Page 1

Service Manual

DCI PXD Series

REFRIGERANT

R410A

HEAT PUMP

APRIL 2005

Indoor Units Outdoor Units

PXD 25 DCI ONG 25 DCI

PXD 35 DCI ONG 35 DCI

PXD 50 DCI ONG 50 DCI

Page 2

A

LIST OF EFFECTIVE PAGES

Revision Y05-01 Service Manual − PXD DCI

LIST OF EFFECTIVE PAGES

Note: Changes in the pages are indicated by a “Revision#” in the footer of each effected page

(when none indicates no changes in the relevant page). All pages in the following list represent

effected/ non effected pages divided by chapters.

Dates of issue for original and changed pages are:

Original ....... 0 ........ April 2005

Total number of pages in this publication is 86 consisting of the following:

Page

No.

Revision

No. #

Page

No.

Revision

No. #

Page

No.

Revision

No. #

Title ....................... 0

A ........................... 0

i ............................. 0

1-1 - 1-3 ................ 0

2-1 - 2-3 ................ 0

3-1 ........................ 0

4-1 - 4-2 ................ 0

5-1 - 5-14 .............. 0

6-1 ........................ 0

7-1 ........................ 0

8-1 ........................ 0

9-1 ........................ 0

10-1-10-19 ............ 1

11-1-11-8 ............... 0

12-1-12-8 .............. 0

13-1 ...................... 0

• Zero in this column indicates an original page.

*Due to constant improvements please note that the data on this service manual can be modified

with out notice.

**Photos are not contractual

Page 3

i

TABLE OF CONTENTS

Revision Y05-01Service Manual - PXD DCI

Table of Contents

1. INTRODUCTION ...................................................................................................1-1

2. PRODUCT DATA SHEET ......................................................................................2-1

3. RATING CONDITIONS ..........................................................................................3-1

4. OUTLINE DIMENSIONS .......................................................................................4-1

5. PERFORMANCE DATA & PRESSURE CURVES ...............................................5-1

6. ELECTRICAL DATA ..............................................................................................6-1

7. WIRING DIAGRAMS .............................................................................................7-1

8. REFRIGERATION DIAGRAMS .............................................................................8-1

9. TUBING CONNECTIONS ......................................................................................9-1

10. CONTROL SYSTEM .............................................................................................10-1

11. TROUBLESHOOTING ..........................................................................................11-1

12. EXPLODED VIEWS AND SPARE PARTS LISTS .................................................12-1

13. APPENDIX A .........................................................................................................13-1

Page 4

1-1

INTRODUCTION

Revision Y05-01Service Manual - PXD DCI

1. INTRODUCTION

1.1 General

The PXD split ceiling mounted range comprise the following RC (heat pump) models:

PXD 25 DCI,

PXD 35 DCI,

PXD 50 DCI

1.2 Main Features

The PXD series benefits from the most advanced technological innovations, namely:

● DC Inverter Technology

● R410A

● High COP.

● Extended temp’ operating range

● Low indoor and outdoor noise levels.

● Microprocessor control.

● Infrared remote control.

● Easy access to the interconnecting tubing and wiring connections, main control

panel can slide out for service.

● Automatic treated air sweep.

● Networking Connectivity.

● Self diagnostics.

● Advanced diagnostics PC softwear “m2ll”

● Pre charged units till the max allowed tubing length.

● Easy installation and service.

1.3 Indoor Unit

The indoor unit is a floor/ ceiling mounted, and can be easily fitted to many types of

residential and commercials applications.

It includes:

● Coil with hydrophilic aluminum fins.

● Motorized flaps (two step motors)

● Advanced electronic control box assembly (DCI storm)

● Mounting plate

Page 5

1-2

INTRODUCTION

Revision Y05-01 Service Manual - PXD DCI

1.4 Filtration

● Easily accessible, and re-usable pre-filters (mesh)

1.5 Control

The microprocessor indoor controller, and an infrared remote control, supplied as

standard, providing complete operating function and programming. For further details

please refer to the Operation Manual, Appendix A.

1.6 Outdoor Unit

The PXD outdoor units can be installed as floor or wall mounted units by using a

wall supporting bracket. The metal sheets are protected by anti- corrosion paint work

allowing long life resistance. All outdoor units are pre-charged. For further information

please refer to the Product Data Sheet, Chapter 2.

It includes :

● Compressor mounted in a soundproofed compartment :

Rotary – for PXD25 DCI and PXD35 DCI.

Scroll – for PXD50 DCI.

It includes:

● Axial fan.

● Outdoor coil with hydrophilic louver fins for RC units.

● Outlet air fan grill.

● Service valves” flare” type connection.

● Interconnecting wiring terminal block.

● Advanced DC inverter controller.

1.7 Tubing Connections

Flare type interconnecting tubing to be produced on site.

For further details please refer to the Installation Manual, Appendix A

1.8 Inbox Documentation

Each unit is supplied with its own installation and operation manuals.

Page 6

1-3

INTRODUCTION

Revision Y05-01Service Manual - PXD DCI

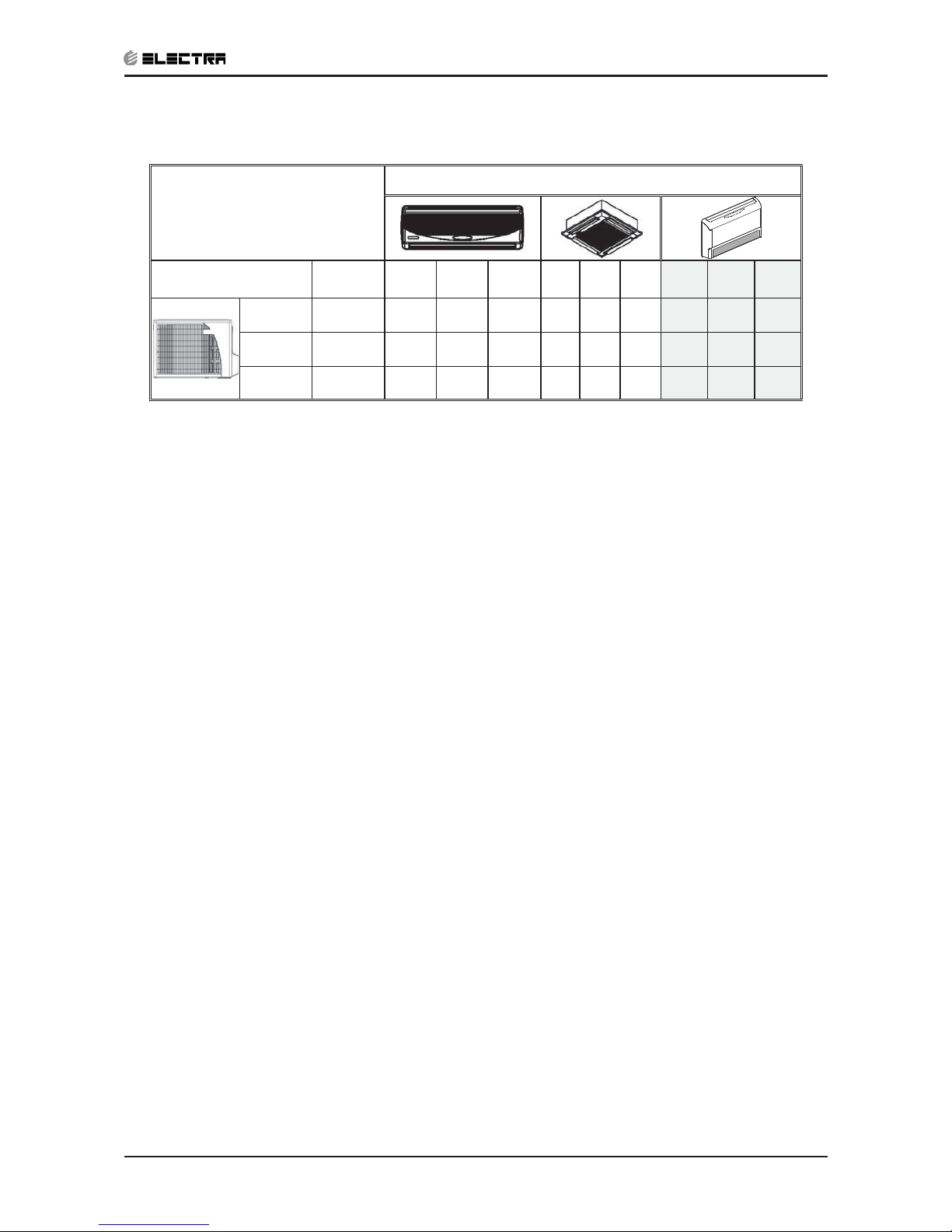

1.9 Matching Table

1.9.1 R410A

OUTDOOR UNITS

INDOOR UNITS

MODEL REFRIGER. WNG25 WNG35 WNG50 K25 K35 K50 PXD25 PXD35 PXD50

ONG25 DCI R410A √ √ √

ONG35 DCI R410A √ √ √

ONG50 DCI R410A √ √ √

The above table lists outdoor units and PXD DCI indoor units which can be matched together.

In addition the listed outdoor units can be matched with other types of indoor units such as

cassettes and wall mounted.

For further information please refer to the relevant Service Manual.

Page 7

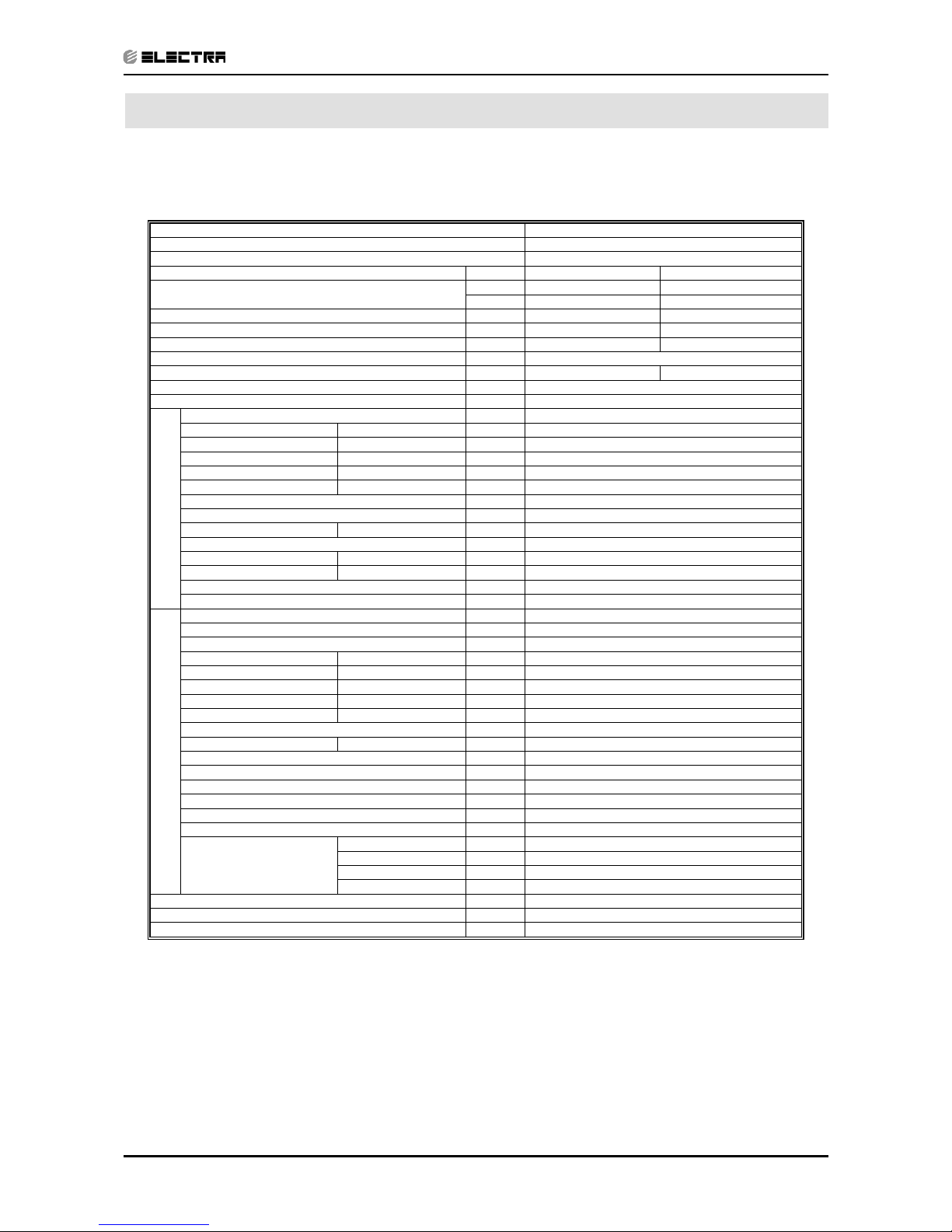

2-1

PRODUCT DATA SHEET

Revision Y05-01Service Manual - PXD DCI

2. PRODUCT DATA SHEET

2.1 PXD 25 DCI R410A

Model Indoor Unit PXD 25 DCI

Model Outdoor Unit ONG-25 DCI

Installation Method of Pipe Flared

Characteristics Units Cooling Heating

Btu/hr 8530(4780~12280) 10920(5120~15350)

Capacity

(1)

kW 2.5(1.4-3.6) 3.2(1.5~4.5)

Power input

(1)

kW 0.62(0.42-1.1) 0.93(0.4~1.6)

EER (Cooling) or COP(Heating)

(1)

W/W 4.03 3.41

Energy efficiency class A B

Power supply V/Ph/Hz 220-240V/Single/50Hz

Rated current A 2.7 4.1

Starting current A 10.5

Circuit breaker rating A 35

Fan type & quantity Centrifugal x 2

Fan speeds H/M/L RPM 760/670/500

Air flow

(2)

H/M/L m3/hr 400/350/300

External static pressure Min-Max Pa 0

Sound power level

(3)

H/M/L dB(A) 50/49/47

Sound pressure level

(4

) H/M/L dB(A) 39/37/35

Moisture removal l/hr 1

Condenstate drain tube I.D mm 16

Dimensions WxDxH mm 820*190*630

Weight kg 21

Package dimensions WxDxH mm 890*280*710

Package weight kg 25

Units per pallet units 14units per pallet

INDOOR

Units stacking units 7 levels

Refrigerant control EEV

Compressor type,model Single Rotary,DC Inverter,Panasonic 5RS102XAB

Fan type & quantity Propeller(direct) x 1

Fan speeds H/L RPM 830

Air flow H/L m3/hr 1780

Sound power level H/L dB(A) 61

Sound pressure level

(4)

H/L dB(A) 51

Dimensions WxDxH mm 795*290*610

Weight kg 38

Package dimensions WxDxH mm 945*395*655

Packaged weight kg 42

Units per pallet Units 9

Stacking height units 3 levels

Refrigerant type R410A

Refrigerant chargless distance kg/m 1.10kg/7.5m

Additional charge per 1 meter g/m No Need

Liquid line In.(mm) 1/4"(6.35)

Suction line In.(mm) 3/8"(9.53)

Max.tubing length m. Max.20

OUTDOOR

Connections between units

Max.height difference m. Max.10

Operation control type Remote control

Heating elements (Option) kW

Others

(1) Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units) and EN 14511.

(2) Airflow in ducted units; at nominal external static pressure.

(3) Sound power in ducted units is measured at air discharge.

(4) Sound pressure level measured at 1 meter distance from unit.

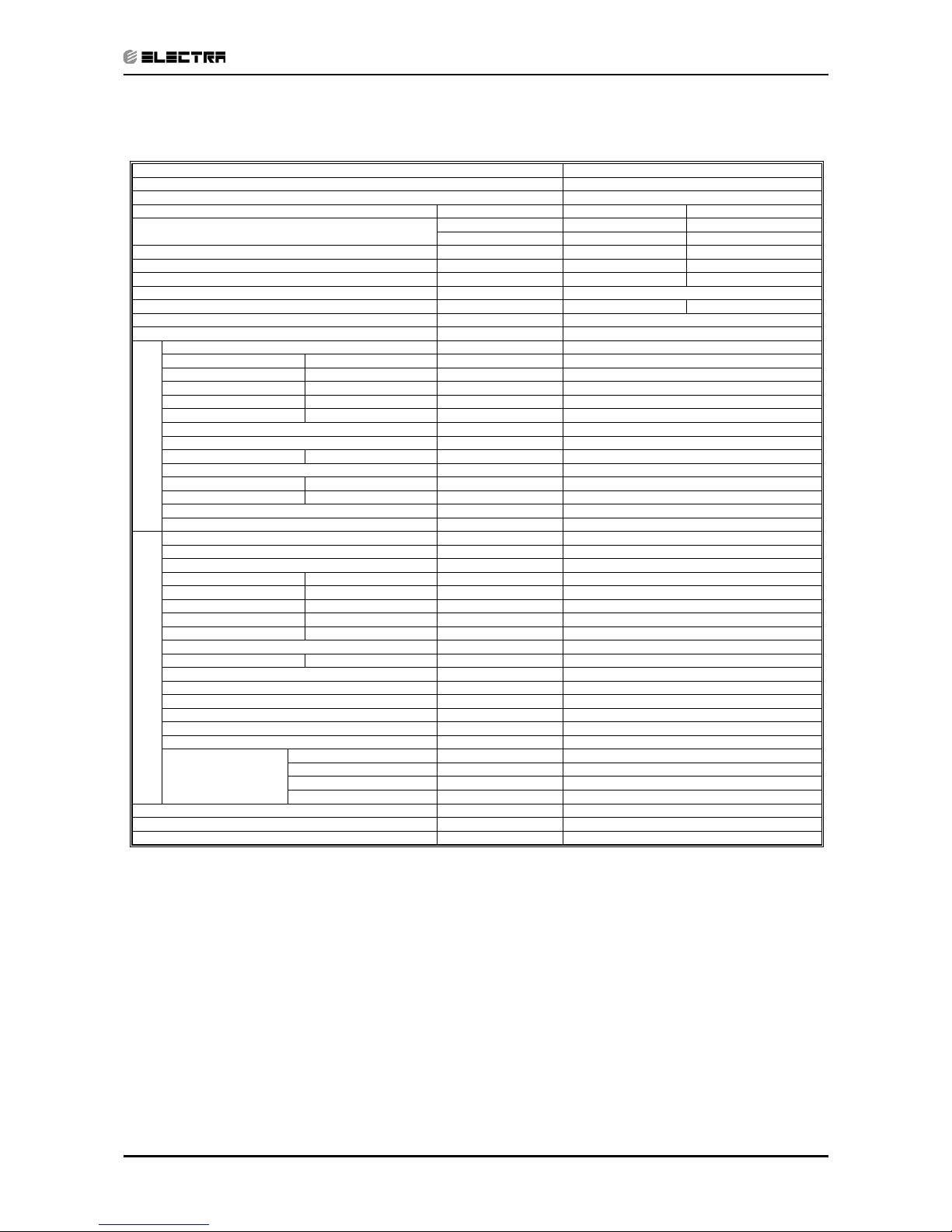

Page 8

2-2

PRODUCT DATA SHEET

Revision Y05-01 Service Manual - PXD DCI

2.2 PXD 35 DCI R410A

Model Indoor Unit PXD 35 DCI

Model Outdoor Unit ONG-DCI 35

Installation Method of Pipe Flared

Characteristics Units Cooling Heating

Btu/hr 11940(5120~15010) 14330(5120~17060)

Capacity

(1)

kW 3.5(1.5-4.4) 4.2(1.5~5.0)

Power input

(1

) kW 0.98(0.46-1.3) 1.31(0.35~1.58)

EER (Cooling) or COP(Heating)

(1)

W/W 3.57 3.21

Energy efficiency class A C

Power supply V/Ph/Hz 220-240V/Single/50Hz

Rated current A 4.3 5.7

Starting current A 10.5

Circuit breaker rating A 35

Fan type & quantity Centrifugal x 2

Fan speeds H/M/L RPM 830/760/500

Air flow

(2)

H/M/L m3/hr 450/400/300

External static pressure Min-Max Pa 0

Sound power level

(3)

H/M/L dB(A) 56/53/51

Sound pressure level

(4)

H/M/L dB(A) 45/41/38

Moisture removal l/hr 1.5

Condenstate drain tube I.D mm 16

Dimensions WxDxH mm 820*190*630

Weight kg 22

Package dimensions WxDxH mm 890*280*710

Package weight kg 26

Units per pallet units 14units per pallet

INDOOR

Units stacking units 7 levels

Refrigerant control EEV

Compressor type,model Single Rotary,DC Inverter,Panasonic 5RS102XAB

Fan type & quantity Propeller(direct) x 1

Fan speeds H/L RPM 830

Air flow H/L m3/hr 1780

Sound power level H/L dB(A) 62

Sound pressure level

(4)

H/L dB(A) 52

Dimensions WxDxH mm 795*290*610

Weight kg 38.5

Package dimensions WxDxH mm 945*395*655

Packaged weight kg 42.5

Units per pallet Units 9

Stacking height units 3 levels

Refrigerant type R410A

Refrigerant chargless distance kg/m 1.20kg/7.5m

Additional charge per 1 meter g/m No Need

Liquid line In.(mm) 1/4"(6.35)

Suction line In.(mm) 3/8"(9.53)

Max.tubing length m. Max.20

OUTDOOR

Connections

between units

Max.height difference m. Max.10

Operation control type Remote control

Heating elements (Option) kW

Others

(1) Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units) and EN 14511.

(2) Airflow in ducted units; at nominal external static pressure.

(3) Sound power in ducted units is measured at air discharge.

(4) Sound pressure level measured at 1 meter distance from unit.

Page 9

2-3

PRODUCT DATA SHEET

Revision Y05-01Service Manual - PXD DCI

Model Indoor Unit PXD 50 DCI

Model Outdoor Unit ONG-DCI 50

Installation Method of Pipe Flared

Characteristics Units Cooling Heating

Btu/hr 17000(5120-20460) 20460(5120-24550)

Capacity

(1)

kW 5.0(1.5-6.0) 5.8(1.5~7.2)

Power input

(1)

kW 1.65(0.5-2.1) 1.69(0.45-2.1)

EER (Cooling) or COP(Heating)

(1)

W/W 3.03 3.43

Energy efficiency class B B

Power supply V/Ph/Hz 220-240V/Single/50Hz

Rated current A 7.2 7.7

Starting current A 10.5

Circuit breaker rating A 35

Fan type & quantity Centrifugal x 2

Fan speeds H/M/L RPM 1050/950/700

Air flow

(2)

H/M/L m3/hr 870/750/600

External static pressure Min-Max Pa 0

Sound power level

(3)

H/M/L dB(A) 65/60/56

Sound pressure level

(4)

H/M/L dB(A) 51/48/45

Moisture removal l/hr 2

Condenstate drain tube I.D mm 16

Dimensions WxDxH mm 1200*190*630

Weight kg 30

Package dimensions WxDxH mm 1270*280*710

Package weight kg 35

Units per pallet units 7units per pallet

INDOOR

Units stacking units 7 levels

Refrigerant control EEV

Compressor type,model Single Rotary,DCI, Panasonic 5CS130XCC03

Fan type & quantity Propeller(direct) x 1

Fan speeds H/L RPM 920

Air flow H/L m3/hr 2160

Sound power level H/L dB(A) 63

Sound pressure leve

l(4)

H/L dB(A) 53

Dimensions WxDxH mm 795*290*610

Weight kg 39

Package dimensions WxDxH mm 945*395*655

Packaged weight kg 43

Units per pallet Units 9

Stacking height units 3 levels

Refrigerant type R410A

Refrigerant chargless distance kg/m 1.50kg/7.5m

Additional charge per 1 meter g/m No Need

Liquid line In.(mm) 1/4"(6.35)

Suction line In.(mm) 1/2"(12.7)

Max.tubing length m. Max.30

OUTDOOR

Connections between

units

Max.height difference m. Max.10

Operation control type Remote control

Heating elements (Option) kW

Others

(1) Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units) and EN 14511.

(2) Airflow in ducted units; at nominal external static pressure.

(3) Sound power in ducted units is measured at air discharge.

(4) Sound pressure level measured at 1 meter distance from unit.

Scroll

Page 10

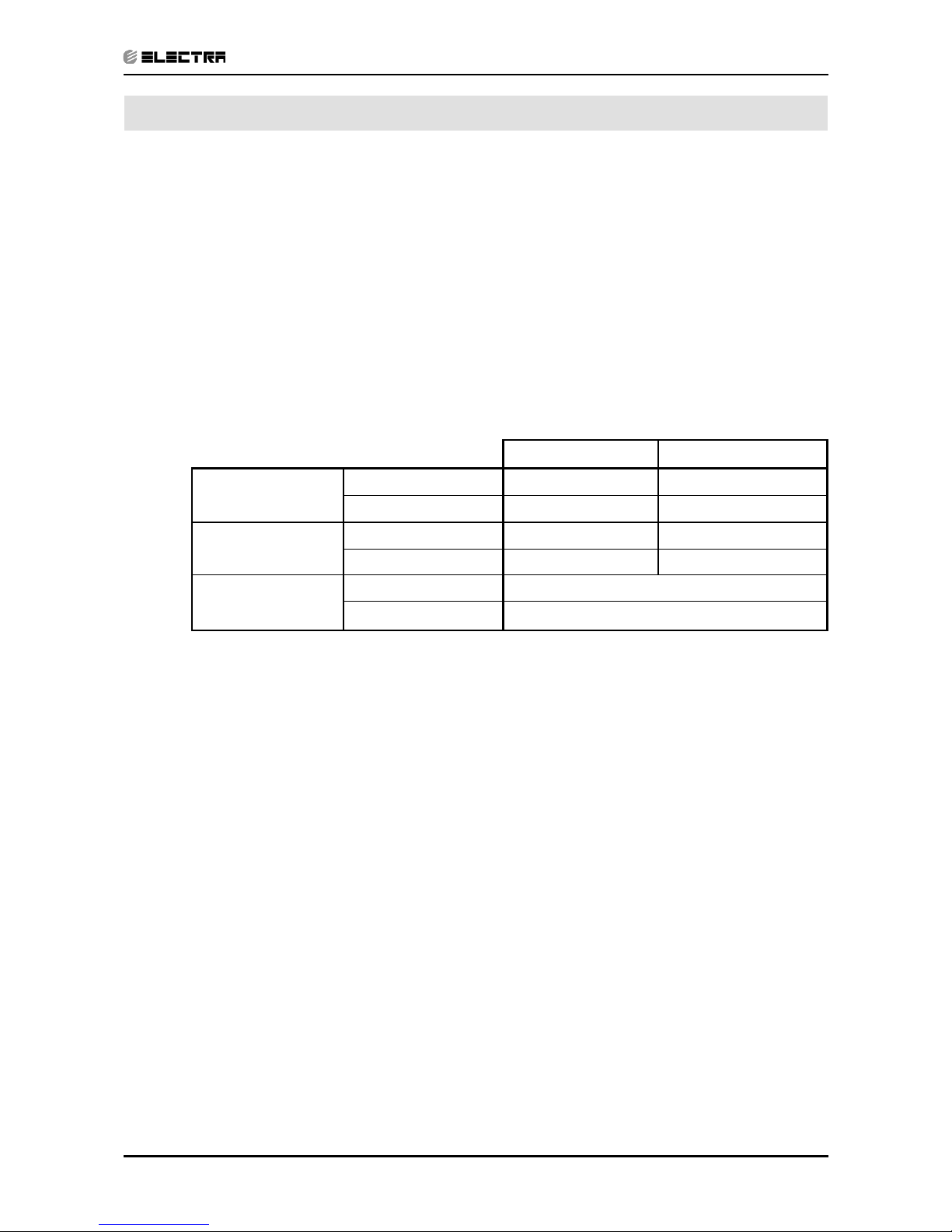

3-1

RATING CONDITIONS

Revision Y05-01Service Manual - PXD DCI

3. RATING CONDITIONS

Standard conditions in accordance with ISO 5151, ISO 13253 (for ducted units)

and EN 14511.

Cooling:

Indoor: 27oC DB 19oC WB

Outdoor: 35 oC DB

Heating:

Indoor: 20oC DB

Outdoor: 7oC DB 6oC WB

3.1 Operating Limits

R410A

Indoor Outdoor

Cooling

Upper limit 32

o

C DB 23oC WB 46oC DB

Lower limit 21

o

C DB 15oC WB -10oC DB

Heating

Upper limit 27

o

C DB 24oC DB 18oC WB

Lower limit 10oC DB -15oC DB -16oC WB

Voltage

1PH 198 – 264 V

3PH N/A

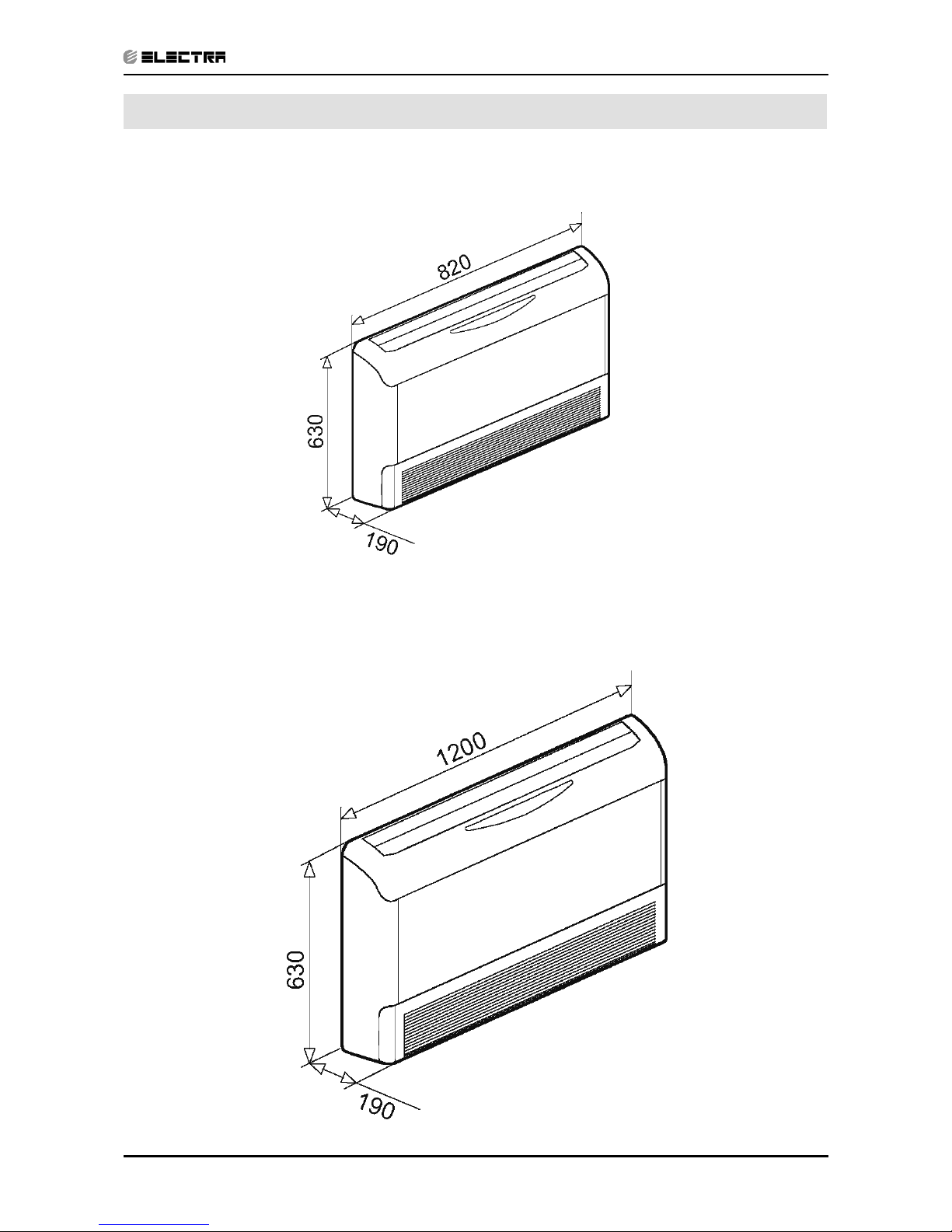

Page 11

4-1

OUTLINE DIMENSIONS

Revision Y05-01Service Manual - PXD DCI

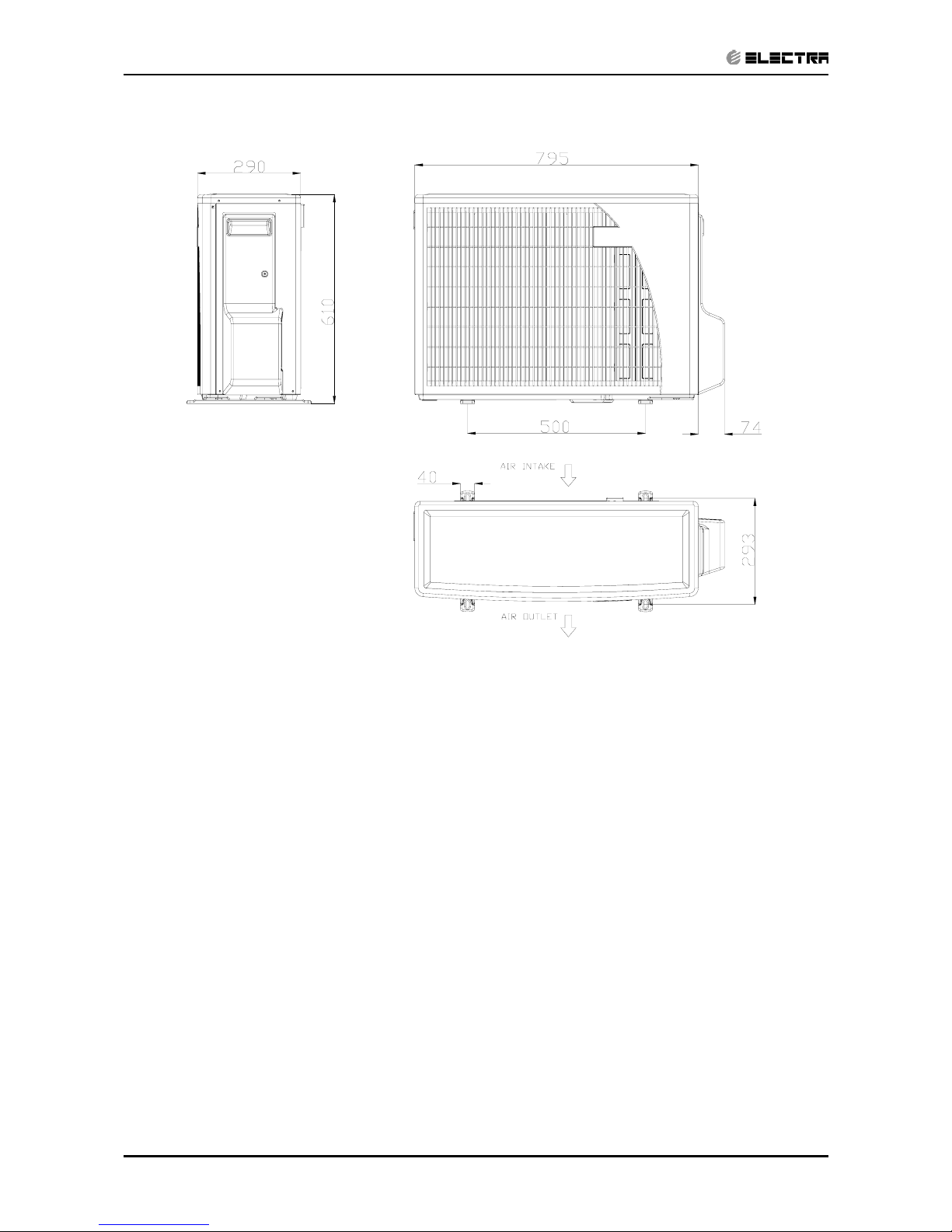

4. OUTLINE DIMENSIONS

4.1 Indoor Unit: PXD 25, 35, DCI

4.2 Indoor Unit: PXD 50 DCI

Page 12

4-2

OUTLINE DIMENSIONS

Revision Y05-01 Service Manual - PXD DCI

4.3 Outdoor Unit: ONG 25, 35, 50 DCI

Page 13

5-1

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01Service Manual - PXD DCI

5. PERFORMANCE DATA

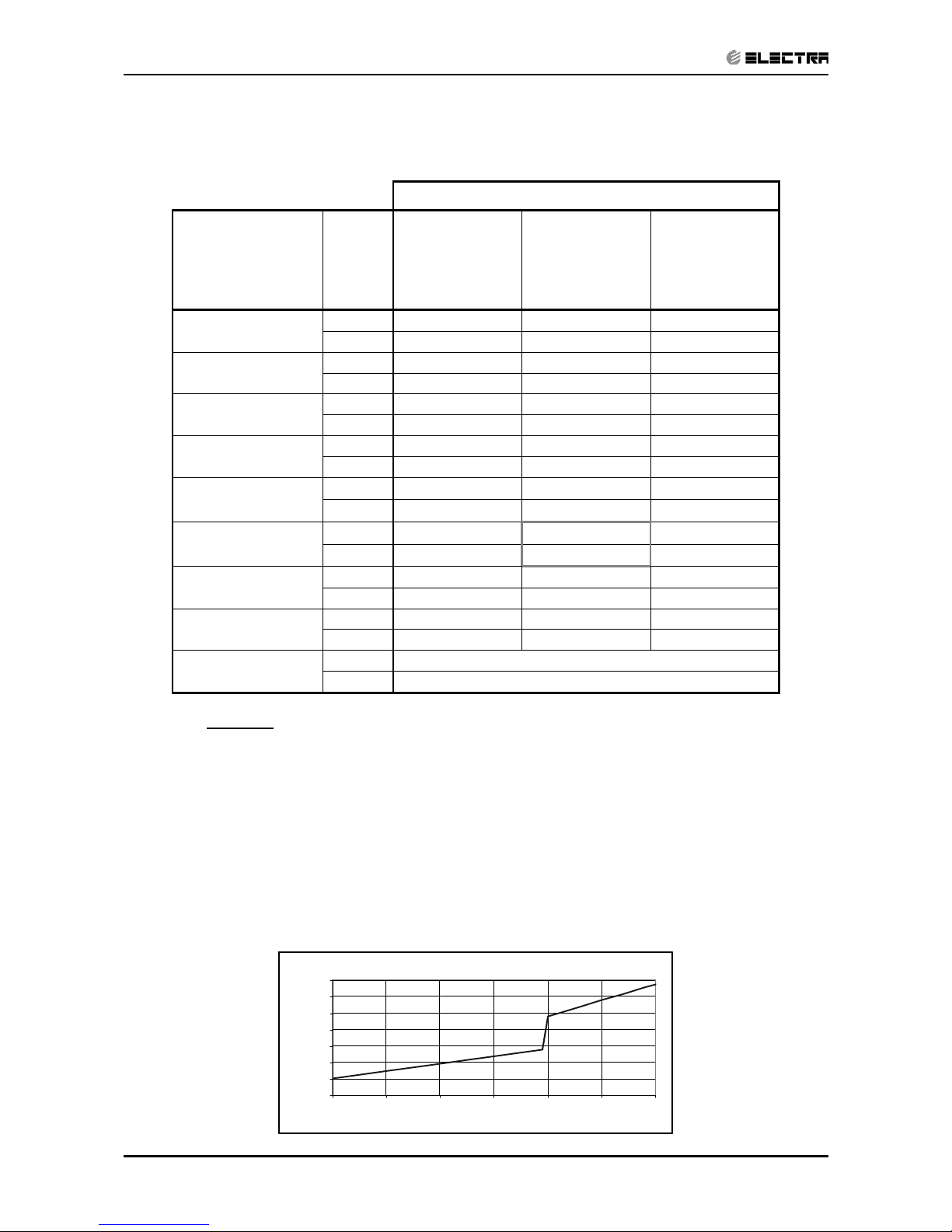

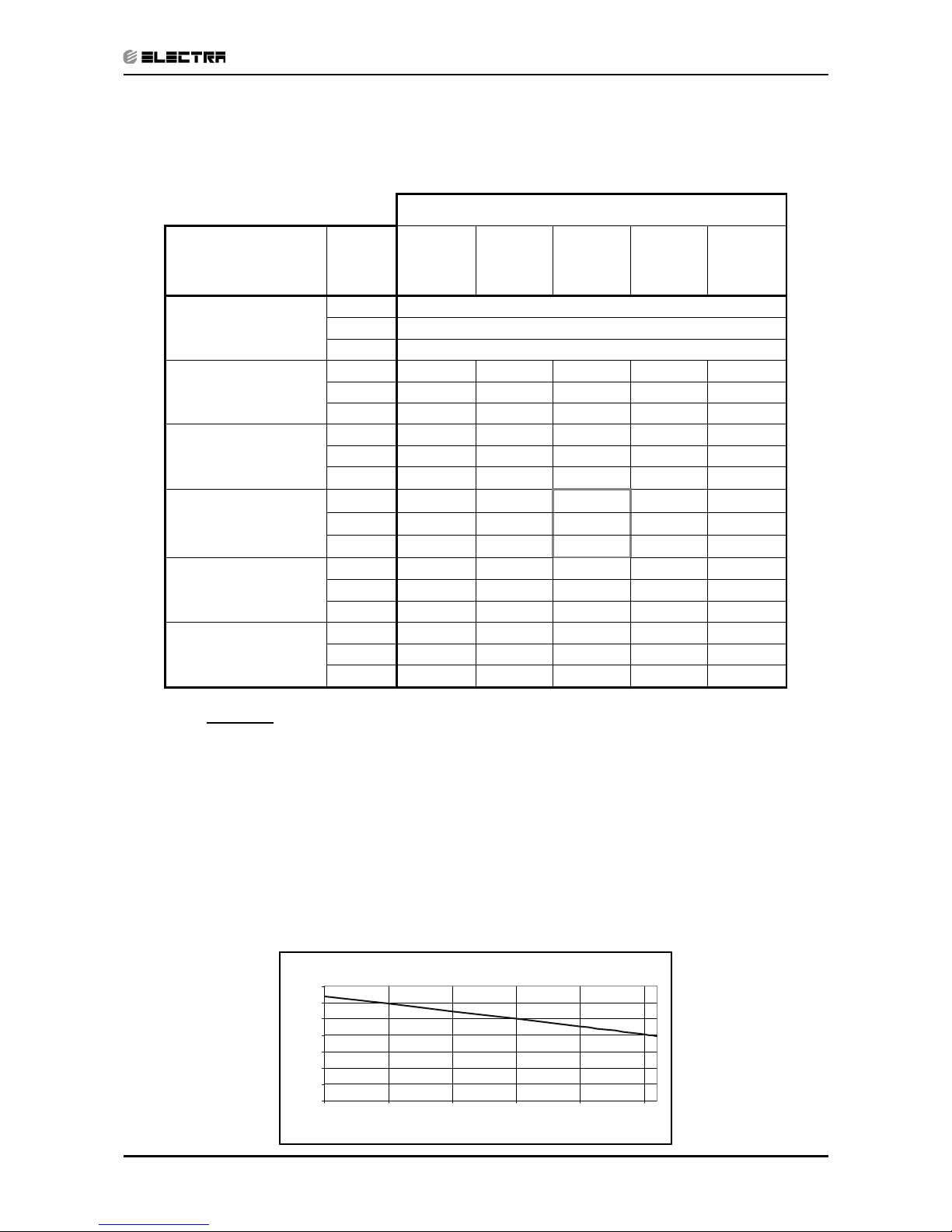

5,1 PXD25 DCI

5.1.1 Cooling Capacity (kW) – Run Mode

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB/WB TEMPERATURE [oC]

OU COIL

ENTERING AIR DB

TEMPERATURE

[oC]

DATA

22/15 24/17 27/19 29/21 32/23

-10 - 20

(protection range)

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

PI 25 - 50 % of nominal

25

TC 2.42 2.57 2.73 2.89 3.05

SC 2.09 2.13 2.18 2.22 2.26

PI 0.49 0.50 0.51 0.52 0.52

30

TC 2.30 2.46 2.62 2.77 2.93

SC 2.04 2.08 2.12 2.17 2.21

PI 0.54 0.55

0.56

0.57 0.58

35

TC 2.18 2.34

2.50

2.66 2.82

SC 1.98 2.03 2.07 2.11 2.16

PI 0.60 0.61

0.62

0.63 0.64

40

TC 2.07 2.23

2.38

2.54 2.70

SC 1.93 1.97 2.02 2.06 2.10

PI 0.66 0.67 0.68 0.69 0.70

46

TC 1.93 2.09 2.24 2.40 2.56

SC 1.87 1.91 1.95 2.00 2.04

PI 0.73 0.74 0.75 0.75 0.76

LEGEND

TC – Total Cooling Capacity, kW

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OU – Outdoor

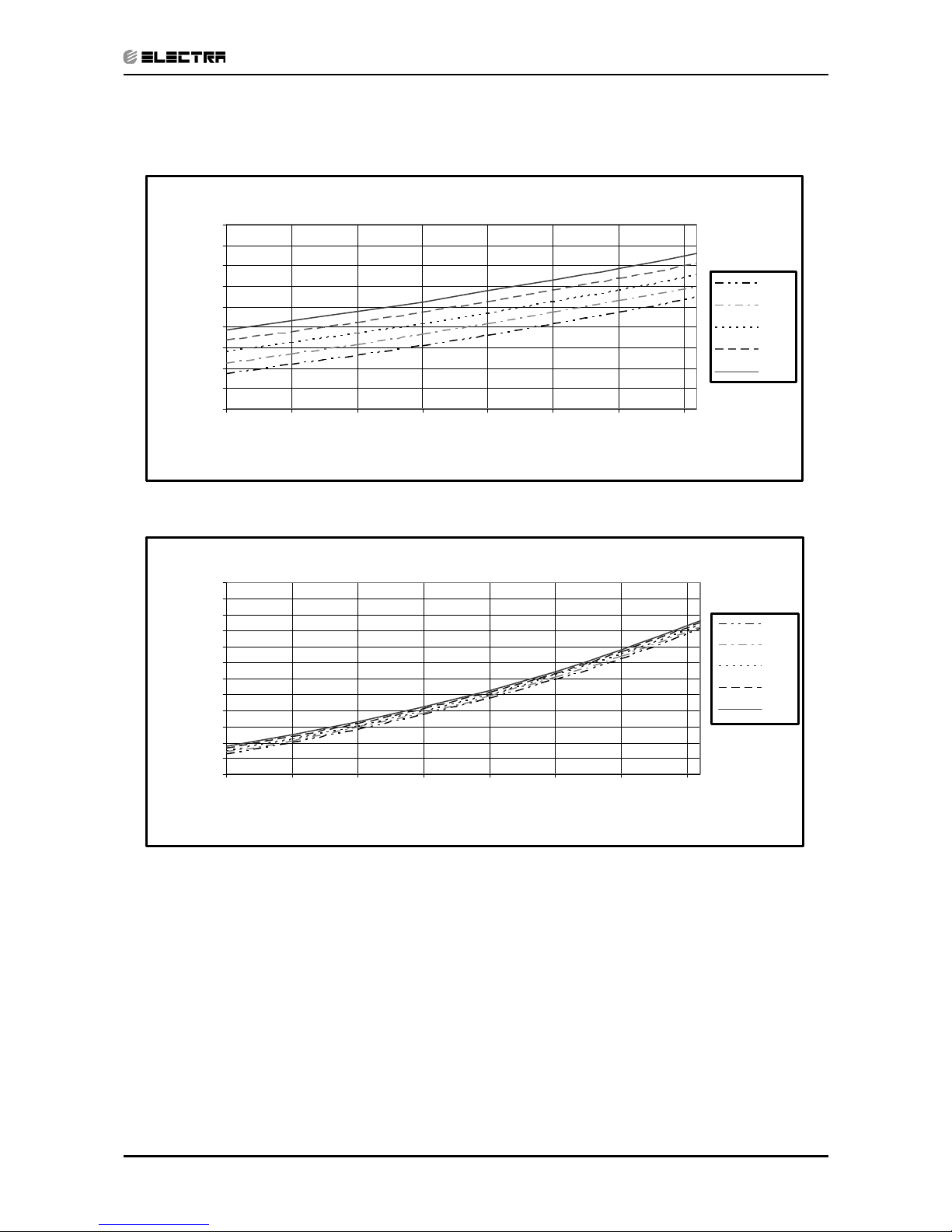

5.1.2 Capacity Correction Factors

Cooling Capac ity Ratio V s. Out door Te mpe rature

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

20 25 30 35 40 45

Outdoor Temperature [ºC]

Capacity Rati

o

Page 14

5-2

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01 Service Manual - PXD DCI

5.1.3 Heating Capacity (kW) - Run Mode

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [oC]

OU COIL

ENTERING

AIR DB/WB

TEMPERATURE

[oC]

DATA 15 20 25

-15/-16

TC 2.04 1.89 1.75

PI 0.56 0.61 0.67

-10/-12

TC 2.27 2.12 1.98

PI 0.67 0.73 0.79

-7/-8

TC 2.44 2.30 2.16

PI 0.76 0.82 0.87

-1/-2

TC 2.53 2.38 2.24

PI 0.80 0.86 0.92

2/1

TC 2.58 2.44 2.30

PI 0.83

0.89

0.94

7/6

TC 3.34

3.20

3.06

PI 0.87

0.93

0.99

10/9

TC 3.53

3.38

3.24

PI 0.93 0.98 1.04

15/12

TC 3.71 3.57 3.43

PI 0.98 1.03 1.09

15-24

TC 85 - 105 % of nominal

(Protection Range)

PI 80 - 120 % of nominal

LEGEND

TC – Total Heating Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (

o

C)

ID – Indoor

OU – Outdoor

5.1.4 Capacity Correction Factors

Heating Ca pacity Ratio Vs . Outdoor Tempe rature

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

-15 -10 -5 0 5 10 15

Outdoor WB Tem pera ture [deg C]

Capaci ty Rati on

Page 15

5-3

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01Service Manual - PXD DCI

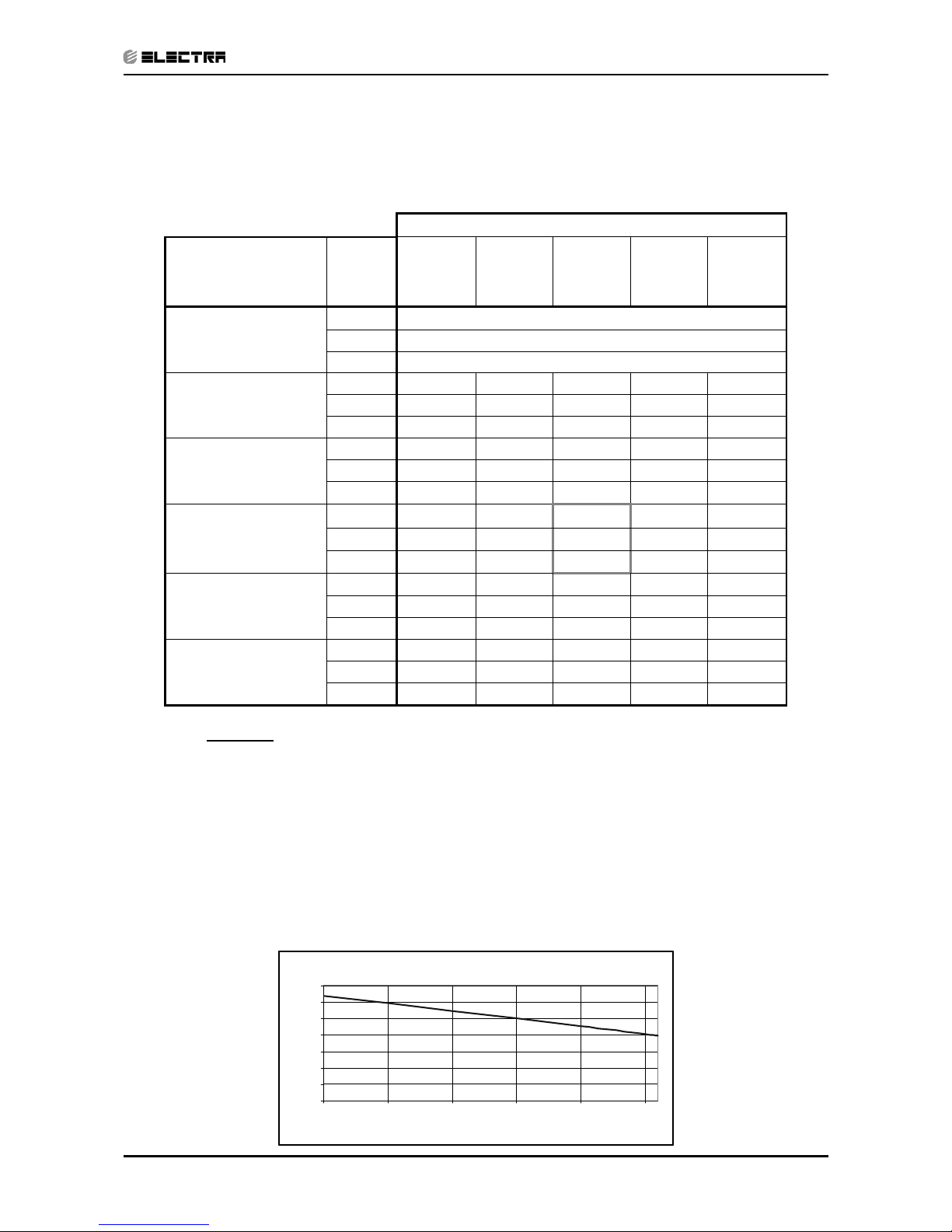

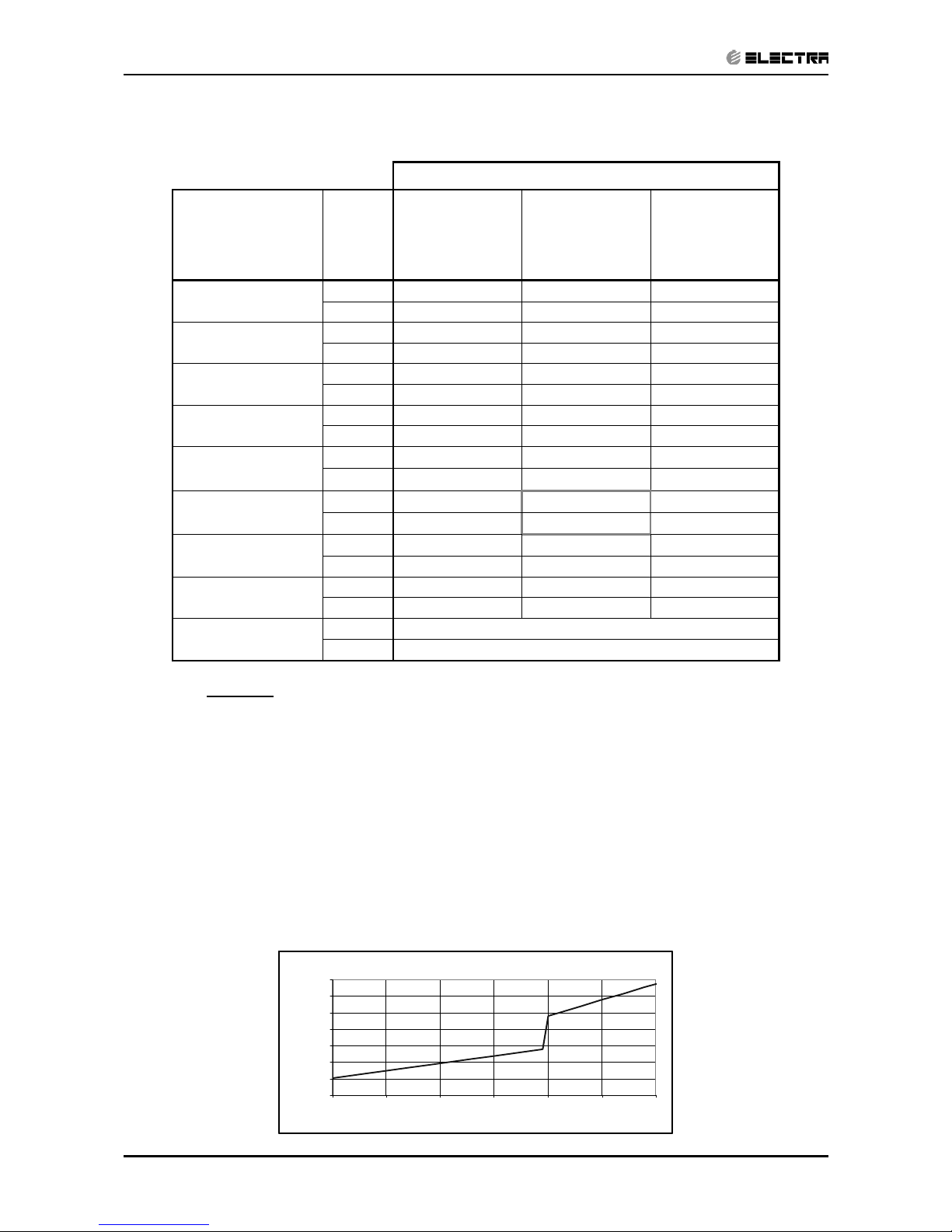

5.2 PXD35 DCI

5.2.1 Cooling Capacity (kW) - Run Mode

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB/WB TEMPERATURE [oC]

OU COIL

ENTERING AIR DB

TEMPERATURE [oC]

DATA

22/15 24/17 27/19 29/21 32/23

-10 - 20

(protection range)

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

PI 25 - 50 % of nominal

25

TC 3.38 3.60 3.83 4.05 4.27

SC 2.65 2.70 2.75 2.81 2.86

PI 0.77 0.78 0.80 0.81 0.83

30

TC 3.22 3.44 3.66 3.88 4.11

SC 2.58 2.63 2.69 2.74 2.79

PI 0.86 0.88

0.89

0.90 0.92

35

TC 3.06 3.28

3.50

3.72 3.94

SC 2.51 2.57 2.62 2.67 2.73

PI 0.95 0.97

0.98

0.99 1.01

40

TC 2.89 3.12

3.34

3.56 3.78

SC 2.45 2.50 2.55 2.61 2.66

PI 1.04 1.06 1.07 1.08 1.10

46

TC 2.70 2.92 3.14 3.36 3.58

SC 2.37 2.42 2.47 2.53 2.58

PI 1.15 1.16 1.18 1.19 1.21

LEGEND

TC – Total Cooling Capacity, kW

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OU – Outdoor

5.2.2 Capacity Correction Factor

Cooling Capac ity Ratio V s. Out door Te mpe rature

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

20 25 30 35 40 45

Outdoor Temperature [ºC]

Capacity Rati

o

Page 16

5-4

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01 Service Manual - PXD DCI

5.2.3 Heating Capacity (kW) - Run Mode

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [oC]

OU COIL

ENTERING

AIR DB/WB

TEMPERATURE

[oC]

DATA 15 20 25

-15/-16

TC 2.67 2.49 2.30

PI 0.79 0.87 0.95

-10/-12

TC 2.98 2.79 2.60

PI 0.95 1.03 1.11

-7/-8

TC 3.20 3.02 2.83

PI 1.07 1.15 1.23

-1/-2

TC 3.32 3.13 2.94

PI 1.13 1.21 1.29

2/1

TC 3.39 3.20 3.02

PI 1.17

1.25

1.33

7/6

TC 4.39

4.20

4.01

PI 1.23

1.31

1.39

10/9

TC 4.63

4.44

4.26

PI 1.30 1.38 1.46

15/12

TC 4.87 4.68 4.50

PI 1.38 1.46 1.54

15-24

TC 85 - 105 % of nominal

(Protection Range)

PI 80 - 120 % of nominal

LEGEND

TC – Total Heating Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OU – Outdoor

5.2.4 Capacity Correction Factors

Heating Ca pacity Ratio Vs . Outdoor Tempe rature

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

-15 -10 -5 0 5 10 15

Outdoor WB Tem pera ture [deg C]

Capacity Ration

Page 17

5-5

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01Service Manual - PXD DCI

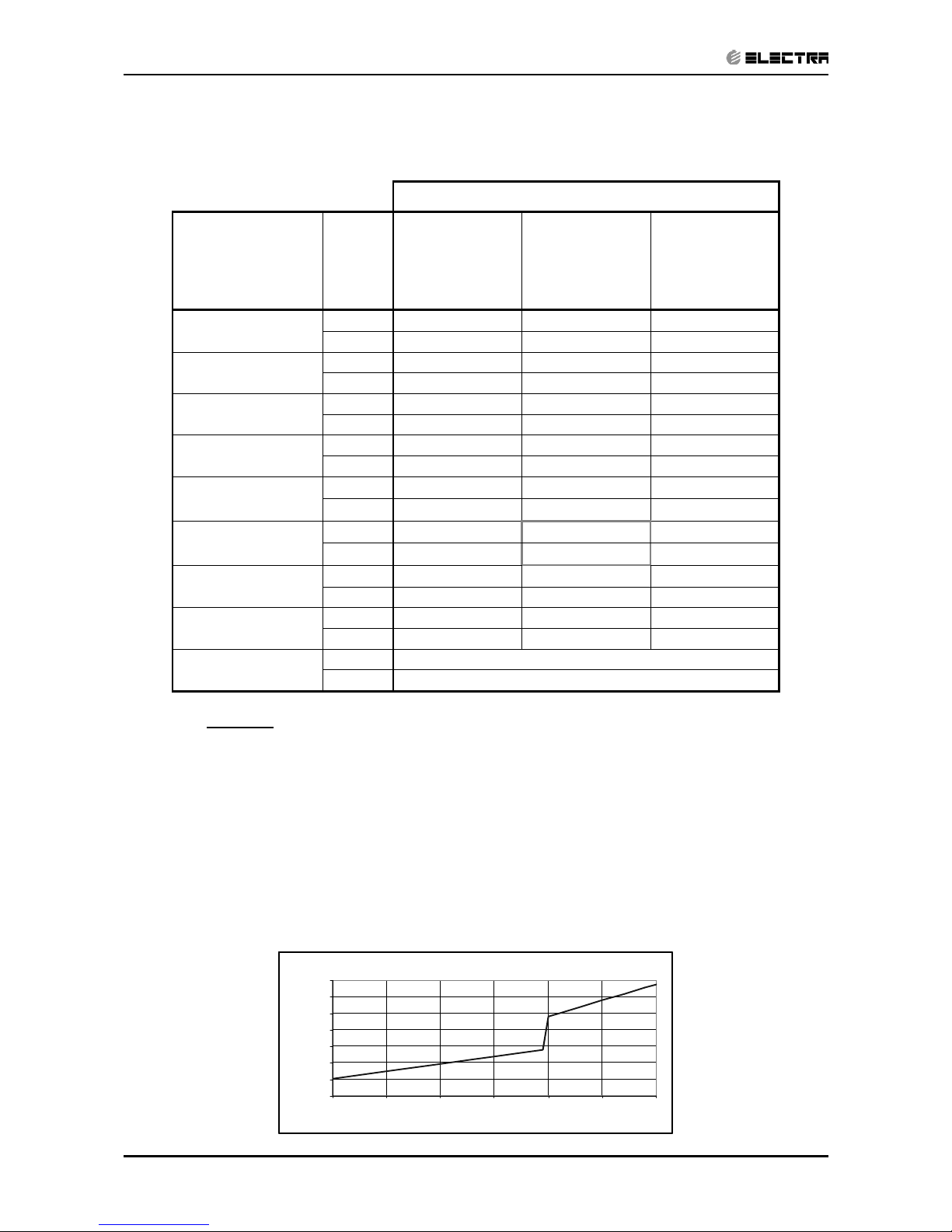

5.3 PXD50 DCI

5.3.1 Cooling Capacity (kW) - Run Mode

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB/WB TEMPERATURE [oC]

OU COIL

ENTERING AIR DB

TEMPERATURE [oC]

DATA

22/15 24/17 27/19 29/21 32/23

-10 - 20

(protection range)

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

PI 25 - 50 % of nominal

25

TC 4.93 5.22 5.51 5.80 6.09

SC 3.35 3.40 3.45 3.50 3.55

PI 1.25 1.28 1.30 1.33 1.36

30

TC 4.67 4.96 5.25 5.54 5.83

SC 3.22 3.27 3.32 3.37 3.42

PI 1.42 1.45

1.48

1.50 1.53

35

TC 4.42 4.71

5.00

5.29 5.58

SC 3.09 3.14 3.19 3.24 3.29

PI 1.59 1.62

1.65

1.68 1.71

40

TC 4.17 4.46

4.75

5.04 5.33

SC 2.96 3.01 3.06 3.11 3.16

PI 1.77 1.80 1.82 1.85 1.88

46

TC 3.86 4.15 4.44 4.73 5.02

SC 2.80 2.85 2.90 2.95 3.00

PI 1.98 2.00 2.03 2.06 2.09

LEGEND

TC – Total Cooling Capacity, kW

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OU – Outdoor

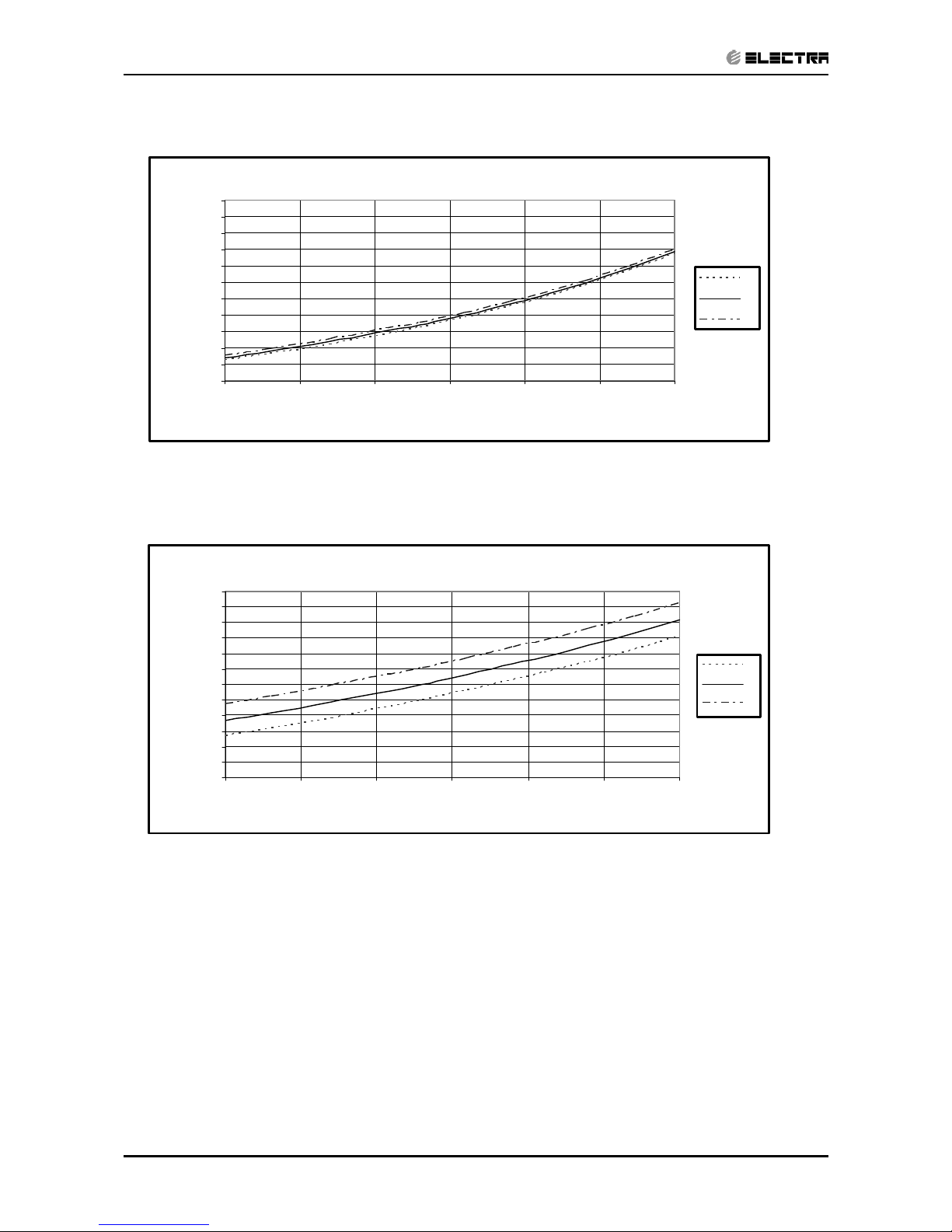

5.3.2 Capacity Correction Factors

Cooling Capac ity Ratio V s. Out door Te mpe rature

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

20 25 30 35 40 45

Outdoor Temperature [ºC]

Capacity Rati

o

Page 18

5-6

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01 Service Manual - PXD DCI

5.3.3 Heating Capacity (kW) - Run Mode

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [oC]

OU COIL

ENTERING

AIR DB/WB

TEMPERATURE

[oC]

DATA 15 20 25

-15/-16

TC 2.64 2.26 1.88

PI 1.18 1.27 1.35

-10/-12

TC 3.48 3.10 2.72

PI 1.34 1.42 1.50

-7/-8

TC 4.12 3.74 3.36

PI 1.45 1.54 1.62

-1/-2

TC 4.43 4.05 3.67

PI 1.51 1.59 1.68

2/1

TC 4.65 4.27 3.89

PI 1.55

1.63

1.72

7/6

TC 6.18

5.80

5.42

PI 1.61

1.69

1.77

10/9

TC 6.50

6.12

5.74

PI 1.64 1.72 1.81

15/12

TC 6.82 6.44 6.06

PI 1.67 1.75 1.84

15-24

TC 85 - 105 % of nominal

(Protection Range)

PI 80 - 120 % of nominal

LEGEND

TC – Total Heating Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (

o

C)

ID – Indoor

OU – Outdoor

5.3.4 Capacity Correction Factors

Hea ting Cap acit y Rat io Vs. O utdo or Tem pera ture

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

-15 -10 -5 0 5 10 15

Outdoor WB Tem pera ture [deg C]

Capaci ty Rati on

Page 19

5-7

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01Service Manual - PXD DCI

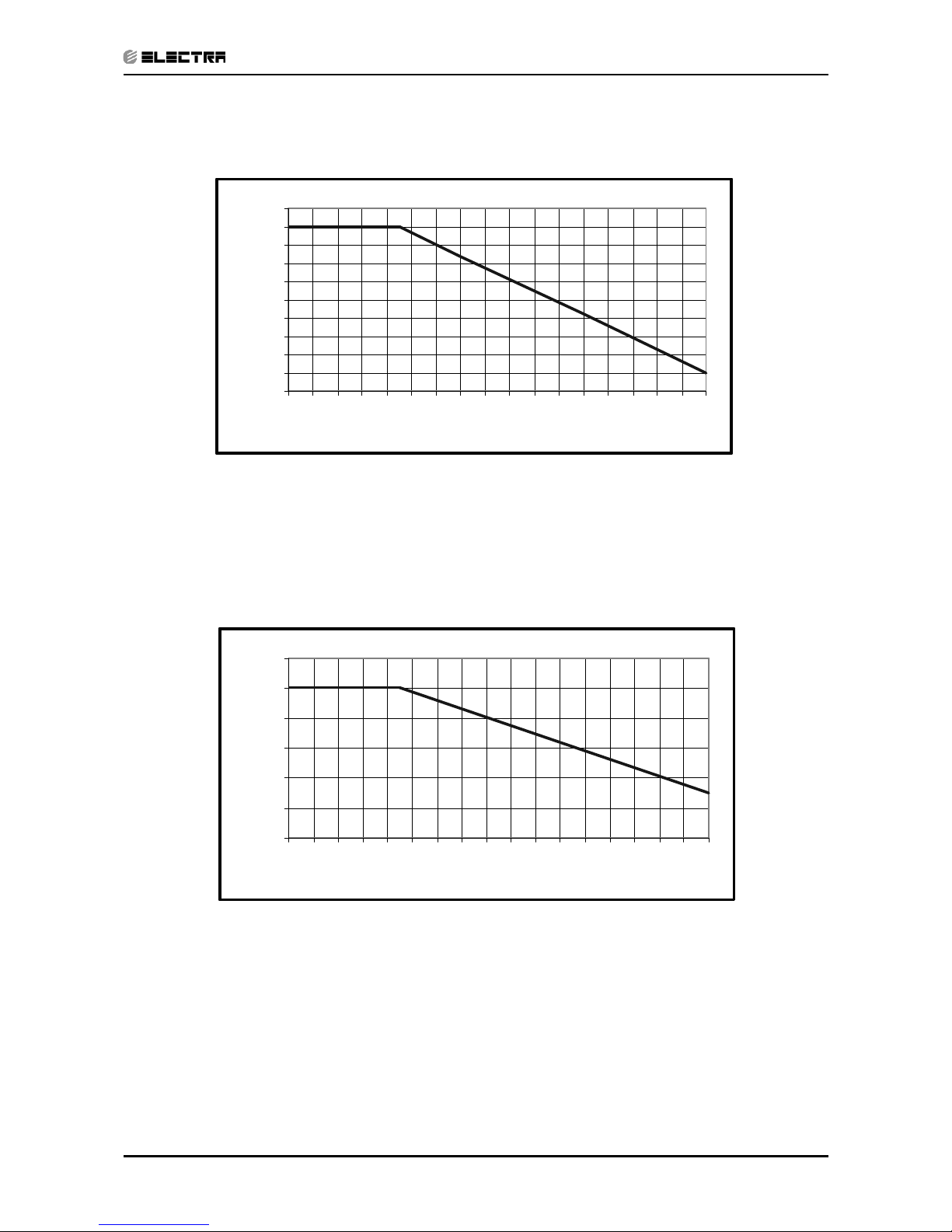

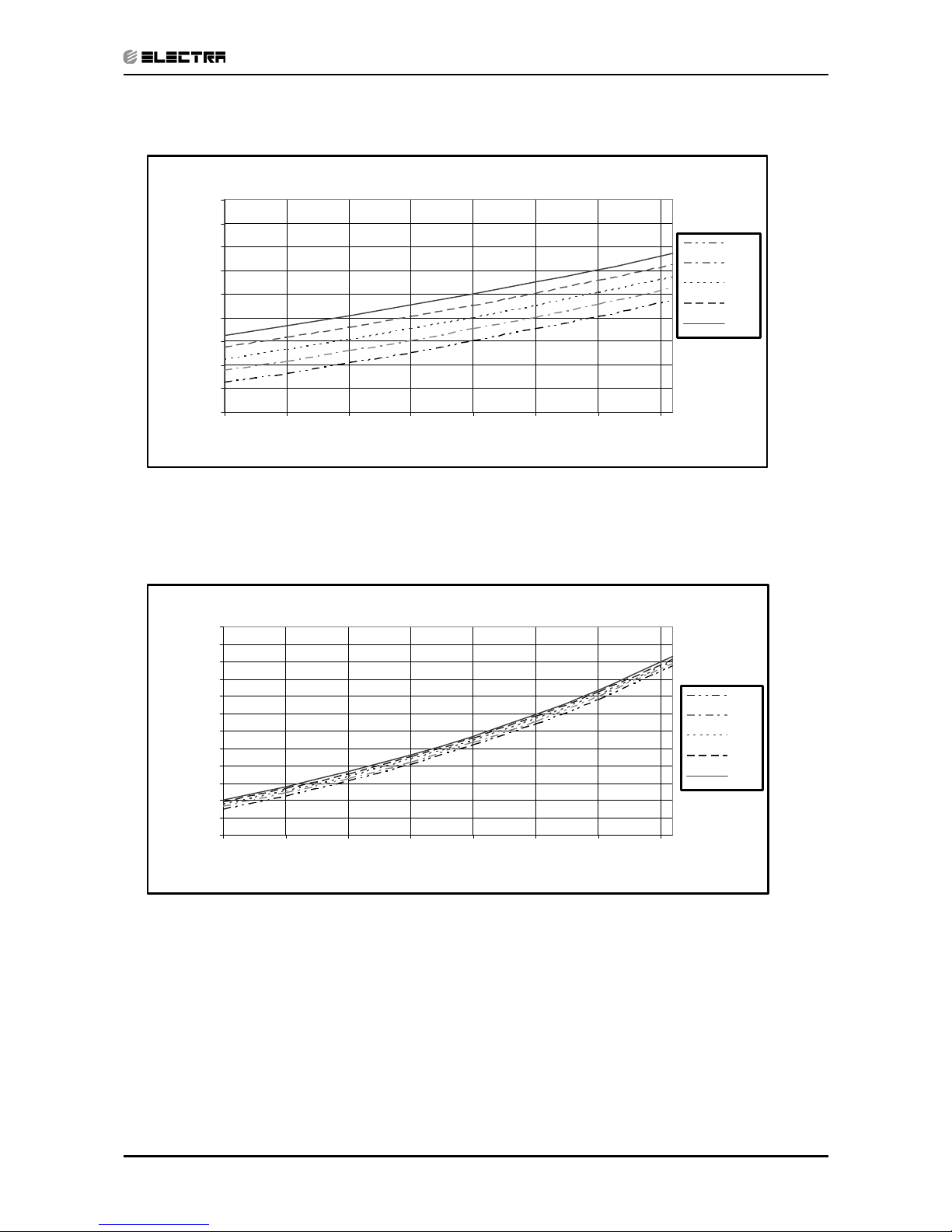

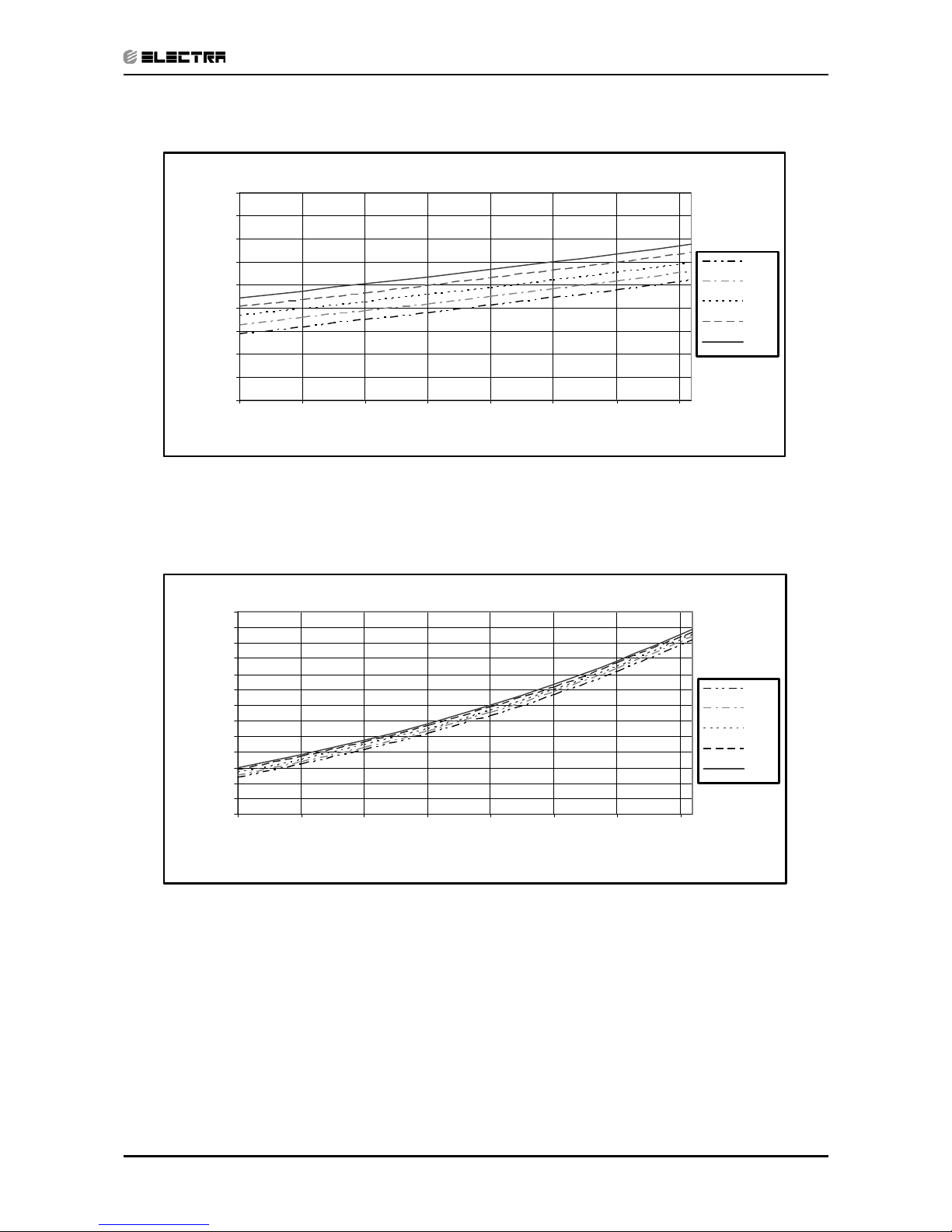

5.4 Capacity Correction Factor Due to Tubing Length

5.4.1 PXD 25/35 DCI :Cooling

5.4.2 Heating

0.91

0.92

0.93

0.94

0.95

0.96

0.97

0.98

0.99

1.00

1.01

3 4 5 6 7 8 9 1011121314151617181920

Tubing Length [m]

Capacity Ratio

0.90

0.92

0.94

0.96

0.98

1.00

1.02

3 4 5 6 7 8 9 1011121314151617181920

Tubing Length [m]

Capacity Ratio

Page 20

5-8

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01 Service Manual - PXD DCI

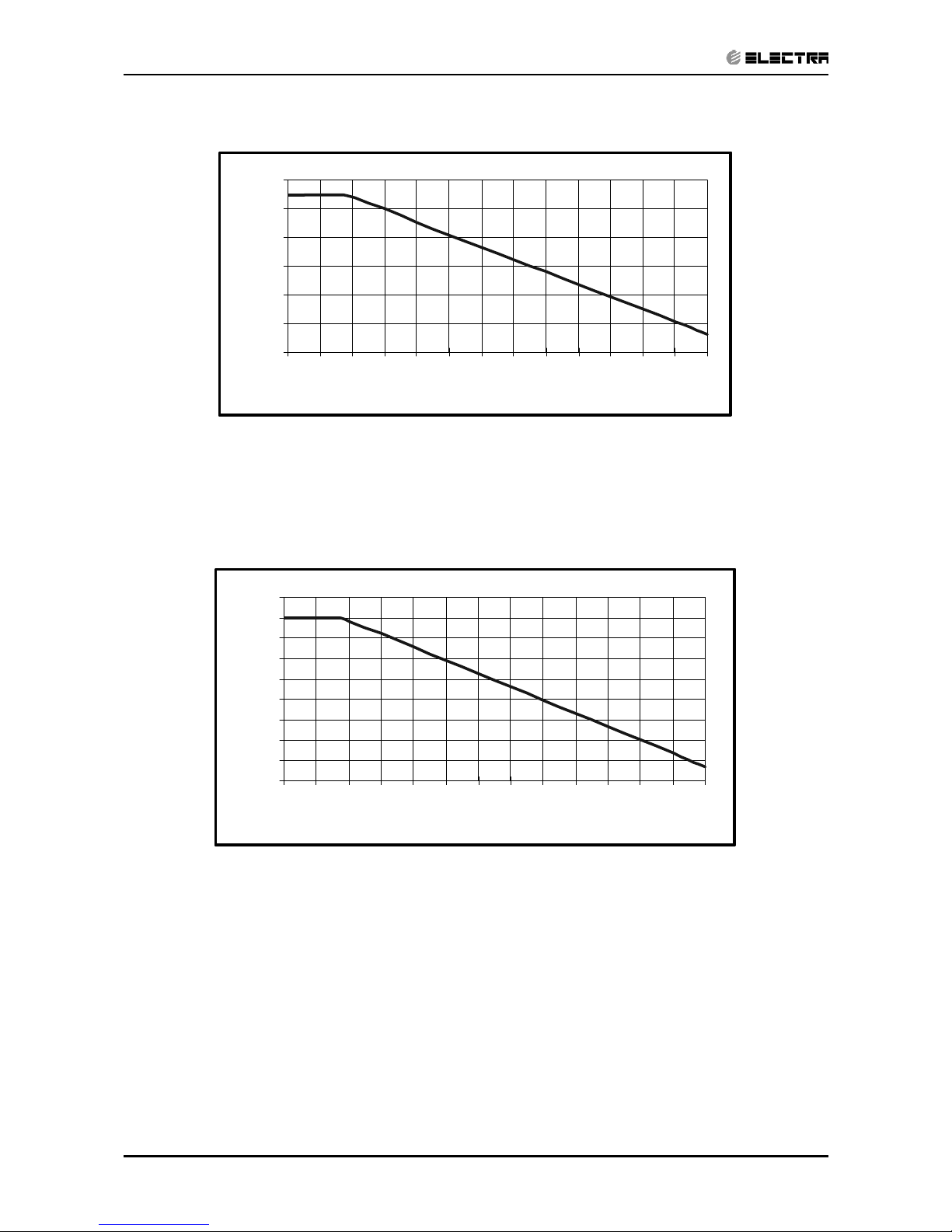

5.4.3 PXD 50 DCI :Cooling

5.4.4 Heating

0.89

0.91

0.93

0.95

0.97

0.99

1.01

4 6 8 1012141618202224262830

Tubing length(m )

Capacity ratio

0.84

0.86

0.88

0.90

0.92

0.94

0.96

0.98

1.00

1.02

4 6 8 101214161820222426 2830

Tubing Length(m)

Capacity ratio

Page 21

5-9

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01Service Manual - PXD DCI

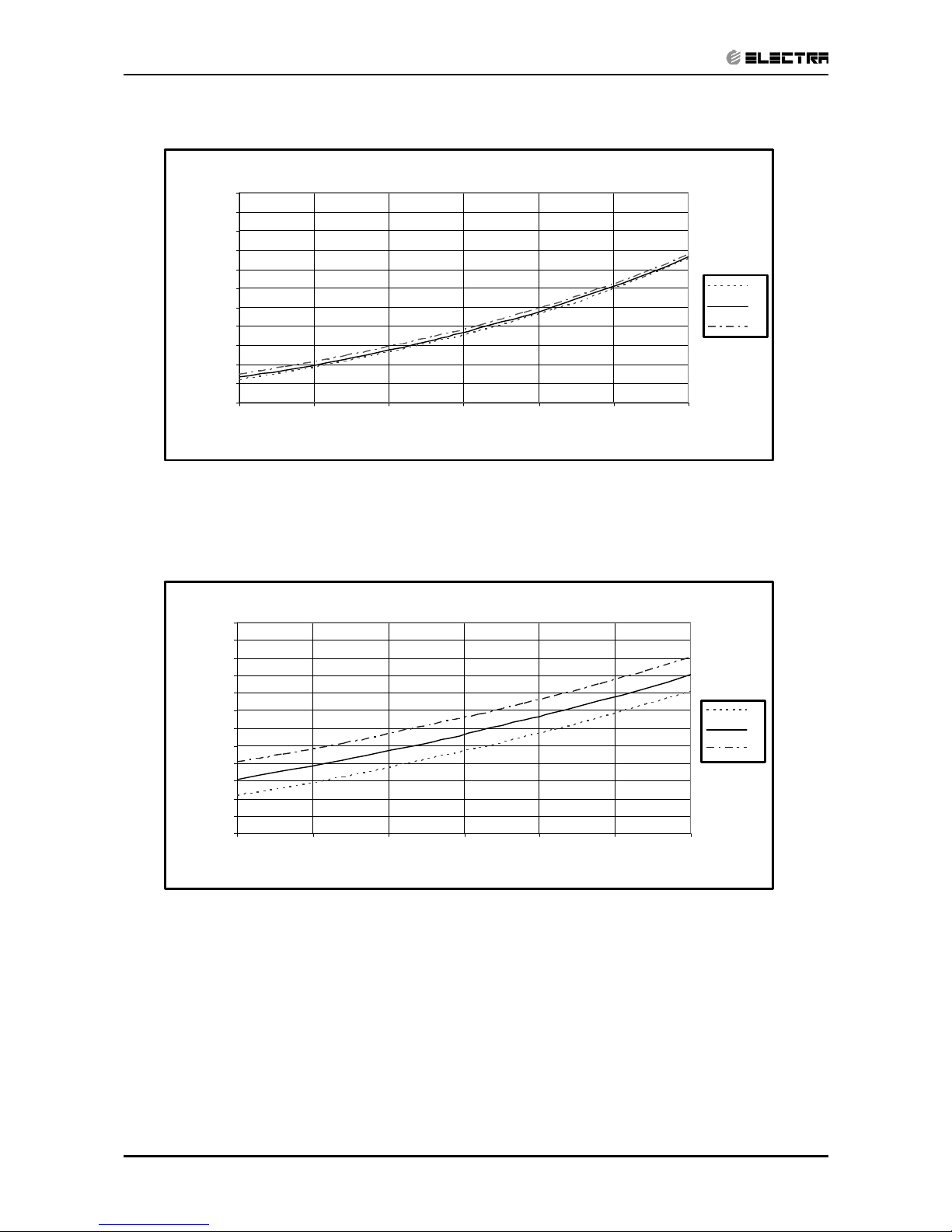

5.5 Pressure Curves

5.5.1 Model: PXD 25 DCI Cooling – Test Mode

Suction Pressure Vs.Outdoor Temp.

500

600

700

800

900

1000

1100

1200

1300

1400

10 15 20 25 30 35 40 45

Outdoor DB Tempe rature[ºC ]

Suction Pressure [kPa]

22/15

24/17

27/19

29/21

32/23

Indoor

DB/WB

Discharge Pressure Vs. Outdoor Temp.

1000

1250

1500

1750

2000

2250

2500

2750

3000

3250

3500

3750

4000

10 15 20 25 30 35 40 45

Outdoor DB Temperature[ºC ]

Discharge Pressure [kPa]

22/15

24/17

27/19

29/21

32/23

Indoor

DB/W B

Page 22

5-10

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01 Service Manual - PXD DCI

5.5.2 Heating – Test Mode

Suction Pressure Vs.Outdoor Temp.

200

300

400

500

600

700

800

900

1000

1100

1200

1300

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [ºC]

Suction Pressure [kPa]

15

20

25

Discharge Pressure Vs. Outdoor Temp.

1000

1250

1500

1750

2000

2250

2500

2750

3000

3250

3500

3750

4000

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [ºC]

Discharge Pressure [kPa]

15

20

25

Indoor DB

Page 23

5-11

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01Service Manual - PXD DCI

5.5.3 Model: PXD 35 DCI Cooling – Test Mode

Suction Pressure VS.Outdoor Temp.

500

600

700

800

900

1000

1100

1200

1300

1400

10 15 20 25 30 35 40 45

Outdoor DB Tempe rature[ºC ]

Suction Pressure [kPa]

22/15

24/17

27/19

29/21

32/23

Indoor

DB/W B

Discharge Pressure VS. Outdoor Temp.

1000

1250

1500

1750

2000

2250

2500

2750

3000

3250

3500

3750

4000

10 15 20 25 30 35 40 45

Outdoor DB Tempe rature[ºC ]

Discharge Pressure [kPa]

22/15

24/17

27/19

29/21

32/23

Indoor

DB/W B

Page 24

5-12

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01 Service Manual - PXD DCI

5.5.4 Heating – Test Mode

Suction Pressure VS.Outdoor Temp.

200

300

400

500

600

700

800

900

1000

1100

1200

1300

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [ºC]

Suction Pressure [kPa]

15

20

25

Discharge Pressure VS. Outdoor Temp.

1000

1250

1500

1750

2000

2250

2500

2750

3000

3250

3500

3750

4000

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [ºC]

Discharge Pressure [kPa]

15

20

25

Indoor DB

Page 25

5-13

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01Service Manual - PXD DCI

5.5.5 Model: PXD 50 DCI Cooling – Test Mode

Suction Pressure VS.Outdoor Temp.

500

600

700

800

900

1000

1100

1200

1300

1400

10 15 20 25 30 35 40 45

Outdoor DB Tempe rature[ºC ]

Suction Pressure [kPa]

22/15

24/17

27/19

29/21

32/23

Indoor

DB/W B

Discharge Pressure VS. Outdoor Temp.

1000

1250

1500

1750

2000

2250

2500

2750

3000

3250

3500

3750

4000

4250

10 15 20 25 30 35 40 45

Outdoor DB Tempe rature[ºC ]

Discharge Pressure [kPa]

22/15

24/17

27/19

29/21

32/23

Indoor

DB/W B

Page 26

5-14

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01 Service Manual - PXD DCI

5.5.6 Heating – Test Mode

Suction Pressure VS.Outdoor Temp.

200

300

400

500

600

700

800

900

1000

1100

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [ºC]

Suction Pressure [kPa]

15

20

25

Discharge Pressure VS. Outdoor Temp.

1000

1250

1500

1750

2000

2250

2500

2750

3000

3250

3500

3750

4000

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [ºC]

Discharge P ressure [kPa]

15

20

25

Indoor DB

Page 27

6-1

ELECTRICAL DATA

Revision Y05-01Service Manual - PXD DCI

6. ELECTRICAL DATA

6.1 Single Phase Units

MODEL PXD 25 DCI PXD 35 DCI PXD 50 DCI

Power Supply

To indoor To indoor To indoor

1PH-230V-50Hz 1PH-230V-50Hz 1PH-230V-50Hz

Max Current, A 10 10 12

Inrush Current A 35 35 35

Starting Current A 10.5 10.5 10.5

Circuit Breaker A 16 16 20

Power Supply Wiring No. X

Cross Section mm

2

3x1.5 mm

2

3x1.5 mm

2

3x2.5 mm

2

Interconnecting Cable No. X

Cross Section mm

2

4x1.5 mm

2

4x1.5 mm

2

4x2.5 mm

2

NOTE

Power wiring cord should comply with local lows and electrical

regulations requirements.

Page 28

7-1

WIRING DIAGRAMS

Revision Y05-01Service Manual - PXD DCI

7. WIRING DIAGRAMS

7.1 PXD 25, 35, 50 DCI

Choke coil

Outdoor unit controller PCB

OUTDOOR UNIT CIRCUIT DIAGRAM

COMP

Bla c k

Red

Brow n

P3

U

V

P9

White

W

P11 P13

COM

P10

L

N

N-COM

Red

Black

Blue

OFAN

3 4

P18

1

Base

heater

valve

Reverse

Blue

P14

2

1

P4

2

P1

1 2

V dc

V cc

E ARTH

Red

P16

Oran ge

Blac k

P17

OCT

P19

2

OAT

5 6

FG

V

sp

P22

Blue

Y ellow

P21

1

2

P2

1

SUCTCTT

1

P8P20

1

22

Red

Brown

magnetic ring

EARTH

COM

EMI f ilter PCB

EARTH

P12

Y/G

Y/G

EARTH

NCOM

N-F

L-F

COM

L

3

JP9

1

2

5

4 6

N

FUSE

EEV

4

P7

6

5

231

Y/G

C/5

L/4

N/3

megatool

2

P6

1

4

3

Y/G

Red

Blue

Brown

Display

POWER SUPPLY

Blue

Red

Brown

Y/G

Page 29

8-1

REFRIGERATION DIAGRAMS

Revision Y05-01Service Manual - PXD DCI

8. REFRIGERATION DIAGRAMS

8.1 PXD 25, 35, 50 DCI / ONG3 25, 35, 50 DCI

EEV

EEV

Page 30

9-1

TUBING CONNECTIONS

Revision Y05-01Service Manual - PXD DCI

9. TUBING CONNECTIONS

TUBE (Inch)

TORQUE (Nm)

¼” ⅜” ½” ⅝” ¾”

Flare Nuts 11-13 40-45 60-65 70-75 80-85

Valve Cap 13-20 13-20 18-25 18-25 40-50

Service Port Cap 11-13 11-13 11-13 11-13 11-13

1. Valve Protection Cap-end

2. Refrigerant Valve Port (use Allen wrench to open/close)

3. Valve Protection Cap

4. Refrigerant Valve

5. Service Port Cap

6. Flare Nut

7. Unit Back Side

8. Copper Tube

When the outdoor unit is installed above the indoor unit an oil trap is required every 5m along the suction

line at the lowest point of the riser. Incase the indoor unit is installed above the outdoor, no trap is

required.

Page 31

10-1

CONTROL SYSTEM

Revision Y05-01Service Manual - PXD DCI

10. CONTROL SYSTEM

10.1 General Functions and Rules (for single split models)

The DCI software is fully parametric.

All the model dependent parameters are shown in Blue color and with Italic style

[parameter].

The parameters values are given in the last section of this control logic chapter of the

service manual.

10.2 System Operation Concept

The control function is divided between indoor and outdoor unit controllers.

Indoor unit is the system ‘Master’, requesting the outdoor unit for cooling/heating

capacity supply. The outdoor unit is the system ‘Slave’ and it must supply the

required capacity unless it enters into a protection mode avoiding it from

supplying the requested capacity.

The capacity request is transferred via indoor to outdoor communication, and is

represented by a parameter called ‘NLOAD’. NLOAD is an integer number with

values between 0 and 127, and it represents the heat or cool load felt by the

indoor unit.

10.3 Compressor Frequency Control

10.3.1 NLOAD setting

The NLOAD setting is done by the indoor unit controller, based on a PI control

scheme.

The actual NLOAD to be sent to the outdoor unit controller is based on the

preliminary LOAD calculation, the indoor fan speed, and the power shedding

function.

NLOAD limits as a function of indoor fan speed:

Indoor Fan Speed Maximum NLOAD Cooling Maximum NLOAD Heating

Low

Max NLOADIF1C

127

Medium

Max NLOADIF2C

127

High

Max NLOADIF3C

127

Turbo

Max NLOADIF4C

127

Auto

Max NLOADIF5C

127

NLOAD limits as a function of power shedding:

Mode Power Shedding OFF Power Shedding ON

Cool No limit Nominal Cooling

Heat No limit Nominal Heating

Page 32

10-2

CONTROL SYSTEM

Revision Y05-01 Service Manual - PXD DCI

10.3.2

Target Frequency Setting

The compressor target frequency is a function of the NLOAD number sent from

the indoor controller and the outdoor air temperature.

Basic Target Frequency Setting:

NLOAD Target Frequency

127

Maximum frequency

10 < NLOAD < 127 Interpolated value between minimum and maximum frequency

10

Minimum frequency

0 Compressor is stopped

Target frequency limits as a function of outdoor air temperature (OAT):

OAT Range Cool mode limits Heat mode limits

OAT < 6 No limit

6 OAT < 15

MaxFreqAsOAT1H

15 OAT < 24

MaxFreqAsOATC

24 OAT No limit

MaxFreqAsOAT2H

10.3.3 Frequency Changes Control

Frequency change rate is 1 Hz/sec.

10.3.4

Compressor Starting Control

Frequency

Time

Min 10 Minutes

1

Minute

Step 1

Step 3

1

Minute

Step 2

10.3.5 Minimum On and Off Time

3 minutes

Page 33

10-3

CONTROL SYSTEM

Revision Y05-01Service Manual - PXD DCI

10.4 Indoor Fan Control

10 Indoor fan speeds are determined for each model. 5 speeds for cool/dry/fan

modes and 5 speeds for heat mode.

When user sets the indoor fan speed to a fixed speed (Low/ Medium/ High), unit

will operate constantly at set speed.

When Auto Fan is selected, indoor unit controller can operate in all speeds. The

actual speed is set according to the cool/heat load.

10.4.1

Turbo Speed

The Turbo speed is activated during the first 30 minutes of unit operation when

auto fan speed is selected and under the following conditions:

x Difference between set point and actual room temperature is bigger then 3

degrees.

x Room temperature > 22 for cooling, or < 25 for heating.

10.5 Heating Element Control

Heating element can be started if LOAD > 0.8 * MaximumNLOAD AND Indoor

Coil temperature < 45.

The heating element will be stopped when LOAD < 0.5 * MaximumNLOAD OR if

Indoor Coil temperature > 50.

10.6 Outdoor Fan Control

7 outdoor fan speeds are determined for each model. 3 speeds for cool and dry

modes, and 3 speeds for heat mode, and a very low speed.

Outdoor fan speed is a function of compressor frequency and outdoor air

temperature (OAT).

4 routines for fan control are determined. The control routine selection depends

on operation mode, compressor speed, and outdoor air temperature (OAT) and

heat sink temperature (HST).

Routine Conditions

A

Heating with OAT < 15

0

C

or

Cooling with OAT > 20

0

C, or HST > 500C

or

Faulty OAT

B Cooling with 20

0

C > OAT > 70C

C Cooling with 7

0

C > OAT

D Heating with OAT > 15

0

C

Page 34

10-4

CONTROL SYSTEM

Revision Y05-01 Service Manual - PXD DCI

Outdoor Fan Speed

Compressor Frequency (CF)

Routine A Routine B Routine C Routine D

CF = 0 OFF OFF OFF OFF

10 CF <

OFLowFreq

Low Low Very Low Low

OFLowFreq CF < OFMedFreq

Medium Low Very Low Low

OFMedFreq CF

High Low Low Medium

In cooling mode, the extra rule is as the below:

Change To Higher

OFAN Cool state (*1)

45

50

HST

Change To lower

OFAN Cool state

(*1) If State C, change to B

If State B, change to A

When compressor is switched to OFF and the heat sink temperature is above 55

degrees, the outdoor fan will remain ON in low speed for up to 3 minutes.

10.7 EEV (electronic Expansion valve) Control

EEV opening is defined as EEV = EEV

OL

+ EEV

CV

x EEVOL is the initial EEV opening as a function of the compressor frequency,

operation mode, unit model and capacity.

x EEV

CV

is a correction value for the EEV opening that is based on the compressor

temperature.

x During the first 10 minutes of compressor operation EEV

CV

= 0.

x Once the first 10 minutes are over, the correction value is calculated as follow:

EEV

CV

(n) = EEVCV(n-1) + EEV

CTT

x EEV

CTT

is the correction based on the compressor temperature. A target

compressor temperature is set depending on frequency and outdoor air

temperature, and the actual compressor temperature is compared to the target

temperature to set the required correction to the EEV opening.

10.8 Reversing Valve (RV) Control

Reversing valve is on in heat mode.

Switching of RV state is done only after compressor is off for over 3 minutes

.

Page 35

10-5

CONTROL SYSTEM

Revision Y05-01Service Manual - PXD DCI

10.9 Ionizer Control

Ionizer is on when unit is on AND indoor fan is on AND Ionizer power switch (on

Ionizer) is on

.

10.10 Electro Static Filter (ESF) Control

ESF is on when ESF switch is on, Safety switch is pressed, unit is on, AND

indoor fan is on.

10.11 Base Heater Control

When OAT is connected, Base Heater will be on when unit is in heating and

OAT<2

0

C.

When OAT is disconnected, Base Heater will be on when unit is in heating.

10.12 Fan Mode

In high/ medium/ low indoor fan user setting, unit will operate fan in selected

speed.

In Auto Fan user setting, fan speed will be adjusted automatically according to

the difference between actual room temperature and user set point temperature.

10.13 Cool Mode

NLOAD is calculated according to the difference between actual room

temperature and user set point temperature by PI control.

In high/ medium/ low indoor fan user setting, unit will operate fan in selected

speed.

In Auto Fan user setting, fan speed will be adjusted automatically according to

the calculated NLOAD.

10.14 Heat Mode

NLOAD is calculated according to the difference between actual room temperature

and user set point temperature by PI control.

In high/ medium/ low indoor fan user setting, unit will operate fan in selected

speed.

In AutoFan user setting, fan speed will be adjusted automatically according to the

calculated NLOAD.

10.15 Temperature Compensation

In wall mounted, ducted, and cassette models, 3 degrees are reduced from room

temperature reading (except when in I-Feel mode), to compensate for

temperature difference between high and low areas in the heated room, and for

coil heat radiation on room thermistor.

The temperature compensation can be enabled/disabled by shortening of J2 on

the indoor unit controller.

Page 36

10-6

CONTROL SYSTEM

Revision Y05-01 Service Manual - PXD DCI

Model J2 Shorted J2 Opened

Wall mounted Compensation Disabled Compensation Enabled

Cassette Compensation Enabled Compensation Disabled

Ducted Compensation Enabled Compensation Disabled

Floor/Ceiling Compensation Disabled Compensation Enabled

10.16 Indoor Fan Control in Heat Mode

Indoor fan speed depends on the indoor coil temperature:

10.17 Auto Cool/Heat Mode

When in auto cool heat mode unit will automatically select between cool and heat

mode according to the difference between actual room temperature and user set

point temperature (T).

Unit will switch from cool to heat when compressor is off for 3 minutes, and T <

-3.

Unit will switch from heat to cool when compressor is off for 5 minutes, and T < -3.

10.18 Dry Mode

As long as room temperature is higher then the set point, indoor fan will work in low

speed and compressor will work between 0 and MaxNLOADIF1C Hz.

When the room temperature is lower than the set point, compressor will be

switched OFF and indoor fan will cycle 3 minutes OFF, 1 minute ON.

10.19 Protections

There are 5 protection codes.

Normal (Norm) – unit operate normally

.

Stop Rise (SR) – compressor frequency can not be raised but does not have to be

decreased.

HzDown1 (D1) – Compressor frequency is reduced by 2 to 5 Hz per minute.

HzDown2 (D2) – Compressor frequency is reduced by 5 to 10 Hz per minute.

Stop Compressor (SC) – Compressor is stopped.

ICTVL ICTH ICTL

ICTST

ICTT

Page 37

10-7

CONTROL SYSTEM

Revision Y05-01Service Manual - PXD DCI

10.19.1 Indoor Coil Defrost Protection

ICT Trend

ICT

Fast

Increasing

Increasing No change Decreasing Fast

Decreasing

ICT < -2 SC SC SC SC SC

-2 ICT < 0 D1 D1 D2 D2 D2

0 ICT < 2 SR SR D1 D2 D2

2 ICT < 4 SR SR SR D1 D2

4 ICT < 6 Norm Norm SR SR D1

6 ICT < 8 Norm Norm Norm SR SR

8 ICT Normal

10.19.2 Indoor Coil over Heating Protection

ICT Trend

ICT

Fast

Decreasing

Decreasing No Change Increasing Fast

Increasing

ICT > 55 SC SC SC SC SC

53 < ICT 55 D1 D1 D2 D2 D2

49 < ICT 53 SR SR D1 D2 D2

47 < ICT 49 SR SR SR D1 D2

45 < ICT 47 Norm Norm SR SR D1

43 < ICT 45 Norm Norm Norm SR SR

ICT 43 Normal

10.19.3 Compressor over Heating Protection

Compressor temperature can be in one of 5 control zones (4 in protection, and 1

normal), according to the following chart.

Normal

P1

P2

Stop-Compresor

CTTOH1

CTTOH2

CTTOH3

CTTOH4

CTT

P3

Page 38

10-8

CONTROL SYSTEM

Revision Y05-01 Service Manual - PXD DCI

Control Status

Compressor Temperature

Increases

Else

P1 Norm SR

P2 D1 SR

P3 D2 D1

Stop Compressor SC

10.19.4 Compressor over Current Protection

Normal

Stop-Rise

HzDown1

HzDown2

Stop-Compresor

CCROC1

CCROC2

CCROC3

CCROC4

CCR

10.19.5 Heat Sink over Heating Protection (NA for DCI 25 and 35

HST Trend

HST

Decreasing No Change Increasing

HST > 90 SC SC SC

85 < HST 90 D1 D2 D2

82 < HST 85 SR D1 D2

80 < HST 82 SR SR D1

78 < HST 80 Norm Norm SR

HST 78 Normal

Page 39

10-9

CONTROL SYSTEM

Revision Y05-01Service Manual - PXD DCI

10.19.6

Outdoor Coil Deicing Protection

Deicing Starting Conditions:

Deicing operation will start when either one of the following conditions exist:

x Case 1: OCT < OAT – 8 AND TLD > DI

x Case 2: OCT < OAT – 12 AND TLD > 30 minutes.

x Case 3: OCT is Invalid AND TLD > DI

x Case 4: Unit is just switched to STBY AND OCT < OAT – 8

x Case 5: NLOAD = 0 AND OCT < OAT -8

OCT – Outdoor Coil Temperature

OAT – Outdoor Air Temperature

TLD – Time from Last Deicing

DI – Deicing Interval (Time Interval between Two Deicing)

Deicing interval time when compressor is first started in heat mode, is 10 minutes

if OCT < -2, and is 40 minutes in other cases.

Deicing interval time is changed (increased/ decreased in 10 minutes steps) as a

function of deicing time. If deicing time is shorter then former deicing time, the

deicing interval time will be increased. If deicing time is longer then former

deicing time, the deicing interval time will be decreased.

10.19.7

Deicing Protection Procedure

COMP

RV

OFAN

EEV

ON

HEAT

COOL

ON

OFF

EEVDeicerOpen

Any

T1 T2

T3 T3

T1

12

0

Threshold

max. 12 minutes

DT

OCT

T1 = T2 = 36 seconds, T3 = 6 seconds

Page 40

10-10

CONTROL SYSTEM

Revision Y05-01 Service Manual - PXD DCI

10.20 Condensate Water Over Flow Protection

Each of the pins P1, P2, P3 can have two options:

1 – When it is shorted with P4

0 – When it is not shorted to P4

10.20.1

3 Levels Logic (used in floor/ceiling models)

P2 P3 Level

0 0 L0

1 0 L1

1 1 L2&3

0 1 L4

Water Level

ANY

0

BLINK

NLOAD

OPER LED

LEVEL1

LEVEL2&3

LEVEL4

NORMAL

ON

Pump

OFF

Page 41

10-11

CONTROL SYSTEM

Revision Y05-01Service Manual - PXD DCI

10.20.2 1 Level Logic (used in all models except for floor/ceiling models)

P2 P3 Level

Don’t

care

1 Normal

Don’t

care

0 Overflow

ANY

0

ON

NLOAD

PUMP

OFF

ON

OPER

LED

OFF

Overflow

Water Level

Normal

BLINK

NLOAD is

forced to 0

8 min 8 min

Overflow when

unit is ON

Overflow when

unit is OFF

8 min

10.21 Indoor Unit Dry Contact

Indoor unit Dry contact has two alternative functions that are selected by

J8.

Function Contact = Open Contact = Short

J8 = Open Presence Detector Connection No Limit Forced to STBY

J8 = Short Power Shedding Function No Limit Limit NLOAD

10.22 Operating the Unit from the Mode Button

Forced operation allows starting, stopping and operating in Cooling or

Heating, in pre-set temperature according to the following table:

Forced operation Mode Pre-set Temperature

Cooling 200C

Heating 28

0

C

Page 42

10-12

CONTROL SYSTEM

Revision Y05-01 Service Manual - PXD DCI

10.23 On Unit Controls and Indicators

10.23.1 Indoor Unit Controller Controls and Indicators for All Models

STAND BY INDICATOR

1. Lights up when the Air Conditioner is connected to power

and ready to receive the R/C commands

OPERATION INDICATOR

1. Lights up during operation.

2. Blinks for 300 msec., to announce that a R/C infrared

signal has been received and stored.

3. Blinks continuously during protections (according to the

relevant spec section).

TIMER INDICATOR

Lights up during Timer and Sleep operation.

FILTER INDICATOR

Lights up when Air Filter needs to be cleaned.

COOLING INDICATOR

Lights up when system is switched to Cool Mode by using the Mode

Switch on the unit

.

HEATING INDICATOR

Lights up when system is switched Heat Mode by using the Mode

Switch on the unit

.

Mode SWITCH

(COOL/HEAT/OFF)

Every short pressing , the next operation mode is selected, in this

order : SB Cool Mode Heat Mode SB …

In long pressing system enters diagnostic mode.

RESET / FILTER SWITCH

For short pressing:

When Filter LED is on - turn off the FILTER INDICATOR after a

clean filter has been reinstalled.

When Filter LED is off – enable/disable the buzzer announcer, if

selected.

Page 43

10-13

CONTROL SYSTEM

Revision Y05-01Service Manual - PXD DCI

10.23.2 Indoor Unit Controls and Indicators for LCD Display

STBY Cool Heat Auto Fan Dry

OFF SPT(1*) SPT(1*) SPT(1*) SPT(1*) SPT(1*)

OFF(2*) ON(2*) ON(2*) ON(2*) ON(2*) ON(2*)

OFF(2*) OFF(2*) OFF(2*) OFF(2*) OFF(2*) OFF(2*)

(Low)

OFF

(Med)

OFF

(High)

OFF

(Turbo)

OFF

(Auto)

OFF

User

setting

IFAN

speed

User

setting

IFAN

speed

User

setting

IFAN

speed

User

setting

IFAN

speed

User

setting

IFAN

speed

Backlight(red)

OFF OFF ON(3*) ON(3*) ON(3*) OFF

Backlight(green)

OFF ON(3*) OFF ON(3*) ON(3*) ON(3*)

10.24 Outdoor Unit Controller Indicators

Unit has three LED’s.

SB LED is ON when power is ON (230 VAC, even when no communication).

STATUS LED is ON when COMP is ON, and Blinks according to diagnostics

mode definitions when either fault or protection occurs.

FAULT LED Blinks according to diagnostics mode definitions when either fault or

protection occurs.

Page 44

10-14

CONTROL SYSTEM

Revision Y05-01 Service Manual - PXD DCI

10.25 Jumper Settings

10.25.1 Indoor Unit Controller

Self test Jumper – J1:

0 = Open Jumper (disconnect jumper) / 1 = Close Jumper (connect jumper).

OPERATION J1

SELF-TEST 1

NORMAL 0

Compensation Jumper – J2

Model J2 (Default) Compensation

WNG/WNG18/WNG30 0 Activated

PXD/AC 1 Deactivated

LS/K/KS 1 Activated

Family selection Jumper – J3, J4, J5and J6

Family J6 J5 J4 J3

WNG 0 0 1 1

PXD 0 1 0 0

KS 0 1 0 1

LS 0 1 1 0

K 0 1 1 1

WNG18 1 0 0 0

WNG30 1 0 0 1

IDU Model

Jumper Setting

J8 J7 J6 J5 J4 J3

WNG25 000011

WNG35 010011

WNG50 001000

WNG60 011000

WNG80 001001

PXD25 000100

PXD35 010100

PXD50 100100

K25 000111

K35 010111

K50 100111

LS35 010110

For wall mounted units Jumpers j7, j8 can be configured by service. All other jumpers on

the above table are factory default (cannot be changed by service).

For unit types as Cassettes, floor ceiling, and ducted, jumpers are set by a model plug.

Page 45

10-15

CONTROL SYSTEM

Revision Y05-01Service Manual - PXD DCI

Model selection Jumper – J7, J8

Model J8 J7

A

B

C

D

0 0

0 1

1 0

1 1

J9- Presence Detector/Power Shedding

OPERATION J9

Presence Detector 0

Power Shedding 1

Jumper – J10

OPERATION J10

WNG DCI LCD 0

LED 1

Note:

Jumper 10 states will be ignored for families other than WNG /WNG18/WNG30 (for other

families it will always be LED operation).

10.25.2 Outdoor Unit Controller

JP9 JUMPER LAYOUT

Reserved (PIN 9) ODU3 (PIN 7) ODU2 (PIN 5) ODU1 (PIN 3) ODU0 (PIN 1)

GND (PIN 10) GND (PIN 8) GND (PIN 6) GND (PIN 4) GND (PIN 2)

10.25.3 ODU MODEL SELECTION

ODU3 ODU2 ODU1 ODU0 ODU Model

OFF OFF OFF OFF Reserved

OFF OFF OFF ON (PIN1 & PIN2) A (DCI 25)

OFF OFF ON (PIN3 & PIN4) OFF B (DCI 35)

OFF OFF ON (PIN3 & PIN4) ON (PIN1 & PIN2) C (DCI 50)

OFF ON (PIN5 & PIN6) OFF OFF D

OFF ON (PIN5 & PIN6) OFF ON (PIN1 & PIN2) E (Duo)

OFF ON (PIN5 & PIN6) ON (PIN3 & PIN4) OFF F

OFF ON (PIN5 & PIN6) ON (PIN3 & PIN4) ON (PIN1 & PIN2) G

ON (PIN7 & PIN8) OFF OFF OFF H

ON (PIN7 & PIN8) OFF OFF ON (PIN1 & PIN2) I

ON (PIN7 & PIN8) OFF ON (PIN3 & PIN4) OFF J

ON (PIN7 & PIN8) OFF ON (PIN3 & PIN4) ON (PIN1 & PIN2) K

ON (PIN7 & PIN8) ON (PIN5 & PIN6) OFF OFF L

ON (PIN7 & PIN8) ON (PIN5 & PIN6) OFF ON (PIN1 & PIN2) M

ON (PIN7 & PIN8) ON (PIN5 & PIN6) ON (PIN3 & PIN4) OFF N

ON (PIN7 & PIN8) ON (PIN5 & PIN6) ON (PIN3 & PIN4) ON (PIN1 & PIN2) O

Page 46

10-16

CONTROL SYSTEM

Revision Y05-01 Service Manual - PXD DCI

10.26 Test Mode

10.26.1 Entering Test Mode

System can enter Test mode in two ways:

x Automatically when the following conditions exists for 30 minutes

continuously:

o Mode = Cool, Set point = 16, Room temperature = 27±1, Outdoor

temperature = 35±1

Or

o Mode = Heat, Set point = 30, Room temperature = 20±1, Outdoor

temperature = 7±1

x Manually when entering diagnostics with the following settings:

o Mode = Cool, Set point = 16

o Mode = Heat, Set point = 30

10.27 Unit Operation in Test Mode

In test mode, the unit will operate in fixed settings according to the indoor fan

speed setting:

Indoor Fan Speed Setting Unit Setting

Low Minimum Capacity Setting

High Nominal Capacity Setting

Auto Maximum Capacity Setting

During test mode, protections are disabled, except for stop compressor status.

10.28 Additional Functions and Rules (for DUAL split models)

The DCI SW is fully parametric.

All the model dependent parameters are shown in Blue color and with Italic style

[parameter].

The parameters values are given in the last section of this control logic chapter of

the service manual.

10.29 System Control Concept

All indoor unit related items control remains the same as in single split

applications.

All outdoor units related control logic remains the same as in single split

applications.

The MSMP controller is responsible only for the following control:

x Setting of system operation mode (cool/heat)

x Setting the NLOAD for the outdoor units

x Controlling of the EEV’s

x Dry contacts control

Page 47

10-17

CONTROL SYSTEM

Revision Y05-01Service Manual - PXD DCI

10.32.1

Indoor Units Operation when Indoor Unit Mode is Different than

Outdoor Unit Mode

x Open louvers according to user selection.

x Indoor fan is forced to OFF.

10.33 Dry Contacts Control

Dry Contact Contact = Open Contact = Short

STBY No Limit System is Forced to STBY

Night No Limit Outdoor fan speed reduced to low in cooling mode

A dry contact output for Alarm will be shorted when any failure exists in the system.

10.30 Compressor Frequency Control

10.30.1 Outdoor Unit NLOAD setting

The MSMP controller gets the NLOAD from each of the indoor units, and sends a

combined NLOAD to the outdoor unit control. The combined NLOAD is a

weighted average of the indoor units NLOAD.

The weight of the indoor units as a function of their nominal capacity:

Indoor Unit Capacity [kW] (kBtu/hr) Capacity Code

2.5 (9000) 1

3.5 (12000) 1.5

5.0 (18000) 2

7.2 (24000) 3

10.31 EEV (electronic Expansion valve) Control

EEV opening is defined as EEV = EEVOL + EEV

CV

x EEVOL is the initial EEV opening as a function of the compressor

frequency, operation mode, unit model and capacity.

x EEV

CV

is a correction value for the EEV opening that is based in cooling

mode on the relevant indoor unit super heat and compressor temperature.

x During the first 10 minutes of compressor operation EEV

CV

= 0.

10.32 System Mode Setting and Reversing Valve (RV) Control

The first indoor unit that is causing the system to be turned ON sets the system

mode.

Page 48

10-18

CONTROL SYSTEM

Revision Y05-01 Service Manual - PXD DCI

10.34 SW Parameters

10.34.1 Indoor Units SW Parameters

General Parameters for All Models:

Parameters defining the indoor fan speed as a function of Indoor Coil

temperature in heat mode (ICT):

ICTST Speed ICT to stop indoor fan 25

ICTVLSpeed ICT to go down to very low speed 28

ICTLSpeed ICT to start in very low speed 30

ICTHSpeed ICT to start in increase speed from very low 32

ICTTSpeed ICT to enable Turbo fan speed 40

Model Depended Parameters:

Wall Mounted Models

Parameter name

DCI 25 DCI 35 DCI 50 DCI 60

NLOAD limits as a function of selected indoor fan speed

MaxNLOADIF1C 40 40 45 50

MaxNLOADIF2C 53 53 62 85

MaxNLOADIF3C 120 120 120 120

MaxNLOADIF4C 127 127 127 127

MaxNLOADIF5C 127 127 127 127

Indoor Fan speeds

IFVLOWC 700 700 700 800

IFLOWC 800 800 900 1000

IFMEDC 900 950 1050 1100

IFHIGHC 1050 1100 1200 1250

IFTURBOC 1150 1200 1250 1300

IFVLOWH 700 700 700 800

IFLOWH 800 850 900 950

IFMEDH 950 1000 1100 1150

IFHIGHH 1100 1150 1200 1250

IFTURBOH 1200 1250 1300 1300

Nominal Compressor Frequency

NomLoadC 40 62 62 85

NomLoadH 55 67 74 80

Cassette / Floor mounted

Parameter Name

25 35 K 35S 50

NLOAD limits as a function of selected indoor fan speed

MaxNLOADIF1C 40 40 40 40

MaxNLOADIF2C 53 56 56 60

MaxNLOADIF3C 120 90 90 90

MaxNLOADIF4C 127 90 90 90

MaxNLOADIF5C 127 90 90 90

Nominal Compressor Frequency

NomLoadC 40 60 56 63

Page 49

10-19

CONTROL SYSTEM

Revision Y05-01Service Manual - PXD DCI

NomLoadH 55 69 73 80

10.34.2 Outdoor Units SW Parameters:

Parameter Name DCI25 DCI35 DCI 50 DCI50 DUO DCI 60

Compressor Parameters

MinFreqC 30 33 20 20 20

MaxFreqC 64 80 85 97 95

MinFreqH 30 35 20 26 26

MaxFreqH 81 93 99 106 94

Step1Freq 60 60 60 60 60

Step2Freq 70 70 70 80 70

Step3Freq 90 90 90 90 90

Frequency limits as a function of outdoor air temperature

MaxFreqAsOATC 50 50 64 62 85

MaxFreqAsOAT1H 65 75 85 85 80

MaxFreqAsOAT2H 60 60 60 60 60

Compressor Over Heating Protection

CTTOH1 94 94 94 90 94

CTTOH2 98 98 98 95 98

CTTOH3 102 102 102 102 102

CTTOH4 105 105 105 105 105

Compressor Over Current Protection [A]

CCR01 7.1 7.1 10 10 11.4

CCR02 7.5 7.5 10.5 10.5 11.8

CCR03 7.9 7.9 10.8 10.8 12.2

CCR04 8.3 8.3 11.2 11.2 12.6

Outdoor Fan Speed (RPM)

VL 200 200 200 200 200

OFLOWC 550 550 600 600 550

OFMEDC 700 700 760 830 700

OFMAXC 830 830 920 920 790

OFLOWH 550 550 600 600 550

OFMEDH 700 700 830 920 700

OFMAXH 830 830 1000 1000 790

Outdoor Fan Limit Control

OFLowFreqC 45 45 40 40 35

OFMedFreqC 57 57 70 70 55

OFLowFreqH 45 45 40 40 40

OFMedFreqH 57 57 86 86 60

Page 50

11-1

TROUBLESHOOTING

Revision Y05-01Service Manual - PXD DCI

11. TROUBLESHOOTING

Warning!!!

When Power Up – the whole outdoor unit controller, including the wiring, is under HIGH

VOLTAGE!!!

Never open the Outdoor unit before turning off the Power!!!

When turned off, the system is still charged (400V)!!!

It takes about 4 Min. to discharge the system.

Touching the controller before discharging may cause an electrical shock!!!

For safe handling of the controller please refer to section 12.6 below.

.1 Single Split system failures and corrective actions

No SYMPTOM PROBABLE

CAUSE

CORRECTIVE ACTION

1 Power supply indicator

(Red LED) does not light

up.

No power supply Check power supply. If power supply

is OK, check display and display

wiring. if OK, replace controller.

2 Unit does not respond to

remote control message

Remote control

message not

reached the indoor

unit

Check remote control batteries, if

batteries are OK, check display and

display wiring, if OK, replace display

PCB.

If still not OK replace controller.

3 Unit responds to remote

control message but

Operate indicator (Green

LED) does not light up

Problem with

display PCB

Replace display PCB.

If still not OK replace controller.

Unit in heat mode

and coil is still not

warm.

Change to cool mode and check. 4 Indoor fan does not start

(louvers are opened and

Green LED does light

up)

Problem with PCB

or capacitor

Change to high speed and Check

power supply to motor is higher than

130

VAC (for triack controlled motor)

or higher than 220VAC for fixed

speed motors, if OK replace

capacitor, if not OK replace

controller

5 Indoor fan works when

unit is OFF, and indoor

fan speed is not

changed by remote

control command.

PCB problem Replace controller

6 Compressor does not

start

Electronics control

problem or

protection

Perform diagnostics (See 12.3

below), and follow the

actions

described.

7 Compressor stops

during operation and

Green LED remains on

Electronic control

or power supply

problem

Perform diagnostics (See 12.3

below), and follow the actions

described.

Page 51

11-2

TROUBLESHOOTING

Revision Y05-01 Service Manual - PXD DCI

No SYMPTOM PROBABLE

CAUSE

CORRECTIVE ACTION

8 Compressor is on but

outdoor fan does not

work

Problem with

outdoor electronics

or outdoor fan

Check outdoor fan motor according

to the procedure in section 12.5.3

below, if not OK replace controller

9 Unit works in wrong

mode (cool instead of

heat or heat instead of

cool)

Electronics or

power connection

to RV

Check RV power connections, if OK,

Check RV operation with direct

230VAC power supply, if

OK,

Replace outdoor controller.

10 All components are

operating properly but

no cooling or no heating

Refrigerant leak Check refrigeration system.

11 Compressor is over

heated and unit does not

generate capacity

EEV problem Check EEV

12 Units goes into

protections and

compressor is stopped

with no clear reason

Control problem or

refrigeration

system problem

Perf

orm diagnostics (See 12.3

below), and follow the actions

described.

13 Compressor motor is

generating noise and no

suction occurs

Phase order to

compressor is

wrong

Check compressor phase order.

14 Water leakage from

indoor unit

Indoor unit

drainage tube is

blocked

Check and open drainage tube.

15 Freezing of outdoor unit

in heat mode and

outdoor unit base is

blocked with ice

Connect base heater.

16 Unit operates with wrong

fan speeds or wrong

frequency

Wrong jumper

settings

Perform diagnostics (See 12.3

below), and check if units is

operating by EEPROM parameters.

.2 Checking the refrigeration system

Checking system pressures and other thermodynamic measures should be done when system

is in Test Mode (in Test mode, system operates in fixed settings). The performance curves

given in this manual are given for unit performance in test mode when high indoor fan speed is

selected.

Entering test mode:

Set unit to Cool/16 degrees/High indoor fan speed, or Heat/30 degrees/High indoor fan speed,

and enter diagnostics.

Page 52

11-3

TROUBLESHOOTING

Revision Y05-01Service Manual - PXD DCI

.3 Judgment by Indoor/Outdoor Unit Diagnostics

Enter diagnostics mode - press for five seconds Mode button in any operation mode.

Acknowledgment is by 3 short beeps and lights of COOL and HEAT LED’s. Then, every short

pressing of Mode button will scroll between Indoor and Outdoor unit diagnostic modes by the

acknowledgment of 3 short beeps and lighting of COOL and HEAT LED’s.

During the Outdoor unit diagnostics all four Indoor LED’s (STBY, Operate, Filter and Timer) are

blinking. When Indoor diagnostics is displayed, a

ll four LED’s (STBY, Operate, Filter and Timer)

are ON.

When system enters diagnostics mode, only one fault code is shown. Order of priority is from

the lower to the higher number. Diagnostics is continuously ON as long as power is ON. The

current system operation mode will not be changed.

If no fault occurred in the system, no fault code will be displayed during normal operation

mode. The last fault code will be displayed even if the system has recovered from th

at fault.

The last fault will be deleted from the EEPROM after the system has exit diagnostics mode.

In diagnostics mode, system fault / status will be indicated by blinking of Heat & Cool LEDs.

The coding method will be as follows:

Heat LED will blink 5 times in 5 seconds, and then will be shut off for the next 5 seconds. Cool

LED will blink during the same 5 seconds according to the following Indoor / Outdoor unit

tables:

Note: 0 – OFF, 1-ON

.3.1 Indoor unit Diagnostics

No Problem 5 4 3 2 1

1 RT-1 is disconnected 0 0 0 0 1

2 RT-1 is shorted 0 0 0 1 0

3 RT-2 is disconnected 0 0 0 1 1

4 RT-2 is shorted 0 0 1 0 0

5 Reserved 0 0 1 0 1

7 Communication mismatch 0 0 1 1 1

8 No Communication 0 1 0 0 0

9 No Encoder 0 1 0 0 1

10 Reserved 0 1 0 1 0

11 Outdoor Unit Fault 0 1 0 1 1

… Reserved

17 Defrost protection 1 0 0 0 1

18 Deicing Protection 1 0 0 1 0

19 Outdoor Unit Protection 1 0 0 1 1

20 Indoor Coil HP Protection 1 0 1 0 0

21 Overflow Protection 1 0 1 0 1

22 Reserved

24 EEPROM Not Updated 1 1 0 0 0

25 Bad EEPROM 1 1 0 0 1

26 Bad Communication 1 1 0 1 0

27 Using EEPROM data 1 1 0 1 1

28 Model A 1 1 1 0 0

29 Model B 1 1 1 0 1

30 Model C 1 1 1 1 0

31 Model D 1 1 1 1 1

Page 53

11-4

TROUBLESHOOTING

Revision Y05-01 Service Manual - PXD DCI

.3.2 Indoor unit diagnosis and corrective actions

No.

Fault

Probable Cause Corrective Action

1

Sensor failures of

all types

Check sensor connections or

replace sensor

2

Communication

mismatch

Indoor and Outdoor

controllers are with different

versions

Replace Indoor controller

3

No Communication

Communication or grounding

wiring is not good.

Check Indoor to Outdoor

wiring and grounding

4

No Encoder

Indoor electronics or motor Check motor wiring, if o

k,

replace motor, if still not ok,

replace Indoor controller.

5

Outdoor Unit Fault

Outdoor controller problem Switch to Outdoor

diagnostics.

6

EEPROM Not

Updated

System is using ROM

parameters and not

EEPROM parameters

No action, unless special

parameters are required for

unit operation.

7

Bad EEPROM

No action, unless special

parameters are required for

unit operation.

8

Bad

Communication

Co

mmunication quality is low

reliability

Check Indoor to Outdoor

wiring and grounding

9

Using EEPROM

data

No problem. System is using

EEPRRRROM parameters

Page 54

11-5

TROUBLESHOOTING

Revision Y05-01Service Manual - PXD DCI

No Problem 5 4 3 2 1

1 OCT is disconnected

0 0 0 0 1

2 OCT is shorted

0 0 0 1 0

3 CTT is disconnected

0 0 0 1 1

4 CTT is shorted

0 0 1 0 0

5 HST is disconnected (when enabled)

0 0 1 0 1

6 HST is shorted (when enabled)

0 0 1 1 0

7 OAT is disconnected (when enabled)

0 0 1 1 1

8 OAT is shorted (when enabled)

0 1 0 0 0

9 TSUC is disconnected (when enabled)

0 1 0 0 1

10 TSUC is shorted (when enabled)

0 1 0 1 0

11 IPM Fault

0 1 0 1 1

12 Bad EEPROM

0 1 1 0 0

13 DC under voltage

0 1 1 0 1

14 DC over voltage

0 1 1 1 0

15 AC under voltage

0 1 1 1 1

16 IDU/ODU Communication mismatch

1 0 0 0 0

17 No Comm

unication

1 0 0 0 1

18 Reserved

1 0 0 1 0

20 Heat sink Over Heating

1 0 1 0 0

21 Deicing

1 0 1 0 1

22 Compressor Over Heating

1 0 1 1 0

23 Compressor Over Current

1 0 1 1 1

24 No OFAN Feedback

1 1 0 0 0

25 OFAN locked

1 1 0 0 1

26 Compressor Lock

1 1 0 1 0

27 Bad Communication

1 1 0 1 1

1 - ON, 0 - OFF

Only one code is shown. Order of priorety is 1-24. Diagnostics is continuously ON as long

power is on.

11.3.3 Outdoor Unit Diagnastics

Page 55

11-6

TROUBLESHOOTING

Revision Y05-01 Service Manual - PXD DCI

11.3.4 Outdoor unit diagnosis and corrective actions

Fault

Probable Cause Corrective Action

Sensors failures of all

types

Check sensors

connections or replace

sensors.

IPM Fault Electronics HW

problem

Check all wiring and

jumper settings, if OK,

replace electronics.

Bad EEPROM No action, unless special

parameters are required

for unit operation.

DC under/over Voltage Electronics HW

problem

Check outdoor unit power

supply voltage

AC under Voltage Check outdoor unit power

supply voltage

Indoor / Outdoor unit

Communication

mismatch

Indoor and Outdoor

controllers are with

different versions

Replace Indoor controller

No Communication Communication or

grounding wiring is not

good.

Check Indoor to Outdoor

wiring and grounding

Compressor Lock Switch unit to STBY and

restart

Bad Communication Communication quality is

low reliability

Check Indoor to Outdoor

wiring and grounding

Page 56

11-7

TROUBLESHOOTING

Revision Y05-01Service Manual - PXD DCI

.4 Judgment by MegaTool

MegaTool is a special tool to monitor the system states.

Using MegaTool requires:

x A computer with RS232C port.

x A connection wire for MegaTool.

x A special MegaTool software.

Use MegaTool according to following procedure:

x Setup MegaTool software: copy the software to the computer.

x Connect RS232C port in computer with MegaTool port in Indoor/Outdoor unit

controller by the connection wire.

x Run the sof

tware and choose the COM port, you can monitor the A/C system state

in monitor tab.

.5 Simple procedures for checking the Main Parts

.5.1 Checking Mains Voltage.

Confirm that the Mains voltage is between 198 and 264 VAC. If Mains voltage is out of this

range, abnormal operation of the system is expected. If in range check the Power (Circuit)

Breaker and look for broken or loosed cable lugs or wiring mistake(s).

.5.2 Checking Power Input.

If Indoor unit power LED is unlighted, power down the system and check the fuse of the Indoor

unit. If the fuse is OK replace the Indoor unit controller. If the fuse has blown, replace the fuse

and power up again.

Checking Power Input procedure for the Outdoor unit is the same as with the Indoor unit.

.5.3 Checking the Outdoor Fan Motor.

Enter Test Mode (where the OFAN speed is high)

Check the voltage between lead wires according to the normal value as following:

x Between red wire and black wire: 310VDC +/- 20V

x Between orange wire and black wire: 15VDC +/- 1V

x Between yellow wire and black wire: 2-6VDC

.5.4 Checking the Compressor.

The compressor is brushless permanence magnetic DC motor. Three coil resistance is

same. Check the resistance between three poles. The normal value should be below 0.5

ohm (TBD).

.5.5 Checking the Reverse Valve (RV).

Running in heating mode, check the voltage between two pins of reverse valve

connector, normal voltage is 220VAC.

.5.6 Checking the electrical expansion valve (EEV).

The EEV has two parts, drive part and valve. The drive part is a step motor; it is ringed on

the valve. Check the drive voltage (12VDC). When Outdoor unit is power on, EEV shall

run and have click and vibration.

Page 57

11-8

TROUBLESHOOTING

Revision Y05-01 Service Manual - PXD DCI

.6 Precaution, Advise and Notice Items

.6.1 High voltage in Outdoor unit controller.

Whole controller, including the wires that are connected to the Outdoor unit controller may

have the potential hazard voltage when power is on. Touching the Outdoor unit controller

may cause an electrical shock.

Advise: Don’t touch the naked lead wire and don’t insert finger, conductor or anything

else into the controller when power is on.

.6.2 Charged Capacitors

Three large-capacity electrolytic capacitors are used in the Outdoor unit controller.

Therefore, charging voltage (380VDC) remains after power down. Discharging takes

about four minutes after power is off. Touching the Outdoor unit controller before

discharging may cause an electrical shock.

.6.3 Additional advises

x When disassemble the controller or the front panel, turn off the power supply.

x When connecting or disconnecting the connectors on the PCB, hold the whole housing,

don’t pull the wire.

x There are sharp fringes and sting on shell. Use gloves when disassemble the A/C

units.

Page 58

12-1

EXPLODED VIEWS AND SPARE PARTS LISTS

Revision Y05-01Service Manual - PXD DCI

12. EXPLODED VIEWS AND SPARE PARTS LISTS

12.1 Indoor Unit: PXD 25, 35 DCI

Page 59

12-2

EXPLODED VIEWS AND SPARE PARTS LISTS

Revision Y05-01 Service Manual - PXD DCI

12.2 Indoor Unit: PXD 25, 35 DCI

No Part No Description Qty

1 307979 Back panel 1

2 382334 Base panel EPS 1

3 452731900 Evap. Assy PXD25/35 1

4 373247 Fan frame 1

5 455000600 Capacitor PXD25/35 1

6 323425 Motor support 1

7 293321 Centrifugal fan 2

8 452987400 Transformer for PXD25/35 1

9 4520158 Motor PXD25/35 1

10 4521029 Spring clip 2

11 372341 Fan cover 2

12 373245 Left panel 1

13 221555 Filter 2

14 307981 Front panel 1

15 484001 Air inlet assy 1

16 4525333 Motor connect wire for PXD25/35 1

17 373244 Right panel 1

18 371257 Vertical louver 10

19 370281 Air outlet 1

375209-01 AIRWELL Display panel 1

375209-05 WESPER Display panel 1

375209-16 ELECTRA Display panel 1

375209-17 JOHNSON Display panel 1

4521827 GORENJEN Display panel 1

20

4521831 FAGOR Display panel 1