Eldom Invest HPS120, HPS120S, HPS150, HPS150S Installation, Use And Maintenance Instructions

HEAT PUMP SYSTEMS WITH ADDITIONAL

WATER HEATERS (HEAT PUMP SYSTEMS)

OF 120 and 150 l.

DESIGNED FOR WALL

MOUNTING

SPECIFICATIONS

INSTALLATION, USE AND MAINT ENANC E INST R UCTIONS

IMPORTANT RUL ES

WARNING! Before installing and operating the water heater read carefully the instructions!

1

SPECIFICATIONS, INSTRUCTIONS FOR INSTALLATION AND USE HEAT

PUMP SYSTEMS WITH ADDITIONAL WATER HEATER

(HEAT PUMP SYSTEMS)

OF 120 AND 150 l. (EN 60335-2-40)

DESIGNED FOR WA LL MOUNTING (hanging)

Before beginning installation and operation of Your unit it is compulsory to read the complete

text of this instruction. It must be observed as well by You, in order to help You operate and use

the system, as well by the qualified workers who shall install and eventually maintain and repair

the unit in case of malfunctioning. Compliance with rules in present instruction booklet shall be a

prerequisite for system safe use and is part of warranty requirements.

CAUTION!

qualified persons and in accordance with the provisions of national legislation.

IT IS COMPULSORY

CAUTION!

The unit must be properly connected to both power conductors and to protective circuit! Do not

connect the unit to power supply before its water tank is completely water filled!

CAUTION!

unit must be properly connected and secured against refrigerant leak into the atmosphere.

WARNING!

water in the water heater is heated to temperatures closer the thermostat higher limit.

WARNING!

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have

been given supervision or instructions concerning use of the appliance by a person responsible

for their safety! Children should be supervised to ensure that they do not play with the

appliance!

Unit installation and connection to the water supply network must be completed by

to install only manufacturer supplied safety and other fittings!

Connection to the power supply network must be completed by qualified workers.

The connection of unit two bodies must be carried out only by qualified workers. The

When using the appliance there is a risk of hot water scalding, especially when the

This appliance is not intended for use by persons (including children) with reduced

ENVIRONMENTAL PROTECTION

This appliance is marked according the REGULATION concerning requirements for marketing

electrical and electronic devices and the treatment and transport of waste from electric and

electronic equipment. By ensuring this product is disposed of correctly, you will help prevent

potential negative consequences for the environment and human health, which could otherwise

be caused by inappropriate waste handling of this product.

The symbol

appliance may not be treated as household waste. Instead it should be handed over to the

applicable collection point for the recycling of electrical and electronic equipment. Disposal must

be carried out in accordance with local environmental regulations for waste disposal. For more

detailed information about treatment, recovery and recycling of this product, please contact your

local city office, your household waste disposal service or the shop where you purchased the

product.

on the product or on the accompanying documents indicates that this

2

SPECIFICATIONS

Water heaters operated with heat pumps are designed for household use and serve to

provide hot water from the water supply network for several consumer points – kitchen,

bathroom, etc.

The appliance transfers heat energy from the environment in the water tank, thus heating

water contained. Energy is extracted directly from the air. A small quantity of electricity is

required to operate the compressor. The amount of heat produced by the heat pump operation

is more than three times the input electricity. The heat pump operated water heaters of

Eldominvest Ltd. Consist of two parts: outdoor unit, or body, with compressor and heat

exchanger, and indoor unit, or body, consisting of water heater with heat exchanger –

condenser. Both units are connected with pipes through which flows refrigerant.

Within the external unit package you shall find the stand for appliance wall mounting and a

corrugated plastic pipe for external unit drainage.

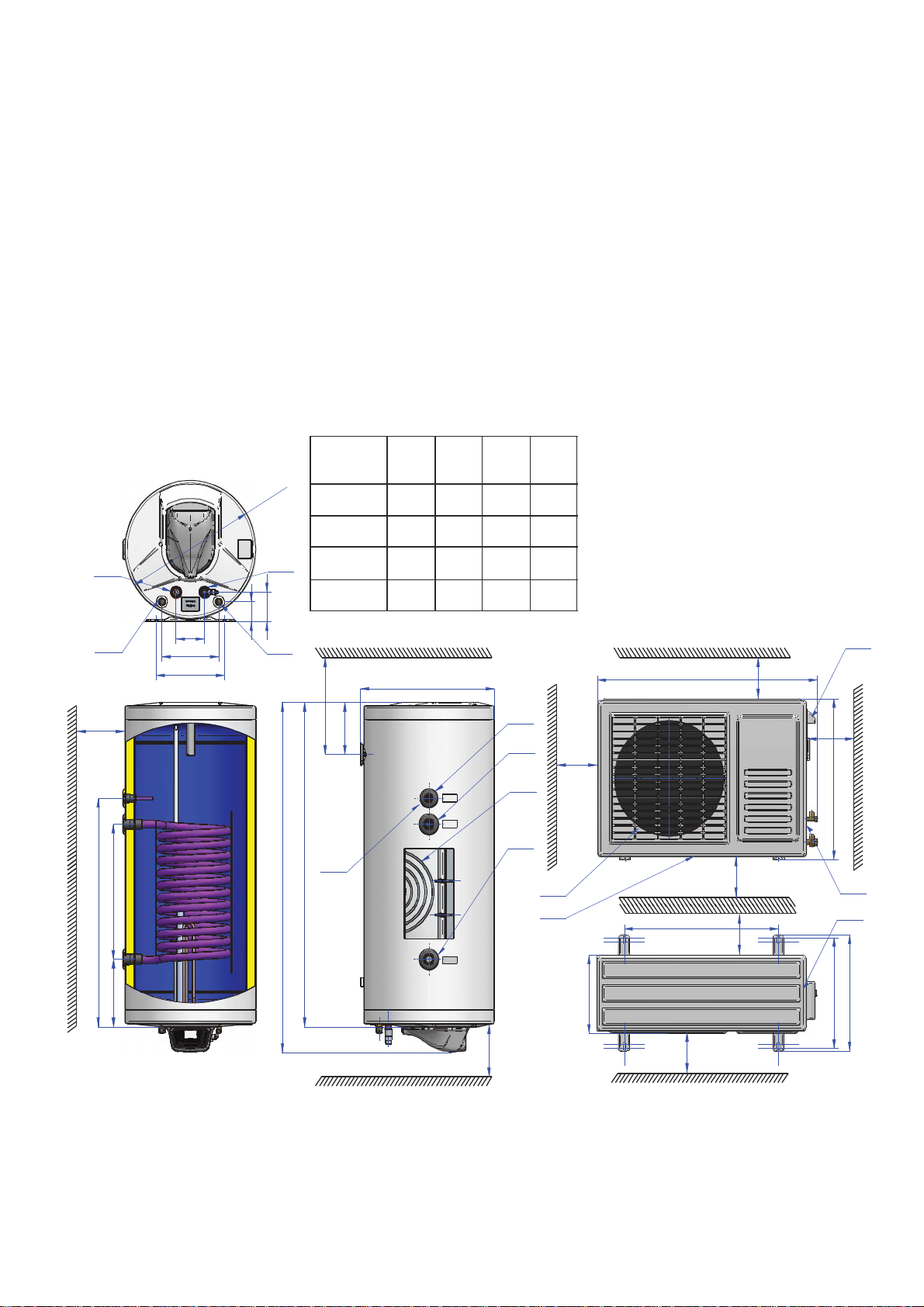

On Fig. 1 you may see a schema with dimensions and the specification data in Table 1.

Fig.1

6

7

min 250

100

200

240

66

Model L1

0

6

4

O

98

HPS120 1165 1090 1070 -

HPS120S 1165 1090 1070 450

HPS150 1415 1330 1310 -

5

HPS150S 1415 1330 1310 537

8

min 250

173

[mm]L2[mm]L3[mm]

471

L4

[mm]

1

2

3

1. Thermostat coupling

2. Solar heat exchanger inlet

3. Condenser

4. Solar heat exchanger outlet

5. Cold water inlet

6. Hot water outlet

7. Refrigerant – gaseous phase

8. Refrigerant – fluid phase.

min 200

8532

min 500

min 800

2

4

B

L3

L4

225

Table 1.

L1

4

M

L2

380

C

D

400

A

E

268

min 350

min 800

min 100

560

min 300

3

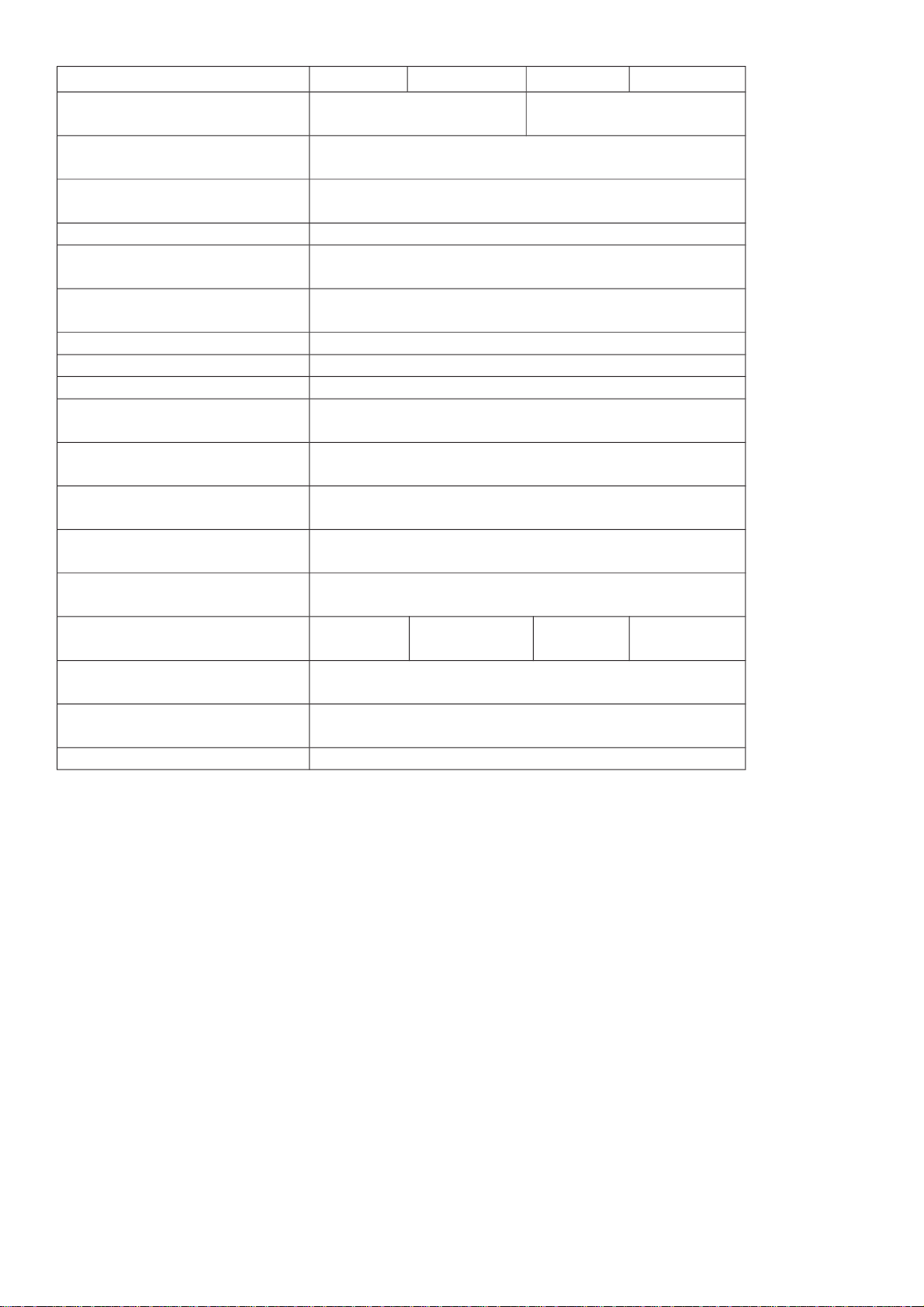

Model

Water heater tank nominal

volume

Heat pump rated nominal

heating power

Electric heater rated

nominal heating power

HPS120 HPS120S HPS150 HPS150S

120 l 150 l

3000 W

2000 W

Nominal tension 220-240 V~

Heat pump nominal electric

capacity

Heat pump maximum

electric power

780 W

1020 W

Total maximum power 3020 W

Starting current 21,15 А

Refrigerant R417A 0,8 kg

Operating temperature

range

System maximum pressure

with refrigerant

System minimum pressure

with refrigerant

Maximum tolerated system

pressure with refrigerant

Water tank nominal

pressure

Surface of the water heater

solar heat exchanger [m

2

]

Outdoor unit waterproof

class

Indoor unit water protection

class

-0,65-0,89

-10° ÷ 40°

2,7 MPa

0,7 MPa

2,8 MPa

0,8 MPa

IPX4

IPX1

Outdoor unit level of noise 49 dB(A)

The water tank unit is properly protected from corrosion with high quality enamel lining or high

quality chrome-nickel steel. Within the enameled water tanks are inserted anodes of special

alloy, which during its wear provide additional protection of the enamel lining.

The water used for heating must comply with legislation in force for household water quality

and in particular its chlorides content must be below 250 mg/l, while its conductivity must be

over 100 μS/cm and below 2000 μS/cm for water heaters with enameled tank and under 600

μS/cm for water heaters with water tank of high quality chrome-nickel steel.

The unit’s outer body is made of steel with epoxy polymer coating, while thermal insulation is

completed with Freon less polyurethane foam.

Water heater modifications are marked with numbers and letters as follow:

„HPS” – means heat pump operated water heater.

The numbers 120 and 150 mean that the water heater tank has a volume of 120 or 150 liters.

„Н“ means that the appliance water tank is made of chrome-nickel alloy steel.

“S” means that the water heater is equipped with solar heat exchanger.

The maximum pressure tolerated in a system with refrigerant for the heat pump water heaters

is 2,8 МРа. These systems are tested and designed to operate at pressures lower than 2,8МРа.

4

For this aim within their structure is mounted a fuse to prevent that the system reaches a higher

than acceptable pressure.

The heat pump heaters are intended to heat water not only with their heat pump system, but

as well with 2 000 W electric heater. It is possible to heat water only with the appliance electric

heating element.

WATER HEATERS WITH SOLAR HEAT EXCHANGERS

These models water heaters provide the opportunity to save electricity thanks to the

integrated heat exchanger. When operating the latter allows heating the water volume from

alternative heat source such as a solar collector. It is necessary to use within the system a heat

transfer fluid not exceeding 85° С.

WARNING!

IT IS ABSOLUTELY FORBIDDEN to allow heat transfer fluid circulation through

the heat exchanger when the water tank is empty. IT IS ABSOLUTELY FORBIDDEN to close

simultaneously the heat exchanger inlet and outlet.

For heat transfer fluid always use a solution of propylene glycol diluted with water in a ratio

consistent with environmental climatic conditions. Installation and connection of the water

heater heat exchanger to it must be carried out only by qualified and licensed companies with

same business in accordance with specific project.

INSTALLING THE WATER HEATER (INDOOR UNIT) TO THE WALL

The water heater (indoor unit) may be installed only in premises with regular fire safety and

where temperature may never drop below 0°С. It is necessary as well that the floor in the

premise be equipped with trap for wastewater, as it is possible during normal operation from the

relief valve outlet from time to time to drip water. The wastewater trap shall ease maintenance,

prevention and service operations for the water heater requiring drain of tank water.

The place for installation of the water heater must comply with its dimensions, way of

mounting, and location of fixing elements and pipes and its waterproof class of protection. The

latter is noted on the appliance plate serial number. It is absolutely necessary that the appliance

is protected from dripping or spraying with water.

Water heater must be rigidly mounted to the premise wall. For the purpose apply firmly

fastened in the wall steel bolts (pins) of 10-12 mm diameter. The fasteners must be secured

against pulling out of the wall, i.e. these must be anchor bolts or bolts passing through the wall

section (depending of wall material). It is not allowed to mount the water heater on decorative

walls (of single bricks or lightweight materials).

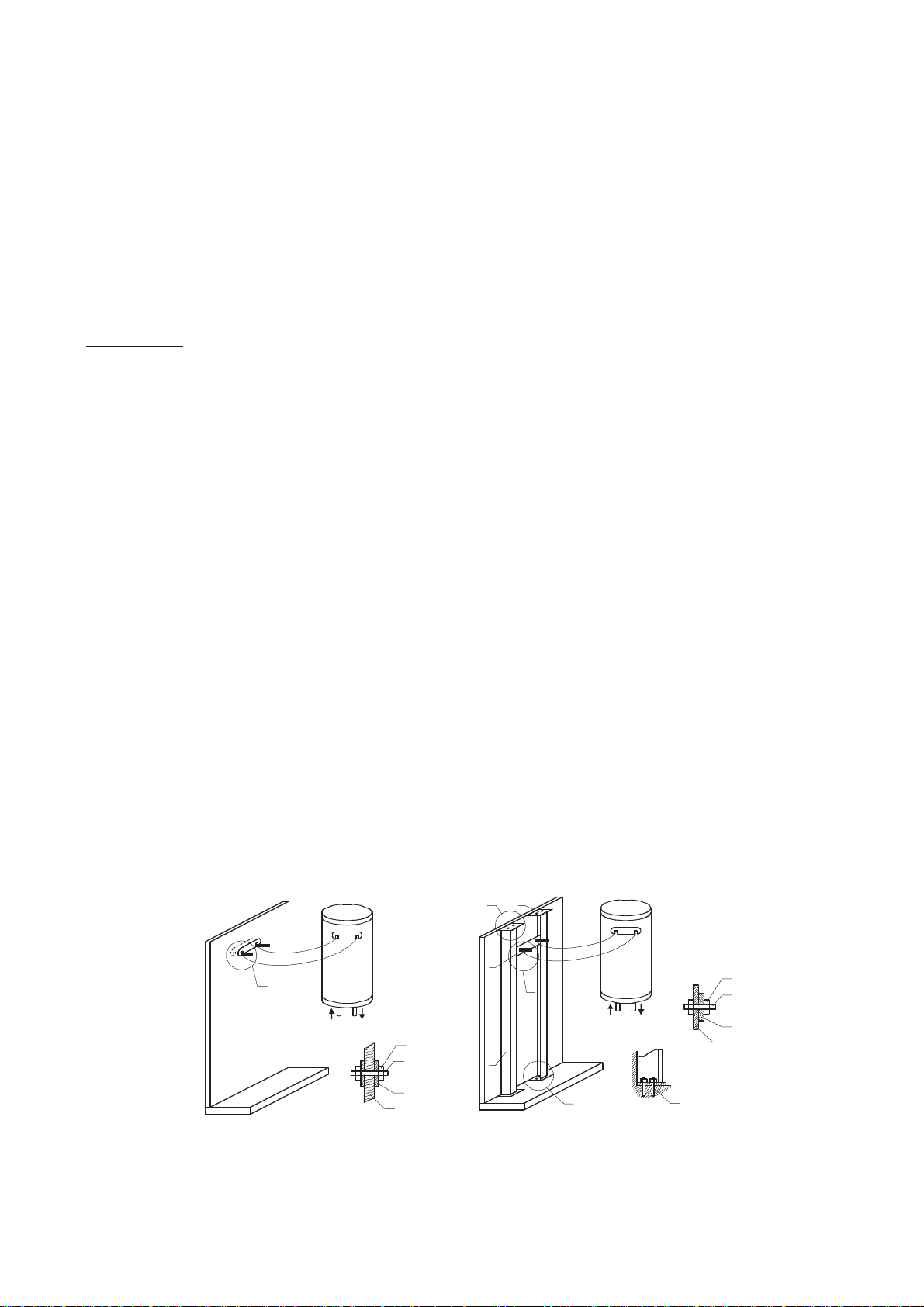

Mounting on support wall. Support walls are those

made of reinforced concrete or masonry with solid

bricks with thickness at least 25 cm.

A

Mounting on curtain wall. Curtain wa lls are those

made of masonr y wit h non-solid bricks or oth er light

materials.

B 6

1

A

A

4

3

Fig. 2

1. Wall; 2. Plate; 3. Pin; 4. Nut

2

A

4

3

2

1

5

B

1. Plate (4x60x3 60); 2. Unit plate; 3. Bol t (pin) M10; 4. Nut;

5. Column (set square 50x50x5); 6. Plate (4x100x100);

7. Treenail for concrete.

NOTES: 1. Posit ions 1, 5 and 6 are welded.

2. The premise floor and c eiling are made of rei nforced concrete.

B

1

7

5

WARNING! Failure to comply with requirements for fixing the water heater to the wall may

cause damage to the appliance or to other appliances in the premise where it is located, to

corrosion or even more severe damages and harms. In such cases eventual damages and

harms shall not be covered by the manufacturer or seller warranty liabilities and shall be at the

expense of those violating these instructions.

Only qualified workers shall be allowed to mount the water heater on the wall.

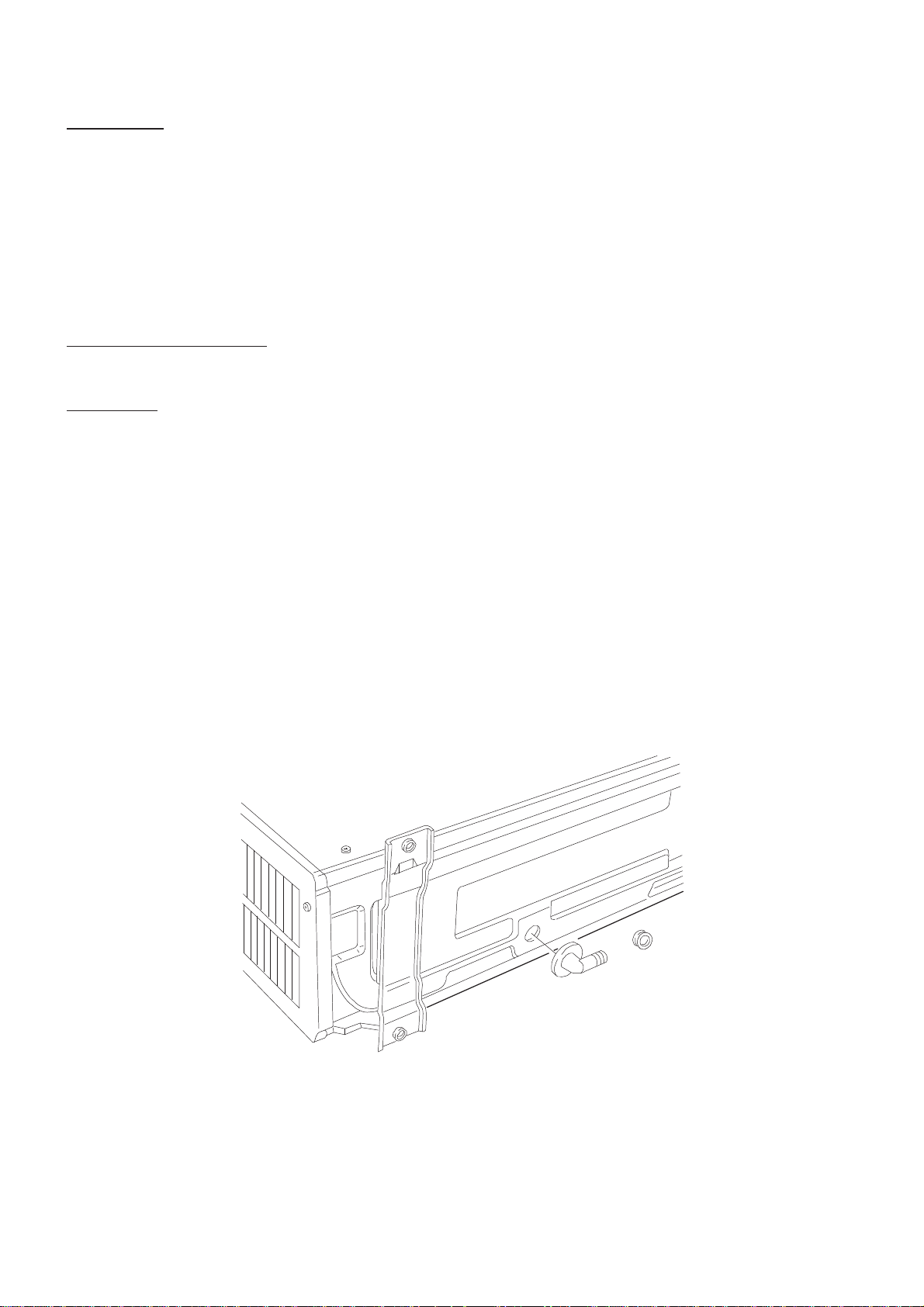

MOUNTING THE OUTDOOR UNIT

RECOMMENDATIONS: Use only the fittings supplied in the delivery set and placed in the

package for the external unit wall mounting stand and the supplied corrugated drainage pipe.

CAUTION!

requirements:

а) Find the most suitable position with enough space on the wall in order to make easier the

installation and maintenance of the outdoor unit (Fig. 1);

b) The outdoor unit is installed on support or curtain wall with built support structure. The place

must be safe in any respect and noise and cold air must not cause any problems. For mounting

the unit use fastening brackets. The place must not allow passage near the outdoor unit and

must ease discharge of condensation water;

c) The outdoor unit must be installed completely horizontal. (Fig. 1);

d) Provide space for connection of pipes and power cables, as well as an opening in the wall

where these shall pass through;

e) Mount the unit securely on the wall with suitable screws or anchors (pay attention for hidden

cables and pipes). Secure the location against vibrations.

f) Condensation or water appearing during outdoor unit operation must be removed and offset

through drainage. A nipple or flexible sleeve may be installed in order to secure free flow of

water (Fig. 3).

Before starting installation be sure that the place selected fulfills the following

Fig.3

6

REFRIGERANT PIPES PREPARATION

Insulation

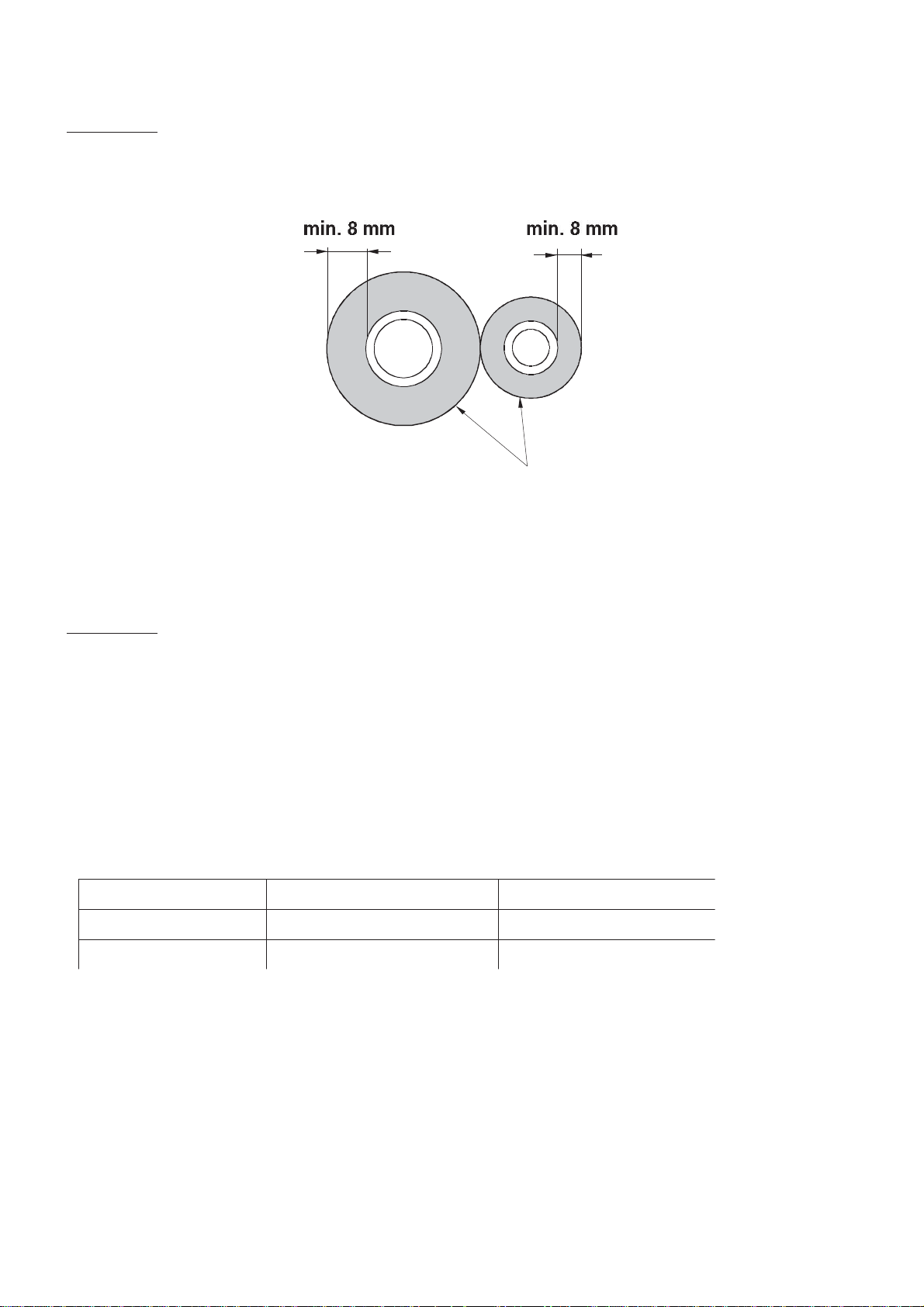

CAUTION! Before starting installation check for the following:

а) Apply copper tubing used for installation of air conditioning systems (1/4'' and 3/8”) with

appropriate insulation (at least 8 mm), Fig. 4, suitable for use with refrigerant R417a;

Fig. 4

b) Do never apply pipes thinner than 0.8 mm;

c) Secure the simplest and shortest passage (max. distance 8 m. length and 3 m displacement),

d) Protect both pipes and cables to prevent damages.

CAUTION!

prevent burns, cuts or loss of product.

The pipes should not be wet and dirty. Avoid any sharp bends of pipes or harm to its cylindrical

shape. Any bending must be carried out with suitable tool.

The pipes and fittings for the refrigerant must be thermally insulated in order to

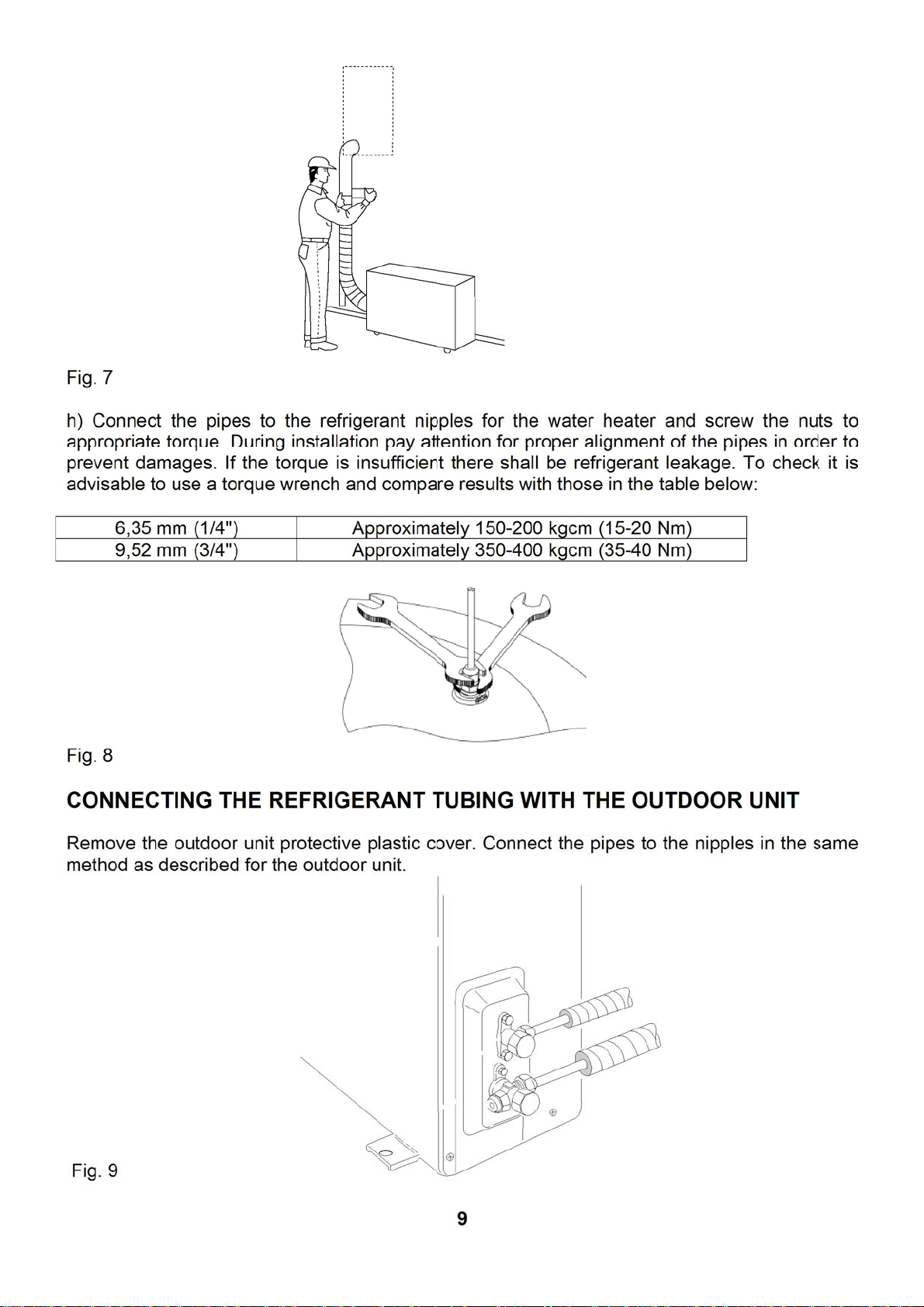

CONNECTING THE REFRIGERANT TUBING WITH THE INDOOR UNIT

(WATER HEATER)

а) Unfold required pipes length from the rolls;

Marking External diameter [mm] Thickness [mm]

1/4“ 6,35 0,8

3/8“ 9,52 0,8

b) Remove the refrigerant nipples protective nuts of the indoor unit (make sure there is no dirt or

moisture);

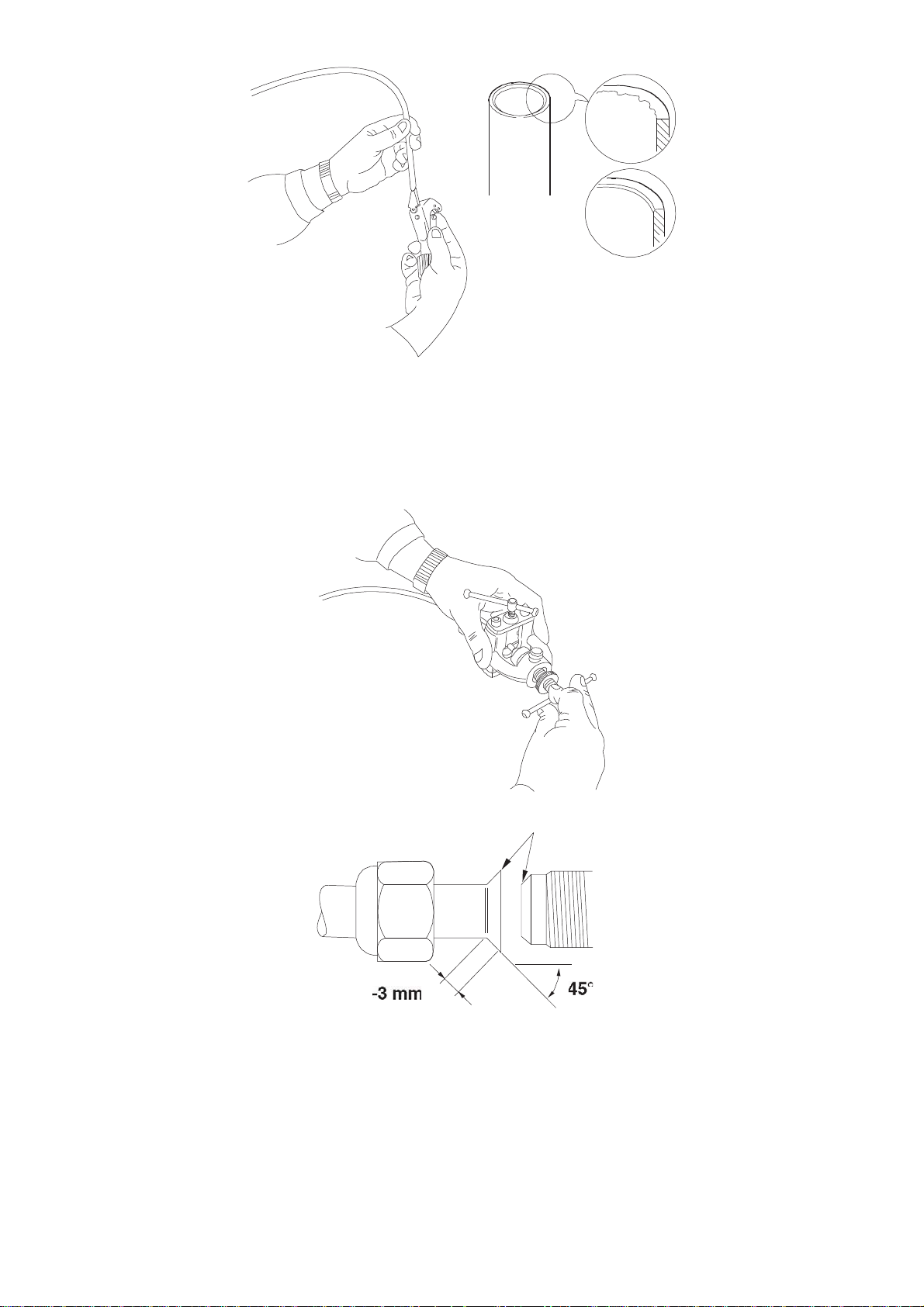

c) Cut the pipes desired length with suitable tool avoiding formation of burrs and distortions. The

cut must be perpendicular to the pipe axis (Fig. 4);

7

Fig.5

Grease

d) Remove the burrs or other contaminants (if any) in order to prevent passing in the system;

e) Place insulation on the pipes;

f) Place the pipes brass nuts in the right direction and make cones on pipe’s both ends in

suitable shape and size with appropriate tool. (Fig. 6):

Fig. 6

g) Connect the two pipes with insulation with the power and communication cable in a bundle

and wrap it tightly with PVC tape with UV protection.

8

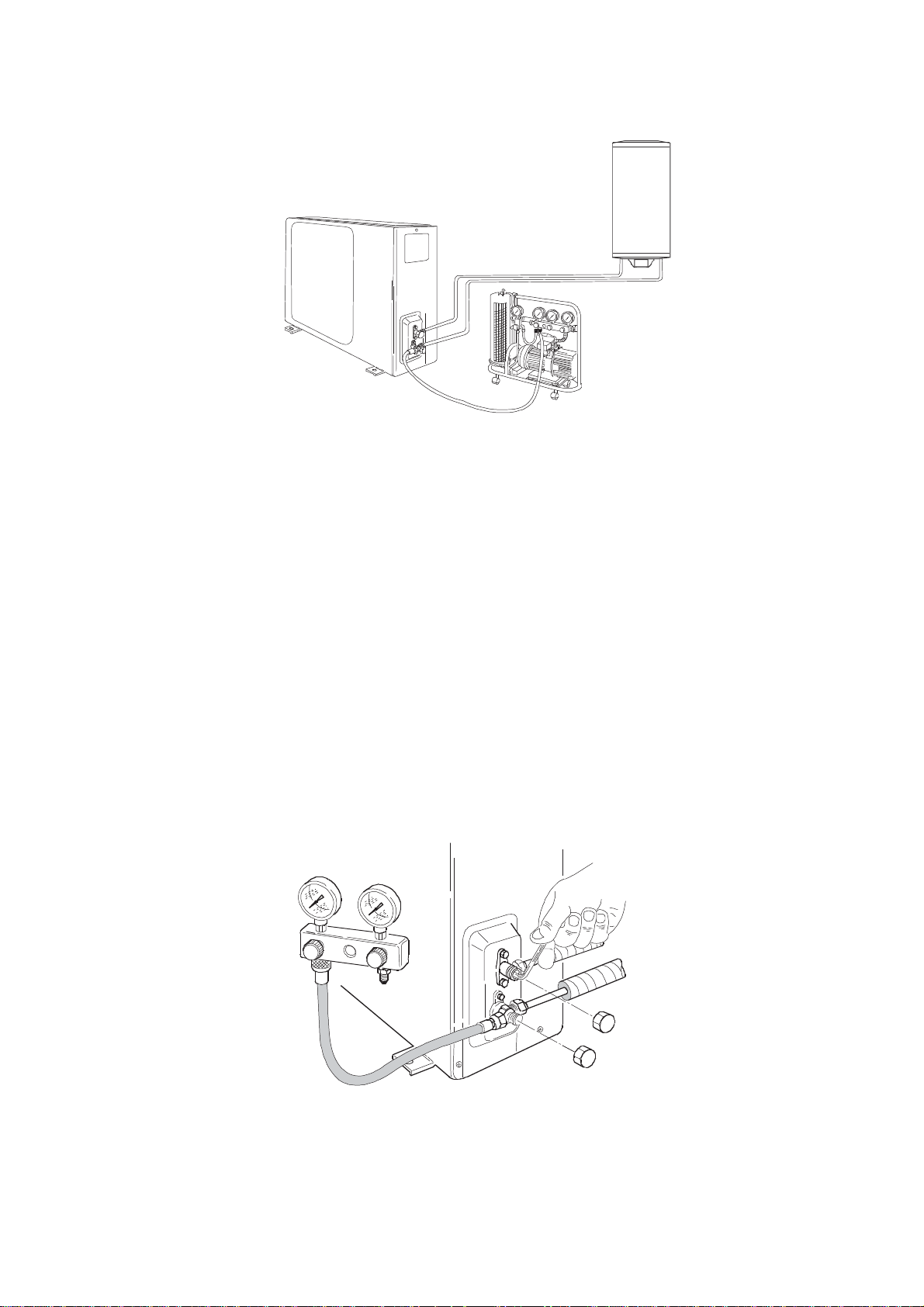

SYSTEM VACUUMING AND CHECK FOR LEAKS

Fig. 10

It is first necessary to purge the air from the system with a vacuum pump. Both connections

and gauges must be adapted to R417A (or R22). Make sure the vacuum pump is in good

working condition.

а) Remove the plugs of the outdoor unit two and three-way valves, as well as of the service

valve. Check if both valves of the outdoor unit are closed;

b) Connect the vacuum pump to the service valve;

c) After opening the valve plug the pump and let it run. It shall make vacuum for about 20-25

minutes.

d) Check whether the pressure gauge indicates pressure equal to 1 bar (or -76 cm Hg);

e) Close the pump valve. Make sure that the pressure gauge arrow does not move for at least 5

minutes. If the arrow is moving it means that within the system penetrates air and it shall be

necessary to check all connections. After finding and fixing the leak repeat the procedure from

start.

f) Turn off the pump and remove the hose connected to the service valve.

g) Open completely the two and three-way valves using Allen key.

h) Screw and tighten the valve plugs.

i) Check for refrigerant leaks with appropriate detector.

Fig. 11

10

ADDING REFRIGERANT

CAUTION! It is compulsory that this procedure be performed only by qualified workers.

The outdoor unit is pre-charged with refrigerant suitable for system operation with tubing length

up to 8 m. Longer piping length may affect adversely system performance. Overflowing with

refrigerant shall have same negative impact on system operation.

If it is necessary to add refrigerant R417a to the system, it should be known that for each

additional meter of tubing must be added 20 g refrigerant and the following shall be necessary:

а) electronic balance with accuracy to 10 g;

b) bottle with refrigerant R417a.

It shall as well be necessary to use a hose with appropriate charging connections.

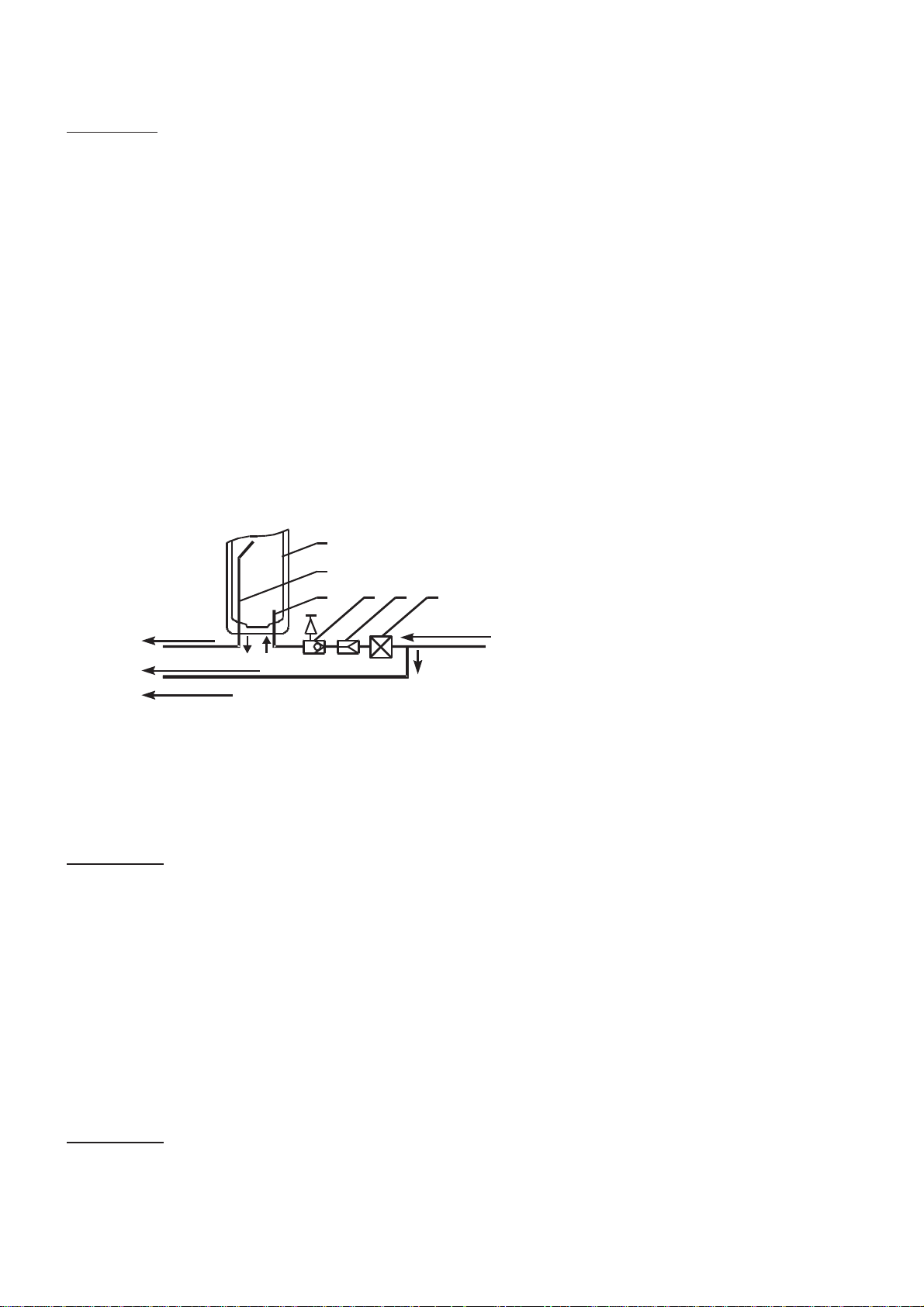

CONNECTING THE WATER HEATER (INDOOR UNIT) TO WATER SUPPLY

NETWORK

When connecting the water heater to the hot and cold water in the building plumbing you must

comply with arrows and pointing rings on water heater pipes. The cold water pipe is indicated

with arrow and blue color (inlet pipe), while with arrow and red colour – the hot water pipe

(outlet pipe). Pipes ends are threaded 1/2”. You may refer to water tank connection scheme on

Fig. 12.

1

1. Water tank;

2. Inlet pipe;

3. Outlet pipe;

4. Closing valve (option);

5. Combined valve;

6. Reduction valve (where necessary, i.e. with

water supply network pressure over 0.6

MPa)

Hot water

To mixing tab

Cold water

3

2564

Cold water

The water heater is fit with combined check-safety valve mounted on the cold water pipe in

factory.

The minimum water supply pressure for system normal functioning is 0,2 МРа.

WARNING!

It is not allowed to install check or shut-off valves between the combined valve and

the water heater! It is absolutely forbidden to clog the combined valve side hole and/or block its

lever!

If necessary you may shape a drainage system for the water dripping from the combined valve

side hole. The drainage water must have constant downward gradient, located in frost free

environment and its ends permanently connected to the atmosphere.

Following its connection to the water supply network the tank must be filled with water. The

steps of this procedure are as follow: open completely the hot water tap of the farthest mixing

tap; then open the shut-off valve, pos. 4 on Fig. 12; and wait until dense water jet flows out;

close the hot water mixing tap and lift the combined valve lever, then wait about 30-60 seconds

until complete and full water jet flows; close the valve lever.

WARNING!

If from the valve there is no water flow or the jet is insignificant (at normal pressure

in the supply network), this is a malfunction indicating that impurities from the plumbing

connections or pipes have blocked the safety valve of the combined valve.

11

Loading...

Loading...