Page 1

DC Inverter 10.0 / 12.5 / 14.0 kW

CONTENTS

Outdoor Units Indoor Units

OU12 4HP DCI

OU12 5HP DCI

OU12 6HP DCI CD 140

DNG 100

EMD 100

DNG 125

EMD 125

SM OU12HP 2-E.2 GB

REFRIGERANT

NOVEMBER 2008

R410A

HEAT PUMP

Page 2

LIST OF EFFECTIVE PAGES

CONTENTS

LIST OF EFFECTIVE PAGES

Note: Changes in the pages are indicated by a “Revision#” in the footer of each effected page

(when none indicates no changes in the relevant page). All pages in the following list represent

effected/ non effected pages divided by chapters.

Dates of issue for original and changed pages are:

Original ....... 0 ........ February 2007

Total number of pages in this publication is 215 consisting of the following:

Page

No.

Title .......................2

A ...........................2

i ............................. 2

1-1 - 1-3 ................2

2-1 - 2-5 ................2

3-1 ........................2

4-1 - 4-3 ................2

5-1 - 5-23 ..............2

6-1 - 6-3 ................2

7-1 - 7-4 ................2

8-1 ........................2

9-1 - 9-6 ................2

10-1 ......................2

11-1 .......................2

12-1-12-26 ............ 2

13-1-13-23 ............ 2

14-1-14-20 ............ 2

15-1-15-18 ............ 2

16-1-16-6 .............. 2

17-1-17-68 ............ 2

Revision

No. #

Page

No.

Revision

No. #

Page

No.

Revision

No. #

Zero in this column indicates an original page.

* Due to constant improvements please note that the data on this service manual can be modified with out notice.

** Photos are not contractual.

A

SM OU12HP 2-E.2 GB

Page 3

TABLE OF CONTENTS

Table of Contents

1. INTRODUCTION ...................................................................................................1-1

2. PRODUCT DATA SHEET ......................................................................................2-1

3. RATING CONDITIONS ..........................................................................................3-1

4. OUTLINE DIMENSIONS .......................................................................................4-1

5. PERFORMANCE DATA & PRESSURE CURVES ................................................5-1

6. AIRFLOW CURVES ..............................................................................................6-1

7. SOUND LEVEL CHARACTERISTICS ..................................................................7-1

8. ELECTRICAL DATA ..............................................................................................8-1

9. WIRING DIAGRAMS .............................................................................................9-1

10. REFRIGERATION DIAGRAMS .............................................................................10-1

11. TUBING CONNECTIONS ......................................................................................11-1

12. CONTROL SYSTEM .............................................................................................12-1

13. TROUBLESHOOTING ..........................................................................................13-1

14. SERVICING ...........................................................................................................14-1

15. EXPLODED VIEWS AND SPARE PARTS LISTS .................................................15-1

16. OPTIONAL ACCESSORIES .................................................................................16-1

APPENDIX A .........................................................................................................17-1

17.

SM OU12HP 2-E.2 GB

i

Page 4

1. INTRODUCTION

CONTENTS

1.1 General

The new 4-5-6HP DC INVERTER ducted split unit range comprises the following RC

(heat pump) models:

• DNG 100

• DNG 125

• EMD 100

• EMD 125

• CD 140

Remote control compatibility

The units are compatible with remote controls RC3, RC4, RCW1, RCW2, RC7.

Inverter description

Unlike standard units (fix RPM) that are selected according to their nominal capacity to

overcome the maximum required load, DC Inverter units can be selected to a smaller

nominal capacity range unit.

It made possible due to the ability of inverters to reach a much higher capacity level

(indicated as Maximum Capacity) which is around 115-130% of the nominal capacity.

1.2 Main Features

INTRODUCTION

High Technology

• Sine wave DC Compressor drive.

• DC-BL-SL (DC Brush-Less Sensor less) Inverter Compressor.

• DC-BL Inverter Outdoor Fan.

• Fuzzy Logic Adaptive Control.

System Features

• Variable cooling and heating capacity from 30% to 115% (of rated capacity).

• High COP “A-B” class energy rating (Most units).

• Low noise levels.

• Pre-charged system up to 30m.

• Tubing up to 70m length / 30m height difference.

• Networking connectivity.

• Current limitation setting for circuit breaker size reduction (if required).

• Dry contact inputs:

Standby.

Night mode (for silent operation in cooling).

Power Shedding (to control maximum power consumption).

SM OU12HP 2-E.2 GB

• Dry contact output:

Alarm

Base Heater

Crank Case Heater

1-1

Page 5

INTRODUCTION

CONTENTS

• HMI Display consists of 7-segments shows system diagnostics and setup.

• Monitoring software (PC port for high level service).

• Cooling operation at outdoor temperature down to -10°C.

• Heating operation at outdoor temperature down to -15°C.

• Up to 100Pa (4-5HP) and 200Pa (6HP) External static pressure.

1.3 Indoor Unit

The DNG DCI indoor unit is a low silhouette ducted unit, and can be easily fitted to many

type of residential and commercials applications.

• Low silhouette units 300 mm height.

• High technology plastic fan and fan housing.

• Drain pool at bottom of unit with internal downward slope.

• Over-flow switch, stops compressor operation in case of a blocked drainage.

• Bended coil hydrophilic coated aluminum fins.

• 3-speed fan motor and an extra speed in case a higher external static pressure re-

quired.

• Tubing connections at the back of the unit to allow easy outlet to both sides of the

unit.

• Easy installation and service access.

• Infrared remote control with liquid display unit (LCD).

• Field options:

(1) External water pump.

(2) Airconet connection.

(3) Plenum kit for connection of flexible duct hoses at air outlet.

1.4 Filtration

• The unit is equipped with pre filters.

• Easy and versatile access, rear or bottom, can be easily adjusted by the installer.

1.5 Control

The micro processor indoor controller, and an infrared remote control, supplied as

standard, provides complete operating function and programming.

For further details, please refer to the Operation Manual, Appendix A.

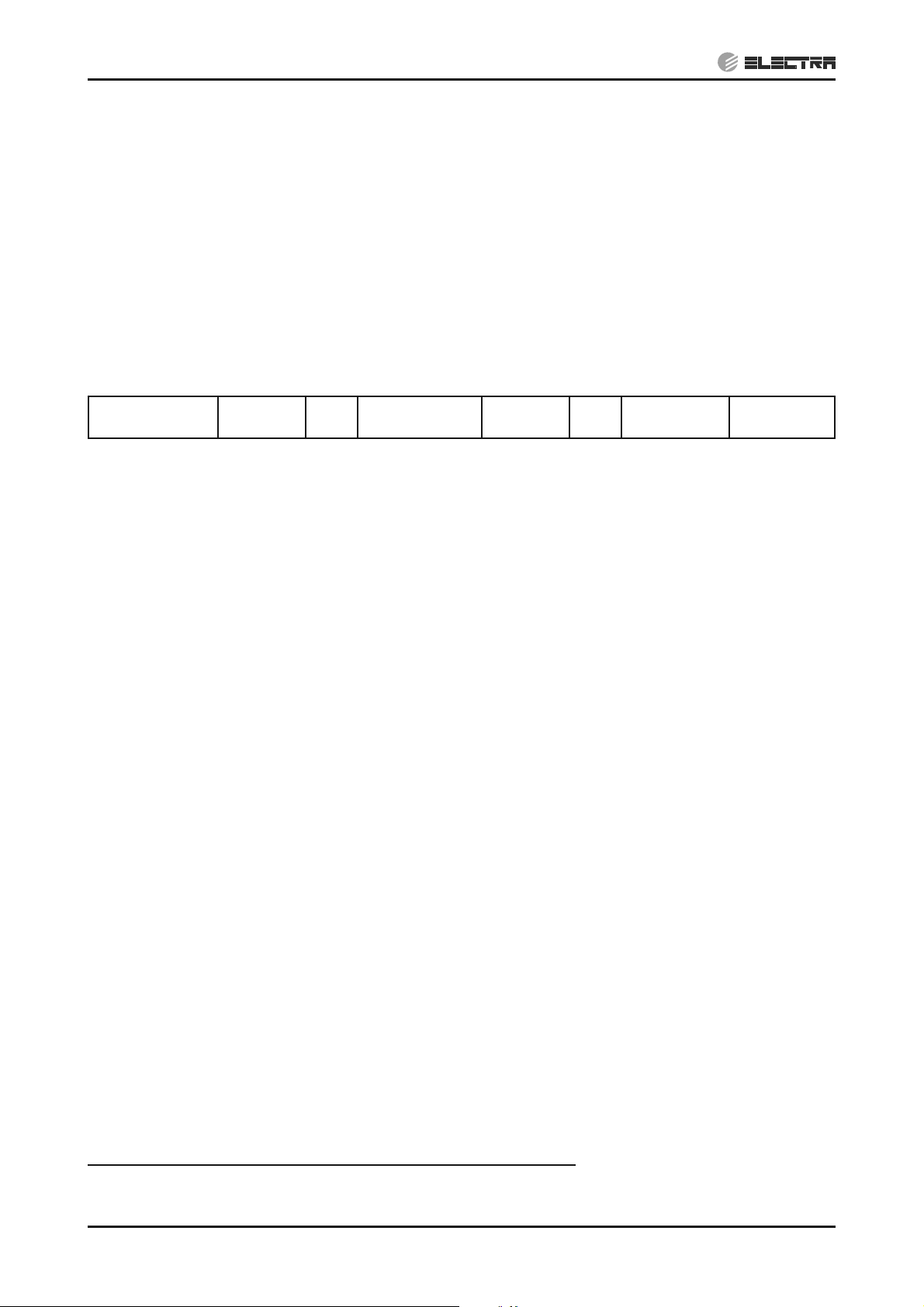

1.6 Outdoor Unit

1-2

The DCI outdoor units can be installed as floor or wall mounted units by using a wallsupporting bracket. The metal sheets are protected by anti- corrosion paint work allowing

long life resistance. All outdoor units are pre-charged. For further information, please

refer to the Product Data Sheet, Chapter 2.

• Compressor mounted in a soundproofed compartment.

• Improved 3-blades axial fans for noise reduction.

• Outdoor coil with hydrophilic fins optimized for operation with R410A refrigerant.

SM OU12HP 2-E.2 GB

Page 6

• Fan grill air outlet.

CONTENTS

• Service valves” flare” type connection.

• Service ports for high/ low pressure measurement.

• Interconnecting wiring terminal blocks.

1.7 Tubing Connections

Flare type-interconnecting tubing to be produced on site.

Units can be installed with 70-meter pipe length and 30 meter height difference without

oil traps.

For further details, please refer to the Installation Manual, Chapter 17.

1.8 Accessories

No. Item

1. RCW Wall Mounted Remote Control

2. RCW2 (BMS) Wall Mounted Remote Control

3. Base Heater

4. Crank case Heater

5. Room thermostat

INTRODUCTION

For further details, please refer the Optional Accessories, Chapter 16.

1.9 Inbox Documentation

Each unit includes its own installation and operation manuals.

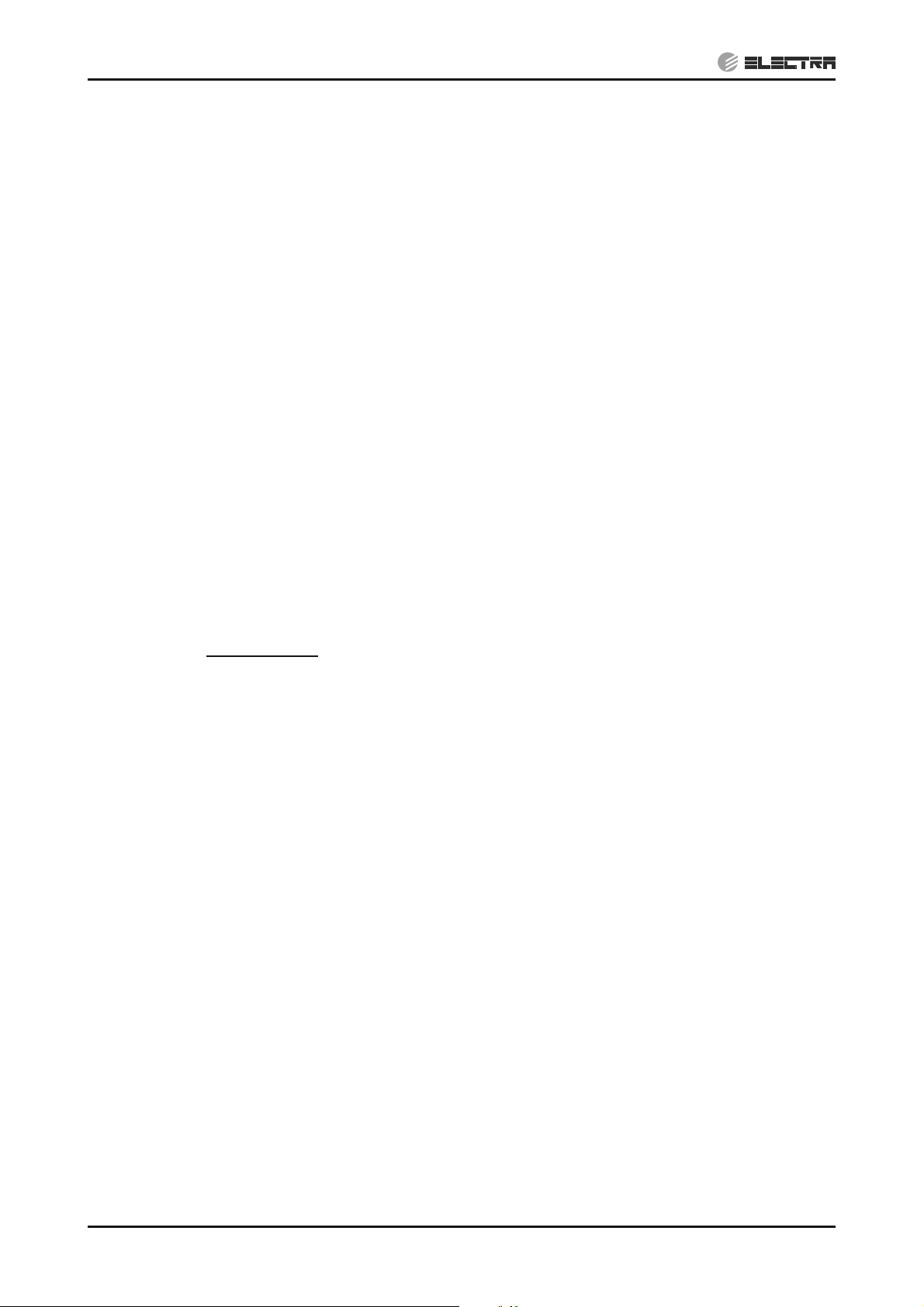

1.10 Matching Table

1.10.1 R410A

OUTDOOR

UNITS

MODEL

DCI 4HP

DNG 100

INDOOR UNITS

DCI

DNG 125

DCI

EMD 100

DCI

EMD 125

DCI

CD140 DCI

SM OU12HP 2-E.2 GB

DCI 5HP

DCI 6HP

1-3

Page 7

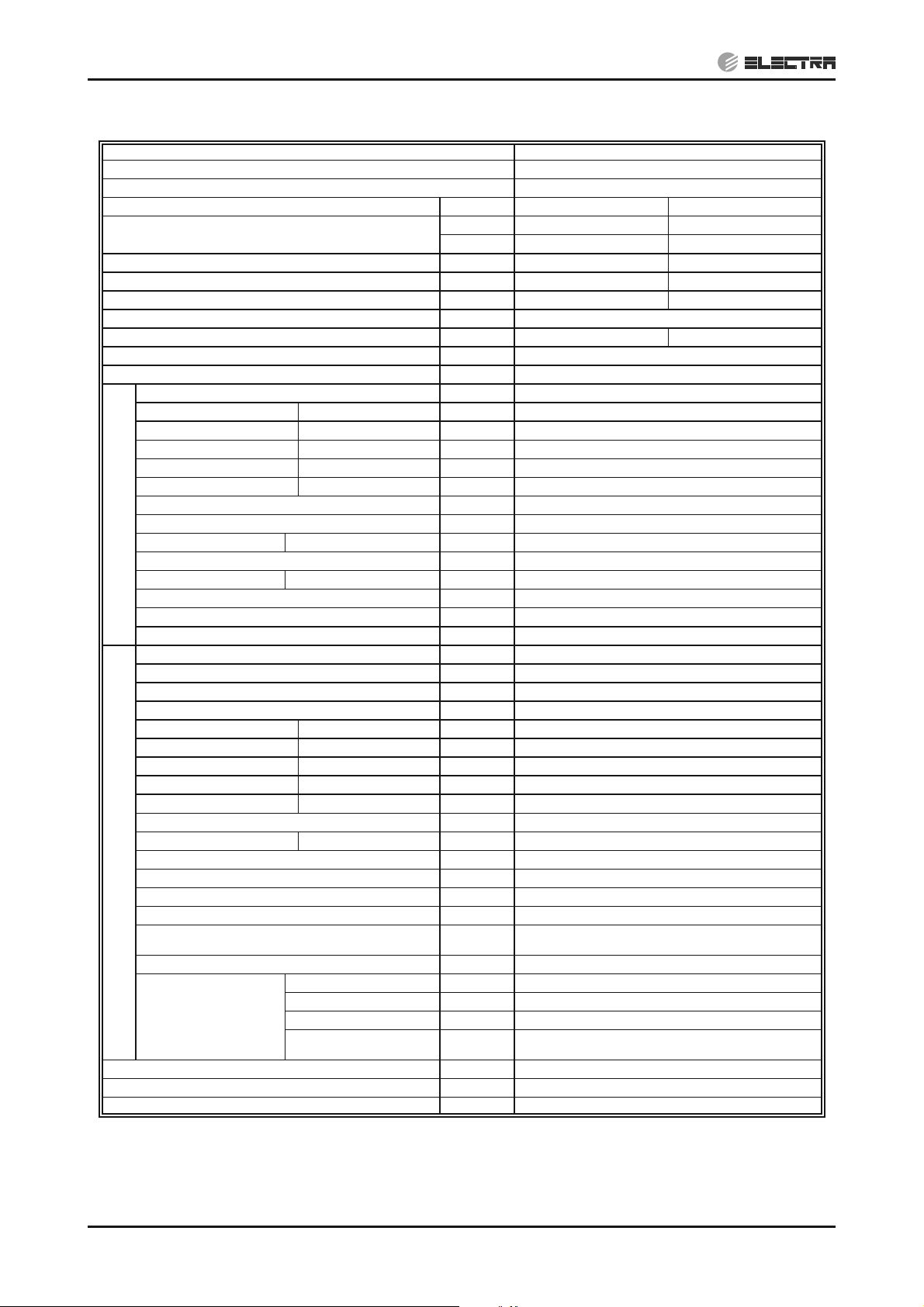

PRODUCT DATA SHEET

CONTENTS

2. PRODUCT DATA SHEET

2.1 DNG 100 DCI / OU12 4HP DCI

Model Indoor Unit DNG 100 DCI

Model Outdoor Unit OU12 4HP DCI

Installation Method DUCTED

Characteristics Units Cooling Heating

Capacity - Nominal (Minimum ~ Maximum)

Power input - Nominal (Minimum ~ Maximum)

EER (Cooling) or COP(Heating)

(1)

(1)

(1)

Energy Efficiency Class “A” “C”

Power supply V/Ph/Hz 230 / 1 / 50

Rated current (Nominal) A 14.0 15.2

Starting current A 10

Circuit breaker rating A 25

Fan type & quantity Centrifugal x 1

Fan speeds H/M/L RPM 890 / 800 / 670

Air flow

(2)

H/M/L m3/hr 2170 / 1880 / 1440

External static pressure Min-Max Pa 20 -100

Sound power level

(3)

Sound pressure level

(4)

H/M/L dB(A) 71 / 67 / 62

H/M/L dB(A) 52 / 49 / 47

Moisture removal (Nominal) l/hr 3.3

Condensate drain tube I.D mm 19

INDOOR

Dimensions WxHxD mm 854/297/816

Weight kg 33

Package dimensions WxHxD mm 1010/342/917

Packaged weight kg 38

Units per pallet units 6

Stacking height units 6

Refrigerant control Electronic Expansion Valve

Compressor type, model Scroll

Motor type DCBL Inverter

Fan type & quantity Axial 2 x 493 Ømm

Fan speeds H/L RPM 900 – 100 (Continuous)

Airflow Max m3/hr 5.200

Sound power level

Sound pressure level

(3)

(4)

Nom C/H dB(A) 67 / 69

Nom C/H dB(A) 56 / 57

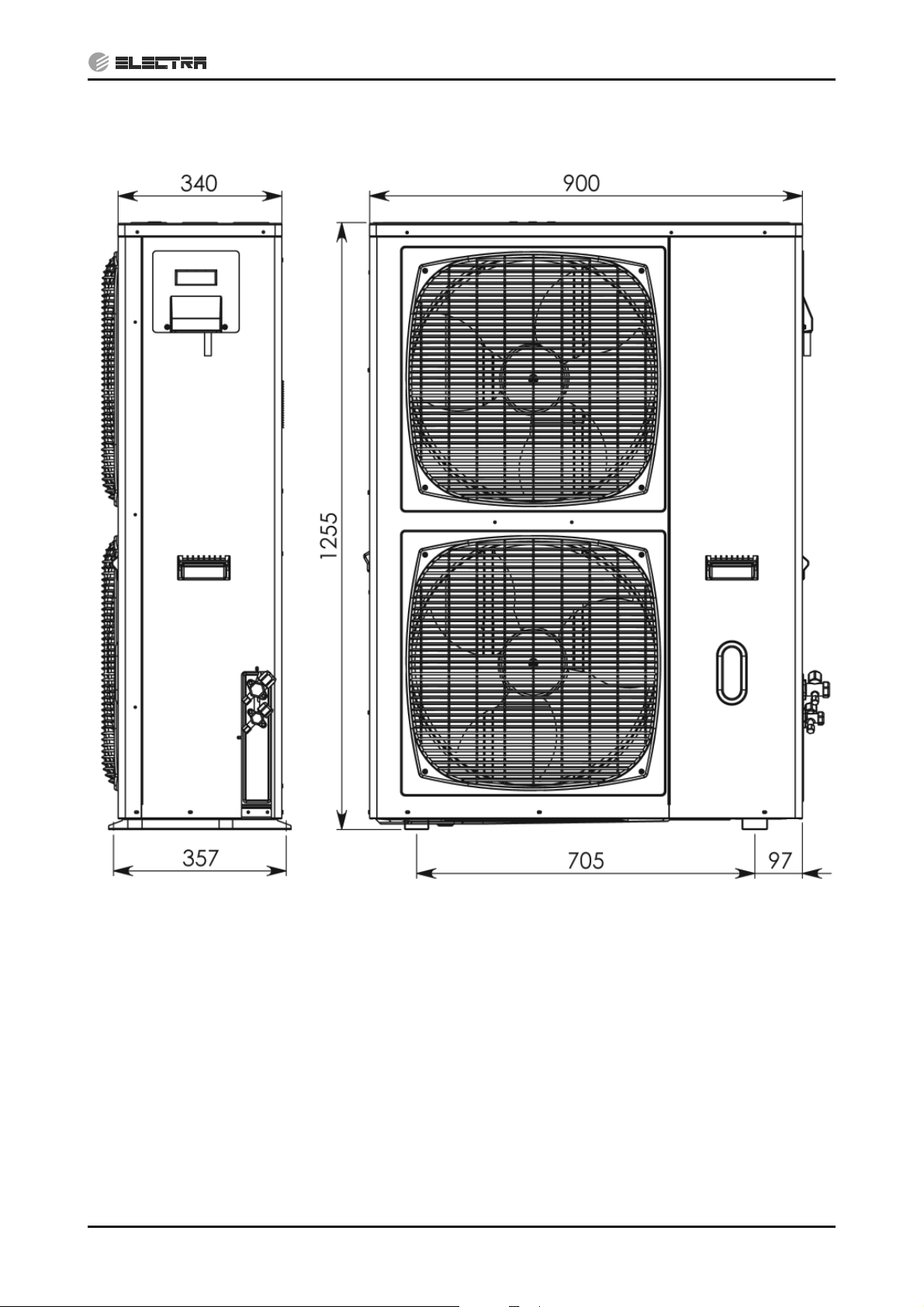

Dimensions WxHxD mm 900 / 1255 / 340

Weight kg 110

Package dimensions WxHxD mm 985 / 1395 / 435

Packaged weight kg 120

Units per pallet Units 1

OUTDOOR

Stacking height units 1

Refrigerant type R410A

Refrigerant charge(standard connecting tubing

length)

Additional charge per 1 meter g/m 38

Liquid line In.(mm) 3/8" (9.52)

Connections between

units

Suction line In.(mm) 5/8" (15.875)

Max.Tubing Length m. 70

Max.Height Difference m. 30

Operation control type LCD Remote control

Heating elements kW

Others

(1)

Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units).

(2)

Airflow in ducted units; at nominal external static pressure.

(3)

Sound power in ducted units is measured at air discharge.

(4)

Sound pressure level measured at 1.0 meter distance from unit.

Btu/hr 34100(10900÷39200) 38200(9200 ÷ 42650)

kW 10.0(3.8 ÷ 11.5) 11.2(2.6 ÷ 12.5)

kW 3.125(1.400 ÷ 4.400) 3.390(1.000 ÷ 4.450)

W/W 3.2 3.3

Kg(m) 2.9 / 30

—

SM OU12HP 2-E.2 GB

2-1

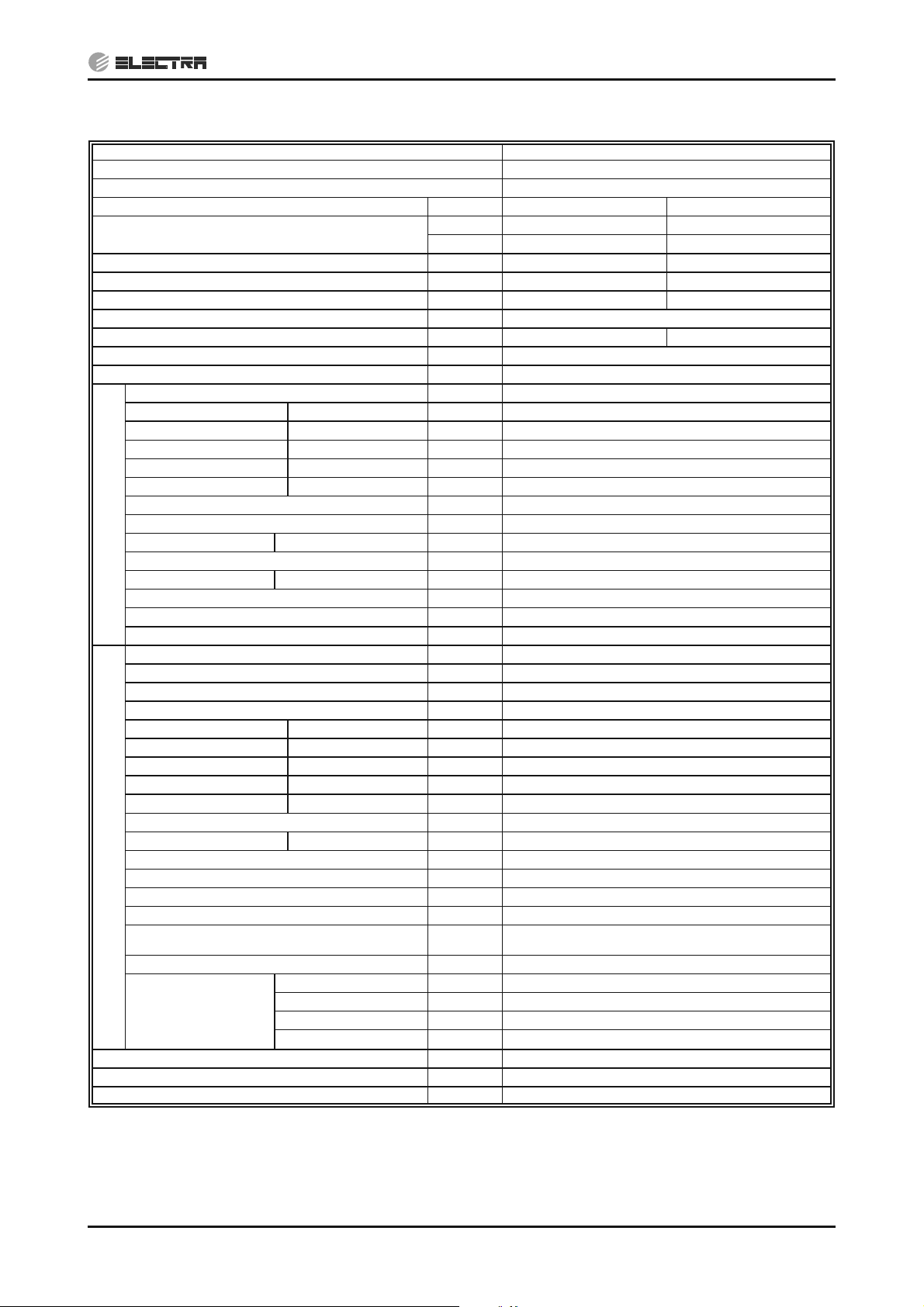

Page 8

PRODUCT DATA SHEET

CONTENTS

2.2 DNG 125 DCI / OU12 5HP DCI

Model Indoor Unit DNG 125 DCI

Model Outdoor Unit OU12 5HP DCI

Installation Method Ducted

Characteristics Units Cooling Heating

Capacity - Nominal (Minimum ~ Maximum)

Power input - Nominal (Minimum ~ Maximum)

EER (Cooling) or COP(Heating)

(1)

(1)

(1)

Energy efficiency class “B” “C”

Power supply V/Ph/Hz 230 / 1 / 50

Rated current (Nominal) A 19.7 19.0

Starting current A 10

Circuit breaker rating A 32

Fan type & quantity Centrifugal x 1

Fan speeds H/M/L RPM 935 / 855 / 760

Air flow

(2)

H/M/L m3/hr 2160 / 1950 / 1620

External static pressure Min-Max Pa 30-100

Sound power level

(3)

Sound pressure level

(4)

H/M/L dB(A) 71 / 67 / 62

H/M/L dB(A) 52 / 49 / 47

Moisture removal (Nominal) l/hr 4.6

Condensate drain tube I.D mm 19

INDOOR

Dimensions WxHxD mm 854 / 297 / 816

Weight kg 33

Package dimensions WxHxD mm 1010 / 342 / 917

Packaged weight kg 38

Units per pallet units 6

Stacking height units 6

Refrigerant control Electronic Expansion Valve

Compressor type, model Scroll

Motor type DCBL Inverter

Fan type & quantity Axial 2 x 493 Ømm

Fan speeds H/L RPM 900 – 100 (Continuous)

Air flow H/L m3/hr 5,700

Sound power level

(3)

Sound pressure level

(4)

Nom C/H dB(A) 69 / 70

Nom C/H dB(A) 56 / 58

Dimensions WxHxD mm 900 / 1255 / 340

Weight kg 110

Package dimensions WxHxD mm 985 / 1395 / 435

Packaged weight kg 120

Units per pallet Units 1

OUTDOOR

Stacking height units 1

Refrigerant type R410A

Refrigerant charge(standard connecting

tubing length)

Additional charge per 1 meter g/m 38

Liquid line In.(mm) 3/8" (9.52)

Connections

between units

Suction line In.(mm) 3/4" (19.0)

Max.Tubing Length m. 70

Max.Height Difference m. 30

Operation control type LCD Remote control

Heating elements kW

Others

(1)

Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units).

(2)

Airflow in ducted units; at nominal external static pressure.

(3)

Sound power in ducted units is measured at air discharge.

(4)

Sound pressure level measured at 1.0 meter distance from unit.

Btu/hr 42650(16050÷47750) 47750(15000÷54600)

kW 12.5 (4.7 ÷ 14.0) 14.0 (4.4 ÷ 16.0)

kW 4.170 (1.500 ÷ 5.700) 4.300 (1.100 ÷ 5.500)

W/W 3.0 3.25

Kg(m) 3.1 / 30

2-2

SM OU12HP 2-E.2 GB

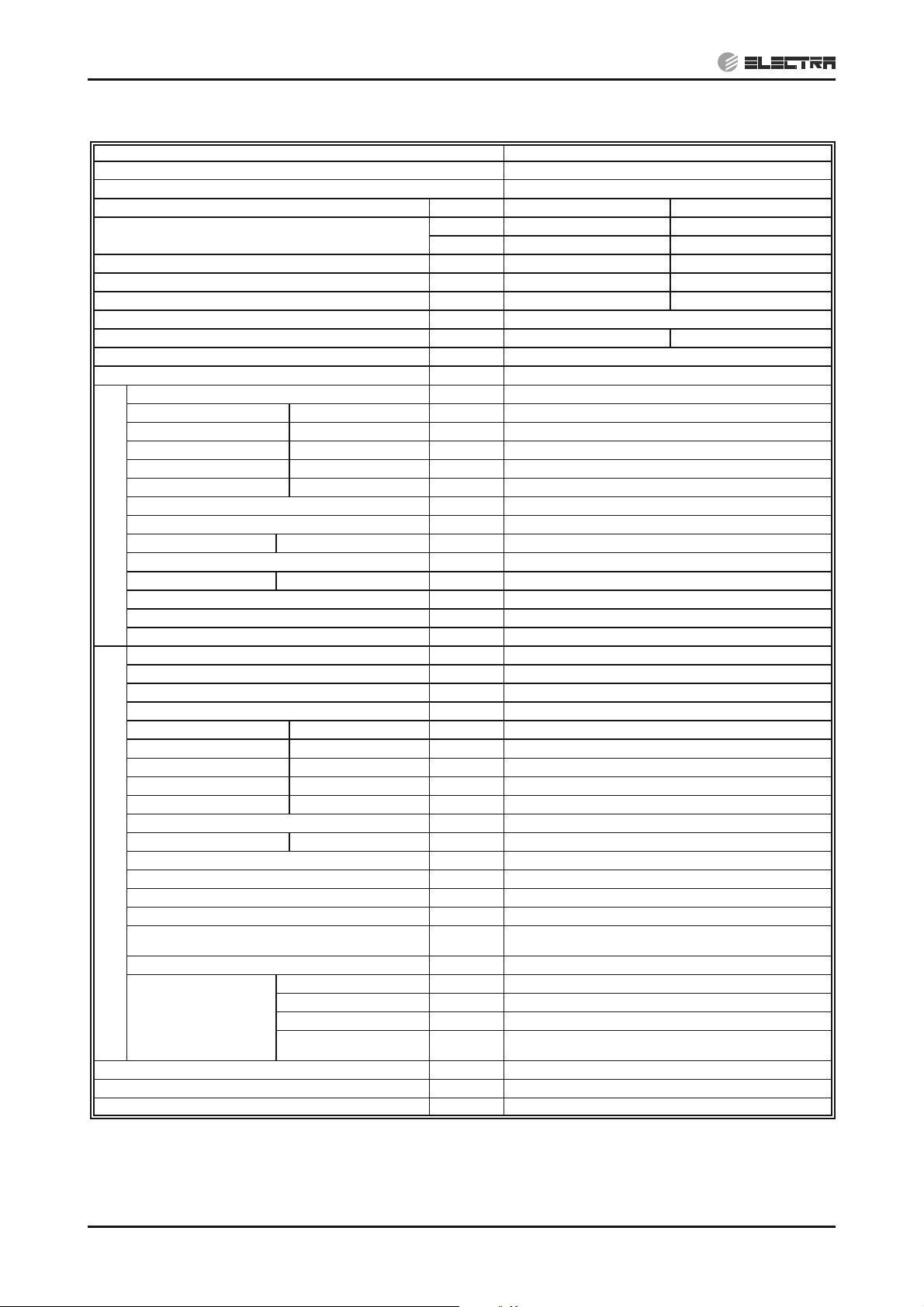

Page 9

PRODUCT DATA SHEET

CONTENTS

2.3 EMD 100 DCI / OU12 4HP DCI

Model Indoor Unit EMD 100 DCI

Model Outdoor Unit OU12 4HP DCI

Installation Method DUCTED

Characteristics Units Cooling Heating

Capacity - Nominal (Minimum ~ Maximum)

Power input - Nominal (Minimum ~ Maximum)

EER (Cooling) or COP(Heating)

(1)

(1)

(1)

Energy efficiency class “A” “A”

Power supply V/Ph/Hz 230 / 1 / 50

Rated current (Nominal) A 14.0 14.2

Starting current A 10

Circuit breaker rating A 25

Fan type & quantity Centrifugal x 1

Fan speeds H/M/L RPM 1060 / 1000 / 840

Air flow

(2)

H/M/L m3/hr 1980 / 1820 / 1390

External static pressure Min-Max Pa 20-100

Sound power level

(3)

Sound pressure level

(4)

H/M/L dB(A) 73 / 71 / 65

H/M/L dB(A) 52 / 50 / 45

Moisture removal (Nominal) l/hr 3.1

Condensate drain tube I.D mm 19

INDOOR

Dimensions WxHxD mm 790X400X600

Weight kg 36

Package dimensions WxHxD mm 825X425X610

Packaged weight kg 38

Units per pallet units 8

Stacking height units 4

Refrigerant control Electronic Expansion Valve

Compressor type, model Scroll

Motor type DCBL Inverter

Fan type & quantity Axial 2 x 493 Ømm

Fan speeds H/L RPM 900 – 100 (Continuous)

Airflow Max m3/hr 5,200

Sound power level

(3)

Sound pressure level

(4)

Nom C/H dB(A) 67 / 69

Nom C/H dB(A) 56 / 57

Dimensions WxHxD mm 900X1255X340

Weight kg 110

Package dimensions WxHxD mm 985X1395X435

Packaged weight kg 120

OUTDOOR

Units per pallet Units 1

Stacking height units 1

Refrigerant type R410A

Refrigerant charge(standard connecting

tubing length)

Additional charge per 1 meter g/m 38

Liquid line In.(mm) 3/8" (9.52)

Connections

between units

Suction line In.(mm) 5/8" (15.875)

Max.tubing length m. 70

Max.height difference m. 30

Operation control type LCD Remote control

Heating elements kW

Others

(1)

Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units).

(2)

Airflow in ducted units; at nominal external static pressure.

(3)

Sound power in ducted units is measured at air discharge.

(4)

Sound pressure level measured at 1.0 meter distance from unit.

Btu/hr 34,100 (10,250-40,950) 39,250 (12,000-42,650)

kW 10.0 (3.0-12.0) 11.5(3.5-12.5)

kW 3.05 (1.30-4.20) 3.10 (1.10-3.60)

W/W 3.30 3.70

Kg(m) 2.9 / 30

—

SM OU12HP 2-E.2 GB

2-3

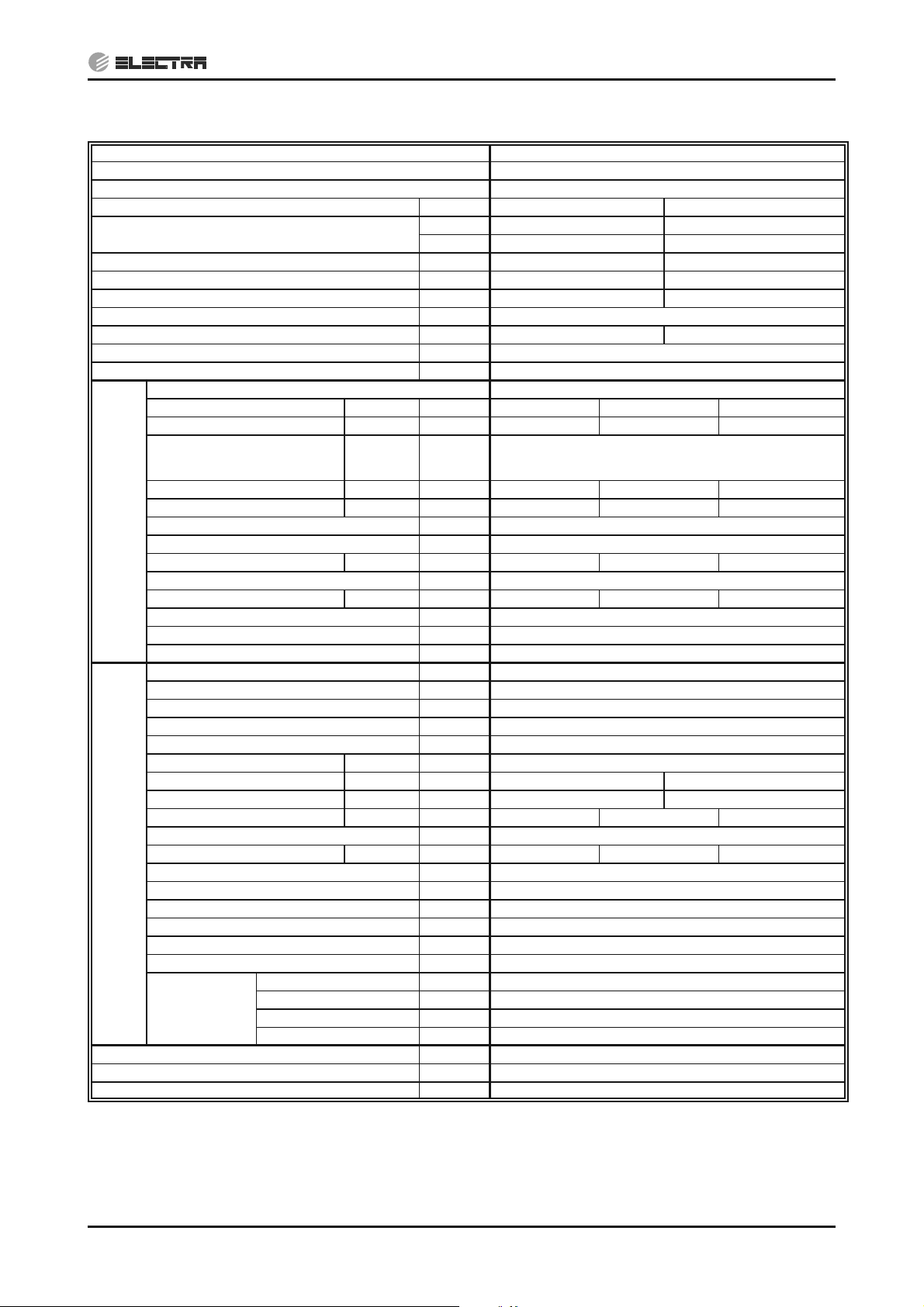

Page 10

PRODUCT DATA SHEET

CONTENTS

2.4 EMD 125 DCI / OU12 5HP DCI

Model Indoor Unit EMD 125 DCI

Model Outdoor Unit OU12 5HP DCI

Installation Method DUCTED

Characteristics Units Cooling Heating

Capacity - Nominal (Minimum ~ Maximum)

Power input - Nominal (Minimum ~ Maximum)

EER (Cooling) or COP(Heating)

(1)

(1)

(1)

Energy efficiency class B B

Power supply V/Ph/Hz 230 / 1 / 50

Rated current A 18.8 18.6

Starting current A 10

Circuit breaker rating A 32

Fan type & quantity Centrifugal x 1

Fan speeds H/M/L RPM 930 / 830 / 740

Air flow

(2)

H/M/L m3/hr 2500 / 2100 / 1600

External static pressure Min-Max Pa 20-100

Sound power level

(3)

Sound pressure level

(4)

H/M/L dB(A) 72 / 68 / 64

H/M/L dB(A) 54 / 51 / 45

Moisture removal (Nominal) l/hr 3.8

Condensate drain tube I.D mm 19

INDOOR

Dimensions WxHxD mm 1150X400X700

Weight kg 46

Package dimensions WxHxD mm 1195X440X730

Packaged weight kg 50

Units per pallet units 8

Stacking height units 4

Refrigerant control Electronic Expansion Valve

Compressor type, model Scroll

Motor type DCBL Inverter

Fan type & quantity Axial 2 x 493 Ømm

Fan speeds H/L RPM 900 – 100 (Continuous)

Air flow Max m3/hr 5,700

Sound power level

(3)

Sound pressure level

(4)

Nom C/H dB(A) 69 / 70

Nom C/H dB(A) 56 / 58

Dimensions WxHxD mm 900X1255X340

Weight kg 110

Package dimensions WxHxD mm 985X1395X435

Packaged weight kg 120

Units per pallet Units 1

OUTDOOR

Stacking height units 1

Refrigerant type R410A

Refrigerant charge(standard connecting

tubing length)

Additional charge per 1 meter g/m 38

Liquid line In.(mm) 3/8" (9.52)

Connections

between units

Suction line In.(mm) 3/4" (19.0)

Max.tubing length m. 70

Max.height difference m. 30

Operation control type LCD Remote control

Heating elements kW

Others

(1)

Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units).

(2)

Airflow in ducted units; at nominal external static pressure.

(3)

Sound power in ducted units is measured at air discharge.

(4)

Sound pressure level measured at 1.0 meter distance from unit.

Btu/hr 42,650 (11,940-47,770) 47,770 (12,280-54,590)

kW 12.5 (3.5-14.0) 14.0 (3.6-16.0)

kW 4.1 (1.65-5.5) 4.1 (1.1-5.2)

W/W 3.05 3.4

Kg(m) 3.3 / 30

—

2-4

SM OU12HP 2-E.2 GB

Page 11

PRODUCT DATA SHEET

CONTENTS

2.5 CD 140 DCI / OU12 6HP DCI

Model Indoor Unit CD 140 DCI

Model Outdoor Unit OU12 6HP DCI

Installation Method DUCTED

Characteristics Units Cooling Heating

Capacity - Nominal (Minimum ~ Maximum)

Power Input - Nominal (Minimum ~ Maximum)

(1)

COP

(1)

( (1)

Energy Efficiency Class - A A

Power Supply V/Ph/Hz 220-240/1/50

Rated Current (Nominal) A 21.6 20.3

Starting Current A <10

Circuit Breaker Rating A 32

Fan Type & Quantity CENTRIFUGAL x2

Fan Speed H/M/L RPM 1,160 1,120 1,000

(2)

Airflow

H/M/L m3/hr 3,300 2,900 2,000

Min-

External Static Pressure

Sound Power Level

(3)

Sound Pressure Level

(4)

Nom-

Max

H/M/L dB (A) 73 71 66

H/M/L dB (A) 58 55 50

Moisture Removal (Nominal) L/hr 4.0

Condensate Drain Tube I.D. mm 19

INDOOR

Dimensions W/H/D mm 1350 400 640

Weight kg 75

Package Dimensions W/H/D mm 1510 440 785

Packaged Weight kg 82

Units per Pallet Units 5

Stacking Height Units 5

Refrigerant Control Electronic Expansion Valve

Compressor Type, Model Twin-Rotary

Motor type DCBL Inverter

Fan Type & Quantity Axial 2x 493mm

Fan Speed RPM 900-100 (continuous)

Airflow Max m

Sound Power Level Nom dB (A) 68 70

Sound Pressure Level

(4)

Nom dB (A) 56 58

Dimensions W/H/D mm 900 1255 340

Weight kg 110

Package Dimensions W/H/D mm 985 1395 435

Packaged Weight kg 120

OUTDOOR

Units per Pallet Units 1

Stacking Height Units 1

Refrigerant Type R410A

Refrigerant Chargeless Distance kg/m 3.8 / 30

Additional Charge Per 1 Meter g/m 80

Liquid Line In 3/8”

Connections

Between Units

Suction Line In 3/4”

Max. Tubing Length m 70

Max. Height Difference m 30

Operation Control Type LCD Remote Control

Heating Elements kW BH 70W - optional

Others

Btu/hr 47,770 (15,700 - 56,300) 54,600 (12,600 – 63,100)

kW 14.0 (4.6 – 16.5) 16.0 (3.7 – 18.5)

W 4,200 (1,500 - 6,000) 4,400 (1,200 - 5,500)

W/W 3.3 3.6

Pa 80-140-200

3

/hr 5,700

SM OU12HP 2-E.2 GB

(1)

Rating conditions in accordance with ISO 5151 and ISO 13253 (for ducted units).

(2)

Airflow in ducted units; at nominal external static pressure.

(3)

Sound power in ducted units is measured at air discharge.

(4)

Sound pressure level measured at 1.0 meter distance from unit.

2-5

Page 12

3. RATING CONDITIONS

CONTENTS

Standard conditions in accordance with ISO 5151 and ISO 13253 (for ducted units) and

EN 14511.

RATING CONDITIONS

Cooling:

Indoor: 27

Outdoor: 35

o

C DB 19oC WB

o

C DB

Heating:

Indoor: 20

Outdoor: 7

o

C DB

o

C DB 6oC WB

3.1 Operating Limits

Cooling

Heating

Voltage 1PH 198 – 253V

Upper limit 32

Lower limit 21

Upper limit 27

Lower limit 10

Indoor Outdoor

o

C DB 23oC WB 46oC DB

o

C DB 15oC WB -10oC DB

o

C DB 24oC DB 18oC WB

o

C DB -15oC DB -16oC WB

SM OU12HP 2-E.2 GB

3-1

Page 13

4. OUTLINE DIMENSIONS

CONTENTS

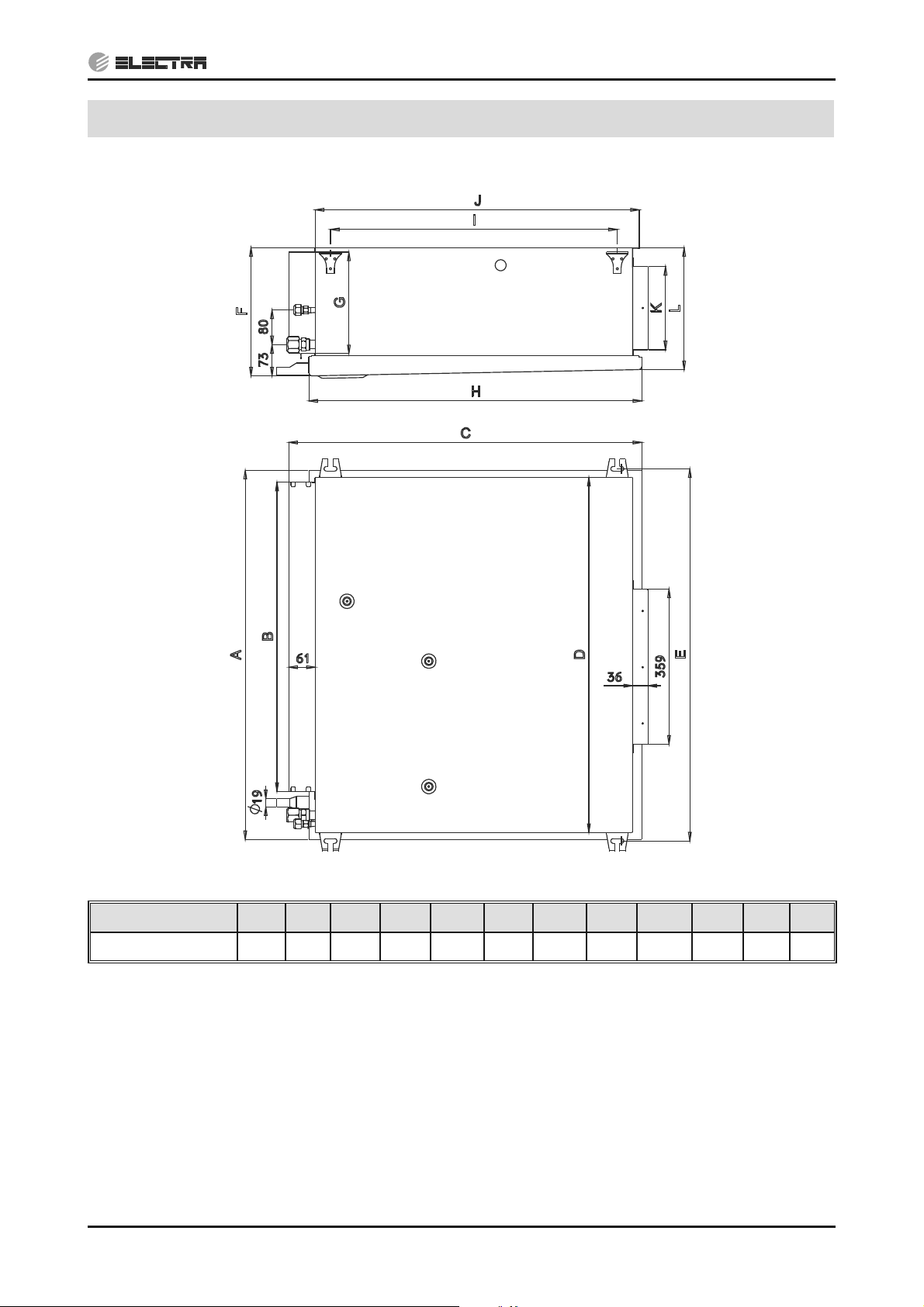

4.1 Indoor Unit: DNG 100, DNG 125 DCI

OUTLINE DIMENSIONS

DNG 100, 125

SM OU12HP 2-E.2 GB

Model A B C D E F G H I J K L

854 715 815 822 861 297 235 770 663 749 193 282

4-1

Page 14

OUTLINE DIMENSIONS

CONTENTS

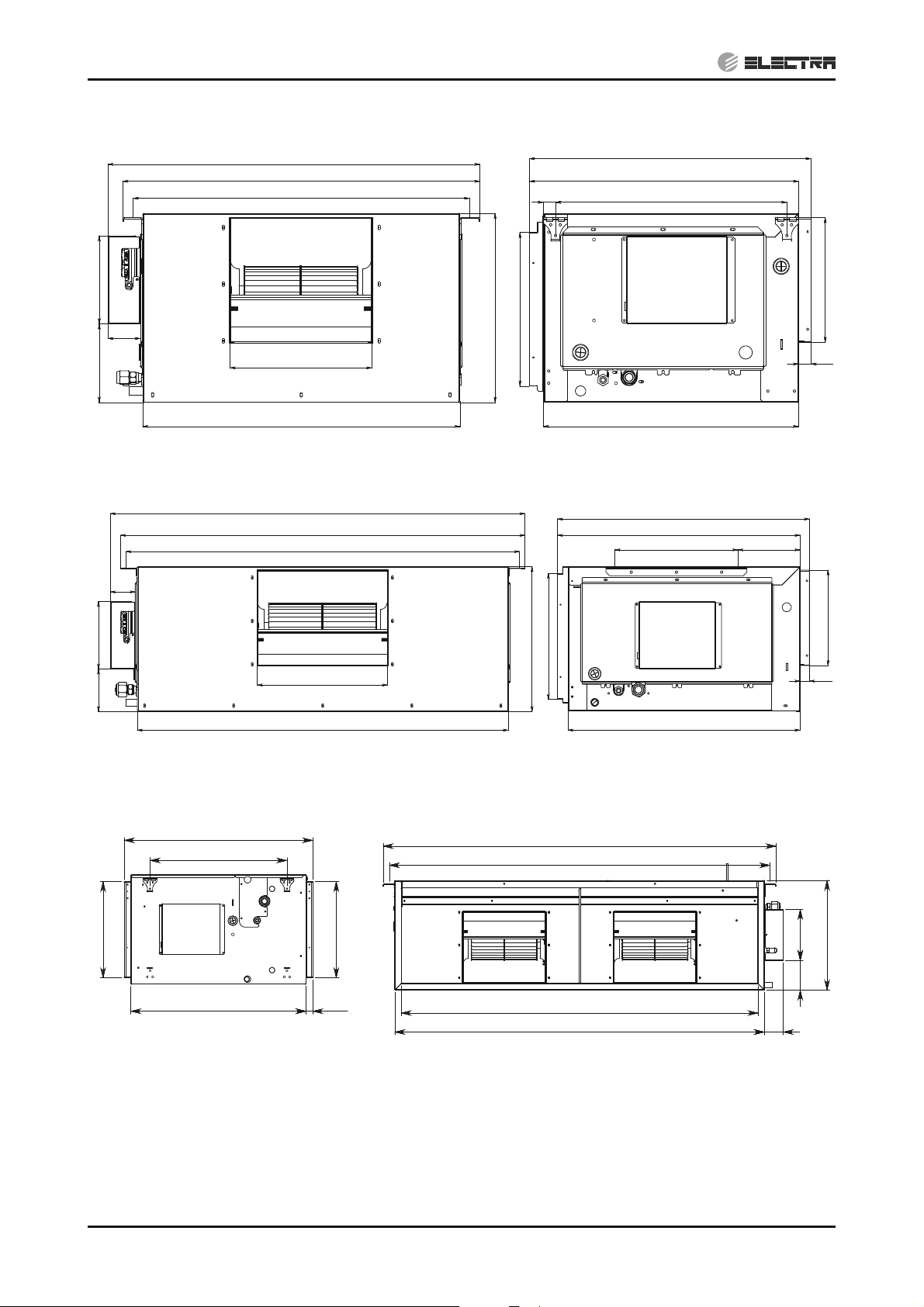

4.2 Indoor Unit: EMD 100 DCI

097

557

017

187

96

166

Indoor Unit: EMD 125 DCI

4.3

96

003

076

0511

0211

0901

400

2

325x610

006

075

5

094

045

007

076

043 0

264

52

71

187118

063

5201

Indoor Unit: CD 140 DCI

t4.4

690

500

352

640

352

25

400

350x995

1435

1390

1303

1350

264

52

046

400

108 187

69

4-2

SM OU12HP 2-E.2 GB

Page 15

OUTLINE DIMENSIONS

CONTENTS

4.4 Outdoor Unit: DCI 100 / 125 / 140 (OU12 DCI 4-5-6HP)

SM OU12HP 2-E.2 GB

4-3

Page 16

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

5. PERFORMANCE DATA & PRESSURE CURVES

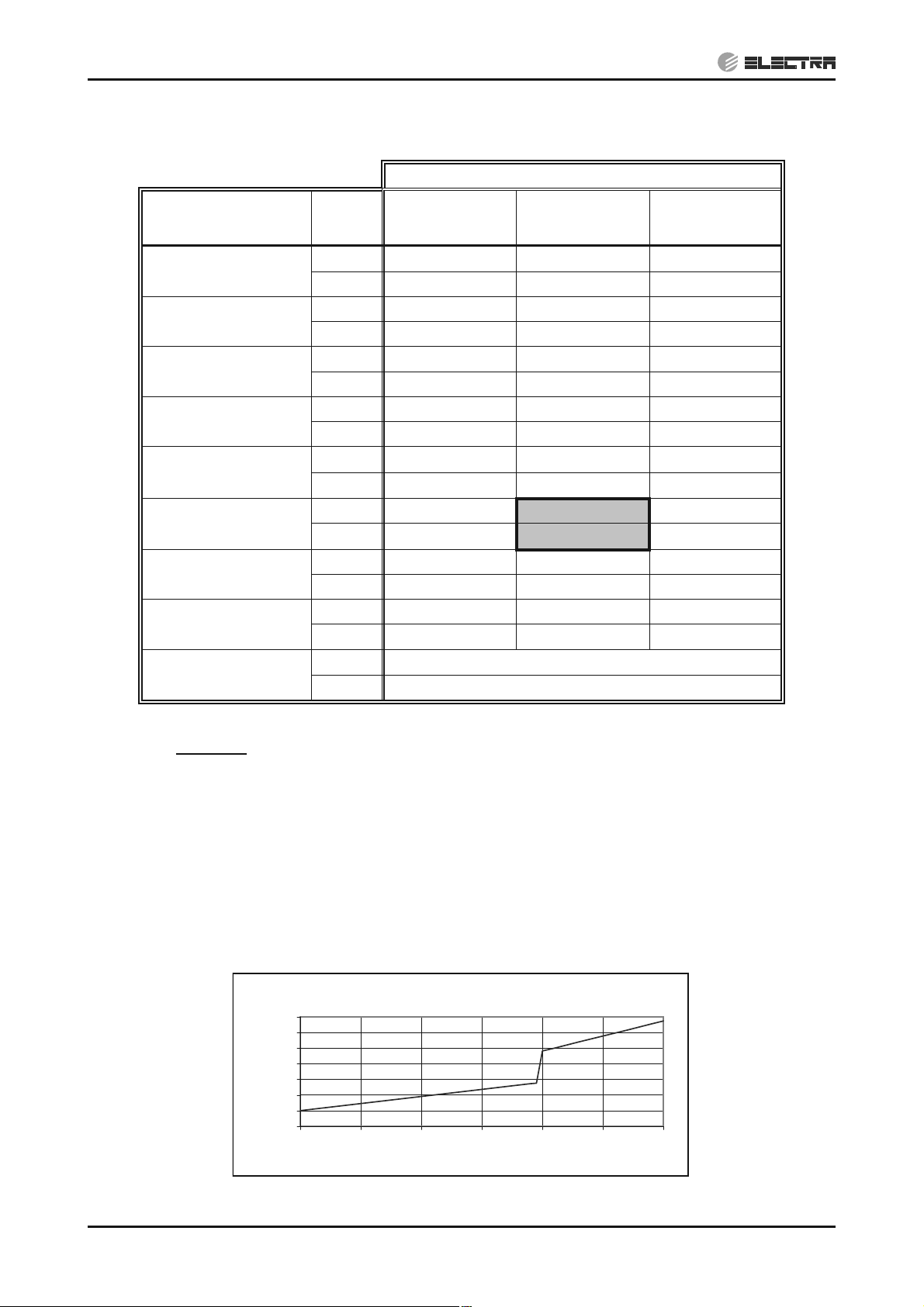

5.1 DNG 100 DCI

5.1.1 Cooling Capacity (kW)

OD COIL

ENTERING AIR DB

TEMPERATURE [qC]

-10 – 20

(protection range)

25

30

35

40

46

ID COIL ENTERING AIR DB/WB TEMPERATURE [qC]

DATA

22/15 24/17 27/19 29/21 32/23

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

PI 25 - 50 % of nominal

TC 9.67 10.30 10.93 11.56 12.19

SC 7.67 7.83 7.99 8.14 8.30

PI 2.46 2.50 2.55 2.60 2.64

TC 9.20 9.83 10.47 11.10 11.73

SC 7.48 7.64 7.79 7.95 8.11

PI 2.74 2.79

TC 8.74 9.37

2.84

10.00

2.88 2.93

10.63 11.26

SC 7.29 7.44 7.60 7.76 7.91

PI 3.03 3.08

TC 8.27 8.90

3.13

9.54

3.17 3.22

10.17 10.80

SC 7.09 7.25 7.41 7.56 7.72

PI 3.32 3.37 3.41 3.46 3.51

TC

SC

7.71 8.35 8.98 9.61 10.24

6.86 7.02 7.17 7.33 7.49

PI 3.66 3.71 3.76 3.80 3.85

LEGEND

TC – Total Cooling Capacity, kW

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

DB – Dry Bulb Temp., (

o

o

C)

C)

ID – Indoor

OD – Outdoor

5.1.2 Capacity Correction Factors (Cooling)

Cooling Capacity Ratio Vs. Outdoor Temperature

1.20

1.10

1.00

0.90

0.80

0.70

Capacity Ratio

0.60

0.50

20 25 30 35 40 45

Outdoor Temperature [deg C]

SM OU12HP 2-E.2 GB

5-1

Page 17

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

5.1.3 Heating Capacity

ID COIL ENTERING AIR DB TEMPERATURE [°C]

OD COIL ENTERING

AIR DB/WB

TEMPERATURE [°C]

-15/-16

-10/-12

-7/-8

-1/-2

2/1

7/6

10/9

15/12

15-24

(Protection Range)

DATA

TC 7.13 6.63 6.13

PI 2.03 2.24 2.45

TC 7.94 7.44 6.94

PI 2.45 2.66 2.87

TC 8.54 8.04 7.54

PI 2.77 2.97 3.18

TC 8.84 8.34 7.85

PI 2.92 3.13 3.34

TC 9.04 8.55 8.05

PI 3.03

TC 11.70

PI 3.18

TC 12.34

PI 3.37 3.58 3.79

TC 12.99 12.49 11.99

PI 3.56 3.77 3.98

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

15 20 25

3.23

11.20

3.39

11.85

3.44

10.70

3.60

11.35

LEGEND

TH – Total Heating Capacity, kW

PI – Power Input, kW

o

WB – Wet Bulb Temp., (

DB – Dry Bulb Temp., (

o

C)

C)

ID – Indoor

OD – Outdoor

5.1.4 Capacity Correction Factors (Heating)

Heating Capacity Ratio Vs. Outdoor Temperature

1.20

1.10

1.00

0.90

0.80

0.70

0.60

Capacity Ration

0.50

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [deg C]

5-2

SM OU12HP 2-E.2 GB

Page 18

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

5.1.5 Pressure Curves (Cooling – Technician Mode)

5.1.5.1 Cooling

Suction Pressure - Cooling (Technician Mode)

1400

1300

1200

1100

1000

900

800

700

600

Suction Pressure [KPa(g)]

500

10 15 20 25 30 35 40 45

Outdoor DB Temperature [°C]

32/23

29/21

27/19

24/17

22/15

Discharge Pressure - Cooling (Technician Mode)

4000

3750

3500

3250

3000

2750

2500

[KPa(g)]

2250

2000

Discharge Pressure

1750

1500

1250

1000

10 15 20 25 30 35 40 45

Outdoor DB Temperature [°C]

32/23

29/21

27/19

24/17

22/15

SM OU12HP 2-E.2 GB

5-3

Page 19

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

5.1.5.2 Heating

Suction Pressure - Heating (Technician Mode)

1300

1200

1100

1000

900

800

700

600

500

400

Suction Pressure [KPa(g)]

300

200

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [°C]

15

20

25

Discharge Pressure - Heating (Technician Mode)

4000

3750

3500

3250

3000

2750

2500

[KPa(g)]

2250

2000

Discharge Pressure

1750

1500

1250

1000

-15-10-5 0 5 1015

Outdoor WB Tempera ture [°C]

15

20

25

5-4

SM OU12HP 2-E.2 GB

Page 20

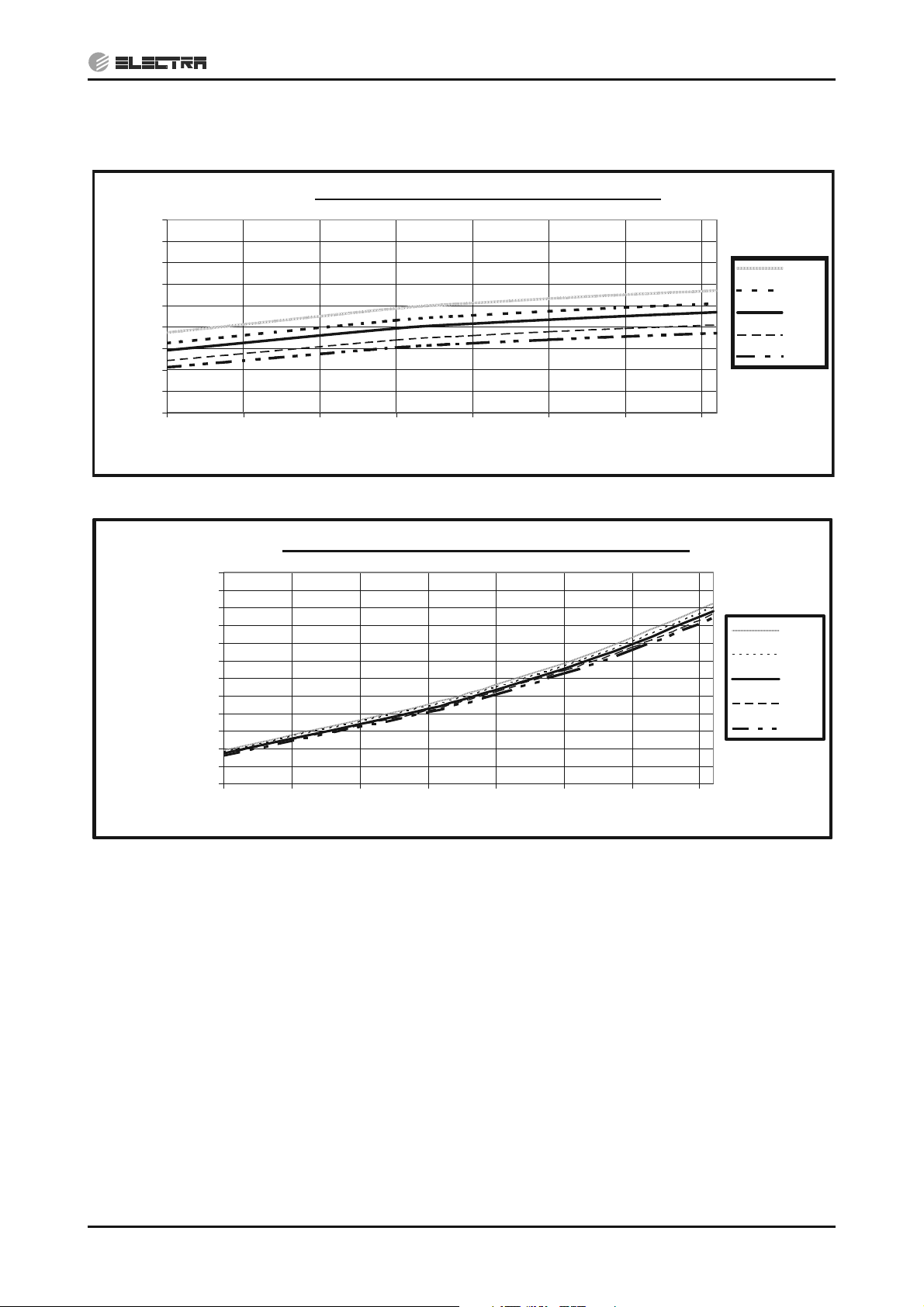

5.2 DNG 125 DCI

CONTENTS

5.2.1 Cooling Capacity (kW)

PERFORMANCE DATA & PRESSURE CURVES

OD COIL

ENTERING AIR DB

TEMPERATURE [qC]

-10 – 20

(protection range)

25

30

35

40

46

ID COIL ENTERING AIR DB/WB TEMPERATURE [qC]

DATA

22/15 24/17 27/19 29/21 32/23

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

PI 25 - 50 % of nominal

TC 12.08 12.87 13.66 14.45 15.24

SC 9.59 9.79 9.98 10.18 10.38

PI 3.28 3.34 3.40 3.47 3.53

TC 11.50 12.29 13.08 13.87 14.66

SC 9.35 9.55 9.74 9.94 10.13

PI 3.66 3.72

TC 10.92 11.71

3.79

12.50

3.85 3.91

13.29 14.08

SC 9.11 9.30 9.50 9.70 9.89

PI 4.04 4.11

TC 10.34 11.13

4.17

11.92

4.23 4.30

12.71 13.50

SC 8.87 9.06 9.26 9.45 9.65

PI 4.43 4.49 4.55 4.62 4.68

TC

SC

9.64 10.43 11.22 12.01 12.80

8.58 8.77 8.97 9.16 9.36

PI 4.89 4.95 5.01 5.08 5.14

LEGEND

TC – Total Cooling Capacity, kW

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

DB – Dry Bulb Temp., (

o

o

C)

C)

ID – Indoor

OD – Outdoor

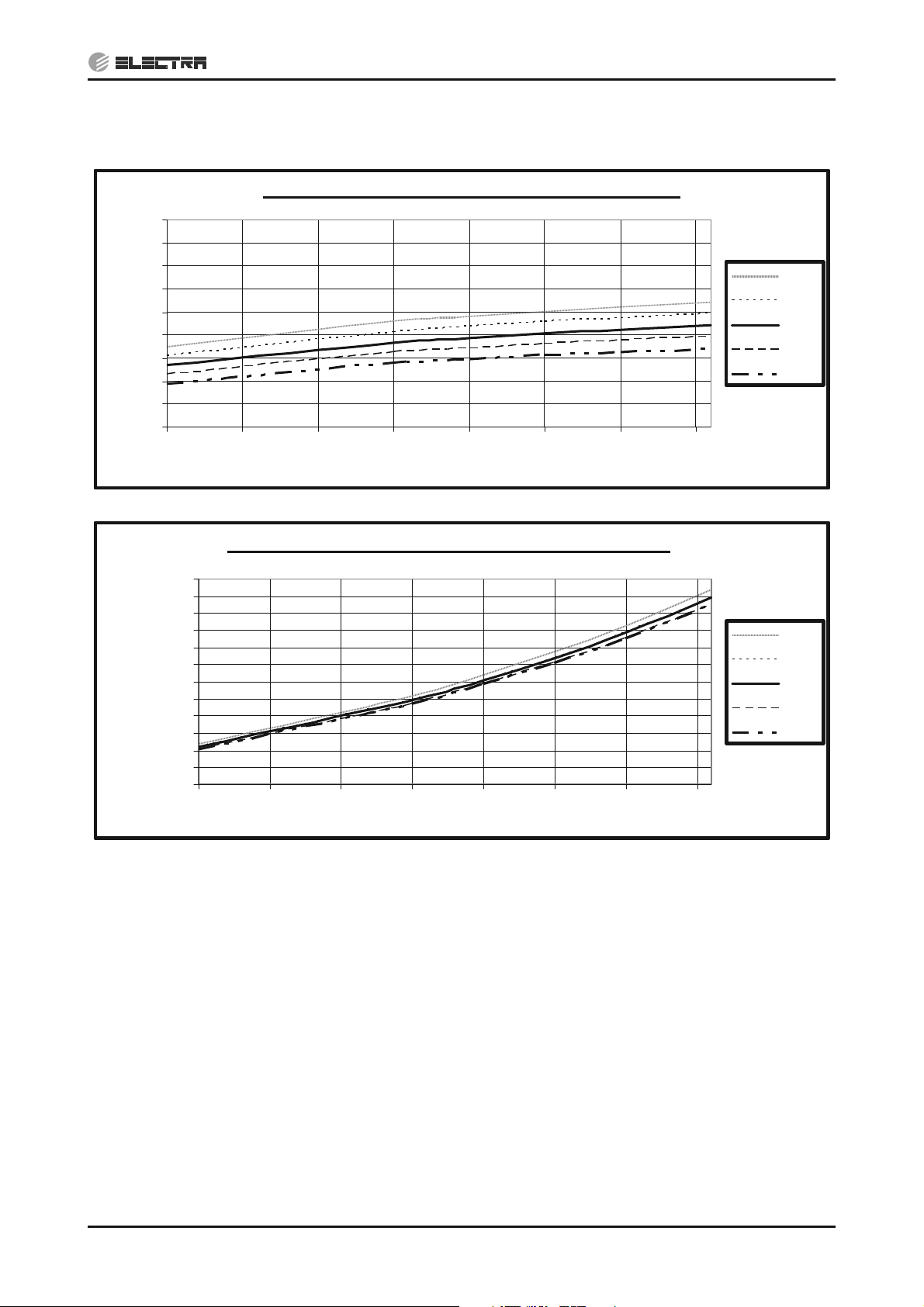

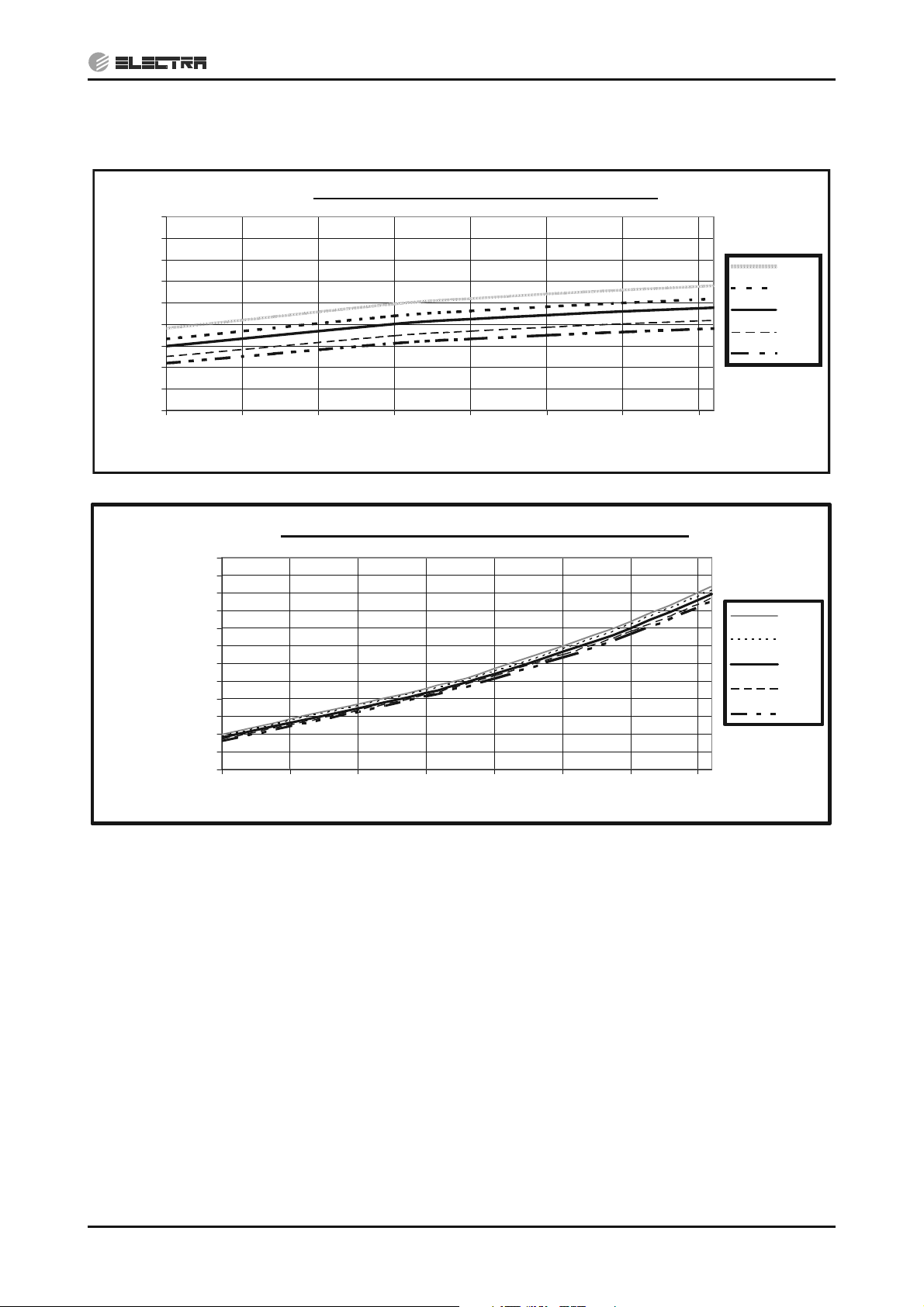

5.2.2 Capacity Correction Factors (Cooling)

Cooling Capacity Ratio Vs. Outdoor Temperature

1.20

1.10

1.00

0.90

0.80

0.70

Capacity Ratio

0.60

0.50

20 25 30 35 40 45

Outdoor Temperature [deg C]

SM OU12HP 2-E.2 GB

5-5

Page 21

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

5.2.3 Heating Capacity

ID COIL ENTERING AIR DB TEMPERATURE [°C]

OD COIL ENTERING

AIR DB/WB

TEMPERATURE [°C]

-15/-16

-10/-12

-7/-8

-1/-2

DATA

TC 8.91 8.20 7.67

PI 2.58 2.84 3.11

TC 9.92 9.30 8.67

PI 3.11 3.37 3.64

TC 10.68 10.05 9.43

PI 3.51 3.77 4.03

TC 11.05 10.43 9.81

PI 3.71 3.97 4.23

15 20 25

2/1

TC 11.31 10.68 10.06

PI 3.84

TC 14.62

7/6

PI 4.04

TC 15.43

10/9

PI 4.28 4.54 4.80

TC 16.24 15.61 14.99

15/12

PI 4.52 4.78 5.04

15-24

(Protection Range)

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

LEGEND

TH – Total Heating Capacity, kW

PI – Power Input, kW

o

WB – Wet Bulb Temp., (

DB – Dry Bulb Temp., (

o

C)

C)

ID – Indoor

OD – Outdoor

4.10

14.00

4.30

14.81

4.36

13.38

4.56

14.18

5.2.4 Capacity Correction Factors (Heating)

5-6

Heating Capacity Ratio Vs. Outdoor Temperature

1.20

1.10

1.00

0.90

0.80

0.70

0.60

Capacity Ration

0.50

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [deg C]

SM OU12HP 2-E.2 GB

Page 22

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

5.2.5 Pressure Curves (Cooling – Technician Mode)

5.2.5.1 Cooling

Suction Pressure - Cooling (Technician Mode)

1400

1300

1200

1100

1000

900

800

700

600

Suction Pressure [KPa(g)]

500

10 15 20 25 30 35 40 45

Outdoor DB Temperature [°C]

32/23

29/21

27/19

24/17

22/15

Discharge Pressure - Cooling (Technician Mode)

4000

3750

3500

3250

3000

2750

2500

2250

[KPa(g)]

2000

1750

Discharge Pressure

1500

1250

1000

10 15 20 25 30 35 40 45

Outdoor DB Temperature [°C]

32/23

29/21

27/19

24/17

22/15

SM OU12HP 2-E.2 GB

5-7

Page 23

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

5.2.5.2 Heating

Suction Pressure - Heating (Technician Mode)

1200

1100

1000

900

800

700

600

500

400

Suction Pressure [KPa(g)]

300

200

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [°C]

15

20

25

Discharge Pressure - Heating (Technician Mode)

3950

3700

3450

3200

2950

2700

2450

[KPa(g)]

2200

1950

1700

Discharge Pressure

1450

1200

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [°C]

15

20

25

5-8

SM OU12HP 2-E.2 GB

Page 24

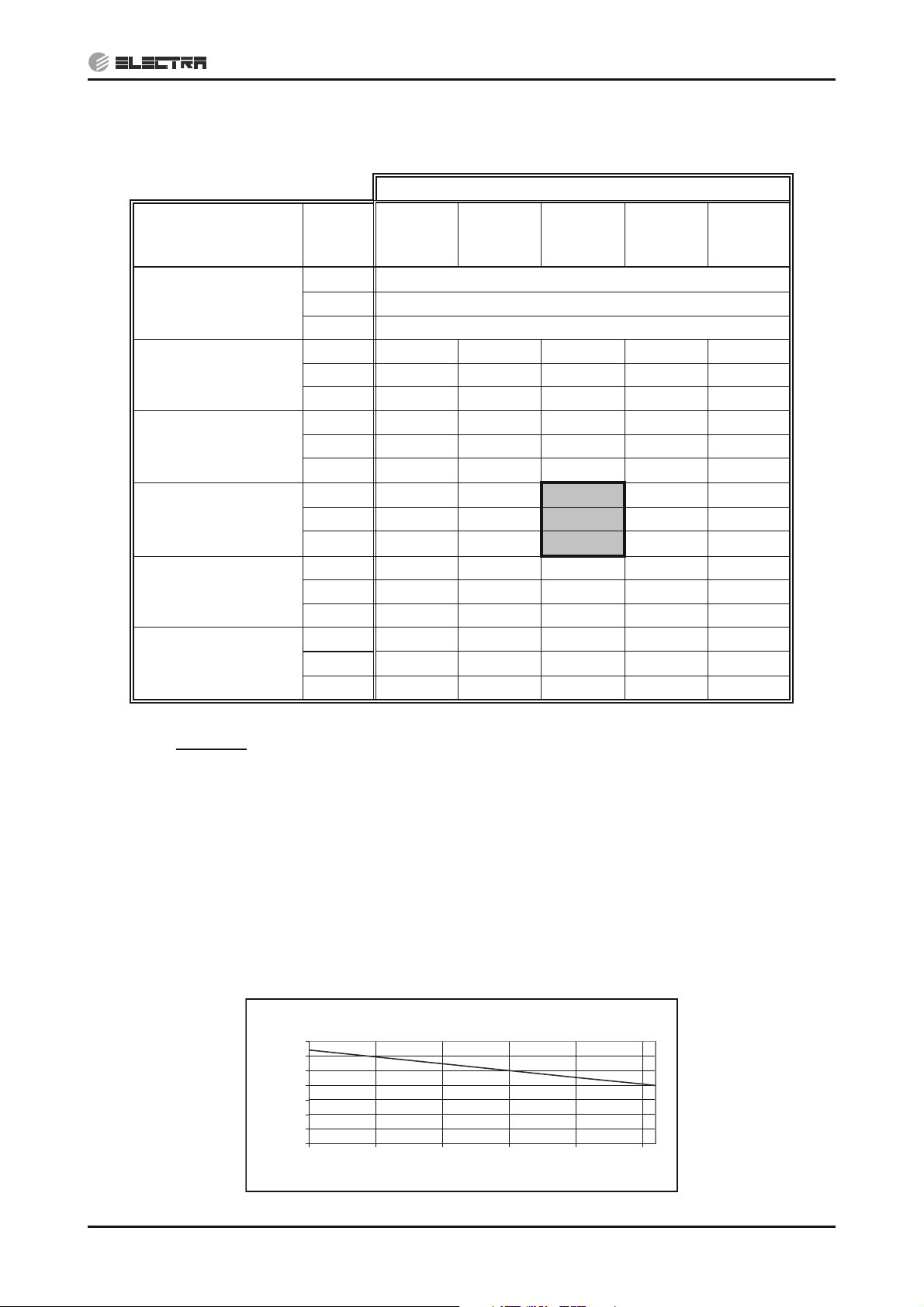

5.3 EMD 100 DCI

CONTENTS

5.3.1 Cooling Capacity (kW)

PERFORMANCE DATA & PRESSURE CURVES

OD COIL

ENTERING AIR DB

TEMPERATURE [qC]

-10 – 20

(protection range)

25

30

35

40

46

ID COIL ENTERING AIR DB/WB TEMPERATURE [qC]

DATA

22/15 24/17 27/19 29/21 32/23

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

PI 25 - 50 % of nominal

TC 9.67 10.30 10.93 11.56 12.19

SC 7.96 8.12 8.28 8.44 8.61

PI 2.40 2.44 2.49 2.53 2.58

TC 9.20 9.83 10.47 11.10 11.73

SC 7.76 7.92 8.08 8.24 8.41

PI 2.68 2.72

TC 8.74 9.37

2.77

10.00

2.82 2.86

10.63 11.26

SC 7.56 7.72 7.88 8.04 8.20

PI 2.96 3.00

TC 8.27 8.90

3.05

9.54

3.10 3.14

10.17 10.80

SC 7.35 7.52 7.68 7.84 8.00

PI 3.24 3.28 3.33 3.38 3.42

TC

SC

7.71 8.35 8.98 9.61 10.24

7.11 7.28 7.44 7.60 7.76

PI 3.58 3.62 3.67 3.71 3.76

LEGEND

TC – Total Cooling Capacity, kW

SC – Sensible Capacity, kW

PI – Power Input, kW

o

WB – Wet Bulb Temp., (

DB – Dry Bulb Temp., (

o

C)

C)

ID – Indoor

OD – Outdoor

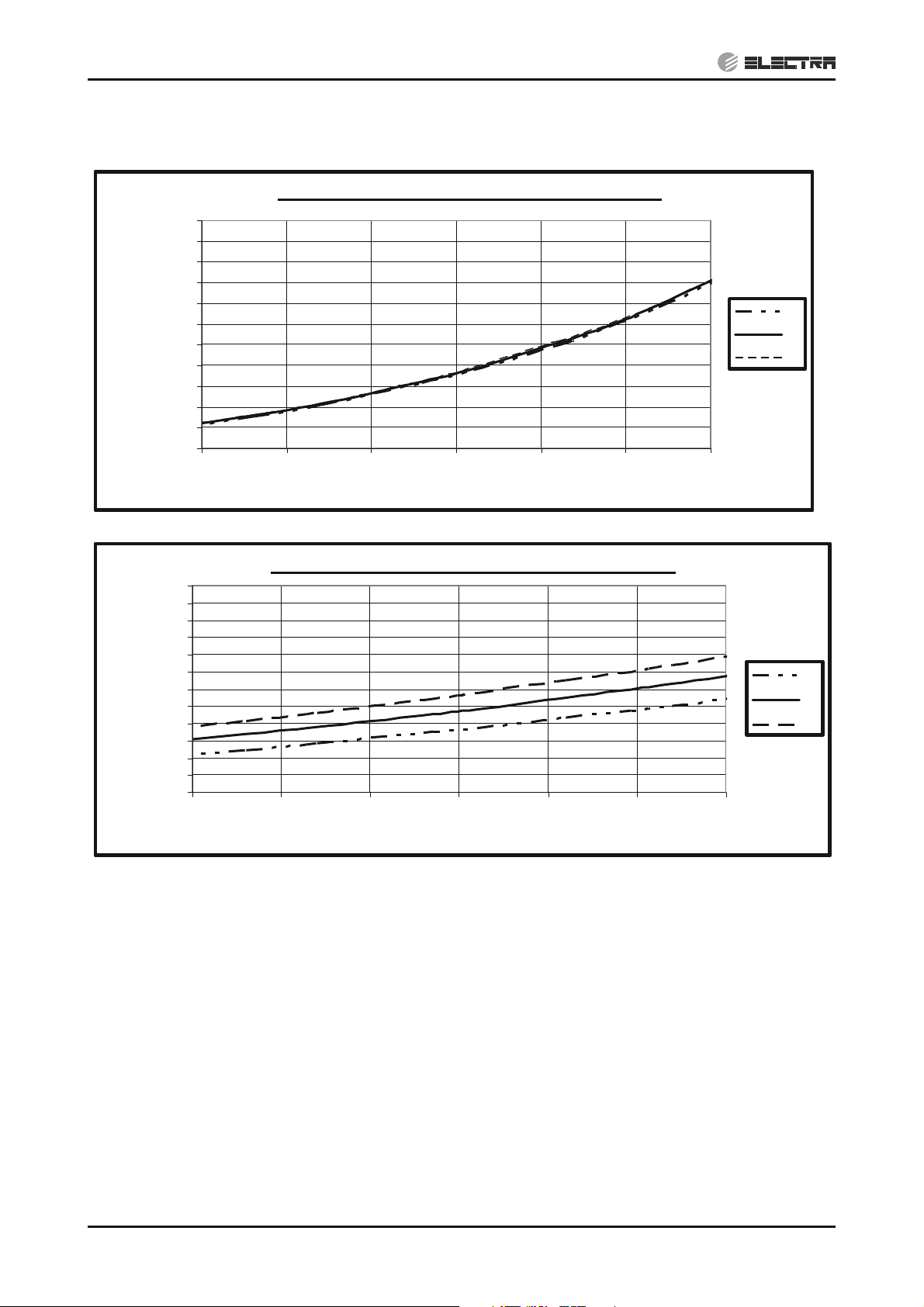

5.3.2 Capacity Correction Factors (Cooling)

Cooling Capacity Ratio Vs. Outdoor Temperature

1.20

1.10

1.00

0.90

0.80

0.70

Capacity Ratio

0.60

0.50

20 25 30 35 40 45

Outdoor Temperature [deg C]

SM OU12HP 2-E.2 GB

5-9

Page 25

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

5.3.3 Heating Capacity

ID COIL ENTERING AIR DB TEMPERATURE [°C]

OD COIL ENTERING

AIR DB/WB

TEMPERATURE [°C]

-15/-16

-10/-12

-7/-8

-1/-2

2/1

7/6

10/9

15/12

15-24

(Protection Range)

DATA

TC 7.32 6.81 6.30

PI 1.86 2.05 2.24

TC 8.15 7.64 7.12

PI 2.24 2.43 2.62

TC 8.77 8.26 7.75

PI 2.53 2.72 2.91

TC 9.08 8.57 8.06

PI 2.67 2.86 3.05

TC 9.29 8.77 8.26

PI 2.77

TC 12.01

PI 2.91

TC 12.67

PI 3.08 3.27 3.46

TC 13.34 12.82 12.31

PI 3.26 3.45 3.64

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

15 20 25

2.96

11.50

3.10

12.16

3.15

10.99

3.29

11.65

LEGEND

TH – Total Heating Capacity, kW

PI – Power Input, kW

o

WB – Wet Bulb Temp., (

DB – Dry Bulb Temp., (

o

C)

C)

ID – Indoor

OD – Outdoor

5.3.4 Capacity Correction Factors (Heating)

Heating Capacity Ratio Vs. Outdoor Temperature

1.20

1.10

1.00

0.90

0.80

0.70

0.60

Capacity Ration

0.50

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [deg C]

5-10

SM OU12HP 2-E.2 GB

Page 26

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

5.3.5 Pressure Curves (Cooling – Technician Mode)

5.3.5.1 Cooling

Suction Pressure - Cooling (Technician Mode)

1400

1300

1200

1100

1000

900

800

700

600

Suction Pressure [KPa(g)]

500

10 15 20 25 30 35 40 45

Outdoor DB Temperature [°C]

32/23

29/21

27/19

24/17

22/15

Discharge Pressure - Cooling (Technician Mode)

4000

3750

3500

3250

3000

2750

2500

[KPa(g)]

2250

2000

Discharge Pressure

1750

1500

1250

1000

10 15 20 25 30 35 40 45

Outdoor DB Temperature [°C]

32/23

29/21

27/19

24/17

22/15

SM OU12HP 2-E.2 GB

5-11

Page 27

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

5.3.5.2 Heating

Suction Pressure - Heating (Technician Mode)

1300

1200

1100

1000

900

800

700

600

500

400

Suction Pressure [KPa(g)]

300

200

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [°C]

15

20

25

Discharge Pressure - Heating (Technician Mode)

4000

3750

3500

3250

3000

2750

2500

[KPa(g)]

2250

2000

Discharge Pressure

1750

1500

1250

1000

-15-10-5 0 5 1015

Outdoor WB Temperature [°C]

15

20

25

5-12

SM OU12HP 2-E.2 GB

Page 28

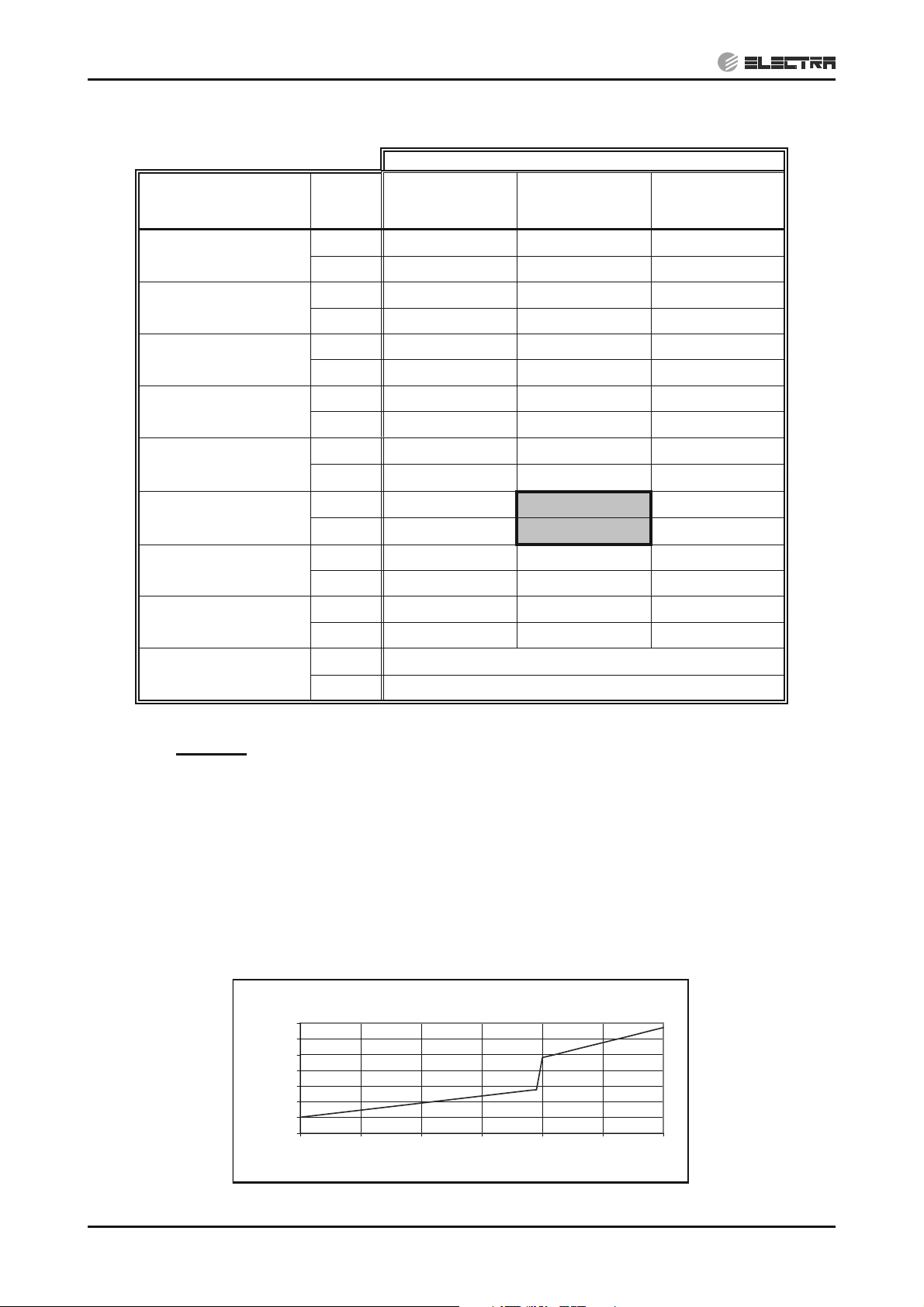

5.4 EMD 125 DCI

CONTENTS

5.4.1 Cooling Capacity (kW)

PERFORMANCE DATA & PRESSURE CURVES

OD COIL

ENTERING AIR DB

TEMPERATURE [qC]

-10 – 20

(protection range)

25

30

35

40

46

ID COIL ENTERING AIR DB/WB TEMPERATURE [qC]

DATA

22/15 24/17 27/19 29/21 32/23

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

PI 25 - 50 % of nominal

TC 12.08 12.87 13.66 14.45 15.24

SC 9.87 10.07 10.27 10.47 10.68

PI 3.22 3.28 3.35 3.41 3.47

TC 11.50 12.29 13.08 13.87 14.66

SC 9.62 9.82 10.02 10.23 10.43

PI 3.60 3.66

TC 10.92 11.71

3.72

12.50

3.78 3.85

13.29 14.08

SC 9.37 9.57 9.78 9.98 10.18

PI 3.98 4.04

TC 10.34 11.13

4.10

11.92

4.16 4.22

12.71 13.50

SC 9.12 9.32 9.53 9.73 9.93

PI 4.35 4.42 4.48 4.54 4.60

TC

SC

9.64 10.43 11.22 12.01 12.80

8.82 9.03 9.23 9.43 9.63

PI 4.71 4.87 4.93 4.99 5.05

LEGEND

TC – Total Cooling Capacity, kW

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

DB – Dry Bulb Temp., (

o

o

C)

C)

ID – Indoor

OD – Outdoor

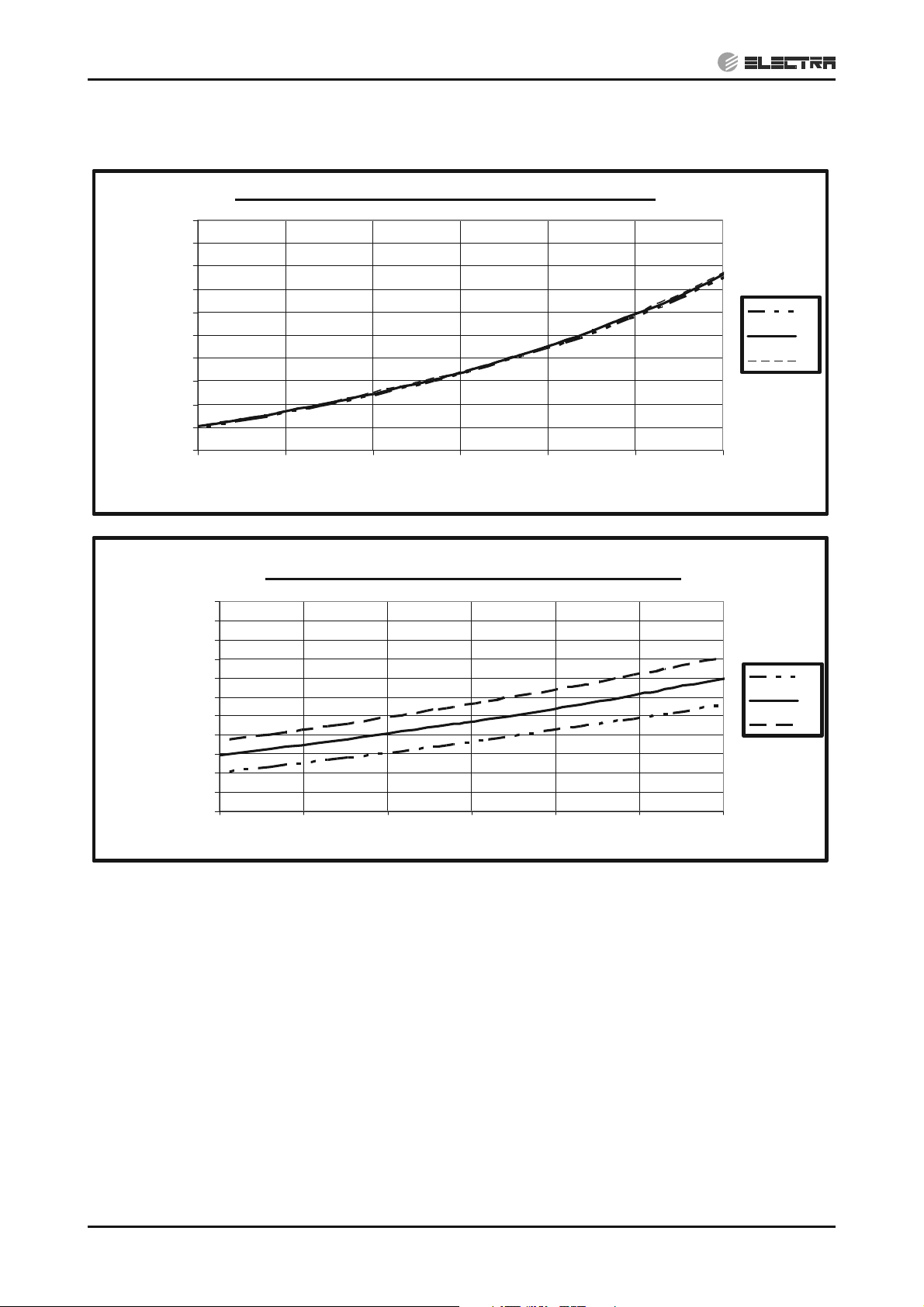

5.4.2 Capacity Correction Factors (Cooling)

Cooling Capacity Ratio Vs. Outdoor Temperature

1.20

1.10

1.00

0.90

0.80

0.70

Capacity Ratio

0.60

0.50

20 25 30 35 40 45

Outdoor Temperature [deg C]

SM OU12HP 2-E.2 GB

5-13

Page 29

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

5.4.3 Heating Capacity

ID COIL ENTERING AIR DB TEMPERATURE [°C]

OD COIL ENTERING

AIR DB/WB

TEMPERATURE [°C]

-15/-16

-10/-12

-7/-8

-1/-2

DATA

TC 8.91 8.29 7.67

PI 2.47 2.72 2.97

TC 9.92 9.30 8.67

PI 2.97 3.22 3.47

TC 10.68 10.05 9.43

PI 3.35 3.60 3.85

TC 11.05 10.43 9.81

PI 3.54 3.79 4.04

15 20 25

2/1

TC 11.31 10.68 10.06

PI 3.67

TC 14.62

7/6

PI 3.86

TC 15.43

10/9

PI 4.09 4.34 4.59

TC 16.24 15.61 14.99

15/12

PI 4.32 4.57 4.82

15-24

(Protection Range)

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

LEGEND

TH – Total Heating Capacity, kW

PI – Power Input, kW

o

WB – Wet Bulb Temp., (

DB – Dry Bulb Temp., (

o

C)

C)

ID – Indoor

OD – Outdoor

3.92

14.00

4.11

14.81

4.17

13.38

4.36

14.18

5.4.4 Capacity Correction Factors (Heating)

5-14

Heating Capacity Ratio Vs. Outdoor Temperature

1.20

1.10

1.00

0.90

0.80

0.70

0.60

Capacity Ration

0.50

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [deg C]

SM OU12HP 2-E.2 GB

Page 30

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

5.4.5 Pressure Curves (Cooling – Technician Mode)

5.4.5.1 Cooling

Suction Pressure - Cooling (Technician Mode)

1400

1300

1200

1100

1000

900

800

700

600

Suction Pressure [KPa(g)]

500

10 15 20 25 30 35 40 45

Outdoor DB Temperature [°C]

32/23

29/21

27/19

24/17

22/15

Discharge Pressure - Cooling (Technician Mode)

4000

3750

3500

3250

3000

2750

2500

[KPa(g)]

2250

2000

Discharge Pressure

1750

1500

1250

1000

10 15 20 25 30 35 40 45

Outdoor DB Temperature [°C]

32/23

29/21

27/19

24/17

22/15

SM OU12HP 2-E.2 GB

5-15

Page 31

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

5.4.5.2 Heating

Suction Pressure - Heating (Technician Mode)

1300

1200

1100

1000

900

800

700

600

500

400

Suction Pressure [KPa(g)]

300

200

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [°C]

15

20

25

Discharge Pressure - Heating (Technician Mode)

4000

3750

3500

3250

3000

2750

2500

[KPa(g)]

2250

2000

Discharge Pressure

1750

1500

1250

1000

-15-10-5 0 5 1015

Outdoor WB Temperature [°C]

15

20

25

5-16

SM OU12HP 2-E.2 GB

Page 32

5.5 CD 140 DCI

CONTENTS

5.5.1 Cooling Capacity (kW)

OD COIL ENTERING AIR

DB TEMPERATURE [ºC]

-10 - 20

(protection range)

25

30

35

40

46

DATA 22/15 24/17 27/19 29/21 32/23

PERFORMANCE DATA & PRESSURE CURVES

ID COIL ENTERING AIR DB/WB TEMPERATURE

[ºC]

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

PI 25 - 50 % of nominal

TC 13.53 14.42 15.30 16.19 17.07

SC 11.31 11.54 11.77 12.00 12.23

PI 3.30 3.36 3.43 3.49 3.55

TC 12.88 13.77 14.65 15.54 16.42

SC 11.02 11.25 11.49 11.72 11.95

PI 3.69 3.75 3.81 3.88 3.94

TC 12.23 13.12 14.00 14.88 15.77

SC 10.74 10.97 11.20 11.43 11.66

PI 4.07 4.14 4.20 4.26 4.33

TC 11.58 12.46 13.35 14.23 15.12

SC 10.45 10.68 10.91 11.15 11.38

PI 4.46 4.52 4.59 4.65 4.71

TC 10.80 11.68 12.57 13.45 14.34

SC 10.11 10.34 10.57 10.80 11.03

PI 4.92 4.99 5.05 5.11 5.18

LEGEND

TC – Total Cooling Capacity, kW

SC – Sensible Capacity, kW

PI – Power Input, kW

WB – Wet Bulb Temp., (

DB – Dry Bulb Temp., (

o

o

C)

C)

ID – Indoor

OD – Outdoor

5.5.2 Capacity Correction Factors (Cooling)

Cooling Capacity Ratio Vs. Outdoor Temperature

1.20

1.10

1.00

0.90

0.80

0.70

Capacity Ratio

0.60

0.50

20 25 30 35 40 45

Outdoor Temperature [deg C]

SM OU12HP 2-E.2 GB

5-17

Page 33

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

5.5.3 Heating Capacity

ID COIL ENTERING AIR DB

TEMPERATURE [°C]

OD COIL ENTERING AIR DB/WB

TEMPERATURE [°C]

-15/-16

-10/-12

-7/-8

-1/-2

2/1

7/6

10/9

15/12

15-24

(Protection Range)

DATA 15 20 25

TC 10.18 9.47 8.76

PI 2.64 2.91 3.18

TC 11.34 10.62 9.91

PI 3.18 3.45 3.72

TC 12.20 11.49 10.78

PI 3.59 3.86 4.13

TC 12.63 11.92 11.21

PI 3.79 4.06 4.33

TC 12.92 12.21 11.50

PI 3.93 4.20 4.47

TC 16.71 16.00 15.29

PI 4.13 4.40 4.67

TC 17.63 16.92 16.21

PI 4.38 4.65 4.92

TC 18.56 17.84 17.13

PI 4.63 4.89 5.16

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

LEGEND

TH – Total Heating Capacity, kW

PI – Power Input, kW

o

WB – Wet Bulb Temp., (

DB – Dry Bulb Temp., (

o

C)

C)

ID – Indoor

OD – Outdoor

5.5.4 Capacity Correction Factors (Heating)

Heating Capacity Ratio Vs. Outdoor Temperature

1.20

1.10

1.00

0.90

0.80

0.70

0.60

Capacity Ration

0.50

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [deg C]

5-18

SM OU12HP 2-E.2 GB

Page 34

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

5.5.5 Pressure Curves (Cooling – Technician Mode)

5.5.5.1 Cooling

Suction Pressure - Cooling (Technician Mode)

1400

1300

1200

1100

1000

900

800

700

Suction Pressure [KPa(g)]

600

500

10 15 20 25 30 35 40 45

Outdoor DB Temperature [°C]

Discharge Pressure - Cooling (Technician Mode)

4000

3750

3500

3250

3000

2750

2500

2250

2000

Discharge Pressure [KPa(g)]

1750

1500

1250

1000

10 15 20 25 30 35 40 45

Outdoor DB Temperature [°C]

32/23

29/21

27/19

24/17

22/15

32/23

29/21

27/19

24/17

22/15

SM OU12HP 2-E.2 GB

5-19

Page 35

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

5.5.5.2 Heating

Suction Pressure - Heating (Technician Mode)

1300

1200

1100

1000

900

800

700

600

500

Suction Pressure [KPa(g)]

400

15

20

25

300

200

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [°C]

Discharge Pressure - Heating (Technician Mode)

4000

3750

3500

3250

3000

2750

2500

2250

2000

Discharge Pressure [KPa(g)]

1750

1500

1250

1000

-15 -10 -5 0 5 10 15

Outdoor WB Temperature [°C]

15

20

25

5-20

SM OU12HP 2-E.2 GB

Page 36

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

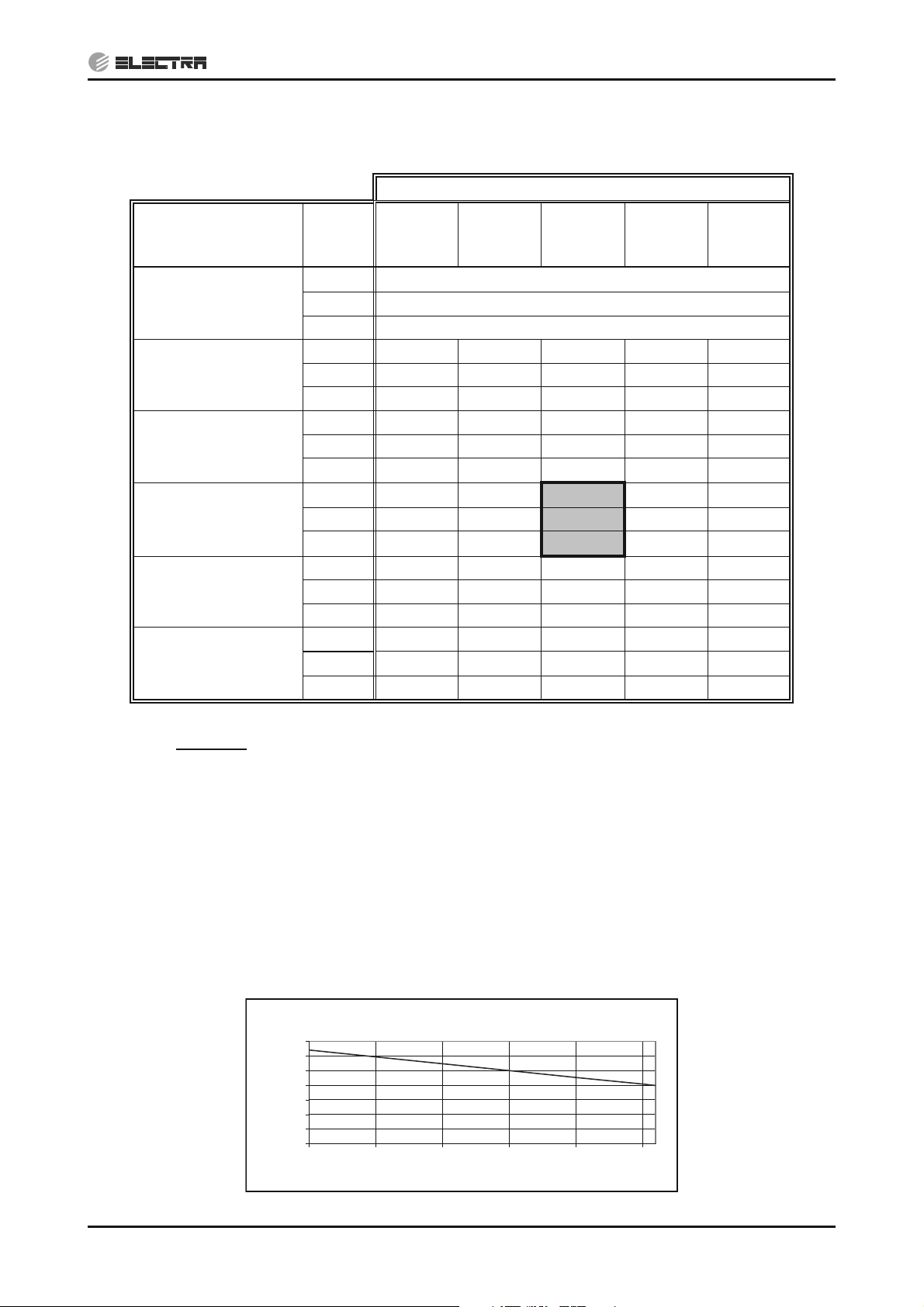

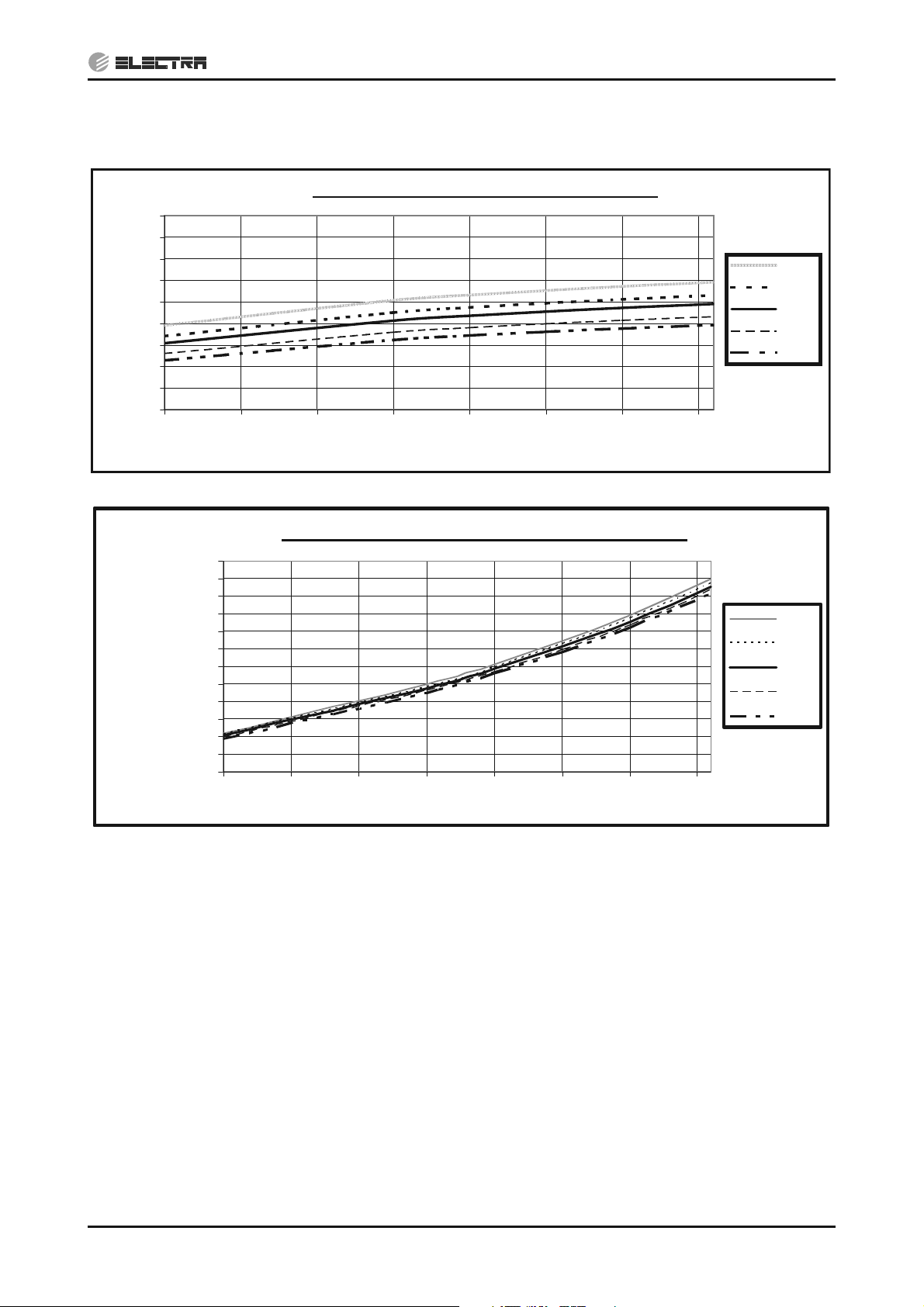

5.6 Capacity Correction Factor for Tubing Length

5.6.1 Cooling

1.05

1.00

0.95

0.90

0.85

Capacity Ratio

0.80

0.75

5 10152025303540455055606570

Tubing Lenght [m]

5.6.2 Heating

1.05

1.00

0.95

0.90

0.85

Capacity Ratio

0.80

0.75

5 10152025303540455055606570

Tubing Lenght [m]

SM OU12HP 2-E.2 GB

5-21

Page 37

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

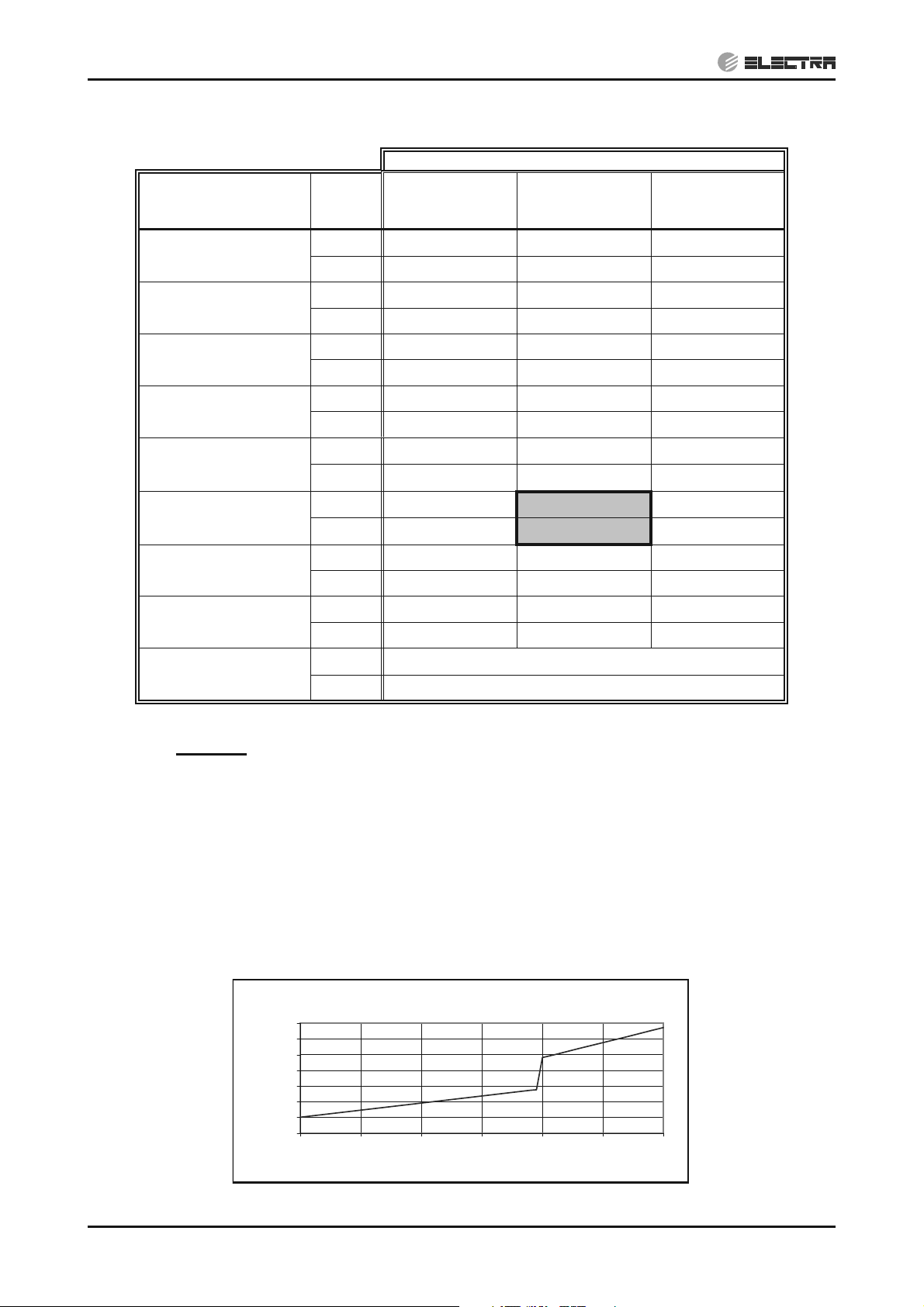

5.7 Pressure Correction Factor for Tubing Length

5.7.1 Cooling

Pressure vs Tubing Lenght (COOLING)

1.02

1.00

0.98

0.96

0.94

0.92

0.90

Suction Pressure Ratio

0.88

0.86

Cooling Suction Pressure

5 10152025303540455055606570

5.7.2 Heating

Cooling Discharge Pressure

Total Tubing Length [m]

Pressure vs Tubing Lenght (HEATING)

1.02

1.00

0.98

0.96

0.94

0.92

0.90

Discharge Pressure Ratio

0.88

0.86

1.02

1.01

1.00

0.99

0.98

0.97

0.96

Suction Pressure Ratio

0.95

0.94

5 10152025303540455055606570

Heating Suction Pressure

Heating Discharge Pressure

Total Tubing Lengtht [m]

1.02

1.01

1.00

0.99

0.98

0.97

0.96

Discharge Pressure Ratio

0.95

0.94

5-22

SM OU12HP 2-E.2 GB

Page 38

PERFORMANCE DATA & PRESSURE CURVES

CONTENTS

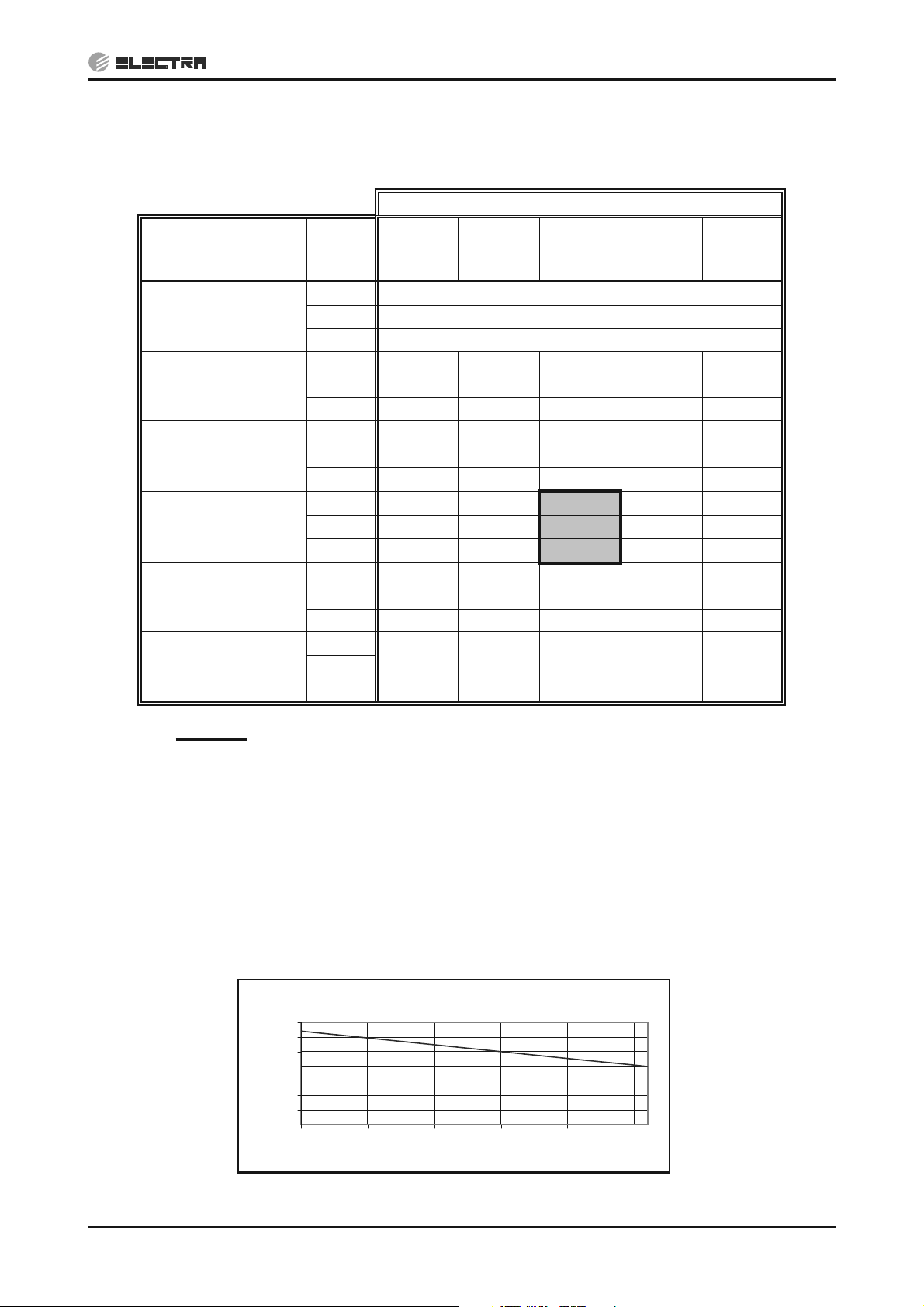

5.8 Calculation Example

Outdoor Unit OU12 5HP DCI

Indoor Unit DNG 125 DCI

Operation Mode Cooling Mode

Conditions Indoor 22qCDB/15qWB

Conditions Oudoor 30qCDB

Tubing length 50m

Cooling Capacity calculation:

Total Cooling Capacity (TC) [KW] = Capacity in conditions table x F

Cooling Capacity in table [KW] Tubing Length Factor (FT) Corrected Capacity [KW]

T

11.5 0.85 TC

Cooling Pressure calculation:

Pressure [KPa(g)] = Nominal Pressure (at 7.5m) x F

Nominal Pressure [KPa(g)] Tubing Length Factor (FT) Corrected Pressure [KPa(g)]

Discharge 2500 0.99 Pd= 2500 x 0.99 = 2475

Suction 800 0.925 Ps= 800 x 0.925 = 740

= 11.5x0.85=9.775

T

SM OU12HP 2-E.2 GB

5-23

Page 39

6. AIRFLOW CURVES

CONTENTS

6.1 Model: DNG 100 DCI

Air Flow vs. External Static Pressure

140

130

]aP[ erusserP citatS lanretxE

120

110

100

90

80

70

60

50

40

30

20

10

0

1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400

AIRFLOW CURVES

Nominal System Curve

Max Sy st em Cur ve

Medium Speed

Low Speed

High Speed

Operating Range

Perf ormance test

point at 37 Pa

Air Flow [m3/h]

6.2 Model: DNG 125 DCI

Air Flow vs. External Static Pressure

140

130

]aP[ erusserP citatS lanretxE

120

110

100

90

80

70

60

50

40

30

20

10

0

1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400

Nomina l Sy st em Cur ve

Max Sy st e m Cu r v e

Medium S p ee d

Low Speed

Hig h Spe ed

Operating Range

Perf ormance test

point at 50 Pa

Air Flow [m3/h]

SM OU12HP 2-E.2 GB

6-1

Page 40

AIRFLOW CURVES

CONTENTS

6.3 Model: EMD 100 DCI

Air Flow vs. External Static Pressure

Nominal System Cur v e

140

130

120

External Static Pressure [Pa]

110

100

90

80

70

60

50

40

30

20

10

0

800 1,000 1,200 1,400 1,600 1,800 2,000 2,200

Air Flow [m /h]

3

Max System Cu r v e

Medi um Speed

Low Speed

Hig h Speed

Operating Range

Performance test

point at 37 Pa

6.4 Model: EMD 125 DCI

Air Flow vs. External Static Pressure

140

130

120

110

100

90

80

70

60

50

40

30

External Static Pressure [Pa]

20

10

0

1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400 2,600 2,800

Air Flow [m /h]

Nominal System Cur v e

Max System Cu r v e

Medium Speed

Low Speed

High Speed

Operating Range

Performance test

point at 50 Pa

3

6-2

SM OU12HP 2-E.2 GB

Page 41

6.5 Model: CD 140 DCI

CONTENTS

AIRFLOW CURVES

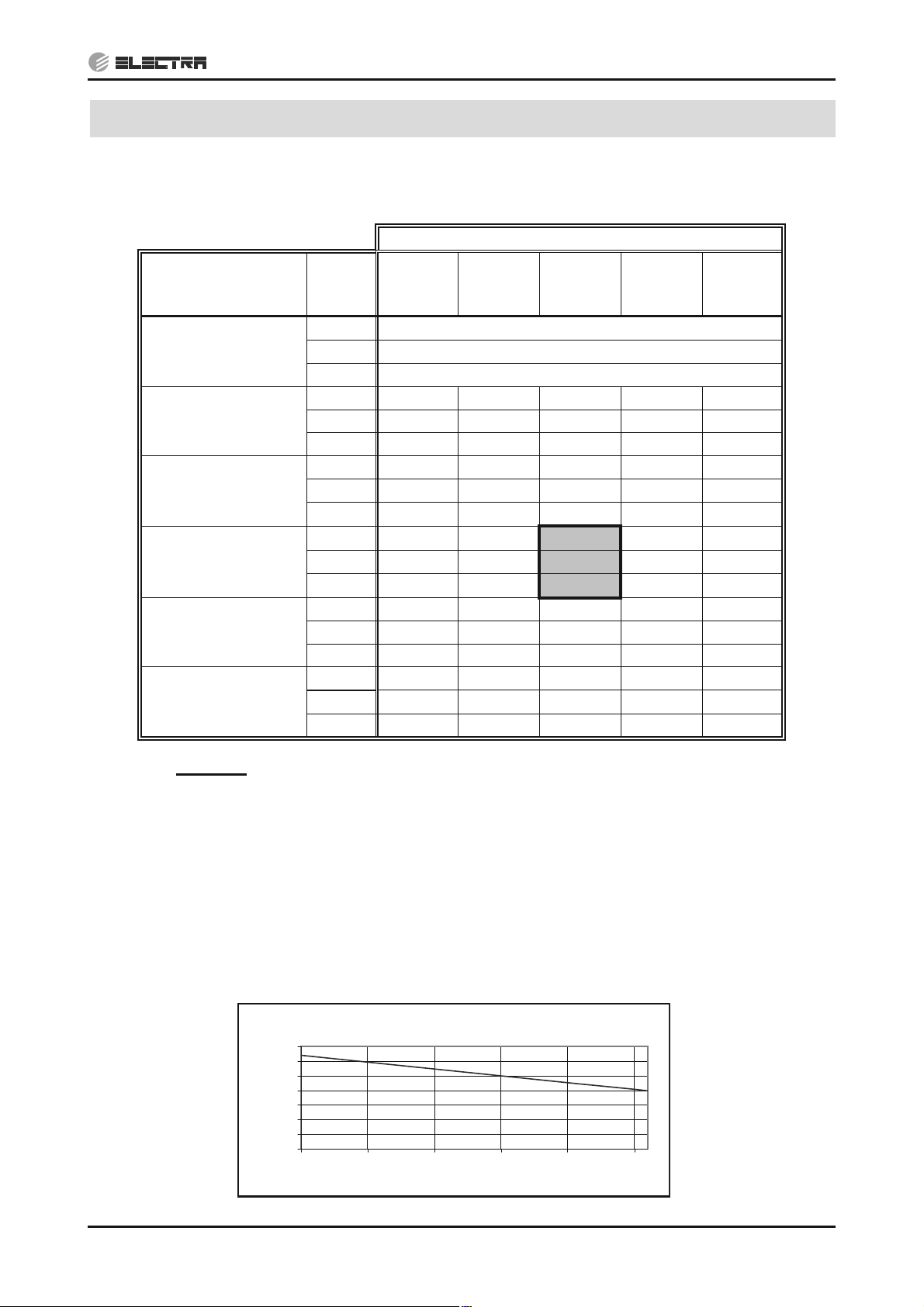

6.6 DNG / EMD / CD UNITS RANGE AIR FLOW CORRECTION

FACTORS

* Permissible Air flow Rate - according to model Air Flow Curves

(at nominal rating conditions — Test mode).

Air Flow Rate [% of nominal]

60% 70% 80% 90% 100%

0.88 0.91 0.94 0.97 1

Cooling

Heating

TC

SC 0.78 0.84 0.89 0.95 1

PI 0.95 0.97 0.98 0.99 1

PI 1.07 1.05 1.03 1.02 1

TC 0.90 0.92 0.95 0.97 1

SM OU12HP 2-E.2 GB

6-3

Page 42

SOUND LEVEL CHARACTERISTICS

CONTENTS

7. SOUND LEVEL CHARACTERISTICS

7.1 Indoor Units Test Scheme

Figure 1

7.2 Sound Pressure Level Spectrum (Measured as Figure 1)

DNG 100 DNG 125

NC-70

NC-60

NC-50

NC-40

NC-30

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

FAN SPEED LINE

SM OU12HP 2-E.2 GB

HI

ME

LO

BAND CENTER FREQUENCIES, Hz

BAND CENTER FREQUENCIES, Hz

7-1

Page 43

SOUND LEVEL CHARACTERISTICS

CONTENTS

EMD 100 EMD 125

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

BAND CENTER FREQUENCIES, Hz

CD 140

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

OCTAVE BAND SOUND PRESSURE LEVEL , dB re 0.002 MICRO BAR

HEARING FOR

CONTINUOUS

NOISE

BAND CENTER FREQUENCIES, Hz

FAN SPEED LINE

HI

ME

LO

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

7-2

SM OU12HP 2-E.2 GB

Page 44

7.3 Outdoor Units

CONTENTS

SOUND LEVEL CHARACTERISTICS

1 m

1 m

Figure 2

7.4 Sound Pressure Level Spectrum (

OU12 4HP DCI Cooling OU12 4HP DCI Heating

Measured as Figure 2)

OU12 5HP DCI Cooling OU12 5HP DCI Heating

SM OU12HP 2-E.2 GB

7-3

Page 45

SOUND LEVEL CHARACTERISTICS

CONTENTS

OU12 6HP DCI Cooling OU12 6HP DCI Heating

7-4

SM OU12HP 2-E.2 GB

Page 46

ELECTRICAL DATA

CONTENTS

8. ELECTRICAL DATA

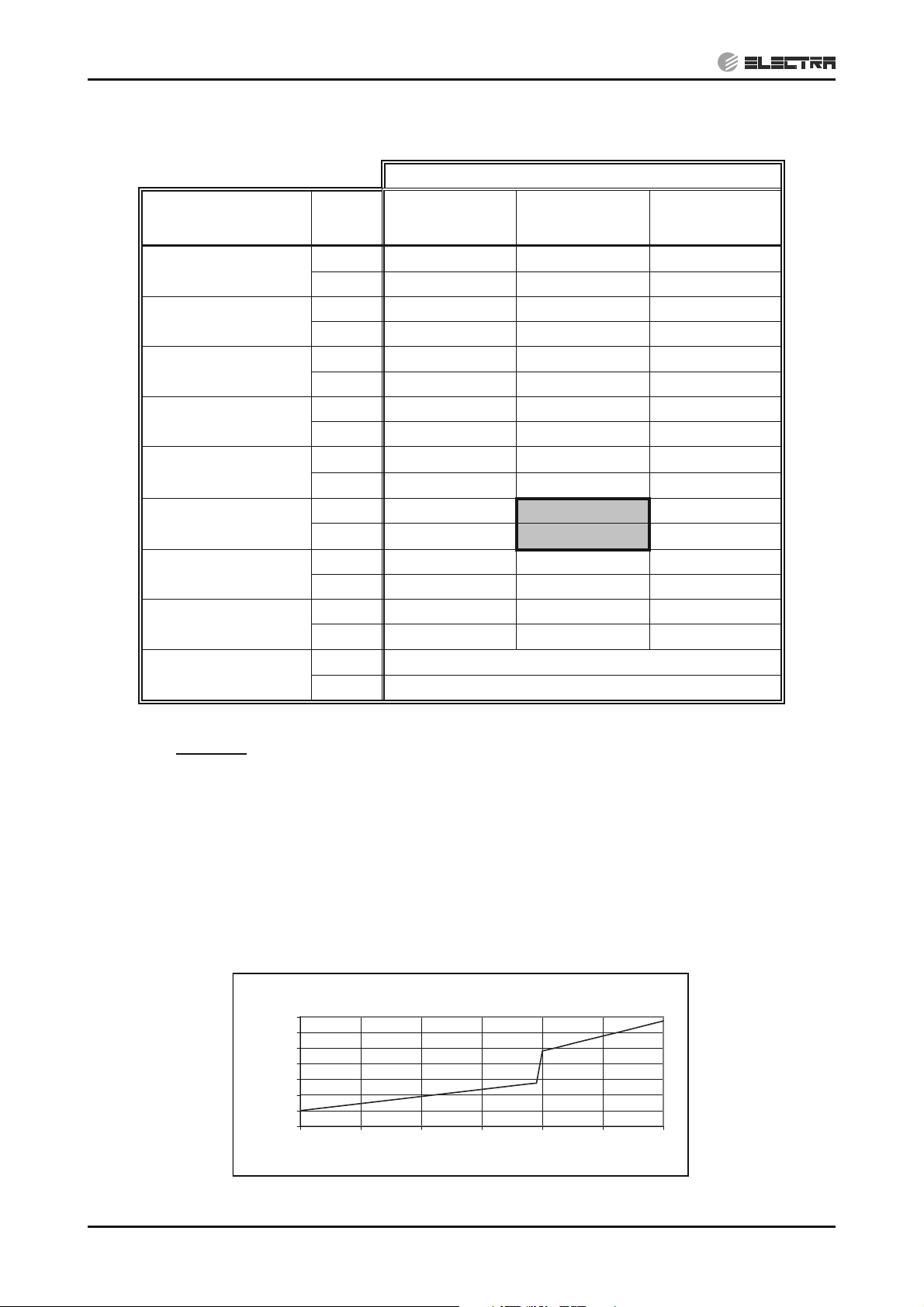

8.1 Single Phase Units

MODEL OU12 4PH DCI OU12 5-6PH DCI

Power Supply 1PH – 230V – 50 Hz

Connected to

(a)

Max Current 23A 5A 28A 5A

Inrush Current

Starting Current

(c)

(d)

Circuit Breaker 25A 10A 32A 10A

Outdoor Indoor Outdoor Indoor

30A

10A

Power Supply Wiring

No. X Cross Section

Interconnecting Cable

No. X Cross Section

(b)

3 X 4.0 mm

3 X 1.5 mm2 +

2 X 0.75 mm

(Communications)

2

3 X 1.5 mm

2

2 X 0.75 mm

(Communications)

2

3 X 6.0 mm23 X 1.5 mm

2

3 X 1.5 mm

2

2 X 0.75 mm

(Communications)

+

2

(Communications)

2 X 0.75 mm

2

2

(a) Power supply can be connected in both ways:

To outdoor unit to supply both outdoor and indoor unit.

To outdoor unit and to Indoor unit separately.

(b) Communication wires must be separated from the power wires and should be shielded type,

earth connectedat both ends.

(c) Inrush current is the current when power is up (charging the DC capacitors at outdoor unit

controller).

(d) Starting current is the current peak when starting the compressor.

NOTE:

Power wiring cord should comply with local lows and electrical regulations requirements.

SM OU12HP 2-E.2 GB

8-1

Page 47

9. WIRING DIAGRAMS

CONTENTS

9.1 Indoor Unit: DNG 100, DNG 125 DCI

WIRING DIAGRAMS

SM OU12HP 2-E.2 GB

ATTENTION! FOR OUTDOOR UNIT ELECTRICAL WIRING REFER TO OUTDOOR UNIT DIAGRAM

CAT No.: 473503/02

9-1

Page 48

WIRING DIAGRAMS

CONTENTS

9.2 Indoor Unit: EMD 100, EMD 125 DCI

9-2

ATTENTION! FOR OUTDOOR UNIT ELECTRICAL WIRING REFER TO OUTDOOR UNIT DIAGRAM

CAT No.: 473503/02

SM OU12HP 2-E.2 GB

Page 49

9.3 Indoor Units: CD 140 DCI

CONTENTS

WIRING DIAGRAMS

SM OU12HP 2-E.2 GB

9-3

Page 50

WIRING DIAGRAMS

CONTENTS

9.4 Outdoor Units: OU12 4-5HP DCI

9.5 Outdoor Units: OU12 6HP DCI

9-4

SM OU12HP 2-E.2 GB

Page 51

9.6 1PH UNITS POWER SUPPLY TO OUTDOOR

CONTENTS

(10.0, 12.5 Kw units)

WIRING DIAGRAMS

Indoor Unit1.

Power Supply Cable2.

Main Power Breaker3.

Outdoor Unit4.

Interconnecting cable (2x0.75mm5.

Power Interconnecting Cable (3x1.5mm6.

2

)**

2

)

Wireless remote Control7.

Display Unit8.

Display Connector9.

Power Breaker (*by installer)10.

Control Cable**11.

Sensor Wire with connector12.

Room Temperature Sensor13.

* The power breaker must be of type that disconnects all poles with 3 mm contact

opening.

** Use shielded cable and connect the shield to earth point

SM OU12HP 2-E.2 GB

9-5

Page 52

WIRING DIAGRAMS

CONTENTS

9.7 1PH UNITS POWER SUPPLY TO OUTDOOR and INDOOR UNIT

SEPERATELY

(10.0, 12.5 Kw units)

1. Indoor Unit

2. Power Supply Cable

3. Main Power Breaker

4. Outdoor Unit

5. Interconnecting cable (2x0.75mm2)*

6. Wireless remote Control

7. Display Unit

8. Display Connector

9. Control Cable*

10. Sensor Wire with connector

11. Room Temperature Sensor

* Use shielded cable and connect the shield to earth point.

9-6

SM OU12HP 2-E.2 GB

Page 53

REFRIGERATION DIAGRAMS

EEV

EEV

EEV

CONTENTS

10. REFRIGERATION DIAGRAMS

10.1 Heat Pump Models

10.1.1 DNG 100 / 125 DCI, EMD 100 / 125 DCI, CD 140 DCI

Cooling mode

Heating mode

SM OU12HP 2-E.2 GB

10-1

Page 54

11. TUBING CONNECTIONS

CONTENTS

TUBING CONNECTIONS

TUBE (Inch)

¼” ” ½” ” ¾”

TORQUE (Nm)

Flare Nuts

Valve Cap

Service Port Cap

1. Valve Protection Cap-end

2. Refrigerant Valve Port (use Allen wrench to open/close)

3. Valve Protection Cap

4. Refrigerant Valve

5. Service Port Cap

6. Flare Nut

7. Unit Back Side

8. Copper Tube

15-18 40-45 60-65 70-75 80-85

13-20 13-20 18-25 18-25 40-50

11-13 11-13 11-13 11-13 11-13

SM OU12HP 2-E.2 GB

11-1

Page 55

12. CONTROL SYSTEM

CONTENTS

12.1 Abbreviations

Abbreviation Definition

A/C Air Conditioner

BMS Building Management System

CCR Compressor Current

CCH Crankcase Heater

COMP Compressor

CTT Compressor Top Temperature sensor

DCI DC Inverter

E²PROM, EEP Erase Enable Programmable Read Only Memory

EEV Electronic Expansion Valve

HE Heating Element

HMI Human Machine Interface

HST Heat Sink Temperature sensor

Hz Hertz (1/sec) – electrical frequency

ICT Indoor Coil Temperature (RT2) sensor

IDU Indoor Unit

IFAN Indoor Fan

M2L Mega Tool (Monitoring SW)

MCU Micro Controller Unit

NA Not Applicable

OAT Outdoor Air Temperature sensor

OCT ODU Coil Temperature sensor

OMT Outdoor middle coil temperature

ODU Outdoor Unit

OFAN Outdoor Fan

PFC Power Factor Corrector

RAC Residential A/C

RC Reverse Cycle (Heat Pump)

RPS Rounds per second (mechanical speed)

RV Reverse Valve

SB,STBY Stand By

SH Superheat

SUCT/SCT Compressor Suction Temperature sensor

S/W Software

TBD To Be Defined

TEMP Temperature

TMR Timer

CONTROL SYSTEM

SM OU12HP 2-E.2 GB

12-1

Page 56

CONTROL SYSTEM

CONTENTS

12.2 Product Overview

12.2.1 Block Diagram

230VAC

IDU Controller

IFAN

Control

Inputs R/C

Dry

contacts

Line Filter

Inrush Control

(4-5HP Only)

Inrush

Control

IDU

Communication

Temp.

Inputs

Compressor

Driver

Driver

Control

ODU Controller

Display

230V

Outputs

EEV

Output

OFAN

Control

OFAN

Control

Dry

contact

M

Speed

HST

AC Current

DC Current

M

M

M

RAT

ICT

Overflow

Power Lines

Low Voltage

RC

RCW

PBMS

12.2.2 Compressor

DC brush less and sensor less motor inverter driven compressor.

12.2.3 Compressor Drive

DC inverter module to drive compressor.

12.2.4 Outdoor Fan

DC brush less motor.

PD

OAT

CTT

OMT

OCT

RV

BH

CCH

EEV

SB

Night

Power Shading

Alarm

HPS

LPS (6HP Only)

12-2

SM OU12HP 2-E.2 GB

Page 57

CONTROL SYSTEM

CONTENTS

12.2.5 RV

Reverse Valve set the direction of refrigerant flow in the system, thus setting the operation

mode for cooling or heating.

When the solenoid is powered, system will work in heat mode.

12.2.6 EEV

Expansion valve operated by step motor which controls the size of the orifice.

12.2.7 HMI

Consists of Four “7-Segments” + four Push buttons for display, monitoring and setup

features.

12.2.8 Dry Contacts

Dry contacts are used to interface the system with an external building management system

(BMS).

12.2.8.1 ODU Dry Contacts

• Night input. Switches the system to night mode when closed. During night mode, the

outdoor unit speed will be reduced in order to reduce the system noise level.

• SB input. System will be turned to Stand-by when the contact is closed.

• Power Shedding input. Limits the maximum power consumption when closed.

• Alarm output indicates a failure in the system.

Alarm output will be activated when there in the following ODU Faults/Protections

1 to 11, 13 to 20, 22 to 26, 28 to 29.

Alarm output will be OFF when the Fault/Protection is cleared.

12.2.8.2 IDU Dry Contacts

Presence detecter input.

12.2.9 Temperature Sensors

CTT – Compressor Top Temperature

OAT – Outdoor Air Temperature

OCT – Outdoor Coil (heat exchanger inlet) Temperature

OMT – Outdoor Coil (heat exchanger) Temperature

HST – Heat Sink Temperature

ICT – Indoor Coil (heat exchanger) Temperature

RAT – Return Air Temperature (Indoor Unit)

SM OU12HP 2-E.2 GB

12-3

Page 58

CONTROL SYSTEM

CONTENTS

12.2.10 Base Heater

Heating element designed to melt any ice that is accumulated on the outdoor unit base during

low heating operation.

12.2.11 Cranck case Heater

Heating element designed to heat up the compressor oil cranck case during low heating

operation.

12.2.12 Internal coil heater

Only exists in 6HP unit. The compressor is equiped with built-in heating coils designed to

heatup the compressor oil cranck case during low heating operation.

12.3 General Operating Rules

12.3.1 Communication with Indoor Unit

12.3.1.1 Communication Failures Definition

12.3.1.1.1 ‘Bad Communication’ fault

The system keeps a balance of a good/bad communication packet ratio. When the ratio

becomes high the system enters ‘Bad Communication’ fault. The system recovers from that

fault when the ratio reduced below the threshold.

When in ‘Bad Communication’ fault, system continues its normal operation and fault code is

shown in diagnostics.

12.3.1.1.2 ‘No Communication’ fault

If no legal transmission or no message received for 30 seconds, system enters ‘No

Communication’ fault.

When in ‘No Communication’ fault, the fault code will be shown in diagnostics. In this case,

the system will force the compressor to off.

The system will recover from ‘No Communication’ fault when counter is below 10 and legal

massage is received

12.3.2 Temperature Measurements

12.3.2.1 Thermistor failures definition

Thermistor Thermistor is Disconnected Thermistor is Shorted

OCT Temp < -35 °C Temp > 75 °C

OAT Temp < -30 °C Temp > 75 °C

CTT Temp < -30 °C Temp > 130 °C

OMT Temp < -30 °C Temp > 75 °C

ICT Temp < -30 °C Temp > 75 °C

RAT Temp < -30 °C Temp > 75 °C

12.3.2.2 System responses for different thermistor failure

Thermistor Default value System Reaction

COOL HEAT

OCT 1°C 1°C

OAT 43°C 6°C

CTT 43°C 43°C Forced compressor to OFF

HST 75°C 75°C

OMT 43°C 43°C Replaced by OCT

ICT 43°C 43°C

RAT SPT+4°C SPT-4°C

(1)

(1)

12-4

Notes:

(1) Whenever both OCT and OMT are faulty the compressor will be forced to OFF.

SM OU12HP 2-E.2 GB

Page 59

(2) Thermistor is defined as faulty (shorted/disconnected) if it’s faulty for more than 10

CONTENTS

seconds continuously. During this time, the system uses the last valid temperature.

12.4 Indoor Unit Control

12.4.1 Indoor Fan Control

When user sets the indoor fan speed to a fixed speed (Low/ Medium/ High), unit will operate

constantly at set speed.

When Auto Fan is selected, indoor fan will operate in all speeds according to the cool/heat

load.

12.4.2 Load calculation

LOAD is calculated according to the difference between actual room temperature and user set

point temperature by PI control.

In high/ medium/ low indoor fan user setting, unit will operate fan in selected speed.

In AutoFan user setting, fan speed will be adjusted automatically according to the calculated

LOAD.

12.4.3 Heat Mode

12.4.3.1 Temperature Compensation

CONTROL SYSTEM

A compensation value of 2-4 degrees is reduced from room temperature reading (except

when in I-Feel mode), to compensate for temperature difference between high and low areas

in the heated room, and for coil heat radiation on room thermistor.

The temperature compensation can be enabled/disabled by closing/opening J2 on the indoor

unit controller.

12.4.3.2 Indoor Fan Control in Heat Mode

When in heat mode, including protections and except Deicing, and when the conditions

in the table below are fulfilled, IFAN will be working according to the graph below.

SM OU12HP 2-E.2 GB

12-5

Page 60

CONTROL SYSTEM

CONTENTS

12.4.4 Auto Cool/Heat Mode

When in auto cool heat mode unit will automatically select between cool and heat mode

according to the difference between actual room temperature and user set point temperature

(T).

Unit will switch from cool to heat when compressor is off for 3 minutes, and T < -3.

Unit will switch from heat to cool when compressor is off for 5 minutes, and T < -3.

12.4.5 Dry Mode

As long as room temperature is higher then the set point, indoor fan will work in low speed and

compressor will work between 0 and maximum frequency in cooling.

When the room temperature is lower than the set point, compressor will be switched OFF and

indoor fan will cycle 3 minutes OFF, 1 minute ON.

12.4.6 Heating Element Control

Heating element can be turn on if high LOAD is more then 80% and Indoor Coil temperature

is less then 45qC.

The heating element will be off when LOAD is less then 50% OR if Indoor Coil temperature is

more then 50qC.

12.4.7 Indoor Unit Dry Contact

“Presence Detector” feature in the indoor unit is done for cases that external SB (Stand-By) is

required via a presence detector sensor or others such as window closed detector, etc.

The dry contact can be set to operate if the contacts are shorted as follows:

Function Contact = Open Contact = Short

Presence Detector Connection No Action – normal operation (Default) Forced to STBY

Notes:

o When the A/C is forced to STBY mode, all R/C commands are ignored, and the operation LED

blinks with 1 seconds cycle time.

o Any change in the Presence Detector state during the first 6 sec after the system reset is

ignored.

12.4.8 Operating the Unit from the Mode Button

Forced operation allows to start, stop and operate in Cooling or Heating, in pre-set temperature

according to the following table:

Forced operation Mode Pre-set Temperature

Cooling 20

Heating 28

0

C

0

C

12.4.9 On Unit Controls and Indicators

12-6

Indications during OFF, Fan, Cool, Heat, Dry, and Auto modes are shown below. For operation

in other modes, check the relevant paragraphs.

SM OU12HP 2-E.2 GB

Page 61

CONTROL SYSTEM

CONTENTS

STANDBY

INDICATOR

OPERATE

INDICATOR

TIMER INDICATOR

COOLING

INDICATOR

HEATING

INDICATOR

Mode SWITCH

(COOL/HEAT/OFF)

Lights up when the Air Conditioner is connected to power and is ready for operation

1. Lights up during operation.

2. Blinks for 300 msec to announce that a R/C infrared signal has been received

and stored.

3. Blinks continuously during protections (according to the relevant spec section).

Lights up during Timer and Sleep operation.

Lights up when system is switched to Cool Mode by using the Mode Switch on the

unit.

Lights up when system is switched to Heat Mode by using the Mode Switch on the

unit.

Every short pressing , the next operation mode is selected, in this order : SB

Cool Mode Heat Mode SB …

In long pressing system enters diagnostic mode.

12.5 Run Mode

Run mode is the default operation mode of the system. This is the standard operation mode that

is active in field application (at customer site).

System can go from run mode to other operation modes through keyboard or serial ports.

12.5.1 Mode Setting

Mode defines the ODU operation mode. There are three possible operation modes:

1. STBY – standby mode

2. COOL - the unit operating at cooling cycle

3. HEAT - the unit operating at heat pump cycle

SB mode can be set also by dry-contact.

12.5.1.1 ODU Protections

There are 4 ODU protections:

x Compressor overheating

x Heat sink overheating

x AC over current

x DC Over curren – not in 6HP unit

12.5.2 Compressor Speed Control

12.5.2.1 Compressor Min On/Off time

Compressor minimum OFF time is 3 minutes except during Deicing protection.

Compressor minimum ON time is 3 minutes, minimum ON time is ignored during protections,

and when unit is turned to STBY.

12.5.2.2 Compressor Startup

When started, compressor speed reaches 40 RPS and will not go below that during the first 5

minutes of compressor operation except when compressor forced OFF.

12.5.2.3 Compressor start up fail

If the compressor does not succeed to complete the startup procedure, it will report a compressorlock fault code.

It than retries the startup procedure for 3 times on every 10 seconds and enter a 3 minutes wait

condition before starting the next compressor startup sequence.

SM OU12HP 2-E.2 GB

12-7

Page 62

CONTROL SYSTEM

CONTENTS

12.5.2.4 Compressor operation while OFAN Error

In case an OFAN error a cured for 10 continues seconds and the compressor is on, the compressor

will be set to OFF until OFAN error will recover.

12.5.2.5 Maximum allowed speed limitation

For cool mode:

MaxFreqH

MaxFreqAsOATC

OATLimitC

OAT

For Heat mode:

MaxFreqH

MaxFreqHMaxFreqC

MaxFreqAsOAT1H

MaxFreqAsOAT2H

2 Degree2 Degree

OATLimit1H

2 Degree

OATLimit2H

Note: If OAT is faulty, there will be no limits.

12.5.2.6 Speed Change Limitations

When rising or lowering speed within the allowed operating range, the acceleration or deceleration

will be 1 RPS/sec.

12.5.2.7 Compressor Speed calculation

During normal operation (excluding protections) the compressor target speed is set according to

the NLOAD number received from the indoor unit and CompFac. CompFac is an indoor-outdoor

matching parameter, once it is 0, the compressor will be forced off, if it is number between 0.01

to1, the compressor target frequency is set by the following table.

OAT

NLOAD Target Speed [Hz]

<10 0

10 MinFreqC in cool OR MinFreqH in heat mode

11– 126 NLOAD*CompFac

127 MaxFreqC in cool OR MaxFreqH in heat mode

12.5.2.8 Speed Step Limitations

The compressor speed have some step limitations which it will not go above them for few minuits

after startup.

12.5.2.9 Compressor shutdown Procedure

There are 2 procedures for compressor shutdown:

1. Immediate shutdown – compressor is stopped on the spot.

2. Gradual shutdown – compressor speed is reduced gradually to the minimum speed by

NormAccel Hz/sec and then stops.

12-8

SM OU12HP 2-E.2 GB

Page 63

CONTROL SYSTEM

CONTENTS

# Shutdown Reason

1 IDU NLOAD=0 (or IDU protections) Gradual Minimum On time is kept.

2 IDU Shutdown (idle) Immediate

3 Deicing Immediate

4 ODU Protections Gradual

5 Sensor faulty (CTT or OCT+OMT) Immediate

6 HPS protection Immediate

7 LPS protection Gradual (Only in 6HP units)

Shutdown

procedure

12.5.3 EEV Control

12.5.3.1 EEV General Rules

The EEV is controlled to keep the discharge superheat temperature within preset control

values.

12.5.3.2 EEV initialization procedure

After power up the EEV performs initialization procedure while it closed completly and reopened

to predefind position. During initialization, the compressor is forced to off.

12.5.3.3 Balance time

During the first minutes after SB the correction is not calculated. After that the correction value is

updated every EEVCVTConst seconds.

12.5.3.4 Operation Range

The EEV operation range is defined according to the operation mode as following

ODU Mode Normal operation Notes

SB 450

COOL 60 to 480

HEAT 60 to 480

12.5.3.5 EEV initial value determination (EEVOL)

The EEV initial value (open loop) is determined according to the operation mode, the actual

frequency and ODU model. The values are determined according to the “EEV

Table”.

12.5.3.6 EEV opening determination in normal run mode

The target EEV value is the sum of open loop value (OL) and a result of the accumulative

correction values (CV). The EEV corrections are calculated every EEVCVTConst seconds.

¦

EEVEEVEEV

May change

according to model

CVOL

Parameters

OL

12.5.4 Outdoor Fan Speed Control

12.5.4.1 Speed Definition

The outdoor fans can work in 16 speed states controlled by OMT sensor in cool mode and ICT

sensor in heat mode in ralation to outdoor conditions.

SM OU12HP 2-E.2 GB

12-9

Page 64

CONTROL SYSTEM

CONTENTS

12.5.4.2 General Rules

The fans will be off when the compressor is off unless HST>55 or faulty and than

OFAN_up will remain ON.

Min time for speed change between speed states is 60 seconds.

The fan speed is also related to protections.

Whenever OFAN fault occurs the compressor will be stopped.

12.5.4.3 Night mode

During night mode, the OFAN and the compressor will be limited to lower speeds (Cool model

only).

12.5.5 RV State Setting

During heat mode (except during Deicing) RV is ON.

During cool/SB mode RV is OFF.

RV status will be changed only if COMP is OFF for 3 minutes or more.

12.5.6 Base Heater Setting

The base heater will be working only when RV is “ON” according to the following graph:

Base

Heater

OFF

ON

0

2

OAT

When OAT is faulty the base heater will be “ON” continuously in HEAT mode.

12.5.7 Crank case heater Operation

The crank case heater operates only when compressor is off and according to CTT as

following:

OFF

ON

-5 0

CTT

12.5.8 Compressor internal heating coil Operation

Only in 6HP unit.

The crank case heater operates only when compressor is off and according to CTT and OAT.

12-10

SM OU12HP 2-E.2 GB

Page 65

CONTROL SYSTEM

CONTENTS

12.5.9 Thermodynamic Protections

12.5.9.1 Protection level definition