Elecro Engineering Spectrum Hybrid SH-55, Spectrum Hybrid SH-110, Spectrum Hybrid SHP-55, Spectrum Hybrid SHP-110 Installation & Operating Manual

Spectrum Hybrid

UV + Hydroxyl Radical Pool Sanitiser

Installation & Operating Manual

ENGLISH

www.elecro.co.uk

ENGLISH

1

www.elecro.co.uk

Important Notes

Congratulations on purchasing the Spectrum Hybrid UV + HO pool

sanitising system, the latest in UV technology, manufactured in England to

the highest standards.

To ensure your new product will give years of trouble free service please

carefully read the following instructions.

Incorrect installation will aect your warranty. Do not discard this

manual, please retain for future reference.

Important safety information

• Consult a qualied electrician

• Never look directly at an illuminated UV lamp

• Do not run this unit dry, do not cover this unit

• Always isolate the unit from mains electricity and turn o the water

supply before carrying out maintenance

• Always disconnect all pool appliances from the mains electricity supply

before servicing

• Power must be supplied through a Residual Current Device (RCD) with

a rated residual operating current not exceeding 30mA

• This unit must be earthed. Never use a higher rated fuse than specied

• The unit must not be submerged in water

• If the quartz sleeve is cracked, replace it immediately

• Young children should always be supervised near water

Specication

Model: SH-55 & SH-110 (Analogue); SHP-55 & SHP-110 (Digital)

Rating: 220~240V 50/60Hz; 110~120V 50/60Hz

MAX Pressure = 3 Bar

This unit is manufactured in conformance with:

Safety: BS EN 60335-1:2002. BS EN 60335-2-55:2003

EMC: EN 55015: 2000. EN 61000-3-2: 2000 EN 61000-3-3: 1995.

EN61547:1995

This unit is CE approved.

ENGLISH

www.elecro.co.uk

2

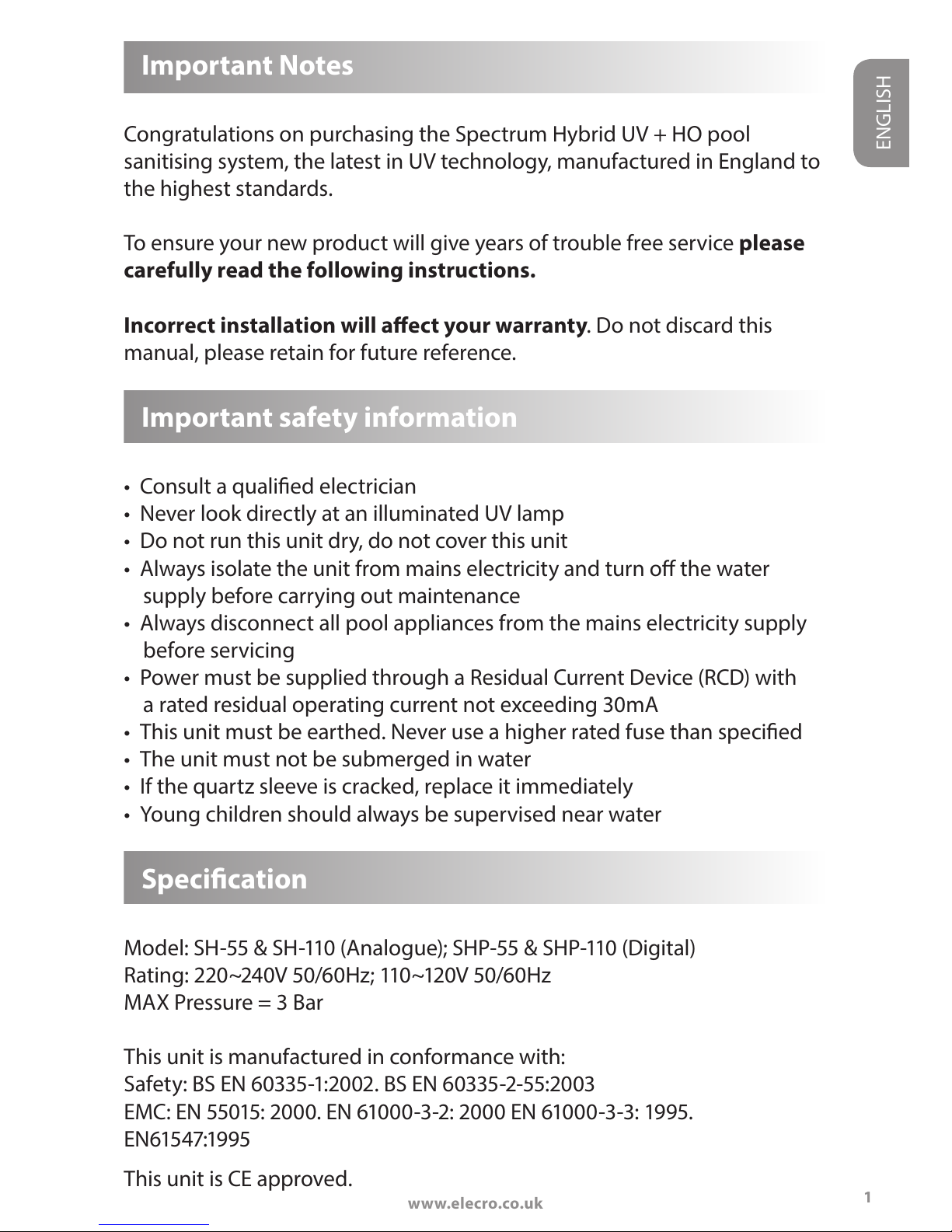

Product Overview

The Spectrum Hybrid is available in 55W single tube and 110W double

tube formats, supplied complete with ow switch and either an analogue

lamp life indicator and reset switch, or digital lamp life countdown with

intelligent dosing pump.

Fig 1.

FLOWTUBE COVER

CONTROL BALLAST

ASSEMBLY

BULB RETAINING

CLIP

BULB CAP

LOCKING NUT

‘O’ RING

UV BULB

QUARTZ GLASS

SLEEVE

REAR WALL

BRACKET

FRONT WALL

BRACKET

BRACKET FIXING

SCREWS

ELECTRONIC

CONTROLLER ASSEMBLY

MANIFOLD

ASSEMBLY

55W Single Tube Unit

Note: Digital Model Shown

2

www.elecro.co.uk

ENGLISH

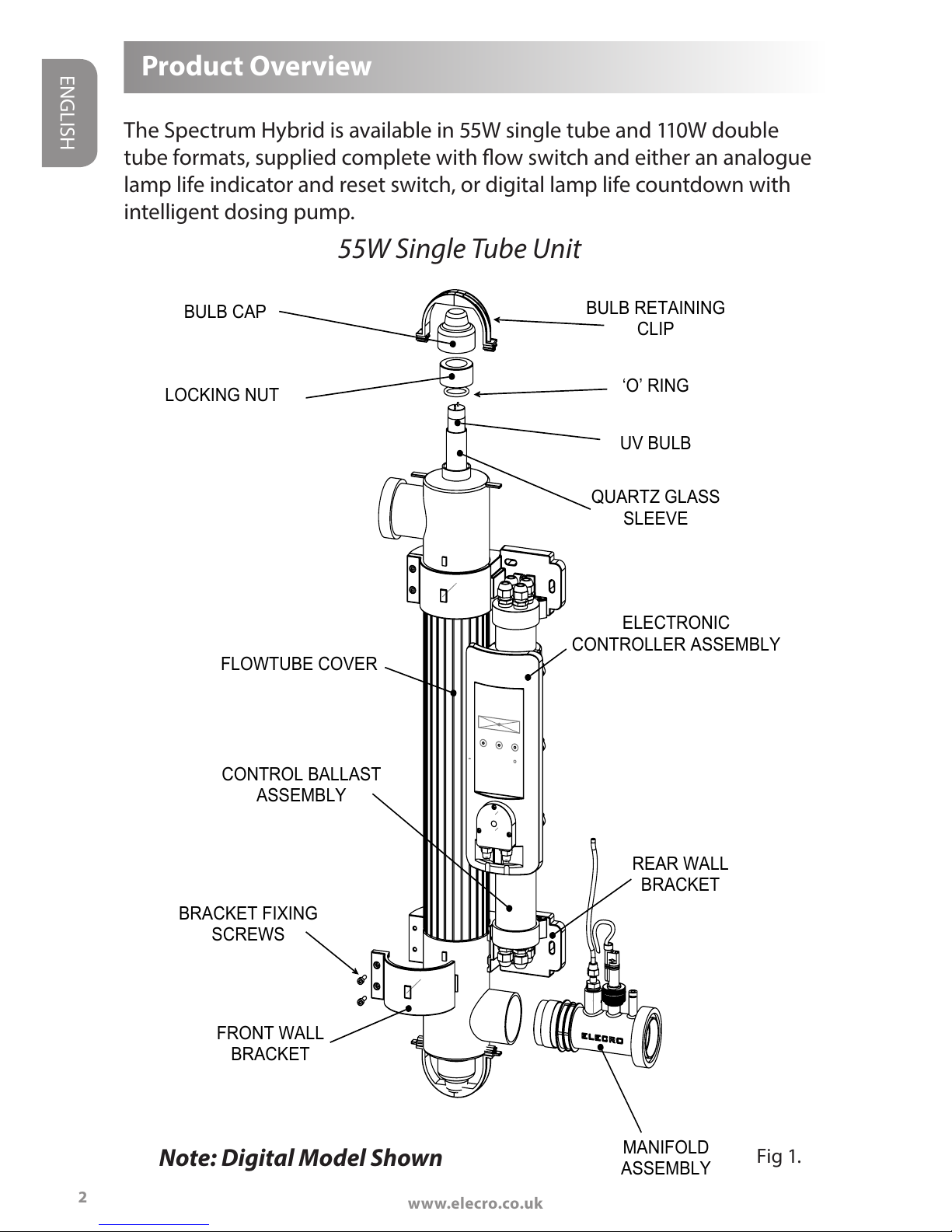

FLOWTUBE COVER

UV LAMP RETAINING

CLIP

LOCKING NUT

‘O’ RING

UV LAMP

QUARTZ GLASS

SLEEVE

BRACKET

ELECTRONIC

CONTROLLER ASSEMBLY

UV LAMP CAP

CONTROL BALLAST

ASSEMBLY

MANIFOLD

ASSEMBLY

Fig 2.

110W Double Tube Unit

3

Note: Digital Model Shown

www.elecro.co.uk

1

ENGLISH

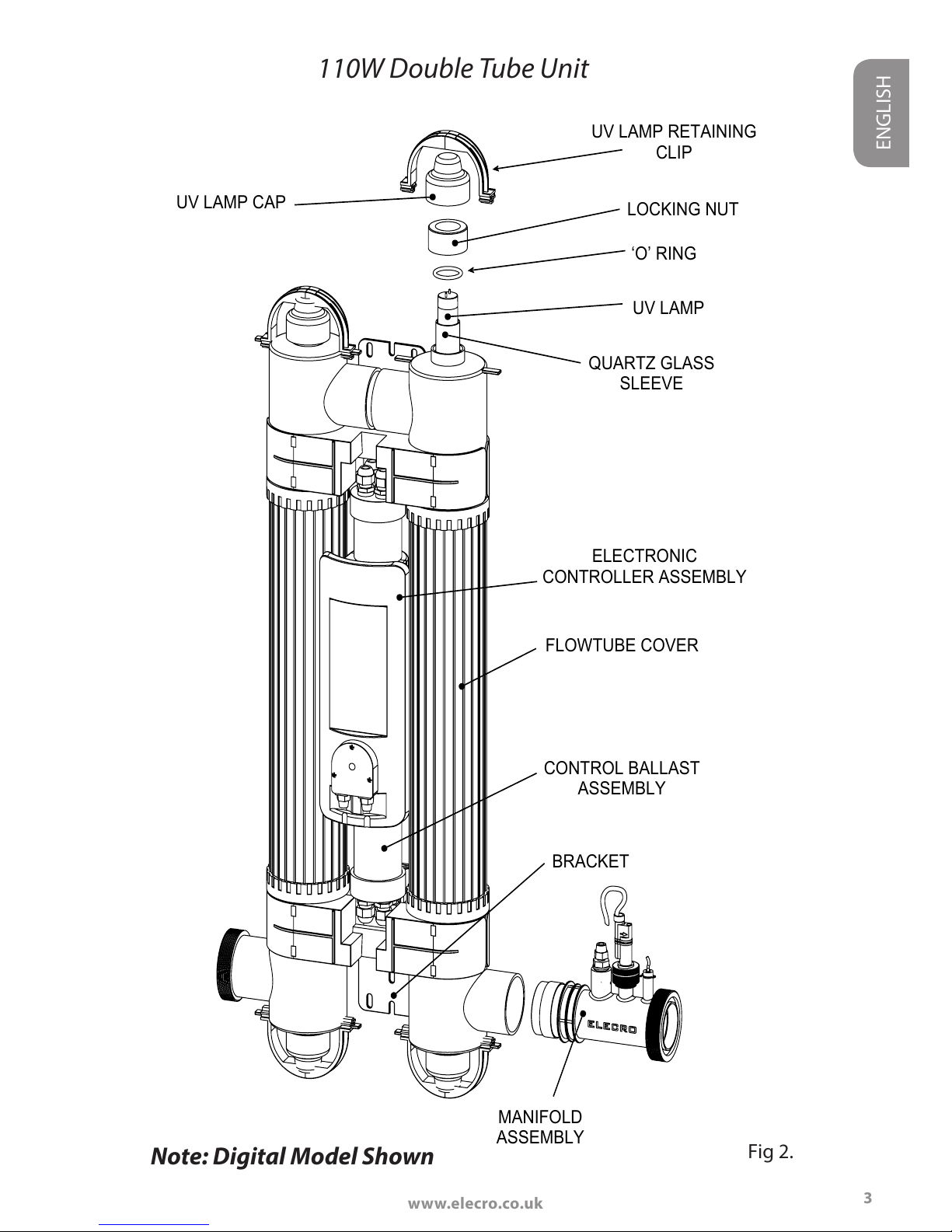

Positioning the Unit

CAUTION: To prevent this unit falling into water, do not install above

or alongside your pool.

The Spectrum Hybrid unit is weatherproof but not waterproof; it must be

installed in a dry weatherproof enclosure. The unit must be mounted on a

at vertical surface horizontally or vertically. It must not be submerged in

water or placed in a position where water may collect around the unit.

To prevent the unit inadvertently being dropped into the pool, the unit

must be installed at least 3.5 metres from the edge of the pool.

The unit must always be plumbed into the water system after the lter as

shown in g 3. to prevent dirt and debris being pumped into the unit.

www.elecro.co.uk

FILTER

PUMP

ELECRO HEATER

POOL

NON RETURN

VALVE

UV SYSTEM

Fig 3.

POOL

ELECRO

SPECTRUM HYBRID

4

ENGLISH

55W

5

www.elecro.co.uk

ENGLISH

www.elecro.co.uk

FILTER

PUMP

ELECRO HEATER

POOL

NON RETURN

VALVE

UV SYSTEM

SPECTRUM

HYBRID

110W

Fig 4.

Mounting the UV Unit

The unit may be mounted on a wall or other suitable vertical surface that

is structurally strong enough (for example: when full of water the unit is

too heavy to mount onto a conventional wooden fence panel). The unit is

supplied with a xing kit. The unit can be mounted vertically as shown in

the next pages in g 5. and 6. or horizontally as shown in g 7.

NOTE!

When mounting the UV it is essential to leave a clearance space of at least 1m

from one side of the unit to allow access to replace the lamp(s) and/or quartz

sleeve(s) when required. Both the lamps and the quartz sleeve can be replaced

from either end of the unit; if installing vertically the 1m clearance space must

be above or below the unit, if installing horizontally the 1m clearance space

must be to the left or right of the unit.

www.elecro.co.uk

1

ENGLISH

WASHER x 4

RAW PLUG x 4

SCREW x 4

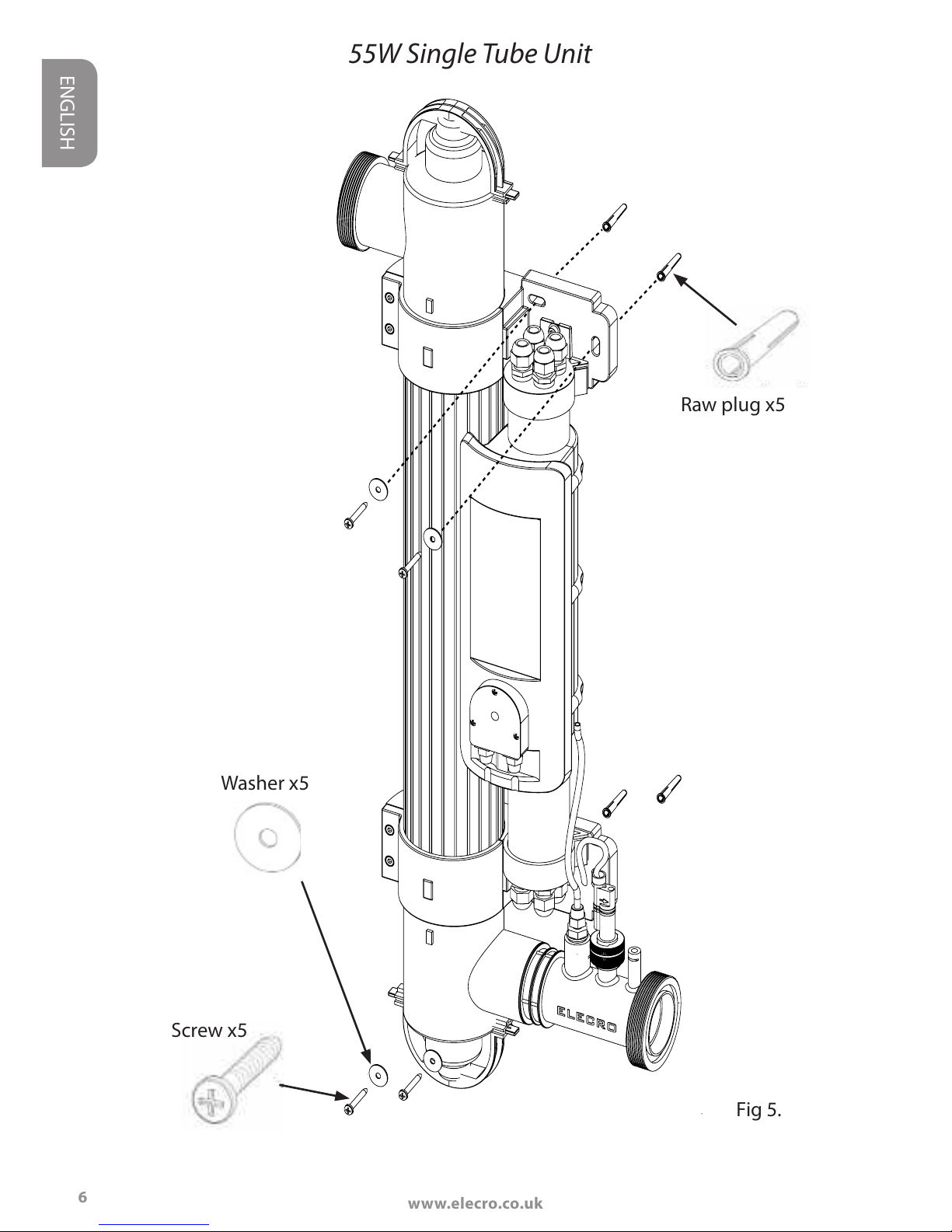

Washer x5

Screw x5

Raw plug x5

Fig 5.

6

55W Single Tube Unit

2

www.elecro.co.uk

ENGLISH

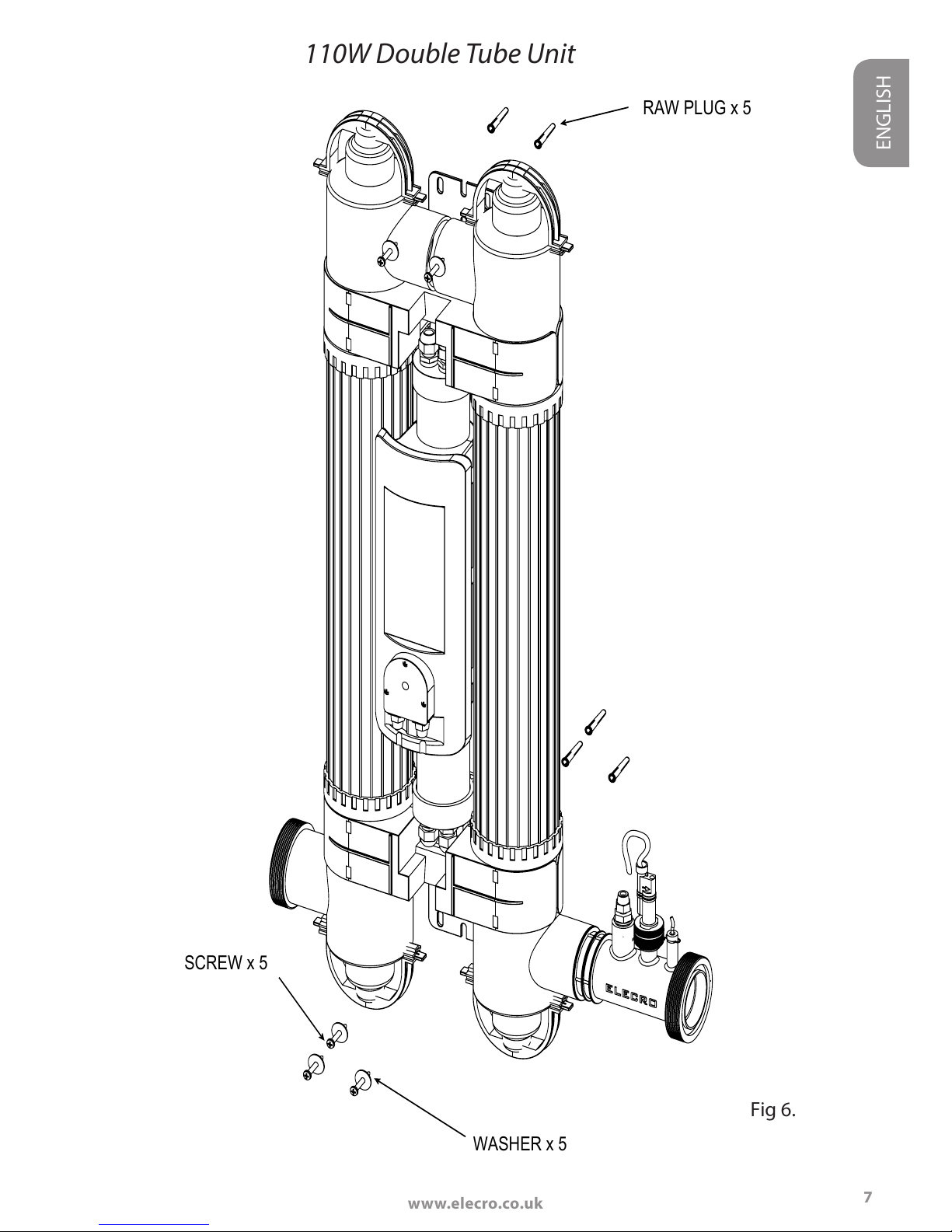

RAW PLUG x 5

WASHER x 5

SCREW x 5

Fig 6.

7

110W Double Tube Unit

www.elecro.co.uk

1

ENGLISH

www.elecro.co.uk

Fig 7.

ENGLISHENGLISH

Vertical

mounting

110W Double Tube Unit

Horizontal mounting

55W Single Tube Unit

Vertical

mounting

Horizontal mounting

8

Water must enter low

and exit high

Water must enter low

and exit high

Factory Default

Optional reverse ow

explained on page 10

Factory Default

Optional reverse ow

explained on page 10

Mounting Continued

2

www.elecro.co.uk

ENGLISH

Connection to the water supply

The unit is supplied with unions to allow connection to 2" or 63-mm rigid

pipe. Reducers are also supplied to allow connection to 50-mm or 1½" rigid

pipe - see g. 8.

For connection to 63mm or 2" diameter pipe

Insert 63-mm

diameter pipe up

to this stop

Insert 2" diameter

pipe up to this

stop

ADHESIVE

ABS

PVC ×

Insert 50-mm

diameter pipe up

to this stop

Insert 1½"

diameter pipe up

to this stop

Solvent weld your

pipe to the correct

stop

2

Solvent weld the

supplied reducer

into the union

1

9

NOTE!

ADHESIVE

ABS

PVC ×

NOTE!

Fig 8.

For connection to 50-mm or 1½" diameter pipe

www.elecro.co.uk

Flow Requirements

Minimum ow rate:

55W (single tube) and 110W (double tube) = 4m/hour

(4,000 litres per hour)

Maximum ow rate:

55W (single tube) = 12m/hour (12,000 litres per hour)

110W (double tube) = 24m/hour (24,000 litres per hour)

Your Spectrum Hybrid is factory set to accept input water ow entering on

the left and exiting on the right, this can be reversed by rotating the ow

switch 180 degrees (i.e ½ turn - see g. 8)

WARNING! The ow switch paddle can be damaged when reversing the ow

direction if it is lifted by more than 5mm from its housing and turned with

force. If the ow switch has been rotated it is important to ensure that it is

nally locked in the correct orientation perpendicular (at right angles) to the

ow of water.

Electrical connection

The unit must be installed in accordance with the country / regional

requirements and regulations. Always disconnect all pool appliances from

the mains electricity supply before servicing. In any event the work must

ENGLISH

10

Flow

Optional

reverse ow

Factory set

ow

Fig 8.

To reverse ow: Loosen retaining

nut (A) and rotate ow switch by

180 degrees as shown (B). Always

ensure the arrow marked on the

plastic ow switch body is in the

same direction as the water ow

B

A

2

www.elecro.co.uk

ENGLISH

11

be carried out by a qualied electrician, who will provide a certicate of

conformity upon completion of the work.

The power supply must be tted with a RCD with a rated residual

operating current not exceeding 30mA. This unit must be installed inside a

dry, weatherproof enclosure.

The unit is tted with 5 metres of power cable. To prevent the unit

inadvertently being dropped into the pool it must be securely positioned

at least 3.5 metres from the edge of the pool.

Lamp Life Indicator Model

(Analogue)

Under normal conditions the UV lamp(s) inside the unit have a usable life

of 9,000 hours. The unit is tted with a ‘Lamp Life Indicator’ LED in order to

remind you to change the lamp(s) after this set period of time.

At initial ‘Power On’ of the Spectrum Hybrid the LED indicator will light in

Red colour for one second to indicate that the time setting is 9,000 hours,

and immediately change colour to Green to indicate that the timer has

started.

When the timer reaches <500 hours the LED indicator will change colour

from Green to Amber to indicate that the UV lamp(s) is getting near to

its end of life; when the timer reaches zero the LED indicator will change

colour from Amber to Red, ashing slowly to signal that the UV lamp(s)

should be changed.

After changing the UV lamp(s) the timer is reset by pressing and holding

the reset button until the LED indicator goes ‘O’ and then comes back

‘On.’ When the reset button is released the LED indicator will come back

‘On’ (Red colour for one second followed by Green colour), this indicates

that the timer has restarted and is reset to count down the subsequent

9,000 hours.

www.elecro.co.uk

ENGLISH

12

Fig 9.

LAMP LIFE INDICATOR

RESET SWITCH

13

www.elecro.co.uk

ENGLISH

How to connect the suction tube to the dosing pump:

This is how the completed

assembly will look

STEP ONE

Components required:

Tubing

Foot Valve

Strainer

STEP TWO

Unscrew securing cap

anti-clockwise

Lamp Life Indicator + Intelligent

Dosing Pump (Digital)

www.elecro.co.uk

ENGLISH

A

B

1

2

3

STEP THREE

Thread tube through

the securing cap (1) and

component (2), then

push the pipe onto

component (3)

STEP FOUR

Once all components are

looped through the tubing

tighten securing cap

STEP FIVE

Lastly unscrew the retaining

gland and insert tube over

the connection point.

Tighten the retaining gland

Place the Foot Valve

Strainer into the

chemical container

Retaining

gland

Connection

point

Fig 10.

14

15

www.elecro.co.uk

ENGLISH

The factory default setting for the language is English.

To change to another language, press the / buttons until the de-

sired language appears, press OK to select and save.

- Language +

English OK ?

Fig 12.

Fig 11.

DIGITAL DISPLAY

BUTTONS

LED INDICATOR

www.elecro.co.uk

16

ENGLISH

To select a mode press the / buttons until the desired mode is

displayed then press the OK button to select that mode.

Operation:

When the unit is powered on the UV lamp is switched on, the UV lamp will

switch o under the following conditions ie:

• Dosing pump ‘On’ (and for 30 minutes after the dosing pump has

completed dosing)

• No or low water ow (the UV lamp(s) cannot be switched on unless

the unit is receiving sucient ow) See page 10 for ow requirements.

UV Lamp Life:

Adjust Dose

The digital controller has three modes ie:

• UV LAMP LIFE

• DOSAGE

• TIMER

Whenever the UV lamp is ‘On’ a timer

counts down from 9,000 hours and

the remaining UV lamp life is dis-

played.

From 9,000 hours to 500 hours the

LED in the control panel will light in

green. When 499 hours is reached

the LED colour will change to amber,

when 0 hours are reached the LED

light will change to red indicating

that the lamp(s) must be changed.

UV Life 460 Hrs

Dose 40m/d

LED Indicator

Fig 13.

Fig 14.

17

www.elecro.co.uk

ENGLISH

Set Dosage Requirements:

Please note: Dosage amounts are set in ml/day (millilitres per day)

Use the below reference table as a guide.

NOTE: The above table is based on dosing Hydrogen Peroxide (HO) with

a 32% concentration and a water temperature of 28C The digital control

ler will automatically sense the temperature of your water and adjust the

required dose accordingly

To calculate your pool volume see page 23-25 at the rear of this manual.

To set or adjust the dosage requirement:

Press the / buttons to scroll through the options until ‘ADJUST

DOSE’ mode is displayed and press the O.K. button to select.

When the UV lamp(s) are replaced

the lamp life timer must be reset

to 9,000 hours. In the UV lamp life

mode select ‘Reset UV Lamp’ by

pressing and releasing the O.K. but-

ton, then immediately press and

hold the O.K. button until the dis-

play shows ‘SAVED’ then release the

O.K. button, the display will then

show ‘UV Life 9,000 Hrs’ Please note

power failure does not aect this

lamp life countdown.

Reset UV Lamp

To 9000 Hours

Volume of

swimming pool

(m

Dosing amount

(ml/day)

35 200

50 320

60 420

80 620

90 700

100 800

130 1040

1

ENGLISH

www.elecro.co.uk

Adjust the dosage in 10ml steps using the / buttons, when the

required dosage is displayed press the O.K. button and the display will im-

mediately show ‘SAVED’ indicating that the new value has been stored in

the memory.

Set Timer:

After setting the required dosage it is necessary to set the start time which

is adjustable from 2 minutes to 23 hours 59 minutes in 1 minute steps

(please note it will always start at that time every 24 hours)

Press the O.K. Button to conrm the start time.

ENGLISH

Adjust Dose

Adjust Dose

40ml

Adjust Dose

SAVED

Start Dose in

1Hr 5Mins

Fig 15.

Fig 16.

Fig 17.

18

19

www.elecro.co.uk

ENGLISH

ENGLISH

EXAMPLE: Start time is set to 1 hour 5 minutes when the actual time is

10:10am therefore dosing will start at 11:15am on subsequent days.

PLEASE NOTE that the time selected for dosing must be at a time when

the main circulation pump is running.

In the event of a power failure (and at every power on) the 24 hour timer

will default to 2 minutes, when power is restored the start time will there-

fore almost certainly be incorrect and will need to be reset by the user. The

unit will not dose at the correct time until the timer is reset, although the

UV Lamp(s) will function as normal.

Intelligent Dosing Pump Routine Maintenance

We recommend that the dosing tube is changed every 12 months in order

to prevent any wear and tear and keep performance to an optimum. The

following steps will guide you how to replace the dosing tube:

STEP ONE

Unscrew the two screws securing the plastic cover and remove. Rotate the

grey connection caps to release the tubing.

STEP TWO

Remove the connection point on the

left hand side, and then carefully

manually rotate the cam clockwise to

allow removal of the dosing tube.

www.elecro.co.uk

ENGLISH

STEP THREE

Cut the two black securing ties

at either end of the pipe. This will

then release the tube, which can

be discarded.

STEP FOUR

Take the replacement tube and re-attach connection points. Loop secur-

ing ties in place in order to seal to the connection points. Once securely in

place cut the excess tie and dispose of.

STEP FIVE

Place dosing tube into position on

the left-hand side. Carefully rotate

the cam clockwise, whilst feeding

the pipe back into place.

STEP SIX

Replace the suction and output

tubes into connection caps, and

rotate to secure tubing back into

place. Replace clear cover and

screw into position.

20

21

www.elecro.co.uk

ENGLISH

Frost Protection

It is essential that the unit is protected from frost during the winter

months, or disconnected from the water and electricity supply and stored

inside a dry weather proof enclosure.

Lamp Replacement & Quartz Glass

Cleaning (all models)

Isolate from the electrical and water supplies before carrying out

any maintenance.

Lamp Holder restraint: A plastic Lamp holder restraint is tted at either

end of each lamp chamber to prevent the lamp holders being accidentally

removed while the unit is connected to the mains.

Each restraint is held in place with a self tapping screw. To carry out any

routine maintenance these restraints must be removed, it is essential to

re-attach them once the maintenance work has been completed. In time

it may be necessary to replace the existing no. 6 size screw with a slightly

larger size 8 screw.

To remove the lamp, carefully remove the blue lamp holder shroud, then

pull the white plastic electrical end caps from the lamp end. Gently slide

the lamp out ensuing that no pressure is applied to the glass quartz sleeve.

Next, unscrew the two blue compression ttings located at either end of

the main body and slide o the ’O’ rings. Then slide out the quartz glass

sleeve. Clean the sleeve and polish with a soft cloth or paper towel.

If you live in a hard water area there maybe some limescale on the quartz

sleeve. This can be easily removed by soaking the sleeve in a proprietary

kettle descaling solution (follow the manufacturer’s instructions). Failure to

remove the limescale will limit the eectiveness of the UV lamp(s).

Assembly process: Slide the clean, dry quartz glass sleeve into the unit.

Ensure that you locate the ’O’ rings carefully on the ends of the quartz.

Failure to do so will result in leaks when the water is turned on. If you are

carrying out the annual lamp change, use new ’O’ rings. When you re-

assemble the unit, ensure that the female threads on the compression

ttings and the male threads on the main body are clean.

www.elecro.co.uk

22

ENGLISH

Wipe a little silicone grease or Vaseline (not silicone sealant) onto these

threads. As these threads are only serviced periodically, this lubrication will

help to prevent them binding together. Then ret and rmly hand tighten

the compression ttings. Ret or replace the UV lamp(s) with a new one.

Relocate the lamp holders and blue lamp holder shrouds ensuring that

you match the correctly numbered lamp holder.

Note: Pinch the blue lamp holder shroud as you reassemble the unit to

release any trapped air. Failure to release the trapped air may cause the

lamp holder to disconnect from the lamp end. Reconnect and turn on the

water supply to check for leaks before reconnecting the electric supply.

Important: The plastic body and blue compression ttings have been

manufactured from polymers that have been specically stabilised to

protect them from the eects of the UVC emitted from the UV lamps.

Despite this UV protection they will be eroded by a combination of the

UVC and water ow. As a matter of course they should be inspected

whenever a lamp change is carried out, to ensure they are not showing

excessive wear and tear. Replacement parts are available.

23

www.elecro.co.uk

ENGLISH

RoHS Compliance Statement

Elecro Engineering Limited certify that our UV Pool sanitiser range

complies in accordance with RoHS Directive 2011/65/EU on the restriction

of hazardous substances.

Waste of Electrical / Electronic Equipment

This product complies with EU directive 2012/19/EU

Do Not dispose of this product as unsorted municipal waste.

This symbol on the product or on its packaging indicates that this product

should not be treated as household waste. Instead it should be handed

over to the applicable collection point for the recycling of electrical and

electronic equipment.

By ensuring this product is disposed of correctly you will

help prevent potential negative consequences for the

environment and human health, which could otherwise be

caused by inappropriate waste handling of this product.

The recycling of materials will help to conserve natural

resources.

For more information please contact your local Civic oce,

your household waste disposal service or the retailer

where you purchased the product.

Guarantee

Your Spectrum Hybrid pool sanitiser is guaranteed for 3 years from the

date of purchase against faulty workmanship and materials.

The manufacturer will replace or repair, at it’s discretion, any faulty units or

components returned to the company for inspection.

Proof of purchase may be required. The manufacturer will not be liable in

cases of incorrect installation of the product, inappropriate use, or neglect.

This guarantee does not include serviceable parts, ie: lamps, quartz

sleeves, dosing tube and o-rings, etc.

Calculating Pool Volumes

The following pages will show you how to calculate the volume of your pool.

NB For pools with dierent depths:

D1 + D2

= Average Depth

2

If your pool has a sloping bottom, then take the deepest measurement (D2) and the shallowest

(D1). If there are dierent levels, then you need to do several calculations of area for each depth

and add them up at the end.

Rectangle & Square Pools

Volume = Length (L) x Width (W) x

Depth (D)

Average Depth

Circular

Volume = π (3.142) x Radius x

Depth (D)

Average Depth

Radius = Diameter divided by 2

Radius

24

ENGLISH

www.elecro.co.uk

25

Ellipses

Volume = π (3.142) x A x B x

Depth (D)

Average Depth

Irregular Shapes

For irregular shapes, calculating the area is less accurate. You will need to

draw up the pool accurately to scale on graph paper using a square on the

paper to represent a metre (or foot) square of pool. When you have nished,

count the squares.

For partial squares, count anything over half as one and ignore any under

a half. When you have the area (A) multiply by depth (D) for the Volume in

cubic metres. If you have several depths, break up your area calculation for

each depth.

A

B

ENGLISH

www.elecro.co.uk

Useful Conversions

Cubic Metres to Litres = Multiply by 1000

Cubic Feet to Cubic Metres = Multiply by 0.0283168

UK Gallons to Litres = Multiply by 4.54609

Litres to Cubic Metres = Multiply by 0.001

Cubic Metres to UK Gallons = Multiply by 219.969

ENGLISH

26

ENGLISH

www.elecro.co.uk

11 Gunnels Wood Park | Stevenage | Hertfordshire | SG1 2BH | United Kingdom

t: +44 (0) 1438 749 474 | f: +44 (0) 1438 361 329 | e: sales@elecro.co.uk

www.elecro.co.uk

© Copyright 2016 Z-INS-SH

Loading...

Loading...