, compressor speed, and outdoor air temperature (OAT) and heat sink temperature

(HST).

Routine Conditions

A

B Cooling with 20

C Cooling with 7

Heating with OAT < 15

Cooling with OAT > 20

0

C > OAT > 70C

0

C > OAT

D Heating with OAT > 15

Compressor Frequency (CF)

CF = 0 OFF OFF OFF OFF

10 CF < OFLowFreq

10 CF < OFMedFreq

OFMedFreq CF

0

C or

0

C, or HST > 500C or Faulty OAT

0

C

Outdoor Fan Speed

Routine A Routine B Routine C Routine D

Low Low Very Low Low

Medium Low Very Low Low

High Low Low Medium

SM TRIO52 1- E.1 GB

When compressor is switched to OFF and the heat sink temperature is above 55 degrees,

the outdoor fan will remain ON in low speed for up to 3 minutes.

11-3

Page 32

CONTROL SYSTEM

CONTENTS

11.7 EEV (electronic Expansion valve) Control

EEVi opening of the ‘i’ indoor unit is defined as EEVi = EEVOLi + EEVCVi

EEV

mode, unit model and capacity.

EEV

temperature.

During the first 5 minutes of compressor operation EEV

Once the first 5 minutes are over, the correction value is calculated as follow: EEV

EEV

EEV

EEV

superheat.

EEV

unit.

EEV

temperature. A target compressor temperature is set depending on frequency and outdoor

air temperature, and the actual compressor temperature is compared to the target

temperature to set the required correction to the EEV opening

i is the initial EEV opening as a function of the compressor frequency, operation

OL

i is a correction value for the EEV opening that is based on the compressor

CV

i = 0.

CV

i(n-1) + EEVSHi + EEV

CV

i = EEV

SH

i is correction for the EEV opening of the ‘i’ indoor unit as of the whole system

minSH

i is correction for the EEV opening of the ‘i’ indoor unit as of balance between each

deltaSH

i is the correction for the EEV opening of the ‘i’ indoor unit based on the compressor

CTT

minSH

i+ EEV

CTT

deltaSH

i

i

.

CV

i(n)=

11.8 Reversing Valve (RV) Control

Reversing valve is on in heat mode.

Switching of RV state is done only after compressor is off for over 3 minutes.

11.9 Electro Static Filter (ESF) Control

ESF is on when ESF switch is on, Safety switch is pressed, unit is on, AND indoor fan is on.

11.10 Base Heater Control

When OAT is connected, Base Heater will be on when unit is in heating and OAT<20C.

When OAT is disconnected, Base Heater will be on when unit is in heating.

11.11 Indoor Units Operation when Indoor Unit Mode is Different than

Outdoor Unit Mode

z Open louvers according to user selection.

z Indoor fan is forced to OFF.

z Led blinks every 2 second

11.12 Fan Mode

In high/ medium/ low indoor fan user setting, unit will operate fan in selected speed.

In Auto Fan user setting, fan speed will be adjusted automatically according to the difference

between actual room temperature and user set point temperature.

11.13 Cool Mode

11-4

NLOADi is calculated according to the difference between actual room temperature and

user set point temperature by PI control.

In high/ medium/ low indoor fan user setting, unit will operate fan in selected speed.

In Auto Fan user setting, fan speed will be adjusted automatically according to the

calculated NLOADi.

SM TRIO52 1- E.1 GB

Page 33

11.14 Heat Mode

CONTENTS

NLOADi is calculated according to the difference between actual room temperature and

user set point temperature by PI control.

In high/ medium/ low indoor fan user setting, unit will operate fan in selected speed.

In Auto Fan user setting, fan speed will be adjusted automatically according to the

calculated NLOADi.

11.14.1 Temperature Compensation

In wall mounted, ducted, and cassette models, 3 degrees are reduced from room

temperature reading (except when in I-Feel mode), to compensate for temperature

difference between high and low areas in the heated room, and for coil heat radiation on

room sensor.

The temperature compensation can be activate or deactivate by shortening of jumper J2 on

the indoor unit controller.

Model J2 Shorted J2 Opened

Wall mounted Compensation Disabled Compensation Enabled

Cassette Compensation Enabled Compensation Disabled

Ducted Compensation Enabled Compensation Disabled

Floor/Ceiling Compensation Disabled Compensation Enabled

CONTROL SYSTEM

11.14.2 Indoor Fan Control in Heat Mode

Indoor fan speed depends on the indoor coil temperature:

ICTST

ICTVL ICTT ICTHICTL

11.15 Auto Cool/Heat Mode

When in auto cool heat mode unit will automatically select between cool and heat mode

according to the difference between actual room temperature and user set point

temperature (T).

Unit will switch from cool to heat when compressor is off for 3 minutes, and T < -3.

Unit will switch from heat to cool when compressor is off for 5 minutes, and T < -3.

11.16 Dry Mode

SM TRIO52 1- E.1 GB

As long as room temperature is higher then the set point, indoor fan will work in low speed

and compressor will work between 0 and MaxNLOADIF1C Hz.

When the room temperature is lower than the set point, compressor will be switched OFF

and indoor fan will cycle 3 minutes OFF, 1 minute ON.

11-5

Page 34

CONTROL SYSTEM

CONTENTS

11.17 Protections

There are 5 protection codes.

Normal (Norm) – unit operate normally.

Stop Rise (SR) – compressor frequency can not be raised but does not have to be

decreased.

HzDown1 (D1) – Compressor frequency is reduced by 2 to 5 Hz per minute.

HzDown2 (D2) – Compressor frequency is reduced by 5 to 10 Hz per minute.

Stop Compressor (SC) – Compressor is stopped.

The MSMP receives the protection status from each one of the indoor unit. It calculates the

overall outdoor unit protection status based on each ‘i’ indoor unit protection status weight

according to the following average:

n

ii1

uproundweightprotectionODU

n

weightstatusprtoctionIDU

11.17.1 Indoor Coil Defrost Protection

ICT

ICT < -2 SC SC SC SC SC

-2 ICT < 0 D1 D1 D2 D2 D2

0 ICT < 2 SR SR D1 D2 D2

2 ICT < 4 SR SR SR D1 D2

4 ICT < 6 Norm Norm SR SR D1

6 ICT < 8 Norm Norm Norm SR SR

8 ICT Normal

Fast Increasing Increasing No change Decreasing Fast Decreasing

ICT Trend

11-6

SM TRIO52 1- E.1 GB

Page 35

11.17.2 Indoor Coil over Heating Protection

CONTENTS

ICT

ICT > 55 SC SC SC SC SC

53 < ICT 55 D1 D1 D2 D2 D2

49 < ICT 53 SR SR D1 D2 D2

47 < ICT 49 SR SR SR D1 D2

45 < ICT 47 Norm Norm SR SR D1

43 < ICT 45 Norm Norm Norm SR SR

ICT 43 Normal

Fast

Decreasing

Decreasing No Change Increasing

11.17.3 Compressor over Heating Protection

Compressor temperature can be in one of 5 control zones (4 in protection, and 1 normal),

according to the following chart.

CONTROL SYSTEM

ICT Trend

Fast

Increasing

CTT

Stop-Compresor

CTTOH4

CTTOH3

CTTOH2

CTTOH1

Control Status

Compressor Temperature

P3

P2

P1

Normal

Increases

P1 Norm SR

P2 D1 SR

P3 D2 D1

Stop Compressor SC

Else

SM TRIO52 1- E.1 GB

11-7

Page 36

CONTROL SYSTEM

CONTENTS

11.17.4 Compressor over Current Protection

CCR

Stop-Compresor

CCROC4

CCROC3

HzDown1

CCROC2

CCROC1

Normal

11.17.5 Outdoor Coil Deicing Protection

11.17.5.1 Deicing Starting Conditions

Deicing operation will start when either one of the following conditions exist:

Case 1: OCT < OAT – 8 AND TLD > DI

Case 2: OCT < OAT – 12 AND TLD > 30 minutes.

Case 3: OCT is Invalid AND TLD > DI

Case 4: Unit is just switched to STBY AND OCT < OAT – 8

Case 5: NLOAD = 0 AND OCT < OAT -8

OCT – Outdoor Coil Temperature

HzDown2

Stop-Rise

TLD – Time from Last Deicing

DI – Deicing Interval (Time Interval Between Two Deicing)

Deicing interval time when compressor is first started in heat mode, is 10 minutes if OCT < 2, and is 40 minutes in other cases.

Deicing interval time is changed (increased/ decreased in 10 minutes steps) as a function of

deicing time. If deicing time is shorter then former deicing time, the deicing interval time will

be increased. If deicing time is longer then former deicing time, the deicing interval time will

be decreased.

11-8

SM TRIO52 1- E.1 GB

Page 37

11.17.5.2 Deicing Protection Procedure

CONTENTS

OCT

12

0

Threshold

CONTROL SYSTEM

COMP

RV

OFAN

EEV

ON

HEAT

COOL

ON

OFF

EEVDeicerOpen

Any

T1 T2

max. 12 minutes

T3 T3

DT

T1

T1 = T2 = 36 seconds, T3 = 6 seconds

11.18 Indoor Unit Dry Contact (excluding Delta range)

Indoor unit Dry contact has two alternative functions that are selected by J8.

Function Contact = Open Contact = Short

J8 = Open Presence Detector Connection No Limit Forced to STBY

J8 = Short Power Shedding Function No Limit Limit NLOAD

11.19 Operating the Unit from the Mode Button

Forced operation allows starting up, shutting down and operating in Cooling or Heating

mode, in pre-set temperature according to the following table:

Forced operation Mode Pre-set Temperature

Cooling 200C

0

Heating 28

SM TRIO52 1- E.1 GB

C

11-9

Page 38

CONTROL SYSTEM

r

r

CONTENTS

11.20 On Unit Controls and Indicators

11.20.1 Indoor Unit Controls and Indicators for Led Display

Timer

STBY/OPER

STBY/OPER

Filter

Filte

Mode Button

STAND BY

INDICATOR

OPERATION

INDICATOR

TIMER

INDICATOR

FILTER

INDICATOR

MODE/RESET

BUTTON

Infra Red Receiver

Infra Red Receive

1. Lights up when the Air Conditioner is connected to power and

the mode is STBY.

2. Blinks for 3 seconds, when the system is switched to Heat

Mode by using the Mode/Reset Switch on the unit (the

operation indicator will be off during this blinking time).

1. Lights up during operation mode (except for item in STBY

indicator).

2. Blinks for 300 msec., to announce that a R/C infrared

signal has been received and stored.

3. Blinks continuously during protections (according to the relevant

spec section).

4. Blinks for 3 seconds when the system is switched to Cool Mode

by using the Mode/Reset Switch on the unit.

Lights up during Timer and Sleep operation.

Lights up when Air Filter needs to be cleaned.

As long as the filter Led is off, the Mode/Reset button functions as

Mode switch. Once filter Led is on, the Mode/Reset button functions

as Reset switch.

Mode Function:

Every short pressing , the next operation mode is selected, in this

order: SB Cool Mode Heat Mode SB …

In long pressing system enters diagnostic mode (refer to diagnostic

mode Sect.)

Reset Function:

For short pressing:

When Filter LED is on, it turns off the filter indicator.

11-10

SM TRIO52 1- E.1 GB

Page 39

CONTROL SYSTEM

,

CONTENTS

Notes

1. Pressing time is defined as the time between press and release.

2. If pressing time is one second or less – press is considered as short pressing.

3. If pressing time is three seconds or longer – pressing is considered as long pressing.

In between, pressing is undetermined and system will not respond to pressing.

4. For the LED functionality during diagnostics, refer to the diagnostics Sect.

11.20.2 Outdoor Unit Controller Indicators

Unit has three LED’s.

SB LED is ON when power is ON (230 VAC, even when no communication).

STATUS LED is ON when COMP is ON, and Blinks according to diagnostics mode

definitions when either fault or protection occurs.

FAULT LED Blinks according to diagnostics mode definitions when either fault or

protection occurs

.

11.21 Test Mode

11.21.1 Entering Test Mode

System can enter Test mode in two ways:

Automatically when the following conditions of outdoor unit and each indoor unit both

exists for 30 minutes continuously:

o Mode = Cool, Set point = 16, Room temperature = 27±1, Outdoor

temperature = 35±1

Or

o Mode = Heat, Set point = 30, Room temperature = 20±1, Outdoor

temperature = 7±1

Manually when entering diagnostics of each indoor unit with the following settings:

o Mode = Cool, Set point = 16

o Mode = Heat

Set point = 30

SM TRIO52 1- E.1 GB

11-11

Page 40

CONTROL SYSTEM

p

CONTENTS

11.22 Unit Operation in Test Mode

In test mode, the unit will operate in fixed settings according to the indoor fan speed

setting:

Indoor Fan Speed Setting Unit Setting

Low Minimum Capacity Setting

High Nominal Capacity Setting

Auto Maximum Capacity Setting

During test mode, protections are disabled, except for stop compressor status.

SW Parameters

Indoor Units SW Parameters

General Parameters for All Models:

Parameters defining the indoor fan speed as a function of Indoor Coil temperature in heat

mode (ICT):

ICTST Speed ICT to stop indoor fan 23

ICTVLSpeed ICT to go down to very low speed 26

ICTLSpeed ICT to start in very low speed 28

ICTHSpeed ICT to start in increase speed from very low 30

ICTTSpeed ICT to enable Turbo fan speed 40

Parameters for defrost protection:

ICTDef1 ICT to go back to normal 8

ICTDef2 ICT to ‘stop rise’ when ICT decrease 6

ICTDef3 ICT to ‘stop rise’ when ICT is stable 4

ICTDef4 ICT to ‘Hz Down’ when ICT decrease 2

ICTDef5 ICT to ‘Hz Down’ when ICT is stable 0

ICTDef6 ICT to stop compressor -2

Parameters for indoor coil over heating protection:

ICTOH1 ICT to go back to normal 45

ICTOH2 ICT to ‘stop rise’ when ICT increase 48

ICTOH3 ICT to ‘stop rise’ when ICT is stable 52

ICTOH4 ICT to ‘Hz Down’ when ICT increase 55

ICTOH5 ICT to ‘Hz Down’ when ICT is stable 60

ICTOH6 ICT to sto

compressor 62

11-12

SM TRIO52 1- E.1 GB

Page 41

Model Depended Parameters:

CONTENTS

CONTROL SYSTEM

Parameter name

Wall Mounted Models

Delta 22 Delta 25 Delta 35

NLOAD limits as a function of selected indoor fan speed

MaxNLOADIF1C 40 40 40

MaxNLOADIF2C 55 51 55

MaxNLOADIF3C 120 90 90

MaxNLOADIF4C 127 127 127

MaxNLOADIF5C 127 127 127

Indoor Fan speeds

IFVLOWC 700 700 700

IFLOWC 800 850 850

IFMEDC 950 1050 1000

IFHIGHC 1050 1200 1200

IFTURBOC 1150 1250 1250

IFVLOWH 700 700 700

IFLOWH 850 950 950

IFMEDH 1000 1050 1100

IFHIGHH 1100 1250 1250

IFTURBOH 1200 1350 1300

Nominal Compressor Frequency

NomLoadC 40 51 61

NomLoadH 55 58 62

Outdoor Units SW Parameters

Parameter Name TRIO 5.2 DELTA

Compressor Parameters

MinFreqC 20

MaxFreqC 100

MinFreqH 25

MaxFreqH 100

Step1Freq 40

Step2Freq 80

Step3Freq 90

Frequency limits as a function of outdoor air temperature

MaxFreqAsOATC 80

MaxFreqAsOAT1H 90

MaxFreqAsOAT2H 60

Compressor Over Heating Protection

CTTOH1 90

CTTOH2 98

CTTOH3 102

CTTOH4 105

Compressor Over Current Protection [A]

CCR01 11.4

CCR02 11.8

CCR03 12.2

CCR04 12.6

Outdoor Fan Speed (RPM)

VL 200

OFLOWC 400

OFMEDC 600

OFMAXC 770

OFLOWH 400

OFMEDH 600

OFMAXH 720

SM TRIO52 1- E.1 GB

11-13

Page 42

TROUBLESHOOTING

CONTENTS

12. TROUBLESHOOTING

1 ELECTRICAL & CONTROL TROUBLESHOOTING

WARNING!!!

When Power Up – the whole outdoor unit controller, including the wiring, is under HIGH VOLTAGE!!!

Never open the Outdoor unit before turning off the Power!!!

When turned off, the system is still charged (400V)!!!

It takes about 3 Min. to discharge the system.

Touching the controller before discharging may cause an electrical shock!!!

For safe handling of the controller please refer to section 1.6 below.

1.1 Dual Split System Failures and Corrective Actions

No

1 Power supply indicator at

indoor unit (Red LED) does

not light up.

2 Indoor fan does not start

(louvers are opened and

Green LED does light up)

3 Compressor does not start Jumper settings of

4 One indoor is operating, in

cool mode, with no capacity,

and the other unit has water

leaks/freezing problems

5 One indoor is operating in

heat mode with a limited

capacity, and the coil on the

other unit is very hot.

6 Compressor operate but unit

generate no capacity

7 One unit only is operating Communication

8 All others Specific problems of

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

No power supply Check power supply from the outdoor. If

Unit in heat mode and

coil is still not warm.

The outdoor unit is in

the opposite mode.

Problem with PCB or

capacitor

outdoor unit is not

correct

The communication

wires of the two indoor

units are switched

EEV is stuck in close

position

problems

indoor or outdoor units

power supply is OK, check display and

display wiring. If OK, replace controller.

Change to cool mode and check.

Change operation mode and check if fan

starts.

Change to high speed and Check power

supply to motor is higher than 130VAC (for

Triac controlled motor) or higher than

220VAC for fixed speed motors, if OK

replace capacitor, if not OK replace controller

Use diagnostics information on MSMP board.

Check and correct the communication wires

connection

Check EEV

Use diagnostics information on MSMP board.

Use diagnostics information on MSMP board,

and perform action items as recommended in

single split systems

SM TRIO52 1- E.1 GB

12-1

Page 43

TROUBLESHOOTING

CONTENTS

1.2 Checking the Refrigeration System

Checking system pressures and other thermodynamic measures should be done when system is in Test Mode

(in Test mode, system operates in fixed settings). The performance curves given in this manual are given for

unit performance in test mode when high indoor fan speed is selected.

Entering test mode:

Set the two indoor units to Cool/16 degrees/High indoor fan speed, or Heat/30 degrees/High indoor fan speed,

and enter diagnostics. Note: the two indoor units should be set to the same mode and fan speed.

1.3 Judgment by MSMP Diagnostics

The MSMP controller has 9 LED’s (4 green Unit LEDs and 5 red Status/Fault LEDs). For the 4 green Unit

LEDs,O-Outdoor unit, A-Indoor unit 1,B-Indoor unit 2,C-Indoor unit 3. For the 5 red Status/Fault LEDs, it should

be read from O-A-B-C-D to get fault numbers. The 4 green Unit LEDs will turn on one at a time and the

corresponding Indoor/Outdoor unit status/fault code will be displayed on the red Status/Fault LEDs. If the unit is

normal (no fault), the green unit LED and the corresponding status will be displayed for 5 seconds and move to

the next green unit LED. On the other hand, if the unit is in fault, the green unit LED and the corresponding fault

will be displayed for 10 seconds, and hence more time to read the fault code.

STBY LED is ON when power is ON.

1.3.1 MSMP Fault Code for Outdoor unit:

No Problem 5 4 3 2 1 Possible reason Corrective Action

OCT is disconnected

1

OCT is shorted

2

CTT is disconnected

3

CTT is shorted

4

HST is disconnected

5

(when enabled)

HST is shorted (when

6

enabled)

OAT is disconnected

7

(when enabled)

OAT is shorted (when

8

enabled)

TSUCis disconnected

9

(when enabled)

TSUC is shorted (when

10

enabled)

IPM

11

Bad ODU EEPROM

12

DC under voltage

13

DC over voltage

14

AC under voltage

15

IDU/ODU

Communication

16

mismatch

No Communication

17

Illegal ODU Model

18

1.OCT is not

connected to controller

0 0 0 0 1

0 0 0 1 0

0 0 0 1 1 Similar as item 1 Similar as item 1

0 0 1 0 0 Similar as item 2 Similar as item 2

0 0 1 0 1 Similar as item 1 Similar as item 1

0 0 1 1 0 Similar as item 2 Similar as item 2

0 0 1 1 1 Similar as item 1 Similar as item 1

0 1 0 0 0 Similar as item 2 Similar as item 2

0 1 0 0 1 Similar as item 1 Similar as item 1

0 1 0 1 0 Similar as item 2 Similar as item 2

0 1 0 1 1 Possibly damaged.

0 1 1 0 0

0 1 1 0 1

0 1 1 1 0

0 1 1 1 1

1 0 0 0 0

1 0 0 0 1

1 0 0 1 0

terminal;

2.OCT is cut out;

3.Controller is

damaged

1.OCT is

shorted;

2.Controller is shorted

Similar as item 11. Similar as item 11.

Similar as item 11. Similar as item 11.

Similar as item 11. Similar as item 11.

Similar as item 11. Similar as item 11.

Possibly miss-wiring

between IDU and ODU.

Possibly mis-wiring

between IDU and ODU.

ODU Model jumper

setting is wrong;

In case1, reinstall OCT and make sure it’s

connected well; If fault still exists, move to

check case2, use a multimeter to check

OCT’s resistor, if it’s +, OCT is damaged

and change a new one; if it’s around10K(at

25), then move to case 3; In case 3, change

a new controller.

In case 1, use a multimeter to check OCT’s

resistor, if it’s 0, OCT is damaged and change

a new one; if it’s around 10K(at 25), then

move to case 2; In case 2, change a new

controller.

Turn OFF the system. Check wiring. Wait for

3 minutes and turn ON again. If the fault still

exists, return the controller to factory and

report the fault code.

Check connection between IDU and ODU.

Check connection between IDU and ODU.

Check the jumper setting according to the

model table on the controller label

12-2

SM TRIO52 1- E.1 GB

Page 44

TROUBLESHOOTING

CONTENTS

Bad MSMP EEPROM

19

Heat sink Over Heating

20

Deicing

21

Compressor Over

22

Heating

Compressor Over

23

Current

No OFAN Feedback

24

OFAN locked

25

Compressor start up fail

26

Bad Communication

27

Reserved

…

No Fault

29

(Heat Mode)

No Fault

30

(Cool, Dry, Fan Mode)

No Fault (Stand By)

31

1 0 0 1 1

1 0 1 0 0 Normal AC protection

1 0 1 0 1

1 0 1 1 0

1 0 1 1 1

1 1 0 0 0

1 1 0 0 1

1 1 0 1 0 Check for compressor wire connection.

1 1 0 1 1

1 1 1 0 1

1 1 1 1 0

1 1 1 1 1

Similar as item 11. Similar as item 11.

Turn OFF the system and wait for 30 minutes.

Turn ON the system again. If the fault still

exists, return the controller to factory and

report the fault code.

Normal AC protection,

no need action.

Normal AC protection,

no need action.

Normal AC protection,

no need action.

Check for OFAN connection between

controller and OFAN.

Check for OFAN connection between

controller and OFAN.

Check for wiring

between IDU and ODU.

SM TRIO52 1- E.1 GB

12-3

Page 45

TROUBLESHOOTING

CONTENTS

1.3.2 MSMP Fault Code for Indoor Unit:

No Problem 5 4 3 2 1 Possible Reason Corrective Action

1

RT-1 is disconnected

2

RT-1 is shorted

3

RT-2 is disconnected

4

RT-2 is shorted

5

RGT is disconnected

6

Reserved

7 Communication

mismatch

8

No Communication

9

No Encoder

10

Reserved

11

Outdoor unit fault

12

Reserved

13

Reserved

14

Reserved

15

Reserved

17

Defrost protection

18

Deicing Protection

19 Outdoor Unit

Protection

20 Indoor Coil HP

Protection

21

Overflow Protection

22

Reserved

23

Reserved

24 EEPROM Not

Updated

25

Bad EEPROM

26

Bad Communication

27

Using EEPROM data

29

No Fault (Heat Mode)

30

No Fault (Cool, Dry,

Fan Mode)

31

No Fault (Stand By)

1 1 1 0 1

1 1 1 1 0

1 1 1 1 1

1. RT-1 is not connected to

controller terminal;

2.RT-1 is cut out;

3.Controller is damaged

1. RT-1 is shorted;

2. Controller is shorted

Similar as item 1 Similar as item 1

Similar as item 2 Similar as item 2

Similar as item 1 Similar as item 1

Possibly mis-wiring.

Possibly mis-wiring.

Possibly mis-wiring, controller

damaged or fan motor damaged.

Refer to 1.3.1

Normal AC protection, no need

action

Normal AC protection, no need

action

Normal AC protection, no need

action

Normal AC protection, no need

action

Possibly damaged.

Possibly damaged.

Check for wiring between IDU and

ODU.

A/C is operating with customized

A/C parameters from EEPROM

In case1, reinstall RT-1 and make sure it’s

connected well; If fault still exists, move to

check case2, use a multimeter to check RT1’s resistor, if it’s +, RT-1 is damaged and

change a new one; if it’s around10K(at 25),

then move to case 3; In case 3, change a new

controller.

In case 1, use a multimeter to check RT-1’s

resistor, if it’s 0, RT-1 is damaged and change

a new one; if it’s around 10K(at 25), then

move to case 2; In case 2, change a new

controller.

Refer to 1.3.1

Use MEGATOOL to reset to default

parameters

12-4

SM TRIO52 1- E.1 GB

Page 46

TROUBLESHOOTING

CONTENTS

1.4 judgment by Mega Tool

Mega Tool is a special tool to monitor the system states.

Using Mega Tool requires:

A computer with RS232C port.

A connection wire for MegaTool.

Special MegaTool software.

Use MegaTool according to following procedure:

Setup MegaTool software: copy the software to the computer.

Connect RS232C port in computer with MegaTool port in Indoor/Outdoor unit controller by the

connection wire.

Run the software and choose the COM port, you can monitor the A/C system state in monitor tab.

1.5 Simple Procedures for Checking the Main Parts

1.5.1 Checking Mains Voltage.

Confirm that the Mains voltage is between 198 and 264 VAC. If Mains voltage is out of this range, abnormal

operation of the system is expected. If in range check the Power (Circuit) Breaker and look for broken or loosed

cable lugs or wiring mistake(s).

1.5.2 Checking Power Input.

If Indoor unit power LED is unlighted, power down the system and check the fuse of the Indoor unit. If the fuse is

OK replace the Indoor unit controller. If the fuse has blown, replace the fuse and power up again.

Checking Power Input procedure for the Outdoor unit is the same as with the Indoor unit.

1.5.3 Checking the PCB.

Appearance inspect: Check discoloration, nick and connection of copper foil, short-circuit and open-circuit,

component soldering, bulgy and distortion of electrolytic capacitor.

Power circuit check: check voltage of every power level (5V, 12V, 15V) printed on back of PCB.

1.5.4 Checking the Outdoor Fan Motor.

Enter Test Mode (where the OFAN speed is high)

Check the voltage between lead wires according to the normal value as following:

Between red wire and black wire: 380VDC +/- 20V

Between orange wire and black wire: 15VDC +/- 1V

Between yellow wire and black wire: 2-6VDC

1.5.5 Checking the Compressor.

The compressor is brushless permanence magnetic DC motor. Three coil resistances are same. Check the

resistance between three poles. The normal value should be 0.642 ohm (U-V), 0.636 ohm (V-W) and 0.652

ohm (U-W). (Environmental temperature 25ºC)

1.5.6 Checking the Reverse Valve (RV).

Running in heating mode, check the voltage between two pins of reverse valve connector, normal voltage is

220VAC.

1.5.7 Checking the Electrical Expansion Valve (EEV).

SM TRIO52 1- E.1 GB

The EEV has two parts, drive part and valve. The drive part is a step motor; it is ringed on the valve. Check

the drive voltage (12VDC). When Outdoor unit is power on, EEV shall run and have click and vibration.

12-5

Page 47

TROUBLESHOOTING

CONTENTS

1.6 Precaution, Advise and Notice Items

1.6.1 High voltage in Outdoor unit controller.

Whole controller, including the wires, connected to the Outdoor unit controller may have the potential hazard

voltage when power is on. Touching the Outdoor unit controller may cause an electrical shock.

Advise: Don’t touch the naked lead wire and don’t insert finger, conductor or anything else into the controller

when power is on.

1.6.2 Charged Capacitors

Three large-capacity electrolytic capacitors are used in the Outdoor unit controller. Therefore, charging

voltage (380VDC) remains after power down. Discharging takes about three minutes after turned off.

Touching the Outdoor unit controller before discharging may cause an electrical shock. When open the

Outdoor unit controller cover, don’t touch the soldering pin by hand or by any conductive material.

Advise:

1. Open the Outdoor unit controller cover only after five minutes from power down.

2. Measure the electrolytic capacitors voltage before farther checking controller for safety.

1.6.3 Additional advises

When disassemble the controller or the front panel, turn off the power supply.

When connecting or disconnecting the connectors on the PCB, hold the whole housing, don’t pull the

wire.

There are sharp fringes and sting on shell. Use gloves when disassemble the A/C units.

12-6

SM TRIO52 1- E.1 GB

Page 48

EXPLODED VIEWS AND SPARE PARTS LISTS

CONTENTS

13. EXPLODED VIEWS AND SPARE PARTS LISTS

13.1 Outdoor Unit: TRIO DELTA 5.2 kw DCI

SM TRIO52 1- E.1 GB

13-1

Page 49

EXPLODED VIEWS AND SPARE PARTS LISTS

CONTENTS

13.2 Outdoor Unit: TRIO DELTA 5.2kw DCI R410A

No. Item Description Qty.

1 4517144 Outlet grid 1

2 452795700 PAINTED LEFT CABINET ASSY 1

3 4526510 OUTDOOR FAN 1

4 453026500R DC Motor SIC-71FW-F170-2 1

5 453036400 Motor Support 1

6 464600019 Base Plate Painting Assy. 1

7 464160004 Partition Plate 1

8 453238900 Outdoor Air Thermistor(OAT) 1

9 4526775 Compressor Top Thermistor(CTT) 1

10 4526776 Outdoor Coil Thermistor(OCT) 1

11 452783100 High Press Valve R410A 1

12 461010018 Low Press Valve R410A 1

13 453030500 Outdoor DCI Controller/2.8kW 1

14 467420009 4 Poles Terminal Block 1

14 467420010 8 Poles Terminal Block 1

15 204107 Cable clip Nylon 4

17 4526827 Electronical expansion valve CAM-BD15 FKS-1 3

18 452682802 EEV COIL(White Connector 530mm) 1

18 452682800 EEV COIL(Red Connector 530mm) 1

18 452682801 EEV COIL(Yellow Connector 700mm) 1

19 4526477 compressor isulation 1

20 4510677 Nut M8 for compressor 3

21 4526221 cable of compressor 1

22 4526486 Scroll DC compressor 5CS130XCC03 1

23 464630008 Side Plate Painting Assy 1

24 464080001 Painted Right Back Cabinet Assy. 1

25 461600015 4-Way Valve Assy. 1

26 4522509 4-way valve coil 1

27 4518952 Four-Way Valve R410A 1

28 464660009 Painted Right Cabinet Assy. 1

29 452890900 Condenser Assy. 1

30 4516788 Painted Top Cover Assy. 1

31 4523141 Nut M10 for fan 1

32 4516758 Left Handle 1

33 4517028 Guard Net Painting Assy. 1

34 4517772 Right Handle 1

38 464860026 Valve Plate Paint Assy. 1

39 4526396 Choke Assy. 1

40 467300039R Filter PCB 1

42 452813100 Liquid-Gas Separator 1

43 467300038R MSMP PCB 1

44 463650003 Manifold Assy. 1

45 463700004 Distributing Pipe Assy. 1

46 464860027 Painted Stop Plate Assy. 1

47 453225700 OAT Support 1

48 452783501 Brass Connector with Flange 3/8" 3

48 452783502 Brass Connector with Flange 1/4" 3

49 463250001 Liquid Accumulator 1

13-2

SM TRIO52 1- E.1 GB

Page 50

APPENDIX A

CONTENTS

APPENDIX A

INSTALLATION AND OPERATION MANUAL

►

INSTALLATION MANUAL TRIO DELTA

5.2kw DCI

SM TRIO52 1- E.1 GB

14-1

Loading...

Loading...