Elecro Engineering Cygnet Aquatic Heater 1-kW, Cygnet Aquatic Heater 3-kW, Cygnet Aquatic Heater 4-kW, Cygnet Aquatic Heater 2-kW Installation & Operating Manual

Page 1

Cygnet Aquatic Heater

Installation & Operating Manual

Page 2

ENGLISH

Contents

Page

ENGLISH ........................................................................................................ 1 - 9

ESPAOL ....................................................................................................... 10 - 19

FRANÇAIS ..................................................................................................... 20 - 29

DEUTSCH ...................................................................................................... 30 - 39

www.elecro.co.uk

Page 3

Important Notes!

Thank you for purchasing the CYGNET Aquatic Heater manufactured in

England to the highest standards.

To ensure your new heater will give years of trouble free service please

carefully read the following instructions.

Incorrect installation will aect your warranty.

Do not discard this manual, please retain for future reference.

The appliance is not to be used by children. The appliance is not to be used

by persons with reduced physical, sensory or mental capabilities, or lack

of experience and knowledge, unless they have been given supervision or

instruction.

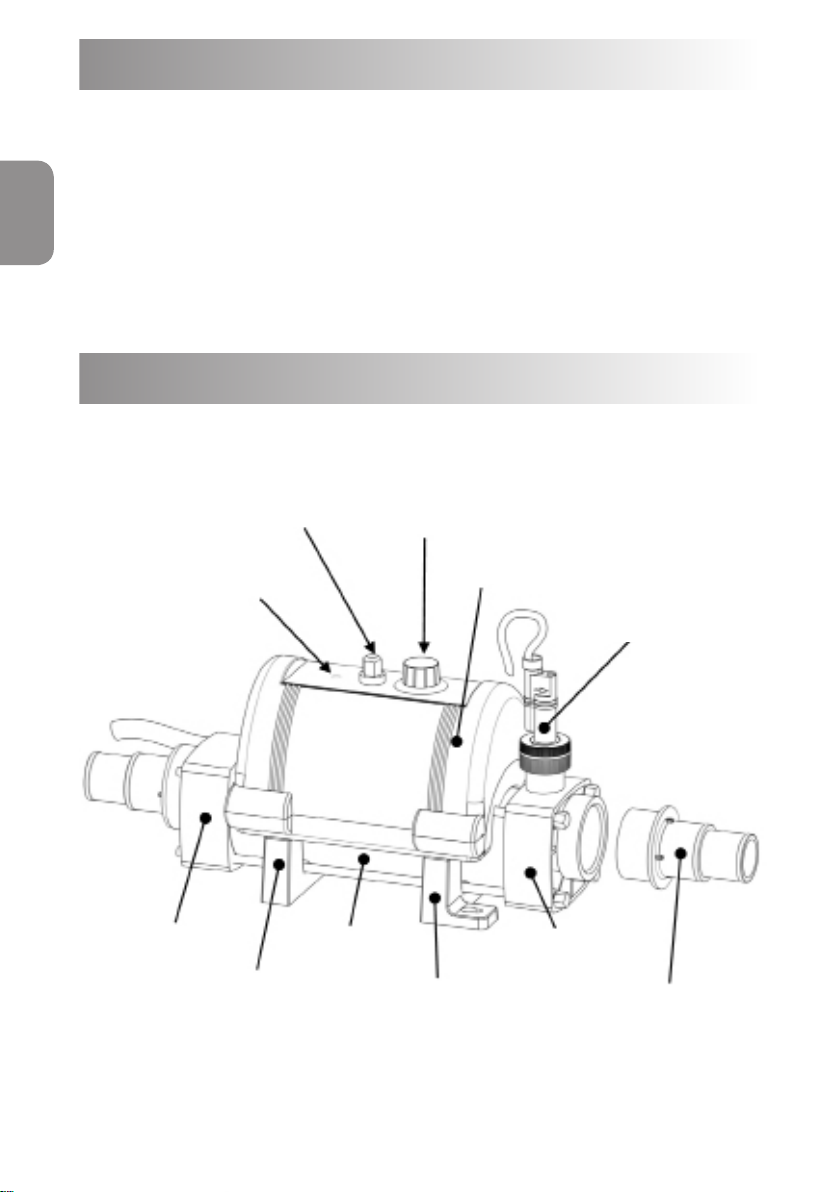

Product Overview

Thermal safety

Cut-out

re-set switch

Heater ‘ON’

Indicator (red)

Temperature

set

point dial

Top cover

Flow switch

ENGLISH

LH End tting

Foot /Carrier – A

Fig 1.

Flow tube

Foot / Carrier—B

www.elecro.co.uk

RH End Fitting

Hosetail Stepped

Connector

1¼” (32mm) or

1½” (38mm)

1

Page 4

ENGLISH

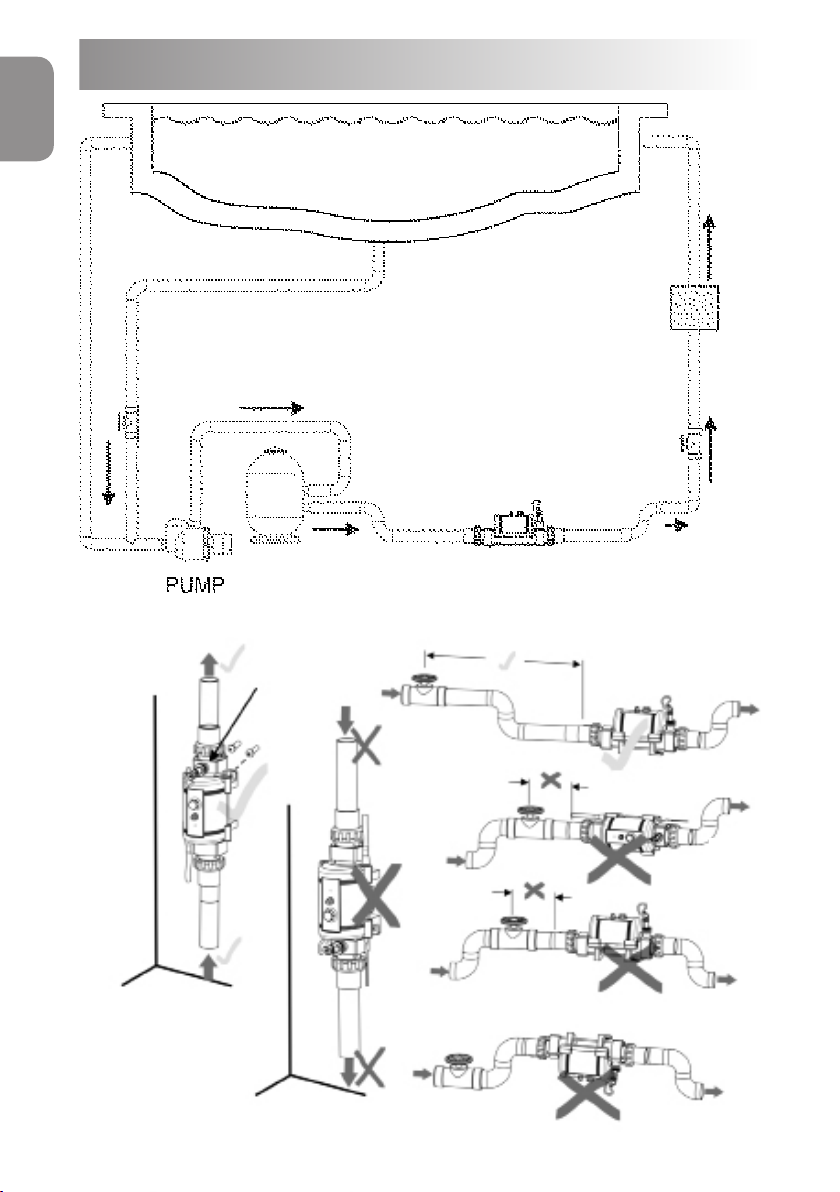

Positioning

POND

WATER

TREATMENT

VALVE

NON RETURN

YES

For vertical wall

mounting water

must always enter

at the bottom

2

PUMP

FILTER

Flow switch

at top

CYGNET AQUATIC HEATER

Fig 2.

NO

NO

NO

NO

Fig 3.

www.elecro.co.uk

Page 5

Positioning (continued)

Your heater should be horizontally or vertically sited allowing sucient

space for pipe connections and wiring, it should be screw xed securely to

a rm base or wall.

The heater should be installed at a low point in the ltration system.

It must be positioned downstream of (after) the lter and upstream of

(before) any dosing or other water treatment plant. (see Fig.2)

Pipe Work

It is essential that the pipe work connecting to and from the heater

has a minimum bore (internal diameter) of 1¼” (32mm).

To assist correct air purging and to ensure the heater remains completely

full of water during operation, the return pipe which carries the water back

to the pond must incorporate a safety loop or ‘kick-up’ in the pipe as close

as possible to the heater (see g 3).

NOTE: When coupling to a exible pipe a safety loop can simply be

created by routing the pipe up and over an obstacle. Remember to

use pipe clips to securely fasten all hose connections.

ENGLISH

Weather Protection

The heater must be installed within a dry weather proof enclosure.

CAUTION! If the heater is not used during winter months it must be drained to

prevent frost damage.

Electrical Connection

The heater has been supplied pre-wired with a power lead. Sizes 1-kW

to 3-kW also have a plug; 4-kW models must be installed by a qualied

electrician.

www.elecro.co.uk

3

Page 6

ENGLISH

requirements and regulations. In any event the work must be carried out

by a qualied electrician, who will provide a certicate of conformity upon

completion of the work.

It is essential that the power supply to the heater is protected by a

30mA RCD (Residual Current Device). If in doubt consult a qualied

Electrician.

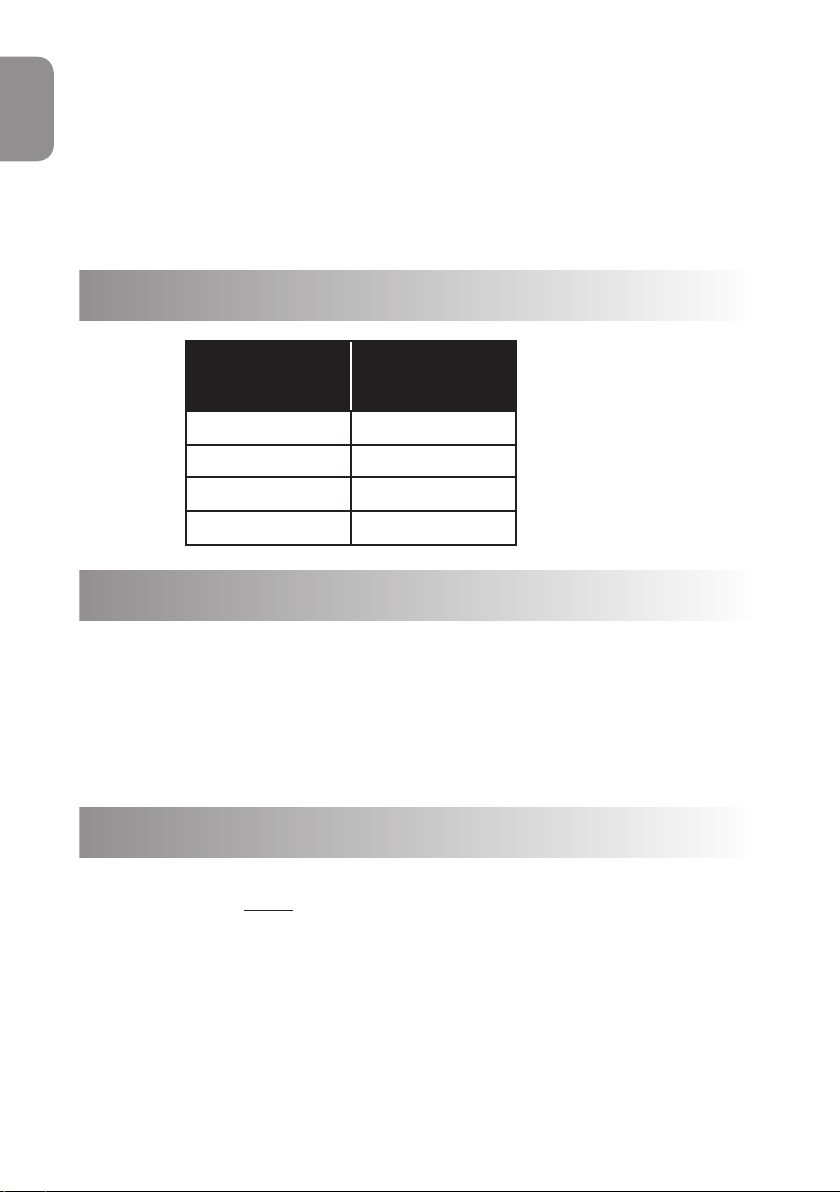

Power Requirements

The heater must be installed in accordance with the country / regional

230V 1 PhasePower Output

1-kW

Load

5-Amp

2-kW 9-Amp

3-kW

4-kW*

13-Amp

18-Amp

*4-kW MUST BE HARDWIRED

BY A QUALIFIED ELECTRICIAN

Flow Requirements

The ow rate of water into the heater must not exceed 17,000 litres per

hour (17m/h / 3,740 UK gallons/hour) A higher ow rate will require the

installation of a bypass to prevent damage to the heater elements. The

heater will not operate with a ow rate below 1,000 litres / hour (1m/h or

220 UK gallons/hour)

Water Quality

The water quality must be within the following limits:

PH 6.8 - 8.0 TA (Total alkalinity) 80—140ppm (parts per million)

TDS (Total Dissolved Solids) / Calcium hardness 200 - 1,000ppm

The Cygnet Aquatic heaters are suitable for use with salt water ponds with

a salt concentration up to 8000ppm (8g/litre).

Water chemistry is complicated if in doubt seek expert advise.

4

www.elecro.co.uk

Page 7

Operating Instructions

Upon completion of the installation, run the water-circulating pump to

purge the system and heater of air (i.e. remove any trapped air in the

system and heater). TIP: You can encourage air out of the heater ow tube

by gently elevating the exit port of the heater when the pump is running.

The heater will only switch ‘On’ (red light indicator illuminated) when the

following criteria are met ie:

· Water circulating pump is ‘On’ delivering in excess of 1,000 litres /

hour (1m/h or 220 UK gallons/hour)

· Required temperature is set to a higher value than the water

temperature.

Useful advice: To reduce running costs and speed up the heating process,

insulate the pond wherever possible.

Quick Function Test

Observe the main electricity meter when the heater is on (ie: red light ‘On’)

and then observe it again when the red light is o. The test should show

that the meter is recording more electricity being used by the heater when

the red light is ‘On’.

ENGLISH

It is impossible for an electric heater to waste energy, if it is

drawing power then that power will be turned into heat that will be

transferred to the water.

Accurate Function Test

If a more accurate test is required to conrm that your heater is delivering

the specied heat output, two electricity meter readings will need to be

taken from the properties main electricity meter, with an exact one hour

interval (ie: take one meter reading and then a second reading exactly one

hour later) then by subtracting the rst reading from the second

reading the number of units (kilowatts / kW) consumed can be calculated.

www.elecro.co.uk

5

Page 8

ENGLISH

Note that your heater is also rated in kW hours. The pond pump and heater

will need to be running continuously during the test (ie: with the heater

red light ’On’) To avoid inaccurate results when performing this test, it is

important to refrain from using other high current consuming appliances

in the property (such as tumble dryer, showers, cookers etc).

A large aquatic pump of 1 horsepower will draw less than 1-kW in a one

hour period. The conclusion of the test should prove that for example

a 3-kW heater and a ½ horsepower pump will draw between 3.3-kW ~

3.5-kW in one hour. It is impossible for an electric heater to waste energy,

if it is drawing power then that power will be turned into heat that will be

transferred to the water.

Trouble Shooting

HEATER WILL NOT SWITCH ‘ON’

In most cases this will be the result of one of the following points not

being met.

Possible cause 1: The required temperature has been achieved.

To conrm: increase the set point value by turning the temperature set

point dial to a value greater than the current water temperature.

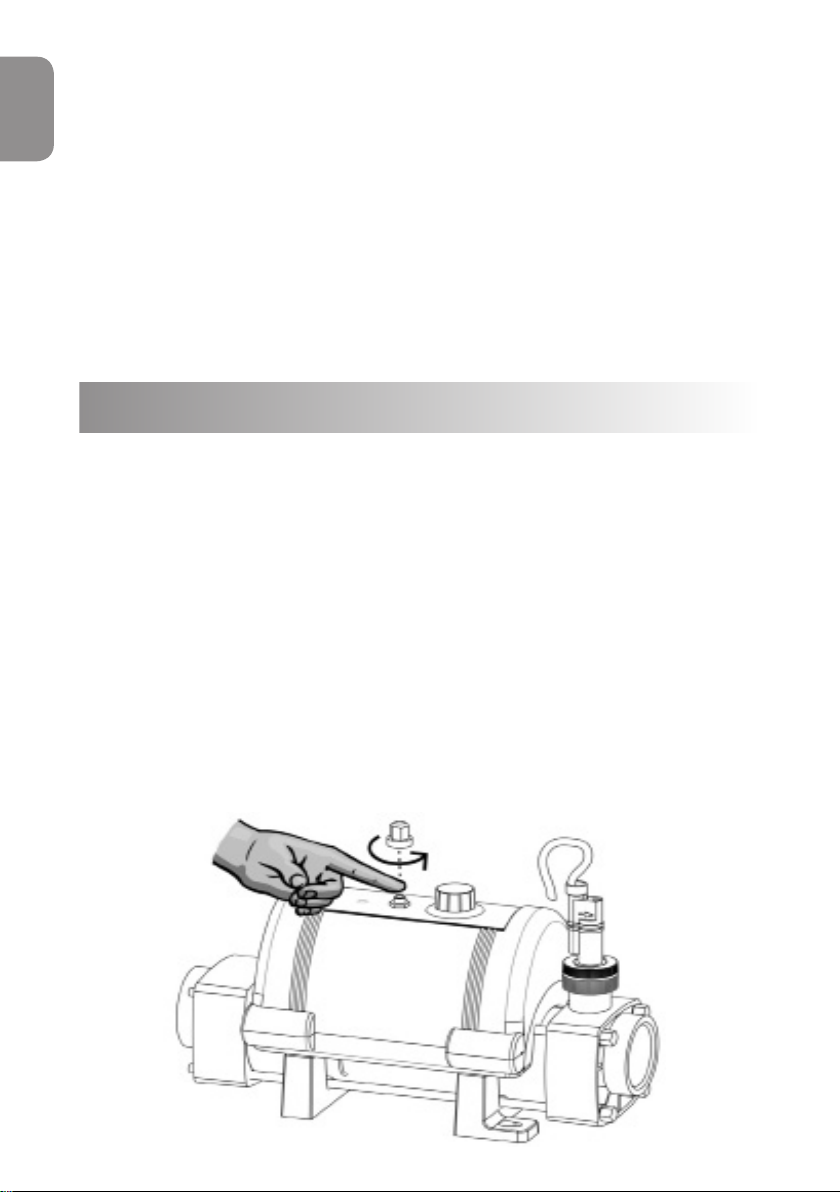

Possible cause 2: The ‘Thermal safety cut-out’ has tripped.

Remedy: Remove button cover and press red button to re-set (see g 4)

If a positive click is felt, the cause of the tripping must be investigated and

could be caused by a debris build-up or air pocket trapped inside the ow

tube of the heater.

6

www.elecro.co.uk

Fig 4.

Page 9

Possible cause 3: Insucient ow.

If using a cartridge lter: Conrm this by running the system with the

cartridge removed from your pump and lter unit, this will supply the

heater with the maximum ow rate your unit is capable of. If the heater

then switches ’On’ (ie: red light ’On’) a blocked cartridge can be conrmed

to be the cause. The cartridge should be cleaned or replaced.

If using a sand lter: Check the pressure indicator on your sand lter and

back wash if necessary.

Note: In some cases the ‘Thermal safety cut-out’ tripping and a low

ow rate can be linked ie: when a lter becomes choked air can be

drawn into the ltration system and become trapped inside the

heater, so causing the thermal cut-out to trip.

General Trouble Shooting

THE FLOW TUBE DOES NOT FEEL WARM

Due to the high eciency of your electric heater no warmth should be

detectable from the ow tube of the heater.

The most likely causes of the ow tube feeling warm are:-

ENGLISH

Possible cause 1: The heater has been positioned in direct sunlight.

Possible cause 2: An air pocket is trapped inside the heater particularly if the

ow tube feels warmer at the highest point (as air rises).

THE WATER ENTERING MY POND DOES NOT FEEL MUCH WARMER

The temperature gain of the water after it has passed through the heater

will be directly proportional to the volume of water being pumped in

relationship to the power output of the heater.

For example: A 6-kW heater, when connected to a 4,000 litre / hour

(4m/h) pump, will produce a lift in temperature of approximately 1.2°C

(almost undetectable to the human hand) however, as the water being

heated is re-circulated from a single body of water, the time required to

heat it remains unaected by the volume of ow. A popular misconception

is that slowing down the ow rate will speed up the heating process.

www.elecro.co.uk

7

Page 10

ENGLISH

RoHS Compliance Statement

Elecro Engineering Limited certify that our Electric Swimming Pool Heater

Range/Heat Exchanger Range complies in accordance with RoHS Directive

2011/65/EU on the restriction of hazardous substances.

Waste of Electrical / Electronic Equipment

This product complies with EU directive 2012/19/EU

Do Not dispose of this product as unsorted municipal waste.

This symbol on the product or on its packaging indicates

that this product should not be treated as household

waste. Instead it should be handed over to the applicable

collection point for the recycling of electrical and

electronic equipment.

By ensuring this product is disposed of correctly you

will help prevent potential negative consequences for

the environment and human health, which could

otherwise be caused by inappropriate waste handling

of this product. The recycling of materials will help to

conserve natural resources. For more information please

contact your local Civic oce, your household waste

disposal service or the retailer where you purchased the

product.

Guarantee

Your heater is guaranteed for 3 years from the date of purchase against

faulty workmanship and materials.

The manufacturer will replace or repair, at it’s discretion, any faulty units

or components returned to the company for inspection. Proof of purchase

may be required.

The manufacturer will not be liable in cases of incorrect installation of the

heater, inappropriate use or neglect of the heater.

8

www.elecro.co.uk

Page 11

ENGLISH

www.elecro.co.uk

9

Page 12

Notas importantes

Gracias por adquirir el calentador para estanques CYGNET, fabricado en

ESPAŇOL

Inglaterra según los niveles de calidad más altos.

Para que su nuevo calentador funcione sin problemas durante años, lea

atentamente las siguientes instrucciones.

Una instalación incorrecta afectará a la garantía de su producto.

Conserve este manual para futura referencia.

Visión general del producto

Interruptor de

reinicio para

seguridad térmica

Indicador (rojo) de

calentador en

marcha

Conexión extremo

izquierdo

Pie / Soporte - A

Fig 1.

Dial de

ajuste de

temperatura

Tubería de paso

Pie / Soporte - B

Cubierta superior

Controlador de

caudal

Conexión

extremo derecho

Conexión

escalonada para

mangueras

1¼’’ (32mm) ó

1½” (38mm)

10

www.elecro.co.uk

Page 13

Ubicación

ESTANQUE

ESPAŇOL

DEL AGUA

TRATAMIENTO

VÁLVULA

ANTIRETORNO

BOMBA

Sĺ

Si se ja

verticalmente a

la pared, el agua

siempre debe

entrar por la parte

inferior

FILTRO

Controlador

de caudal

en la parte

superior

CALENTADOR CYGNET

NO

www.elecro.co.uk

Fig 2.

NO

NO

NO

Fig 3.

11

Page 14

Ubicación (continuación)

El calentador debería colocarse en posición horizontal o vertical, dejando

ESPAŇOL

suciente espacio para las conexiones de las tuberías y el cableado.

Además, debería atornillarse bien a una base sólida o a una pared.

El calentador debería instalarse en un punto bajo del sistema de ltrado y

colocarse (en el sentido del uir del agua) en una posición posterior al ltro

y anterior a cualquier sistema de dosicación u otro sistema de tratamiento

del agua (véase Fig.2)

Tuberías

Es fundamental que el diámetro interno de las tuberías que transportan el

agua hacia y desde el calentador sea de 1¼” (32mm) como mínimo.

Para contribuir a que la purga del aire se realice correctamente y garantizar

que el calentador esté constantemente lleno de agua mientras esté en

marcha, la tubería de retorno que lleva el agua de vuelta al estanque debe

disponer de una curva de seguridad o un eyector lo más cerca posible del

calentador (véase Fig. 3).

NOTA: Si el calentador se conecta a una tubería exible, la curva de

seguridad puede crearse simplemente haciendo que la tubería pase

por encima de un obstáculo. Acuérdese de utilizar abrazaderas para

jar bien todas las conexiones de las tuberías.

Protección contra la intemperie

El calentador debe instalarse dentro de un espacio cerrado, seco y

resistente a los elementos.

ATENCIÓN: Si el calentador no se utiliza durante los meses de invierno, el

agua del interior del mismo debe drenarse para evitar daños causados por las

heladas.

12

www.elecro.co.uk

Page 15

Conexión eléctrica

Por su seguridad, el calentador se distribuye con el cableado preinstalado

y con un cable de alimentación eléctrica con enchufe. Los calentadores

de 1kW hasta 3 kW tienen enchufes y pueden ser conectados fácilmente.

Los calentadores de 4 KW deben de ser instalado por un electricista

cualicado.

El calentador debe instalarse de conformidad con los requisitos y

reglamentos nacionales y regionales. En todo caso, las operaciones

de conexión eléctrica las llevará a cabo un electricista debidamente

cualicado, quien deberá presentarle un certicado de conformidad al

completar las tareas.

El suministro eléctrico que abastece el calentador debe protegerse

con un dispositivo de corriente residual (RCD) de 30mA. En caso de

duda, consulte con un perito electricista.

Requisitos eléctricos

ESPAŇOL

230V 1 Fasico

Potencia

1-kW

Amperios

5-Amp

2-kW 9-Amp

3-kW

4-kW*

13-Amp

18-Amp

*4-kW debe de ser cableado por

un electricista cualicado

Requisitos del caudal

El caudal de agua que llega al calentador no debe ser superior a 17.000

litros por hora (17m/h / 3.740 galones británicos/hora). Si el caudal es

superior, será necesario realizarse una derivación para evitar posibles

daños a los elementos del calentador. Si el caudal es inferior a 1.000 litros/

hora (1m/h / 220 galones británicos/hora), el calentador no funcionará.

www.elecro.co.uk

13

Page 16

Calidad del agua

La calidad del agua debe cumplir los siguientes parámetros:

ESPAŇOL

PH 6,8 - 8,0

AT (alcalinidad total) 80 - 140ppm (partes por millón)

TDS (Total de Sólidos Disueltos) / Dureza del calcio 200 - 1.000 ppm

Los calentadores Cygnet son adaptados para el tratamiento de sal con una

concentración máxima es del 8000ppm (8g/litre).

La composición química del agua es compleja. En caso de dudas,

asesórese con un experto.

Instrucciones de uso

Tras completar la instalación del calentador, ponga en funcionamiento

la bomba de circulación de agua para purgar el aire del sistema y del

calentador (es decir, para eliminar el aire que hubiera podido quedar

atrapado en el sistema y en el calentador). CONSEJO: Para facilitar la salida

del aire de la tubería de paso del calentador, eleve ligeramente el puerto

de salida del calentador cuando la bomba esté en funcionamiento. El

calentador solamente se pondrá en marcha (se iluminará el indicador rojo)

cuando se cumplan los siguientes criterios, es decir:

• Cuando la bomba de circulación de agua esté en marcha y suministre

más de 1.000 litros/hora (1m/h / 220 galones británicos/hora)

• Cuando el dial de ajuste de la temperatura esté colocado en un valor

superior a la temperatura del agua.

Consejo útil: Aislar el estanque permite minimizar y acelerar el proceso de

calentamiento.

Prueba rápida de funcionamiento

Observe el contador principal de electricidad cuando el calentador esté en

marcha (es decir, con la luz roja encendida) y, a continuación, cuando la luz

roja esté apagada. Esta prueba debería mostrarle que el contador registra

14

www.elecro.co.uk

Page 17

un mayor uso de electricidad por parte del calentador cuando la luz roja

está encendida.

Es imposible que un calentador eléctrico desperdicie energía, puesto

que si consume electricidad, ésta se transformará en calor, que a su

vez será transferido al agua.

Prueba precisa de funcionamiento

Si necesita realizar una prueba más precisa para conrmar que su

calentador proporciona el calor especicado, deberán tomarse dos

lecturas del contador eléctrico principal de la propiedad con un intervalo

exacto de una hora (es decir, tomar una primera lectura y después,

transcurrida exactamente una hora, tomar una segunda lectura) y

entonces se calculará el número de unidades (kilovatios o kW) consumidas

restándose las unidades de la primera lectura de las de la segunda.

Fíjese que el consumo del calentador también se expresa en kW/hora.

Durante esta prueba, tanto la bomba del estanque como el calentador

deberán encontrarse en constante funcionamiento (es decir, con la luz

roja del calentador encendida). Para evitar que esta prueba dé resultados

incorrectos, es importante no utilizar en la propiedad otros aparatos que

requieran un alto consumo de energía (como la secadora, duchas o cocinas

eléctricas, etc).

Una bomba del estanque de un caballo de potencia utiliza menos de

1kW en una hora. La conclusión de esta prueba debería ser que, por

ejemplo, un calentador de 6-kW y una bomba de medio caballo de

potencia consumirán entrre 6,3 y 6,5-kW en una hora. Es imposible que

un calentador eléctrico desperdicie energía, puesto que si consume

electricidad, ésta se transformará en calor, que a su vez será transferido al

agua.

ESPAŇOL

Solución de problemas

EL CALENTADOR NO SE PONE EN MARCHA

En la mayoría de casos, se deberá a que no se cumple alguno de los

siguientes factores:

Posible causa n°1:

dial.

Se ha alcanzado la temperatura a la que está ajustada el

www.elecro.co.uk

15

Page 18

Para conrmarlo, coloque el dial a una temperatura superior a la

temperatura actual del agua.

Posible causa n°2:

ESPAŇOL

Solución: Retire la cubierta del botón rojo y púlselo para reiniciar el

equipo (véase Fig. 4). Si percibe un claro “click”, deberá investigarse

Ha saltado el interruptor de seguridad térmica.

la causa que provoca que el botón salte. Esta causa podría ser una

acumulación de partículas residuales o una bolsa de aire atrapada en el

interior de la tubería de paso del agua del calentador.

Fig 4.

Posible causa n°3:

Caudal insuciente.

Si utiliza un ltro de cartucho: Compruebe que éste es el problema

haciendo funcionar el sistema tras haber retirado el cartucho de la unidad

de la bomba y el ltro. Esto hará que llegue al calentador el máximo caudal

de agua con el que pueda operar su unidad. Si entonces el calentador se

pone en marcha (es decir, si la luz roja se enciende), puede conrmarse que

el cartucho estaba obturado y que ésta era la causa. Entonces, el cartucho

deberá limpiarse o sustituirse.

Si se utiliza un ltro de arena: Compruebe el indicador de presión del

ltro de arena y, en caso necesario, realice un contralavado.

Nota: En algunos casos, puede haber una relación entre el hecho

de que salte el interruptor de seguridad térmica y un caudal bajo;

es decir, cuando un ltro se bloquea, puede acumularse aire en el

sistema de ltrado y quedarse atrapado en el interior del calentador,

lo que hace que salte el interruptor de seguridad térmica.

16

www.elecro.co.uk

Page 19

Solución De Problemas Generales

LA TUBERÍA DE PASO DEL AGUA NO SE NOTA CALIENTE

Debido a la alta eciencia energética del calentador eléctrico, no debería

poder detectarse calor en la tubería de paso del agua del calentador.

Si la tubería se nota caliente, las causas más probables de esto son las

siguientes:

Posible causa n°1: El calentador se ha colocado en un lugar donde le toca

la luz directa del sol.

Posible causa n°2: Hay una bolsa de aire atrapada en el interior del

calentador, especialmente si el depósito se nota más caliente en su punto

más alto (porque el aire sube).

EL AGUA QUE LLEGA AL ESTANQUE NO PARECE MUCHO MÁS

CALIENTE

El aumento de la temperatura del agua después de su paso por el

calentador será directamente proporcional al volumen de agua que se

bombee en relación con la potencia de salida del calentador.

Por ejemplo: Un calentador de 6-kW, cuando se conecta a una bomba

de 4.000 litros/hora, proporcionará un aumento de la temperatura de

aproximadamente 1,2°C (casi imperceptible al tacto). Sin embargo, como el

agua que se calienta se recircula desde un único cuerpo de agua, el tiempo

necesario para calentarla no se ve afectado por el volumen del caudal.

Existe la creencia popular errónea de que, si se disminuye el caudal, se

acelera el proceso de calentamiento.

ESPAŇOL

Declaración de cumplimiento de

la directiva RoHS

Elecro Engineering Limited certica que nuestra gama de calentadores

eléctricos acuático cumple con la directiva RoHS 2011/65/EU sobre la

restricción de sustancias peligrosas.

www.elecro.co.uk

17

Page 20

Eliminación de equipos eléctricos y

electrónicos

ESPAŇOL

Este producto se ajusta a la directiva europea 2012/19/EU.

No deseche este producto en el contenedor municipal de residuos

generales.

Este símbolo, que aparece en el producto o en su

envoltorio, indica que este producto no se puede tratar

comoun residuo doméstico general, sino que debe =]

llevarse al centro de recogida correspondiente para el

reciclaje de equipos eléctricos y electrónicos.

Al asegurarse de que este producto se elimine de

manera correcta, usted estará contribuyendo a evitar las

consecuencias potencialmente negativas para el medio

ambiente y la salud de las personas derivadas de una

manipulación inadecuada de este producto como

deshecho. El reciclaje de materiales ayudará a conservar

los recursos naturales. Si desea más información, póngase

en contacto con su ocina de atención al ciudadano más

cercana, el servicio de recogida de basura doméstica o el

minorista que le vendió este producto.

Garantía

Su calentador cuenta con una garantía de 3 años desde de fecha de

compra. Esta garantía cubre defectos de fabricación y materiales en

malas condiciones.

A su discreción, el fabricante sustituirá o arreglará las unidades o

componentes defectuosos que sean devueltos a la empresa para su

inspección. Puede que sea necesario presentar prueba de compra.

El fabricante no se responsabiliza de problemas ocasionados por una

instalación incorrecta del calentador, un uso inadecuado ni negligencia.

18

www.elecro.co.uk

Page 21

ESPAŇOL

www.elecro.co.uk

19

Page 22

Avis à l’utilisateur

Merci d’avoir choisi le Réchaueur CYGNET, fabriqué en Angleterre selon

les plus hauts critères de qualité.

Pour vous assurer que votre réchaueur vous servira des années sans

problèmes, merci de lire attentivement les instructions suivantes.

FRANÇAISE

Une installation incorrecte aectera votre garantie.

Faites attention à bien conserver ce manuel pour pouvoir vous y référer

dans le futur.

Vue d’ensemble du produit

Interrupteur de

redémarrage pour

Témoin « En

Marche » (Rouge)

Raccord

d’extrémité

Gauche

Pied/Porteur-A

Fig 1.

sécurité

température

Tube de

chauage

Cadran de

réglage

Boitier Haut

Pied/Porteur-B

Débitmètre

Raccord d’extrémité

Droit

Connecteur

tétine à niveaux

1¼ (32mm) or 1½

(38mm)

20

www.elecro.co.uk

Page 23

Positionnement

Fig 2.

BASSIN

L’E A U

OUI

POMPE

FILTRE

Débitmètre

en haut

RECHAUFFEUR CYGNET

NON

Fig 3.

NON

TRAITEMENT DE

VALVE DE NON

FRANÇAISE

RETOUR

Pour la pose sur

mur vertical, l’eau

entrante doit

toujours arriver

par le dessous.

www.elecro.co.uk

NON

NON

21

Page 24

Positionnement (continuation)

Votre réchaueur devra être placé horizontalement ou verticalement, en

laissant un espace susant pour les connections de tuyaux et le câblage. Il

devra être vissé avec précaution sur une base ferme ou un mur.

Le réchaueur devra être placé à une position basse dans le système de

FRANÇAISE

ltration. Il devra être positionné en aval (après) du ltre et en amont

(avant) d’éventuelles installations de traitement d’eau ou de dosage (voir

Fig. 2).

Tuyauterie

Il est essentiel que la tuyauterie entrante et sortante du réchaueur ait un

calibre (diamètre interne) de 1¼ (32mm) minimum.

Ceci permet une purge de l’air adéquate et assure que le réchaueur soit

systématiquement rempli d’eau durant son fonctionnement. Le tuyau

de retour transportant l’eau vers la piscine doit incorporer une boucle ou

« soulèvement » de sécurité dans le tuyau aussi proche que possible du

réchaueur (voir g. 3).

Remarque : Quand connecté à un tuyau souple, la boucle de sécurité

peut être créée en faisant passer le tuyeau par-dessus un obstacle.

Souvenez vous d’utiliser des colliers de serrage pour attacher les

tuyaux de façon sure.

Protection contre les intempéries

Le réchaueur doit être placé dans un espace sec a l’abri des intempéries.

ATTENTION: si le réchaueur n’est pas utilisé durant l’hiver, il doit être

purgé an d’éviter des dommages liés au gel.

Connections électriques

Pour votre sécurité Le réchaueur vous est fourni pré-câblé avec un câble

d’alimentation. Les réchaueurs d’une taille de 1kW à 3 kW sont câblés et

22

www.elecro.co.uk

Page 25

peuvent être branchés à une prise. Les réchaueurs de 4kW doivent être

installés par un électricien qualié.

Le réchaueur doit être installé en accord avec les règlements et

régulations nationales ou régionales en vigueur. Dans tous les cas, le

travail doit être eectué par un électricien qualié, qui vous procurera un

certicat de conformité quant à l’accomplissement du travail.

Il est essentiel que l’alimentation électrique du réchaueur soit

protégée par un 30mA RCD.

Puissance Requise

Rendement de 230V

monophasé

1-kW 5-Amp

2-kW

3-kW

4-kW*

Charge

9-Amp

13-Amp

18-Amp

*4-kW debe de ser cableado por

un electricista cualicado

Flux requis

L’importance du ux d’eau circulant dans le réchaueur ne doit pas

excéder les 17.000 litres / heures (17m/h). Un ux d’eau plus important

nécessitera l’installation d’une dérivation pour éviter d’endommager les

pièces de l’appareil. Le réchaueur ne s’activera pas avec un ux inferieur a

1.000 litres/ heures.

Qualité de l’eau

FRANÇAISE

La qualité d’eau doit être dans les limites suivantes:

PH : 6.8-8.0

TA (alcalinité Totale) 80 - 140ppm (particules par million)

TDS (Totales Solides Dissous) / la dureté de Calcium 200 - 1000ppm

(particules par million)

www.elecro.co.uk

23

Page 26

Seuls les réchaueurs équipés de résistances en Titane sont adaptés pour

les traitements au sel d’une concentration allant jusqu’à 8000ppm (8g/

litres).

La chimie d’eau est compliquée. Si vous avez des doutes, n’hésitez

pas à consulter un expert.

Instruction de mise en routens

FRANÇAISE

A la n de l’installation, mettez en marche la pompe de circulation pour

purger l’air hors du système et du réchaueur (i.e. enlever toute poche d’air

emprisonné dans le système et du réchaueur). ASTUCE: vous pouvez

aider l’air à sortir du tube en élevant doucement la sortie du réchaueur

pendant que la pompe fonctionne.

Le réchaueur se mettre en route (témoin lumineux rouge) quand les

critères suivants sont respectés.

• La pompe de circulation est en marche et génère un ux supérieur à

1000 litres/heures.

• La température désirée est plus haute que la température réelle de l’eau

Conseil Pratique : Pour minimiser et accélérer le processus le processus

de chaue, isolez le bassin au mieux.

Test de fonctionnement rapide

Regardez le compteur électrique central lorsque le réchaueur est

en marche (voyant rouge allumé) puis lorsque le voyant est éteint.

Ce test devrait démontrer que le compteur électrique enregistre une

consommation d’électricité plus élevée quand le voyant rouge est allumé.

Il est impossible que le réchaueur gaspille de l’énergie. Toute la puissance

utilisée par le réchaueur est changée en chaleur et transférée à l’eau.

Test de fonctionnement Précis

Si un test plus précis est nécessaire an de vérier que votre réchaueur

24

www.elecro.co.uk

Page 27

envoie la quantité de chaleur adéquate, deux lectures du compteur

électrique central de la propriété doivent être faites à une heure

d’intervalle exactement, prenez donc une première lecture, puis une

seconde exactement une heure plus tard. En soustrayant le résultat de la

première lecture au résultat de la seconde, la consommation (kilo watts /

kW) peut être calculée.

N’oubliez pas que la consommation de votre réchaueur est aussi mesurée

en kW/heure. La pompe du bassin et le réchaueur devront fonctionner

sans arrêt durant le test, c’est-a-dire avec le voyant rouge allumé. An

d’éviter un résultat erroné, il est important d’éteindre tout les appareils qui

utilisent une quantité importante d’électricité (tel que les sèche-linge, les

douches électrique, four etc.).

Une pompe pour grand bassin de 1 cheval-vapeur utilise moins de 1-kW

en une heure. Le résultat du test doit montrer que, par exemple un

réchaueur de 6-kW avec une pompe de 1 cheval-vapeur utilisent entre

6,3-kW et 6,5-kW en une heure. Il est impossible que le réchaueur gaspille

de l’énergie. Toute la puissance utilisée par le réchaueur est changée en

chaleur et transférée à l’eau.

Dicultés d’allumage

FRANÇAISE

LE RÉCHAUFFEUR NE S’ALLUME PAS

Dans la plupart des cas, l’une des éventualités ci-dessous est en cause.

Cause Possible 1: La température de consigne a été atteinte.

An de conrmer le résultat - augmentez la température de consigne en

tournant le thermostat de régulation pour qu’il indique une température

plus élevée que la température actuelle.

Cause Possible 2: Le thermostat de sécurité a disjoncté.

Remède: retirer la couverture du bouton et réarmer en appuyant sur le

bouton rouge (voir Fig 4). Si au cours de l’opération un click se fait sentir,

la raison pour laquelle le thermostat a disjoncté doit être recherchée. Elle

pourrait être due à la présence de débris ou d’air, à l’intérieur du tube de

chauage du réchaueur

www.elecro.co.uk

25

Page 28

Fig 4.

FRANÇAISE

Cause Possible 3: Circulation d’eau insusante

Si vous utilisez un ltre à cartouche: Pour conrmer, faîtes fonctionner

l’appareil après avoir retiré la cartouche de la pompe & du ltre, cela fera

passer le volume d’eau maximum que votre appareil peut accepter. Si le

réchaueur se met en marche (c’est-a-dire que le voyant rouge s’allume)

c’est que la cartouche est bouchée. Celle-ci doit donc être nettoyée ou

remplacée.

Si vous utilisez un ltre a sable: Vériez l’indicateur de pression de celuici et procédez a la purge du ltre si nécessaire.

Remarque: Dans certains cas, le thermostat de régulation peut

disjoncter dû à un courant trop faible ; Quand le ltre est saturé, l’air

peut être aspiré dans le système de ltrage et rester coincé

à l’intérieur du réchaueur faisant disjoncter le thermostat de

régulation.

Dépannage général

LE TUBE DE CHAUFFAGE N’EST PAS CHAUD

En raison du rendement élevé de votre réchaueur électrique en aucune

chaleur ne devrait être détectée au niveau du Tube de chauage du

réchaueur. Si le tube de chauage de votre réchaueur est chaud, ce sera

souvent pour les raisons suivantes:

26

www.elecro.co.uk

Page 29

1ere possibilité: Le réchaueur est resté en plein soleil.

2eme possibilité: Une poche d’air est prisonnière à l’intérieur du réchaueur,

surtout si c’est la partie supérieure du corps du réchaueur qui est plus chaude

(l’air monte).

L’EAU DE MON BASSIN N’A PAS L’AIR BEAUCOUP PLUS CHAUDE

L’augmentation de la température de l’eau, une fois passée par le

réchaueur, est directement proportionnelle au volume d’eau pompé en

relation avec la puissance du réchaueur.

Par exemple: connecté à une pompe de 4 000 litres par heure, un

réchaueur de 6-kW produira approximativement une augmentation

de température de 1,2˚C (ceci est a peine ressenti par la main humaine).

Cela dit, au fur et a mesure que l’eau passe et repasse par le réchaueur,

le temps nécessaire reste inchangé par la quantité du volume d’eau. C’est

donc une erreur commune que de penser que de diminuer la quantité

d’eau qui passe par le réchaueur augmentera le processus de chauage.

En eet, le temps nécessaire à chauer l’eau n’est pas en rapport avec le

volume d’eau passant par le réchaueur.

Respect de la directive ROHS

Elecro Engineering Limited certie que sa gamme de réchaueurs

électriques aquatiques est conforme à la directive 2011/65/EU (ROHS)

relative à la limitation de l’utilisation de certaines substances dangereuses

dans les équipements électriques et électroniques.

Elimination des déchets électriques

et électroniques

FRANÇAISE

Ce produit est soumis à la norme 2012/19/EU

Ne jetez pas ce produit dans les déchets municipaux non triés

Ce symbole, sur le produit ou sur l’emballage, signie que

ce produit ne doit pas être traité comme un déchet

domestique. Il devra être, au contraire, déposé à l’

endroit adéquat an que l’on procède au recyclage,

correspondant aux équipements électriques et

électroniques.

www.elecro.co.uk

27

Page 30

En vous débarrassant de ce produit en respectant la

norme, vous contribuerez à ce que d’éventuelles

conséquences, graves pour l’environnement et la santé

humaine et provoquées par une manutention inadéquate

de ce produit, soit évitées. Le recyclage des matériaux

aidera à la sauvegarde des ressources naturelles. Pour plus

d’information, s’il vous plait, contactez le service municipal

adéquat de votre commune, ou l’administration chargée

FRANÇAISE

du contrôle de l’élimination des déchets ou le détaillant

qui vous a vendu ce produit.

Garantie

Votre réchaueur est garanti 3 ans depuis la date de la facture contre

d’éventuels defaults de fabrication et de matériaux.

Le constructeur procédera, à sa discrétion, à la réparation ou l’échange

de tout élément ou matériels défectueux renvoyés à la société pour

inspection. Un justicatif d’achat pourra être demandé.

Toute installation incorrecte du réchaueur, utilisation non conforme au

mode d’emploi ou négligence n’engagera d’aucune façon la responsabilité

du constructeur.

28

www.elecro.co.uk

Page 31

FRANÇAISE

www.elecro.co.uk

29

Page 32

Wichtige Hinweise!

Vielen Dank, dass Sie sich für das CYGNET Heizgerät, das unter Einhaltung

strengster Normen in England hergestellt wurde.

Bitte lesen Sie die folgende Anleitung genau durch, um sicherzustellen,

dass Ihnen Ihr neu erworbenes Heizgerät viele Jahre lang zuverlässige

Dienste leisten wird.

Ein falscher Einbau beeinträchtigt Ihre Gerätegarantie.

Bitte heben Sie diese Anleitung zur späteren Verwendung auf.

DEUTSCH

Produktübersicht

30

zur thermischen

Heizanzeige für

‚AN‘ (rot)

Hinteres

Anschlussstück

(links)

Fuß / Träger- A

Abb 1.

Rückstell- und

Abstellschalter

Sicherheit

Flussrohr

Einstellrad

für den

Sollwert der

Temperatur

Obere

Abdeckung

Fuß / Träger-B

www.elecro.co.uk

Strömungswächter

Hinteres

Anschlussstück

(rechts)

Abgestufter

Rohrstutzenanschluss

1 ¼ Zoll (32 mm) oder

1 ½ Zoll (38 mm)

Page 33

Positionierung

TEICH

WASSERAUFBEREITUNGRÜCKSCHLAGVENTIL

DEUTSCH

PUMPE

JA

Bei einer

senkrechten

Wandbefestigung

muss der

Wassereintritt

immer von unten

geschehen

FILTER

Strömungswächter

bendet sich oben

www.elecro.co.uk

CYGNET HEIZGERÄT

NEIN

Abb 2.

NEIN

NEIN

NEIN

Abb 3.

31

Page 34

Positionierung (fortgesetzt)

Ihr Heizgerät sollte sich in einer waagerechten oder senkrechten Position

benden, und dabei sollte ausreichend Platz für Rohrverbindungen und

Verkabelung gelassen werden, und das Gerät sollte sicher auf einem festen

Untergrund oder an einer Wand befestigt werden.

Das Heizgerät sollte an einem Tiefpunkt im Filtersystem eingebaut

werden. Es sollte dem Filter nachgelagert und jeglicher Dosier- oder

anderer Wasseraufbereitungsanlagen vorgelagert eingebaut werden.

(siehe Abb.2)

DEUTSCH

Rohrleitungen

Es ist wichtig, dass die Rohre, die zum Heizgerät und von ihm wegführen,

einen Innendurchmesser von mindestens 1 ¼ Zoll (32 mm) besitzen.

Um eine richtige Luftspülung durchzuführen und um zu gewährleisten,

dass das Heizgerät während des Betriebs immer mit Wasser gefüllt bleibt,

muss das Rückschlagrohr, das das Wasser zurück in den teich transportiert,

eine Sicherheitsschleife besitzen, die sich so nah wie möglich am Heizgerät

bendet (siehe Abb. 3).

HINWEIS: Beim Anschluss an ein exibles Rohr kann ein

Sicherheitsschleife gelegt werden, indem das Rohr nach oben

über ein erhöhtes Hindernis verlegt wird. Denken Sie daran, dass

Sie Rohrschellen benutzen, um alle Schlauchanschlüsse sicher zu

befestigen.

Witterungsschutz

Das Heizgerät muss in ein trockenes und witterungsfestes Gehäuse

eingebaut werden.

VORSICHT! Wenn das Heizgerät während der Wintermonate nicht genutzt

wird, muss das Wasser herausgelassen werden, damit es nicht zu Frostschäden

kommt.

32

www.elecro.co.uk

Page 35

Elektrische Anschlüsse

Das Heizgerät wird mit einem anschlussfertigen Stromkabel geliefert.

Geräte mit 1-3 kW verfügen auch über einen Anschlussstecker; 4-kW

Modelle müssen durch einen qualizierten Elektriker installiert werden.

Das Heizgerät muss gemäß den landesspezischen/regional gültigen

Anforderungen & Vorschriften installiert werden. Sämtliche Arbeiten

müssen in jedem Falle von einem qualizierten Elektriker ausgeführt

werden, der nach Abschluss der Arbeiten ein Konformitätszertikat

ausstellen kann.

Die Stromversorgung des Heizgerätes muss durch einen FI-Schalter

(Fehlerstromschutzschalter) mit 30 mA geschützt werden. Bei Fragen

wenden Sie sich bitte an einen qualizierten Elektriker.

Erforderliche Leistung

DEUTSCH

230 V

1 Phasenstrom-Ausgang

Leistungsangabe

1-kW 5-Amp

2-kW

3-kW

4-kW*

9-Amp

13-Amp

18-Amp

*4-kW MUSS VON EINEM

QUALIFIZIERTEN ELEKTRIKER

FEST VERDRAHTET WERDEN

Anforderungen an die Durchussrate

Die maximale Durchussrate des zirkulierenden Wassers liegt bei

17.000 Litern pro Stunde (3.740 britische Gallonen/Stunde). Für eine

höhere Durchussrate muss ein Bypass installiert werden, der die

Heizelemente vor jedweden Schäden bewahrt. Das Heizgerät ist nur bei

einer Durchussrate von mindestens 1.000 Litern pro Stunde (220 britische

Gallonen/Stunde) funktionsfähig.

Wasserqualität

Die Wasserqualität muss innerhalb der folgenden Grenzen liegen:

www.elecro.co.uk

33

Page 36

PH-Wert: 6,8–8,0

Gesamtalkalinität: 80–140 ppm

Vollständig gelöste Feststoe I Kalkhärte: 200–1000 ppm

Edelstahl-Heizkörper mit Titanium Heizelemente eignen sich für den

Einsatz auf Teiche mit einer Salzkonzentration bis zu 8000 ppm (8g/Liter).

Wasserchemie ist kompliziert. Fragen Sie also einen Fachmann um

Rat, wenn Sie sich nicht sicher sind.

Betriebsanleitung

DEUTSCH

Nachdem die Installation abgeschlossen ist, schalten Sie die

Wasserumwälzpumpe an, um System und Heizgerät zu entlüften

(Lufteinschlüsse werden aus System & Heizgerät entfernt). TIPP: Indem

Sie den Ausgangsport des Heizgerätes leicht anheben während die

Pumpe arbeitet, kann die Luft leichter aus dem Flussrohr des Heizgerätes

entweichen. Das Heizgerät schaltet sich nur ‚An‘ (rote Kontrolllampe

erleuchtet), wenn u.a. die folgenden Kriterien erfüllt sind:

• Die Wasserumwälzpumpe ist ‚An‘ und liefert mehr als 1.000 Liter pro

Stunde (220 britische Gallonen/Stunde)

• Der Temperatur-Sollwert ist auf einen höheren Wert eingestellt, als der

des Wassers

Nützlicher Hinweis: Zur Senkung der Betriebskosten und schnelleren

Erwärmung sollten Sie den Teich wo immer möglich isolieren.

Schneller Funktionstest

Überwachen Sie den Hauptstromzähler, wenn das Heizgerät angeschaltet

ist (also wenn das rote Licht ‚An‘ ist) und beobachten Sie den Zähler

nochmals, wenn das rote Licht aus ist. Der Test sollte zeigen, dass der

Zähler mehr Strom zählt, wenn das rote Licht ‚An‘ ist.

Es ist nicht möglich, dass elektrische Heizgeräte Strom

verschwenden, da der verbrauchte Strom in Wärme umgewandelt

wird, die dann in das Wasser übertragen wird.

34

www.elecro.co.uk

Page 37

Akkurater Funktionstest

Wird ein genauerer Test benötigt, um zu bestätigen, dass das Heizgerät die

spezizierte Wärmeleistung liefert, muss der Hauptstromzähler innerhalb

von genau einer Stunde zwei Mal abgelesen werden (Sie lesen den Zähler

also einmal und dann genau eine Stunde später das zweit Mal ab). Sie

können dann die Anzahl der verbrauchten Einheiten (in kW) berechnen,

indem Sie die Zahlen der ersten Ablesung von den Zahlen der zweiten

abziehen.

Beachten Sie, dass Ihr Heizgerät ebenfalls in kW-Stunden ausgelegt ist. Die

Teich-Pumpe und das –Heizgerät müssen während des Tests kontinuierlich

in Betrieb sein (also mit dem roten Licht des Heizgerätes auf ‚An‘). Um

ungenaue Ergebnisse während des Tests zu vermeiden, ist es wichtig, dass

keine anderen Geräte genutzt werden, die Hochstrom nutzen (wie z. B.

Wäschetrockner, Dusche, Herd etc.).

Eine große Teich-Pumpe mit 1 PS wird weniger als 1 kW pro Stunde

verbrauchen. Das Testergebnis sollte nachweisen, dass z. B. ein Heizgerät

mit 6 kW und eine Pumpe mit ½ PS zwischen 6,3 kW–6,5 kW pro Stunde

verbrauchen. Es ist nicht möglich, dass ein elektrisches Heizgerät Strom

verschwendet, da der abgezogene Strom in Wärme umgewandelt wird,

die dann in das Wasser übertragen wird.

DEUTSCH

Fehlerbehebung

Heizgerät schaltet sich nicht auf ‚An‘

In den meisten Fällen gibt es dafür die folgenden Gründe:

Möglichkeit 1:

Zur Bestätigung: Erhöhen Sie den Sollwert indem Sie das Einstellrad für

den Sollwert auf einen Wert einstellen, der größer ist als die derzeitige

Wassertemperatur.

Möglichkeit 2:

Sicherheit‘ hat ausgelöst.

Abhilfe: Entfernen Sie die Abdeckung des Schalters und drücken

Sie den roten Reset-Knopf (siehe Abb. 4). Wenn ein positives Klicken

wahrgenommen wird, muss die Ursache für die Auslösung gesucht

werden. Zu den möglichen Ursachen können Ablagerungen oder

Der Sollwert für die Temperatur wurde erreicht.

Der ‚Rückstell- und Abstellschalter zur thermischen

www.elecro.co.uk

35

Page 38

Lufteinschlüsse im Flussrohr des Heizgerätes gehören.

DEUTSCH

Abb 4.

Möglichkeit 3: Mangelhafter Durchuss.

Bei der Nutzung eines Kartuschenlters: Um dies zu bestätigen, lassen

Sie das System laufen, nachdem Sie die Kartusche aus der Pumpen- und

Filtereinheit entfernt haben. Dies sorgt für eine maximale Durchussrate

im Heizgerät (die maximale Rate, für die Ihre Einheit ausgelegt ist). Wird

das Heizgerät dann ‚An‘ (sprich: das rote Licht ist ‚An‘) geschaltet, ist ein

blockierter Kartuschenlter die Ursache. Die Kartusche sollte gereinigt

oder ersetzt werden.

Bei der Nutzung eines Sandlters: Überprüfen Sie die Druckanzeige auf

Ihrem Sandlter und, wenn nötig, spülen Sie diesen.

Hinweis: Manchmal kann die Auslösung des ‚Rückstell- und

Abstellschalters zur thermischen Sicherheit‘ mit einer niedrigen

Durchussrate zusammenhängen. Dies geschieht, wenn ein Filter

verstopft und Luft in das Filtersystem gelangt, dann im Heizgerät

eingeschlossen wird und so dazu führt, dass der Rückstellschalter

auslöst.

Generelle Fehlersuche

Das Flussrohr fühlt sich nicht warm an

Durch die hohe Eektivität Ihres elektrischen Heizgerätes sollte keine

Wärme über das Flussrohr wahrnehmbar sein. Die wahrscheinlichsten

36

www.elecro.co.uk

Page 39

Ursachen dafür, dass sich das Flussrohr warm anfühlt, sind:

Möglichkeit 1: Das Heizgerät wurde direktem Sonnenlicht ausgesetzt.

Möglichkeit 2: Ein Lufteinschluss im Heizgerät; vor allem dann, wenn sich

der Tank im obersten Bereich wärmer anfüllt (Luft steigt nach oben).

Das Wasser, das in meinen teich ießt, fühlt sich nicht viel wärmer an

Der Temperaturanstieg des Wassers, nachdem es durch das Heizgerät

geossen ist, steht direkt proportional zum gepumpten Wasservolumen,

hinsichtlich der Ausgangsleistung des Heizgerätes.

Beispiel: Schließt man ein Heizgerät mit 6-kW an eine Pumpe mit

einer Leistung von 4,000 Litern pro Stunde an, kommt es zu einem

Temperaturanstieg von ungefähr 1,2°C (wird von einer menschlichen

Hand so gut wie nicht wahrgenommen). Da das Wasser jedoch in einem

einzigen System umgewälzt wird, wird die Aufwärmzeit nicht durch die

Durchussmenge beeinusst. Es ist ein weitverbreiteter Irrglaube, dass

eine langsamere Durchussrate den Aufwärmprozess beschleunigt.

RoHS-Konformitätserklärung

DEUTSCH

Elecro Engineering Limited bescheinigt hiermit, dass das elektrische

Wasserheizung Reihe die RoHS-Richtlinie 2011/65/EC über die Reduzierung

von Schadstoen erfüllt.

Entsorgung von elektrischen und

elektronischen Geräten

Dieses Produkt erfüllt die Vorgaben der EU-Richtlinie 2012/19/EC.

Dieses Produkt darf nicht als unsortierter kommunaler Abfall

entsorgt werden.

Dieses auf dem Produkt und auf der Verpackung

angebrachte Symbol bedeutet, dass das Produkt nicht

als Hausmüll angesehen werden darf. Stattdessen sollte

das Produkt in der zuständigen Sammelstelle zum

Recycling von Elektro- und Elektronikgeräten abgegeben

werden.

www.elecro.co.uk

37

Page 40

Indem Sie die korrekte Entsorgung dieses Produkts

sicherstellen, helfen Sie potenziell negative Konsequenzen

für die Umwelt und die menschliche Gesundheit zu

vermeiden, die ansonsten durch die unsachgemäße

Entsorgung dieses Produkts entstehen können. Die

Wiederverwertung der Materialien hilft dabei, natürliche

Ressourcen zu bewahren. Weitere Informationen

erhalten Sie von Ihrer zuständigen Kommune, Ihrem

Hausmüll-Entsorgungsunternehmen oder dem Händler,

bei dem Sie dieses Produkt erworben haben.

Garantie

DEUTSCH

Auf das Heizgerät wird, ab Verkaufsdatum, eine Garantie von 3 Jahren

gegeben. Diese umfasst Material- und Verarbeitungsfehler.

Der Hersteller ersetzt oder repariert nach seinem Ermessen jedwede

defekten Geräte oder Bauteile, die zur Inspektion an ihn eingeschickt

werden. Vorlage des Kaufbelegs kann dazu angefordert werden.

Der Hersteller übernimmt keine Verantwortung für eine fehlerhafte

Installation des Produktes, den unsachgemäßen Gebrauch oder

Fahrlässigkeit.

38

www.elecro.co.uk

Page 41

DEUTSCH

www.elecro.co.uk

39

Page 42

Page 43

Page 44

11 Gunnels Wood Park | Stevenage | Hertfordshire | SG1 2BH | United Kingdom

t: +44 (0) 1438 749 474 | f: +44 (0) 1438 361 329 | e: sales@elecro.co.uk

www.elecro.co.uk

© Copyright 2016 Z-INS-N-KC

Loading...

Loading...