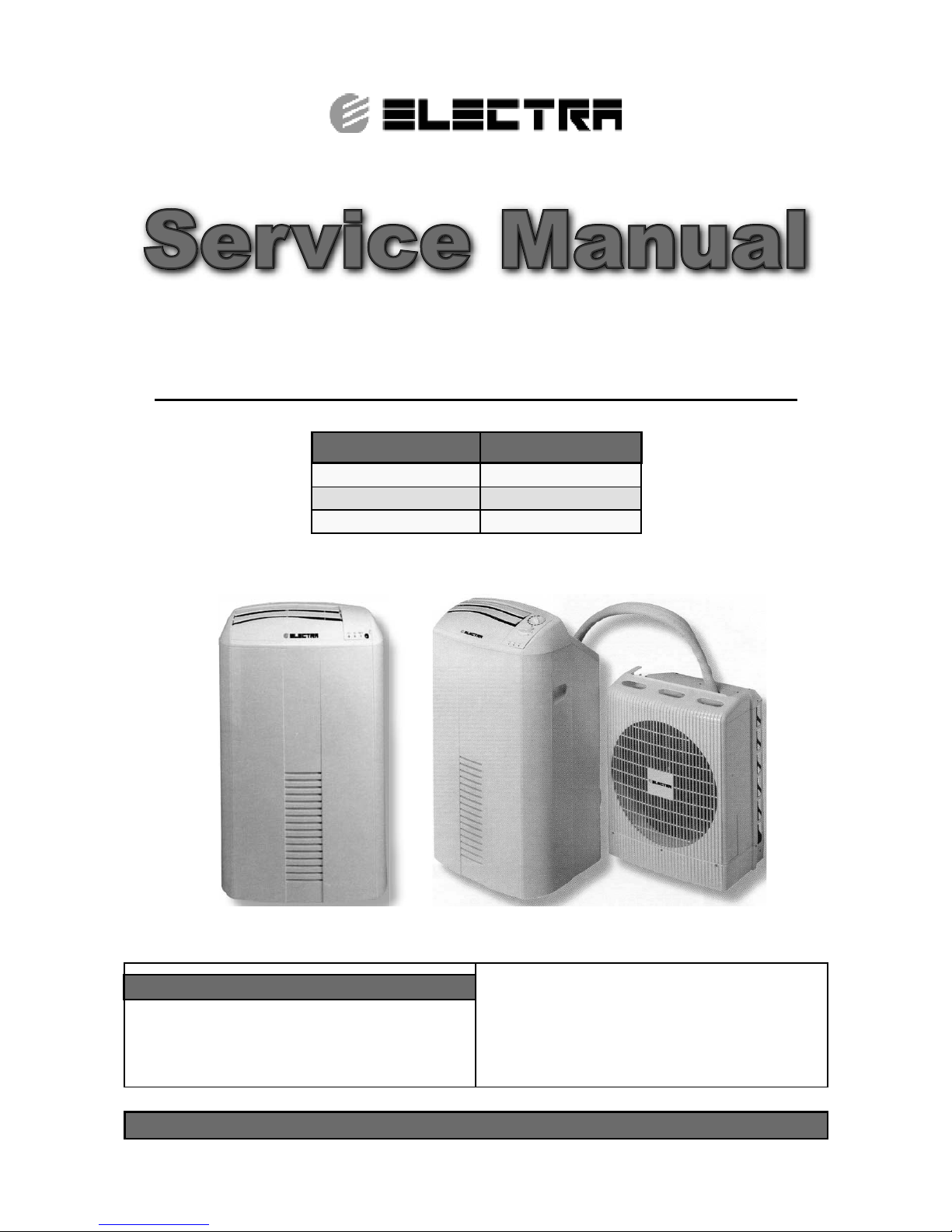

Page 1

Service Manual

Mobile Series

REFRIGERANT

R410A

COOLING ONLY

HEAT PUMP

JANUARY 2005

Indoor Units Outdoor Units

Monoblock 7 N/A

SP 11 SP 11

SP 16 SP 16

Page 2

A

LIST OF EFFECTIVE PAGES

Revision Y05-01

Service Manual - MOBILE Series

LIST OF EFFECTIVE PAGES

Note: Changes in the pages are indicated by a “Revision#” in the footer of each effected page

(when none indicates no changes in the relevant page). All pages in the following list represent

effected/ non effected pages divided by chapters.

Dates of issue for original and changed pages are:

Original ....... 0 ........ 15 December 2004

Total number of pages in this publication is 131 consisting of the following:

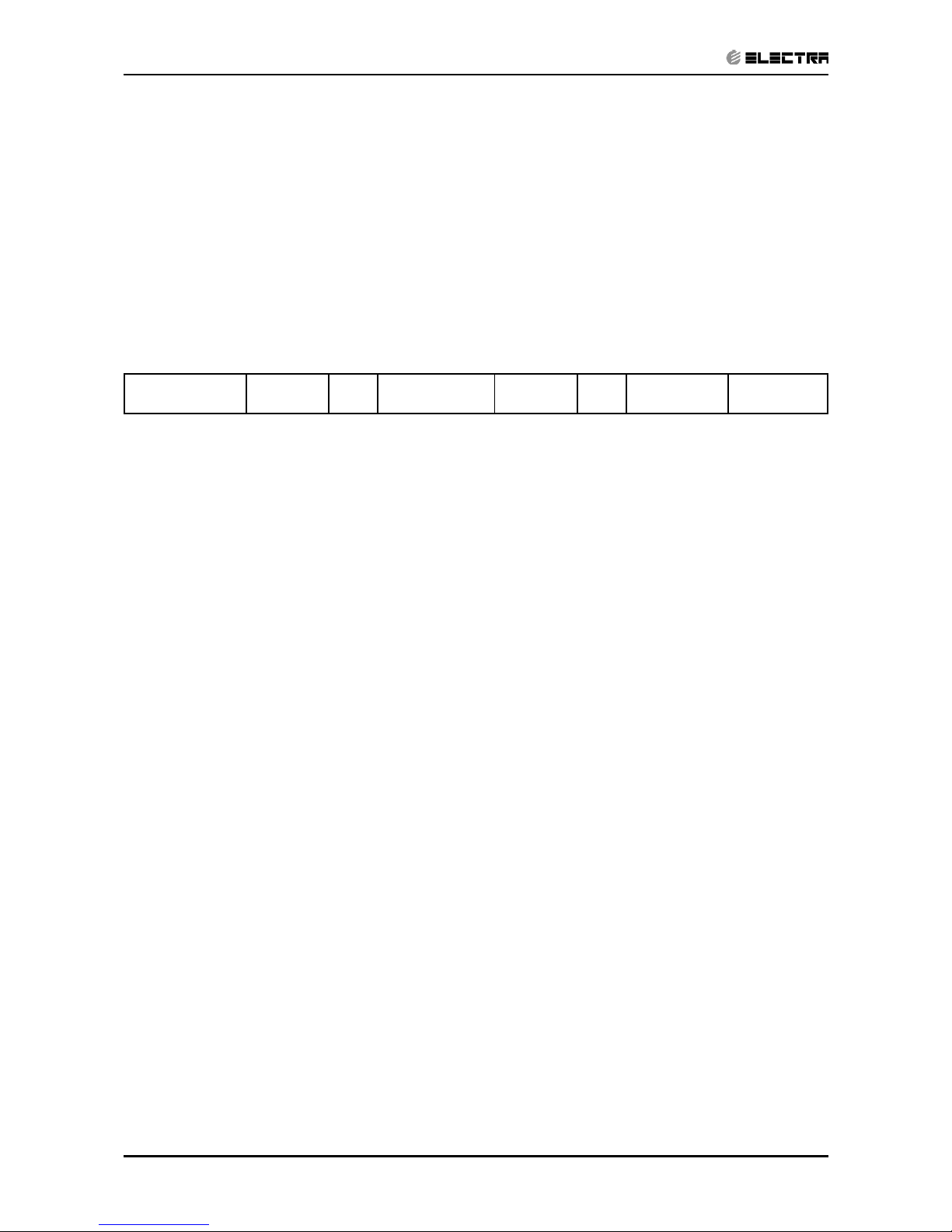

Page

No.

Revision

No. #

Page

No.

Revision

No. #

Page

No.

Revision

No. #

Title ....................... 0

A ........................... 1

i ............................. 0

1-1 - 1-2 ................ 0

2-1 - 2-3 ................ 0

3-1 ........................ 0

4-1 ........................ 0

5-1 - 5-10 .............. 1

6-1 - 6-2 ................ 0

7-1 ........................ 0

8-1 - 8-4 ................ 0

9-1 - 9-2 ................ 0

10-1-10-36 ............ 0

11-1-11-3 ............... 0

12-1-12-62 ............ 0

Appendix -A ...........0

• Zero in this column indicates an original page.

*Due to constant improvements please note that the data on this service manual can be modified with out notice.

**Photos are not contractual

Page 3

i

TABLE OF CONTENTS

Revision Y05-01Service Manual - MOBILE Series

Table of Contents

1. INTRODUCTION ...................................................................................................1-1

2. PRODUCT DATA SHEET ......................................................................................2-1

3. RATING CONDITIONS ..........................................................................................3-1

4. OUTLINE DIMENSIONS .......................................................................................4-1

5. PERFORMANCE DATA & PRESSURE CURVES ................................................5-1

6. SOUND LEVEL CHARACTERISTICS ..................................................................6-1

7. ELECTRICAL DATA ..............................................................................................7-1

8. WIRING DIAGRAMS .............................................................................................8-1

9. REFRIGERATION DIAGRAMS .............................................................................9-1

10. CONTROL SYSTEM .............................................................................................10-1

11. TROUBLESHOOTING ..........................................................................................11-1

12. EXPLODED VIEWS AND SPARE PARTS LISTS .................................................12-1

13. APPENDIX A .........................................................................................................13-1

Page 4

1-1

INTRODUCTION

Revision Y05-01Service Manual - MOBILE Series

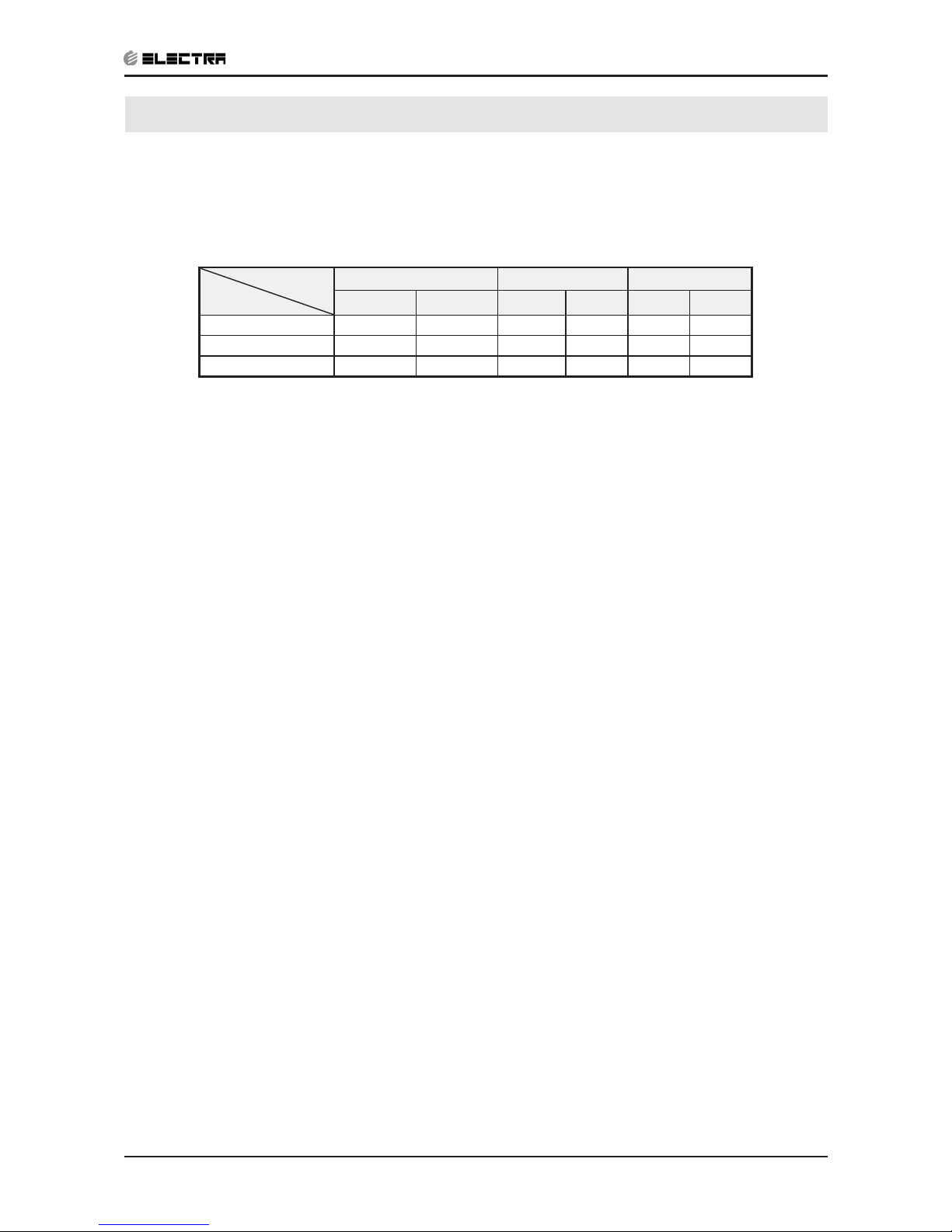

1. INTRODUCTION

1.1 General

The Mobile range comprise the ST (cooling only) and RC (heat pump) models, as

follows:

Model

Mode

Monoblock 7 R410A SP11 R410A SP16 R410A

M E M EME

Cooling Only

√ √ √ √√√

Heat Pump

N/A N/A N/A √ N/A √

Electric Heater

N/A √ N/A N/A N/A N/A

* E – Electronic / Remote control Type.

* M –Electro Mechanical control.

The split type units consists indoor and outdoor unit, interconnected by a flexible hose.

The mobiles indoor units are equipped with four castors for easy mobility.

The electronic models are equipped with a Microprocessor control system, giving the

user a choice of local or remote control operation, as well as precise temperature

setting and control,

1.2 Main Features

The Mobile series benefits from the most advanced technological innovations, namely:

• Easy mobility.

• Easy installation, (no spacial installation is Required).

• R410A .

• Microprocessor control (Electronic model only).

• High COP.

• Automatic vertical treated air sweep (Electronic only).

• Pre charged refrigerant system.

• High reliability quick connectors for split models which enables temporary separation

between indoor and outdoor units for a fix installation type (optional).

• Compact dimensions.

1.3 Filtration

The Mobile series presents several types of air filters:

• Easily accessible, and re-usable pre-filters (mesh)

• Carbon and electrostatic filter (optional)

Page 5

1-2

INTRODUCTION

Revision Y05-01 Service Manual - MOBILE Series

1.4 Control

Electronic model: a microprocessor indoor controller, and an infrared remote control,

supplied as standard, provides complete operating function and programming.

Mechanical model: Electro mechanical control .

For further details please refer to the Installation and Operation Manual, Appendix A.

1.5 Inbox Documentation

Each unit is supplied with its own installation and operation manuals.

Page 6

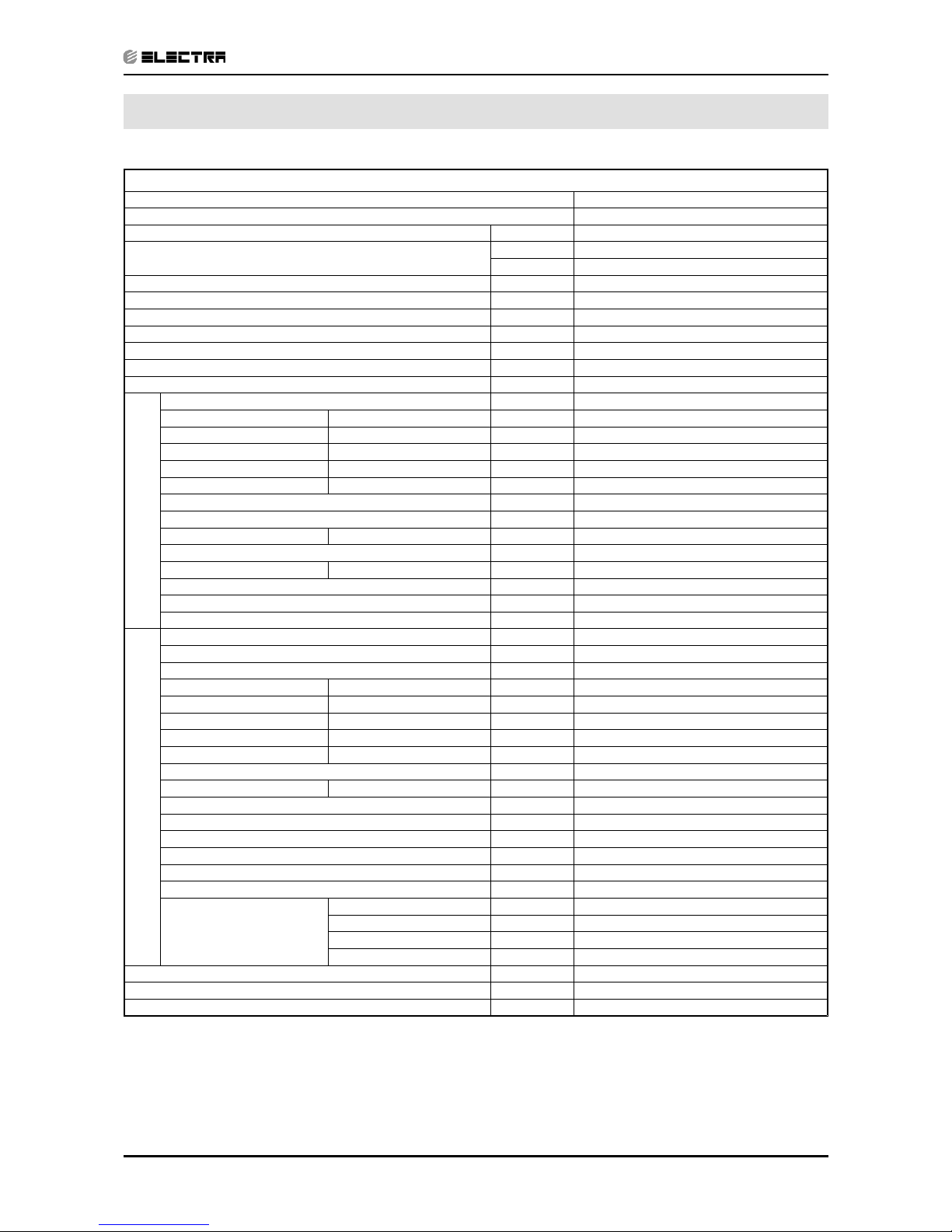

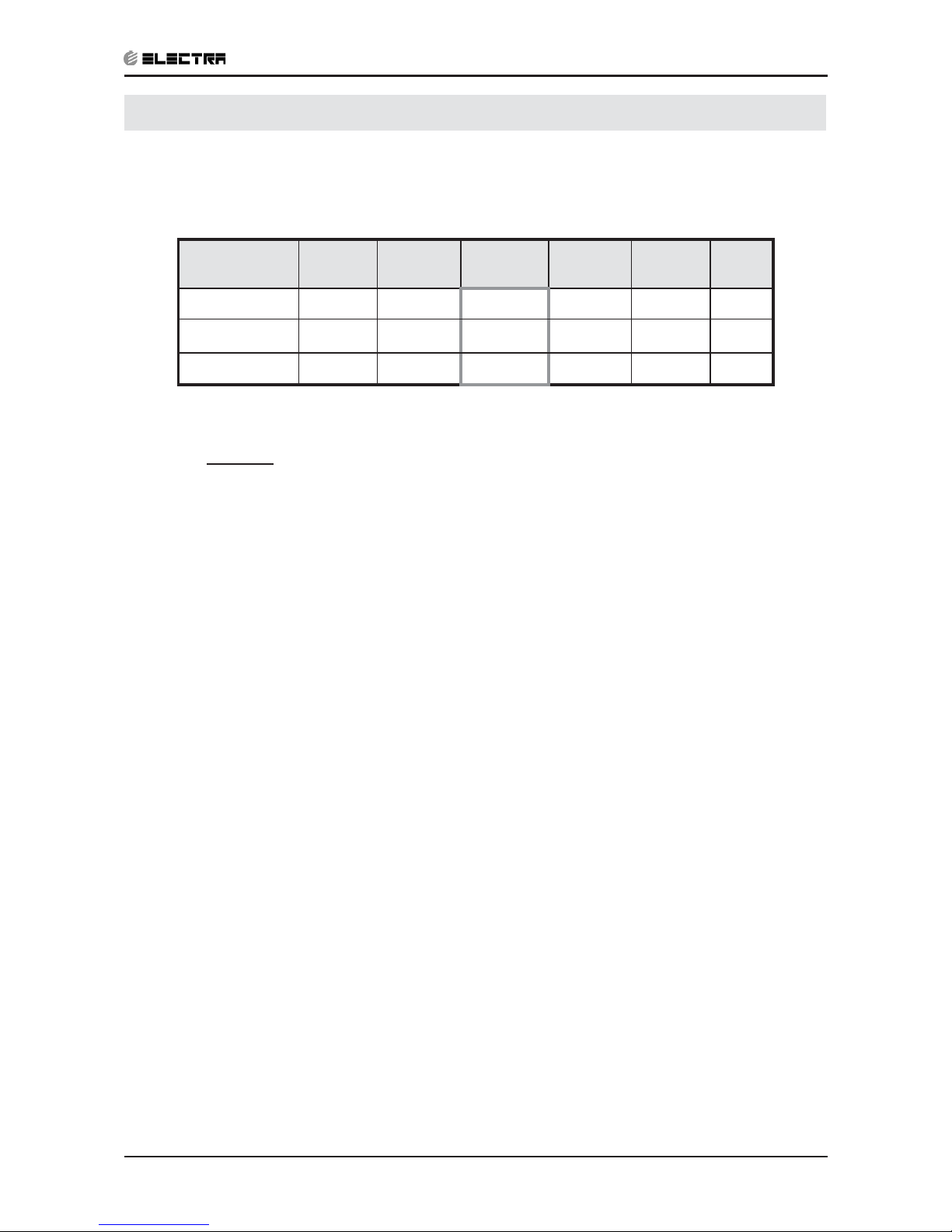

2-1

PRODUCT DATA SHEET

Revision Y05-01Service Manual - MOBILE Series

2. PRODUCT DATA SHEET

2.1 R410A

Model Indoor Unit Monoblock 7 R410A

Model Outdoor Unit N/A

Installation Method of Pipe N/A

Characteristics Units Cooling

Capacity

(1)

Btu/hr 7850

kW 2.30

Power input

(1)

kW 0.95

EER (Cooling) or COP(Heating)

(1)

W/W 2.42

Energy efficiency class B

Power supply V/Ph/Hz 220-240V/Single/50Hz

Rated current A 4.3

Starting current A 17

Circuit breaker rating A 10

INDOOR

Fan type & quantity Centrifugalx1

Fan speeds H/M/L RPM 1390/1280/1170

Air flow

(2)

H/M/L m3/hr 275/257/234

External static pressure Min-Max Pa 0

Sound power level

(3)

H/M/L dB(A) 63/62.5/61.5

Sound pressure level

(4)

H/M/L dB(A) 49/48/47

Moisture removal l/hr 0.9

Condensate drain tube I.D mm 11.5

Dimensions WxHxD mm 470x800x360

Weight kg 32

Package dimensions WxHxD mm 550*450*935

Packaged weight kg 37.5

Units per pallet units 8

Stacking height units 2 levels

OUTDOOR

Refrigerant control Capillary tube

Compressor type, model Rotary,Sanyo C-1RV096H1A

Fan type & quantity N/A

Fan speeds H/L RPM N/A

Air flow H/L m3/hr N/A

Sound power level H/L dB(A) N/A

Sound pressure level

(4)

H/L dB(A) N/A

Dimensions WxHxD mm N/A

Weight kg N/A

Package dimensions WxHxD mm N/A

Packaged weight kg N/A

Units per pallet Units N/A

Stacking height units N/A

Refrigerant type R410A

Refrigerant chargless distance kg/m 0.51kg

Additional charge per 1 meter g/m N/A

Connections between

units

Liquid line In.(mm) N/A

Suction line In.(mm) N/A

Max.tubing length m. N/A

Max.height difference m. N/A

Operation control type Remote control or Rotary switch control

Heating elements kW 2 (Electronic model only)

Others

(1) Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units) and EN 14511.

(2) Airflow in ducted units; at nominal external static pressure.

(3) Sound power in ducted units is measured at air discharge.

(4) Sound pressure level measured at 1 meter distance from unit.

Page 7

2-2

PRODUCT DATA SHEET

Revision Y05-01 Service Manual - MOBILE Series

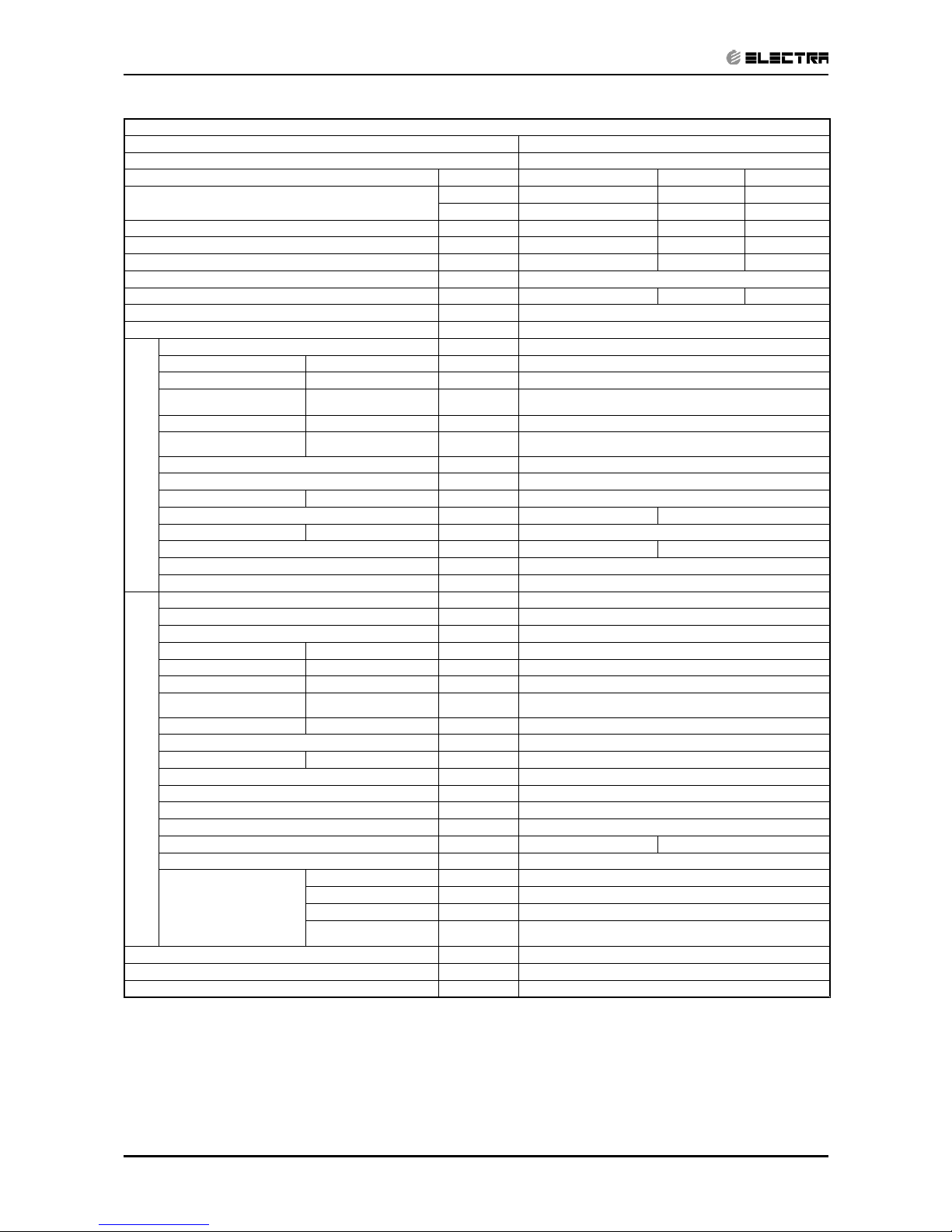

Model Indoor Unit SP11 R410A

Model Outdoor Unit SP11 R410A

Installation Method of Pipe Installed already or Quick connector

Characteristics Units Cooling only Cooling Heating

Capacity

(1)

Btu/hr 10300 10300 11600

kW 3.02 3.02 3.4

Power input

(1)

kW 0.977 0.977 0.95

EER (Cooling) or COP(Heating)

(1)

W/W 3.09 3.09 3.58

Energy efficiency class

B

BB

Power supply V/Ph/Hz 220-240V/Single/50Hz

Rated current A 4.5 4.5 4.3

Starting current A 18

Circuit breaker rating A 10

INDOOR

Fan type & quantity Centrifugalx1

Fan speeds H/M/L RPM 1280/1170/920

Air flow

(2)

H/M/L m3/hr 503/451/335

External static

pressure

Min-Max Pa 0

Sound power level

(3)

H/M/L dB(A) 62/60/57

Sound pressure level

(4)

H/M/L dB(A) 48/46/43

Moisture removal l/hr 1.25

Condensate drain tube I.D mm 11.5

Dimensions WxHxD mm 470x800x360

Weight kg 33 34.5

Package dimensions WxHxD mm 650x860x550

Packaged weight kg 55 56.5

Units per pallet units 4

Stacking height units 2 levels

OUTDOOR

Refrigerant control Capillary tube

Compressor type, model Rotary, HITACHI ASG108CV-B7AT

Fan type & quantity Propeller(direct) x 1

Fan speeds H/L RPM 1080

Air flow H/L m3/hr N/A

Sound power level H/L dB(A) 69

Sound pressure level

(4)

H/L dB(A) 62

Dimensions WxHxD mm 440*540*320

Weight kg 17

Package dimensions WxHxD mm In the same package of INDOOR

Packaged weight kg See INDOOR

Units per pallet Units See INDOOR

Stacking height units See INDOOR

Refrigerant type R410A

Refrigerant chargless distance kg/m 0.99kg/3m 1.04kg/3m

Additional charge per 1 meter g/m N/A

Connections between

units

Liquid line In.(mm) 3/16(4.76)

Suction line In.(mm) 1/2(12.7)

Tubing length m. 3

Max.height

difference

m. 1.6

Operation control type Remote control or Rotary switch control (5)

Heating elements kW N/A

Others

(1) Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units) and EN 14511.

(2) Airflow in ducted units; at nominal external static pressure.

(3) Sound power in ducted units is measured at air discharge.

(4) Sound pressure level measured at 1 meter distance from unit.

Page 8

2-3

PRODUCT DATA SHEET

Revision Y05-01Service Manual - MOBILE Series

Model Indoor Unit SP16 R410A

Model Outdoor Unit SP16 R410A

Installation Method of Pipe Installed already or Quick connector

Characteristics Units Cooling only Cooling Heating

Capacity

(1)

Btu/hr 14230 14230 15660

kW 4.17 4.17 4.59

Power input

(1)

kW 1.544 1.544 1.387

EER (Cooling) or COP(Heating)

(1)

W/W 2.70 2.70 3.31

Energy efficiency class

D

DC

Power supply V/Ph/Hz 220-240V/Single/50Hz

Rated current A 7.1 7.1 6.3

Starting current A 28

Circuit breaker rating A 15

INDOOR

Fan type & quantity Centrifugalx1

Fan speeds H/M/L RPM 1360/1290/1126

Air flow

(2)

H/M/L m3/hr 433/401/356

External static

pressure

Min-Max Pa 0

Sound power level

(3)

H/M/L dB(A) 64/63.5/61

Sound pressure level

(4)

H/M/L dB(A) 51/50/48

Moisture removal l/hr 1.8

Condensate drain tube I.D mm 11.5

Dimensions WxHxD mm 470x800x360

Weight kg 38 39.5

Package dimensions WxHxD mm 650x860x550

Packaged weight kg 60 61.5

Units per pallet units 4

Stacking height units 2 levels

OUTDOOR

Refrigerant control Capillary tube

Compressor type, model Rotary, Sanyo C-RV168H1A

Fan type & quantity Propeller(direct) x 1

Fan speeds H/L RPM 1080

Air flow H/L m3/hr N/A

Sound power level H/L dB(A) 69

Sound pressure level

(4)

H/L dB(A) 62

Dimensions WxHxD mm 440*540*320

Weight kg 17

Package dimensions WxHxD mm In the same package of INDOOR

Packaged weight kg See INDOOR

Units per pallet Units See INDOOR

Stacking height units See INDOOR

Refrigerant type R410A

Refrigerant chargless distance kg/m 1.13kg/3m 1.16kg/3m

Additional charge per 1 meter g/m N/A

Connections between

units

Liquid line In.(mm) 3/16(4.76)

Suction line In.(mm) 1/2(12.7)

Tubing length m. 3

Max.height

difference

m. 1.6

Operation control type Remote control or Rotary switch control (5)

Heating elements kW N/A

Others

(1) Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units) and EN 14511.

(2) Airflow in ducted units; at nominal external static pressure.

(3) Sound power in ducted units is measured at air discharge.

(4) Sound pressure level measured at 1 meter distance from unit.

Page 9

3-1

RATING CONDITIONS

Revision Y05-01Service Manual - MOBILE Series

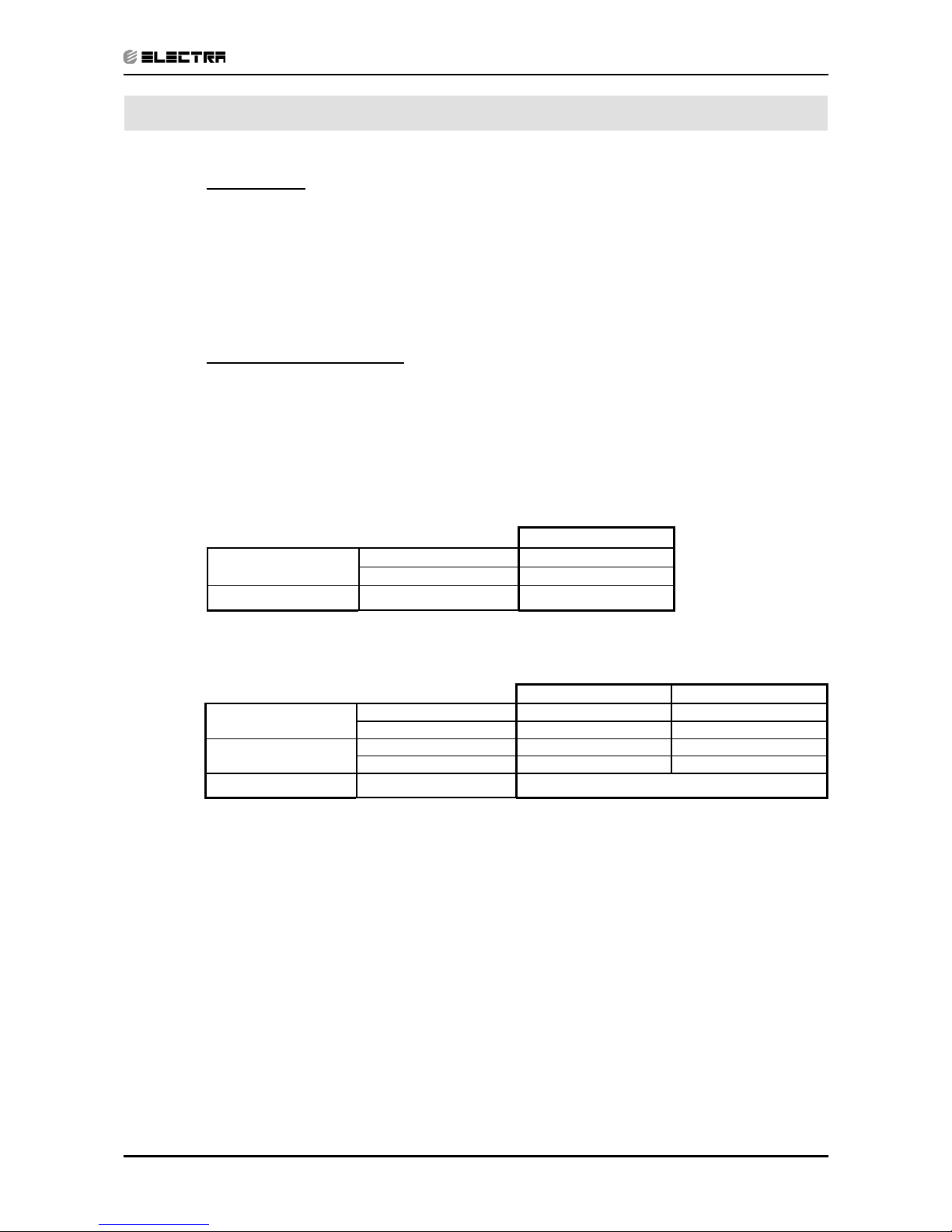

3. RATING CONDITIONS

Standard conditions in accordance with ISO 5151.

For Split unit

Cooling:

Indoor: 27oC DB 19oC WB

Outdoor: 35 oC DB

Heating:

Indoor: 20oC DB

Outdoor: 7oC DB 6oC WB

For monoblock (EN14511)

Standard condition: 35oC DB 24oC WB

Application condition: 27oC DB 19oC WB

3.1 Operating Limits

3.1.1 Monoblock 7

Indoor

Cooling

Upper limit 35

o

C DB 24oC WB

Lower limit 21

o

C DB 15oC WB

Voltage

1PH

198 – 264 V

3.1.2 SP11/16

Indoor Outdoor

Cooling

Upper limit 32

o

C DB 23oC WB 46oC DB

Lower limit 21oC DB 15oC WB 21oC DB

Heating

Upper limit 27

o

C DB 24oC DB 18oC WB

Lower limit 10

o

C DB -9oC DB -10oC WB

Voltage

1PH

198 – 264 V

Page 10

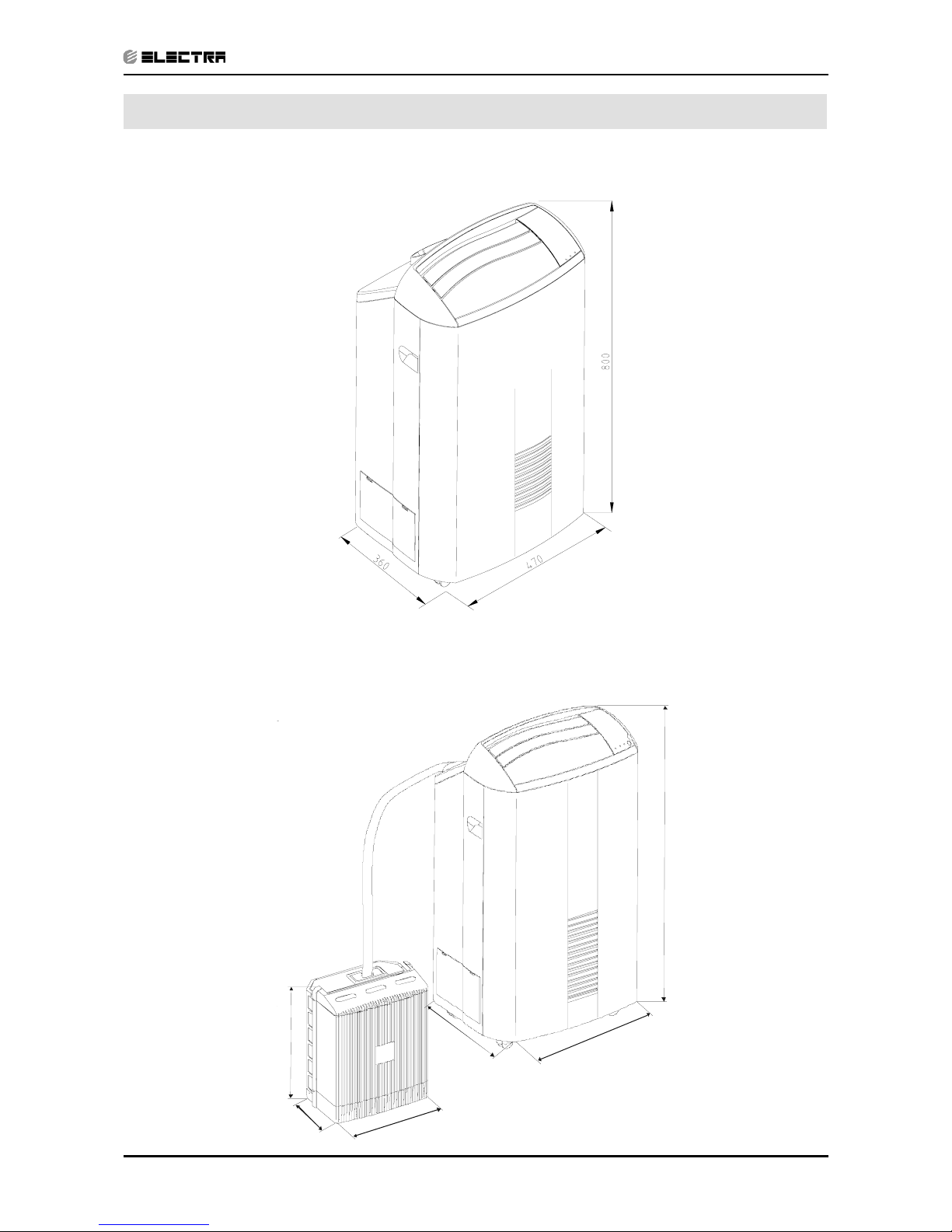

4-1

OUTLINE DIMENSIONS

Revision Y05-01Service Manual - MOBILE Series

4. OUTLINE DIMENSIONS

4.1 Monoblock 7

4.2

SP 11/16

4

3

6

0

4

7

0

8

0

0

4

0

5

4

0

3

2

0

Page 11

5-1

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01Service Manual - MOBILE Series

5. PERFORMANCE DATA & PRESSURE CURVES

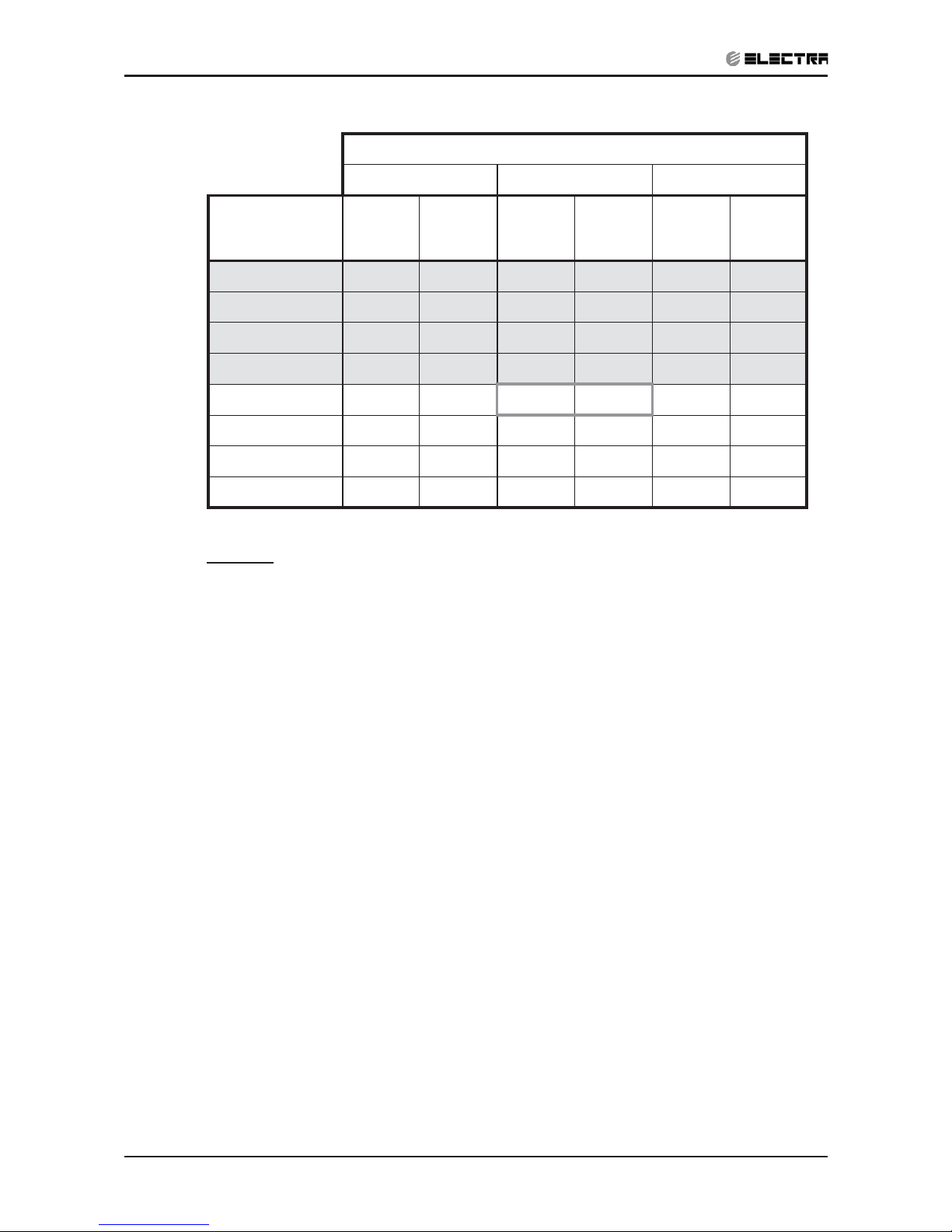

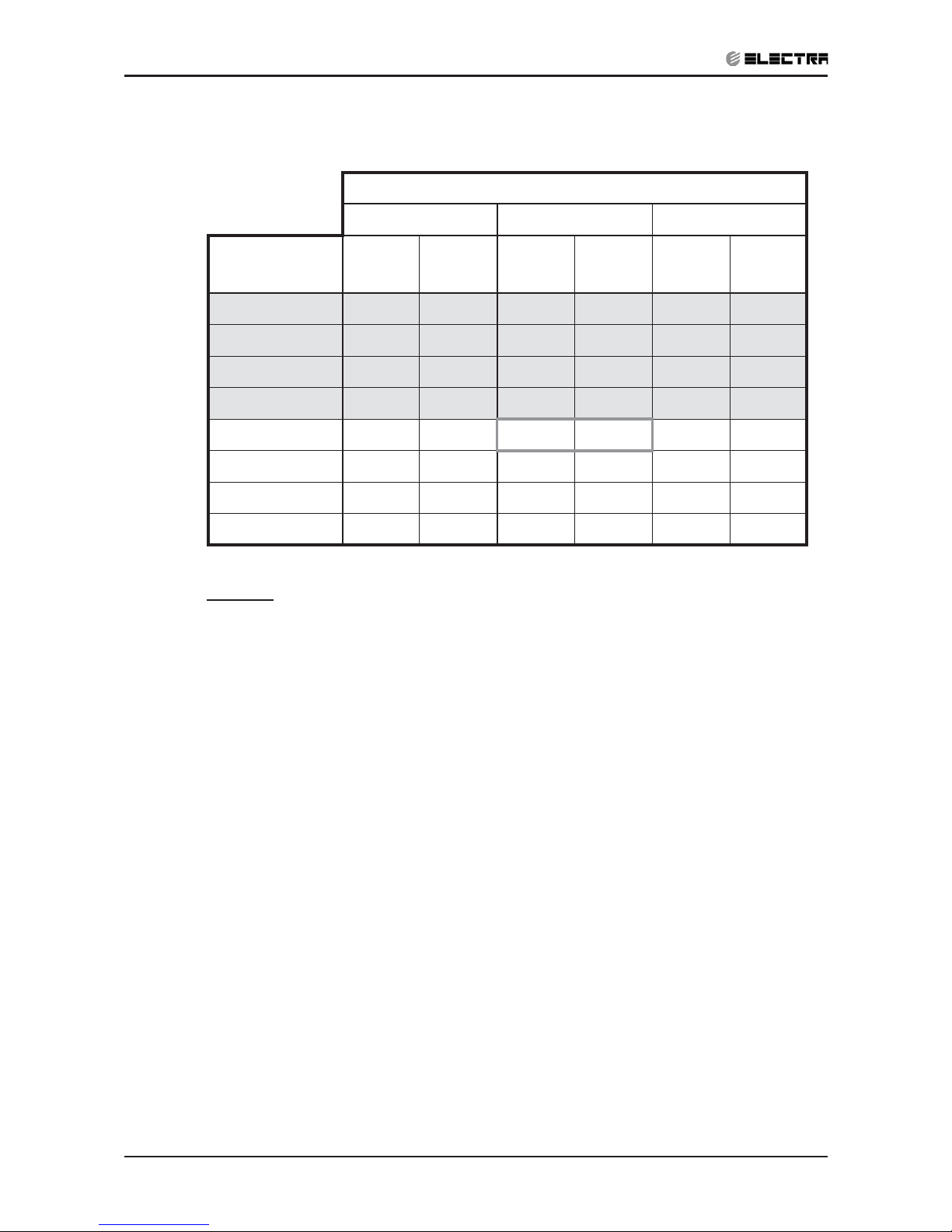

5.1 Monoblock 7

5.1.1 Cooling Capacity (kW)

Entering Air

WB/DB (

o

C)

15/21 17/24

19/27

21/29 23/32 24/35

TC 2.20 2.24

2.30

2.36 2.30 2.29

SC 1.38 1.41 1.47 1.42 1.38 1.56

PI 0.81 0.90 0.95 0.98 1.09 1.14

*indoor and outdoor air inlet temp’ are equal for monoblock type

LEGEND

TC – Total Cooling Capacity, kW

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (

o

C)

Page 12

5-2

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01 Service Manual - MOBILE Series

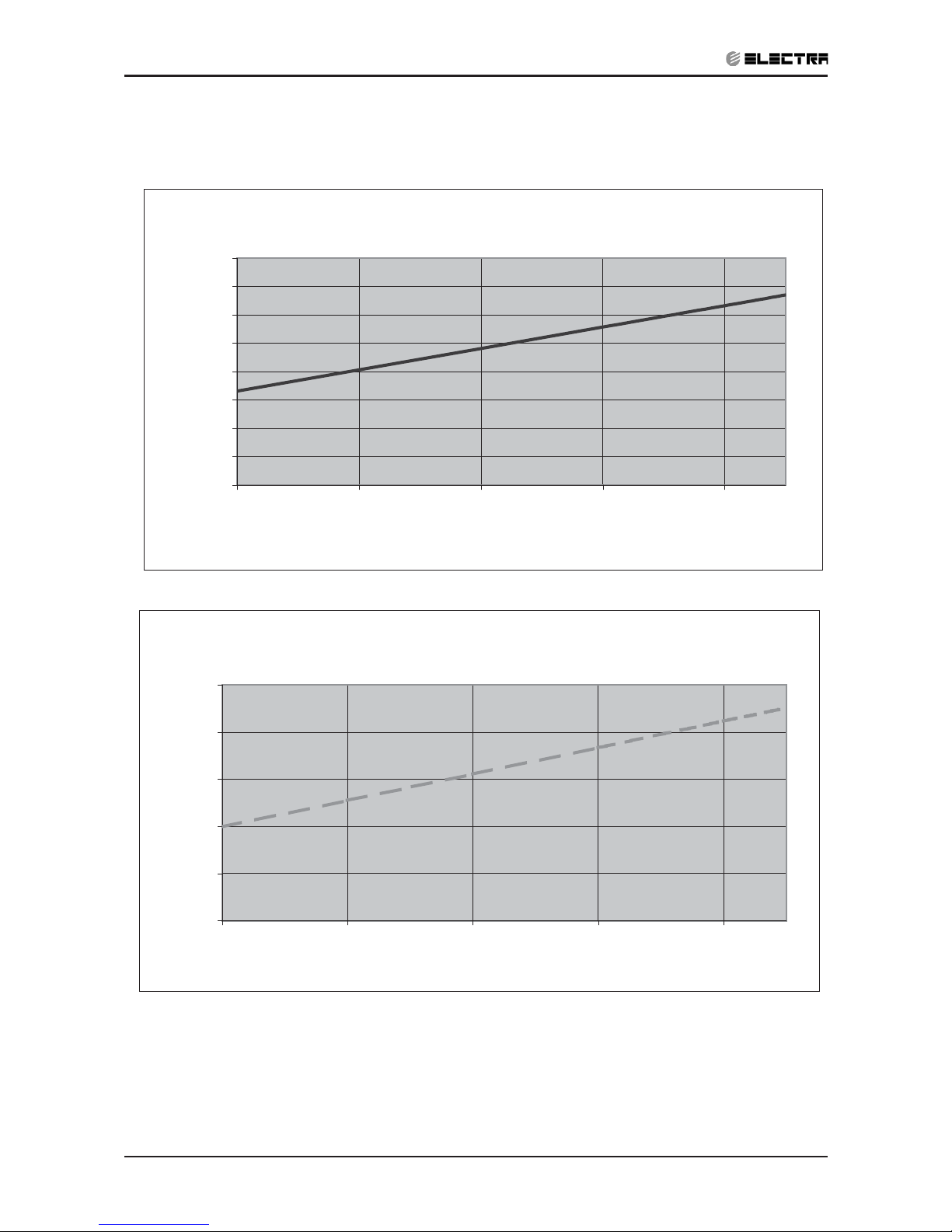

5.2 Pressure Curves

5.2.1 Cooling

Temp

15 17 19 21 23 24

Disch 29.9 32.7 35.5 38.3 41.1 42.5

Suction Pressure Vs. Condensing Inlet Air Temp'

4

5

6

7

8

9

10

11

12

15 17 19 21 23

Inlet Condensing Air Temp'( WB ºC)

Suction Pressure (Bar[g]

Discharge Pressure Vs. Condensing Inlet Air Temp'

20

25

30

35

40

45

15 17 19 21 23

Inlet Condensing Air Temp'( WB ºC)

Discharge Pressure (Bar[g]

Page 13

5-3

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01Service Manual - MOBILE Series

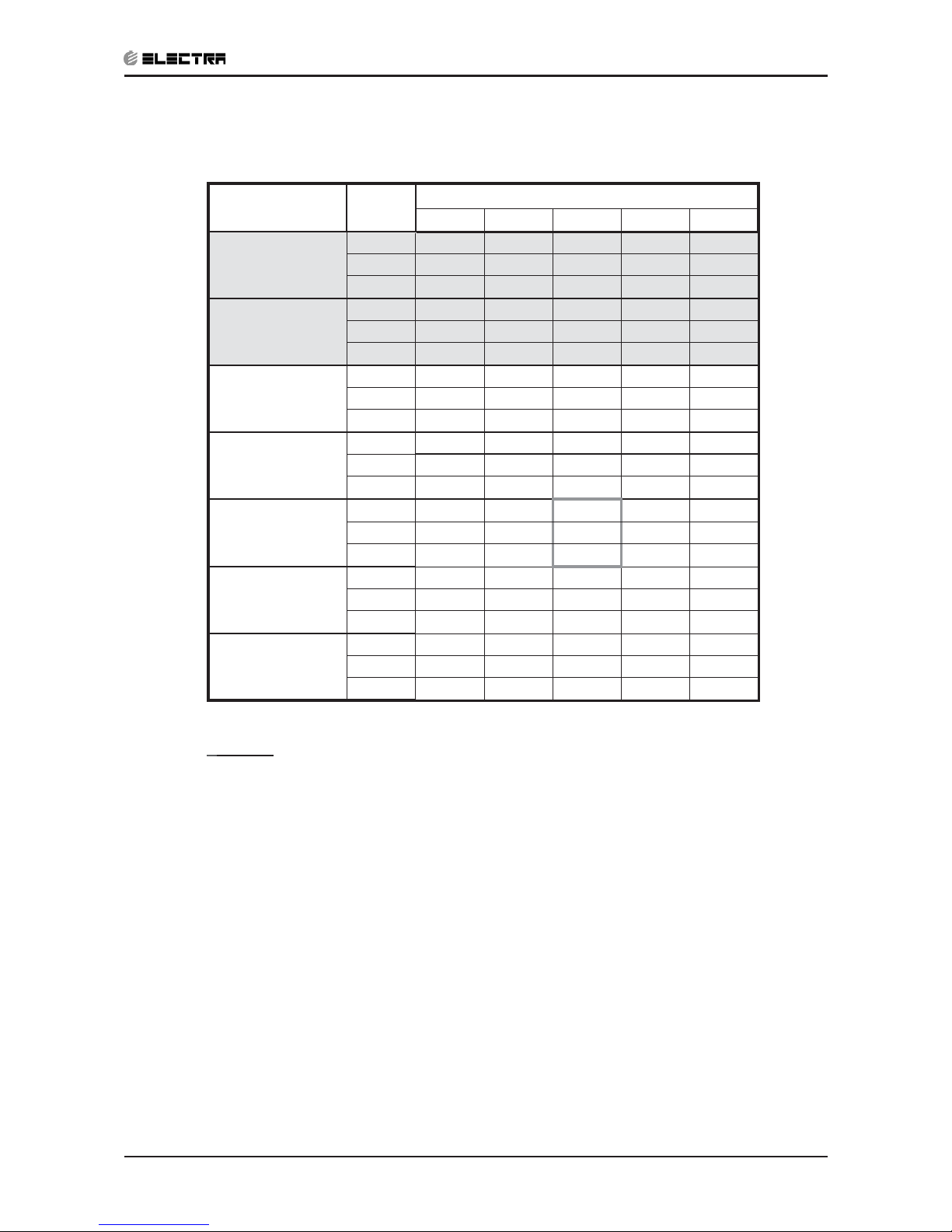

5.3 SP11 R410A

5.3.1 Cooling Capacity (kW)

ENTERING AIR

DB OU Coil(

o

C)

Data

ENTERING AIR WB/DB ID Coil(

o

C)

15/21 17/24 19/27 21/29 23/32

15

TC

3.18 3.30 3.37 3.45 3.51

SC 2.09 2.18 2.26 2.32 2.36

PI

0.69 0.70 0.70 0.70 0.70

20

TC

3.08 3.25 3.35 3.43 3.50

SC 2.04 2.16 2.25 2.31 2.35

PI

0.75 0.76 0.76 0.76 0.76

25

TC

2.91 3.15 3.31 3.41 3.49

SC 1.99 2.11 2.23 2.29 2.34

PI

0.82 0.82 0.83 0.83 0.84

30

TC

2.73 2.97 3.21 3.32 3.42

SC 1.93 2.05 2.18 2.24 2.29

PI

0.88 0.89

0.90

0.91 0.92

35

TC

2.52 2.74

3.02

3.17 3.32

SC 1.83 1.97 2.13 2.19 2.23

PI

0.95 0.96

0.98

0.99 0.99

40

TC

2.29 2.50

1.16

2.98 3.13

SC 1.73 1.86 2.01 2.08 2.12

PI

1.02 1.04 1.06 1.07 1.08

46

TC

1.99 2.18 2.39 2.64 2.85

SC 1.59 1.71 1.84 1.90 1.94

PI

1.12 1.13 1.16 1.18 1.19

LEGEND

TC – Total Cooling Capacity, kW

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (

o

C)

ID – Indoor

OU – Outdoor

(1) Marked area is below standard operating limits.

Page 14

5-4

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01 Service Manual - MOBILE Series

5.3.2 Heating Capacity (kW)

ENTERING AIR DB ID COIL(OC)

15 20 25

ENTERING

WB OU

COIL(

o

C)

TH Pl TH Pl TH Pl

-10 1.79 0.76 1.72 0.81 1.65 0.85

-7 1.92 0.78 1.85 0.82 1.79 0.87

-2 2.04 0.79 1.97 0.84 1.90 0.88

2 2.48 0.83

2.38 0.88

2.28 0.93

6 3.50 0.89 3.40 0.95 3.28 1.01

10 3.81 0.94

3.71 1.00

3.60 1.07

15 4.11 0.98 4.01 1.05 3.91 1.12

20 4.34 1.01 4.23 1.09 4.11 1.18

LEGEND

TH – Total Heating Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (

o

C)

ID – Indoor

OU – Outdoor

Page 15

5-5

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01Service Manual - MOBILE Series

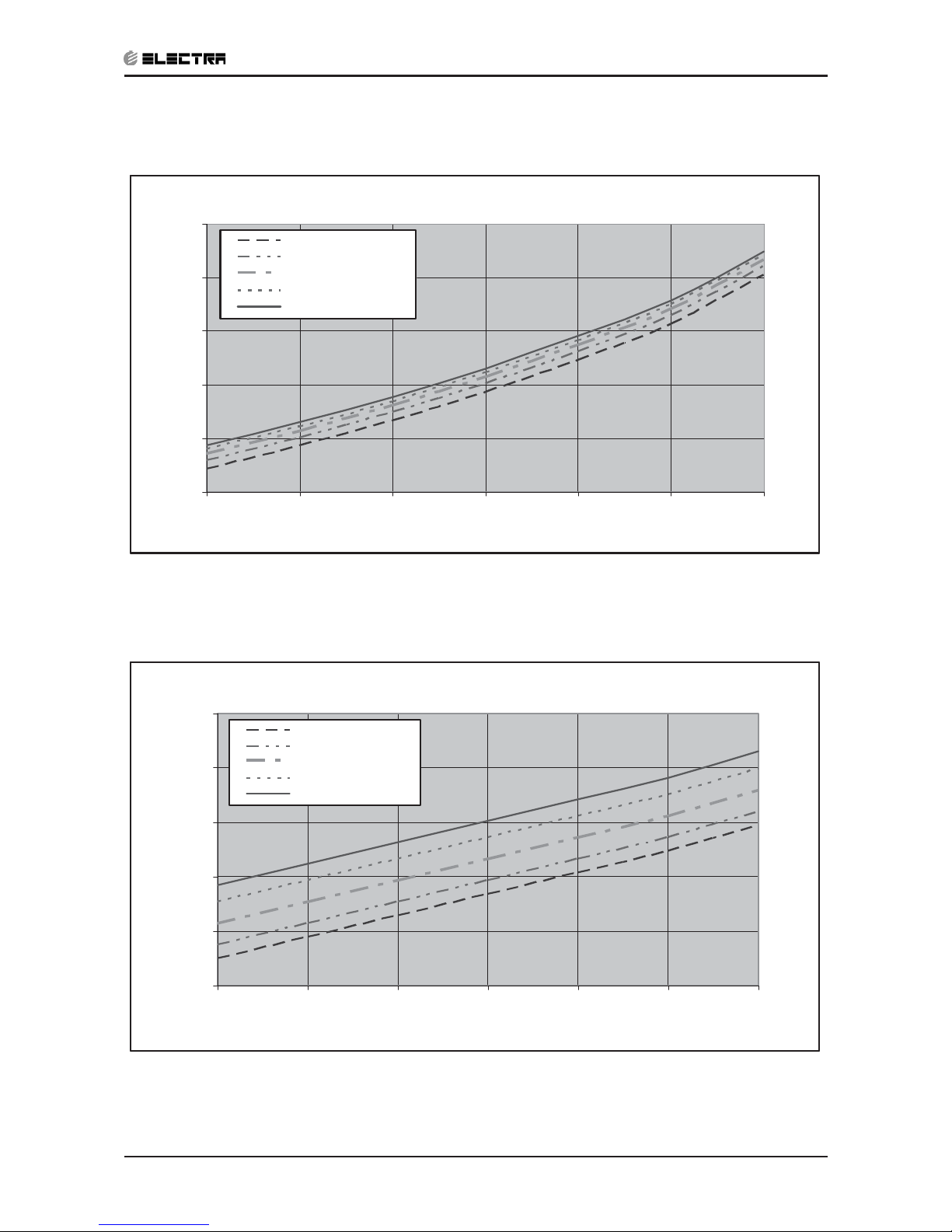

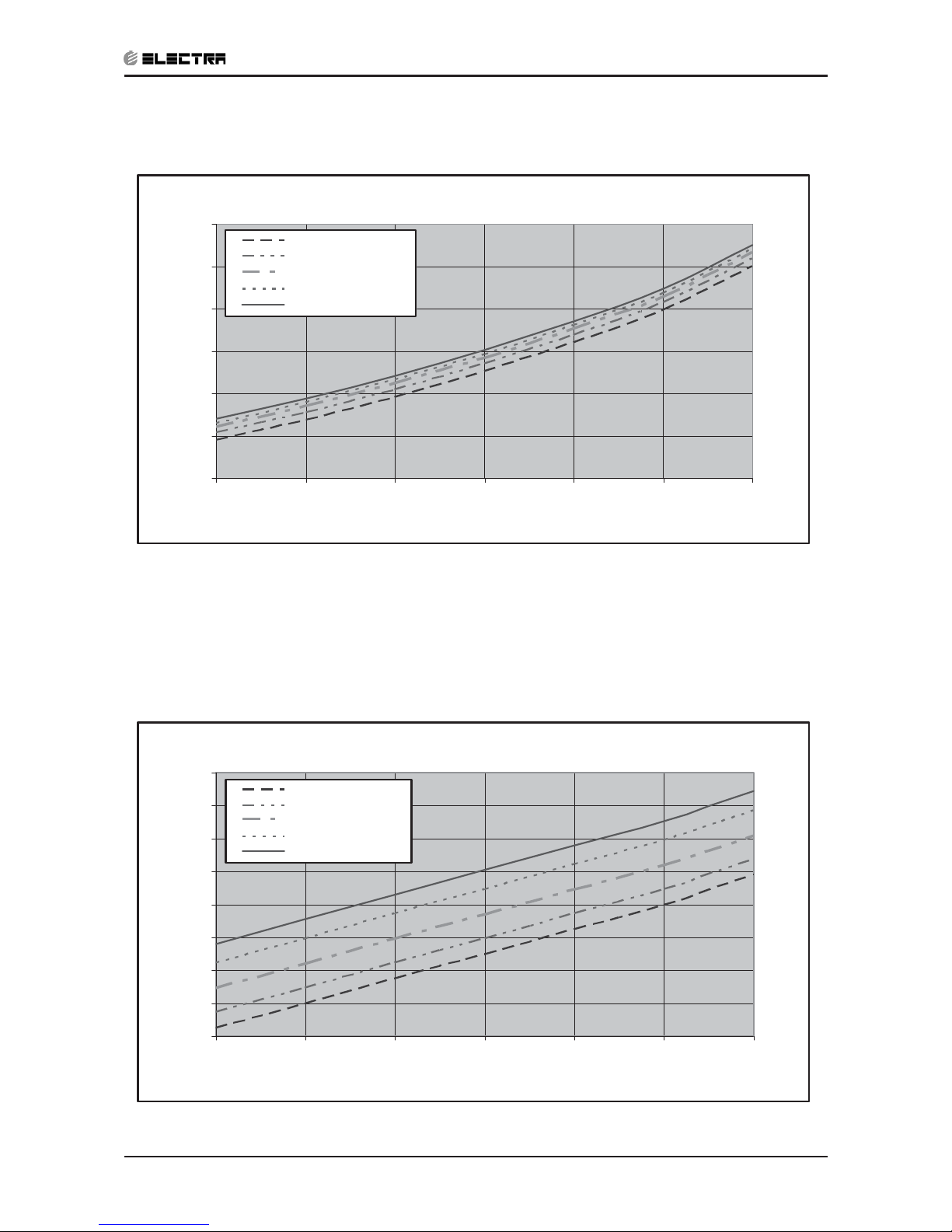

5.4 Pressure Curves

5.4.1 Cooling

Discharge Pressure VS.Outdoor Temp

15

20

25

30

35

40

15 20 25 30 35 40 46

Outdoor Temp.(DB oC )

Discharge Pressure (Bar[g])

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Suction Pressure VS.Outdoor Temp

6.5

7.5

8.5

9.5

10.5

11.5

15 20 25 30 35 40 46

Outdoor Temp.(DB oC )

Suction Pressure (Bar[g])

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Page 16

5-6

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01 Service Manual - MOBILE Series

5.4.2 Heating

Discharge Pressure VS.Outdoor Temp

20

22

24

26

28

30

32

34

36

38

-10 -5 0 5 10 15 20

Outdoor Temp.( WB oC )

Discharge Pressure(Bar[g])

25 DB (ºC)

20 DB (ºC)

15 DB (ºC)

Suction Pressure VS.Outdoor Temp

4.0

5.0

6.0

7.0

8.0

9.0

10.0

-10 -5 0 5 10 15 20

Outdoor Temp.( WB oC )

Suction Pressure(Bar[g])

15 DB (ºC)

20 DB (ºC)

25 DB (ºC)

Page 17

5-7

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01Service Manual - MOBILE Series

5.5 SP16 R410A

5.5.1 Cooling Capacity (kW)

ENTERING AIR

DB OU Coil(

o

C)

Data

ENTERING AIR WB/DB ID Coil(

o

C)

15/21 17/24 19/27 21/29 23/32

15

TC 4.40 4.55 4.66 4.77 4.84

SC 2.64 2.76 2.86 2.94 2.99

PI 1.09 1.09 1.10 1.10 1.10

20

TC 4.25 4.48 4.62 4.73 4.83

SC 2.59 2.73 2.85 2.93 2.98

PI 1.19 1.19 1.19 1.20 1.20

25

TC 4.02 4.34 4.57 4.71 4.82

SC 2.53 2.68 2.83 2.91 2.96

PI 1.28 1.29 1.30 1.31 1.32

30

TC 3.76 4.10 4.43 4.58 4.72

SC 2.45 2.60 2.76 2.84 2.90

PI 1.38 1.40

1.41

1.43 1.44

35

TC 3.48 3.78

4.17

4.38 4.59

SC 2.33 2.49 2.70 2.78 2.83

PI 1.49 1.52

1.54

1.55 1.56

40

TC 3.17 3.45

1.16

4.11 4.33

SC 2.19 2.36 2.55 2.64 2.69

PI 1.61 1.63 1.66 1.68 1.70

46

TC 2.75 3.00 3.30 3.65 3.93

SC 2.02 2.16 2.33 2.41 2.46

PI

1.76 1.78 1.82 1.85 1.87

LEGEND

TC – Total Cooling Capacity, kW

SC – Sensible Capacity, kW

PI – Power Input, kWה

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (

o

C)

ID – Indoor

OU – Outdoor

(1) Marked area is below standard operating limits.

Page 18

5-8

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01 Service Manual - MOBILE Series

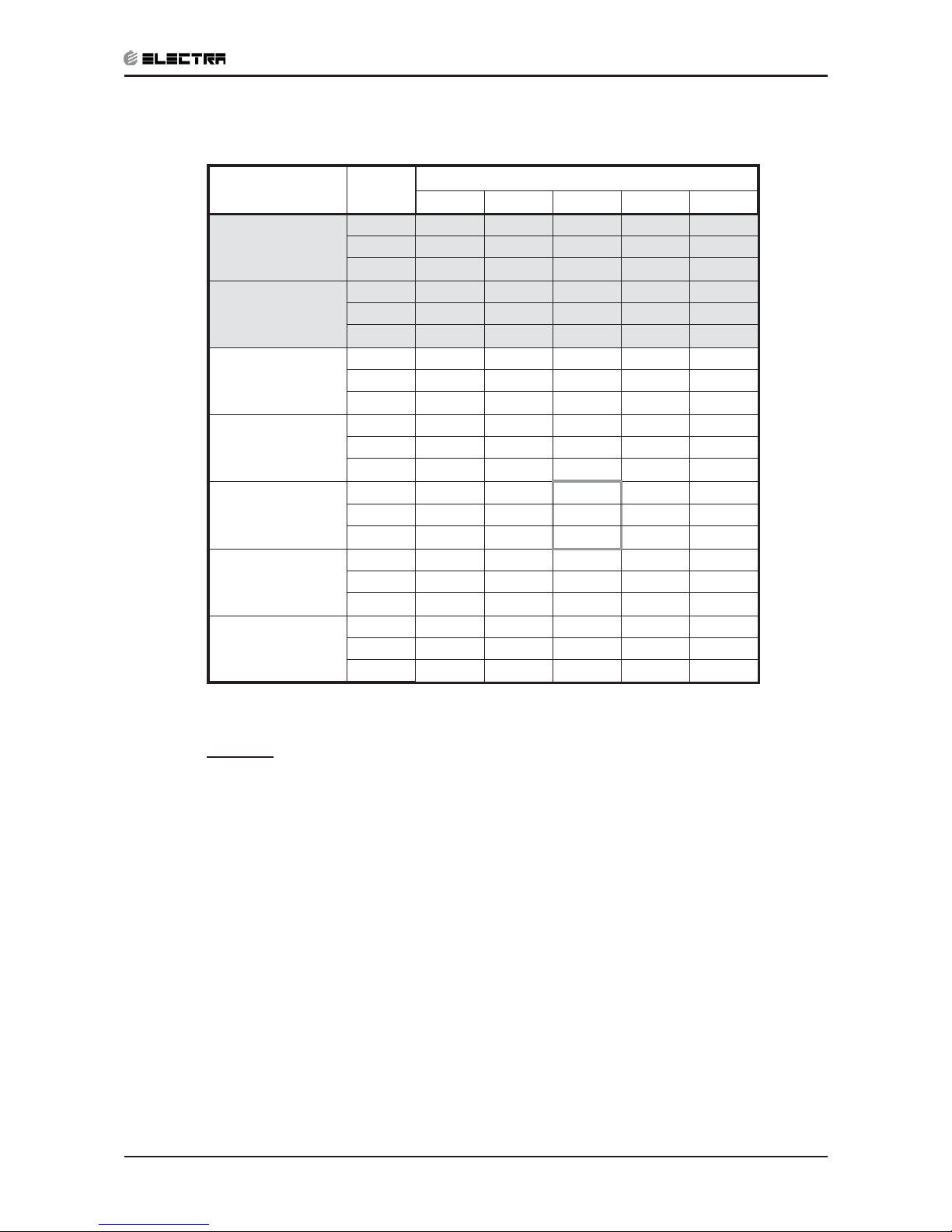

5.5.2 Heating Capacity (kW)

ENTERING AIR DB ID COIL(Oc)

15 20 25

ENTERING

WB OU

COIL(

o

C)

TH Pl TH Pl TH Pl

-10 2.41 1.11 2.32 1.18 2.23 1.24

-7 2.59 1.14 2.50 1.20 2.41 1.26

-2 2.75 1.15 2.66 1.22 2.57 1.29

2 3.35 1.21

3.21 1.28

3.08 1.36

6 4.73 1.30 4.59 1.39 4.43 1.47

10 5.14 1.37

5.00 1.46

4.87 1.56

15 5.55 1.43 5.42 1.54 5.28 1.64

20 5.85 1.47 5.71 1.60 5.55 1.72

LEGEND

TH – Total Heating Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (

o

C)

ID – Indoor

OU – Outdoor

Page 19

5-9

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01Service Manual - MOBILE Series

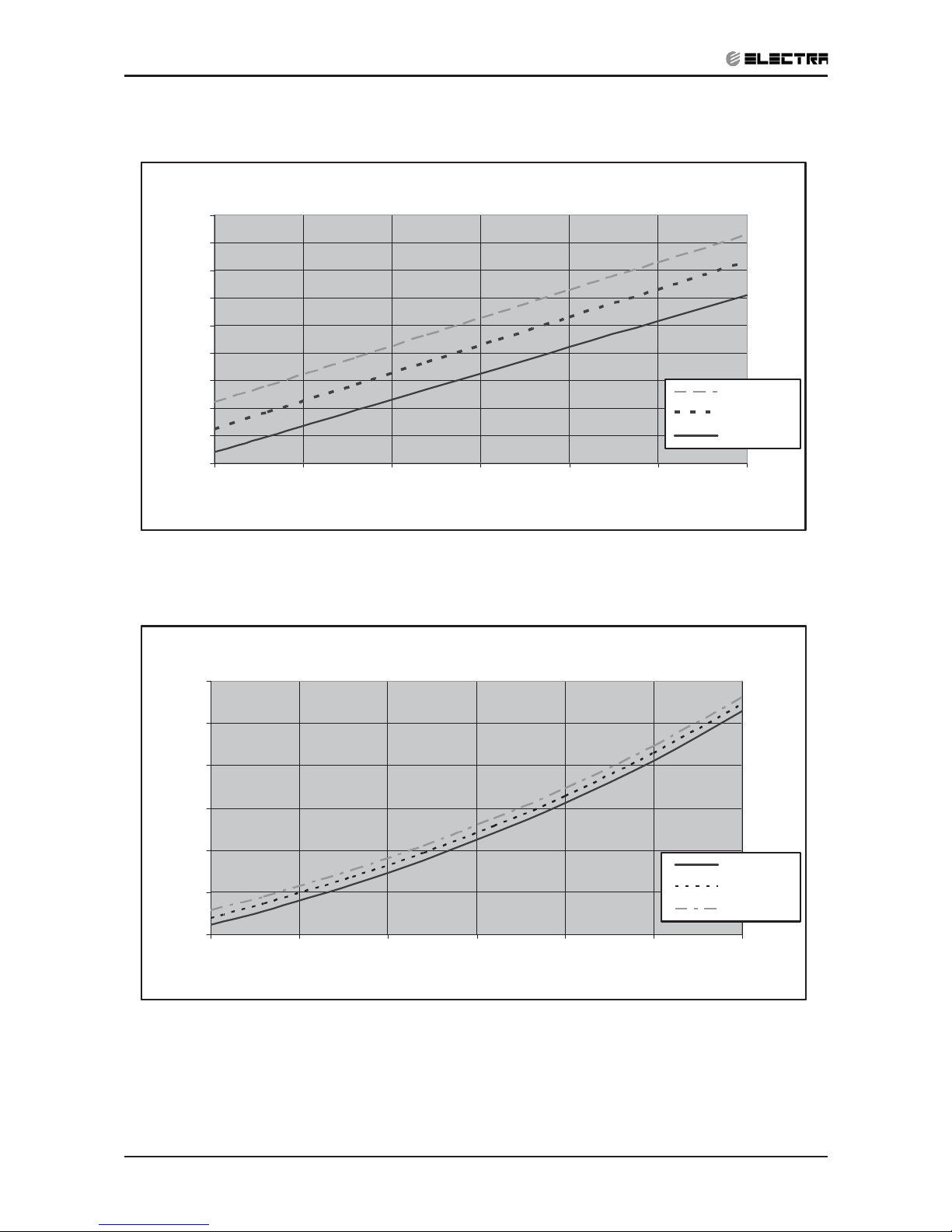

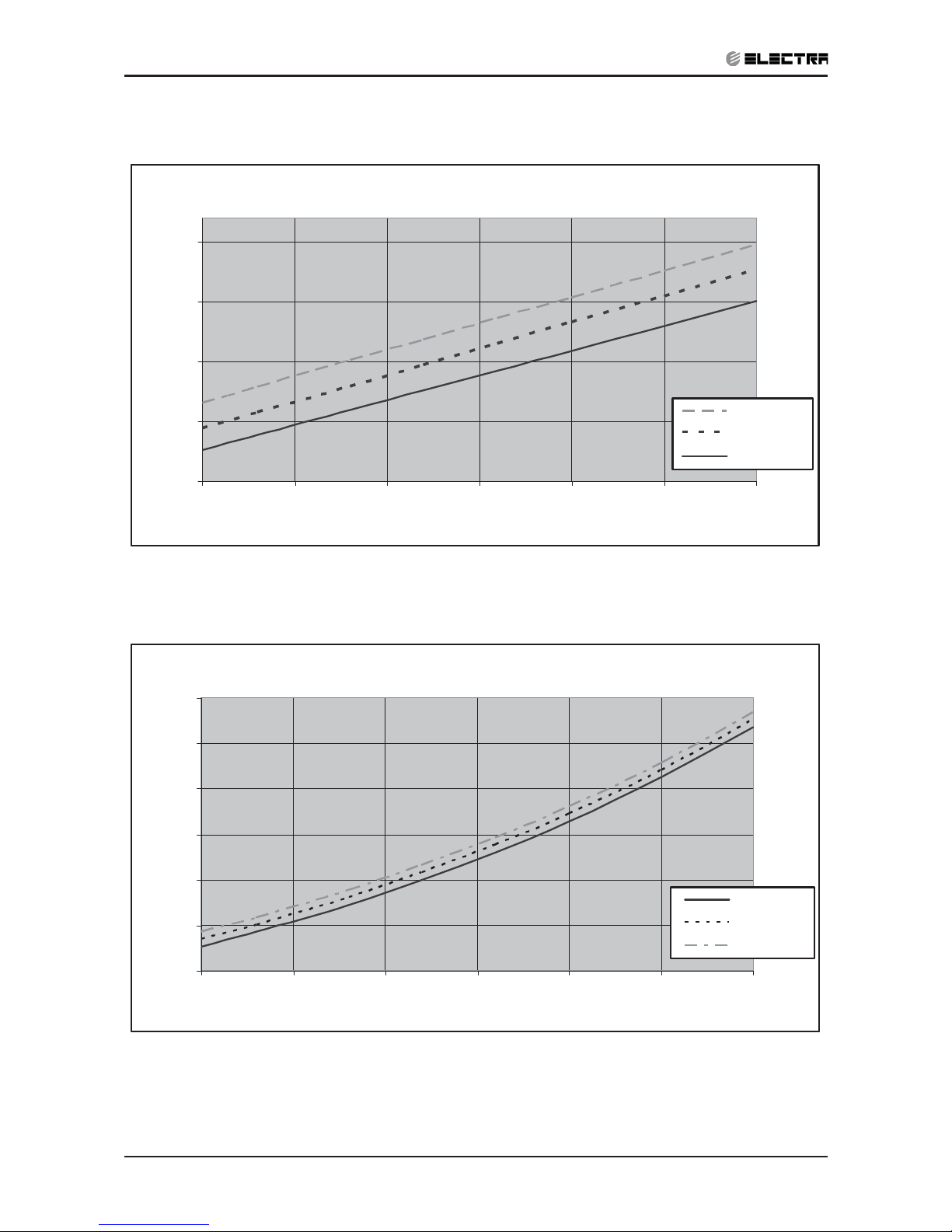

5.6 Pressure Curves

5.6.1 Cooling

Discharge Pressure VS.Outdoor Temp

15

20

25

30

35

40

45

15 20 25 30 35 40 46

Outdoor Temp.(DB oC )

Discharge Pressure (Bar[g])

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(W B/DB ºC)

21/29(W B/DB ºC)

23/32(W B/DB ºC)

Suction Pressure VS.Outdoor Temp

6.5

7.0

7.5

8.0

8.5

9.0

9.5

10.0

10.5

15 20 25 30 35 40 46

Outdoor Temp.(DB oC )

Suction Pressure (Bar[g])

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Page 20

5-10

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01 Service Manual - MOBILE Series

5.6.2 Heating

Discharge Pressure VS.Outdoor Temp

20

25

30

35

40

-10 -5 0 5 10 15 20

Outdoor Temp.( WB oC )

Discharge Pressure(Bar[g])

25 DB (ºC)

20 DB (ºC)

15 DB (ºC)

Suction Pressure VS.Outdoor Temp

3.5

4.5

5.5

6.5

7.5

8.5

9.5

-10 -5 0 5 10 15 20

Outdoor Temp.( WB oC )

Suction Pressure(Bar[g])

15 DB (ºC)

20 DB (ºC)

25 DB (ºC)

Page 21

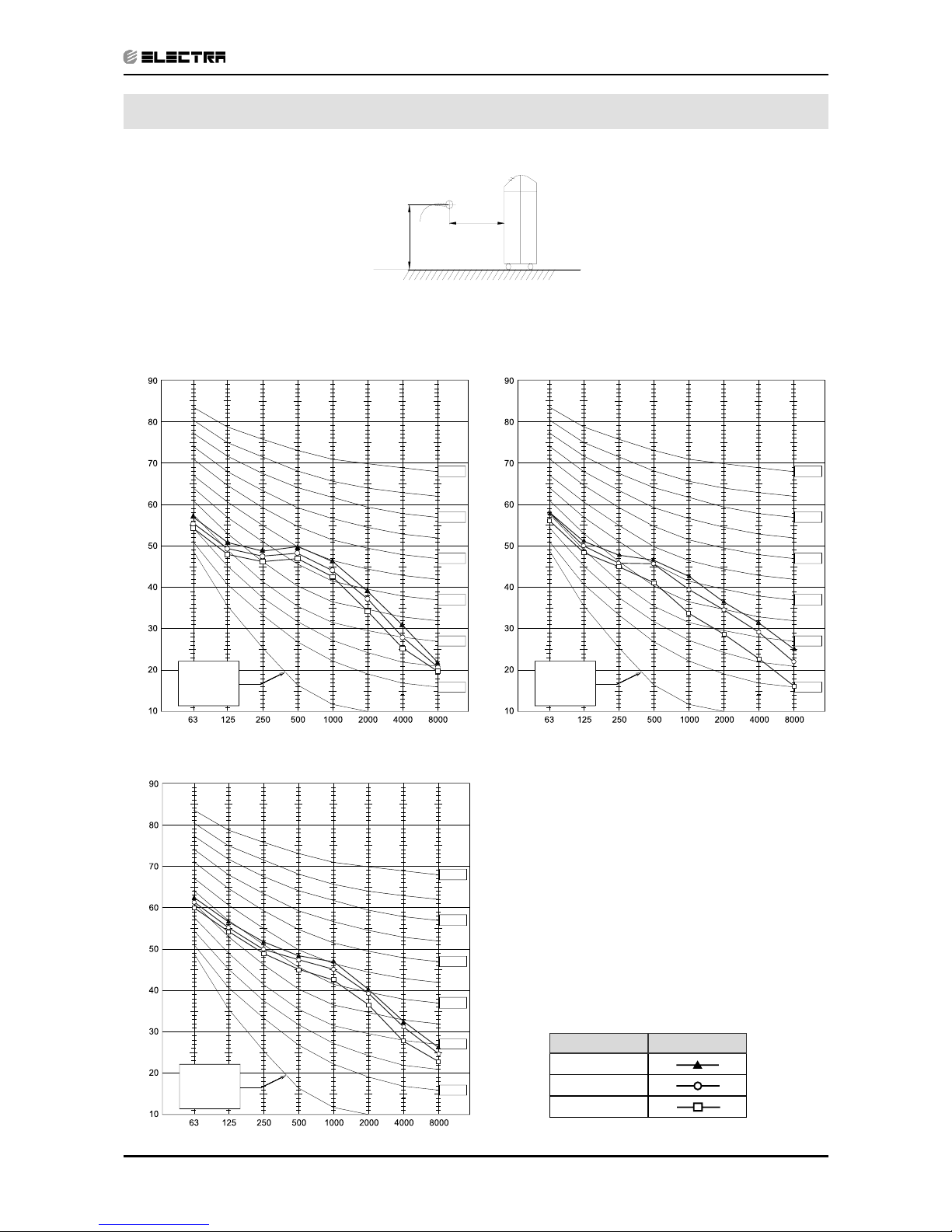

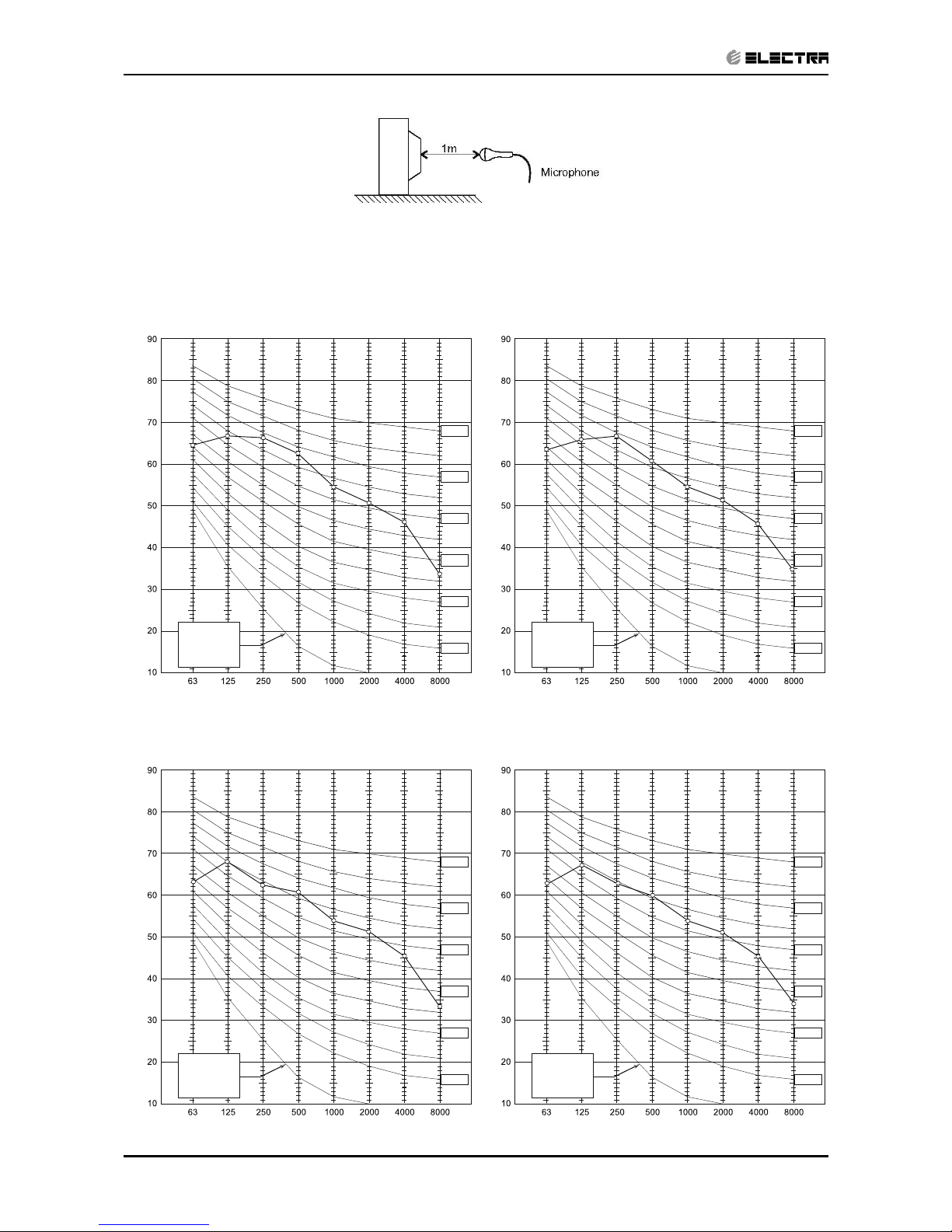

6-1

SOUND LEVEL CHARACTERISTICS

Revision Y05-01Service Manual - MOBILE Series

6. SOUND LEVEL CHARACTERISTICS

6.1 Sound Pressure Level

6.2 Soud Pressure Level Spectrum (Measured as Figure 1)

Monoblock 7 SP 11

FAN SPEED LINE

HI

ME

LO

0.9m

microphone

1m

Fig.1 Monoblock

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

SP 16

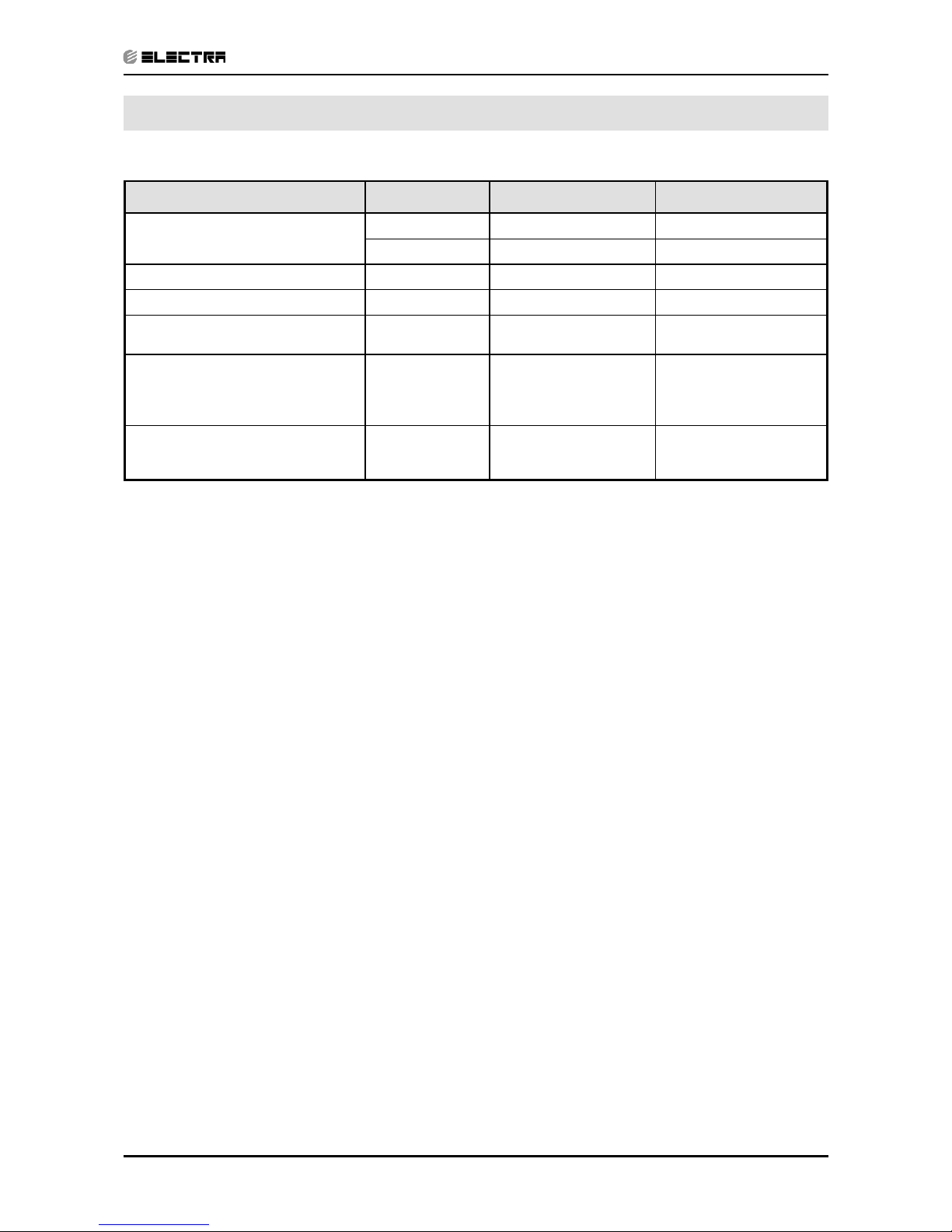

Page 22

6-2

SOUND LEVEL CHARACTERISTICS

Revision Y05-01 Service Manual - MOBILE Series

6.3 Sound Pressure Level Spectrum (Measured as Figure 2)

SP 11 Cooling SP 11 Heating

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

SP 16 Cooling

SP 16 Heating

Fig.2 Microphone Distance from Unit

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

OCTAVE BANDSOUNDPRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

Page 23

7-1

ELECTRICAL DATA

Revision Y05-01Service Manual - MOBILE Series

7. ELECTRICAL DATA

7.1 Single Phase Units

MODEL Monoblock 7 SP 11 SP 16

Power Supply

To indoor To indoor To indoor

1PH-230V-50Hz 1PH-230V-50Hz 1PH-230V-50Hz

Max Current, A 5.4 6.2 11

Circuit Breaker,A 10 10 15

Power Supply Wiring

(No. X Cross Section, mm2 )

3x1.0 mm

2

3x1.0 mm

2

3x1.5 mm

2

*Interconnecting Cable RC

Model (No. X Cross Section, mm2)

N/A

4x1.0 mm2 +2x0.5 mm

2

(OCT sensor)

4x1.0 mm2 +2x0.5 mm

2

(OCT sensor)

*Interconnecting Cable ST

Model (No. X Cross Section, mm2)

N/A 4x1.0 mm

2

4x1.0 mm

2

*Already connected on factory as standard

NOTE

Power wiring cord should comply with local lows and electrical

regulations requirements.

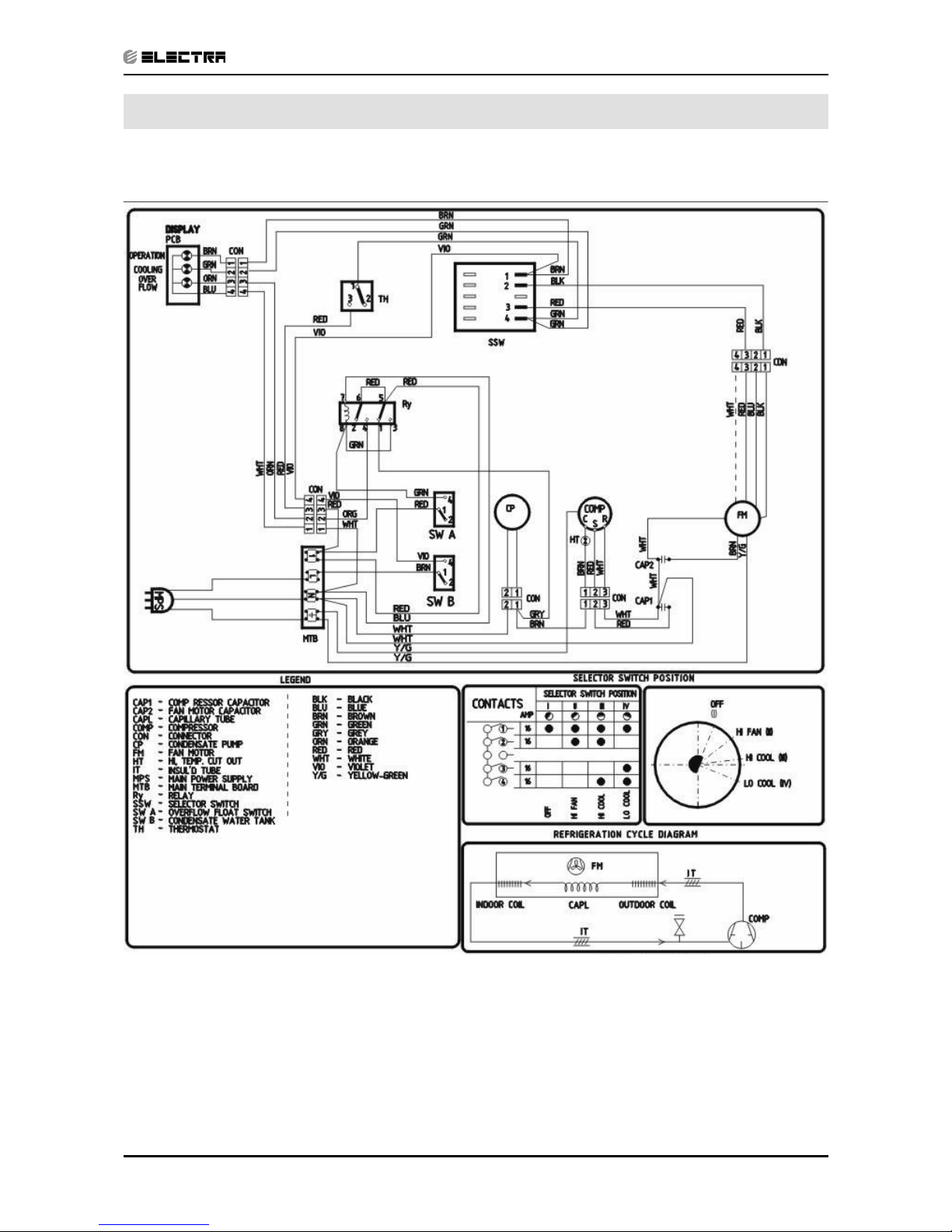

Page 24

8-1

WIRING DIAGRAMS

Revision Y05-01Service Manual - MOBILE Series

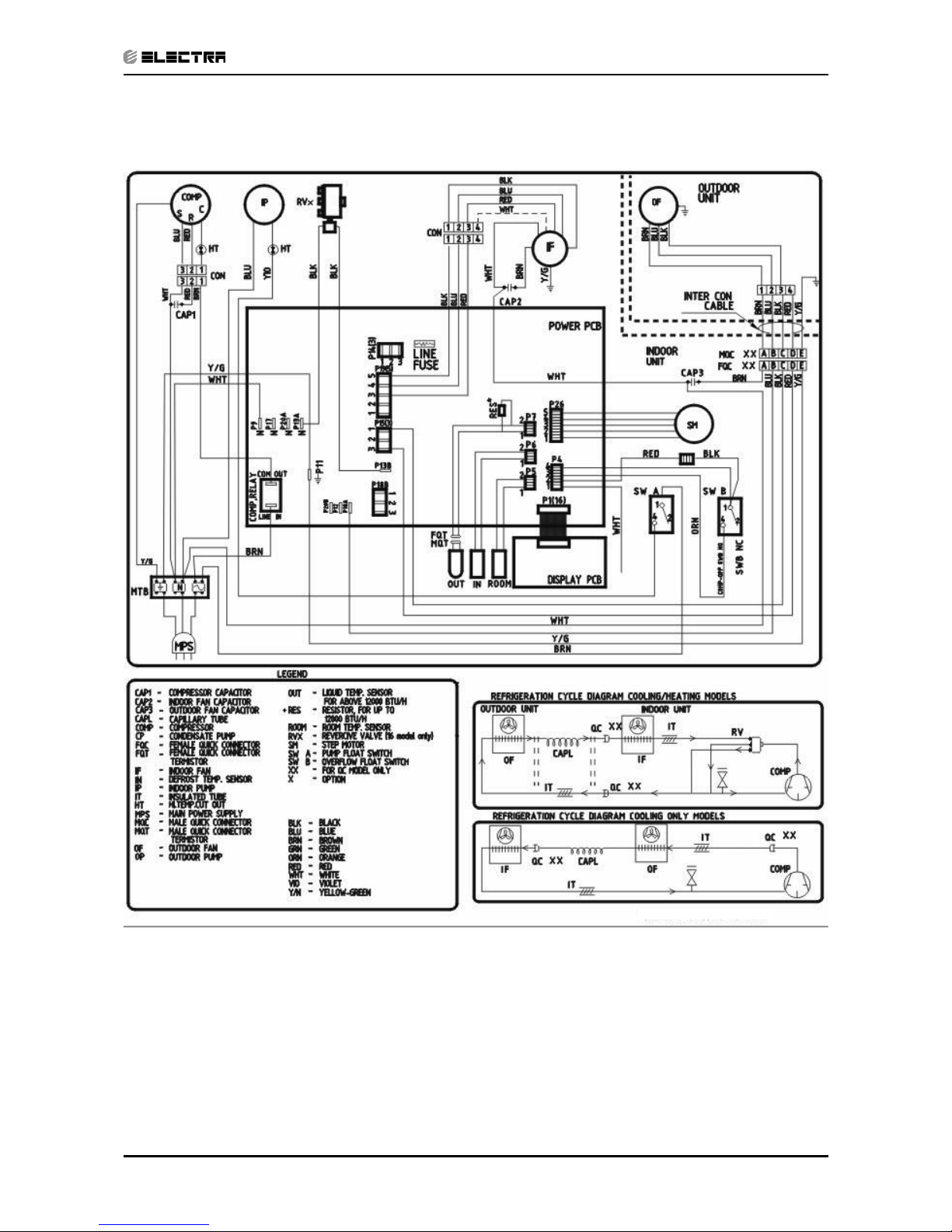

8. WIRING DIAGRAMS

8.1 Monoblock 7 (Mechanical Model)

Page 25

8-2

WIRING DIAGRAMS

Revision Y05-01 Service Manual - MOBILE Series

8.2 Monoblock 7 (Electronic Model)

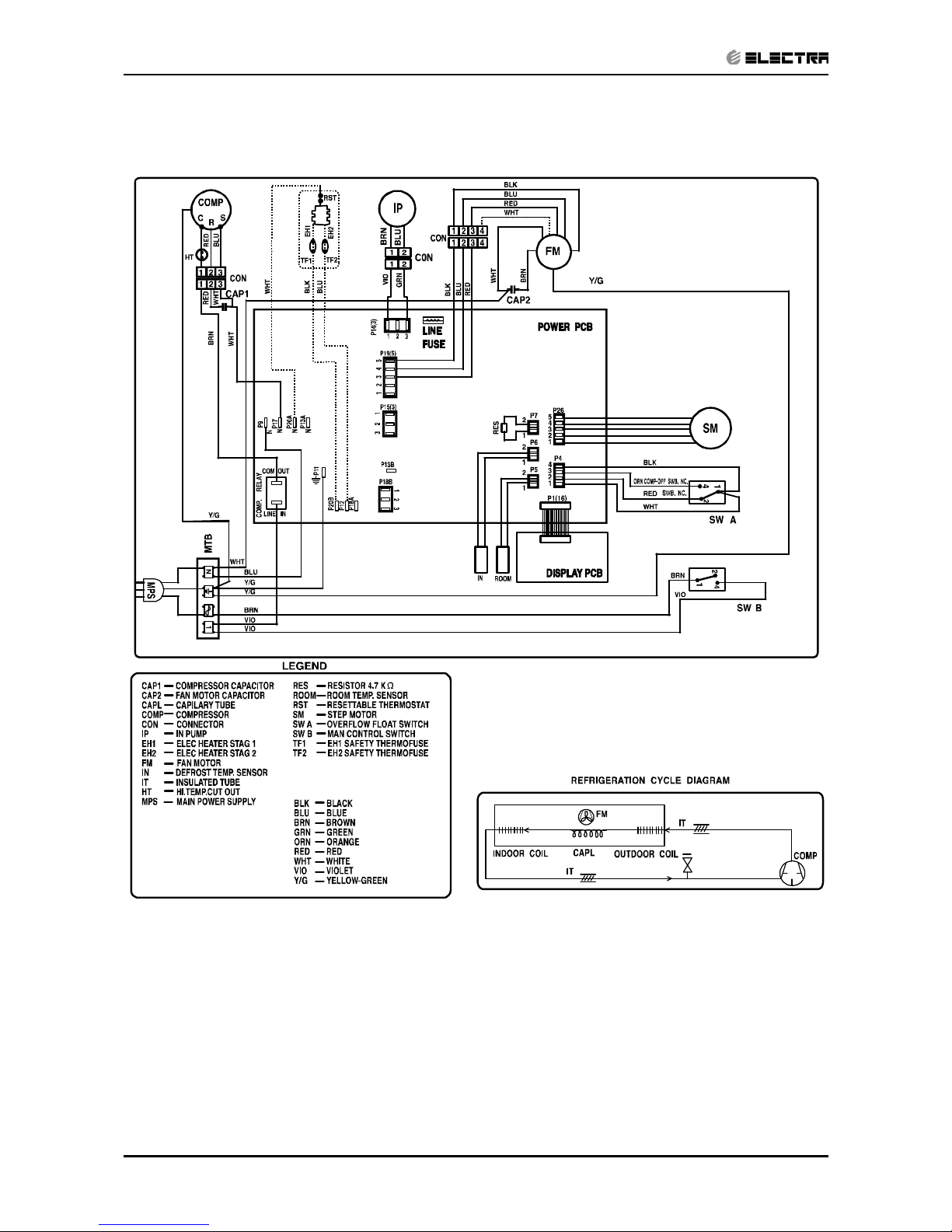

Page 26

8-3

WIRING DIAGRAMS

Revision Y05-01Service Manual - MOBILE Series

8.3 SP 11/16 (Electronic Model)

Page 27

8-4

WIRING DIAGRAMS

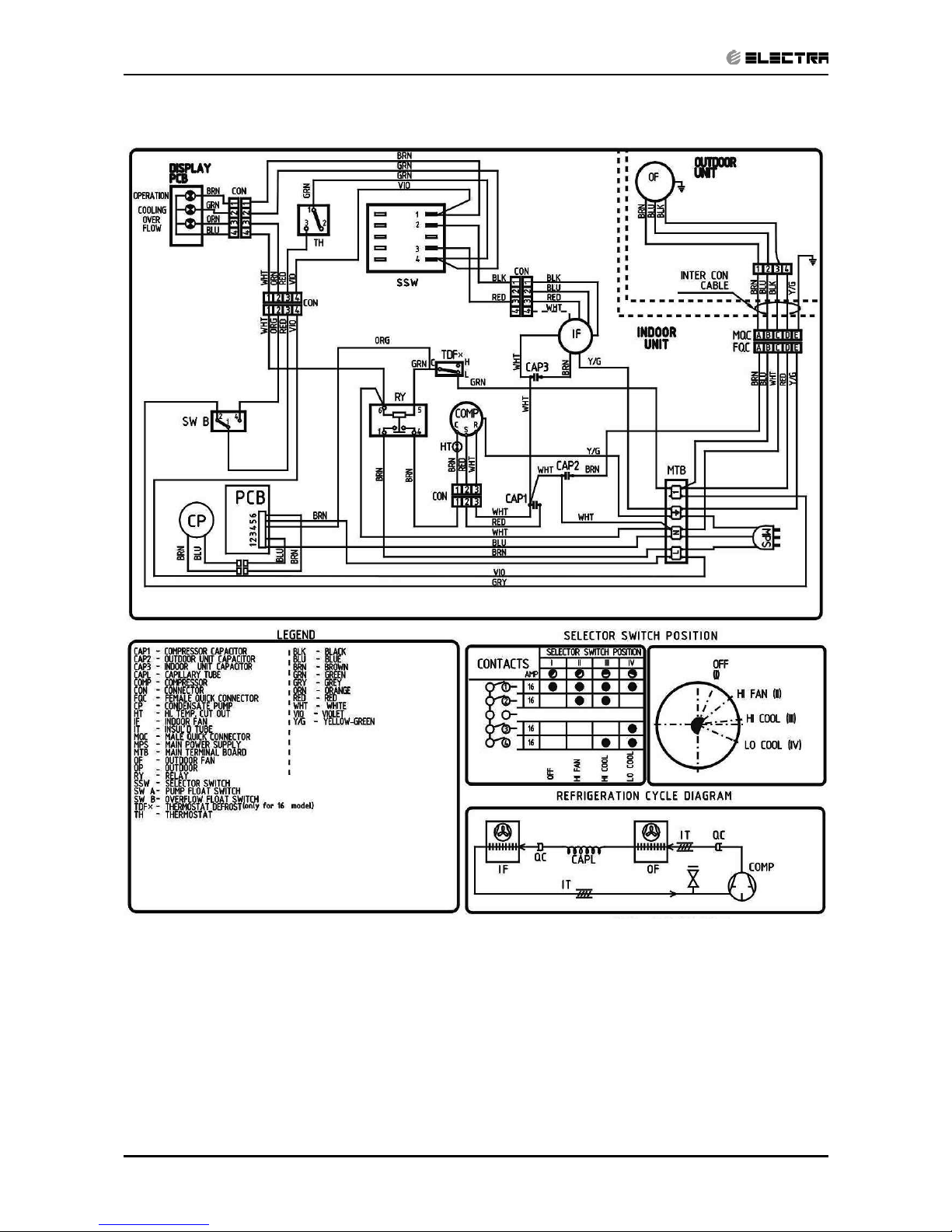

Revision Y05-01 Service Manual - MOBILE Series

8.4 SP 11/16 (Mechanical Model)

Page 28

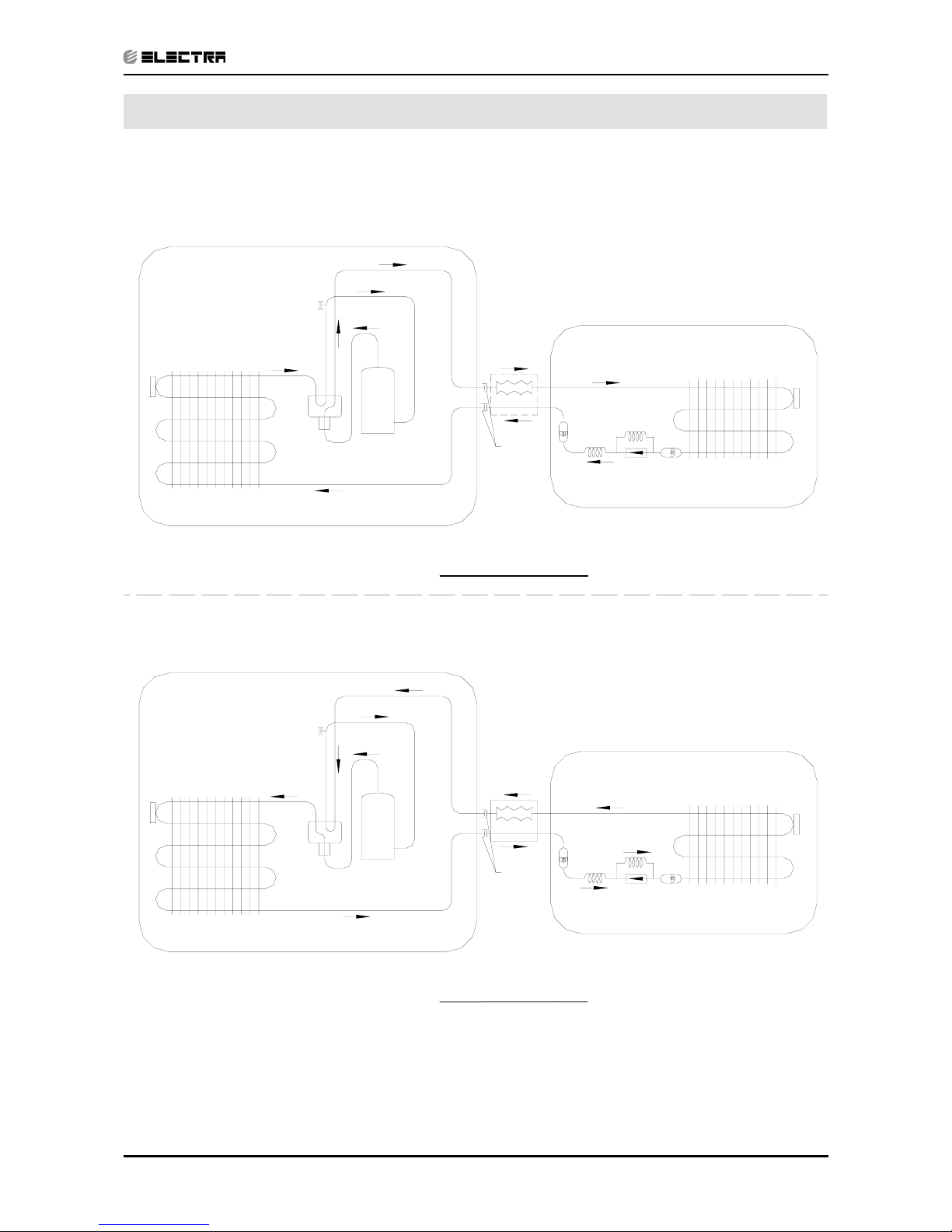

9-1

REFRIGERATION DIAGRAMS

Revision Y05-01Service Manual - MOBILE Series

9. REFRIGERATION DIAGRAMS

9.1 Heat Pump Models

9.1.1 SP11, 16 RC

HEATING MODE

Flexible

Tube

Quick

Connector

COOLING MODE

Flexible

Tube

Quick

Connector

INDOOR UNIT

Sensor

Indoor coil

valve

Reverse

Compressor

port

Service

*

INDOOR UNIT

Sensor

Indoor coil

valve

Reverse

Compressor

port

Service

*

Sensor

*

Opt i onal

*

Opt i onal

OUTDOOR UNIT

tube

Capillary

Filter

tube

Single

Valve

Capillary

Outdoor coil

Filter

Sensor

OUTDOOR UNIT

tube

Capillary

Filter

Single

Valve

Capillary

tube

Outdoor coil

Filter

*Optional

*Optional

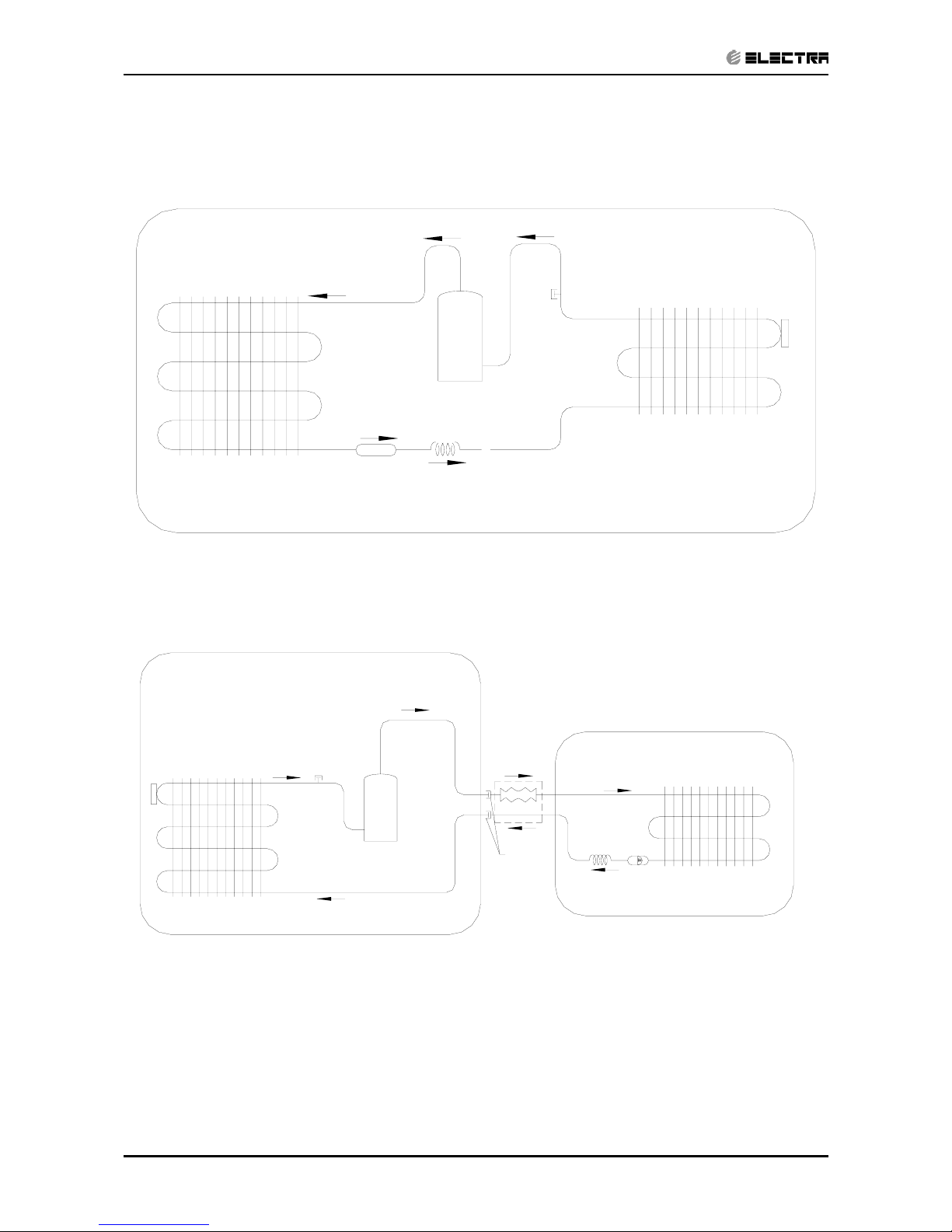

Page 29

9-2

REFRIGERATION DIAGRAMS

Revision Y05-01 Service Manual - MOBILE Series

9.2 Cooling Only Models

9.2.1 Monoblock 7 ST

10.2.2 SP 11, 16 ST

Capillary

tube

Condenser

Filter

Evaporator

Compressor

port

Service

Sensor

Indoor coil

Sensor

Service

port

Compressor

INDOOR UNIT

* Opt i onal

Filter

OUTDOOR UNIT

Quick

Connector

Flexible

Tube

*

Capillary

tube

Outdoor coil

*Optional

Page 30

10-1

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

10. CONTROL SYSTEM

10.1 Electronic Control

10.1.1 Introduction

The electronic control information is designed for service applications, and is common

to the following groups of air-conditioners:

• ST/ RC group -Cooling only / cooling and heating by heat pump.

• SH group -Cooling and heating by heat pump and supplementary

heater.

• RH group -Cooling, heating by heaters only.

10.1.2 Jumpers Settings

GROUP J6 Setting J2 Setting

ST / RC Open Open

SH Closed Open

RH Closed Closed

Model Plug

Page 31

10-2

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

10.2 Legend

AC - Alternate Current

A/C - Air-Conditioner

ANY - ON or OFF status

CLOCK - ON/OFF Operation Input, (dry contact)

COMP - Compressor

CPU - Central Processing Unit

ELUM - Extended Louver Upward Movement (Software Jumper)

E²PROM, EEP - Erase Enable Programmable Read Only Memory

HE - Heating Element

HPC - High Pressure Control

H/W - Hardware

ICP - Indoor Condensation Pump

ICT - Indoor Coil Temperature (RT2) sensor

IF, IFAN - Indoor Fan

IR - Infra Red

LEVEL1 - Normal Water Level

LEVEL2/3 - Medium/High Water Level

LEVEL4 - Overflow Level

Max - Maximum

Min - Minimum

min - Minute (time)

NA - Not Applicable

OCP - Outdoor Condensation Pump

OCT - Outdoor Coil Temperature (RT3) sensor

OF, OFAN - Outdoor Fan

OPER - Operate

Para. - Paragraph

RAT - Return Air Temperature (RT1) sensor

RC - Reverse Cycle (Heat Pump)

R/C - Remote Control

RCT - Remote Control Temperature

RH - Resistance Heater

RT - Room Temperature (i.e. RCT in IFEEL mode, RAT otherwise)

RV - Reversing Valve

SB, STBY - Stand-By

sec - Second (time)

Sect - Section

SH - Supplementary Heater

SPT - Set Point Temperature

ST - Standard (a Model with Cooling Only)

S/W - Software

TEMP - Temperature

W/O - Without

WVL - Water Valve

∆T - The difference between SPT and RT.

in Heat Mode: ∆T = SPT-RT

in Cool/Dry/Fan Mode: ∆T = RT-SPT

Page 32

10-3

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

10.3 Main PCB Controller

Page 33

10-4

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

10.4 General functions

10.4.1 COMP operation

For each Mode including POWER OFF & SB, a Min time delay of 3 min

before COMP restarting, excluding DEICING Mode

The Min operation time of COMP under different operating conditions is

Operation Mode

Min operation time of

COMP

Heat, Cool or Auto Modes 3 min.

Fan, Dry, Overflow, Protection modes, or mode change ignored

10.4.2 IFAN operation

• Min time interval between IFAN speed change in AUTOFAN Mode, is 30 sec.

• Min time interval between IFAN speed change in H/M/L Mode is 1 sec.

• IFAN speed in Heat/Cool Autofan Mode is determined according to the following table:

∆T IFAN Speed

∆T ≥ 2 HIGH

2 ≥ ∆T ≥ 1 MED

1 ≥ ∆T LOW

where in Heat Mode: ∆T = SPT-RT

in Cool Mode: ∆T = RT-SPT

Note:

• In Heat Mode, the rules in section 4.0.3 have the higher priority.

• The table above can be represent by a hysteresis curve which

will minimize the switching of the IFAN relay and will minimize the

change in IFAN speed:

T [oc]

L

M

H

IFAN speed

321

10.4.3 OFAN operation

• Min time interval between OFAN ON/OFF state change is 30 sec.

• In general, OFAN starts together with COMP.

10.4.4 HE operation

• Minimum Heaters ON or OFF time is 30 sec.

• Heaters can be activated only if IFAN is on.

Page 34

10-5

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

10.4.5 Protections

• High pressure protection is applicable to all operating modes.

• Deicing control is valid in Heat and Auto Heat Mode only.

• Defrosting control is valid in Dry, Cool, Heat and Auto Modes.

• No reset after protection modes.

10.4.6 Thermistors operation

• Return air Temp. is detected by RAT (RT1) in normal Mode, or by RCT (R/C sensor)

in I-FEEL Mode.

• Indoor Coil Temp. is detected by ICT (RT2).

10.4.6.1 Definition of thermistor faults:

a. Thermistor is disconnected The thermistor reading is below -30

o

c.

b. Thermistor is shorted The thermistor reading is over 75

o

c.

c. Thermistor Temp reading doesn’t change (irrelevant for RT1) -

(i) This test is performed only once after a unit is switched from

OFF/STBY to operation. At the first occurrence of 10 min

continuous COMP operation, the current ICT & OCT are

compared with those when the COMP was switched from OFF

to ON 10 min before. If the ∆T is less than 3

o

c, the thermistor is

regarded as defective.

(ii) The ICT and OCT no-change error can be disabled together by

connecting a4.7 kohm resistor (5%) to the OCT connector. These

resistors are equivalent to a thermistor at 43+/-1

o

c and 48+/-1oc

respectively.

(iii) Connecting a 4.7k resistor to the ICT connector will disable the

ICT no-change error only.

Page 35

10-6

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

10.4.6.2 Cases for disabling thermistor short/disconnected detection

i. The detection of thermistor faults (a) and (b) above, are disabled when Deicer

Protection is started. The detection will be enabled again only after (1) the

deicing is completed, and (2) COMP has been restarted and operated for 30

sec.

ii. When all the following conditions are fulfilled:

a. 4.7K Ohm resistor is connected on the OCT

b. IFAN is OFF

c. Compressor is ON

d. ICT < -30 (disconnected)

This condition come to detect and prevent IFAN operation in Deicer in multi spilt

units.

10.4.6.3 Handling the thermistor faults in a COMP unit

i. ICT/OCT thermistor is disconnected or shorted -

The invalid thermistor temperature is replaced by 43oc, so that the unit

can continue the normal operation. All protections related to that faulty

thermistor will be disabled. For example, in case of any ICT fault, the ICT

high pressure protection in Heat Mode and ICT defrost protection in Cool

Mode will not operate anymore. The same is also applied to the OCT fault.

ii. RAT thermistor is disconnected or shorted –

The RAT will be derived from the ICT by using the equations :

Heat Mode: RAT=ICT/2.3

Cool Mode RAT=ICT*4

Notes:

• In case of any thermistor failure, the STBY LED will be blinking until the

fault condition is corrected.

• User can use the system diagnostics function to find out the nature of

the thermistor faults.

i. RAT thermistor is disconnected or shorted –

System will operate continuously in the last IFAN & WVL status when

turned ON.

Notes:

• As in the COMP unit, the STBY LED will be blinking to indicate a

thermistor fault. And, the user can use the system diagnostics function

to find out the nature of the fault.

Page 36

10-7

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

10.5 Cooling Mode - General

1) Room Temperature, RT, is detected by

• RAT in normal operation, or

• RCT (R/C sensor) in I-FEEL mode.

2) The resolution of RT is 1oc.

• RT is activating COMP/WVL if (RT > SPT), and

• RT is stopping COMP/WVL if (RT =< SPT).

3) Indoor Coil Temp is detected by ICT (RT2).

4) Outdoor Coil Temp is detected by OCT (RT3).

5) A WVL-RC/SH will work in Cooling Mode when

• ICT < 16

o

c in general (see Sect 2.2.2 for details), and

• Unit is not operating in Fan Mode.

6) OFAN OPERATIONS

• OFAN starts together with COMP in general.

Page 37

10-8

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

10.5.1 Cooling

Mode: Cool, Auto (at Cooling)

Temp: Selected desired temperature.

Fan: HIGH, MED, LOW

Timer: Any

I Feel: On or Off

Control function

Maintains room temp at desired level by comparing RT and SPT.

(RT - SPT) [oc]

+3

+2

+1

0

-1

-2

ON

OFF

ON

OFF

USER FAN SPEED

ON

OFF

COMP

(WVL)

OFAN

IFAN

RV

Note:

1) IFAN is always running at High, Medium or Low speed selected by user.

2) In IFEEL mode, the Room Temperature (RT) is the RCT from a R/C. Otherwise, the

RT is the RAT from the Room Thermistor.

Page 38

10-9

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

10.5.2 Cooling with Autofan

Mode: Cool, Auto (at cooling)

Temp: Selected desired temperature

Fan: Auto

Timer: Any

I Feel: On or Off

Control function

Maintains room temp at desired level and controls the IFAN speed for optimal comfort.

(RT - SPT) [oc]

+3

+2

+1

0

-1

-2

ON

OFF

ON

OFF

H

L

M

ON

OFF

COMP

(WVL)

OFAN

IFAN

RV

Page 39

10-10

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

10.6 Heating Mode

10.6.1 Heating Mode - General

• In heating Mode, temp. compensation schedule will be activated for wall mounted

units.

SPT [oc]

Add to SPT

I-FEEL ON I-FEEL OFF

18 ≤ SPT ≤ 27 0

o

c+2

o

c

27 < SPT ≤ 30 0

o

c+3

o

c

Notes :

• No compensation will be activated in Forced operation modes

10.6.2 IF operating rules

• As a general rule for RC and SH groups, when COMP is ON, excluding

protection modes, IFAN will be switched ON if

• ICT > 35oc or

at the IFTC 30 sec after the COMP is switched ON. In

this case, the IFAN will be started at low speed.

Notes :

1) In SH or RC group, if HE is set to OFF due to low ICT, IFAN will be

switched to LOW and will be turned OFF after 30 sec.

2) An exception to this rule (4.0.3.a) is the Back-up mode for SH.

• In RC and SH groups, whenever COMP & HE are both

OFF, excluding protection modes, IFAN operation will be according

to the following:

In other models IFAN will operate in low speed for 30 sec and then stop. If

COMP is OFF for more than 3 minutes and IFEEL Mode is inactive, IFAN will

operate in low speed according to the following graph:

IFAN Speed

Any

Low

Stop

30 35 40

EMD/ELD

EMD/ELD

ICT [oc]

15 20 25

General :

For WAX :

SPT+4 SPT+6 ICT

[

o

c

]

ON

OFF

IFAN (Low Speed)

Page 40

10-11

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

10.6.3 HE operation

• For all Groups, HE can be ON only when IFAN is ON.

• For all Groups, HE switches to OFF when ICT > 50

o

c, and is activated

again when ICT ≤ 45oc.

• In SH or RC group, HE operation is limited by the following graph:

• Back-up mode for SH group

After COMP has been working for 5 minutes, HE & IFAN are activated even

if the ICT is still below 35

o

c. This situation is called Back-up Mode. Both

HE & IFAN will work in Back-up Mode until the ICT reaches 35oc. Then, the

operation goes on in the usual mode .

HE

ON

OFF

30

45 50

ICT [oc]

15

General :

For WAX :

35

20

40

Page 41

10-12

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

10.6.4 Heating, RC or SH Group

Mode: Heat, Auto (at heating)

Temp: Selected desired temperature

Fan: HIGH, MED, LOW

Timer: Any

I Feel: On or Off

Control function

Maintains room temp. at desired level by comparing RAT or RCT to SPT.

(RT - SPT) [oc]

+2

+1

0

-1

-2

-3

ON

OFF

ON

OFF

H/M/L

OFF

L

ON

OFF

Note 1 Note 2

COMP

(WVL)

HE1

HE2

IFAN

ON

OFF

RV

Page 42

10-13

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

10.6.5 Heating, RC or SH Group with Autofan

Mode: Heat, Auto (at heating)

Temp: Selected desired temperature

Fan: Auto

Timer: Any

I Feel: On or Off

Control function

Maintains room temp at desired level by controlling COMP, IFAN and OFAN.

(RT - SPT) [oc]

+2

+1

0

-1

-2

-3

ON

OFF

ON

OFF

H

OFF

L

M

ON

OFF

Note 1 Note 2

COMP

(WVL)

HE1

HE2

IFAN

RV

ON

OFF

Page 43

10-14

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

10.6..6 OFAN operation is controlled by the graph below when

1. (RAT ≥ SPT – 2oc), AND

2. (ICT ≥ 45

o

c), AND

3. (COMP is ON)

Otherwise, OFAN runs together with COMP.

OCT [oc]

+3

+2

+1

0

-1

OFAN

ON

OFF

Page 44

10-15

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

10.7 Automatic Cooling or Heating

10.7.1 Automatic Cooling or Heating - General

• Switching-temperature between Cooling and Heating is SPT ± 3oc.

• Autofan in Automatic Cooling and Heating Mode will activate “Cooling

with Autofan Mode” and “Heating with Autofan Mode” respectively.

• When the Auto Mode is started with SPT +/-0

o

c, the unit will not select

Auto Heat or Auto Cool mode immediately. Instead, the unit will be in

a temporary Fan Mode with IFAN operating at low speed.

The proper Auto Heat mode or Auto Cool will be started whenever the RT

reaches SPT-1oc or SPT+1oc respectively.

• For RC & SH units, Mode change between Auto Heat & Auto Cool

Modes is possible only after the COMP has been OFF during the

last T minutes.

Mode Change time, T

Auto Cool to Auto Heat 3 min

Auto Heat to Auto Cool 4 min

• When unit is changed form Cool/Dry mode to Auto Mode, the unit

will continue to operate at (Auto) Cool Mode until the conditions for

switching from Auto Cool to Auto Heat are satisfied.

Similarly, when unit is changed from Heat Mode to Auto Mode, the

unit will continue to operate at (Auto) Heat Mode until the conditions

for switching from Auto Heat to Auto Cool are satisfied.

Page 45

10-16

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

10.7.2 Auto Cooling or Heating, RC or SH Groups

Mode: Auto

Temp: Selected desired temperature

Fan: Any

Timer: Any

I Feel: On or Off

Control function

Maintains room temp at desired level by selecting between cooling and heating modes.

(RT - SPT) [oc]

+3

+2

+1

0

-1

-2

-3

ON

OFF

ON

OFF

H/M/L/OFF

L/OFF

ON

OFF

ON

OFF

COMP

& OFAN

HE1

HE2

IFAN

RV

H/M/L/OFF

L/OFF

USER FAN SPEED H/M/L/OFF

L/OFF

Auto Cool Mode Auto Heat Mode

> 4 min > 3 min

> 3 min > 2 min

(3) (3)

(4)

(4)

(5)

Auto Heat Mode

Page 46

10-17

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

10.8 Dry Mode

10.8.1 Dry, ST or RC group

Mode: Dry

Temp: Selected desired temp

Fan: Low (automatically selected by software)

Timer: Any

I FEEL: Any

Control function

Reduce room humidity with minimum temp. fluctuations by operating in Cool Mode with

low speed IFAN.

Notes :

• When Dry is ON, the COMP is forced OFF for 3.5 min (longer than the

3 min Min COMP-Off time) after every 15 min of continuous COMP

operation.

• When Dry is OFF, the COMP is forced ON for 6 min (longer than the 3

min Min COMP-On time) after every 15 min of continuous COMP OFF

time.

• When Dry is changed from ON to OFF or vice versa, the limits

mentioned in (1) & (2) are ignored. The COMP operation is only

controlled by the 3 min Min OFF time and 1 min Min ON time.

• In Dry Mode, IFAN is LOW when COMP is ON, and is OFF when

COMP is OFF.

DRY

(RT - SPT) [oc]

+2

+1

0

-1

-2

ON

OFF

ON

OFF

LOW

OFF

DRY-ON

DRY-OFF

ON

OFF

Time [min]

10

20

30

40 50

Max 15 minutes

3.5

min

Note1

6 min

Note 2

COMP

& OFAN

HE1

& HE2

IFAN

RV

Max 15 minutes

5 minutes COMP

ON time

Page 47

10-18

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

10.9 Protection

10.9.1 Cooling Mode Protections

Indoor Coil Defrost

Mode: Cooling, Dry, Auto

Temp: Selected desired temp.

Fan: Any

Timer: Any

I Feel: On or Off

Control Function

Protect the indoor coil from ice formation at low ambient temperature.

t1 = 5 min minimum for each COMP starting

t2 = OFAN cycling (alternate between ON and OFF every 30 sec) for 20 min

maximum

t3 = COMP and OFAN stop for 10 min minimum

Notes:

• When J7 is closed (connected), OFAN cycling is cancelled and the

set temperature for COMP & OFAN cut-out and cut-in are changed.

COMP & OFAN are forced OFF when ICT =< -6oc, and are kept OFF

until ICT > 14oc.

• For WAX model, the defrost processes is simpler. When J7 is open,

COMP & OFAN are forced OFF when ICT =< -1oc, and are kept OFF

until ICT > 5oc. When J7 is closed, the WAX defrosting process is the

same as that of the other models (R.H.S. of the graph above). In both

cases, the ICT checking in t2 and t3 are not applied.

ICT [oc]

+2

ON

OFF

ON

OFF

t1 t2 t3

COMP

OFAN

+1

+5

+14

0

-1

-6

ON

OFF

IFAN

J7 OPEN J7 CLOSED

t1 t1

Page 48

10-19

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

10.9.2 High Pressure Protection

Mode: (Auto) Cooling or Dry

Temp: Selected desired temp.

Fan: Any

Timer: Any

I Feel: On or Off

Control Function

To protect the COMP from the high pressure built-up in the outdoor coil during normal

cooling operation, by switching OFF the IFAN and COMP.

OCT [oc]

Any

OFF

Any

ON

Any

Blink

ON

COMP

OFAN

IFAN

OPER

LED

52

55

61

66

L

COMP is forced OFF

OFAN is forced ON

IFAN forced

to LOW

68

OFAN follow operation of

COMP

COMP is forced OFF

OFAN is forced ON

For all models except WAX & P2000 For WAX & P2000 models

Note:

• The ICT is also monitored during Cool and Dry mode, in case the RV control circuit

is faulty. Whenever ICT reaches 70oc, which indicates a high pressure in the indoor

coil, the COMP will be forced off automatically. The COMP can be turned on again only

after the ICT is under 70oc again and after the 3 min COMP ON delay time. The OPER

LED will not blink in this case.

Page 49

10-20

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

10.9.3 Heating Mode Protections

Outdoor coil Deicing (excluding RH Group)

Mode: Heating, Auto (at heating)

Temp: Selected desired Temp

Fan: Any

Timer: Any

I FEEL: Any

Control function

Protects the Outdoor coil from ice formation by controlling COMP & RV operation.

Scope

This new deicer is designed to operate at extreme temp conditions. The deicing cycle

could be triggered from:

1. OCT temp and time between two consecutive deicing cycles.

2. Detection of ice forming by change of the OCT temp.

Both algorithms adjust the time between deicing cycles to optimize the A/C

performance. The algorithm will automatically increase the time between deicing cycles

and reduce the deicing cycle as needed.

The algorithm uses EEPROM data to operate.

Page 50

10-21

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

Deicing procedure

OCT [oc]

ON

OFF

ON

OFF

ON

L

ANY

COMP

OFAN

RV

IFAN

DST

(DDT)

0

12

OFF

HEs are forced ON

DOC

ANY

ON

HE

36s 36s

DT

30s

max 12 min.

Note 3

DI (note 1)

DI (note 2)

30s

3 min 3 min

IFAN

OFF

ANY

HE

OFF

ANY

all SH units

except WAX

RC or WAX units

HEs are forced OFF

IFAN is forced to Low Speed

BLINK

ON

OPER

LED

Notes :

• At the first COMP activation after SB or OFF, if (OCT < 0oc), then DI = 10

min, else DI = 40 min.

• In the following Deicing cycles, the time interval between two Deicing

cycles activation is between 30 to 80 min (refer to the flow chart).

• For RC group, HEs are forced OFF. IFAN operation is as in Heat

Mode, Sect 4.0.3.a, i.e. IFAN will be set to OFF when ICT<30

o

c.

For WAX, the IFAN is simply forced OFF.

• For SH group, HEs are forced ON and IFAN is forced to operate in Low

speed, regardless of the ICT and difference between RAT & SPT.

Page 51

10-22

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

10.9.4 High pressure protection (excluding RH Group)

Mode: (Auto) Heating

Fan: Any

Timer: Any

I Feel: On or Off

Control Function

Protect the Compressor from high pressure by switching OFF the OFAN and COMP.

ICT [oc]

Any

Off

Any

Off

COMP

OFAN

52

55

61

66

COMP is forced OFF

67

OFAN is force

Off

COMP is forced OFF

For all models except WAX For WAX model

ON

BLINK

OPER

LED

Notes:

• IFAN, HE1 and HE2 will be activated according to the relevant

Heating Mode Sect.

• In case of any malfunction in the relay control circuit, the OCT is also

monitored during heating mode. Whenever OCT reaches 70

o

c, which indicates

a high pressure in the outdoor coil, the COMP will be forced off automatically.

The COMP can be turned on again only after the 3 min COMP ON delay and the

OCT is under 70oc. The OPER LED will not blink in this case.

Page 52

10-23

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

10.9.5 Indoor Condensation Pump (ICP) Operation and Overflow

Protection (PXD, P2000 and MBX Models)

Mode: Cooling, Dry, Auto (at Cooling)

Temp: Desired temp selected

Fan: Any

Timer: Any

I Feel: On or Off

Control function:

To prevent the overflow of condensed water by turning ON the ICP.

Notes:

• When water level reaches LEVEL 4, ICP will be turned ON even if the unit is

in SB mode.

• Under normal operation, at least one of the water level inputs must be active.

If all LEVEL1, LEVEL2&3 and LEVEL4 are inactive, it is assumed that the

connection has been broken and the ICP will be turned ON when the unit is

operating in Cool or Dry mode.

• The operation of the pump is not related to the ON/OFF state of the COMP.

On the contrary, the COMP can be forced to OFF when the water level is high

(level 4).

• The water level inputs are low active. That is, when a water level is reached,

the voltage at the corresponding input pin of the MCU would be changed from

5V (inactive) to 0V (active).

Water Level

ANY

OFF

BLINK

COMP

& OFAN

FILTER LED

LEVEL1

LEVEL2&3

LEVEL4

NORMAL

ON

ICP

OFF

Page 53

10-24

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

10.9.6 Outdoor condensation pump (P2000 Model)

Mode: Cooling, Auto (at Cooling), Dry.

Temp: Selected Desired temp.

Fan: Any

Timer: Any

Feel: On or Off

Control Function

Pumps condensed water from Indoor unit to Outdoor unit.

Outdoor Condensation Pump Control

The Outdoor pump relay is activated in parallel with the COMP at: Cooling, Dry, and Auto

cooling as described in the following table:

COMP Condensation Pump

ON ON

OFF OFF

Note:

• In Heating Mode, OCP is OFF.

Page 54

10-25

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

10.10 Timer

Mode: Any

Temp. Selected desired temp

Fan: Any

Timer: Timer On, Timer Off

I Feel: On or Off

Control function

• Starts or stops the unit operation after pre-set time. If RC-1 is used,

the timer setting will be (0.5 - 24 Hr) from the moment the timer is set.

The minimum resolution is 30 minutes.

If RC-2 or later version of remote controls is used, the timer

setting will be (0:00 - 23:50) real time with 10 minutes resolution.

• After power failure, all pre-set timers are cleared. The system is

forced to STBY mode and the Timer LED indicator is blinked to

indicate the situation. The LED keeps blinking until the timer settings

can be reloaded from a R/C message.

Note: If all timers are inactive, the system will not be forced

OFF after the power failure. The last OPER/STBY status will

be loaded from the EEP instead.

• When the A/C receives any valid message from a R/C, the current

ON/OFF timer settings will be replaced by the new timer settings in

the R/C message.

Note: The following timer related operations will not affect the

A/C operating mode (Heat/Cool/Auto/Dry/Fan) setting.

• Set ON/OFF timer

• Clear ON/OFF timer

• R/C ON Timer is time-up

• R/C OFF Timer is time-up

E.g. When a STBY A/C unit (with Cool Mode setting in its EEP) is

turned on by the ON-TIMER of a R/C with heat mode setting,

the A/C will start in Cool Mode.

Page 55

10-26

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

10.11 Forced Operation

Forced operation allows units to start, stop and operate in Cooling or Heating in pre-set

temperature according to the following table:

Forced operation

mode

Pre-set Temp for ;

MBX, P2000, PRX,

PX, PXD models

Pre-set Temp for :

FCD, RWK, ELD, ECC,

WAX, WMF, WMN, WNG

models

Cooling 20°C22°C

Heating 25°C28°C

Note:

• While under the forced operation, the temperature compensation

schedule.

• The forced operation is activated when the mode button on the

Display Board is used to switch the unit to Cool or Heat mode.

• The IFAN is always set to Autofan Speed in forced operation.

Page 56

10-27

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

10.12 Sleep Mode

Mode: Any

Temp: Set – desired temperature selected

Fan: Any

Timer: Interact with Sleep Timer as described in sect 12.2

I Feel: On or Off

The Sleep mode is activated by using the sleep button on the R/C. In Sleep Mode,

the unit will automatically adjust the SPT to turn up/down the room temperature (RT)

gradually to provide maximum comfort to the user in sleep.

Sleep is treated as TIMER function. Therefore, the TIMER LED is activated similar to

TIMER function.

10.12.1 Adjustment in Sleep Mode

1. in cool, auto cool or dry modes, the SPT adjustment is positive (from 0 to +3oc).

2. In heat or auto heat modes, the SPT adjustment is negative (from 0 to -3

o

c).

3. In other modes, there is no SPT adjustment.

4. The SPT adjustment is cancelled when the Sleep mode is cancelled.

Note: If Off-timer is active, the unit may go to SB before or after 7 hours of

sleep operation.

SPT

Time [Hr]

485326

Start

Sleep

7

RT

SPT-1

SPT-2

SPT-3

SPT+2

SPT+1

SPT+3

1

7 Hours Sleep operation

for Normal Sleep Mode

Unit is turned to SB

after Sleep

Cool, Dry modes

Heat mode

Page 57

10-28

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

10.12.2 Time adjustment in Sleep Mode

The user can make use of the Off-Timer to extend the Sleep Time from 7 hours to 12

hour (max). The operation of the new “Extended Sleep Mode” is illustrated by the

graphs below.

Case 1 is the Standard Sleep Mode, which is the only sleep mode in previous version

of MCU. The A/C unit simply works for 7 hours, then goes to SB.

Case 2 is the new Extended Sleep Mode. If an active Off-Timer is set to turn off the

A/C between 7-12 hour, relative to the starting of Sleep, the Sleep time is extended.

And, instead of going to SB at the 7th hour, the A/C will work until reaching the Off-time.

Case 3 is an exception to case 2. The Sleep Mode will not be extended to the Off-Time

when the Off-Timer is preceded by an On-Timer, which is also between 7-12 hour.

Oper

Time [Hr]

48101226

Start

Sleep

7

Case 1 : Standard Sleep Mode

Condition : Off-timer is not set or is beyond 12 hour.

SB

Oper

Time [Hr]

48101226

Start

Sleep

7

Case 2 : Extended Sleep Mode

Condition : Off-timer is set at 7-12 hour.

SB

Off-timer

Oper

Time [Hr]

48101226

Start

Sleep

7

Case 3 : Exception to Case 2

Condition : Off-timer is set at 7-12 hour

On-timer is set at 7-12 hour and before Off-timer

SB

Off-timerOn-timer

Page 58

10-29

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

10.13 Clogged Air Filter

Filter LED ON after 512 HR.

Filter LED is turned OFF, and the Filter Timer is restarted by pressing the reset button.

Page 59

10-30

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

10.14 Controller Self-Test Procedure

10.14.1 By Shorting Test Jumper J1

RC/ST TEST

MODEL

CONFIGURATION

TEST

STEP MOTOR TEST

FREQUENCY

TEST

LEDS OFF

LEDS ON TEST

AUTO RELAY

TEST

SHORT JUMPER

J1

(CONTROL PCB)

PRESS ON

POWER

BUTTON

PRESS ON

MODE BUTTON

INDOOR FAN

SPEED TEST

SELF-TEST FLOW CHART

Step 1

Step 2

Step 3

FOR CONTROLLER (VERSION 4V5 OR HIGHER)

COOL

HEAT

COMPRESSOR

OUTDOOR FAN

R.V.

LOW

MEDIUM

HIGH

TIMER

OPERATE

STANDBY

BUZZER TEST

(ONE BEEP SOUND)

REMOTE CONTROL

TO CPU COMUNICATION

(TWO BEEPS SOUNDS)

THERMISTOR ANALOG

VOLTAGE CHECKING

EEPROM MEMORY

TEST

END OF SELF

TEST

PRESS ON RESET

BUTTON

PRESS ON FAN

BUTTON ON THE

REMOTE CONTROL

PRESS ON MODE

BUTTON

PRESS ON MODE

BUTTON

Step 4

Step 5

Step 6

Step 7

Step 8

DISCONNECT

JUMPER

J1

Page 60

10-31

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

10.14.2 By Remote Control Settings:

a. 1: TURNING ON THE POWER.

Turn ON the power, make sure that the unit is in operation.

b. STEP 2 : ENABLE SELF-TEST MODE

• Use the remote control to send the first settings to display / indoor unit

HEAT mode, HIGH IFAN, set temperature to 16 ºC, no I-FEEL Sleep or

any other timer settings are needed.

• Cover the IR transmitter components in the remote control so that it will

not transmit the signals to the indoor unit display.

• Use the remote control to send the second settings to display / indoor unit

COOL mode, LOW IFAN, no I-FEEL Sleep or any other timer settings.

• Uncover the remote control IR transmitter and change the temperature

settings. If the display/indoor unit receive the settings properly the

following steps will start:

c. STEP 3: MODEL SETTING CONFIRMATION

• The STAND-BY and COOL LEDS will indicate the operation mode as

follows:

OPERATION MODE STAND-BY LED COOL LED

ST ON OFF

RC OFF OFF

SH OFF ON

RH ON ON

• Testing the Model configuration. Selected by the COMP, STAND-BY,

TIMER LEDS and FILTER will indicate the model configuration as follows

(the relevant line for this manual is highlighted):

MODEL COMP OPERATE LED TIMER LED FILTER LED

WNG ON OFF OFF OFF

WMN1 ON ON OFF ON

WMN4 OFF OFF ON OFF

WMN2/WHX OFF ON OFF ON

WMN3 OFF ON ON ON

P2000 OFF OFF OFF ON

In this term the step motor will turn to HOME POSITION.

Page 61

10-32

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

d. STEP 4 : AUTO LED WALK TEST.

• All the LEDS will turn OFF.

• All the LEDS will turn ON for 1 second one by one in the following

sequence:

STAND-BY OPERATE TIMER FILTER COOL HEAT.

• In PRX all the LEDS will turn ON for 1 second one by one in the following

sequence : 18 °c 20 °c 22 °c 24 °c 26 °c 28 °c 30 °c

High IFAN Auto IFAN Med IFAN Low IFAN STAND-BY

TIMER FILTER COOL HEAT.

e. STEP 5: AUTO REALY WALK TEST:

• All relays will energize one by one in the following sequence:

COMPRESSOR OUTDOOR FANR. V. HEATER 1 HEATER 2

INDOOR WATER PUMP SWING or OUTDOOR WATER PUMP

INDOOR FAN: LOW MID HIGH.

• When the relay walk test is completed, the next test will start

automatically.

f. STEP 6: FREQUENCY TESTING:

• If the frequency measuring process fails the COOL LED will turn ON.

In order to move to the next step, press ON/OFF button on the remote

control.

g. STEP 7: INPUT TEST.

• The test purpose is to check the analog real time indicators (thermistors,

LEVEL and clock) according to the table below.

LED Indicator Condition for LED to be ON

STBY LED Room thermistor ≠ 25°c

OPER LED Indoor coil thermistor ≠ 25°c

TIMER LED Outdoor coil thermistor ≠ 25°c

FILTER LED Clock

COOL LED LEVEL 2&3

HEAT LED LEVEL 4

h. STEP 8: TIMING RESET TEST (WATCH DOG).

• The test purpose is to verify that the CPU rise time after power failure

is between 1 to 3 sec, test results are indicated on the LEDS : STANDBY,OPER, TIMER and FILTER turning ON one by one.

• The results of the test are coded as follows:

Pass condition:

1 sec - STAND-BY and OPER are turned ON

2 sec - STAND-BY, OPER and TIMER are turned ON

Page 62

10-33

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

Fail condition:

0 sec - STAND-BY is turned ON

3 sec - STAND-BY, OPER, TIMER and FILTER are turned ON

• When the timing reset test is completed, the next test will start

automatically.

i. STEP 9: MEMORY TEST (EEPROM)

• The test purpose is to check if the memory is functioning correctly. The test

result is reported by using the STAND-BY and FILTER LEDS:

LED Indicator Condition for LED to be ON

STAND-BY LED Test passed

FILTER LED Test failed

AT THIS POINT THE SELF-TEST IS COMPLETED.

In order to terminate Self-Test mode the User can change the unit setting from COOL

Mode, LOW FAN to COOL Mode, MED FAN or to wait without using the remote control

for 60 sec.

Values of Sensors Temperature VS. Voltage (DC)

Temp. (*C) Voltage (V) Temp. (*C) Voltage (V) Temp. (*C) Voltage (V) Temp. (*C) Voltage (V)

-20 4.554 2 3.744 24 2.555 46 1.487

-19 4.529 3 3.695 25 2.5 47 1.447

-18 4.502 4 3.646 26 2.445 48 1.409

-17 4.475 5 3.595 27 2.391 49 1.371

-16 4.446 6 3.544 28 2.338 50 1.334

-15 4.417 7 3.492 29 2.284 51 1.298

-14 4.386 8 3.439 30 2.232 52 1.263

-13 4.354 9 3.386 31 2.18 53 1.228

-12 4.322 10 3.332 32 2.128 54 1.195

-11 4.287 11 3.278 33 2.077 55 1.162

-10 4.252 12 3.223 34 2.027 56 1.13

9 4.216 13 3.168 35 1.978 57 1.099

-8 4.178 14 3.113 36 1.929 58 1.069

-7 4.14 15 3.058 37 1.881 59 1.04

-6 4.1 16 3.002 38 1.834 60 1.011

-5 4.059 17 2.946 39 1.798 61 0.983

-4 4.017 18 2.89 40 1.742 62 0.956

-3 3.974 19 2.833 41 1.698 63 0.929

-2 3.93 20 2.777 42 1.654 64 0.904

-1 3.885 21 2.722 43 1.611 65 0.879

0 3.839 22 2.666 44 1.569 66 0.854

1 3.792 23 2.61 45 1.527 67 0.831

Page 63

10-34

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

10.15 On Unit Indicators and Controls

STAND BY

INDICATOR

Lights up when the Air Conditioner is connected to power and

ready to receive the R/C commands

Blinks continuously in case of any thermistor failure.

OPERATION

INDICATOR

Lights up during operation.

Blinks for 300 ms, to announce that a R/C infrared signal has

been received and stored.

Blinks continuously during

• OCT High Pressure Protection Mode

• ICT High Pressure Protection Mode

• Deicing in Heating Mode

• Water Over Flow in ECC Model

TIMER INDICATOR Lights up during Timer and Sleep operation.

FILTER INDICATOR

Lights up when Air Filter needs to be cleaned.

Blinks during Water Over Flow in MBX/P2000 models.

COOLING

INDICATOR

Lights up when system is switched to Cool Mode by using the

Mode Switch on the unit.

Show the thermistor status in Diagnostic Mode

HEATING

INDICATOR

Lights up when system is switched Heat Mode by using the

Mode Switch on the unit.

Show the thermistor status in Diagnostic Mode.

MODE BUTTON

(Cool, Heat, SB)

Use to cycle the operation mode of the A/C unit among COOL,

HEAT and SB modes, without using the R/C.

Every time this switch is pressed, the next operation mode is

selected, in this order :

SB Cool Mode Heat Mode SB ...

Press this button continuously for 5 sec or more to start the

Diagnostic Mode.

RESET / FILTER

BUTTON

When the Filter LED is ON, press to turn off the Filter LED

after a clean filter has been reinstalled.

When the Filter LED is OFF, use this button to enable/disable

the buzzer announcer.

Page 64

10-35

CONTROL SYSTEM

Revision Y05-01Service Manual - MOBILE Series

10.16 Clock Random Delay From 0 to 2.5 seconds

0 = Clock Switch Open

1 = Clock Switch close

The Clock is activate according to the following table:

A/C STATE

(before clock is changed)

CLOCK STATE

(before clock is changed)

CLOCK ACTION

(clock is changed)

A/C NEW STATE

(after clock is changed)

ON 1 0 OFF

OFF 0 1 ON

OFF by

interrupt

(1)

1 0 OFF

ON by

interrupt

(1)

01ON

Notes :

1. Clock can be interrupted by :

• R/C - POWER ON/OFF Push-button.

• R/C - TIMER.

• R/C - SLEEP.

• A/C - MODE SWITCH.

2. Any change in the CLOCK level during the first 6 sec after the system

Reset is ignored.

Page 65

10-36

CONTROL SYSTEM

Revision Y05-01 Service Manual - MOBILE Series

10.17 System Diagnostics

Pressing Mode button for 5-10 seconds in SB or any other operation mode will activate

diagnostic mode by the acknowledgment of 3 short beeps and lighting of COOL and

HEAT LEDs.

In diagnostic mode, system problems will be indicated by blinking of Heat & Cool LEDs.

The coding method will be as follow:

Heat led will blink 5 times in 5 seconds, and then will be shut off for the next 5 seconds.

Cool led will blink during the same 5 seconds according to the following table:

No Problem ○○○○○

1 RT1 is disconnected ○●●●●

2RT1 is shorted ○●●●○

3 (Reserved) ○●●○●

4 RT2 is disconnected ●○●●●

5RT2 is shorted ●○●●○

6 (Reserved) ●○●○●

7 RT2 temp reading doesn’t change ●○●○○

8 RT3 is disconnected ●●○●●

9RT3 is shorted ●●○●○

10 (Reserved) ●●○○●

11 RT3 temp reading doesn’t change ●●○○○

12 RT2 & RT3 temp reading doesn’t change ●○○○○

○ - ON, ● - OFF

Notes:

1. If faults occur in more than one thermistor (except case number 12 on the

table above), only one fault will be indicated according to the following order:

RT3, RT2, RT1.

2. A/C will jump out to normal mode if sending a command by the R/C in the

system diagnostics mode. If this command from the R/C contain a Group ID, this

ID will become the new Group ID of the ELCON unit.

Page 66

11-1

TROUBLESHOOTING

Revision Y05-01Service Manual - MOBILE Series

11. TROUBLESHOOTING

CONNECT THE AIR CONDITIONER TO

POWER SUPPLY.

DOES THE ST ANDBY

INDICATOR LIGHT UP?

START THE UNIT BY THE REMOTE

CONTROL.

START THE UNIT BY THE

ON UNIT CONTROL.

DOES THE SOPERATING

INDICATOR LIGHT UP?

IS THE CONTROLS SET

PROPERLY?

DOES THE

SOPERATING

INDIC ATOR LIGHT

UP?

IS THERE CO RRECT

VOLTAGE BETWEEN THE

LINE AND NEUT RAL

TERMINALS ON THE MAIN

P.C.B?

REPLACE MAIN P.C.B OR DISPLAY P.C.B

DOES THE OPE RATION

INDICATORS LIGHT UP

WHEN STARTING FROM ON

UNIT PANEL CNTROL.

IS THERE VO LTAGE BETWEEN THE

CONDENSATE PUMP TERMINALS ON

THE MAIN P.C.B?

IF LOW OR NO VOLTAGE, REPAIR POWER

SUPPLY.

REPLACE BATTERIES OR RESET THE

REMOTE C ONTROL, OR REPLACE P.C.B.

REPLACE MAIN P.C.B OR DISPLAY P.C.B

SET THE REM OTE CONTROL

DOES THE CO NDENSATE

SYSTEM FUNCTION

CORRECTLY?

REPLACE MAIN P.C.B

IS THERE VOLTAGE BETWEEN THE

CONDENSATE PUM P TERMINALS ON

THE MAIN P.C.B?

DOES THE CO NDENSATE FLOAT OR

FLOAT SWITCH FUNCTIONS

PROPERLY?

REPAIR OR REPLACE FLOAT OR M ICRO

SWITCH

REPAIR WATER TUBING OR REPLACE

PUMP

CHECK ELECTRIC AL WIRING OR

REPLACE CAPACIT OR OR MOTOR

RESISTOR OR FAN.

DOES THE INDOO R FAN

FUNCTION CORRECTLY ?

REPLACE MAIN P.C.B

IS THERE VO LTAGE ON THE TPUMP

TERMINALS ?

IS THERE VOLTAG E BETWEEN THE

TERMINALS ON THE MAIN P.C.B?

IS THERE VOLTAGE BETWEEN

INDOOR FAN TE RMINALS ON THE

MAIN P.C.B?

REPLACE CAPACITOR OR O UTDOOR FAN

OR PUMP

IF NO VOLTAG E REPLACE MAIN P .C.B - IF

LOW VOLTAGE REPAI R PO WER S UPPLY.

REPLACE CAPACI TOR OR OVER LOAD

PROTECTOR O R COMPRESOR.

DOES THE OUTDOOR FAN

OR OUTDOOR

CONDENSATE P UMP

FUNCTION CORRECTLY ?

DOES THE OVER

FLOW SWI TCH

FUNCTION

CORRECTLY?

DOES THE COMPRESSOR

START UP ( CHECK WITH

AMPMETE R)

REPAIR ELECTRI CAL WIRING

IS THERE C ORRECT VOLTAGE

(AT START) BETWEE N THE

COMPRES SOR TERMINALS ON THE

MAIN P.C.B?

IS THERE C ORRECT VOLTAGE

(AT START) ETWEEN COMPRESSOR

TERMINALS ?

DOES THE

REFRIGERATION SYSTEM

FUNCTION CORE CTLY FOR

COOOLING AND HEATING

*?(CHECK WITH

AMPMETER AND OR

PRESSURE GUAGES OR

SURFACE THERMOMETER

CHECK FOR LEAKS O R TUBING RESTRICTION,

REPAIR REFRIGERATION SYSTEM AND

CHARGE REFRIG ERANT IF NECESSARY.

CHECK IF 4-WAY REVE RSING VALVE GETS

POWER (FOR HEATI NG) OR IS DISCONNECTE D

(FOR COOLING), IF VALVE DOES NOT

FUNCTION REPAIR WITH ASSOCIATED

TUBING .

NORMAL

CHECK AND REP AIR ELECTRICAL WIRING

REPLACE MAIN P.C.B

CHECK AND REP AIR ELECTRICAL WIRING

DRAIN THE COND ENSATE OR REPAIR

FLOAT OR OVERFLOW SWITCH.

No Yes

No

No

No

No

Yes

No

No

Yes

Yes

No

No

No

No

No

No

No

Yes

No

No

No

IS THERE VOLTAGE O N THE

TERMINALS BL OCK OF THE

OUTDOOR SECTION?

Yes

No

Yes

Yes

Yes

No

Yes

MOBILE SP LIT - TROUBLE SHOOTIN G CONTRO LS AND REFRIGERATION

Yes

Yes

Yes

Yes

Yes

* FOR HEAT PUMP MODELS

NOTE: The Standby indicator is not in use for the portable units.

Page 67

11-2

TROUBLESHOOTING

Revision Y05-01 Service Manual - MOBILE Series

CONNECT THE AIR CONDITIONER TO

POWER SUPPLY.

DOES THE STANDBY

INDICATOR LIGHT UP?

START THE COOL MODE BY THE

REMOTE CONTROL.

START THE COOL MODE

BY ON UNIT CONTROL.

DOES THE SOPERATING

INDICATOR LIGHT UP?

IS THE CONTROLS SET

PROPERLY?

DOES T HE

INDICATORS

LIGHT UP ?

IS THERE CORRECT VOLTAGE

BETWEEN THE LINE AND

NEUTRAL TERMINALS ON THE

MAIN P.C.B?

REPLACE MAIN P.C.B OR DISPLAY P.C.B

DOES THE OPERATION

INDICATORS LIGHT UP

WHEN STARTING FROM ON

UNIT PANEL CNTROL.

IS THERE VOLTAGE BETWEEN THE

CONDENSATE PUMP TERMINALS ON

THE MAIN P.C.B?

IF LOW OR NO VOLTAGE, REPAIR POWER

SUPPLY.

REPLACE BATTERIES OR RESET THE

REMOTE CONTROL, OR REPLACE P.C.B.

REPLACE MAIN P.C.B OR DISPLAY P.C.B

SET THE REMOTE CONTROL

DOES THE CONDENSATE

SYSTEM FUNCTION

CORRECTLY?

REPLACE MAIN P.C.B

IS THERE VOLTAGE BETWEEN THE

CONDENSATE PUMP TERMINALS ON

THE MAIN P.C.B?

DOES THE CONDENSATE FLOAT OR

FLOAT SWITCH FUNCTIONS

PROPERLY?

REPAIR OR REPLACE FLOAT OR MICRO

SWITCH

REPAIR WATER TUBING OR REPLACE

PUMP

CHECK ELECTRICAL WIRING OR

REPLACE CAPACITOR O R MOTO R

RESISTOR OR FAN.

DOES THE INDOOR FAN

FUNCTION CORRECTLY?

REPLACE MAIN P.C.B

IS THERE VOLTAGE BETWEEN

INDOOR FAN TERMINALS ON THE

MAIN P.C.B ?

IS THERE VOLTAGE ON THE

TERMINALS ON THE CONDENSATE

PUMP TERMINALS?

IS THERE VOLTAGE BETWEEN THE

TERMINALS ON THE MAIN P.C.B?

CHECK AIR TUBE OR CHECK

ELECTRICAL WIRING OR REPLACE

CAPACITOR.

IF NO VOLTAGE REPLACE MAIN P.C.B - IF

LOW VOLTAGE REPAIR POWER SUPPLY.

REPLACE CAPACITO R OR CVER LOAD

PROTECTOR OR COMPRESOR.

DOES THE FAN FUNCTION

CORRECTLY?

DOES THE OVERFLOW

SWITCH FUNCTION

CORRECTLY?

OVERFL OW LED

BLINKING IF THE

WATER PAN IS FULL

DOES THE COMPRESSOR

START UP (CHECK WITH

AMPMETER)

REPAIR ELECTRICAL WIRING

IS THERE CORRECT VOLTAGE

(AT START) BETWEEN THE

COMPRESSOR TERMINALS ON THE

MAIN P.C.B?

IS THERE CORRECT VOLTAGE

(AT START) ETWEEN COMPRESSOR

TERMINALS ?

DOES THE

REFRIGERATION SYSTEM

FUNCTION CORECTLY?

(CHECK WITH AMPMETER

AND OR PRESSURE

GUAGES OR SURFACE

THERMOMETER

CHECK FOR LEAKS OR TUBING

RESTRICTION, REPAIR REFRIGERATION

SYSTEM AND CHARGE REFRIGERANT IF

NECESSARY.

NORMAL

CHECK AND REPAIR ELECTRICAL WIRING

REPLACE MAIN P.C.B

DRAIN THE CONDENSATE OR REPAIR

FLOAT OR OVERFLOW SWITCH.

No

Yes

No

No

No

Yes

No

Yes

No

No

Yes

Yes

No