Electra Alpha 12 SP ISR R410A, Alpha 9 SP EU R410A, CSP 9 R22, CSP 12 R22, CSP 9 R410A EU Service Manual

...Page 1

Alpha SP Series

CONTENT

Indoor Units Outdoor Units

Alpha 9 SP R22 CSP 9 R22

Alpha 12 SP R22 CSP 12 R22

Alpha 9 SP EU R410A CSP 9 R410A EU

Alpha 12 SP EU R410A CSP 12 R410A EU

Alpha 9 SP ISR R410A

Alpha 12 SP ISR R410A

CSPI 9 R410A RC

CSPI 9 R410A A2 RC

CSPI 12 R410A RC

CSPI 12 R410A A2 RC

SM ASP 1-E.2 GB

REFRIGERANT

R22 COOLING ONLY

R410A

HEAT PUMP

AUGUST – 2008

Page 2

LIST OF EFFECTIVE PAGES

CONTENT

LIST OF EFFECTIVE PAGES

Note: Changes in the pages are indicated by a “Revision#” in the footer of each effected page

(when none indicates no changes in the relevant page). All pages in the following list represent

effected/ non effected pages divided by chapters.

Dates of issue for original and changed pages are:

Original ....... 0 ........ March 2007

Total number of pages in this publication is 137 consisting of the following:

Page

No.

Title ....................... 2

A ........................... 2

i ............................. 2

1-1 - 1-3 ................ 2

2-1 - 2-8 ................ 2

3-1 ........................ 2

4-1 - 4-4 ................ 2

5-1 - 5-32 .............. 2

6-1 - 6-6 ................ 2

7-1 ........................ 2

8-1 - 8-2 ................ 2

9-1 ........................ 2

10-1-10-2 .............. 2

11-1 ....................... 2

12-1-12-31 ............ 2

13-1-13-2 .............. 2

14-1-14-28 ............ 2

Appendix -A ...........2

Revision

No. #

Page

No.

Revision

No. #

Page

No.

Revision

No. #

● Zero in this column indicates an original page.

*Due to constant improvements please note that the data on this service manual can be modified with out notice.

**Photos are not contractual

A

SM ASP 1-E.2 GB

Page 3

TABLE OF CONTENTS

Table of Contents

1. INTRODUCTION ...................................................................................................1-1

2. PRODUCT DATA SHEET ......................................................................................2-1

3. RATING CONDITIONS ..........................................................................................3-1

4. OUTLINE DIMENSIONS .......................................................................................4-1

5. PERFORMANCE DATA & PRESSURE CURVES ................................................5-1

6. SOUND LEVEL CHARACTERISTICS ..................................................................6-1

7. ELECTRICAL DATA ..............................................................................................7-1

8. WIRING DIAGRAMS .............................................................................................8-1

9. ELECTRICAL CONNECTIONS .............................................................................9-1

10. REFRIGERATION DIAGRAMS .............................................................................10-1

11. TUBING CONNECTIONS ......................................................................................11-1

12. CONTROL SYSTEM .............................................................................................12-1

13. TROUBLESHOOTING ..........................................................................................13-1

14. EXPLODED VIEWS AND SPARE PARTS LISTS .................................................14-1

15. APPENDIX A .........................................................................................................15-1

SM ASP 1-E.2 GB

i

Page 4

1. INTRODUCTION

CONTENT

1.1 General

The new Alpha split wall mounted basic on comapct indoor and outdoor unit, it range

comprise the ST (cooling only) and RC (heat pump) models, as follows:

• Cooling Only:

ASP 9 410A (Flat,DF) ST / CSP 9 R410A ST;

ASP 12 R410A (Flat, DF) ST / CSP 12 R410A ST;

ASP 9 R22 (Flat,DF) ST / CSP 9 R22 ST;

ASP 12 R22 (Flat, DF) ST / CSP 12 R22 ST.

• Heat Pump:

ASP 9 R410A (Flat,DF) RC / CSP 9 R410A RC;

ASP 12 R410A (Flat, DF) RC / CSP 12 R410A RC;

ASP 9 R22 (Flat,DF) RC / CSP 9 R22 RC

ASP 12 R22 (Flat, DF) RC / CSP 12 R22 RC.

INTRODUCTION

The indoor Alpha SP units are available as LED display types only, featuring esthetic

design, compact dimensions, and low noise operation.

Display type models availability:

• LED Type: ASP 9 R410A (Flat, DF), ASP 12 R410A (Flat, DF).

1.2 Main Features

The Alpha SP series benefits from the most advanced technological innovations,

namely:

• R410A/R22 models.

• Microprocessor control.

• Infrared remote control with liquid crystal display.

• Supports Indoor Air Quality features, such as –.

• Indoor large diameter cross flow fan, allowing low noise level operation.

• Bended indoor coil with treated aluminum fins and coating for improved efficiency.

• Easy access to the interconnecting tubing and wiring connections, so that removing

the front grill or casing is not necessary.

• Refrigerant pipes can be connected to the indoor unit from 5 different optional

directions.

SM ASP 1-E.2 GB

• Automatic treated air sweep.

• Low indoor and outdoor noise levels.

• Easy installation and service.

• New package design for indoor unit, it should be based on open sleeve and open

sides

• Installation manual to be printed on one page with back and front printing

• One RC simply manual printing on two side as the standard

1-1

Page 5

INTRODUCTION

CONTENT

1.3 Indoor Unit

The indoor unit is wall mounted, and can be easily fitted to many types of residential

and commercials applications.

It includes:

• Casing with air inlet and outlet grills.

• A large-diameter tangential fan.

• Bended coil with treated aluminum fins.

• Motorized flaps

• Multi-speed motor with internal protection

• Advanced electronic control box assembly

• Interconnecting wiring terminal block

• Mounting plate

1.4 Filtration

The Alpha SP series presents only one type of air filters:

• Easily accessible, and re-usable pre-filters (mesh)

1.5 Control

The microprocessor indoor controller, and an infrared remote control, supplied as

standard, provide complete operating function and programming. For further details

please refer to the Operation Manual, Appendix A.

1.6 Outdoor Unit

The Alpha SP outdoor units can be installed as floor or wall mounted units by using a

wall supporting bracket. The metal sheets are protected by anti- corrosion paint work

allowing long life resistance. All outdoor units are pre-charged. For further information

please refer to the Product Data Sheet, Chapter 2.

It includes :

• Compressor mounted in a soundproofed compartment :

Rotary – for CSP 9 R410A (R22)ST/RC, CSP 12 R410A (R22) ST/RC

1-2

• Axial fan.

• Outdoor coil with hydrophilic louver fins for RC units.

• Outlet air fan grill.

• Interconnecting wiring terminal block.

SM ASP 1-E.2 GB

Page 6

1.7 Tubing Connections

CONTENT

Flare type interconnecting tubing to be produced on site.

For further details please refer to the Installation Manual, Outdoor Chapter 3.

1.8 Inbox Documentation

Each unit is supplied with its own installation and operation manuals, one simply

remote control manual Matching Table

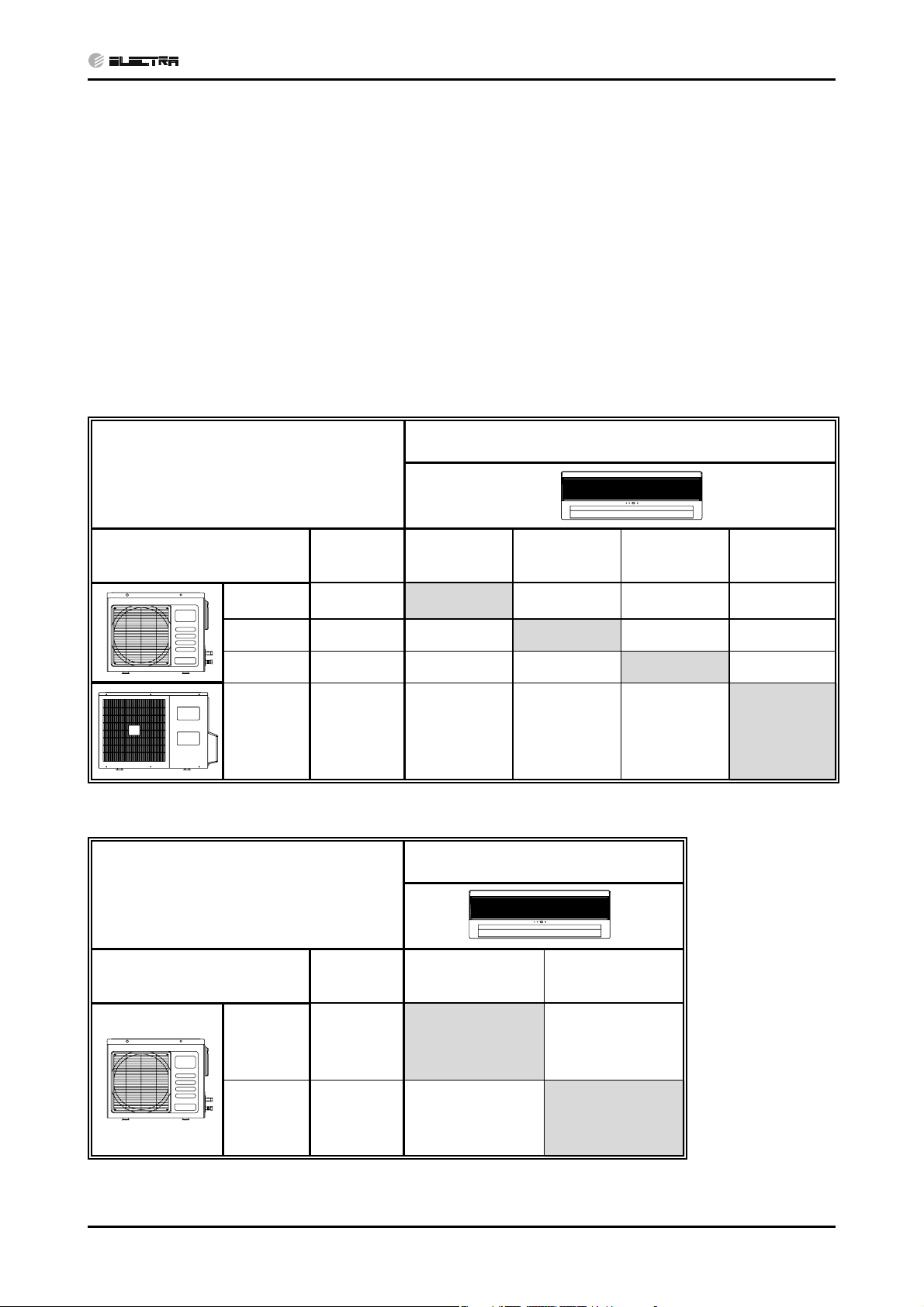

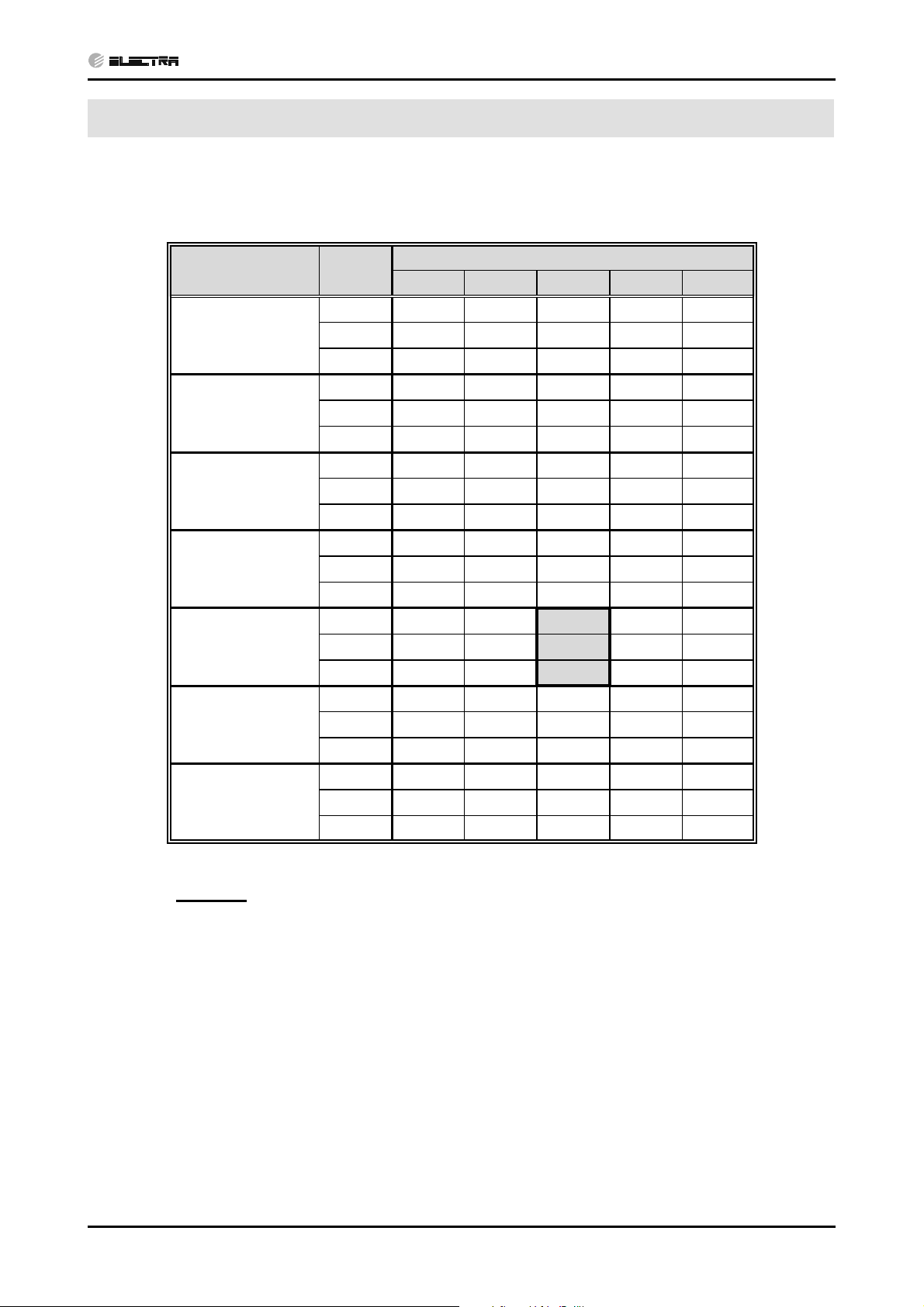

1.9 Matching Table

1.9.1 R410A

OUTDOOR UNITS

INTRODUCTION

INDOOR UNITS

MODEL

1.9.2 R22

OUTDOOR UNITS

MODEL

REFRIGER.

CSP 9 EU

CSP 9 ISR R410A

CSP 12 EU R410A

CSP 12 ISR R410A

R410A

REFRIGER. ASP 9 R22 ASP 12 R22

ASP9 R410A EUASP9 R410A

ISR

√

√

INDOOR UNITS

ASP12 R410A EUASP12 R410A

ISR

√

√

SM ASP 1-E.2 GB

CSP 9

CSP 12 R22

R22

√

√

1-3

Page 7

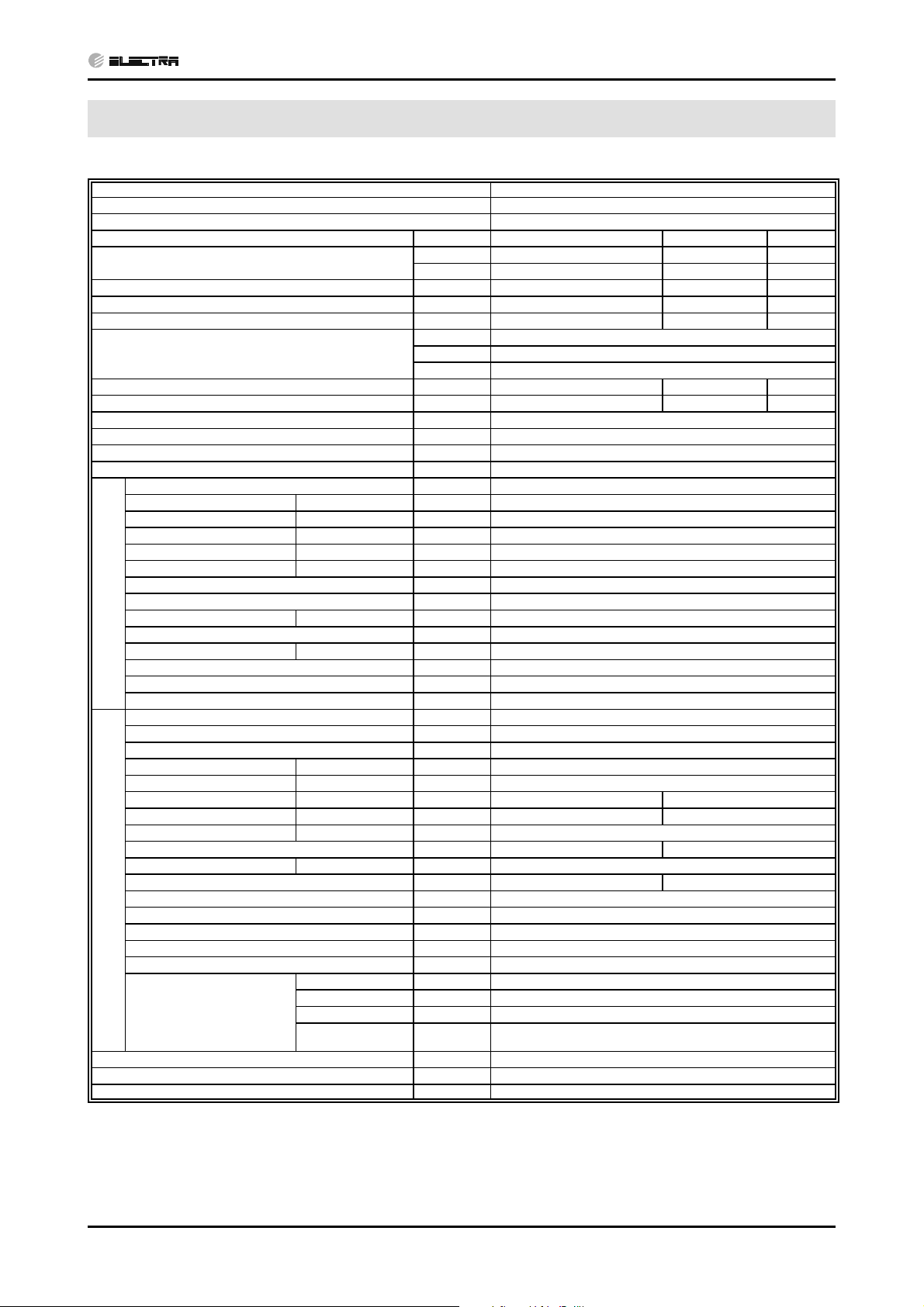

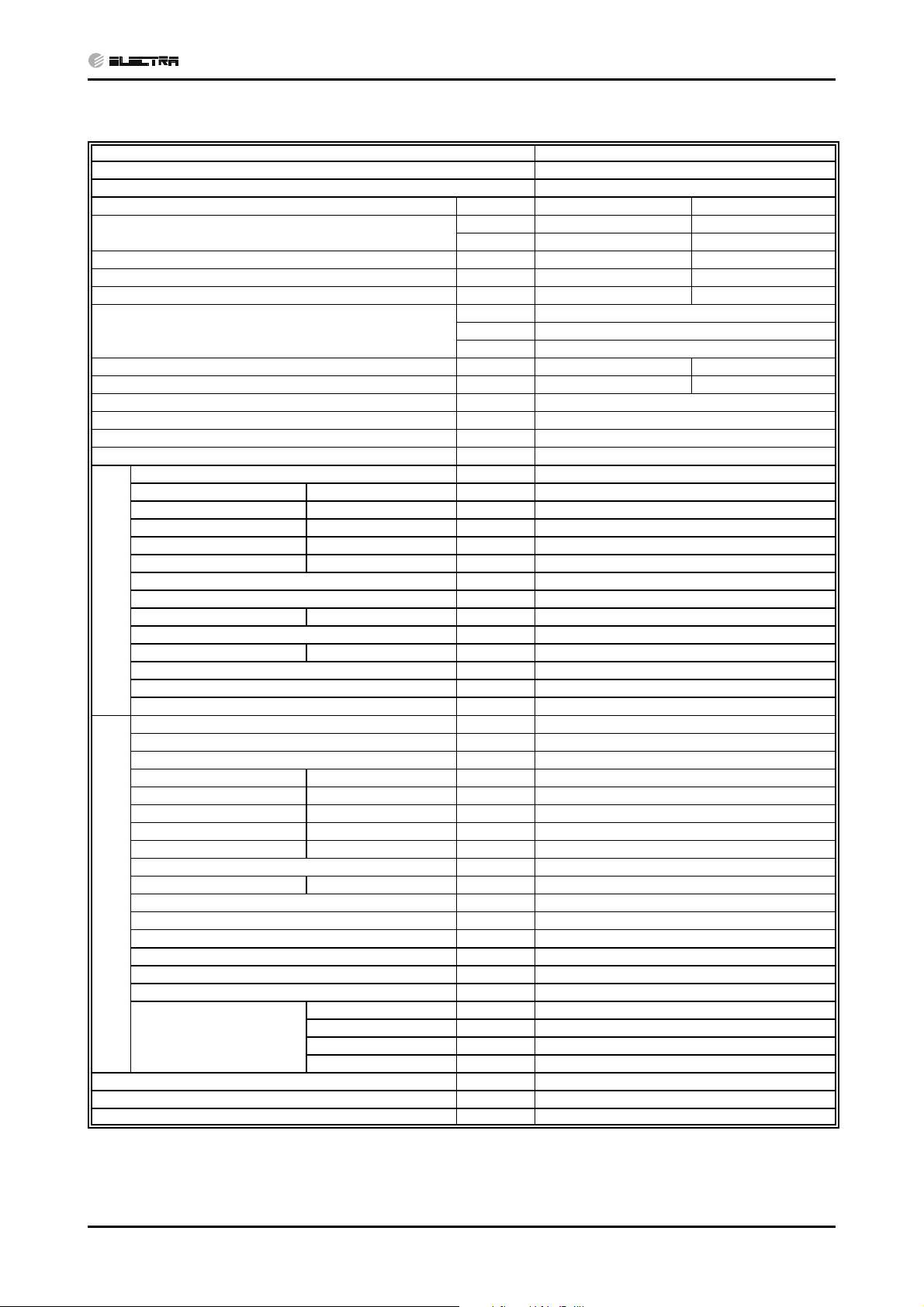

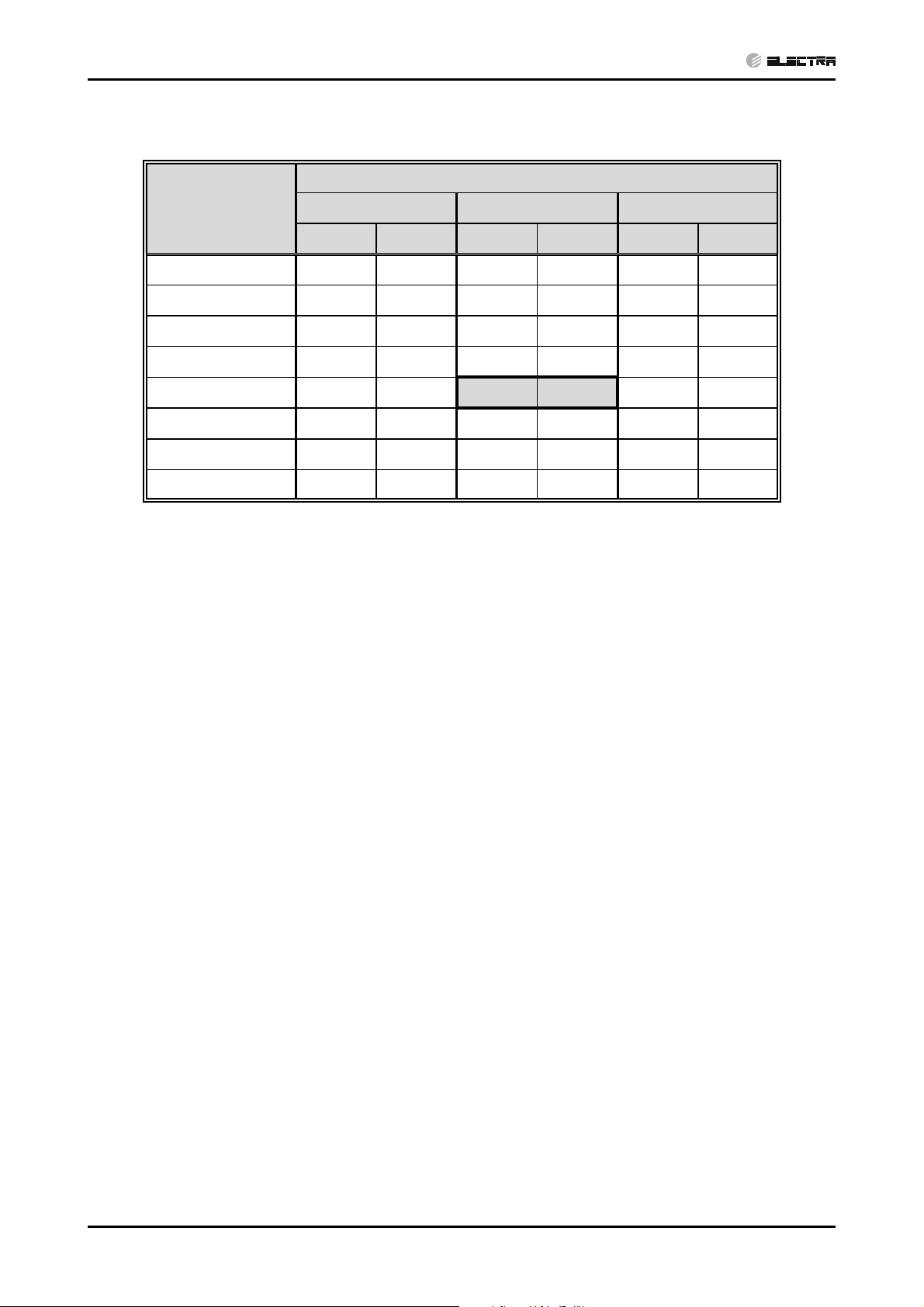

PRODUCT DATA SHEET

CONTENT

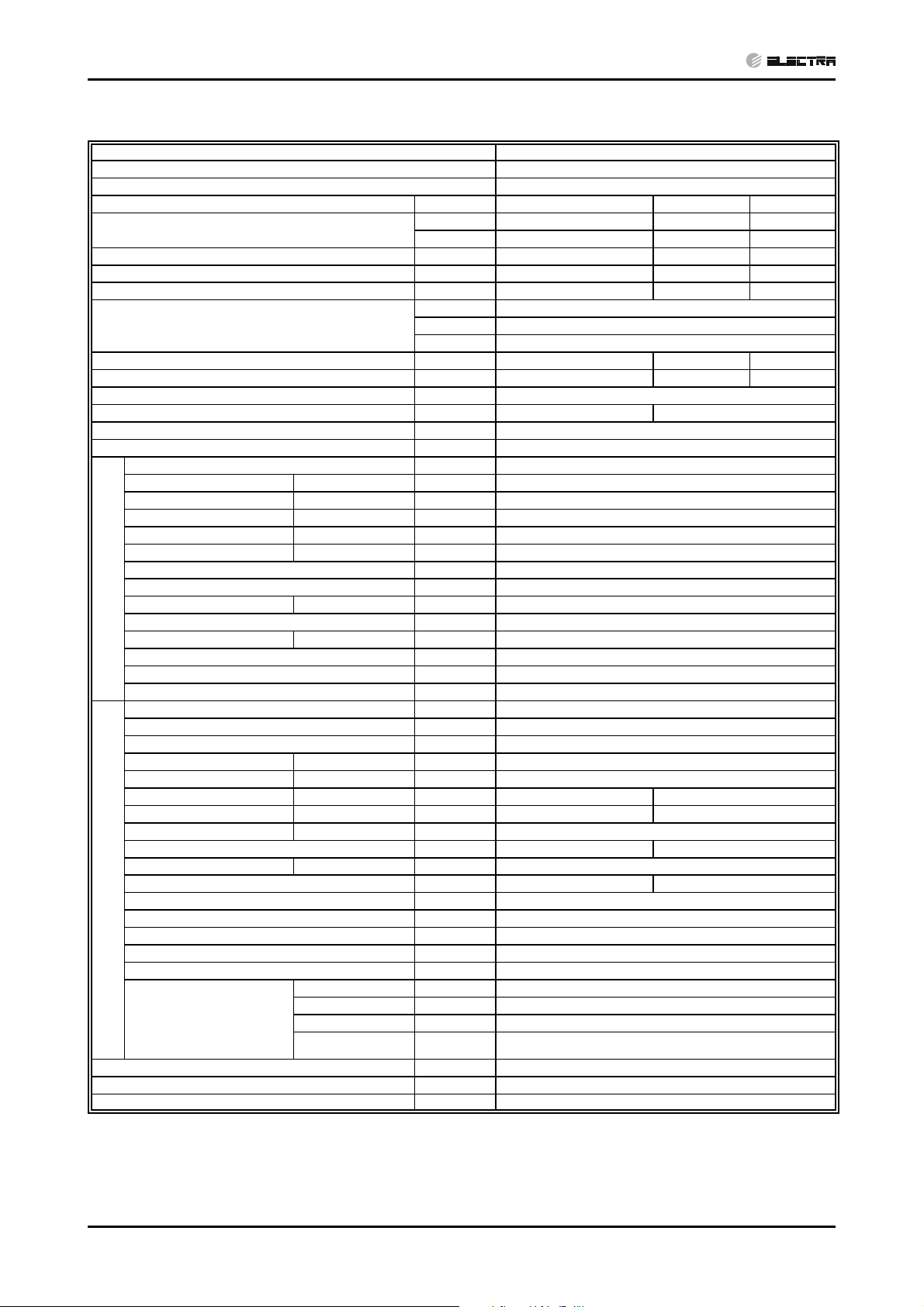

2. PRODUCT DATA SHEET

2.1 Alpha 9 SP R22 / CSP 9 R22

Model Indoor Unit ASP 9(ASP FLAT,ASP DF)

Model Outdoor Unit CSP 9

Installation Method of Pipe Flared

Characteristics Units Cooling Only Cooling Heating

Capacity

Power input

EER (Cooling) or COP(Heating)

(4)

(4)

(4)

Energy efficiency class D D C

Power supply

Rated current A 4.4 4.4 4.0

Power factor

Prated (IDU)

Prated (IDU+ODU)

Starting current A 26

Circuit breaker rating A 10

Fan type & quantity Crossflow x 1

Fan speeds H/M/L RPM 1250/-/1050

(1)

Air flow

External static pressure Min Pa 0

Sound power level

Sound pressure level

(2)

(3)

H/M/L m3/hr 450/-/350

H/M/L dB(A) 52/-/48

H/M/L dB(A) 40/-/35

Moisture removal l/hr 1

Condenstate drain tube I.D mm 16

INDOOR

Dimensions WxHxD mm 680*180*250

Net Weight kg 6

Package dimensions WxHxD mm 740x310x248

Packaged weight kg 8.5

Units per pallet units 36

Stacking height units 9 levels

Refrigerant control Capillary tube

Compressor type,model Rotary,TOSHIBA PH170X1C-4DZDE3

Fan type & quantity Propeller(direct) x 1

Fan speeds H RPM 900

Air flow H m3/hr 1265

Sound power level H dB(A) 62 63

Sound pressure level

(3)

H dB(A) 52 53

Dimensions WxHxD mm 610x520x240

Net Weight kg 26 26.5

Package dimensions WxHxD mm 725*550*355

Packaged weight kg 29 29.5

Units per pallet Units 12

OUTDOOR

Stacking height units 4 levels

Refrigerant type R22

Refrigerant chargless distance kg(4m) 0.63kg

Additional charge 4m<Lin<8m:+5g/m; Lin>8m:+15g/m

Liquid line In.(mm) 1/4”(6.35)

Suction line In.(mm) 3/8”(9.53)

Connections between units

Max.tubing length m. Max.15

Max.height

difference

Operation control type Remote control

Heating elements (Option) kW

Others

(1)

Airflow in ducted units;at nominal external static pressure.

(2)

Sound power in ducted units is measured at air discharge.

(3)

Sound pressure level measured at 1-meter distance from unit.

(4)

Rating conditions in accordance to ISO 5151 and ISO 13253 (for ducted units).

(5)

Declaration torlenance is in accordance with EN14511.

Btu/hr 8770 8770 9550

kW 2.57 2.57 2.80

kW 0.94 0.94 0.85

W/W 2.73 2.73 3.30

V 220-230

Ph 1

Hz 50

0.95 0.95 0.95

W 27

W 1090

m. Max.7

SM ASP 1-E.2 GB

2-1

Page 8

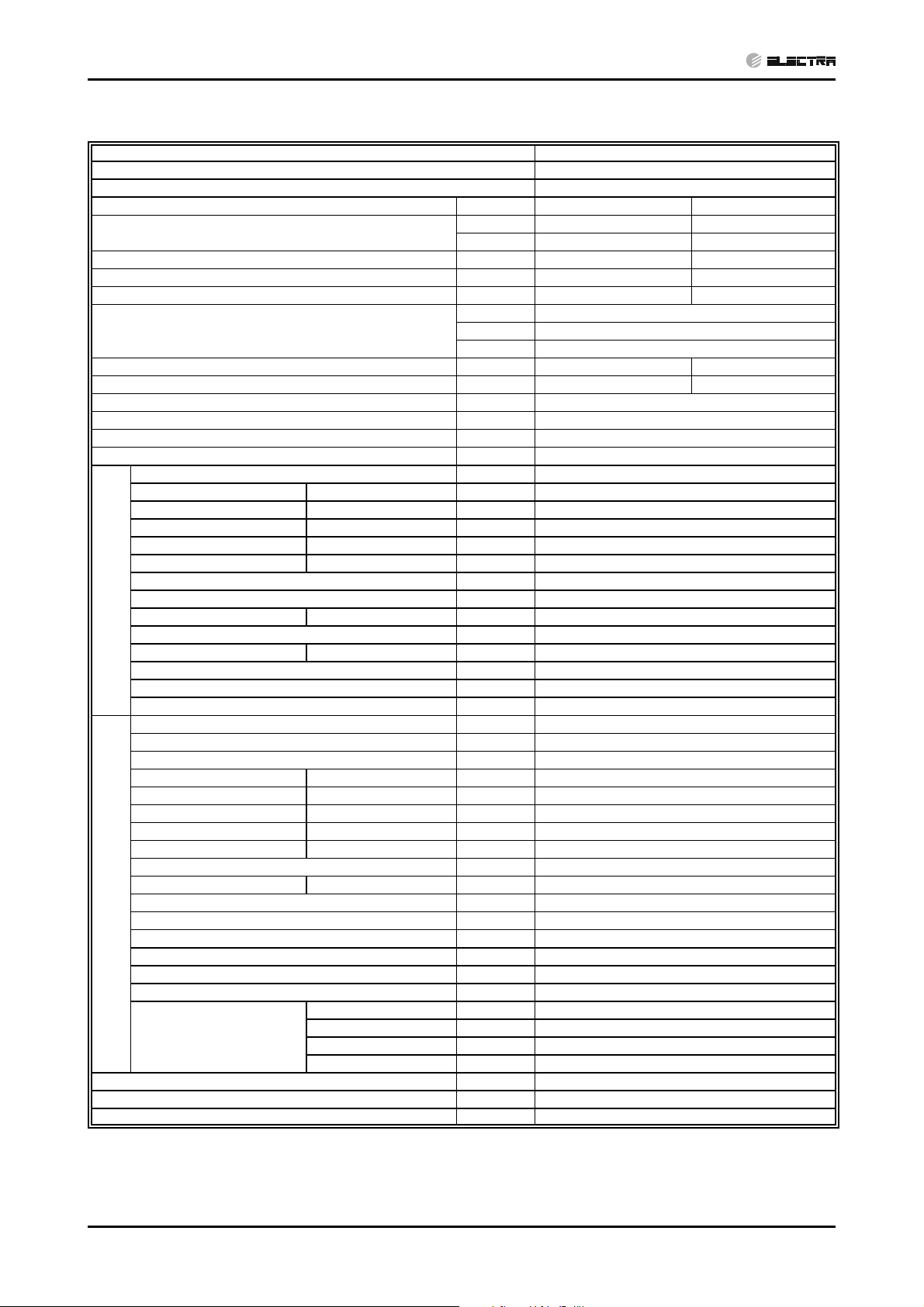

PRODUCT DATA SHEET

CONTENT

2.2 Alpha 12 SP R22 / CSP 12 R22

Model Indoor Unit ASP 12(ASP FLAT,ASP DF)

Model Outdoor Unit CSP 12

Installation Method of Pipe Flared

Characteristics Units Cooling Only Cooling Heating

Capacity

Power input

EER (Cooling) or COP(Heating)

(4)

(4)

(4)

Energy efficiency class C C C

Power supply

Rated current A 5.2 5.2 4.9

Power factor 0.95 0.95 0.95

Prated (IDU) W 30

Prated (IDU+ODU) W 1425 1446

Starting current A 28

Circuit breaker rating A 10

Fan type & quantity Crossflow x 1

Fan speeds H/M/L RPM 1250/-/1000

Air flow

(1)

H/M/L m3/hr 650/-/500

External static pressure Min Pa 0

Sound power level

Sound pressure level

(2)

(3)

H/M/L dB(A) 55/-/49

H/M/L dB(A) 41/-/34

Moisture removal l/hr 1.1

Condenstate drain tube I.D mm 16

INDOOR

Dimensions WxHxD mm 840x250x180

Net Weight kg 7

Package dimensions WxHxD mm 900x310x248

Packaged weight kg 9.5

Units per pallet units 36

Stacking height units 9 levels

Refrigerant control Capillary tube

Compressor type,model Rotary,Sanyo,C-RV212H51BA

Fan type & quantity Propeller(direct) x 1

Fan speeds H RPM 900

Air flow H m3/hr 1200

Sound power level H dB(A) 63 65

Sound pressure level

(3)

H dB(A) 52 54

Dimensions WxHxD mm 610x520x240

Net Weight kg 29.5 30

Package dimensions WxHxD mm 725x550x355

Packaged weight kg 31.5 32

Units per pallet Units 12

OUTDOOR

Stacking height units 4 levels

Refrigerant type R22

Refrigerant chargless distance kg(7.5m) 0.88kg/7.5m

Additional charge 4m≤Length≤10m: +0g; 10m Length≤15m: +100g

Liquid line In.(mm) 1/4”(6.35)

Suction line In.(mm) 1/2”(12.7)

Connections between units

Max.tubing length m. Max.15

Max.height

difference

Operation control type Remote control

Heating elements kW

Others

Btu/hr 10920 10920 11940

kW 3.20 3.20 3.50

kW 1.14 1.14 1.06

W/W 2.81 2.81 3.30

V 220-230

Ph 1

Hz 50

m. Max.7

(1)

Airflow in ducted units; at nominal external static pressure.

(2)

Sound power in ducted units is measured at air discharge.

(3)

Sound pressure level measured at 1-meter distance from unit.

(4)

Rating conditions in accordance to ISO 5151 and ISO 13253 (for ducted units).

(5)

Declaration torlenance is in accordance with EN14511.

2-2

SM ASP 1-E.2 GB

Page 9

PRODUCT DATA SHEET

CONTENT

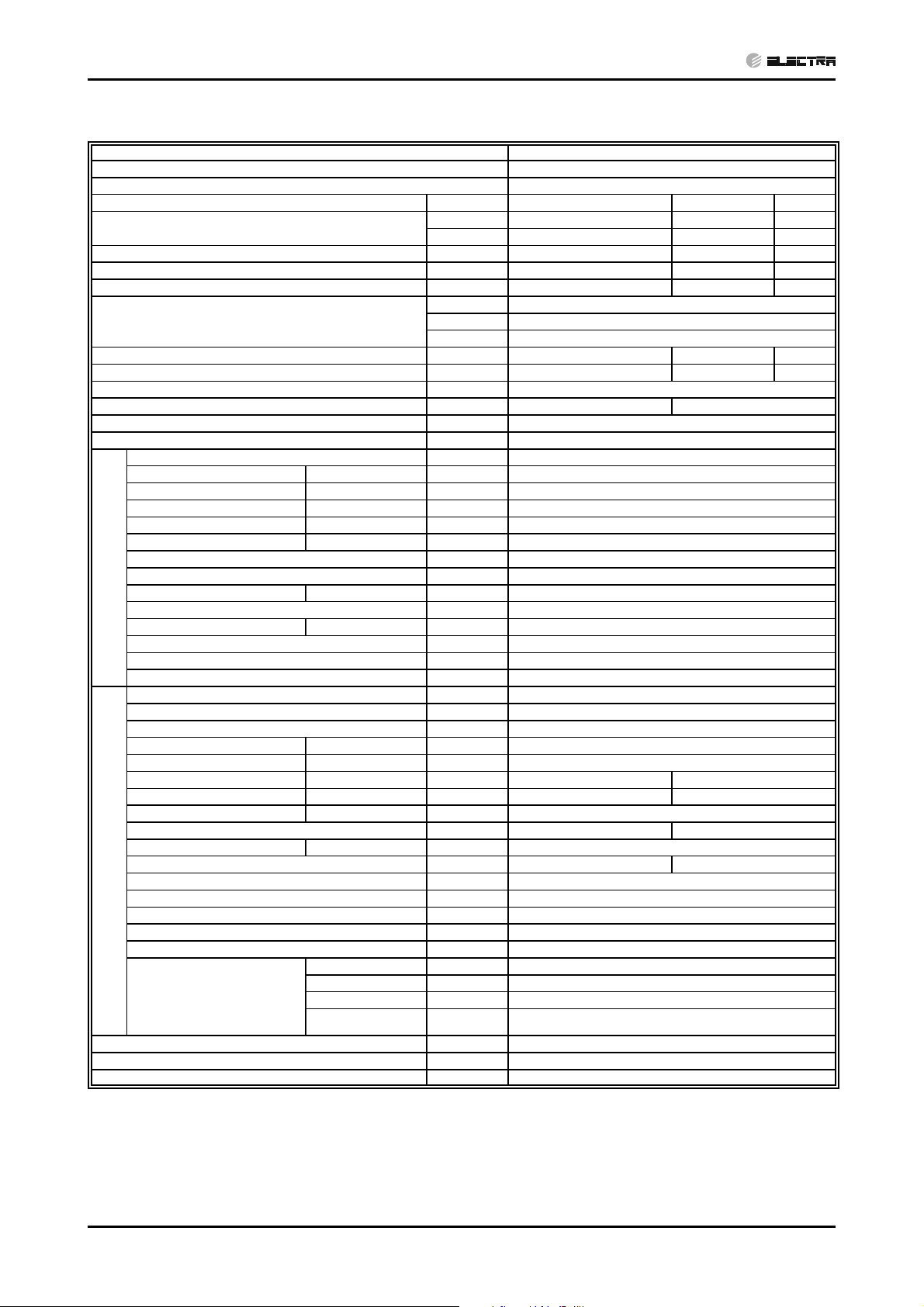

2.3 Alpha 9 SP EU R410A / CSP 9 EU R410A

Model Indoor Unit ASP 9 R410A flat for EU

Model Outdoor Unit CSP 9 R410A for EU

Installation Method of Pipe Flared

Characteristics Units Cooling Only Cooling Heating

Capacity

Power input

EER (Cooling) or COP(Heating)

Energy efficiency class C C C

Power supply

Rated current A 4.0 4.0 3.7

Power factor W 0.97 0.97 0.97

Prated(IDU) W 30

Prated(IDU+ODU) W 1072 1072

Starting current A 16.5

Circuit breaker rating A 10

Operation control type Remote control

Heating elements kW Remote control(RC-5)

Others

(4)

(4)

(4)

Fan type & quantity Crossflow x 1

Fan speeds H/M/L RPM 1310/-/1100

(1)

Air flow

External static pressure Min Pa 0

Sound power level

Sound pressure level

Moisture removal l/hr 0.9

Condenstate drain tube I.D mm 16

INDOOR

Dimensions WxHxD mm 680x250x180

Net Weight kg 6

Package dimensions WxHxD mm 740x310x248

Packaged weight kg 8.5

Units per pallet units 36

Stacking height

Refrigerant control

Compressor type,model Rotary,Sanyo(Hua Run),C-1RV107

Fan type & quantity Propeller(direct) x 1

Fan speeds H RPM 900

Air flow H m3/hr 1200

Sound power level H dB(A) 62 62

Sound pressure level

Dimensions WxHxD mm 610x520x240

Net Weight kg 23.5 24

Package dimensions WxHxD mm 725x550x355

Packaged weight kg 26 26.5

Units per pallet Units 12

OUTDOOR

Stacking height units 4 levels

Refrigerant type R410A

Standard charge kg(7.5m) 0.58kg

Additional charge 4m≤Length≤10m: +0g; 10m≤Length≤15m: +50g

Connections between units

(2)

(3)

(3)

H/M/L m3/hr 450/-/360

H/M/L dB(A) 53/-/49

H/M/L dB(A) 41/-/35

H dB(A) 51 51

Liquid line In.(mm) 1/4”(6.35)

Suction line In.(mm) 3/8”(9.53)

Max.tubing length m. Max.15

Max.height difference m. Max.7

Btu/hr 8700 8700 9040

kW 2.55 2.55 2.65

kW 0.89 0.89 0.82

W/W 2.84 2.84 3.22

V 220-230

Ph 1

Hz 50

units

9 levels

Capillary tube

(1)

Airflow in ducted units; at nominal external static pressure.

(2)

Sound power in ducted units is measured at air discharge.

(3)

Sound pressure level measured at 1-meter distance from unit.

(4)

Rating conditions in accordance to ISO 5151 and ISO 13253 (for ducted units).

(5)

Declaration torlenance is in accordance with EN14511.

SM ASP 1-E.2 GB

2-3

Page 10

PRODUCT DATA SHEET

CONTENT

2.4 Alpha 12 SP EU R410A / CSP 12 SP EU R410A

Model Indoor Unit ASP 12 R410A (Flat) for EU

Model Outdoor Unit CSP 12 R410A for EU

Installation Method of Pipe Flared

Characteristics Units Cooling Only Cooling Heating

Capacity

Power input

EER (Cooling) or COP(Heating)

(4)

(4)

(4)

Energy efficiency class C C C

Power supply

Rated current A 5.13 5.13 4.65

Power factor 0.98 0.98 0.98

Prated(IDU) W 30

Prated(IDU+ODU) W 1295 1440

Starting current A 28

Circuit breaker rating A 10

Fan type & quantity Crossflow x 1

Fan speeds H/M/L RPM 1250/-/1000

(1)

Air flow

H/M/L m3/hr 650/-/500

External static pressure Min Pa 0

Sound power level

Sound pressure level

(2)

(3)

H/M/L dB(A) 55/-/49

H/M/L dB(A) 41-/34

Moisture removal l/hr 1.1

Condenstate drain tube I.D mm 16

INDOOR

Dimensions WxHxD mm 840x250x180

Net Weight kg 7

Package dimensions WxHxD mm 900x310x248

Packaged weight kg 9.5

Units per pallet units 36

Stacking height units 9 levels

Refrigerant control Capillary tube

Compressor type,model Rotary,Sanyo(Hua Run),C-RV133H1D

Fan type & quantity Propeller(direct) x 1

Fan speeds H RPM 900

Air flow H m3/hr 1200

Sound power level H dB(A) 63 64

Sound pressure level

(3)

H dB(A) 53 55

Dimensions WxHxD mm 610x520x240

Net Weight kg 29 30

Package dimensions WxHxD mm 725x550x355

Packaged weight kg 31 32

Units per pallet Units 12

OUTDOOR

Stacking height units 4 levels

Refrigerant type R410A

Standard charge kg(7.5m) 0.89kg

Additional charge 4m≤Length≤10m: +0g; 10m Length≤15m: +50g

Liquid line In.(mm) 1/4”(6.35)

Suction line In.(mm) 3/8”(9.53)

Connections between units

Max.tubing length m. Max.15

Max.height

difference

Operation control type Remote control

Heating elements kW Remote control(RC-5)

Others

Btu/hr 11260 11260 11600

kW 3.30 3.30 3.40

kW 1.16 1.16 1.05

W/W 2.84 2.84 3.22

V 220-230

Ph 1

Hz 50

m. Max.7

(1)

Airflow in ducted units; at nominal external static pressure.

(2)

Sound power in ducted units is measured at air discharge.

(3)

Sound pressure level measured at 1-meter distance from unit.

(4)

Rating conditions in accordance to ISO 5151 and ISO 13253 (for ducted units).

(5)

Declaration torlenance is in accordance with EN14511.

2-4

SM ASP 1-E.2 GB

Page 11

PRODUCT DATA SHEET

CONTENT

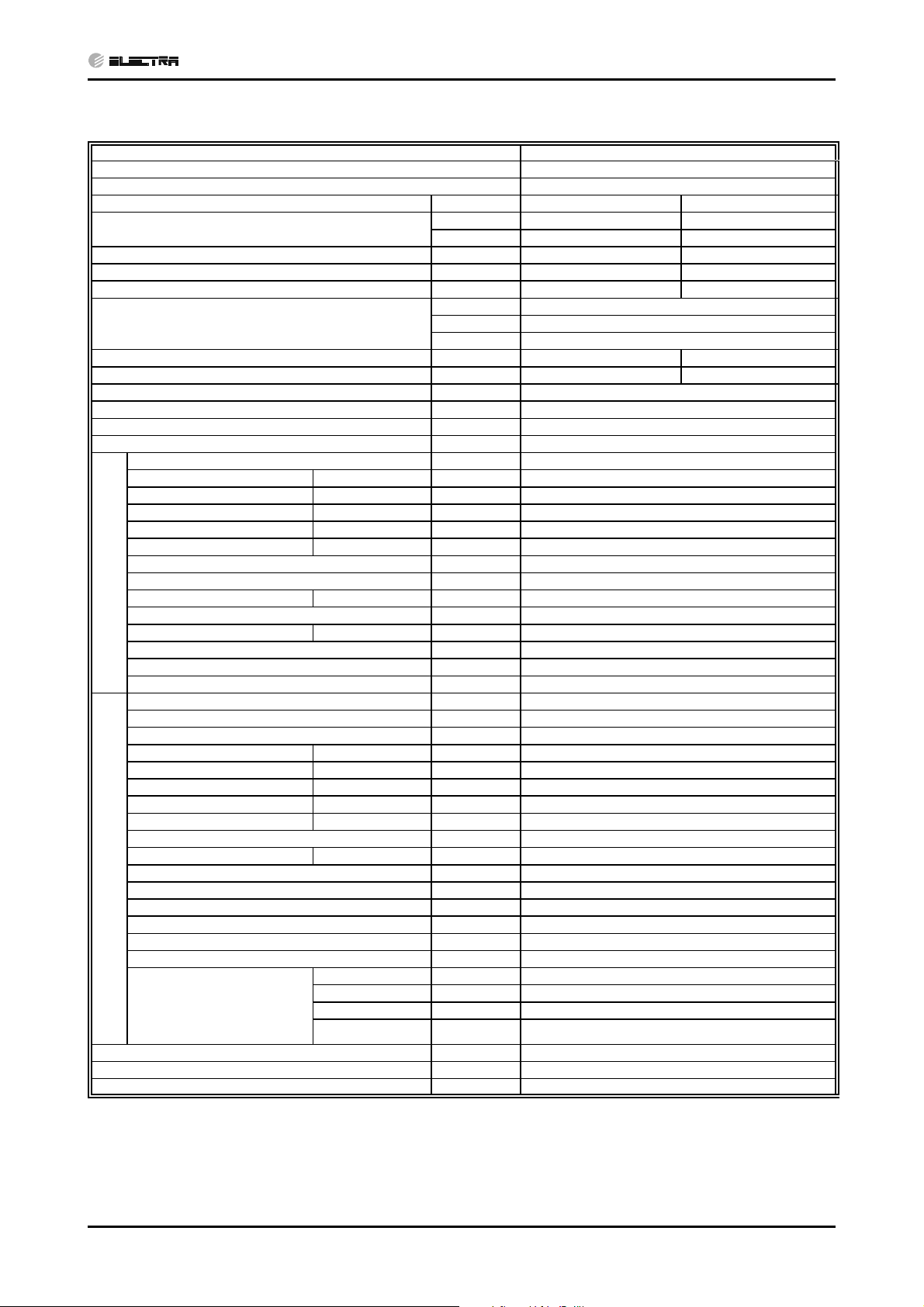

2.5 Alpha 9 SP ISR R410A / CSPI 9 R410A RC A1

Model Indoor Unit ASP 9 R410A(ASP FLAT, ASP DF) FOR ISRAEL

Model Outdoor Unit CSPI 9 R410A RC

Installation Method of Pipe Flared

Characteristics Units Cooling Heating

Capacity

Power input

EER (Cooling) or COP(Heating)

(4)

(4)

(4)

Energy efficiency class(SII) C C

Power supply

Rated current A 3.7 3.6

Power factor 0.95 0.95

Prated (IDU) W 30

Prated (IDU+ODU) W 1185

Starting current A 16.5

Circuit breaker rating A 10

Fan type & quantity Crossflow x 1

Fan speeds H/M/L RPM 1310/-/1100

Air flow

(1)

H/M/L m3/hr 450/-/360

External static pressure Min Pa 0

Sound power level

(2)

Sound pressure level

(3)

H/M/L dB(A) 53/-/49

H/M/L dB(A) 41/-/35

Moisture removal l/hr 0.9

Condenstate drain tube I.D mm 16

INDOOR

Dimensions WxHxD mm 680x250x180

Net Weight kg 6

Package dimensions WxHxD mm 740x310x248

Packaged weight kg 8.5

Units per pallet units 36

Stacking height units 9 levels

Refrigerant control Capillary tube

Compressor type,model Rotary,Sanyo,C-1RV107

Fan type & quantity Propeller(direct) x 1

Fan speeds H RPM 900

Air flow H m3/hr 1200

Sound power level H dB(A) 62

Sound pressure level

(3)

H dB(A) 52

Dimensions WxHxD mm 610x520x240

Net Weight kg 26.5

Package dimensions WxHxD mm 725x550x355

Packaged weight kg 28.5

Units per pallet Units 12

OUTDOOR

Stacking height units 4 levels

Refrigerant type R410A

Refrigerant chargless distance kg(7.5m) 0.80kg

Additional charge 4m≤Length≤10m: +0g; 10m Length≤15m: +50g

Liquid line In.(mm) 1/4”(6.35)

Suction line In.(mm) 3/8”(9.53)

Connections between units

Max.tubing length m. Max.15

Max.height

difference

Operation control type Remote control

Heating elements kW

Others

Btu/hr 8900 9550

kW 2.60 2.80

kW 0.81 0.80

W/W 3.20 3.50

V230

Ph 1

Hz 50

m. Max.7

(1)

Airflow in ducted units;at nominal external static pressure.

(2)

Sound power in ducted units is measured at air discharge.

(3)

Sound pressure level measured at 1-meter distance from unit.

(4)

Rating conditions in accordance to ISO 5151 and ISO 13253 (for ducted units).

SM ASP 1-E.2 GB

2-5

Page 12

PRODUCT DATA SHEET

CONTENT

2.6 Alpha 12 SP ISR R410A / CSPI 12 R410A RC A1

Model Indoor Unit ASP 12 R410A(ASP FLAT,ASP DF) FOR ISRAEL

Model Outdoor Unit CSPI 12 R410A RC

Installation Method of Pipe Flared

Characteristics Units Cooling Heating

Capacity

Power input

EER (Cooling) or COP(Heating)

(4)

(4)

tt

Energy efficiency class(SII) F F

Power supply

Rated current A 5.0 5.3

Power factor 0.95 0.95

Prated (IDU) W 30

Prated (IDU+ODU) W 1405

Starting current A 28

Circuit breaker rating A 10

Fan type & quantity Crossflow x 1

Fan speeds H/M/L RPM 1250/-/1000

Air flow

(1)

H/M/L m3/hr 630/-/480

External static pressure Min Pa 0

Sound power level

(2)

Sound pressure level

(3)

H/M/L dB(A) 55/-/50

H/M/L dB(A) 41/-/36

Moisture removal l/hr 1.1

Condenstate drain tube I.D mm 16

INDOOR

Dimensions WxHxD mm 840x250x180

Net Weight kg 7

Package dimensions WxHxD mm 900x310x248

Packaged weight kg 9.5

Units per pallet units 36

Stacking height units 9 levels

Refrigerant control Capillary tube

Compressor type,model Rotary,Sanyo,C-RV133H1D

Fan type & quantity Propeller(direct) x 1

Fan speeds H RPM 735

Air flow H m3/hr 1450

Sound power level H dB(A) 65

Sound pressure level

(3)

H dB(A) 54

Dimensions WxHxD mm 760x545x245

Net Weight kg 32.5

Package dimensions WxHxD mm 870x600x320

Packaged weight kg 35

Units per pallet Units 12

OUTDOOR

Stacking height units 3 levels

Refrigerant type R410A

Refrigerant chargless distance kg(7.5m) 0.91kg

Additional charge 4m≤Length≤10m: +0g; 10m Length≤15m: +50g

Liquid line In.(mm) 1/4”(6.35)

Connections between units

Suction line In.(mm) 3/8”(9.53)

Max.tubing length m. Max.15

Max.height difference m. Max.7

Operation control type Remote control

Heating elements (Option) kW

Others

(1)

Airflow in ducted units;at nominal external static pressure.

(2)

Sound power in ducted units is measured at air discharge.

(3)

Sound pressure level measured at 1-meter distance from unit.

(4)

Rating conditions in accordance to ISO 5151 and ISO 13253 (for ducted units).

Btu/hr 11600 12300

kW 3.40 3.60

kW 1.11 1.16

W/W 3.05 3.10

V230

Ph 1

Hz 50

2-6

SM ASP 1-E.2 GB

Page 13

PRODUCT DATA SHEET

CONTENT

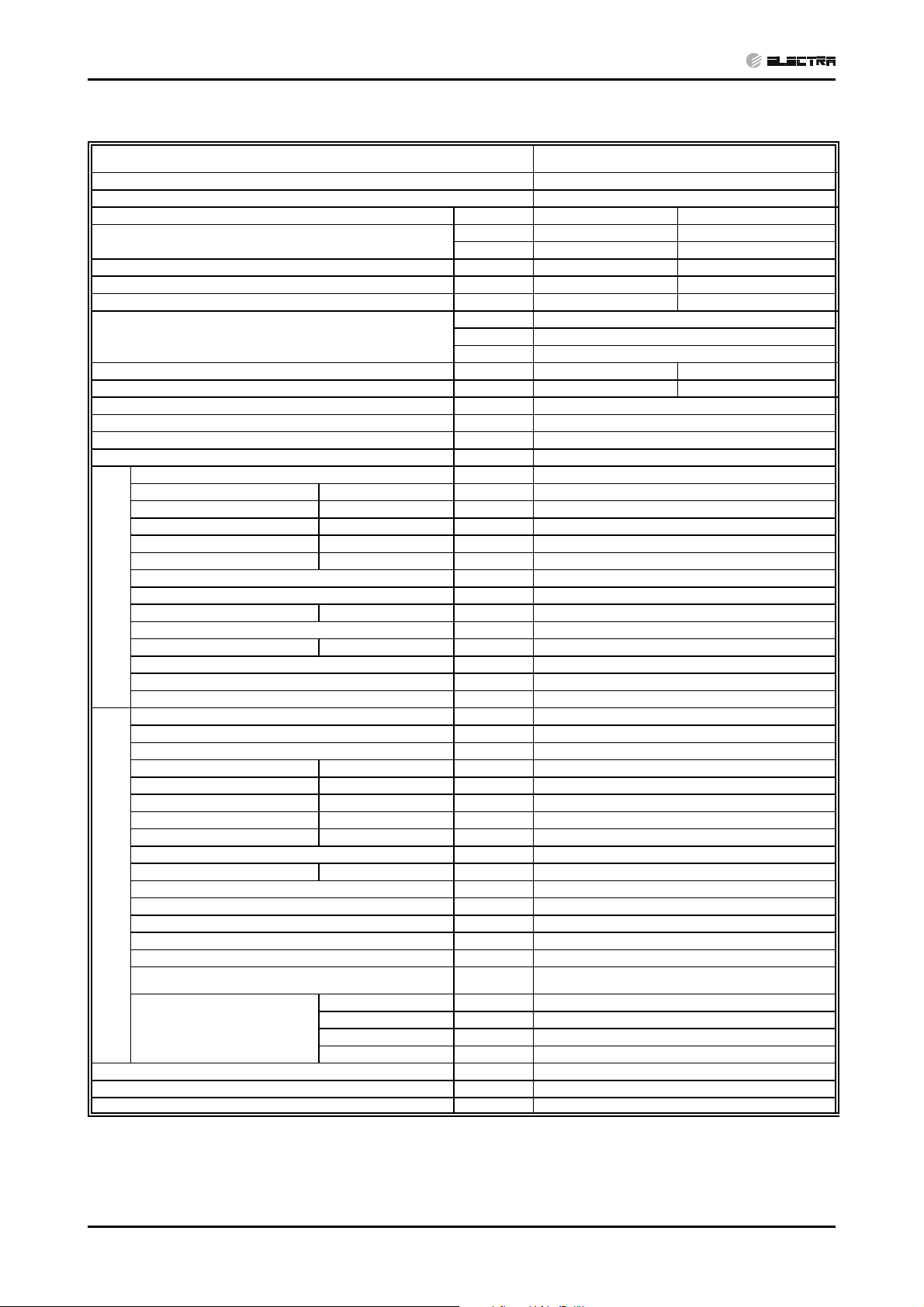

2.7 ASP 9 R410A A2 ISR / CSPI 9 R410A A2 ISR

Model Indoor Unit ASP 9 R410A A2 ISR

Model Outdoor Unit CSPI 9 R410A A2 ISR

Installation Method of Pipe Flared

Characteristics Units Cooling Heating

Capacity (4)

Power input (4) kW 0.8 0.80

EER (Cooling) or COP(Heating) (4) W/W 3.46 3.30

Energy efficiency class(SII) E E

Power supply

Rated current A 3.6 3.67

Power factor 0.95 0.95

Prated (IDU) W 30

Prated (IDU+ODU) W 970

Starting current A 16.65

Circuit breaker rating A 10

Fan type & quantity Crossflow x 1

Fan speeds H/M/L RPM 1320/-/1100

Air flow (1) H/M/L m3/hr 450/-/360

External static pressure Min Pa 0

Sound power level (2) H/M/L dB(A) 53/-/49

Sound pressure level(3) H/M/L dB(A) 41/-/35

Moisture removal l/hr 0.99

Condenstate drain tube I.D mm 16

INDOOR

Dimensions WxHxD mm 680x250x180

Net Weight kg 6

Package dimensions WxHxD mm 740x310x248

Packaged weight kg 8.5

Units per pallet units 32

Stacking height units 8 levels

Refrigerant control Capillary tube

Compressor type,model Rotary,Toshiba(GMCC),PA103X1C-4FZDE1

Fan type & quantity Propeller(direct) x 1

Fan speeds H RPM 900

Air flow H m3/hr 1200

Sound power level H dB(A) 62

Sound pressure level(3) H dB(A) 52

Dimensions WxHxD mm 610x520x240

Net Weight kg 26.5

Package dimensions WxHxD mm 720x550x360

Packaged weight kg 28.5

Units per pallet Units 12

OUTDOOR

Stacking height units 4 levels

Refrigerant type R410A

Refrigerant chargless distance kg(7.5m) 0.80kg

Additional charge 4m≤Length≤10m: +0g; 10mLength≤15m: +50g

Liquid line In.(mm) 1/4”(6.35)

Connections between units

Operation control type Remote control

Heating elements (Option) kW

Others

(1)Airflow in ducted units;at nominal external static pressure.

(2)Sound power in ducted units is measured at air discharge.

(3)Sound pressure level measured at 1-meter distance from unit.

(4)Rating conditions in accordance to ISO 5151 and ISO 13253 (for ducted units).

Suction line In.(mm) 3/8”(9.53)

Max.tubing length m. Max.15

Max.height difference m. Max.7

Btu/hr 9380 9040

kW 2.75 2.65

V230

Ph 1

Hz 50

SM ASP 1-E.2 GB

2-7

Page 14

PRODUCT DATA SHEET

CONTENT

2.8 ASP 12 R410A A2 ISR / CSPI 12 R410A A2 ISR

Model Indoor Unit ASP 12 R410A A2 ISR

Model Outdoor Unit CSPI 12 R410A A2 ISR

Installation Method of Pipe Flared

Characteristics Units Cooling Heating

Capacity (4)

Power input (4) kW 1.04 1.00

EER (Cooling) or COP(Heating) (4) W/W 3.38 3.50

Energy efficiency class(SII) C C

Power supply

Rated current A 4.7 4.6

Power factor 0.95 0.95

Prated (IDU) W 30

Prated (IDU+ODU) W 1400

Starting current A 26

Circuit breaker rating A 10

Fan type & quantity Crossflow x 1

Fan speeds H/M/L RPM 1250/-/880

Air flow (1) H/M/L m3/hr 620/-/390

External static pressure Min Pa 0

Sound power level (2) H/M/L dB(A) 53/-/47

Sound pressure level(3) H/M/L dB(A) 40/-/33

Moisture removal l/hr 1.22

Condenstate drain tube I.D mm 16

INDOOR

Dimensions WxHxD mm 840x250x180

Net Weight kg 8

Package dimensions WxHxD mm 900x310x248

Packaged weight kg 10.5

Units per pallet units 32

Stacking height units 8 levels

Refrigerant control Capillary tube

Compressor type,model Rotary,Panasonic,5PS132EAC22

Fan type & quantity Propeller(direct) x 1

Fan speeds H RPM 735

Air flow H m3/hr 1450

Sound power level H dB(A) 65

Sound pressure level(3) H dB(A) 54

Dimensions WxHxD mm 760x545x245

Net Weight kg 32.5

Package dimensions WxHxD mm 870x600x320

Packaged weight kg 35

Units per pallet Units 12

OUTDOOR

Stacking height units 3 levels

Refrigerant type R410A

Refrigerant chargless distance kg(7.5m) 0.92kg

Additional charge 4m≤Length≤10m: +0g; 10mLength≤15m: +50g

Liquid line In.(mm) 1/4”(6.35)

Connections between units

Operation control type Remote control

Heating elements (Option) kW

Others

(1)Airflow in ducted units;at nominal external static pressure.

(2)Sound power in ducted units is measured at air discharge.

(3)Sound pressure level measured at 1-meter distance from unit.

(4)Rating conditions in accordance to ISO 5151 and ISO 13253 (for ducted units).

Suction line In.(mm) 3/8”(9.53)

Max.tubing length m. Max.15

Max.height difference m. Max.7

Btu/hr 11970 11970

kW 3.51 3.51

V230

Ph 1

Hz 50

2-8

SM ASP 1-E.2 GB

Page 15

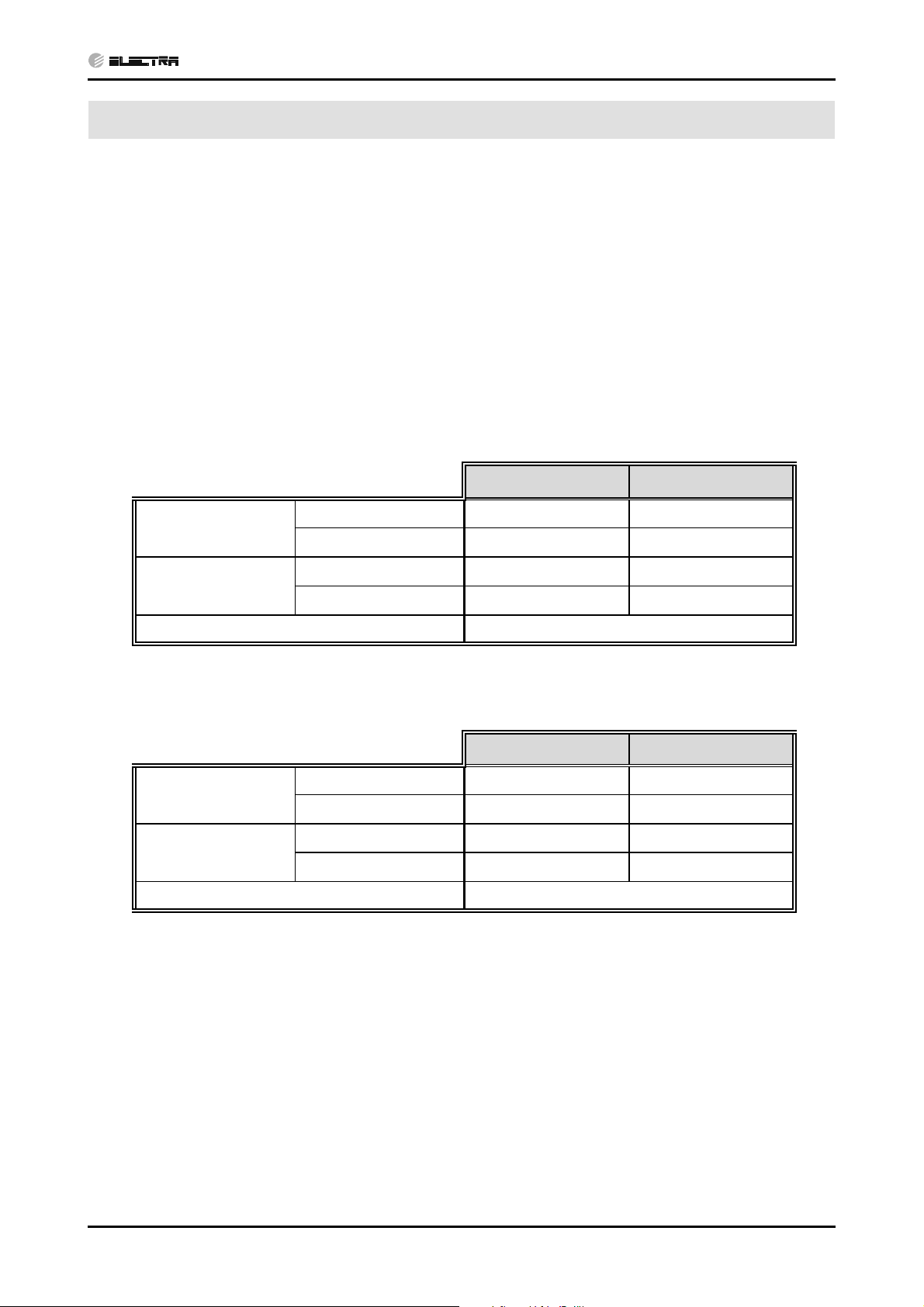

3. RATING CONDITIONS

CONTENT

Standard conditions in accordance with ISO 5151, ISO 13253 (for ducted units)

and EN 14511.

Cooling:

Indoor: 27oC DB 19oC WB

Outdoor: 35 oC DB

Heating:

Indoor: 20oC DB

Outdoor: 7oC DB 6oC WB

3.1 Operating Limits

3.1.1 R410A

Upper limit

Cooling

Lower limit 21

Upper limit 27

Heating

Lower limit 10

RATING CONDITIONS

Indoor Outdoor

o

C DB 23oC WB 46oC DB

32

o

C DB 15oC WB 10oC DB

o

C DB 24oC DB 18oC WB

o

C DB -9oC DB -10oC WB

3.1.2 R22

Cooling

Heating

Voltage 198 – 264 V

Indoor Outdoor

o

32

Upper limit

Lower limit 21

Upper limit 27

Lower limit 10

C DB 23oC WB 46oC DB

o

C DB 15oC WB 10oC DB

o

C DB 24oC DB 18oC WB

o

C DB -5oC DB -10oC WB

Voltage 198 – 264 V

SM ASP 1-E.2 GB

3-1

Page 16

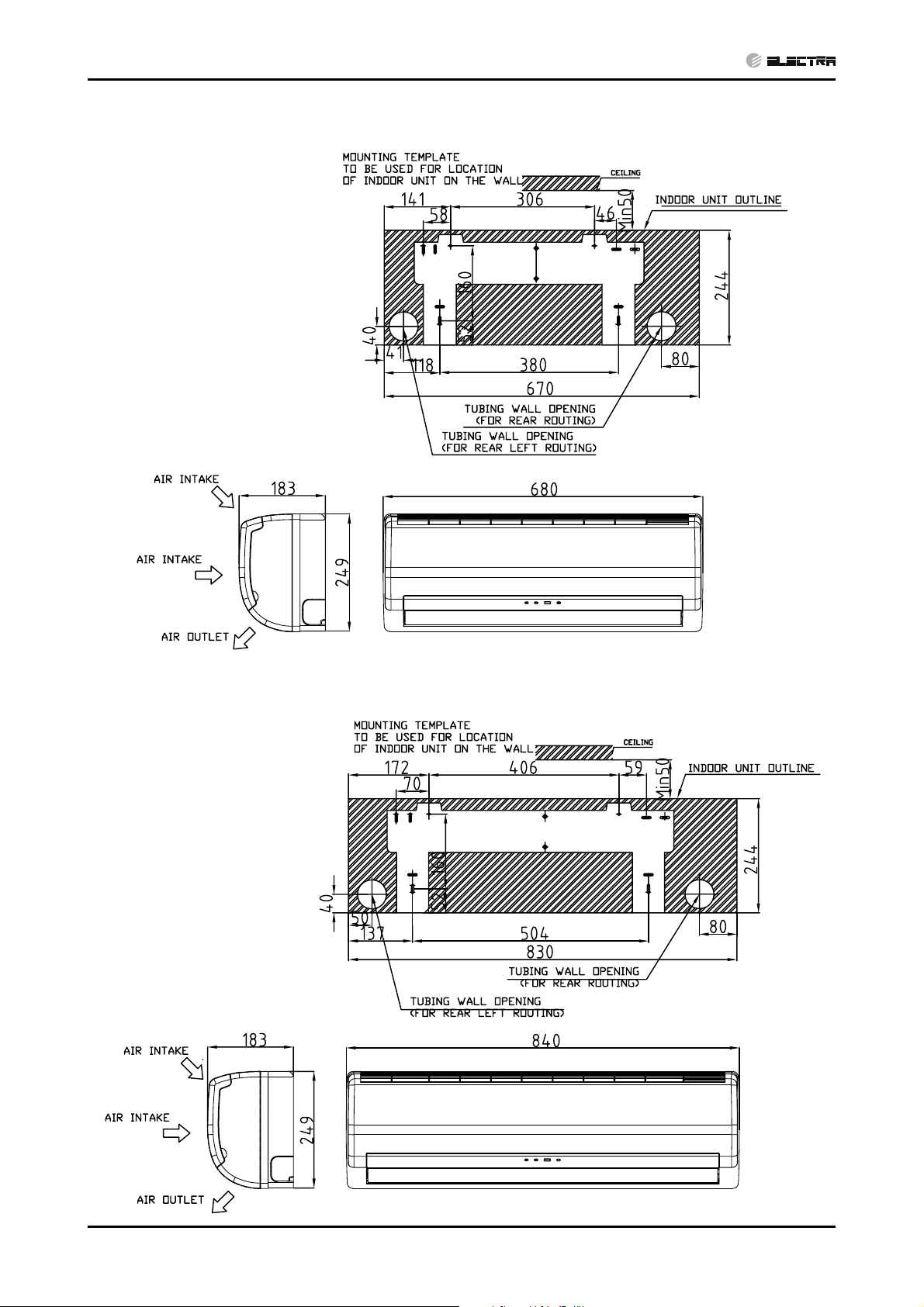

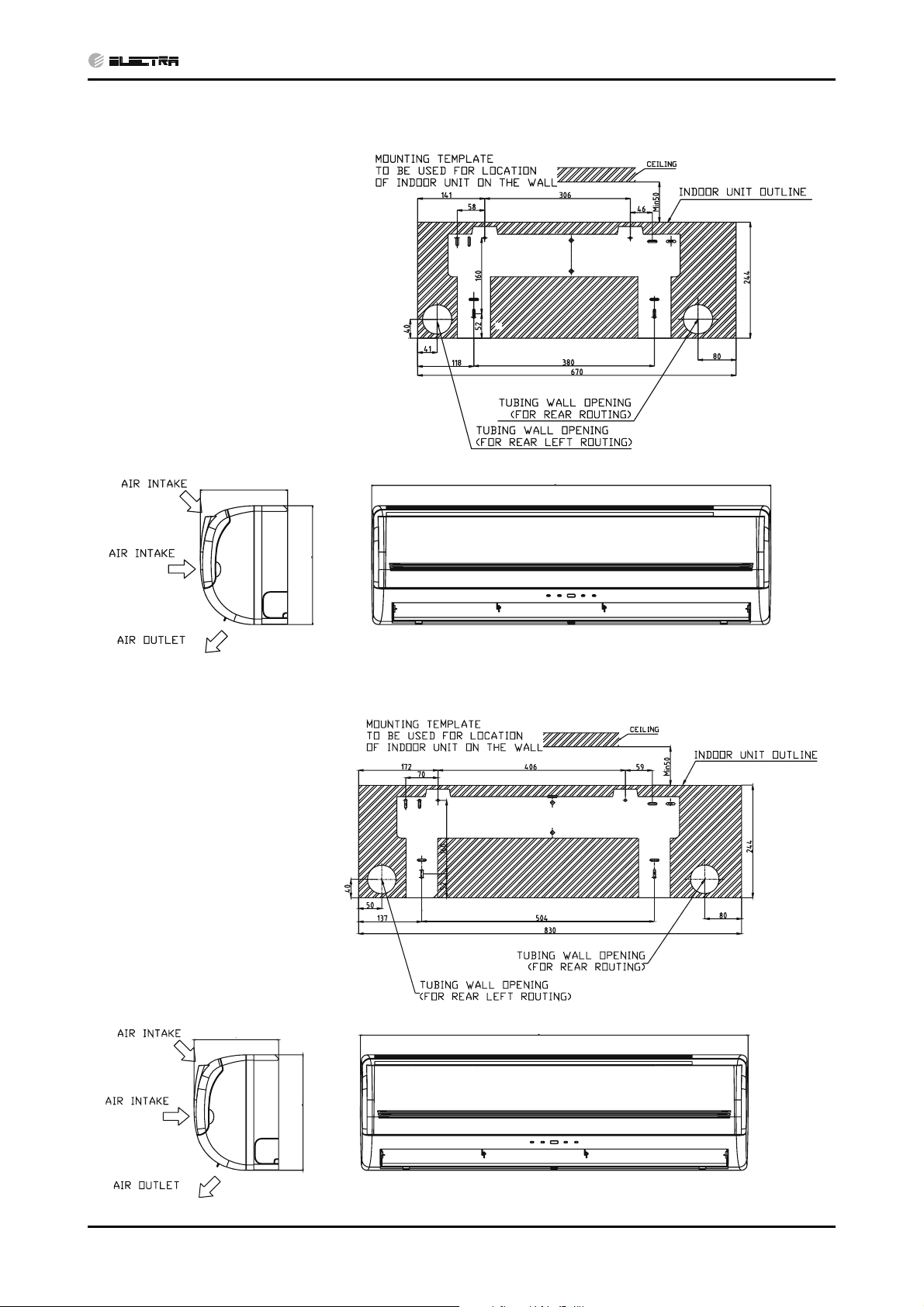

4. OUTLINE DIMENSIONS

CONTENT

4.1 Alpha SP 9

OUTLINE DIMENSIONS

Alpha SP 12

4.2

SM ASP 1-E.2 GB

4-1

Page 17

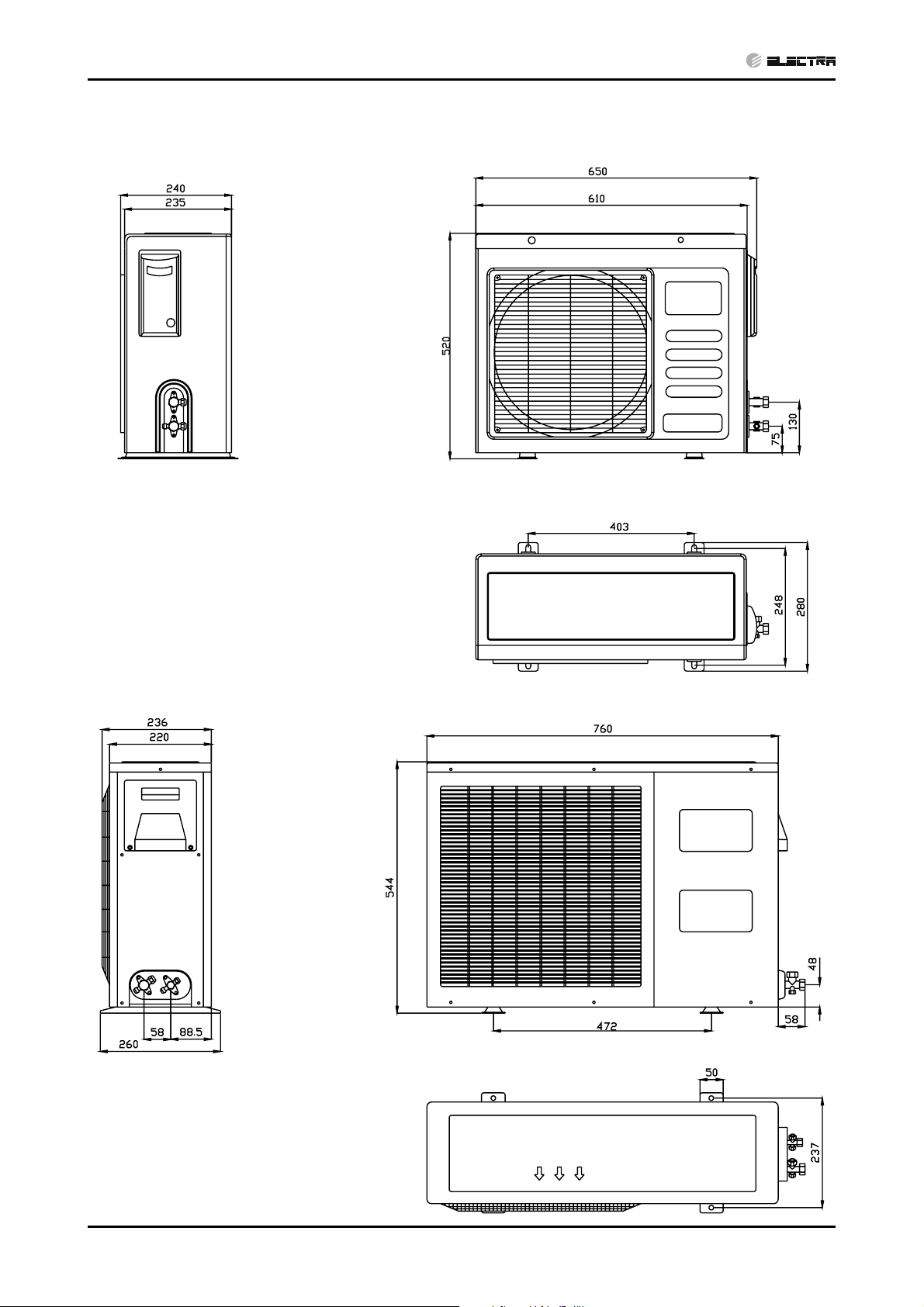

OUTLINE DIMENSIONS

CONTENT

4.3 Alpha 7, 9 (Omega)

Alpha 12 (Omega)

4.4

4-2

SM ASP 1-E.2 GB

Page 18

4.5 Alpha 9 DF

CONTENT

OUTLINE DIMENSIONS

Alpha 12 DF

4.6

180

680

250

SM ASP 1-E.2 GB

180

840

250

4-3

Page 19

OUTLINE DIMENSIONS

CONTENT

4.7 CSP9/12 R410A (EU), CSP(I)9 R410A, CSP9/12 R22 (CON9)

4.8 CSP(I)12 R410A (GCZ)

4-4

SM ASP 1-E.2 GB

Page 20

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5. PERFORMANCE DATA & PRESSURE CURVES

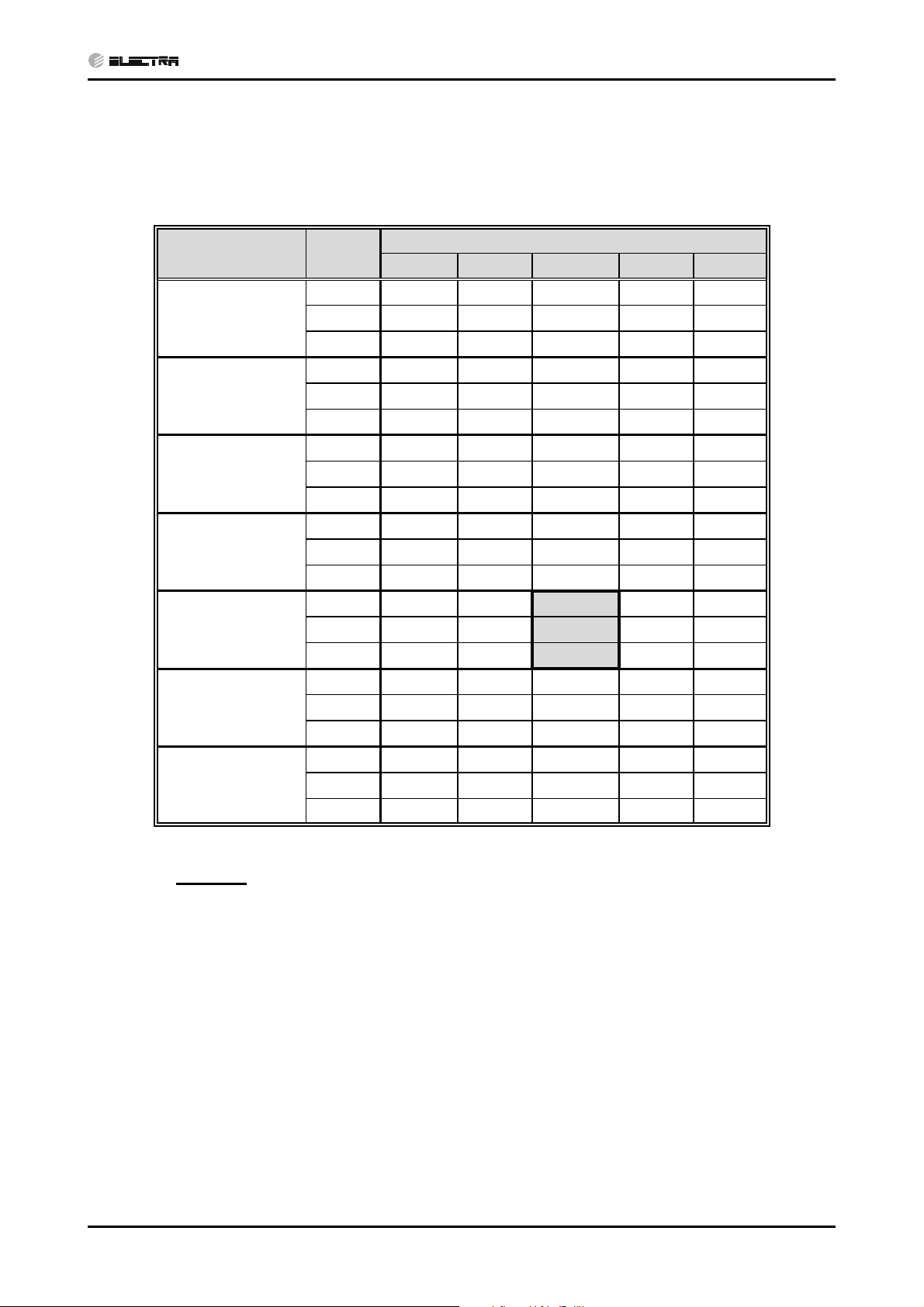

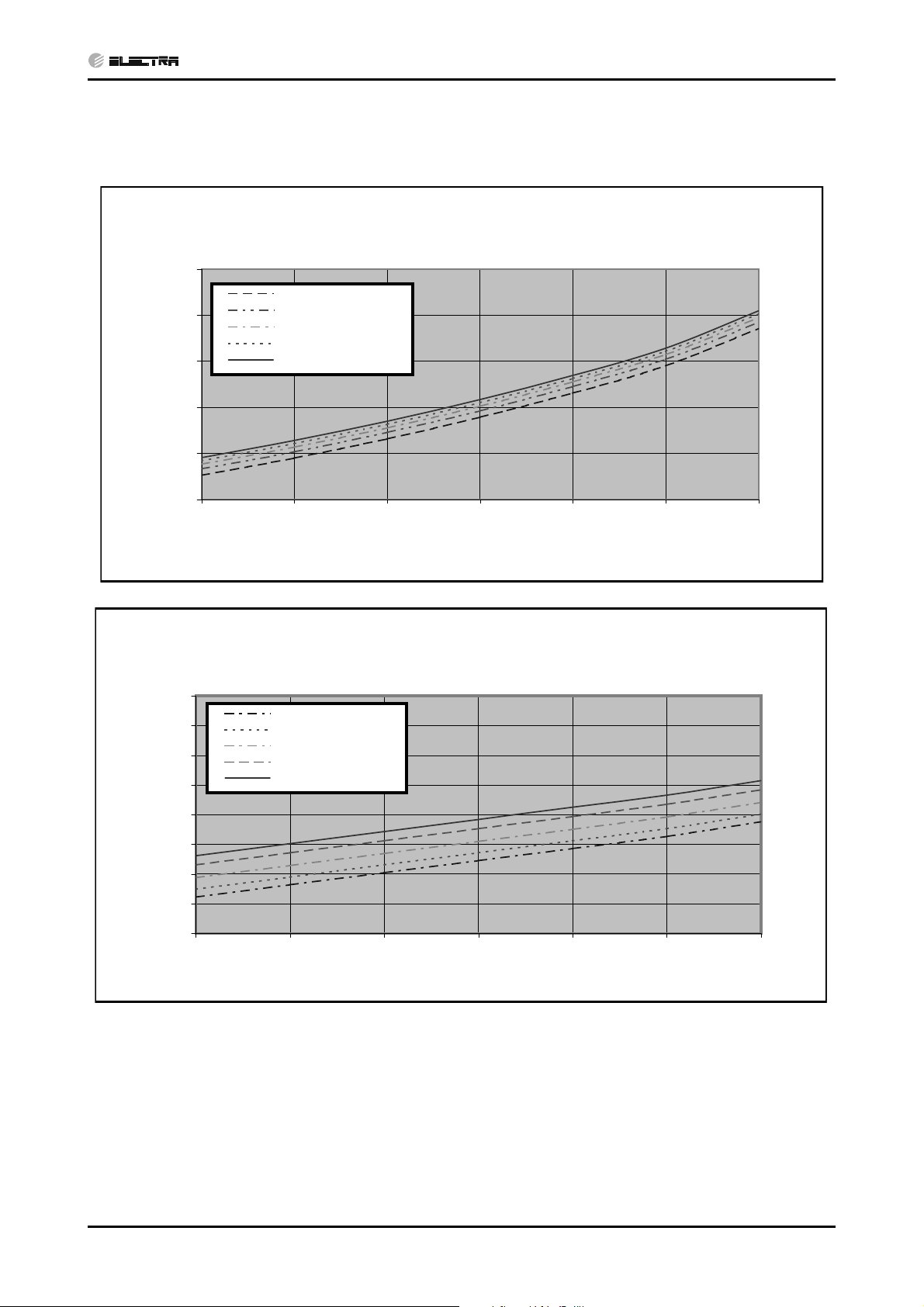

5.1 Alpha9 SP/CSP9 R22

5.1.1 Cooling Mode at 7.5m Tubing Connection.

230V : Indoor Fan at High Speed.

o

Entering Air DB

OD Coil(oC)

15

20

25

30

35

40

46

Data

Entering Air WB/DB ID Coil(

15/21 17/24 19/27 21/29 23/32

TC 2.71 2.81 2.87 2.94 2.98

SC 1.89 1.97 2.05 2.10 2.14

PI 0.67 0.67 0.67 0.67 0.67

TC 2.62 2.76 2.85 2.92 2.98

SC 1.85 1.95 2.04 2.09 2.13

PI 0.72 0.73 0.73 0.73 0.73

TC 2.48 2.68 2.82 2.90 2.97

SC 1.81 1.92 2.02 2.08 2.12

PI 0.78 0.79 0.79 0.80 0.80

TC 2.32 2.53 2.73 2.82 2.91

SC 1.75 1.86 1.98 2.03 2.07

PI 0.84 0.86 0.86 0.87 0.88

TC 2.15 2.33 2.57 2.70 2.83

SC 1.66 1.78 1.93 1.99 2.02

PI 0.91 0.93 0.94 0.95 0.95

TC 1.95 2.13 2.32 2.54 2.67

SC 1.57 1.69 1.83 1.88 1.92

PI 0.98 1.00 1.01 1.03 1.04

TC 1.69 1.85 2.04 2.25 2.42

SC 1.44 1.55 1.66 1.72 1.76

PI 1.07 1.09 1.11 1.13 1.14

C)

SM ASP 1-E.2 GB

LEGEND

TC – Total Cooling Capacity, kW

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (

ID – Indoor

OD – Outdoor

(1) Marked area is below standard operating limits. For operating in low ambient

conditions, an A.S.K Kit is required.

o

C)

5-1

Page 21

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

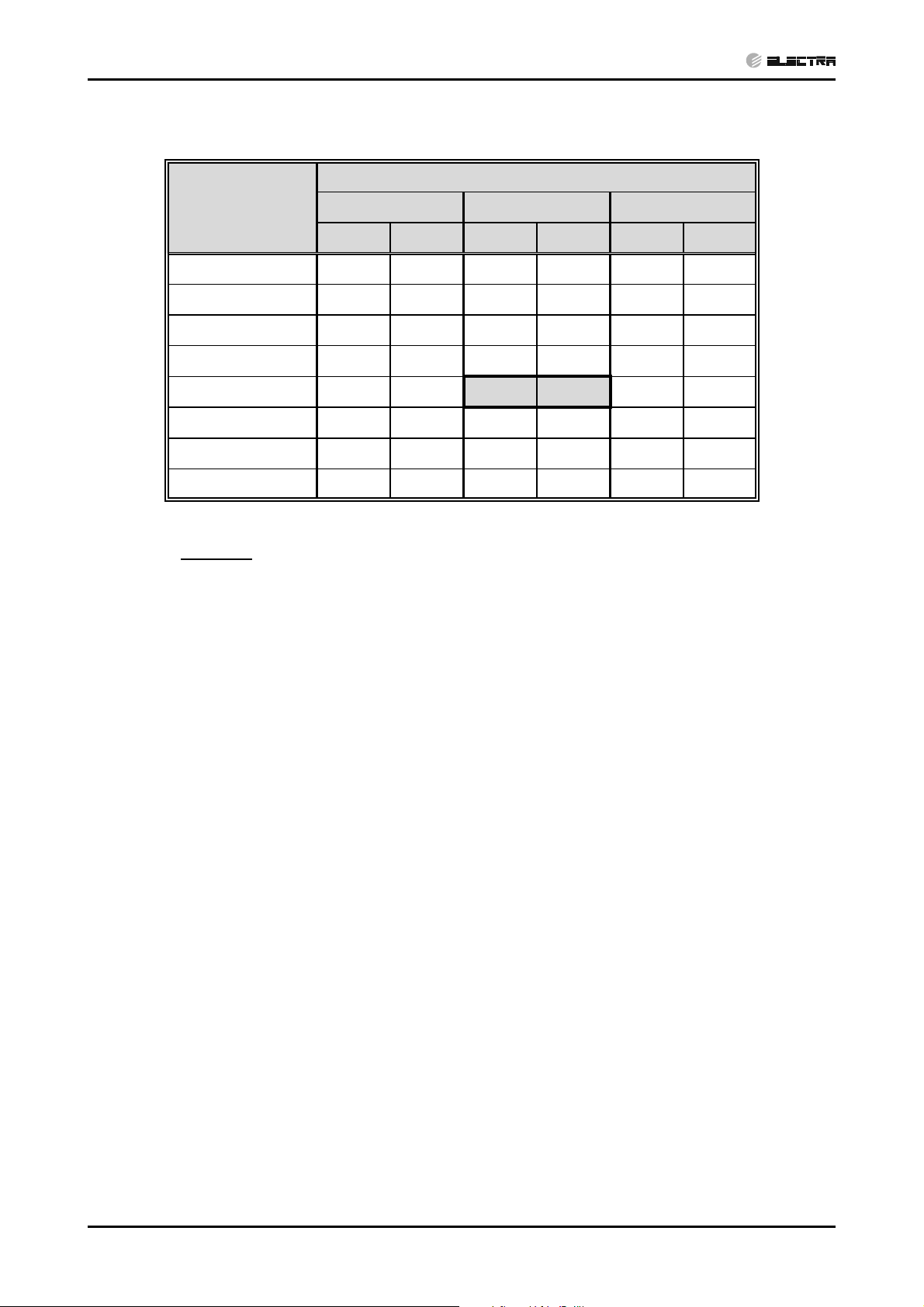

5.1.2 Heating

ENTERING AIR DB ID COIL(OC)

ENTERING WB

OD COIL(oC)

15 20 25

TH Pl TH Pl TH Pl

-10 1.47 0.68 1.41 0.72 1.36 0.76

-7 1.58 0.70 1.53 0.74 1.47 0.78

-2 1.68 0.71 1.62 0.75 1.57 0.79

2 2.04 0.74 1.96 0.79 1.88 0.83

6 2.88 0.79 2.80 0.85 2.70 0.90

10 3.14 0.84 3.05 0.90 2.97 0.96

15 3.39 0.88 3.30 0.94 3.22 1.00

20 3.57 0.90 3.49 0.98 3.39 1.05

LEGEND

TH – Total Heating Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

5-2

SM ASP 1-E.2 GB

Page 22

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

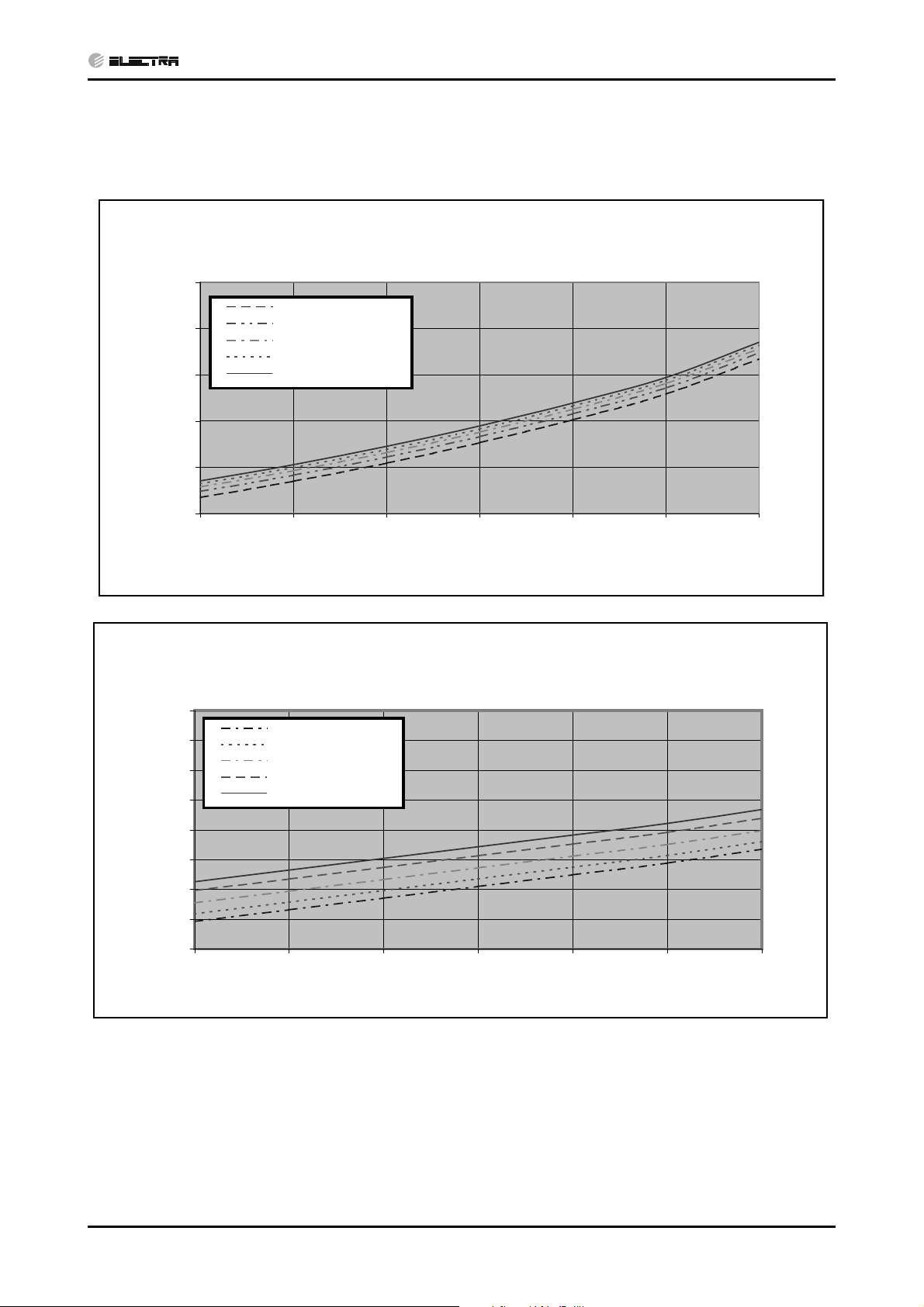

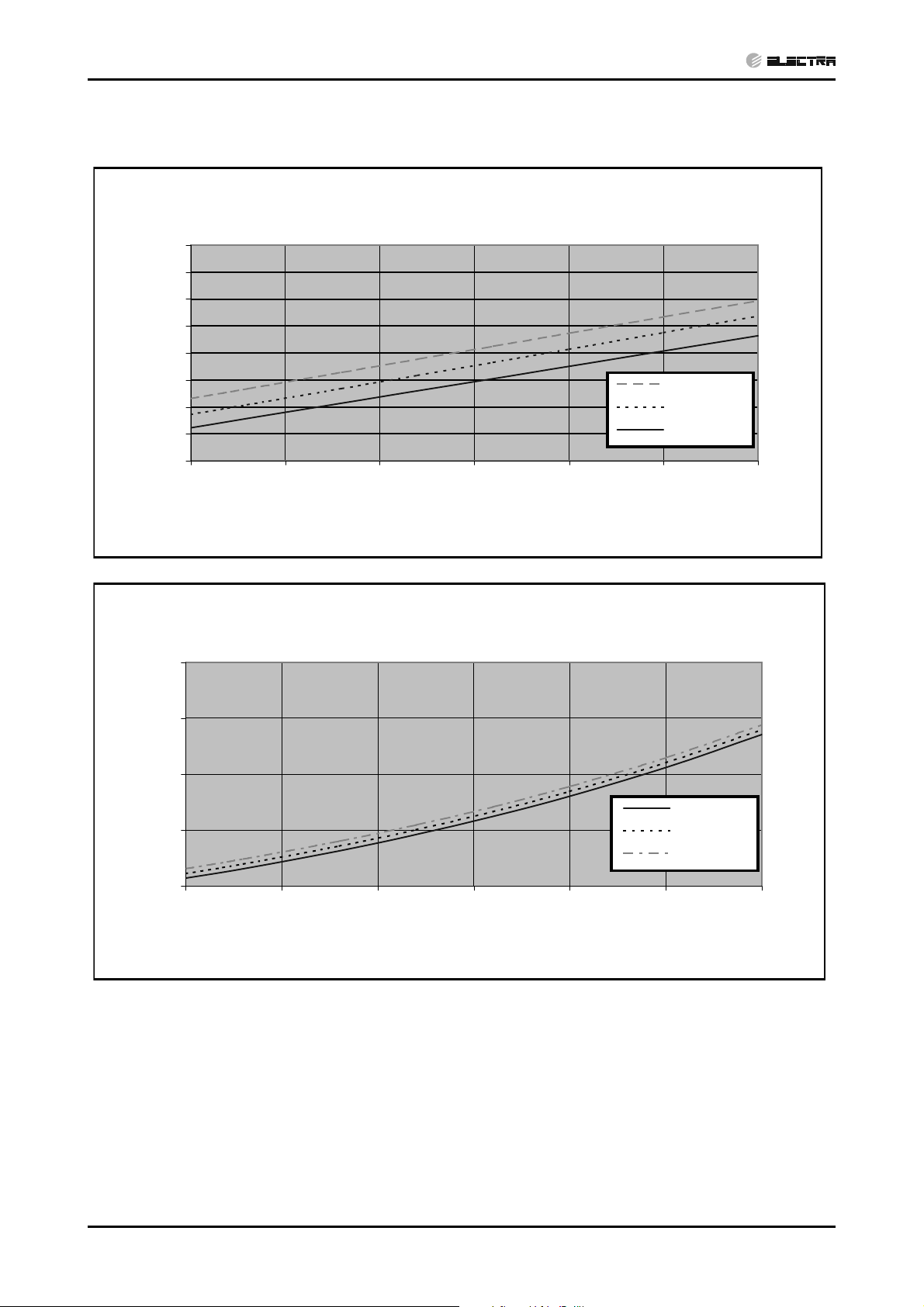

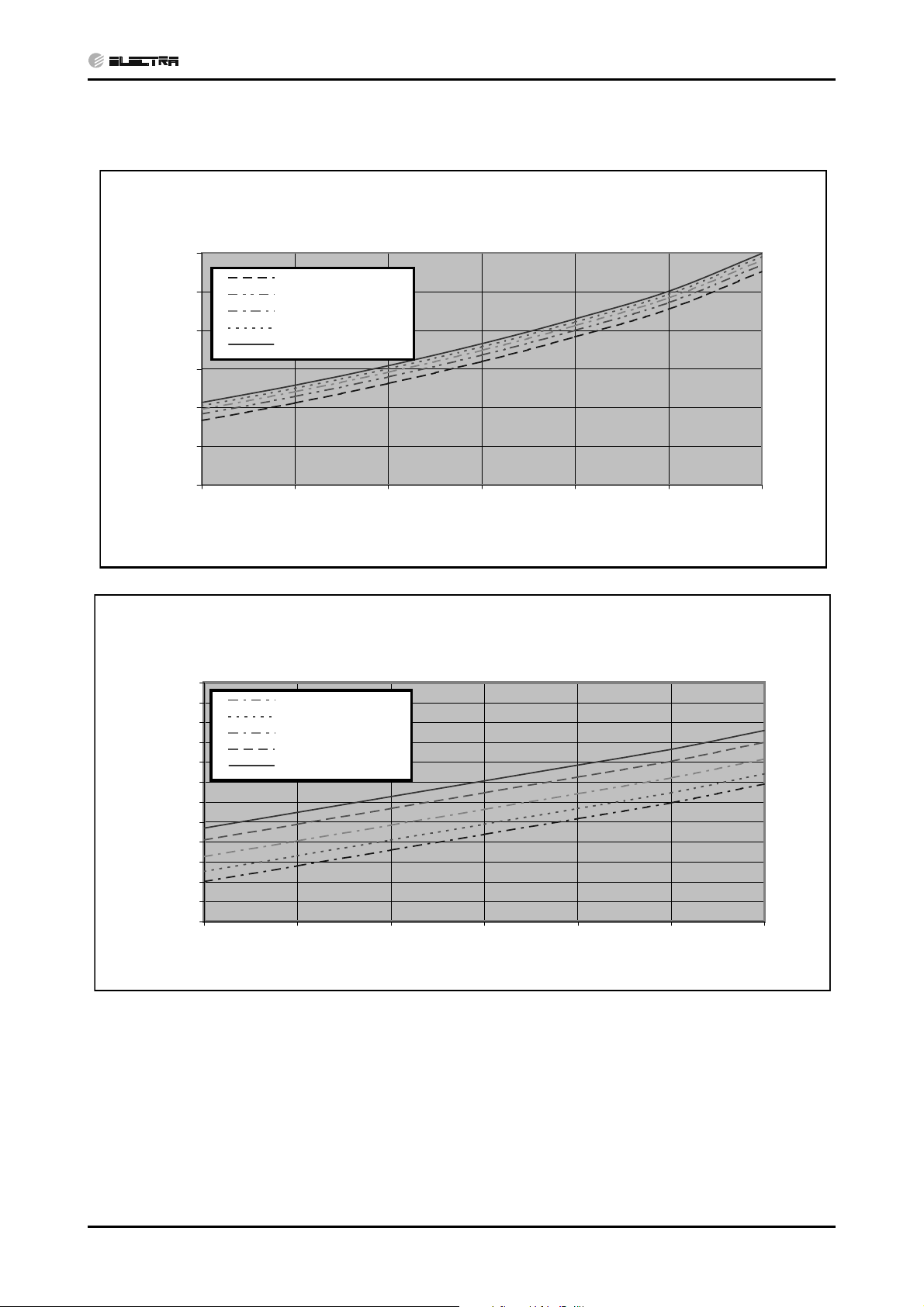

5.2 Model: Alpha9 SP/CSP9 R22

5.2.1 Cooling

Discharge Pressure VS.Outdoor Temp

30

15/21(WB/DB ºC)

26

22

18

14

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

10

Discharge Pressure (Bar[g])

15 20 25 30 35 40 46

Outdoor Temp.(DB oC )

Suction Pressure VS.Outdoor Temp

7.0

6.5

6.0

5.5

5.0

4.5

4.0

3.5

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Suction Pressure (Bar[g])

3.0

15 20 25 30 35 40 46

Outdoor Temp.(DB oC )

SM ASP 1-E.2 GB

5-3

Page 23

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

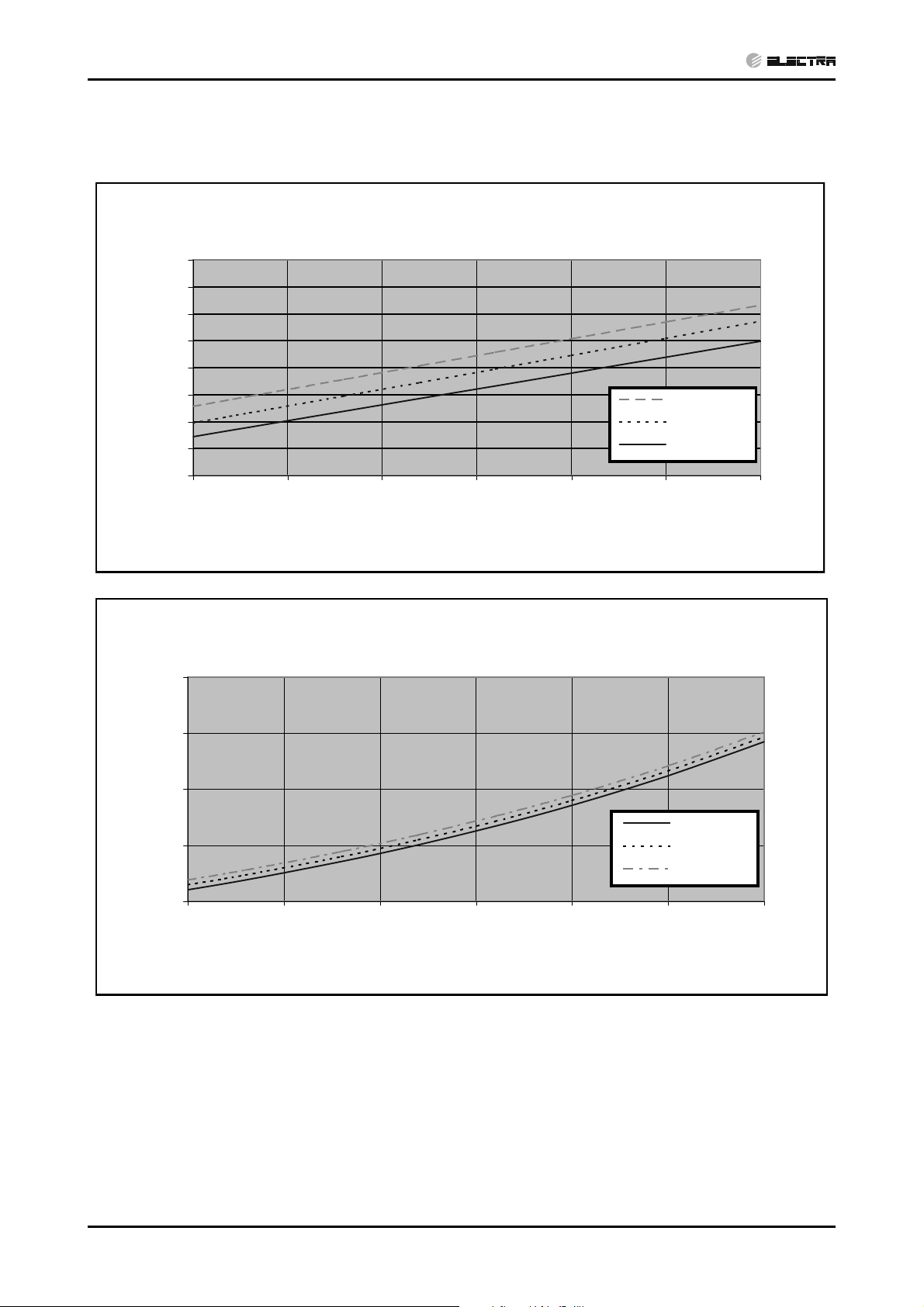

5.2.2 Heating

Discharge Pressure VS.Outdoor Temp

26

24

22

20

18

16

14

12

10

Discharge Pressure(Bar[g])

-10 -5 0 5 10 15 20

25 DB (ºC)

20 DB (ºC)

15 DB (ºC)

Outdoor Temp.( WB oC )

Suction Pressure VS.Outdoor Temp

6.0

5.0

4.0

15 DB (ºC)

3.0

Suction Pressure(Bar[g])

2.0

-10 -5 0 5 10 15 20

20 DB (ºC)

25 DB (ºC)

Outdoor Temp.( WB oC )

5-4

SM ASP 1-E.2 GB

Page 24

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

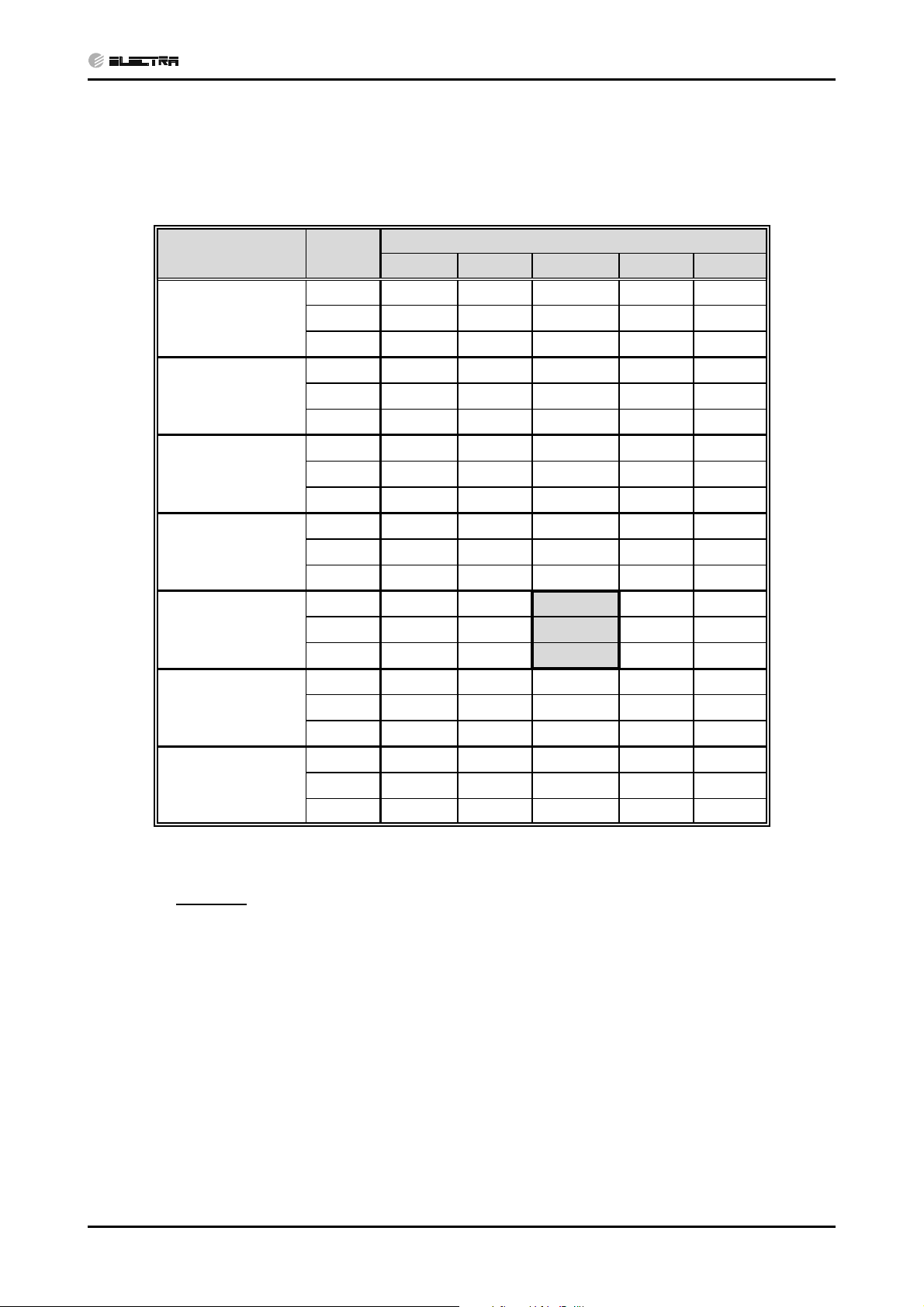

5.3 Alpha12 SP/CSP12 R22

5.3.1 Cooling Mode at 7.5m Tubing Connection.

230V : Indoor Fan at High Speed.

Entering Air DB

OD Coil(oC)

15

20

25

30

35

40

46

Data

TC 3.37 3.49 3.58 3.66 3.72

SC 2.35 2.45 2.55 2.61 2.66

PI 0.81 0.81 0.81 0.81 0.82

TC 3.26 3.44 3.55 3.63 3.71

SC 2.30 2.43 2.53 2.60 2.65

PI 0.88 0.88 0.88 0.89 0.89

TC 3.09 3.33 3.51 3.61 3.70

SC 2.24 2.38 2.51 2.58 2.63

PI 0.95 0.95 0.96 0.97 0.97

TC 2.89 3.14 3.40 3.52 3.62

SC 2.17 2.31 2.46 2.53 2.58

PI 1.02 1.04 1.05 1.06 1.06

TC 2.67 2.90 3.20 3.36 3.52

SC 2.07 2.22 2.40 2.47 2.52

PI 1.10 1.12 1.14 1.15 1.16

TC 2.43 2.65 2.89 3.16 3.32

SC 1.95 2.10 2.27 2.34 2.39

PI 1.19 1.21 1.23 1.24 1.26

TC 2.11 2.31 2.54 2.80 3.02

SC 1.79 1.92 2.07 2.14 2.19

PI 1.30 1.32 1.35 1.37 1.38

Entering Air WB/DB ID Coil(

15/21 17/24 19/27 21/29 23/32

o

C)

SM ASP 1-E.2 GB

LEGEND

TC – Total Cooling Capacity, kW

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

(1) Marked area is below standard operating limits. For operating in low ambient

conditions, an A.S.K Kit is required.

5-5

Page 25

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.3.2 Heating

ENTERING AIR DB ID COIL(

ENTERING WB

o

OD COIL(

C)

15 20 25

TH Pl TH Pl TH Pl

-10 1.84 0.85 1.77 0.90 1.70 0.95

-7 1.98 0.87 1.91 0.92 1.84 0.97

-2 2.10 0.88 2.03 0.93 1.96 0.99

2 2.56 0.92 2.45 0.98 2.35 1.04

6 3.61 0.99 3.50 1.06 3.38 1.13

10 3.92 1.05 3.82 1.12 3.71 1.20

15 4.24 1.09 4.13 1.18 4.03 1.25

20 4.46 1.12 4.36 1.22 4.24 1.31

LEGEND

TH – Total Heating Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)w

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

O

C)

5-6

SM ASP 1-E.2 GB

Page 26

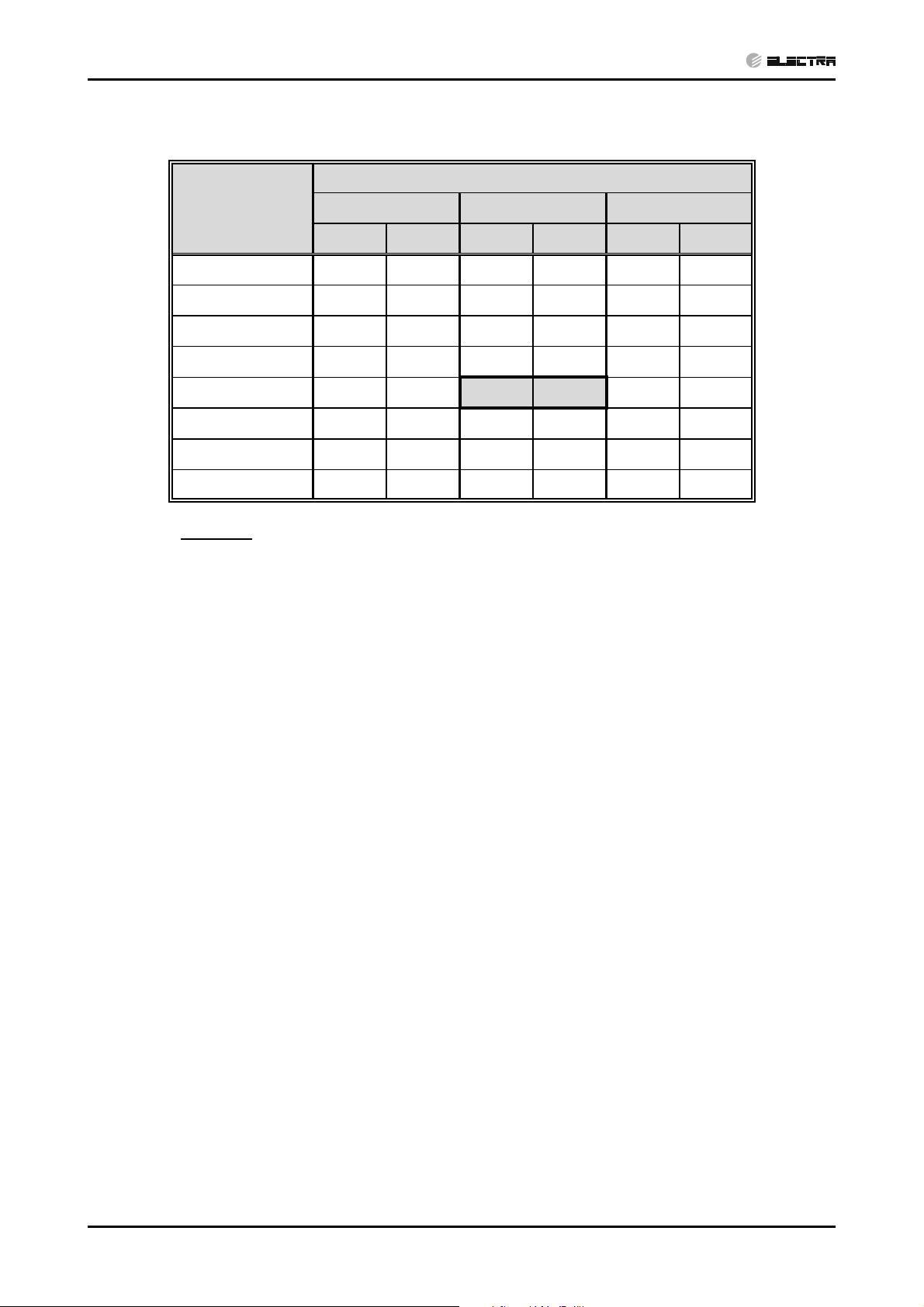

5.4 Alpha12 SP/CSP12 R22

CONTENT

5.4.1 Cooling

Discharge Pressure VS.Outdoor Temp

30

15/21(WB/DB ºC)

26

22

18

14

10

Discharge Pressure (Bar[g])

15 20 25 30 35 40 46

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Outdoor Temp.(DB oC )

PERFORMANCE DATA & PRESSURE CURVES

Suction Pressure VS.Outdoor Temp

7.0

6.5

6.0

5.5

5.0

4.5

4.0

3.5

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Suction Pressure (Bar[g])

3.0

15 20 25 30 35 40 46

Outdoor Temp.(DB oC )

SM ASP 1-E.2 GB

5-7

Page 27

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.4.2 Heating

Discharge Pressure VS.Outdoor Temp

26

24

22

20

18

16

14

12

10

Discharge Pressure(Bar[g])

-10 -5 0 5 10 15 20

25 DB (ºC)

20 DB (ºC)

15 DB (ºC)

Outdoor Temp.( WB oC )

Suction Pressure VS.Outdoor Temp

6.0

5.0

4.0

3.0

Suction Pressure(Bar[g])

2.0

-10 -5 0 5 10 15 20

Outdoor Temp.( WB oC )

15 DB (ºC)

20 DB (ºC)

25 DB (ºC)

5-8

SM ASP 1-E.2 GB

Page 28

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.5 Alpha9 SP EU/CSP9 EU R410A

5.5.1 Cooling Mode at 7.5m Tubing Connection.

230V : Indoor Fan at High Speed.

Entering Air DB

OD Coil(oC)

15

20

25

30

35

40

46

Data

TC 2.69 2.78 2.85 2.92 2.96

SC 1.87 1.95 2.03 2.08 2.12

PI 0.63 0.63 0.63 0.63 0.64

TC 2.60 2.74 2.83 2.89 2.96

SC 1.83 1.93 2.01 2.07 2.11

PI 0.69 0.69 0.69 0.69 0.69

TC 2.46 2.66 2.79 2.88 2.95

SC 1.79 1.90 2.00 2.06 2.09

PI 0.74 0.75 0.75 0.76 0.76

TC 2.30 2.51 2.71 2.80 2.89

SC 1.73 1.84 1.96 2.01 2.05

PI 0.80 0.81 0.82 0.82 0.83

TC 2.13 2.31 2.55 2.68 2.80

SC 1.65 1.76 1.91 1.97 2.00

PI 0.86 0.88 0.89 0.90 0.90

TC 1.94 2.11 2.30 2.52 2.65

SC 1.55 1.67 1.81 1.86 1.90

PI 0.93 0.94 0.96 0.97 0.98

TC 1.68 1.84 2.02 2.23 2.41

SC 1.43 1.53 1.65 1.70 1.74

PI 1.02 1.03 1.05 1.07 1.08

Entering Air WB/DB ID Coil(

15/21 17/24 19/27 21/29 23/32

o

C)

SM ASP 1-E.2 GB

LEGEND

TC – Total Cooling Capacity, kW

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

(1) Marked area is below standard operating limits. For operating in low ambient

conditions, an A.S.K Kit is required

5-9

Page 29

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.5.2 Heating

ENTERING AIR DB ID COIL(OC)

ENTERING WB

OD COIL(oC)

15 20 25

TH Pl TH Pl TH Pl

-10 1.39 0.66 1.34 0.70 1.29 0.73

-7 1.50 0.67 1.44 0.71 1.39 0.75

-2 1.59 0.68 1.54 0.72 1.48 0.76

2 1.93 0.71 1.86 0.76 1.78 0.80

6 2.73 0.77 2.65 0.82 2.56 0.87

10 2.97 0.81 2.89 0.87 2.81 0.93

15 3.21 0.84 3.13 0.91 3.05 0.97

20 3.38 0.87 3.30 0.94 3.21 1.02

LEGEND

TH – Total Heating Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

5-10

SM ASP 1-E.2 GB

Page 30

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.6 Model: Alpha9 SP EU/CSP9 EU R410A

5.6.1 Cooling

Discharge Pressure VS.Outdoor Temp

40

35

30

25

20

15

10

Discharge Pressure (Bar[g])

15 20 25 30 35 40 46

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Outdoor Temp.(DB oC )

Suction Pressure VS.Outdoor Temp

12.0

11.5

11.0

10.5

10.0

9.5

9.0

8.5

8.0

7.5

7.0

6.5

Suction Pressure (Bar[g])

6.0

15 20 25 30 35 40 46

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Outdoor Temp.(DB oC )

SM ASP 1-E.2 GB

5-11

Page 31

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.6.2 Heating

Discharge Pressure VS.Outdoor Temp

34

32

30

28

26

24

22

20

18

16

14

Discharge Pressure(Bar[g])

-10 -5 0 5 10 15 20

Outdoor Temp.( WB oC )

25 DB (ºC)

20 DB (ºC)

15 DB (ºC)

Suction Pressure(Bar[g])

Suction Pressure VS.Outdoor Temp

10.0

9.0

8.0

7.0

6.0

5.0

4.0

3.0

-10 -5 0 5 10 15 20

15 DB (ºC)

20 DB (ºC)

25 DB (ºC)

Outdoor Temp.( WB oC )

5-12

SM ASP 1-E.2 GB

Page 32

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.7 Model: Alpha12 SP EU/CSP12 EU R410A

5.7.1 Cooling Mode at 7.5m Tubing Connection.

230V : Indoor Fan at High Speed.

Entering Air DB

OD Coil(oC)

15

20

25

30

35

40

46

Data

15/21 17/24 19/27 21/29 23/32

TC 3.48 3.60 3.69 3.77 3.83

SC 2.53 2.64 2.74 2.81 2.86

PI 0.82 0.82 0.83 0.83 0.83

TC 3.37 3.55 3.66 3.75 3.83

SC 2.48 2.61 2.72 2.80 2.85

PI 0.89 0.90 0.90 0.90 0.91

TC 3.18 3.44 3.61 3.72 3.81

SC 2.41 2.56 2.70 2.78 2.83

PI 0.97 0.97 0.98 0.98 0.99

TC 2.98 3.24 3.50 3.63 3.73

SC 2.34 2.48 2.64 2.72 2.77

PI 1.04 1.06 1.07 1.07 1.08

TC 2.76 2.99 3.30 3.47 3.63

SC 2.22 2.38 2.58 2.65 2.71

PI 1.12 1.14 1.16 1.17 1.18

TC 2.51 2.73 2.98 3.26 3.42

SC 2.09 2.25 2.44 2.52 2.57

PI 1.21 1.23 1.25 1.27 1.28

TC 2.18 2.38 2.62 2.89 3.11

SC 1.93 2.07 2.23 2.30 2.35

PI 1.32 1.34 1.37 1.39 1.41

Entering Air WB/DB ID Coil(

o

C)

SM ASP 1-E.2 GB

LEGEND

TC – Total Cooling Capacity, kWv

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

(1) Marked area is below standard operating limits. For operating in low ambient

conditions, refer to Optional Accessories (Chapter 15).

5-13

Page 33

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.7.2 Heating

ENTERING AIR DB ID COIL(

ENTERING WB

OD COIL(oC)

15 20 25

TH Pl TH Pl TH Pl

-10 1.79 0.84 1.72 0.89 1.65 0.94

-7 1.92 0.86 1.85 0.91 1.79 0.96

-2 2.04 0.87 1.97 0.92 1.90 0.98

2 2.48 0.91 2.38 0.97 2.28 1.03

6 3.50 0.98 3.40 1.05 3.28 1.12

10 3.81 1.04 3.71 1.11 3.60 1.18

15 4.11 1.08 4.01 1.17 3.91 1.24

20 4.34 1.11 4.23 1.21 4.11 1.30

LEGEND

TH – Total Heating Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OU – Outdoor

O

C)

5-14

SM ASP 1-E.2 GB

Page 34

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.8. Model: Alpha12 SP EU/CSP12 EU R410A

5.8.1 Cooling

Discharge Pressure VS.Outdoor Temp

40

35

30

25

20

15

10

Discharge Pressure (Bar[g])

15 20 25 30 35 40 46

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Outdoor Temp.(DB oC )

Suction Pressure VS.Outdoor Temp

12.0

11.5

11.0

10.5

10.0

9.5

9.0

8.5

8.0

7.5

7.0

6.5

Suction Pressure (Bar[g])

6.0

15 20 25 30 35 40 46

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Outdoor Temp.(DB oC )

SM ASP 1-E.2 GB

5-15

Page 35

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.8.2 Heating.

Discharge Pressure VS.Outdoor Temp

36

34

32

30

28

26

24

22

20

18

16

Discharge Pressure(Bar[g])

-10 -5 0 5 10 15 20

Outdoor Temp.( WB oC )

25 DB (ºC)

20 DB (ºC)

15 DB (ºC)

Suction Pressure VS.Outdoor Temp

10.0

9.0

8.0

7.0

6.0

5.0

4.0

Suction Pressure(Bar[g])

3.0

-10 -5 0 5 10 15 20

15 DB (ºC)

20 DB (ºC)

25 DB (ºC)

Outdoor Temp.( WB oC )

5-16

SM ASP 1-E.2 GB

Page 36

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.9 Model: Alpha9 SP ISR/CSP9 ISR R410A A1

5.9.1 Cooling Mode at 7.5m Tubing Connection.

230V : Indoor Fan at High Speed.

Entering Air DB

OD Coil(oC)

15

20

25

30

35

Entering Air WB/DB ID Coil(

o

C)

Data

15/21 17/24 19/27 21/29 23/32

TC 2.74 2.84 2.91 2.97 3.02

SC 1.99 2.07 2.15 2.21 2.25

PI 0.57 0.58 0.58 0.58 0.58

TC 2.65 2.79 2.88 2.95 3.01

SC 1.95 2.05 2.14 2.20 2.24

PI 0.62 0.63 0.63 0.63 0.63

TC 2.51 2.71 2.85 2.93 3.01

SC 1.90 2.01 2.12 2.19 2.23

PI 0.67 0.68 0.68 0.69 0.69

TC 2.35 2.55 2.76 2.86 2.94

SC 1.84 1.95 2.08 2.14 2.18

PI 0.73 0.74

TC 2.17 2.36

0.74

2.60

0.75 0.76

2.73 2.86

SC 1.75 1.87 2.03 2.09 2.13

PI 0.78 0.80

0.81

0.82 0.82

40

TC 1.98 2.15

2.35

SC 1.65 1.77 1.92 1.98 2.02

2.57 2.70

PI 0.85 0.86 0.87 0.88 0.89

TC 1.71 1.87 2.06 2.28 2.45

46

SC 1.52 1.63 1.75 1.81 1.85

PI 0.92 0.94 0.96 0.97 0.98

LEGEND

TC – Total Cooling Capacity, kWv

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (

ID – Indoor

OD – Outdoor

(1) Marked area is below standard operating limits. For operating in low ambient

conditions, refer to Optional Accessories (Chapter 15).

o

C)

SM ASP 1-E.2 GB

5-17

Page 37

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.9.2 Heating

ENTERING AIR DB ID COIL(

ENTERING WB

OD COIL(oC)

15 20 25

TH Pl TH Pl TH Pl

-10 1.47 0.64 1.41 0.68 1.36 0.72

-7 1.58 0.66 1.53 0.69 1.47 0.73

-2 1.68 0.66 1.62 0.70 1.57 0.74

2 2.04 0.70 1.96 0.74 1.88 0.78

6 2.88 0.75 2.80 0.80 2.70 0.85

10 3.14 0.79 3.05 0.84 2.97 0.90

15 3.39 0.82 3.30 0.89 3.22 0.94

20 3.57 0.85 3.49 0.92 3.39 0.99

LEGEND

TH – Total Heating Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OU – Outdoor

O

C)

5-18

SM ASP 1-E.2 GB

Page 38

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.10. Model: Alpha9 SP ISR/CSP9 ISR R410A A1

5.10.1 Cooling

Discharge Pressure VS.Outdoor Temp

40

35

30

25

20

15

10

Discharge Pressure (Bar[g])

15 20 25 30 35 40 46

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Outdoor Temp.(DB oC )

Suction Pressure VS.Outdoor Temp

12.0

11.5

11.0

10.5

10.0

9.5

9.0

8.5

8.0

7.5

7.0

6.5

Suction Pressure (Bar[g])

6.0

15 20 25 30 35 40 46

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Outdoor Temp.(DB oC )

SM ASP 1-E.2 GB

5-19

Page 39

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.10.2 Heating.

Discharge Pressure VS.Outdoor Temp

38

36

34

32

30

28

26

24

22

20

18

Discharge Pressure(Bar[g])

-10 -5 0 5 10 15 20

Outdoor Temp.( WB oC )

25 DB (ºC)

20 DB (ºC)

15 DB (ºC)

Suction Pressure VS.Outdoor Temp

10.0

9.0

8.0

7.0

6.0

5.0

4.0

Suction Pressure(Bar[g])

3.0

-10 -5 0 5 10 15 20

15 DB (ºC)

20 DB (ºC)

25 DB (ºC)

Outdoor Temp.( WB oC )

5-20

SM ASP 1-E.2 GB

Page 40

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.11 Model: Alpha12 SP ISR/CSP12 ISR R410A A1

5.11.1 Cooling Mode at 7.5m Tubing Connection.

230V : Indoor Fan at High Speed.

Entering Air DB

OD Coil(oC)

Data

15/21 17/24 19/27 21/29 23/32

Entering Air WB/DB ID Coil(

o

C)

TC 3.58 3.71 3.80 3.89 3.95

15

SC 2.50 2.60 2.71 2.77 2.82

PI 0.79 0.79 0.79 0.79 0.80

TC 3.47 3.65 3.77 3.86 3.94

20

SC 2.45 2.58 2.69 2.77 2.82

PI 0.85 0.86 0.86 0.86 0.87

TC 3.28 3.54 3.72 3.84 3.93

25

SC 2.39 2.53 2.67 2.75 2.80

PI 0.92 0.93 0.94 0.94 0.95

TC 3.07 3.34 3.61 3.74 3.85

30

SC 2.31 2.46 2.61 2.69 2.74

PI 1.00 1.01 1.02 1.03 1.04

TC 2.84 3.08 3.40 3.57 3.74

35

SC 2.20 2.35 2.55 2.62 2.68

PI 1.07 1.09 1.11 1.12 1.12

TC 2.58 2.81 3.07 3.35 3.53

40

SC 2.07 2.23 2.41 2.49 2.54

PI 1.16 1.18 1.20 1.21 1.22

TC 2.24 2.45 2.69 2.98 3.21

46

SC 1.91 2.04 2.20 2.28 2.33

PI 1.27 1.29 1.31 1.33 1.35

SM ASP 1-E.2 GB

LEGEND

TC – Total Cooling Capacity, kWv

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

(1) Marked area is below standard operating limits. For operating in low ambient

conditions, refer to Optional Accessories (Chapter 15).

5-21

Page 41

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.11.2 Heating

ENTERING AIR DB ID COIL(OC)

15 20 25

ENTERING WB

o

OD COIL(

C)

TH Pl TH Pl TH Pl

-10 1.89 0.93 1.82 0.99 1.75 1.04

-7 2.03 0.95 1.96 1.00 1.89 1.06

-2 2.16 0.96 2.09 1.02 2.02 1.08

2 2.63 1.01

6 3.71 1.08 3.60 1.16 3.47 1.23

10 4.03 1.14

15 4.36 1.19 4.25 1.29 4.14 1.37

20 4.59 1.23 4.48 1.33 4.36 1.44

LEGEND

TH – Total Heating Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OU – Outdoor

2.52 1.07

3.92 1.22

2.41 1.14

3.82 1.31

5-22

SM ASP 1-E.2 GB

Page 42

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.12. Model: Alpha12 SP ISR/CSP12 ISR R410A A1

5.12.1 Cooling

Discharge Pressure VS.Outdoor Temp

40

35

30

25

20

15

10

Discharge Pressure (Bar[g])

15 20 25 30 35 40 46

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Outdoor Temp.(DB oC )

Suction Pressure VS.Outdoor Temp

12.0

11.5

11.0

10.5

10.0

9.5

9.0

8.5

8.0

7.5

7.0

6.5

Suction Pressure (Bar[g])

6.0

15 20 25 30 35 40 46

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Outdoor Temp.(DB oC )

SM ASP 1-E.2 GB

5-23

Page 43

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.12.2 Heating.

Discharge Pressure VS.Outdoor Temp

38

36

34

32

30

28

26

24

22

20

18

Discharge Pressure(Bar[g])

-10 -5 0 5 10 15 20

Outdoor Temp.( WB oC )

25 DB (ºC)

20 DB (ºC)

15 DB (ºC)

Suction Pressure VS.Outdoor Temp

10.0

9.0

8.0

7.0

6.0

5.0

4.0

Suction Pressure(Bar[g])

3.0

-10 -5 0 5 10 15 20

15 DB (ºC)

20 DB (ºC)

25 DB (ºC)

Outdoor Temp.( WB oC )

5-24

SM ASP 1-E.2 GB

Page 44

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.13 Model: Alpha SP 9 R410A A2 ISR / CSP 9 R410A A2 ISR

5.13.1 Cooling Mode at 7.5m Tubing Connection.

230V : Indoor Fan at High Speed.

Entering Air

DB OD Coil(oC)

Data

o

Entering Air WB/DB ID Coil(

C)

15/21 17/24 19/27 21/29 23/32

TC 2.90 3.00 3.07 3.15 3.19

15

SC 2.10 2.19 2.27 2.33 2.37

PI 0.57 0.57 0.57 0.57 0.57

TC 2.80 2.96 3.05 3.12 3.19

20

SC 2.05 2.17 2.26 2.32 2.36

PI 0.62 0.62 0.62 0.62 0.62

TC 2.65 2.86 3.01 3.10 3.18

25

SC 2.00 2.12 2.24 2.30 2.35

PI 0.67 0.67 0.67 0.68 0.68

TC 2.48 2.70 2.92 3.02 3.11

30

SC 1.94 2.06 2.19 2.25 2.30

PI 0.72 0.73

0.73

0.74 0.75

TC 2.30 2.49

35

SC 1.84 1.98 2.14 2.20 2.24

PI 0.77 0.79

TC 2.09 2.27

40

SC 1.74 1.87 2.02 2.09 2.13

PI 0.84 0.85 0.86 0.87 0.88

TC 1.81 1.98 2.18 2.41 2.59

46

SC 1.60 1.71 1.85 1.91 1.95

PI 0.91 0.93 0.95 0.96 0.97

LEGEND

TC – Total Cooling Capacity, kWv

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

2.75

0.80

2.48

2.89 3.02

0.81 0.81

2.71 2.85

SM ASP 1-E.2 GB

(1) Marked area is below standard operating limits. For operating in low ambient

conditions, refer to Optional Accessories (Chapter 15).

5-25

Page 45

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.13.2 Heating

ENTERING AIR DB ID COIL(OC)

15 20 25

ENTERING WB

o

OD COIL(

C)

-10 1.39 0.64 1.34 0.68 1.29 0.72

-7 1.50 0.66 1.44 0.69 1.39 0.73

-2 1.59 0.66 1.54 0.70 1.48 0.74

2 1.93 0.70

6 2.73 0.75 2.65 0.80 2.56 0.85

10 2.97 0.79

15 3.21 0.82 3.13 0.89 3.05 0.94

20 3.38 0.85 3.30 0.92 3.21 0.99

LEGEND

TH – Total Heating Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OU – Outdoor

TH Pl TH Pl TH Pl

1.86 0.74

2.89 0.84

1.78 0.78

2.81 0.90

5-26

SM ASP 1-E.2 GB

Page 46

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.14. Model: Alpha 9 SP ISR / CSP 9 ISR R410A A2

5.14.1 Cooling

Discharge Pressure VS.Outdoor Temp

40

35

30

25

20

15

10

Discharge Pressure (Bar[g])

15 20 25 30 35 40 46

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Outdoor Temp.(DB oC )

Suction Pressure VS.Outdoor Temp

12.0

11.5

11.0

10.5

10.0

9.5

9.0

8.5

8.0

7.5

7.0

6.5

Suction Pressure (Bar[g])

6.0

15 20 25 30 35 40 46

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Outdoor Temp.(DB oC )

SM ASP 1-E.2 GB

5-27

Page 47

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.8.2 Heating.

Discharge Pressure VS.Outdoor Temp

38

36

34

32

30

28

26

24

22

20

18

Discharge Pressure(Bar[g])

-10 -5 0 5 10 15 20

Outdoor Temp.( WB oC )

25 DB (ºC)

20 DB (ºC)

15 DB (ºC)

Suction Pressure VS.Outdoor Temp

10.0

9.0

8.0

7.0

6.0

5.0

4.0

Suction Pressure(Bar[g])

3.0

-10 -5 0 5 10 15 20

15 DB (ºC)

20 DB (ºC)

25 DB (ºC)

Outdoor Temp.( WB oC )

5-28

SM ASP 1-E.2 GB

Page 48

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.15 Model: Alpha SP 12 R410A A2 ISR / CSP 12 R410A A2 ISR

5.15.1 Cooling Mode at 7.5m Tubing Connection.

230V : Indoor Fan at High Speed.

Entering Air DB

OD Coil(oC)

Data

15/21 17/24 19/27 21/29 23/32

Entering Air WB/DB ID Coil(oC)

TC 3.70 3.83 3.92 4.02 4.08

15

SC 2.68 2.80 2.91 2.98 3.03

PI 0.74 0.74 0.74 0.74 0.75

TC 3.58 3.77 3.89 3.98 4.07

20

SC 2.63 2.77 2.89 2.97 3.03

PI 0.80 0.80 0.81 0.81 0.81

TC 3.39 3.66 3.84 3.96 4.06

25

SC 2.56 2.72 2.87 2.95 3.00

PI 0.87 0.87 0.88 0.88 0.89

TC 3.17 3.45 3.73 3.86 3.97

30

SC 2.48 2.64 2.80 2.89 2.94

PI 0.93 0.95 0.96 0.96 0.97

TC 2.93 3.18 3.51 3.69 3.86

35

SC 2.36 2.53 2.74 2.82 2.87

PI 1.01 1.02 1.04 1.05 1.05

TC 2.67 2.90 3.17 3.46 3.64

40

SC 2.22 2.39 2.59 2.67 2.73

PI 1.09 1.10 1.12 1.14 1.15

TC 2.31 2.53 2.78 3.07 3.31

46

SC 2.05 2.20 2.36 2.45 2.50

PI 1.19 1.20 1.23 1.25 1.26

LEGEND

TC – Total Cooling Capacity, kWv

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OD – Outdoor

SM ASP 1-E.2 GB

(1) Marked area is below standard operating limits. For operating in low ambient

conditions, refer to Optional Accessories (Chapter 15).

5-29

Page 49

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.15.2 Heating

ENTERING AIR DB ID COIL(OC)

15 20 25

ENTERING WB

OD COIL(oC)

-10 1.84 0.80 1.77 0.85 1.70 0.90

-7 1.98 0.82 1.91 0.87 1.84 0.91

-2 2.11 0.83 2.04 0.88 1.97 0.93

2 2.56 0.87 2.46 0.93 2.35 0.98

6 3.62 0.94 3.51 1.00 3.39 1.06

10 3.93 0.99 3.83 1.06 3.72 1.13

15 4.25 1.03 4.14 1.11 4.04 1.18

20 4.48 1.06 4.37 1.15 4.25 1.24

LEGEND

TH – Total Heating Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (oC)

DB – Dry Bulb Temp., (oC)

ID – Indoor

OU – Outdoor

TH Pl TH Pl TH Pl

5-30

SM ASP 1-E.2 GB

Page 50

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.16. Model: Alpha 12 SP ISR / CSP 12 ISR R410A A2

5.16.1 Cooling

Discharge Pressure VS.Outdoor Temp

40

35

30

25

20

15

10

Discharge Pressure (Bar[g])

15 20 25 30 35 40 46

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Outdoor Temp.(DB oC )

Suction Pressure VS.Outdoor Temp

12.0

11.5

11.0

10.5

10.0

9.5

9.0

8.5

8.0

7.5

7.0

6.5

Suction Pressure (Bar[g])

6.0

15 20 25 30 35 40 46

15/21(WB/DB ºC)

17/24(WB/DB ºC)

19/27(WB/DB ºC)

21/29(WB/DB ºC)

23/32(WB/DB ºC)

Outdoor Temp.(DB oC )

SM ASP 1-E.2 GB

5-31

Page 51

PERFORMANCE DATA & PRESSURE CURVES

CONTENT

5.16.2 Heating.

Discharge Pressure VS.Outdoor Temp

38

36

34

32

30

28

26

24

22

20

18

Discharge Pressure(Bar[g])

-10 -5 0 5 10 15 20

Outdoor Temp.( WB oC )

25 DB (ºC)

20 DB (ºC)

15 DB (ºC)

Suction Pressure VS.Outdoor Temp

10.0

9.0

8.0

7.0

6.0

5.0

4.0

Suction Pressure(Bar[g])

3.0

-10 -5 0 5 10 15 20

15 DB (ºC)

20 DB (ºC)

25 DB (ºC)

Outdoor Temp.( WB oC )

5-32

SM ASP 1-E.2 GB

Page 52

SOUND LEVEL CHARACTERISTICS

CONTENT

6. SOUND LEVEL CHARACTERISTICS

6.1 Sound Pressure Level

Unit

Wall

0.8m

Mic.

Figure 1

6.2 Soud Pressure Level Spectrum

ASP 9 ASP 12

NC-70

NC-60

NC-50

NC-40

NC-30

APPROXIMATE

THRESHOLD OF

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

HEARING FOR

CONTINUOUS

NOISE

BAND CENTER FREQUENCIES, Hz

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

(Measured as Figure 1)

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

FAN SPEED LINE

SM ASP 1-E.2 GB

HI

ME

LO

6-1

Page 53

SOUND LEVEL CHARACTERISTICS

CONTENT

6.3 Outdoor units

Unit

Mic.

Ground

Figure 2

6.4 Sound Pressure Level Spectrum

CSP9 RC R22 Cooling CSP9 RC R22 Heating

NC-70

NC-60

(Measured as Figure 2)

NC-70

NC-60

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

NC-50

NC-40

NC-30

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-20

BAND CENTER FREQUENCIES, Hz

CSP12 RC R22 Cooling CSP12 RC R22 Heating

NC-50

NC-40

NC-30

NC-20

6-2

SM ASP 1-E.2 GB

Page 54

CSP12 ST R22 Cooling

CONTENT

SOUND LEVEL CHARACTERISTICS

CSP9 RC R410A Cooling CSP9 RC R410A Heating

FAN SPEED LINE

SM ASP 1-E.2 GB

HI

ME

LO

6-3

Page 55

SOUND LEVEL CHARACTERISTICS

CONTENT

CSP9 ST R410A Cooling

CSP12 RC R410A Cooling CSP12 RC R410A Heating

6-4

SM ASP 1-E.2 GB

Page 56

CSP12 ST R410A Cooling

CONTENT

SOUND LEVEL CHARACTERISTICS

CSP(I)9 RC R410A Cooling CSP(I)9 RC R410A Heating

SM ASP 1-E.2 GB

6-5

Page 57

SOUND LEVEL CHARACTERISTICS

CONTENT

CSP(I)12 RC R410A Cooling CSP(I)12 RC R410A Heating

6-6

SM ASP 1-E.2 GB

Page 58

7. ELECTRICAL DATA

CONTENT

7.1 Single Phase Units

MODEL ASP 9 ASP 12

Power Supply

Max Current, A 6.5 7.7

Circuit Breaker,A 10 10

Power Supply Wiring No. X

Cross Section mm

Interconnecting Cable RC

Model No. X Cross Section mm

Interconnecting Cable ST

Model No. X Cross Section mm

2

5x1.0 mm2 +2x0.5 mm2 (OCT senser) 5x1.0 mm2 +2x0.5 mm2 (OCT senser)

2

2

To indoor To indoor

1PH-230V-50Hz 1PH-230V-50Hz

3x1.0 mm

4x1.0 mm

2

2

3x1.0 mm

4x1.0 mm

NOTE

ELECTRICAL DATA

2

2

Power wiring cord should comply with local lows and electrical

regulations requirements.

Service Manual - ALPHA

7-1

Page 59

8. WIRING DIAGRAMS

CONTENT

8.1 Indoor Unit : ASP9,12

WIRING DIAGRAMS

SM ASP 1-E.2 GB

8-1

Page 60

WIRING DIAGRAMS

CONTENT

8.2 Outdoor Unit: CSP9, 12

8-2

SM ASP 1-E.2 GB

Page 61

9. ELECTRICAL CONNECTIONS

CONTENT

9.1 ASP9, 12/CSP9, 12

ELECTRICAL CONNECTIONS

SM ASP 1-E.2 GB

9-1

Page 62

10. REFRIGERATION DIAGRAMS

CONTENT

10.1 Heat Pump Models

10.1.1 Alpha9, 12 SP/CSP9, 12

OUTDOOR UNIT

Service

Sensor

port

REFRIGERATION DIAGRAMS

INDOOR UNIT

Sensor

Sensor

Outdoor coil

Reverse

valve

Capillary

tube

Strainer

OUTDOOR UNIT

Valves

Capillary

tube

Check

valve

Compressor

COOLING MODE

Service

port

Flared

connection

Indoor coil

INDOOR UNIT

Sensor

SM ASP 1-E.2 GB

Outdoor coil

Reverse

valve

Strainer

Compressor

Capillary

Capillary

tube

tube

Check

valve

HEATING MODE

Valves

Flared

connection

Indoor coil

10-1

Page 63

REFRIGERATION DIAGRAMS

CONTENT

10.2 Cooling Only Models

10.2.1 Alpha9, 12 SP/CSP9, 12

INDOOR UNIT

Sensor

Indoor coil

Flared

connection

Valves

rosserpmo

port

Service

C

tube

Capillary

iner

Stra

10-2

OUTDOOR UNIT

Outdoor coil

Service Manual - ALPHA SP

Page 64

11. TUBING CONNECTIONS

CONTENT

TUBING CONNECTIONS

TUBE (Inch)

¼” ⅜” ½” ⅝” ¾”

TORQUE (Nm)

Flare Nuts 11-13 40-45 60-65 70-75 80-85

Valve Cap 13-20 13-20 18-25 18-25 40-50

Service Port Cap 11 - 13 11-13 11- 1 3 11-13 11-13

1. Valve Protection Cap-end

2. Refrigerant Valve Port (use Allen wrench to open/close)

3. Valve Protection Cap

4. Refrigerant Valve

5. Service Port Cap

6. Flare Nut

7. Unit Back Side

8. Copper Tube

When the outdoor unit is installed above the indoor unit an oil trap is required every 5m along

the suction line at the lowest point of the riser. Incase the indoor unit is installed above the

outdoor, no trap is required.

SM ASP 1-E.2 GB

11-1

Page 65

12. CONTROL SYSTEM ASP9, ASP12

CONTENT

12.1 Electronic Control

12.1.1 Introduction

The electronic control information is designed for service applications, and is common

to the following groups of air-conditioners:

● ST/ RC group -Cooling only / cooling and heating by heat pump.

● SH group -Cooling and heating by heat pump and supplementary

heater.

● RH group -Cooling, heating by heaters only.

12.1.2 Jumpers Settings

GROUP J6 Setting J2 Setting

ST / RC Open Open

SH Closed Open

CONTROL SYSTEM

RH Closed Closed

SM ASP 1-E.2 GB

12-1

Page 66

CONTROL SYSTEM

CONTENT

12.2 Legend

AC - Alternate Current

A/C - Air-Conditioner

ANY - ON or OFF status

CLOCK - ON/OFF Operation Input, (dry contact)

COMP - Compressor

CPU - Central Processing Unit

ELUM - Extended Louver Upward Movement (Software Jumper)

E²PROM, EEP - Erase Enable Programmable Read Only Memory

HE - Heating Element

HPC - High Pressure Control

H/W - Hardware

ICP - Indoor Condensation Pump

ICT - Indoor Coil Temperature (RT2) sensor

IF, IFAN - Indoor Fan

IR - Infra Red

LEVEL1 - Normal Water Level

LEVEL2/3 - Medium/High Water Level

LEVEL4 - Overflow Level

Max - Maximum

Min - Minimum

min - Minute (time)

NA - Not Applicable

OCP - Outdoor Condensation Pump

OCT - Outdoor Coil Temperature (RT3) sensor

OF, OFAN - Outdoor Fan

OPER - Operate

Para. - Paragraph

RAT - Return Air Temperature (RT1) sensor

RC - Reverse Cycle (Heat Pump)

R/C - Remote Control

RCT - Remote Control Temperature

RH - Resistance Heater

RT - Room Temperature (i.e. RCT in IFEEL mode, RAT otherwise)

RV - Reversing Valve

SB, STBY - Stand-By

sec - Second (time)

Sect - Section

SH - Supplementary Heater

SPT - Set Point Temperature

ST - Standard (a Model with Cooling Only)

S/W - Software

TEMP - Temperature

W/O - Without

WVL - Water Valve

ΔT - The difference between SPT and RT.

in Heat Mode: ΔT = SPT-RT

in Cool/Dry/Fan Mode: ΔT = RT-SPT

12-2

SM ASP 1-E.2 GB

Page 67

CONTROL SYSTEM

CONTENT

12.3 General functions

12.3.1 COMP operation

For each Mode including POWER OFF & SB, a Min time delay of 3 min

before COMP restarting, excluding DEICING Mode

The Min operation time of COMP under different operating conditions is

Operation Mode

Heat, Cool or Auto Modes 3 min.

Fan, Dry, Overflow, Protection modes, or mode change ignored

Min operation time of

COMP

12.3.2 IFAN operation

• Min time interval between IFAN speed change in AUTOFAN Mode, is 30 sec.

• Min time interval between IFAN speed change in H/M/L Mode is 1 sec.

• IFAN speed in Heat/Cool Autofan Mode is determined according to the following table:

ΔT IFAN Speed

ΔT ≥ 2 HIGH

2 ≥ ΔT ≥ 1 MED

1 ≥ ΔT LOW

where in Heat Mode: ΔT = SPT-RT

in Cool Mode: ΔT = RT-SPT

Note:

• In Heat Mode, the rules in section 4.0.3 have the higher priority.

• The table above can be represent by a hysteresis curve which

will minimize the switching of the IFAN relay and will minimize the

change in IFAN speed:

IFAN speed

H

M

L

12.3.3 OFAN operation

• Min time interval between OFAN ON/OFF state change is 30 sec.

• In general, OFAN starts together with COMP.

12.3.4 HE operation

• Minimum Heaters ON or OFF time is 30 sec.

• Heaters can be activated only if IFAN is on.

SM ASP 1-E.2 GB

321

T [oc]

12-3

Page 68

CONTROL SYSTEM

CONTENT

12.3.5 Protections

• High pressure protection is applicable to all operating modes.

• Deicing control is valid in Heat and Auto Heat Mode only.

• Defrosting control is valid in Dry, Cool, Heat and Auto Modes.

• No reset after protection modes.

12.3.6 Thermistors operation

• Return air Temp. is detected by RAT (RT1) in normal Mode, or by RCT (R/C sensor)

in I-FEEL Mode.

• Indoor Coil Temp. is detected by ICT (RT2).

12.3.6.1 Definition of thermistor faults:

a. Thermistor is disconnected -

The thermistor reading is below -30

b. Thermistor is shorted -

The thermistor reading is over 75

o

c.

o

c.

c. Thermistor Temp reading doesn’t change (irrelevant for RT1) -

(i) This test is performed only once after a unit is switched from

OFF/STBY to operation. At the first occurrence of 10 min

continuous COMP operation, the current ICT & OCT are

compared with those when the COMP was switched from OFF

to ON 10 min before. If the ΔT is less than 3

o

c, the thermistor is

regarded as defective.

(ii) The ICT and OCT no-change error can be disabled together by

connecting a4.7 kohm resistor (5%) to the OCT connector. These

resistors are equivalent to a thermistor at 43+/-1

o

c and 48+/-1oc

respectively.

(iii) Connecting a 4.7k resistor to the ICT connector will disable the

ICT no-change error only.

12-4

SM ASP 1-E.2 GB

Page 69

12.3.6.2 Handling the thermistor faults in a COMP unit

CONTENT

i. ICT/OCT thermistor is disconnected or shorted -

The invalid thermistor temperature is replaced by 43oc, so that the unit

can continue the normal operation. All protections related to that faulty

thermistor will be disabled. For example, in case of any ICT fault, the ICT

high pressure protection in Heat Mode and ICT defrost protection in Cool

Mode will not operate anymore. The same is also applied to the OCT fault.

ii. RAT thermistor is disconnected or shorted –

The RAT will be derived from the ICT by using the equations :

Heat Mode: RAT=ICT/2.3

Cool Mode RAT=ICT*4

Notes:

• In case of any thermistor failure, the STBY LED will be blinking until the

fault condition is corrected.

• User can use the system diagnostics function to find out the nature of

the thermistor faults.

CONTROL SYSTEM

i. RAT thermistor is disconnected or shorted –

System will operate continuously in the last IFAN & WVL status when

turned ON.

Notes:

• As in the COMP unit, the STBY LED will be blinking to indicate a

thermistor fault. And, the user can use the system diagnostics function

to find out the nature of the fault.

SM ASP 1-E.2 GB

12-5

Page 70

CONTROL SYSTEM

CONTENT

12.4 Cooling Mode - General

1) Room Temperature, RT, is detected by

• RAT in normal operation, or

• RCT (R/C sensor) in I-FEEL mode.

2) The resolution of RT is 1oc.

• RT is activating COMP/WVL if (RT > SPT), and

• RT is stopping COMP/WVL if (RT =< SPT).

3) Indoor Coil Temp is detected by ICT (RT2).

4) Outdoor Coil Temp is detected by OCT (RT3).

5) OFAN OPERATIONS

• OFAN starts together with COMP in general.

12-6

SM ASP 1-E.2 GB

Page 71

12.4.1 Cooling

CONTENT

Mode: Cool, Auto (at Cooling)

Temp: Selected desired temperature.

Fan: HIGH, MED, LOW

Timer: Any

I Feel: On or Off

Control function

Maintains room temp at desired level by comparing RT and SPT.

(RT - SPT) [oc]

+3

+2

CONTROL SYSTEM

+1

0

-1

-2

COMP

(WVL)

OFAN

IFAN

ON

OFF

ON

OFF

USER FAN SPEED

Note:

SM ASP 1-E.2 GB

ON

RV

OFF

1) IFAN is always running at High, Medium or Low speed selected by user.

2) In IFEEL mode, the Room Temperature (RT) is the RCT from a R/C. Otherwise, the

RT is the RAT from the Room Thermistor.

12-7

Page 72

CONTROL SYSTEM

CONTENT

12.4.2 Cooling with Autofan

Mode: Cool, Auto (at cooling)

Temp: Selected desired temperature

Fan: Auto

Timer: Any

I Feel: On or Off

Control function

Maintains room temp at desired level and controls the IFAN speed for optimal comfort.

(RT - SPT) [oc]

+3

+2

+1

0

-1

-2

COMP

(WVL)

OFAN

ON

OFF

ON

OFF

12-8

IFAN

RV

H

M

L

ON

OFF

SM ASP 1-E.2 GB

Page 73

12.5 Heating Mode

[

]

CONTENT

12.5.1 Heating Mode - General

• In heating Mode, temp. compensation schedule will be activated for wall mounted

units.

CONTROL SYSTEM

SPT [oc]

18 ≤ SPT ≤ 27 0

27 < SPT ≤ 30 0

Notes :

• No compensation will be activated in Forced operation modes

12.5.2 IF operating rules

• As a general rule for RC and SH groups, when COMP is ON, excluding

protection modes, IFAN will be switched ON if

• ICT > 35oc or

at the IFTC 30 sec after the COMP is switched ON. In

this case, the IFAN will be started at low speed.

IFAN Speed

Any

Low

Stop

Add to SPT

I-FEEL ON I-FEEL OFF

o

c +2 oc

o

c+3

EMD/ELD

EMD/ELD

o

c

General :

For WAX :

30 35 40

15 20 25

ICT [oc]

Notes :

1) In SH or RC group, if HE is set to OFF due to low ICT, IFAN will be

switched to LOW and will be turned OFF after 30 sec.

2) An exception to this rule (4.0.3.a) is the Back-up mode for SH.

• In RC and SH groups, whenever COMP & HE are both

OFF, excluding protection modes, IFAN operation will be according

to the following:

In other models IFAN will operate in low speed for 30 sec and then stop. If

COMP is OFF for more than 3 minutes and IFEEL Mode is inactive, IFAN will

operate in low speed according to the following graph:

IFAN (Low Speed)

ON

OFF

SM ASP 1-E.2 GB

SPT+4 SPT+6 ICT

o

c

12-9

Page 74

CONTROL SYSTEM

CONTENT

12.5.3 HE operation

• For all Groups, HE can be ON only when IFAN is ON.

• For all Groups, HE switches to OFF when ICT > 50

again when ICT ≤ 45oc.

• In SH or RC group, HE operation is limited by the following graph:

HE

ON

OFF

o

c, and is activated

General :

For WAX :

30

15

35

20

40

45 50

ICT [oc]

• Back-up mode for SH group

After COMP has been working for 5 minutes, HE & IFAN are activated even

o

if the ICT is still below 35

c. This situation is called Back-up Mode. Both

HE & IFAN will work in Back-up Mode until the ICT reaches 35oc. Then, the

operation goes on in the usual mode .

12-10

SM ASP 1-E.2 GB