Page 1

Technical Service Manual

REFRIGERANT

Rev.: Date:

SERIES: FS KFR120L

Free Standing

R

407C

HEAT PUMP

01

29/02/04

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

F

M

F

M

12

A

U

T

O

C

A

M

Page 2

T

U

B

E

S

O

U

T

D

O

O

R

U

N

I

T

I

N

D

O

O

R

U

N

I

T

FS 1200

Model

Wall mountedInstallation method

HeatingCoolingUnitsCharacteristic

1280011000Kcal/hr

Capacity

5120044000Btu/hr

1500012900W

45674824WTotal input

2.862.55W/WCOP/EER

400/50/3Power supply (voltage, cycle)

3X16ACircuit breaker rating

Centrifugal

Fan type & qty.

RPM

Fan speed (HI)

2000

1177

m3/hr

)CFM(

Airflow (HI)

52 / 56dBANoise Power

25mmCondensate drain tube I.D

600mmW

Dimensions

370mmD

1900mmH

70KgWeight

2000*710*490mmPackage dimensions

4unitsUnits per palet

1unitsHeight stacking

R-407CRefrigerant control

SCROLL HR61YAB LGCompressor type & model

AXIAL X 2Fan type & qty.

1125RPMFan speed - HI

4200

(2470)

m /hr

(CFM)

Airflow

69dBANoise Power

900mmW

Dimensions

340mmD

970mmH

95KgWeight

985*406*1016mmPacking dimensions

2unitsHeight stacking

6unitsUnits per palet

R407CRefrigerant

3750gramCharge

16mmCondensate drain tube I.D

3/8in.liquid

Tube size O.D

3/4in.suction

Indoor-Outdoor

Connection between units

MAX. 20mheight difference

MAX. 40mtubing length

Operation by hand on LCDOperation control type

A

WHeating elements

C

Ducts

C.

Others

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

Page 3

NOTES:

1. Rating conditions ISO/CD 13253R

Cooling: indoor: 27°C (80°F) DB 19°C (66°F) WB

Outdoor: 35°C (95°F) DB

Heating: indoor: 20°C (68°F) DB

Outdoor: 7°C (45°F) DB 6° C (43°F) WB

Refrigerant tubing length (one way) 7.5m (24.6 ft)

2. Guaranteed operating range:

Indoor Outdoor

Upper limit

32°C DB, 23°C WB 46°C DB

Cooling

Lower limit

21°C DB, 15°C WB 21°C DB

Upper limit

27°C DB 24°C DB, 18°C WB

Heating

Lower limit

20°C DB -9°C DB, -10°C WB

1 PH 198 – 242 V

Voltage

3 PH 360 – 440 V

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

Page 4

FS KFR 120L /OU10-50 R407C

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

Page 5

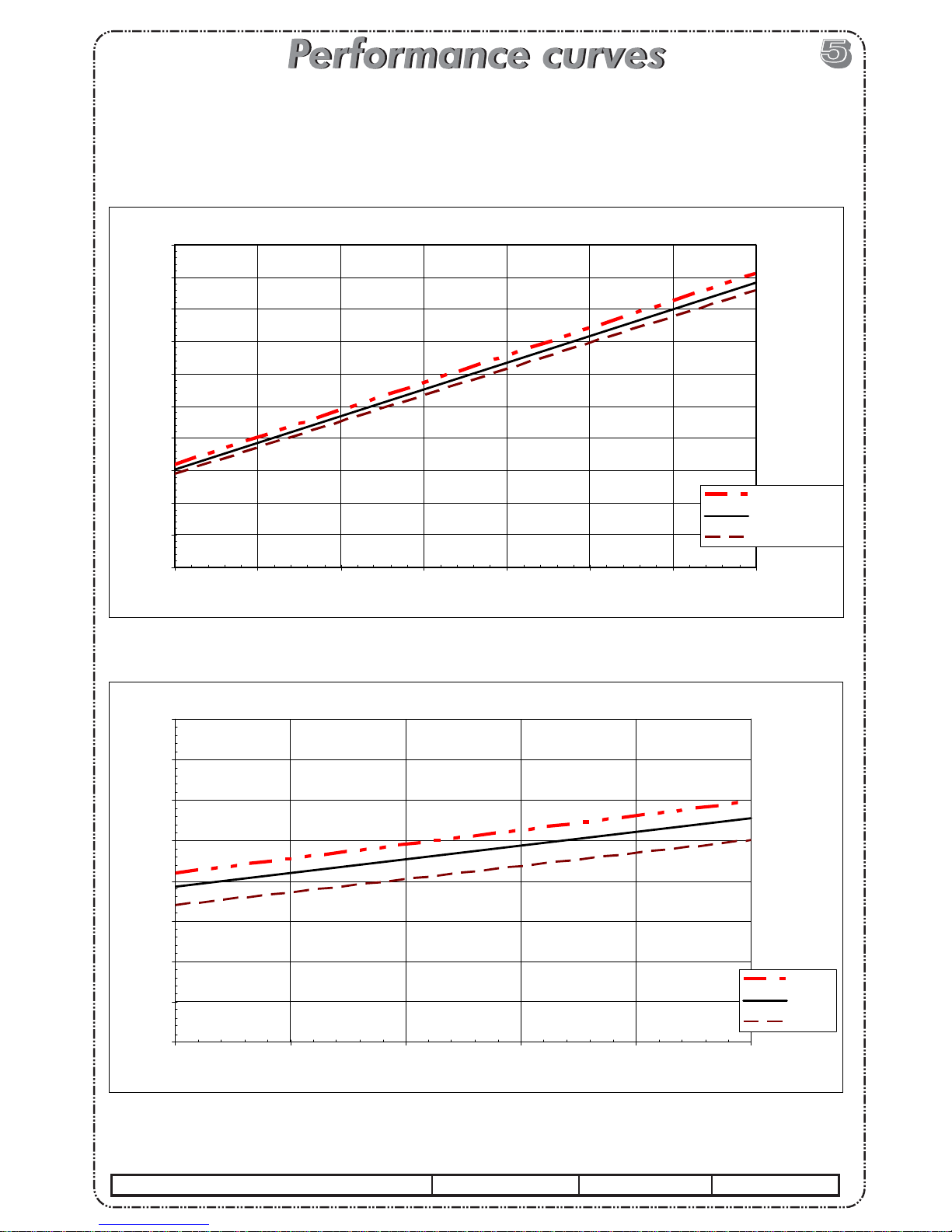

Model:

FS1200T R407c COOLING CAPACITY

10,000

11,000

12,000

13,000

14,000

15,000

16,000

17,000

18,000

10 15 20 25 30 35 40 45

Outdoor Te mp. (C DB)

CAPACITY [W)

30 C DB/ 50% RH

26 C DB/ 50% RH

23 C DB/ 50% RH

Indoor Temp.

FS1200T R407c HEATING CAPACITY

6,000

8,500

11,000

13,500

16,000

18,500

21,000

-10 -5 0 5 10 15

Outdoor Te mp. (C DB)

CAPACITY [W)

20 C DB

18 C DB

15 C DB

Indoor Temp.

FS KFR 120L

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

Page 6

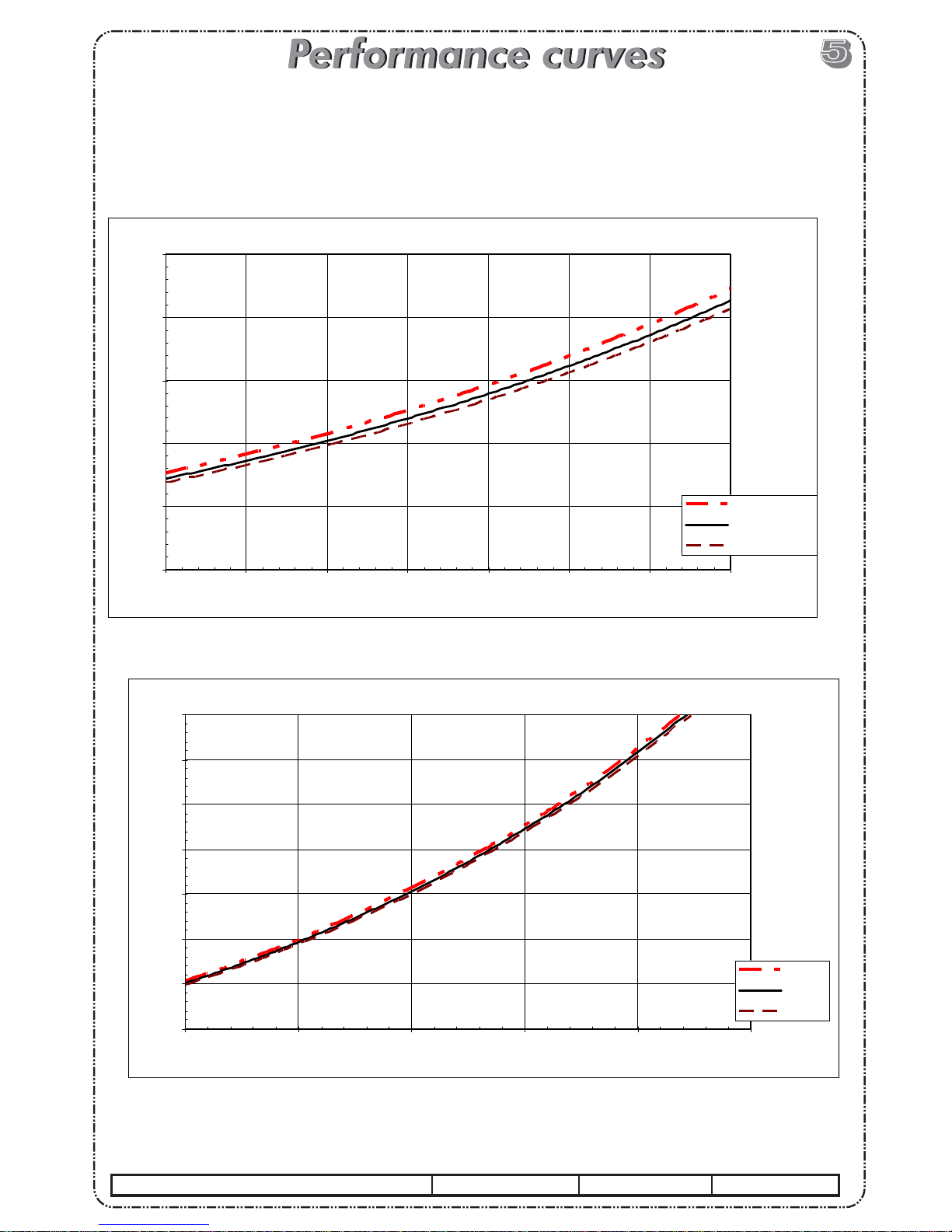

Model:

FS1200T R407c COOLING TOTAL INPUT

1,500

2,000

2,500

3,000

3,500

4,000

4,500

5,000

5,500

6,000

6,500

10 15 20 25 30 35 40 45

Outdoor Te mp. (C DB)

TOTAL INPUT (W

)

30 C DB/ 5 0% RH

26 C DB/ 5 0% RH

23 C WB /50 %RH

Indoor Temp.

FS1200T R407c HEATING TOTAL INPUT

2,500

3,000

3,500

4,000

4,500

5,000

5,500

6,000

6,500

-10 -5 0 5 10 15

Outdoor Te mp. (C DB)

TOTAL INPUT (W

)

20 C DB

18 C DB

15 C DB

Indoor Temp.

FS KFR 120L

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

Page 7

Model:

FS1200T R407c COOLING DISCHARGE PRESS URE

5.0

10.0

15.0

20.0

25.0

30.0

10 15 20 25 30 35 40 45

Outdoor Te mp. (C DB)

DISCHARGE PRESSURE [Bar(g

30 C DB/50%RH

26 C DB/50%RH

23 C DB/50%RH

Indoor Temp.

FS1200T R407c HEATING SUCTION PRESSURE

1.50

2.00

2.50

3.00

3.50

4.00

4.50

5.00

-10 -5 0 5 10 15

Outdoor Te mp. (C DB)

SUCTION PRESSURE [Bar(g

)

20 C DB

18 C DB

15 C DB

Indoor Temp.

FS KFR 120L

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

Page 8

Model:

FS1200T R407c COOLING SUCTION PRESSURE

3.0

3.5

4.0

4.5

5.0

5.5

10 15 20 25 30 35 40 45

Outdoor Te mp. (C DB)

SUCTION PRESSURE [Bar(g

)

30 C DB/50%RH

26 C DB/50%RH

23 C DB/50%RH

Indoor Temp.

FS1200T R407cHEATING DISCHARGE PRESSURE

14

15

16

17

18

19

20

21

22

23

24

-10 -5 0 5 10 15

Outdoor Te mp. (C DB)

DISCHARGE PRESSURE [Bar(g

20 C DB

18 C DB

15 C DB

Indoor Temp.

FS KFR 120L

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

Page 9

Model:

FS KFR 120L

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

Page 10

HEAT PUMP MODELS

SERIES:

FS KFR 120L

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

Page 11

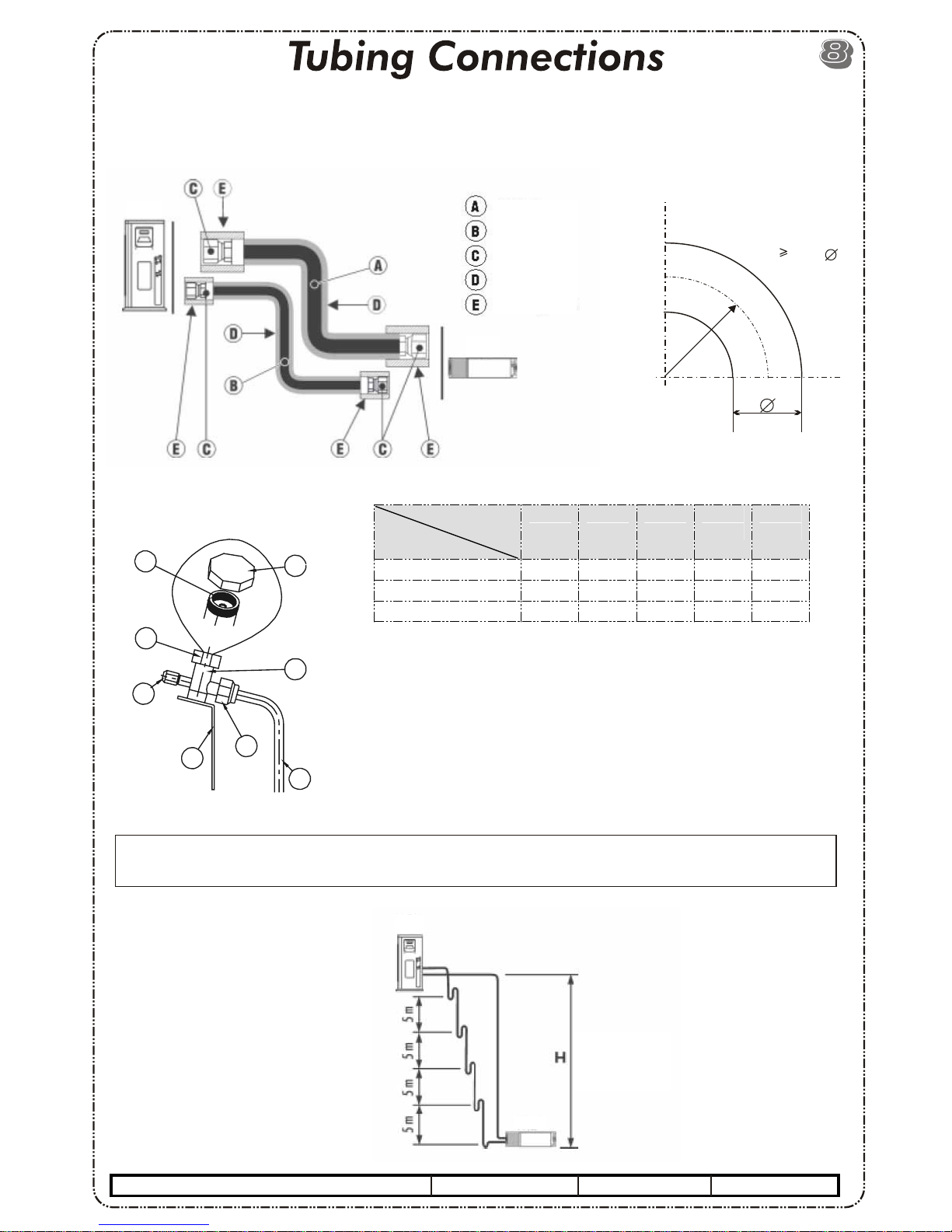

Tubing Connections

Model:

Tube (Inch)

1/4” 3/8” 1/2” 5/8” 3/4”

TORQUE(N.m.)

11-13

13-20

11-13 11-13 11-13 11-13 11-13

13-20 18-25 18-25 40-50

FLARE NUTS 40-45 60-65 70-75 80-85

VALVE CAP

SERVICE PORT CAP

Tightening Torque Values

2

1

4

3

5

7

8

6

1. Valve Protection Cap-end

2. Use Allen Wrench to open/close

the Refrigerant Valve

3. Valve Protection Cap

4. Refrigerant Valve

5. Service Port Cap

6. Flare Nut

7. Unit Back Side

8. Copper Tube

When the outdoor unit is installed above the indoor unit an oil trap is required every 5m along the suction line

at the lowest point of the riser. In case the indoor unit is installed above the outdoor no trap is required.

R

R

Tube bending

3.5

Outdoor

Unit

Indoor

Unit

Suction line

Liquid line

Flare nut

Pipe insulation

Insulating sleeve

Outdoor

Indoor

Outdoor

:

FS KFR 120L

R

R

Tube bending

3.5

Outdoor

Unit

Indoor

Unit

Suction line

Liquid line

Flare nut

Pipe insulation

Insulating sleeve

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

Page 12

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

Page 13

F

M

F

M

12

AUTO

C

A

M

Free Standing Air Conditioner

Operation Instructions & Installation Manual

Page 14

Introduction

System Description

Operation Modes, Functions and Features

Indicator Lights of the Indoor Unit and Control

Buttons on the Unit

Operational Principal of the Unit

Specifications and Technical Parameters

Operation Procedure (Operations on the Unit)

Turning on the Air Conditioner

Ventilating Operation

Cooling Operation

Cooling Operation with Auto Fan Mode

Heating Operation

Heating Operation With Auto Fan Mode

Dry Operation

Temperature Selecting

Sleep Function

Timer Function

Operation Modes for Timer Function

Air Direction Control

Turning Off

Lock Function

Protection Modes and Instructions for Service

Electric Heater

Maintenance and Care

Operating Tips

Preventive Measures

Before Calling For Service

If your air conditioner is for

cooling only, please

disregard the heating

instructions.

before

Please read these instructions

operating the air

conditioner.

The change of function

parameters and circuit

diagram will not be notified;

please refer to the nameplate

and the circuit diagram on

the unit.

1

2

3

5

6

7

8

8

8

8

9

9

9

9

9

10

10

10

12

12

12

13

14

15

16

18

Operation Instructions Page

Page 15

19

20

21

21

22

24

24

27

29

29

31

32

33

34

36

37

38

Installation Instructions Page

1. Outline Dimensions for Indoor & Outdoor Unit

2. Installation Process Chart

3. Installation of Indoor Unit

3.1 Selecting Location for Indoor Unit Installation

3.2 Indoor Unit Installation

3.3 Refrigerant Line Installation

3.4 Drain Line Installation

3.5 Electrical Cable Connections

4. Outdoor Unit Installation

4.1 Selecting Location for Outdoor Unit Installation

4.2 Outdoor Unit Installation

4.3 Interconnection and leak detection of Refrigerant Line

4.4 System Installation

4.5 Electrical Layout and Wiring Method

4.6 Test Operation

4.7 Drain Condensing Water

(used only by heat pump unit)

5. Wiring Diagram

Page 16

F

M

FM

1

2

A

U

T

O

C

A

M

The free Standing air conditioner is designed for various uses:

Cooling in summer

Dehumidifying at high humidity conditions.

Heating

Air Filter

Ventilation

INTRODUCTION

Operating Temperature Range

Indoor

Outdoor

Cooling

16C~30C

oo

Heating

16C~30C

oo

10 C ~ 46 C

oo

-10 C~21 C

oo

The air conditioner must be

grounded to protect against

electrical shock.

Installation of the air

conditioner must be

performed by an experienced

air conditioning installer,

observing good refrigeration

practice.

Electrical connections and

power cord replacement

should only be made by

authorized electricians and in

accordance with electrical

regulations and local codes.

Failure to comply with the

manufacturer s installation

and operation instructions

could affect the performance

of the air conditioner and the

validity of the warranty.

IMPORTANT NOTICE:

Page 17

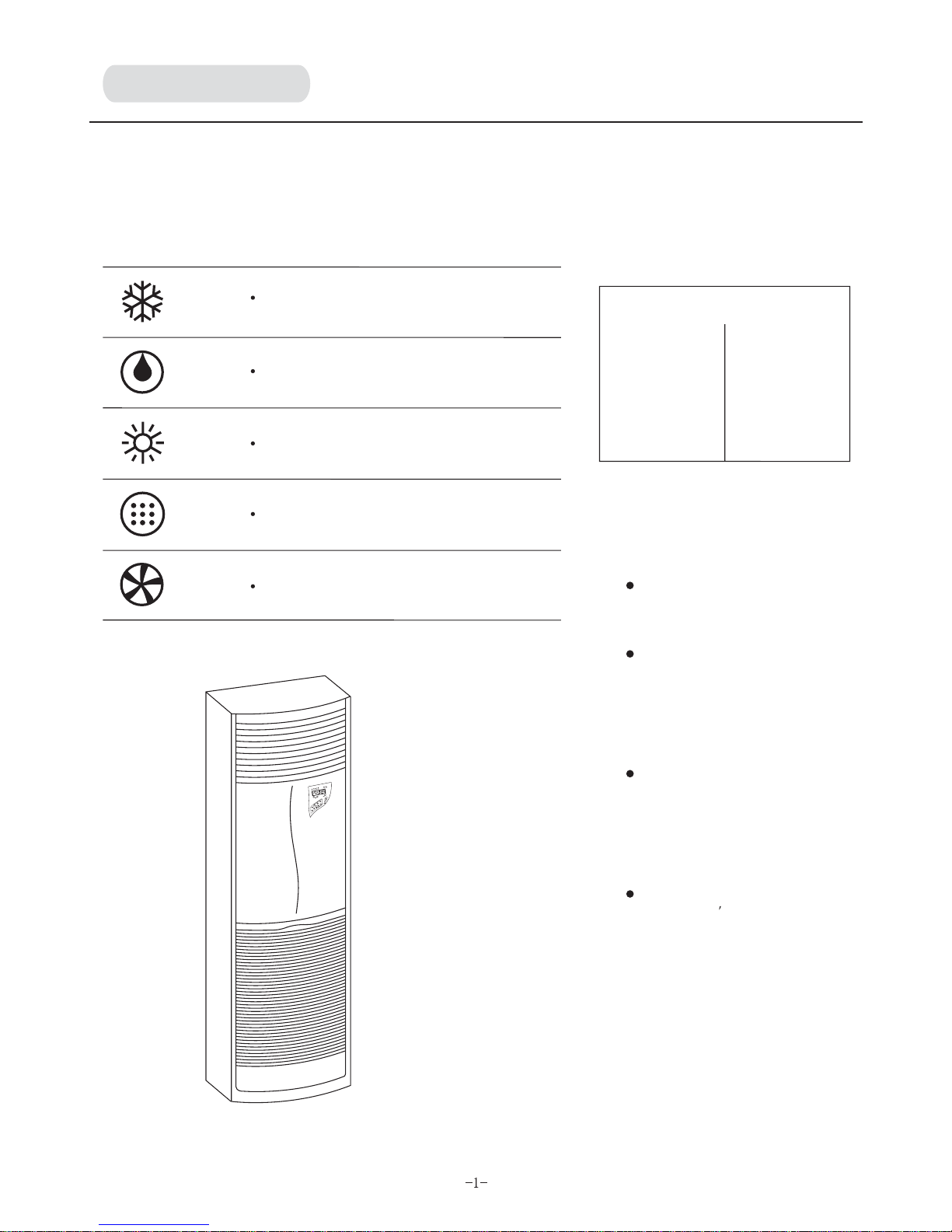

FM

FM

12

AUTO

C

AM

Indoor Unit

Air Out

Air Outlet

Outdoor Unit

Air In

Control Panel

Air Out

Air Out

Air In

Drain Tube

Interconnecting Lines

Air Inlet

SYSTEM DESCRIPTION

Page 18

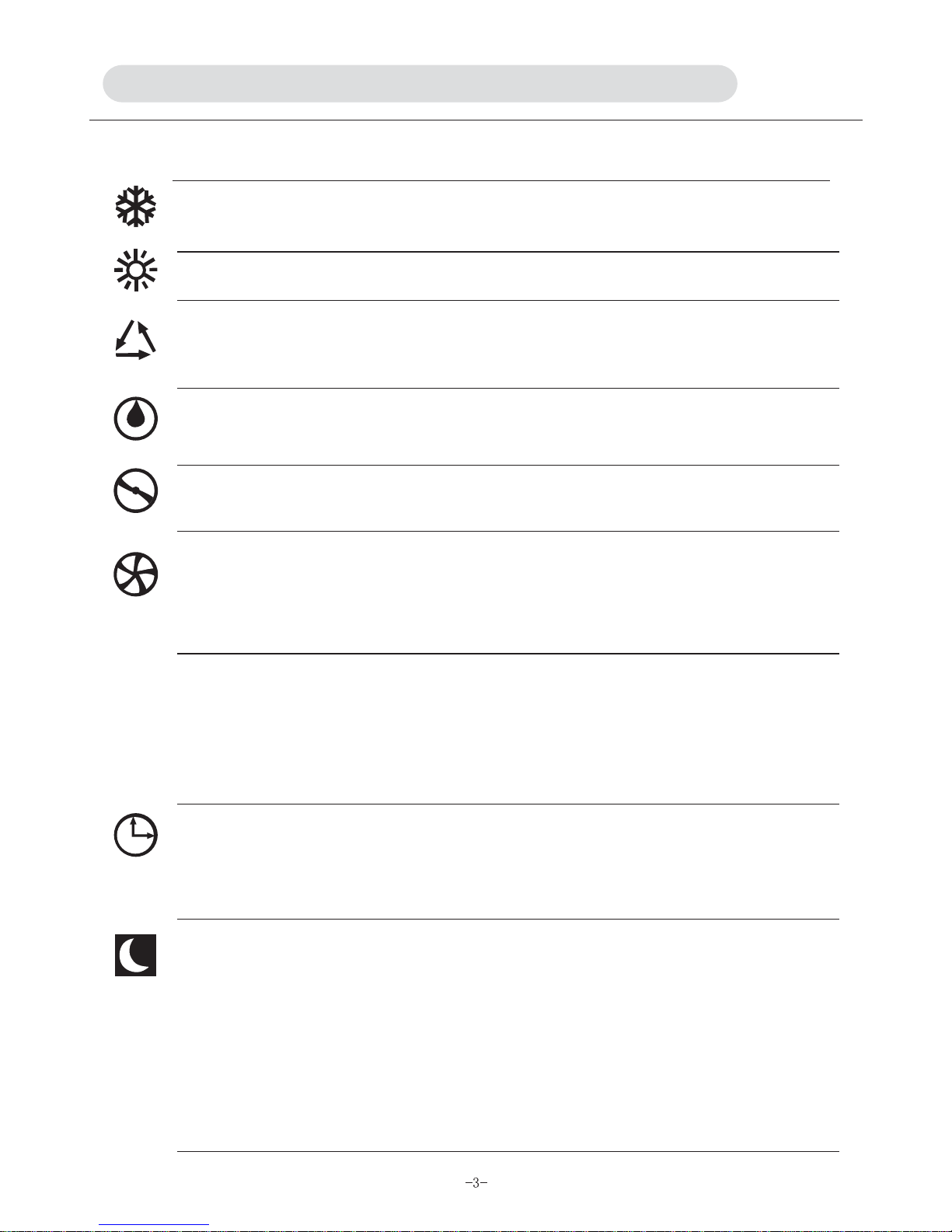

OPERATION MODES, FUNCTIONS AND FEATURES

Cools, dehumidifies and filters the room air. Maintains desired room

temperature.

Heats and filters the room air. Maintains the desired room temperature.

Automatically switches from COOLING to HEATING or from HEATING to

COOLING, maintaining the desired temperature according to the room

conditions.

Decreases humidity of atmosphere and maintains the room temperature. It

is suitable to use in dankish and rainy season.

Recirculates and filters the room air. Maintains constant air movement in the

room.

The air conditioner automatically selects the fan speed according to the

room temperature. At the start, the unit operates at high fan speed. As the

room air approaches to the set temperature, the fan switches automatically

to a lower speed for quieter operation.

In HEATING and in AUTO FAN, the fan will be turned off when the

compressor is not in operation and will not be restarted, unless the indoor

coil reaches adequate temperature. This HOT KEEP feature prevents

uncomfortable cold air drafts. Use of AUTO FAN is, therefore, recommended

when the air conditioner is in HEATING mode.

Real time control and display, automatically turns the air conditioner ON and

OFF according to the time of day setting, ensuring comfort conditions before

returning home, without wasting electricity. It turns the air conditioner off

automatically when sleeping.

This series of conditioners have the following functions:

HOT KEEP

TIMER

AUTO FAN

HEAT

COOL

FAN

DRY

AUTO

SLEEP

Designed to create comfortable sleeping conditions. When in cooling mode,

the temperature rises one-degree centigrade after each consecutive hour,

up to three hours, from the start of the mode. The rising temperature

prevents the feeling of over-cooling while sleeping (when your body is at

rest). In heating mode the reverse occurs; the air conditioner lowers its

temperature one-degree every hour. When in sleeping mode, air conditioner

will be automatically turned off after operating for seven hours. The result is

a more comfortable and invigorating sleep, which leaves you feeling fresh

and energetic on the next morning.

Page 19

Filter indicator on the indoor unit display is turned on when when the filter

requires cleaning. After cleaning and reinstalling the filter. The system

should be reset.

The compressor is protected by a three-minute delayed restart.

The microprocessor retains the last data entry whether or not the unit is

plugged in. Therefore, when the unit restarts after a power distruption or

failure, it will resume operating in the same mode as before the power was

disrupted.

Freezes the last operation setting on the remote control. When LOCK is

activated, the remote control will the be able to control the air-conditioner.

FILTER

INDICATOR

3-MIN.

DELAYED RNU

MEMORY

LOCK

OPERATION MODES, FUNCTIONS AND FEATURES

Page 20

INDICATOR LIGHTS AND CONTROL BUTTONS ON THE UNIT

A. Stand-by Indicator

B. Fan Speed Button: To select

Low Fan / Mid Fan / High Fan / Auto

Fan.

for option

C. Timer Indicator

D. Filter Indicator

E. Operation Indicator

F. Mode

G. Ionizer Button

ionizer

ionizer

H. Temperature Button

I. Ionizer Indicator

ionizer

ionizer

J. Temperature Button

L/K.Timer Button

Lights up when the air conditioner is

connected to power.

Four modes

Lights up when the unit is proceeding

timer mode.

Lights up to remind you that the filter

needs to be cleaned.

Lights up when the conditioner is in

operation.

By pressing the button to select

Cool/Heat/Dry/Auto Fan/Auto mode.

When pressing this button, I lights up

indicating that is working ; I

indicator does not light up indicating

that is not working.

Pressing the button to decrease the

set room temperature.

Lights up when is working.

Goes out when is not working.

Pressing the button to increase the set

room temperature.

When pressing the button, to set

operation time longer or shorter by

pressing L button.

""

""

""

M. Reset Button

N & V Power Switch Button and Indicator

O/Q/P Clock Set Button

R. Air Swing Button

will be

S. Sleep Button

T. Self-Lock Button

After cleaning filter, press this button to reset filter function.

The filter indicator goes out.

Press this button to set power on or off. Indicator lights up

when power is connected. Indicator goes out when power is

disconnected.

Press O or P button to decide clock time up or down.

Press Q button to cancel present clock set.

Press this button to decide if vertical air swing working

or not.

Decide whether or not to proceed sleep operation mode.

All set modes or status are locked after pressing this button.

Cancellation of self-lock button is necessary when adjusting

set status, otherwise it cannot be proceeded.

""""

""""""

"" ""

""

FM

FM

12

AUTO

C

AM

A

E

D

C

M

H

J

L

K

F

I

G

LCD

B

N

V

O

P

Q

R

S

T

POWER RUN FILTER TIMER RESET

IONIZER

FAN SPEED

TEMP

ON/OFF

MODE

TIMER

SET

HR

SWING

SLEEP

CLEAR

LOCK

Page 21

OPERATIONAL PRINCIPLE OF THE UNIT

Both outdoor unit and indoor unit start operation after connected to power. When operating in cooling mode,

low-pressure refrigerant vapour from evaporator of indoor unit is absorbed into compressor and become

high-pressure vapour through compressing; after entering condenser of outdoor unit, it proceeds heat

exchange with outdoor air through axial fan to become refrigerant liquid and enter evaporator after

decreasing pressure and temperature by capillary throttle; then to proceed heat exchange with indoor air

needing to be conditioned through centrifugal fan of indoor unit and become low-pressure refrigerant vapour;

in such way to circulate in circles to reach the purpose of cooling. When operating in heating mode, by action

of selector valve on four-way electric valve, refrigerant proceeds circulation against cooling procedures.

Refrigerant gives out heat through room heat exchanger and absorbs heat through outdoor heat exchanger

to operate in heating circles through heat pump to reach the purpose of heating.

Operational Principle Chart for Free Standing Room Air Conditioner with Heat Pump

Operational Principle Chart for Free Standing Cooling Only Room Air Conditioner

Both outdoor unit and indoor unit start operation after connected to power. Low-pressure refrigerant vapour

from heat exchanger of indoor unit is absorbed into compressor and become high-pressure vapour through

compressing; after entering heat exchanger of outdoor unit, it proceeds heat exchange with outdoor air to

become refrigerant liquid and enter heat exchanger of indoor unit after decreasing pressure and temperature

by capillary throttle; then to proceed heat exchange with indoor air needing to be conditioned and become

low-pressure refrigerant vapour; in such way to circulate in circles and reach the purpose of cooling.

Compressor

Senssor

Reverse

valve

Outdoor coil Strainer

Service

port

Suction

accumulator

Capilary

tube

Check

valve

Strainer

Valves

Flared

connection

Main

Capilary

tube

Strainer

Indoor coil

Senssor

INDOOR UNIT

OUTDOOR UNIT

HEATING MODE

Compressor

Senssor

Capilary

tube

Check

valve

Valves

Flared

connection

Main

Capilary

tube

Strainer

Indoor coil

Senssor

INDOOR UNIT

OUTDOOR UNIT

COOLING MODE

Service

port

Suction

accumulator

Outdoor coil Strainer

Reverse

valve

Strainer

Page 22

OPERATION PROCEDURE (Operations on the Unit)

Turning on the Air Conditioner

Ventilating Operation

Cooling Operation

1. Connect the unit to the power supply, indicator A lights up, indicating that the unit is ready for operation.

2. Press N (on/off) button, the unit now is in operation and indicator E lights up.

3. When the unit is turned off, the unit will save the last setting. When it is turned on

again, the unit will automatically start and operate in the last set mode.

Select the ventilating mode by pressing F(mode selection) button.

Select desired fan speed by pressing B (fan speed) button.

Different fan speed will be displayed on display panel after each pressing.

Below are four modes for fan speed : low fan, middle fan, high fan and auto fan

1. Select the cooling mode by pressing F (mode selection) button.

2. Press B (fan speed) button to select desired fan speed or auto fan.

3. Press H or J button to set appropriate room temperature.

FM

FM

12

AUTO

C

AM

A

E

D

C

M

H

J

L

K

F

I

G

LCD

B

N

V

O

P

Q

R

S

T

POWER RUN FILTER TIMER RESET

IONIZER

FAN SPEED

TEMP

ON/OFF

MODE

TIMER

SET

HR

SWING

SLEEP

CLEAR

LOCK

Page 23

OPERATION PROCEDURE

Cooling Operation with Auto Fan Mode

Heating Operation

Heating Operation with Auto Fan Mode

Dry Operation

Temperature Selecting

This operation starts with the highest airflow in order to lower the room temperature quickly. Then it will

automatically switch to a lower airflow to maintain the set temperature.

1. Select "Heating" by pressing F (mode selection) button.

2. Press B (fan speed) button to select desired fan speed or auto fan.

3. Press H or J button to set appropriate room temperature.

This operation starts with the highest airflow in order to raise the room temperature quickly. Then it will

automatically switch to a lower airflow to maintain the selected temperature. Heating operation with auto fan

mode will automatically provide you a cold air preventive function. The fan will be turned off when temperature

of indoor heat exchanger is very low , preventing uncomfortable cold air drafts.

Select the Dry mode by pressing mode button (F). Select the suitable temperature setting. While in Dry mode,

the air conditioner will operate at low fan speed, regardless of the fan setting on the Liquid Crystal Display

(LCD) operation display. The fan will operate intermittently to prevent over cooling.

Press TEMP buttons (H) or (J) to change the temperature setting on the Liquid Crystal Display (LCD) of the

display panel. The temperature setting is shown in centigrade degrees. The number indicates room

temperature.

Page 24

L L L

ON

ON

OFF

OPERATION PROCEDURE

Sleep Function

Timer Function

Operation Modes of Timer Function

Press Sleep button (S) to select the Sleep function. After Sleep function is activated, air conditioner will be

automatically turned off after 7 hours. If Timer function is also activated, the air conditioner will be turned on or

off according to Timer setting.

Press one of the following buttons to cancel Sleep function:

ON/OFF button (N)

SLEEP button (N)

Press Timer button (K) to activate Timer operation . After each pressing Timer button, one of the

following four operation modes will be displayed on LCD display. Timer operation mode appears in arrow

directions in turn and indicator on the unit will light up when Timer function is in operation.

Note: After a power failure (when the unit in Timer mode), the unit will be automatically turned to stand-by mode

and the Timer operation will be cancelled. To resume the use of Timer function, follow the above instructions

T1: timing of the first time everyday; T2: timing of the second time everyday; T1wk: timing of Saturday; T2wk

timing of Sunday.

T1 and T2 are two everyday timings, representing different time periods. Such time period will be repeated

everyday.

T1wk and T2wk are the timing of the weekend. The timer indicator lights up when timer is activated. T1wk is

only used for Saturday's timing and is valid only at that day, T2wk is only used for Sunday's timing and is

valid only at that day.

The everyday timing will be turned off when operating at the weekend. The WK timer must be activated before

every weekend.

This mode enable you to set the operation time, refer to figure 1

A) Press timer button (K) to select T1, T1 blinks.

B) Press "SET" button (L) , "ON" will appear.

C) Press up and down button (O) & (P) respectively to adjust start time of operation.

D) Press "SET" button (L) again to activate timing start function, "OFF" will appear at the same time.

E) Repeat step (c) to set the closedown time.

F) Press "SET" button (L) to activate timing closedown function. The buzzer will sound and end the timing

setting.

This mode enables you to set the operation time, refer to figure 2.

A) Press timer button (K), T2 will appear and blink.

Four operation modes are available:

1. T1 the first time timing startup and closedown everyday

2. T2 the second time timing startup and closedown everyday

Page 25

L L L

ON

ON

OFF

L L L

ON

ON

OFF

WK WK WK

L L LL L L

ON

ON

OFF

WK WK WK

OPERATION PROCEDURE

B) Press "SET" button (L), "ON" will appear.

C) Press up and down button (O) & (P) respectively to adjust start time of operation.

D) Press "SET" button (L) again to activate timing start function, "OFF" will appear at the same time.

E) Repeat step (c) to set the closedown time.

F) Press "SET" button (L) to activate timing closedown function. The buzzer will sound and end the timing

setting.

3. T1wk timing of Saturday

This mode enables you to set the operation time, refer to figure 3.

A) Press timer button (K) to select T1wk, T1wk blinks.

B) Press "SET" button (L), "ON" will appear.

C) Press up and down button (O) & (P) respectively to adjust start time of operation.

D) Press "SET" button (L) again to activate timing start function, "OFF" will appear.

E) Repeat step (c) to set the closedown time.

F) Press "SET" button (L) to activate timing closedown function. The buzzer will sound and end the timing

setting.

4. T2wk timing of Saturday

This mode enables you to set the operation time, refer to figure 4.

A) Press timer button (K) to select T2wk, T2wk blinks.

B) Press "SET" button (L), "ON" will appear.

C) Press up and down button (O) & (P) respectively to adjust start time of operation.

D) Press "SET" button (L) again to activate timing start function, "OFF" will appear.

E) Repeat step (c) to set the closedown time.

F) Press "SET" button (L) to activate timing closedown function. The buzzer will sound and end the timing

setting.

5. Clear

Apply this mode to cancel timer function, press timer button (K) and press clear button (Q) to terminate the

timer function.

Page 26

OPERATION PROCEDURE

Automatic Vertical Air Swing

Press button (R) to activate the auto air swing function. Press button (R) again to cancel the function.

Press ON/OFF button (N) to turn off the air conditioner. Indicator (V) on the air conditioner will be turned off.

Indicator (A) may stay lit, indicating that the air conditioner is in stand-by mode.

Press Lock button (T) to lock the last operation mode. All the function buttons will be inoperative, including

ON/OFF button. Press Lock button (T) again to release locked position.

Air Direction Control

Turning Off

Lock Function

Page 27

No. Description Specification Remark

1 Electric Heating Tube 600W/110V 4

2 Temperature-limited unit 65

2

3 Fuse 99

/10A 2

PROTECTION MODES AND INSTRUCTIONS FOR SERVICE ELECTRIC HEATER

This series of conditioners include a great variety of automatic protection modes, some of the protection

modes are listed below:

Mode Operation Conditions Protection from Controlled remedy

Cooling and

Dry

Low outdoor

temperature

Evaporator

freezing up

Stops outdoor fan and compressor when

approaching freezing conditions.

Resumes operation automatically.

High outdoor

temperature (only for

the unit with heat

pump)

Condenser

overheating

Stops compressor automatically when

approaching over heating temperature.

Resumes operation automatically.

Heating Low outdoor

temperature

Condenser

freezing up

Reverses operation from heating to

cooling for short periods to defrost the

condenser.

High indoor or outdoor

temperature

Evaporator

overheating

Stops outdoor fan and compressor

automatically when evaporator

approaching over heating temperature.

Resumes operation automatically.

Instructions for Service Electric Heater

If any damages happened on electric heating tube, temperature-limited unit and fuse, please get professional

technicians to replace with adoption of parts provided by the company.

Heater works only in heating mode when indoor coil temperature is lower than 45 C.

o

Page 28

inlet grid

handle

filter

FM

FM

12

AUTO

C

AM

MAINTENANCE AND CARE

Cleaning the Air Conditioner

1. Cut power off before cleaning.

2. A dry soft cloth must be used for cleaning

body case

3. Avoid using organic solvent like acid and

alkali to clean the unit.

4. Avoid rinsing indoor unit with water

For the sake of safety, the unit must be turned

off and disconnected from power supply before

cleaning the equipment to avoid electricity

shock accident.

When body case is very

dirty, please soak the

cloth with warm water

below 40 and

gently wipe off the dirty

part after wresting the

cloth dry.

There are microcomputer

elements and wiring

pad in the indoor unit,

it absolutely can not

be wet and water

soaked.

Cloth must be

wrested before

cleaning.

Make sure air intake and output on the outdoor unit

are not blocked.

One of the reasons to

cause poor performance

of the unit.

Cleaning Air Filter

Whether or not to clean the air filter depends on the

instruction of the filter indicator.

Steps of removing the filter

Please make sure that the unit has terminated

operation.

Please remove the fix bolt on inlet grid.

Pull handle out in arrow direction to open the

inlet grid.

Air filter is installed on internal side of inlet grid.

and can be removed by pulling out in arrow

direction.

Cleaning Method

Please gently flick the filter or clean the filter with

electric dust collector. When there are too much

scales on the filter, to clean with warm water

modulated with neutral detergent and then clean

the detergent on the filter. Dry the filter after

cleaning and then restore its original position and

install.

Note:

Do not put the air filter under direct sun or dry it

beside stove, which will cause distortion.

Distortion may happen to filter when being

cleaned with warm water over 50

eradicator

acid

gasoline

Page 29

OPERATING TIPS

Set a suitable room temperature; excessively low room temperature is not good for your health and wastes

electricity. Avoid frequent setting of the temperature.

During cooling, avoid direct sun into the room and keep curtains closed. Close doors and windows to keep

the cool air in the room.

Avoid using heater while the air conditioner in cooling mode.

Please make sure air lead blades on the unit are in appropriate angle: in cooling mode, air should flow in

horizontal direction, in heating mode in vertical downward direction.

Keep room temperature evenly through adjusting vertical air blades.

During prolonged operation, ventilate the room by opening windows.

After power failure, microprocessor will keep memory. Operation of the unit will be resumed in the last mode

of operation once start again.

After turning on, allow more than 3 minutes for cooling, heating or dry operation to start.

When dry mode is used, make sure that the room temperature is between 20 to 27 C. When used out of this

range, the unit may protect itself and become inoperative.

If the conditioner is used for a prolonged time in high humidity (relative humidity is above 78%) environment,

moisture may form on the air outlets and drip down.

o

Page 30

PREVENTIVE MEASURES

Do not block up or plug up inlets or outlets of air conditioner.

Do not put any obstacles in the outlets of indoor unit or outdoor unit.

There may have "buzz"

when air conditioner is in

operation or just turned

off, which is produced by

refrigerant circling within

air conditioner.

Do not splash water on air conditioner.

Page 31

PREVENTIVE MEASURES

Accident may occur when touching rotating fan or electrical parts.

inlet grid can only be opened after making sure the air conditioner is turned

off. Otherwise electric shock and injuries may be caused.

Avoid using iron strings in place of fuse. Or breakdown may be caused or

occurrence of fire disaster.

Avoid inserting sticks and other objects into suction entrance and

blowing outlet.

During operation, please do not open inlet grid of indoor unit.

Voltage, fuse and electric breaker with rated capacity must be used.

Avoid sprayed by pesticides or flammable gas.

Page 32

BEFORE CALLING FOR SERVICE

Before calling for service, please check the following malfunctions and correct it as needed.

Problem Cause Remedy

Unit does not operate.

Operation indicator does

not light up.

Unit not connected to power

Power failure

Insert the plug to power supply.

Check main fuse.

Air does not blow out from

indoor unit.

Defrost protection mode is

activated.

Unit is in Auto Fan mode.

Over cooling in Dry mode.

Normal operation in heating

mode.

Normal operation in dry mode.

Cooling, dry or heating will

not start immediately.

3min. delay start.

Normal operation in these

modes.

Unit functions but is not up

to its performance.

Improper temperature setting.

Unit capacity is insufficient for

load or room size.

Reset temperature.

Consult service center.

Filter indicator lights up

Air filter needs to be cleaned. Clean filter and reinstall, press

reset button to close indicator.

When compressor is in

operation, noise and

shock is great, running

current is less than the

corresponding current

on the nameplate,

suction pressure

doesn't fall and exhaust

pressure doesn't rise. .

Compressor doesn't

work while indoor motor

and outdoor motor are

still working. .

The antiphase indicator

doesn't light up.

Antiphase

Cut off the power immediately.

Adjust the phase sequence

exchange the random two

poles of the three external line

L1/L2/L3 on terminal of the

power, or exchange random

two poles of line 2, 4, 6 on the

AV contactor directly until the

antiphase indicator lights up.

Page 33

FM

FM

12

AUTO

C

AM

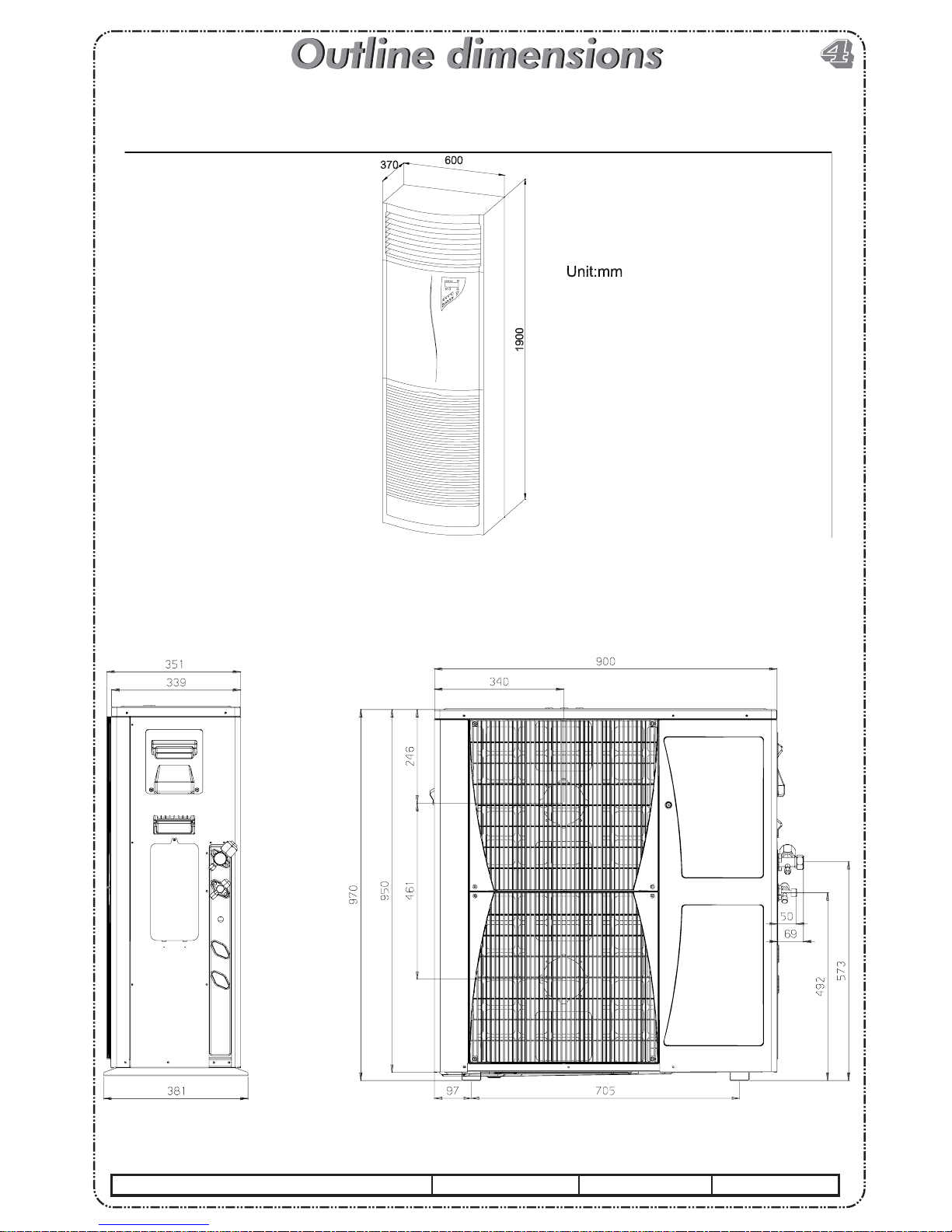

600

370

1900

INSTALLATION MANUAL 1. Outline dimensions for indoor & outdoor unit

OUTLINE DIMENSIONS FS 1200

INDOOR UNIT

FC 1200

OUTDOOR UNIT

OU 10 RC

900

340

246

461

950

970

97 705

69

50

492

573

351

339

381

Page 34

INSTALLATION MANUAL 2. Installation Process Chart

1. Installation Process Chart for Indoor Unit

2. Installation Process Chart for Outdoor Unit

Selecting Location

for Installation

Installation of

indoor unit

Installation of

Refrigerant Lines

Installation of

Drain Line

Electrical Connections

Selecting Location

for Installation

Installation of

Outdoor unit

Installation of

Refrigerant Lines

Evacuation of Air in the

Unit and Detection

Electrical Layout & Wiring

Methods

Test Operation

Drainage of Condensing

Water Out of Outdoor Unit

Page 35

INSTALLATION MANUAL 3.1 Selecting Location for Indoor Unit Installation

FM

FM

12

AUTO

C

AM

To be located at a place that the air blown-out can reach all room corners.

Avoid location that could be influenced by outdoor air.

Avoid location with obstructions interfering free flow of air blowing out and air intake.

Avoid places with oily mist and vapors.

Avoid location that may produce, inflow, and hold and leak flammable gas.

Avoid installing near the equipment that may produce high frequency (such as high frequency electric

welder).

Please do not set up fire alarm at air outlet.

(When in heating mode, fire alarm may produce wrong actions because of the warm air.)

Avoid location using special sprayer (sulfur type) frequently.

1.Installed on leveled and firm floor.

2.Space for installation and service.

(Unit:mm)

Min 300

Min 50

Min 100

Min 100

In consideration of easy and safe operation on installation, make sure there are enough spaces between

the unit and wall .

Dimension which marked with sign ,floor and wall must fit the fireproof requirement.

3.As for height difference between indoor unit and outdoor unit, length

of refrigerant tube and quantities of bending tubes, please check if

they are within the limits.

1. Length of tube 2. Height difference 3. Quantities of

(single way) bending tubes

Max. 40m. Max. 20 m Max. 10

PCS

.

Indoor Unit

Outdoor

Unit

It makes no difference which one of indoor unit or outdoor unit is higher.

Page 36

Example of measures preventing dumping

FM

FM

12

AUTO

C

AM

INSTALLATION MANUAL 3.2 Indoor Unit Installation

1.Measures preventing dumping

"Wall mounting iron piece against dumping is necessary to prevent dumping"

As the unit is slim and tall, for safe caution, please proceed immediately measures preventing dumping

after installation location for the unit is confirmed.

Wall mounting iron piece against

dumping is set on top of the unit. Loose

tap bolt (2), and remove, please reverse the

frontback of iron piece preventing dumping,

aligning one side with adaptable

dimensions to wall surface and proceeding

mounting on the other side.

tap bolt

long side

short side

Wall mounting iron

piece against

dumping

When wall and floor are not made by materials except for

wooden plates, please use M8X60 expansion bolt to

proceed appropriate mounting.

Wall mounting iron

piece preventing

dumping

Tap bolt 4.2X9.5

To secure with

removed tap

bolts (2)

Screw...... 1

Prepare expansion

bolts locally and

secure at 4 places.

Please dismantle screw (1),

pull the grid to your own

direction and take it out.

Page 37

Clamp preventing

dumping for wall

mounting

Cordon

Tap bolt

Spacing about

1mm

Wall decoration material

Install clamp on the wall in

advance. Tighten bolts as

stated in above figure and

keep clamp able to slide

up or down.

3.Floor mounting

INSTALLATION MANUAL 3.2 Indoor Unit Installation

2.Setting clamp preventing dumping for wall mounting

According to the location of cordon in the wall ( height calculated from the floor ), select suitable method

from the following figures.

Cordons are not applicable when wall is floored with light steel base, please mount the clamp on

supporting or one of pillars. (Please purchase materials like bolts for application here locally).

When installing air outlet tube on the ceiling of the unit, please do not cap the clamp on the ceiling outlet

on the unit and bolt hole for installation of air outlet tube. ( e.g., keep long side of clamp directed to wall

lateral, which will not produce any capping conditions).

Clamp upwards Clamp downwards

Short side toward wall Long side toward wall Short side toward wall Long side toward wall

Unit: mm Unit: mm Unit: mm Unit: mm

Dimensions between the unit and wall indicate adjustable dimensions.

Upper dimensions calculated from the floor indicate the location for clamp to install

bolts (center cordon is within the range where the screws are installed.)

Remove inlet grid, set the drilling hole on the floor base to fasten ceiling holes, and secure

on the floor with expansion bolts.

(Please purchase the required accessory such as screw, etc. locally).

Page 38

INSTALLATION MANUAL 3.3/3.4Installation of Refrigerant Lines & Drain Line

Thermal insulation treatment is required on refrigerant lines and drain line to prevent condensation as

both lines have dews to drip down.

When using pipes purchased from market as refrigerant lines, please wrap and tighten the liquid line and

the suction line with thermal insulation materials purchased in the market (thickness of heat resistance

insulation material is over 12mm).

Drain line crossing indoor must be wrapped and tightened with thermal insulation material ( foam polyethylene, with

specific gravity of 0.03 kg/m3and over 9 mm of thickness) purchased from the market.

INDOOR UNIT

1.Location of Refrigerant Lines and Drain Line

Push-out hole for floor mounting

4- 10 Hole

Push-out hole for

bottom connection

Push-out hole for bottom

connection 120X70

As for push-out holes at the bottom

marked with for connection, use

saw blade to open the hole along the

direction of channel only within the

necessary range.

Unit:mm

Connection terminal for

indoor/outdoor unit

electrical organs box (control unit box)

Power supply terminal

Liquid pipe

Suction pipe

External dia. of drain line

26 ( Connecting

PVC pipe ).

140X80 push-out hole for refrigerant,

drain line & cables.

90X60 long push-out hole for

refrigerant, drain line (same

hole also at left lateral)

Push-out hole for cable 27 (same

hole also located at left lateral)

Page 39

3.Installation of Refrigerant Lines (outdoor unit)

9.52 350~420

15.88 750~800

19.05 1000~1400

9.52 60 ~90

15.88 30 ~60

19.05 20 ~35

2.Operation on Tubing Connection

1) Remove 1 screw from handle of inlet grid, pull out to

your own direction and take inlet grid out. (As the

underside of inlet grid, is embedded in the bottom base,

please pull upward and take it out.)

2) Take down tap bolt (1) for securing pipe protection

cover, and remove pipe protection cover.

Pipe protection cover

inlet grid,

Bolt ... 1

Tap bolt 4X10 ... 1

After end of operation, it is necessary to install

according to original conditions.

Tubing procedure:

1. Keep stop valve on outdoor unit in "off" status (ex-factory specification) as original, dismantle end caps

on refrigerant lines and the unit, and proceed quickly flare connection.

If being put aside for long period after end caps being removed, breakdown may happen to tubes

because of invasion of dust, water and foreign matter into pipe, so please proceed connection operation

rapidly.

Before tightening flare nuts, a layer of attached cooling engine oil should be thinly applied on the sealed

pad surface between tubes and connectors.

Please proceed tubing connections with two wrenches and refer to the following table for tightening

torque.

2. Proceed flare-connecting operation in succession and interconnect all refrigerant lines.

After pipes being connected, leakage detector or soup water must be used to check if there are any

leaks.

3. Proceed evacuation from service entrance of stop valve on the outdoor unit.

4. After completion of above operation, keep stop valve (commonly used by liquid and gas) on the outdoor

unit totally open. By then, refrigerant cycle between indoor and outdoor unit is all connected.

Attentions on application of flexible couplings

Please apply flexible couplings at indoor lateral interconnecting areas.

Bending angle cannot exceed 90 degree, and bending cannot be repeated more than 3 times.

To reach appropriate torque as per torque wrench

When without torque wrench,

please take following method as

standard: when tightening flare

nut with wrench, stop it and only

rotate to angle stated as right

table when tightening torque

increases quickly.

External dia. of

copper pipe(mm)

Torque (kg.cm)

Standard for torque angle

Note: Please apply attached refrigerant lines thermal insulation materials for insulation on indoor

lateral flare connection areas, and please make sure to proceed the operations stated as item

3&4.

Nonoxide brazing must be applied to pipes when proceeding brazing.

INSTALLATION MANUAL 3.3/3.4Installation of Refrigerant Lines & Drain Line

Page 40

4. Installation of Refrigerant Lines (indoor unit)

Thermal insulation on interconnecting areas

Please use reliable thermal insulation on the areas, do not let flare connection and where

refrigerant lines come out.

(Condensing frost may produce and drip down without proceeding thermal insulation on interconnecting

areas.)

Liquid Tube

thermal insulation

material for liquid

tubes

Suction Tube

thermal insulation

material for suction

tube

Tie

Frame

Angular hole

Tie

Please get the tie across the angular hole on the frame to secure lines.refrigerant

Please locate thermal insulation material for

suction tube and thermal insulation material for

liquid tube as per up and down position, which will not

produce sliding and align in one line one by one. .

After installation of thermal insulation material,

please secure refrigerant tubes with tie on the

frame below interconnecting area of tubes to prevent

moving of refrigerant tubes. Intake grille is unable to be

installed when refrigerant lines are in moving

condition

5.Installation of Drain Line

Drain line must be inclined downward (minimum 1/100).

Drain line must be PVC pipes with 26 of external diameter.

Drain hose can be matched according to spot construction to cut

with knife.

Attached drainpipe union shall be applied when interconnecting

and glued securely with PVC binding agent, making sure that

the pipe is not leaking.

Please do not put drain pipe directly to the sewer that may produce sulfur gas or a location that may

produce bad smell.

Please make sure no water leakage at interconnecting area of drain pipes.

When drain pipe has to cross indoor, thermal insulation material (foam polyethylene with gravity of

0.03kg/m and minimum 9mm of thickness) from the market must be applied to wrap the pipe and stick

adhesive tape on the surface to prevent invasion of air and condensation.

3

Drain hose

Drain pipe union

Plastic water pipe

Drain pipe

(On the spot)

6.Ensuring drainage

After completion of installing drainage line, make sure that the line is draining

water out and there is no water leakage at connecting area. ( It must be

ensured too during suction operation when installation).

Insert effusion pipe (self-configuration by installation personnel) into the

evaporator water-guide plate on the right lateral of air outlet with injection

of about 1000ml water.

Gently proceed effusion oriented to water-guide plate on the right side of heat

exchanger or internal wall of the unit.

For the conditioner with heater, please be careful not to wet the unit as there is a heater installed in front of

heat exchanger.

Water

Water-guide plate

Internal wall

Catch basin

INSTALLATION MANUAL 3.3/3.4Installation of Refrigerant Lines & Drain Line

Page 41

1

2

3

INSTALLATION MANUAL 3.5Electrical Cable Connections

Power supply connections cannot be proceeded on sub-circuit.

Electrical configuration shall be based on suitable technical standard.

Electrical connections must be proceeded strictly according to diagram. Bolts shall be tightened

securely to avoid tear-off.

Interconnecting wires between indoor and outdoor unit and power lines are not touchable mutually

outside the unit.

Please note that terminal board for control wiring cannot be connected to 230V power supply. (Which

may cause problem)

Wiring between terminal boards of indoor and outdoor unit f or controlling electric lines must be

connected by yourself.

(Due to polarity relations, interconnections must be proceeded according to terminal code.)

Compressor is inoperative when interconnection of power lines is wrong.

ELECTRIC CONNECTION ON INDOOR UNIT

1.Electrical Cable Connections (Please make sure terminal bolts

are tightened)

1) Dismantle tap bolts (3) from fixed electrical box

cover and remove the cover.

2) Connect power cable and controlling cable.

(Please refer to the schematic diagram on page

28 for position of terminal board)

3) Secure wiring that has been connected with wiring

fixation ties (2).

Ground connection must be proceeded. (Diameter

of ground electrode is over 1.6mm).

Please note that proper treatment is needed for

wiring when wiring and tubing are touchable due

to condensation.

Once you finish wiring, it is necessary to install

dismantled parts back according to its original

status.

1. Connecting group

terminal block

2. Tap bolt(3)

3. Electric box cover

Overline jacket

Page 42

1.For the Unit with Cooling Only

2.Interconnecting Cable between Indoor and Outdoor Unit

Wiring Method of Indoor Unit

Dismantle bolts on electrical case cover and

display electrical case cover.

Interconnect wires as per figure below and

secure with fixation clamp.

Bolts

Electrical case cover

Comb

Liquid tube

Suction tube

Wiring Line on Indoor Unit Wiring Line on Outdoor Unit

Brown

Blue

Red

Yellow/Green

2.For the heat pump unit ( power line and

signal line connection must be proceeded.)

Defrost signal connection line

of indoor unit

Signal connection line

Defrost cable from Outdoor Unit

Wiring Line on Indoor Unit Wiring Line on Outdoor Unit

Black

Violet

Brown

Blue

Red

Yellow/Green

INSTALLATION MANUAL 3.5Electrical Cable Connections

R/V O/F

Comp

NL

Black

R/V O/F

Comp

NL

Page 43

Min. 150

Min.

10

Min. 10 Min. 10

Min. 500

Min. 500

Min. 3800

Min. 150

Min. 300

INSTALLATION MANUAL 4.1 Selecting Installation Location for Outdoor Unit

Avoid directing sunlight.

When sunlight is inevitable, please install shelter from sun to prevent direct sunlight.

Noises from the unit will not influence neighbors.

Location easier for interconnecting power and tubing with indoor unit.

Installation should not be located at a place that flammable gas may be produced, flow in, stop and leak.

When in operation, please pay attention to the high temperature air drained out from the unit.

DETAILED DISTANCES OF SURROUNDING SPACES NECESSARY

FOR OUTDOOR UNIT

1.Detailed distances of surrounding spaces necessary for separate

setup

4) When obstructions at front and backside.

5) When there are obstructions at four lateral

sides, upper side opens up. The unit cannot

be installed when obstructions exist at four

lateral sides.

1) Upper obstruction

When obstruction only exists at back, it

does not matter even if there are

obstructions indicated as figure.

2) When front (air outlet) opens

As long as the spaces indicated as figure are

kept, it does not matter even if obstructions

exist at three lateral sides. (Upper is open)

3) Obstruction only at front (air outlet)

By then, backside, two lateral sides and

upper side should be kept open.

Maintenance Spaces

Keep maintenance space in the

front of the unit stated as the

following figure.

Min

500

Min. 500

Page 44

Min. 150

Min. 10

Min.

300

Min. 1000

Min. 300

Min.

500

2.Interrelations when installing more than one unit at one place

(1) When in horizontal continuous centralized Installation

Please dismantle bolts on lateral protection cover of tubing.

Maximum 10 units

Upper space opens up

(2) Front-to-Back Configuration

Used only when ventilation

guide unit on outdoor unit is

set to be "ventilation upwards"

means.

When outdoor ventilation

guide unit is not in use.

When outdoor ventilation guide unit is not in use.

When outdoor ventilation guide unit is in use.

3800 1500 (mm)

Min. Min.

When outdoor unit will be installed on the housetop or a place without any shelters around, avoid strong

wind blowing directly to air outlet on outdoor unit. If strong wind directly blows to air outlet, it may result

in insufficient airflow and possibly cause problems.

Example

Monsoon

Monsoon

Ventilation guide unit

Air outlet

INSTALLATION MANUAL 4.1 Selecting Installation Location for Outdoor Unit

Min. 300 Min. 300 Min. 300

Min.

500

Min. 1500

When there is wall nearby, air

outlet should be directed to the

wall with minimum 500mm

away from the wall.

Ventilation guide unit (optional)

should be installed when air

outlet may be affected by

strong wind like typhoon.

When the outdoor unit operates

in monsoon season, please

change location of the outdoor

unit so that the air outlet should

be in right angle with air direction

of monsoon.

Page 45

Maximum 25

INSTALLATION MANUAL 4.2 Outdoor Unit Installation

Try your best to deliver the unit in original package to the installation location.

Please be care not to overturn the unit when lifting up the unit with sling, as the gravity of the unit is

not in the center.

When moving, the unit is not to be inclined over 45 degree. (Do not store the unit horizontally).

Outdoor Unit Mounting

Bolts should be applied when installing outdoor unit to secure the foundation part of the unit.

Before securing, the shock absorption block rubber accompanying the unit must be placed between the

sole and the installation plane (Foundation bolts for securing are purchased locally).

In order not to collapse in case of earthquake or strong wind, it is necessary to secure the installation.

Please refer to the following figure for concrete foundation.

Deeply

buried

location

Distances between units when set in parallel.

M10 bolt

Secure with bolts

Minimum 380

A little wider

Note: Measured from bottom lateral

installation cardinal plane,

a maximum 25mm Shall be kept

for the length of foundation bolts

Length of foundation bolts

Installation cardinal

plane

(Mm)

With

Minimum 10

Page 46

INSTALLATION MANUAL

4.3Interconnection and Leak Detection of Refrigerant Lines

Please refer to Construction Work of Refrigerant Lines for torque requested to tighten nuts.

Open up push-out hole for tubing at the bottom according to

the location of indoor unit, get the connection tube across the

hole and connected with tube joint on the indoor unit (Upper

Right Figure).

Align right with the center of tube, and fully tighten conical nut

by hand.

Tighten conical nut by wrench (Right Figure).

Wrap the non-heat insulated connection tube and joint with

sponge, and bind tightly with plastic tape to prevent a

ccumulated water on base plate.

Dismantle the conical nut cap on stop valve of outdoor unit.

Align right with the center of tube, and fully tighten conical nut by hand.

Tighten conical nut cap by wrench.

Remove single-way valve caps on liquid valve and suction valve.

Screw down core of liquid valve with socket wrench, and push out single-way

valve core on suction valve with screwdriver, by which gas vents out.

Gas continues to vent out for 15 seconds till refrigerant vapour appears, close

single-way valve and tighten valve cap.

Open up core of liquid valve and suction valve completely.

Tighten valve cap, and detect if any leakage exist on interconnections between

indoor/outdoor unit and tubing with soap water and leakage detection unit.

Connection of Tubing on Indoor Unit

Connection of Tubing on Outdoor Unit

Joint Rotating nut

Torque wrench

Tighten

Indoor parts

Outdoor parts

Evacuate air in the connecting tube

If condition allows, evacuate air in the

connecting tube with vacuum pump or

self-provide refrigerant.

1. Connecting suction tube

2. Connecting liquid tube

3. Suction tube conical nut

4. Liquid tube conical nut

5. Suction valve nut cap

6. Single-way valve

7. Liquid valve nut cap

8. Socket wrench

1

2

5

78

3

6

4

Page 47

7.5M

7.5~40M

1

2

3

6

5

4

1

2

3

4

5

6

1

2

3

4

LO

HI

INSTALLATION MANUAL 4.4 System Evacuating

Length of Evacuation Method Charging quantity

Connection Tube of refrigerant

B. Evacuation using self-provide cooling

agent of the installing worker

1. Joint the self-provide refrigerant pot to the

nozzle of the low-pressure valve.

2. Slacken the high-pressure valve copper

nut cap.

3. Open the refrigerant pot so that the

refrigerant can come into the tube.

4. After 15 seconds, you may feel cold at ,

tighten and close . If the high-pressure

valve has nozzle, the operation will be easier,

just open the inner valve to evacuate the air

in the tube.

5. Take off the tube and evacuate the excessive

refrigerant through the inner core.

Evacuation with

self-provide refrigerant

of the installing worker

or by vacuum pump.

Nameplate

(55g of refrigerant for

each meter of added

pipe length.)

1. Refer to section of vacuum pump or using refrigerant

jar.

2. Quantity of charging refrigerant to be proceeded

as per above table.

When relocate air conditioner, evacuate with

vacuum pump or refrigerant jar.

Open valve rod to the suitable are, do not try to

open it more widely.

Tighten valve cap with wrench or similar tools.

Tighten torque on valve cap.

1. Joint multiple meter charging tube to single-way

valve nozzle of low-pressure valve.

2. Connect charging tube joint with vacuum pump.

3. Open up multiple meter low-pressure valve (L0)

handle and tighten the high-pressure handle

completely.

4. Start vacuum pump for evacuation.

5. After completion of evacuation, completely close

multiple meter low-pressure valve (L0) hardle and

stop vacuum pump.

Make sure if multiple meter is at -10 X 10 Pa (76cmHg) after evacuation for over 15 minutes.

6. Remove charging tube from single-way valve nozzle

of low-pressure valve.

7. Tighten low-pressure valve cap.

Note: It is not recommended to evacuate using

refrigerant in the outdoor unit, which will

result in refrigerant insuffient. If conditions

not allow, it is necessary to use the refrigerant in the

system and charge more 80g-100g refrigerant.

Attentions on Operation of Stop Valve

A. Evacuation with vacuum pump

5

1. Multiple meter

2. Multiple meter charging tube B

3. Multiple meter charging tube A

4. Single-way valve of the low-pressure

valve

1. Refrigerant pot

2. Refrigerant charging pipe

3. Low-pressure suction valve

4. High-pressure liquid valve

5. High-pressure liquid valve copper nut

6. Single-way valve of the low-pressure

valve

7. Connecting tube

The schematic diagram of suction valve

1. Connecting tube nut

2. Valve rod

3. Stopper (the set in the valve rod)

4. Valve cap

5. Single-way valve cap

6. Single-way valve rod (have valve core inside)

Evacuation using vacuum pump

Page 48

INSTALLATION MANUAL 4.5Electrical Layout & Wiring Method

Electrical wiring varies as per models. Please refer to electrical wiring diagram for details when

proceeding electrical operation.

(Example)

Power supply

Main Power Switch / Fuse

(Purchased locally)

Power line for indoor and outdoor unit

Indoor Unit

Power line of

indoor and

outdoor unit

Outdoor Unit

Signal line of

indoor and

outdoor unit

Earth Connection Earth Connection

Interconnecting cable between indoor and outdoor unit

(With polarity)

Earth connection is necessary for air conditioner.

Power supply

Phase

Three-phase

Frequency & Voltage

50Hz, 400V

Input capacity

Main switch / Fuse

Indoor Unit (A)

Outdoor Unit (A)

Electrical

Wiring

Power supply for

indoor unit

Wiring qty.

Section area (mm )

2

Power supply for

outdoor unit

Wiring qty.

5

Section area(mm )

2

2.5

Dimensions for earth connection wire (mm )

2

2.5

Wiring section for interconnecting indoor and

outdoor unit

Cooling only: 4 X1.5

Heat pump

unit: 3X2.5

Heat pump

unit with service

electric heater:

(2X3)X2.5

3X16A

Attention:

1. Environmental conditions (environmental temperature, direct sun and rainwater, etc.) shall be

considered when proceeding electrical wiring and connection.

2. Dimensions of wires are minimum value of copper core wire. In case of voltage decreasing,

dimensions of power core wire should be increased by one grade.

3. Ground wire should be connected to outdoor unit and indoor unit.

4. The following diagram is an example of spot electric wiring so that the detailed wiring should be in

accordance with technical standard.

Page 49

Dismantle front lateral board

Open up outdoor wire-cross hole and put on square wire-cross diagram.

Induce connection wire out from 6 bit wiring board on outdoor unit, drill through outdoor wire-cross hole

and indoor wire-cross hole, and connect the wire to the 6 bit wiring board on indoor unit. Please refer to

the following diagram for power line wiring.

Secure lines with fixation clamps after wiring as the diagram.

Signal connection

line on outdoor unit

Signal connection line

Checking the phase sequence:

Phase sequence protection:

How to adjust phase sequence:

The pressure protection:

When there is phase sequence protection, the fan of indoor and outdoor unit will run, but the compressor

will not run, or will run with abnormal noise.

The product is equipped with antiphase protector to make sure that when the compressor is in the

antiphase situation (below three phase), the power will be cut off immediately, so the compressor will

not work while the motor of indoor and outdoor unit can still work. The protector has an indicator, which

will light up only when the phase sequence is correct and without antiphase. When the indicator doesn't

light up, it indicates accidents to be handled. Refer to how to adjust the phase sequence to solve the

accident.

If there is an accident, please cut off the power immediately. To adjust the phase sequence

exchange the random two poles of the three external line L1/L2/L3 on wiring layout of the power wire, or

exchange random two poles of line 2 4 6 on the AV contactor directly. Two steps are needed to

adjust the phase sequence of the conditioner with phase sequence protector: first, make sure that the

phase sequence of the compressor is consistent with that of the phase sequence protector; second,

make sure that the phase sequence of the power is consistent with that of the phase sequence

protector. Usually, the first is adjusted before the conditioner leaves factory, but the latter must be

adjusted on site when installing. If the indicator lights and there is abnormal noise when the compressor

is in operation, please make sure that the phase sequence of the compressor is consistent with that of

the phase sequence protector.

Some products of our company have pressure protection equipment. If your unit has such equipment,

please read the following content:

High-pressure protection switch: to assure that the system will not be damaged by the overhigh pressure.

Low-pressure protection switch: to protect the compressor when the system is badly short of refrigerate.

If the above product is damaged, please use the accessory designated by our company.

INSTALLATION MANUAL 4.5Electrical Layout & Wiring Method

L1 L2 L3 N

Red Black

Brown

Blue

Yellow

Green

Power lines on outdoor unit

Page 50

INSTALLATION MANUAL 4.6Test Operation

Cooling or Heating Test Operation

To be set in Cooling mode

Proceed Cooling or Heating test operation after completing leak detection on leakage.

THE CHECKING ITEMS OF TEST OPERATION:

1. Checking the phase sequence: this item is very important, refer to the content of checking the phase

sequence on page 35.

2. Checking temperature difference of the outlet air, that is, whether the temperature difference

between the outlet air and the inlet air is equal or above 8 C.

3. Checking outdoor unit:

a. When in operation mode, whether or not the motor is running; when fan is rotating, whether or

not there is abnormal noise.

b. When the stop valve is connected to the pressure gauge, whether or not the displayed pressure

is normal.

c. Check to make sure that the stop valve is opened completely and the valve cap is installed and

tightened.

d. Check to make sure that the wiring of lines is correct.

4. Checking indoor unit:

a. When in operation mode, whether or not the motor is running; when fan is rotating, whether or

not there is abnormal noise.

b. Whether or not the connection of drain lines is firm and is water-leaky.

c. Whether or not the connecting copper between the indoor unit and the outdoor unit is reliable

and without leak.

d. Whether or not the connecting tube is distorted at the bend.

e. Because the unit is tall and large, measures preventing overturn must be taken; check to make

sure that the installation is firm.

f. Make sure that the wiring is correct.

5. Checking the operation of the conditioner:

a. Does it work normally in cooling or heating mode;

b. Does the air swing work correctly;

c. Does the ionizer work correctly and its indicator light up.

The above content of check operation shall be confirmed and recorded by the installing personnel,

only after user's confirmation, can the installing personnel leave.

o

Set the Cooling or Heating mode.

Refer to the instruction

for the procedure.

Note: the compressor has 3-min delay

protection function to prevemt damage

to the compressor when freguently

startup the conditioner.

Page 51

INSTALLATION MANUAL 4.7Draining Condensing Water Out of Outdoor Unit

THIS FUNCTION IS ONLY

APPLICABLE FOR HEAT PUMP UNIT

When in heating mode, condensing water formed on outdoor

unit and defrost water produced when defrost can be drained

out to the suitable place through drain line.

Installation method: Insert the outdoor drain coupling into the

25 hole on base plate as per figure. Then connect the drain

tube with the coupling, which will lead condensing water and

defrost water to the suitable place.

Base plate on

outdoor unit

Outdoor drain coupling

Page 52

No further notice will be given in case of any further change to the wiring diagram. Please use the wiring diagram on the unit as reference.

INSTALLATION MANUAL

5W

iring Diagram

13 456

FAN

MOTOR 2

COMPRESSOR CAP 2

Y/C

BRN

WHT

BLU

RED

BLK

Y/C

BRN

WHT

BLU

RED

BLK

123456 654321

123456 654321

Y/C

BLU

WHT

WHT

BRN

WHT

BLK

BLK

WHT

BRN

Y/C

BLU

WHT

WHT

123

456

321

654

CONNEC.

CABLE

CONNEC.

CABLE

BLK

BRN

RED

L0

Cap

N

HI

HI

N

Cap

L0

FOR HEATPUMPONLY.

RV

L1

L2

C

S

L3

R

123

N

HEAT

N

FAN

MOTOR 1

CAP 1

AT

OCT

IN

IMPRTANT

EBFOR CONNECTING

THE FH CUT THE

WIRE BETWEEN 2 TABs

FHCONTACTES

3PHRELAY

BLK

CH

BLK

L3

L2 L N

COMP R/V O/F

F.S .C

OPTIONAL

DNG

89

OCT OUT

(8, 9)

POWERSUPPLY:(BYINSTALLER)

3PH ~ 400V 50Hz

5x2.5

CABLESBETWEEN INDOOR

ANDOUTDOOR UNIT:

A.8X1.5

B.2X2.5

L3

L2

L1

N

POWER SUPLLY

HEATER

(L3) (L2)

YL/GN

BLU

BRN

BLK

RED

VID

MODELPLUG

IELD=RC

BLU

BRN

VID

BLK

YEL/GRN

RED

LEVEL

TO

DISPLAY

PCB RM

IN

OUT

CONSEMSPR

ROOM SENSPR

DISPLAYBOARD

654

N

3

GND

GNYE

WH(N)

BK(L)

YE(M)

BU(H)

HE1

HE2

1HE N2 N1

FUSE

3.15A T

WH

WH

WH

BU

BU

BU

FAN I MOT OR

M

~

GN/YE

CAP

OG

RD

OUT PUMP

SWOMG IMOTOR

M

~

WIRING DIAGIRAMOFINDOORUNIT

WIRING DIAGIRAM OFOUTDOOR UNIT

GN/YE

ONZER

Page 53

Part No:452809000/01

Page 54

Model:

FS KFR 120L Indoor Unit

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

Page 55

Model:

FS KFR 120L Indoor Unit

No. Part No. Name Qty. Ver.

457874

outlet grid

2 459858

middle front

3 459523

display panel assy.

4 457870

inlet grid

5 457400

screw M4*18

6 457872

left track

7 45823

protect plate and insulation

8 45805

right track

9 45787

filter

0 457885

leading air ring

457884

air house

2 453682

fan nut

0

3 45373

casing of air house

9 0

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

4 453755

fixed block

0

5 457886

centrifugal fan

6 457883

motor

7 457882

Controller box cover

8 45793

storm

9 45562

fan cap.

0

20 457804

Controller box

2 45788

base plate

22 457802

Supporter for air house

23 457800

copper tube protect plate(up)

24 45780

copper tube protect plate(down)

25 457799

L&R strengthen plate

2

26 457803

wire fixed plate

27 457797

back plate paint assy.

28 458050

right side plate paint assy.

29 458073

fix plate paint assy.

30 459043

cover of copper tube

3 457798

left side plate paint assy.

32 45775

right support plate

33 45776

down support plate

34 45774

Upper support plate

35 45773

left support plate

36 457543

Collection gas tube assy.

37 457542

division capillary assy.

38 456729

evaporator assy.

39 458048

liquid tube insulation

40 458049

gas tube insulation

4 457545

gas tube assy.

42 457544

liquid tube assy.

43 457877

Gathering water pan

44 457878

drain pipe

45 457876

drain pan and insulation assy.

46 457880

support plate of drain pan

48 457905

ionizer assy.

49 457879

top cover paint assy.

50 453769

swing motor

0

5 454539

swing bar

0

52 457795

swing motor bracket

Page 56

Model:

FS KFR 120L Outdoor Unit

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

Page 57

Model:

FS KFR 120L Outdoor Unit

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

Page 58

Model:

FS KFR 120L Outdoor Unit

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

Page 59

Model:

FS KFR 120L Outdoor Unit

1 437045 LARGE UPPER COVER OU 1 4

2 439655 SIDE PANEL OU10 1 3

3 439656 SIDE COVER OU10 1 2

4 439653 FRONT PANEL OU10 1 3

5 439662 GRILLE OU10 2 1

6 439833 NEW BASE ASSY OU 1 1

7 439744 COIL OU10-50 R407C 1 1

8 439650 AXIAL FAN D400*112 2 1

9 439651 MOTOR 70W,3S,OU10 2 2

10 439654 NET SIDE PANEL OU10 1 3

11 436358 OU LEADING HANDLE 1 1

12 439657 MOTOR SUPPORT OU10 1 2

13 436357 SMALL ELECTRICAL COVER OU 1 3

14 439767 COMPRESSOR HR061YAA 1 1

15 439746 CAPILLARY ASSY OU10-50 R407C 1 1

16 439829 TUBING ASSY OU10-50 R407C 1 1

17 402494 BOARD TPHN 3C 1 1

18 442378 CAPACITOR 400V 3mF 2 2

19 434716 THERMISTOR+CAP WTH CONNECTOR L1050 1 1

21 442462 VALVE COIL L700 4-WAY MOLEX 1 1

22 435545 COMPRESSOR WIRING WTH PLUG L1100 3PH 1 1

23 439661 CONES OU10 2 1

24 402189 SUCTION ACCUMULATOR 5" x 3/4" 7Lb 1 1

25 439795 BOARD 3PH PROTECTOR 1 1

26 436352 RAISING HANDLE OU10 1 1

27 190442 HEATER CRANKCASE OU10 LG 1 1

Rev.: 01

Series: FS

Date: 20/02/2004

ELECTRA CONSUMER PRODUCTS LTD

Loading...

Loading...