Eldex

Eldex®

Optos Metering Pumps

Operator’s Manual

Eldex Laboratories, Inc.

30 Executive Court

Napa, CA 94558

Tel: (707) 224-8800

Fax: (707) 224-0688

www.eldex.com

© 2018 Eldex Laboratories, Inc.

Rev. Z: 09112018

All Rights Reserved

TABLE OF CONTENTS

CONTENTS PAGE

I. INTRODUCTION 1

Optos Metering Pumps 1

Principles of Operation 1

Materials of Construction 1

About This Manual 1

A Guided Tour of Optos Metering Pumps 2

Specifications 7

Stainless Steel Pump Specifications 7

PEEK Pump Specifications 8

Hastelloy C-276 Specifications 9

II. INSTALLATION 10

What You Will Need 10

The Unit 10

Tools 10

Unpacking and Location 10

Electrical Connections 10

Power Entry Module 10

Inputs/Outputs 10

Plumbing 11

Solvent Preparation 11

Attaching Inlet Tubing 12

Priming The Pump 12

Attaching Outlet Tubing 12

Pulse Damper Use 12

Using the Piston Wash System 13

III. OPERATION 14

Basic Operation 14

General Notes on Software Operation 14

Setting the Flow Rate 14

Setting the High Pressure Limit 14

Setting the Low Pressure Limit 14

Configuration Screens 15

Setting the Compressibility Compensation Factor 15

Sending the Piston to the Home Position 15

Changing the Refill Rate Setup 15

Setting the Liquid End Type 15

Setting the Remote Control Setting 16

Viewing the EPROM Revision Level 16

Advanced Screens 16

Setting the Home Position Offset 16

Setting the Output Function 17

Setting the High/Low Pressure Limit Shutdown 17

Setting the Motor Stall Shutdown 17

Setting the Error Delay 18

Setting the Save State 18

Setting the Save in Run Flow Rate 18

Setting the Contact Closures during Remote Analog Mode 19

Viewing the Stroke Length 19

Zeroing the Pressure Transducer 19

Pump Limits 20

Viscosity Limits 20

Chemical Limits 20

Mechanical Limits 20

Temperature Limits 20

Shutdown Procedures 20

IV. MAINTENANCE 21

Cleaning 21

Piston Seals 21

Replacing The Piston Seal 21

Replacing Valves 23

Removal Of Existing Valves 23

Installation Of New Valves 23

Replacing Valve Cartridges 23

Troubleshooting 25

V. SPARE PARTS AND ACCESSORIES 26

For 3/32” Stainless Steel Pumps 26

For 1/8” Stainless Steel Pumps 27

For ¼” Stainless Steel Pumps 28

For 3/32” PEEK Pumps 29

For 1/8” PEEK Pumps 30

For ¼” PEEK Pumps 31

For 1/8” Hastelloy C-276 Pumps 32

For ¼” Hastelloy C-276 Pump 32

VI. APPENDIX 33

RS232 33

Warranty 34

Return Procedure 34

Trademarks 34

CAUTION: The exclamation point within an equilateral triangle is intended to

alert the user to the presence of important operating and maintenance (servicing)

instructions in the literature accompanying the appliance.

ATTENTION: Le point d’exclamation dans un triangle equilatéral signale à

alerter l’utilisateur qu’il y a des instructions d’operation et d’entretien tres

importantes dans la litérature qui accompagne l’appareil.

ACHTUNG: Ein Ausrufungszeichen innerhalb eines gleichwinkeligen Dreiecks

dient dazu, den Benutzer auf wichtige Bedienungs-und Wartungsanweisungen in

der dem Gerät beiliegended Literatur aufmerksam zu machen.

CAUTION: We have tested this pump with 2 propanol. Residual amounts of 2

propanol may be in the pump. You may wish to flush with an appropriate,

miscible solvent.

You may be using a variety of fluids which require special handling procedures

and safety precautions. Consult the appropriate MSDS (Material Safety Data

Sheet) supplied with the materials you will be using. Be certain to follow all

handling, safety, and disposal procedures appropriate for the materials you use.

ATTENTION: Gardez à l’esprit que nous avons testé cette pompe avec le

propanol-2. Les quantités résiduelles du propanol-2 peuvent se trouver sur le

dispositif de raccordement du liquide et vous souhaiterez certainement les

chasser avec un solvant miscible approprié.

Vous pouvez utiliser une variété de liquides qui nécessitent des manipulations et

des précautions particulières. Consultez la fiche technique de sécurité

appropriée; elle est fournie avec le matériel que vous utiliserez. Veillez a bien

respecter toutes les procédures de manipulation, sécurité et élimination du

matériel.

ACHTUNG: Die Pumpe wurde mit 2-Propanol getestet. Geringe Restmengen

von 2-Propanol können sich noch im System befindend, so dass wir Ihnen vor

Inbetriebnahme das Spülen mit einem geeigneten Lösungsmittel empfehlen.

Sie können eine Vielzahl von Lösungsmitteln einsetzen, deren Verwendung unter

Umständen spezielle Sicherheitsvorkehrungen voraussetzt. Bitte beachten Sie

in allen Fällen die, den Lösungsmitteln vom Hersteller beigelegten

Sicherheitsdatenblätter.

Environmental Protection

Waste electrical products should not be disposed of with household waste.

Please recycle where facilities exist. Check with your Local Authority or retailer

for recycling advice.

INTRODUCTION

Laboratory and industrial procedures often require metering precise amounts of fluids in a controlled and

reproducible manner. Optos pumps were developed in response to this need. These pumps are capable of

delivering measured amounts of fluids against significant backpressure.

Pump Features Include:

Piston wash chamber for backflushing piston to extend seal life.

Electronic control of piston motion to minimize pulsation.

Optional pulse damper for further pulse reduction.

Easy to use interface for flow setting and other pump parameters.

Metal-free options

Principles of Operation

Optos pumps attain precise metering at intermediate and high pressures by a positive displacement, reciprocating

piston. The piston is driven by a stepper motor via an eccentric. Advanced software algorithms control motor

speed based on piston position, achieving rapid fluid intake and smooth, constant fluid delivery, minimizing

pulsation. Additional reductions of pulsation can be achieved by use of the optional damper.

Ball and seat inlet and outlet valves ensure precise metering. The suction created by the piston retracting to refill

the piston chamber pulls the inlet ball off the inlet seat allowing fluid to travel through the inlet check valve.

Simultaneously, the outlet ball is pulled back onto its’ seat, preventing fluid from exiting the piston chamber.

During the delivery portion of the piston’s duty cycle, the inlet ball is pushed back onto its’ seat as the piston

moves forward, preventing fluid from travelling back to the pump reservoir. Simultaneously, the outlet ball is

forced off its’ seat, allowing fluid to exit the outlet valve. For the valves to operate effectively, a pressure

differential of at least 25 psi is required on the outlet side of the pump.

The pump’s flow rate is set directly in mL/min. using the up and down buttons on the user interface. Flow rates

are determined by piston displacement (diameter, and stroke length) and motor speed.

Some Optos pumps may be fitted with a pulse damper. The damper is a diaphragm type damper, where a

diaphragm made of an inert material flexes against a compressible fluid (spiked with red dye), thereby absorbing

pulses in fluid delivery. To maximize the damper’s efficiency, the system should operate against at least 500 psi.

If your system does not normally generate such pressures and you wish to increase the efficiency of the damper,

you can install a backpressure device, or some narrow ID tubing downstream of the pump.

Materials of Construction

The materials used for the liquid end of your Optos Pump were carefully chosen for corrosion resistance. The

piston is sapphire, and the inlet and outlet valves incorporate sapphire seats and ruby balls.

The piston seal material is made from specially formulated PTFE and has excellent chemical compatibility

characteristics.

The liquid end housing is made of passivated type 316 stainless steel because of its superior resistance to

corrosion. In applications requiring the use of chemicals corrosive to type 316 stainless steel, you may order a

PEEK (polyetheretherketone) liquid end or one made of Hastelloy.

About This Manual

This manual provides instructions and information on Optos metering pumps.

Section II of this manual, beginning on page 8, describes the unpacking, location, and initial installation of your

metering pump. Section III, beginning on page 11, describes the operation of the Optos hardware and the menu

system in detail.. Section IV, beginning on page 16, describes maintenance procedures. Section V, beginning on

page 20, contains appendixes, including, lists spare parts and accessories for the various pump models.

1

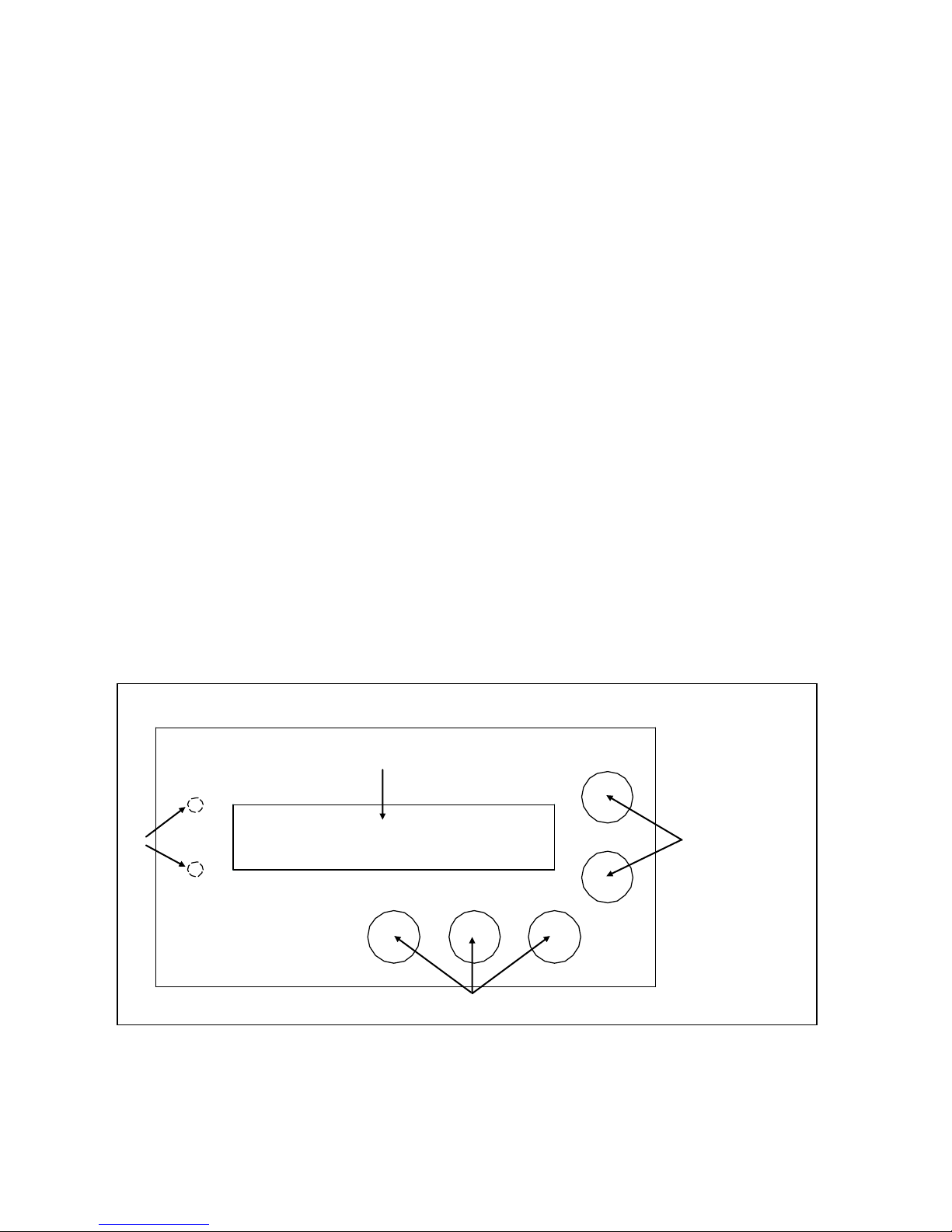

A Guided Tour of the Optos Metering Pumps

Front Panel

As you look at the front panel of your Optos Metering Pump (Figure 1.1), you will see:

Component Details

Local Interface:

1. Liquid Crystal Display (LCD). Displays flow rate, pressure (with optional pulse damper), other

allowed functions.

2. Up/Down Keys. UP and DOWN arrow keys set flow rates, change pump settings.

3. Permanent Functions Keys. DISPLAY, ΔMENU, and RUN/STOP keys are control keys permanently

defined for direct control of major instrument functions.

4. Status LEDs. Indicate pump running or fault.

Pulse Damper: optional pulse damper for minimized fluid delivery pulsation.

5. Outlet Port: Connection to downstream device.

6. Inlet Port: Connection from pump outlet.

Liquid End Assembly:

7. Outlet Valve: Provides tubing connection for pump output.

8. Cylinder: Contains pumping chamber and piston wash ports.

9. Inlet Valve: Provides tubing connection to fluid source. Inlet valve has an additional groove on

the hexagonal portion of the valve.

Rear Panel

As you look at the rear panel of your Optos Metering Pump (Figure 1.2), you will see:

Component Details

1. RS232: RJ11 connector for RS232 communication.

2. I/O: Input/output connections for remote analog control, pressure out, error out, remote start, stop.

3. Power Entry: Provides power connection with modular cord.

4. Fuse: Housing for pump fuses.

5. On/Off: Turns the power to the pump on and off.

2

Figure 1.1: Front View of Optos

Figure 1.2: Rear View of Optos

1

2

3

4

5

6 7 8

9

1

2 3 4

5

3

Figure 1.3: Local Interface

1

2

3

4

An Overall Look at the Local Interface

Operation of the Optos Pump is controlled from a series of menus and there is no need to remember esoteric

control codes or command sequences. A detailed description of the menu sequence is given in Section III.

As you look at the local interface (Figure 1.3), you will see:

Component Details

1. Status LEDs: Upper green LED indicates pump is running; lower red LED indicates a pump fault (for

example, an overpressure limit, or motor stall condition.

2. Display: A one line, 16 character LCD display is used to provide readout of flow and pressure (with

optional pulse damper), and access to pump functions.

3. Up/Down Keys: UP and DOWN arrow keys set flow rates, pressure limits (with optional pulse damper),

and function settings.

4. Permanent Function Keys: ΔMENU key changes the display to different pump functions, DISPLAY key

toggles display back to main display of flow, or flow and pressure (with optional pulse damper),

RUN/STOP key runs the pump and stops the pump.

Key Definitions

ΔMENU: The ΔMENU (Change Menu) key scrolls through the main menu selections.

DISPLAY: The DISPLAY key toggles back to main display of flow, or flow and pressure (with optional pulse

damper).

UP/DOWN: UP and DOWN arrow keys increase or decrease flow rate setting, high or low pressure limit settings,

and change setting of other pump parameters.

DISPLAY, then ΔMENU: Holding down the DISPLAY key followed by pressing the ΔMENU key brings up a series

of sub menus which pertain to various pump settings. Pressing the DISPLAY key alone returns to main display.

ΔMENU, then DISPLAY: Holding down the ΔMENU followed by pressing the DISPLAY key brings up a series of

sub menus which pertain to obscure pump settings. Pressing the DISPLAY key alone returns to main display.

4

XX.XXXmL XXXXpsi

MAIN

HI LIMIT: XXXX

H

LO LIMIT: XXXX

L

Read/set flow

rate

Read pressure

Set high

pressure limit

Set low pressure

limit

ΔMENU

ΔMENU

Menu Schematic

The menu schematic indicates the general structure of the menu map. The specific screens shown may vary

from your specific configuration (e.g., pressure is only displayed and high and low limit settings are only

available on the Plus versions).

Basic Screens

5

GO HOME: HIT RUN

HP

COMPRESS: XX

C

REFILL: FULL OUT

R

HEAD: 1/8 SS

LE

REMOTE: OFF

REM

VERSION: X.XX

V

HOME OFFSET: XX

HO

0-5V OUT: PRESS

S

STROKE: .125

ST

PRESS LIMIT: ENA

LI

Adjust

compressibility

compensation

Set refill:output

ratio

View EPROM

level

Set remote

control

configuration

Set piston &

materials of

pump

Send piston to

forward position

Set pressure

limit ON/OFF

View stroke

length

View/set

voltage out

Set home

position offset

PRESS 0: HIT RUN

XDC

Zero Pressure

Transducer

STOP STALL: ON

SS

Set motor stall

ON/OFF

ERROR DELAY: 0

ED

Set error delay

0-10 (seconds)

SAVE STATE: OFF

SP

Save OFF/ON

state

SAVE IN RUN: OFF

SR

Save flow rate

set during run

OFF/IN

REM CONTACT: OFF

RC

Use start/stop

contacts in

remote OFF/ON

Configuration Screens: DISPLAY & ΔMENU

Advanced Screens: ΔMENU & DISPLAY

6

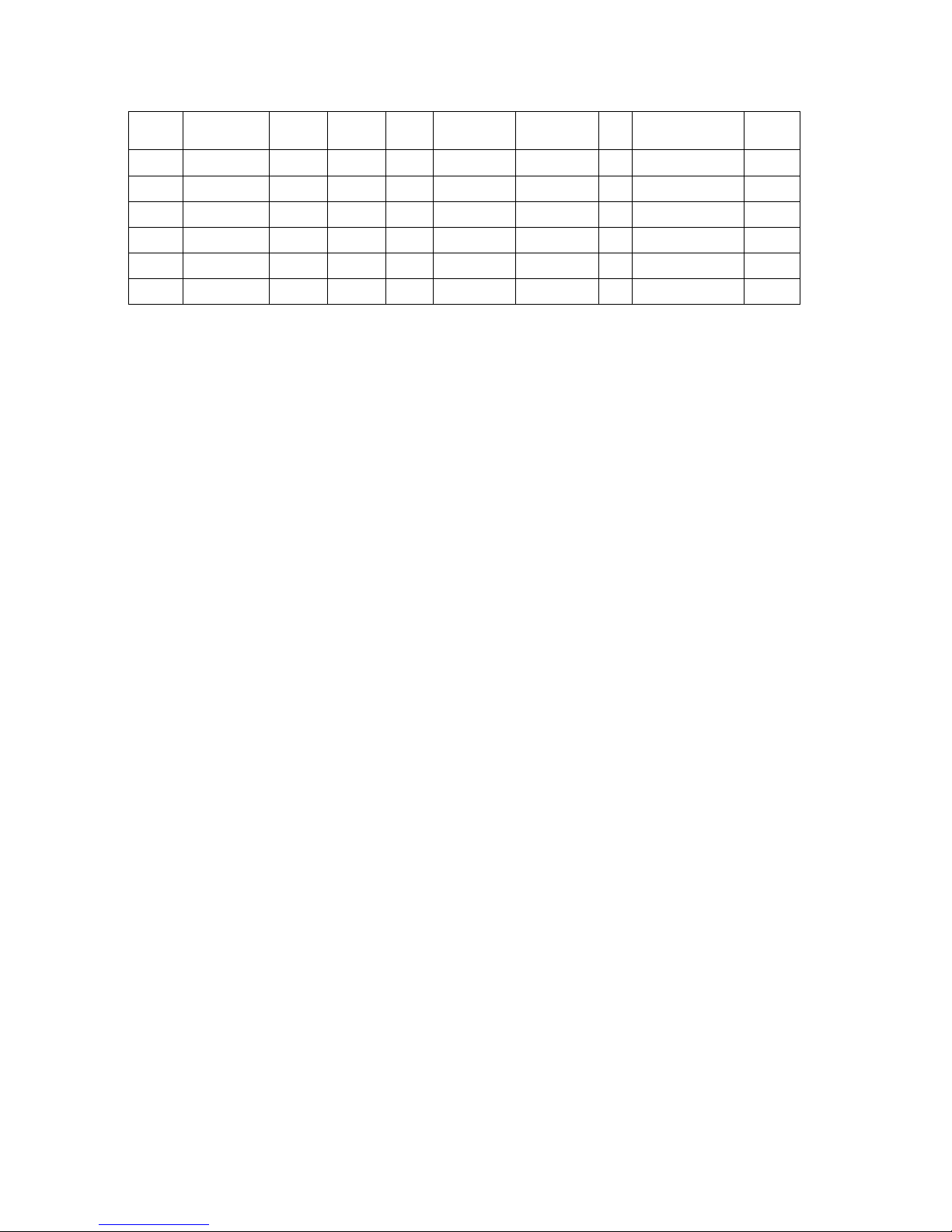

Model

Flow Rate

Range (min.to

max.) mL/min.

Max

Pressure

(psi)

Piston

Diameter

(inches)

Max.

Piston

Stroke

Piston

Displacement

Electrical

VA

Dimensions (L x W

x H inches)

Weight

(lbs.)

1LM

0.002 - 2.5

6000

.093

.125”

.014 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

1LMP

0.002 - 2.5

6000

.093

.125”

.014 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

1SM

0.003 - 5.0

6000

.125

.125”

.025 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

1SMP

0.003 - 5.0

6000

.125

.125”

.025 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

1HM

0.01 - 20.0

3000

.250

.125”

.1 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

Model

Flow Rate

Range (min.to

max.) mL/min.

Max

Pressure

(psi)

Piston

Diameter

(inches)

Max.

Piston

Stroke

Piston

Displacement

Electrical

VA

Dimensions (L x W

x H inches)

Weight

(lbs.)

2LM

0.003 - 5.0

6000

.093

.250”

.028 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

2LMP

0.003 - 5.0

6000

.093

.250”

.028 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

2SM

0.01 - 10.0

6000

.125

.250”

.05 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

2SMP

0.01 - 10.0

6000

.125

.250”

.05 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

2HM

0.02 - 40.0

1500

.250

.250”

.2 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

Model

Flow Rate

Range (min.to

max.) mL/min.

Max

Pressure

(psi)

Piston

Diameter

(inches)

Max.

Piston

Stroke

Piston

Displacement

Electrical

VA

Dimensions

(L x W x H inches)

Weight

(lbs.)

3LM

0.01 - 10.0

3000

.093

.500”

.057 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

3SM

0.01 - 20.0

1500

.125

.500”

.1 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

3HM

0.04 - 80.0

750

.250

.500”

.4 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

Specifications

Stainless Steel Optos/Model 1 Pump Specifications

Stainless Steel Optos/Model 2 Pump Specifications

Stainless Steel Optos/Model 3 Pump Specifications

Maximum flow rate specifications are based on the theoretical volume displacement; actual flow rates will vary depending on such factors as fluid viscosity, compressibility, and

temperature.

Common Specifications:

Wetted Parts: Type 316 stainless steel, PTFE, CTFE, sapphire, ruby

Reproducibility: ±0.3% typical

Tubing Connections: Inlet valve: ¼” –28 plastic fitting for 1/8” Teflon® tubing

Outlet valve: 1/16” I.D. ferrule and tube nut, 10-32 thread

Pumps with .250” pistons use 1/8” Swagelok style connections on the inlet and

Other connections available on request

Viscosity Limit: 500 Centipoise

Fuses: .8 A

Operating Environment:

Temperature: 5 – 35ºC

Maximum Humidity: 85%, non-condensing

Maximum Altitude: 2,000 meters

Optional Damper

Type: Diaphragm

Wetted Parts: Type 316 stainless steel, Kalrez

outlet valves

7

Model

Flow Rate

Range (min.to

max.) mL/min.

Max

Pressure

(psi)

Piston

Diameter

(inches)

Max.

Piston

Stroke

Piston

Displacement

Electrical

VA

Dimensions (L x W

x H inches)

Weight

(lbs.)

1LI

0.002 - 2.5

4000

.093

.125”

.014 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

1LIP

0.002 - 2.5

4000

.093

.125”

.014 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

1SI

0.003 - 5.0

4000

.125

.125”

.025 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

1SIP

0.003 - 5.0

4000

.125

.125”

.025 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

1HI

0.01 - 20.0

3000

.250

.125”

.1 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

Model

Flow Rate

Range (min.to

max.) mL/min.

Max

Pressure

(psi)

Piston

Diameter

(inches)

Max.

Piston

Stroke

Piston

Displacement

Electrical

VA

Dimensions (L x W

x H inches)

Weight

(lbs.)

2LI

0.003 - 5.0

4000

.093

.250”

.028 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

2LIP

0.003 - 5.0

4000

.093

.250”

.028 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

2SI

0.01 - 10.0

4000

.125

.250”

.05 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

2SIP

0.01 - 10.0

4000

.125

.250”

.05 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

2HI

0.02 - 40.0

1500

.250

.250”

.2 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

Model

Flow Rate

Range (min.to

max.) mL/min.

Max

Pressure

(psi)

Piston

Diameter

(inches)

Max.

Piston

Stroke

Piston

Displacement

Electrical

VA

Dimensions

(L x W x H inches)

Weight

(lbs.)

3LI

0.01 - 10.0

3000

.093

.500”

.057 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

3SI

0.01 - 20.0

1500

.125

.500”

.1 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

3HI

0.04 - 80.0

750

.250

.500”

.4 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

PEEK Optos/Model 1 Pump Specifications

PEEK Optos/Model 2 Pump Specifications

PEEK Optos/Model 3 Pump Specifications

Maximum flow rate specifications are based on the theoretical volume displacement; actual flow rates will vary depending on such factors as fluid viscosity, compressibility, and

temperature.

Common Specifications:

Wetted Parts: PEEK, UHMW Polyethylene, CTFE, sapphire, ruby

Reproducibility: ±0.3% typical

Tubing Connections: Inlet valve: ¼” –28 plastic fitting for 1/8” Teflon® tubing

Outlet valve for Plus versions: 1/16” I.D. ferrule and tube nut, 10-32 thread

Outlet valve for non-Plus versions: 1/16” I.D. fitting, ¼”-28 thread

Other connections available on request

Viscosity Limit: 500 Centipoise

Fuses: .8 A

Operating Environment:

Temperature: 5 – 35ºC

Maximum Humidity: 85%, non-condensing

Maximum Altitude: 2,000 meters

Optional Damper

Type: Diaphragm

Wetted Parts: PEEK, Kalrez

8

Model

Flow Rate

Range (min.to

max.) mL/min.

Max

Pressure

(psi)

Piston

Diameter

(inches)

Max.

Piston

Stroke

Piston

Displacement

Electrical

VA

Dimensions (L x W

x H inches)

Weight

(lbs.)

1SMH

0.003 - 5.0

6000

.125

.125”

.025 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

2SMH

0.01 - 10.0

6000

.125

.250”

.05 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

3SMH

0.01 - 20.0

6000

.125

.500”

.1 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

1HMH

0.01 - 20.0

3000

.250

.125

.1 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

2HMH

0.02 - 40.0

1500

.250

.250

.2 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

3HMH

0.04 - 80.0

750

.250

.500

.4 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

Hastelloy C-276 Optos/Pump Specifications

Maximum flow rate specifications are based on the theoretical volume displacement; actual flow rates will vary depending on such factors as fluid viscosity, compressibility, and

temperature.

Common Specifications:

Wetted Parts: Hastelloy C, PTFE, CTFE, sapphire, ruby

Reproducibility: ±0.3% typical

Tubing Connections: Inlet valve: 1/8” compression fitting

Outlet valve: 1/8” compression fitting

Viscosity Limit: 500 Centipoise

Fuses: .8 A

Operating Environment:

Temperature: 5 – 35ºC

Maximum Humidity: 85%, non-condensing

Maximum Altitude: 2,000 meters

9

CAUTION: We have tested this pump with 2 propanol. Residual amounts of 2

propanol may be in the pump. You may wish to flush with an appropriate,

miscible solvent.

You may be using a variety of fluids which require special handling procedures

and safety precautions. Consult the appropriate MSDS (Material Safety Data

Sheet) supplied with the materials you will be using. Be certain to follow all

handling, safety, and disposal procedures appropriate for the materials you use.

Figure 2.1: Power Entry Module

1

2

3

4

INSTALLATION

What You Will Need

The Unit

A Optos Pump consists of the pump assembly, a fittings kit for tubing connections (except for ¼” piston

stainless steel pumps, which have fittings attached to the valves), a syringe (except ¼” pumps), a power cord,

this manual and warranty card.

Tools

You will not need special tools for the routine use of your OptosPump. For installation, all you will need are a

few wrenches to attach the fittings and perhaps a small blade screwdriver if you are making I/O connections.

The tool sizes you will need will depend on the specific fittings used (and are referenced in the appropriate

section of the instruction manual). If you have not already ordered a Preventive Maintenance Kit, we suggest

you consider doing so now. A listing of the various PM Kits beings on page 17.

Unpacking and Location

Before attempting to operate your pump, unpack it carefully. You should not discard any packing material, as

you will want to re-use it for storage and shipping. If any damage is evident from improper handling from

shipping, you should contact the freight company that delivered the unit to file a claim.

You must use your Optos Pump in a clean, well ventilated and dust free environment, free of corrosive or

explosive vapors. Optos Pumps are designed for table top use; you should not install your pump on the floor.

Your Optos Pump must be operated in a horizontal position. Safety may be impaired if use of your Optos pump

is not as instructed.

Electrical Connections

Power Entry Module

As you look at the Power Entry Module (Figure 2.1), you will see:

1. ON/OFF Switch

2. Fuse Drawer

The power entry module is self selecting for voltage within the range of

100-240V. The power cord (a 110/115V cord is provided) is plugged into

the power inlet. Plug the power cord of the pump into a grounded, properly

rated outlet and turn the power switch to ON. The power is turned on by

positioning the ON/OFF switch so the “1” is depressed. After you have

confirmed there is electrical power, turn the power off by positioning the

ON/OFF switch so the “0” is depressed.

3. Power Inlet

4. Fuses

I/O functions are available on the connector on the rear panel. To wire the

I/O connector for inputs or outputs, use a small screwdriver to depress the lever in the upper port of the I/O

10

Inputs/Outputs

Table 2.1

I/O Position

Label

Function

Description

1

4-20mA

4-20mA current loop

Allows for remote control of flow rate using a 4-20mA

current loop. Wire signal to position 1 and common to

position 2.

2

Common

Common

Used in conjunction with position 1.

3

5VDC

5 VDC

Allows for remote control of flow rate using a 0-5VDC

control. Wire signal to position 3 and common to

position 5.

5

GND

Ground

Ground position for use in conjunction with position 3, 6

or position 7.

6

RUN

Run pump

Contact closure, starts running pump at set flow rate.

7

STOP

Stop pump

Contact closure, stops pump.

Table 2.2

I/O Position

Label

Function

Description

4

PRESS

Output of pressure

0-5 VDC output of pressure (when optional damper is

installed), or flow (0-5VDC). Signal output is on

position 4; use with ground on position 5.

5

GND

Ground

Used in conjunction with position 4 or position 8.

8

ERROR

Error output

TTL high output indicating pump error (pressure limit

violation when used with optional damper; motor stall).

Signal output is on position 8; use with ground on

position 5.

connector; this will open the lower port of the I/O connector. Insert the wire (strip wires by between 1/8” to ¼”)

and release the upper port lever.

Inputs

The Optos can be remotely controlled from devices which can send current loop or voltage signals. In addition,

the Optos can be remotely controlled using contact closures. The remote inputs available are defined in Table

2.1:

Outputs

The Optos can send contact closures and an analog signal to remote devices. The remote outputs available are

defined in Table 2.2:

RS232

The RJ11 connector on the rear panel provides an RS232 communication port. For details on use of the RS232,

consult Section VI.

Plumbing

Solvent Preparation

Solvent Degassing

We strongly recommend you degass the fluid prior to using it to prevent cavitation. There are many means of

degassing the fluid, including ultrasonication and vacuum systems. Many users find helium sparging convenient

and effective. The usual procedure is to sparge the solvent vigorously for 15 minutes or so and then maintain a

11

Figure 2.2: Liquid End Assembly

Wash Ports

Inlet Valve

Outlet Valve

trickle of helium during solvent use. Some users blanket the reservoir with helium after sparging (pressurize

reservoirs to about 3 psi with helium).

Solvent Filtration

You must filter your solvents. We recommend you install a 10 micron sintered stainless steel filter (P/N 5776)

on the inlet line. When you wish to avoid metal, a 10 micron plastic filter is available (P/N 1279).

Attaching Inlet Tubing

Most Optos pumps come supplied with a fittings kit, which includes inlet tubing, as well as inlet and outlet nuts

and ferrules. Attach the 1/8” Teflon tubing to the inlet valve. Hand tighten the nut onto the valve.

Optos stainless steel pumps with ¼” diameter pistons use 1/8” Swagelok® fittings on the inlet and outlet valves

and use 1/8” tubing (not supplied) and require a 7/16” wrench to tighten the fittings and a ½” wrench to tighten

the valves.

Priming the Pump

After you attach the inlet tubing to the pump, place the other end of the tubing in a reservoir of the liquid you

will be pumping. Be certain you completely submerge the end of the tubing (or the filter) in the liquid. Insert

the syringe into the outlet (top) valve opening. You should exercise care when handling the syringe. Improper

use can cause the syringe to break off in the valve (and you will have to install a new valve).

Turn the power switch to ON, set a flow rate (usually, for priming, an elevated flow is desireable) and press the

run key. Manually draw a few milliliters of fluid into the syringe. Remove the syringe and look at the valve

opening. There should not be traces of air bubbles. If the air bubbles persist, turn off the pump, check the liquid

level in the reservoir and the tightness of the inlet fitting. If the inlet tubing is above the surface of the liquid, or

if the inlet fitting is loose, you will need to correct the condition and repeat the priming procedure. When the

pump is primed, press the stop key.

Attach Outlet Tubing to Pump (if required)

With a ¼” wrench, attach 1/16” tubing (not supplied) to the outlet (top) valve using the tube nut and ferrule. Do

not set the ferrule in the valve, since doing so may compress and damage the valve components. Instead, set the

ferrule onto the tubing in a column or similar non-compressible fixture. Always stabilize the valve housing with

a ½” wrench when attaching fittings. Never tighten fittings to beyond 40 in./lbs., or the point where no leakage

occurs. Excessive force in tightening fittings can result in valve compression and damage. On PEEK® pumps,

the fitting on the outlet valve is hand tightened.

Optos stainless steel pumps with ¼” pistons use

1/8” Swagelok® fittings on the inlet and outlet

valves and use 1/8” tubing (not supplied) and

require a 7/16” wrench to tighten the fittings and

a ½” wrench to tight the valves.

Pulse Damper Use (optional

damper on Optos pumps with

.093 or .125 pistons)

Optos pumps provided with a pulse damper

have a line already connected between the pump

outlet and the damper inlet. Priming the system

is achieved in the same way as outlined above,

except the syringe is attached to the outlet port

of the damper.

Attaching outlet tubing to the outlet port of the

damper is achieved in the same way as outlined

above. Excessive force in tightening fittings can

damage the damper, which is expensive to

replace.

12

Using the Piston Wash system

The use of buffers or solutions which crystallize when exposed to air can lead to abrasion of the piston seal.

Optos pumps have a built-in wash chamber. The wash system is designed to flush the back end of the primary

piston seal. By using the wash system, you can significantly extend the life of the piston seal (particularly when

pumping salt solutions). Your choice of a wash solution depends on the nature of the fluid being pumped

(usually a mixture of water with 20% methanol is suggested).

The pump cylinder has two barbed fittings installed. Usually, the lower fitting is used as the wash inlet and the

upper fitting is used as the wash outlet. Attach 1/8” ID tubing to the inlet and outlet ports of the wash system. A

common means of employing the wash system is to use a syringe attached to the wash outlet tubing to pull fluid

into the wash chamber (when fluid comes out the outlet port, you know you have filled the wash chamber). We

recommend flushing the wash chamber periodically to minimize piston seal abrasion.. Alternatively, you could

deliver fluid continuously through the wash system by circulating the wash solution with a pump.

13

Turn power ON

Use UP and DOWN keys to set

Press RUN/STOP key to run pump

XX.XXXmL XXXXpsi

MAIN

HI LIMIT: XXXX

H

Press ΔMENU key

Use UP and DOWN keys to set

Press DISPLAY key to return to

main display

LO LIMIT: XXXX

L

Press ΔMENU key (twice from

main display)

Use UP and DOWN keys to set

Press DISPLAY key to return to

main display

OPERATION

Basic Operation

Optos pumps perform more reproducibly if there is some degree of backpressure (preferably at least 25 psi). In

all cases, outlet resistance must exceed inlet pressure. Otherwise, the fluid will simply flow through the pump

without being metered. If the system in which the pump is being used does not generate enough backpressure,

we suggest you install a device, e.g., a “dummy” column or a backpressure regulator, to artificially maintain the

appropriate backpressure. The ideal setup for the pump is where there is a little positive pressure on the inlet

side of the pump (achieved by elevating or pressurizing the reservoir) to minimize cavitation, and substantially

greater outlet pressure to maximize valve efficiency.

General Notes on Software Operation

The Optos pumps have intuitive software control. Three separate levels of software control can be accessed.

The most common commands, setting the flow rate and the high and low pressure limits, are accessed either

from the main display screen, or by pressing the ΔMENU key (the ΔMENU key will cycle through commands for

each level of software control). More infrequently used commands are accessed by holding down the DISPLAY

key and pressing the ΔMENU key (commands which send the piston to the home position, setting the

compressibility compensation factor, setting the refill/output ratio, changing the liquid end type, setting the

remote mode, and viewing the EPROM revision). Least frequently used commands are accessed by holding

down the ΔMENU key and pressing the DISPLAY key (commands which set the home offset, voltage output,

whether the high and low pressure limits will be activated, and the stall stop condition).

The UP and DOWN keys change the setting of the various parameters. When the setting is numeric, the longer the

key is held down, the faster the value changes. The DISPLAY key returns to the main display of flow (and

pressure when the optional damper is installed).

Setting the Flow Rate

When the power is turned ON, the

display shows the set flow rate (and

pressure when the optional damper is

installed).

To set the flow rate, press the UP arrow

key to increase the flow set point, press the DOWN arrow key to decrease the flow set point. The longer you hold

down the up or down arrow, the faster the display scrolls through flow settings. To run the pump at the flow set

point, press the RUN/STOP key. The green LED will be illuminated when the pump is running.

Setting the High Pressure Limit

Optos pumps fitted with a pulse damper

are able to have high pressure limits set.

The default setting is the maximum

pressure capability of the model. To

change the setting, press the ΔMENU key

once. Use the UP or DOWN arrow key to

increase or decrease the high pressure limit. To return to the main screen, press the DISPLAY key.

When the high pressure limit is violated, the pump stops running, the lower red LED lights and the display

shows HI PRESS XXXX.

Setting the Low Pressure Limit

Optos pumps fitted with a pulse damper are

able to have low pressure limits set.

The default setting is the zero psi. The

maximum setting is 50 psi less than the

high pressure limit. To change the setting,

14

COMPRESS: XX

C

Hold DISPLAY & press ΔMENU key

from main display, press ΔMENU

key

Use UP and DOWN keys to set

Press DISPLAY key to return to

main display

REFILL: FULL OUT

R

Hold DISPLAY & press ΔMENU key

from main display, press ΔMENU

key

Use UP and DOWN keys to set

Press DISPLAY key to return to

main display

Hold DISPLAY & press ΔMENU key

from main display

Press RUN to send piston to home

(forward) position

GO HOME: HIT RUN

HP

press the ΔMENU key twice. Use the UP or DOWN arrow key to increase or decrease the low pressure limit. To

return to the main screen, press the DISPLAY key.

When the low pressure limit is violated, the pump stops running, the lower red LED lights and the display shows

LO PRESS XXXX.

Configuration Screens

To access the configuration screens, hold the DISPLAY key while pressing the ΔMENU key. To cycle to the next

command, press the ΔMENU key.

Setting the Compressibility Compensation Factor

Various fluids have different

compressibilities at different pressures.

You can adjust for compressibility by

setting the compressibility compensation

factor. The default setting is 0. The

maximum setting is 60. Each increment

increases motor speed by approximately

1%.

To change the compressibility compensation factor, hold the DISPLAY key and press the ΔMENU key (from the

main display), or, when in the configuration screens press the ΔMENU key to display the “compress” screen. Use

the UP or DOWN arrow key to increase or decrease the compressibility compensation factor. To return to the

main screen, press the DISPLAY key.

Sending the Piston to the Home Position

The piston can be sent to the fully forward

position, useful when changing piston

seals.

To send the piston to the forward position,

hold the DISPLAY key and press the

ΔMENU key (from the main display). Press the RUN key. The motor will drive the piston to the home position.

To return to the main screen, press the DISPLAY key.

Changing the Refill Rate Setup

Optos pumps can be set to a variety of refill:output ratios. The default setting, refill: full out, optimizes the ratio

for minimal pulsation throughout the flow

rate range, by minimizing the refill portion

of the duty cycle. Other settings are:

refill: 15 out: 85 (sets the ratio to 15:85),

refill: 30 out: 70 (sets the ratio to 30:70),

refill: 50 out: 50 (sets the ratio to 50:50),

refill: 70 out: 30 (sets to ratio to 70:30).

To change the refill rate, hold the DISPLAY key and press the ΔMENU key (from the main display), or, when in the

configuration screens press the ΔMENU key to display the “refill” screen. Use the UP or DOWN arrow key to

change the refill:output ratio. To return to the main screen, press the DISPLAY key.

Setting the Liquid End Type (Piston size and Liquid End material)

Optos pumps can have one of several different liquid ends and pistons installed. When shipped from the factory,

the setting is for the model purchased.

15

HEAD: 1/8 SS

LE

Hold DISPLAY & press ΔMENU key

from main display, press ΔMENU

key twice times

Use UP and DOWN keys to set

Press DISPLAY key to return to

main display

REMOTE: OFF

REM

Hold DISPLAY & press ΔMENU key

from main display, press ΔMENU

key three times

Use UP and DOWN keys to set

Press DISPLAY key to return to

main display

VERSION: X.XX

V

Hold DISPLAY & press ΔMENU key

from main display, press ΔMENU

key four times

Use UP and DOWN keys to set

Press DISPLAY key to return to

main display

HOME OFFSET: XX

HO

Hold ΔMENU & press DISPLAY key

from main display

Use UP and DOWN keys to set

Press DISPLAY key to return to

main display

You may have occasion to wish to change the piston and/or liquid end type to change the flow rate range or

material of construction.

To change the liquid end type, hold the

DISPLAY key and press the ΔMENU key

(from the main display), or, when in the

configuration screens press the ΔMENU

key to display the “head” screen. Use the

UP or DOWN arrow key to change the

liquid end type. The numeric field

indicates piston size (3/32, 1/8, ¼), and

alpha field indicates material of construction of the head (SS, PK). To return to the main screen, press the

DISPLAY key. The high and low pressure limits are reset when changing the liquid end type to the default for that

type.

Setting the Remote Control Setting

Optos pumps can be controlled remotely

via an analog signal (either 4-20 mA or 05 VDC). If you wish to operate the Optos

pump remotely using one of the available

analog signals, you need to set the field to

that signal (operating via RS232 does not

require any setup).

To change the remote control setting, hold the DISPLAY key and press the ΔMENU key (from the main display),

or, when in the configuration screens press the ΔMENU key to display the “remote” screen. Use the UP or DOWN

arrow key to change the remote control setting. To return to the main screen, press the DISPLAY key.

Viewing the EPROM Revision Level

Optos pumps have EPROM software.

You can view the version of software

installed.

To view the software version, hold the

DISPLAY key and press the ΔMENU key

(from the main display), or, when in the

configuration screens press the ΔMENU

key to display the “version” screen. To

return to the main screen, press the DISPLAY key.

Advanced Screens

To access the configuration screens, hold the ΔMENU key while pressing the DISPLAY key. To cycle to the next

command, press the ΔMENU key.

Setting the Home Position Offset

The software for speeding up and slowing

down the motor is set off the home

position sensor location. The software is

optimized for running flows with minimal

pulse at substantial pressures. If your

conditions are different, you may wish to

change the home offset setting to

minimize pulsation. The default setting is 0. Other settings are from -99 to +99.

16

PRESS LIMIT: ENA

LI

Hold ΔMENU & press DISPLAY key

from main display, press ΔMENU

Use UP and DOWN keys to set

Press DISPLAY key to return to

main display

STOP STALL: ON

SS

Hold ΔMENU & press DISPLAY key

from main display, press ΔMENU

Use UP and DOWN keys to set

Press DISPLAY key to return to

main display

0-5V OUT: PRESS

S

Hold ΔMENU & press DISPLAY key

from main display, press ΔMENU

Use UP and DOWN keys to set

Press DISPLAY key to return to

main display

To change the home position offset setting, hold the ΔMENU key and press the DISPLAY key (from the main

display), or, when in the advanced screens press the ΔMENU key to display the “home offset” screen. Use the UP

or DOWN arrow key to change the home offset setting. To return to the main screen, press the DISPLAY key.

Setting the Output Function

One of the outputs on the I/O ports is a

0-5V output. This output can be changed

between pressure (if the Plus option is

present) and flow.

A bug in the software may require you to

press the up and down arrow keys to set

the output (even without the Plus option

being present).

To change the output, hold the ΔMENU key and press the DISPLAY key (from the main display), or, when in the

advanced screens press the ΔMENU key to display the “output” screen. Use the UP or DOWN arrow key to change

the setting (PRESS means the output will correspond to pressure, FLOW means the output will correspond to

flow). Always press the UP arrow to select FLOW. To return to the main screen, press the DISPLAY key.

Setting the High/Low Pressure Limit Shutdown

Optos pumps (with the optional damper)

can have their high and low pressure

limits de-activated. The default setting is

ENA (limits are active).

To change the limit setting, hold the

ΔMENU key and press the DISPLAY key

(from the main display), or, when in the

advanced screens press the ΔMENU key to display the “limit” screen. Use the UP or DOWN arrow key to change

the limit setting (DIS = limits de-activated; ENA = limits activated). To return to the main screen, press the

DISPLAY key.

Setting the Motor Stall Shutdown

If Optos pumps are not fitted with the

optional damper or if the pressures limits

are de-activated, the motor will stall

when exposed to excessive pressure.

When the stall stop field is set to ON, the

pump will stop pumping when a stall

condition is noted; when the stall stop

field is set to OFF, the pump will

continue pumping, or trying to pump even in the presence of a motor stall. The default setting is OFF.

To change the stall setting, hold the ΔMENU key and press the DISPLAY key (from the main display), or, when in

the advanced screens press the ΔMENU key to display the “stall” screen. Use the UP or DOWN arrow key to

change the limit setting (OFF = pump runs after stall; ON = pump stops after stall). To return to the main screen,

press the DISPLAY key.

17

ERROR DELAY: 0

ED

Hold ΔMENU & press DISPLAY key

from main display, press ΔMENU

Use UP and DOWN keys to set

Press DISPLAY key to return to

main display

SAVE STATE: 0

SP

Hold ΔMENU & press DISPLAY key

from main display, press ΔMENU

Use UP and DOWN keys to set

Press DISPLAY key to return to

main display

SAVE IN RUN: 0

SR

Hold ΔMENU & press DISPLAY key

from main display, press ΔMENU

Use UP and DOWN keys to set

Press DISPLAY key to return to

main display

Setting the Error Delay

When an error occurs, the red light is

illuminated. If the motor stall

shutdown is set to ON, the pump will

stop pumping. These occur

immediately when the Error Delay is

set to 0. You may wish for a delay to

be built into the response to an error (in

the event of a transient problem). You

can set a delay of up to 10 seconds. With the delay, the pump will not illuminate the red light or stop the pump

(when the motor stall shutdown is set to ON) until the error condition persists for the set number of seconds (0-

10). The default setting is 0.

To change the error delay setting, hold the ΔMENU key and press the DISPLAY key (from the main display), or

when in the advanced screens press the ΔMENU key to display the “error” screen. Use the UP or DOWN arrow key

to change the error delay setting. To return to the main screen, press the DISPLAY key.

Setting the Save State

When a power failure occurs, the pump

does not normally start again when

power is restored. If you want the

pump to start pumping again when

power is restored, you can set the “save

state” to ON. The default setting is

OFF.

To change the save state, hold the ΔMENU key and press the DISPLAY key (from the main display), or, when in

the advanced screens press the ΔMENU key to display the “save state” screen. Use the UP or DOWN arrow key to

change the limit setting (OFF = pump does not start pumping after power is restored; ON = pump starts running

after power is restored). To return to the main screen, press the DISPLAY key.

Setting the Save In Run Flow Rate

Depending on conditions, the pump may

not “remember” the set flow rate when

turning the pump off. If you want the

pump to always remember the last run

flow rate, set the save in run to ON. The

default setting is OFF.

To change the save in run, hold the

ΔMENU key and press the DISPLAY key

(from the main display), or, when in the advanced screens press the ΔMENU key to display the “save in run”

screen. Use the UP or DOWN arrow key to change the limit setting (OFF = pump may not remember the last run

flow rate; ON = pump remembers the last run flow rate). To return to the main screen, press the DISPLAY key.

18

PRESS 0: HIT RUN

XDC

Hold ΔMENU & press DISPLAY key

from main display, press ΔMENU

Press RUN key to zero

Press DISPLAY key to return to

main display

STROKE: .125

ST

Hold ΔMENU & press DISPLAY key

from main display, press ΔMENU

Press RUN key to zero

Press DISPLAY key to return to

main display

REM CONTACT: 0

RC

Hold ΔMENU & press DISPLAY key

from main display, press ΔMENU

Use UP and DOWN keys to set

Press DISPLAY key to return to

main display

Setting the Contact Closures during Remote Analog Mode

Normally, the contact closures start and

stop are used in conjunction with the

local keypad. The keypad is used to set

the flow rate and the start and stop

contacts are used to mimic the function

of the RUN/STOP key. Normally, when

using the remote analog modes of

operation, if you do not want the pump to

run, you do not send an appropriate signal to the relevant remote analog port on the I/O. If you want to use the

contact closures to start and stop the pump when sending an analog signal, change the setting in the REM

Contact screen to ON. The default setting is OFF.

To change the REM Contact, hold the ΔMENU key and press the DISPLAY key (from the main display), or, when

in the advanced screens press the ΔMENU key to display the “REM Contact” screen. Use the UP or DOWN arrow

key to change the limit setting (OFF = contact closures cannot be used in conjunction with the remote analog

controls; ON = contact closures must be used in conjunction with the remote analog controls). To return to the

main screen, press the DISPLAY key.

Viewing the Stroke Length

You may view the stroke length of the

piston of your pump by holding the

ΔMENU key and pressing the DISPLAY key

(from the main display), or, when in the

advanced screens press the ΔMENU key to

display the “stroke” screen. To return to

the main screen, press the DISPLAY key.

Zeroing the Pressure Transducer

If the Optos pump is fitted with the

“Plus” option, a pressure transducer is

present in the damper assembly. The

pressure transducer is sensitive to

temperature changes and can read a

pressure when no pressure is present. It

is possible to re-zero the pressure

transducer.

To zero the pressure transducer, hold the ΔMENU key and press the DISPLAY key (from the main display), or,

when in the advanced screens press the ΔMENU key to display the ‘press” screen. Press the RUN key to zero the

transducer. Be sure to do this when there is no pressure on the pump. To return to the main screen, press the

DISPLAY key.

19

CAUTION: It is important to note that salts and buffers can lead to corrosion of stainless steel or distortion

of plastics if they are left in contact with the pump for long periods of time. Failure to flush potentially

corrosive substances from the pump may void your warranty.

Pump Limits

You should note the limits of your Optos pump. Exceeding or violating these limits may damage your pump and

will void your warranty.

Viscosity Limits

Liquids with viscosities of 100 centipoise or higher often reduce nominal flow rate values. You cannot pump

liquids with viscosities exceeding 500 centipoise.

Chemical Limits

Some buffers, particularly halide salts at high concentrations, can cause corrosion of type 316 stainless steel. If

you leave buffers in the pump, crystallization may occur and cause damage to the seal material. Some solvents

can swell the plastic material in the valves or the piston seal. Usually, you can substitute less damaging fluids,

and you can minimize potential damage by carefully flushing the pump. You can sometimes substitute special

materials; please consult with the factory.

Mechanical Limits

Pumped fluids should be free of particulate matter, since clogged valves may result in erratic flow rates. We

strongly recommend the use of a filter on the inlet line to protect the valves from small particles. A 10 micron

sintered stainless steel filter is available from Eldex (Part No. 5776) and is suitable for most applications. When

you need to avoid metal, a 10 micron plastic filter is available from Eldex (Part No. 1279).

Damage to the mechanical parts will result from subjecting the pump to excessive pressure. Do not try to pump

fluid against pressures which exceed the maximum pressure capability of your model.

Temperature Limits

Eldex pumps are designed to operate under ambient temperature conditions. If you take appropriate precautions

to prevent condensation, you can use the pump in a cold room. Do not use the pump in an environment which

exceeds 35ºC.

It is possible to pump fluids which are at elevated temperatures. Although the reaction of specific fluids at

elevated temperatures to the wetted parts may vary, it is usually the plastic materials in the liquid end which will

be of concern. Generally, the CTFE maintains integrity at temperatures up to 200ºC. The PTFE piston seal

material is generally good to 260ºC. You will want to consult the factory when pumping fluids at elevated

temperatures if there is any question in your mind about how the wetted parts will react.

Shutdown Procedures

Eldex pumps are manufactured using materials selected to resist corrosion. However, some buffers, most

notably halide salts at high concentration, are capable of corroding type 316 stainless steel, and some solvents

are capable of distorting CTFE or other plastics used in the pumps. Therefore, it is important to flush the pump

after using any potentially damaging materials.

To flush the pump, first pump distilled water to remove any salt(s) or solids. You should do this for a minimum

of ten minutes as soon as possible after using the pump. Next, you should flush the pump with an inert solvent

such as methanol for at least five minutes.

20

Figure 4.1: Pump Assembly

TIP: We have found, especially with metal-free seals, that

“breaking-in” the seals with IPA or methanol for an hour

or so, under conditions similar to your expected operating

conditions enhances seal life.

Liquid End

Wash Ports

Piston Seal

Backup Washer

Retainer/Wash

Piston

MAINTENANCE

We have designed Eldex Metering Pumps to give years of trouble-free service. By following a few simple

maintenance procedures, you can ensure the longevity of your pump.

Cleaning

Before cleaning your pump, disconnect the pump from the power supply. Cleaning can be accomplished by

wiping down with a damp cloth.

Piston Seal

The seal material used is usually a specially

formulated PTFE. It is the standard seal

material because of its broad range of chemical

compatibility, its mechanical properties, and its

stability in reciprocating applications.

The length of service to be expected from any given piston seal depends on a wide variety of factors, including

the fluid being pumped and the pressure of the system. It is critically important that the seal be replaced

immediately upon failure, or better yet, before failure, because fluid can travel into the mechanical housing of

the pump and cause corrosion damage.

When a leak occurs, you may notice fluid just underneath the liquid end. However, a leak may not always be

visible, particularly at low flow rates. We suggest you place a wick or litmus paper up the drain slots just

underneath the liquid end. You should remove the wick or litmus paper periodically and check for wetness or

color changes to see if leakage has occurred.

Piston seal life can often be significantly extended by using the piston wash system integrated in the pump.

Replacing the Piston Seal

1. Use tools supplied with Part Nos, 5911, (3/32” installation tool and 5/32 hex key); 5941(installation tool

and 5/32 hex key); 5944, (1/4” diameter dowel pin and 5/32 hex key).

2. Send the piston to the home position. Turn the power switch to OFF.

3. Remove the liquid end from the pump as follows: Unscrew the two 5/32” socket head bolts. Pull the

liquid end straight out from the pump housing, in line with the axis of the piston. If you cock or tilt the

liquid end, you may break the piston. See Figure 4.1.

21

Figure 4.2: Piston Seal Assembly

Figure 4.3: Piston Seal Replacement

Retainer/Wash

O Ring

Backup

Washer

Piston Seal

4. Remove the retainer/wash from the liquid end,

and insert the installation tool/dowel pin into

the liquid end through the piston seal (if your

pump uses a 3/32” or 1/8” diameter piston, the

installation tool has a “hooked” end, which is

used to remove the seals). If you are using the

installation tool, hook the existing seals and

remove and discard both the washer and the

seal. If you are using the ¼” dowel pin, rock

the dowel pin back and forth gently, and

remove and discard both the washer and seal.

Do not scratch the walls of the piston seal gland

in the liquid cylinder with the tool/dowel pin.

5. Inspect the piston. You can remove the piston by moving the piston up in the slot which holds it in

place. If the piston has scratches on the sapphire, or significant corrosion on the stainless steel piston

holder, you should replace it. If there is minor corrosion on the piston holder, clean the piston holder.

Also inspect for evidence of deposits on the sapphire. If deposits are present on the sapphire

(discoloration or particulates), clean it. If the sapphire does not clean, you should replace the piston.

6. Inspect the retainer. Clean the retainer/wash if necessary. If there is evidence of wear, or if the piston

does not fit snugly in the retainer/wash, or if the retainer/wash grips the piston too tightly, you should

replace the retainer/wash.

7. Inspect the liquid cylinder, paying special attention to the gland for the piston seal. Any scratches or

irregularities will require replacement of the liquid end.

8. Clean all parts with a liquid detergent, followed by a rinse. Clean any fluid in the mechanical end of the

pump.

9. Insert the installation tool/dowel pin into the

retainer/wash and then into the new seal backup washer

(used on 1HI, 2HI, and 3HI pumps) and new piston seal.

When inserting the tool through the new piston seal, the

piston seal should lay flat on a hard surface with the

spring side down (the seal will generally “snap” onto the

tool). Position the parts on the tool in the order shown.

Insert the tool into the liquid end bore. CAUTION:

The open side of the seal (side revealing the spring or

the O ring) should face the closed (fluid side) end of the

liquid end.

10. Keeping the tool perpendicular with the face of the liquid end, push the piston seal and washer into the

liquid end bore, by pressing down gently and evenly on the edge of the retainer/wash with both thumbs.

11. Withdraw the tool, while holding the retainer/wash and liquid end firmly in place. When installing the

retainer/wash, make sure you line up the holes in the retainer with the wash system.

12. Reinstall the liquid end on the pump. See Figure 4.1.

PRECAUTIONS:

1. Do not re-use the old piston seal.

2. Cleanliness is very important for optimal seal and check valve operation.

3. Note suggestion regarding seal “break-in” on page 15.

NOTE: If you retain the tools supplied with Eldex Part Nos. 5911, 5941, or 5944, you can purchase just the

seals and re-use the tools.

22

Figure 4.4: Liquid End Assembly

Valve

Seal

Valve

Seal

Outlet Valve

Housing

Insert

Valve

Seal

Valve Cartridge:

Triangular Opening

faces up

Fittings

Valve

Seal

Fittings

Inlet Valve

Housing

Insert

Valve Cartridge:

Triangular Opening

faces up

Replacing Valves

Always replace valves in a clean area to prevent dust and dirt from entering the pump.

Removal of Existing Valves

The valves are the two hexagon-shaped components on the liquid end assembly (see Figure 4.4). Inlet valves

can be distinguished from outlet valves by the groove on the hexagonal part of the valve. Remove the valves

with a ½” wrench, turning in a counter-clockwise direction. After removal, be careful to keep the valve oriented

so the translucent washers face upwards to prevent parts from falling out. If you wish to replace the cartridge in

the valve, you may purchase

replacement cartridges,

which include the cartridge

and instructions.

Installation of New

Valves

1. Inlet valves can be

distinguished from

outlet valves by the

groove on the

hexagonal part of

the valve.

2. Unscrew the

shipping nut and

remove the metal

shipping washer, as

these are not used

for installation of

the valves.

3. Insert the new valve

into the liquid end

assembly and

tighten by hand

until just fingertight. Then use a

½” wrench and

tighten ¼ turn more.

You should tighten

valves to the point

at which no further

leakage occurs, or

not more than 4.5

ft./lbs.

OVERTIGHTENING THE VALVES CAN CAUSE THE SAPPHIRE SEATS TO CRACK.

STABILIZE THE VALVE WITH A ½” WRENCH WHEN ATTACHING YOUR FITTINGS TO PREVENT

FURTHER VALVE TIGHTENING. DO NOT TIGHTEN FITTINGS TO BEYOND 40 IN./LBS., OR THE

POINT WHERE NO FURTHER LEAKAGE OCCURS.

Replacing Valve Cartridges

1. Remove the valve from the cylinder (see above for detailed instructions).

2. Using the smaller dowel pin provided (1-1/4” long by 1/8”diameter), press out the internal components

of the valve assembly using a steady pressure. Do not hammer parts through with the dowel pin or

hammer on the dowel pin. Do not allow the valve parts to fall out of the valve onto a hard surface.

23

3. Reassemble the valve by placing the valve insert in the valve housing using the larger (3/16”) dowel pin

provided (1373 and 1374 valves use a total of 3 washers, one is installed before installing the valve

insert). Make sure it is oriented correctly (see Figure 4.4). Press a CTFE seal into place. Slide the

valve cartridge into the valve housing making certain it is oriented correctly. Press another new CTFE

seal into place. The CTFE seal will extend approximately 0.020 – 0.030” from the valve housing.

4. Re-install the rebuilt valve into the liquid end assembly and tighten by hand until just finger-tight. Then

use a ½” wrench and tighten ¼ turn more. You should tighten valves to the point at which no further

leakage occurs, or not more than 4.5 ft./lbs.

24

Question

Answer

Solution

Is the motor turning?

No

Check electrical connections:

1. Is instrument plugged in?

2. Does outlet provide electricity?

3. Is fuse blown? If so, replace.

Is fluid degassed prior to use?

No

Degass fluid prior to use:

1. Boil.

2. Bubble helium through fluid.

3. Subject fluid to a vacuum.

Is fluid filtered?

No

1. Do not pump fluids with suspended particles (a

particle as small as ten microns can clog a valve).

2. Install an inlet line filter.

3. Flush with liquid detergent or 20% solution of nitric

acid (at max. flow for about 10 minutes), or suck

cleaning fluid through pump with a syringe.

4. Ultrasonicate valve assembly.

Is filter clogged?

Yes

Clean filter (clogged filter can create restriction to flow,

causing cavitation).

Is mechanical assembly OK?

No

Inspect parts of mechanical assembly; is piston broken?,

pushrod frozen in bushing?

Are valves OK?

No

Rebuild or replace valves (excessive force used to tighten

fittings to valves or valves to cylinder can cause sapphire

seats to crack, chip, or shatter, thereby inhibiting flow).

Question

Answer

Solution

What is backpressure on pump

Less

than 25

psi

Insufficient backpressure, create more pressure on pump so

valves can work properly (install backpressure regulator, or

length of small I.D. tubing).

Is fluid degassed prior to use?

No

Degass as per above.

Is fluid filtered?

No

Clean valves as per above, install inlet line filter.

Is filter clogged?

Yes

Clean filter.

Is there a leak at fitting(s)

Yes

Tighten fittings.

Is there a leak at valve

connection?

Yes

Tighten valves

Are valves OK?

No

Rebuild or replace valves.

Question

Answer

Solution

Are seals worn?

Yes

Replace piston seal.

Question

Answer

Solution

Is fluid degassed prior to use?

No

Degas as per above.

Troubleshooting

Symptom: No flow (probably cause(s) shown in bold)

Symptom: Erratic flow (probable cause(s) shown in bold)

Symptom: Leakage

Symptom: Steadily decreasing flow rate

25

Order

No.

Description

Preventive Maintenance Kits

5918

Includes two PTFE piston seals, tools for installation, two valve cartridges, one retainer/wash, a sintered stainless

steel filter.

Piston Seals

5911

Piston seal assembly kit; includes one PTFE seal, and tools for installation.

5912

Piston seal replacement kit; includes two PTFE seals.

5913

Piston seal replacement kit; includes five PTFE seals.

Valves

1369

Inlet valve assembly, cartridge style, 1/4"-28 fitting.

1372

Outlet valve assembly, cartridge style, 10-32 fitting.

1373

Inlet valve assembly, cartridge style, 1/8" Swagelok® style fitting.

1374

Outlet valve assembly, cartridge style, 1/8" Swagelok® style fitting.

1371

Inlet valve assembly, cartridge style, 10-32 fitting.

1370

Outlet valve assembly, cartridge style, 1/4"-28 fitting.

1381

Valve cartridge kit (rebuilds one inlet or one outlet valve).

Piston

5819

1/8" sapphire piston.

Liquid End Assembly

5902

Includes inlet and outlet valve assemblies, cylinder, piston seals and retainer. Piston not included.

Fittings

5988

Includes 60 cm of 1/8" Teflon inlet tubing, inlet (1/4-28) and outlet (10-32) tube nuts, and outlet ferrule.

Filters

5776

10 micron sintered stainless steel filter, with 60 cm long Teflon inlet tube and tube nut.

Other Parts

5899

Retainer/wash assembly.

For other parts, consult factory.

Optos SPARE PARTS AND ACCESSORIES

For 3/32” Stainless Steel Pumps

26

Order No.

Description

Preventive Maintenance Kits

5920

Includes two PTFE piston seals, tools for installation, two valve cartridges, one retainer/wash, a sintered stainless

steel filter.

Piston Seals

5941

Piston seal assembly kit; includes one PTFE seal, and tools for installation.

5942

Piston seal replacement kit; includes two PTFE seals.

5943

Piston seal replacement kit; includes five PTFE seals.

Valves

1369

Inlet valve assembly, cartridge style, 1/4"-28 fitting.

1372

Outlet valve assembly, cartridge style, 10-32 fitting.

1373

Inlet valve assembly, cartridge style, 1/8" Swagelok® style fitting.

1374

Outlet valve assembly, cartridge style, 1/8" Swagelok® style fitting.

1371

Inlet valve assembly, cartridge style, 10-32 fitting.

1370

Outlet valve assembly, cartridge style, 1/4"-28 fitting.

1381

Valve cartridge kit (rebuilds one inlet or one outlet valve).

Piston

5820

1/8" sapphire piston.

Liquid End Assembly

5903

Includes inlet and outlet valve assemblies, cylinder, piston seals and retainer. Piston not included.

Fittings

5988

Includes 60 cm of 1/8" Teflon inlet tubing, inlet (1/4-28) and outlet (10-32) tube nuts, and outlet ferrule.

Filters

5776

10 micron sintered stainless steel filter, with 60 cm long Teflon inlet tube and tube nut.

Other Parts

5900

Retainer/wash assembly.

For other parts, consult factory.

For 1/8” Stainless Steel Pumps

27

Order No.

Description

Preventive Maintenance Kits

5922

Includes two PTFE piston seals, tools for installation, two valve cartridges, one retainer, a sintered stainless steel

filter.

Piston Seals

5944

Piston seal assembly kit; includes PTFE seal, and tools for installation.

5945

Piston seal replacement kit; includes two PTFE seals, no tools..

5946

Piston seal replacement kit; includes five PTFE seals, no tools..

Valves

1373

Inlet valve assembly, cartridge style, 1/8" Swagelok® style fitting.

1374

Outlet valve assembly, cartridge style, 1/8" Swagelok® style fitting.

1381

Valve cartridge kit (rebuilds one inlet or one outlet valve).

Pistons

5821

1/4" sapphire piston.

Liquid End Assembly

5904

Includes inlet and outlet valve assemblies, cylinder, piston seals and retainer. Piston not included.

Other Parts

5901

Retainer/wash assembly.

For other parts, consult factory.

For 1/4” Stainless Steel Pumps

28

Order No.

Description

Preventive Maintenance Kits

5923

Includes two uhmw polyethylene seals, tools for installation, two valve cartridges, one retainer, a sintered stainless

steel filter.

Piston Seals

5914

Piston seal assembly kit; includes one uhmw polyethylene seal, and tools for installation.

5915

Piston seal replacement kit; includes two uhmw polyethylene seals.

5916

Piston seal replacement kit; includes five uhmw polyethylene seals.

Valves

1377

Inlet valve assembly, cartridge style.

1378

Outlet valve assembly, cartridge style.

1383

Valve cartridge kit (rebuilds one inlet or one outlet valve).

Pistons

5819

1/8" sapphire piston.

Liquid End Assembly

5905

Includes inlet and outlet valve assemblies, cylinder, piston seals and retainer. Piston not included.

Fittings

5987

Includes 60 cm of 1/8" Teflon inlet tubing, inlet (1/4-28) and outlet (1/4-28) tube nuts.

Filters

1279

10 micron plastic filter, with 60 cm long Teflon inlet tube and tube nut.

Other Parts

5896

Retainer assembly.

For other parts, consult factory.

For 3/32” PEEK Pumps

29

Order No.

Description

Preventive Maintenance Kits

5924

Includes two uhmw polyethylene seals, tools for installation, two valve cartridges, one retainer, a 10 micron plastic

filter.

Piston Seals

6007

Piston seal assembly kit; includes one uhmw polyethylene metal-free seal, and tools for installation.

6008

Piston seal replacement kit; includes two uhmw polyethylene metal-free seals.

6009

Piston seal replacement kit; includes five uhmw polyethylene metal-free seals.

Valves

1377

Inlet valve assembly, cartridge style.

1378

Outlet valve assembly, cartridge style.

1383

Valve cartridge kit (rebuilds one inlet or one outlet valve).

Pistons

5820

1/8" sapphire piston.

Liquid End Assembly

5906

Includes inlet and outlet valve assemblies, cylinder, piston seals and retainer. Piston not included.

Fittings

5987

Includes 60 cm of 1/8" Teflon inlet tubing, inlet (1/4-28) and outlet (1/4-28) tube nuts, and outlet ferrule.

Filter

1279

10 micron plastic filter, with 60 cm long Teflon inlet tube and tube nut.

Other Parts

5897

Retainer assembly.

For other parts, consult factory.

For 1/8” PEEK Pumps

30

Order No.

Description

Preventive Maintenance Kits

5925

Includes two uhmw polyethylene seals, backup washers, tools for installation, two valve cartridges, one retainer, a

10 micron plastic filter.

Piston Seals

6010

Piston seal assembly kit; includes one uhmw polyethylene metal-free seal, backup washer, and tools for installation.

6011

Piston seal replacement kit; includes two uhmw polyethylene metal-free seals and backup washers.

6012

Piston seal replacement kit; includes five uhmw polyethylene metal-free seals and backup washers.

Valves

1377

Inlet valve assembly, cartridge style.

1378

Outlet valve assembly, cartridge style.

1383

Valve cartridge kit (rebuilds one inlet or one outlet valve).

Pistons

5821

1/8" sapphire piston.

Liquid End Assembly

5907

Includes inlet and outlet valve assemblies, cylinder, piston seals and retainer. Piston not included.

Fittings

5987

Includes 60 cm of 1/8" Teflon inlet tubing, inlet (1/4-28) and outlet (1/4-28) tube nuts, and outlet ferrule.

Filter

1279

10 micron plastic filter, with 60 cm long Teflon inlet tube and tube nut.

Other Parts

5898

Retainer assembly.

For other parts, consult factory.

For ¼” PEEK Pumps

31

Order No.

Description

Piston Seals

6048

Piston seal assembly kit; includes one PTFE seal, and tools for installation.

6100

Piston seal replacement kit; includes two PTFE seals, no tools..

6101

Piston seal replacement kit; includes five PTFE seals, no tools..

Valves

6045

Inlet valve assembly, cartridge style, 1/8" Swagelok® style fitting.

6046

Outlet valve assembly, cartridge style, 1/8" Swagelok® style fitting.

6047

Valve cartridge kit (rebuilds one inlet or one outlet valve).

Piston

5820

1/8" sapphire piston.

Liquid End Assembly