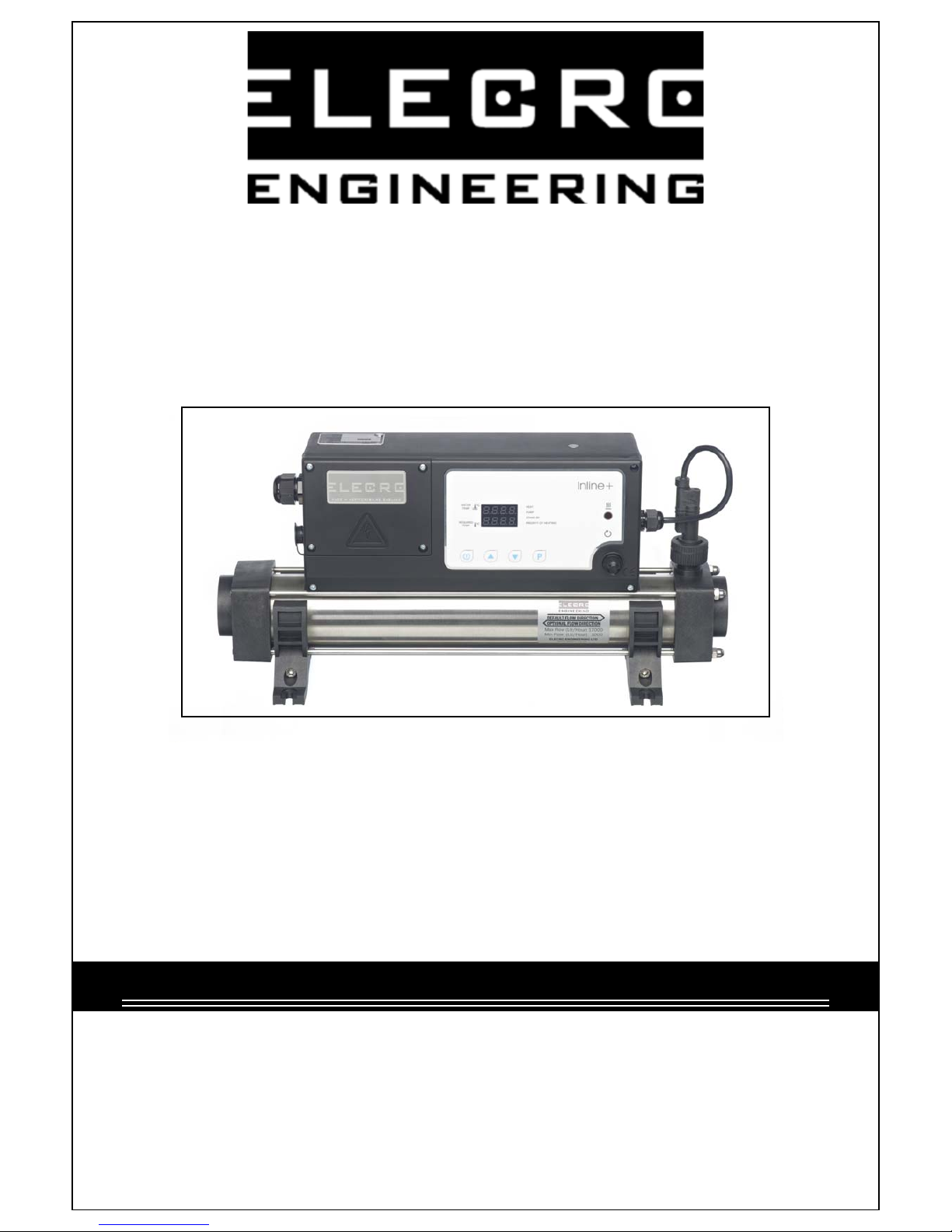

Elecro Engineering In-Line + Swimming Pool Heater, In-Line+ Installation Instructions & Operating Manual

PLEASE READ CAREFULLY BEFORE INSTALLING

Do Not Discard, Keep For Future Reference

Incorrect Installation Will Affect Your Warranty

In-Line + Swimming

Pool Heater

Installation Instructions

& Operating Manual

POSITIONING

Your heater must be screw fixed to a firm base or wall. The heater MUST be horizontal and

upright i.e. with the control enclosure located above the flow tube (see diagram below). Under no

circumstances should the heater be operated in any other orientation.

The heater should be installed at a low point in the filtration system. It should be positioned after

(i.e. downstream) of the filter but before (i.e. upstream) of any dosing or other water treatment

plant.

NOTE If the

flow direction

is reversed

(explained

later in this

booklet) the

heater MUST

remain sited

after the filter.

Only clean filtered water

should ente r the heater.

It is essential that the pipe work connecting to and from the heater has a minimum bore (internal

diameter) of 1¼’’ (32-mm).

To assist correct air purging and to ensure the heater remains completely full of water during

operation, the return pipe which carries the water back to the pool must incorporate a safety loop

or kick up in the pipe, installed as close as possible to the heater (see diagram on following

page).

Note: When coupling to flexible pipe a safety loop can simply be created by routing the pipe up

and over an obstacle. Remember to use pipe clips to securely fasten all hose connections.

PIPE WORK

WEATHER PROTECTION

The heater should be installed within a dry weatherproof enclosure.

CAUTION

If the heater is not used during winter months it must be drained to prevent frost damage.

Upon completion of the installation, run the water-circulating pump to purge the system & heater

of air (i.e. remove any trapped air in the system & heater).

The heater must be installed in accordance with the country / regional requirements &

regulations. In any event the work must be carried out by a qualified electrician, who will

provide a certificate of conformity upon completion of the work.

The power supply must be fitted with a RCD. If required your electrician may replace the

supplied cable entry gland with a larger one to secure the cable powering the heater, this will not

affect your warranty if carried out by a qualified electrician.

Cable section: should be calculated at 5-amp / mm² for distances up to 20 metres (these sections

are indicative and should be checked and adapted if necessary for cable lengths over 20 metres).

POWER REQUIREMENTS

Power Output Volt (V) Amp

2-kW 230 9

3-kW 230 13

4.5-kW 230 20

6-kW 230 27

9-kW 230 40

12-kW 230 53

15-kW 230 66

18-kW 230 79

ELECTRICAL CONNECTION

3 Phase

Power

Output

400V

St ar /

230V

Delta

Amp

6-kW 400V / 230V 9 / 15

9-kW 400V / 230V 13 / 23

12-kW 400V / 230V 18 / 31

15-kW 400V / 230V 22 / 38

18-kW 400V / 230V 26 / 46

24-kW 400V 35

Loading...

Loading...