Page 1

Service Manual

DC Inverter Delta Series

REFRIGERANT

R410A

HEAT PUMP

MARCH 2005

Indoor Units Outdoor Units

Delta 25 DCR 25

Delta 35 DCR 35

Page 2

A

LIST OF EFFECTIVE PAGES

Revision Y05-01 Service Manual - Delta DCI

LIST OF EFFECTIVE PAGES

Note: Changes in the pages are indicated by a “Revision#” in the footer of each effected page

(when none indicates no changes in the relevant page). All pages in the following list represent

effected/ non effected pages divided by chapters.

Dates of issue for original and changed pages are:

Original ....... 0 ........ 15 March 2005

Total number of pages in this publication is 54 consisting of the following:

Page

No.

Revision

No. #

Page

No.

Revision

No. #

Page

No.

Revision

No. #

Title ....................... 0

A ........................... 0

i ............................. 0

1-1 - 1-3 ................ 0

2-1 - 2-2 ................ 0

3-1 ........................ 0

4-1 - 4-2 ................ 0

5-1 - 5-10 .............. 0

6-1 - 6-2 ................ 0

7-1 - 7-1 ................ 0

8-1 - 8-1 ................ 0

9-1 - 9-1 ................ 0

10-1-10-1 .............. 0

11-1-11-14 ............. 0

12-1-12-6 .............. 0

13-1-13-6 .............. 0

Appendix -A ...........0

• Zero in this column indicates an original page.

*Due to constant improvements please note that the data on this service manual can be modified

with out notice.

**Photos are not contractual

Page 3

i

TABLE OF CONTENTS

Revision Y05-01Service Manual - Delta DCI

Table of Contents

1. INTRODUCTION ...................................................................................................1-1

2. PRODUCT DATA SHEET ......................................................................................2-1

3. RATING CONDITIONS ..........................................................................................3-1

4. OUTLINE DIMENSIONS .......................................................................................4-1

5. PERFORMANCE DATA & PRESSURE CURVES ...............................................5-1

6. SOUND LEVEL CHARACTERISTICS ..................................................................6-1

7. ELECTRICAL DATA ..............................................................................................7-1

8. WIRING DIAGRAMS .............................................................................................8-1

9. REFRIGERATION DIAGRAMS .............................................................................9-1

10. TUBING CONNECTIONS ......................................................................................10-1

11. CONTROL SYSTEM .............................................................................................11-1

12. TROUBLESHOOTING ..........................................................................................12-1

13.

EXPLODED VIEWS AND SPARE PARTS LISTS .................................................13-1

14. APPENDIX A .........................................................................................................14-1

Page 4

1-1

INTRODUCTION

Revision Y05-01Service Manual - Delta DCI

1. INTRODUCTION

1.1 General

The new Delta DC Inverter split wall mounted series comprise RC (heat pump)

models, as follows:

● Delta 25

● Delta 35

The indoor Delta units are available as LED display types only, featuring esthetic

design, compact dimensions, and low noise operation.

1.2 Main Features

The Delta series benefits from the most advanced technological innovations, namely:

●

DC Inverter Technology

● R410A

● Microprocessor control.

● Infrared remote control with liquid crystal display.

● Indoor large diameter cross flow fan, allowing low noise level operation.

● Bended indoor coil with treated aluminum fins and coating for improved

efficiency.

● High COP.

● Pre-Charged units up to the max allowing tubing distance.

● Cooling operation at outdoor temperature down to 10ºC

● Heating operation at outdoor temperature down to -15ºC

● Advanced test and diagonstics mode.

● M2L diagnistics softwear cable port (for PC)

● Easy access to the interconnecting tubing and wiring connections, so that

during installation removing the front grill or casing is not necessary.

● Refrigerant pipes can be connected to the indoor unit from 5 different optional

directions.

● Automatic treated air sweep.

● Easy installation and service.

Page 5

1-2

INTRODUCTION

Revision Y05-01 Service Manual - Delta DCI

1.3 Indoor Unit

The indoor unit is wall mounted, and can be easily fitted to many types of residential

and commercials applications.

It includes:

● Casing with air inlet and outlet grills.

● A large-diameter tangential fan.

● Bended coil with treated aluminum fins.

● Motorized flaps.

● Variable Speed motor (PG).

● Advanced electronic control box assembly.

● Interconnecting wiring terminal block.

● Mounting plate

.

1.4 Filtration

The Delta series presents several types of air filters:

● Easily accessible, and re-usable pre-filters (mesh)

● Pre-charged electrostatic filter (optional)

● Active carbon filter (optional)

1.5 Control

The microprocessor indoor controller, and an infrared remote control, supplied as

standard, provide complete operating function and programming. For further details

please refer to the Operation Manual, Appendix A.

1.6 Outdoor Unit

The Delta outdoor units can be installed as floor or wall mounted units by using a

wall supporting bracket. The metal sheets are protected by anti- corrosion paint work

allowing long life resistance. All outdoor units are pre-charged. For further information

please refer to the Product Data Sheet, Chapter 2.

It includes :

● Single DC Rotary Compressor mounted in a soundproofed compartment

● Axial fan.

● Outdoor coil with hydrophilic louver fins.

● Outlet air fan grill.

● Outdoor advanced contoler.

● 2 fan speed AC motor

Page 6

1-3

INTRODUCTION

Revision Y05-01Service Manual - Delta DCI

1.7 Tubing Connections

Flare type interconnecting tubing to be produced on site.

For further details please refer to the Installation Manual, Appendix A

1.8 Inbox Documentation

Each unit is supplied with its own installation and operation manuals,

1.9 Matching Table

OUTDOOR UNITS

INDOOR UNITS

MODEL REFR” Delta 25 Delta 35

DCR 25 R410A √

DCR 35 R410A

√

Page 7

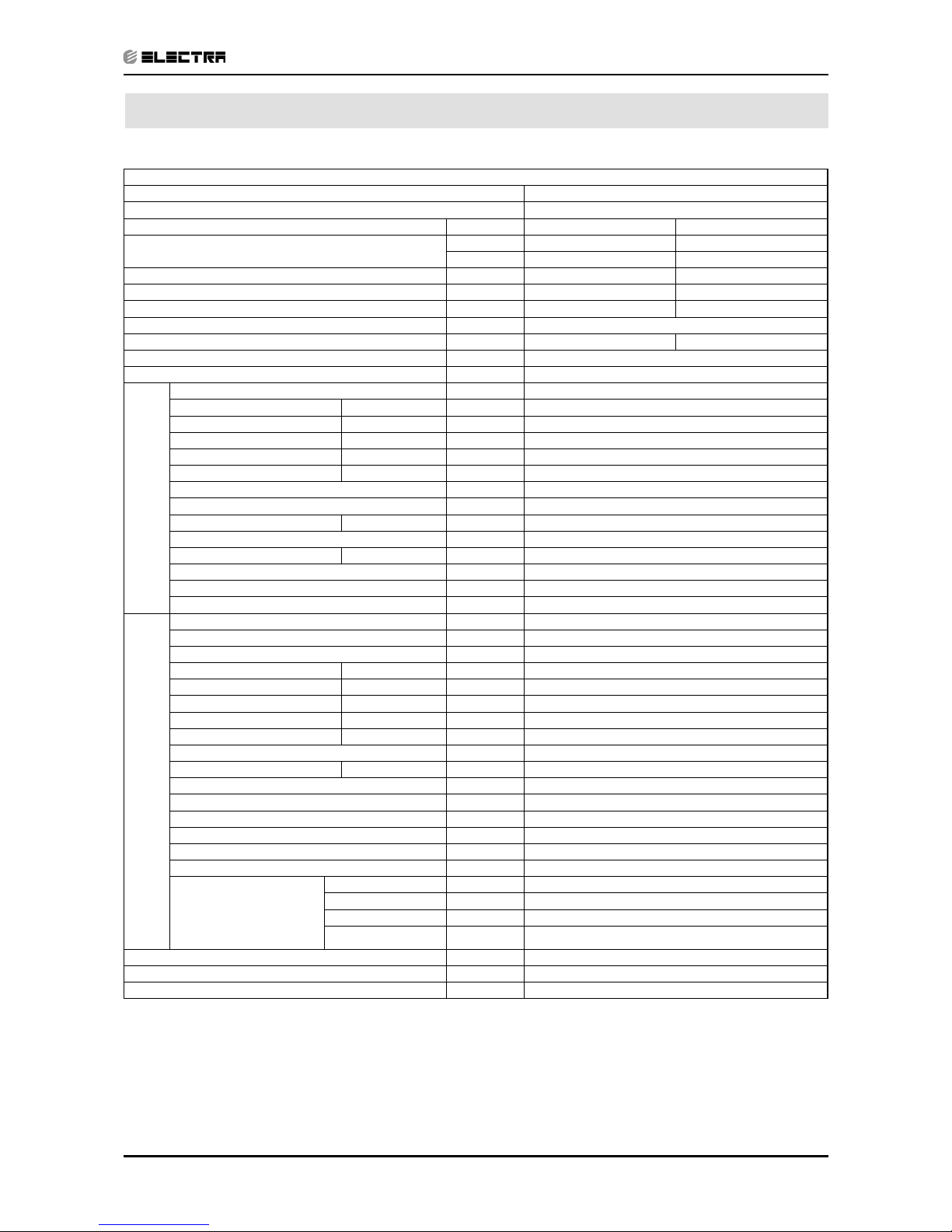

2-1

PRODUCT DATA SHEET

Revision Y05-01Service Manual - Delta DCI

2. PRODUCT DATA SHEET

2.1 R410A

Model Indoor Unit DELTA 25

Model Outdoor Unit DCR 25

Installation Method of Pipe Flared

Characteristics Units Cooling Heating

Capacity

(1)

Btu/hr 8530(4440-10240) 9550(4774-11940)

kW 2.5(1.3-3.0) 2.8(1.4-3.5)

Power input

(1)

kW 0.75 0.82

EER (Cooling) or COP(Heating)

(1)

W/W 3.38 3.41

Energy efficiency class A B

Power supply V/Ph/Hz 220-240V/Single/50Hz

Rated current A 3.2 3.6

Starting current A 10

Circuit breaker rating A 12

INDOOR

Fan type & quantity Crossflow x 1

Fan speeds H/M/L RPM 1200/1050/850

Air flow

(2)

H/M/L m3/hr 420/350/270

External static pressure Min-Max Pa 0

Sound power level

(3)

H/M/L dB(A) 52/48/45

Sound pressure level

(4)

H/M/L dB(A) 39/35/32

Moisture removal l/hr 1

Condensate drain tube I.D mm 16

Dimensions WxHxD mm 680x200x250

Weight kg 7

Package dimensions WxHxD mm 740x265x320

Packaged weight kg 10

Units per pallet units 36 units per pallet

Stacking height units 9 levels

OUTDOOR

Refrigerant control EEV

Compressor type, model Rotary, Panasonic 5RS092XDJ01

Fan type & quantity Propeller(direct) x 1

Fan speeds H/L RPM 760

Air flow H/L m3/hr 1390

Sound power level H/L dB(A) 64

Sound pressure level

(4)

H/L dB(A) 54

Dimensions WxHxD mm 760x245x545

Weight kg 36

Package dimensions WxHxD mm 880x310x610

Packaged weight kg 39

Units per pallet Units 12 units per pallet

Stacking height units 3 levels

Refrigerant type R410A

Refrigerant chargless distance kg/m 0.85kg/7.5m

Additional charge per 1 meter g/m No need

Connections between

units

Liquid line In.(mm) 1/4”(6.35)

Suction line In.(mm) 3/8”(9.53)

Max.tubing length m. Max.15

Max.height

difference

m. Max. 10

Operation control type Remote control

Heating elements kW

Others

(1) Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units) and EN 14511.

(2) Airflow in ducted units; at nominal external static pressure.

(3) Sound power in ducted units is measured at air discharge.

(4) Sound pressure level measured at 1 meter distance from unit.

Page 8

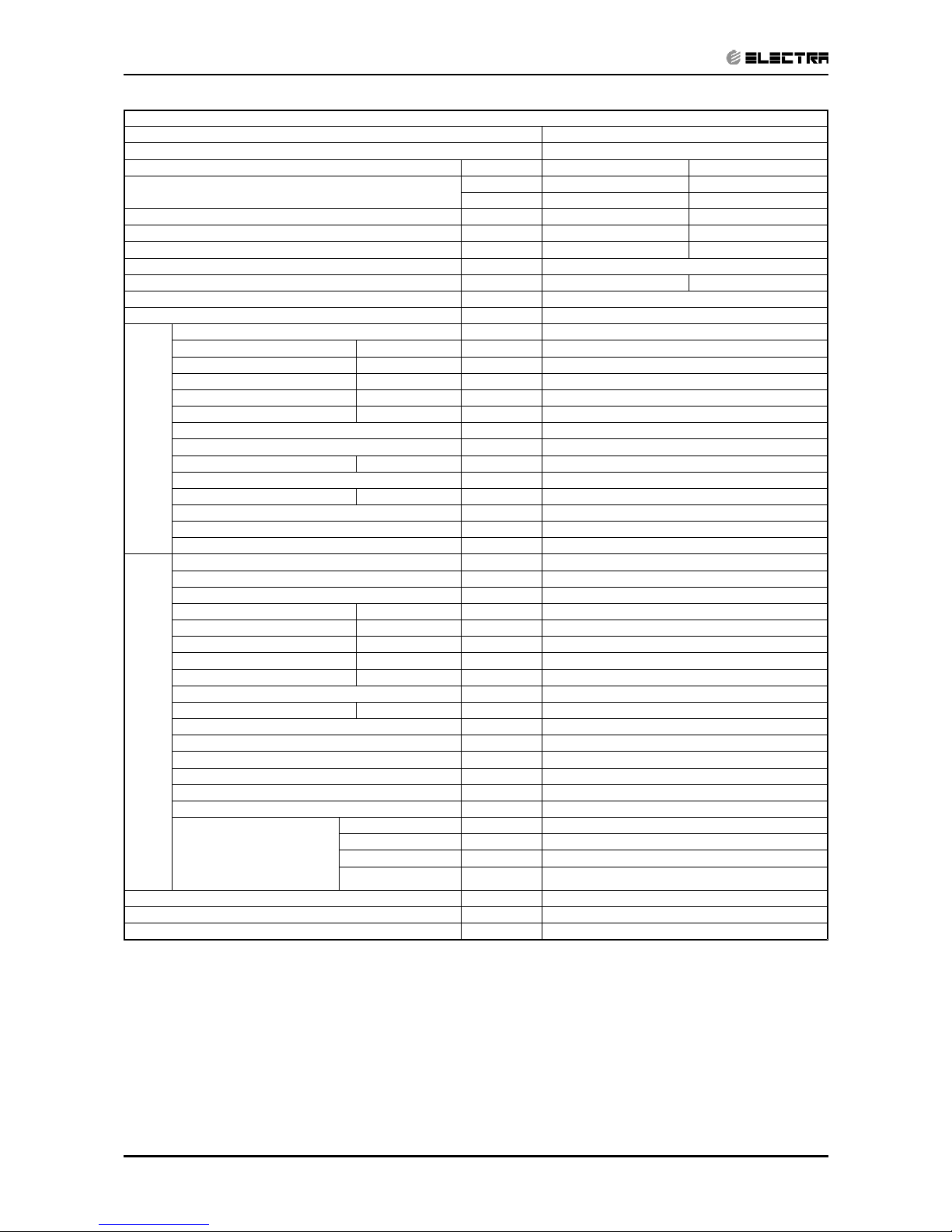

2-2

PRODUCT DATA SHEET

Revision Y05-01 Service Manual - Delta DCI

Model Indoor Unit DE LTA 35

Model Outdoor Unit DCR 35

Installation Method of Pipe Flared

Characteristics Units Cooling Heating

Capacity

(1)

Btu/hr 11940(4440-13990) 12280(5115-13990)

kW 3.5(1.3-4.1) 3.6(1.65-4.1)

Power input

(1)

kW 1.03 1.05

EER (Cooling) or COP(Heating)

(1)

W/W 3.39 3.43

Energy efficiency class A B

Power supply V/Ph/Hz 220-240V/Single/50Hz

Rated current A 4.9 4.8

Starting current A 10.5

Circuit breaker rating A 15

INDOOR

Fan type & quantity Crossflow x 1

Fan speeds H/M/L RPM 1200/1000/850

Air flow

(2)

H/M/L m3/hr 550/450/350

External static pressure Min-Max Pa 0

Sound power level

(3)

H/M/L dB(A) 52/46/42

Sound pressure leve

l

(4)

H/M/L dB(A) 39/33/29

Moisture removal l/hr 1.5

Condensate drain tube I.D mm 16

Dimensions WxHxD mm 840x200x250

Weight kg 8

Package dimensions WxHxD mm 930x265x320

Packaged weight kg 11

Units per pallet units 36 units per pallet

Stacking height units 9 levels

OUTDOOR

Refrigerant control EEV

Compressor type, model Rotary, Panasonic 5RS102XAB

Fan type & quantity Propeller(direct) x 1

Fan speeds H/L RPM 760

Air flow H/L m3/hr 1390

Sound power level H/L dB(A) 65

Sound pressure level

(4)

H/L dB(A) 55

Dimensions WxHxD mm 760x245x545

Weight kg 37

Package dimensions WxHxD mm 880x310x610

Packaged weight kg 40

Units per pallet Units 12 units per pallet

Stacking height units 3 levels

Refrigerant type R410A

Refrigerant chargless distance kg/m 1.0kg/7.5m

Additional charge per 1 meter g/m No need

Connections between units

Liquid line In.(mm) 1/4”(6.35)

Suction line In.(mm) 3/8”(9.53)

Max.tubing length m. Max.15

Max.height

difference

m. Max. 10

Operation control type Remote control

Heating elements kW No

Others

(1) Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units) and EN 14511.

(2) Airflow in ducted units; at nominal external static pressure.

(3) Sound power in ducted units is measured at air discharge.

(4) Sound pressure level measured at 1 meter distance from unit.

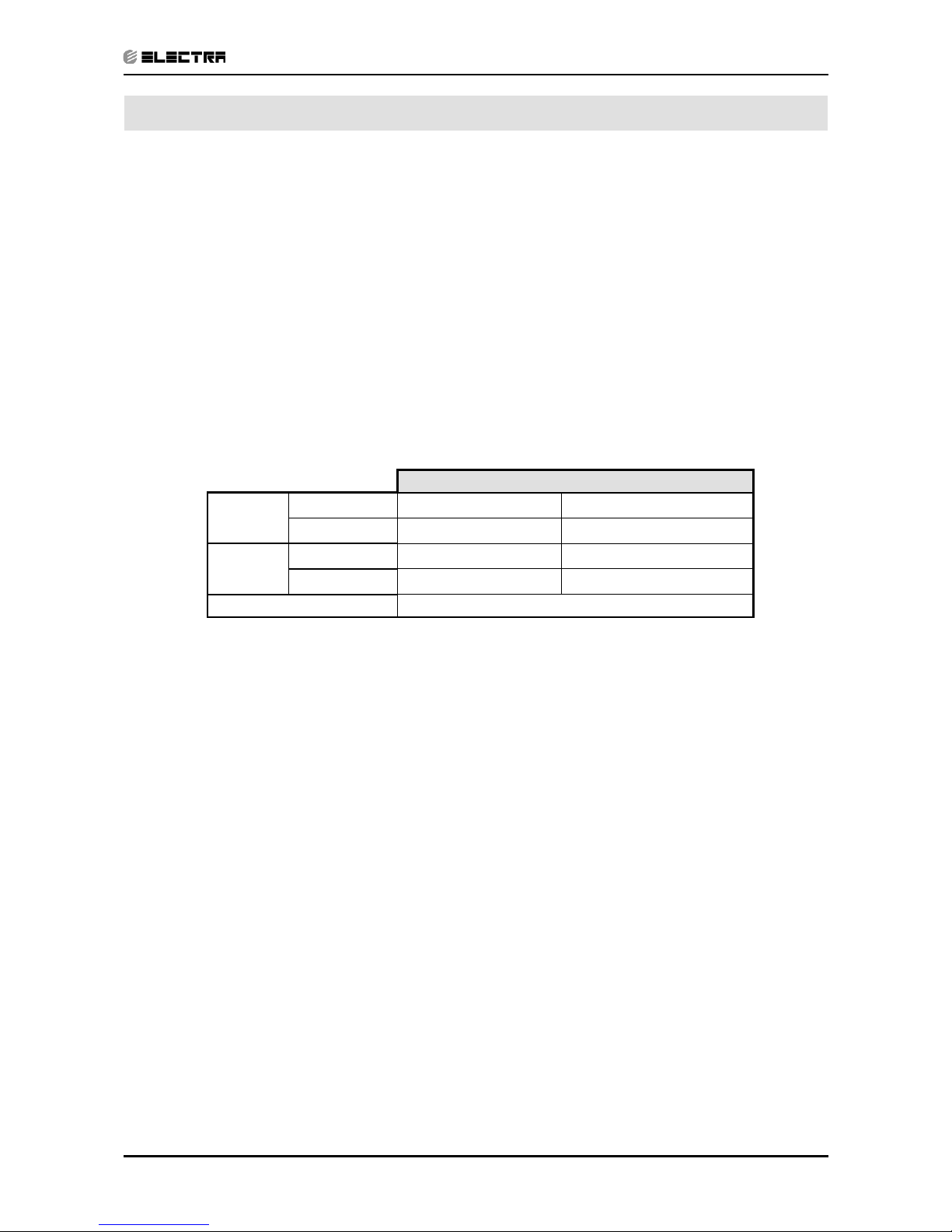

Page 9

3-1

RATING CONDITIONS

Revision Y05-01Service Manual - Delta DCI

3. RATING CONDITIONS

Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units).

Cooling:

Indoor: 27

o

C DB 19oC WB

Outdoor: 35

o

C DB

Heating:

Indoor: 20

o

C DB

Outdoor: 7

o

C DB 6oC WB

3.1 Operating Limits

3.1.1 R410A

Indoor Outdoor

Cooling

Upper limit

32oC DB 23oC WB 46oC DB

Lower limit

21oC DB 15oC WB 10oC DB

Heating

Upper limit

27oC DB 24oC DB 18oC WB

Lower limit

10oC DB -15oC DB -16oC WB

Voltag e

198 – 264 V

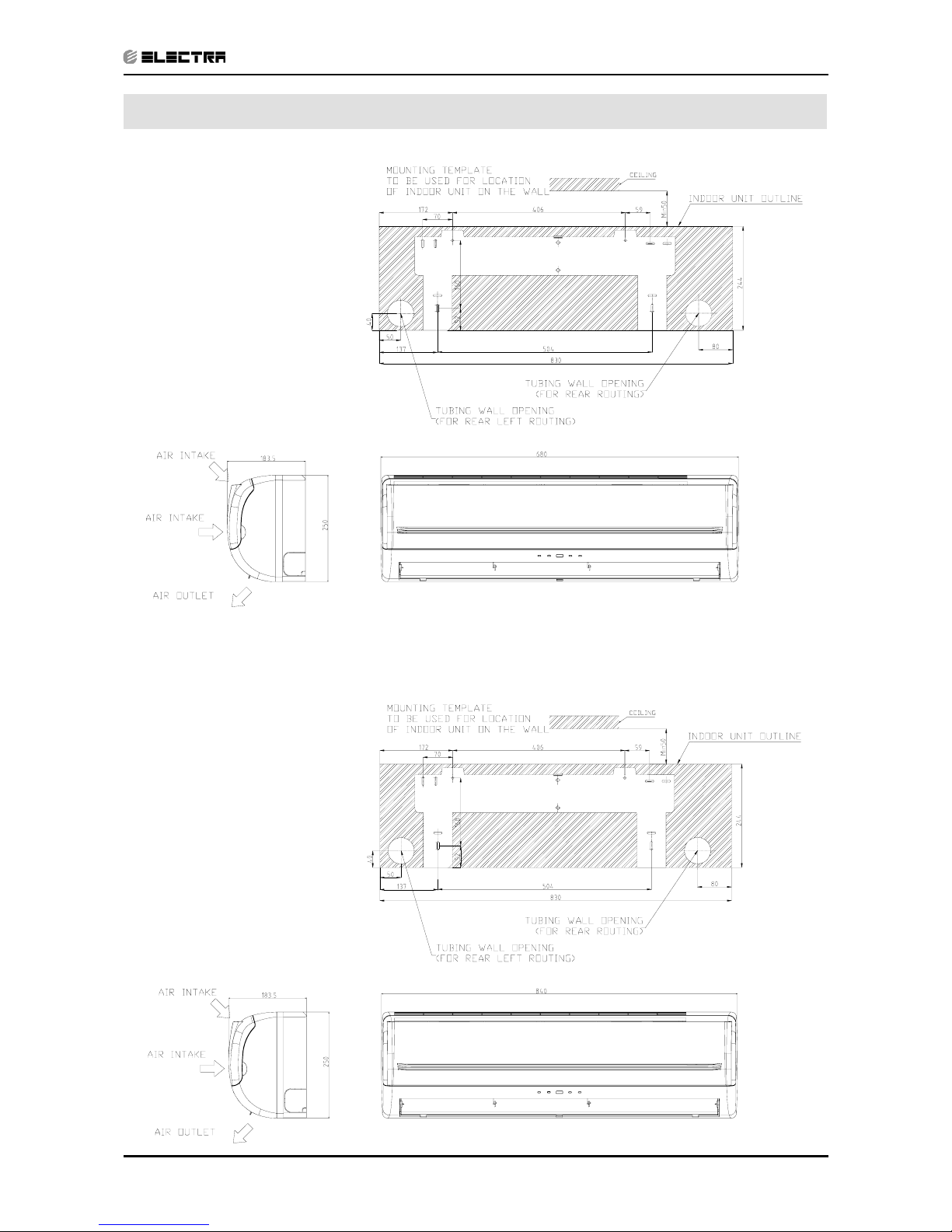

Page 10

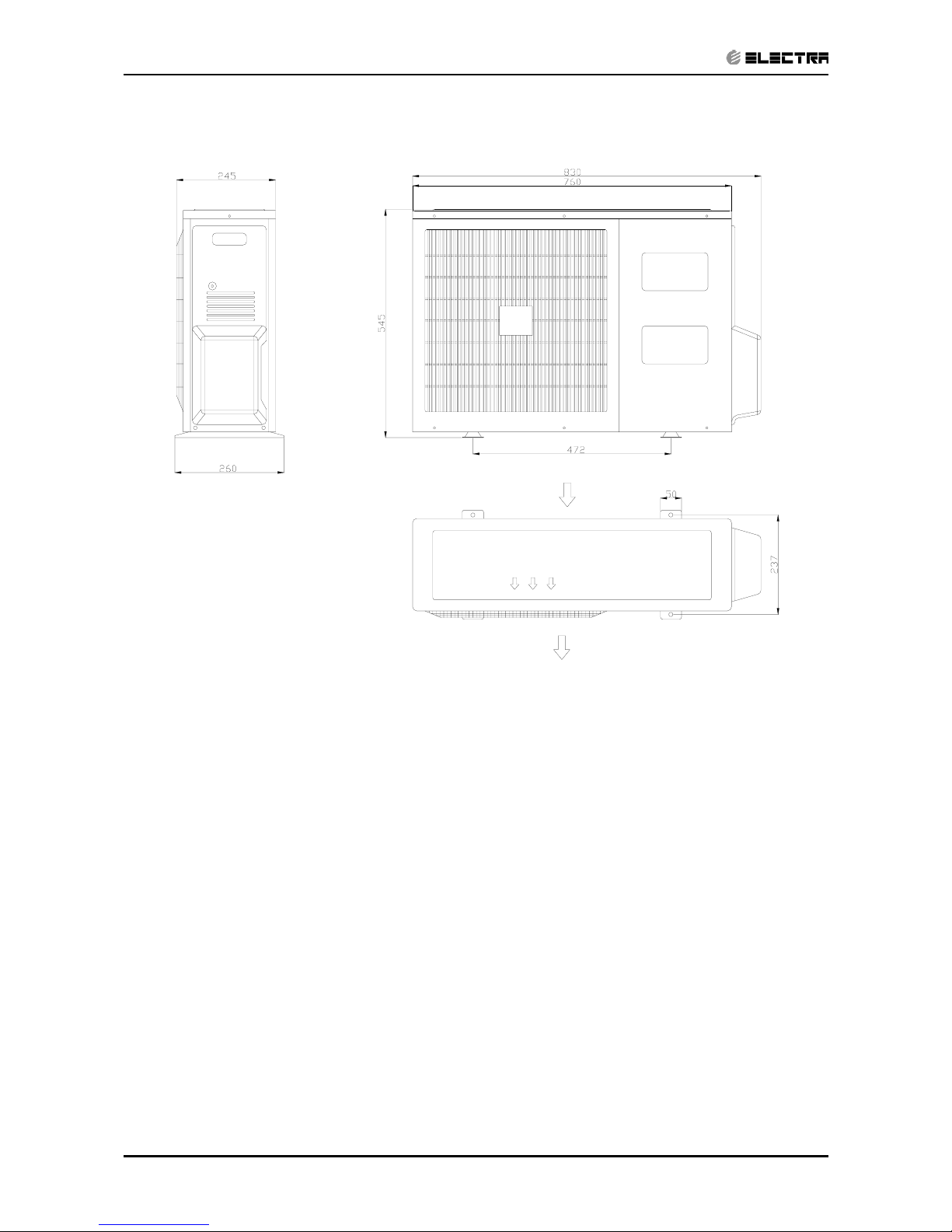

4-1

OUTLINE DIMENSIONS

Revision Y05-01Service Manual - Delta DCI

4. OUTLINE DIMENSIONS

4.1 Indoor Unit: Delta 25 DCI

4.2

Indoor Unit: Delta 35 DCI

Page 11

4-2

OUTLINE DIMENSIONS

Revision Y05-01 Service Manual - Delta DCI

4.3 Outdoor Unit: DCR 25/35 DCI

AI R OUTL E T

AI R I NTAKE

Page 12

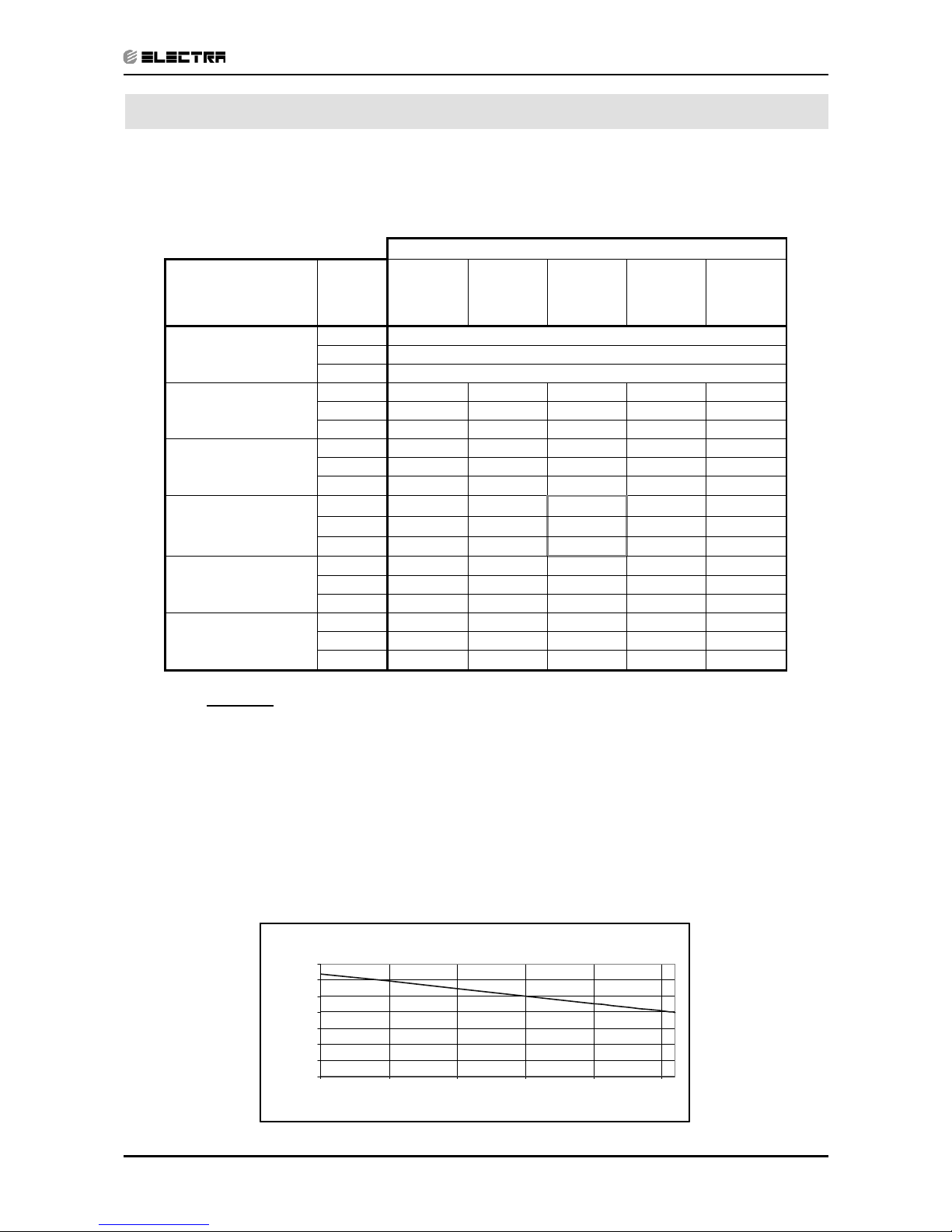

5-1

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01Service Manual - Delta DCI

5. PERFORMANCE DATA

5.1 Delta 25 DCI

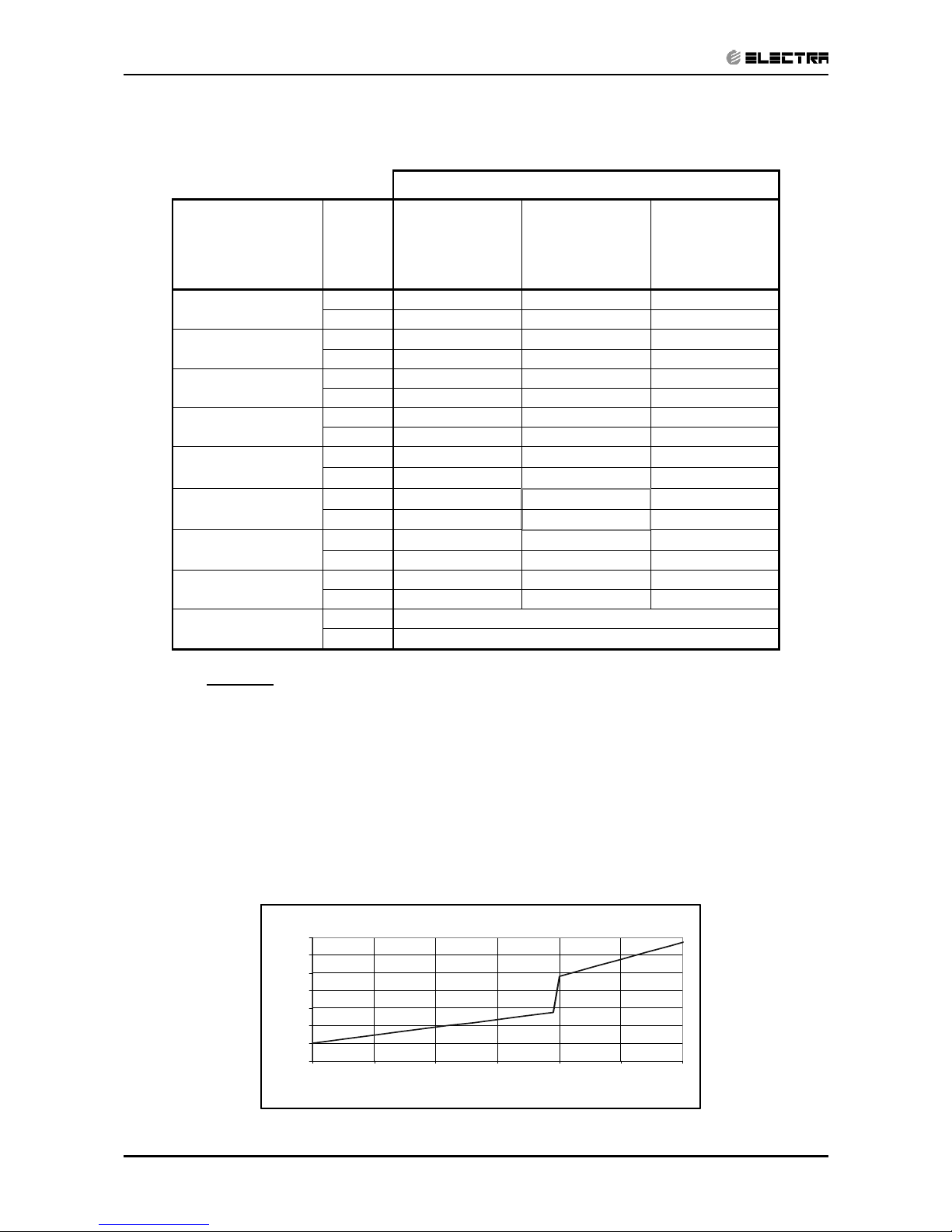

5.1.1 Cooling Capacity (kW) - Run Mode (Unit A or B)

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB/WB TEMPERATURE [

0

C]

OD COIL

ENTERING AIR DB

TEMPERATURE

[0C]

DATA

22/15 24/17 27/19 29/21 32/23

-10 - 20

(protection range)

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

PI 25 - 50 % of nominal

25

TC 2.41 2.57 2.73 2.89 3.05

SC 1.67 1.71 1.74 1.77 1.81

PI 0.57 0.58 0.60 0.61 0.62

30

TC 2.30 2.46 2.62 2.77 2.93

SC 1.63 1.67 1.70 1.76 1.77

PI 0.64 0.65

0.66

0.67 0.68

35

TC 2.18 2.34

2.50

2.66 2.82

SC 1.59 1.63 1.66 1.69 1.73

PI 0.71 0.72

0.73

0.74 0.75

40

TC 2.07 2.23

2.39

2.54 2.70

SC 1.55 1.59 1.62 1.65 1.69

PI 0.78 0.79 0.80 0.81 0.82

46

TC 1.93 2.09 2.25 2.41 2.56

SC 1.50 1.54 1.57 1.61 1.64

PI 0.86 0.87 0.88 0.89 0.90

LEGEND

TC – Total Cooling Capacity, kW

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (

o

C)

ID – Indoor

OD – Outdoor

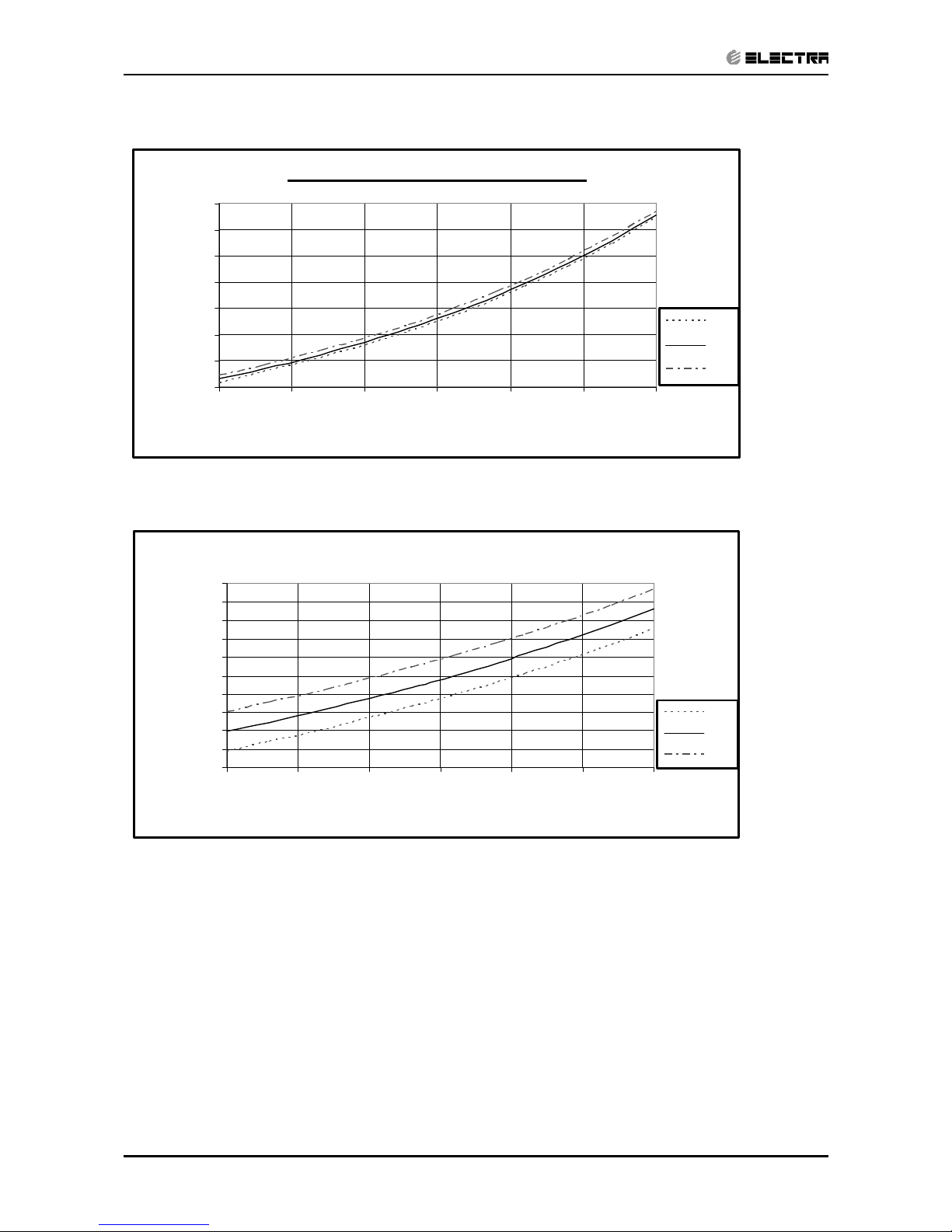

5.1.2 Capacity Correction Factors

Cooling Capacity Ratio Vs. Outdoor Temperature

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

20 25 30 35 40 45

Outdoor Temperature [deg C]

Capacity Ratio

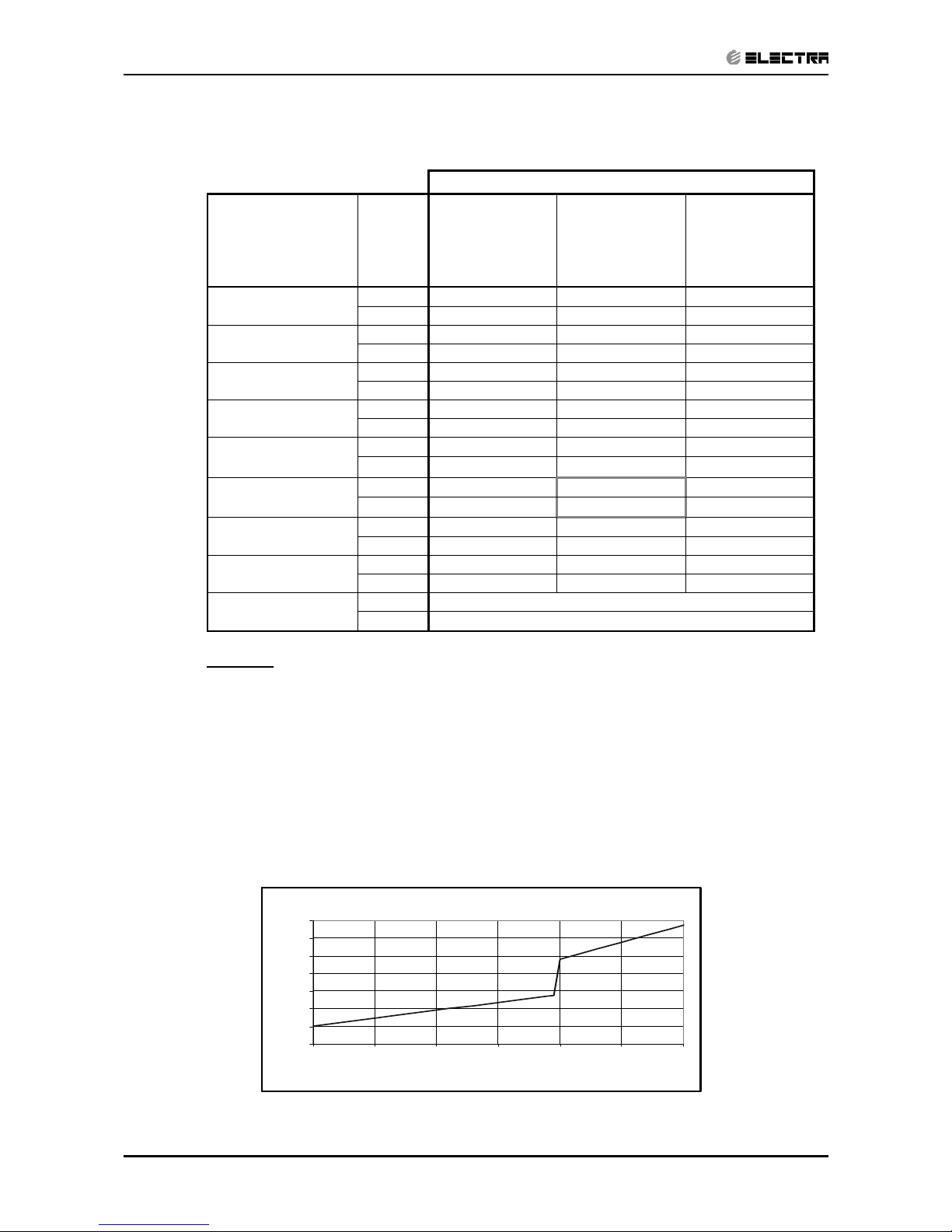

Page 13

5-2

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01 Service Manual - Delta DCI

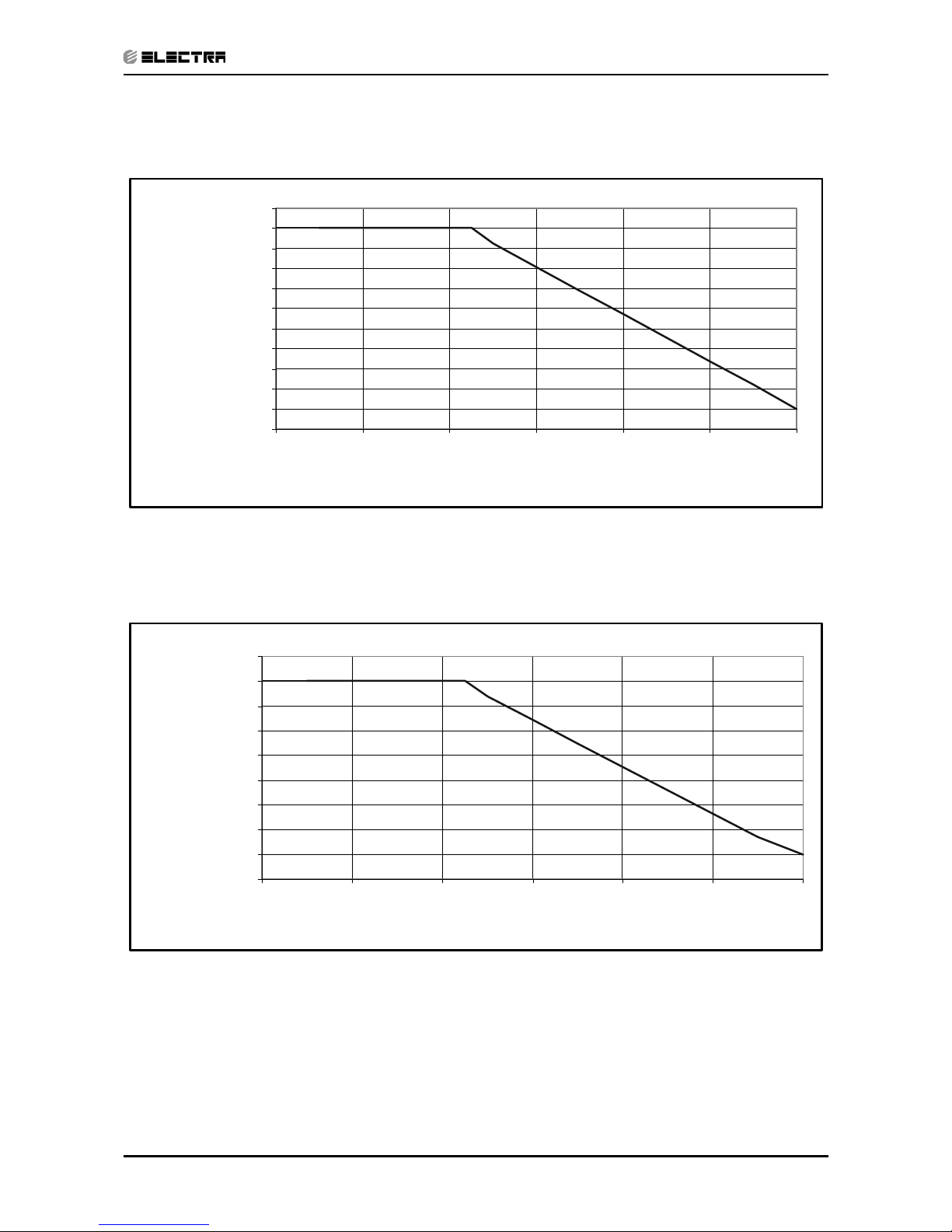

5.1.3 Heating Capacity (kW) - Run Mode(Unit A or B)

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [0C]

OD COIL

ENTERING

AIR DB/WB

TEMPERATURE

[

0

C]

DATA 15 20 25

-15/-16

TC 1.78 1.66 1.53

PI 0.49 0.54 0.59

-10/-12

TC 1.98 1.86 1.73

PI 0.59 0.64 0.69

-7/-8

TC 2.14 2.01 1.89

PI 0.67 0.72 0.77

-1/-2

TC 2.21 2.09 1.96

PI 0.71 0.76 0.81

2/1

TC 2.26 2.14 2.01

PI 0.73

0.78

0.83

7/6

TC 32.92

2.80

2.68

PI 0.77

0.82

0.87

10/9

TC 3.09

2.96

2.84

PI 0.82 0.87 0.92

15/12

TC 3.25 3.12 3.00

PI 0.86 0.91 0.96

15-24

TC 85 - 105 % of nominal

(Protection Range)

PI 80 - 120 % of nominal

LEGEND

TC – Total Cooling Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (

o

C)

ID – Indoor

OD – Outdoor

5.1.4 Capacity Correction Factors

Hea ting Cap acity Ra tio V s. Outdoo r Te mperature

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [deg C]

Capacit y Ration

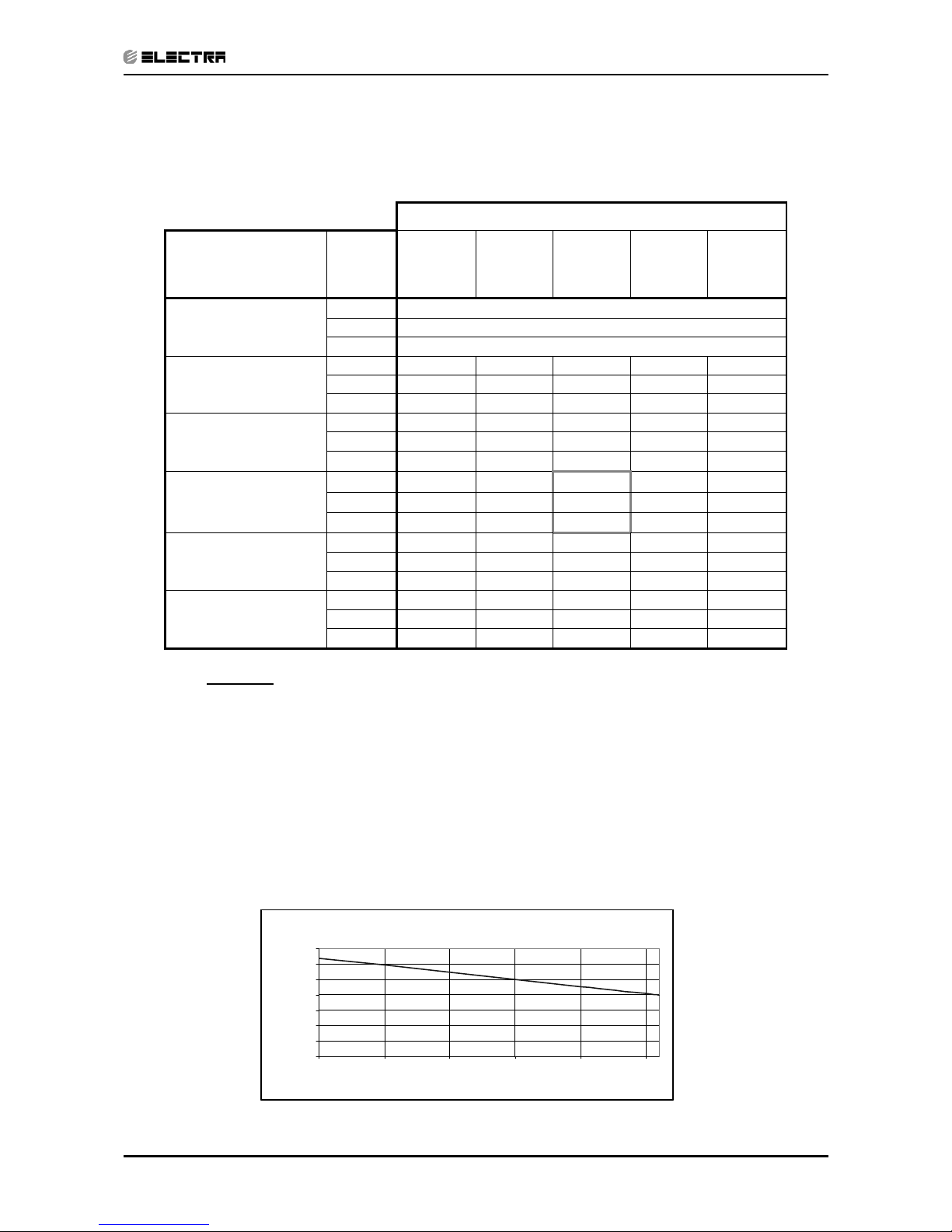

Page 14

5-3

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01Service Manual - Delta DCI

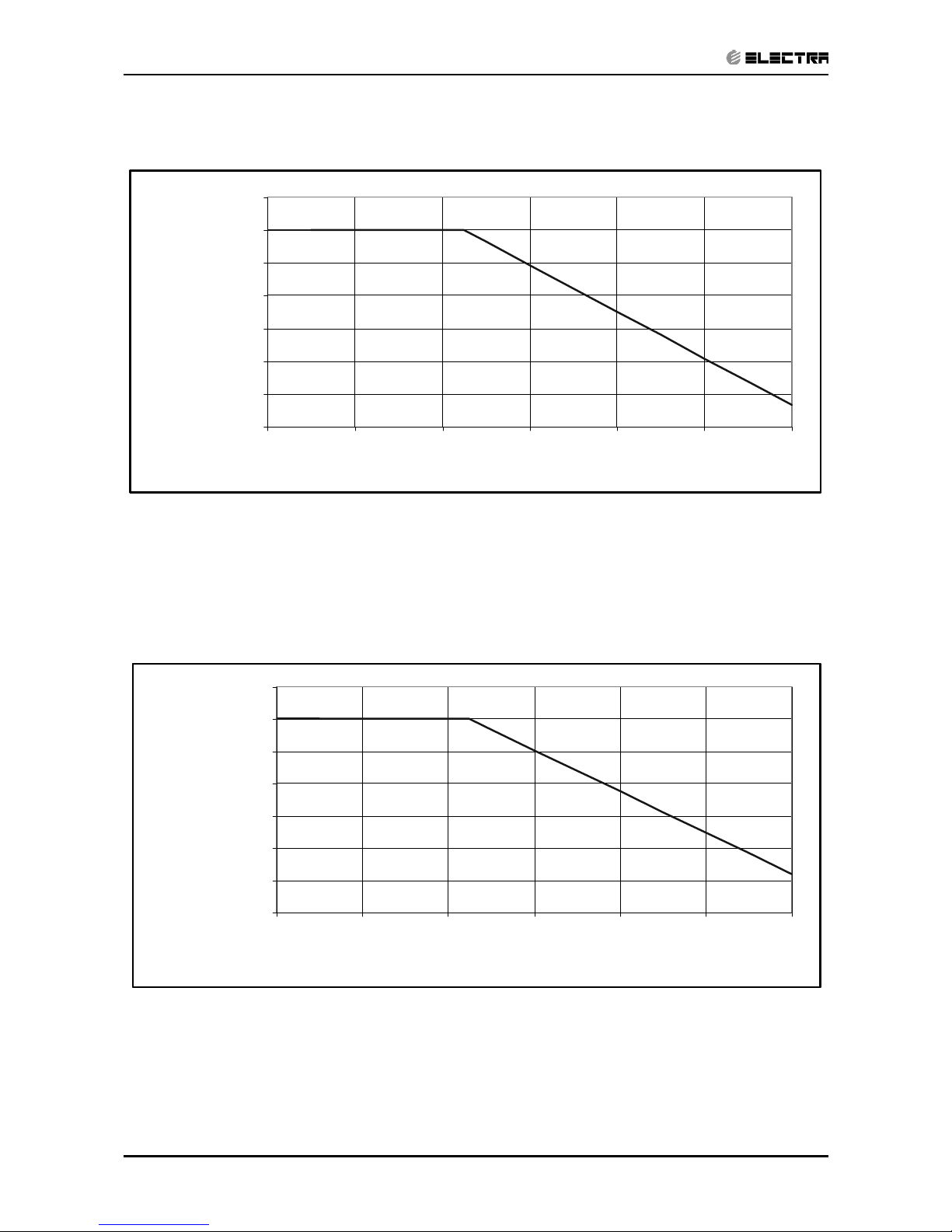

5.2 Delta 35 DCI

5.2.1 Cooling Capacity (kW) - Run Mode (Unit A or B)

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB/WB TEMPERATURE [0C]

OD COIL

ENTERING AIR DB

TEMPERATURE [

0

C]

DATA

22/15 24/17 27/19 29/21 32/23

-10 - 20

(protection range)

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

PI 25 - 50 % of nominal

25

TC 3.38 3.60 3.82 4.04 4.26

SC 2.54 2.59 2.64 2.69 2.74

PI 0.79 0.81 0.82 0.84 0.85

30

TC 3.22 3.44 3.66 3.88 4.10

SC 2.48 2.53 2.58 2.63 2.68

PI 0.89 0.90

0.92

0.93 0.95

35

TC 3.06 3.28

3.50

3.72 3.94

SC 2.42 2.47 2.52 2.57 2.62

PI 0.98 0.99

1.01

1.03 1.04

40

(Protection Range)

TC 2.90 3.12

3.34

3.56 3.78

SC 2.36 2.41 2.46 2.51 2.56

PI 1.07 1.09 1.10 1.12 1.13

46

(Protection Range)

TC 2.70 2.92 3.15 3.37 3.59

SC 2.28 2.34 2.39 2.44 2.49

PI 1.18 1.20 1.21 1.23 1.24

LEGEND

TC – Total Cooling Capacity, kW

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (

o

C)

ID – Indoor

OD – Outdoor

5.2.2 Capacity Correction Factors

Cooling Capacity Ratio Vs. Outdoor Temperature

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

20 25 30 35 40 45

Outdoor Temperature [deg C]

Capacity Ratio

Page 15

5-4

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01 Service Manual - Delta DCI

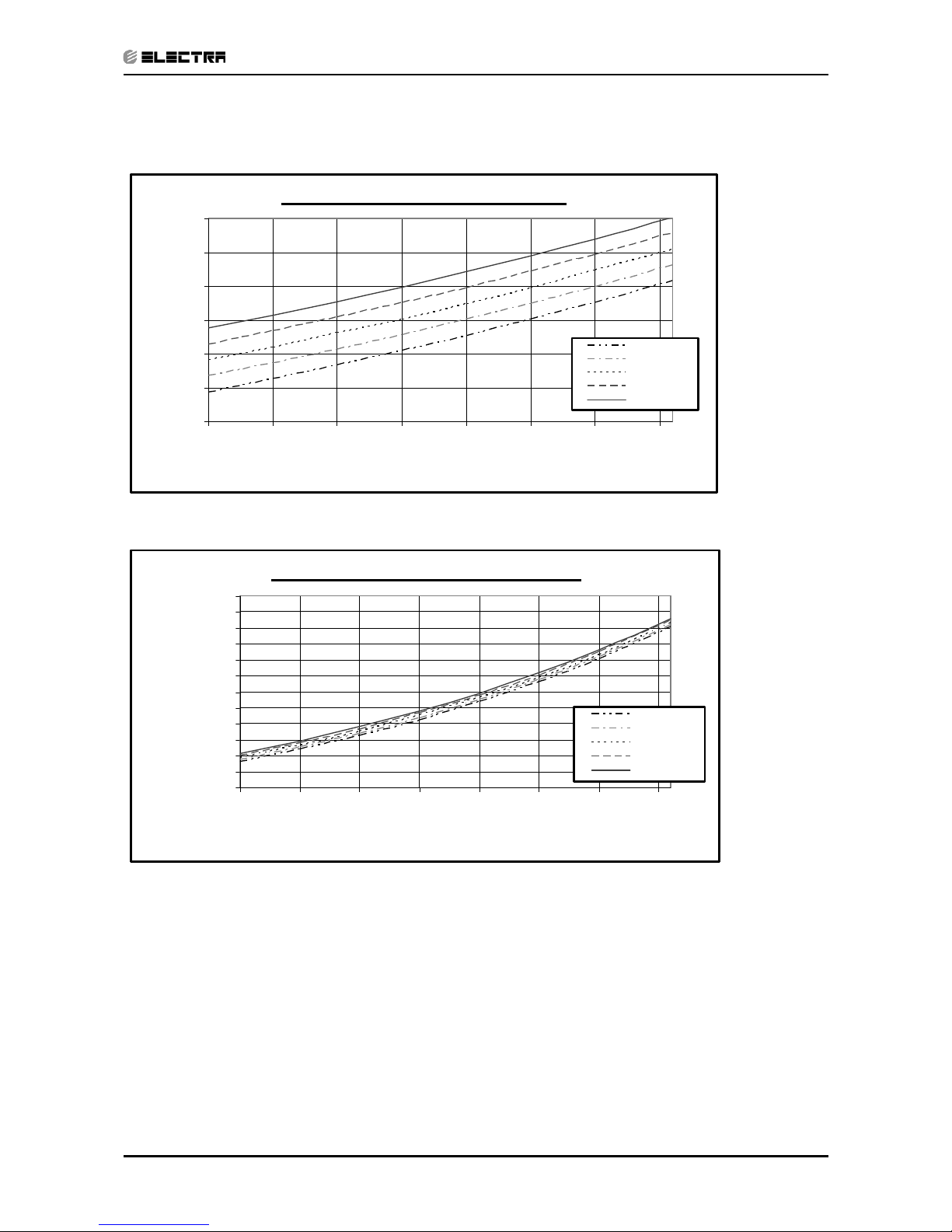

5.2.3 Heating Capacity (kW) - Run Mode(Unit A or B)

230[V] : Indoor Fan at High Speed.

ID COIL ENTERING AIR DB TEMPERATURE [0C]

OD COIL

ENTERING

AIR DB/WB

TEMPERATURE

[

0

C]

DATA 15 20 25

-15/-16

TC 2.29 2.13 1.97

PI 0.61 0.67 0.73

-10/-12

TC 2.55 2.39 2.23

PI 0.73 0.79 0.85

-7/-8

TC 2.75 2.58 2.42

PI 0.82 0.89 0.95

-1/-2

TC 2.84 2.68 2.52

PI 0.87 0.93 0.99

2/1

TC 2.91 2.75 2.59

PI 0.90

0.96

1.02

7/6

TC 3.76

3.60

3.44

PI 0.95

1.01

1.07

10/9

TC 3.97

3.81

3.65

PI 1.01 1.07 1.13

15/12

TC 4.17 4.01 3.85

PI 1.06 1.12 1.18

15-24

TC 85 - 105 % of nominal

(Protection Range)

PI 80 - 120 % of nominal

LEGEND

TC – Total Cooling Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

o

C)

DB – Dry Bulb Temp., (

o

C)

ID – Indoor

OD – Outdoor

5.2.4 Capacity Correction Factors

Hea ting Cap acity Ra tio V s. Outdoo r Te mperature

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [deg C]

Capacit y Ration

Page 16

5-5

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01Service Manual - Delta DCI

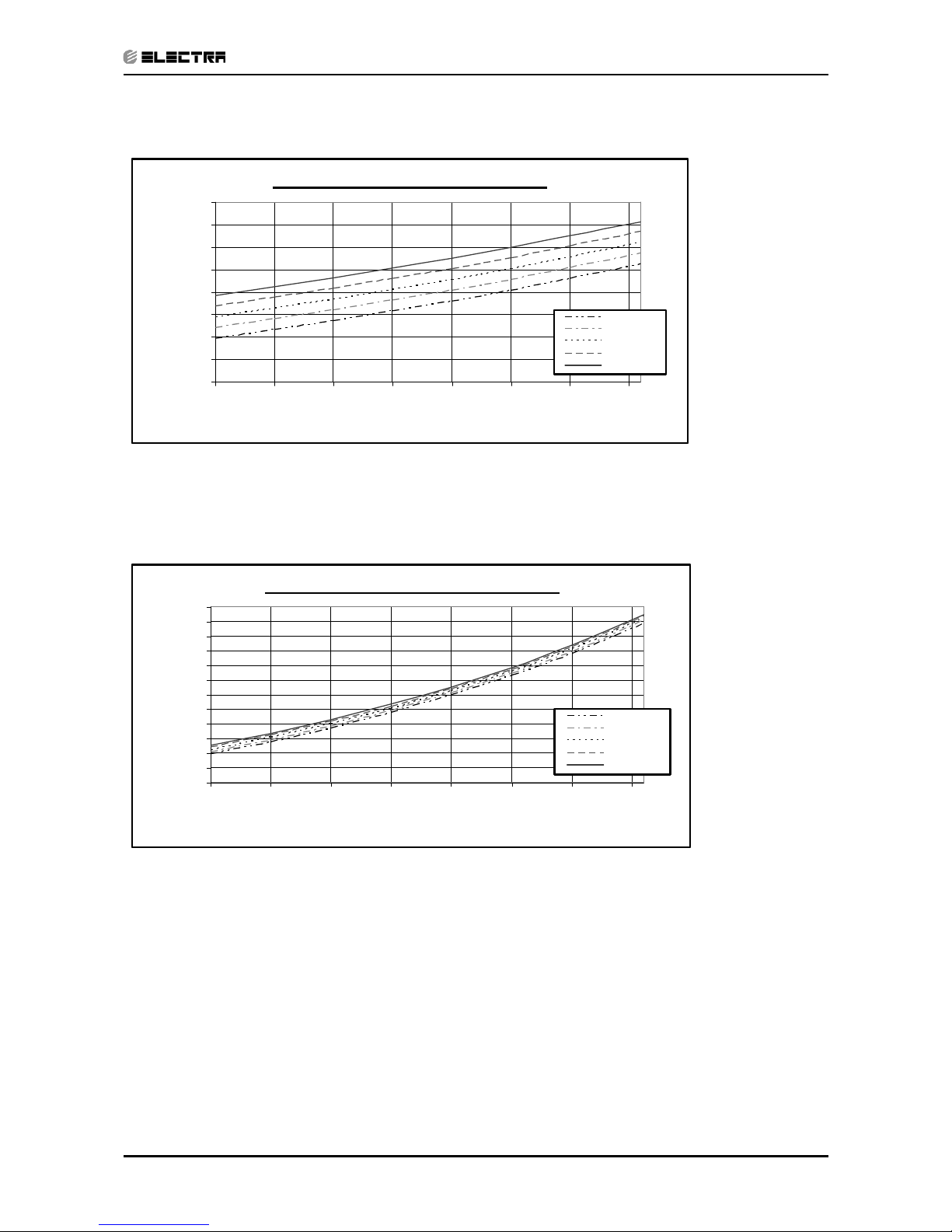

5.3 Capacity Correction Factor Due to Tnbing Length

5.3.1 Delta 25 DCI: Cooling

5.3.2 Heating

0.90

0.91

0.92

0.93

0.94

0.95

0.96

0.97

0.98

0.99

1.00

1.01

3579111315

Tubing Length [m]

Capacity Ratio

0.84

0.86

0.88

0.90

0.92

0.94

0.96

0.98

1.00

1.02

3579111315

Tubing Length [m]

Capacity Ratio

Page 17

5-6

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01 Service Manual - Delta DCI

5.3.3 Delta 35 DCI: Cooling

5.3.4 Heating

0.94

0.95

0.96

0.97

0.98

0.99

1.00

1.01

3 5 7 9 11 13 15

Tubing Length [m]

Capacity Ratio

0.97

0.98

0.98

0.99

0.99

1.00

1.00

1.01

3 5 7 9 11 13 15

Tubing Length [m]

Capacity Ratio

Page 18

5-7

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01Service Manual - Delta DCI

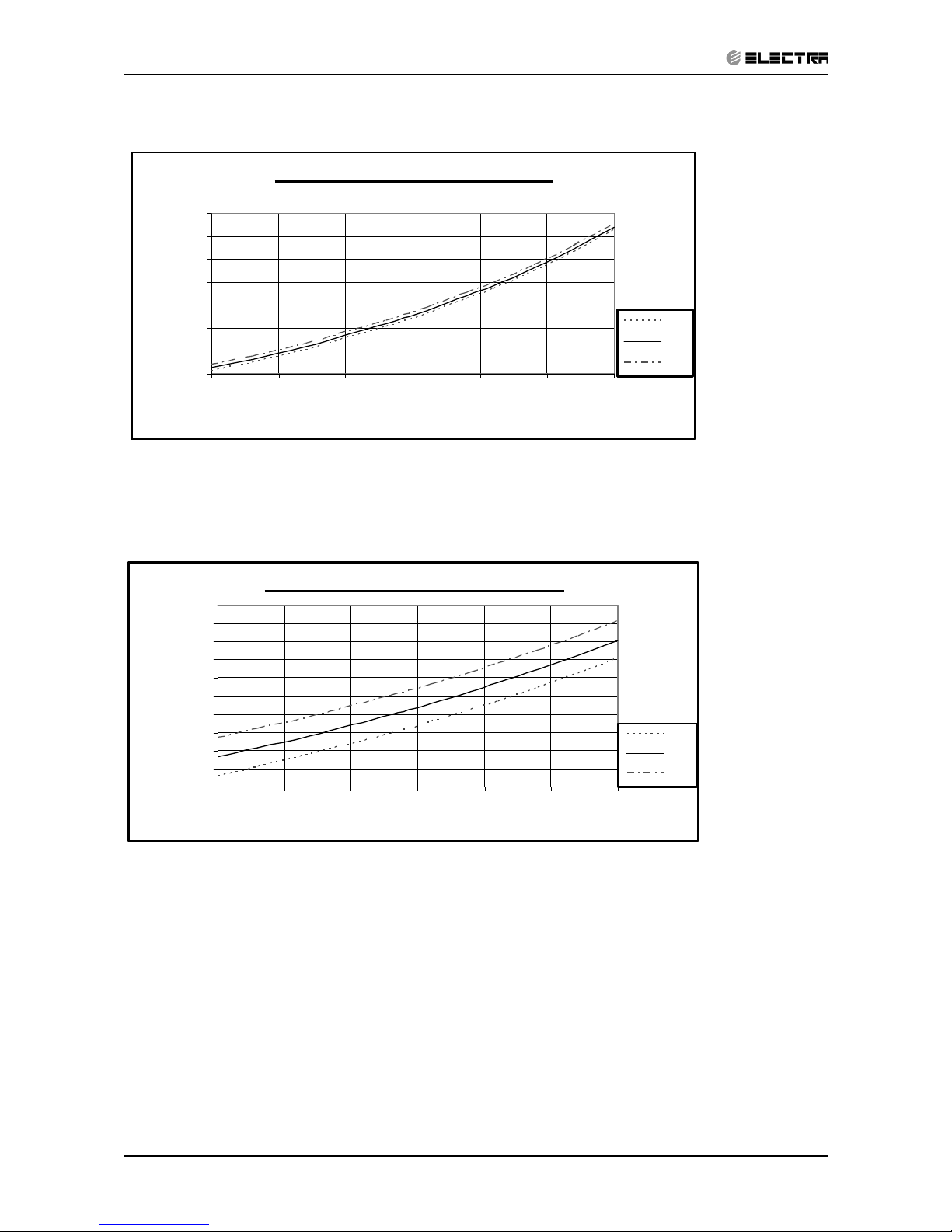

5.4 Pressure Curves

5.4.1. Model: Delta 25 DCI Cooling — Test Mode

Suction Pressure VS.Outdoor Temp.

500

600

700

800

900

1000

1100

10 15 20 25 30 35 40 45

Outdoor DB Temperature [ºC]

Suction Pressure [kPa]

22/15 D B/WB

24/17 D B/WB

27/19 D B/WB

29/21 D B/WB

32/23 D B/WB

Discharge Pressure VS. Outdoor Temp.

1000

1250

1500

1750

2000

2250

2500

2750

3000

3250

3500

3750

4000

10 15 20 25 30 35 40 45

Outdoor DB Temperature [ºC]

Discharge Pressure [kPa]

22/15 D B/WB

24/17 D B/WB

27/19 D B/WB

29/21 D B/WB

32/23 D B/WB

Page 19

5-8

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01 Service Manual - Delta DCI

5.4.2 Heating — Test Mode.

Suction Pressure VS. Outdoor Temp.

300

400

500

600

700

800

900

1000

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [ºC]

Suction Pressure [kPa]

15 DB

20 DB

25 DB

Discharge Pressure VS. Outdoor Temp.

1500

1750

2000

2250

2500

2750

3000

3250

3500

3750

4000

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [ºC]

Discharge Pressure [kPa]

15 DB

20 DB

25 DB

Page 20

5-9

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01Service Manual - Delta DCI

5.5 Model: Delta 35 DCI Cooling — Test Mode

Suction Pressure VS. Outdoor Temp.

400

500

600

700

800

900

1000

1100

1200

10 15 20 25 30 35 40 45

Outdoor DB Temperature [ºC]

Suction Pressure [kPa]

22/15 D B/WB

24/17 D B/WB

27/19 D B/WB

29/21 D B/WB

32/23 D B/WB

Discharge Pressure VS. Outdoor Temp.

1000

1250

1500

1750

2000

2250

2500

2750

3000

3250

3500

3750

4000

10 15 20 25 30 35 40 45

Outdoor DB Temperature [ºC]

Discharge Pressure [kPa]

22/15 DB /WB

24/17 DB /WB

27/19 DB /WB

29/21 DB /WB

32/23 DB /WB

Page 21

5-10

PERFORMANCE DATA & PRESSURE CURVES

Revision Y05-01 Service Manual - Delta DCI

5.6 Heating — Test Mode

Suction Pressure VS. Outdoor Temp.

300

400

500

600

700

800

900

1000

-15 -10 -5 0 5 10 15

Outdoor WB Tempera ture [ºC]

Suction Pressure [kPa]

15 DB

20 DB

25 DB

Discharge Pressure VS. Outdoor Temp.

1500

1750

2000

2250

2500

2750

3000

3250

3500

3750

4000

-15 -10 -5 0 5 10 15

Outdoor WB Temperature[ºC]

Discharge Pressure [kPa]

15 DB

20 DB

25 DB

Page 22

6-1

SOUND LEVEL CHARACTERISTICS

Revision Y05-01Service Manual - Delta DCI

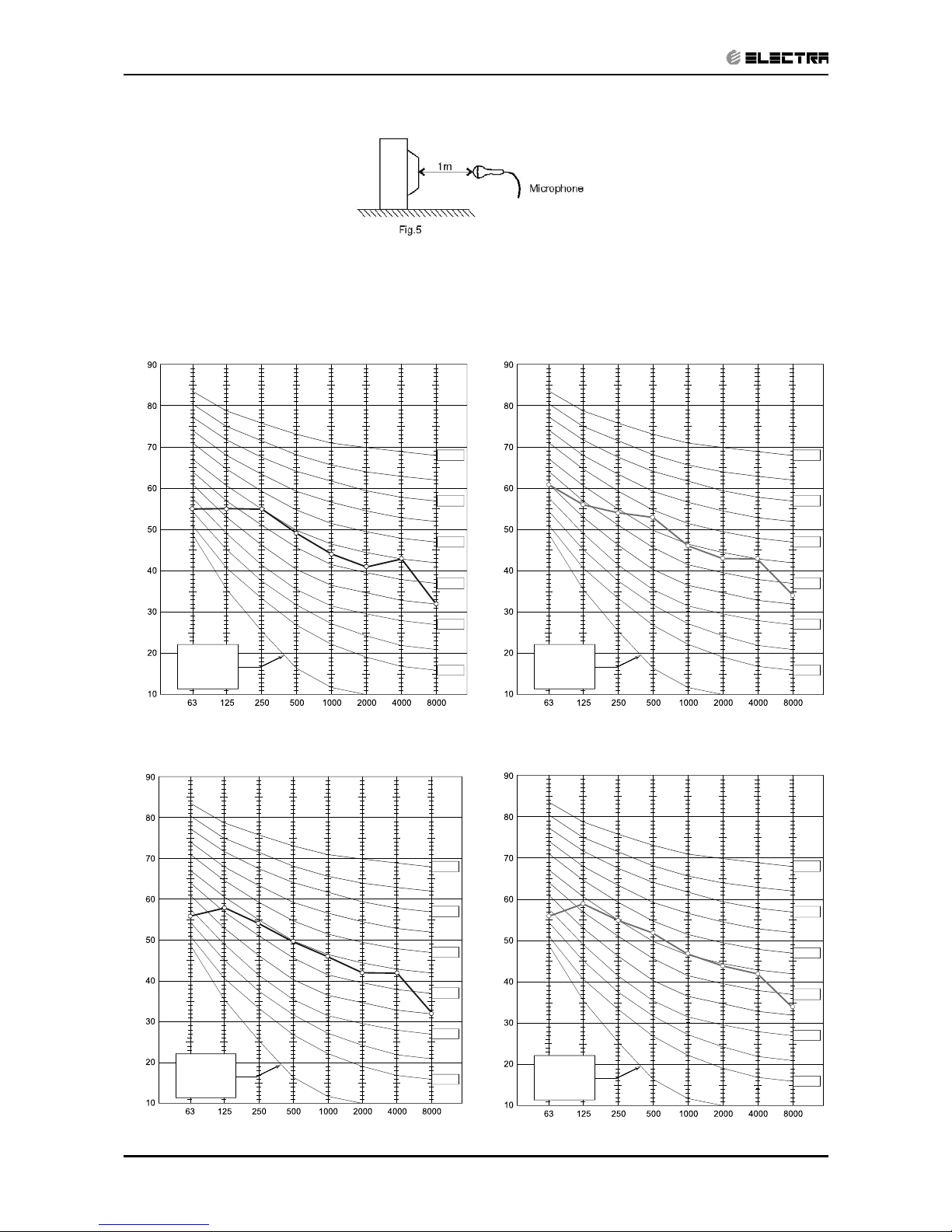

6. SOUND LEVEL CHARACTERISTICS

6.1 Sound Pressure Level

Figure 1. Wall Mounted Figure 2. Floor Mounted

Figure 3. Ducted Figure 4. Cassette

6.2 Soud Pressure Level Spectrum (Measured as Figure 1)

Delta 25 Delta 35

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

FAN SPEED LINE

HI

ME

LO

Page 23

6-2

SOUND LEVEL CHARACTERISTICS

Revision Y05-01 Service Manual - Delta DCI

6.3 Outdoor units

6.4 Sound Pressure Level Spectrum (Measured as Figure 5)

DCR 25 Cooling DCR 25 Heating

DCR 35 Cooling DCR 35 Heating

Microphone Distance from Unit

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

Page 24

7-1

ELECTRICAL DATA

Revision Y05-01Service Manual - Delta DCI

7. ELECTRICAL DATA

7.1 Single Phase Units

MODEL Delta 25 Delta 35

Power Supply

To indoor To indoor

1PH,220-240V,50Hz 1PH,220-240V,50Hz

Max Current, A 6.3 7.5

Circuit Breaker,A 12 15

Power Supply Wiring No. X

Cross Section mm

2

3x1.0 mm

2

3x1.5 mm

2

Interconnecting Cable RC

Model No. X Cross Section mm

2

4x1.0 mm

2

5x1.5 mm

2

NOTE

Power wiring cord should comply with local lows and electrical

regulations requirements

Page 25

8-1

WIRING DIAGRAMS

Revision Y05-01Service Manual - Delta DCI

8. WIRING DIAGRAMS

8.1 Delta 25/35 DCR 25/35 DCI

Blue

Blue

Blue

Blue

N/3

Indoor unit controller PCB

Note: The dashed part is optional

Power supply

~230V 50Hz

J3

INDOOR UNIT CIRCUIT DIAGRAM

P20P19

P2

3 4

P1

1 2

P4

P3 P9 P11

Outdoor unit controller PCB

EEV

P7

N

COML

P10

4

5

6

23

1

Y/G

Y/G

C/5

Brown

L/4

Red

Brown

Red

Y/G

Brown

Red

C

N

L

Jumper

Flash

4

3

2

JP9

1

JP1

6

5

31

24

P10 P1

P8

P22

To metal sheet

1

2

JUMPER

J1

J2

L-OFAN

OFAN

1 2

Red

OUTDOOR UNIT CIRCUIT DIAGRAM

Reverse

COMP

Red

Black

Brown

W

V

U

1

2

Blue

H-OFAN

Yellow

capacitor

2uF 450V

valve

Green

3 4

Black

1

2

11

22

Sheet

Y/G

NEUTRAL

To Metal

red

blue

1uF 450V

gray

gray

black

white

P4

P15P16 P11 P3P14P19

2112

PH-12

P5(white)

( red)

P9

brown

capacitor

312

5

6

4

Display

OCT

OAT CTT

IFAN

ICT

RAT

Brown

Y/G

P2

P20

32

3

4

1

4

MEGATOOL

P7(White)

J4

P13

M1

FLASH

3

3

45

2

1

1

2

P6(White)

54

6

Step motor

magnetic ring

Page 26

9-1

REFRIGERATION DIAGRAMS

Revision Y05-01Service Manual - Delta DCI

9. REFRIGERATION DIAGRAMS

9.1 Heat Pump Models

9.1.1 Delta 25/35 DCR 25/35 DCI => Cooling Mode

EEV

EEV

Page 27

10-1

TUBING CONNECTIONS

Revision Y05-01Service Manual - Delta DCI

10. TUBING CONNECTIONS

TUBE (Inch)

TORQUE (Nm)

¼” ⅜” ½” ⅝” ¾”

Flare Nuts 11-13 40-45 60-65 70-75 80-85

Valve Cap 13-20 13-20 18-25 18-25 40-50

Service Port Cap 11-13 11-13 11-13 11-13 11-13

1. Valve Protection Cap-end

2. Refrigerant Valve Port (use Allen wrench to open/close)

3. Valve Protection Cap

4. Refrigerant Valve

5. Service Port Cap

6. Flare Nut

7. Unit Back Side

8. Copper Tube

When the outdoor unit is installed above the indoor unit an oil trap is required every 5m along the suction

line at the lowest point of the riser. Incase the indoor unit is installed above the outdoor, no trap is

required.

Page 28

11-1

CONTROL SYSTEM

Revision Y05-01Service Manual - Delta DCI

11. CONTROL SYSTEM

11.1 General Functions and Operating Rules

The DCI software is fully parametric.All the model dependent parameters are shown in Blue color

and with Italic style [parameter].

The parameters values are given in the last section of this control logic chapter of the service

manual.

11.1.1 System Operation Concept

The control function is divided between indoor and outdoor unit controllers. Indoor unit is the system

‘Master’, requesting the outdoor unit for cooling/heating capacity supply. The outdoor unit is the

system ‘Slave’ and it must supply the required capacity unless it enters into a protection mode

avoiding it from supplying the requested capacity.

The capacity request is transferred via indoor to outdoor communication, and is represented by a

parameter called ‘NLOAD’. NLOAD is an integer number with values between 0 and 127, and it

represents the heat or cool load felt by the indoor unit.

11.1.2 Compressor Frequency Control (NLOAD setting)

The NLOAD setting is done by the indoor unit controller, based on a PI control scheme.

The actual NLOAD to be sent to the outdoor unit controller, is based on the preliminary LOAD

calculation, the indoor fan speed, and the power shedding function.

NLOAD limits as a function of indoor fan speed:

Indoor Fan Speed Maximum NLOAD Cooling Maximum NLOAD Heating

Low Max NLOADIF1C 127

Medium Max NLOADIF2C 127

High Max NLOADIF3C 127

Turbo Max NLOADIF4C 127

Auto Max NLOADIF5C 127

11.1.3 Target Frequency Setting

The compressor target frequency is a function of the NLOAD number sent from the indoor

controller and the outdoor air temperature.

Basic Target Frequency Setting:

NLOAD Target Frequency

127 Maximum frequency

10 < NLOAD < 127 Interpolated value between minimum and maximum frequency

10 Minimum frequency

0 Compressor is stopped

Page 29

11-2

CONTROL SYSTEM

Revision Y05-01 Service Manual - Delta DCI

Target frequency limits as a function of outdoor air temperature (OAT):

OAT Range Cool mode limits Heat mode limits

OAT < 6

MaxFreqAsOATC

No limit

6 ≤ OAT < 15 MaxFreqAsOAT1H

15 ≤ OAT < 28

MaxFreqAsOAT2H

28 ≤ OAT No limit

11.1.4 Frequency Changes Control

Frequency change rate is 1 Hz/sec.

11.1.5 Compressor Starting Control

11.1.6 Minimum On and Off Time

3 minutes.

11.1.7 Indoor Fan Control

10 Indoor fan speeds are determined for each model. 5 speeds for cool/dry/fan modes and 5

speeds for heat mode.

When user sets the indoor fan speed to a fixed speed (Low/ Medium/ High), unit will operate

constantly at set speed.

When Auto Fan is selected, indoor unit controller can operate in all speeds. The actual speed is set

according to the cool/heat load.

11.1.8 Turbo Speed

The Turbo speed is activated during the first 30 minutes of unit operation when auto fan speed is

selected and under the following conditions:

• Difference between set point and actual room temperature is bigger then 3 degrees.

• Room temperature > 22 for cooling, or < 25 for heating.

Frequency

Time

Min 10 Minutes

1

Minute

Step 1

Step 3

1

Minute

Step 2

Page 30

11-3

CONTROL SYSTEM

Revision Y05-01Service Manual - Delta DCI

11.1.9 Heating Element Control

Heating element can be started if LOAD > 0.8 * MaximumNLOAD AND Indoor Coil

temperature < 45.

The heating element will be stopped when LOAD < 0.5 * MaximumNLOAD OR if Indoor Coil

temperature > 50.

11.1.10 Outdoor Fan Control

• The OFAN motor is an AC type that operates with 2 speeds (Low/High),

controlled by Relays.

• OFAN speed depends on the compressor Target Frequency, and it’s set according to the

following table and graphs.

• OFAN can change its Speed only if it has been working in the current

speed for

at least 35 seconds:

Compressor

Target Frequency

OFAN Speed

Normal cases

State A at cool / Heat

State B

at cool

State C

at cool

OAT>15

o

C

at heat

Freq=0 OFF OFF OFF OFF

10 ≤ Freq < OFLowFreq Low Low Low Low

OFLowFreq ≤ Freq< OFMedFreq High Low Low Low

OFMedFreq≤ Freq High Low Low High

Notes:

When OAT is faulty or disabled OFAN will follow ‘Normal cases’ rules (left column).

1. OFLowFreq =

OFLowFreqC in cool mode, and OFLowFreqH in heat mode.

2. OFMedFreq =

OFMedFreqC in cool mode, and OFMedFreqH in heat mode.

The OFAN will be off when the compressor is off.

• An exception for the following rule is when compressor was operating in cool

mode before stopped. In this case OFAN will remain on in low speed for 1

minute.

• Whenever the indoor unit is under indoor coil overheating protection, as long as the

protection status is HzD2, the outdoor fan will change to off. It will be enabled to be back on

when the status of this protection becomes normal.

• Upon receiving night mode signal (ON), through communication, the OFAN will be

operating in LOW speed only in Cool. It will be back to its normal operation when receiving

OFF signal.

OAT

OFAN Stat

e

at Cool Mode

20

A

B

C

3 Degrees

3 Degrees

7

Not e: Pe r i or i t i es A>B>C

Page 31

11-4

CONTROL SYSTEM

Revision Y05-01 Service Manual - Delta DCI

11.1.1 EEV (electronic Expansion valve) Control

EEV opening is defined as EEV = EEVOL + EEV

CV

EEVOL is the initial EEV opening as a function of the compressor frequency, operation mode, unit

model and capacity.

EEV

CV

is a correction value for the EEV opening that is based on the compressor temperature.

During the first 5 minutes of compressor operation EEV

CV

= 0.

Once the first 5 minutes are over, the correction value is calculated as follow: EEV

CV

(n) = EEVCV(n-

1) + EEV

CTT

EEV

CTT

is the correction based on the compressor temperature. A target compressor temperature is

set depending on frequency and outdoor air temperature, and the actual compressor temperature

is compared to the target temperature to set the required correction to the EEV opening.

11.1.2 Reversing Valve (RV) Control

Reversing valve is on in heat mode.

Switching of RV state is done only after compressor is off for over 3 minutes.

11.2 Fan Mode

In high/ medium/ low indoor fan user setting, unit will operate fan in selected speed.

In AutoFan user setting, fan speed will be adjusted automatically according to the difference

between actual room temperature and user set point temperature.

11.3 Cool Mode

NLOAD is calculated according to the difference between actual room temperature and user set

point temperature by PI control.

In high/ medium/ low indoor fan user setting, unit will operate fan in selected speed.

In AutoFan user setting, fan speed will be adjusted automatically according to the calculated

NLOAD.

11.4 Heat Mode

NLOAD is calculated according to the difference between actual room temperature and user set

point temperature by PI control.

In high/ medium/ low indoor fan user setting, unit will operate fan in selected speed.

In AutoFan user setting, fan speed will be adjusted automatically according to the calculated

NLOAD.

11.4.1 Temperature Compensation

4 degrees are reduced from RT sensor temperature reading (excluding I-Feel mode), to

compensate for temperature difference between high and low areas in the heated room, and due

to coil heat radiation on RT sensor.

Page 32

11-5

CONTROL SYSTEM

Revision Y05-01Service Manual - Delta DCI

11.4.2 Indoor Fan Control in Heat Mode

Indoor fan speed depends on the indoor coil temperature:

11.5 Auto Cool/Heat Mode

When in auto cool heat mode unit will automatically select between cool and heat mode according

to the difference between actual room temperature and user set point temperature (ΔT).

Unit will switch from cool to heat when compressor is off for 3 minutes, and ΔT < -3.

Unit will switch from heat to cool when compressor is off for 5 minutes, and ΔT < -3.

11.6 Dry Mode

As long as room temperature is higher then the set point, indoor fan will work in low speed and

compressor will work between 0 and MaxNLOADIF1C Hz.

When the room temperature is lower than the set point, compressor will be switched OFF and

indoor fan will cycle 3 minutes OFF, 1 minute ON.

11.7 Protections

There are 5 protection codes.

Normal (Norm) – unit operate normally.

Stop Rise (SR) – compressor frequency can not be raised but does not have to be decreased.

HzDown1 (D1) – Compressor frequency is reduced by 2 to 5 Hz per minute.

HzDown2 (D2) – Compressor frequency is reduced by 5 to 10 Hz per minute.

Stop Compressor (SC) – Compressor is stopped.

11.7.1 Indoor Coil Defrost Protection

ICT

ICT Trend

Fast

Increasing

Increasing No change Decreasing

Fast

Decreasing

ICT < -2 SC SC SC SC SC

-2 ≤ ICT < 0 D1 D1 D2 D2 D2

0 ≤ ICT < 2 SR SR D1 D2 D2

2 ≤ ICT < 4 SR SR SR D1 D2

4 ≤ ICT < 6 Norm Norm SR SR D1

6 ≤ ICT < 8 Norm Norm Norm SR SR

8 ≤ ICT Normal

ICTVL ICTT ICTHICTL

ICTST

Page 33

11-6

CONTROL SYSTEM

Revision Y05-01 Service Manual - Delta DCI

11.7.2 Indoor Coil over Heating Protection

ICT

ICT Trend

Fast

Decreasing

Decreasing No Change Increasing

Fast

Increasing

ICT > 55 SC SC SC SC SC

53 < ICT ≤ 55 D1 D1 D2 D2 D2

49 < ICT ≤ 53 SR SR D1 D2 D2

47 < ICT ≤ 49 SR SR SR D1 D2

45 < ICT ≤ 47 Norm Norm SR SR D1

43 < ICT ≤ 45 Norm Norm Norm SR SR

ICT ≤ 43 Normal

11.7.3 Compressor over Heating Protection

Compressor temperature can be in one of 5 control zones (4 in protection, and 1 normal),

according to the following chart.

Control Status

Compressor Temperature

Increases

Else

P1 Norm SR

P2 D1 SR

P3 D2 D1

Stop Compressor SC

Normal

P1

P2

Stop-Compresor

CTTOH1

CTTOH2

CTTOH3

CTTOH4

CTT

P3

Page 34

11-7

CONTROL SYSTEM

Revision Y05-01Service Manual - Delta DCI

11.7.4 Compressor over Current Protection

11.7.5 Heat Sink Over Heating Protection (NA for DCI 25 and 35)

HST

HST Trend

Decreasing No Change Increasing

HST > 90 SC SC SC

85 < HST ≤ 90 D1 D2 D2

82 < HST ≤ 85 SR D1 D2

80 < HST ≤ 82 SR SR D1

78 < HST ≤ 80 Norm Norm SR

HST ≤ 78 Normal

11.7.6 Outdoor Coil Deicing Protection

Deicing Starting Conditions

Deicing operation will start when either one of the following conditions exist:

• Case 1: OCT < OAT – 8 AND TLD > DI

• Case 2: OCT < OAT – 12 AND TLD > 30 minutes.

• Case 3: OCT is Invalid AND TLD > DI

• Case 4: Unit is just switched to STBY AND OCT < OAT – 8

• Case 5: NLOAD = 0 AND OCT < OAT -8

OCT – Outdoor Coil Temperature

OAT – Outdoor Air Temperature

TLD – Time from Last Deicing

DI – Deicing Interval (Time Interval Between Two Deicing)

Deicing interval time when compressor is first started in heat mode, is 10 minutes if OCT < -2, and

is 40 minutes in other cases.

Deicing interval time is changed (increased/ decreased in 10 minutes steps) as a function of

deicing time. If deicing time is shorter then former deicing time, the deicing interval time will be

increased. If deicing time is longer then former deicing time, the deicing interval time will be

decreased.

Normal

Stop-Rise

HzDown1

HzDown2

Stop-Compresor

CCROC1

CCROC2

CCROC3

CCROC4

CCR

Page 35

11-8

CONTROL SYSTEM

Revision Y05-01 Service Manual - Delta DCI

Deicing Protection Procedure

T1 =60 seconds, T2 = 36 seconds, T3 = 6 seconds

COMP

RV

OFAN

EEV

ON

HEAT

COOL

ON

OFF

EEVDeicerOpen

Any

T1 T2

T3 T3

T1

12

0

Threshold

max. 12 minutes

DT

OCT

Page 36

11-9

CONTROL SYSTEM

Revision Y05-01Service Manual - Delta DCI

11.8 Operating the Unit from the Mode Button

Forced operation allows to start, stop and operate in Cooling or Heating, in pre-set temperature

according to the following table:

Forced operation Mode Pre-set Temperature

Cooling 20

0

C

Heating 28

0

C

11.9 On Unit Controls and Indicators

The following is schematic drawing for the display:

STBY/OPER

Mode/Reset Button

Infra Red Receiver

Filter

Timer

Page 37

11-10

CONTROL SYSTEM

Revision Y05-01 Service Manual - Delta DCI

STAND BY

INDICATOR

1. Lights up when the Air Conditioner is connected to power and

the mode is STBY.

2. Blinks for 3 seconds, when the system is switched to Heat Mode

by using the Mode/Reset Switch on the unit (the operation

indicator will be off during this blinking time).

OPERATION INDICATOR

1. Lights up during operation mode (except for item in STBY

indicator).

2. Blinks for 300 msec., to announce that a R/C infrared

signal has been received and stored.

3. Blinks continuously during protections (according to the relevant

spec section).

4. Blinks for 3 seconds when the system is switched to Cool Mode

by using the Mode/Reset Switch on the unit.

TIMER INDICATOR Lights up during Timer and Sleep operation.

FILTER INDICATOR Lights up when Air Filter needs to be cleaned.

MODE / RESET BUTTON

As long as the filter Led is off, the Mode/Reset button functions as

Mode switch. Once filter Led is on, the Mode/Reset button functions as

Reset switch.

Mode Function:

Every short pressing , the next operation mode is selected, in this order:

SB → Cool Mode → Heat Mode → SB → …

In long pressing system enters diagnostic mode (refer to diagnostic

mode Sect.)

Reset Function:

For short pressing:

When Filter LED is on, it turns off the filter indicator.

Notes

1. Pressing time is defined as the time between press and release.

2. If pressing time is one second or less – press is considered as short pressing.

3. If pressing time is three seconds or longer – pressing is considered as long pressing. In

between, pressing is undetermined and system will not respond to pressing.

4. For the LED functionality during diagnostics, refer to the diagnostics Sect.

Page 38

11-11

CONTROL SYSTEM

Revision Y05-01Service Manual - Delta DCI

11.10 Outdoor Unit Controller Indicators

Unit has three LED’s. SB LED, STATUS LED, FAULT LED.

SB LED is ON when power is ON (230 VAC),

STATUS LED is ON when COMP is ON, and Blinks according to diagnostics mode definitions

when either fault or protection occurs.

FAULT LED Blinks according to diagnostics mode definitions when either fault or protection occurs.

11.11 Jumper Settings

11.11.1 Indoor Unit Controller

0 = Open Jumper (disconnect jumper).

1 = Close Jumper (connect jumper).

Self test Jumper – J1

OPERATION J1

SELF-TEST 1

NORMAL 0

Family selection Jumper – J2

Family J2

Delta 25/35 0

Model selection Jumper – J3, J4

Model J3 J4

A

B

C

D

0 0

0 1

1 0

1 1

Page 39

11-12

CONTROL SYSTEM

Revision Y05-01 Service Manual - Delta DCI

11.11.2 Outdoor Unit Controller

JP9 JUMPER LAYOUT

EEPROM Data (PIN 9) ODU3 (PIN 7) ODU2 (PIN 5) ODU1 (PIN 3) ODU0 (PIN 1)

GND (PIN 10) GND (PIN 8) GND (PIN 6) GND (PIN 4) GND (PIN 2)

ODU MODEL SELECTION

ODU3 ODU2 ODU1 ODU0 ODU Model

OFF OFF OFF OFF Reserved

OFF OFF OFF ON (PIN1 & PIN2) A (Single DCR 20)

OFF OFF ON (PIN3 & PIN4) OFF B (Single DCR 25)

OFF OFF ON (PIN3 & PIN4) ON (PIN1 & PIN2) C (Single DCR 35)

OFF ON (PIN5 & PIN6) OFF OFF D

OFF ON (PIN5 & PIN6) OFF ON (PIN1 & PIN2) E (Duo DCI 50)

OFF ON (PIN5 & PIN6) ON (PIN3 & PIN4) OFF F

OFF ON (PIN5 & PIN6) ON (PIN3 & PIN4) ON (PIN1 & PIN2) G

ON (PIN7 & PIN8) OFF OFF OFF H

ON (PIN7 & PIN8) OFF OFF ON (PIN1 & PIN2) I

ON (PIN7 & PIN8) OFF ON (PIN3 & PIN4) OFF J

ON (PIN7 & PIN8) OFF ON (PIN3 & PIN4) ON (PIN1 & PIN2) K

ON (PIN7 & PIN8) ON (PIN5 & PIN6) OFF OFF L

ON (PIN7 & PIN8) ON (PIN5 & PIN6) OFF ON (PIN1 & PIN2) M

ON (PIN7 & PIN8) ON (PIN5 & PIN6) ON (PIN3 & PIN4) OFF N

ON (PIN7 & PIN8) ON (PIN5 & PIN6) ON (PIN3 & PIN4) ON (PIN1 & PIN2) O

11.12 Test Mode

11.12.1 Entering Test Mode

System can enter Test mode in two ways:

• Automatically when the following conditions exists for 30 minutes continuously:

o Mode = Cool, Set point = 16, Room temperature = 27±1, Outdoor temperature =

35±1

Or

o Mode = Heat, Set point = 30, Room temperature = 20±1, Outdoor temperature =

7±1

• Manually when entering diagnostics with the following settings:

•

o Mode = Cool, Set point = 16

o Mode = Heat, Set point = 30

11.12.2 Unit Operation in Test Mode

In test mode, the unit will operate in fixed settings according to the indoor fan speed setting:

Indoor Fan Speed Setting Unit Setting

Low Minimum Capacity Setting

High Nominal Capacity Setting

Auto Maximum Capacity Setting

During test mode, protections are disabled, except for stop compressor status.

Page 40

11-13

CONTROL SYSTEM

Revision Y05-01Service Manual - Delta DCI

11.13 SW Parameters

11.13.1 Indoor Units SW Parameters

General Parameters for All Models:

Parameters defining the indoor fan speed as a function of Indoor Coil temperature in heat mode

(ICT):

ICTST Speed ICT to stop indoor fan 25

ICTVLSpeed ICT to go down to very low speed 28

ICTLSpeed ICT to start in very low speed 30

ICTHSpeed ICT to start in increase speed from very low 32

ICTTSpeed ICT to enable Turbo fan speed 40

Parameters for defrost protection:

ICTDef1 ICT to go back to normal 8

ICTDef2 ICT to ‘stop rise’ when ICT decrease 6

ICTDef3 ICT to ‘stop rise’ when ICT is stable 4

ICTDef4 ICT to ‘Hz Down’ when ICT decrease 2

ICTDef5 ICT to ‘Hz Down’ when ICT is stable 0

ICTDef6 ICT to stop compressor -2

Parameters for indoor coil over heating protection:

ICTOH1 ICT to go back to normal 45

ICTOH2 ICT to ‘stop rise’ when ICT increase 48

ICTOH3 ICT to ‘stop rise’ when ICT is stable 52

ICTOH4 ICT to ‘Hz Down’ when ICT increase 55

ICTOH5 ICT to ‘Hz Down’ when ICT is stable 60

ICTOH6 ICT to stop compressor 62

Model Depended Parameters:

Parameter name

Models

22 25 35

NLOAD limits as a function of selected indoor fan speed

MaxNLOADIF1C 40 40 40

MaxNLOADIF2C 55 51 55

MaxNLOADIF3C 120 90 90

MaxNLOADIF4C 127 127 127

MaxNLOADIF5C 127 127 127

Indoor Fan speeds

IFVLOWC 700 700 700

IFLOWC 800 850 850

IFMEDC 950 1050 1000

IFHIGHC 1050 1200 1200

IFTURBOC 1150 1250 1250

IFVLOWH 700 700 700

IFLOWH 850 950 950

IFMEDH 1000 1050 1100

IFHIGHH 1100 1250 1250

IFTURBOH

1200 1350 1300

Nominal Compressor Frequency

NomLoadC 40 51 61

NomLoadH 55 58 62

Page 41

11-14

CONTROL SYSTEM

Revision Y05-01 Service Manual - Delta DCI

11.13.2 Outdoor Units SW Parameters

Parameter Name DCI25 DCI35 DCI 50

Compressor Parameters

MinFreqC 30 35 35

MaxFreqC 52 62 70

MinFreqH 30 35 40

MaxFreqH 60 73 66

Step1Freq 45 45

Step2Freq 55 55

Step3Freq 65 65

Frequency limits as a function of outdoor air temperature

MaxFreqAsOATC 50 60

MaxFreqAsOAT1H 58 60

MaxFreqAsOAT2H 50 50

Compressor Over Heating Protection

CTTOH1 94 94 94

CTTOH2 98 98 98

CTTOH3 102 102 102

CTTOH4 105 105 105

CTTOH5 120 120 120

Compressor Over Current Protection [A]

CCR01 40 40 40

CCR02 42 42 42

CCR03 44 44 44

CCR04 47 47 47

Outdoor Fan Speed (RPM)

OFLOWC 610 600 600

OFMEDC 700 760 760

Page 42

12-1

TROUBLESHOOTING

Revision Y05-01Service Manual - Delta DCI

12. TROUBLESHOOTING

WARNING!!!

When Power Up – the whole outdoor unit controller, including the wiring, is

under HIGH VOLTAGE!!!

Never open the Outdoor unit before turning off the Power!!!

When turned off, the system is still charged (400V)!!!

It takes about 4 Min. to discharge the system.

Touching the controller before discharging may cause an electrical shock!!!

12.1

Single Split system failures and corrective

actions

No SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

1

Power supply indicator

(Red LED) does not light

up.

No power supply

Check power supply. If power supply

is OK, check display and display

wiring. if OK, replace controller.

2

Unit does not respond to

remote control message Remote control message

not reached the indoor

unit

Check remote control batteries, if

batteries are OK, check display and

display wiring, if OK, replace display

PCB.

If still not OK replace controller.

3

Unit responds to remote

control message but

Operate indicator (Green

LED) does not light up

Problem with display

PCB

Replace display PCB.

If still not OK replace controller.

Unit in heat mode and

coil is still not warm.

Change to cool mode and check.

4

Indoor fan does not start

(louvers are opened and

Green LED does light up)

Problem with PCB or

capacitor

Change to high speed and Check

power supply to motor is higher than

130VAC (for triack controlled motor)

or higher than 220VAC for fixed

speed motors, if OK replace

capacitor, if not replace controller

5

Indoor fan works when

unit is OFF, and indoor

fan speed is not changed

by remote control

command.

PCB problem

Replace controller

6

Compressor does not

start

Electronics control

problem or protection

Perform diagnostics , and follow the

actions described.

7

Compressor stops during

operation and Green

LED remains on

Electronic control or

power supply problem

Perform diagnostics ,and follow the

actions described.

8

Compressor is on but

outdoor fan does not

work

Problem with outdoor

electronics or outdoor fan

Check outdoor fan motor according

to the procedure in section, if not OK

replace controller

Page 43

12-2

TROUBLESHOOTING

Revision Y05-01 Service Manual - Delta DCI

No

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

9

Unit works in wrong

mode (cool instead of

heat or heat instead of

cool)

Electronics or power

connection to RV

Check RV power connections, if OK,

Check RV operation with direct

230VAC power supply, if OK,

Replace outdoor controller.

10

All components are

operating properly but no

cooling or no heating

Refrigerant leak Check refrigeration system.

11

Compressor is over

heated and unit does not

generate capacity

EEV problem Check EEV

12

Units goes into

protections and

compressor is stopped

with no clear reason

Control problem or

refrigeration system

problem

Perform diagnostics and follow the

actions described.

13

Compressor motor is

generating noise and no

suction occurs

Phase order to

compressor is wrong

Check compressor phase order.

14

Water leakage from

indoor unit

Indoor unit drainage tube

is blocked

Check and open drainage tube.

15

Freezing of outdoor unit

in heat mode and

outdoor unit base is

blocked with ice

Connect base heater.

16

Unit operates with wrong

fan speeds or wrong

frequency

Wrong jumper settings

Perform diagnostics, and check if

units is operating by EEPROM

parameters.

12.2 Checking the refrigeration system

Checking system pressures and other thermodynamic measures should be

done when system is in Test Mode (in Test mode, system operates in fixed

settings). The performance curves given in this manual are given for unit

performance in test mode when high indoor fan speed is selected.

Entering test mode:

Set unit to Cool/16 degrees/High indoor fan speed, or Heat/30 degrees/High

indoor fan speed, and enter diagnostics.

Page 44

12-3

TROUBLESHOOTING

Revision Y05-01Service Manual - Delta DCI

12.3 Judgment by Indoor/Outdoor Unit Diagnostics

Enter diagnostics mode - press for five seconds Mode/Reset button in any

operation mode. Acknowledgment is by 3 short beeps and lights of all Display

LED’s. Then, The units will enter into Indoor and Outdoor unit diagnostic

modes.

During the Outdoor unit diagnostics all three Indoor LED’s (STBY/Operate,

Filter and Timer) are blinking. When Indoor diagnostics is displayed, all three

LED’s (STBY/Operate, Filter and Timer) are ON.

When system enters diagnostics mode, only one fault code is shown. Order

of priority is from the lower to the higher number. Diagnostics is continuously

ON as long as power is ON. The current system operation mode will not be

changed.

If no fault occurred in the system, no fault code will be displayed during

normal operation mode. The last fault code will be displayed even if the

system has recovered from that fault. The last fault will be deleted from

the EEPROM after the system has exit diagnostics mode.

In diagnostics mode, system fault / status will be indicated by blinking of Filter

& Timer LEDs.

The coding method will be as follows:

Filter LED will blink 5 times in 5 seconds, and then will be shut off for the next 5

seconds. Timer LED will blink during the same 5 seconds according to the following

Indoor / Outdoor unit tables:

Note: 0 – OFF, 1-ON

12.3.1 Indoor unit Diagnostics

No Problem 5 4 3 2 1

1

RT-1 is disconnected

2

RT-1 is shorted

3

RT-2 is disconnected

4

RT-2 is shorted

5

Reserved

7

Communication mismatch

8

No Communication

9

No Encoder

10

Reserved 0 1 0 1 0

11

Outdoor Unit Fault 0 1 0 1 1

…

Reserved

17

Defrost protection

18

Deicing Protection

19

Outdoor Unit Protection

20

Indoor Coil HP Protection

21

Reserved

22

Reserved

24

EEPROM Not Updated

25

Bad EEPROM

26

Bad Communication

27

Using EEPROM data

28

Model A

29

Model B

30

Model C

31

Model D

Page 45

12-4

TROUBLESHOOTING

Revision Y05-01 Service Manual - Delta DCI

12.3.2 Indoor unit diagnosis and corrective actions

No. Fault Probable Cause Corrective Action

1

Sensor failures of all

types

Check sensor connections or

replace sensor

2

Communication

mismatch

Indoor and Outdoor controllers are

with different versions

Replace Indoor controller

3

No Communication

Communication or grounding wiring is

not good.

Check Indoor to Outdoor wiring

and grounding

4

No Encoder

Indoor electronics or motor Check motor wiring, if ok,

replace motor, if still not ok,

replace Indoor controller.

5

Outdoor Unit Fault

Outdoor controller problem Switch to Outdoor diagnostics.

6

EEPROM Not

Updated

System is using ROM parameters and

not EEPROM parameters

No action, unless special

parameters are required for

unit operation.

7

Bad EEPROM

No action, unless special

parameters are required for

unit operation.

8

Bad Communication

Communication quality is low reliabilit

y

Check Indoor to Outdoor wiring

and grounding

9

Using EEPROM

data

No problem. System is using

EEPRRRROM parameters

12.3.3 Outdoor unit Diagnostics

No Problem 5 4 3 2 1

1

OCT is disconnected

0 0 0 0 1

2

OCT is shorted

0 0 0 1 0

3

CTT is disconnected

0 0 0 1 1

4

CTT is shorted

0 0 1 0 0

5

HST is disconnected (when enabled)

0 0 1 0 1

6

HST is shorted (when enabled)

0 0 1 1 0

7

OAT is disconnected (when enabled)

0 0 1 1 1

8

OAT is shorted (when enabled)

0 1 0 0 0

9

TSUC is disconnected (when enabled)

0 1 0 0 1

10

TSUC is shorted (when enabled)

0 1 0 1 0

11

IPM Fault

0 1 0 1 1

12

Bad EEPROM

0 1 1 0 0

13

DC under voltage

0 1 1 0 1

14

DC over voltage

0 1 1 1 0

15

AC under voltage

0 1 1 1 1

16

Indoor / Outdoor unit Communication mismatch

1 0 0 0 0

17

No Communication

1 0 0 0 1

18

Reserved

1 0 0 1 0

20

Heat sink Over Heating

1 0 1 0 0

21

Deicing

1 0 1 0 1

22

Compressor Over Heating

1 0 1 1 0

23

Compressor Over Current

1 0 1 1 1

…

Reserved

27

Bad Communication

1 1 0 1 1

Page 46

12-5

TROUBLESHOOTING

Revision Y05-01Service Manual - Delta DCI

12.3.4 Outdoor unit diagnosis and corrective actions

NO

Fault

Probable Cause Corrective Action

1

Sensors failures of all

types

Check sensors connections

or replace sensors.

2

IPM Fault

Electronics HW

problem

Check all wiring and jumper

settings, if OK, replace

electronics.

3

Bad EEPROM

No action, unless special

parameters are required for

unit operation.

4

DC under/over Voltage

Electronics HW

problem

Check outdoor unit power

supply voltage

5

AC under Voltage

Check outdoor unit power

supply voltage

6

Indoor / Outdoor unit

Communication mismatch

Indoor and Outdoor

controllers are with

different versions

Replace Indoor controller

7

No Communication

Communication or

grounding wiring is not

good.

Check Indoor to Outdoor

wiring and grounding

8

Compressor Lock

Switch unit to STBY and

restart

9

Bad Communication

Communication quality is

low reliability

Check Indoor to Outdoor

wiring and grounding

12.4 Judgment by MegaTool

MegaTool is a special tool to monitor the system states.

Using MegaTool requires:

A computer with RS232C port.

A connection wire for MegaTool.

A special MegaTool software.

Use MegaTool according to following procedure:

Setup MegaTool software: copy the software to the computer.

Connect RS232C port in computer with MegaTool port in

Indoor/Outdoor unit controller by the connection wire.

Run the software and choose the COM port, you can monitor the

A/C system state in monitor tab.

12.5 Simple procedures for checking the Main Parts

12.5.1 Checking Mains Voltage.

Confirm that the Mains voltage is between 198 and 264 VAC. If Mains

voltage is out of this range, abnormal operation of the system is expected. If

in range check the Power (Circuit) Breaker and look for broken or loosed

cable lugs or wiring mistake(s).

Page 47

12-6

TROUBLESHOOTING

Revision Y05-01 Service Manual - Delta DCI

12.5.2 Checking Power Input.

If Indoor unit power LED is unlighted, power down the system and check

the fuse of the Indoor unit. If the fuse is OK replace the Indoor unit

controller. If the fuse has blown, replace the fuse and power up again.

Checking Power Input procedure for the Outdoor unit is the same as with

the Indoor unit.

12.5.3 Checking the Outdoor Fan Motor.

Enter Test Mode (where the OFAN speed is high)

Check the voltage between lead wires according to the normal value

as following:

Between red wire and black wire: 310VDC +/- 20V

Between orange wire and black wire: 15VDC +/- 1V

Between yellow wire and black wire: 2-6VDC

12.5.4 Checking the Compressor.

The compressor is brushless permanence magnetic DC motor. Three

coil resistance is same. Check the resistance between three poles.

The normal value should be below 0.5 ohm (TBD).

12.5.5 Checking the Reverse Valve (RV).

Running in heating mode, check the voltage between two pins of

reverse valve connector, normal voltage is 220VAC.

12.5.6 Checking the electrical expansion valve (EEV).

The EEV has two parts, drive part and valve. The drive part is a step motor; it is

ringed on the valve. Check the drive voltage (12VDC). When Outdoor unit is

power on, EEV shall run and have click and vibration.

12.6 Precaution, Advise and Notice Items

12.6.1 High voltage in Outdoor unit controller.

Whole controller, including the wires that are connected to the Outdoor unit

controller may have the potential hazard voltage when power is on. Touching

the Outdoor unit controller may cause an electrical shock.

Advise: Don’t touch the naked lead wire and don’t insert finger,

conductor or anything else into the controller when power is on.

12.6.2 Charged Capacitors

Three large-capacity electrolytic capacitors are used in the Outdoor

unit controller. Therefore, charging voltage (380VDC) remains after

power down. Discharging takes about four minutes after power is off.

Touching the Outdoor unit controller before discharging may cause an

electrical shock.

12.6.3 Additional advises

When disassemble the controller or the front panel, turn off the power

supply.

When connecting or disconnecting the connectors on the PCB, hold the

whole housing, don’t pull the wire.

Page 48

13-1

EXPLODED VIEWS AND SPARE PARTS LISTS

Revision Y05-01Service Manual - Delta DCI

13. EXPLODED VIEWS AND SPARE PARTS LISTS

13.1 Indoor Unit: Delta 25/35 DCI

Page 49

13-2

EXPLODED VIEWS AND SPARE PARTS LISTS

Revision Y05-01 Service Manual - Delta DCI

13.2 Intdoor Unit: Delta 25 DCI

No. Part No. Name QTY

1

453037000

GRILL A / DELTA 20,25 1

2

453100500

GRILL L AXIS 1

3

453100600 GRILL R AXIS

1

4

453036500

FILTER FOR DELTA 7/9 2

7

465720000

SILK-SCREEN FRONT FRAME FOR ELECTRA 1

8

4525987

SCREW COVER 3

9

453070701

EVAP. SYSTEM ASSY./DELTA 20,25 1

10

4523526

BERAING ASSY FAN 1

11

4523523

FAN ASSY PLASTIC 1

12

452784400

IOD-7,9 AIR OUTLET ASSY. (NO WIRE) 1

13

4523693

DRAIN HOSE 1

14

4526659

REAR PANEL ASSY 1

15

453027400

MOUNT BRACKET ASSY./ALFA 7,9 1

16

4526000

TUBE CLIP 1

17

453130700

REMOTE CONTROLLER RC-7 (SILVER )EHK P/N 977-800-40 1

18

4526133

POWER CORD CABLE 1

19

4523507

STEP MOTOR 1

20

453089600

DISPLAY ASSY. FOR DELTA EHK:936-034-00 1

21

453088600

PG RESIN MOTOR 12W 1

22

453089500

DELTA DCI INDOOR CONTROLLER EHK: 916-540-00 1

23

4525998

MOTOR COVER 1

24

438082

THERMISTOR INDOOR COIL BLACK 1

25

4519813

THERMISTOR ROOM 1

26

453027000

TERMINAL COVER 1

Page 50

13-3

EXPLODED VIEWS AND SPARE PARTS LISTS

Revision Y05-01Service Manual - Delta DCI

13.3 Indoor Unit: Delta 35 DCI

No. Part No. Name QTY

1

453036800 GRILL A / DELTA 12

1

2

453100500 GRILL L AXIS

1

3

453100600 GRILL R AXIS

1

4

453082900 FILTER FOR DELTA 12

2

7

465720001 SILK-SCREEN FRONT FRAME FOR ELECTRA

1

8

4525987 SCREW COVER

3

9

453058201 EVAP. SYSTEM ASSY./DELTA 35

1

10

4523526 BERAING ASSY FAN

1

11

4527111 FAN ASSY PLASTIC

1

12

452784401 IOD-12 AIR OUTLET ASSY. (NO WIRE)

1

13

4523693 DRAIN HOSE

1

14

4527186 IOD-12 REAR PANEL ASSY

1

15

453027500 MOUNT BRACKET ASSY./ALFA 12

1

16

4527512 TUBE CLIP

1

17

453130700 REMOTE CONTROLLER RC-7 SILVER )EHK P/N 977-800-40

1

18

4526133 POWER CORD CABLE

1

19

4523507 STEP MOTOR

1

20

453089600 DISPLAY ASSY. FOR DELTA EHK:936-034-00

1

21

453088600 PG RESIN MOTOR 12W

1

22

453089500 DELTA DCI INDOOR CONTROLLER EHK: 916-540-00

1

23

4525998 MOTOR COVER

1

24

438082 THERMISTOR INDOOR COIL BLACK

1

25

4519813 THERMISTOR ROOM

1

26

453027000 TERMINAL COVER

1

Page 51

13-4

EXPLODED VIEWS AND SPARE PARTS LISTS

Revision Y05-01 Service Manual - Delta DCI

13.4 Outdoor Unit: DCR 25/35 DCI

Page 52

13-5

EXPLODED VIEWS AND SPARE PARTS LISTS

Revision Y05-01Service Manual - Delta DCI

13.5 Outdoor Unit: DCR 25 DCI

No. Part No. Name QTY

1

4522551

GRILLE A OF GCN 1

2

4523441

FRONT PANEL A PAINTING ASSY 1

3

4519251 AXIAL FAN OD=400

1

4

453238900

SENSOR/OAT 1

5

4526775

COMPRESSOR TOP THERMISTOR(CTT) 1

6

4526776

OUTDOOR COIL THERMISTOR(OCT) 1

7

453170100

COMPRESSOR ASSY. MATSUSHITA 5RS092XDJ01 1

8

453052500

PAINTING BASE ASSY. 1

9

4526221

COMPRESSOR WIRE 1

10

4518951

4-W VALVE SHF-4H FOR R410A 1

11

4522509

4-WAY VALVE COIL 1

12

453058700

4WAY VALVE SOLDERING ASSY FOR DCR 9 1

13

453026600

ELECTRONIC EXPANSION VALVE ZDPF(L)-1.5C-01 1

14

4526216

EEV COIL QA(L)12-MD-02 1

15

453047000

LOW PRESSURE STOP VALVE FOR R410A 1

16

4516857

BIG SIDE COVER 1

17

453046900

HIGH PRESSURE STOP VALVE FOR R410A 1

18

464630000

SIDE PLATE PAINTING ASSY. 1

19

253046

CLIP SET PVC 1

20

4519188

4 POLES TERMINAL BLOCK 1

21

4516156

REAR PANEL PAINTING ASSY 1

22

453230000

CONNECT PLATE 1

23

453048200

CONDENSER ASSY. (OD7X2ROWS) FOR DCR 9 1

24

453052700

PARTITION 1

25

323156

MOTOR SUPPORT ASSY 1

26

4516158

COVER PANEL PAINTING ASSY 1

27

453031300

METAL MOTOR 20W 1

28

453031000

DC INVERTER CONTROLLER EHK:906-106-00 1

29

452841100

EARTH WIRE

1

30

453129300

WIRE UL1007 16AWG/CONTROLLER WITH 250 CONNECTOR

1

Page 53

13-6

EXPLODED VIEWS AND SPARE PARTS LISTS

Revision Y05-01 Service Manual - Delta DCI

13.6 Outdoor Unit: DСR 35 DCI

No. Part No. Name QTY

1

4522551

GRILLE A OF GCN 1

2

4523441

FRONT PANEL A PAINTING ASSY 1

3

4519251 AXIAL FAN OD=400

1

4

453238900

SENSOR/OAT 1

5

4526775

COMPRESSOR TOP THERMISTOR(CTT) 1

6

4526776

OUTDOOR COIL THERMISTOR(OCT) 1

7

4526204

COMPRESSOR ASSY. MATSUSHITA 5RS102XAB 1

8

453052500

PAINTING BASE ASSY. 1

9

4526221

COMPRESSOR WIRE 1

10

4518951

4-W VALVE SHF-4H FOR R410A 1

11

4522509

4-WAY VALVE COIL 1

12

453058800

4WAY VALVE SOLDERING ASSY FOR DCR 35 1

13

453026600

ELECTRONIC EXPANSION VALVE ZDPF(L)-1.5C-01 1

14

4526216

EEV COIL QA(L)12-MD-02 1

15

453047000

LOW PRESSURE STOP VALVE FOR R410A 1

16

4516857

BIG SIDE COVER 1

17

453046900

HIGH PRESSURE STOP VALVE FOR R410A 1

18

464630000

SIDE PLATE PAINTING ASSY. 1

19

253046

CLIP SET PVC 1

20

4519188

4 POLES TERMINAL BLOCK 1

21

4516156

REAR PANEL PAINTING ASSY 1

22

453230000

CONNECT PLATE 1

23

453048400

CONDENSER ASSY. (OD7.94X2ROWS) FOR DCR 35 1

24

453052700

PARTITION 1

25

323156

MOTOR SUPPORT ASSY 1

26

4516158

COVER PANEL PAINTING ASSY 1

27

453031200

METAL MOTOR 27W 1

28

453031000

DC INVERTER CONTROLLER EHK:906-106-00 1

29

452841100

EARTH WIRE

1

30

453129300

WIRE UL1007 16AWG/CONTROLLER WITH 250 CONNECTOR

1

Page 54

14-1

APPENDIX A

Revision Y05-01

Service Manual - Delta DCI

APPENDIX A

INSTALLATION AND OPERATION MANUAL

► INSTALLATION & OPERATING MANUAL DELTA 25/35 DCI

Page 55

EN G L I S H

AIR CONDITIONER SPLIT WALL MOUNTED

DC

RETAIL

FRAN AISG

FRAN AISG

CLMATISEUR SPLIT MURAL

KLIMAGERAET IN SPLIT BAUWEISE

DEUTSCH

CLIMATIZADOR SPLIT MURAL

ESPA OLY

ESPA OLY

CONDIZIONATORE D'ARIA APARETE SPLIT

ITALIANO

PROGRAMMING AND OPERATING MANUAL

MANUEL D'UTILISATION DE PROGRAMMATION

BEDIENUNGS UND PROGRAMMIERUNGS HANDBUCH

MANUAL DE UTILIZACION Y DE PROGRAMMACION

MANUALE DI UTILIZZO E DI PROGRAMMAZIONE

Page 56

ENGLISH

AIR CONDITIONER

SPLIT WALL MOUNTED

PROGRAMMING

AND OPERATING

Page 57

10

INTRODUCTION

SYSTEM DESCRIPTION

MODES OF OPERATION, FUNCTIONS AND FEATURES

ON-UNIT INDICATORS AND CONTROLS

PROTECTION MODES

CARE AND MAINTENANCE

OPERATING TIPS

PRECAUTIONS

BEFORE CALLING FOR SERVICE

1

2

3

5

6

7

8

9

CONTENTS

PLEASE READ THESE

INSTRUCTIONS

OPERATING THE AIR

CONDITIONER

BEFORE

Page 58

Cooling.

Dehumidifying.

Heating.

Ventilation

1

Dear customer:

The DC Inverter air conditioner you have purchased is one of advanced

units of its kind. The DC Inverter air conditioner is a variable capacity air

conditioner which uses high efficiency DC motor for the compressor.

Unlike other models, it can adjust its capacity according to the user

setting and the environmental condition, thus saving up to 30% of the

seasonal power consumption, while keeping maximum comfort level.

Detailed instruction as to the DC Inverter air conditioner provided in the

following pages.

This Split Air Conditioner is designed for versatile application:

INTRODUCTION

OPERATING TEMPERATURE

RANGE:

-15 46

IMPORTANT NOTICE:

The air conditioner must be

grounded to protect against

electrical shock.

Installation of the air

conditioner must be

performed by an experienced

air conditioning installer,

observing good refrigeration

practice.

Electrical connections and

power cord replacement

should only be made by

authorized electricians and in

accordance with electrical

regulations and local codes.

Failure to comply with the

manufacturer's installation

and operation instructions

could affect the performance

of the air conditioner and the

validity of the warranty.

Test Mode

Test Mode is set on only for

performance testing purposes,

and not for user operation.

Test mode can be initiated by either

one of the following conditions:

1) Operating the unit with the

following remote control settings

and temperature conditions:

Cool Mode, SPT = 16 and

RAT = 27 1

OAT = 35 1 for 30 minutes;

Heat Mode, SPT = 30 and

RAT = 20 1 ,

OAT = 7 1 for 30 minutes;

2) Entering Diagnostics with

Cool/SPT = 16 or

Heat/SPT = 30 .

Air Filtration.

Page 59

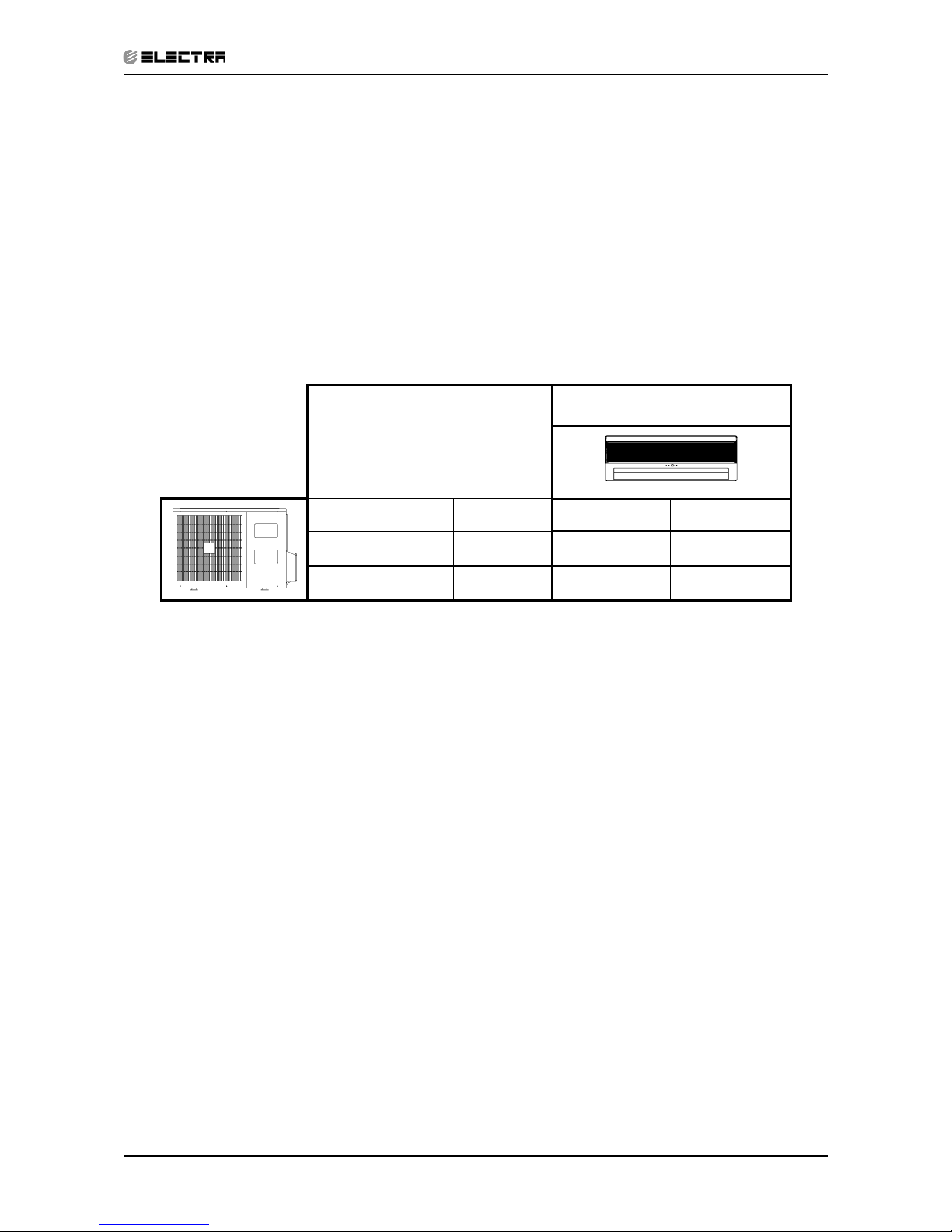

1. Air intake grill

2. Air filter

3. Supply air flap (louver)

4. Horizontal Air flow

Deflecting lovers

5. Air outlet

6. Unit's indicator and on

unit control

7. Power cord

8. Outdoor unit air intake

9. Power cable

10. Condensate tube

11. Liquid line

12. Suction line

13. Outdoor unit air outlet

14. Remote control

2

SYSTEM DESCRIPTION

14

12

9

10

11

8

13

7

6

4

5

3

2

1

AUTO

c

F

AMPMAM

PM

ON

OFF

WK

1

2

AM

PM

MODE

SLEEP

SET

IFEEL

ROOM

CLEAR TIMER

HOUR

IFEEL

Page 60

MODES OF OPERATION, FUNCTIONS

AND FEATURES

3

SLEEP

COOL

Cools, dehumidifies and filters the room air. Maintains desired room

temperature.

HEATING

Heats and filters the room air. Maintains desired room temperature.

AUTO

DRY

Dehumidifies and softly cools the room In DRY Mode, the air conditioner

operates at an increased dehumidifying power. This function is

recommended to be used when temperature is rather low but the humidity

is high.

FAN

Recirculates and filters the room air. Maintains constant air movement in the

room.

AUTO FAN

HOT KEEP

I FEEL

TIMER

Real time control and display, automatically turns the air conditioner ON and

OFF according to the time of day setting, ensuring comfort conditions before

returning home, without wasting electricity. It turns the air conditioner off

automatically when sleeping.

The air conditioner automatically selects the FAN speed in accordance with

the room temperature. At the start, the unit operates at high fan speed.