Page 1

CENTRAL AIR CONDITIONER

SPLIT SYSTEM

WITH ELECTRONIC CONTROL

SERIES LS

INSTALLATION INSTRUCTIONS

Page 2

SUMMARY

GENERAL.......................................................................................................................................................... 1

SELECTING THE LOCATION OF UNITS......................................................................................................... 3

RELATIVE LOCATION OF THE UNITS............................................................................................................ 3

SELECTING THE OUTDOOR UNIT (CONDENSER) LOCATION ................................................................... 3

SELECTING THE INDOOR UNIT (EVAPORATOR) LOCATION ..................................................................... 4

INSTALLATION OF THE INDOOR UNIT (THE EVAPORATOR) ..................................................................... 5

INSTALLATION OF THE INDOOR UNIT.......................................................................................................... 5

CONDENSATE DRAIN PIPING OF THE INDOOR UNIT................................................................................. 6

OUTDOOR UNIT INSTALLATION .................................................................................................................... 7

CONNECTION OF REFRIGERANT TUBING BETWEEN INDOOR AND OUTDOOR UNITS ........................ 8

GENERAL ......................................................................................................................................................... 8

RECOMMENDATIONS FOR REFRIGERANT TUBING INSTALLATION ........................................................ 9

SETTING IN OPERATION ................................................................................................................................ 9

FLARE PREPARATION .................................................................................................................................. 10

CONNECTING THE TUBES ........................................................................................................................... 10

EVACUATION AND SETTING IN OPERATION ............................................................................................. 10

ELECTRICAL CONNECTIONS....................................................................................................................... 12

POWER SUPPLY ............................................................................................................................................ 12

INTERCONNECTING CABLE......................................................................................................................... 14

DISPLAY CONTROL UNIT ............................................................................................................................. 15

LOCATION CRITERIA .................................................................................................................................... 15

INSTALLATION OF DISPLAY CONTROL UNIT ON WALL ........................................................................... 15

CONSIDERATIONS IN LOCATING THE REMOTE-CONTROLLER ............................................................. 15

REMOTE-CONTROLLER MOUNTING.................................................................................................... ....... 16

LS REMOTE CONTROL (OPTIONAL) ........................................................................................................... 16

FINAL TASKS.................................................................................................................................................. 17

Page 3

English 1

1. GENERAL

The installation instructions relate to LS air-conditioners. LS air-conditioners are made up of two units: an

indoor unit (evaporator) and an outdoor unit (condenser). The two units are interconnected by two refrigerant

tubes, an electric cable and a control cable.

Below are recommendations for correct installation of apartment air-conditioner systems:

• Evaluate the building’s heat absorption.

• Choose the shortest route for the refrigerant lines, with minimum bends.

• A 0.3% loss of efficiency for each meter of tubing beyond the first 7.5 meters should be taken into

account.

• Check the return air route from the air-conditioned area through the return air grille to the inlet grille

of the indoor unit. The route must be free of obstruction and must not pass through non airconditioned areas.

• On a second level of homes (with two levels) the return air grille will be installed close to the floor

and with verification of air outlet from the rooms.

• Use air manifold and return air grilles of a correct size, in conformity with the company's

recommendations.

• In systems with articulated air ducts:

− Articulated ducts of a correct diameter, following the shortest and straightest possible routes

without bends.

− Use of deep adapters only (at least 220 mm) for connecting air ducts and grilles.

ATTENTION

!

Frequent problems in installations are presented below. In order to avoid them, relate to them prior to the

planned installation:

A. Lack of suitable ducts for air return. Air exchange through an open door - a bad solution!

B. No access to air filters and the electrical component box.

C. There are openings and passages to unconditioned floors, or even open to outside air.

D. Air circulation between rooms.

E. Use of incorrect air distributors. The injection and distribution cannot be properly directed.

F. De-icing thermostat does not work, telephone cable was not installed between the outdoor unit and the

indoor unit.

G. Noise in the ducts, when there is no sound insulation inside the ducts.

H. Absence of fresh air influx in a public place.

I. Feeling of discomfort in a office having internal areas and rooms with outside looking windows both

connected to the same unit.

J. Units installed in high places may not provide sufficient heating on a cold day. Installation of an auxiliary

heating element is recommended. This is extremely important in units that operate at night. (An optional

heating element kit can be ordered from the factory).

Page 4

English 2

LS Indoor Unit (Evaporator)

1. Flare coupling

2. Fresh air intake Ø 100 and Ø 125

3. Filter

4. Electrical component box 250x190x70

5. Condensate Drain Port

6. Air inlet

7. Air outlet

LS Outdoor Unit (Condenser)

1. Electric connections

2. Suction line connection (flare)

3. Air inlet

4. Service cocks

5. Liquid line connection (flare)

6. Air outlet

Dimensions (mm) LS 35 LS 35-35 LS 40 LS 55 LS 65 LS 85

A 795 845 795 845 845 900

B 610 690 610 690 690 860

C 315 370 315 370 370 380

D 500 545 500 545 545 706

E 265 300 265 300 300 333

F 270 350 270 350 350 450

G 148 152 148 152 152 98

H 290 300 290 300 300 340

I 293 330 293 330 330 357

Figure 1: LS models, general dimensions

LS 35/40/55

LS 65/85

Page 5

English 3

2. SELECTING THE LOCATION OF UNITS

Only trained and qualified service personnel recommended by the company should install the air conditioner,

in pursuance of the company specifications and using pipes, wiring, and the standard installation

accessories of the company. Any service call, maintenance or repair carried out by the company on

equipment that was installed in noncompliance with the company's instructions will require payment.

In selecting the location of the units, the following requirements should be taken into account:

2.1 Relative location of the units

Install the outdoor unit (condenser) and the indoor unit (evaporator) as close as possible to each other.

For determining the maximum permitted distance between them, see page 8. If it is necessary to

exceed this distance, consult the company.

2.2 Selecting the outdoor unit (condenser) location

• Allow sufficient space for servicing and air flow around the unit.

• Avoid the unit’s exposure to direct sunlight.

• Select a place for the unit that will cause minimum disturbance and/or inconvenience to the user

and the neighbors.

• A minimum of 200 mm is required between the unit and any wall.

• When installing in an enclosed space (balcony, laundry room etc.), make sure that there are vents

ensuring the release of the warm air outside and preventing its return into the outdoor unit.

• In the case of several outdoor units installed in a group, make sure that the warm air discharged by

one outdoor unit is not directed toward another outdoor unit.

• Make sure that the wall on which the outdoor unit is to be installed has a minimum thickness of 200

mm and is strong enough to support the weight of the unit. Do not install on a light structure that is

not resonance vibration-proof (for instance I-tung).

• When the outdoor unit is installed below the level of the indoor unit, ensure that the height

difference between the units is as explained on page 8.

• When installing on the balcony of a second floor or higher, make sure that the level of the upper

housing of the outdoor unit is at the height of the railing. If the outdoor unit is nonetheless installed

lower, ensure that it is installed in a way that will allow easy access and possibility of removing the

cover when servicing the unit.

• When the outdoor unit is installed in an alcove or in a place without free access, install tubing

longer than that usually required, with several loops, to allow for moving the unit when servicing.

• Take into account that water dripping occurs during the heating operation. If it disturbs neighbors,

ensure drainage.

• It is recommended not to hang outdoor units on bedroom walls.

• Do not install outdoor units on tile and asbestos roofs.

Page 6

English 4

2.3 Selecting the indoor unit (evaporator) location

Take into account the following requirements when selecting the place of the indoor unit:

• Allow maximum air diffusion, to as great as possible a distance within the space to be airconditioned.

• Allow free passage for the return air coming into the air-conditioner.

• Ensure adequate drainage of condensation water produced inside the unit.

• Ensure maximum quiet near the bedrooms.

• A minimum of 150 mm is required between the filter and the nearby wall.

• Easy access to the electrical component box and other parts of the indoor unit for servicing.

• Lower ceiling at least 70 mm under the bottom of the unit.

Page 7

English 5

3. INSTALLATION OF THE INDOOR UNIT (THE EVAPORATOR)

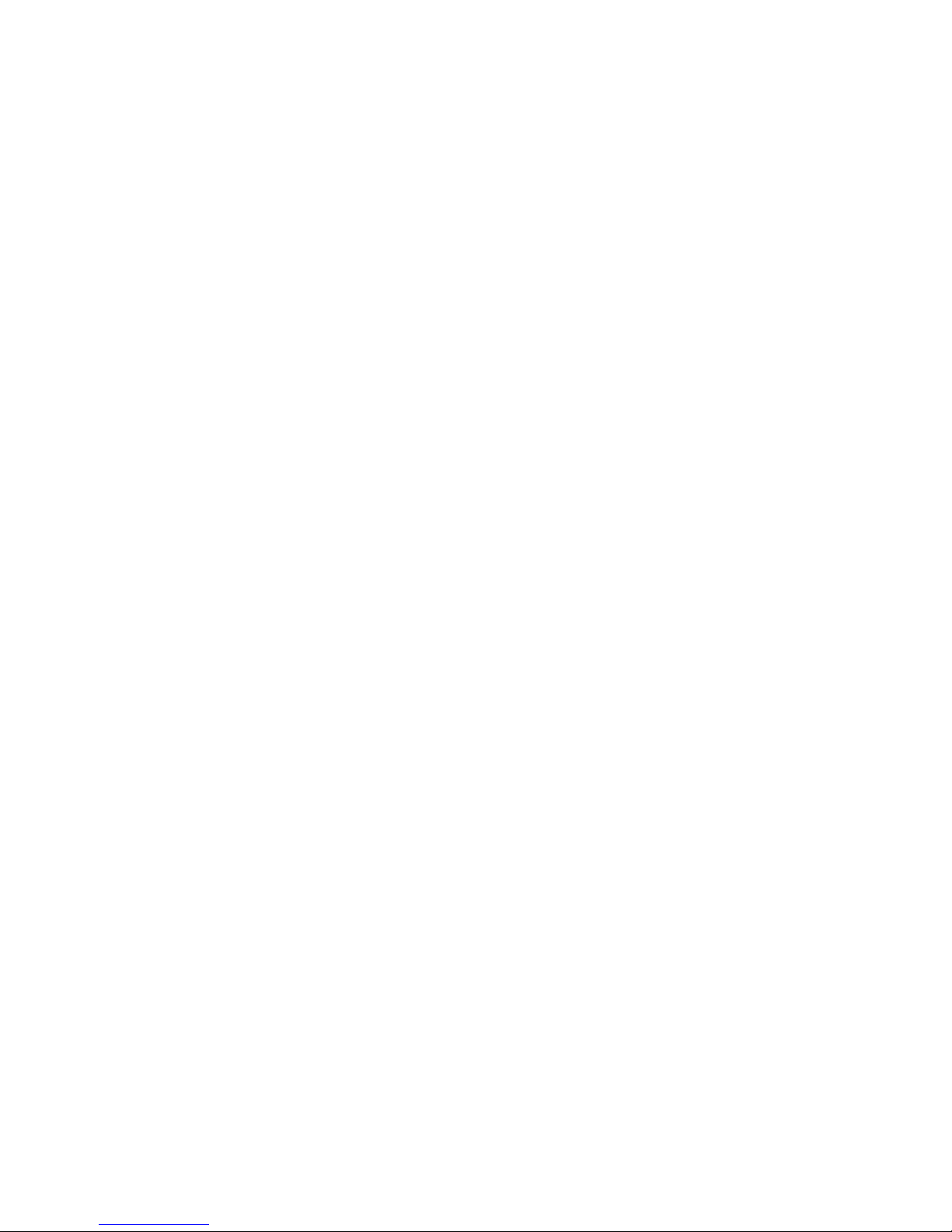

3.1 Installation of the indoor unit (see fig. 2)

A. The indoor unit is designed for installation inside the building in a place not exposed to outdoor

conditions.

B. When it is necessary to install the unit outside the building or in a roof space, take the following

steps:

• Protect the unit from damp and from heat radiation and provide it with additional glass wool

external thermal insulation with 1" thick aluminum coating.

• Plan as short as possible a return air duct with two arcs at most; the duct opening at its

connection to the unit must be of the same size as the backside of the unit.

• In order to reduce noise from vibrations, avoid rigid contact of the unit with the building’s structure

by using suitable shock absorbers and flexible sleeves between the units and the ducts.

• The return air grille must be as close as possible to the air suction side

50

A=30 max

1

2

3

5

6

4

1. Concrete ceiling

2. 8 mm max rod

3. Rubber shock absorber

4. Washer

5. Nut

6. Tightening nut

Figure 2: Installation of indoor unit on ceiling

Plan in advance an easy access to the unit for servicing:

The unit is accessible for servicing from its bottom only.

• Allow a minimum of 150 mm between the wall and the air filters.

• Height of the space required for installation is 80 mm minimum under the unit.

• Access for servicing to all the bottom area of the unit to the size of the service panel.

• Seal the space in which the unit is installed in order to prevent penetration of unconditioned air into

the return air. Also insulate with thermal insulation every partition bordering on an area that is not airconditioned.

1. Vibration absorbers

2. Return air intake

3. Air-conditioned air outlet

4. Opening for removing air filters

5. Control access aperture at the bottom of the unit

6. False ceiling in the access area for servicing

Attention!

A possibility must be left for

reaching all the bottom area

of the unit for servicing.

150 mm min.

80 mm min.

1

2

3

4 5

6

Figure 3: Installation of indoor unit

Page 8

English 6

3.2 Condensate drain piping of the indoor unit

• It is recommended to have a professional plumber prepare a

drain outlet having a 32 mm diameter rigid PVC tube near the

indoor unit, to which a flexible drain pipe for the drainage of the

indoor unit can be attached.

• Install a siphon on the drain line near the unit as portrayed in

fig. no. 4.

• Plan in advance the path of the drain line with a downward

slope of at least 2% and a water trap (siphon) on the line in

order to prevent intake of air through the tube into the unit and

to facilitate the evacuation of condensate water from the unit.

• The rigid drain tube end must be 50 mm lower than the bottom

of the unit.

Figure 4: Siphon on the drain

line

Page 9

English 7

4. OUTDOOR UNIT INSTALLATION

Installation on flat surface (roof, ground, etc.)

The outdoor unit should be elevated at least 100 mm above the ground by using concrete pad, concrete

blocks or wooden beams, in order to allow free flow of condensate water (See Figure 5).

1500 mm

200 mm

Min

Min

Figure 5: Outdoor Unit Installation Criteria

1. Outside the building

2. Outdoor Unit

3. Serrated Rubber 40x80 mm

4. Floor

5. Concrete base or floor tiles

6. Anchor bolts

7. Wall

Page 10

English 8

5. CONNECTION OF REFRIGERANT TUBING BETWEEN INDOOR AND

OUTDOOR UNITS

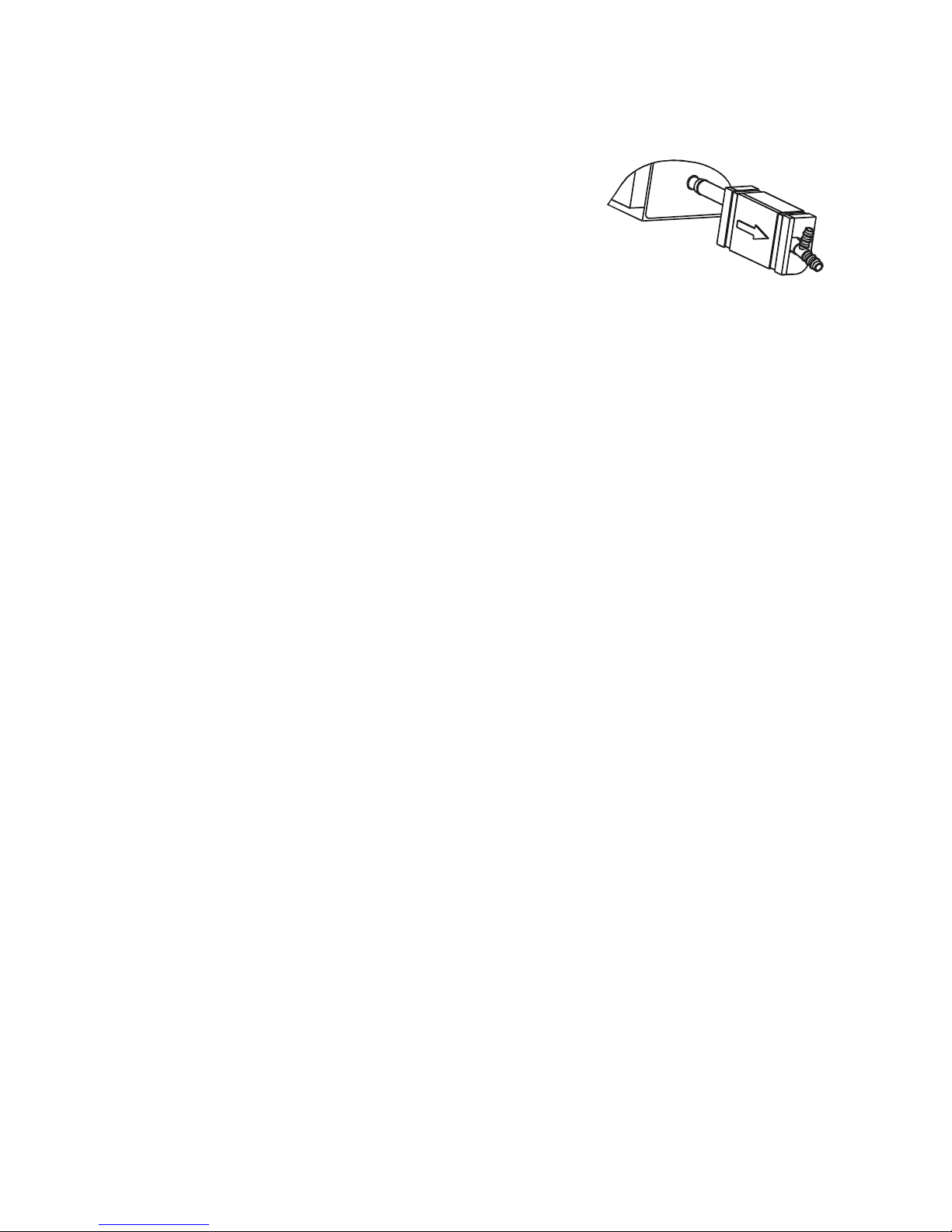

5.1 General (See Figure 6)

The indoor and outdoor units are

connected by two copper tubes and

an electric cable, all passed through a

60-mm wall opening. In addition, a

drainage hose connects the indoor

unit with the nearest drain system.

Connect both units taking the shortest,

most direct route.

1. To outdoor unit

2. Connecting tubing

3. Electric cable

4. Inclination angle

5. To indoor unit

Figure 6: Connection of tubing

and cable

WARNING!

When laying the tubing for the installation, make sure that the ends are sealed to prevent penetration of dirt,

moisture etc. To prevent dust or moisture from entering the tubes, seal them with caps or masking tape. It is

recommended to clean the inside space of the tubes with nitrogen before connecting them to the unit.

Whenever possible, avoid passing tubes through hot zones, such as walls next to ovens, chimneys, etc.

When not possible to avoid this, additional insulation or other means of protection should be provided.

Route the tubing as straight as possible. Keep the number of tube bends to a minimum. If bends are

necessary, perform them only by using professional tube benders and not manually.

Make sure that tubing is insulated on its entire length, including tube ends and quick-attach couplings, or

flared nuts, to avoid tube “sweating” and water dripping from it.

Tubing must be of the “L” type, without any damage. Tubes’ inner walls must be kept absolutely clean prior

to and during installation operations.

Each tube must be individually insulated as follows: tubes up to 5/8” O. D. with 6 mm wall thick sleeve;

above 3/4” O. D. with 9 mm wall thick sleeve.

For diameters, length of liquid and suction lines, and height difference, see Table No. 1 for each model. If the

liquid or suction tube diameters differ from the corresponding flared nuts (mounted on the unit’s branch

pipes) diameter, use a suitable adapter (it is forbidden to insert a tube into another tube) between the flare

connection and the unit’s branch pipes.

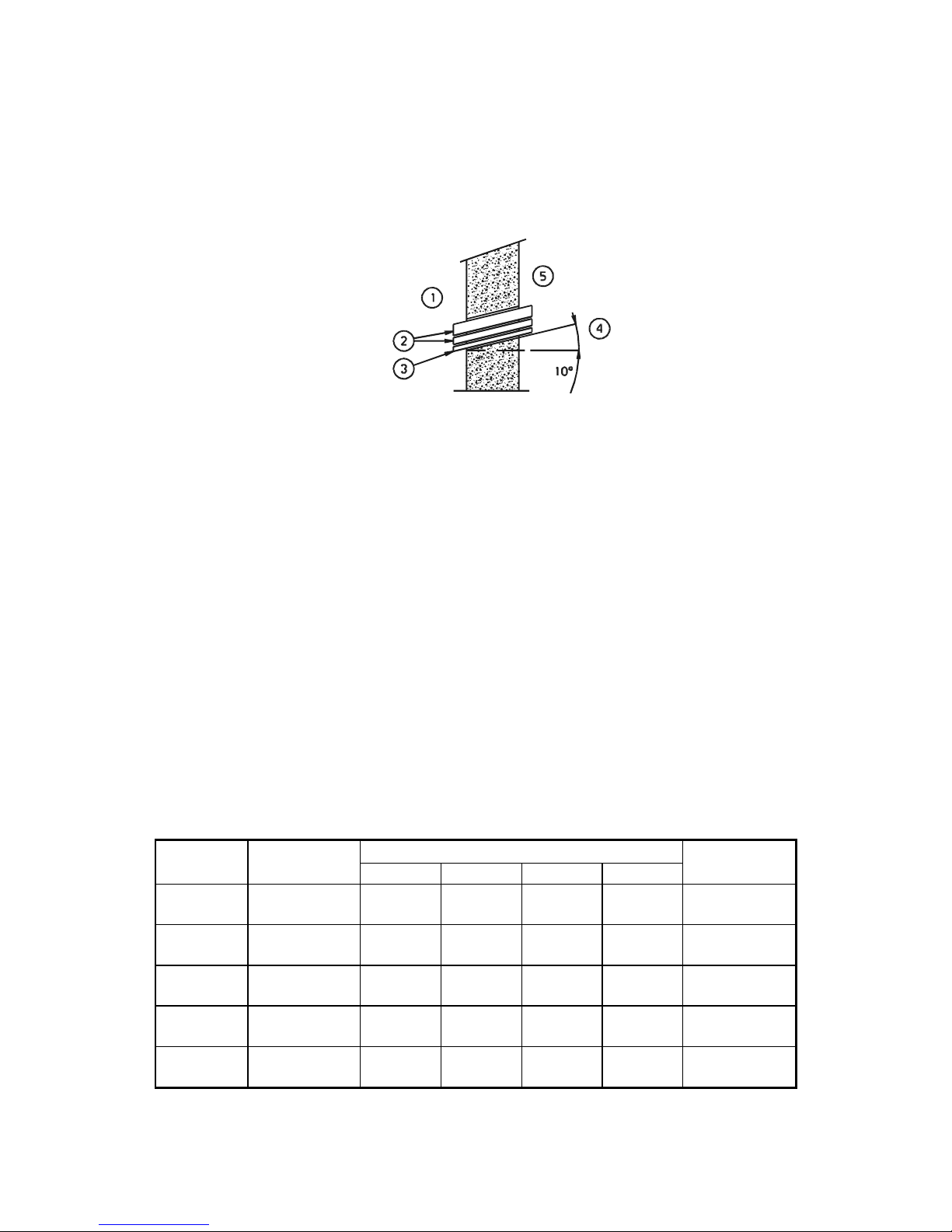

TUBING LENGTH, UP TO - (IN METERS) UNIT MODEL REFRIGERANT

LINE

12 16 20 30

MAX HEIGHT

DIFFERENCE

LS 35 Suction

Liquid

1/2”

1/4”

- - - 7

LS 40 Suction

Liquid

1/2”

1/4”

1/2”

1/4”

- - 7

LS 55 Suction

Liquid

5/8”

3/8”

5/8”

3/8”

5/8”

3/8”

- 10

LS 65 Suction

Liquid

5/8”

3/8”

5/8”

3/8”

5/8”

3/8”

- 10

LS 85 Suction

Liquid

5/8”

3/8”

5/8”

3/8”

5/8”

3/8”

5/8”

3/8”

10

Table No. 1

Page 11

English 9

5.2 Recommendations for refrigerant tubing installation

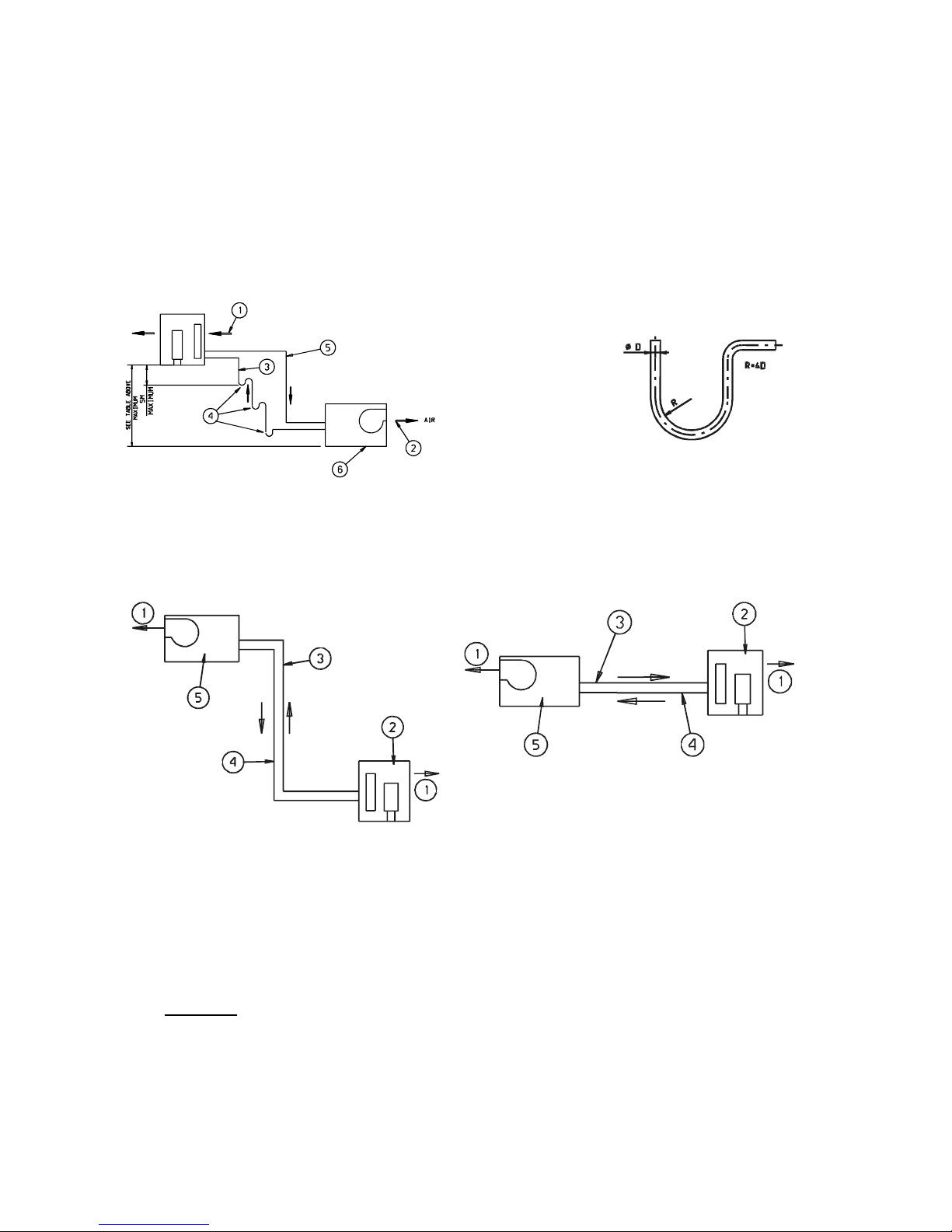

There are three possible variants, a shown on the diagrams:

1. The outdoor unit is installed above the indoor unit (Figure 7) - such installation requires an oil trap

in the suction line at the lowest point of the riser. The radius of the oil trap should be as short as

possible (see Figure 8). Horizontal runs of the suction line should have a 0.5% minimum pitch

toward the outdoor unit. The liquid line should parallel the suction line (except for the oil trap). In

case the tubing insulation had to be partially removed for installation purposes, it is imperative

that the lines be fully insulated with Armaflex, or equivalent insulation, after installation has been

completed.

1. Air inlet

2. Air outlet

3. Suction Line

4. Oil trap every 5 m

5. Liquid Line

6. Indoor unit

Figure 7: Connection of refrigerant tubing-

Outdoor Unit above Indoor Unit

Figure 8: Tube Bending

2. The outdoor unit is installed below the indoor unit (Figure 9) - no trap is required in such

installation. Besides it, the same applies as above.

3. The units are installed at the same level (Figure 10) - no trap is required in such installation.

Besides it, the same applies as above.

1. Air outlet

2. Outdoor Unit

3. Liquid Line

4. Suction Line

5. Indoor Unit

1. Air outlet

2. Outdoor Unit

3. Suction Line

4. Liquid Line

5. Indoor Unit

Figure 9: Connection of refrigerant tubing -

Outdoor Unit below Indoor Unit

Figure 10: Connection of refrigerant tubing -

Outdoor Unit and Indoor Unit at the same level

5.3 Setting in Operation

WARNING

This paragraph describes the necessary steps for setting the unit into operation; be sure to follow the

instructions, to assure proper functioning of the air-conditioner.

The outdoor unit is charged with the correct amount of refrigerant. In extended runs, for additional

refrigerant charge please refer to the outdoor unit nameplate. This operation shall be performed only

by qualified refrigeration technicians with a professional charging set.

Page 12

English 10

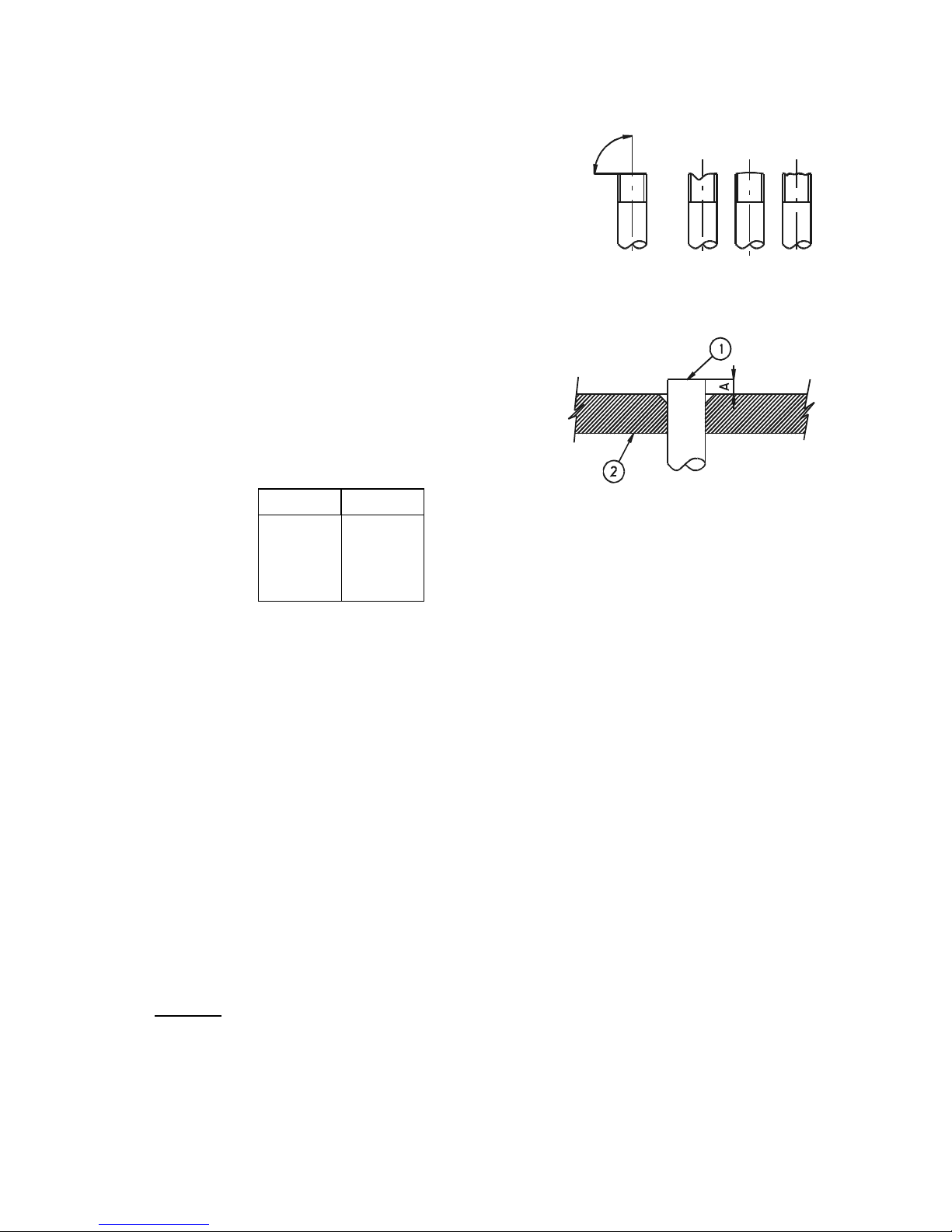

5.3.1 Flare preparation

a) Cut the tube, using a tube cutter. Make sure that the cut

is perpendicular to the tube axis and free of burrs (see

Figure 11).

b) Slip the flared nut over the tube, secure the tube in the

flaring tool, as shown in Figure 12 and perform the flare

on the tube end. The tube projection length (A) from the

flaring block varies with tube diameter and shall be set as

indicated in the table. Apply few drops of refrigeration oil

to the tube before flaring.

CORRECT

90º

INCORRECT

Figure 11: Tube cutting

5.3.2 Connecting the tubes (See Figure 13)

Connect and tighten the flare nuts to the refrigeration valves

on the outdoor unit and to the male connectors of the indoor

unit. Coat the flared surfaces lightly with refrigeration oil to

improve sealing.

Note: First tighten manually the flare nuts, and then use a

wrench. See Table No. 2 for tightening torque values.

A (mm)

TUBE OD

Figure 12: Tube flaring

1.3

1.6

1.9

2.1

3/8”

1/2”

5/8”

3/4”

1. Copper Tube

2. Flaring Tool

5.3.3 Evacuation and setting in operation

a) Take two charging hoses equipped with a pushpin on one side, as shown in Figure 13. Connect

the two hose ends without the push-pin to the LOW (suction) and HIGH (liquid) valves of the

charging set; remove the guard caps from the service ports of the tree-way suction and liquid

valves and connect the hose ends with the push-pins to the service ports (see Figure 14). On

units without service valve on the liquid port, connect only the hose to the suction 3-way valve.

b) Connect the center hose of the charging set to a vacuum pump.

c) Turn on the vacuum pump and make sure that the low pressure gauge reading moves

from 0 cm Hg to 76 cm Hg; then evacuate the system for 10 minutes.

If gauge needle does not move from 0 cm Hg to 76 cm Hg, this indicate a leak. In this case,

tighten all connections; if leaking stops after the tightening of tubing connections, proceed from

step c. If leaking persists even after the connections had been tighten, detect the leak and

repair it; be sure to proceed only after all leaks have been eliminated.

d) Close the valves of both the suction and liquid ports of the charging set and turn off the vacuum

pump. Make sure that the gauge needle does not move for about 5 minutes.

e) Disconnect the charging hoses from the vacuum pump and from the service ports of both the

tree-way valves.

f) Replace the service port and valve caps of both tree-way valves and tighten them with a torque

wrench; see table of torque values in table No. 2.

CAUTION

When performing the following steps, avoid any exposure to the service valve ports; remember that the

system is under pressure.

g) Remove the valve caps (1) from both valves; position both valves to “Open” using an hexagonal

wrench (See Figure 14).

h) Replace valve caps of both three-way valves. Check for gas leakage with a leak detector or

soapy water.

Page 13

English 11

1. Charging set

2. Vacuum pump

3. Outdoor unit

4. Service port

5. Valve cap

6. Suction valve

7. Valve cap

8. Liquid valve

9. Indoor unit

10. Suction flare connection

11. Liquid flare connection

NOTE:

1. For additional refrigerant

charge, for various tubing

lengths refer to outdoor unit

nameplate.

2. Service port on liquid line

3-way valve is not supplied

on all units.

Figure 13: Refrigerant Tubing Service Connection

TUBE (Inch)

TORQUE (N.m.)

1/4" 3/8" 1/2" 5/8" 3/4"

FLARE NUTS 11-13 40-45 60-65 70-75 80-85

VALVE CAP 13-20 13-20 18-25 18-25 40-50

SERVICE PORT CAP 11-13 11-13 11-13 11-13 11-13

Table No. 2: Tightening Torque Values

1

2

3

4

6

7

8

5

1. Valve Protection Cap-end

2. Use Allen Wrench to open/close the Refrigerant Valve

3. Valve Protection Cap

4. Refrigerant Valve

5. Service Port Cap

6. Flare Nut

7. Unit Back Side

8. Copper Tube

Figure 14: Service Refrigeration Valve

Page 14

English 12

6. ELECTRICAL CONNECTIONS

6.1 Power Supply

WARNING

Electrical connection shall be made only by authorized electricians and in accordance with local

electrical requirements and codes. The system must be grounded.

Single-phase models and three phase models are available; for each of them, the necessary wiring

diagram is shown. Connect the unit to the main power supply as for its applicable wiring diagram.

a) Single phase-models (See Figure 16).

The main power supply cable must be HO5VV-K5G-type and contain 3x4 mm

2

leads.

b) Three phase-models (See Figure 17).

The main power supply cable must be HOVV-K5G-type and contain 5x2.5 mm

2

leads.

WARNING

On unit with scroll type compressors, it is mandatory to listen to compressor operation upon initial

startup. Should there be an unusual noise in operation, it is necessary to interchange the phases at the

power supply connection.

1. Outdoor unit

2. Inter connecting cable

3. Power supply cord

4. Semi-automatic switch

5. Indoor unit

6. Quick-attach coupling

7. Display control unit

8. Wireless Remote Control

9. Wired Remote Control

10. Remote ON/OFF Switch (by Installer)

11. Control Cable

Figure 15: Single Phase Units – Indoor Supply: Electrical Scheme

MODEL CIRCUIT BREAKER

LS 35 10 A

LS 40 16 A

LS 55 16 A

LS 65 16 A

Page 15

English 13

1. Outdoor unit

2. Inter connecting cable

3. Power Supply

4. Semi-automatic switch

5. Indoor unit

6. Display Quick connector

7. Display control unit

8. Wireless Remote Control

9. Wired Remote Control (optional)

10. Remote ON/OFF Switch (by Installer)

11. Control Cable (Shielded)

12. Switch ON/OFF (by Installer)

Figure 16: Single Phase Units – Outdoor Supply: Electrical Scheme

MODEL CIRCUIT BREAKER

LS 85 20 A

Page 16

English 14

1. Outdoor unit

2. Inter connecting cable

3. Power Supply

4. Semi-automatic switch

5. Indoor unit

6. Display Quick connector

7. Display control unit

8. Wireless Remote Control

9. Wired Remote Control (optional)

10. Remote ON/OFF Switch (by Installer)

11. Control Cable (Shielded)

12. Switch ON/OFF (by Installer)

13. Heater Cable (Optional)

14. Switch ON/OFF for Heater (by Installer)

Figure 17: Three Phase Units: Electrical Scheme

MODEL CIRCUIT BREAKER

LS 55 3X16 A

LS 65 3X16 A

LS 85 3x16 A

6.2 Interconnecting cable

The electrical cable between the indoor and outdoor units, for all models, must be HO5VV-K5G type.

Conductors shall be of size and number as indicated in Figure 15, 16 or 17. The electrical cable must

be one-piece, without any joints. When installing the cable under the floor, it must be protected and

isolated from any possible contact with water. When the cable path runs through a wall or an acoustic

ceiling, it will be protected with fireproof tubing. In addition, the two units should be interconnected by a

telephone-type cable, 2 x 0.5 mm². See applicable wiring diagram in Figure 15, 16 or 17.

Page 17

English 15

6.3 Display control unit

6.3.1 Location criteria

It is recommended to install the Display Control Unit close to a ceiling in a central and neutral zone at

typical conditions. In addition, the aesthetic aspect should be considered. The Display Control Unit is

connected to the main control board on the air conditioner (the indoor unit) by a communication cable.

The cable is connected to the Display Control Unit by a quick-attach 8-pin connector.

6.3.2 Installation of Display Control Unit on Wall

Drill a 12 mm diameter hole on the wall, for routing the communication cable. Open the unit cover, drill 3

holes in the wall to match the holes in the Display Control Unit, install the wall studs and fasten the unit

to the wall with 3 screws.

The Display Control Unit (4) is provided with a 7 meters long special communication cable (2),

terminated by a plug for connecting to a distribution box (3), which enables the control of the air

conditioner from several different rooms, each one from its own Display Control Unit (See figure 18 and

19). Connect the quick-attach connector to the appropriate socket on the main control board in the

indoor unit electrical component box (1). Should it not be possible to route the communication cable

plug (2) through the wall to the display board (4), the cable end may be cut off and connected to the

terminal board on the display unit, according to the colors indicated in figure 18.

WARNING

The plug should not be cut off the communication cable if the cable length is insufficient. In such case, a

5-meter extension cable may be added.

6.3.3 Considerations in locating the Remote-controller

a) Locate the Remote-controller in such a way that when mounted on its support on the wall, it will be

in line sight with the Display Control Unit (at less than 8 m).

b) It is recommended to establish the final location of the Remote Control Unit only after the first

operation, assuring proper transmission and reception between the Remote Control Unit and the

Display Control Unit.

1

2

3

1. Main Control Board on Indoor Unit

2. Control Display Unit

3. Connection Wire

*Option:

Connecting the cable to control

display terminal.

COLOR CHART

Conn. Point Wire Color

1

2

3

4

5

6

7

8

Gold

Green

Black

Brown

Purple

Yellow

Orange

Red

Figure 18: Connection of a single Display Control Unit

Page 18

English 16

1

2

3

4

1. Main Control Board on Indoor Unit, Cat. N.

402616 and 402676

2. Distribution Board, Cat N. 402729

3. Communication cable Cat. N. 402730

4. Display Control Unit N. 1 Cat. N. 402713

5. Display Control Unit N. 2 Cat. N. 402713

6. Display Control Unit N. 3 Cat. N. 402713

7. Display Control Unit N. 4 Cat. N. 402713

Figure 19: Connection to 4 Display Control Units in Parallel (optional)

6.3.4 Remote-controller mounting

a) Secure the Remote-controller bracket on the wall, using two screws and wall studs (supplied with

the unit) and peel the outside protection paper from the adhesive surface.

b) Prior to operating the air conditioner, open the battery compartment cover and make sure that the

red tab protecting the batteries has been removed. Replace the cover and verify that the Remotecontroller functions properly.

c) Attach the Remote-controller to the bracket with a firm movement.

6.4 LS Remote Control (Optional)

The wall-mounted remote control is available in two versions, in infrared wireless or wired.

The remote control installation instructions are supplied with the unit.

NOTE

: The infra-red remote control should be located in a place that have eye contact with the

display unit, at a distance no more then 10 m.

The system can measure the temperature in two alternative modes:

• By a sensor located at the air inlet of the indoor unit

• By a sensor located in the Remote-controller, in mode “I FEEL” or “LOCAL”. In this mode, the

temperature measuring point shifts with the location of the Remote-controller. Its location should

therefore be determined as follows:

a) Avoid installation at location exposed to direct sunlight or near heat sources.

b) Select a location free of any obstructions such as curtains, etc.

c) Select a neutral zone where the conditions are those typical for the whole air conditioned space;

avoid direct exposure to cool air blown out by the air conditioner.

d) Select a location about 1.5 m above the floor, to assure accurate sensing of room

temperature.

e) Avoid locations exposed to water splashing, dampness or humidity.

• Batteries should be replaced when the LCD no longer displays data. Remove the Remotecontroller from its bracket, open the battery compartment cover in the back of the unit and

change the batteries.

• Use two 1.5 Volt, size AAA batteries.

Page 19

English 17

7. FINAL TASKS

1. Replace all caps and covers and check that they are well shut.

2. Seal all the cracks and holes at the sides of the tubes and bores.

3. Attach the wiring and tubes to the wall with clamps.

4. Check all the operations of the air-conditioner. If necessary, use the operating manual.

4.1 Indoor unit

− Are all the remote commands received on the air-conditioner control panel?

− Do the indicator led on the control board work properly?

− Does the air-conditioner execute all the remote control commands?

4.2 Outdoor unit

− Check for any abnormal noise or vibrations during operation of the air conditioner.

− Check that the noise, condensate drain water or airflow does not disturb the neighbors.

5. Run the air-conditioner for cooling and heating

6. Instruct customer on air conditioner exploitation:

− How to remove, clean and replace the filter.

− How to turn the air-conditioner on and off.

− How to choose between heating and cooling and how to set the desired temperature.

− How to adjust on or off time using the timer.

− How to operate the air conditioner from the control panel.

− Give the customer the operating and installation manuals.

− Help the customer fill in the guarantee certificate.

Page 20

CENTRAL AIR CONDITIONER

SPLIT SYSTEM

WITH ELECTRONIC CONTROL

SERIES LS

INSTALLATION INSTRUCTIONS

Page 21

English 2

SUMMARY

GENERAL...........................................................................................................................................................3

SELECTING THE LOCATION OF UNITS................................ ..........................................................................5

RELATIVE LOCATION OF THE UNITS.............................................................................................................5

SELECTING THE OUTDOOR UNIT (CONDENSER) LOCATION ....................................................................5

SELECTING THE INDOOR UNIT (EVAPORATOR) LOCATION ......................................................................6

INSTALLATION OF THE INDOOR UNIT (EVAPORATOR) ..............................................................................7

INDOOR UNIT LOCATION ................................................................................................................................7

CEILING MOUNTING.........................................................................................................................................8

CONDENSATE DRAIN PIPING OF THE INDOOR UNIT ..................................................................................9

OUTDOOR UNIT INSTALLATION ...................................................................................................................10

CONNECTION OF REFRIGERANT TUBING BETWEEN INDOOR AND OUTDOOR UNITS .......................11

GENERAL.........................................................................................................................................................11

RECOMMENDATIONS FOR REFRIGERANT TUBING INSTALLATION .......................................................12

SETTING IN OPERATION ...............................................................................................................................12

FLARE PREPARATION ...................................................................................................................................13

CONNECTING THE TUBES ............................................................................................................................13

EVACUATION AND SETTING IN OPERATION ..............................................................................................13

ELECTRICAL CONNECTIONS ........................................................................................................................15

POWER SUPPLY .............................................................................................................................................15

INTERCONNECTING CABLE ..........................................................................................................................16

DISPLAY CONTROL UNIT...............................................................................................................................17

LOCATION CRITERIA......................................................................................................................................17

INSTALLATION OF DISPLAY CONTROL UNIT ON WALL ............................................................................17

CONSIDERATIONS IN LOCATING THE REMOTE-CONTROLLER...............................................................17

REMOTE-CONTROLLER MOUNTING............................................................................................................18

LS REMOTE CONTROL (OPTIONAL).............................................................................................................18

FINAL TASKS...................................................................................................................................................19

Page 22

English 3

1. GENERAL

The installation instructions relate to LS air-conditioners. LS air-conditioners are made up of two units: an

indoor unit (evaporator) and an outdoor unit (condenser). The two units are interconnected by two refrigerant

tubes, an electric cable and a control cable.

Below are recommendations for correct installation of apartment air-conditioner systems:

• Evaluate the building’s heat absorption.

• Choose the shortest route for the refrigerant lines, with minimum bends.

• A 0.3% loss of efficiency for each meter of tubing beyond the first 7.5 meters should be taken into

account.

• Check the return air route from the air-conditioned area through the return air grille to the inlet grille of the

indoor unit. The route must be free of obstruction and must not pass through non air-conditioned areas.

• On a second level of homes (with two levels) the return air grille will be installed close to the floor and

with verification of air outlet from the rooms.

• Use air manifold and return air grilles of a correct size, in conformity with the company's

recommendations.

• In systems with articulated air ducts:

- Articulated ducts of a correct diameter, following the shortest and straightest possible routes without

bends.

- Use of deep adapters only (at least 220 mm) for connecting air ducts and grilles.

ATTENTION

!

Frequent problems in installations are presented below. In order to avoid them, relate to them prior to the

planned installation:

A. Lack of suitable ducts for air return. Air exchange through an open door - a bad solution!

B. No access to air filters and the electrical component box.

C. There are openings and passages to unconditioned floors, or even open to outside air.

D. Air circulation between rooms.

E. Use of incorrect air distributors. The injection and distribution cannot be properly directed.

F. De-icing thermostat does not work; telephone cable was not installed between the outdoor unit and the

indoor unit.

G. Noise in the ducts, when there is no sound insulation inside the ducts.

H. Absence of fresh air influx in a public place.

I. Feeling of discomfort in a office having internal areas and rooms with outside looking windows both

connected to the same unit.

J. Units installed in high places may not provide sufficient heating on a cold day. Installation of an auxiliary

heating element is recommended. This is extremely important in units that operate at night. (An optional

heating element kit can be ordered from the factory).

Page 23

English 4

INDOOR UNIT (Evaporator)

Figure 1

Dimensions (mm) LS 90 LS 105 LS 125

A 1100 1100 1185

B 965 965 1140

C 200 200 168

D 930 930 1105

E 256 256 312

G 5/8" 5/8" 3/4"

1. Air Supply

2. Electrical Box

3. Refrigeration Tubing

Port

4. Drain port - G (OD)

5. Filters

6. Access Panel

7. Control Unit Port

8. Main Power

Port

OUTDOOR UNIT (Condenser)

Figure 2: LS Series Air Conditioner - General Outline Dimensions

LS 105, 125

LS 90

1. Electric connections

2. Suction line connection

(flare)

3. Air inlet

4. Service cocks

5. Liquid line connection

(flare)

6. Air outlet

Page 24

English 5

2. SELECTING THE LOCATION OF UNITS

Only qualified service personnel trained by the company should install the air conditioner. The installation will

be performed in pursuance of the company specifications and using pipes, wiring, and the standard

installation accessories of the company. Any service call, maintenance or repair carried out by the company

on equipment that was installed in noncompliance with the company's instructions will require payment.

In selecting the location of the units, the following requirements should be taken into account:

2.1 Relative location of the units

Install the outdoor unit (condenser) and the indoor unit (evaporator) as close as possible to each other.

For determining the maximum permitted distance between them, see page 10. If it is necessary to

exceed this distance, consult the company.

2.2 Selecting the outdoor unit (condenser) location

• Allow sufficient space for servicing and air flow around the unit.

• Avoid the unit’s exposure to direct sunlight.

• Select a place for the unit that will cause minimum disturbance and/or inconvenience to the user

and the neighbors.

• A minimum of 200 mm is required between the unit and any wall as illustrated in figure 7.

• When installing in an enclosed space (balcony, laundry room etc.), make sure that there are vents

ensuring the release of the warm air outside and preventing its return into the outdoor unit.

• In the case of several outdoor units installed in a group, make sure that the warm air discharged by

one outdoor unit is not directed toward another outdoor unit.

• It is recommended to attach the condenser to the wall by using a special, hot-dip galvanized

bracket. When installing it on the floor or a platform, the unit should be elevated at least 100 mm

above the surface.

• Make sure that the wall on which the outdoor unit is to be installed has a minimum thickness of 200

mm and is strong enough to support the weight of the unit. Don’t install the outdoor unit on a light

structure that is not resonance vibration-proof.

• When the outdoor unit is installed below the level of the indoor unit, ensure that the height

difference between the units is as explained on page 10.

• When installing on the balcony of a second floor or higher, make sure that the level of the upper

housing of the outdoor unit is at the height of the railing. If the outdoor unit is nonetheless installed

lower, ensure that it is installed in a way that will allow easy access and possibility of removing the

cover when servicing the unit.

• When the outdoor unit is installed in an alcove or in a place without free access, install tubing longer

than that usually required, with several loops, to allow for moving the unit when servicing.

• Take into account that water dripping occurs during the heating operation. If it disturbs neighbors,

ensure drainage.

• It is recommended not to hang outdoor units on bedroom walls.

• Do not install outdoor units on tile and asbestos roofs. Servicing would not be provided for these

condensers.

Page 25

English 6

2.3 Selecting the indoor unit (evaporator) location

Take into account the following requirements when selecting the place of the indoor unit:

• Allow maximum air diffusion, to as great as possible a distance within the space to be airconditioned.

• Allow free passage for the return air coming into the air-conditioner.

• Ensure adequate drainage of condensation water produced inside the unit.

• Ensure maximum quiet near the bedrooms.

• A minimum of 100 mm is required between the filter and the nearby wall.

• Easy access to the electrical component box and other parts of the indoor unit for servicing.

• Lower ceiling at least 70 mm under the bottom of the unit.

• Allow easy access to the outdoor unit at the bottom of the units. Take care to provide for a

corresponding aperture in the lower ceiling.

Page 26

English 7

3. INSTALLATION OF THE INDOOR UNIT (EVAPORATOR)

3.1 Indoor Unit Location (See Figure 3)

The indoor unit is designed for installation on a false ceiling or other compartment, where there is no

influence from outdoor conditions.

While selecting the location, the following conditions must be assured:

a) The location should assure free flow of the return air into the unit without interference.

b) The unit should not be installed close to rooms where noise should be avoided (bedrooms,

children rooms, etc.).

The location should allow good air circulation.

1. Frame installed by Technical

Personnel

2. Flexible Joint

3. 1" thick Duct Acoustic

insulation

4. Cross Section Area min.

800X300 mm

5. Return Air Intake Grille

800x900 (or similar)

6. Return Air Intake

7. Air Filter Opening and Cover

8. Bottom Access

9. Acoustic Insulation

ATTENTION!

BOTTOM ACCESS MUST BE

KEPT FREE FOR MAINTENANCE

Figure 3: Requirements for Indoor Unit Location

Where the unit must be installed in an attic space or outside, the following conditions must be assured:

a) The unit must be protected from rain, heat and radiation by an additional layer of 1" thick

thermal insulation.

b) The return-air duct should be as short as possible, with a minimum dimension of 700x300 mm

(or similar cross section) with full acoustical lining inside, and no more than two long-radius

elbows. The cross sections at the duct connection to the unit shall be equal to that of the unit.

c) The distance between the return air grille and the air intake on the unit must be as short as

possible. A minimum free passage of 0.3 m is necessary along the entire return-air path.

d) The installation should be designed to withstand the weight of the unit and avoid resonance

vibrations. Use serrated rubber mounting under the unit and flexible joints for the air duct.

Design and prepare in advance easy access for servicing as follows: (See Figure 3)

Page 27

English 8

2. The minimum height clearance for the installation is 370 mm.

3. A minimum distance of 200 mm must be kept between the rear side of the unit and any near-by wall, to

allow free air passage.

4. A minimum distance of 300 mm must be kept to allow free air intake and convenient access to air filters.

5. Allow access for the maintenance only from the bottom panel. Allow the access to the electrical control

box to facilitate its easy removal by opening the cover (fastened by 3 screws).

The unit must be insulated so that outside air can flow into the return air opening. Every surface facing

outdoor environment should be thermally insulated. The indoor unit may be installed on the ceiling

(suspended) or mounted on a concrete floor.

3.2 Ceiling Mounting

The indoor unit can be mounted using spring or

serrated rubber isolators.

a) Spring isolators mouting

Insert four 3/8" studs in the ceiling according to

the dimensions of the spring-Type isolators.

Mount four spring type isolators as shown in

Figure 4. Attach indoor unit to the spring-type

isolators and level it, using the leveling nuts.

Secure in place by tightening the fastening nuts.

NOTE

The location of units should allow proper

clearance from the bottom to facilitate

maintenance.

1. Concrete Ceiling

2. Bolt for Ceiling Insert

3. Leveling Nut

4. Fastening Nut

Figure 4: Indoor Unit Installation

Ceiling Mounting using Spring Isolators

b) Serrated Rubber Mounting

In sites where the spring isolators assemble

cannot be installed, mount the unit as show in

Figure 5. Insert four 3/8" studs in the ceiling

according to the dimensions of the suspension

angle frame mounted on the unit. Prepare two

30x30 mm, 1.5 mm thick galvanized sheet metal

for each stud and assemble according to Figure

5. The rubber pads may be substituted by

springs suitable for this type of installation.

1. Concrete Ceiling

2. Bolt for Ceiling Insert

3. Leveling Nut

4. Fastening Nut

Figure 5: Indoor Unit Installation

Ceiling Mounting using Rubber Isolators

Page 28

English 9

3.3 Condensate drain piping of the indoor unit

• It is recommended to have a professional plumber prepare a

drain outlet having a 32 mm diameter rigid PVC tube near the

indoor unit, to which a flexible drain pipe for the drainage of

the indoor unit can be attached.

• Install a siphon on the drain line near the unit as portrayed in

figure no. 6.

• Plan in advance the path of the drain line with a downward

slope of at least 2% and a water trap (siphon) on the line in

order to prevent intake of air through the tube into the unit and

to facilitate the evacuation of condensate water from the unit.

• The rigid drain tube end must be 50 mm lower than the bottom

of the unit.

Figure 6: Siphon on the drain

line

Plan in advance an easy access to the unit for servicing:

• The unit is accessible for servicing from its bottom only. Allow a minimum of 100 mm between the

wall and the air filters.

• Height of the space required for installation is 100 mm minimum.

• Access for servicing to all the bottom area of the unit to the size of the service panel.

• Seal the space in which the unit is installed in order to prevent penetration of unconditioned air into

the return air. Also insulate with thermal insulation every partition bordering on an area that is not

air-conditioned.

Page 29

English 10

4. OUTDOOR UNIT INSTALLATION

Installation on flat surface (roof, ground, etc.)

The outdoor unit should be elevated at least 100 mm above the ground by using concrete pad, concrete

blocks or wooden beams, in order to allow free flow of condensate water. (See Figure 7).

1500 mm

200 mm

Min

Min

Figure 7: Outdoor Unit Installation Criteria

1. Outside the building

2. Outdoor Unit

3. Serrated Rubber 40x80 mm

4. Floor

5. Concrete base or floor tiles

6. Anchor bolts

7. Wall

Page 30

English 11

5. CONNECTION OF REFRIGERANT TUBING BETWEEN INDOOR AND

OUTDOOR UNITS

5.1 General (See Figure 8)

The indoor and outdoor units are

connected by two copper tubes and an

electric cable, all passed through a 60mm wall opening. In addition, a

drainage hose connects the indoor unit

with the nearest drain system. Connect

both units taking the shortest, most

direct route.

1. To outdoor unit

2. Connecting tubing

3. Electric cable

4. Inclination angle

5. To indoor unit

Figure 8: Connection of tubing

and cable

WARNING!

When laying the tubing for the installation, make sure that the ends are sealed to prevent penetration of dirt,

moisture etc. To prevent dust or moisture from entering the tubes, seal them with caps or masking tape. It is

recommended to clean the inside space of the tubes with nitrogen before connecting them to the unit.

Whenever possible, avoid passing tubes through hot zones, such as walls next to ovens, chimneys, etc.

When not possible to avoid this, additional insulation or other means of protection should be provided.

Route the tubing as straight as possible. Keep the number of tube bends to a minimum. If bends are

necessary, perform them only by using professional tube benders and not manually.

Make sure that tubing is insulated on its entire length, including tube ends and quick-attach couplings, or

flared nuts, to avoid tube “sweating” and water dripping from it.

Tubing must be of the “L” type, without any damage. Tubes’ inner walls must be kept absolutely clean prior to

and during installation operations.

Each tube must be individually insulated as follows: tubes up to 5/8” O. D. with 6 mm wall thick sleeve; above

3/4” O. D. with 9 mm wall thick sleeve.

For diameters, length of liquid and suction lines, and height difference, see Table No. 1 for each model. If the

liquid or suction tube diameters differ from the corresponding flared nuts (mounted on the unit’s branch

pipes) diameter, use a suitable adapter (it is forbidden to insert a tube into another tube) between the flare

connection and the unit’s branch pipes.

TUBING LENGTH, UP TO -

(

IN METERS, ONE WAY)

UNIT

MODEL

INTERCONNECTING

TUBING

10 15 20 25 30 50

MAX TUBING

LENGHT

MAX

HEIGHT

DIFFERENCE

Suction

5/8” 5/8” 5/8” 5/8” 5/8” 5/8” *

LS 90

Liquid

3/8” 3/8” 3/8” 3/8” 3/8” 3/8” *

30/50* 10/25*

Suction

3/4” 3/4” 3/4” 3/4” 3/4” 3/4”

LS 105

Liquid

3/8” 3/8” 3/8” 3/8” 3/8” 3/8”

50 25

Suction

3/4” 3/4” 3/4” 3/4” 3/4” 3/4”

LS 125

Liquid

3/8” 3/8” 3/8” 3/8” 3/8” 3/8”

50 25

* Special order

Table No. 1: Unit Interconnecting Tubing (indoor and outdoor units)

Page 31

English 12

5.2 Recommendations for refrigerant tubing installation

There are three possible variants, a shown on the diagrams:

1. The outdoor unit is installed above the indoor unit (Figure 9) - such installation requires an oil

trap in the suction line at the lowest point of the riser. The radius of the oil trap should be as

short as possible (see Figure 10). Horizontal runs of the suction line should have a 0.5%

minimum pitch toward the outdoor unit. The liquid line should parallel the suction line (except

for the oil trap). In case the tubing insulation had to be partially removed for installation

purposes, it is imperative that the lines be fully insulated with Armaflex, or equivalent

insulation, after installation has been completed.

1. Air inlet

2. Air outlet

3. Suction Line

4. Oil trap every 5 m

5. Liquid Line

6. Indoor unit

Figure 9: Connection of refrigerant tubing-

Outdoor Unit above Indoor Unit

Figure 10: Tube

Bending

2. The outdoor unit is installed below the indoor unit (Figure 11) - no trap is required in such

installation. Besides it, the same applies as above.

3. The units are installed at the same level (Figure 12) - no trap is required in such installation.

Besides it, the same applies as above.

1. Air outlet

2. Outdoor Unit

3. Liquid Line

4. Suction Line

5. Indoor Unit

1. Air outlet

2. Outdoor Unit

3. Suction Line

4. Liquid Line

5. Indoor Unit

Figure 11: Connection of refrigerant tubing -

Outdoor Unit below Indoor Unit

Figure 12: Connection of refrigerant tubing -

Outdoor Unit and Indoor Unit at the same level

5.3 Setting in Operation

WARNING

This paragraph describes the necessary steps for setting the unit into operation; be sure to follow the

instructions, to assure proper functioning of the air-conditioner.

The outdoor unit is charged with the correct amount of refrigerant. In extended runs, for additional

refrigerant charge please refer to the outdoor unit nameplate. Only qualified refrigeration technicians

with a professional charging set shall perform this operation.

Page 32

English 13

5.3.1 Flare preparation

a) Cut the tube, using a tube cutter. Make sure that the

cut is perpendicular to the tube axis and free of

burrs (see Figure 13).

b) Slip the flared nut over the tube, secure the tube in

the flaring tool, as shown in Figure 14 and perform

the flare on the tube end. The tube projection length

(A) from the flaring block varies with tube diameter

and shall be set as indicated in the table. Apply few

drops of refrigeration oil to the tube before flaring.

CORRECT

90º

INCORRECT

Figure 13: Tube cutting

5.3.2 Connecting the tubes (See Figure 15)

Connect and tighten the flare nuts to the refrigeration valves

on the outdoor unit and to the male connectors of the indoor

unit. Coat the flared surfaces lightly with refrigeration oil to

improve sealing.

Note: First tighten manually the flare nuts, then use a

wrench. See Table No. 2 for tightening torque values.

A (mm)

TUBE OD

Figure 14: Tube flaring

1.3

1.6

1.9

2.1

3/8”

1/2”

5/8”

3/4”

1. Copper Tube

2. Flaring Tool

5.3.3 Evacuation and setting in operation

a) Take two charging hoses equipped with a push-pin on one side, as shown in Figure 15.

Connect the two hose ends without the push-pin to the LOW (suction) and HIGH (liquid)

valves of the charging set; remove the guard caps from the service ports of the tree-way

suction and liquid valves and connect the hose ends with the push-pins to the service ports

(see Figure 16). On units without service valve on the liquid port, connect only the hose to the

suction 3-way valve.

b) Connect the center hose of the charging set to a vacuum pump.

c) Turn on the vacuum pump and make sure that the low pressure gauge reading moves

from 0 cm Hg to 76 cm Hg; then evacuate the system for 10 minutes.

If gauge needle does not move from 0 cm Hg to 76 cm Hg, this indicate a leak. In this case,

tighten all connections; if leaking stops after the tightening of tubing connections, proceed from

step c. If leaking persist even after the connections had been tighten, detect the leak and repair

it; be sure to proceed only after all leaks have been eliminated.

d) Close the valves of both the suction and liquid ports of the charging set and turn off the

vacuum pump. Make sure that the gauge needle does not move for about 5 minutes.

e) Disconnect the charging hoses from the vacuum pump and from the service ports of both the

tree-way valves.

f) Replace the service port and valve caps of both tree-way valves and tighten them with a torque

wrench; see table of torque values in table No. 2.

CAUTION

When performing the following steps, avoid any exposure to the service valve ports; remember that the

system is under pressure.

g) Remove the valve caps (1) from both valves, position both valves to “Open” using an

hexagonal wrench (See Figure 16).

h) Replace valve caps of both three-way valves. Check for gas leakage with a leak detector or

soapy water.

Page 33

English 14

1. Charging set

2. Vacuum pump

3. Outdoor unit

4. Service port

5. Valve cap

6. Suction valve

7. Valve cap

8. Liquid valve

9. Indoor unit

10. Suction flare connection

11. Liquid flare connection

NOTE:

1. For additional refrigerant

charge, for various tubing

lengths refer to outdoor

unit nameplate.

2. Service port on liquid line

3-way valve is not supplied

on all units.

Figure 15: Refrigerant Tubing Service Connection

Tube (Inch)

TORQUE (N.m.)

1/4" 3/8" 1/2" 5/8" 3/4"

FLARE NUTS 11-13 40-45 60-65 70-75 80-85

VALVE CAP 13-20 13-20 18-25 18-25 40-50

SERVICE PORT CAP 11-13 11-13 11-13 11-13 11-13

Table N. 2: Tightening Torque Values

1

2

3

4

6

7

8

5

1. Valve Protection Cap-end

2. Use Allen Wrench to open/close the Refrigerant Valve

3. Valve Protection Cap

4. Refrigerant Valve

5. Service Port Cap

6. Flare Nut

7. Unit Back Side

8. Copper Tube

Figure 16: Service Refrigeration Valve

Page 34

English 15

6. ELECTRICAL CONNECTIONS

6.1 Power Supply

WARNING

Electrical connection shall be made only by authorized electricians and in accordance with local

electrical requirements and codes. The system must be grounded.

Single-phase models and three phase models are available; for each of them, the necessary wiring

diagram is shown. Connect the unit to the main power supply as for its applicable wiring diagram.

a) Single phase-models (See Figure 17).

The main power supply cable must be HO5VV-K5G-type and contain 3x4 mm

2

leads.

b) Three phase-models (See Figure 18).

The main power supply cable must be HOVV-K5G-type and contain 5x2.5 mm

2

leads.

WARNING

On unit with scroll type compressors, it is mandatory to listen to compressor operation upon initial

startup. Should there be an unusual noise in operation, it is necessary to interchange the phases at the

power supply connection.

1. Outdoor unit

2. Inter connecting cable

3. Power supply cord

4. Semi-automatic switch

5. Indoor unit

6. Display Quick connector

7. Display control unit

8. Wireless Remote Control

9. Wired Remote Control (optional)

10. Remote ON/OFF Switch (by Installer)

11. Control Cable (Shielded)

12. Switch ON/OFF (by Installer)

Figure 17: Single Phase Units: Electrical Scheme power to outdoor

MODEL INTERCONNECTING CABLE

WIRELESS

(mm2)

CIRCUIT BREAKER WITHOUT

HEATING ELEMENT

LS 90 6x2.5 20A

LS 105 6x2.5 25A

Page 35

English 16

1

1. Outdoor unit

2. Inter connecting cable

3. Power Supply

4. Semi-automatic switch

5. Indoor unit

6. Display Quick connector

7. Display control unit

8. Wireless Remote Control

9. Wired Remote Control (optional)

10. Remote ON/OFF Switch (by Installer)

11. Control Cable (Shielded)

12. Switch ON/OFF (by Installer)

13. Heater Cable (Optional)

14. Switch ON/OFF for Heater (by Installer)

MODEL INTERCONNECTING CABLE

WIRELESS

(mm2)

CIRCUIT BREAKER WITHOUT

HEATING ELEMENT

LS 90 6x2.5 3x16A

LS 105 6x2.5 3x16A

LS 125 6x2.5 3x16A

Figure 18: Three Phase Units

6.2 Interconnecting cable

The electrical cable between the indoor and outdoor units, for all models, must be HO5VV-K5G-type.

Conductors shall be of size and number as indicated in Figure 17, 18. The electrical cable must be onepiece, without any joints. When installing the cable under the floor, it must be protected and isolated

from any possible contact with water. When the cable path runs through a wall or an acoustic ceiling, it

will be protected with fireproof tubing. In addition, the two units should be interconnected by a telephonetype cable, 2 x 0.5 mm². See applicable wiring diagram in Figure 17, 18.

Page 36

English 17

6.3 Display control unit

6.3.1 Location criteria

It is recommended to install the Display Control Unit close to a ceiling in a central and neutral zone at

typical conditions. In addition, the aesthetic aspect should be considered. The Display Control Unit is

connected to the main control board on the air conditioner (the indoor unit) by a communication cable.

The cable is connected to the Display Control Unit by a quick-attach 8 pin connector.

6.3.2 Installation of Display Control Unit on Wall

Drill a 12 mm diameter hole on the wall, for routing the communication cable. Open the unit cover, drill 3

holes in the wall to match the holes in the Display Control Unit, install the wall studs and fasten the unit

to the wall with 3 screws.

The Display Control Unit (4) is provided with a 7 meters long special communication cable (2),

terminated by a plug for connecting to a distribution box (3), which enables the control of the air

conditioner from several different rooms, each one from its own Display Control Unit (See figure 19 and

20). Connect the quick-attach connector to the appropriate socket on the main control board in the

indoor unit electrical component box (1). Should it not be possible to route the communication cable plug

(2) through the wall to the display board (4), the cable end may be cut off and connected to the terminal

board on the display unit, according to the colors indicated in figure 19.

WARNING

The plug should not be cut off the communication cable if the cable length is insufficient. In such case, a

5-meter extension cable may be added.

6.3.3 Considerations in locating the Remote-controller

a) Locate the Remote-controller in such a way that when mounted on its support on the wall, it will

be in line sight with the Display Control Unit (at less than 8 m).

b) It is recommended to establish the final location of the Remote Control Unit only after the first

operation, assuring proper transmission and reception between the Remote Control Unit and

the Display Control Unit.

1

2

3

1. Main Control Board on Indoor

Unit

2. Control Display Unit

3. Connection Wire

*Option:

Connecting the cable to control

display terminal

COLOR CHART

Conn. Point Wire Color

1

2

3

4

5

6

7

8

Gold

Green

Black

Brown

Purple

Yellow

Orange

Red

Figure 19: Connection of a single Display Control Unit

Page 37

English 18

1

2

3

4

1. Main Control Board on Indoor Unit, Cat. N.

402616 and 402676

2. Distribution Board, Cat N. 402729

3. Communication cable Cat. N. 402730

4. Display Control Unit N. 1 Cat. N. 402713

5. Display Control Unit N. 2 Cat. N. 402713

6. Display Control Unit N. 3 Cat. N. 402713

7. Display Control Unit N. 4 Cat. N. 402713

Figure 20: Connection to 4 Display Control Units in Parallel (optional)

6.3.4 Remote-controller mounting

a) Secure the Remote-controller bracket on the wall, using two screws and wall studs (supplied

with the unit) and peel the outside protection paper from the adhesive surface.

b) Prior to operating the air conditioner, open the battery compartment cover and make sure that

the red tab protecting the batteries has been removed. Replace the cover and verify that the

Remote-controller functions properly.

c) Attach the Remote-controller to the bracket with a firm movement.

6.4 LS Remote Control (Optional)

The wall-mounted remote control is available in two versions, in infrared wireless or wired.

The remote control installation instructions are supplied with the unit.

NOTE

: The infra-red remote control should be located in a place that have eye contact with the

display unit, at a distance no more then 10 m.

The system can measure the temperature in two alternative modes:

• By a sensor located at the air inlet of the indoor unit

• By a sensor located in the Remote-controller, in mode “I FEEL” or “LOCAL”. In this mode, the

temperature measuring point shifts with the location of the Remote-controller. Its location should

therefore be determined as follows:

a) Avoid installation at location exposed to direct sunlight or near heat sources.

b) Select a location free of any obstructions such as curtains, etc.

c) Select a neutral zone where the conditions are those typical for the whole air conditioned space;

avoid direct exposure to cool air blown out by the air conditioner.

d) Select a location about 1.5 m above the floor, to assure accurate sensing of room

temperature.

e) Avoid locations exposed to water splashing, dampness or humidity.

• Batteries should be replaced when the LCD no longer displays data. Remove the Remote-controller

from its bracket, open the battery compartment cover in the back of the unit and change the

batteries.

• Use two 1.5 Volt, size AAA batteries.

Page 38

English 19

7. FINAL TASKS

1. Replace all caps and covers and check that they are well shut.

2. Seal all the cracks and holes at the sides of the tubes and bores.

3. Attach the wiring and tubes to the wall with clamps.

4. Check all the operations of the air-conditioner. If necessary, use the operating manual.

4.1 Indoor unit

− Are all the remote commands received on the air-conditioner control panel?

− Do the indicator led on the control board work properly?

− Does the air-conditioner execute all the remote control commands?

4.2 Outdoor unit

− Check for any abnormal noise or vibrations during operation of the air conditioner.

− Check that the noise, condensate drain water or air flow does not disturb the neighbors.

5. Run the air-conditioner for cooling and heating

6. Instruct customer on air conditioner exploitation:

− How to remove, clean and replace the filter.

− How to turn the air-conditioner on and off.

− How to choose between heating and cooling and how to set the desired temperature.

− How to adjust on or off time using the timer.

− How to operate the air conditioner from the control panel.

− Give the customer the operating and installation manuals.

− Help the customer fill in the guarantee certificate.

Loading...

Loading...