Page 1

Elecraft XV Series Transverters

Models XV50, XV144, XV222

Rev B, November 7, 2003

Page 2

Table of Contents

Introduction..........................................................................................................................................................................................1

Specifications.......................................................................................................................................................................................3

Preparing for Assembly .......................................................................................................................................................................4

Parts Inventory...................................................................................................................................................................................10

Front Panel Board Assembly............................................................................................................................................................. 24

RF Board Assembly – Part I ..............................................................................................................................................................29

RF Board Assembly – Part II .............................................................................................................................................................42

RF Board Assembly – Part III ............................................................................................................................................................51

Final Assembly .................................................................................................................................................................................. 54

Alignment and Test............................................................................................................................................................................58

Installation..........................................................................................................................................................................................64

Using Your Transverter...................................................................................................................................................................... 76

Options and Modifications..................................................................................................................................................................78

Circuit Description..............................................................................................................................................................................82

Schematic and Parts Layout Diagrams……………………………………………….……………………………...……………..Appendix A

Troubleshooting...................................……………………………………………….……………………....……...………….....Appendix B

Page 3

— — 1

Introduction

The Elecraft XV Series high-performance transverters may be used with

any transceiver or transmitter/receiver pair that covers 28 MHz. Separate

transverters are offered for the following bands:

• Model XV50: 50 to 52 MHz.

• Model XV144: 144 to 146 MHz.

• Model XV222: 222 to 224 MHz

I.F. connections to the transceiver can be either single-port (single RF

cable) or dual port (separate receive and transmit cables).

The transverters include an adjustable input level control that will provide

full output from I.F. power levels from as low as 0.01 watts up to 8 watts

continuous. Full protection against accidental high-power transmit of up

to 100 watts into the I.F. port is also included.

The receiver features a very low noise figure with a PHEMT RF stage for

weak-signal work. Relays are used for transmit/receive switching to avoid

receive performance degradation by diode switches in the signal path.

The transmitter is conservatively rated at 20 watts output PEP SSB, CW

or data modes. The RF output is displayed on the front panel with a 10segment LED bargraph. The LED display may be switched between dot or

bar modes and has two brightness levels when used with an Elecraft K2

transceiver.

The transverters are housed in attractive, low-profile enclosures that may

be stacked for multi-band operation. An illuminated band label identifies

the transverter in use. Several transverters may be connected to the

transceiver in most cases. Internal relays select only the transverter for the

band in use, avoiding the need to switch I.F. cables.

Using an Elecraft K2 as the I.F. Transceiver

While the transverters will work with nearly any HF transceiver, using

them with our Elecraft K2 (or K2/100) offers additional benefits. The

high-performance K2 provides:

• Low noise, single-conversion, wide dynamic range receiver

• Four adjustable I.F. crystal filter bandwidths per mode

• Automatic transverter band switching with individual menu-

selected output power levels for up to three transverters.

• Direct display of the transverter operating frequency to 10 Hz,

including per-band adjustable offsets of +/- 9.99 kHz

• Four RIT ranges from +/- 0.6 to +/- 4.8 kHz

We recommend that K2’s with serial numbers 3445 and below be

equipped with Elecraft-approved modifications that reduce spurious

responses and enhance frequency stability. See page 68 for details.

Figure 1. Three Transverters May Be Controlled by an Elecraft K2.

Page 4

— — 2

Transverter Kits

The XV Transverters are intermediate-to-advanced kits, yet you'll be

surprised at how uncomplicated they are to build. All of the radio

frequency (RF) circuits are on one printed circuit board (PCB). A second

smaller PCB holds the microcontroller and front-panel LEDs. Highquality, double-sided PCBs are used, with plated-through holes for

optimal RF performance. Point-to-point wiring is minimal. All

components to be installed have wire leads; the few surface-mount devices

required are pre-installed on the circuit board.

This kit uses just one torodial inductor, which is easy to wind. However, if

you prefer not to wind this inductor yourself, you can order one prewound with the leads tinned and ready to install from an Elecraft-qualified

source. Ordering information is on our web site at

www.elecraft.com.

Customer Service and Support

Whether you build the kit or buy a factory-built transverter, you’ll find a

wealth of information on our web site at

www.elecraft.com. Among the

materials there you’ll find the latest application notes, photographs, any

updates to this manual, and information on new products. We also have a

popular e-mail forum, for which you can sign up from the web site. It's a

great way to interact with other Elecraft owners, exchange ideas and find

answers to many questions.

You can also get assistance by telephone or by sending an e-mail to

support@elecraft.com. E-mail is preferable because it gives us a written

record of your question. Telephone assistance is available from 9 A.M. to

5 P.M. Pacific time, Monday through Friday (except US Holidays) at 831662-8345.

Repair Service

Contact Elecraft before returning your equipment to obtain the current

information on repair fees.

To ship the unit, first seal it in a plastic bag to protect the finish. Use a

sturdy packing carton with at least 3-in (8 cm) of foam or shredded paper

on all sides. Seal the package with reinforced tape. (Neither Elecraft or the

carrier will accept liability for damage due to improper packaging.) Ship

the equipment to:

Elecraft

P.O. Box 69

Aptos, CA 95001-0069

Elecraft 1-Year Limited Warranty

If building a kit, complete the assembly, carefully following all instructions in

the manual, before requesting warranty service.

What is covered: During the first year after the date of first consumer

purchase, Elecraft will replace defective parts free of charge (post-paid). We

will also correct any malfunction caused by defective parts and materials. You

must send the unit at your expense to Elecraft. We will pay return shipping.

What is not covered: This warranty does not cover correction of assembly

errors or misalignment; repair of damage caused by misuse, negligence or

builder modifications; or any performance malfunctions involving non-Elecraft

accessory equipment. The use of acid-core solder or any corrosive or

conductive flux or solvent will void this warranty in its entirety. Also

not covered is any reimbursement for loss of use, inconvenience, customer

assembly or alignment time, or cost of unauthorized service.

Limitation of incidental or consequential damages: This warranty does not

extend to non-Elecraft equipment or components used in conjunction with our

products. Any such repair or replacement is the responsibility of the customer.

Elecraft will not be liable for any special, indirect, incidental or consequential

damages, including but not limited to any loss of businesses or profits.

Page 5

— — 3

Specifications

Numeric values are typical; your results will be somewhat different. Also,

specifications may be affected by the options or accessories chosen. See

www.elecraft.com for details about options and accessories currently

available. Specifications are subject to change without notice.

General

Size

Cabinet: 1.3” H x 7.8” W x 8.3” D

(3.3 x 19.8 x 21 cm)

Overall: 1.5 H x 7.8 W x 9.5 D incl. feet and connectors.

(3.8 x 19.8 x 21 cm)

Weight: 2.5 lbs (1.1 kg)

Supply Voltage: 13.8 VDC

Current Drain:

Receive: 250 mA (typical)

Transmit

1

: 4 A (typical)

Frequency Ranges:

XV50: 50 – 52 MHz

XV144: 144 – 146 MHz

XV222: 222 – 224 MHz

T/R Switching Time: 3 ms (typical)

T/R Key Input: Ground for transmit: must pull 5 volt

logic level to within 0.5 volts of ground

at < 1 ma.

I.F. Overload Protection: Survives 100 watts RF input at the I.F.

Port without damage with transverter

un-keyed (in receive mode).

1

Current varies with supply voltage, load impedance and power output. We

recommend a minimum 5 A supply.

Amplifier Key Output: Ground on transmit: 200 VDC at 1 A

maximum.

Connectors:

K2 Interface: DB9

Keying Line Input: RCA

Keying Line Output: RCA

I.F. In/Out: BNC

Aux (Rx-Only Ant): BNC

Antenna: SO-239 (UHF) on XVR 50

Type N on XVR 144 & XVR 222

Transmitter

Power Output: 20 watts into 50 ohms

Minimum Supply

Voltage Recommended: 12 VDC

Operating Modes: CW, SSB, AM, FM, PSK

I.F. Input Frequency Range: 28 – 30 MHz

I.F. Input Power Range: 0.01 mW (-20 dBm) to

8 watts (+ 39 dBm)

Harmonic Content: < - 60 dBc at 20 watts output.

Receiver

Noise Figure: < 1 dB

Conversion Gain: 25 dB (typical)

Image Rejection: > 60 dB

3rd-Order Intercept: +20 dBm (typical)

Page 6

— — 4

Preparing for Assembly

Overview of the Kit

The Elecraft XV transverters use modular construction, both physically

and electrically. This concept extends to the chassis (Figure 2). Any

chassis element can be removed to provide access for troubleshooting.

Figure 2. XV Transverter Modular Cabinet Parts.

There are two printed circuit boards (PCBs) in the transverter: the front

panel board, which sits vertically behind the front panel, and the large RF

board.

The boards are interconnected using board-to-board connectors which

eliminates the need for a wiring harness. Gold-plated contacts are used on

these connectors for reliability.

Tools Required

You will need the following tools to build this kit:

• Fine-tip temperature-controlled soldering station with 700 or

800°F tip (370-430°C). Do not use a high-wattage iron or gun

with small components since this can damage pads, traces, or the

parts themselves.

• IC-grade, small-diameter (.031”) solder (Kester #44 or

equivalent).

• Desoldering tools and supplies are invaluable if you make any

modifications or need to do any repairs. Narrow solder wick or a

good vacuum desoldering tool such as the Soldapullt® model

DS017LS are recommended. See Soldering, Desoldering and

Plated-Through Holes, on page 9 for more information.

i

DO NOT use acid-core solder, water-soluble flux solder,

additional flux or solvents of any kind. Use of any of these will void

your warranty.

• Screwdrivers: a small, #2 Phillips and a small flat-blade for slotted

screws.

• Needle-nose pliers.

• Small-point diagonal cutters, preferably flush-cutting.

• Digital Multimeter (DMM) for voltage checks and confirming

resistor values. A DMM with capacitance measurement capability

is desirable, but not required.

• Noise generator (Elecraft N-Gen or equivalent

2

) or signal

generator with output in the RF frequency range of the transverter.

• RF power meter capable of measuring RF power levels up to 25

watts at the RF frequency used by the transverter.

• 50-ohm dummy load capable of handling 25 watts, minimum.

Refer to www.elecraft.com for tool sources and solder recommendations.

2

Check www.elecraft.com for availability.

BACK PANEL

LEFT

SIDE PANEL

TOP

COVER

FRONT

PANEL

BOTTOM

COVER

(RIGHT SIDE

PANEL NOT

SHOWN)

.

Page 7

— — 5

Preventing Electro-Static Discharge Damage

Your XV transverter uses integrated circuits and transistors that can be

damaged by electrostatic-static discharge (ESD). Problems caused by ESD

often can be difficult to troubleshoot because components may be

degraded but still operating at first rather than fail completely.

To avoid such problems, simply touch an unpainted, grounded metal

surface before handling any such components and occasionally as you

build, especially after moving about.

For maximum protection, we recommend you take the following antistatic precautions (listed in order of importance):

1. Leave ESD-sensitive parts in their anti-static packaging until you

install them. The packaging may be a special container or

conductive foam (Figure 3). Parts which are especially ESDsensitive are identified in the parts list.

2. Ground yourself briefly before touching any sensitive parts or

wear a conductive wrist strap with a series 1 megohm resistor.

DO NOT ground yourself directly as this poses a serious

shock hazard.

3. Make sure your soldering iron has a grounded tip.

4. Use an anti-static mat on your work bench.

Figure 3. A common anti-static packaging is conductive foam which

keeps all of the terminals of a device at the same potential.

Unpacking and Inventory

We strongly recommend that you do an inventory of the parts before

beginning to assemble the kit. Even if you don’t count all the parts, an

inventory is helpful to familiarize yourself with them. A complete parts

list is included in the next section.

Identifying Parts

The parts list contains illustrations of the parts to help you identify them.

Identifying marks on the individual parts are shown in the text in

parenthesis. For example, “Transistor Q4 (PN2222)…” indicates a

transistor, Q4, which may be located in the parts list that has the

characters shown in parenthesis printed on it. Sometimes these letters are

not obvious. They may be printed in light gray on a black body, for

example. Also, there may be other marks on the device in addition to the

letters listed.

Identifying Resistors

Resistors are identified by their power capacity and their resistance value.

The power rating in watts determines the physical size of a resistor. The

most common resistors are 1/4 watt. Higher wattage resistors are

proportionately larger. The resistance value and wattage of each resistor is

shown in the Parts Lists and in the individual steps of the assembly

procedures. The silk screened outlines on the circuit boards indicate the

relative physical size of the resistors as well.

Most resistors use a color code. The color bands are listed in the text along

with the values of each resistor. For example, “R4, 100k (brn-blk-yel)…”

indicates a 100k ohm resistor and the colors to look for are brown, black

and yellow, starting with the band nearest the end of the resistor.

Some resistors use numbers instead of color bands. For example, an 820

ohm resistor might be stamped with the digits 821 instead of having gray,

red and brown color bands. Some larger resistors have their value in ohms

stamped on the body using numbers. For, example the 820 ohm resistor

would be stamped with 820 instead of 821 as described above. Normally,

when the value is shown in ohms it will be followed with the word

“ohms” or the Greek letter omega: Ω

Page 8

— — 6

Reading Resistor Color Codes

It is very helpful if you learn to read the color codes. A color-code chart

showing how to read the four-color bands on resistors with a 5% or 10%

tolerance is shown in Figure 4. 1% resistors are similar except that they

use a fifth band to provide a way of showing another significant digit. For

example, a 1,500 ohm (1.5 k-ohm) 5% resistor has the color bands brown,

green and red signifying one, five and two zeros. A 1,500 ohm (1.5 kohm) 1% tolerance resistor has the color bands brown, green, black and

brown signifying one, five, zero, and one zero.

The optional band shown in Figure 4 indicates other performance

specifications for the resistor. When used, it is separated from the other

color bands by a wider space.

i

If in doubt of a resistor’s value, use a DMM. It may be difficult to see

the colors on some resistors, particularly 1% tolerance resistors with a dark blue

body. Do NOT be concerned with minor deviations of your DMM reading from

the expected value. Typical errors in most DMMs and the tolerances of the

resistors normally produce readings that are slightly different from the value

indicated by the color bands.

Identifying Molded Inductors

Small molded inductors have color bands that use the same numeric

values as resistors but they start near the center of the inductor and work

toward the end. These colors are listed in the text after the value of the

inductor, for example: 27µH (red-vio-blk). The red stripe would be near

the center of the inductor and the black strip would be closer to the end.

On very small chokes, the first color will be only slightly farther from one

end than the last color. There may be a variety of other stripes on

inductors as well, indicating their tolerance, conformance to certain

specifications and other data.

FIRST DIGIT

TOLERANCE:

OPTIONAL

SECOND DIGIT

MULTIPLIER

Black

Brown

Red

Orange

Yellow

Green

Blue

Violet

Gray

White

Silver

Gold

0

1

2

3

4

5

6

7

8

9

-

-

X 1

X 10

X 100

X 10K

X 10K

X 100K

X 1M

-

-

X 0.01

X 0.1

COLOR

DIGIT

MULTIPLIER

GOLD = 5%

SILVER = 10%

Figure 4. Resistor Color Code.

Page 9

— — 7

Identifying Capacitors

Capacitors are identified by their value and the spacing of their leads.

Small-value fixed capacitors usually are marked with one, two or three

digits and no decimal point. The significant digits are shown in

parenthesis in the text. For example: “C2, .01 (103)”.

If one or two digits are used, that is always the value in picofarads (pF). If

there are three digits, the third digit is the multiplier. For example, a

capacitor marked “151” would be 150 pF (15 multiplied by 10

1

).

Similarly, “330” is 33 pF and “102” is 1000 pF (or .001 µF). You may

think of the multiplier value as the number of zeros you need to add on to

the end of the value.

Note: In rare cases, a capacitor manufacturer may use “0” as a

decimal placeholder. For example, “820” might mean 820 pF rather than

82 pF. Such exceptions are usually covered in the parts lists. If possible,

measure the values of all capacitor below .001 µF. Most DMMs include

capacitance measurement capability.

Fixed capacitors with values of 1000 pF or higher generally use a decimal

point in the value, such as .001 or .002. This is the value in microfarads

(µF). Capacitors also may have a suffix after the value, such as “.001J”.

The lead spacing is noted in the Parts Lists for most capacitors. If two

different types of capacitors have the same value, the lead spacing will

indicate which one to use. When the lead spacing is important, both the

value and the lead spacing is shown in the assembly procedure. For

example, “LS 0.1” means that the Lead Spacing is 0.1 in.

Hard-to-Identify Capacitor Values

2.2 pF: These are “disc ceramic” capacitors with round, pillow-shaped

bodies about 1/8” (3 mm) in diameter and a black mark on the top. The

capacitor should be labeled “2.2” but the marking sometimes requires a

magnifying glass to see clearly.

150 pF: These capacitors are marked “151” on one side, but the other side

may be marked #21ASD. The “#21” may look like “821”.

Page 10

— — 8

Assembly Process

There are seven steps in the transverter assembly process:

1. Front Panel board assembly.

2. RF Board Assembly, Part I, parts common to all models.

3. RF Board Assembly, Part II, band-specific parts.

4. RF Board Assembly, Part III, installing the RF Power

Module.

5. Final Assembly.

6. Interconnect cabling.

7. Test and alignment.

Follow the assembly process in the order given. Each part builds on what

has been completed before it. For example, the Front Panel assembly

procedure contains details about installing certain parts that are not

repeated when similar parts are installed later.

Forming Component Leads

Sometimes the space provided for a component on the PC board is larger

than the distance between the leads on the part itself. In such cases, you’ll

need to carefully bend the leads out and then down to fit the given space.

Always use long-nose pliers to accomplish this task, and bend the leads –

don’t tug on them. This is especially important with capacitor leads, which

are fragile.

Step-By-Step Procedures

Perform the assembly steps in each procedure in the order given, and

do not skip any steps. Otherwise you may find that you’ve installed

one component that hinders the installation of another. When groups

of components are installed, they are listed in a logical order as you work

around the circuit board to reduce the time needed to find where each part

goes.

Each step in the assembly procedures has a check box.

Some steps have more than one task. For example, you may be installing a

number of components listed. When a step has a number of tasks, each

task is indented with space for a check mark:

Check off each task as you complete it.

Page 11

— — 9

Soldering, Desoldering and Plated-Through Holes

CAUTION: Solder contains lead, and its residue can be toxic. Always

wash your hands after handling solder.

The printed circuit boards have circuitry on both sides (“double-sided”).

Boards of this type require plated-through holes to complete the electrical

connections between the two sides.

When you solder components on these boards the solder fills the plated

holes making excellent contact. This means that you do not need to leave a

large “fillet” or build-up of solder on top of the pads themselves. A small

amount of solder will do for all connections.

Unfortunately, removing components from double-sided PC boards can be

difficult. To remove a multi-pin component you’ll need to get all of the

solder out of every hole to free the leads. You will need to use solder wick

or a vacuum desoldering tool (see Techniques below).

The best strategy for avoiding de-soldering is to place all components

properly the first time. Double-check values, component placement and

orientation. Take care to avoid ESD damage to components.

Techniques

• Don’t pull a lead or pin out of a hole unless the solder has been

removed completely, or you are applying heat. Otherwise you can

literally pull the plating out of the plated-through hole.

• Limit soldering iron contact to a few seconds at a time.

• Use small-size solder wick, about 0.1” (2.5 mm) wide. Use wick

on both the top and bottom solder pads when possible. This helps

get all of the solder out of the hole.

• Buy and learn to use a large hand-operated vacuum desoldering

tool such as the Soldapullt® model DS017LS. Small solder

suckers are not effective.

• When removing ICs and connectors, clip all of the pins at the

body first, then remove each pin one at a time, working slowly.

You may damage pads and traces by trying to remove a

component intact, possibly leaving a PC board very difficult to

repair.

• Invest in a PC board vise with a heavy base if possible. This

makes removing parts easier because it frees up both hands.

• If in doubt about a particular repair, ask for advice from Elecraft

or someone with PCB repair experience. Our e-mail reflector is an

excellent source of help.

Page 12

— — 10

Parts Inventory

You should do a complete inventory. Contact Elecraft if you find anything missing.

i

Leave painted panels wrapped until they are needed during assembly. This will protect the finish.

Cabinet and RF circuit board components used in all transverters.

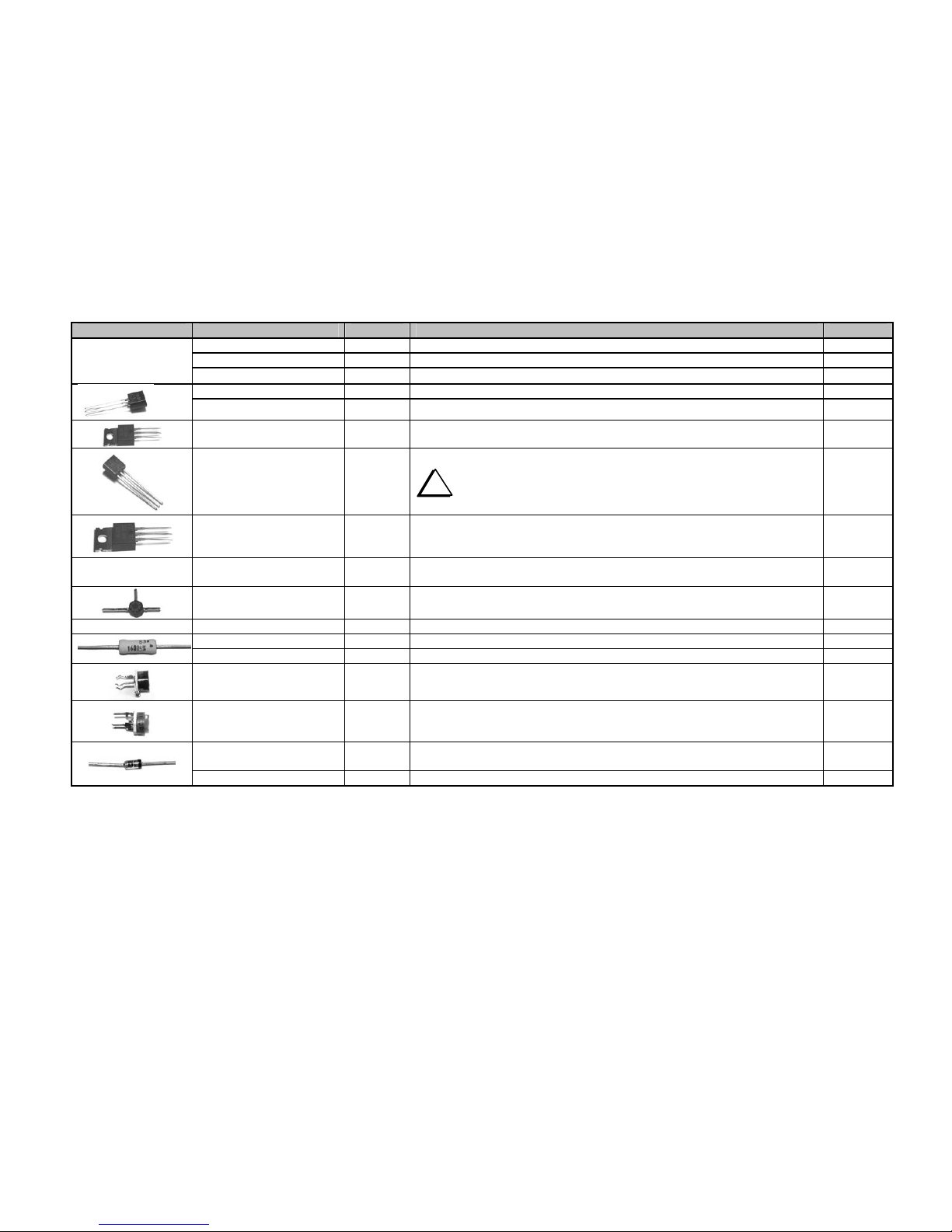

Picture Ref. Designator(s) QTY Description Part #

1

Printed Circuit Board, XV, 50,144,222

i

Handle with care – ESD Sensitive. This board is supplied with

several surface mount components pre-installed. Some of these components

are static-sensitive and are vulnerable until the other parts are installed on

the board. There is a temporary jumper across the solder pads for L1 on the

board to prevent static damage to Q3. Do not remove this jumper until

instructed to do so.

E100169

1 Front Panel E100153

1 Rear Panel E100154

2 Side Panel E100140

1 Top Cover E100146

See Figure 2.

1 Bottom Cover E100155

1 Heat Spreader E100156

8 2D Connector E100078

2 Right Angle Bracket E700073

40 Pan Head Black Machine Screw, 3/16 inch. 4-40. E700015

5 Pan Head Zinc Machine Screw, 5/16 inch, 4-40 E700077

2 Pan Head Black Machine Screw, 1/2 inch, 4-40 E700030

Page 13

— — 11

Picture Ref. Designator(s) QTY Description Part #

10 Machine Screw Nut, 4--40 E700011

14 Split Lock washer, #4 (Includes two spares) E700004

8 Internal Tooth Lock washer, #4 E700010

2 Flat Washer, #4 E700044

1 Ground Lug E700062

2 M-F Standoff for DB9 Connector E700078

4

Rubber Foot, Self Adhesive

i

A Bail kit is available as an optional accessory if desired. The

Bail will hold the front of the transverter up at a convenient viewing angle.

See www.elecraft.com for details

E980067

2 RCA Jack E620057

3 BNC Connector assy. with nut and lock washer, PC Mount E620020

3 Nut for BNC Connector E700059

3 Lock washer for BNC Connector E700058

1 DB9 Female Connector, PC Mount E620058

1 DB9 Male Cable Connector E620049

1

DB9 Back Shell (Shell components are normally packaged together in a

transparent bag).

E620050

4 Anderson Crimp Terminal E620062

Page 14

— — 12

Picture Ref. Designator(s) QTY Description Part #

1 Anderson Roll Pin E700071

2 Anderson Power Pole, Shell, Red E620059

2 Anderson Power Pole, Shell, Black E620060

P1 1 Header Connector, 12 Pin , Right Angle E620065

JP5,JP6, JP9 3 Header Connector, 2 Pin E620054

JP1,JP2,JP3,JP4, JP5,

JP6, JP9

3

7 Header Connector, 3 Pin E620007

9 Header Shorting Block, 2 Pin E620055

S2 1 DPDT Power switch E640006

SW1 1 4 Pole DIP switch E640014

1 Key Cap, Black E980023

F1 1 Resettable Fuse, 5A PolySwitch (Thin, about 3/8” [9.5mm] square.) E980065

K1, K2, K4, K5, K6, K7,

K8, K9

8

Relay, Small

(G6E-134P)

E640011

K3 1 Relay, SPDT, 12 A, 12 VDC, Large (KLT1C12DC12). E640012

D3 1 Diode, Zener, 6.8 volt, 1N5235B E560011

D5 1 Diode, SB530 E560003

D10, D11 2 Diode, LED, Red E570007

3

JP9 comprises a three pin and a two pin header connector.

Page 15

— — 13

Picture Ref. Designator(s) QTY Description Part #

Z1 1 Frequency Mixer, ADEX-10H E600050

U1 1 MMIC Amplifier, ERA-6 E600051

Pre-mounted on the

PCB

U5 1 MMIC Amplifier, MAR-3 E600073

U2 1 Voltage Regulator, 9 volt, LM78L09 E600054

Q6 1 Transistor, NPN, PN2222A E580001

U4 1 Voltage Regulator, 5 volt, LM7805 E600024

Q5 1

Transistor, MOSFET, 2N7000

i

Handle with care – ESD Sensitive. Do not remove it from its

ESD-protective packaging until you are instructed to install it.

E580002

Q4 1

Transistor, HEXFET, IRL620

E580018

Pre-mounted on

the PCB

Q3 1 Transistor, PHEMT, ATF 34143 E580020

Q2 1 Transistor, NPN , BFR96 E580021

R21 1 Resistor, metal oxide, 1 watt, 5%, 820 ohm (821) E500094

R20, R26, R27 3 Resistor, metal oxide, 3 watt, 5%,160 ohm (160) E500095

R10 1 Trimmer Potentiometer, PC mount, 100K (104) E520001

R13, R22 2 Trimmer Potentiometer, PC mount, 100 ohm (101) E520008

D1, D2, D4, D13, D6,

D12, D9, D14, D15, D16

10 Diode, 1N4148 E560002

D7, D8 2 Diode, 1N5711 E560004

Page 16

— — 14

Picture Ref. Designator(s) QTY Description Part #

R25 1 Resistor , 1/4 watt, 5%, 56 ohm (grn-blu-blk) E500096

R14 1 Resistor , 1/4 watt, 5%, 4.7 ohm (yel-vio-gld) E500062

R1, R7, R9, R33 4 Resistor , 1/4 watt, 5% , 10K ohm (brn-blk-org) E500015

R11 1 Resistor, 1/4 watt, 5%, 1K ohm (brn-blk-red) E500013

R18 1 Resistor, 1/4 watt, 5%, 620 ohm (blu-red-brn) E500097

R4, R5 2 Resistor, 1/4 watt, 5%, 5.6K ohm (grn-blu-red) E500007

R23, R34 2 Resistor, 1/4 watt, 5%, 100K ohm (brn-blk-yel) E500006

R40 1 Resistor, 1/4 watt, 5%, 22k ohm (red-red-org) E500090

R31 1 Resistor , Metal Film, 1/4 watt, 1%, 15.0K ohm (brn-grn-blk-red) E500112

R32 1 Resistor, Metal Film, 1/4 watt, 1%, 3.92K ohm (org-wht-red-brn) E500110

R30 1 Resistor, Metal Film, 1/4 watt, 1%, 7.50K ohm (vio-grn-blk-brn) E500111

R35 1 Resistor, Metal Film, 1/4 watt, 1%, 5.11K ohm (grn-brn-brn-brn) E500109

R16, R8 2 Resistor , 1 watt , 5%,120 ohm (brn-red-brn) E500105

R12, R19 2 Resistor, 1 watt, 5%, 180 ohm (brn-gry-brn) E500113

R15 1 Resistor 56 ohm SMD, 1206 size E500099 Pre-mounted on the

PCB

R17 1 Resistor, .02 ohm SMD, 2512 size E500100

C2,C57 2 Ceramic Capacitor, 100 pF (101) E530117

C35 1 Ceramic Capacitor, 10 pF (100) E530118

C55,C56 2 Ceramic Capacitor, 270 pF (271) E530050

C52,C54 2 Ceramic Capacitor , 150 pF (151) E530049

C53 1 Ceramic Capacitor, 18 pF (180) or (18), LS 0.2 E530088

C3, C17, C15, C7, C39 5

Ceramic Capacitor, .001

µF (102), LS 0.1

E530129

C8, C9, C10, C27, C16,

C19, C23, C20, C34,

C38, C37, C36, C63,

C22, C40, C6, C61, C62,

C64, C67, C71

21

Ceramic Capacitor, .01µF (103), LS 0.1

E530130

C65, C68, C29 3

Ceramic Capacitor, .047 µF (473), LS 0.1

E530131

Capacitors shown

are typical. Different

styles may be

supplied.

C30 1

Ceramic Capacitor, .22 µF (224), LS 0.1

E530132

C18 1 Ceramic Capacitor, 2.2 pF (2.2), LS 0.1 E530047

C70 1 Ceramic SMD Capacitor, 27 pF E530121

C72 1 Ceramic SMD Capacitor, 4.7 pF E530125

Pre-mounted on the

PCB

C25, C21, C24, C41, C32

C66, C31, C4, C84, C85

10

Ceramic SMD Capacitor, .047 µF, 50 V

E530120

Page 17

— — 15

Picture Ref. Designator(s) QTY Description Part #

C26, C60 2

Electrolytic Capacitor, 22 µF, 25 volt

E530012

L9 1

Molded Inductor, .47 µH (yel-vio-silver)

E690020

L8 1

Molded Inductor, 15 µH (brn-grn-blk)

E690012

L15,L16,L17 3 Variable Inductor, .243-.297 µH, shielded, grey plastic insert. E690025

L7 2 Ferrite Bead E980029

T1 1 Toroid Core, FT37-43 E680003

12 in.

(30 cm)

Solid Insulated Wire, #24 E760005

12 in.

(30 cm)

Red magnet wire, , #26 E760002

12 in.

(30 cm)

Green magnet wire, #26 E760004

3 in.

(7.5 cm)

Bare copper wire, , #14 E760023

5 ft.

(1.5 m)

Red/Black 2-conductor wire, #12 stranded (for DC power wiring) E760017

3 ft.

(91 cm)

4-conductor shielded cable (serial I/O cable) E760009

1 Heat sink gasket, large E100170

1 Heat sink gasket, small E100171

1 5” Hex Tuning Tool E980068

Page 18

— — 16

Front panel circuit board components.

Picture Ref. Designator(s) QTY Description Part #

1 Printed Circuit Board E100168

2 Screw, Fillister Head, 1/8 inch, 2-56 E700023

U1 1

Microcontroller PIC16F872, Programmed (packaged in foam)

i

Handle with care – ESD Sensitive. Do not remove it from its

conductive foam until you are instructed to install it.

E610014

1 IC Socket, 28 pin (packaged in foam) E620011

J1 1 Header Socket, 12 Pin E620008

D1, D2 2 Rectangular LED, Red E570007

D3 1 Rectangular LED, Yellow E570009

D4, D5, D6, D7, D8,

D9, D10,

7 Rectangular LED, Green E570008

R6, R7, R8, R9, R10,

R11, R12, R13,R14,

R15, R16, R21, R22,

R23

14 Resistor, Metal Film, 1/4 watt 120 ohm (brn-red-brn) E500022

R1 1 Resistor, Metal Film 1/4 watt, 5%, 220 ohm (red-red-brn) E500002

R2 1 Resistor, Metal Film 1/4 watt, 5%, 470 ohm (yel-vio-brn) E500003

R3 1 Resistor, Metal Film 1/4 watt, 5%, 10K ohm (brn-blk-orn) E500015

R4, R17 2 Resistor, Metal Film 1/4 watt, 5%, 100K ohm (brn-blk-yel) E500006

R25 1 Resistor, Metal Film 1/4 watt, 5%, 270K ohm (red-vio-yel) E500101

R18, R19, R20,R24 4 Resistor, Metal Film 1/4 watt, 5%, 2.2K ohm (red-red-red) E500104

R5 1 Resistor, Metal Film 1/4 watt, 5%, 1 megohm (brn-blk-grn) E500024

C4 1

Capacitor, Monolithic, .001 µF, (102), LS 0.1

E530129

C2, C3 2

Capacitor, Monolithic, .01 µF, (103), LS 0.1

E530130

C1 1

Capacitor, Monolithic, .047 µF (473), LS 0.1

E530131

D11 1 LED Light Bar, Yellow (packaged in foam) E570011

Page 19

— — 17

Picture Ref. Designator(s) QTY Description Part #

Q1,Q2,Q3,Q4,Q5,Q6 6 Transistor, NPN, PN2222 E580001

Z1 1 Ceramic Resonator, 4 MHz E660001

JP1 1 Header Connector, 2 pin E620054

1 Header Shorting block, 2 pin E620055

Page 20

— — 18

i

The remainder of the parts in your kit depend upon the band of operation. Check only the list that corresponds to your transverter.

XV50: The following parts are included only in the XV50 transverter.

Picture Ref. Designator(s) QTY Description Part #

1 Front Panel Label, XV50 E980059

Pre-mounted on the

PCB

U6 1

SGA7489, Sirenza Gain Block Amplifier (Three-lead device with tab. Two leads

and tab are soldered to the board. Center lead is not connected)

E600055

U3 1 Voltage Regulator, 9-volt, LM78L09 E600054

Q1 1 Transistor, NPN, MPS918 E580022

U7 1 RF Power Module, M57735 E600056

J1 1 SO-239 Chassis Mount Connector E620064

R24 1 Resistor, Metal Oxide, 2 watt, 5%, 56 ohm (56J) E500102

Z4 1 Resistor, 1/4 watt, 5%, 56 ohm (grn-blu-blk) E500096

R6 1 Resistor, 1/4 watt, 5%, 330 ohm (org-org-brn) E500103

C69 1 Ceramic Capacitor, LS 0.1, 10 pF (100) E530118

C14, C58, C59 3 Ceramic Capacitor, LS 0.1, 390 pF (391) E530051

C12 1 Ceramic Capacitor LS 0.1, 100 pF (101) E530117

C42,C43 2 Ceramic Capacitor, SMD, 50 V, 82 pF E530133

C44 1 Ceramic Capacitor, SMD, 50 V, 150 pF E530134

C5,C49,C50 3 Ceramic Capacitor, SMD, 50 V, 2.2 pF E530123

C48,C51 2 Ceramic Capacitor, SMD, 50 V, 10 pF E530135

C28 1 Ceramic Capacitor, SMD, 50 V, 15 pF E520127

C45,C47 2 Ceramic Capacitor, SMD, 50 V, 22 pF E530136

Pre-Mounted on the

PCB.

C46 1 Ceramic Capacitor, SMD, 50 V, 27 pF E530121

C1, C33 2 Ceramic Trimmer Cap, 5-30 pF E540001

Page 21

— — 19

Picture Ref. Designator(s) QTY Description Part #

Z3 1

Molded Inductor, .15 µH (brn-grn-silver)

E690022

L2, L3 2

Molded Inductor, .22 µH (red-red-silver)

E690028

L10,L11 2

Variable Inductor,

.198-.240 µH, Blue

E690032

L1 1

Variable Inductor,

.333-.407 µH, Grey

E690033

L12,L13,L14 3 Variable Inductor, .243-.297 µH, Shielded, Grey Plastic Insert. E690025

L3 2 Ferrite Bead E980029

Y1 1 Crystal, 22 MHz Fundamental (22.00) E660004

Page 22

— — 20

XV144: The following parts are included only in the XV144 transverter.

Picture Ref. Designator(s) QTY Description Part #

1 Front Panel Label, XV144 E980060

Pre-mounted on the

PCB

U6 1

Amplifier, MMIC, ERA-5 (Four-lead device with no tab. All four leads soldered to

board)

E600052

U3 1 Voltage Regulator, 5-volt, LM78L05 E600029

Q1 1 Transistor, NPN, MPS918 E580022

U7 1 RF Power Module, RA30H1317M E600058

R39 1 Pot, PC mount, 1K ohm (102) E520010

Z4, R29 2 Resistor, 1/4 watt, 56 ohm (grn-blu-blk) E500096

R24 1 Resistor, 1 watt, 120 ohm (brn-red-brn) E500105

R28 1 Resistor, 1/4 watt, 1K ohm (brn-blk-red) E500013

R6 1 Resistor, 1/4 watt, 470 ohm (yel-vio-brn) E500003

C14 1 Ceramic Capacitor, 0.1 LS, 33 pF (330) E530116

C12 1 Ceramic Capacitor, 0.1 LS, 10 pF (100) E530118

C13 1

Ceramic Capacitor, 0.1 LS, .047

µF (473)

E530131

C42,C43 2 Ceramic Capacitor, SMD, 50 V , 27 pF E530121

C44 1 Ceramic Capacitor, SMD, 50 V , 47 pF E530122

C5 1 Ceramic Capacitor, SMD, 50 V, 2.2 pF E530123

C48,C51, C28 3 Ceramic Capacitor, SMD, 50 V, 4.7 pF E530125

C45,C47 2 Ceramic Capacitor, SMD, 50 V, 12 pF E530126

C46 1 Ceramic Capacitor, SMD, 50 V, 15 pF E530127

Pre-mounted on the

PCB

C49,C50 2 Ceramic Capacitor, SMD, 50 V, 1 pF E530128

C1 1 Ceramic Trimmer Capacitor, 4-15 pF (Has a blue dot for identification) E540003

Page 23

— — 21

Picture Ref. Designator(s) QTY Description Part #

L2, Z3 2

Molded Inductor, .1 µH (brn-blk-silver)

E690021

L4 1

Molded Inductor, .15 µH (brn-grn-silver)

E690022

L10,L11 2 Variable Inductor,

.085-0.1µH, Orange E690023

L1 1

Variable Inductor,

.108-.132 µH, Orange

E690024

L12,L13,L14 3

Variable Inductor,

.059-070 µH, Red Plastic Insert.

E690027

Y1 1 Crystal, 116 MHz, 5th Overtone Series Resonant (116.000) E660016

J1 1 Type “N” Chassis Mount Female Connector E620069

Teflon Tubing E980075

Page 24

— — 22

XV222: The following parts are included only in the XV222 transverter.

Picture Ref. Designator(s) QTY Description Part #

1 Front Panel Label, XV222 E980061

Pre-Mounted on the

PCB

U6 1

SGA7489, Sirenza Gain Block Amplifier (Three-lead device with tab. Two leads

and tab are soldered to the board. Center lead is not connected)

E600055

U3 1 Voltage Regulator, 5-volt, LM78L05 E600029

Q1 1 Transistor, NPN, MPS918 E580022

U7 1 RF Power Module, RA30H2125M or RA30H2127M E600057

R28 1 Resistor, 1/4 watt, 5%, 1K ohm (brn-blk-red) E500013

R6 1 Resistor, 1/4 watt, 5%, 220 ohm (red-red-brn) E500002

R24 1 Resistor, 2 watt, 5%, 56 ohm (grn-blu-blk) E500102

R29, Z4 2 Resistor, 1/4 watt, 5%, 56 ohm (grn-blu-blk) E500096

C14 1 Ceramic Capacitor, LS 0.1, 22 pF (220) E530139

C12 1 Ceramic Capacitor, LS 0.1, 10 pF (100) E530118

C13 1

Ceramic Capacitor LS 0.1, .047 µF (473)

E530131

R39 1 Trimmer Potentiometer, PC mount, 1K ohm (102) E520010

C42, C43, C44, C44A,

C45, C47

6 Ceramic Capacitor, SMD, 50 V, 10 pF E530135

C5, 1 Ceramic Capacitor, SMD, 50 V, 2.2 pF E530123

C48,C51 2 Ceramic Capacitor, SMD, 50 V, 3.3 pF E530124

C46 1 Ceramic Capacitor, SMD, 50 V 12 pF E530126

C49, C50, C45A,

C46A, C47A

5 Ceramic Capacitor, SMD, 50 V, 1 pF E530128

Pre-mounted on the

PCB

C28 1 Ceramic Capacitor, SMD, 50 V, 4.7 pF E530125

C1 1 Ceramic Trimmer Capacitor, 4-15 pF (Has a blue dot for identification) E540003

L2, Z3 2

Molded Inductor, .1 µH (brn-blk-silver)

E690021

Page 25

— — 23

Picture Ref. Designator(s) QTY Description Part #

L10, L11, L4A, L19 4

Variable Inductor,

.064-.080 µH, Red

E690029

L1 1

Variable Inductor,

.041-.044 µH, Brown

E690034

L12, L13, L14 3

Variable Inductor, Shielded,

.038-.040 µH, Brown Plastic Insert

E690031

Y1 1 Crystal, 194 MHz 7th Overtone Series Resonant (194.000) E660017

J1 1 Type “N” Chassis Mount Female Connector E620069

1 in Teflon Tubing E980075

Page 26

— — 24

Front Panel Board Assembly

Place the front panel board on top of the heat spreader with the silk

screened side down as shown in Figure 5. Temporarily attach the board to

the heat spreader with a single 3/16” (4.8 mm) pan-head screw.

FRONT-PANEL PCB

SILK-SCREENED SIDE DOWN

Figure 5. Preparing Front Panel to Install Light Bar.

Prepare the leads of the yellow light bar for mounting on the board

by bending them as shown in Figure 6. Press the leads against a smooth,

hard surface and roll the roll the light bar until they are at about a 45

degree angle to the side of the light bar.

1

23

.

Figure 6. Preparing Light Bar Leads.

Position the light bar in the cutout of the board as shown in Figure 7.

Adjust the leads as necessary so they line up with the six solder pads at

the edge of the cutout. The leads will NOT pass through the solder pads.

The tips of the leads will rest just inside the top of each solder pad.

Figure 7. Installing Light Bar.

Solder the six terminals to the circuit board pads.

Remove the front panel board from the heat spreader.

Page 27

— — 25

i

The front panel board has parts on BOTH sides of the board.

Follow the instructions carefully. If parts are placed on the wrong

side of the board, it will not mate with the RF board properly or it

will not fit inside the enclosure when construction is finished. Parts

that go on the back (not silk screened) side of the board are identified

by asterisks on the silk screening.

Place the 28 pin IC socket in the holes provided on the front panel

board at the end opposite the light bar you just installed. The socket goes

on the BACK of the board (the side opposite the silk screened outline).

Orient the socket so the notch in the end is facing away from the end of

the board, as shown on the outline.

While holding the IC socket against the board, wet the tip of your

soldering iron with a very small amount of solder and then touch it a pin

and solder pad at one end of the socket to tack-solder it in place.

Tack-solder a second pin at the opposite end of the socket.

Check the IC socket carefully to ensure:

The socket is on the side of the board that is NOT silk-screened.

The notched end of the socket is on the end farthest from the end

of the board (as shown on the silk-screened outline).

The socket is against the board at both ends. If necessary, heat the

tack-soldered joints and adjust the socket so it is flush.

Solder all 28 pins of the IC socket and trim the leads. Be sure to

solder properly the two pins you tack-soldered above.

i

If your solder joints are not clean and shiny, your iron may

not be hot enough, or you may be using the wrong type of solder.

These "cold" solder joints will likely result in poor performance,

reliability problems, or component failure. You may wish to consult

our web site for additional soldering instructions and tool

recommendations.

Locate the silk screened outline for Q5 near the yellow light bar.

Install a PN2222 transistor on the BACK side of the board (the side that

is not silk screened). The transistor’s leads should protrude through the

board on the silk screened side.

Note: The wide, flat side of the transistor must line up with the flat

side of the silk screened outline on the board (See Figure 9). The

part number may be on either side of the transistor.

O

R

FLATTENED

BACK

ROUNDED

BACK

PCB OUTLINE

Figure 8. Transistor Orientation Guide.

Position the transistor on the board as shown in Figure 9 and bend

the leads to hold it in place. Solder and trim the leads as short as

possible.

A

PPROX.

3/16” (3 mm

)

SPACE

SOLDER & TRIM LEADS

Figure 9. Installing Transistors.

Page 28

— — 26

i

In the steps that follow, you'll be installing groups of

components. When working from a long list, install all of the items on

one line before moving on to the next. Arrows (⇒) appear in the list

to remind you of this order. Components may be soldered one at a

time or in groups. Leads can be trimmed either before or after

soldering. After trimming, leads should be 1/16" (1.5 mm) or less in

length.

Install six additional PN2222 transistors on the BACK side of the

board (the side that is NOT silk screened) just as you did Q1. Align the

flat side of each transistor with the outline shown on the silk screening.

__ Q6

⇒

__ Q1 __ Q7

__ Q2

⇒

__ Q3 __ Q4

Install capacitor C1, .047 µF (473) on the BACK side of the board

(the side that is NOT silk screened). Position the capacitor as shown in

Figure 10 .

INSERT LEADS UP

TO THE PLASTIC

COATING

473

BE SURE NUMBERS SHOWN IN PARENTHESIS

IN TEXT APPEAR ON BODY. THERE MAY BE

ADDITIONAL MARKINGS AS WELL.

SOLDER & TRIM LEADS

Figure 10. Installing Capacitors.

Install capacitor C4, .001 µF (102) on the BACK side of the board

(the side that is NOT silk screened).

Install ceramic resonator Z1 (4.0 MG) on the BACK side of the

board (the side that is NOT silk screened). This part may be inserted in

either direction. Like the capacitors, insert the resonator as far as the

plastic coating on the leads will allow.

Install JP1, a two-pin header connector on the BACK side of the

board (the side that is NOT silk screened) as shown in Figure 11 .

Temporarily place a shorting block on the pins to provide a finger rest

while soldering. Do not hold the solder iron on the pins more than 1

or 2 seconds. Excessive heat will melt the plastic part of the header.

SILK SCREENED SID

E

SHORT PINS GO

THROUGH

BOARD

Figure 11. Installing Header Connectors.

Check to ensure that:

_ All of the above parts were installed in the BACK of the

BOARD (the side with NO silk-screening).

_ All parts are soldered.

_ All leads are trimmed to 1/16” (1.5 mm) or less.

Page 29

— — 27

i

The remaining parts will be installed on the FRONT of the

circuit board

Follow the LED installation instructions carefully to preserve the

appearance of your transverter’s front panel. When finished, the

LEDs should be perpendicular to the board and in a straight line (See

Figure 12).

Figure 12. Power LEDs Installed on Front Panel Board.

Sort the rectangular LEDs into groups according to color.

Note that one lead of each LED is longer than the other. This is the

anode lead. It must be inserted in the right hand hole for each LED as

shown on the front panel board. The right hand holes have square

PCB pads to help identify them. The LEDs will not illuminate if the

leads are reversed.

Insert the leads of a green LED through the holes provided for D10

on the silk screened side of the front panel board. Be sure the long lead is

in the right-hand hole (with the square pad). Do not solder yet.

Hold the LED with the back of the plastic housing flat against the

board (not tilted). Bend the leads outward on the bottom side to hold it in

place.

Solder one lead of the LED, keeping soldering time to 1 to 2 sec.

If the LED is tilted or is not flat against the board, re-heat the lead

while pressing the LED down.

Once the LED is correctly positioned, solder the other lead, again

keeping soldering time to 1 or 2 seconds. Then trim both leads.

Install a green LED at D9. Make sure the long lead is to the right

as shown on the board. Before soldering, adjust the LED's position as

with D10.

Install green LEDs at D8, D7, D6, D5, and D4. Make sure the long

lead is to the right for these and all remaining LEDs.

Install a yellow LED at D3.

Install red LEDs at D2 and D1.

Page 30

— — 28

Sort all of the resistors by value. If the color bands are difficult to

read, use a DMM (digital multimeter) to verify their values. Tape them to

a piece of paper with the values labeled.

Install the resistors below on the front (silk screened) side of the

board. Align each resistor to rest against the board inside the silk screened

outline (See Figure 13). Start with R1 near the light bar end of the board.

__R1, 220 ohm (red-red-brn)

⇒

__R16, 120 ohm (brn-red-brn)

__R22, 120 ohm (brn-red-brn)

__R21, 120 ohm (brn-red-brn)

__R24, 2.2k (red-red-red)

__R2, 470 ohm (yel-vio-brn)

__R25, 270k (red-vio-yel)

__R23, 120 ohm (brn-red-brn)

__R14, 120 ohm (brn-red-brn)

__R15, 120 ohm (brn-red-brn)

__R13, 120 ohm (brn-red-brn)

__R5, 1 meg (brn-blk-grn)

__R3, 10k (brn-blk-org)

__R18, 2.2k (red-red-red)

__R20, 2.2k (red-red-red)

__R4, 100k (brn-blk-yel)

__R17, 100k (brn-blk-yel)

__R19, 2.2k (red-red-red)

__R12, 120 ohm (brn-red-brn)

__R11, 120 ohm (brn-red-brn)

__R10, 120 ohm (brn-red-brn)

__R9, 120 ohm (brn-red-brn)

__R8, 120 ohm (brn-red-brn)

__R7, 120 ohm (brn-red-brn)

__R6, 120 ohm (brn-red-brn)

BODY OF PART

AGAINST THE BOAR

D

ENSURE MARKINGS AGREE WITH

INSTRUCTIONS IN TEXT

SOLDER & TRIM LEADS

Figure 13. Installing Resistors.

Install the two capacitors listed below on the front (silk screened)

side of the board, near the outline of the 28-pin IC socket. Check each

capacitor's labeling carefully (shown in parentheses).

__C2, .01µF (103) __C3, .01 µF (103)

Inspect the board carefully for the following:

All connections soldered.

No solder bridges between pads (use a magnifier as needed).

All leads clipped to no more than 1/16” (2 mm) long.

Uninstalled Components

Verify that all component locations on the front panel board are

filled, except the following:

U4 (controller 16F872) should not be installed in its socket yet.

J1 at the bottom center of the board. This will be installed in the next

section.

You’ve finished the Front Panel Board Assembly Procedure. Go to the

RF Board Assembly – Part I on the next page to continue.

Page 31

— — 29

RF Board Assembly – Part I

RF circuit assembly is divided into three parts:

Part 1: DC, control circuits and RF components common to all of the

transverters.

Part 2: Additional RF components unique to each band.

Part 3: Installation of the RF power module.

i

Handle the RF board carefully. Some surface-mounted components are

used in the RF circuits for optimum transverter performance. The RF circuit

board is supplied with these components pre-mounted. Take care not to damage

them.

i

Do NOT remove the temporary wire jumper across the solder pads

for L1 until instructed to do so. This jumper protects U1 from static damage

until the circuits are completed.

Locate the two small L-brackets. Identify the shorter side of the "L",

which will be attached to the RF board.

On the RF board, locate the hole at either end of the silk screened

lettering:

P1 MOUNTS ON OTHER SIDE OF BOARD. These are the holes

where “L” brackets will be installed.

Secure the shorter leg of an L-bracket loosely to the RF board in

each hole using a 4-40 x 3/16” (4.8 mm) black screw. A lock washer is

not required at this time.

Locate the 12-pin female connector (J1) and the 12-pin male

connector (P5). Normally J1 is included with the Front Panel board parts

and P5 is with the RF Board parts.

Slide the 12-pin female connector (J1) onto the pins of the 12-pin

male connector (P1). There should be no gap between them.

Insert P1's right-angle pins into the holes on the bottom of the RF

board near the letters:

P1 MOUNTS ON THIS SIDE OF BOARD. Do not

solder yet.

Position the Front Panel board as shown in Figure 14. The pins of

J1 should be inserted into the holes in the Front Panel board, and the two

L-brackets should be aligned with their outlines on the back of the Front

Panel board.

Secure the L-brackets loosely to the Front Panel using two 4-40 x

3/16" (4.8 mm) screws (black). It is not necessary to use lock washers at

this time.

Adjust the L-bracket positions so the Front Panel board is aligned

with the RF board If the gap between the Front Panel board and the RF

board is wider at one end than the other, you probably have one of the

brackets in backwards. Be certain the shorter legs are attached to the RF

board.

P1

Top of RF board

J1

Figure 14. Installing J1 and P1.

Tighten all four L-bracket screws.

Solder all pins of J1 and P1.

Remove the two screws holding the Front Panel board to the

brackets. Unplug the Front Panel board and set it aside in a safe place.

Remove the brackets and screws from the RF Board and set them

aside.

Page 32

— — 30

Sort the fixed resistors by wattage and value as follows:

Divide the resistors by wattage: 3-watt (physically largest), 1-watt

and 1/4 watt (smallest).

Among the 1/4 watt resistors, separate the four 1% tolerance

resistors. These resistors have five color bands: four color bands

show the value plus a brown color band at one end that is wider

than the others. The wide band indicates that it is a 1% tolerance

resistor.

Sort the remaining 1/4 watt resistors by value. If the color bands

are difficult to read, use a DMM (digital multimeter) to verify

their values. Tape them to a piece of paper with the values

labeled.

Place the circuit board with the silk screened side up and the cutout

to your left. The lettering in the center of the board will read right side up.

All of the remaining parts will be installed on the top, silk screened side

of the board.

i

Save the longer clipped leads from the following resistors.

You will use several of them to make jumpers and test points later.

Install the 1-watt resistors listed below. Space each resistor about

1/16” (1.5 mm) above the board by placing the long end of one of the

right-angle brackets between the resistor and circuit board until the

resistor is soldered in place (See Figure 15). The objective is to leave

space for air to flow around the resistor. These resistors that should be

spaced above the board are shown by a double silk screen outline.

R12, 180 ohm (brn-gry-brn), near U1 in the upper left area of the

board.

R16, 120 ohm (brn-red-brn) next to R12.

R21, 820 ohms (821), 1 watt next to Q6.

R19, 180 ohm (brn-gry-brn), near U5 at the center of the board.

R8, 120 ohm (brn-red-brn) near Z1 in the lower right area of the

board.

PLACE RIGHT-ANGLE BRACKET

UNDER EACH RESISTOR UNTIL

IT IS SOLDERED IN PLACE

SOLDER & TRIM LEADS

Figure 15. Spacing the 1-watt and 3-watt Resistors above the PCB.

Install the following 3-watt resistors above R21 near the center of

the board. Space each resistor about 1/16” (1.5 mm) above the board just

like you did for the 1-watt resistors.

__R20, 160 ohm (160)

⇒

__R26, 160 ohm (160)

__R27, 160 ohm (160)

Install the 1/4-watt 1% tolerance resistors listed below in the lower

left area of the circuit board. Place these and all of the rest of the resistors

directly against the circuit board.

R35, 5.11k (grn-brn-brn-brn)

R31, 15.0k (brn-grn-blk-red)

R30, 7.5k (vio-grn-blk-brn)

R32, 3.92k (or-wht-red-brn)

Page 33

— — 31

Install the 1/4 watt resistors listed below. Start with R1, which is on

the left side just above the cutout in board. The locations follow the

perimeter of the board going clockwise.

__R1, 10k (brn-blk-org)

⇒

__R11, 1k (brn-blk-red)

__R14, 4.7 ohm (yel-vio-gld) __R23, 100k (brn-blk-yel)

Install the 1/4 watt resistors listed below. Start with R4, which is on

the lower right above Z1. The locations follow the perimeter of the board

going clockwise.

__R4, 5.6k (grn-blu-red)

⇒

__R25, 56 ohm (grn-blu-blk)

__R5, 5.6K (grn-blu-red) __R7, 10k (brn-blk-org)

__R34 (on the right edge of the board), 100k (brn-blk-yel)

__R9, 10k (brn-blk-org) __R33, 10k (brn-blk-org)

Install the following 1/4 watt resistors next to Q6 at the center of the

board:

R18, 620 ohm (blu-red-brn)

R40, 22k (red-red-org)

Locate the silk screened space for D5 on the board near R23 in the

upper right area of the board.

i

Diodes must be oriented correctly. A black band around the

diode indicates the cathode end. Install each diode so the cathode end

goes to the square solder pad and the band is oriented to match the silk

screened outline (see Figure 16 below). If a diode has more than one

band, the widest band indicates the cathode end.

Figure 16. Circuit Board Diode Orientation Guides. The cathode

always goes to the square solder pad on the board.

Install D5 (SB530) so it is against the board and the banded end of

the diode is aligned with the banded end of the PC board outline. Save

the excess leads when you clip them.

Put the clipped leads from D5 in a safe place. Keep them separate

from the other clipped leads you are saving for test points and jumpers.

You will use the leads from D5 when you install antenna connector J1

later.

Sort the small glass diodes by type. If necessary use a strong

magnifier to read the tiny numbers printed on the glass body. Tape each

group to a piece of paper marked by the type number.

1 ea. 1N5235

2 ea. 1N5711

10 ea. 1N4148

Page 34

— — 32

Install zener diode D3 (1N5235) in the upper left quadrant of the

board near R12. Position it against the board with the banded end aligned

with the banded end of the PC board outline.

Install the two 1N5711 diodes in the lower right quadrant of the

board. Place each diode against the board with the cathode band oriented

as you did in the previous steps.

__D7 __D8

Install the 1N4148 diodes listed below. Start with D1, which is near

resistor R1 in the upper left portion of the board and work clockwise

around the board.

__D1

⇒

__D12 __D6 __D9 __D13

__D14 __D15 __D16 (In lower right quadrant),

__D2 __D4

i

In the following steps you will install molded inductors. These

inductors look much like 1-watt resistors but the color codes read

differently. The color codes on the inductors read from the center to

the end instead of from the end towards the center like resistors.

Install molded inductor L8, 15µH (brn-grn-blk) in the upper right

quadrant of the board.

Install molded inductor L9, 0.47 µH (yel-vio-silver) about half way

up the board about 2 inches (5 cm) from the right-hand edge.

Install transistor Q6 (PN2222) next to R21 near the center of the

board. Orient the transistor as shown by the silk-screened outline on the

board.

Prepare transistor Q2 (BFR96) for installation as follows:

Place the transistor over the outline on the board with the lettered

side up and note the lead lengths required to match the three

solder pad areas on the board. Trim the leads to match these

pads.

Gently bend the leads down so they make solid contact with the

board starting close to the body of the transistor. This is easily

done by pressing down on the lead with a small flat-blade

screwdriver (see Figure 17).

Figure 17. Installing Transistor Q2. Use gentle pressure with a small

screwdriver blade to form the leads.

Page 35

— — 33

Solder Q2 in place as follows:

_ Wet your soldering iron with a small amount of solder and touch

it to one lead of Q2 tack-solder it in place.

_ Check alignment of the other two leads to be sure they are over

the solder pads. If necessary reheat the tack-soldered lead and

adjust the position of the transistor.

_ Solder all three leads properly, soldering the tack-soldered lead

last. Keep your soldering time as short as possible to avoid overheating the transistor. Do not hold the iron on the leads more

than two seconds.

i

Check each capacitor's labeling carefully to ensure the values

agree with the numbers shown in parenthesis.

Install the monolithic capacitors listed below near U3 and Q6 at the

center of the board.

__C68, .047 µF(473) ⇒ __C67, .01 µF (103) __C64, .01µF (103)

__C65, .047µF (473)

__C10, .01 µF (103) __C9, .01 µF (103)

Install the monolithic capacitors listed below. With the board

oriented with the cutout to the left, start with C62 near the lower left and

work around the board clockwise to the upper right quadrant.

__C62, .01 µF (103)

⇒

__C40, .01 µF (103) __C7, .001 µF (102)

__C8, .01 µF (103)

__C3, .001 µF (102) __C63, .01µF (103)

__C6, .01 µF (103)

__C22, .01 µF (103) __C61, .01 µF (103)

__C2, 100 pF (101)

__C23, .01 µF (103) __C38, .01 µF (103)

__C27, .01 µF (103)

__C29, .047 µF(473) __C37, .01 µF (103)

__C35, 10 pF (100)

__C36, µF .01 (103) __C34, .01 µF (103)

__C39, .001 µF (102)

Install the monolithic capacitors listed below. Start with C71 on the

edge of the board in the lower quadrant and work from right to left across

the lower part of the board.

__C71,.01 µF (103) ⇒ __C15, .001 µF (102) __C16, .01 µF (103)

__C20, .01 µF (103)

__C30, 0.22 µF (224) __C17, .001 µF (102)

__C19, .01 µF (103)

__C57, 100 pF (101)

Install disc ceramic capacitor C18 (2.2) next to C17 in the lower

right area of the board.

Install the capacitors listed below in the area near the center of the

board marked

28 MHZ IF BANDPASS FILTER. The lead spacing of these

capacitors may be narrower than the hole spacing on the board. If

necessary, form the leads to avoid stress on the capacitor when they are

inserted in the board. Do not force the capacitors down against the

board. The capacitors may sit about 1/16” (1.5 mm) above the board as

shown in Figure 18 .

__C55, 270 (271)

⇒

__C54, 150 (151) __C53, 18 (180) or (18)

__C52, 150 (151)

__C56, 270 (271)

The capacitors shown are typical.

Other styles may be supplied.

Figure 18. Installing I.F. Filter Capacitors.

Page 36

— — 34

Use a discarded lead to create test point TP3. Two holes for TP3 are

directly below R17 in the upper right quadrant of the board. Bend the lead

in a “U” shape and insert it in the holes indicated with a line between

them on the board. The loop formed should rise about 1/4” (4 mm) above

the board. Solder the leads.

Use a discarded lead to create TP4 next to TP3, following the

procedure described above. Solder the leads.

Make two ground test points just like you did for TP3 and TP4. The

places on the board are indicated by ground symbols. One is directly

below the “Elecraft” label and the other is in the lower left quadrant

below U6. Solder the leads.

Remove the eight small relays (G6E-134P) from the carrier tube. If

any of the pins are bent, straighten them carefully using long-nose pliers.

i

Most likely you’ll want to use a single antenna for both transmitting

and receiving with your transverter. However, some operators use separate

transmitting and receiving antennas and separate feed lines. See Connecting

the Transverter to an Antenna System. on page 74 for more information. The

following step provides special instructions to follow ONLY if you are

building your transverter for use with SEPARATE transmit and receive

antennas.

If you are building your transceiver for separate (split-path) transmit

and receive antenna connections, do the following:

_ In the next step, cross out relay “K1”. It will not be installed.

Remove K1 from your parts and set it aside in a safe place. You

may want it later if you decide to re-wire your transverter for

single antenna operation.

_ Use discarded leads to form jumpers across W2 and W3 near the

outline for K1 as shown in Figure 19.

Figure 19. Installing W2 and W3 for split path (separate transmit

and receive antenna) operation. Do NOT Install Relay K1

Working around the board clockwise from the upper left quadrant,

place the relays at the following locations. They can only be installed one

way. Do not solder the relays yet and do not clip or bend the relay

leads.

__K1

⇒

__K8 __K9 __K7

__K4

__K5 __K6 __K2

Using a thin, hardcover book to hold the relays in place, flip the

board and book over together.

Solder just two diagonally opposite corner pins on each relay.

Turn the book back over and check each relay. If any relay is not flat

against the board, re-heat its corner pins while pressing it down against

the board.

Once all the relays are properly seated, solder the remaining pins.

Take care to locate and solder all five pins on every relay. Do not trim

the relay pins. Trimming the pins can cause mechanical stress which

may reduce the life of the relay.

i

Note that W2 and W3 are used ONLY when separate

transmit and receive antennas are used and K1 is NOT installed.

Page 37

— — 35

Install resettable fuse F1 in the space provided next to relay K9. F1

may be oriented either way. Solder and trim the leads.

Check the pins on the large relay (KLT1C12DC12). If any pins are

bent, straighten them carefully using long-nose pliers.

Install the main power relay (KLT1C12DC12) next to F1 and solder

two diagonally opposite corner pins. Check the relay to ensure it is flush

against the circuit board. If necessary, reheat the solder while pressing

down on the relay.

Solder all five pins on the main power relay. Do not trim the relay

pins. Trimming the pins can cause mechanical stress which may reduce

the life of the relay.

Install a 3-terminal header at JP1 adjacent to relay K8. Put a shorting

block over two pins of the header to provide a surface where you can

place your finger to keep it straight and against the board. While holding

the assembly, touch one of the pins on the bottom of the board with a

soldering iron to tack-solder it in place. Check to ensure that the header is

sitting vertically on the board (see Figure 11). Reheat and adjust as

necessary, then solder all three pins. Do not hold the solder iron on the

pins more than 1 or 2 seconds. Excessive heat will melt the plastic

part of the header.

Remove the shorting block from JP1.

Install the following 3-terminal headers:

JP2 next to relay K8.

JP3 next to relay K8.

JP4 near resistor R21.

JP5 near relay K6.

JP6 near relay K6.

Install JP9 next to K4 and K5. JP9 requires one 2-terminal header

and one 3-terminal header.

Install the 100 k-ohm (104) potentiometer R10 (Power Cal) in the

upper left area of the board. The center lead goes toward the beveled end

of the silk screen outline (see Figure 20).The shoulders on the leads

should touch the top of the board.

Figure 20. Installing PC Board Pots. Orient the center pin toward

the beveled end of the silk screened outline.

Spread the leads on R10 to hold it in place, then solder and trim the

leads.

Install the two 100 ohm PC board potentiometers just as you did

R10:

R13 (101) in the upper left quadrant of the board near D3.

R22 (101) below the three 160-ohm 3-watt resistors near the

center of the board.

Verify that all three terminals on each pot are soldered.

Page 38

— — 36

Install 4-pole DIP switch SW1 in the space provided in the lower left

quadrant of the board. The DIP switch may not have a notch at one end to

line up with the silk screened outline. Orient the switch so that the ON

positions are on the side with the silk screened numbers. If you aren’t

sure, use your DMM to check the orientation of the switch assembly so

there is continuity through each switch when the toggle is toward the silk

screened number on the circuit board.

Bend the leads of voltage regulator U4 (UA78M05C) to fit on the

board as shown in Figure 21. Bend the leads around the shaft of a small

screwdriver to create smooth rather than sharp bends.

USE SMOOTH BEND

Figure 21. Installing Voltage Regulator U4.

Insert U4’s leads into the holes. Secure it with a zinc 4-40 x 5/16” (8

mm) screw, #4 lock washer and 4-40 nut as shown. The metal tab on the

transistor sits directly against the metal foil on the circuit board.

Solder all three leads to U4 on the bottom side of the board and trim

them short.

Install two 22 µF, 25 VDC electrolytic capacitors near the notch on

the left side of the board. Be sure to observe polarity. The longer

positive lead goes in the square solder pad with a

+ silk screened next

to it.

__C26 __C60

Locate diodes D10 and D11. They are square, red LEDs identical to

the ones you installed on the front panel board.

Locate the positions for D10 and D11 on the board, near the center

on the right hand side. Note that the square solder pad for D10 is to the

left and the square solder pad for D11 is to the right. The diodes must be

installed turned 180 degrees with respect to each other.

Position diode D10 on the board with the long lead through the

square pad on the left and the short lead through the round pad. Position

the body of the LED directly against the board within the silk screen

outline and spread the leads under the board to hold the diode in place.

Solder one lead on the bottom of the board. Check to be sure the

LED is still positioned directly against the board. Reheat and adjust the

LED as necessary, then solder and trim both leads.

Position diode D11 on the board with the long lead through the

square pad on the right, opposite the orientation of D10. Solder and trim

the leads as you did for D10.

Locate the inductors provided for L15, L16 and L17 in the I.F.

Bandpass filter. They will have grey plastic forms visible inside the

shields. Prepare the inductors for installation as follows:

Use the inductor alignment tool to exercise the core in each

inductor. If the alignment tool fits tightly, insert it from the

bottom to avoid pushing the inductor out of the shield. Run the

core up and down through the coil to ensure it runs smoothly

(some inductors are very stiff at first) then position the core near

the top of the coil.

Check the two leads and the two tabs on the case of each

inductor. If they are bent, straighten them carefully using long

nose pliers.

Page 39

— — 37

Position each inductor on the board so that its tabs and pins protrude

through on the bottom. The inductors can be positioned either way.

Ensure that the shoulders of the tabs are against the top of the board, and

then bend the tabs toward each other until they are flat on the board to

hold the inductor in place.

__L16

⇒

__L15 __L17

Solder the two tabs and the two pins on all three inductors.

Install voltage regulator U2 (78L09) in the space provided near L17.

Be sure to align the body with the silk screen outline on the board.

Install transistor Q4 (IRF 620) in the space provided near diodes D7

and D8 as shown in Figure 19. Be sure the leads are inserted until their

shoulders are against the top of the board. If the leads are not

inserted far enough, the tab on the top of the transistor may short

against the top cover when the cabinet is assembled. Trim the leads as

short as possible on the bottom of the board.

Figure 22. Installing Transistor Q4.

i

The following transistor is particularly sensitive to electrostatic discharge (ESD) damage. If you are not wearing a grounded

anti-static wrist strap, touch an unpainted, grounded object before

handling Q5.

Install transistor Q5 (2N7000) in the space provided on the right

edge of the board.

Install two 2-pin header connectors next to Q5.

__JP8 __JP7

Page 40

— — 38

Wind torodial transformer T1 on the FT37-43 toroid core as follows4.

T1 uses a bi-filar winding, which means that two wires are wound on the

core together. The wires will be twisted together loosely before they’re

wound onto the core.

Twist the red and green enameled wires together over their entire

length. The wires should cross over each other 2 to 4 times per

inch (1 to 2 times per cm).

Wind 4 turns of the twisted pair on the FT37-43 toroid core as

shown in Figure 23. Each time the wire passes through the core

counts as one turn, so verify that the wires pass through the toroid

four times. Spread the turns around the core as shown in the

figure.

Separate the leads and trim them to a length of about 1” (2.5 cm).

Figure 23. Installing T1.

4

A pre-wound toroid is available from an Elecraft-approved source. See page 4.

i

In the next step the toroid leads will be stripped and tinned. The

leads must be prepared correctly to provide good electrical contact when

installed.

Strip the insulation and tin the leads using one of the following

techniques:

1. Heat Stripping:

a. Place a small amount of solder (a.k.a. a “blob” of solder) on

your soldering iron.

b. Insert the clipped end of the wire into the hot solder. If the

iron is hot enough, you should see the insulation bubble and

vaporize after 4 to 6 seconds.

c. Add more solder and feed more wire into the solder as the

enamel melts. Continue tinning the wire up to the edge of the

core, and then slowly pull the wire out of the solder.

d. If any enamel remains on the lead, scrape it away using your

thumbnail or sharp tool.

2. Burning: The insulation can be burned off by heating it with a