Page 1

ELECRAFT

PX3

H

IGH-PERFORMANCE

P

ANADAPTER

OWNER’S MANUAL

Revision A2, October 1, 2014

Copyright © 2014, Elecraft, Inc.

All Rights Reserved

Page 2

For Owners of the Elecraft K3

Transceiver and P3 Panoramic Display:

The PX3 has nearly all of the same features as the

P3*, including the same high-resolution color display,

2 to 200 kHz SPAN, fast sweep rates, and eight

programmable “hot keys” to do quick setup. The

primary difference between the two is in the interface

to the transceiver. The P3 digitally down-converts the

K3’s 8.215-MHz I.F. signal, while the PX3 uses

quadrature baseband demodulation (I/Q) to convert

signals from the KX3’s RX I/Q output jack. The

PX3’s method requires less interface and

demodulation circuitry, resulting in a significantly

lower-cost unit with lower power consumption

(consistent with portable use). For details on how

baseband I/Q demodulation impacts performance, see

PX3 Compared to the P3 and PC-Based Panadapters

on page 32

* “Fixed tune" mode is not yet available in the PX3.

If this feature is added at a future date, it may have

somewhat different performance than in the P3, in

terms of displayed bandwidth and allowed offset from

the currently-tuned frequency.

2

Page 3

Contents

If you purchased the PX3 Kit, go directly to page 35 to assemble your PX3

Key to Symbols and Text Styles ...................... 4

In the Box ........................................................ 5

Serial Data Cable ................................................. 5

PX3-KX3 Interface Cable (PX3CBL) ................. 5

DC Power Cable (E850524) ................................ 5

Quick-Start Guide ............................................ 6

Introduction .................................................... 10

PX3 Features ..................................................... 10

Easy Set-Up ................................................... 10

Display .......................................................... 10

Ergonomic Design ......................................... 10

Field Upgradable ........................................... 10

Front Panel ..................................................... 11

Control Groups .................................................. 11

Display .............................................................. 12

Primary Controls ............................................... 12

Menu ................................................................. 13

Programmable Function Keys ........................... 13

Side Panel Connectors ................................... 14

Basic Operation ............................................. 15

Using Tap/Hold Switches ................................. 15

Initial Power-Up ................................................ 15

Configuring the Display .................................... 15

Using the Menu ................................................. 15

Programmable Functions .................................. 15

Adjusting the Amplitude ................................... 16

Adjusting the Frequencies Displayed ................ 16

Using Markers ................................................... 16

Waterfall Markers ............................................. 17

Using Cursors .................................................... 17

Noise Blanker .................................................... 18

How to Set Up and Interpret the PX3 Display

....................................................................... 19

Spectrum Display .............................................. 19

Waterfall Display .............................................. 20

Averaging and Peak Hold ................................. 20

Span ................................................................... 20

Typical Spectra .................................................. 20

Advanced Operating Features ........................ 22

Remote-Control Commands .............................. 22

PX3 Utility Program ......................................... 22

Configuring the Power Switch .......................... 22

Firmware Upgrades ........................................ 23

Checking your Firmware Revision ................... 23

Forcing a Firmware Download ......................... 23

Updating KX3 Firmware .................................. 23

Opposite Sideband Nulling ............................ 24

Getting Ready ................................................... 24

Setting up the PX3 and KX3 to use the PX3

Internal Calibration Signal ................................ 27

Menu Functions ............................................. 28

PX3 Menu ......................................................... 28

Troubleshooting ............................................. 30

Power On/Off Issues ......................................... 30

Display Issues ................................................... 30

Parameter Initialization .................................. 31

PX3 Compared to the P3 and PC-Based

Panadapters .................................................... 32

Theory of Operation ....................................... 33

RS-232 Serial Interface Cable ....................... 34

Kit Assembly Instructions ............................. 35

Preventing Electrostatic Discharge Damage ..... 35

Tools Required ................................................. 35

Parts List ........................................................... 36

PX3 Front Panel Assembly Bag E850621 .... 36

Individually Wrapped Components .............. 36

PX3 Misc Bag - E850615 ................................ 37

PX3 Hardware Envelope – E850614 ................ 38

Assembly Procedure ......................................... 39

Overview of the Kit ...................................... 39

Servicing the PX3 .......................................... 50

Accessing the PC Boards .................................. 50

Cleaning the LCD Bezel ................................... 50

Replacing the LCD ........................................... 51

Specifications ................................................. 52

Customer Service and Support....................... 53

Technical Assistance .................................... 53

Repair / Alignment Service .......................... 53

Elecraft manuals with color images may be downloaded from

www.elecraft.com

3

.

Page 4

Key to Symbols and Text Styles

Identifies important information.

Operating or kit assembly tip.

-100

DISP

AVERAGE

MENU:Font

Characters displayed on the LCD screen

Tap switch function (labeled above a switch)

Hold switch function (labeled below a switch; hold for 1/2 sec. to activate)

Typical menu entry

4

Page 5

In the Box

In addition to the PX3 display itself, check the shipping box for the following contents.

Serial Data Cable

Connects the PX3 to a serial port on your personal computer to upload updated firmware and provide other

functions. If needed a serial cable with an RS232 interface is available (order the KXSER). These cables are

identical to and interchangeable with the serial interface cable used with the KX3 transceiver. If desired, you can

make your own RS232 serial interface cable. See page 34 for the schematic diagram.

PX3-KX3 Interface Cable (PX3CBL)

Connects the PX3 to your KX3 (See Figure 2 on page 8 or Figure 3 on page 9).

Do not substitute different or longer cables for the PX3CBL set supplied. Doing so may degrade the

performance of your PX3. See PX3 Compared to the P3 and PC-Based Panadapters on page 32 for details.

DC Power Cable (E850524)

Connects the PX3 your 9 to 16 Vdc power supply with tinned leads to connect to your power supply. Optionally

you can purchase the PX3 DC Power Supply that plugs into a mains outlet as shown below. Order the

(PWR121A-US).

The optional power supply comes with a right angle extension (PWR2.1RA)

5

Page 6

Quick-Start Guide

To get started using your PX3 right away, please read this page and the pages that follow, to connect your PX3

to your KX3 and explore the features and controls.

Figure 1. PX3 Front Panel.

Prepare your

KX3

Ensure your KX3 is equipped with Firmware version 2.19 or later: See your KX3 Owner’s

Manual for information about checking and updating the firmware if needed.

In the KX3 menu, set RX I/Q: On and exit the menu.

Setup and

Connections

Position the KX3 and PX3 as shown in the photograph on the cover, with the PX3 on the left

side of the KX3. This keeps the PX3 away from the RF fields around the KX3’s antenna

connectors that can interfere with the PX3.Do not substitute longer cables for the PX3CBL set

provided. Doing so may allow noise pickup from various sources, including switching power

supplies, 60-Hz AC, ground loops, and interface cables. You can pass the PX3CBL cables

connecting the KX3 and PX3 under or behind the PX3.

When adjusting the legs to position on your PX3, be sure the thumb screws are loose.

They thread into the legs, and forcing a leg into position without loosening the thumb

screw may tighten the thumb screw so much it becomes very difficult to loosen.

Connect a dc power supply to the

Specifications, page. 10 for more about the power requirements). A power cable with a right

angle 2.1 mm barrel connector is supplied. Connect the wire with the white strip to the positive

(+) terminal on your power supply. If you purchased the optional PWA121V1A-US power

supply for your PX3, plug it into a 100 to 240 volt mains outlet. It is provided with a rightangle cable adapter (PW2.1RA) that you can use for a neater cable installation.

We recommend that you turn off the external supply before connecting power to the

PX3. Some power connectors have an exposed center terminal that can create a short

circuit if it touches the metal ground when it is being inserted.

If your KX3 installation includes the Elecraft KXPA100 amplifier connected using the

KX3 to KXPA100 Adapter Cable, connect the PX3 as shown in Figure 3on page 9.

If you do not have the KXPA100 and adapter cable, connect the PX3 as shown in Figure

2 on page 8.

9-16 VDC input jack on the PX3 side panel (see

6

Page 7

The Basics

Other

Features

TAP AND HOLD: Most PX3 switches have two functions, similar to the KX3.Tap (press

briefly) to activate the function labeled on the switch. Hold (press for 1/2 second) activates the

function labeled below the switch. In the text, tap functions are shown like this:

DISP while a

hold function is shown like this: AVERAGE. Additional typographical conventions are shown

on the previous page.

The controls and indicators shown in Figure 1 are identified by the circled numbers in the

following text (e.g.

Apply power to the PX3 and tap

refers to the display screen).

PWR

to turn it on.

Tap DISP to cycle between spectrum and waterfall display modes (Page 15).

Activating many functions enables the SELECT knob so you can adjust the

parameter associated with the function. The current parameter value is shown on the screen

. You can exit and save the parameter by tapping the same key a second time, even for

hold functions.

For hold functions, you can also hold the key a second time to exit parameter-entry mode.

Holding the four keys along the right edge of the front panel

, , , , a second time

de-activates the function itself. For example, holding CENTER a second time returns

the display center frequency to the transceiver frequency and holding MKR B a second

time turns off marker B.

Tap MENU

and use the

SELECT knob to scroll through the menu.

Tapping the SELECT knob while the menu is active causes the currently-selected

menu function to execute. For example, select

LCD Brt from the menu and tap the knob.

The knob now adjusts the brightness of the LCD display backlight. Tap the knob again to

exit the selection or tap

MENU

to select a different menu item. Some menu items are

toggle functions. Instead of changing the parameter by turning the SELECT knob, it

changes automatically whenever the knob is tapped. The new value is displayed briefly

near the top of the spectrum display. Menu items are listed on page 28.

As you become familiar with the menu options, you may find that you want to adjust

certain items frequently. You can assign up to eight menu items to the function keys

, , , . Tap FN1 through FN4 or hold FN5 through FN8 to assign the function key

to a menu item while the menu item is displayed.

Hold LABELS

to display the labels you have assigned to the switches (page 15). They

are displayed at the bottom of the screen, just above the function keys (Pages 12 and 13).

Hold LABELS

Tap MKR A or hold MKR B

again to toggle the labels off.

to turn on marker A or B. Rotate the

SELECT knob to

place the selected marker at a desired frequency on the display. Markers may be used to

measure the frequency of an interesting signal and tapping the

(change the frequency of) the KX3 to that frequency.

MKR A controls the KX3's VFO A

SELECT knob will QSY

and MKR B controls VFO B. The marker colors match the corresponding VFO cursors to

emphasize the correspondence. Whichever marker is currently selected is the one that

causes the KX3 to QSY (Page 12).

To return from the last QSY to the original frequency ("undo" function), hold the

SELECT knob pushbutton while the marker is selected.

To turn off the markers, tap MKR A while marker A is selected or hold MKR B while

marker B is selected.

7

Page 8

Tap

Hold CENTER

Tap

Hold SCALE

Hold AVERAGE to turn on display averaging and allow adjustment of the averaging

SPAN

displayed at the top (left and right edge respectively) of the spectrum window (Page 13).

(Page 13). This function may be disabled by selecting

SELECT knob pushbutton to toggle between CENTER Key ON and CENTER Key OFF.

REF

displays. The reference level is the signal level corresponding to the bottom of the

spectrum display (Page 13).

waterfall displays. For example, Scale (dB): 60 means that the bottom of the display is 60

dB below the top (Page 13).

time by turning the

to set the frequency span of the display. The start and stop frequencies are

and turn the

to set the amplitude reference level of both the spectrum and waterfall

to set the scale, or signal amplitude range, of both the spectrum and

SELECT knob (Page 13).

SELECT knob set the center frequency of the display

MENU:CenterEn and tapping the

Figure 2. Basic KX3-PX3 Cabling.

8

Page 9

When used with the KXPA100 Amplifier as shown here, the PX3 RS232 data rate must be set

to 38400 baud (see menu entry RS232 on page 29).

Figure 3. PX3 Signal Cabling with KXPA100 Amplifier and KX3 to KXPA100 Adapter Cable.

.

9

Page 10

Introduction

This comprehensive manual covers all the features and capabilities of the Elecraft PX3 panoramic display. We

recommend that you begin with the Quick-Start Guide (page 6). The Front Panel (page. 11) and Side panel

Connectors (page 14) sections are for general reference. Basic Operation (page 15) and Advanced Operating

Features (page 22) fill in the details of the full capabilities of the PX3.

PX3 Features

The PX3 Integrates very closely with the Elecraft KX3 with point-and-click QSY and an “undo” feature with

simple control press to return to the previous frequency. A number of advanced features enhance the PX3’s

performance and versatility:

Easy Set-Up

Only three cables for basic operation (I/Q for signal, ACC1 for frequency data and power). Cables are

provided with the PX3.

Optional additional connections provided for transceiver communications, a personal computer and

optional accessories.

Simple configuration and calibration for optimum performance with your KX3.

Display

Bright, high-resolution, full color display.

Efficient LED backlight for long life and low power consumption.

The frequency display tracks the KX3.

Both Spectrum and Waterfall display s.

Fast display update.

Up to 200 kHz span.

Frequency resolution automatically increases as span is decreased.

Excellent sensitivity and dynamic range.

Ergonomic Design

Uncluttered interface.

No unused controls on the screen.

Adjustable legs to match the viewing angle of the KX3.

Field Upgradable

Software defined architecture so many new features will require only a simple firmware update using the

provided PX3 utility program that can be downloaded from www.elecraft.com.

10

Page 11

Front Panel

This section describes all front panel controls and the liquid crystal display (LCD). Operating instructions are

covered in later sections.

Figure 4. PX3 Control Groups.

Control Groups

Primary Controls (see page 12): These switches

are hard-coded with permanent function

assignments. They provide the most important

operational features needed for basic panadapter

operation, including display options, amplitude

scaling, frequency control and markers.

Programmable Function Switches (see page 13):

The function keys may be assigned to any of the

functions in the

operational features, test functions, and setup and

calibration routines.

MENU list. These include less-used

11

Page 12

Display

The 480x272-pixel, color TFT-LCD display is used

both for the panadapter spectrum and waterfall

graphics as well as for general-purpose information

needed by the operator. All graphics and text are

bit-mapped and so are software-defined. The

display brightness and the text size can be changed

via

MENU entries (Page 28).

Figure 5. PX3 Display.

Primary Controls

PWR turns the PX3 on or off. The PX3 may be

configured to turn on automatically whenever

power is applied by moving a jumper inside the

PX3 enclosure (see Configuring the Power Switch

on page 22for details). Holding the

more than 20 seconds places the PX3 in boot-load

mode, ready to receive new firmware. If you do this

accidentally, simply cycle the

again to restore normal operation.

MKR A and MKR B each cause a marker to appear

on the display, using different colors for A and B.

MKR A controls the KX3's VFO A and MKR B

controls VFO B. The marker colors match the

corresponding VFO cursors to emphasize the

correspondence.

The

symbol next to the marker frequency means

the frequency can be adjusted by selecting it with

the MKR A or MKR B switch and turning the

PWR switch for

PWR off, then on

SELECT knob. Tapping the SELECT knob

changes (QSY) the frequency of the corresponding

KX3 VFO to the marker frequency. To undo the

QSY and return to the original VFO frequency,

select the marker and hold the

SELECT knob

pushbutton.

To turn off markers, tap

MKR A while marker A is

selected or hold MKR B while marker B is selected.

When a marker is turned back on after having been

turned off, it will come back at the same frequency

unless it is off-screen, in which case the marker

defaults to the center frequency.

When another function that uses the

SELECT

knob is activated, the marker(s) will stay visible and

when that other function is de-selected the last

active marker automatically becomes active again.

12

Page 13

SPAN sets the frequency span of the display. The

available range is 2 kHz to 200 kHz. The start and

stop frequencies are displayed at the top (left and

right edge respectively) of the spectrum window.

For example, a 200 kHz span will be displayed with

-100.0 in the upper left and +100.0 in the upper

right corners.

CENTER sets the center frequency of the display,

which is also displayed at the top center of the

spectrum window. The center frequency of the

display may be offset from the KX3’s frequency

with the

SELECT knob. The center frequency

will then track changes in the KX3’s frequency,

maintaining the same offset.

Menu

MENU accesses an alphabetical list of functions

(see Menu Functions, page.28). Scroll through the

list with the

select an item. For items with only two or three

values, tapping the

between the parameter values. For other items, turn

the

SELECT knob to choose the parameter value.

Tapping the

selects the item and exits the menu. If you wish to

terminate the item but keep the menu active, tap

MENU. When you wish to exit the menu, tap

MENU again.

SELECT knob and tap the knob to

SELECT knob toggles

SELECT knob a second time un-

Hold CENTER a second time to return the center

frequency to the KX3's VFO A frequency.

This function is disabled if

MENU:CenterEn is set

to OFF.

REF sets the amplitude reference level of the

display, both spectrum and waterfall. The reference

level is the signal level in dBm that corresponds to

the bottom of the spectrum display and the

minimum (dark blue) signal level of the waterfall

display. The amplitude labels that appear along the

left edge of the spectrum display may be in S-units

plus dB over S9 or dBm, depending on the setting

of

MENU:Lvl Mode. The KX3's attenuator and

preamp have no affect on the displayed amplitude

when dBm is selected, but the effect of the

attenuator and preamp will be seen when the

display is in S-units.

SCALE sets the scale, or range, of both the

spectrum and waterfall displays. For example,

Scale (dB):

60

means that the bottom of the

display is 60 dB below the top.

DISP toggles between the spectrum, and

combination spectrum/waterfall display modes.

Programmable Function Keys

Most menu functions can be assigned to a function

key by tapping FN1 through FN4 or holding FN5

through FN8 while the menu item is displayed but

not selected. When a menu function is selected, the

text on the screen prompts you to either tap the

knob to select it or a FN key to assign it to the key.

If a function was previously assigned to a key,

assigning a new function over-writes the original

function.

LABELS displays the function assigned to each

key. Keys identified with the label FN number have

not been assigned to a menu function. LABELS

toggles the function key labels on and off. Note that

the function keys are still active even when the

labels are turned off.

AVERAGE allows you to turn on and adjust display

averaging. The averaging is adjusted in units of

display update periods. For example,

time:

every 20 update cycles. Tap

20 means the display is averaged over

DISP to exit the

Averaging

average parameter adjustment mode while

maintaining the selected averaging period. Hold

AVERAGE to turn off averaging.

13

Page 14

Side Panel Connectors

Figure 6. PX3 Side Panels.

See Figure 2 on page 8 or on page 9 for normal cable interconnections between the PX3 and KX3.

The following describes the function and pin-out of each connector.

Power: 9-16 VDC is a standard 2.1 mm barrel connector for dc power. The center pin is the positive (+)

connection.

ACC1 PC is a 3.5 mm stereo jack that allows firmware updates, configuration, and remote control of the PX3

and KX3 via a personal computer. The tip connection is RX data coming from the computer and the ring is data

going to the computer. If needed, suitable cables for either a USB or RS232 computer interface are available

from Elecraft (see Firmware Upgrades on page 23 for more information).

ACC1 XCVR is a 3.5 mm stereo jack that allows communications between the PX3 and the KX3. When the

PX3 is turned off, data applied at ACC1 PC passed directly through the PX3 to the ACC1 XCVR connector.

The tip connection is RX data going to the KX3 and the ring is data coming from the KX3.

RX I/Q XCVR is a 2.5 mm stereo jack that receives quadrature outputs from the KX3 receive mixer (I=inphase, Q=quadrature).

RX I/Q PC is a 2.5 mm stereo jack that provides the quadrature (I/Q) outputs from the KX3 to a personal

computer. If you had a I/Q connection directly to the KX3 before installing the PX3, this connector feeds the

same signals through to your computer with the PX3 installed.

KEYBD is for future use.

CALIBRATOR SIGNAL OUTPUT on the right side panel is a single pin output that provides a signal

required to adjust the opposite sideband nulling for your KX3 (see page 24).

14

Page 15

Basic Operation

This section covers the fundamentals of PX3

operation. Once you're familiar with the PX3,

please go on to Advanced Operating Features

(page 17).

Using Tap/Hold Switches

Most PX3 switches have two options. Tapping

(pressing for less than 1/2 second) activates the

function labeled in white on the switch. Holding

(pressing for more than 1/2 second) activates the

function labeled in yellow below the switch.

Initial Power-Up

Connect your PX3 to the KX3 as shown in

Figure 2 on page 8 or Figure 3 on page 9.

Apply power to the KX3 and enable operation

with the PX3 in the KX3’s menu:

I/Q On

Press PWR to turn the PX3 on, if it is not on

already. The screen should light and you should

see a spectrum or combined spectrum and

waterfall display. If a KX3 is connected via the

ACC1 cable you should see the correct

frequency at the top center of the display.

MENU: RX

Using the Menu

Tap MENU to access the menu. The menu

will appear near the top of the display .

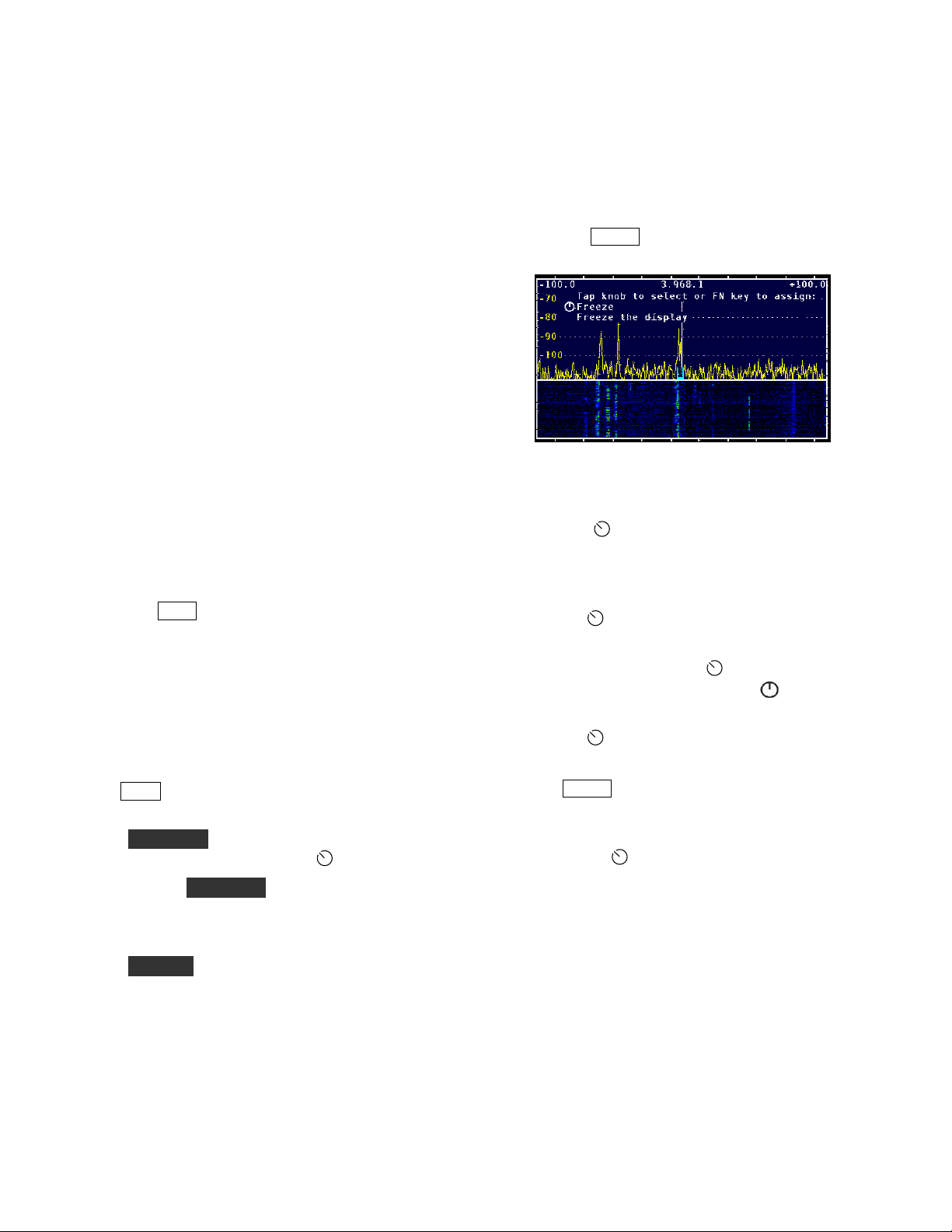

Figure 7. Typical Display Showing a Menu

Selection.

Turn the

alphabetical list of available menu functions, as

documented in the Menu Functions section

(page.28).

Tap the

Most functions have a parameter which can

then be changed with the

Those functions all start with the

the display.

SELECT knob to scroll through an

SELECT knob to select a function.

SELECT knob.

symbol on

Configuring the Display

Tap DISP to cycle between spectrum and combined

spectrum and waterfall displays.

Hold AVERAGE to turn on averaging and to set the

averaging time constant with the

You can hold AVERAGE again to turn off

averaging or just tap the same switch to clear the

parameter-entry text from the display while leaving

averaging enabled.

Hold LABELS to show or hide the function switch

labels.

There are also several MENU functions that

configure the display, such as LCD Brt (display

brightness), Peak hold, Freeze display, Font size

and Waterfall height.

SELECT knob.

Tap the

function.

Tap

Some menu items are toggle functions. The

parameter changes automatically every time

you tap the

SELECT knob again to exit the

MENU again to exit the menu.

SELECT knob.

Programmable Functions

Most menu functions can be assigned to any

programmable function switch, FN1 to FN8 to

allow quick access without using the menu.

Common examples of such functions you may wish

to access quickly are

15

Peak hold and Freeze display.

Page 16

Tap or hold the desired function switch while the

function is visible on the display but not selected by

tapping the

then becomes the function switch label which can

be seen if labels are currently displayed.

Figure 8. PEAK assigned to Function Switch FN1.

Assigning a function to a previously-assigned key

overwrites the previous function. Optionally you

can remove any assignment from a function switch

with

MENU:FN Erase and tap or hold the function

switch you wish to erase.

SELECT knob. The function name

Adjusting the Amplitude

Tap REF to adjust the reference level, which is the

signal level that corresponds to the bottom of the

spectrum display and the low-signal level of the

waterfall display. Hold SCALE to adjust the

"vertical gain" of the display. For example if the

reference level is set to -100 dBm and the scale to

30 dB, then the top of the spectrum display is at -70

dBm and the bottom at -100 dBm.

The waterfall display is most useful if the reference

level is adjusted to place the noise level near the

bottom of the display and the scale is adjusted so

that the strongest signals of interest are near the top.

Adjusting the Frequencies Displayed

Tap SPAN to adjust the range of frequencies that

can be seen on the display at one time. The start and

stop frequencies in KHz are indicated at the top left

and right of the display. They are shown as offsets

from the center frequency.

Hold CENTER to adjust the display center

frequency by turning the

center frequency of the display is now offset from

the KX3’s VFO A frequency by the amount shown.

SELECT knob. The

The center frequency will then track changes in the

KX3’s frequency, maintaining the same offset.

Hold CENTER a second time to return the center

frequency to the KX3’s VFO A frequency.

The center function may be disabled in the menu:

MENU: CenterEn. Press the SELECT knob to

toggle the function on or off.

Hold CENTER again to re-center the display on the

transceiver VFO frequency.

The tic marks that appear along the top and bottom

edges of the spectrum and waterfall widows

indicate RF frequency in integer multiples of 0.5, 1,

2, 5, 10 or 20 kHz, depending upon the span.

Using Markers

Tap MKR A to turn on marker A and allow you to

change the marker frequency by rotating the

SELECT knob. To determine the frequency of a

signal, move the marker so that it overlays the

carrier and read the frequency from the display. For

single sideband signals, place the marker where the

carrier would be if it were transmitted, i.e. on the

lower frequency (left) edge of an upper sideband

signal and on the upper frequency (right) edge of a

lower sideband signal.

You can QSY (change the frequency of) the KX3’s

VFO A to the marker A frequency by tapping the

SELECT knob. To return to the previous

frequency, hold the knob. To turn off marker A, tap

MKR A again.

Similarly, marker B is turned on and off with the

MKR B switch and you can change the marker

frequency with the

SELECT knob changes the KX3’s VFO B

frequency in the same way

VFO A frequency

To turn off a marker you must first make it active, if

necessary, by tapping MKR A or holding MKR B.

Then tap or hold the switch a second time to turn

off the marker.

If some other function that uses the

knob is activated, the marker stays on and

automatically becomes active again (you can adjust

it with the knob) when the other function is

terminated. The tap-to-QSY function affects VFO

SELECT knob. Tapping the

MKR A changes the

SELECT

16

Page 17

A if marker A is active and VFO B if marker B is

active.

When a marker is turned on, it will be at the same

frequency as the last time it was on unless that

frequency is off-screen. In that case the marker is

automatically reset to the display center frequency.

(If you lose a marker off-screen, just turn it off and

on again to return it to the center frequency.)

When you change bands on the KX3, the markers

are automatically set at the new center frequency.

Waterfall Markers

Select MENU: WfallMkrs. Tapping the

SELECT knob will turn the waterfall markers

on, causing the marker line(s) to travel down into

the waterfall display, or turn the markers off.

Figure 9. Marker A Enabled at 3563 KHz for Both

Spectrum and Waterfall.

Using Cursors

Figure 10. Bar Cursor on Upper Sideband Signal at

14.250 kHz.

Figure 11. “U” Cursor on Upper Sideband Signal at

14.250 kHz.

VFO A has a green cursor and VFO B has a

magenta cursor unless split mode is activated at the

KX3. In split mode, the VFO B cursor changes to

red as a reminder that you will transmit on that

frequency. Similarly, if XIT is on, or if split is off

and RIT is on, a new red cursor appears at the

transmit frequency.

Cursors show the position of the KX3’s A and B

VFOs, The position and width of each cursor shows

the passband being received. Two cursor shapes

may be selected using

MENU: Cursor . The

translucent bar cursor or a “U” shaped cursor at the

bottom of the spectrum display may be selected.

Figure 12. Red Bar Cursor Showing Transmit Frequency

Above the Receive Frequency.

Whenever a cursor is tuned off-screen a small

triangle of the same color appears at the bottom left

17

Page 18

or right of the spectrum window to indicate the

direction to the missing cursor

The VFO B cursor may be turned off using

VFO B. Tap the knob to select VFO B ON or

VFO B OFF as desired.

MENU:

Noise Blanker

Adjust the aggressiveness of the noise blanker with

MENU: NB Level and turn the SELECT knob.

A setting of 1 is least aggressive and 15 is

maximum. The higher the setting the more

completely it blanks the pulse noise, but the more

likely it will cause distortion of the desired signals.

Use the lowest value that does an adequate job.

About 10 or 11 is a good starting point.

The noise blanker reduces the effect of impulse

noise on the display. It has no effect on the audio

from the KX3.

Impulse noise frequently comes from such sources

as the AC power line and unshielded automobile

ignition systems.

Engage the noise blanker in the menu with MENU:

NB En. Tapping the SELECT knob toggles

the noise blanker on and off. When the noise

blanker is enabled ,

NB appears near the upper right

corner of the display after you exit the menu.

Note that the REF and SCALE settings have no

effect on the noise blanker.

If there are one or more very strong signals within

the PX3’s displayed frequency range, the noise

blanker will have a hard time detecting the

difference between the unwanted pulses and the

wanted signal. Narrow the

CENTER frequency if possible to place the strong

SPAN and/or offset the

signals well outside the PX3’s display frequency

range.

18

Page 19

How to Set Up and Interpret the PX3 Display

There are several options to customize the layout of

your PX3 display.

spectrum-only and spectrum-plus-waterfall display.

The height of the waterfall can be adjusted with

MENU: Waterfall. The function (FN) switch

labels appear at the bottom of the screen by default.

You can hide them to maximize the screen area by

holding LABELS. The FN switches remain active

even when the labels are hidden. Another trick to

maximize viewing area is to choose a smaller type

font via

MENU: Font.

DISP switches between a

Spectrum Display

The spectrum display on a panadapter is similar to

the display on a laboratory spectrum analyzer. The

horizontal axis is frequency and signal strength is

represented by the vertical height of each signal.

The PX3’s spectrum display is similar to most in

that the signal height is proportional to the

logarithm of the amplitude, represented in decibels

(dB). Each 3 dB represents a doubling of power and

10 dB means ten times the power.

The vertical scale at the left edge of the spectrum

display may be in units of dBm or S-units, as

selected by

means decibels with respect to one milliwatt. 0

dBm is one milliwatt, +10 dBm is 10 milliwatts, -10

dBm is 1/10 milliwatt and so on. An S9 signal is

normally considered to be 50 microvolts into 50

ohms, which is -73 dBm, an easy number for a ham

to remember! Assuming the standard 6 dB per Sunit, the following table applies.

MENU:

S-Units Signal Level

S9 -73 dBm

S8 -79 dBm

S7 -85 dBm

S6

S5 -97 dBm

S4 -103 dBm

S3 -109 dBm

S2 -115 dBm

S1 -121 dBm

Lvl Mode

-91 dBm

. The dBm unit

50 V

25 V

12.5 V

6.25 V

V

1.56 V

0.78 V

0.39 V

0.2 V

You would expect the S meter on the KX3 and the

signal on the PX3 display to indicate the same level,

however there are several reasons why that might

not be the case. One is that the PX3 is not affected

by the preamplifier and attenuator in the KX3 when

the signal amplitude is shown in dBm.

The noise level will generally be lower on the PX3

display compared to the KX3’s S meter. The reason

is that the effective bandwidth of the PX3 is

generally one display pixel, which is approximately

the span divided by 450. The smaller the

bandwidth, the less noise. For example, if the span

is 45 kHz, the effective PX3 bandwidth is 45,000 /

450 = 100 Hz. If the KX3 bandwidth is 400 Hz, it

will show a 6 dB (one S-unit) higher noise level

than the PX3.

A similar thing happens with spread-out signals like

SSB. Even at the maximum 200 kHz span, the

PX3’s effective bandwidth is only about 440 Hz so

that not all the SSB signal is within one pixel.

That’s why the PX3 tends to read a lower level on

SSB signals than the KX3’s S meter.

REF (reference level) on the PX3 shifts all the

signals up or down. The level that you are adjusting

is the signal level at the bottom of the display,

measured in dBm.

SCALE is used to expand or contract the vertical

scale. Think of it as a vertical gain control. The

scale is defined as the dB difference between the

top and the bottom of the display. For example, if

the reference level is -100 dBm and the scale is 20

dB, then a signal at the top of the display is at -80

dBm. For both REF and SCALE, turning the knob

clockwise makes the signals taller.

The PX3 automatically compensates for the

preamplifier and attenuator in the KX3 when the

display amplitude is shown in dBm. When you turn

them on or off, the signal levels on the PX3 should

stay the same. The indicated dBm level should be

the signal level at the KX3’s antenna input. Perhaps

counter-intuitively, this means that if you turn on

the preamplifier in the KX3, the noise level

displayed on the PX3 may decrease, rather than

increase. That is because the PX3 automatically

reduces its gain when the KX3 preamplifier is

turned on, in order to keep the signal levels the

19

Page 20

same. When the PX3 display amplitude is shown in

S-Units, the signal level will vary according to the

preamplifier and attenuator settings, just like the

KX3’s S-meter.

Waterfall Display

The waterfall allows you to see a history of band

activity for the past few seconds. Like the spectrum

display, the horizontal axis is frequency but in this

case the vertical axis is time. Signal amplitude is

represented by colors, from dark blue for weak

signals, then brighter blue as signals increase in

strength, through shades of green, yellow and red

for the strongest signals. Each horizontal line

represents one update of the spectrum display.

As each new line is written the old ones are shifted

down, creating a waterfall effect.

While the spectrum display is better at accurately

displaying signal strength and the shape of a

signal’s modulation, it can only show what is

happening right now. The waterfall is better for

showing transient signals, such as a DX station

running a pileup that only transmits for a few

seconds at a time. Often you can easily see a weak

fading signal on the waterfall that is invisible on the

spectrum display.

The scaling of the waterfall is the same as for the

spectrum. That is, the bottom of the spectrum

display corresponds to dark blue on the waterfall

and the top corresponds to bright red. For maximum

visibility of signals on the waterfall, it is best to set

REF so that the noise level is right at the bottom of

the spectrum display and then expand SCALE as

much as possible while keeping signals of interest

below the top of the spectrum display. That

improves the color contrast on the waterfall and

makes weak signals appear to pop out of the noise.

the waterfall as well by setting

to

On.

MENU:

Wfall Avg

Peak hold is a way to display a memory of past

signals on the spectrum display. It shows the

strongest signals that have appeared at each

frequency since the last time peak mode was

enabled. To reset the peak trace, simply disable

peak hold and then re-enable it. This mode is most

useful if you assign

MENU:

Peak

to a FN switch

so you can turn it on and off with a single touch.

One use for peak hold is to monitor a dead band for

activity while you are away from the operating

position. If you glance at the display every now and

then you can see if any signals have appeared in the

meantime. Peak hold is also useful to see the shape

of a modulation spectrum. Since the sidebands are

continually changing with modulation, the peak is a

better indication of the spectrum than the

instantaneous value.

Span

Adjusting the span is yet another way to make weak

signals more visible. As you narrow the span, there

is less noise within the range of each frequency

display point. That reduces the apparent noise level

while the signal levels stay the same, which

increases the signal-to-noise ratio. At narrow spans,

signals that are difficult or impossible to hear

become visible, especially on the waterfall.

As mentioned before, it is useful to keep the noise

level right at the bottom of the display. The PX3

can automatically keep the noise level constant as

you adjust the span by setting

SpanScale: REF LVL only

the level at the top of the screen to remain constant

as you adjust the span, set

REF LVL & Scale.

MENU:

. If you would also like

MENU:

SpanScale:

Averaging and Peak Hold

Another way to make weak signals more visible is

averaging. Because noise is random in nature,

averaging reduces the jaggedness of the noise

spectrum trace, making signals easier to pick out.

More averaging improves the noise reduction but at

the expense of a slower response. To turn on

averaging and adjust the averaging time, hold

AVERAGE and then turn the knob. The averaging

time is in units of the spectrum update rate,

typically about 50 ms. You can apply averaging to

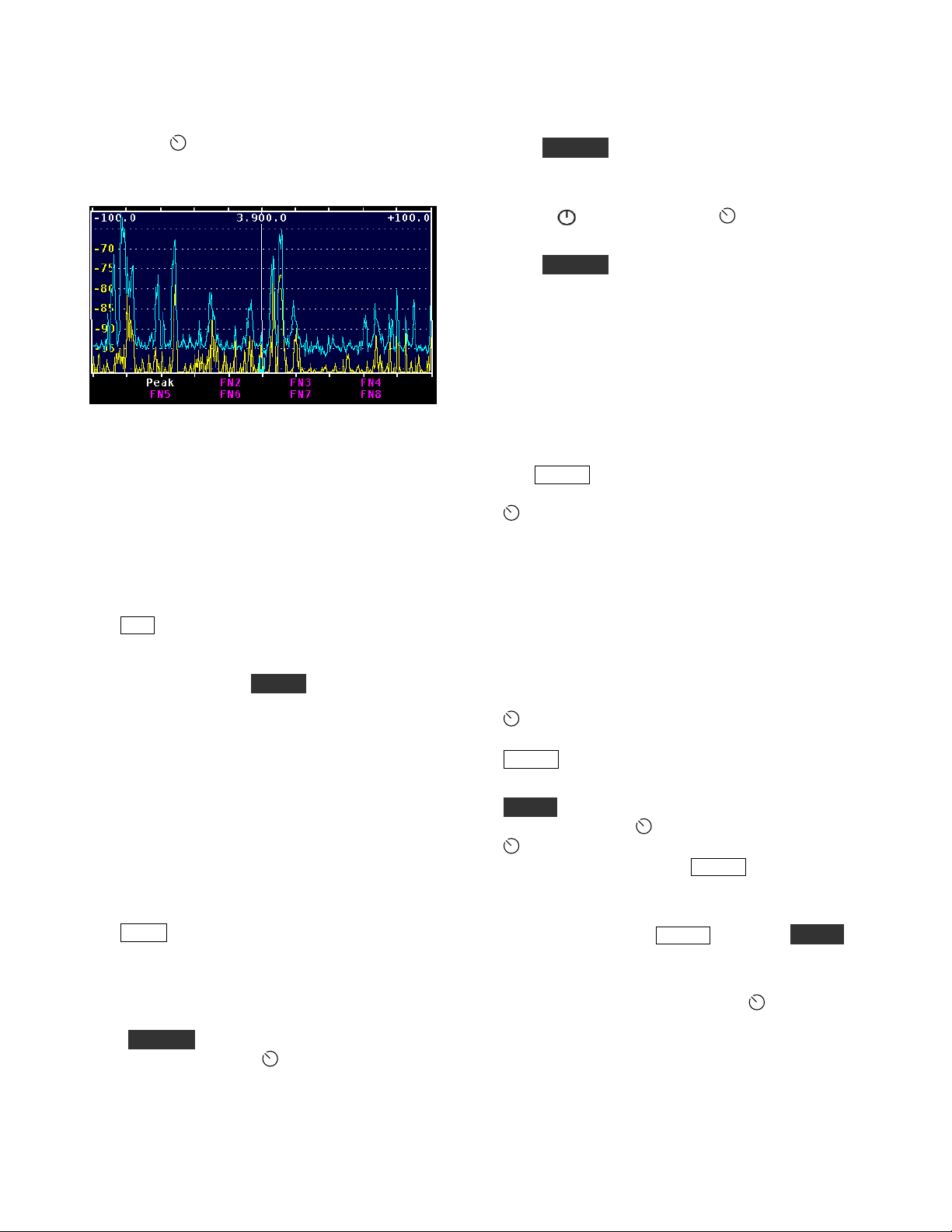

Typical Spectra

Figure 13 is a typical screen shot of the 40 meter

band during the day. At the center is a weak CW

signal that was inaudible on the KX3 transceiver

during fades. It is hard to see on the spectrum

display at the top but is clearly visible on the

waterfall. Just to the right of that is a strong

interfering carrier. At the far right is another steady

carrier and just to the left of that is a spurious

emission, probably from a switching power supply,

that is wavering back and forth in frequency. A

20

Page 21

panadapter is a powerful tool for tracking down

interference.

Figure 15. Typical AM Spectra using Peak Hold.

Figure 13. Typical Spectra Display.

Figure 14 is another example of interference, this

time from a LAN router. The QRM includes both

wideband noise as well as discrete carriers and is

constantly heaving and writhing as the processor in

the router executes different portions of its software

routines.

Figure 14. Typical Interference Display.

Spurious signals generated in the transceiver are

sometimes visible as well. As you tune the

transceiver you may see carriers that scroll across

the screen much faster than other signals,

sometimes tuning in the opposite direction. These

are created by high-order harmonics of the VFO,

BFO and other signal sources in the transceiver.

Normally you won’t hear them in the receiver

unless one falls within the passband, but they are

easy to see on the panadapter display because of its

much wider bandwidth.

Figure 15 is a shot of a local AM broadcast station,

illustrating the use of peak hold to show the shape

of the modulation spectrum, which extends to plus

and minus 10 kHz from the carrier and then drops

off abruptly to meet FCC regulations.

Normally the PX3 display is frozen while the KX3

is transmitting. However if you temporarily

disconnect the

ACC1 cable between the PX3 and

KX3, that function is disabled and it is possible to

view your own transmissions for test purposes. You

may need to experiment with

REF on the PX3 and

the power level and on the KX3 to properly display

the signal.

Figure 16 shows a typical LSB spectrum obtained in

this way. Peak hold is enabled in order to get a

better view of the spectrum shape. Notice that the

low audio frequencies (on the right) are much

stronger than the high audio frequencies. A flatter

spectrum is considered desirable to improve the

signal’s “punch” in the presence of noise and

interference, especially when speech compression is

used. The PX3 is a handy tool for adjusting the

transmit equalizer in the KX3.

Figure 16. Typical SSB Spectra using Peak Hold.

Figure 16

also illustrates an important point when

using markers. On SSB, the frequency that is shown

on the display of the KX3 transceiver is the

suppressed carrier frequency. When you QSY the

transceiver using MKR A or MKR B on the PX3,

where the marker is set is the frequency the KX3

will go to. So on bands where LSB is used, you

should place the marker just above the spectrum of

the SSB signal you are trying to net (approximately

in the center of the above display) and for USB,

place the marker just below the spectrum.

21

Page 22

Advanced Operating Features

Remote-Control Commands

Many PX3 functions may be accessed by remotecontrol commands sent via RS232. These

commands use ordinary ASCII text, so they can be

tested using a terminal emulator or the Command

Tester tab in PX3 Utility. When the PX3’s XCVR

RS232 port is connected to a KX3, then both PX3

and KX3 commands may be sent and received via

the PC RS232 port.

To distinguish them from KX3 commands, PX3

commands begin with the “#” symbol. For example,

“#RVM;” returns the PX3 firmware revision and

“RVM;” returns the KX3 main firmware revision.

PX3 remote-control commands are fully described

in the PX3 Programmer’s Reference.

PX3 Utility Program

In addition to downloading firmware (page 23) the

PX3 Utility can perform several other functions.

For example, it can upload a bitmap image of the

PX3 display which can be saved to a file or pasted

into a graphics program on the computer. Refer to

the Help menu in PX3 Utility for more information.

Configuring the Power Switch

The front panel PWR switch may be bypassed so

the PX3 turns on when power is applied.

To configure the power control, loosen the four

thumb screws and remove the PX3 bottom cover.

The jumper is located near the edge of the Power

Supply (PS) board as shown in

Figure 17.

Figure 17. Power Control Jumper.

The jumper may be positioned on the pins as

follows:

Pins 3 & 4: Normal operation of the

The jumper is shown in this position in Figure 17.

Pins 1 & 2:

automatically and remains on as long as power is

applied to the rear panel connector.

Even if bypassed so power is on all the time, the

PWR switch is still used in the event it is necessary

to put the PX3 in Boot Loader mode to force a

firmware download. To cancel Boot Loader mode,

remove power from the PX3.

PWR switch is disabled. PX3 turns on

PWR switch.

22

Page 23

Firmware Upgrades

New features and improvements are available to all

PX3 owners via firmware upgrades.

The simplest and quickest way to upgrade your PX3

is with computer running Windows, Macintosh or

Linux operating systems. If you don’t have Internet

access, you can obtain a firmware upgrade on CD.

If you don’t have a computer, you can send your

PX3 to Elecraft to be upgraded. See Customer

Service and Support on page 53.

Please visit the Elecraft KX3 software page

(www.elecraft.com) to obtain our free firmware

download application, PX3 Utility. Versions of the

Utility program are available for all of the above

Operating systems. The PX3 communicates with

your personal computer through the

connector on the PX3 left side panel.

You can upgrade both PX3 and KX3 firmware

through the same connector on the PX3. Simply

turn the PX3 off before using the KX3 Utility

program.

Some applications or peripheral devices may

interfere with PX3 downloads; check the Help

information in PX3 Utility if you have difficulty.

ACC1 PC

Checking your Firmware Revision

Use the MENU: FW Rev to determine your

firmware revision.

PX3 Firmware Self-Test

The PX3 checks for firmware errors at turn-on. If

an error occurs, the PX3 Boot Loader is started

automatically. Connect the PX3 to your computer

and reload firmware.

Forcing a Firmware Download

If you accidentally load an old or incompatible

firmware version and find the PX3 unresponsive, do

the following:

(1) Turn the PX3 off. If necessary disconnect the

PX3 from the power supply briefly.

(2) With the power supply connected, hold the

PX3’s PWR switch; Boot Loader screen will appear

on the display after about 10 seconds.

(3) Load the correct firmware version.

Updating KX3 Firmware

If you have the PX3 ACC1 port connected to the

KX3

ACC1 port, you can update your KX3

firmware without disconnecting the cables to the

PX3. Switch the PX3 off. Turning the PX3 off

automatically bypasses the PX3 so there is a direct

connection between the computer and the KX3. If

you have configured the PX3 so you cannot turn it

off with the

Power Switch on page 22), unplug the power

connector on the PX3’s side panel. Leave the PX3

off until the download is finished.

PWR switch (see Configuring the

23

Page 24

Opposite Sideband Nulling

Complete nulling of the opposite (unwanted) sidebands depends upon accurate setting of the phase and

amplitude of the I/Q outputs from the KX3. Although the PX3 comes with settings that should provide good

suppression of the unwanted sideband, it may be possible to improve them if you wish.

Getting Ready

A signal source with a variable level of about -40 dBm on each of the bands listed in Table 1 is required. The

PX3 contains a built-in signal generator that is suitable or you can use an external signal generator such as the

Elecraft XG3. If you use the built in signal generator in the PX3, set up the equipment with a coupling wire to

introduce signal into the KX3 antenna as shown on page 27.

Remove your microphone, keys, etc., that might be accidentally bumped to avoid transmitting into your

signal source.

You can save a lot of button-pushing by assigning the

OSB Phaz (Opposite Side Band Phase) menu functions to the function keys. For example, to use FN1

for

OSB Ampl and FN2 for OSB Phaz as follows:

o Hold LABELS to display the labels assigned to the FN keys.

o Tap

o Turn the

Tap Menu (if you aren’t still in the menu) turn the

again to display dBm. Exit the menu.

On the PX3 front panel, set the display parameters as follows:

o

o REF : 130 (dBm)

o SCALE : 80.0 (dB)

o

MENU and turn the SELECT knob to OSB Ampl, then tap FN1 and note that the

label for FN1 changes to OSB Ampl.

SELECT knob to OSB Phaz, then tap FN2 and note that the label for FN2

changes to

SPAN : 50 (kHz).

DISP : Tap to turn off the waterfall display.

OSB Phaz.

OSB Ampl (Opposite Side Band Amplitude) and

SELECT knob to Lvl Mode and tap the knob

Before changing any settings, record the current amplitude and phase values in the initial settings

columns for each band on Table 1 on page 24. This is important in case you want to return to the factory

defaults. Tap the

FN2 switches on the PX3 to display the OSB Ampl and OSB Phase values shown.

If you have transverters installed, the settings obtained on the HF band the transverter uses for an I.F.

may not be optimum because the tuning range the transverter requires may fall outside of the normal

Ham band. If you have a suitable signal generator, you can adjust the amplitude and phase for each

transverter band. Those settings will not change the adjustments for normal H.F. operation on the band

used as the I.F. You will need a signal generator capable of covering the input frequency for each

transverter. Table 2 provides you a place to note and record the settings.

BAND+ and BAND- switches on the KX3 to select each band and tap the FN1 and

24

Page 25

Table 1. 160 – 6 Meter Band Amplitude and Phase Settings.

Freq.

MHz*

1.818

3.6

5.357

7.20

10.112

14.063

18.0

21.429

25.0

28.125

50.0

Ampl. Phase Ampl. Phase

Initial Settings New Settings

* The frequencies shown are those generated by the PX3 internal calibrator. Any frequency near the

middle of each band may be used.

Table 2. Transverter Amplitude and Phase Settings.

Transverter

Adr

Frequency

Initial Settings New Settings

Ampl. Phase Ampl. Phase

Only adjust those transverter bands you actually use. There is no benefit in adjusting the other bands.

The frequency is the center frequency transverter tuning range.

25

Page 26

If you haven’t already, connect your signal generator to the KX3 BNC antenna connector or set up the

PX3 to use the internal signal source as shown on page 27. Set the signal generator for about -40 dBm

output (if you are using the XG3 set it for -33 dBm output). If using the PX3 internal signal source, you

can adjust the coupling to the KX3 antenna input for about -40 dBm as needed when you tune in the

signal in the next steps.

If using the PX3 internal signal source, turn on the signal with

MENU: Cal Sig and tap the

SELECT knob to display On.

Switch your KX3 to 160 meters and tune to a frequency 10 kHz above that of the signal generator. That

is, if your signal source is at 1.818 kHz, tune the KX3 to 1.828 kHz. You should see a strong signal to

the left of the center cursor and, if the opposite sideband is not completely suppressed, you will see a

weaker signal the same distance to the right of the center cursor (see Figure 18). The weaker signal to

the right is the opposite sideband. If you are using the internal PX3 signal source, adjust the coupling to

the KX3 antenna input as needed for an easily visible signal level.

Select

OSB Phaz and adjust the SELECT knob for minimum signal level of the opposite side band,

then select

OSB Ampl and adjust the knob for minimum. The controls interact, so switch back and forth

until you have achieved minimum amplitude of the opposite side band (or it is buried in the noise).

Always start by adjusting

OSB Phaz.

When you have the best null, record the numbers on the tables above for future reference.

Figure 18. Typical Opposite Side Band Signal Displays.

Repeat the procedure for each remaining band, ad justing the signal levels as needed for clear

displays.

Be sure to tune the KX3 10 kHz above the signal generator frequency on each band.

When finished, carefully remove the signal wire from the PX3 if you used its internal signal source,

turn the calibrator signal off:

the bottom cover.

Do not over-tighten the thumb screws on the bottom cover. If over-tightened, they can become

very hard to remove.

MENU: Cal Sig, tap the SELECT knob to display off, and replace

26

Page 27

Setting up the PX3 and KX3 to use the PX3 Internal Calibration Signal

On the PX3, loosen the four knurled thumb screws and remove the bottom cover. Cut a length of insulated hook

wire about 12 inches (30 cm) long. About 20 or 22 gauge will fit nicely. Pass it through the side panel opening

in the PX3 and through opening in J103 as shown in Figure 19. Do not remove the insulation and do not push it

through so far the exposed conductors at the cut end might contact components inside the PX3.

You can leave the bottom cover off while doing the nulling procedure. It will not affect the results.

Figure 19. Calibrator Signal Pickup Wire Installed in the PX3.

Arrange the PX3 and KX3 as shown in Figure 20. Take care not to dislodge the pickup wire you installed in the

PX3.Capacitively couple signal from the pickup wire to the KX3 as shown. Use enough wire to vary the

capacitive coupling to the KX3 as needed by the nulling procedure.

Figure 20. Opposite Sideband Nulling Setup Using Internal Signal Source.

27

Page 28

Menu Functions

Tap MENU and then turn the SELECT knob to scroll through the following list of menu functions. Tap the

SELECT knob to select the displayed function.

PX3 Menu

Entry Default Description

Cal Sig Off

CenterEn Off

Cursors Bar

DispTest Off

Font 9 x 14 Changes the font size.

FN Erase N/A

Freeze Off

FW Rev N/A

Knob Tap N/A

Knob Hold N/A

LCD Brt 100

Enable/Disable Calibrator signal output.

When OFF, the CENTER key does not adjust the center frequency.

Bar produces a full height translucent bar on the spectrum display. “U” produces a

U-shaped cursor at the bottom of the spectrum display.

Shows a test pattern with a color bar and the complete character set of each font.

Tap

MENU to exit.

Resets a function key to its un-programmed state. Tap or hold the function key to

be erased while this menu item is displayed.

Freezes or un-freezes the current spectrum and waterfall display. This function is

most useful when assigned to a function key, which toggles between the frozen and

un-frozen state.

Displays the main firmware version number. It is not necessary to tap the

SELECT knob for this function.

When assigned to a function key, duplicates the

When assigned to a function key, duplicates the

Adjusts the display brightness from 0-100.

SELECT knob’s tap function.

SELECT knob’s hold function.

LCD Test Off

Lvl Lines Dotted

Lvl Mode dBm

MKRA

zero

MKRB

zero

NB En Off

NB Level 11

OSB Ampl 0

OSB Phaz 0

N/A

N/A

Set all display pixels to white at full brightness.

Select dotted or solid lines for the amplitude level graticule.

Select the amplitude level display units, either dBm or S-units plus dB over S9.

Resets marker A to the center of the screen.

Resets market B to the center of the screen.

Turns noise blanker on and off.

Sets the noise blanker level (see Noise Blanker on page 18).

Adjusts the I/Q amplitude balance (see page 24).

Adjusts the I/Q phase balance (see page 24).

28

Page 29

Entry Default Description

Peak Off

Rate 80

Reset N/A

RS232 38400

SpanScale

Span Set N/A

Step Span Off

REF LVL

only

Toggles peak-hold mode on and off. This function is most useful when assigned to

a function key.

Changes the display update rate in milliseconds. Although values down to zero may

be entered, the minimum display period is actually limited by hardware.

Resets the PX3.

Change the baud rate in bits per second of the serial port that connects to a host

computer. During firmware download (via the PX3 Utility program), the baud rate

is set automatically to 38400 baud, but it is then restored to the value selected in

this menu entry.

Specifies the way the PX3 responds to changes in SPAN. “Off” means do not

change REF_LVL or SCALE when SPAN is changed. “REF LVL only” means

change the reference level to keep the noise level approximately constant. “REF

LVL & SCALE” means also change SCALE to keep the level corresponding to the

top of the screen at a constant level as well.

Tap or hold a function key to assign a current SPAN to that key. Once assigned the

function key can be used to set the span with a single key press. The key label

shows the span in kHz.

When Off, adjusting the SPAN occurs in 0.5 kHz steps for spans between 2 and 11

kHz, 1 kHz steps for spans between 11 and 102 kHz and in 2 kHz steps for spans

between 102 and 200 kHz. When Step Span is On, adjusting the SPAN occurs in

steps of 2, 5, 10, 20, 50, 100 and 200 kHz.

Toggle switch test mode on or off. When on, a special test screen is displayed that

Sw Test Off

VFO B On

Waterfall 100

Wfall Avg Off

Wfall Clr

WfallMkrs Off Enables or disables markers on the waterfall display.

Default

Colors

shows the state of each switch and the current encoder count. Tap the

knob twice to exit.

Turns the VFO B cursor on or off.

Changes the height of the waterfall window when the display is in waterfall mode.

Enables or disables application of averaging to the waterfall display

Selects either color or gray scale (no color).

SELECT

29

Page 30

Troubleshooting

The most common symptoms and their causes are listed below.

Power On/Off Issues

Can't turn power off. The most likely cause is the power turn-on jumper located on I/O board is set

incorrectly. See Configuring the Power Switch on page 22.

PX3 BOOT LOADER appears on the screen instead of the normal display. Occurs if PWR is held for

more than 20 seconds. To correct, cycle PWR off, the on again. .

"FAILED CHECKSUM" message appears in the "PX3 BOOT LOADER" screen. Main PX3

firmware is not present or corrupted. Use PX3 Utility to download new firmware (see page 23).

"DOWNLOAD FIRMWARE, READY FOR DOWNLOAD" message appears in the "PX3 BOOT

LOADER" screen. Either cycle power to return to normal operation or use PX3 Utility to download

new firmware (see page. 23).

Display Issues

Wrong Center Frequency or no Frequency Displayed: Be sure the cable between ACC1 XCVR on

the PX3 and ACC1 on the KX3 is installed. Hold the CENTER key to select the center frequency

adjustment and then hold it again to re-tune the PX3 center frequency to the KX3 VFO A frequency. If

Center Disabled appears on the screen enable it:

obtain

CENTER key ON.

MENU:CenterEn and tap the SELECT knob to

Unexpected Signals Displayed or Signals Appear in Two Places: If a signal on the left side of the

display is also visible equidistant on the right side, check to be sure the I/Q cable between the KX3 and

PX3 is fully seated at both ends. Unplug and plug in the cables at both ends. Also see Opposite

Sideband Nulling on page 24. Try turning the PX3 noise blanker off (see page 18), adjusting its setting

or reducing the KX3’s gain. Turn the PX3 off, then on again to restart its firmware.

Display Noise Floor Jumps Up and Down: PX3 noise blanker (see page 18) may be turned on and set

to high for the band conditions causing signal artifacts. Signal level from the KX3 may be too high. Try

turning off the KX3’s preamp or setting a lower preamp gain level in the KX3 menu. This is a per-band

setting.

Dip in Spectral Response Close to VFO Frequency: I/Q demodulation at baseband (used by the PX3

and many SDR applications) may introduce small, very narrow-band amplitude variations in the

response close to the carrier. This effect varies with operating mode and usually has no effect on

operation. In CW mode the artifact can be moved by switching to CW reverse mode (ALT switch on

KX3). Setting RX Shift to 8.0 rather than NOR in the KX3 menu may also vary to location of the

artifact.

Some or All of the Spectrum Display is Magenta or Purple: This occurs when the filter bandwidth

assigned to VFO B is nearly as wide as or even wider than the PX3 spectral display. The VFO B cursor/

bandwidth can be turned off using the VFO B menu entry.

30

Page 31

Parameter Initialization

Menu parameters are stored in non-volatile EEPROM memory. It is possible, though rare, for parameters to

become altered in such a way as to prevent the firmware from running correctly. If you suspect this, you can

reinitialize parameters to defaults.

Reinitializing the parameters will erase any Function key assignments you have made

and return all of the MENU entries to the default values shown in page 28.

Write down your function (FN) key assignments and MENU parameters you have set.

Turn the PX3 OFF (tap the PX3’s

power-on jumper on the I/O board is in the "always-on" position.

While holding in the LABELS key, tap the PWR switch to turn the PX3 on. After about 2 seconds, let go of

the LABELS key. You should now see CONFIGURATION RESET on the LCD screen.

Re-enter all the menu parameters and function key assignments you wrote down.

See if the original problem has been resolved.

PWR switch, not by turning off your power supply). Skip this step if the

31

Page 32

PX3 Compared to the P3 and PC-Based Panadapters

The PX3 can display spans of up to 200 kHz, whereas most PC-based panadapters using I/Q demodulation are

limited to about 40 kHz spans. The PX3 is also very tightly integrated with the KX3, making it very convenient

to use.

Like PC-based panadapter applications, the PX3 makes use of baseband RX I/Q signals from the KX3. These

signals are sampled by an analog-to-digital converter (ADC), and then mathematically processed to create the

spectral and waterfall displays.

Because the process is analog, it is subject to possible noise pickup from various sources, including switching

power supplies, 60-Hz AC, ground loops, and interface cables. That is why we recommend you use the cables

supplied (see PX3CBL on page 5) and arrange the PX3 and KX3 as described under Setup and Connections on

page 6.

In the case of a PC panadapter application, a sound card must be used and performance will only be as good as

the ADC used on the sound card. The PX3’s ADC is very high performance, resulting in a low noise floor, and

the supplied cables are very short to minimize noise pickup. However, the PX3 is still subject to pickup from

some noise sources, and the operator may see a few discrete spurs from station power supplies, etc., especially

when wider spans are used (over 70 kHz or so). I/Q demodulation may also show a greater number of artifacts,

such as opposite-sideband images, than I.F.-derived digital down-conversion (which is used in the P3).

However, when the PX3 is properly aligned, such artifacts will be significantly suppressed (typically by 60 dB

or better).

32

Page 33

Theory of Operation

Figure 21. PX3 Simplified Block Diagram.

The input to the PX3 is a pair of signals from the KX3 transceiver that represent the in-phase (I) and quadrature

(Q) components of the received RF signal. These signals are also buffered and sent back out so you can connect

them to a personal computer or other device for additional processing. Both the I/Q input and output use

differential amplifiers to isolate the grounds so that isolation transformers are not needed. The low-noise

amplifier and high-dynamic-range analog to digital converter (ADC) ensure that weak signals can be received

without overloading from strong signals. The ADC output is passed to a Microchip dsPIC digital signal

processor/controller IC, which processes the digital I/Q signal from the ADC for presentation on the 480x272pixel color TFT LCD display

The "circuitry" shown inside the processor box in the block diagram above is actually implemented as software

routines. The FFT is the fast Fourier transform, which is a software version of a hardware spectrum analyzer. It

reads the incoming signal and calculates the frequency spectrum. Further software routines calculate the power

of the spectrum, take the logarithm, and then scale and offset the result so that it reads correctly in dBm on the

display.

The dsPIC also acts as a controller for the rest of the circuitry. For example whenever the user changes the span,

both the ADC decimation rate and the clock frequency are re-calculated. In that way, the optimum sample rate is

used for any span, which optimizes the display update speed and ensures that each horizontal pixel on the

display represents a distinct frequency, with minimum bleed-over between pixels.

One firmware task is to maintain communications with the KX3 transceiver over one of the RS232 ports. A

special PX3-specific command set has been implemented to maximize communications efficiency. In addition, a

special PX3-KX3 communications protocol was set up to ensure that the PX3 gets the information it needs when

it needs it, so that the PX3 acts as a fully-integrated extension of the KX3. Communications between the

computer and the KX3 is passed transparently through the PX3 so that the computer "thinks" it is talking

directly to the KX3.

In addition to two UART (universal asynchronous receiver-transmitter) ports for the two RS232 connectors, SPI

(serial peripheral interface) and I

Those interfaces, plus power supplies and other signals, are passed via a 40-pin connector through the power

supply board.

For best efficiency, the +3.3 V and +5 V internal power supplies are supplied by a pair of switching DC-DC

converters from the +12 VDC input. The input power is approximately independent of the voltage, which means

the lower the input voltage the higher the current.

2

C (inter-integrated circuit) interfaces are provided for future option modules.

33

Page 34

RS-232 Serial Interface Cable

Your PX3 was furnished with a serial interface cable that uses an USB port on your computer. Optionally you

can use a cable designed for an RS-232 port. You can order a cable from Elecraft. Order part number KXSER.

You can also assemble your own if desired. Figure 22 is a schematic diagram of the cable.

Figure 22. RS-232 Cable Schematic Diagram.

34

Page 35

Kit Assembly Instructions

Preventing Electrostatic Discharge Damage

Sensitive components in your PX3 are may be damaged by Electrostatic Discharge (ESD) in any location or

climate unless you take specific steps to prevent such damage. Many components can be damaged by static

discharges of only a few volts: far too little for you to notice.

ESD damage may not be apparent at first. The damaged components may not fail completely. Instead, the

damage may result in below-normal performance for an extended period of time before you experience a total

failure.

We strongly recommend you take the following anti-static precautions (listed in order of importance) to ensure

there is no voltage difference between the components and any object that touches them:

Leave ESD-sensitive parts in their anti-static packaging until you install them. The packaging may be a

special plastic bag that allow static charges to flow harmlessly over their surface, or the component’s

leads may be inserted in conductive foam that keep them at the same potential. Parts which are

especially ESD-sensitive are identified in the parts list and in the assembly procedures.

Wear a conductive wrist strap with a series 1-megohm resistor that will constantly drain off any static

charge that accumulates on your body. If you do not have a wrist strap, touch a ground briefly before

touching any sensitive parts to discharge your body. Do this frequently while you are working. You can

collect a destructive static charge on your body just sitting at the work bench.

WARNING

DO NOT attach a ground directly to yourself without a current-limiting resistor as this poses a

serious shock hazard. A wrist strap must include a 1-megohm resistor to limit the current flow. If

you choose to touch an unpainted, metal ground to discharge yourself, do it only when you are

not touching any live circuits with any part of your body.

Use a grounded anti-static mat on your work bench.

If you choose to use a soldering iron to work on your PX3 for any reason, be sure your iron has an

ESD-safe grounded tip tied to the same common ground used by your mat or wrist strap.

Tools Required

1. #0 and #1 size Phillips screwdrivers. Use the screwdriver that best fits the screw in each step. To avoid

damaging screws and nuts, a power screwdriver is not recommended.

2. Needle-nose pliers.

3. Knife with small sharp tip (e.g hobby knife)

The following tools are strongly recommended:

1. ESD wrist strap.

2. Static dissipating work pad.

35

Page 36

Parts List

PX3 Front Panel Assembly Bag E850621

ILLUSTRATION DESCRIPTION QTY.

Individually Wrapped Components

ILLUSTRATION DESCRIPTION QTY.

ELECRAFT

PART NO.

Front Panel 1 E100484SS

Display Bezel 1 E100479

ELECRAFT

PART NO.

Right Side Panel 1 E850618

Left Side Panel 1 E850617

Rear Panel 1 E850619

Serial Number Label 1 E850623

PX3 Cable 1 PX3CBL

Power Cable, 18AWG, Right Angle 1 E850524

36

Page 37

ILLUSTRATION DESCRIPTION QTY.

PX3 Front Panel Board with LCD and

Switch Matrix.

ELECRAFT

PART NO.

Do not remove the rubber band or

protective film on the LCD until

instructed to do so.

Take ESD Precautions before

handling this board.

1 E850624

PX3 Power Supply Board

Take ESD Precautions before

handling this board.

1 E850604

PX3 Misc Bag - E850615

ILLUSTRATION DESCRIPTION QTY.

Tilt Foot, Left 1 E980183

ELECRAFT

PART NO.

Tilt Foot, Right 1 E980184

Rubber Foot 4 E980185

Knob 1 E980088

PX3 Hardware Envelope (see below for contents) 1 E850614

37

Page 38

PX3 Hardware Envelope – E850614

ILLUSTRATION DESCRIPTION QTY.

4-40 Thumb Screws 4 E700300

Screw, Black, Pan Head, 2-56 1/4” (6.4 mm) 10 E700124

Screw, Black Nylon, Pan Head4-40 1/4" (6.4mm) 6 E700282

Screw, Black, Flat Head, 4-40 1/4” (6.4 mm) 4 E700253

ELECRAFT

PART NO.