Page 1

Elecraft XV432 High Accuracy Crystal Option

Installation Instructions

Revision D, September 1, 2014

Copyright © 2014, Elecraft, Inc. All Rights Reserved

Introduction

The XV432 High Accuracy Option is designed to allow the local oscillator of the XV432 to be set exactly to 404 MHz. This

results in zero frequency offset needed when used with an Elecraft K2 or K3 or the need to manually calculate the actual

frequency when used with other transceivers.

The High Accuracy Option consists of selected crystal and a replacement inductor for L19. The crystal is selected for series

resonance close to the desired frequency and for low series resistance and high Q. Low series resistance and high Q allow the

frequency to be trimmed over an increased range without risk of the oscillator not starting reliably.

Tools Required

You will need a DMM for making voltage checks, an inductor alignment tool (one was supplied with your transverter), a

No. 1 Phillips screwdriver, long nose pliers, a temperature controlled ESD-safe soldering iron with rosin core small diameter

solder and solder wick or desoldering tool to clear the solder pads to replace the inductor.

Observe ESD precautions when working inside your XV432. Wear an ESD wrist strap or touch an

unpainted, metal ground frequently while working.

Installing the New Components

Remove the XV432 top and bottom covers. To remove the bottom cover, first remove the four corner screws

and then remove the two long screws that extend through the heat spreader and are secured by nuts at the ends of the

RF power module on the top of the board. (You don’t need to remove the other two screws. They hold the heat

spreader on the bottom cover.) Be sure you don’t lose the two flat washers that fit between the heat spreader and the

bottom of the PC board. You should have two long screws, two nuts, two lock washers and two flat washers.

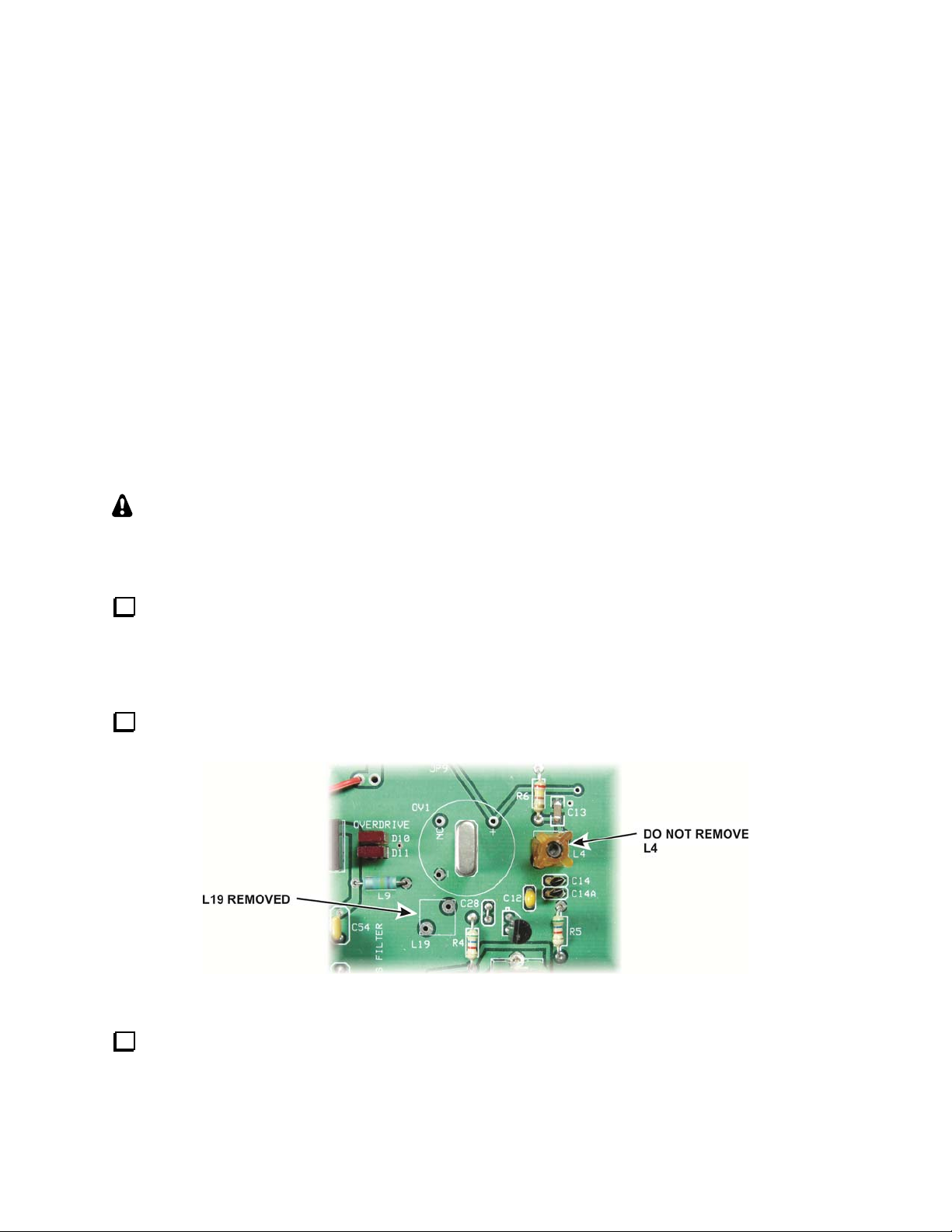

Remove L19 from the circuit board. (See Figure 1). Be sure you remove L19 and not L4 which is also near

the OV1 circle.

Figure 1. L19 Location.

Remove the crystal oven (if so equipped) and the crystal. Replace it with the new crystal. The crystal may be

oriented either way. Be sure the crystal case is sitting directly against the PCB. Do not hold your soldering iron on

the leads more than 2 or 3 seconds maximum. Excessive heat may damage the crystal.

Elecraft • www.elecraft.com • 831-662-8345

Page 2

Install the new L19 (yellow form). Be sure it is down against

the board and solder it in place.

Replace the crystal oven (if used).

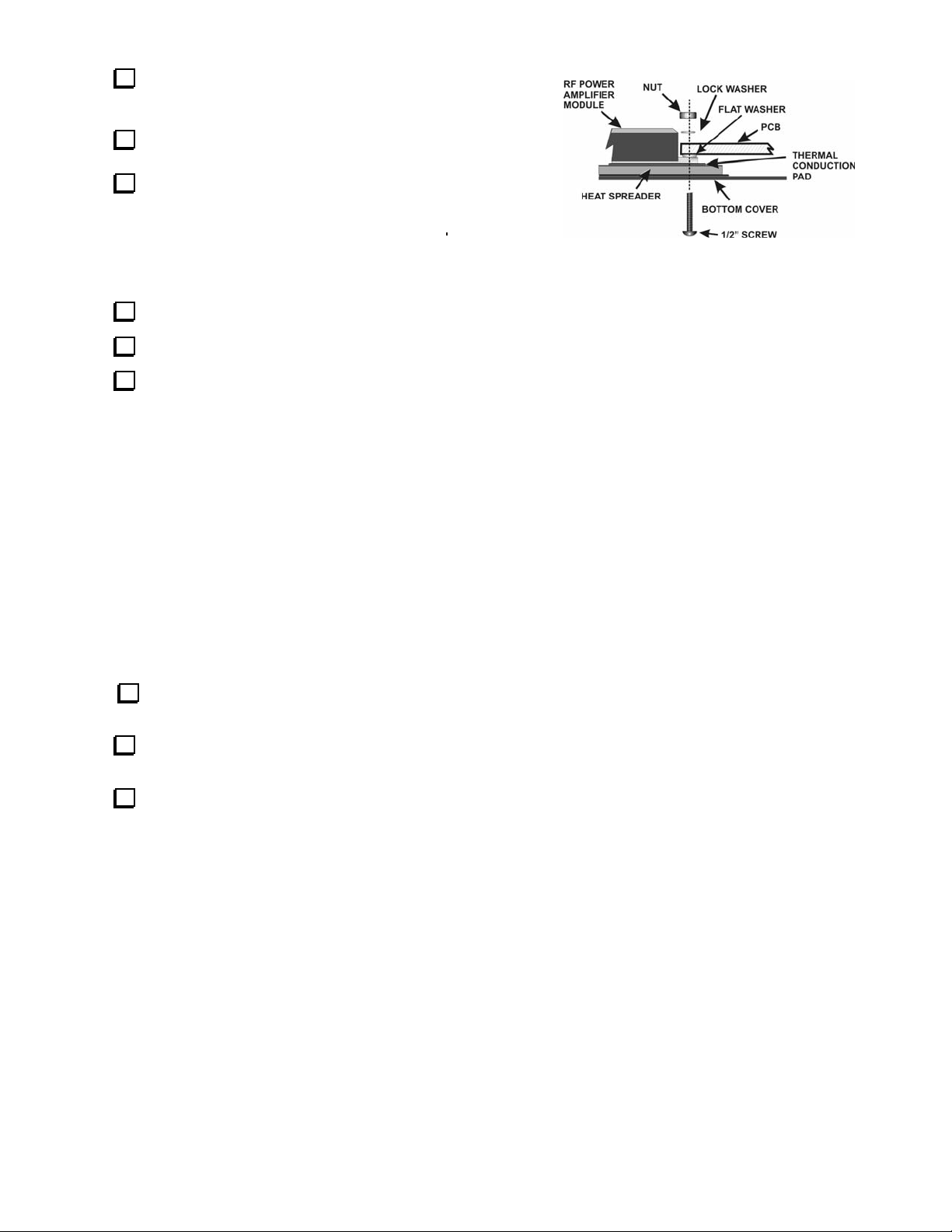

Replace the bottom cover on your XV432. Be sure to replace

the hardware around the RF power amplifier module as shown in

Figure 2, especially the flat washer between the pc board and

module, otherwise your power amplifier may overheat and fail.

Figure 2. RF Module Mounting Hardware .

Alignment

Preset the slug in L19 so it is flush with the top of the form.

Preset the slug in L4 so it is two turns down into the form from the top.

Choose and set up your equipment to measure the local oscillator frequency using one of the following:

a) Connect a frequency counter to either end of molded inductor (L3) near T1 on the RF board to measure the local

oscillator frequency directly. This method connects your counter to a circuit containing direct current. If your

counter isn’t protected against d-c levels (or you aren’t sure) connect the counter through a capacitor. Any value

from 100 pF to 0.01 µF is suitable.

b) Connect a dummy load to your transverter output and connect a frequency counter to sample the RF output from the

transverter. Do NOT connect your counter directly to the antenna output without a suitable attenuator to

protect the counter input. If you do not have a suitable attenuator, connect an insulated wire to the counter input

and position the wire near antenna relay K1 on the RF PCB. You may need to experiment with the position of the

wire to pick up enough RF to operate the counter. Do not wrap the wire around L10 or L11. That would detune the

output filter and could damage the RF power module. Be sure your transceiver SPLIT and RIT functions are off and,

if using a K2 or K3, be sure the XV offset (in the MENU) is set to zero.

c) Set up an external signal source at 432.000 MHz that you will receive to measure the frequency, either tuning your

transceiver for zero beat or by centering the signal in the i.f. bandpass. Be sure your transceiver SPLIT and RIT

functions are off and, if using a K2 or K3, be sure the XV offset (in the MENU) is set to zero.

Connect a DMM to measure the voltage at TP1 (2 to 3.5 vdc). This voltage will indicate whether the local oscillator is

starting reliably and with the proper output level.

Turn on the equipment, including the XV432 and (if used) the associated transceiver and allow it to warm up at least 10

minutes.

Adjust L4 and L19 for a local oscillator frequency of exactly 404 MHz if measuring the L.O. directly, or for the correct

transmitted or received signal frequency if using methods b) or c) to measure the local oscillator frequency indirectly. After

adjusting, turn power to the transverter off and on while monitoring the DMM to ensure it starts reliably and the voltage at

TP1 is between 2 and 3.5 vdc. Start your adjustments with L4 and, if its range is not adequate to provide the correct

frequency and reliable oscillator startup, adjust L19. Both coils raise the local oscillator frequency as the core is extracted and

lower the frequency as they are moved deeper into the coils. If the voltage at TP1 is outside the range of 2 and 3.5 vdc, adjust

L4 and compensate with L19 to return to the correct frequency.

That completes the installation of your high-accuracy local oscillator crystal.

Elecraft XV432 High Accuracy Crystal Option Installation Instructions Page 2 of 2

Loading...

Loading...