Electra ECF 9 DCI INV, ECF 12 DCI INV, ECF 18 DCI INV, PXD 9 DCI INV, PXD 12 DCI INV Technical Manual

...Page 1

Technical Manual

Multi Split Trio Quattro DCI

Indoor Units Outdoor Units

WNG 9 DCI INV

WNG 12 DCI INV

WNG 18 DCI INV

ECF 9 DCI INV

ECF 12 DCI INV

ECF 18 DCI INV

PXD 9 DCI INV

PXD 12 DCI INV

PXD 18 DCI INV

LS 35 DCI INV

TRIO DCI

QUATTRO DCI

REFRIGERANT

R410A

TM TQDCI E 0 GB 08-2005

HEAT PUMP

Page 2

LIST OF EFFECTIVE PAGES

LIST OF EFFECTIVE PAGES

Note: Changes in the pages are indicated by a “Revision#” in the footer of each effected page

(when none indicates no changes in the relevant page). All pages in the following list represent

effected/ non effected pages divided by chapters.

Dates of issue for original and changed pages are:

Original ....... 0 ........ August 2005

otal number of pages in this publication is 88 consisting of the following:

T

Page

No.

Title ....................... 0

A ........................... 0

i ............................. 0

1-1 - 1-4 ................ 0

2-1 - 2-4 ................ 0

3-1 - 3-2 ................ 0

4-1 - 4-2 ................ 0

5-1 - 5-10 .............. 0

6-1 - 6-2 ................ 0

7-1 - 7-2 ................ 0

8-1 - 8-2 ................ 0

9-1 - 9-2 ................ 0

10-1-10-2 .............. 0

11-1-11-18 .............

12-1-12-6 .............. 0

Revision

No. #

0

Page

No.

Revision

No. #

Page

No.

Revision

No. #

• Zero in this column indicates an original page.

*Due to constant improvements please note that the data on this service manual can be modified

with out notice.

**Photos are not contractual

A

Revision 0

Page 3

TABLE OF CONTENTS

Table of Contents

1. INTRODUCTION ...................................................................................................1-1

2. PRODUCT DATA SHEET ......................................................................................2-1

3. RATING CONDITIONS ..........................................................................................3-1

4. OUTLINE DIMENSIONS .......................................................................................4-1

5. PERFORMANCE DATA .......................................................................................5-1

6. PRESSURE CURVES ...........................................................................................6-1

7. ELECTRICAL DATA..............................................................................................7-1

8. WIRING DIAGRAMS .............................................................................................8-1

9. REFRIGERATION DIAGRAMS .............................................................................9-1

10. TUBING CONNECTIONS ......................................................................................10-1

11. CONTROL SYSTEM .............................................................................................11-1

12. TROUBLESHOOTING ..........................................................................................12-1

Revision 0 i

Page 4

INTRODUCTION

1. INTRODUCTION

1.1 General

The Trio/Quattro DCI Multi series is a full line multi-tubing system with 3 to 4 connected indoor

units. The multi-split inverter is a high level technology product for residential and commercial

application offering comfort, low noise operation and energy saving.

1.2 Main Features

1.2.1 High Technology

• Sine wave form in both OFAN and Compressor drives.

• DC-BL-SL (Sensor less) Inverter Compressor drive.

• DC-BL Inverter OFAN drive in the controller.

• DSP Power (Digital Signal Processing) – High speed calculation for accurate Sine wave

form vector control.

• Smart PFC control.

• Fuzzy Logic Control

1.2.2 System Features

• R410A

• High COP (“A” class energy rating)

• Low noise levels

• IAQ (Indoor Air Quality) features (WNG series)

• Lego concept - Products line of wall mounted, floor/ceiling, cassette, ducted with capacity

models of 2.5, 3.5 and 5.0 kW

• Networking connectivity.

• Pre-charged system.

• Dry contact inputs:

o STBY

o Night (in cool mode only)

o Power Shedding

o Forced Mode operation

• Dry contact output – Alarm.

• Ready for Base heater connection and logic.

• Cooling operation at outdoor temperature down to -10

• Heating operation at outdoor temperature down to -150C.

• HMI Display Board (Human-Machine Interface) – 3x7-segment display shows both indoor

and outdoor diagnostics and setting up features.

• Monitoring softwear(PC port).

• EEV (Electronic Expansion Valve) for each indoor unit.

.

0

C.

1.3 Tubing Connections

Flare type interconnecting tubing to be produced on site.

1.4 Inbox Documentation

.

Each indoor unit is supplied with its own installation and operation manuals.

Revision 0 1-1

Page 5

INTRODUCTION

1.5 Matching Table

R410A

OUTDOOR UNITS

MODEL REFRIGER. WNG 9/12/18 ECF 9/12/18 PXD 9/12/18 LS 35

DCI INDOOR UNITS

Trio DCI

Quattro DCI

DCI

R410A

R410A

√√√√

√√√√

1.6 Indoor Unit combinations

Trio Quattro

Unit A Unit B Unit D Code Sum Unit A Unit B Unit C Unit D Code Sum

9 9 9 3 9 9 9 9 4

9 9 12 3.5 9 9 9 12 4.5

9 9 18 4 9 9 12 12 5

9 12 12 4 9 9 9 18 5

12 12 12 4.5 9 9 12 18 5.5

9 12 18 4.5 9 12 12 12 5.5

12 12 18 5 9 12 12 18 6

12 12 12 12 6

1-2

Nominal Indoor Units Combination

Revision 0

Page 6

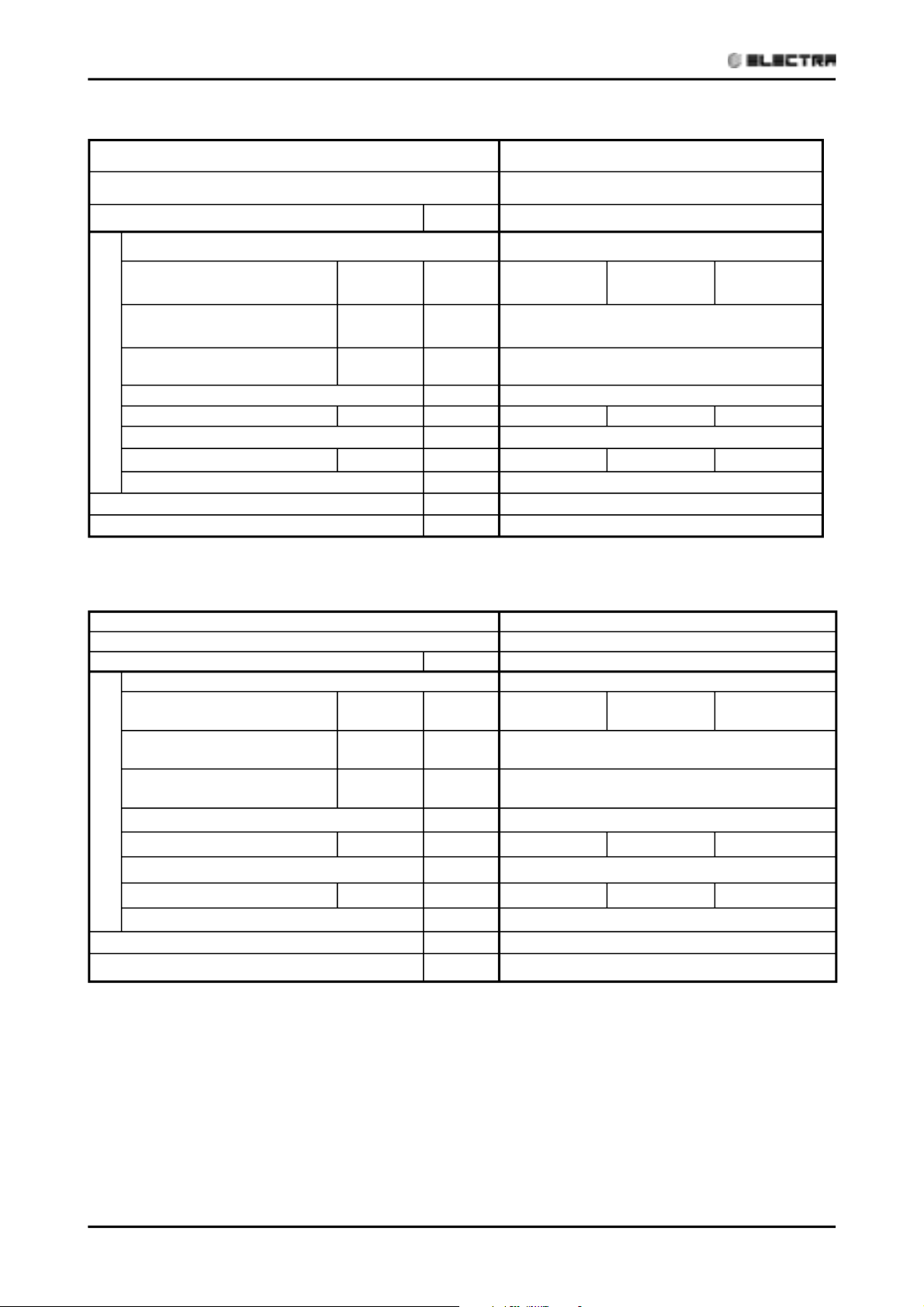

PRODUCT DATA SHEET

2. PRODUCT DATA SHEET

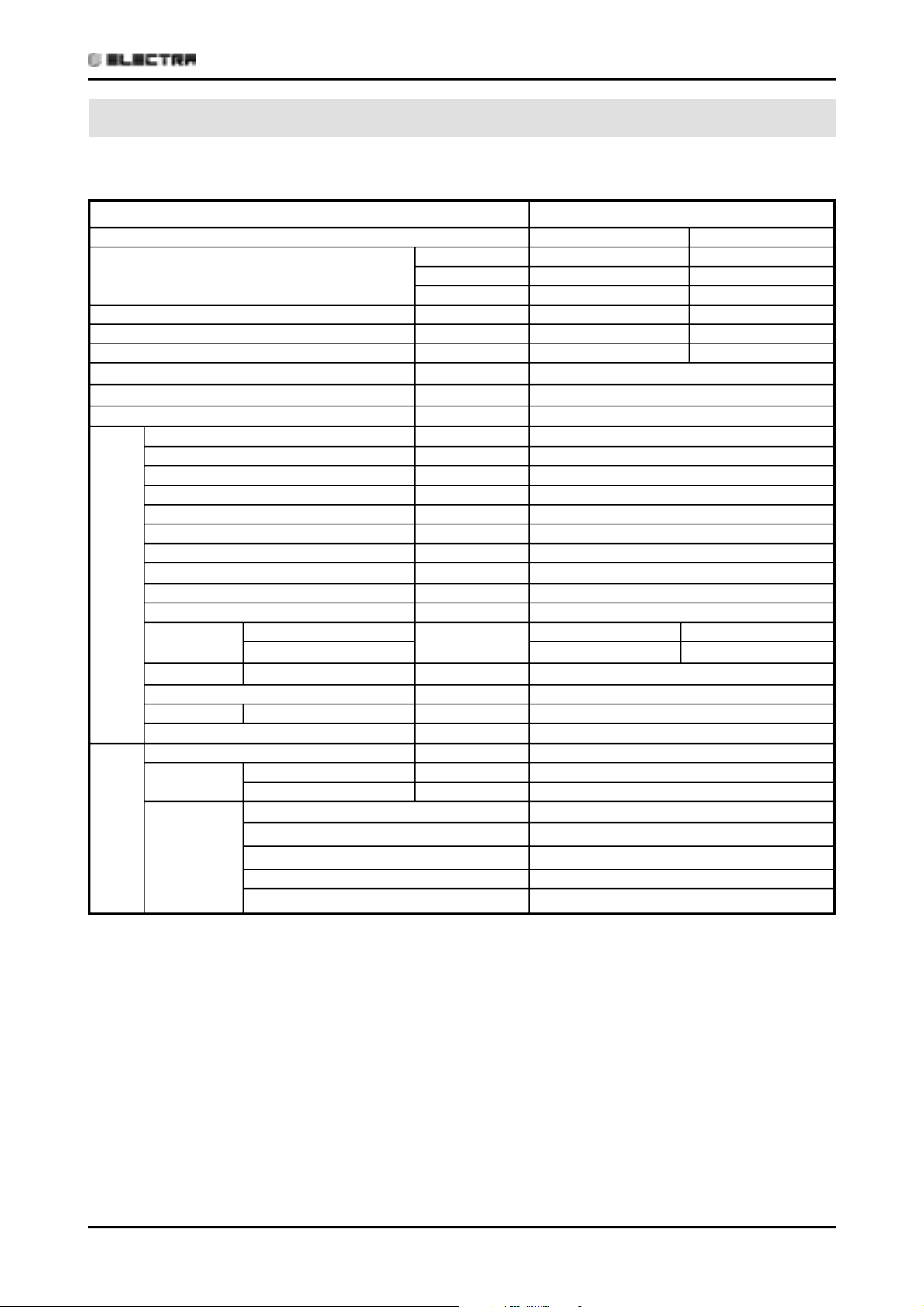

2.1 Outdoor TRIO DCI Specifications.

Model TRIO DCI R410A

Operation Mode Cooling Heating

Capacity

Total Input W 2,240 (500~3,000) 2,370 (500~3,000)

E.E.R (Cooling) / C.O.P (Heating) W/W 3.21 3.80

Running Current

Starting Current A 10

Inrush Current A <35.0

Power Supply V/Ph/Hz 220-240V/ 1PH / 50Hz

(1), (2)

(3)

Refrigerant control Electronic expansion valve

Compressor type Twin Rotary DC Inverter

Model MELCO TNB220FLBM

Starter type

Protection device Outdoor SW control

Heat exchanger Hydrophilic corrugated fins ,Grooved tubes

Fan x No. Propeller x 1

Airflow

Motor output W 90

Defrost method Reverse cycle

OUTDOOR UNIT

Noise level

Dimensions W*D*H mm 950*835*340

Weight Kg 69

Package W*D*H mm 1,070X510X940

Unit stacking # 3

Refrigerant Charge Kg R410A - 3,200

Tube size O.D.

Connection

method

between the

TUBING

indoor and

outdoor units

(4)

Indoor & outdoor Flared

Height difference between indoor units Max.15m

Height difference between indoor & outdoor Max.15m

Tubing length Max.25m for one unit and 50m total

Additional charge No need

Pressure

Power 63 64

Liquid mm 3x 6.35

Suction mm 2x 9.53 + 1x 12.7

Kcal/hr 6,190 (1,120~7,740) 7,740 (820~9,460)

Btu/hr 24,570 (4,440~30,710) 30,710 (3,240~37,530)

W 7,200 (1,300~9,000) 9,000 (950~11,000)

A 9.7 9.8

---

3

/hr

m

dB(A)

53 54

3,200

Note:

(1) Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units).

(2) Nominal capacity is measured with the combination of 4x WNG 25 DCI (Quattro) or 3x WNG 25 DCI (Trio) and 5m tubing each unit.

Maximum capacity is measured with the combination of WNG 25 DCI + 2x WNG 35 DCI + WNG 50 DCI (Quattro) or 2x WNG 35

DCI + WNG 50 DCI (Trio) and 5m tubing each unit.

Minimum capacity is measured with WNG 25 DCI (Quattro/Trio) and 5m tubing.

(3) Running Current is measured in nominal conditions at 230V.

(4) Sound pressure level measured at 1 meter distance from unit at nominal (cool/heat) conditions

Revision 0 2-1

Page 7

PRODUCT DATA SHEET

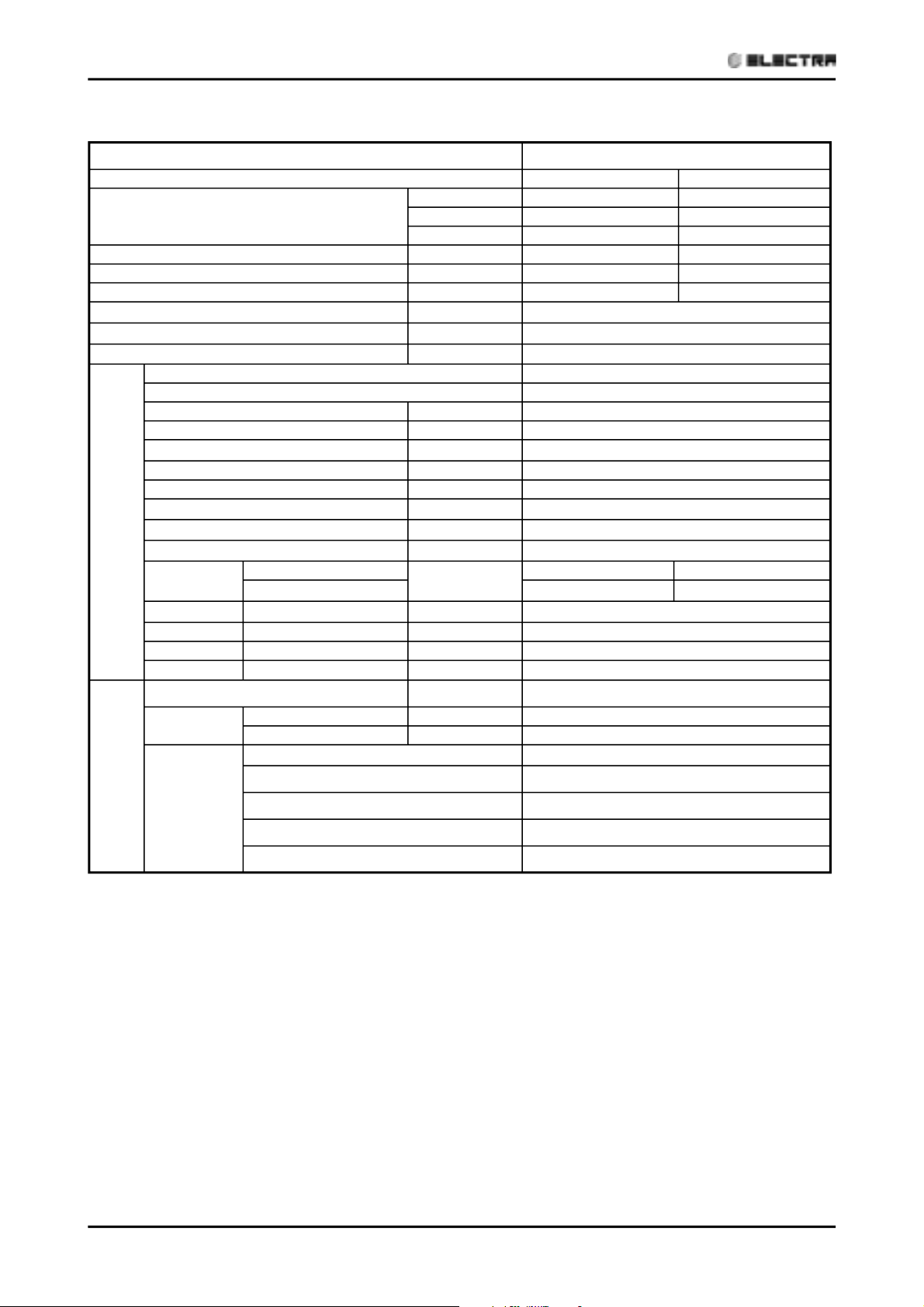

2.2 Outdoor QUATTRO DCI Specifications.

Model QUATTRO DCI R410A

Operation Mode Cooling Heating

Capacity

Total Input W 2,490 (500~3,000) 2,380 (400~3,000)

E.E.R (Cooling) / C.O.P (Heating) W/W 3.21 4.00

Running Current

Starting Current A 11

Inrush Current A <35.0

Power Supply V/Ph/Hz 220-240V/ 1PH / 50Hz

(1), (2)

(3)

Refrigerant control Electronic expansion valve

Compressor type Twin Rotary DC Inverter

Model MELCO TNB220FLBM

Starter type

Protection device Outdoor SW control

Heat exchanger Hydrophilic corrugated fins ,Grooved tubes

Fan x No. Propeller x 1

Airflow

Motor output W 90

Defrost method Reverse cycle

OUTDOOR UNIT

Noise level

Dimensions W*D*H mm 950*835*340

Weight Kg 70

Package W*D*H mm 1,070X510X940

Unit stacking 3

Refrigerant Charge Kg R410A - 3,400

Tube size O.D.

Connection

method

TUBING

between the

indoor and

outdoor units

(4)

Indoor & outdoor Flared

Height difference between indoor units Max.15m

Height difference between indoor & outdoor Max.15m

Tubing length Max.25m for one unit and 70m total

Additional charge No need

Pressure

Power 63 64

Liquid mm 4x 6.35

Suction mm 3x 9.53 + 1x 12.7

Kcal/hr 6,880 (1,200~7,910) 8,170 (820~9,460)

Btu/hr 27,300 (4,780~31,390) 32,410 (3,240~37,530)

W 8,000 (1,400~9,200) 9,500 (950~11,000)

A 10.8 10.3

---

3

m

/hr

dB(A)

53 54

3,200

Note:

(1) Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units).

(2) Nominal capacity is measured with the combination of 4x WNG 25 DCI (Quattro) or 3x WNG 25 DCI (Trio) and 5m tubing each unit.

Maximum capacity is measured with the combination of WNG 25 DCI + 2x WNG 35 DCI + WNG 50 DCI (Quattro) or 2x WNG 35

DCI + WNG 50 DCI (Trio) and 5m tubing each unit.

Minimum capacity is measured with WNG 25 DCI (Quattro/Trio) and 5m tubing.

(3) Running Current is measured in nominal conditions at 230V.

(4) Sound pressure level measured at 1 meter distance from unit at nominal (cool/heat) conditions.

2-2

Revision 0

Page 8

PRODUCT DATA SHEET

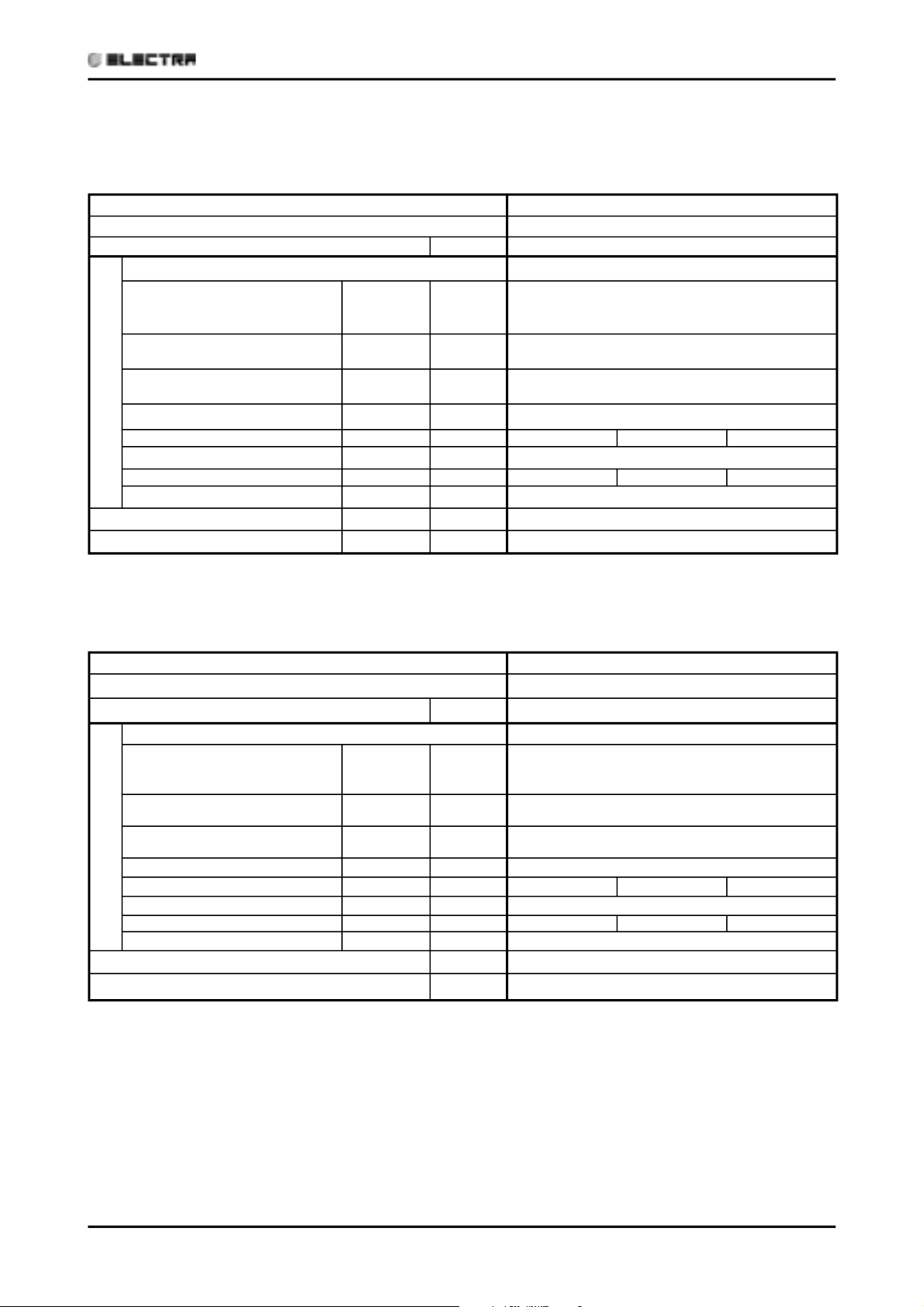

2.3 Indoor Units Data

2.3.1 WNG 9 DCI Specifications

Model Indoor Unit / Type WNG 9 DCI / Wall Mounted

Installation Method FLARE

Power Supply V/Ph/Hz 220-240 / 1/ 50

Fan Type & Quantity Crossflow *1

(2)

Airflow

Cooling / Heating

Sound Power Level

Cooling / Heating

Sound Pressure Level

Cooling / Heating

INDOOR

Condensate Drain Tube I.D. mm 16

Dimensions W/H/D mm 810 285 202

Weight kg 11

Package Dimensions W/H/D mm 885 360 285

Stacking Height Units 7

Heating Elements kW N/A

Moisture Removal L/hr 1

(3)

(4)

H/M/L m3/hr

L - H dB (A) 39-50 / 39-51

L - H dB (A) 26-38 / 26-39

530/570

430/460

330/350

2.3.2 WNG 12 DCI Specifications

Model Indoor Unit / Type WNG 12 DCI / Wall Mounted

Installation Method FLARE

Power Supply V/Ph/Hz 220-240 / 1/ 50

Fan Type & Quantity Crossflow *1

(2)

Airflow

Cooling / Heating

Sound Power Level

Cooling / Heating

Sound Pressure Level

Cooling / Heating

INDOOR

Condensate Drain Tube I.D. mm 16

Dimensions W/H/D mm 810 285 202

Weight kg 11

Package Dimensions W/H/D mm 885 360 285

Stacking Height Units 7

Heating Elements kW N/A

Moisture Removal L/hr 1.5

(3)

(4)

H/M/L m3/hr

L - H dB (A) 39-52 / 39-52

L - H dB (A) 26-39 / 26-40

NOTE:

1) Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units) and EN14511.

(2) Airflow in ducted units; at nominal external static pressure.

(3) Sound power in ducted units is measured at air discharge.

(4) Sound pressure level measured at 1 meter distance from unit.

550/580

450/480

350/370

Revision 0 2-3

Page 9

PRODUCT DATA SHEET

2.3.3 WNG 18 DCI Specifications

Model Indoor Unit / Type WNG 18 DCI / Wall Mounted

Installation Method FLARE

Power Supply V/Ph/Hz 220-240 / 1/ 50

Fan Type & Quantity Crossflow *1

(2)

Airflow

Cooling / Heating

Sound Power Level

Sound Pressure Level

INDOOR

Condensate Drain Tube I.D. mm 16

Dimensions W/H/D mm 1060 295 210

Weight kg 15

Package Dimensions W/H/D mm 1125 360 280

Stacking Height Units 8

Heating Elements kW N/A

Moisture Removal L/hr 2

(3)

(4)

H/M/L m3/hr 850 760 620

L - H dB (A) 47 - 55

L - H dB (A) 34 -43

2.3.4 ECF 9 DCI Specifications

Model Indoor Unit / Type ECF 9 DCI / Cassette

Installation Method FLARE

Power Supply V/Ph/Hz 220-240 / 1/ 50

Fan Type & Quantity Centifugal *1

(2)

Airflow

Cooling / Heating

Sound Power Level

Cooling / Heating

Sound Pressure Level

Cooling / Heating

INDOOR

Condensate Drain Tube I.D. mm 16

Dimensions W/H/D mm 571 287 571

Weight kg 22.7

Package Dimensions W/H/D mm 685 415 685

Stacking Height Units 5

Heating Elements kW N/A

Moisture Removal L/hr 1

(3)

(4)

NOTE:

1) Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units) and EN14511.

(2) Airflow in ducted units; at nominal external static pressure.

(3) Sound power in ducted units is measured at air discharge.

(4) Sound pressure level measured at 1 meter distance from unit.

H/M/L m3/hr 530/600 500/530 435/450

L - H dB (A) 42-48 / 42-47

L - H dB (A) 32-38 / 32-37

2-4

Revision 0

Page 10

PRODUCT DATA SHEET

2.3.5 ECF 12 DCI Specifications

Model Indoor Unit / Type ECF 12 DCI / Cassette

Installation Method FLARE

Power Supply V/Ph/Hz 220-240 / 1/ 50

Fan Type & Quantity Centifugal *1

(2)

Airflow

Cooling / Heating

Sound Power Level

(3)

Cooling / Heating

Sound Pressure Level

Cooling / Heating

INDOOR

Condensate Drain Tube I.D. mm 16

(4)

H/M/L m

L - H dB (A) 42-49 / 42-48

L - H dB (A) 32-38 / 32-38

Dimensions W/H/D mm 571 287 571

Weight kg 24.4

Package Dimensions W/H/D mm 685 415 685

Stacking Height Units 5

Heating Elements kW N/A

Moisture Removal L/hr 1.5

3

/hr 580/620 510/560 435/450

2.3.6 ECF 18 DCI Specifications

Model Indoor Unit / Type ECF 18 DCI / Cassette

Installation Method FLARE

Power Supply V/Ph/Hz 220-240 / 1/ 50

Fan Type & Quantity Centifugal *1

(2)

Airflow

Sound Power Level

Sound Pressure Level

(3)

(4)

Condensate Drain Tube I.D. mm 16

INDOOR

Dimensions W/H/D mm 571 287 571

Weight kg 28

Package Dimensions W/H/D mm 685 415 685

Stacking Height Units 5

Heating Elements kW N/A

Moisture Removal L/hr 2

NOTE:

1) Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units) and EN14511.

(2) Airflow in ducted units; at nominal external static pressure.

(3) Sound power in ducted units is measured at air discharge.

(4) Sound pressure level measured at 1 meter distance from unit.

H/M/L m3/hr 730 630 510

L - H dB (A) 46 - 59

L - H dB (A) 36 – 48.5

Revision 0 2-5

Page 11

PRODUCT DATA SHEET

2.3.7 PXD 9 DCI Specifications

Model Indoor Unit / Type PXD 9 DCI Floor/ceiling

Installation Method FLARE

Power Supply V/Ph/Hz 220-240 / 1/ 50

Fan Type & Quantity Centifugal *2

(2)

Airflow

Cooling / Heating

Sound Power Level

Cooling / Heating

Sound Pressure Level

Cooling / Heating

INDOOR

(3)

(4)

H/M/L m

L - H dB (A) 47-50

L - H dB (A) 39-35

Condensate Drain Tube I.D. mm 16

Dimensions W/H/D mm 820 630 190

Weight kg 21

Package Dimensions W/H/D mm 890 710 280

Stacking Height Units 7

Heating Elements kW N/A

Moisture Removal L/hr 1

3

/hr 400 350 300

2.3.8 PXD 12 DCI Specifications

Model Indoor Unit / Type PXD 12 DCI Floor/ceiling

Installation Method FLARE

Power Supply V/Ph/Hz 220-240 / 1/ 50

Fan Type & Quantity Centifugal *2

(2)

Airflow

Cooling / Heating

Sound Power Level

(3)

Cooling / Heating

Sound Pressure Level

(4)

Cooling / Heating

Condensate Drain Tube I.D. mm 16

INDOOR

Dimensions W/H/D mm 820 630 190

Weight kg 22

Package Dimensions W/H/D mm 890 710 280

Stacking Height Units 7

Heating Elements kW N/A

Moisture Removal L/hr 1.5

NOTE:

1) Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units) and EN14511.

(2) Airflow in ducted units; at nominal external static pressure.

(3) Sound power in ducted units is measured at air discharge.

(4) Sound pressure level measured at 1 meter distance from unit.

H/M/L m3/hr 450 400 300

L - H dB (A) 51-56

L - H dB (A) 45 -38

2-6

Revision 0

Page 12

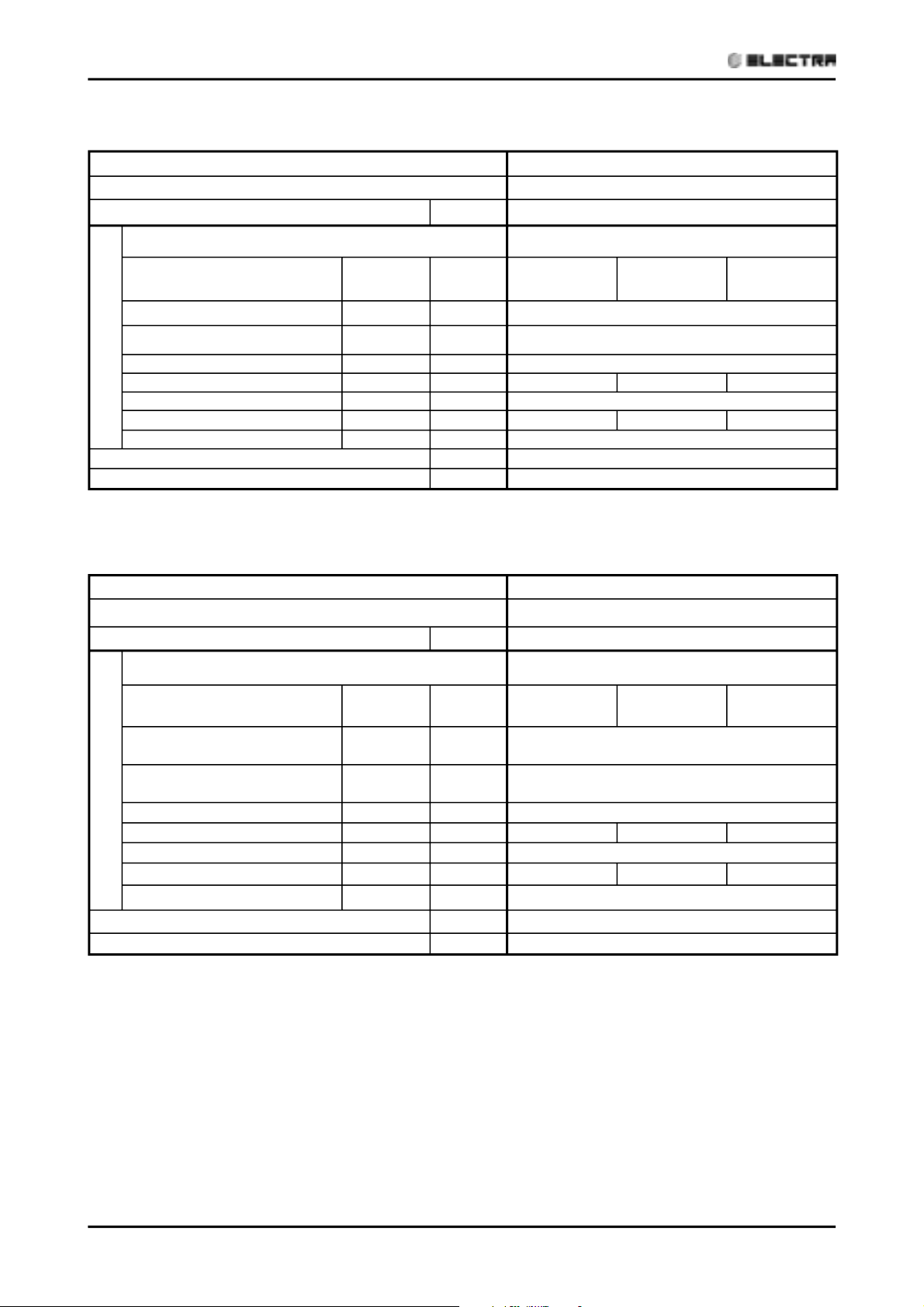

PRODUCT DATA SHEET

2.3.9 PXD 18 DCI Specifications

Model Indoor Unit / Type PXD 18 DCI Floor/ceiling

Installation Method FLARE

Power Supply V/Ph/Hz 220-240 / 1/ 50

Fan Type & Quantity Centifugal *2

(2)

Airflow

Cooling / Heating

Sound Power Level

(3)

Cooling / Heating

Sound Pressure Level

Cooling / Heating

INDOOR

(4)

Condensate Drain Tube I.D. mm 16

Dimensions W/H/D mm 1200 630 190

Weight kg 30

Package Dimensions W/H/D mm 1270 710 280

Stacking Height Units 7

Heating Elements kW N/A

Moisture Removal L/hr 2

H/M/L m3/hr 870 750 600

L - H dB (A) 56 - 65

L - H dB (A) 45 - 51

2.3.10 LS 35 DCI Specifications

Model Indoor Unit / Type LS 35 DCI / Ducted

Installation Method FLARE

Power Supply V/Ph/Hz 220-240 / 1/ 50

Fan Type & Quantity Centifugal *2

(2)

Airflow

Cooling / Heating

Sound Power Level

(3)

Cooling / Heating

Sound Pressure Level

(4)

Cooling / Heating

INDOOR

Condensate Drain Tube I.D. mm 16

Dimensions W/H/D mm 860 245 680

Weight kg 30

Package Dimensions W/H/D mm 1055 305 728

Stacking Height Units 6

Heating Elements kW N/A

Moisture Removal L/hr 1.3

NOTE:

H/M/L m3/hr 590 50 400

L - H dB (A) 52 - 59

L - H dB (A) 35 - 42

1) Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units) and EN14511.

(2) Airflow in ducted units; at nominal external static pressure.

(3) Sound power in ducted units is measured at air discharge.

(4) Sound pressure level measured at 1 meter distance from unit.

Revision 0 2-7

Page 13

3. RATING CONDITIONS

Standard conditions in accordance with ISO 5151, ISO 13253 (for ducted units)

and EN 14511.

Cooling:

Indoor: 27oC DB 19oC WB

Outdoor: 35 oC DB

RATING CONDITIONS

Heating:

o

Indoor: 20

Outdoor: 7

C DB

o

C DB 6oC WB

3.1 Operating Limits

Cooling

Heating

Voltage

Upper limit 32

Lower limit 21

Upper limit 27

Lower limit 10oC DB -15oC DB -16oC WB

1PH 198 – 264 V

3PH N/A

Indoor Outdoor

o

C DB 23oC WB 46oC DB

o

C DB 15oC WB -10oC DB

o

C DB 24oC DB 18oC WB

Service Manual - Trio_Quattro DCI Revision Y05-01 3-1

Page 14

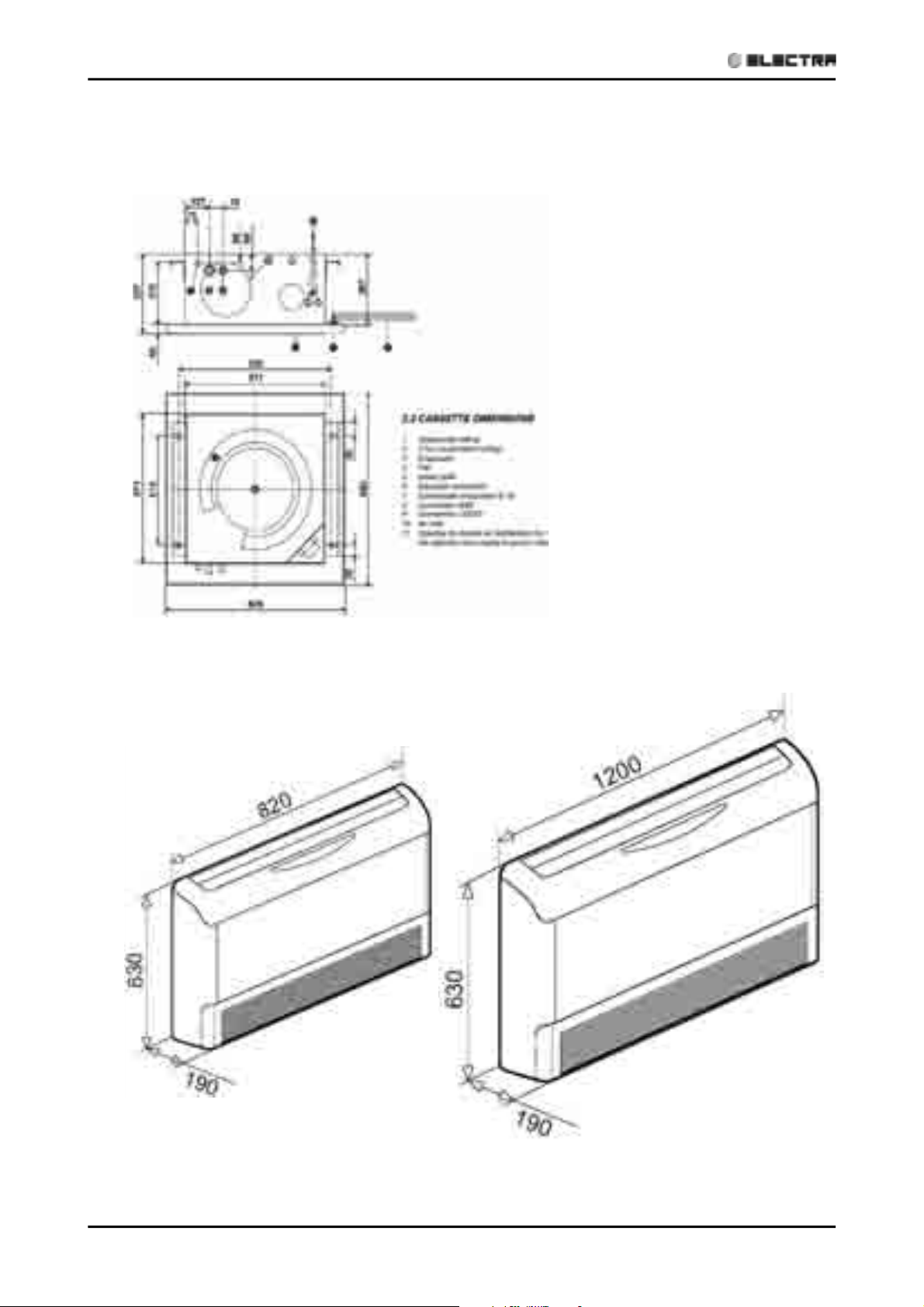

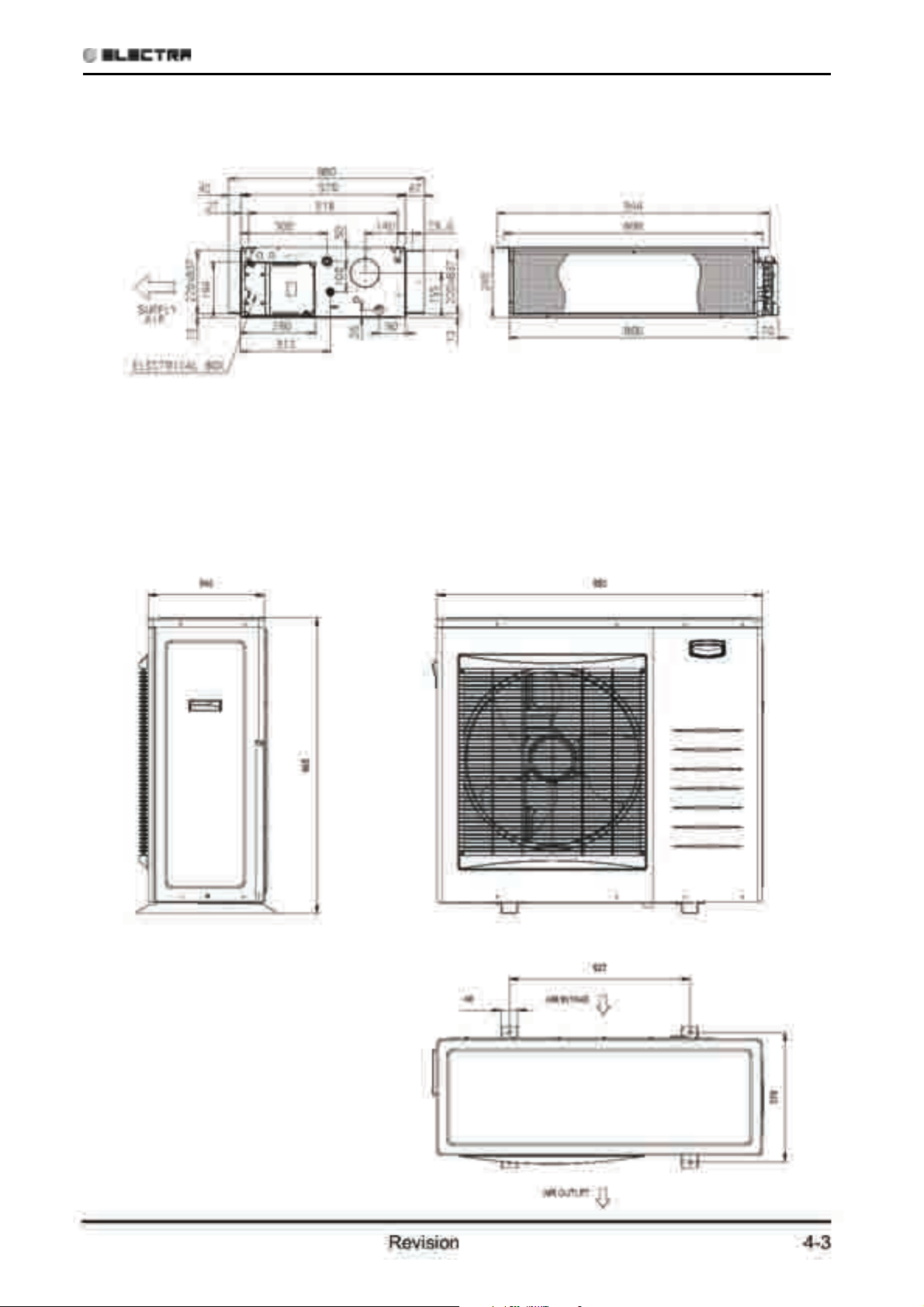

4. OUTLINE DIMENSIONS

4.1 Indoor Unit: WNG 9/12 DCI

OUTLINE DIMENSIONS

Indoor Unit: WNG 18 DCI

4.2

Revision 0

4-1

Page 15

OUTLINE DIMENSIONS

4.3 Indoor Unit: ECF 9, 12, 18 DCI

4.4 Indoor Unit: PXD 9, 1, 18 DCI

4-2

Revision 0

Page 16

4.5 Indoor Unit: LS 35 DCI

OUTLINE DIMENSIONS

4.6 Outdoor Unit

s: TRIO, QUATTRO DCI

0

Page 17

PERFORMANCE DATA

5. PERFORMANCE DATA

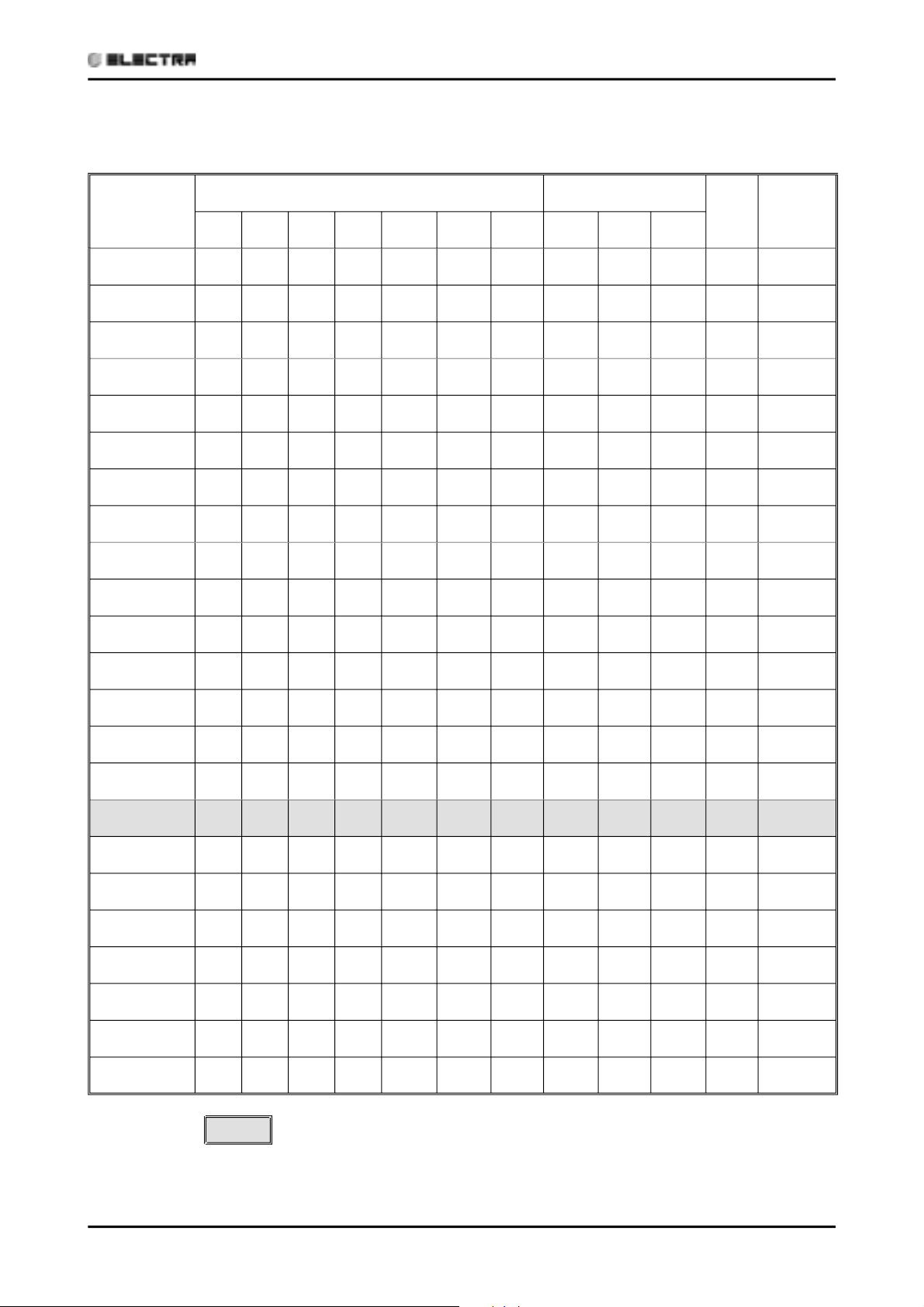

5.1 Outdoor Unit Trio DCI Combinations (Based on WNG)

5.1.1 Cooling

Model

9

25

12

35

18

50

9

9+

25+25

12

9+

25+35

18

9+

25+50

12+12

35+35

12+18

35+35

+9+9

9

25+25+25

9+9+12

25+25+35

Cooling Capacity [KW] Power Consumption [W]

A B C Nom. Min. Max. Nom. Min. Max.

- - 2.50 2.50 1.30 3.70 685 500 1,025 3.65 A

- - 3.50 3.50 1.30 4.40 968 500 1,223 3.62 A

- - 5.00 5.00 1.49 5.93 1,393 566 1,656 3.59 A

- 2.54 2.54 5.08 1.86 6.56 1,498 683 1,856 3.39 A

- 2.57 3.42 5.99 1.86 7.73 1,783 683 2,541 3.36 A

- 2.44 4.88 7.32 1.86 9.00 2,203 659 3,046 3.32 A

- 3.46 3.46 6.92 1.86 9.00 2,075 683 2,246 3.33 A

- 2.93 4.39 7.32 1.86 9.00 2,203 659 3,055 3.32 A

2.40 2.40 2.40 7.20 2.69 8.98 2,240 949 3,049 3.21 A

2.20 2.20 2.93 7.33

2.69 9.00 2,281 949 3,157 3.21 A

COP

Nom.

Energy

Efficiency

Class

9+18

9+

25+25+50

12+12

9+

25+35+35

12+18

9+

25+35+50

12+12+12

35+35+35

12+12+18

35+35+50

1.83 1.83 3.66 7.32 2.69 9.00 2,278 962 3,097 3.21 A

1.99 2.66 2.66 7.31 2.69 9.00 2,275 949 3,097 3.21 A

1.69 2.25 3.37 7.31 2.69 9.00 2,275 962 3,061 3.21 A

2.44 2.44 2.44 7.32 2.69 9.00 2,278 990 3,085 3.21 A

2.09 2.09 3.13 7.30 2.69 9.00 2,272 962 3,086 3.21 A

Nominal Indoor Units Combination

Revision 0 5-1

Page 18

PERFORMANCE DATA

5.1.2 Heating

Model

25

9

12

35

18

50

9+9

25+25

25+35

9+12

25+50

9+18

35+35

12+12

12+18

35+35

25+25+25

+9+9

9

9+9+12

25+25+35

Heating Capacity [KW]

A B C Nom. Min. Max. Nom. Min. Max.

- - 3.40 3.40 0.95 4.00 685 500 897 4.96 A

- - 4.30 4.30 0.95 5.20 1,003 485 1,320 4.29 A

- - 6.20 6.20 1.11 7.50 1,673 549 2,131 3.71 A

- 3.60 3.60 7.20 1.43 9.10 1,883 649 2,636 3.82 A

- 3.26 4.34 7.60 1.43 9.50 2,009 649 2,711 3.78 A

- 3.00 6.00 9.00 1.43 10.10 2,451 622 2,737 3.67 A

- 4.00 4.00 8.00 1.43 9.80 2,135 649 2,711 3.75 A

- 3.60 5.40 9.00 1.43 10.50 2,451 622 2,871 3.67 A

3.00 3.00 3.00 9.00 2.06 10.99 2,370 804 3,013 3.80 A

2.70 2.70 3.60 9.00 2.06 11.00 2,370 804 2,966 3.80

Power Consumption

[W]

COP

Nom.

Energy

Efficiency

Class

A

25+25+50

9+9+18

25+35+35

9+12+12

9+12+18

25+35+50

35+35+35

12+12+12

12+12+18

35+35+50

2.25 2.25 4.50 9.00 2.06 11.00 2,370 773 2,826 3.80 A

2.45 3.27 3.27 8.99 2.06 11.00 2,367 804 2,938 3.80 A

2.07 2.76 4.14 8.98 2.14 11.00 2,365 773 2,752 3.80 A

3.00 3.00 3.00 9.00 2.06 11.00 2,370 804 2,845 3.80 A

2.57 2.57 3.85 8.99 2.14 11.00 2,367 773 2,696 3.80 A

Nominal Indoor Units Combination

5-2

Revision 0

Page 19

PERFORMANCE DATA

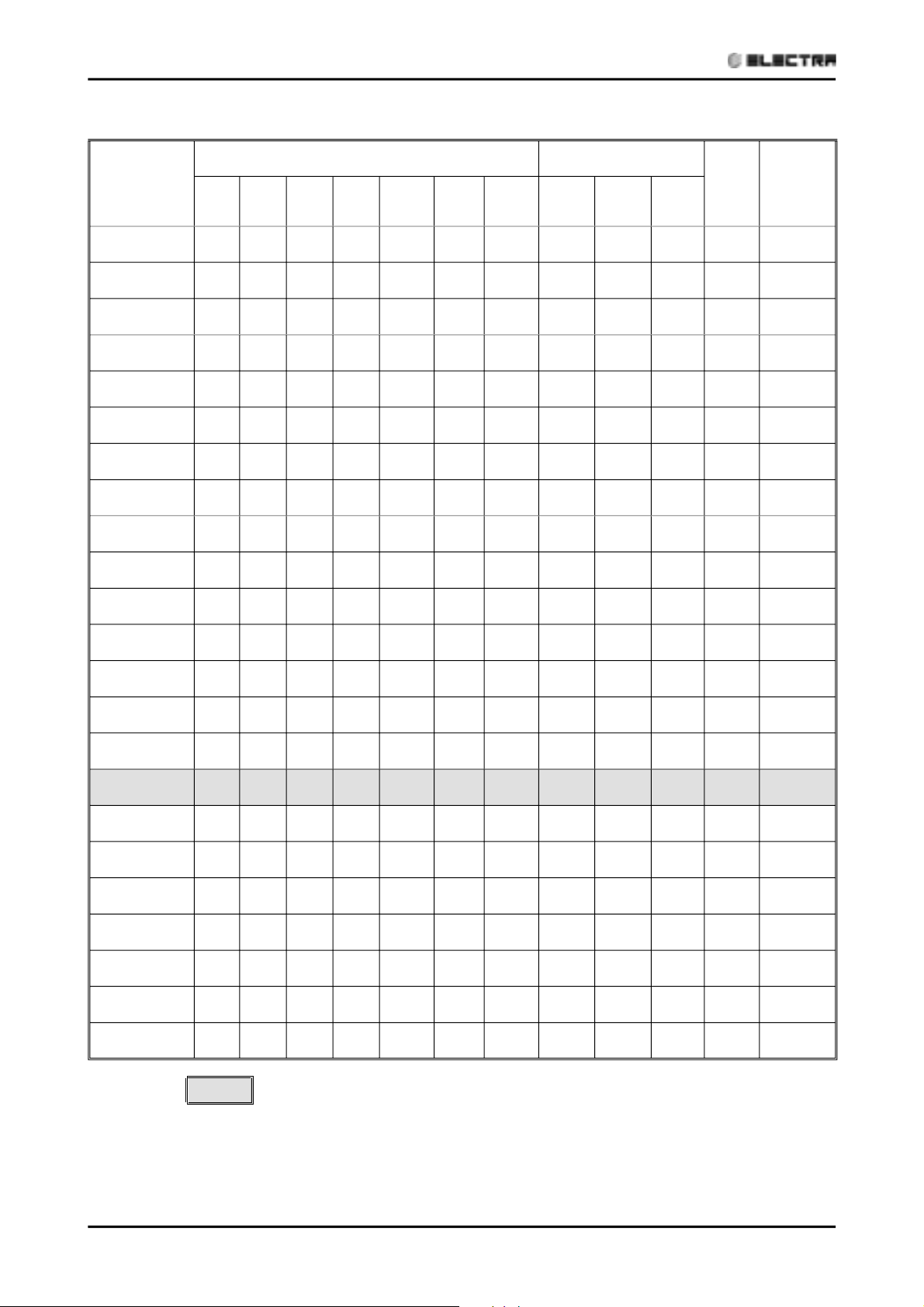

5.2 Outdoor Unit Quattro DCI Combinations (Based on WNG)

5.2.1 Cooling

Model

25

9

12

35

18

50

9+9

25+25

9+12

25+35

9+18

25+50

12+12

35+35

12+18

35+35

9+9+9

25+25+25

25+25+35

9+9+12

9+9+18

25+25+50

Cooling Capacity [KW]

A B C D Nom. Min. Max. Nom. Min. Max.

- - - 2.50 2.50 1.40 3.70 685 500 1,025 3.65 A

- - - 3.50 3.50 1.40 4.40 968 500 1,223 3.62 A

- - - 5.00 5.00 1.60 5.60 1,393 570 1,563 3.59 A

- - 2.54 2.54 5.08 2.00 6.20 1,453 689 1,742 3.49 A

- - 2.56 3.42 5.98 2.00 7.30 1,722 689 2,385 3.47 A

- - 2.54 5.08 7.61 2.00 8.50 2,210 665 2,858 3.45 A

- - 3.45 3.45 6.90 2.10 8.80 1,998 689 2,921 3.46 A

- - 3.15 4.72 7.87 2.10 8.80 2,285 665 2,876 3.44 A

- 2.40 2.40 2.40 7.19 2.90 9.00 2,112 915

- 2.36 2.36 3.15 7.87 2.90 9.00 2,445 915 2,899 3.22 A

- 2.00 2.00 4.01 8.01 2.90 9.00 2,466 928 2,851 3.25 A

Power Consumption

[W]

2,938 3.40 A

COP

Nom.

Energy

Efficiency

Class

9+12+12

25+35+35

25+35+50

9+12+18

12+12+12

35+35+35

12+12+18

35+35+50

9+9+9+9

25+25+25+25

9+9+9+12

25+25+25+35

9+9+9+18

25+25+25+50

9+9+12+12

25+25+35+35

25+25+35+50

9+9+12+18

25+35+35+35

9+12+12+12

9+12+12+18

25+35+35+50

35+35+35+35

12+12+12+12

- 2.17 2.90 2.90 7.97 2.90 9.00 2,445 915 2,851 3.26 A

- 1.87 2.50 3.74 8.11 2.90 9.00 2,476 928 2,821 3.28 A

- 2.69 2.69 2.69 8.07 2.90 9.00 2,372 955 2,841 3.40 A

- 2.31 2.31 3.47 8.10 2.90 9.00 2,372 928 2,802 3.42 A

2.00 2.00 2.00 2.00 8.00 3.70 9.17 2,490 1,091 2,937 3.21 A

1.87 1.87 1.87 2.49 8.10 3.70 9.20 2,524 1,091 2,915 3.21 A

1.62 1.62 1.62 3.25 8.12 3.70 9.20 2,445 1,064 2,882 3.32 A

1.74 1.74 2.32 2.32 8.11 3.70 9.20 2,513 1,091 2,882 3.23 A

1.52 1.52 2.03 3.05 8.12 3.70 9.20 2,410 1,064 2,849 3.37 A

1.62 2.16 2.16 2.16 8.11 3.70 9.20 2,501 1,091 2,871 3.24 A

1.43 1.91 1.91 2.87 8.12 3.70 9.20 2,410 1,064 2,890 3.37 A

2.03 2.03 2.03 2.03 8.12 3.70 9.20 2,490 1,091 2,838 3.26 A

Nominal Indoor Units Combination

Revision 0 5-3

Page 20

PERFORMANCE DATA

5.2.2 Heating

Model

25

9

12

35

18

50

25+25

9+9

9+12

25+35

9+18

25+50

12+12

35+35

35+35

12+18

9+9+9

25+25+25

25+25+35

9+9+12

Heating Capacity [KW]

A B C D Nom. Min. Max. Nom. Min. Max.

- - - 3.40 3.40 0.95 4.00 685 400 859 4.96 A

- - - 4.30 4.30 0.95 5.20 946 388 1,207 4.54 A

- - - 6.20 6.20 1.11 7.50 1,497 455 1,875 4.14 A

- - 3.64 3.64 7.28 1.43 8.63 1,707 539 2,172 4.26 A

- - 3.29 4.39 7.68 1.43 9.01 1,838 539 2,235 4.18 A

- - 3.03 6.06 9.10 1.43 9.58 2,261 516 2,255 4.02 A

- - 4.04 4.04 8.09 1.43 9.29 1,920 539 2,235 4.21 A

- - 3.80 5.70 9.50 1.43 9.96 2,317 516 2,366 4.10 A

- 3.03 3.03 3.03 9.10 2.06 11.00 2,151 671 2,621 4.23 A

- 2.85 2.85 3.80 9.50 2.06 11.00 2,231 671 2,891 4.26 A

Power Consumption

[W]

COP

Nom.

Energy

Efficiency

Class

25+25+50

9+9+18

9+12+12

25+35+35

25+35+50

9+12+18

12+12+12

35+35+35

35+35+50

12+12+18

25+25+25+25

9+9+9+9

9+9+9+12

25+25+25+35

9+9+9+18

25+25+25+50

9+9+12+12

25+25+35+35

9+9+12+18

25+25+35+50

25+35+35+35

9+12+12+12

25+35+35+50

9+12+12+18

35+35+35+35

12+12+12+12

- 2.38 2.38 4.75 9.50 2.06 11.00 2,072 646 2,883 4.59 A

- 2.59 3.45 3.45 9.48 2.06 11.00 2,171 671 2,874 4.37 A

- 2.19 2.92 4.38 9.48 2.14 11.00 2,012 646 2,731 4.71 A

- 3.16 3.16 3.16 9.49 2.06 11.00 2,151 671 2,857 4.41 A

- 2.71 2.71 4.06 9.48 2.14 11.00 1,993 646 2,671 4.76 A

2.38 2.38 2.38 2.38 9.50 2.69 10.97 2,380 657 2,935 3.99 A

2.19 2.19 2.19 2.91 9.47 2.69 11.00 2,355 657 2,900 4.02 A

1.90 1.90 1.90 3.80 9.50 2.77 11.00 2,294 646 2,779 4.14 A

2.03 2.03 2.71 2.71 9.49 2.69 11.00 2,306 657 2,857 4.12 A

1.78 1.78 2.37 3.56

1.90 2.53 2.53 2.53 9.48 2.69 11.00 2,269 657 2,822 4.18 A

1.67 2.23 2.23 3.35 9.48 2.77 11.00 2,195 646 2,903 4.32 A

2.38 2.38 2.38 2.38 9.50 2.69 11.00 2,380 646 2,796 3.99 A

9.49 2.77 11.00 2,195 646 2,762 4.32 A

5-4

Nominal Indoor Units Combination

Revision 0

Page 21

PERFORMANCE DATA

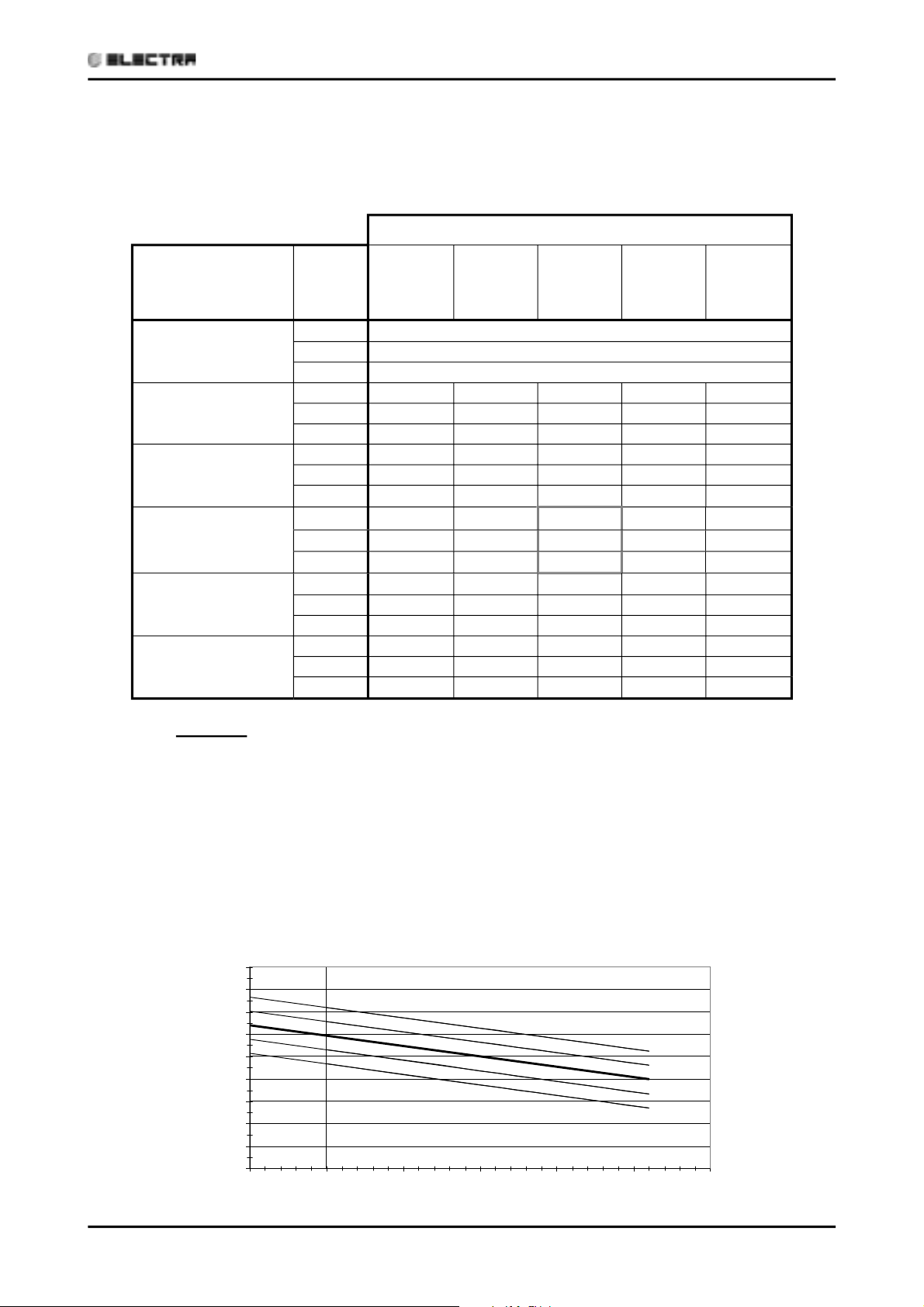

5.3 WNG 9 DCI

- -

5.3.1 Cooling Capacity Factors - Unit A,B,C or D

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB/WB TEMPERATURE [ºC]

OD COIL

ENTERING AIR DB

TEMPERA

TURE

[ºC]

-10 - 20

(protection range)

25 SC 1.01 1.03 1.05 1.07 1.09

30

35

40

46

DATA

TC

SC

PI

TC 0.97 1.03 1.09 1.16 1.22

PI 0.79 0.80 0.82 0.83 0.85

TC 0.92 0.98 1.05 1.11 1.17

SC 0.98 1.00 1.03 1.05 1.07

PI 0.88 0.89

TC 0.87 0.94

SC 0.96 0.98 1.00 1.02 1.04

PI 0.97 0.99

TC 0.83 0.89

SC 0.93 0.95 0.97 1.00 1.02

PI 1.06 1.08 1.09 1.11 1.12

TC 0.77 0.83 0.90 0.96 1.02

SC 0.90 0.92 0.94 0.96 0.99

PI 1.17 1.19 1.20 1.22 1.23

22/15 24/17 27/19 29/21 32/23

80 - 110 % of nominal

80 - 105 % of nominal

25 - 50 % of nominal

0.91

1.00

1.00

0.95

0.92 0.94

1.06 1.13

1.02 1.03

1.02 1.08

LEGEND

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

DB – Dry Bulb Temp., (

o

o

C)

C)

ID – Indoor

OD – Outdoor

5.3.2 Capacity Correction Factors

1.4

1.3

1.2

1.1

1.0

0.9

Capa ci t y Rat io

0.8

0.7

0.6

0.5

20 25 30 35 40 45 50

Outdoor Temperature [ deg C]

32/23

29/21

27/19

24/17

22/15

Revision 0 5-5

Page 22

PERFORMANCE DATA

5.5.3 Heating Capacity Factors - Unit A,B,C or D

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [ºC]

OD COIL

ENTERING

AIR DB/WB DATA 15 20 25

TEMPERATURE

[ºC]

-15/-16

-10/-12

-7/-8

-1/-2

2/1

7/6

10/9

15/12

15-24

(Protection Range)

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

0.64

0.60

0.71

0.72

0.76

0.82

0.79

0.86

0.81

0.89

1.04

0.94

1.10

1.00

1.16

1.05

0.59

0.66

0.66

0.78

0.72

0.88

0.75

0.92

0.76

0.95

1.00

1.00

1.06

1.06

1.12

1

1.1

0.55

0.72

0.62

0.85

0.67

0.94

0.70

0.98

0.72

1.01

0.96

1.06

1.01

1.12

1.07

1.17

LEGEND

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

DB – Dry Bulb Temp., (

o

o

C)

C)

ID – Indoor

OD – Outdoor

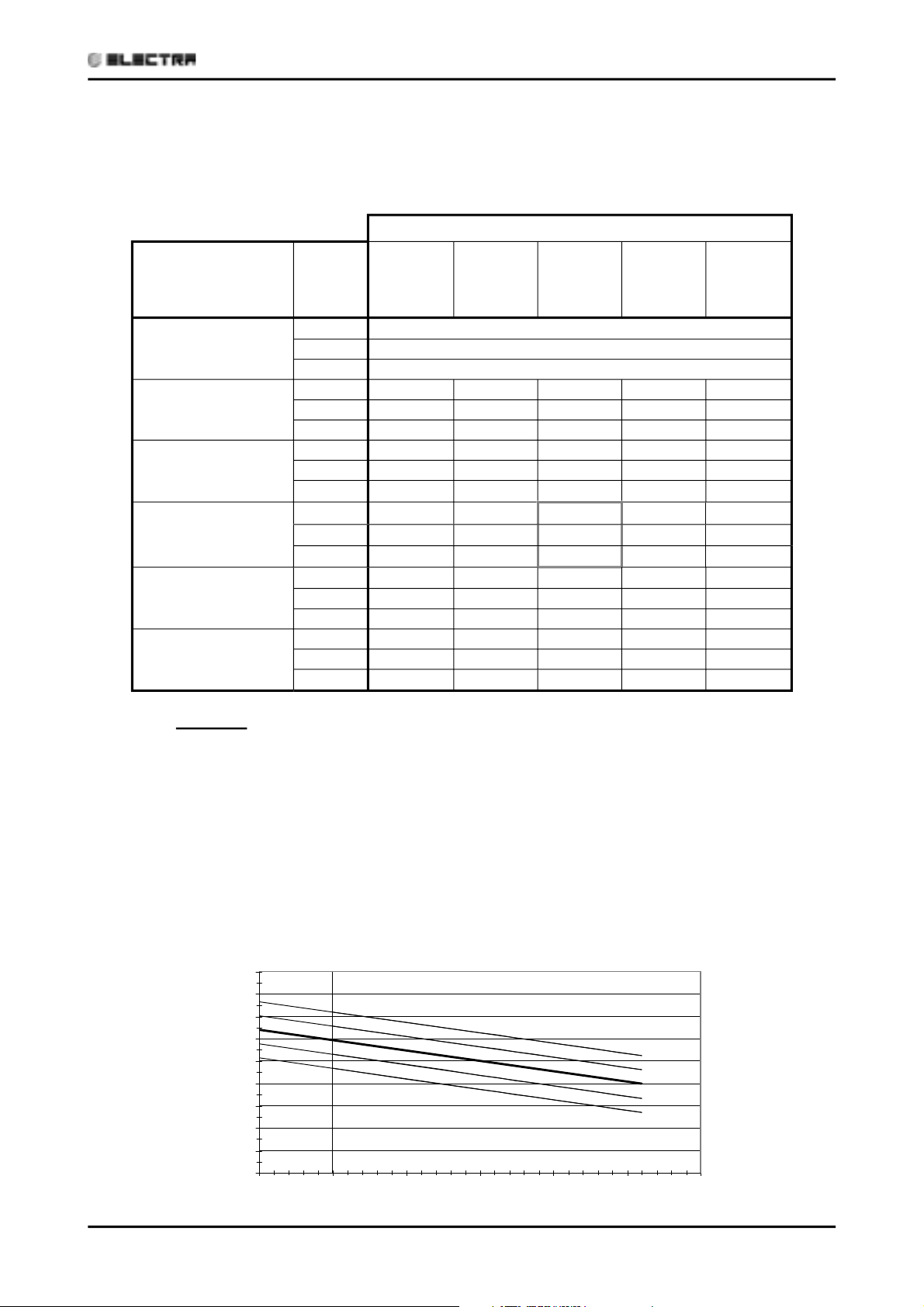

5.5.4 Capacity Correction Factors

1.3

1.2

1.1

1.0

0.9

0.8

0.7

Capa ci ty Rat io

0.6

0.5

0.4

0.3

-20 -15 -10 -5 0 5 10 15

Outdoor WB Temperature [deg C]

15

20

25

5-6

Revision 0

Page 23

PERFORMANCE DATA

5.4 WNG 12 DCI

-

5.4.1 Cooling Capacity Factors - Unit A,B,C or D

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB/WB TEMPERATURE [ºC]

OD COIL

ENTERING AIR DB DATA

TEMPERATURE [ºC]

-10 - 20

(protection range)

TC

SC

PI

TC 0.97 1.03 1.09 1.16 1.22

25 SC 1.01 1.03 1.05 1.07 1.09

PI 0.79 0.80 0.82 0.83 0.85

TC 0.92 0.98 1.05 1.11 1.17

30

SC 0.98 1.00 1.03 1.05 1.07

PI 0.88 0.89

TC 0.87 0.94

35

SC 0.96 0.98 1.00 1.02 1.04

PI 0.97 0.99

TC 0.83 0.89

40

SC 0.93 0.95 0.97 1.00 1.02

PI 1.06 1.08 1.09 1.11 1.12

TC 0.77 0.83 0.90 0.96 1.02

46

SC 0.90 0.92 0.94 0.96 0.99

PI 1.17 1.19 1.20 1.22 1.23

22/15 24/17 27/19 29/21 32/23

80 - 110 % of nominal

80 - 105 % of nominal

25 - 50 % of nominal

0.91

1.00

1.00

0.95

0.92 0.94

1.06 1.13

1.02 1.03

1.02 1.08

LEGEND

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

5.4.2 Capacity Correction Factors

1.4

1.3

1.2

1.1

io

1.0

0.9

Capaci ty Rat

0.8

0.7

0.6

0.5

20 25 30 35 40 45 50

Outdoor Temperature [ deg C]

32/23

29/21

27/19

24/17

22/15

Revision 0 5-7

Page 24

PERFORMANCE DATA

5.4.3 Heating Capacity Factors - Unit A,B,C or D

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [ºC]

OD COIL

ENTERING

AIR DB/WB DATA 15 20 25

TEMPERATURE

[ºC]

-15/-16

-10/-12

-7/-8

-1/-2

2/1

7/6

10/9

15/12

15-24

(Protection Range)

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

0.64

0.60

0.71

0.72

0.76

0.82

0.79

0.86

0.81

0.89

1.04

0.94

1.10

1.00

1.16

1.05

0.59

0.66

0.66

0.78

0.72

0.88

0.75

0.92

0.76

0.95

1.00

1.00

1.06

1.06

1.12

1

1.1

0.55

0.72

0.62

0.85

0.67

0.94

0.70

0.98

0.72

1.01

0.96

1.06

1.01

1.12

1.07

1.17

LEGEND

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

5.4.4 Capacity Correction Factors

1.3

1.2

1.1

1.0

0.9

0.8

0.7

Capa ci ty Rat io

0.6

0.5

0.4

0.3

-20 -15 -10 -5 0 5 10 15

Outdoor WB Temperature [deg C]

15

20

25

5-8

Revision 0

Page 25

PERFORMANCE DATA

5.5 WNG 18 DCI

-

5.5.1 Cooling Capacity Factors - Unit D

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB/WB TEMPERATURE [ºC]

OD COIL

ENTERING AIR DB DATA

TEMPERATURE [ºC]

-10 - 20

(protection range)

TC

SC

PI

TC 0.99 1.04 1.10 1.16 1.22

25 SC 1.05 1.07 1.08 1.10 1.11

PI 0.76 0.77 0.79 0.81 0.82

TC 0.93 0.99 1.05 1.11 1.17

30

SC 1.01 1.03 1.04 1.06 1.07

PI 0.86 0.88

TC 0.88 0.94

35

SC 0.97 0.98 1.00 1.02 1.03

PI 0.97 0.98

TC 0.83 0.89

40

SC 0.93 0.94 0.96 0.97 0.99

PI 1.07 1.09 1.11 1.12 1.14

TC 0.77 0.83 0.89 0.95 1.00

46

SC 0.88 0.89 0.91 0.93 0.94

PI 1.20 1.21 1.23 1.25 1.27

22/15 24/17 27/19 29/21 32/23

80 - 110 % of nominal

80 - 105 % of nominal

25 - 50 % of nominal

0.90

1.00

1.00

0.95

0.91 0.93

1.06 1.12

1.02 1.03

1.01 1.07

LEGEND

TC – Total Cooling Capacity, kW

SC – Sensible Capacity, kW

PI – Power Input, kW

o

WB – Wet Bulb Temp., (

DB – Dry Bulb Temp., (

o

C)

C)

ID – Indoor

OD – Outdoo

r

5.5.2 Capacity Correction Facto

1.4

1.3

1.2

1.1

1.0

0.9

Capacit y Rat i o

0.8

0.7

0.6

0.5

20 25 30 35 40 45 50

Outdoor Temperature [deg C]

32/23

29/21

27/19

24/17

22/15

Revision 0 5-9

Page 26

PERFORMANCE DATA

5.5.3 Heating Capacity Factors - Unit D

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [ºC]

OD COIL

ENTERING

AIR DB/WB DATA 15 20 25

TEMPERATURE

[ºC]

-15/-16

-10/-12

-7/-8

-1/-2

2/1

7/6

10/9

15/12

15-24

(Protection Range)

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

0.46

0.70

0.60

0.79

0.71

0.86

0.76

0.89

0.80

0.92

1.07

0.95

1.12

0.97

1.18

0.99

0.39

0.75

0.54

0.84

0.64

0.91

0.70

0.94

0.74

0.97

1.00

1.00

1.06

1.02

1.11

1.04

0.32

0.80

0.47

0.89

0.58

0.96

0.63

0.99

0.67

1.02

0.93

1.05

0.99

1.07

1.04

1.09

LEGEND

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

5.5.4 Capacity Correction Factors

1.3

1.2

1.1

1.0

0.9

0.8

0.7

Capac it y Ra ti o

0.6

0.5

0.4

0.3

-20 -15 -10 -5 0 5 10 15

Outdoor W B Tem perature [deg C]

15

20

25

5-10

Revision 0

Page 27

PERFORMANCE DATA

5.6 ECF 9 DCI

-

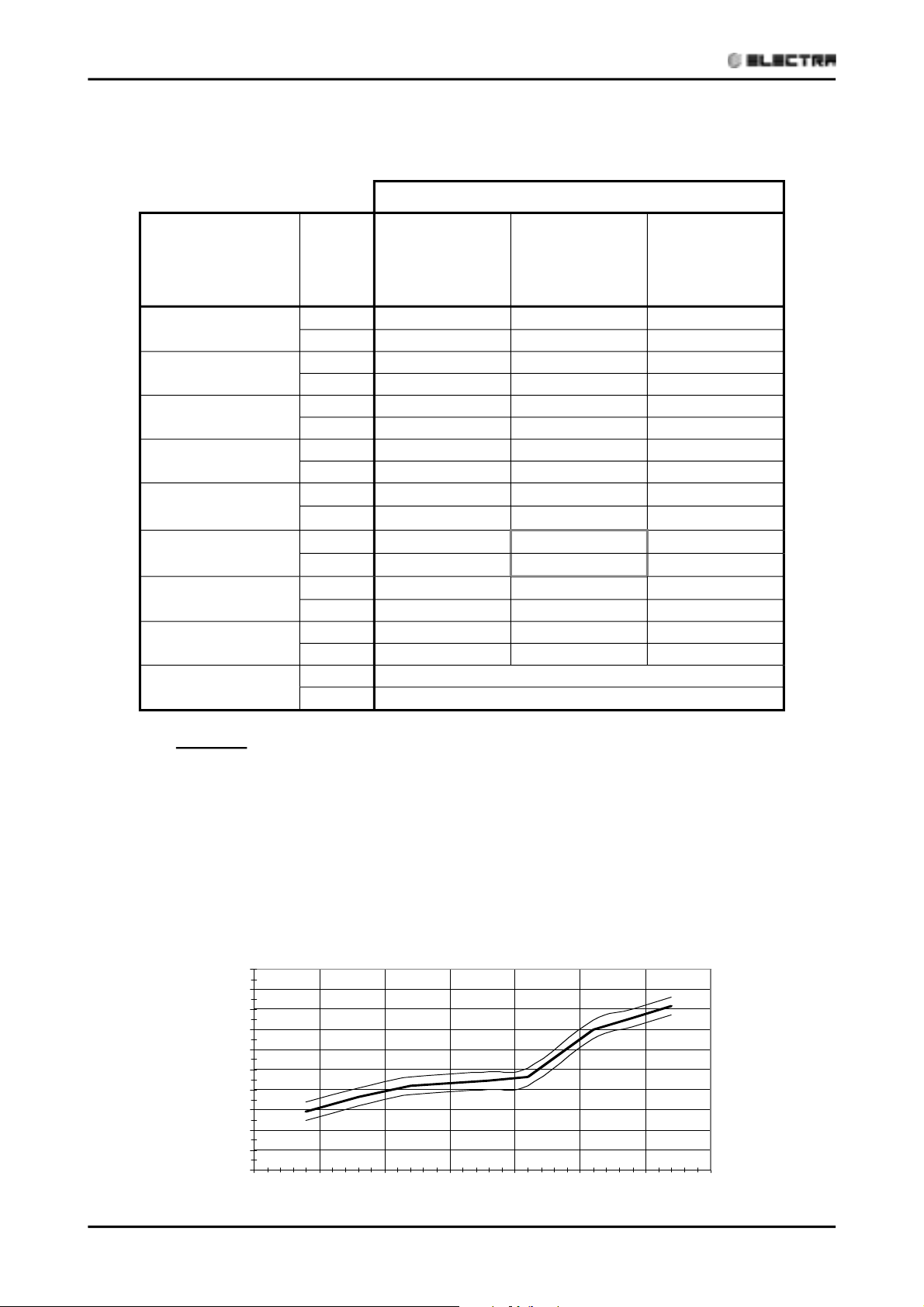

5.6.1 Cooling Capacity Factors - Unit A,B,C or D

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB/WB TEMPERATURE [ºC]

OD COIL

ENTERING AIR DB

TEMPERA

TURE

[ºC]

-10 - 20

(protection range)

25 SC 1.01 1.03 1.05 1.07 1.09

30

35

40

46

DATA

TC

SC

PI

TC 0.97 1.03 1.09 1.16 1.22

PI 0.79 0.80 0.82 0.83 0.85

TC 0.92 0.98 1.05 1.11 1.17

SC 0.98 1.00 1.03 1.05 1.07

PI 0.88 0.89

TC 0.87 0.94

SC 0.96 0.98 1.00 1.02 1.04

PI 0.97 0.99

TC 0.83 0.89

SC 0.93 0.95 0.97 1.00 1.02

PI 1.06 1.08 1.09 1.11 1.12

TC 0.77 0.83 0.90 0.96 1.02

SC 0.90 0.92 0.94 0.96 0.99

PI 1.17 1.19 1.20 1.22 1.23

22/15 24/17 27/19 29/21 32/23

80 - 110 % of nominal

80 - 105 % of nominal

25 - 50 % of nominal

0.91

1.00

1.00

0.95

0.92 0.94

1.06 1.13

1.02 1.03

1.02 1.08

LEGEND

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

5.6.2 Capacity Correction Factors

1.4

1.3

1.2

1.1

1.0

i io

0.9

Capa c t y Rat

0.8

0.7

0.6

0.5

20 25 30 35 40 45 50

Outdoor Temperature [deg C]

32/23

29/21

27/19

24/17

22/15

Revision 0 5-11

Page 28

PERFORMANCE DATA

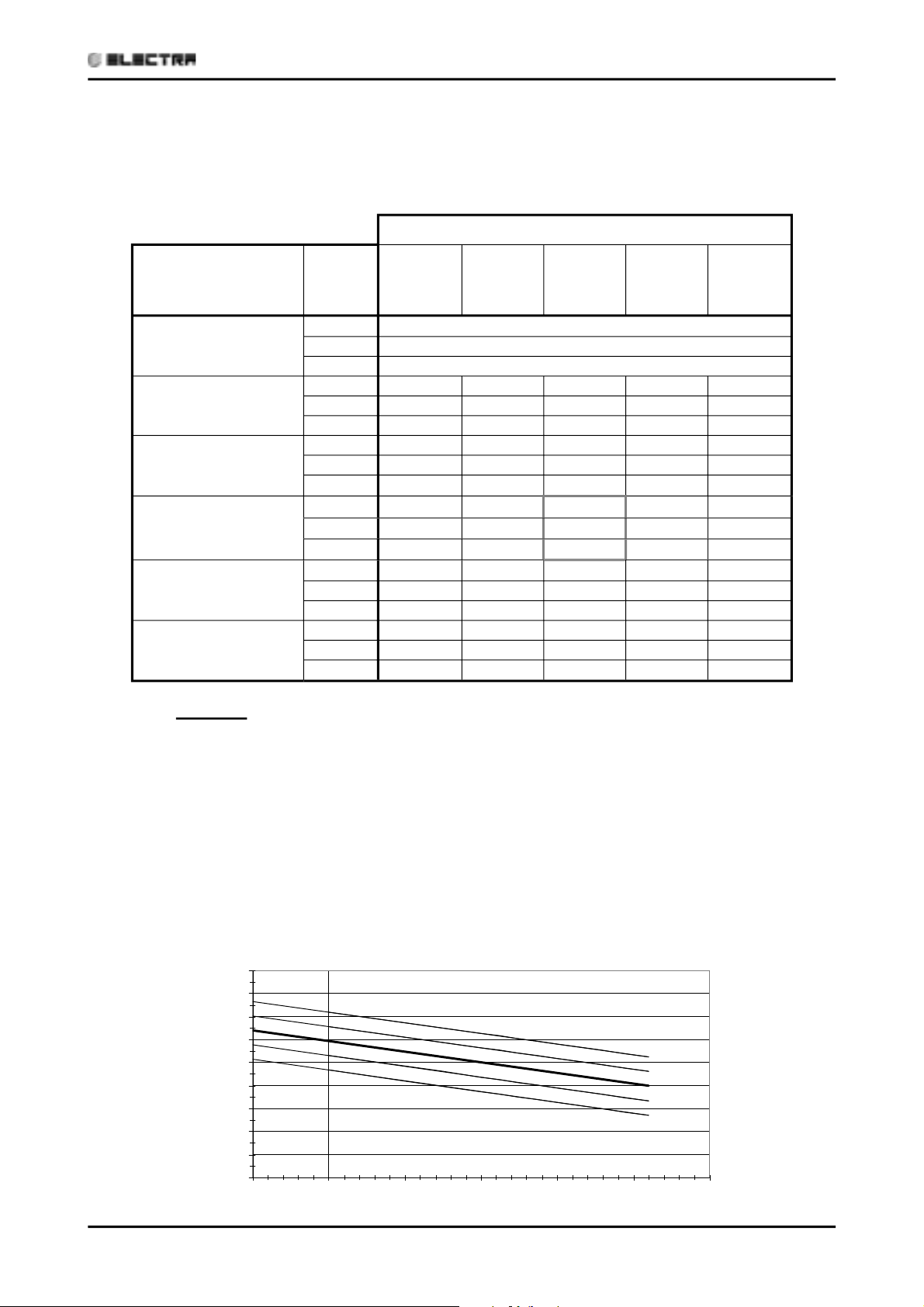

5.6.3 Heating Capacity Factors - Unit A,B,C or D

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [ºC]

OD COIL

ENTERING

AIR DB/WB DATA 15 20 25

TEMPERATURE

[ºC]

-15/-16

-10/-12

-7/-8

-1/-2

2/1

7/6

10/9

15/12

15-24

(Protection Range)

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

0.64

0.60

0.71

0.72

0.76

0.82

0.79

0.86

0.81

0.89

1.04

0.94

1.10

1.00

1.16

1.05

0.59

0.66

0.66

0.78

0.72

0.88

0.75

0.92

0.76

0.95

1.00

1.00

1.06

1.06

1.12

1

1.1

0.55

0.72

0.62

0.85

0.67

0.94

0.70

0.98

0.72

1.01

0.96

1.06

1.01

1.12

1.07

1.17

LEGEND

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (oC)

ID – Indoor

5.6.4 Capacity Correction Factors

1.3

1.2

1.1

1.0

0.9

0.8

0.7

Capa ci ty Rati o

0.6

0.5

0.4

0.3

-20 -15 -10 -5 0 5 10 15

Outdoor WB Temperature [deg C]

15

20

25

5-12

Revision 0

Page 29

PERFORMANCE DATA

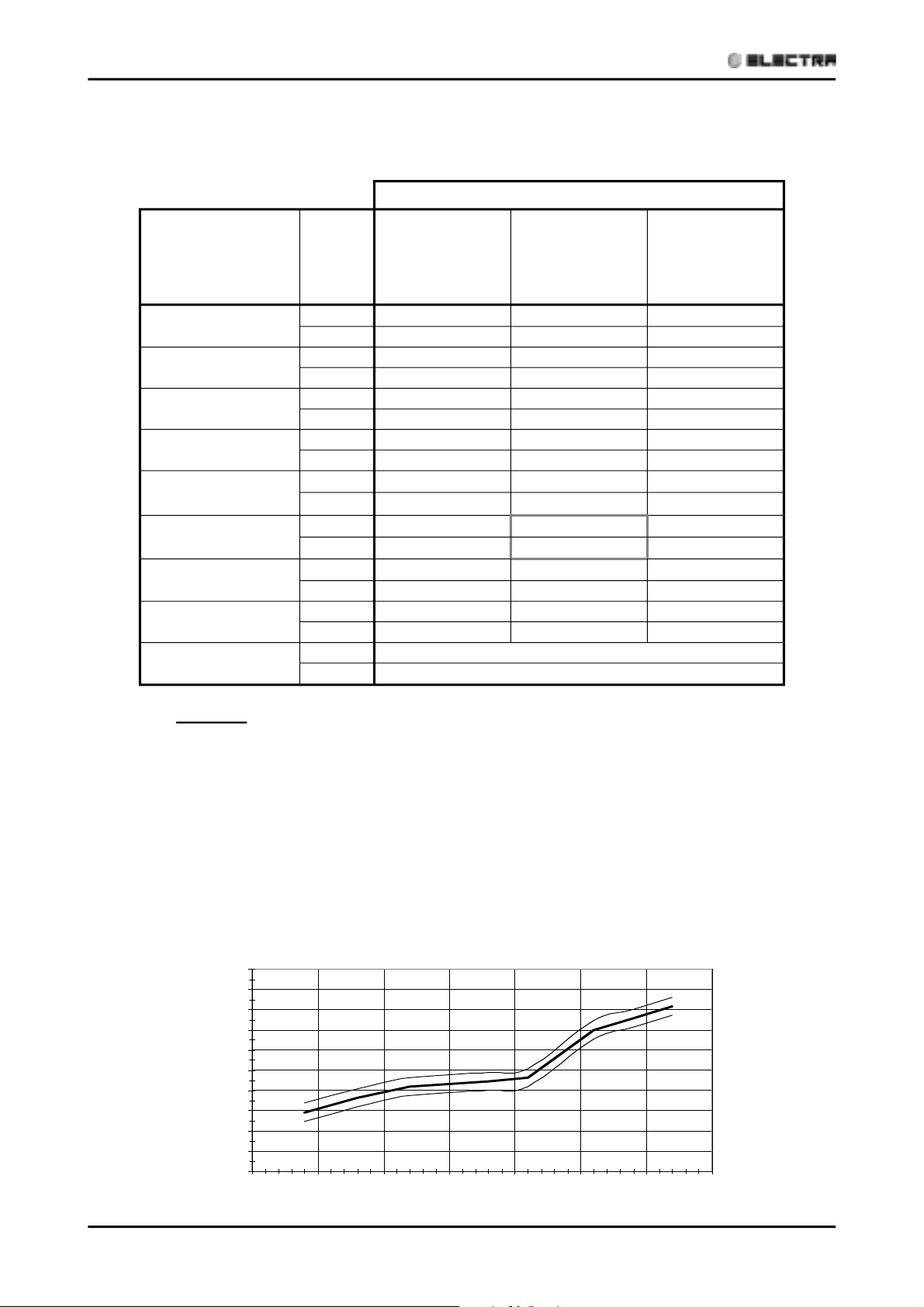

5.7 ECF 12 DCI

-

5.7.1 Cooling Capacity Factors - Run Mode (Unit A,B,C or D)

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB/WB TEMPERATURE [ºC]

OD COIL

ENTERING AIR DB

TEMPERA

TURE

[ºC]

-10 - 20

(protection range)

25 SC 1.01 1.03 1.05 1.07 1.09

30

35

40

46

DATA

TC

SC

PI

TC 0.97 1.03 1.09 1.16 1.22

PI 0.79 0.80 0.82 0.83 0.85

TC 0.92 0.98 1.05 1.11 1.17

SC 0.98 1.00 1.03 1.05 1.07

PI 0.88 0.89

TC 0.87 0.94

SC 0.96 0.98 1.00 1.02 1.04

PI 0.97 0.99

TC 0.83 0.89

SC 0.93 0.95 0.97 1.00 1.02

PI 1.06 1.08 1.09 1.11 1.12

TC 0.77 0.83 0.90 0.96 1.02

SC 0.90 0.92 0.94 0.96 0.99

PI 1.17 1.19 1.20 1.22 1.23

22/15 24/17 27/19 29/21 32/23

80 - 110 % of nominal

80 - 105 % of nominal

25 - 50 % of nominal

0.91

1.00

1.00

0.95

0.92 0.94

1.06 1.13

1.02 1.03

1.02 1.08

LEGEND

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

5.7.2 Capacity Correction Factors

1.4

1.3

1.2

1.1

1.0

i io

0.9

Capac ty Rat

0.8

0.7

0.6

0.5

20 25 30 35 40 45 50

Outdoor Temperature [deg C]

32/23

29/21

27/19

24/17

22/15

Revision 0 5-13

Page 30

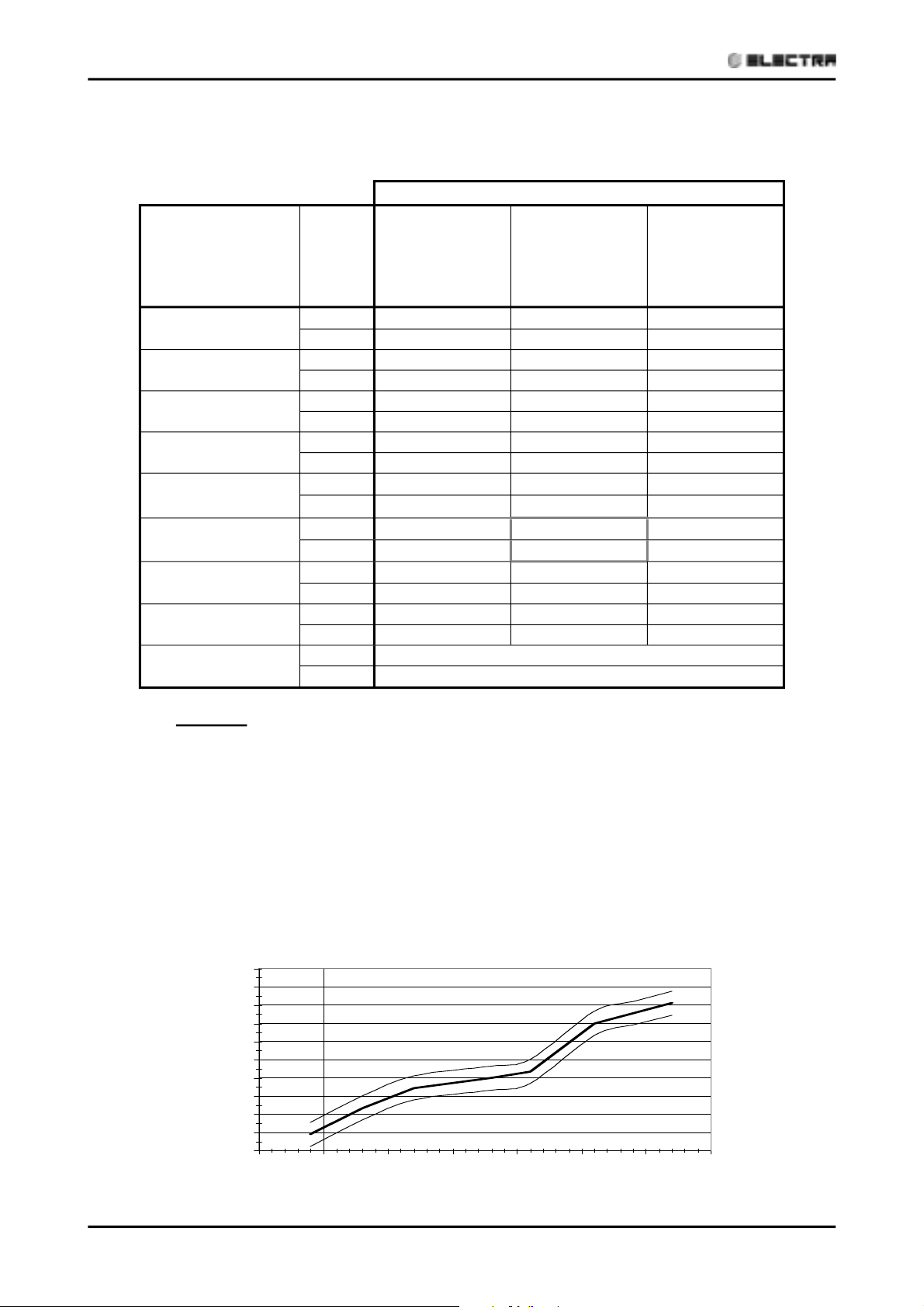

PERFORMANCE DATA

5.7.3 Heating Capacity Factors - Unit A,B,C or D

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [ºC]

OD COIL

ENTERING AIR DB/

WB TEMPERA

TURE

[ºC]

DATA 15 20 25

-15/-16

-10/-12

-7/-8

-1/-2

2/1

7/6

10/9

15/12

15-24

(Protection Range)

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

LEGEND

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (

o

C)

ID – Indoor

OD – Outdoor

0.64

0.60

0.71

0.72

0.76

0.82

0.79

0.86

0.81

0.89

1.04

0.94

1.10

1.00

1.16

1.05

0.59

0.66

0.66

0.78

0.72

0.88

0.75

0.92

0.76

0.95

1.00

1.00

1.06

1.06

1.12

1.1

1

0.55

0.72

0.62

0.85

0.67

0.94

0.70

0.98

0.72

1.01

0.96

1.06

1.01

1.12

1.07

1.17

5.7.4 Capacity Correction Factors

1.3

1.2

1.1

1.0

0.9

0.8

0.7

Capa ci ty Rat io

0.6

0.5

0.4

0.3

-20 -15 -10 -5 0 5 10 15

5-14

Outdoor WB Temperature [deg C]

Revision 0

15

20

25

Page 31

PERFORMANCE DATA

5.8 ECF 18 DCI

-

5.8.1 Cooling Capacity Factor - Unit D

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB/WB TEMPERATURE [ºC]

OD COIL

ENTERING AIR DB DATA

TEMPERATURE [ºC]

-10 - 20

(protection range)

TC

SC

PI

TC 0.99 1.04 1.10 1.16 1.22

25 SC 1.05 1.07 1.08 1.10 1.11

PI 0.76 0.77 0.79 0.81 0.82

TC 0.93 0.99 1.05 1.11 1.17

30

SC 1.01 1.03 1.04 1.06 1.07

PI 0.86 0.88

TC 0.88 0.94

35

SC 0.97 0.98 1.00 1.02 1.03

PI 0.97 0.98

TC 0.83 0.89

40

SC 0.93 0.94 0.96 0.97 0.99

PI 1.07 1.09 1.11 1.12 1.14

TC 0.77 0.83 0.89 0.95 1.00

46

SC 0.88 0.89 0.91 0.93 0.94

PI 1.20 1.21 1.23 1.25 1.27

22/15 24/17 27/19 29/21 32/23

80 - 110 % of nominal

80 - 105 % of nominal

25 - 50 % of nominal

0.90

1.00

1.00

0.95

0.91 0.93

1.06 1.12

1.02 1.03

1.01 1.07

LEGEND

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

5.8.2 Capacity Correction Factors

1.4

1.3

1.2

1.1

1.0

i io

0.9

Capa c t y Rat

0.8

0.7

0.6

0.5

20 25 30 35 40 45 50

Outdoor Temperature [deg C]

32/23

29/21

27/19

24/17

22/15

Revision 0 5-15

Page 32

PERFORMANCE DATA

5.8.3 Heating Capacity Factor - Unit D

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [ºC]

OD COIL ENTERING

AIR DB/WB DATA 15 20 25

TEMPERATURE [ºC]

-15/-16

-10/-12

-7/-8

-1/-2

2/1

7/6

10/9

15/12

15-24

(Protection Range)

LEGEND

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

0.46

0.70

0.60

0.79

0.71

0.86

0.76

0.89

0.80

0.92

1.07

0.95

1.12

0.97

1.18

0.99

0.39

0.75

0.54

0.84

0.64

0.91

0.70

0.94

0.74

0.97

1.00

1.00

1.06

1.02

1.11

1.04

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

0.32

0.80

0.47

0.89

0.58

0.96

0.63

0.99

0.67

1.02

0.93

1.05

0.99

1.07

1.04

1.09

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

5.8.4 Capacity Correction Factors

1.3

1.2

1.1

1.0

0.9

0.8

0.7

apacity Ratio

C

0.6

0.5

0.4

0.3

-20 -15 -10 -5 0 5 10 15

Outdoor W B Temperature [deg C]

15

20

25

5-16

Revision 0

Page 33

PERFORMANCE DATA

5.9 PXD 9 DCI

-

5.9.1 Cooling Capacity Factors - Unit A,B,C or D

230[V] : Indoor Fan at High Speed

ID COIL ENTERING AIR DB/WB TEMPERATURE [ºC]

OD COIL

ENTERING AIR DB DATA

TEMPERATURE [ºC]

-10 - 20

(protection range)

TC

SC

PI

TC 0.97 1.03 1.09 1.16 1.22

25 SC 1.01 1.03 1.05 1.07 1.09

PI 0.79 0.80 0.82 0.83 0.85

TC 0.92 0.98 1.05 1.11 1.17

30

SC 0.98 1.00 1.03 1.05 1.07

PI 0.88 0.89

TC 0.87 0.94

35

SC 0.96 0.98 1.00 1.02 1.04

PI 0.97 0.99

TC 0.83 0.89

40

SC 0.93 0.95 0.97 1.00 1.02

PI 1.06 1.08 1.09 1.11 1.12

TC 0.77 0.83 0.90 0.96 1.02

46

SC 0.90 0.92 0.94 0.96 0.99

PI 1.17 1.19 1.20 1.22 1.23

22/15 24/17 27/19 29/21 32/23

80 - 110 % of nominal

80 - 105 % of nominal

25 - 50 % of nominal

0.91

1.00

1.00

0.95

0.92 0.94

1.06 1.13

1.02 1.03

1.02 1.08

LEGEND

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

5.9.2 Capacity Correction Factors

1.4

1.3

1.2

1.1

1.0

0.9

Capa ci t y Ra ti o

0.8

0.7

0.6

0.5

20 25 30 35 40 45 50

Outdoor Temperature [deg C]

32/23

29/21

27/19

24/17

22/15

Revision 0 5-17

Page 34

PERFORMANCE DATA

5.9.3 Heating Capacity Factors - Unit A,B,C or D

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [ºC]

OD COIL

ENTERING AIR DB/

WB TEMPERA

TURE

[ºC]

DATA 15 20 25

-15/-16

-10/-12

-7/-8

-1/-2

2/1

7/6

10/9

15/12

15-24

(Protection Range)

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

LEGEND

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

DB – Dry Bulb Temp., (

ID – Indoor

OD – Outdoor

o

o

C)

C)

0.64

0.60

0.71

0.72

0.76

0.82

0.79

0.86

0.81

0.89

1.04

0.94

1.10

1.00

1.16

1.05

0.59

0.66

0.66

0.78

0.72

0.88

0.75

0.92

0.76

0.95

1.00

1.00

1.06

1.06

1.12

1.1

1

0.55

0.72

0.62

0.85

0.67

0.94

0.70

0.98

0.72

1.01

0.96

1.06

1.01

1.12

1.07

1.17

5.9.4 Capacity Correction Factors

1.3

1.2

1.1

1.0

o

0.9

0.8

0.7

Capacity Rati

0.6

0.5

0.4

0.3

-20 -15 -10 -5 0 5 10 15

5-18

Outdoor WB Temperature [deg C]

Revision 0

15

20

25

Page 35

PERFORMANCE DATA

5.10 PXD 12 DCI

-

5.10.1 Cooling Capacity Factors - Run Mode (Unit A,B,C or D)

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB/WB TEMPERATURE [ºC]

OD COIL

ENTERING AIR DB DATA

TEMPERATURE [ºC]

-10 - 20

(protection range)

TC

SC

PI

TC 0.97 1.03 1.09 1.16 1.22

25 SC 1.01 1.03 1.05 1.07 1.09

PI 0.79 0.80 0.82 0.83 0.85

TC 0.92 0.98 1.05 1.11 1.17

30

SC 0.98 1.00 1.03 1.05 1.07

PI 0.88 0.89

TC 0.87 0.94

35

SC 0.96 0.98 1.00 1.02 1.04

PI 0.97 0.99

TC 0.83 0.89

40

SC 0.93 0.95 0.97 1.00 1.02

PI 1.06 1.08 1.09 1.11 1.12

TC 0.77 0.83 0.90 0.96 1.02

46

SC 0.90 0.92 0.94 0.96 0.99

PI 1.17 1.19 1.20 1.22 1.23

22/15 24/17 27/19 29/21 32/23

80 - 110 % of nominal

80 - 105 % of nominal

25 - 50 % of nominal

0.91

1.00

1.00

0.95

0.92 0.94

1.06 1.13

1.02 1.03

1.02 1.08

LEGEND

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (

o

C)

ID – Indoor

OD – Outdoor

5.10.2 Capacity Correction Factors

1.4

1.3

1.2

1.1

1.0

0.9

Capacit y Rati o

0.8

0.7

0.6

0.5

20 25 30 35 40 45 50

Outdoor Temperature [deg C]

32/

29/

27/

24/

22/

23

21

19

17

15

Revision 0 5-19

Page 36

PERFORMANCE DATA

5.10.3 Heating Capacity Factors - Unit A,B,C or D

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [ºC]

OD COIL

ENTERING AIR DB/

WB TEMPERA

TURE

[ºC]

-15/-16

-10/-12

-7/-8

-1/-2

2/1

7/6

10/9

15/12

15-24

(Protection Range)

DATA 15 20 25

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

0.64

0.60

0.71

0.72

0.76

0.82

0.79

0.86

0.81

0.89

1.04

0.94

1.10

1.00

1.16

1.05

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

0.59

0.66

0.66

0.78

0.72

0.88

0.75

0.92

0.76

0.95

1.00

1.00

1.06

1.06

1.12

1

1.1

0.55

0.72

0.62

0.85

0.67

0.94

0.70

0.98

0.72

1.01

0.96

1.06

1.01

1.12

1.07

1.17

LEGEND

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

5.10.4 Capacity Correction Factors

1.3

1.2

1.1

1.0

0.9

0.8

0.7

Capac ity Ra tio

0.6

0.5

0.4

0.3

-20 -1 5 -10 -5 0 5 10 1 5

Outdoor WB Temperature [deg C]

15

20

25

5-20

Revision 0

Page 37

PERFORMANCE DATA

5.11 PXD 18 DCI

-

5.11.1 Cooling Capacity Factor - Unit D

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB/WB TEMPERATURE [ºC]

OD COIL

ENTERING AIR DB DATA

TEMPERATURE [ºC]

-10 - 20

(protection range)

TC

SC

PI

TC 0.99 1.04 1.10 1.16 1.22

25 SC 1.05 1.07 1.08 1.10 1.11

PI 0.76 0.77 0.79 0.81 0.82

TC 0.93 0.99 1.05 1.11 1.17

30

SC 1.01 1.03 1.04 1.06 1.07

PI 0.86 0.88

TC 0.88 0.94

35

SC 0.97 0.98 1.00 1.02 1.03

PI 0.97 0.98

TC 0.83 0.89

40

SC 0.93 0.94 0.96 0.97 0.99

PI 1.07 1.09 1.11 1.12 1.14

TC 0.77 0.83 0.89 0.95 1.00

46

SC 0.88 0.89 0.91 0.93 0.94

PI 1.20 1.21 1.23 1.25 1.27

22/15 24/17 27/19 29/21 32/23

80 - 110 % of nominal

80 - 105 % of nominal

25 - 50 % of nominal

0.90

1.00

1.00

0.95

0.91 0.93

1.06 1.12

1.02 1.03

1.01 1.07

LEGEND

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

5.11.2 Capacity Correction Factors

1.4

1.3

1.2

1.1

1.0

i

0.9

Capa c t y Rat i o

0.8

0.7

0.6

0.5

20 25 30 35 40 45 50

Outdoor Temperature [deg C]

32/23

29/21

27/19

24/17

22/15

Revision 0 5-21

Page 38

PERFORMANCE DATA

5.11.3 Heating Capacity Factor - Unit D

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [ºC]

OD COIL

ENTERING AIR DB/

WB TEMPERA

TURE

[ºC]

-15/-16

-10/-12

-7/-8

-1/-2

2/1

7/6

10/9

15/12

15-24

(Protection Range)

DATA 15 20 25

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

0.46

0.70

0.60

0.79

0.71

0.86

0.76

0.89

0.80

0.92

1.07

0.95

1.12

0.97

1.18

0.99

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

0.39

0.75

0.54

0.84

0.64

0.91

0.70

0.94

0.74

0.97

1.00

1.00

1.06

1.02

1.11

1.04

0.32

0.80

0.47

0.89

0.58

0.96

0.63

0.99

0.67

1.02

0.93

1.05

0.99

1.07

1.04

1.09

LEGEND

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

5.11.4 Capacity Correction Factors

1.3

1.2

1.1

1.0

0.9

0.8

0.7

Capacity Ratio

0.6

0.5

0.4

0.3

-20 -15 -10 -5 0 5 1 0 15

Outdoor WB Temperature [deg C]

15

20

25

5-22

Revision 0

Page 39

PERFORMANCE DATA

5.12 LS 35 DCI

5.12.1 Cooling Capacity Factors - Run Mode (Unit A,B,C or D)

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB/WB TEMPERATURE [ºC]

OD COIL

ENTERING AIR DB DATA

TEMPERATURE [ºC]

22/15 24/17 27/19 29/21 32/23

-10 - 20

(protection range)

TC

SC

PI

TC 0.97 1.03 1.09 1.16 1.22

25 SC 1.01 1.03 1.05 1.07 1.09

PI 0.79 0.80 0.82 0.83 0.85

TC 0.92 0.98 1.05 1.11 1.17

30

SC 0.98 1.00 1.03 1.05 1.07

PI 0.88 0.89

TC 0.87 0.94

35

SC 0.96 0.98 1.00 1.02 1.04

PI 0.97 0.99

TC 0.83 0.89

40

SC 0.93 0.95 0.97 1.00 1.02

PI 1.06 1.08 1.09 1.11 1.12

TC 0.77 0.83 0.90 0.96 1.02

46

SC 0.90 0.92 0.94 0.96 0.99

PI 1.17 1.19 1.20 1.22 1.23

LEGEND

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

o

C)

80 - 110 % of nominal

80 - 105 % of nominal

25 - 50 % of nominal

0.91

1.00

1.00

0.95

0.92 0.94

1.06 1.13

1.02 1.03

1.02 1.08

5.12.2 Capacity Correction Factors

1.4

1.3

1.2

1.1

1.0

0.9

Capa ci t y Rat i o

0.8

0.7

0.6

0.5

20 25 30 35 40 45 50

Outdoor Temperature [deg C]

Revision 0 5-23

32/23

29/21

27/19

24/17

22/15

Page 40

PERFORMANCE DATA

5.12.3 Heating Capacity Factors - Unit A,B,C or D

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [ºC]

OD COIL ENTERING

AIR DB/WB DATA 15 20 25

TEMPERATURE [ºC]

-15/-16

-10/-12

-7/-8

-1/-2

2/1

7/6

10/9

15/12

15-24

(Protection Range)

LEGEND

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

0.64

0.60

0.71

0.72

0.76

0.82

0.79

0.86

0.81

0.89

1.04

0.94

1.10

1.00

1.16

1.05

0.59

0.66

0.66

0.78

0.72

0.88

0.75

0.92

0.76

0.95

1.00

1.00

1.06

1.06

1.12

1

1.1

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

0.55

0.72

0.62

0.85

0.67

0.94

0.70

0.98

0.72

1.01

0.96

1.06

1.01

1.12

1.07

1.17

TC – Total Cooling Capacity, kW

SC –

Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (

o

C)

ID – Indoor

OD – Outdoor

5.12.4 Capacity Correction Factors

1.3

1.2

1.1

1.0

0.9

0.8

0.7

Capacity Ratio

0.6

0.5

0.4

0.3

-20 -15 -10 -5 0 5 10 15

Outdoor WB Temperature [deg C]

15

20

25

5-24

Revision 0

Page 41

PERFORMANCE DATA

5.13 Tubing Length Capacity Correction Factor (FT) - one way

5.13.1 Cooling

Tubing Length Capacity Ratio - Cooling (1 Unit)

1.06

1.01

0.96

0.91

0.86

Capacity Ratio

0.81

0.76

0 5

10 15 20 25 30

Tubing Length [m]

5.13.2 Heating

1.06

1.01

0.96

0.91

0.86

Capacity Ratio

0.81

0.76

0 5

Tubing Length Capacity Ratio - Heating (1 Unit)

10 15 20 25 30

Tubing Length [m]

Revision 0 5-25

Page 42

PERFORMANCE DATA

5.14 Model Correction Factors (FM)

Model

Capacity Power input

Cooling Heating Cooling Heating

WNG DCI

K DCI

ECF DCI

PXD DCI

PXD DCI

LS DCI

LS DCI

1.00 1.00 1.00 1.00

1.03 1.07 1.01 1.10

TBD TBD TBD TBD

TBD TBD TBD TBD

15.15 Calculation Example

Outdoor Unit

Indoor Combination

Operation Mode

Conditions Indoor

Conditions Oudoor

Tubing length

Cooling Capacity calculation:

C

[KW] = Nominal x FM x F x F

A-D

Total System Capacity [KW] (TC) = C

Quattro DCI

WNG9+WNG12+ECF12+WNG18

Cooling Mode

22°CDB/15°WB

30°CDB

20m+10m+5m+25m

TC

+ C + CC + C

A

B D

Nom’ Cooling

Indoor Unit

Capacity

[KW]

Room A – WNG9 1.43 1.00 0.92 0.95 CA = 1.43x1.00x0.92x0.95=1.25

Room B – WNG12 1.91 1.00 0.92 0.985 C

Room C – ECF12 1.91 1.03 0.92 1.00 C

Room D – WNG18 2.87 1.00 0.93 0.93 C

Model

Factor

(FM)

Condition

Factor

(FC)

Tubing(L)

Factor

(FT)

Total TC =1.25+1.73+1.81+2.48=7.27

Corrected Capacity

[KW], (C

= 1.91x1.00x0.92x0.985=1.73

B

= 1.91x1.03x0.92x1.00=1.81

C

= 2.87x1.00x0.93x0.93=2.48

D

A-D

)

Cooling Power Input calculation:

P

[KW] = Nominal x FM x FC x F

A-D

Total System Power Input [W] (TP) = PA + PB + PC + P

Nom’ Cooling

Indoor Unit

Room A – WNG9 1.00 0.88 PA = 602.5 x 1.00 x 0.88 = 530

Room B – WNG12 1.00 0.88 PB = 602.5 x 1.00 x 0.88 = 530

Room C – ECF12

Room D – WNG18 1.00 0.86 P

Power Input

[W]

2,410 / 4 = 602.5

T

Model

Factor

(FM)

1.01 0.88 P

Condition

Factor

(FC)

Total TP = 530 + 530 + 535 + 518 =

D

Corrected Power Input [W]

(P

)

A-D

= 602.5 x 1.01 x 0.88 = 535

C

= 602.5 x 1.00 x 0.86 = 518

D

2,113

5-26

Revision 0

Page 43

6. PRESSURE CURVES

6.1 Model: TRIO DCI

6.1.1 Cooling – Technician Mode

PRESSURE CURVES

32/23

29/21

27/19

24/17

22/15

Bar (g)

40.0

35.0

30.0

25.0

20.0

15.0

10 15 20 25 30 35 40 45

Discharge Pressure - Cooling (Technician Mode)

(WNG25+25+ 25 ; 5m each)

Outdoor DB Temperature [ºC]

32/23

29/21

27/19

24/17

22/15

Bar( g)

12.00

11.00

10.00

9.00

8.00

7.00

6.00

10

Suction Pressure - Cooling (Technician Mode)

(WNG25+ 25+25 ; 5m eac h)

15 20 25 30 35 40 45

Outdoor DB Temperature [ºC]

Revision 0 6-1

Page 44

PRESSURE CURVES

6.1.2 Heating – Technician Mode

25

20

15

Discharge Pressure - Heating (Technician Mode)

Bar(g)

34.00

32.00

30.00

28.00

26.00

24.00

22.00

20.00

18.00

16.00

14.00

12.00

10.00

-15 -10 -5 0 5 10 15 20

(WNG25+25+25 ; 5m each)

Outdoor DB Temperature [ºC]

25

20

15

Bar

(g)

12.00

11.00

10.00

9.00

8.00

7.00

6.00

5.00

4.00

-15 -10 10 15 20

Suction Pressure - Heating Techn cian Mode

WNG25+ 25+25 ; 5m each)

(

-5 0 5

Outdoor DB Temperature ºC

( i )

[ ]

6-2

Revision 0

Page 45

6.1.3 Tubing Length correction Factor

PRESSURE CURVES

1.02

Tubing Length Pressure Ratio - Cooling

1.01

i

Cool ng Ps

1.00

Suction Pressure Ratio

0.99

0.98

0

1.02 1.02

10 20 30 40 50

Total Tubing Lengtht [m]

Tubing Length Pressure Ratio - Heating

i

Cool ng Pd

1.02

1.01

1.00

0.99

0.98

Discharge Pressure Ratio

1.01 1.01

1.00 1.00

o

0.99 0.99

0.98 0.98

0.97 0.97

Suction Pressur e Rati

0.96 0.96

0.95 0.95

0.94 0.94

Heating Ps

0 10

20 3040 50

Total Tubing Lengtht [m]

6.1.4 Outdoor Unit Code correction Factor (F

Cooling Heating

ODU Code

Suction

Pressure

3 1.00 1.00 1.00 1.00

3.5 1.02 1.00 1.00 0.98

4 1.05 1.01 0.99 0.97

4.5 1.07 1.02 0.99 0.95

5 1.09 1.02 0.98 0.93

Discharge

Pressure

Suction

Pressure

)

C

Discharge

o

Discharge Pressure Rati

Heating P d

Pressure

Revision 0 6-3

Page 46

PRESSURE CURVES

6.2 Model: QUATTRO DCI

6.2.1 Cooling – Technician Mode

32/

29/

27/

24/

22/

23

21

19

17

15

Bar (g)

40.0

35.0

30.0

25.0

20.0

15.0

10 15 20 25 30 35 40

Discharge Pressure - Cooling (Technician Mode)

(WNG25+ 25+25+25 ; 5m each)

Outdoor DB Temperature[ºC]

45

32/23

29/21

27/19

24/17

22/15

Bar (g)

13.0

12.0

11.0

10.0

9.0

8.0

7.0

6.0

10 15 20 25 30 35 40

Suction Pressure - Cooling (Technician Mode

(WNG25+25+25+25 ; 5m eac h)

Outdoor DB Temperature[ºC]

)

45

6-4

Revision 0

Page 47

6.2.2 Heating – Technician Mode

PRESSURE CURVES

25

20

15

Bar (g)

30.00

28.00

26.00

24.00

22.00

20.00

18.00

16.00

14.00

12.00

10.00

-15 -10 -5 0 5 10 15 20

Discharge Pressure - Heating (Technician Mode)

(WNG25+25+25+25 ; 5m each)

Outdoor W B Temperature [ºC]

25

20

15

Bar (g)

12.00

11.00

10.00

9.00

8.00

7.00

6.00

5.00

4.00

-15 -10 -5 0 5 10 15 20

Suction Pressure - Heating (Technician Mode

(WNG25+25+25+25 ; 5m each)

Outdoor WB Temperature [ºC]

)

Revision 0 6-5

Page 48

PRESSURE CURVES

6.2.3 Tubing Length correction Factor (F

1.02 1.02

1.01 1.01

1.00 1.00

Suction Pressure Ratio

0.99 0.99

0.98 0.98

0 10203040506070

Tubing Length Pressure Ratio - Cooling

Cooling Ps

Total Tubing Lengtht [m]

)

T

Cooling Pd

Discharge Pressure Ratio

1.02 1.02

Tubing Length Pressure Ratio - Heating

1.01 1.01

1.00 1.00

0.99 0.99

0.98 0.98

0.97 0.97

Suction Pressure Ratio

0.96 0.96

0.95 0.95

0.94 0.94

Heating Ps

Heating Pd

0 10203040506070

Total Tubing Lengtht [m]

Discharge Pressure Ratio

6-6

Revision 0

Page 49

PRESSURE CURVES

6.2.4 Outdoor Unit Code correction Factor (F

ODU

Code

Suction

Pressure

4 1.00 1.00 1.00 1.00

4.5 1.02 1.01 1.00 0.99

5 1.04 1.01 0.99 0.98

5.5 1.05 1.02 0.99 0.97

6 1.07 1.02 0.98 0.96

Cooling Heating

Discharge

Pressure

Suction

Pressure

Discharge

Pressure

6.3 Calculation Example

Outdoor Unit

Indoor Combination

Operation Mode

Conditions Indoor

Conditions Oudoor

Tubing length

Quattro DCI

WNG9+WNG12+ECF12+WNG18

Cooling Mode

22°CDB/15°WB

30°CDB

20m+10m+5m+25m = 60m

)

C

Cooling Pressure calculation:

Pressure [Barg] = Nominal x FC x F

Unit Code

Room A – WNG9_______________ 1.0

Room B – WNG12__________________ 1.5

Room C – ECF12___________________1.5

Room D – WNG18__________________2.0

ODU Code (Total) 6.0

Nominal Pressure

[Barg]

Discharge 24.5 1.02 1.005 Pd= 24.5 x 1.02 x 1.005 = 25.11

Suction 9.0 1.07 0.988 Ps= 9.0 x 1.07 x 0.988 = 9.51

ODU Code Factor

____

T

(FC)

Tubing (L) Factor

(FT)

Corrected Pressure

[Barg]

Revision 0 6-7

Page 50

ELECTRICAL DATA

7. ELECTRICAL DATA

Power Supply 1 PH, 220-240 VAC, 50Hz

Connected to Outdoor

Maximum Current 16 A

Inrush Current 35 A

Starting Current 11 A

Circuit breaker 20 A

Power supply wiring - No. x cross section 3 X 2.5 mm

Interconnecting cable - No. x cross section 4 X 1.5 X 1.5 mm2 (For each IDU)

Note:

• Inrush current is the current when power is up. (charging the DC capacitors

at outdoor PCB).

• Starting current is the current at comp; start up.

2

NOTE

Power wiring cord should comply with local lows and electrical

regulations requirements.

Revision 0 7-1

Page 51

8. WIRING DIAGRAMS

8.1 Outdoor Units: TRIO, QUATTRO DCI

WIRING DIAGRAMS

Revision 0 8-1

Page 52

9. REFRIGERATION DIAGRAMS

9.1 TRIO DCI, QUATTRO DCI

Outdoor Unit Refrigerant System Diagram

REFRIGERATION DIAGRAMS

Revision 0 9-1

Page 53

10. TUBING CONNECTIONS

TUBING CONNECTIONS

TUBE (Inch)

¼” ⅜” ½” ⅝” ¾”

TORQUE (Nm)

Flare Nuts 40-45 60-65 70-75 80-85

Valve Cap

Service Port Cap

1.

Valve Protection Cap-end

2.

Refrigerant Valve Port (use Allen wrench to open/close)

3.

Valve Protection Cap

4.

Refrigerant Valve

5.

Service Port Cap

6.

Flare Nut

7. Unit Back Side

8.

Copper Tube

11-13

13-20 13-20 18-25 18-25 40-50

11-13 11-13 11-13 11-13 11-13

Revision 0 10-1

Page 54

11. CONTROL SYSTEM

11.1 Abbreviations

Abbreviation Definition

A/C

BMS

PWR

CTT

DCI

EEV

HE

HMI

HST

Hz

ICT

IDU

MCU

OAT

OCT

ODU

OFAN

PFC

RAC

RC

RGT

RPS

RV

SB,STBY

SUCT

S/W

TBD

TMR

Air Condition

Building Management System

System Power

Compressor Top Temperature sensor

DC Inverter

Electronic Expansion Valve

Heating Element

Human Machine Interface

Heat Sink Temperature sensor

Hertz (1/sec) – electrical frequency

Indoor Coil Temperature (RT2) sensor

Indoor Unit

Micro Controller Unit

Outdoor Air Temperature sensor

ODU Coil Temperature sensor

Outdoor Unit

Outdoor Fan

Power Factor Corrector

Residential A/C

Reverse Cycle (Heat Pump)

Return Gas Temperature sensor

Rounds per second (mechanical speed)

Reverse Valve

Stand By

Compressor Suction Temperature sensor

Software

To Be Defined

Timer

CONTROL SYSTEM

Revision 0

11-1

Page 55

CONTROL SYSTEM

3URGXFW2YHUYLHZ

%ORFN'LDJUDP

230V/ 50Hz

1ph/

a

Dry Cont cts

Control

Power

per ture ensors

Tem a S

PFC

380V

dc

IPM

IFAN

IPM

COMP

&RPSUHVVRU

'&EUXVKOHVVDQGVHQVRUOHVVKRUVHSRZHUPRWRULQYHUWHUGULYHQFRPSUHVVRU

2XWGRRU)DQ

Input

Filter

230V ac

Power supply

Feedback

230V ac

Low voltage

12V

EEV’s

5V

3.3V

RV

Ba se

Heater

Application

Control

Ala r m

Disp

la y

unic tion

Comm a

EEPROM

le

Modu

ndoor Units

I

'&EUXVKOHVVPRWRU

59

5HYHUVH9DOYHVHWWKHGLUHFWLRQRIUHIULJHUDQWÀRZLQWKHV\VWHPWKXVVHWWLQJWKHRSHUDWLRQ

PRGHIRUFRROLQJRUKHDWLQJ

:KHQWKHVROHQRLGLVSRZHUHGV\VWHPZLOOZRUNLQKHDWPRGH

((9¶V

([SDQVLRQYDOYHRSHUDWHGE\VWHSPRWRUZKLFKFRQWUROVWKHVL]HRIWKHRUL¿FH

+0,

7KUHH³6HJPHQWV´IRXU3XVKEXWWRQV

11-2

Revision 0

Page 56

11.2.7 Dry Contacts

Dry contacts are used to interface the system with an external building management system

(BMS).

CONTROL SYSTEM

Night

During night mode, the outdoor unit speed will be reduced in order to reduce the system

noise level.

SB input. System will be turned to Stand-by whe

Pow

Forced Mo

Alarm output indicate

Alarm output will be activated when there in the following ODU Faults/Protections

1 to 6, 8 to 22, 24, 25, 27 and 28.

Alarm output will be OFF when the Fault/Protection is cleared.

input. Switches the system to night mode when closed.

er Shedding input. Limits the maximum power consumption when closed.

de input. Used to force the operation mode of the system

s a failure at the system.

11.2.8 Temperature Sensors

CTT – Compressor Top Temperature

OAT – Outdoor Air Temperature

SUCT – Suction/Evaporating Temperature

OCT – Outdoor Coil (heat exchanger) Temperature

HST – Heat Sink Temperature

RGT1..4 – Indoor Unit 1..4 Returned Gas Temperatures

11.2.9 Base Heater

Heating element designed to melt any ice that is accumulated on the outdoor unit base

during low heating operation.

n the contact is closed.

Revision 0

11-3

Page 57

CONTROL SYSTEM

11.3 General Operating Rules

11.3.1 Initialization

Initialization process is the first operation done each time power is up.

The targets of the initialization are:

Addressing

Identificat

IDU Matchin

EEV’s homi

Restoring Parameters from EEPROM/Jumpers/

11.3.1.1 IDU’s Initialization

11.3.1.1.1 Capacity Codes Setting

The capacity groups of the IDU’s are translated into capacity codes according to the

following tab

0 (2.0 - 2.9kw) 1.2

1 (3.0 - 3.9kw) 1.5

2 (4.0 - 4.9kw) Reserved

3 (5.0 to 60) 2

4 (6.1kw and above) 3

le:

Capacity group

of IDU’s

ion of connected IDU’s

g Check

ng (reset position)

Dipswitches

Capacity Code

11.3.1.1.2 IDU Matching Check

The following procedure comes to verify that the total capacity of connected indoor units is

suitable for t

he capacity of the outdoor, and that indoor units with a large capacity are

connected to the channels with EEV and refrigerant tubing that is suitable for large

capacities.

Compare IDU’s family and capacity code to the values stored at the EEPROM.

If more then one IDU is connected (multi split application), the following items

should be checked:

o CodeA ≤ 1.5

o CodeB ≤ 1.5

o CodeC ≤ 1.

5

o CodeD ≤ 2