Page 1

Installation and maintenance manual

Notice d’installation et de maintenance

Installations und Wartungshandbuch

Manuale di installazione e di manutanzione

Manual de instalacion y de mantenimiento

IOM TRIO 01-EL-1ALL

Part number / Code / Code / Codice / Código : 3990216

Supersedes / Annule et remplace / annulliert und ersezt /

Annulla e sostituisce / anula y sustituye : None / Néant / Nichht / Nulla / Ninguno

WMT 090914 RC

HIGH TECH

MULTISPLITS

SIMULTANEOUS COOLING - HEATING

FROID – CHAUD SIMULTANE

GLEICHZEITIGER HEIZ UND KÜHLBETRIEB

FREDDO – CALDO SIMULTANEI

FRÍO – CALOR SIMULTÁNEO

7.5 0kW

7.06kW

WMN9 - WMN12

WMZ9 - WMZ12

PXD9 - PXD12

ECF9 - ECF11

WMF9 - WMF12

LS11

Page 2

Page 3

INSTINST

INSTINST

INST

ALLAALLA

ALLAALLA

ALLA

TION INSTRUCTIONSTION INSTRUCTIONS

TION INSTRUCTIONSTION INSTRUCTIONS

TION INSTRUCTIONS

NOTICE D’INSTALLATION

INSTALLATIONSHANDBUCH

ISTRUZIONI INST ALLAZIONE

INSTRUCCIONES DE INSTALACIÓN

Page 4

22

22

2

CONTENTSCONTENTS

CONTENTSCONTENTS

CONTENTS

GENERAL RECOMMENDGENERAL RECOMMEND

GENERAL RECOMMENDGENERAL RECOMMEND

GENERAL RECOMMEND

AA

AA

A

TIONSTIONS

TIONSTIONS

TIONS

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

.......................................................................................................

33

33

3

SAFETY AD VICE...................................................................................................................................3

WARNING .........................................................................................................................................3

PP

PP

P

AA

AA

A

CKACKA

CKACKA

CKA

GE CONTENTSGE CONTENTS

GE CONTENTSGE CONTENTS

GE CONTENTS

..............................................................................................................................................................................................................................................

..............................................................................................................................................................................................................................................

.......................................................................................................................

44

44

4

ACCESSORIESACCESSORIES

ACCESSORIESACCESSORIES

ACCESSORIES

........................................................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................................................

....................................................................................................................................

44

44

4

GENERALGENERAL

GENERALGENERAL

GENERAL

......................................................................................................................................................................................................................................................................................

......................................................................................................................................................................................................................................................................................

...........................................................................................................................................

44

44

4

CHARACTERISTICS...............................................................................................................................4

CONFIGURATION POSSIBILITIES ..........................................................................................................5

OUTDOO RS UNIT – DESCRI PTION.......................................................................................................6

DIMENSIONSDIMENSIONS

DIMENSIONSDIMENSIONS

DIMENSIONS

..........................................................................................................................................................................................................................................................................

..........................................................................................................................................................................................................................................................................

.....................................................................................................................................

77

77

7

HANDLING PROCEDUREHANDLING PROCEDURE

HANDLING PROCEDUREHANDLING PROCEDURE

HANDLING PROCEDURE

....................................................................................................................................................................................................................................

....................................................................................................................................................................................................................................

..................................................................................................................

88

88

8

TECHNICAL SPECIFICATECHNICAL SPECIFICA

TECHNICAL SPECIFICATECHNICAL SPECIFICA

TECHNICAL SPECIFICA

TIONSTIONS

TIONSTIONS

TIONS

......................................................................................................................................................................................................................

......................................................................................................................................................................................................................

...........................................................................................................

88

88

8

ELECTRICAL SPECIFICAELECTRICAL SPECIFICA

ELECTRICAL SPECIFICAELECTRICAL SPECIFICA

ELECTRICAL SPECIFICA

TIONSTIONS

TIONSTIONS

TIONS

......................................................................................................................................................................................................................

......................................................................................................................................................................................................................

...........................................................................................................

99

99

9

REFRIGERAREFRIGERA

REFRIGERAREFRIGERA

REFRIGERA

TING SPECIFICATING SPECIFICA

TING SPECIFICATING SPECIFICA

TING SPECIFICA

TIONSTIONS

TIONSTIONS

TIONS

..................................................................................................................................................................................................

..................................................................................................................................................................................................

.................................................................................................

1010

1010

10

WMT 090914 RC INSTWMT 090914 RC INST

WMT 090914 RC INSTWMT 090914 RC INST

WMT 090914 RC INST

ALLAALLA

ALLAALLA

ALLA

TIONTION

TIONTION

TION

..........................................................................................................................................................................................................

..........................................................................................................................................................................................................

.....................................................................................................

1111

1111

11

GROUND AGROUND A

GROUND AGROUND A

GROUND A

TTTT

TTTT

TT

AA

AA

A

CHMENTCHMENT

CHMENTCHMENT

CHMENT

..................................................................................................................................................................................................................................

..................................................................................................................................................................................................................................

.................................................................................................................

1111

1111

11

CONDENSACONDENSA

CONDENSACONDENSA

CONDENSA

TE EVTE EV

TE EVTE EV

TE EV

AA

AA

A

CUCU

CUCU

CU

AA

AA

A

TION – DRAIN POSITIONINGTION – DRAIN POSITIONING

TION – DRAIN POSITIONINGTION – DRAIN POSITIONING

TION – DRAIN POSITIONING

....................................................................................................................................

....................................................................................................................................

..................................................................

1111

1111

11

DISTDIST

DISTDIST

DIST

ANCES AND LEVEL DIFFERENCES BETWEEN ST AND WMT 090914 RCANCES AND LEVEL DIFFERENCES BETWEEN ST AND WMT 090914 RC

ANCES AND LEVEL DIFFERENCES BETWEEN ST AND WMT 090914 RCANCES AND LEVEL DIFFERENCES BETWEEN ST AND WMT 090914 RC

ANCES AND LEVEL DIFFERENCES BETWEEN ST AND WMT 090914 RC

................................................................

................................................................

................................

1212

1212

12

PIPE CONNECTIONSPIPE CONNECTIONS

PIPE CONNECTIONSPIPE CONNECTIONS

PIPE CONNECTIONS

..............................................................................................................................................................................................................................................

..............................................................................................................................................................................................................................................

.......................................................................................................................

1313

1313

13

REFRIGERATION PIPE CONNECTIONS BETWEEN WMT 090914 RC AND ST..........................................13

PIPE WORK TO BE PRODUCED ON SITE............................................................................................. 1 3

REFRIGERATING PIPE CONNECTIONSLIAISONS FRIGORIFIQUES.........................................................13

REFRIGERATING PIPE CONNECTIONS BETWEEN THE INDOORS UNITS AND THE OUTDOORS UNIT ..... 1 4

EXAMPLE OF CONNECTION REQUIRING ADDITION OF R407C REFRIGERANT .................................... 15

VV

VV

V

AA

AA

A

CUUM DRAINING THE INDOORS UNIT AND THE REFRIGERACUUM DRAINING THE INDOORS UNIT AND THE REFRIGERA

CUUM DRAINING THE INDOORS UNIT AND THE REFRIGERACUUM DRAINING THE INDOORS UNIT AND THE REFRIGERA

CUUM DRAINING THE INDOORS UNIT AND THE REFRIGERA

TING PIPESTING PIPES

TING PIPESTING PIPES

TING PIPES

............................................................

............................................................

..............................

1616

1616

16

VACUUM DRAINING PROCEDURE.....................................................................................................16

WIRING DIAGRAM AND LEGENDWIRING DIAGRAM AND LEGEND

WIRING DIAGRAM AND LEGENDWIRING DIAGRAM AND LEGEND

WIRING DIAGRAM AND LEGEND

....................................................................................................................................................................................................

....................................................................................................................................................................................................

..................................................................................................

1717

1717

17

ELECTRICAL CONNECTIONSELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONSELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

....................................................................................................................................................................................................................

....................................................................................................................................................................................................................

..........................................................................................................

1919

1919

19

INDO ORS U NITS:..............................................................................................................................19

OUT DOOR S UNI T : ............................................................................................................................ 19

INDOORS UNITS INSTINDOORS UNITS INST

INDOORS UNITS INSTINDOORS UNITS INST

INDOORS UNITS INST

ALLAALLA

ALLAALLA

ALLA

TIONTION

TIONTION

TION

..........................................................................................................................................................................................................

..........................................................................................................................................................................................................

.....................................................................................................

2020

2020

20

SCHEMATIC DIAGRAM - WMT 090914 RC WITH ST AND WITHOUT ELECTRICAL HEA TING.....................21

SCHEMATIC DIAGRAM - WMT 090914 RC WITH ST - WITH ELECTRICAL HEA TING ..................................22

FUSE HOLDE R CONNECTIO N DET AILS ON MODEL WITH E LECTRICAL H EAT ING................................... 2 3

REGULAREGULA

REGULAREGULA

REGULA

TION SYSTEMTION SYSTEM

TION SYSTEMTION SYSTEM

TION SYSTEM

............................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................

......................................................................................................................

2424

2424

24

GENERAL OPERATING PRINCIPLES.....................................................................................................24

SAFET Y PRO TEC TION........................................................................................................................ 24

DE-ICING......................................................................................................................................... 24

CHECKS BEFORE STCHECKS BEFORE ST

CHECKS BEFORE STCHECKS BEFORE ST

CHECKS BEFORE ST

ARAR

ARAR

AR

TINGTING

TINGTING

TING

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

............................................................................................................

2525

2525

25

POWER SUPPLY.................................................................................................................................25

ELECT RICAL T UBING ......................................................................................................................... 25

CONDENSA T ES DRAINA GE ............................................................................................................... 25

REFRIGE RANT CON NECTIONS.......................................................................................................... 25

CONNECT IONS THR OUGH A WA LL................................................................................................... 25

ATTACHMENT...................................................................................................................................25

FINAL TFINAL T

FINAL TFINAL T

FINAL T

ASKSASKS

ASKSASKS

ASKS

..........................................................................................................................................................................................................................................................................

..........................................................................................................................................................................................................................................................................

.....................................................................................................................................

2525

2525

25

MAINTENANCE AND SERVICINGMAINTENANCE AND SERVICING

MAINTENANCE AND SERVICINGMAINTENANCE AND SERVICING

MAINTENANCE AND SERVICING

......................................................................................................................................................................................................

......................................................................................................................................................................................................

...................................................................................................

2626

2626

26

Page 5

33

33

3

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

POWER SUPPLPOWER SUPPL

POWER SUPPLPOWER SUPPL

POWER SUPPL

Y MUST BEY MUST BE

Y MUST BEY MUST BE

Y MUST BE

CUT OFF BEFORECUT OFF BEFORE

CUT OFF BEFORECUT OFF BEFORE

CUT OFF BEFORE

STST

STST

ST

ARAR

ARAR

AR

TING ANY WORK ONTING ANY WORK ON

TING ANY WORK ONTING ANY WORK ON

TING ANY WORK ON

THE ELECTRICAL BOTHE ELECTRICAL BO

THE ELECTRICAL BOTHE ELECTRICAL BO

THE ELECTRICAL BO

XESXES

XESXES

XES

GENERAL RECOMMENDGENERAL RECOMMEND

GENERAL RECOMMENDGENERAL RECOMMEND

GENERAL RECOMMEND

AA

AA

A

TIONSTIONS

TIONSTIONS

TIONS

Firstly, congratulations for having selected an air conditioner.

SAFETY ADVICE

Always follow current safety regulations when working on your equipment.

Only qualified personnel should perform equipment installation and maintenance.

Make sure that the electrical voltage and frequency are adapted to the required operating

power supply, taking account of the specific installation conditions and the power required by

any other appliance connected on the same circuit.

WARNING

The power supply must be cut off before starting any work or maintenance operation.

The manufacturer declines all liability, and the guarantee becomes void, in the event of non-

compliance with these installation instructions.

In case of difficulties, please contact your local Technical Department.

If possible, assemble the mandatory or optional accessories before placing the appliance on

its final location (refer to the instructions provided with each accessory).

The information contained in these instructions is subject to change without prior notice.The information contained in these instructions is subject to change without prior notice.

The information contained in these instructions is subject to change without prior notice.The information contained in these instructions is subject to change without prior notice.

The information contained in these instructions is subject to change without prior notice.

This appliance complies with

EC STEC ST

EC STEC ST

EC ST

ANDAND

ANDAND

AND

ARDSARDS

ARDSARDS

ARDS

..

..

.

Page 6

44

44

4

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

GENERALGENERAL

GENERALGENERAL

GENERAL

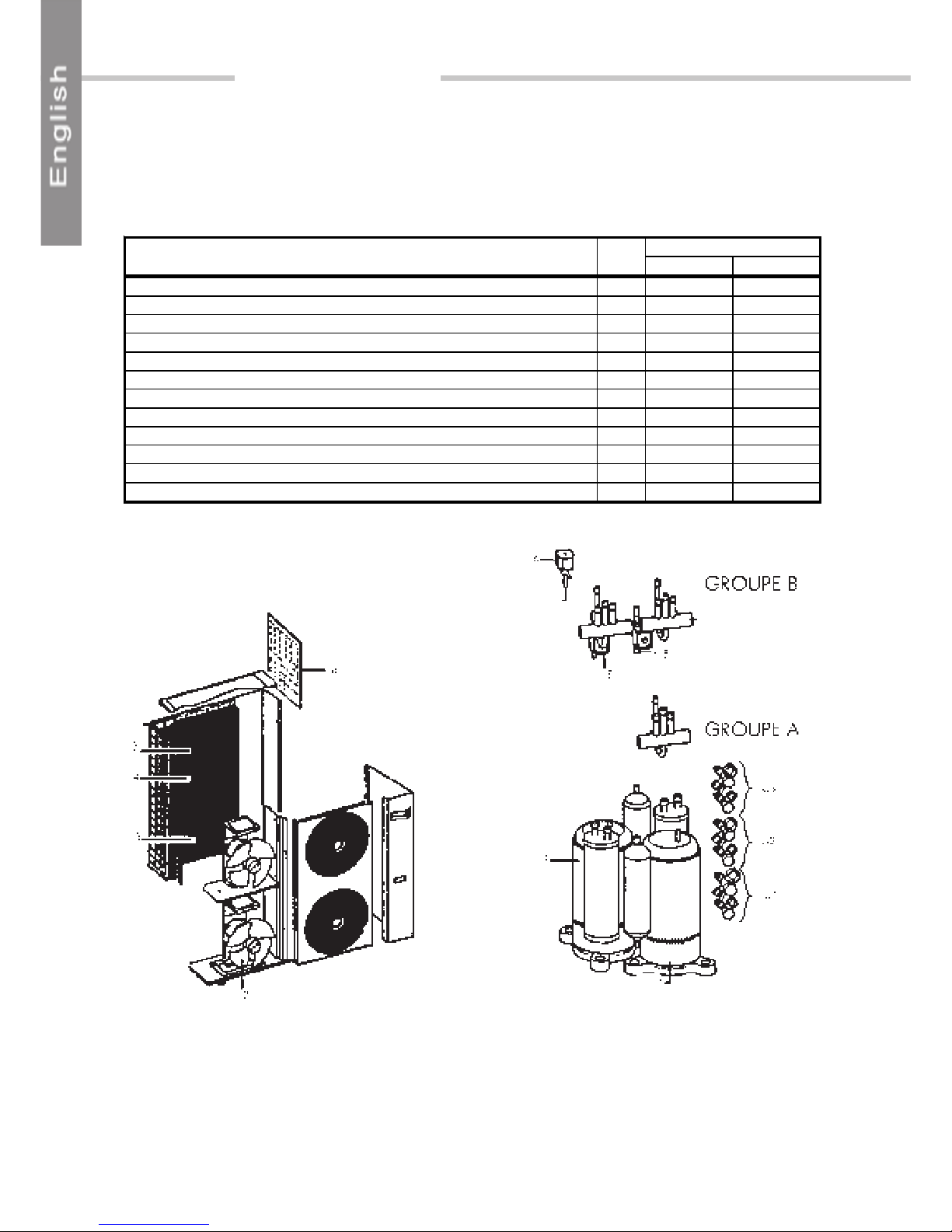

CHARACTERISTICS

The outdoors reversible unit (WMT 090914 RC) comprises:

2 independent refrigerating circuits

1 unit per circuit A and 2 unitS per circuit B

Rotary compressor

Microprocessor control

It is compatible with Comfort range indoors units

PP

PP

P

AA

AA

A

CKACKA

CKACKA

CKA

GE CONTENTSGE CONTENTS

GE CONTENTSGE CONTENTS

GE CONTENTS

1 WMT 090914 RC outdoors unit

4 rubber pads

1 bag of fasteners

1 shunts (model with electrical heating)

10 cable ties

1 drain + seal

3 connectors

1 identification label for the wiring and pipe connections between the indoors unit and the

WMT 090914 RC

1 bag of documentation

AA

AA

A

CCESSORIESCCESSORIES

CCESSORIESCCESSORIES

CCESSORIES

Wall bracket

1/2"-1/4" Flare connectors

3/8"-1/4" Flare connectors

Page 7

55

55

5

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

CONFIGURATION POSSIBILITIES

The difference in capacities between the two circuits added to the broad variety of installation

configurations mean that «Made to measure» air conditioning installations, perfectly adapted

to each application, can be created.

WMN9 - WMN 12

WMZ9 - WMZ12

PXD9 - PXD12

ECF9 - ECF11

WMF9 - WMF 12

LS11

Page 8

66

66

6

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

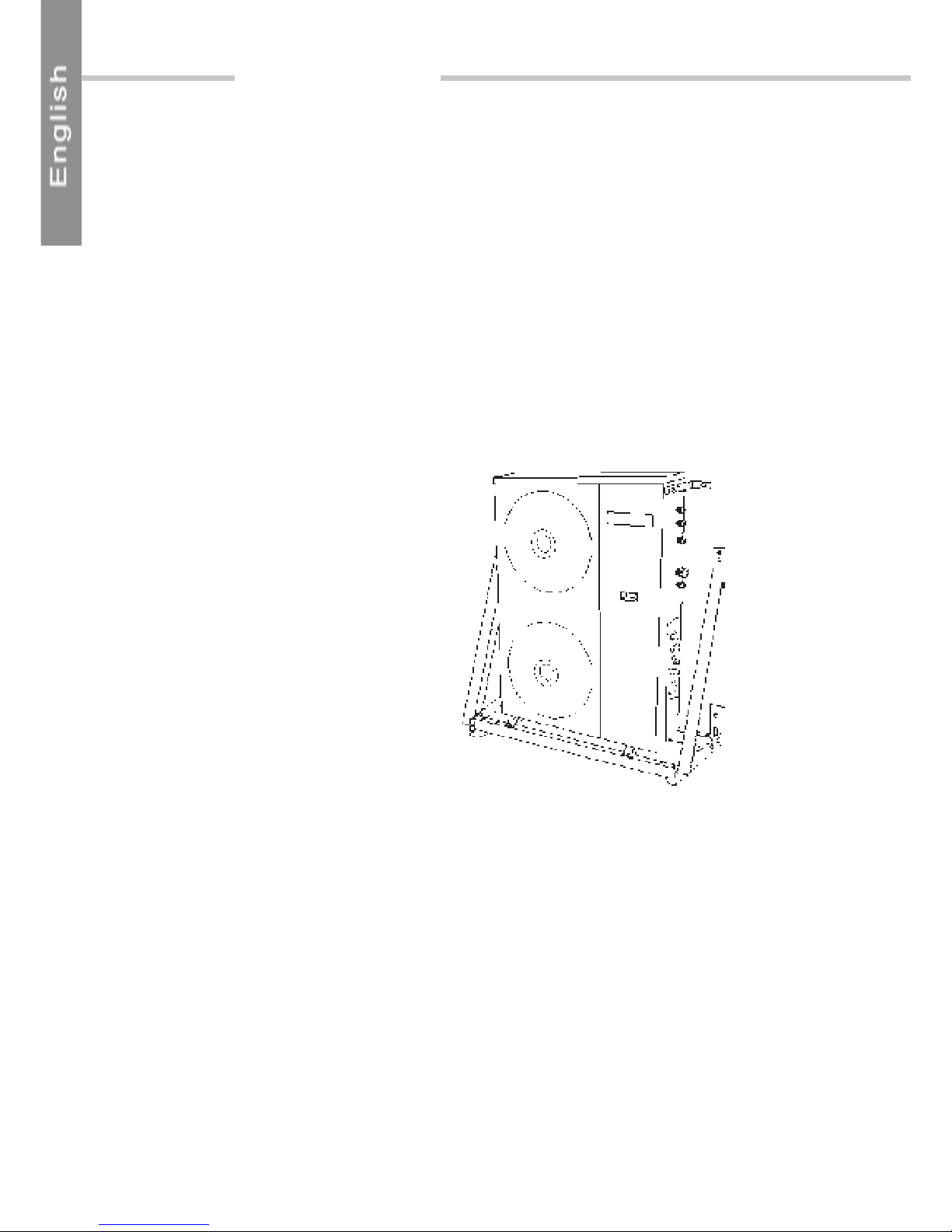

OUTDOORS UNIT – DESCRIPTION

One of the WMT 090914 RC HIGH TECH’s advantages is its compact design, taking up

very little floor space. Each circuit comprises:

REP.

AB

Rotary compressor 1 1 1

Ax i al fan (dual speed) 2 1 1

Main ex changer 3 1 1

Aux i l iary ex c hanger for optim ising operat ion under parti al l oad condit i ons 4 1

3/8’’ s ol enoid valves for cont roll i ng t he following m odes : 5 2

Eac h S T unit’ s Unoccupied or Standby m ode

One ¼’’ solenoid valve for discharging refrigerant into the auxiliary exchang 6 1

A s i ngle S T in operati on

4 way valves for thermodynami c heat ing 7 1 2

Temperature sensors

OAT (Outdoors A ir Temperature) 1 1

OCT (Out doors Coil Temperature) 1 2

DESCRIPTION UNIT

A regulator in the electrical box automatically manages the functions of the entire installation

in accordance with the demands expressed by the indoors units.(8)

Page 9

77

77

7

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

902

1275

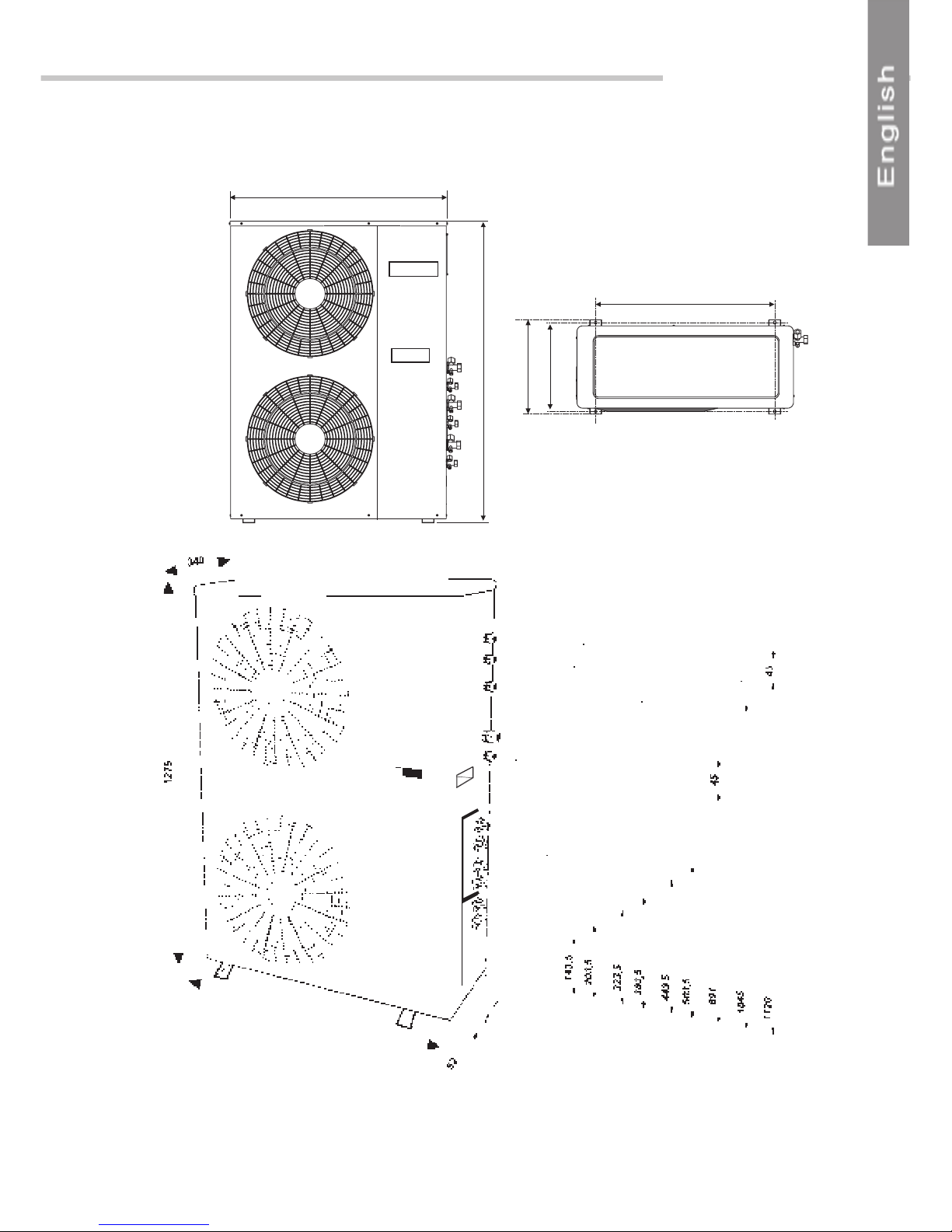

DIMENSIONSDIMENSIONS

DIMENSIONSDIMENSIONS

DIMENSIONS

**

**

*

2 packing boxes for the mains power supply.

2 different sizes: installer to choose size in relation to mains power supply cable section (ST

with or without electrical heating).

*

CIRCUIT ACIRCUIT A

CIRCUIT ACIRCUIT A

CIRCUIT A

GAS

LIQUID

GAS

LIQUID

CIRCUIT BCIRCUIT B

CIRCUIT BCIRCUIT B

CIRCUIT B

GAS

LIQUID

902 Without valves

952 · With valves

Dimensions in relation to ground

705

357

380

Page 10

88

88

8

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

TECHNICAL SPECIFICATECHNICAL SPECIFICA

TECHNICAL SPECIFICATECHNICAL SPECIFICA

TECHNICAL SPECIFICA

TIONSTIONS

TIONSTIONS

TIONS

R407C

HE

A

T PUMP

Refrigerant char g e (*) g

757

Connecting pipe

s

Gas pipe

in (") - mm ½” - 12

Liquid pi pe

in(") - mm 1/4" - 6

Refrigerant char g e (*)

1315

Connecting pipe

s

Gas pipe

in(") - mm

3/8” - 10

Liquid pi pe

in(") - mm 1/4" - 6

Upper limit °C

43°C DB

Lower limit °C

21°C DB

Upper limit °C

24°C DB / 18°C WB

Lower limit °C

-5°C DB / -6°C WB

CIRCUIT B

CIRCUIT A

Model

Unit operating range

Cooling mode operating ran ge

Heating mode operating range

HANDLING PROCEDUREHANDLING PROCEDURE

HANDLING PROCEDUREHANDLING PROCEDURE

HANDLING PROCEDURE

Centre of gravity

113 kg Net weight

124 Kg Packed weight

* The R407C refrigerant charge value is given for 4 m pipe length connections with WMN

type outdoors units on both circuits

For any installations with longer pipe lengths, please refer to: § REFRIGERATING

SPECIFICATIONS and Example of connection requiring addition of R407c refrigerant

(DB)(DB)

(DB)(DB)

(DB) Dry Bulb temperature

(WB)(WB)

(WB)(WB)

(WB) Wet bulb temperature

Page 11

99

99

9

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

ELECTRICAL SPECIFICAELECTRICAL SPECIFICA

ELECTRICAL SPECIFICAELECTRICAL SPECIFICA

ELECTRICAL SPECIFICA

TIONSTIONS

TIONSTIONS

TIONS

TRIO HEAT PUMP

ABCD

Number of ST units without heating 3

3

2 1 0

Number of ST units with heating 0

0

1 2 3

Unité

Total nominal current A 12.2 20.7 27.3 33.9

Total maxi mum curre nt A 15 23.5 30.1 36.7

Total s tarting curre nt A 70 78.5 85.1 91.7

Fuse ra ting aM/VD E A 20/20 25/25 32/35 40/50

3G type power supply cable section mm² 2,5 6 10 10

CONFIG URATION EXA M PLE Unité A B C D

Ma x . curren t / ST w/o elec. h ea ting A 1 X 1,5 0 0 0

Ma x c urrent / ST wit h elec. heat in g (U NI T A) A ¬0 1 X 10,2 1 X 10,2 1 X 10,2

Max. current / ST w/o elec. heating A 2 X 1,5 2 X 1,5¬¬1 X 1,5¬ 0

Ma x current / ST wi t h el ec. hea t in g (U NI T B ) A 0 0 1 X 6,6 2 X 6,6

Fus e r ati ng with electric a l h ea ting aM A 0 10 10 /10 10 / 20

6G type ST connecting cable section mm² 1,5 1,5 1,5 1,5

UNIT A: FUSE QF1

UNIT B: FUSE QF23

ELECTRICAL CONNECTIONS TO ST UNITS

Indoors unit type Electrical heating capacity

(W)

Maximu m c u rr ent

(A)

PXD 9 1250 6,6

ECF 9 900 4,7

LS 11 1600 8, 5

PXD 12 1250 6,6

ECF 11 900 4,7

IMPORIMPOR

IMPORIMPOR

IMPOR

TT

TT

T

ANTANT

ANTANT

ANT

* The installer must comply with all local standards. The cable section must be suitable for the

installation method, the type of cable insulation and the cable length.

These values are provided for information purposes only. They must be verified and adapted

in relation to existing standards.

These values may vary in relation to the type of installation and the choice of conductors.

Comments:

This data is given for the most unfavourable installation in terms of maximum current

draw: 1 LS11 on circuit A / 2 PXD9 on circuit B

Case with 3 cassettes (2 x ECF9 + 2 x ECF11):

8A fuse is to be provided for unit A

16A fuse is to be provided for unit B .

Electrical heating details for each ST for determining the appropriate fuse rating

Page 12

1010

1010

10

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

REFRIGERAREFRIGERA

REFRIGERAREFRIGERA

REFRIGERA

TING SPECIFICATING SPECIFICA

TING SPECIFICATING SPECIFICA

TING SPECIFICA

TIONSTIONS

TIONSTIONS

TIONS

The WMT 090914 RC HIGH TECH comprises 2 independent non-identical circuits.

The unit is factory filled with refrigerant for the following installation configuration:

Circuit A: 1 WMN12/WMZ12 type indoors units and 4 m pipe lengths per way.

Circuit B: 2 WMN9/WMZ9 type indoors units and 4 m pipe lengths per way.

For longer pipe lengths the amount of charge to be added is

15g/m for each way15g/m for each way

15g/m for each way15g/m for each way

15g/m for each way.

The range of authorised configurations is as follows:

HHP

P

HP-B

HHP

P

HP-A

UNIT A - RC UNIT B - RC

WMN12 / WMZ 12

WMN9 / WMZ9

WMN9 / WMZ9

PXD12

WMN9 / WMZ9

PXD9

EC F11

WMN9 / WMZ9

ECF9

WMF12

WMN9 / WMZ9

WMF9

LS11

WMF9

PXD9

PXD9

PXD9

ECF9

ECF9

Page 13

1111

1111

11

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

WMT 090914 RC INSTALLATION

Minimum free clearances:

GROUND AGROUND A

GROUND AGROUND A

GROUND A

TTTT

TTTT

TT

AA

AA

A

CHMENTCHMENT

CHMENTCHMENT

CHMENT

On concrete slab with rubber pads supplied or PAULSTRA 521571 type vibration absorption

pads.

100 mm

500 mm

600 mm

200 mm

300 mm

705 mm

357 mm

Oblongs 13 x 10 (H8 screws)

CONDENSACONDENSA

CONDENSACONDENSA

CONDENSA

TE EVTE EV

TE EVTE EV

TE EV

AA

AA

A

CUCU

CUCU

CU

AA

AA

A

TION – DRAIN POSITIONINGTION – DRAIN POSITIONING

TION – DRAIN POSITIONINGTION – DRAIN POSITIONING

TION – DRAIN POSITIONING

To ensure effective condensate drainage, the drain pipe should be routed on a downward

slope of 2.5 cm/metre.

Adequate heat insulation for the condensate drain pipe should be provided for harsh

climates, or sub-zero temperatures.

Fit the drain pipe and its seal (supplied) if required, BEFORE attaching the unit to the ground.

For Heat pump models, in locations where the outdoors temperature may fall below 1°C, a

condensate anti-freezing protection device must be provided (a heated wrap for example).

When installing the unit in harsh climates, sub-zero temperatures, snow, or humidity it is

recommended that it is raised about 10 cm above ground level.

Page 14

1212

1212

12

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

DISTDIST

DISTDIST

DIST

ANCES AND LEVEL DIFFERENCES BETWEEN ST ANDANCES AND LEVEL DIFFERENCES BETWEEN ST AND

ANCES AND LEVEL DIFFERENCES BETWEEN ST ANDANCES AND LEVEL DIFFERENCES BETWEEN ST AND

ANCES AND LEVEL DIFFERENCES BETWEEN ST AND

WMT 090914 RCWMT 090914 RC

WMT 090914 RCWMT 090914 RC

WMT 090914 RC

H1 10 m

H2 5 m

L1

L2

L3

MAXIMUM HEIGHT

MAXIMUM LENGTH

15 m

Any pipe length of level difference exceeding the values stated in the above table is to be

avoided.

H1

H2

L1 L2 L3

UNIT B

UNIT A

H1

H2

L1

L2 L3

UNIT A

UNIT B

Page 15

1313

1313

13

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

REFRIGERATION PIPE CONNECTIONS BETWEEN WMT 090914 RC

AND ST

Labels supplied with the WMT 090914 RC unit enable the valves to be marked as the

installation operations advance.

The indoors units can be installed in 3 different rooms.

Refrigeration pipe lengths are available as an accessory in fixed lengths of 2.5, 5 and 8m.

The pipe lengths are supplied in rolls. They are insulated and fitted with FLARE nuts.

Unroll the pipes carefully, in the opposite direction to the spirals, to avoid bending them.

This operation must only be performed by qualified personnel, in accordance with

refrigeration engineering best practices (brazing, vacuum draining, charge addition, etc...).

The pipe bend radius must be equal to or greater than 3.5 times the outside tube diameter.

GOOD BAD

PIPE WORK TO BE PRODUCED ON SITE

REFRIGERATING PIPE CONNECTIONSLIAISONS FRIGORIFIQUES

PIPE CONNECTIONSPIPE CONNECTIONS

PIPE CONNECTIONSPIPE CONNECTIONS

PIPE CONNECTIONS

Pipe connections between the GC and the ST units must be performed before undertaking the

electrical connections.

Page 16

1414

1414

14

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

REFRIGERATING PIPE CONNECTIONS BETWEEN THE INDOORS UNITS

AND THE OUTDOORS UNIT

Indoors units contain a small amount of neutral GAS.

Do not unscrew the nuts on the indoors and outdoors units before being ready to proceed

with connecting the refrigerating pipes.

The outdoors unit contains sufficient refrigerant fluid for pipes up to a length of 4 metres per

way.

Only use proper pipe bending tools to form the pipe bends in order to avoid any breakages.

To ensure a perfect seal, cover the valve surface with refrigeration oil.

NONO

NONO

NO

TT

TT

T

AA

AA

A

Only use «refrigeration engineering «quality, copper piping and designed for withstanding

pressures at least equal to 30 bars

Use pipe with the appropriate Ø for each model. (Refer to pipe dimensions and tightening

torque values table above).

Insulate each pipe as well as its connectors separately, with insulation material having a

minimum thickness of 6mm.

Attach the refrigerating pipes, the condensate drain pipe and the electrical cable together with

a strap.

Place the FLARE nuts on the pipe ends and prepare them with a pipe end flaring tool.

Use the FLARE nuts fitted to the indoors and outdoors units.

Connect the four ends of the two pipes to the indoors and outdoors units.

Repeat these operations for connecting the 2nd, 3rd and 4th indoors units

THE USE OF A COUNTER SPTHE USE OF A COUNTER SP

THE USE OF A COUNTER SPTHE USE OF A COUNTER SP

THE USE OF A COUNTER SP

ANNER IS INDISPENSABLEANNER IS INDISPENSABLE

ANNER IS INDISPENSABLEANNER IS INDISPENSABLE

ANNER IS INDISPENSABLE

FOR TIGHTENING THE VFOR TIGHTENING THE V

FOR TIGHTENING THE VFOR TIGHTENING THE V

FOR TIGHTENING THE V

ALAL

ALAL

AL

VESVES

VESVES

VES

..

..

.

The tightening torque values are specified in table below:

PIPE Ø TIGHTENING TORQUE

1/4"" 15-20 Nm

3/8"" 30-35 Nm

1/2"" 50-54 Nm

5/8"" 70-75 N m

7/8"" 90-95 Nm

Page 17

1515

1515

15

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

EXAMPLE OF CONNECTION REQUIRING ADDITION OF R407C

REFRIGERANT

NOTA:

The R407C refrigerant charge value is given for 4 m pipe length .

For longer pipe lengths the amount of charge to be added is

15g/m for each way15g/m for each way

15g/m for each way15g/m for each way

15g/m for each way

CIRCUIT A (U1-A)

The additional quantity of R407C will be:

+ 165 g (15m pipe lengths)

being, in this example, an increase of 255 g for circuit A,

and

CIRCUIT B (U2-B / U3-B)

+ 165 g (15 m pipe lengths)

+ 15 g (5 m pipe lengths)

being, in this example, an increase of 180 g for circuit B,

U3-B

U2-B

U1-A

WMN9R

with 5 metres of pipe connections

WMN12R

with 15 metres of pipe connections

WMN9R

with 15 metres of pipe connections

NONO

NONO

NO

TT

TT

T

A :A :

A :A :

A :

This operation must only be performed by qualified personnel, in accordance with

refrigeration engineering best practices.

The values in the example of connection for these pipe lengths require the addition of R407C

refrigerant on site. Any interventions on the refrigeration circuits must be performed in strict

compliance with CECOMAF GT1-001 recommendations (recommendations on R407C

emissions into the atmosphere).

Page 18

1616

1616

16

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

VV

VV

V

AA

AA

A

CUUM DRAINING THE INDOORS UNIT AND THE REFRIGERACUUM DRAINING THE INDOORS UNIT AND THE REFRIGERA

CUUM DRAINING THE INDOORS UNIT AND THE REFRIGERACUUM DRAINING THE INDOORS UNIT AND THE REFRIGERA

CUUM DRAINING THE INDOORS UNIT AND THE REFRIGERA

TING PIPESTING PIPES

TING PIPESTING PIPES

TING PIPES

VACUUM DRAINING PROCEDURE

The R407C charge is only contained in the outdoors unit.

The indoor unit contains a small quantity of neutral GAS. F or this reason, after having

installed the pipe connections, it is imperative to proceed with vacuum draining the

connections and the indoor unit.

The outdoors unit has a valve provided for the installation to be vacuum drained (large valve).

1. Connect the refrigerating pipes between the indoors and the outdoors units.

2. Connect the vacuum pump to the FLARE connector of the outdoor unit equipped

with the service valve (large connector).

3. Start the vacuum pump and check that the vacuum gauge drops to -0.1Mpa

(-76cm Hg). The pump should be run for at least 15 minutes.

4. Before removing the vacuum pump, you must check that the vacuum gauge

remains stable for 5 minutes.

5. Disconnect the vacuum pump and close the service valve.

6. Remove the cap from the «GAS» and LIQUID» valves and open them with a

hexagonal spanner, in order to release the R407C refrigerant fluid contained in

the outdoor unit.

7. In the case where the refrigerant pipe connection of one way is longer than 4 m.

add an additional charge in accordance with the values stated in Table N° 1.

8. Check the seal on all the connections. Use an electronic leakage detector or a

soapy sponge.

9. Repeat these operations for connecting the 2

nd

, 3rd indoors units.

Page 19

1717

1717

17

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

!

> >

WIRING DIAWIRING DIA

WIRING DIAWIRING DIA

WIRING DIA

GRAM AND LEGENDGRAM AND LEGEND

GRAM AND LEGENDGRAM AND LEGEND

GRAM AND LEGEND

Page 20

1818

1818

18

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

MFA/MFB COMPRESOR

FFA/FFB EXTERNAL PROTECTION MFA/B

CFA/CFB CVA/CVB CAPACI TOR

EFA/EFB CRANKCASE HEATER

PCB ELECTRONIC CONTROLL-BOARD

TA/TB TRANSFORMER 230/12V

OCT1...OCT4 DEFROSTING SENSOR

OAT AMBIENCE SENSOR

SV-A1...SV-B3 / SVA3 A..B SOLENOID VALVE

ORV-A1...ORV-B2 REVERSING VALVE

J1/J2/J0 JUMPER

R1...R4 DUMMY PROBE

HPA/HPB A UTOMATIC HIGH PRESSURE PRESSOSTAT

KA1/KA2/ KA3/KA4 KHP A/KH PB RELAY

MVA/MVB MOTEUR CONDE N SING F A N M OTOR

FV A/FVB IN TERNA L PROTECTION OF M V A/B

XIU1...XIU4 INDOOR UNIT TERMINAL

X MAIN TE RMINAL STRIP

QF 1-2/3-4 QF 1/2-3 HEA TER FUSE SWITCH (N OT FI TTED)

WIRING DIAGRAM LEGEND SE 3172/3173

CODE: 399734

Page 21

1919

1919

19

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

U3 - B

U2 - B

U1 - A

Power supply

))

))

)

vis

vis

ELECTRICAL CONNECTIONSELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONSELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

INDOORS UNITS:

Do not take account of the electrical connections instructions contained in the indoors units

Installation Instructions.

OUTDOORS UNIT:

On the WMT 090914 RC, remove the front panel (Fig. below. Ref.

AA

AA

A - 5 screws).

Connection to the mains power supply is via the WMT 090914 RC unit.

Mains cable not supplied. (Refer to electrical specifications).

- Pass the cable into the stuffing box (fitted to the unit).

- Block the stuffing box in position.

- Connect this cable to the X terminal block X (Refer to the schematic diagram)

Connecting cable to the indoors units from the WMT 090914 RC not supplied. (Refer to

electrical specifications).

- Pass the cables into the corresponding stuffing boxes (fitted to the unit).

- Block the stuffing boxes in position.

- Connect the cable to the corresponding terminal blocks: U1A - U2B - U3B.

2

1

Page 22

2020

2020

20

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

INDOORS UNITS INSTINDOORS UNITS INST

INDOORS UNITS INSTINDOORS UNITS INST

INDOORS UNITS INST

ALLAALLA

ALLAALLA

ALLA

TIONTION

TIONTION

TION

For setting up the ST units, refer to the Installation Instructions provided with these indoors

units.

WMFWMF

WMFWMF

WMF

, WMN and WMZ, WMN and WMZ

, WMN and WMZ, WMN and WMZ

, WMN and WMZ

ALAL

ALAL

AL

WW

WW

W

AA

AA

A

YS DISCONNECT THE POWER CABLEYS DISCONNECT THE POWER CABLE

YS DISCONNECT THE POWER CABLEYS DISCONNECT THE POWER CABLE

YS DISCONNECT THE POWER CABLE

HARNESSES BEFORE STHARNESSES BEFORE ST

HARNESSES BEFORE STHARNESSES BEFORE ST

HARNESSES BEFORE ST

ARAR

ARAR

AR

TING ANY WORKTING ANY WORK

TING ANY WORKTING ANY WORK

TING ANY WORK

Page 23

2121

2121

21

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

SCHEMATIC DIAGRAM - WMT 090914 RC WITH ST AND WITHOUT

ELECTRICAL HEATING

Connector supplied

Fuse holder not

supplied

Bornier général X

WMNR - WMZ - WMF

PXD - ECF - LS

4.7k:

4.7k:

4.7k:

Power supply

Page 24

2222

2222

22

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

SCHEMATIC DIAGRAM - WMT 090914 RC WITH ST- WITH ELECTRICAL

HEATING

* Wires supplied

NONO

NONO

NO

TT

TT

T

A :A :

A :A :

A :

If 2 or more indoors units are equipped with electrical heating, the installation of one or two

single pole fuse holders with a neutral cut out (17.5 mm module – not supplied) is required.

Location and connection of fuse holders (not supplied) with the shunts supplied.

Main terminal block: X

Fuse holder not supplied: Refer

to note - Fuse holder rating in

relation to number of ST units

with electrical heating

PXD - ECF - LS

4.7k

:

4.7k

:

4.7k

:

Fuse holder rating in

relation to number of

ST units with electrical

heating.

Power supply cable

section in relation to

number of ST units

with electrical heating.

Page 25

2323

2323

23

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

FUSE HOLDER CONNECTION DETAILS ON MODEL WITH ELECTRICAL

HEATING

1

BEFORE INTEGRATION

OF THE FUSE HOLDER

AFTER INTEGRATION

OF THE FUSE HOLDER

(wiring harness

supplied)

2

WIRE DISCONNECT

WIRE DISCONNECT

Page 26

2424

2424

24

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

REGULAREGULA

REGULAREGULA

REGULA

TION SYSTEMTION SYSTEM

TION SYSTEMTION SYSTEM

TION SYSTEM

GENERAL OPERATING PRINCIPLES

The regulation PCB input data is directly linked to the demands expressed by the indoors units

(demands for compressor, fan, 4 ways valve). These inputs, associated with an outdoors

sensor, provide a truth table translating the unit’s operating characteristics in each mode.

Fan

The fan operation is linked directly to the outdoors temperature.

The values for passing from Low Speed to High Speed are determined by the operating mode.

Compressor

The regulation system includes anti-short cycle protection for the compressor to avoid

excessive start/stop actions than could damage its operation.

SAFETY PROTECTION

The machine is protected against any malfunctions by 2 levels of HP protection.

A first level of protection by an automatic reset safety protecting the machine when the

condensing temperature has exceeded the set threshold.

A second level of protection by a manual reset safety activated when the condensing

pressure is higher than the threshold set by the safety pressostat.

It is important to check the quantity of the refrigerant charge in the system if these protection

devices are activated repeatedly.

The HP protection is only activated for the unit A or B in question. The other circuit will

continue to operate normally.

DE-ICING

The regulation system provides automatic control of the de-icing function for the outdoors

exchanger in relation to outdoors temperature conditions

When one of the units triggers the demand for de-icing, the entire system (units A and B) is

de-iced simultaneously .

Page 27

2525

2525

25

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

POWER SUPPLY

The electrical supply voltage and frequency must comply with the values stated on the

Maker’s Plates on both the indoors and outdoors units.

ELECTRICAL TUBING

The units are designed connected as a fixture to fixed electric tubing. Do not use removable

plugs or flex for the power cable or the connection cables between the indoors and outdoors

units.

CONDENSATES DRAINAGE

Check that water drains properly by pouring a quantity into the indoors unit condensate tray.

Check that all connections are watertight and, as required, protect the pipe work with

insulation material if there is a risk of freezing or of condensation.

REFRIGERANT CONNECTIONS

Using an appropriate detection device, check the tightness of all refrigerant connections,

notably around the connecting valves of the outdoors unit. Check that all pipe work is

properly insulated.

CONNECTIONS THROUGH A WALL

Check the seal of the passage hole through a wall where connections pass outside the

building. Check that there is no direct contact between the connection tube and the wall

surface.

ATTACHMENT

Check that the outdoors and indoors units are attached securely. Refit any previously

removed items

CHECKS BEFORE STCHECKS BEFORE ST

CHECKS BEFORE STCHECKS BEFORE ST

CHECKS BEFORE ST

ARAR

ARAR

AR

TINGTING

TINGTING

TING

Replace the caps on the valves and check that they are properly tightened.

Attach the cables and connections to the wall with clamps as required.

Run the air conditioning system in the client’s presence and explain all its functions.

Demonstrate the method of removing, cleaning and refitting the filters.

FINAL TFINAL T

FINAL TFINAL T

FINAL T

ASKSASKS

ASKSASKS

ASKS

Page 28

2626

2626

26

WMTWMT

WMTWMT

WMT

090914 RC090914 RC

090914 RC090914 RC

090914 RC

High THigh T

High THigh T

High T

echech

echech

ech

MAINTENANCE AND SERVICING

All the units are factory-filled with a predetermined R407C charge.

R407C is a mixture of three refrigerant fluids: R32 (23%), R125 (25%) and R134a (52%).

As opposed to R22 that is a pure fluid, R407C is a non-azeotropic fluid. One of the

consequences of using R407C is the glide causing temperature variations during the phase

of changing from the liquid to the vapour state.

HOW TO IDENTIFY A REFRIGERANT FLUID LEAK?

There may be a refrigerant leak in the system if the following conditions occur with the two

indoors units in operation:

Overheating higher than 15°C.

Compressor output temperature higher than 105°C.

Under-cooling lower than 3°C.

In the event of a leak:

Identify the source of the leak.

Completely drain the circuit by forcing the opening of the solenoid valves

Repair the cause of the leak.

Charge the circuit with nitrogen at a pressure of 2 bars and pass soapy water over the

pipe work to check that the leak has been properly repaired.

Vacuum drain the circuit down to 10

-

² bars.

Charge with R407C refrigerant as indicated on the Maker’s plate, taking account of

the installation’s pipe lengths.

CONDENSER

It is recommended that the finned exchanger is checked on a regular basis.

Use a neutral pH cleaning product to avoid any corrosion.

The cleaning operation must be performed with a low pressure water jet to avoid damaging

the fins.

Page 29

Déclaration CE de conformité

Nous déclarons sous notre responsabilité que les produits désignés dans la présente notice sont conformes aux

dispositions des directives CEE énoncées ci- après et aux législations nationales les transposant.

CE Compliance declaration

Under our own responsibility, we declare that the product designated in this manual comply with the provisions of the

EEC directives listed hereafter and with the national legislation into which these directives have been transposed.

EG-Konformitätserklärung

Wir erklarën in eigener Verantwortung, das die in der vorliegenden Beschreibung angegebenen Produkte den

Bestimungen der nachstehend erwähnten EG-Richtlinien und den nationalen Gesetzesvorschriffen entsprechen, in

denen diese Richtinien umgesetz sind.

Dichiarazione CE di conformità

Dichiariamo, assurmendone la responsasabilità, che i prodotti descritti nel presente manuale sono conformi alle

disposizioni delle direttive CEE di cui sott e alle lagislazionni nazionali che li recepiscono

Declaramos, bajo nuestra responsabilidad, que los productos designados en este manual son conformes a las

disposiciones de las directivas CEE enunuciadas a continuacion, asi como a las legislaciones nacionales que las

contemplan.

Declaración CE de conformidad

And that the following paragraphs of the harmonised standards have been applied.

Et que les paragraphes suivants les normes harmonisées ont été appliqués.

Und dass die folgenden Paragraphen der vereinheitlichten Normen Angewandt wurden.

E che sono stati applicati i seguenti paragraphi delle norme armonnizzate.

Y que se han aplicado los siguientes apartados de las normas armonizadas.

A Tillières Sur Avre

27570 - FRANCE

Le: 22/05/2002

Richard FALCO

Directeur Qualité

WMT 090914 RC HIGH TECH

REF : 7 SP 09

MACHINERY DIRECTIVE 98 / 37 / CEE

LOW VOLTAGE DIRECTIVE (DBT) 73 / 23 / CEE AMENDED BY DIRECTIVE 93 / 68 CEE

ELECTROMAGNETIC COMPATIBILITY DIRECTIVE 89 / 336 / CEE

PRESSURISE EQUIPMENT DIRECTIVE (DESP) 97 / 23 / CEE

SUB-MODULE A CATEGORY I

DIRECTIVE MACHINES 98 / 37 C.E.E.

DIRECTIVE BASSE TENSION (DBT) 73 /23 C.E.E. , AMENDEE PAR DIRECTIVE 93 / 68 C.E.E.

DIRECTIVE COMPATIBILITE ELECTROMAGNETIQUE 89 / 336 / C.E.E.

DIRECTIVE DES EQUIPEMENTS SOUS PRESSION (DESP) 97 / 23 C.E.E.

MODULE

A CATEGORIE I

RICHTLINIE MASCHINEN 98 / 37 / EG

RICHTLINIE NIERDERSPANNUNG (DBT) 73 / 23 / EG ABGEÄNDERT DURCH DIE RICHTLINIE 93 / 68 EG

RICHTLINIE ELEKTROMAGNETISHE VERTRÄGLICHKEIT 89 / 336 / EG

RICHTLINIE FÜR AUSRÜSTUNGEN UNTER DRUCK (DESP) 97 / 23 / EG

UNTER MODUL

A, KATEGORIE I

DIRETTIVA MACHINE 98 / 37 / CEE

DIRETTIVA BASSA TENSIONE (DBT) 73 / 23 / CEE EMENDATA DALLA DIRETTIVA 93 / 68 CEE

DIRETTIVA COMPATIBILITA ELETTROMAGNATICA 89 / 336 / CEE

DIRETTIVA DEGLI IMPIANTI SOTTO PRESSIONE (DESP) 97 / 23 / CEE

SOTTOMODULO

A, CATEGORIA I

DIRECTIVA MAQUIAS 98 / 37 / CEE

DIRECTIVA BAJA TENSION (DBT) 73 / 23 / CEE ENMENDATA POR LA DIRECTIVA 93/ 68 CEE

DIRECTIVA COMPATIBILIDAD ELECTROMAGNETICA 89 / 336 / CEE

DIRECTIVA DE LOS EQUIPOS A PRESION (DESP) 97 / 23 / CEE

BAJA MODULO

A, CATEGORIA I

NF EN 60 204-1 / 1998 NF EN 60 335-1 / 1995 NF EN 60 335-2-40 / 1994

NF EN 55 022 / 1998 NF EN 61 000-3-2 / 1998 NF EN 50 082-1 / 1998

NF EN 814 / 1997 NF EN 378 / 99 NF EN 255 / 1997

NF EN 60 204-1 / 1998 NF EN 60 335-1 / 1995 NF EN 60 335-2-40 / 1994

Page 30

Loading...

Loading...