Eldex 3LM, 3HM, 3SM, 1HM, 1LM Instruction Manual

...

Eldex

Eldex®

Optos Metering Pumps

Operator’s Manual

Eldex Laboratories, Inc.

30 Executive Court

Napa, CA 94558

Tel: (707) 224-8800

Fax: (707) 224-0688

www.eldex.com

© 2008 Eldex Laboratories, Inc.

Rev. M: 022708

All Rights Reserved

TABLE OF CONTENTS

CONTENTS PAGE

I. INTRODUCTION 1

Optos Metering Pumps 1

Principles of Operation 1

Materials of Construction 1

About This Manual 1

A Guided Tour of Optos Metering Pumps 2

Specifications 6

Stainless Steel Pump Specifications 6

PEEK Pump Specifications 7

II. INSTALLATION 8

What You Will Need 8

The Unit 8

Tools 8

Unpacking and Location 8

Electrical Connections 8

Power Entry Module 8

Inputs/Outputs 8

Plumbing 9

Solvent Preparation 9

Attaching Inlet Tubing 10

Priming The Pump 10

Attaching Outlet Tubing 10

Pulse Damper Use 10

Using the Piston Wash System 10

III. OPERATION 11

Basic Operation 11

General Notes on Software Operation 11

Setting the Flow Rate 11

Setting the High Pressure Limit 11

Setting the Low Pressure Limit 11

Configuration Screens 12

Setting the Compressibility Compensation Factor 12

Sending the Piston to the Home Position 12

Changing the Refill Rate Setup 12

Setting the Liquid End Type 12

Setting the Remote Control Setting 13

Viewing the EPROM Revision Level 13

Advanced Screens 13

Setting the Home Position Offset 13

Setting the Output Function 14

Setting the High/Low Pressure Limit Shutdown 14

Setting the Motor Stall Shutdown 14

Pump Limits 15

Viscosity Limits 15

Chemical Limits 15

Mechanical Limits 15

Temperature Limits 15

Shutdown Procedures 15

IV. MAINTENANCE 16

Cleaning 16

Piston Seals 16

Replacing The Piston Seal 16

Replacing Valves 17

Removal Of Existing Valves 17

Installation Of New Valves 18

Replacing Valve Cartridges 18

Troubleshooting 19

V. SPARE PARTS AND ACCESSORIES 20

For 3/32” Stainless Steel Pumps 20

For 1/8” Stainless Steel Pumps 21

For ¼” Stainless Steel Pumps 22

For 3/32” PEEK Pumps 23

For 1/8” PEEK Pumps 24

For ¼” PEEK Pumps 25

VI. APPENDIX 26

RS232 26

Warranty 27

Return Procedure 27

Trademarks 27

CAUTION: The exclamation point within an equilateral triangle is intended to

alert the user to the presence of important operating and maintenance (servicing)

instructions in the literature accompanying the appliance.

ATTENTION: Le point d’exclamation dans un triangle equilatéral signale à

alerter l’utilisateur qu’il y a des instructions d’operation et d’entretien tres

importantes dans la litérature qui accompagne l’appareil.

ACHTUNG: Ein Ausrufungszeichen innerhalb eines gleichwinkeligen Dreiecks

dient dazu, den Benutzer auf wichtige Bedienungs-und Wartungsanweisungen in

der dem Gerät beiliegended Literatur aufmerksam zu machen.

CAUTION: We have tested this pump with 2 propanol. Residual amounts of 2

propanol may be in the pump. You may wish to flush with an appropriate,

miscible solvent.

You may be using a variety of fluids which require special handling procedures

and safety precautions. Consult the appropriate MSDS (Material Safety Data

Sheet) supplied with the materials you will be using. Be certain to follow all

handling, safety, and disposal procedures appropriate for the materials you use.

ATTENTION: Gardez à l’esprit que nous avons testé cette pompe avec le

propanol-2. Les quantités résiduelles du propanol-2 peuvent se trouver sur le

dispositif de raccordement du liquide et vous souhaiterez certainement les

chasser avec un solvant miscible approprié.

Vous pouvez utiliser une variété de liquides qui nécessitent des manipulations et

des précautions particulières. Consultez la fiche technique de sécurité

appropriée; elle est fournie avec le matériel que vous utiliserez. Veillez a bien

respecter toutes les procédures de manipulation, sécurité et élimination du

matériel.

ACHTUNG: Die Pumpe wurde mit 2-Propanol getestet. Geringe Restmengen

von 2-Propanol können sich noch im System befindend, so dass wir Ihnen vor

Inbetriebnahme das Spülen mit einem geeigneten Lösungsmittel empfehlen.

Sie können eine Vielzahl von Lösungsmitteln einsetzen, deren Verwendung unter

Umständen spezielle Sicherheitsvorkehrungen voraussetzt. Bitte beachten Sie

in allen Fällen die, den Lösungsmitteln vom Hersteller beigelegten

Sicherheitsdatenblätter.

INTRODUCTION

Laboratory and industrial procedures often require metering precise amounts of fluids in a controlled and

reproducible manner. Optos pumps were developed in response to this need. These pumps are capable of

delivering measured amounts of fluids against significant backpressure.

Pump Features Include:

Piston wash chamber for backflushing piston to extend seal life.

Electronic control of piston motion to minimize pulsation.

Optional pulse damper for further pulse reduction.

Easy to use interface for flow setting and other pump parameters.

Metal-free options

Principles of Operation

Optos pumps attain precise metering at intermediate and high pressures by a positive displacement, reciprocating

piston. The piston is driven by a stepper motor via an eccentric. Advanced software algorithms control motor

speed based on piston position, achieving rapid fluid intake and smooth, constant fluid delivery, minimizing

pulsation. Additional reductions of pulsation can be achieved by use of the optional damper.

Ball and seat inlet and outlet valves ensure precise metering. The suction created by the piston retracting to refill

the piston chamber pulls the inlet ball off the inlet seat allowing fluid to travel through the inlet check valve.

Simultaneously, the outlet ball is pulled back onto its‟ seat, preventing fluid from exiting the piston chamber.

During the delivery portion of the piston‟s duty cycle, the inlet ball is pushed back onto its‟ seat as the piston

moves forward, preventing fluid from travelling back to the pump reservoir. Simultaneously, the outlet ball is

forced off its‟ seat, allowing fluid to exit the outlet valve. For the valves to operate effectively, a pressure

differential of at least 25 psi is required on the outlet side of the pump.

The pump‟s flow rate is set directly in mL/min. using the up and down buttons on the user interface. Flow rates

are determined by piston displacement (diameter, and stroke length) and motor speed.

Some Optos pumps may be fitted with a pulse damper. The damper is a diaphragm type damper, where a

diaphragm made of an inert material flexes against a compressible fluid (spiked with red dye), thereby absorbing

pulses in fluid delivery. To maximize the damper‟s efficiency, the system should operate against at least 500 psi.

If your system does not normally generate such pressures and you wish to increase the efficiency of the damper,

you can install a backpressure device, or some narrow ID tubing downstream of the pump.

Materials of Construction

The materials used for the liquid end of your Optos Pump were carefully chosen for corrosion resistance. The

piston is sapphire, and the inlet and outlet valves incorporate sapphire seats and ruby balls.

The piston seal material is made from specially formulated PTFE and has excellent chemical compatibility

characteristics.

The liquid end housing is made of passivated type 316 stainless steel because of its superior resistance to

corrosion. In applications requiring the use of chemicals corrosive to type 316 stainless steel, you may order a

PEEK (polyetheretherketone) liquid end.

About This Manual

This manual provides instructions and information on Optos metering pumps.

Section II of this manual, beginning on page 8, describes the unpacking, location, and initial installation of your

metering pump. Section III, beginning on page 11, describes the operation of the Optos hardware and the menu

system in detail.. Section IV, beginning on page 16, describes maintenance procedures. Section V, beginning on

page 20, contains appendixes, including, lists spare parts and accessories for the various pump models.

1

A Guided Tour of the Optos Metering Pumps

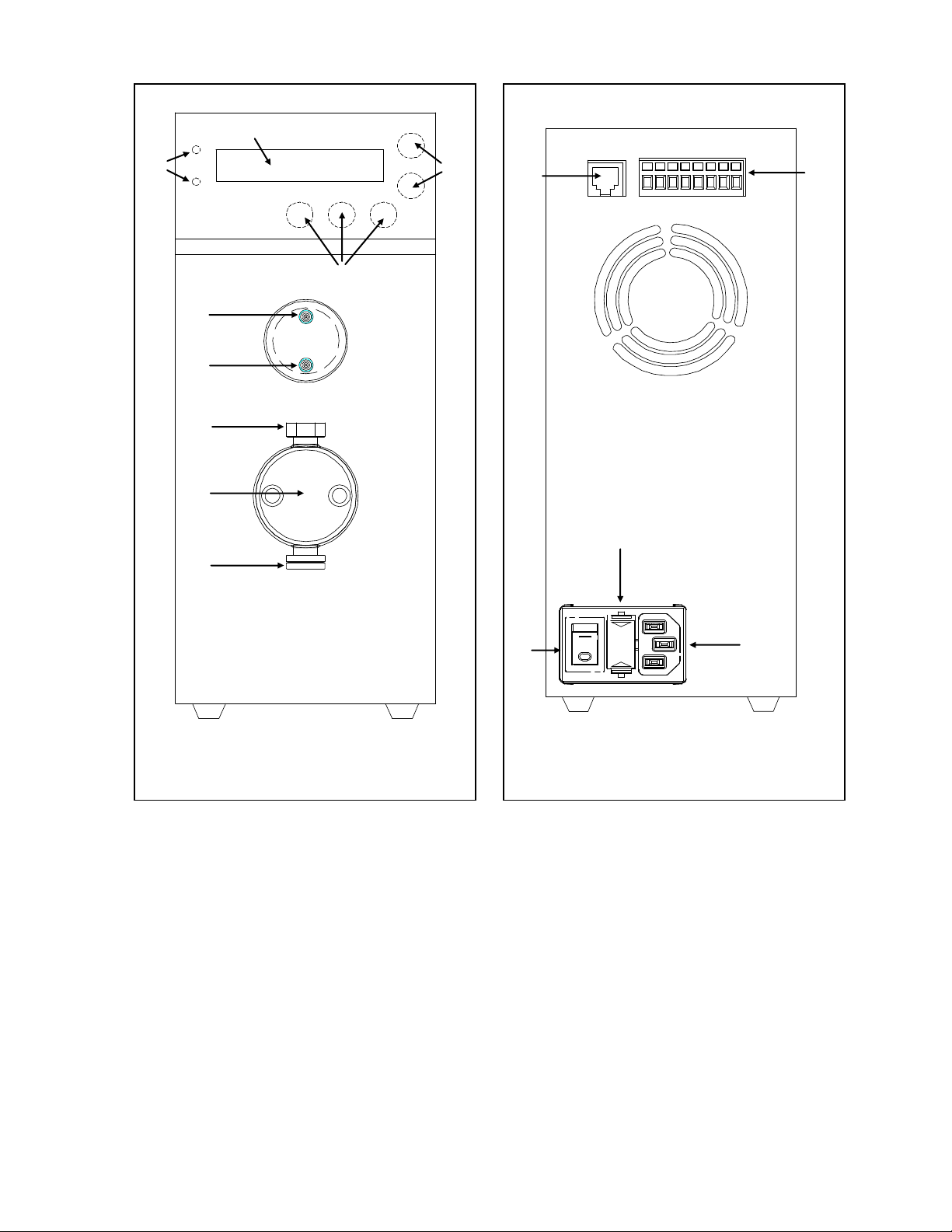

Front Panel

As you look at the front panel of your Optos Metering Pump (Figure 1.1), you will see:

Component Details

Local Interface:

1. Liquid Crystal Display (LCD). Displays flow rate, pressure (with optional pulse damper), other

allowed functions.

2. Up/Down Keys. UP and DOWN arrow keys set flow rates, change pump settings.

3. Permanent Functions Keys. DISPLAY, ΔMENU, and RUN/STOP keys are control keys permanently

defined for direct control of major instrument functions.

4. Status LEDs. Indicate pump running or fault.

Pulse Damper: optional pulse damper for minimized fluid delivery pulsation.

5. Outlet Port: Connection to downstream device.

6. Inlet Port: Connection from pump outlet.

Liquid End Assembly:

7. Outlet Valve: Provides tubing connection for pump output.

8. Cylinder: Contains pumping chamber and piston wash ports.

9. Inlet Valve: Provides tubing connection to fluid source. Inlet valve has an additional groove on

the hexagonal portion of the valve.

Rear Panel

As you look at the rear panel of your Optos Metering Pump (Figure 1.2), you will see:

Component Details

1. RS232: RJ11 connector for RS232 communication.

2. I/O: Input/output connections for remote analog control, pressure out, error out, remote start, stop.

3. Power Entry: Provides power connection with modular cord.

4. Fuse: Housing for pump fuses.

5. On/Off: Turns the power to the pump on and off.

2

Figure 1.1: Front View of Optos

Figure 1.2: Rear View of Optos

1

2

3

4

5

6 7 8

9

1

2 3 4

5

3

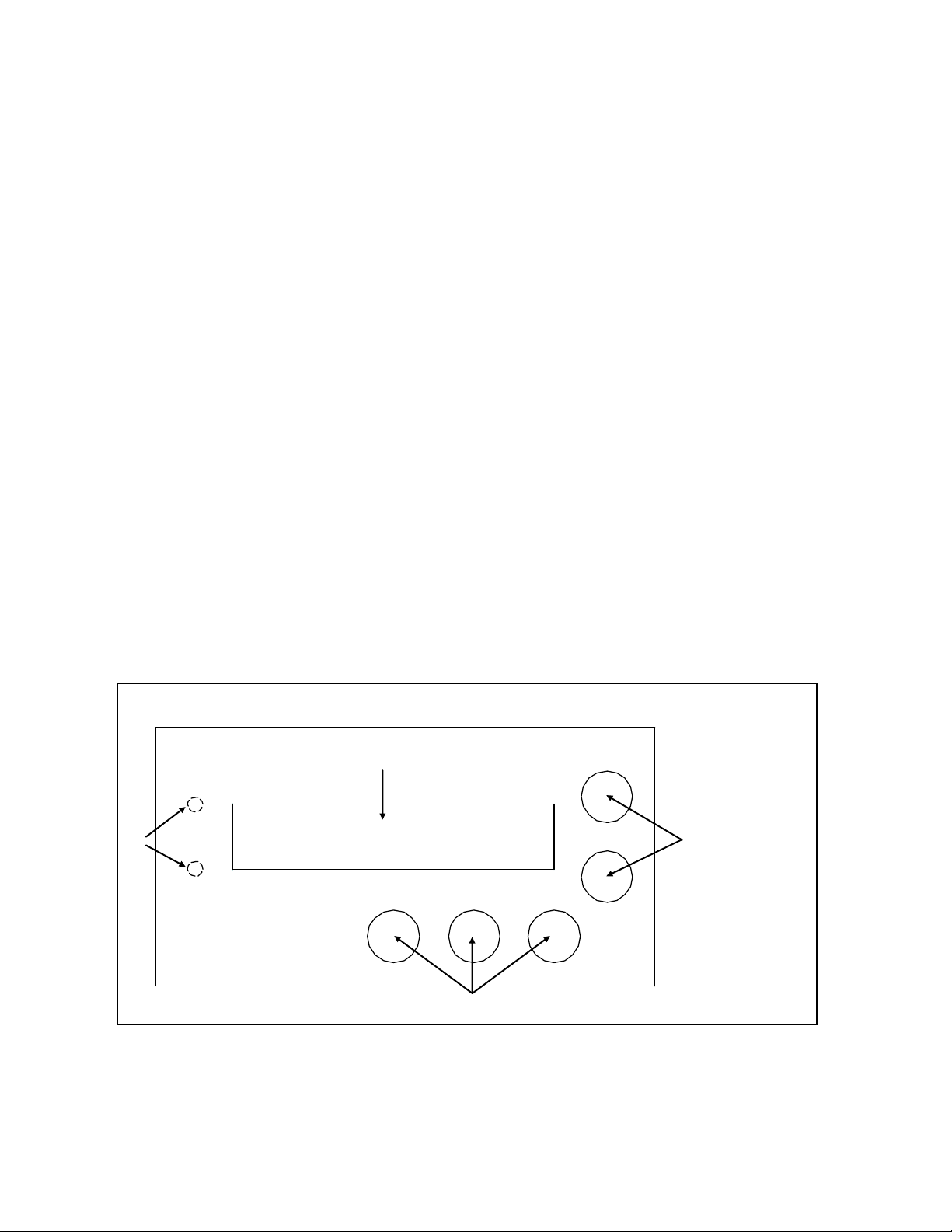

Figure 1.3: Local Interface

1

2

3

4

An Overall Look at the Local Interface

Operation of the Optos Pump is controlled from a series of menus and there is no need to remember esoteric

control codes or command sequences. A detailed description of the menu sequence is given in Section III.

As you look at the local interface (Figure 1.3), you will see:

Component Details

1. Status LEDs: Upper green LED indicates pump is running; lower red LED indicates a pump fault (for

example, an overpressure limit, or motor stall condition.

2. Display: A one line, 16 character LCD display is used to provide readout of flow and pressure (with

optional pulse damper), and access to pump functions.

3. Up/Down Keys: UP and DOWN arrow keys set flow rates, pressure limits (with optional pulse damper),

and function settings.

4. Permanent Function Keys: ΔMENU key changes the display to different pump functions, DISPLAY key

toggles display back to main display of flow, or flow and pressure (with optional pulse damper),

RUN/STOP key runs the pump and stops the pump.

Key Definitions

ΔMENU: The ΔMENU (Change Menu) key scrolls through the main menu selections.

DISPLAY: The DISPLAY key toggles back to main display of flow, or flow and pressure (with optional pulse

damper).

UP/DOWN: UP and DOWN arrow keys increase or decrease flow rate setting, high or low pressure limit settings,

and change setting of other pump parameters.

DISPLAY, then ΔMENU: Holding down the DISPLAY key followed by pressing the ΔMENU key brings up a series

of sub menus which pertain to various pump settings. Pressing the DISPLAY key alone returns to main display.

ΔMENU, then DISPLAY: Holding down the ΔMENU followed by pressing the DISPLAY key brings up a series of

sub menus which pertain to obscure pump settings. Pressing the DISPLAY key alone returns to main display.

4

XX.XXXmL XXXXpsi

MAIN

HI LIMIT: XXXX

H

LO LIMIT: XXXX

L

GO HOME: HIT RUN

HP

COMPRESS: XX

C

REFILL: FULL OUT

R

HEAD: 1/8 SS

LE

REMOTE: OFF

REM

VERSION: X.XX

V

HOME OFFSET: XX

HO

0-5V OUT: PRESS

S

STOP STALL: ON

SS

PRESS LIMIT: ENA

LI

Read/set flow

rate

Read pressure

Set high

pressure limit

Set low pressure

limit

Adjust

compressibility

compensation

Set refill:output

ratio

View EPROM

level

Set remote

control

configuration

Set piston &

materials of

pump

Send piston to

forward position

Set pressure

limit ON/OFF

Set motor stall

ON/OFF

View/set

voltage out

Set home

position offset

ΔMENU

ΔMENU

PRESS 0: HIT RUN

XDC

Zero Pressure

Transducer

STROKE: .125

ST

View stroke

length

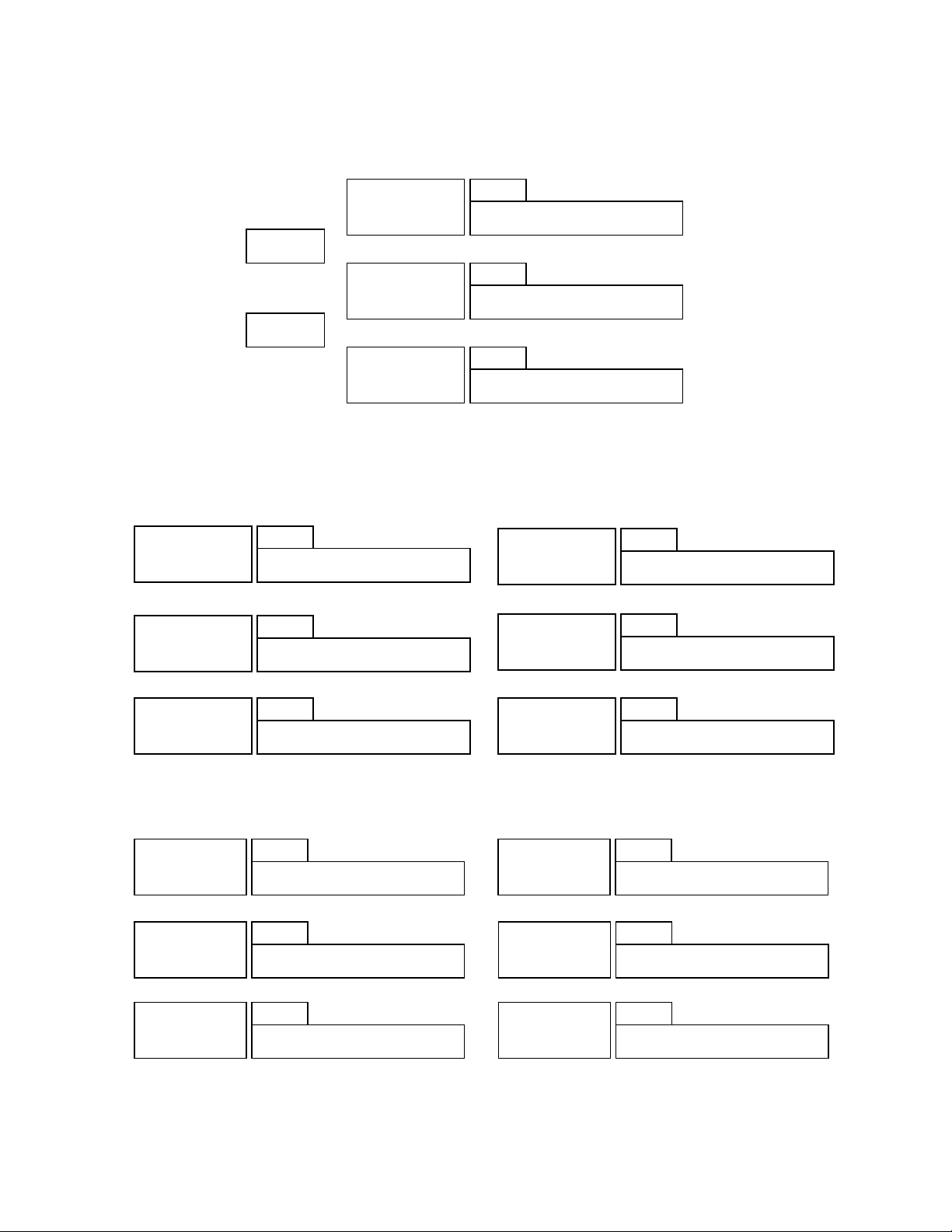

Menu Schematic

The menu schematic indicates the general structure of the menu map. The specific screens shown may vary

from your specific configuration.

Basic Screens

Configuration Screens: DISPLAY & ΔMENU

Advanced Screens: ΔMENU & DISPLAY

5

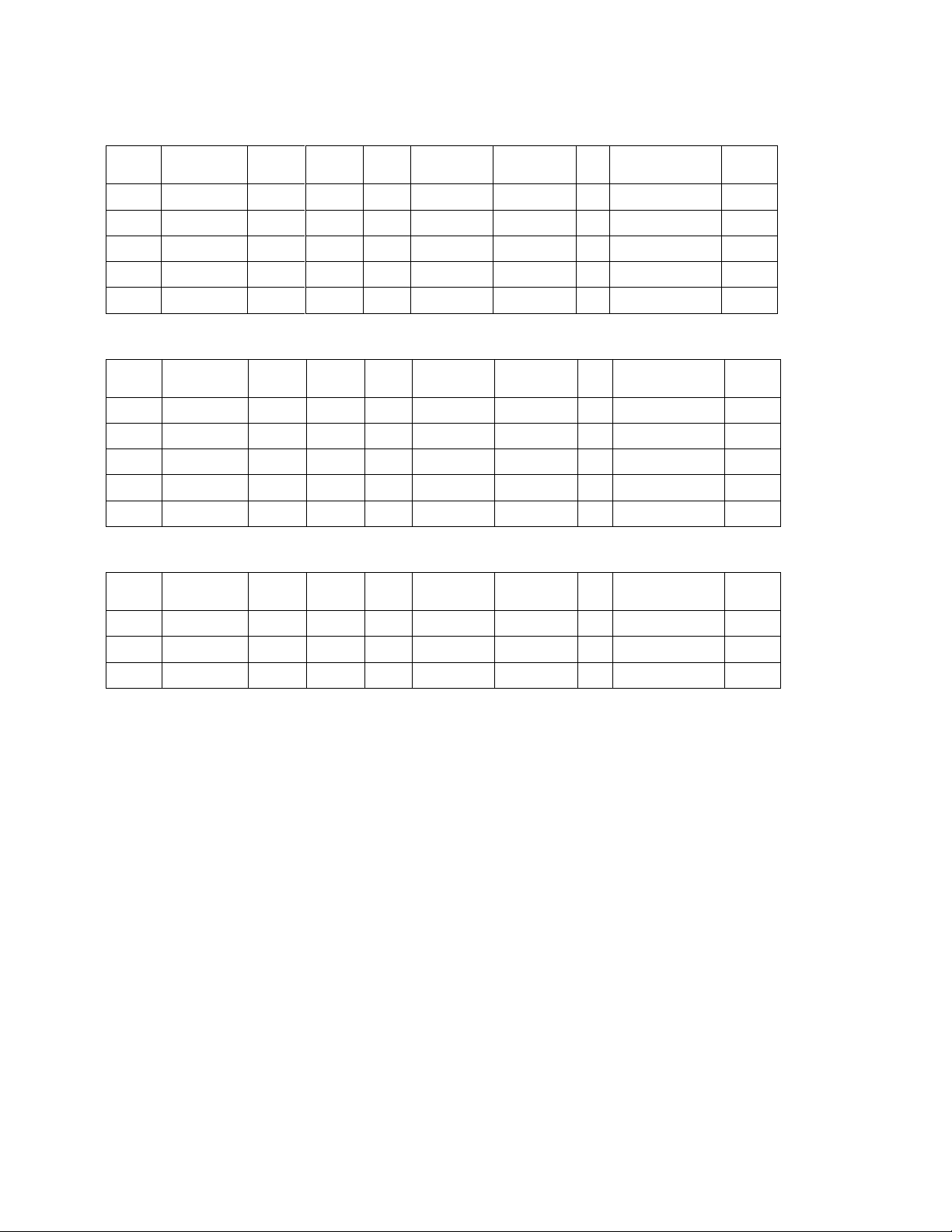

Model

Flow Rate

Range (min.to

max.) mL/min.

Max

Pressure

(psi)

Piston

Diameter

(inches)

Max.

Piston

Stroke

Piston

Displacement

Electrical

VA

Dimensions (L x W

x H inches)

Weight

(lbs.)

1LM

0.002 - 2.5

6000

.093

.125”

.014 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

1LMP

0.002 - 2.5

6000

.093

.125”

.014 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

1SM

0.003 - 5.0

6000

.125

.125”

.025 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

1SMP

0.003 - 5.0

6000

.125

.125”

.025 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

1HM

0.01 - 20.0

3000

.250

.125”

.1 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

Model

Flow Rate

Range (min.to

max.) mL/min.

Max

Pressure

(psi)

Piston

Diameter

(inches)

Max.

Piston

Stroke

Piston

Displacement

Electrical

VA

Dimensions (L x W

x H inches)

Weight

(lbs.)

2LM

0.003 - 5.0

6000

.093

.250”

.028 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

2LMP

0.003 - 5.0

6000

.093

.250”

.028 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

2SM

0.01 - 10.0

6000

.125

.250”

.05 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

2SMP

0.01 - 10.0

6000

.125

.250”

.05 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

2HM

0.02 - 40.0

1500

.250

.250”

.2 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

Model

Flow Rate

Range (min.to

max.) mL/min.

Max

Pressure

(psi)

Piston

Diameter

(inches)

Max.

Piston

Stroke

Piston

Displacement

Electrical

VA

Dimensions

(L x W x H inches)

Weight

(lbs.)

3LM

0.01 - 10.0

3000

.093

.500”

.057 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

3SM

0.01 - 20.0

1500

.125

.500”

.1 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

3HM

0.04 - 80.0

750

.250

.500”

.4 mL

100-230V;

50/60Hz

80

9.5 x 4 x 9

12

Specifications

Stainless Steel Optos/Model 1 Pump Specifications

Stainless Steel Optos/Model 2 Pump Specifications

Stainless Steel Optos/Model 3 Pump Specifications

Maximum flow rate specifications are based on the theoretical volume displacement; actual flow rates will vary depending on such factors as fluid viscosity, compressibility, and

temperature.

Common Specifications:

Wetted Parts: Type 316 stainless steel, PTFE, CTFE, sapphire, ruby

Reproducibility: ±0.3% typical

Tubing Connections: Inlet valve: ¼” –28 plastic fitting for 1/8” Teflon® tubing

Outlet valve: 1/16” I.D. ferrule and tube nut, 10-32 thread

Pumps with .250” pistons use 1/8” Swagelok connections on the inlet and outlet

Other connections available on request

Viscosity Limit: 500 Centipoise

Fuses: .63 A

Operating Environment:

Temperature: 5 – 35ºC

Maximum Humidity: 85%, non-condensing

Maximum Altitude: 2,000 meters

Optional Damper

Type: Diaphragm

Wetted Parts: Type 316 stainless steel, Kalrez

valves

6

Loading...

Loading...