Models CG70ABDL

& CG70BDL

en

Corrosion Gauge

Operating Instructions

0

en

This product meets the Electromagnetic Compatibility Directive.

The product is Class A, Group 1 ISM equipment according to CISPR 11

Group 1 ISM product: A product in which there is intentionally generated and/or used conductively

coupled radio-frequency energy which is necessary for the internal functioning of the equipme nt

itself.

Class A product are suitable for use in all establishments other than domestic and those directly

connected to a low voltage power supply network which supplies buildings used for domestic

purposes.

Note: In the close presence of some radio transmitters, erroneous readings may be given. If this

occurs tests should be repeated at another location.

These operating instructions are available for download on our website www.elcometerndt.com.

The following trademarks are registered trademarks of Elcometer Limited, Edge Lane, Manchester,

M43 6BU. United Kingdom:

Material Safety Data Sheets for the ultrasonic couplant supplied with the CG70ABDL & CG70BL

and available as an accessory, are available to download via our website:

Elcometer NDT Ultrasonic Couplant Material Safety Data Sheet :

www.elcometerndt.com/images/MSDS/elcometer_ultrasonic_couplant.pdf

Elcometer NDT Ultrasonic Couplant Material Safety Data Sheet :

www.elcometerndt.com/images/MSDS/elcometer_ultrasonic_couplant_hi_temp.pdf

All other trademarks acknowledged. © Elcometer Limited 2011/2012. All rights reserved. No part of

this document may be reproduced, transmitted, transcribed, stored (in a retrieval system or

otherwise) or translated into any language, in any form or by any means (electronic, mechanical,

magnetic, optical, manual or otherwise) without the prior written permission of Elcometer Limited.

TMA-0552 Issue 01

Text with cover: 23708

1

Contents

1 About your Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 The Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Getting Started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 The Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5 The Measurement Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6 Measurement - Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7 Setting up the Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8 Taking Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9 Gates (CG70ABDL only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

10 ThruPaint™ Measurement Technique. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

11 Measurement - Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

12 Flaw Mode (CG70ABDL only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

13 Measurement - Recording your Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

en

14 Gauge Setups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

15 Data Transfer Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

16 Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

17 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

18 Technical Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

19 Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

20 Spares & Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

21 Condition and preparation of surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

22 Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

23 Sound Velocities of Common Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

24 THE MENU commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

26 Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2

en

Thank you for purchasing this Elcometer NDT product. Welcome to Elcometer NDT.

The CG70 range of Corrosion Gauges are a world beating product. With the purchase of this gauge

you now have access to the worldwide service and support network of Elcometer. For more

information visit our website at www.elcometer.com.

1 ABOUT YOUR GAUGE

The CG70 series are corrosion gauges that measure with extreme versatility. They have the ability

to measure material thickness as well as locating pits, flaws and defects in the material. Based on

the same operating principles as SONAR and are capable of measuring the thickness of various

materials with accuracy as high as 0.01 millimetres (0.001 inches). The principal advantage of

ultrasonic measurement over traditional methods is that ultrasonic measurements can be

performed with access to only one side of the material being measured.

Both models also include a data-logging (memory) facility which allows readings to be stored in

batches before being downloaded to a computer.

Note : Some functions are only applicable to certain models and these are highlighted througho ut

this Instruction Manual

1.1 STANDARDS

Your gauge can be used in accordance with the following Standards and test methods;

ASTM E 797, EN 14127 and EN 15317.

1.2 GAUGE OVERVIEW & WHAT THIS BOX CONTAINS

1

5

1. Transducer connection

3

2. Alarm LEDs

3. Battery compartment cover and zero block

4. Display

4

5. Keypad

6. RS232 Output Socket

2

0(18

&/5

2. (6&

(17(5

08/7,

02'(

&25526, 21* $8*(

0($6

5

6

CG70 series gauge

, Bottle of couplant, Battery (3 x), Carrying case, Test Certificate, Operating

instructions, CD with software to enable you to transfer your readings and settings to and from a

PC, RS232 cable and USB to serial converter.

Note: The box does not include a transducer; these must be ordered separately.

1.3 FEATURES OF THE GAUGE

• Adjustable gain settings.

• Stores up to 64 custom setups for specific applications.

• High speed scan mode of up to 50 readings per second.

• Audible/visual alarm with high and low limit settings.

• RF and RECT A-Scan displays (CG70ABDL only).

• Time based B-Scan display.

3

• Measurement data storage formats: Alpha numeric grid.

0(18

Data can be downloaded to a computer for analysis and storage.

To maximise the benefits of your new Elcometer NDT gauge, please take some time to read

these Operating Instructions. Do not hesitate to contact Elcometer NDT or your Elcom eter

NDT supplier if you have any questions.

1.4 PACKAGING

The gauge is packed inside its carrying case within a cardboard box. Please ensure that the

packaging is disposed of in an environmentally sensitive manner. Consult your Local Environmental

Authority for further guidance.

2 THE KEYPAD

Activates the primary menu structure containing 7 (CG70BDL) & 9

(CG70ABDL) menu tab groups. These tab groups then cont ain sub menu items,

or functions.

Clears a measurement from a log file cell location or set obstruct and back-

&/5

space in an Alpha Edit Box.

en

0($6

2.

(6&

(17(5

08/7,

02'(

Press to start taking measurements. Scroll forwards through the hot menu.

Press to confirm a change or selection. When in measurement mode, enables

or disables the Hot Menu. If your gauge is displaying a grid log, this key toggles

an advance to row number option.

In the MENU, MEAS, and EDIT functions this key acts as a back or escape

function. If your gauge is displaying a grid the ESC key toggles the display

options; RF, RECT (CG70ABDL only) B-SCAN or DIGITS (all models)

Navigation keys.

In menus this key activates list and edit boxes, displays and saves measurements to grid files locations.

Press to select a measurement mode. The measurement modes available

depend on which transducer is being used. See Section 6 “Measurement Modes” on page 10.

Switches the gauge ON or OFF.

4

en

3 GETTING STARTED

3.1 FITTING BATTERIES

Your gauge may be used with dry cell or rechargeable batteries. 3 x LR6 (AA) alkaline batteries are

supplied with this gauge.

When the battery voltage is low the entire display will start to flash. When this occurs the batteries

should be replaced.

To fit or replace batteries:

1. Unscrew battery compartment cover.

2. Referring to battery polarity instructions on rear of gauge, insert batteries.

3. Replace battery compartment cover.

Note: Remove the batteries from the gauge if it is to remain unused for a long period of time. This

will prevent damage to the gauge in the event of malfunction of the batteries.

3.2 FITTING THE TRANSDUCER

The transducer transmits and receives ultrasonic sound

waves that the gauge uses to calculate the thickness of the

material being measured.

The transducer connects to the gauge via the attached

cable, and two coaxial connectors. When using transducers

manufactured by Elcometer, the orientation of the dual

coaxial connectors is not critical; either plug may be fitted to

either socket.

Further information on transducers can be found on the Elcometer NDT Knowledge Centre on

www.elcometerndt.com.

3.3 SWITCHING ON/OFF

To switch on or off, press the on/off key .

The gauge will switch off automatically after 5 minutes of inactivity.

4 THE MENUS

Your gauge has two menu systems:

• Full menu - displays all the functions and settings of the gauge (see also page 25).

• Hot menu - displays a sub-set of functions and settings related to taking measurements.

4.1 FULL MENU

Press once to

0(18 0(18

access the menus...

then press to

scroll to the right along

the sub menu bar and

(6&

to scroll left to

the sub menu you

want.

and scroll

to the desired function

and right

adjust the selected

function

5

4.2 HOT KEY MENU

en

Press once to

0($6 0($6

access the

measurement screen.

The hot menu

functions are

displayed at the

bottom of the reading

screen.

Press to scroll

right along the hot

menu functions and

(6&

to scroll left

Use , ,

and to adjust the

value of the function.

Alternatively, adjust

values by pressing

(17(5

then use ,

, and

to scroll and adjust

values. Press

2.

when finished.

4.3 OVERVIEW

Throughout these instructions menu locations will be described using a simple system to guide the

user. Locations or menu items will be described in the order that they must be navigated to

separated by a "/"

For example, to reach the option “Zero Transducer” MENU/PROBE/ZERO TRANSDUCER wou ld

be written. After adjusting the desired function press MEAS to return to the measurement screen

4.4 SELECTING MENU LANGUAGE

The menus can be displayed in English, Spanish, and German.

1.Select MENU/SETUP/LANGUAGE and adjust

5 THE MEASUREMENT SCREEN

Your gauge has up to four types of measurement screen:

• A-Scan Waveform, RF (CG70ABDL only)

• A-Scan Waveform, RECT (CG70ABDL only)

•B-Scan

•Digits

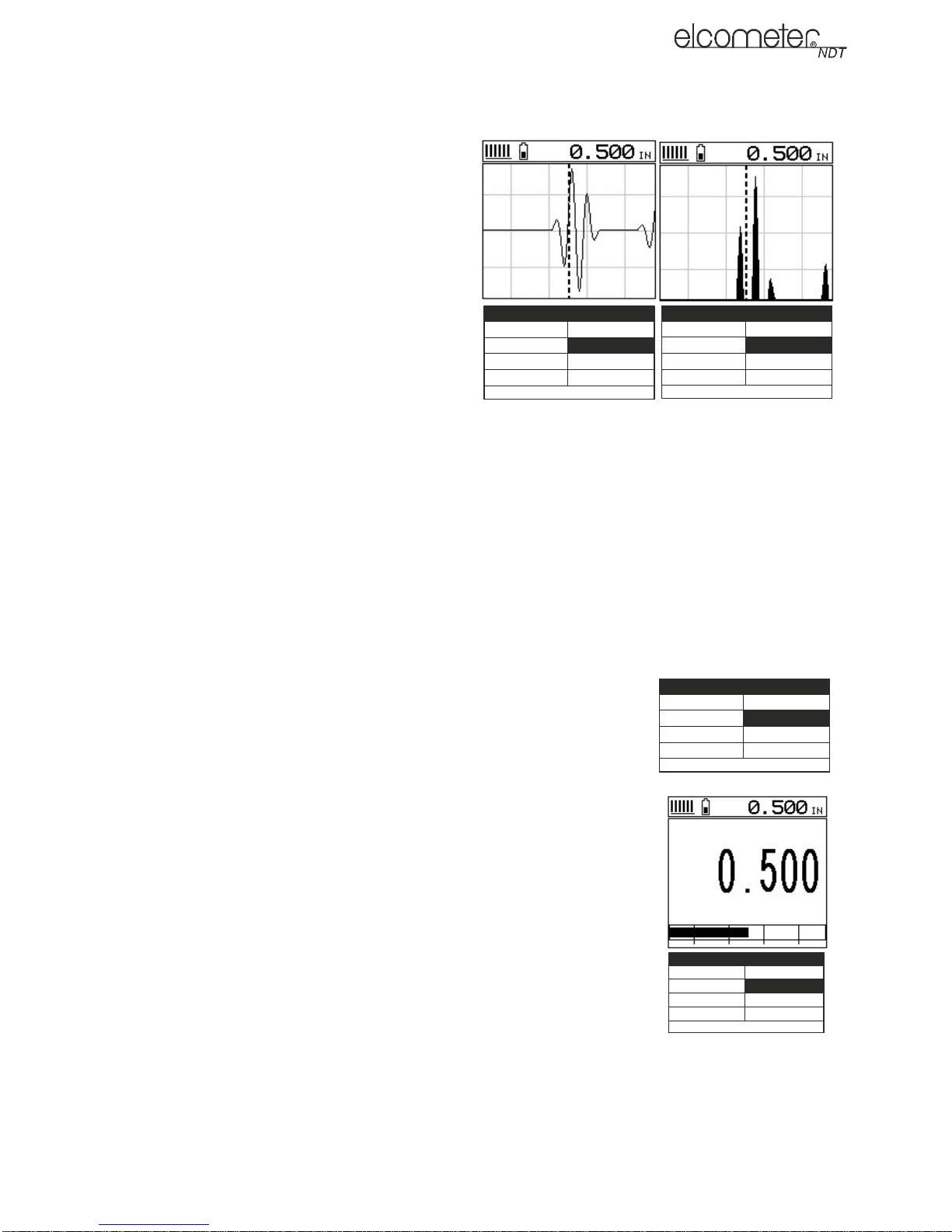

A-SCAN B-SCAN DIGITS

RF RECT

A-SCAN

6

en

To see the measurement screen, press MEAS.

To select which measurement screen to use, press MENU/DISP/VIEW and then select RF, RECT,

B-SCAN or DIGITS.

5.1 ITEMS COMMON TO ALL MEASUREMENT SCREENS

A number of items are common to all the measurement screens:

A

B

E

F

0.16 0.39 0.61 0.83

DELAY: 0.00 W IDTH: 1.00

MO D E : P-E

G

GATE 1: 0.00 GATE 2: 0.00

THR: 2

GRID :

G A I N : 36

LOC: G9

C

D

A Battery Icon Remaining battery life.

B Repeatability/Stability

Indicator

This indicator is used in conjunction with the digital thickness

values displayed. When all the vertical bars are fully illuminated

and the last digit on the digital thickness value is stable, your

gauge is reliably measuring the value.

C Material Thickness

Value/

The thickness or sound velocity of the material under the

transducer (type depends upon measurement view)

Material Velocity Value

D Units The current measurement units (Metric/English).

E Me asurement View Area RF, RECT, B-SCAN or DIGITS view area.

F Measurement Labels

Bar

G Hot Menu (CG70ABDL

only)

Displays the viewable range and are based on the values of

DELAY/B-START and WIDTH/B-DEPTH

The hot menu contains a selection of the most commonly used

options, allowing you to conveniently adjust these to your needs

while the graphical display is active

7

5.2 RF A-SCAN MEASUREMENT SCREEN (CG70ABDL only)

The RF view shows the full sound wave as

received by the gauge. The vertical axis

indicates the amplitude of the received wave

and the horizontal position indicates the time it

is received, which is converted into thickness

units using the material velocity.

The point on the scan that is being used to

calculate the digital thickness reading is

displayed as the vertical dashed line (see

section 9 on gates). The RF screen is used for

gauge setup prior to inspection.

5.3 RECT A-SCAN MEASUREMENT

0.16 0.39 0.61 0.83

0.16 0.39 0.61 0.83

DELAY: 0.00 W IDTH: 1.00

DELAY: 0.00 WIDTH: 1.00

MODE: P-E

MODE : P-E

GATE 1: 0.00 GATE 2: 0.00

GATE 1: 0.00 GATE 2: 0.00

THR: 2

THR: 2

GRID :

GRID :

G AI N : 36

GAIN: 36

LOC: G9

LOC: G9

0.16 0.39 0.61 0.83

DELAY: 0.00 WIDTH: 1.00

MODE : P-E

GATE 1: 0.00 GATE 2: 0.00

THR: 2

GRID :

SCREEN (CG70ABDL only)

The rectified view shows only half of the

waveform, either the positive or negative half depending on the POLARITY selected.

The RECT display is the preferred view for flaw and pit inspections

en

GAIN: 36

LOC: G9

5.4 B-SCAN MEASUREMENT SCREEN

The time-based B-Scan display provides a cross sectional view of the

material being tested. In this example, the top, or accessible side of the

material is represented as 0.00”, and the bottom, or blind surface at

.500”.

This mode is used when you need to inspect the profile of the blind

surface. It can also be a useful view when scanning for pits and flaws.

The B-Scan display is equipped with a scan bar representing the

overall thickness. The scan bar gives the user a visual indication when

a flaw or defect passed over during the scan process.

If you are scanning a pipe, for instance, and pass over a pit during the

process, the scan bar will quickly deflect and alarm you to go back and

search for the defect.

0.16 0.39 0.61 0.83

DELAY: 0.00 WIDTH: 1.00

MODE : P-E

GATE 1: 0.00 GATE 2: 0.00

THR: 2

GRID :

GAIN: 36

LOC: G9

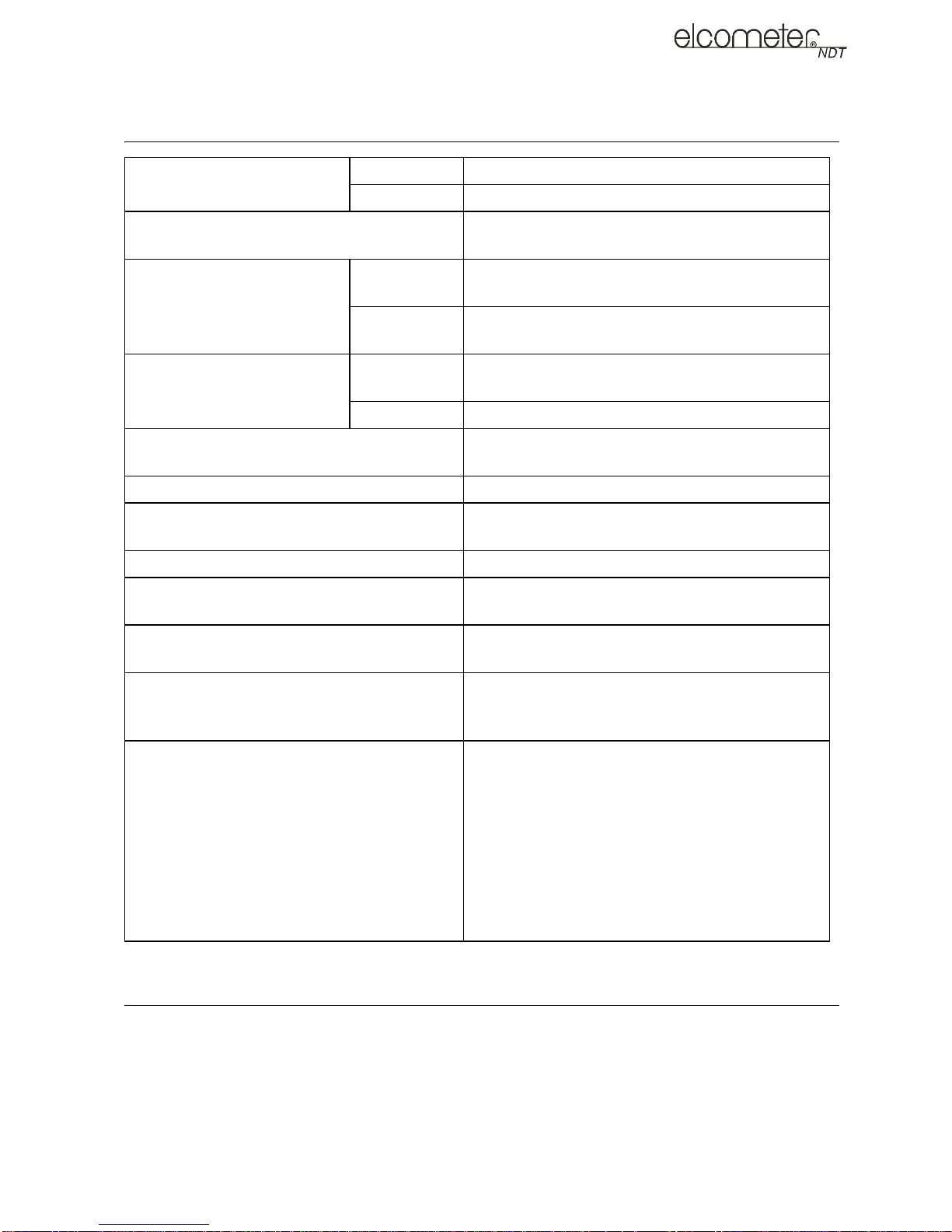

5.5 DIGITS MEASUREMENT SCREEN

The digits display shows the thickness as a value using a large font

size. This view is used typically when the gauge is being used as a

basic thickness gauge. The digits display includes the same scan bar

as the B-Scan display.

5.6 CHANGING THE VIEWABLE RANGE

In RF view, RECT view and B-SCAN view, if the waveform around the

detection point is not visible on the display, use one of the following

methods to adjust the viewable range of the display:

• When in RF view or RECT view, change the values of the DELAY

and WIDTH functions until the measurement falls inside the

0.16 0.39 0.61 0.83

DELAY: 0.00 WIDTH: 1.00

MO D E : P-E

GATE 1: 0.00 GATE 2: 0.00

THR: 2

GRID :

G AI N : 36

LOC: G9

viewable range of the display - see instructions below.

• When in B-SCAN view, change the values of the B-START and B-DEPTH functions until the

measurement falls inside the viewable range of the display. B-START is the equivalent of

DELAY and B-DEPTH is the equivalent of WIDTH and the instructions for changing these

values is identical to those for DELAY and WIDTH - see instructions below.

8

en

• Use the Auto Find function - see ‘Auto Find (CG70ABDL only)” on page 14.

Note: Even if the waveform is outside of the viewable range of the display, a measurement can be

taken and viewed using the DIGITS view.

5.6.1 DELAY AND WIDTH

The DELAY is the thickness value from which the A-Scan display starts on the left of the screen.

The WIDTH is used to adjust the value at the right side of the screen. Using these two parameters

allows the user to zoom in to a specific measurement range and increase the level of detail on the

display. For example, if a wall thickness was nominally 25mm and an operator was assessing for

corrosion on this wall they might set the DELAY to 10mm and the WIDTH to 20mm to fit as much

relevant information on the display as possible.

B-START and B-DEPTH are analogous to DELAY and WIDTH or a B-SCAN display respectively.

DELAY and WIDTH or B-START and B-DEPTH may be adjusted in the hot menu or in the DISP

section of the main menu.

5.6.2 Adjusting DELAY and WIDTH (or B-START and B-DEPTH)

The quickest way to adjust DELAY and WIDTH is directly fr om the hot menu. Alternatively, adjust

the values using the menus:

1. Select MENU/DISP/DELAY or WIDTH and adjust using LEFT and RIGHT or press ENTER to

use the DIGITS EDIT BOX

2. Press OK to set the value

3. Press MEAS to return to the measurement.

5.7 GAIN

The gain (the amplitude of the transmitted pulse) can be adjusted to suit a variety of applications.

To obtain valid readings the gain must be set to the correct level to give reliable return echoes:

• Too much gain may result in erroneous measurements by detecting noise rather than the

material back wall itself.

• Not enough gain may result in intermittent detection. It may also result in lack of detection on

internal flaws, pits, or porosity.

The gain setting on your gauge can be compared to the volume control of a home stereo system.

If you turn it up too much you cannot hear the music clearly. If it is turned down too much, you cannot

hear it at all.

Note: When the echo-echo ThruPaint™ measurement mode is selected, the manual gain feature is

disabled and greyed out in the menu items. In this mode, your gauge switches to an automatic gain

mode (AGC) that optimises the gain setting automatically.

Your gauge has been optimised for a medium gain setting and for the majority of applications it can

be used at this setting. Some applications however may require lower or higher gain settings:

• Lower values might be necessary for noisy or granular cast materials. If the reading becomes

sporadic and will not settle down or resolve on a thickness value.

• Higher values may be necessary when trying to measure a material that is hard to penetra te

(due to the material type, or the overall thickness of the material) and when locating fine pits or

flaws. In these instances, increase the gain until the stability indicator reports a good

measurement.

5.7.1 To Adjust the Gain Value

The quickest way to adjust GAIN is directly from the hot menu. Alternatively, adjust the value using

the menus:

9

1. Select MENU/TUNE/GAIN and adjust using LEFT and RIGHT or press ENTER to use the

DIGITS EDIT BOX

2. Press OK to set the value

3. Press MEAS to return to the measurement screen.

5.8 THRESHOLD (CG70ABDL only)

The threshold is the level of signal amplitude required to trigger a gate and activate the digital

thickness reading. Increasing the threshold value decreases the sensitivity of the gauge as a more

powerful signal is required to trigger the gate. For example on the A-scan display it may be clear

that there is a flaw in the material but the thickness reading is not taking this into account; lowering

the threshold has the effect of increasing the sensitivity of the gauge to a level that the flaw can be

detected. More information on thresholds can be found on the Elcometer NDT Knowledge Centre

on www.elcometerndt.com

5.8.1 To Adjust the Threshold Value

The threshold value may be adjusted from the hot menu when in the P-E GT or E-E measurement

mode.

5.9 GATES (CG70ABDL only)

Your gauge is equipped with gates which control the time measurement process. Further

information on gates can be found on the Elcometer NDT Knowledge Centre on

www.elcometerndt.com.

en

6 MEASUREMENT - MODES

To select the measurement mode, press MULTI MODE until the correct mode is displayed or select

MENU/GATE/MEASURE MODE

Note: The availability of the modes depends upon the type of transducer fitted to the gauge.

6.1 PULSE-ECHO MODE (P-E)

The standard measurement mode providing maximum sensitivity. This general purpose mode

should be used for corrosion and flaw inspections and will measure the total thickness of a material.

6.2 PULSE ECHO WITH GATE MODE (P-E GT) (CG70ABDL only)

Pulse to echo measurement with an adjustable gate for problematic applications. see section 9 on

gates.

6.3 ECHO-ECHO MODE (E-E), THRUPAINT™

This special mode allows the user to measure the material thickness of a substrate underneath a

coating while ignoring the coating thickness by using two echoes from the material back wall. This

mode is useful when the coating thickness makes up a sizeable proportion of a material, but has

the impact of reducing sensitivity so should not be used in pit and flaw inspections.

6.4 FLAW MODE (CG70ABDL only)

The Model CG70ABDL includes a Flaw Mode function which provides basic prove-up flaw detection

using an angle beam transducer. This mode enables inspectors to locate porosity, defects,

inclusions and cracks in a variety of test materials. Further information on the Flaw Mode can be

found on the Elcometer NDT Knowledge Centre on www.elcometerndt.com.

For instructions on how to use the Flaw Mode see ‘Flaw Mode (CG70ABDL only)” on page 16.

10

en

7 SETTING UP THE GAUGE

7.1 SELECTING THE TRANSDUCER TYPE MANUALLY

Follow these steps to select your transducer type.

1. Select MENU/PROBE/TYPE and press ENTER

2. Scroll through the transducer list until the appropriate transducer is

highlighted.

3. Press ENTER to select the transducer.

4. Perform a probe zero

7.2 TRANSDUCER - ZEROING

Setting the zero point for the transducer is important in the same way it

is important for a mechanical micrometer. Zeroing takes into account

slight variations in the manufacturing process for maximum accuracy.

If zeroing is not carried out correctly, the measurements taken by the

gauge will be in error by some fixed value.

To perform a probe zero:

1. Press MEAS to display the measurement screen.

2. Remove all couplant from the face of the transducer and check that the wearface is clean and

free of any debris.

3. Apply a drop of couplant on the transducer and place the

transducer as shown in diagram.

Note: Disregard the value displayed; it is not important. What is

important is accurately performing these steps to ensure reliability

of the zero calculation.

4. Select MENU/PROBE/ZERO TRANSDUCER and press ENTER.

The ZERO TRANSDUCER screen is displayed.

5. Press OK (or ESC to cancel).

When the manual probe zero is completed the measurement

screen is displayed.

6. Remove the transducer from the probe zero disk.

5

Your gauge should now be zeroed.

7.3 CALIBRATING - FOR A MATERIAL

Sound travels through different materials at different speeds, and in

order to measure these materials accurately the correct sound velocity must be programmed into

the gauge. There are three methods of calibrating the gauge.

Known Material Calibration - The material to be measured is selected from a list in the gauge

Known Velocity Calibration - If the material sound velocity is known this may be entered manually

into the gauge.

Known Thickness Calibration - A sample of the material to be inspected is measured using

alternative means and then used to calibrate the gauge.

• One Point calibration is the simplest and most commonly used calibration procedure with best

performance over large measurement ranges

• Two Point calibration uses two samples of different thicknesses, with enhanced accuracy over

small ranges close to the sample thicknesses used

11

0(18

&/5

0($6

For the highest measurement accuracy use the known thickness calibration as this takes into

account variation in material composition, temperature and a variety of other factors.

7.3.1 Known Material Calibration

If the material velocity is unknown, and a sample thickness cannot be taken from the material, you

can choose a material type from a list stored in the gauge. For each material stored in the list there

is a corresponding velocity value.

Note: These velocities will not always be an exact representation of the material being tested. Use

these values only if a close approximation is acceptable.

1. Select MENU/CAL/MATERIAL and press ENTER.

2. Scroll through the material list until the appropriate material is highlighted

3. Press ENTER to select the material type followed by OK.

4. Press MEAS to return to the measurement screen.

7.3.2 Known Velocity Calibration

If the material velocity is known, you can enter the velocity value directly into the gauge. For a list

of the sound velocities of common materials see ‘Sound Velocities of Common Materials” on

page 25

1. Select MENU/CAL/VELOCITY and press ENTER to display the DIGITS EDIT BOX.

2. Adjust to match the material velocity using the LEFT, RIGHT, UP and DOWN arrows then

press OK.

3. Press MEAS to return to the measurement screen.

en

7.3.3 Known Thickness Calibration

If the sound velocity of a material is unknown, a sample with one or two known thicknesses can be

used to determine the sound velocity.

Note: Although the gauge has a ThruPaint™/coating feature, known thickness calibration must be

performed on material with the paint or coating removed.

One-point Calibration: The one point calibration option is most suited for linearity over large

ranges. You should always calibrate on high side of the intended measurement range. For example,

if the measurement range is 2.54 mm to 25.4 mm (.100" to 1.0"), you should calibrate on a known

thickness sample close to 25.4 mm (1.0").

Note: Before you start this calibration procedure, perform a probe zero.

1. Apply a drop of couplant on the transducer and place the transducer in steady contact with the

sample or the material being tested. Be sure that the reading is stable and the repeatability

indicator, in the top left corner of the display, is fully lit and stable.

2. Select MENU/CAL/ONE POINT and press ENTER to display the DIGITS EDIT BOX.

3. Adjust to match the material thickness using the LEFT, RIGHT, UP and DOWN arrows.

4. Press OK to calculate the velocity and return to the measurement screen, or ESC to cancel.

Note: Place the transducer back on the calibration point. The thickness reading should now match

the known thickness but if outside tolerance, repeat the steps above.

Two-point Calibration: For improved accuracy over a smaller measurement range, conduct

one-point calibration followed by a two-point calibration. For example, if the measurement range is

2.03 mm to 6.35 mm (.080" to 0.250"), perform a one point calibration on a known thickness sample

close to 6.35 mm (.250"), followed by a two-point calibration close to 2.03 mm (.080").

Note: Before you start this calibration procedure, perform a probe zero.

12

en

Two - Point calibration

1. Conduct a one point calibration routine as described previously in this section. You should

conduct this routine at the high end of the measurement range

2. Repeat the routine with another sample at the low end of th e mea surement range, exce pt this

time enter the thickness into the TWO POINT area in the CAL menu.

Note: CHECK YOUR CALIBRATION. Place the transducer back on both calibration points. If the

thickness is out of tolerance repeat the steps above.

8 TAKING READINGS

Disclaimer: Inherent in ultrasonic thickness measurement is the possibility that the instrument will

use the second rather than the first echo from the back surface of the material being measured. This

may result in a thickness reading that is TWICE what it should be.

Responsibility for proper use of the instrument and recognition of this phenomenon rests solely with

the user of the instrument.

Other errors may occur from measuring coated materials where the coating is insufficiently bonded

to the material surface. Irregular and inaccurate readings may result. Again, the user is responsible

for proper use and interpretation of the measurements acquired.

8.1 BEFORE YOU START

• Prepare the surface.

• Ensure the correct transducer is selected and set in the gauge.

• Select the correct measurement mode - see ‘Measurement - Modes” on page 10.

• Set the zero point of the transducer - see:

• ‘Transducer - Zeroing” on page 11 and

• Calibrate the gauge - see:

• ‘Calibrating - for a Material” on page 11 and

• Choose the measurement view (DIGITS, RF or RECT, or B-SCAN) - see ‘The Measurement

Screen” on page 6.

8.2 PROCEDURE

1. Apply couplant

For the gauge to work correctly there must be no air gap between the transducer and the

surface of the material to be measured. This is achieved using a couplant.

Before the transducer is placed on the surface, put a small amount of couplant supplied with

the gauge on the surface of the material. Typically a single drop is sufficient.

2. Place transducer onto the surface of the material to be measured

Press the transducer wearface into the couplant. Only moderate pressure is necessary to

keep the transducer stationary and the wearface seated flat against the surface of the

material.

3. Read display

If six or seven bars of the stability indicator are showing, the display will be reading the correct

thickness of the material directly beneath the transducer.

If the stability indicator has fewer than five bars showing, or the numbers on the display seem

erratic, check to make sure that there is an adequate film of couplant beneath the transducer,

and that the transducer is seated flat against the material. If the condition persists, it may be

necessary to:

• adjust the gain, or

• select a different transducer (size or frequency) for the material being measured.

13

The gauge will perform a number of measurements every second when the transducer is in

contact with the surface of the material. The display is updated as each reading is taken.

4. Remove transducer from surface

The display will show the last measurement made.

Note: Occasionally, a small film of couplant will be drawn out between the transducer and the

surface as the transducer is removed. When this happens, the gauge may perform a measurement

through this couplant film. This phenomenon can be seen when one thickness value is observed

while the transducer is in place, and another value is observed after the transducer is remove d. If

this happens, take the reading again using less couplant.

9 GATES (CG70ABDL only)

9.1 INTRODUCTION

The Model CG70ABDL is equipped with gates which control the time measurement process

allowing you to measure a specific region on or between waveforms.

Further information on gates may be found on the Elcometer NDT Knowledge Centre on

www.elcometerndt.com.

en

9.2 ADJUSTING THE GATES

In P-E GT mode one gate is available and may be adjusted from the hot menu. In E-E mode both

gates may be adjusted from the hot menu or alternatively select MENU/GATE.

10 THRUPAINT™ MEASUREMENT T ECHNIQUE

10.1 INTRODUCTION

Your gauge is equipped with a ThruPaint

technique to allow measurement of the material thickness beneath a coating. This is useful for

checking the material thickness of painted object.

ThruPaint

measurement mode using the MULTI MODE key.

Special "High Damped" or Coating Thickness transducers are required for this mode to function.

Further information may be found on the Elcometer NDT Knowledge Centre on

www.elcometerndt.com.

™ capability is available in E-E mode, to activate ThruPaint™ operation select this

™ measurement mode that uses a multiple echo

11 MEASUREMENT - OPTIONS

11.1 AUTO FIND (CG70ABDL only)

When using a scan type display, the DELAY and WIDTH (or B-START and B-DEPTH) must be set

correctly for the waveform to be shown on the display. If these parameters are set up incorrectly

nothing will be seen. The AUTO FIND function solves this problem by automatically adjusting these

parameters so that the relevant part of the waveform is shown on the screen.

To use the AUTO FIND function place the transducer on the material to obtain a reading, select

MENU/UTIL/AUTO FIND.

11.2 HIGH SPEED SCAN

Although your gauge excels at making single point measurements, it is sometimes desirable to

examine a larger region, searching for the thinnest point. The gauge includes a feature, called Scan

Mode, which allows it to do just that.

14

en

This mode increases the overall repetition rate to a maximum of 32 Hz with a high speed screen

refresh rate of 25 times a second.

This feature enables the user to make scanned passes over an arbitrary length of the test material

while still maintaining a reasonable representation of thickne ss over the scanned area or region.

This feature can be used in conjunction with High and Low alarm limit s features to keep track of

both values dynamically.

To enable/disable the high speed Scan Mode:

1. Select MENU/UTIL/SCAN MODE.

2. Use the LEFT and RIGHT arrows to toggle the SCAN MODE on/off.

3. Press MEAS to return to the measurement screen, ready to begin taking readings.

11.3 ALARM MODE

Your gauge includes an Alarm Mode. Set the limits, and if a measurement falls outside of these

limits your gauge will signal an alarm (a red light on the front panel of the instrument and/or an

audible beep).

This feature may be used for a variety of applications to verify the material is within the manufacturer

specifications.

There are two limit values, ALARM LOW and ALARM HIGH. You can choose to activate both or

just one of these values depending on your requirements.

To enable/disable Alarm Mode:

1. Select MENU/UTIL/ALARM STATUS

2. Use the LEFT and RIGHT arrows to toggle the ALARM on/off/audible.

3. Press MEAS to return to the measurement screen, ready to begin taking readings.

To set the Alarm limits:

1. Select MENU/UTIL/ALARM LO LIMIT or ALARM HI LIMIT and press ENTER to display the

DIGITS EDIT BOX.

2. Adjust to suit the measurement application using the LEFT, RIGHT, UP and DOWN arrows.

3. Press OK to set the alarm value and return to the menu screen, or ESC to cancel.

4. Press MEAS to return to the measurement screen.

11.4 POLARITY (CG70ABDL only)

The polarity that your gauge detects on can be set to either positive or negative to obtain the best

detection results depending on the specific measurement conditions of your application. Polarity

affects both the gate (above or below the x axis in the RF A-Scan) and the Rectified A-Scan display

(whether the top or bottom half of the RF display is shown).

For further information refer to the Elcometer NDT Knowledge Centre on www.elcometerndt.com.

To adjust POLARITY:

1. Set the measurement screen view to RF, MENU/DISP/VIEW.

2. Select MENU/TUNE/POLARITY.

11.5 PULSE WIDTH (CG70ABDL only)

Your gauge has an adjustable pulse width option. Pulse width refers to the duration o f time the

pulser is switched on. Pulse width determines the amount of energy transmitted into the material

being tested.

There are three pulse width options:

15

Spike: The Spike option is used for high resolution and general applications and can be considered

as the standard setting.

Thin: When additional energy is needed for more penetration, the Thin option may be necessary.

Wide: When even more energy is needed for more penetration, the Wide option may be necessary.

High frequency applications, where resolution is a requirement, may require the Spike or Thin

settings to achieve optimal results. Low frequency applications, where more penetration is a

requirement, may require the Thin or Wid e settings, offering incr eased penetration. The variety of

transducer frequencies and diameters used in conjunction with the pulse width setting, enable you

to fine tune the gauge to your application needs.

To adjust the Pulse setting:

Select MENU/PROBE/PULSE

12 FLAW MODE (CG70ABDL only)

12.1 INTRODUCTION

Your gauge includes a basic flaw prove up mode. Further in formation on flaw detection can be

found on the Elcometer NDT Knowledge Centre on www.elcometerndt.com.

en

12.2 FLAW MODE VIEW

Feature Description

A

Horizontal gridlines on the display represent

increments of 25% of the full screen height

The thickness reading normally occupying

B

this space is not relevant to flaw detection. It

is replaced by a dashed line

The peak hold symbol is only visible when

flaw mode is set to peak. Indicates the high-

C

est amplitude reflection detected during a

scan. Pressing CLR will reset the position of

the peak hold symbol to zero

Vertical gridlines on the labelled with quad-

D

rant numbers. Unlike thickness mode they do

not correspond to the material thickness

12.3 ENABLING FLAW MODE

To use Flaw Mode, an angle beam transducer and dual lemo to single microdot cable are required.

These are available from Elcometer NDT.

1. Attach the dual lemo to microdot cable and angle beam transducer to the gauge.

2. Select MENU/PROBE/FLAW MODE

3. Use the LEFT and RIGHT arrows to adjust the value of the FLAW MODE function (OFF, ON,

PEAK):

• OFF - Disables Flaw Mode

• ON - Enables Flaw Mode

16

en

• PEAK - Enables the Flaw Mode and Peak Hold options and view. When this option is

enabled, the peak hold symbol is displayed on the right side of the display (to reset to

zero, press CLR).

4. Press MEAS to return to the measurement screen.

Note: When flaw mode is activated, a transducer delay will still be configured from the previously

loaded transducer. This will only affect the position of the starting point from the initial pulse. The

zero delay can be set to zero by loading the default setup located in the setup menu. Alternatively,

you can load a factory flaw mode setup, and begin making any adjustments necessary.

13 MEASUREMENT - RECORDING YOUR READINGS

Your gauge is equipped with a data logger. With a data file open, all your measurements are saved

into the file for later review and download to PC.

13.1 ABOUT THE DATA LOGGER

With a data file open, as you take measurements, the measurement data is stored in files in the

gauge memory in Grid format similar to a spreadsheet format in which each cell is used to store a

reading. Cells are referenced by the row number (1 to 999) and the column label (A to ZZ).

Data logger filename character sets

Any combination of the following characters can be used for file names:

• Numeric characters: 0 - 9

• Alpha Characters: A - Z

• Special Characters: ! ' _ # space / . - ( )

What measurement data is saved

When a measurement is taken (irrespective of log file format), the following information is saved:

• The reading value.

• A screenshot, the nature of which will depend on what view the gauge was in at the time the

reading was taken. For example, if the view was in B-SCAN, then a B-SCAN screenshot will

be saved with the reading. This 'Save Graphics' option can be toggled on/off.

Memory capacity

You can create and save as many data files as required up to the maximum capacity of the gauge

memory (32 Mbit). If you try to create a new file which exceeds the memory capacity, the gauge will

display an error message. Saved data must be deleted in order to make the space available.

.

Save Graphics Option

Memory Capacity

(readings)

On 12 000 +

Off 210 000 +

13.2 CREATING A NEW DATA LOGGER FILE - GRID FORMAT

To create a GRID log data file:

1. Select MENU/DATA/NEW and press ENTER to continue

2. Fill in a name and a note (if desired) for your data logger file

3. Select the size of the grid. Grid positions are denoted by a number and a letter, where the

letter is the column and the number is the row.

Use TOP LEFT and LOWER RIGHT to define the size of the grid. For example, a with the TOP

LEFT set to A001 and LOWER RIGHT C003 would produce a 3x3 grid

17

The grid can have a maximum of 52 columns and 999 rows

4. Set the Auto Increment direction. This option allows you to select which direction the cursor

moves after a reading is stored in terms of compass points. For example NORTH would move

the cursor up a row, and WEST would move a column left.

5. Choose whether to activate SAVE GRAPHICS or not (snapshot of the A OR B scan on

screen).

6. Finally create the log by scrolling to CREATE LOG, pressing ENTER and then OK to confirm.

The measurement grid is now displayed along with the grid name on screen.

13.3 HANDLING LOGGER FILES

Once created, logger files may be opened or closed using the functions "OPEN" and "CLOSE"

Closing logger files places the gauge in immediate mode and will prevent accidental saving of data

into an inappropriate log.

13.4 STORING READINGS IN A DATA LOGGER FILE

1. Create a new data logger file or open an existing file.

The grid is displayed in the lower half of the measurement screen.

Note: Once the file is open, it will remain open until it is closed or another file is opened. If the

gauge is switched off, the file will be opened automatically when the gauge is switched on

again. Press the ENTER key to display the file from the measurement screen.

2. If you want to save the reading to a particular cell location, scroll to the desired cell.

Note: The cell location must be empty. If it already contains a reading and you want to save a

new reading to the same location, refer to the instructions given in ‘Viewing and Deleting

readings” on page 18.

3. Take a reading and then press ENTER.

The reading value is saved in the file at the location selected and the cursor advances to the

next cell according to the rules set for the data logger file:

• If INCR. DIR is set to NORTH, EAST, SOUTH or WEST, the cursor will advance one cell in

the chosen direction. When the cursor reaches the last cell in the row or column it will

return to the other end of the row or column.

Note: If you try to save a reading into a cell location which already contains a reading value, a

warning message is displayed (see Deleting a reading).

4. To advance to a specific row number, press OK enter the row number. Press OK to advance

directly to that row number in the grid log.

5. To toggle the display between DIGITS view and B-SCAN view, press ESC.

6. If you are unable to take a measurement due to the measurement location being physically

inaccessible, press CLR.

The cell location in the data file is marked OBST (Obstruct).

7. The display of the log data file on the measurement screen can be switched on and off:

• To switch off, press MEAS

• To switch on, press ENTER.

en

13.5 VIEWING AND DELETING READINGS

With a data file open:

1. Use the arrows to scroll through the cells in the data file.

As the cursor is moved to a different cell, the display is updated with the display view saved

with the reading (if SAVE GRAPHICS was set to YES). Readings stored in memory are

indicated by MEM in the top left corner of the measurement screen (in place of the bars of the

stability indicator).

18

en

2. To delete a reading, scroll to the cell location, press CLR and then OK (or ESC to cancel).

The reading is deleted and if you wish you can now take another measurement and save the

reading in this cell location.

13.6 EDITING A DATA LOGGER FILE

You can edit the following fields of data files:

• NAME, NOTE, and INCRement DIRection

To edit a file:

1. Open the data file. (Select MENU/DATA/OPEN)

2. Select MENU/DATA/EDIT and press ENTER

The EDIT GRID screen is displayed and lists all the fields which can be edited.

3. Scroll to the field you want to edit, press ENTER and then adjust the contents of the field using

the techniques previously described to create a data file - see page 17.

4. When finished, scroll to SAVE CHANGES, press ENTER and then OK (or ESC to cancel).

13.7 DELETING A DATA LOGGER FILE

1. Select MENU/DATA/DELETE ONE GRID and press ENTER.

The DELETE GRID screen is displayed and lists all the data files stored in your gauge

memory.

2. Scroll through the list until the data file you want to delete is highlighted.

3. Press OK (or ESC to cancel).

The file is deleted.

13.8 DELETING ALL DATA LOGGER FILES

Note: This will delete all the data logger files in gauge memory - use with caution.

1. Select MENU/DATA/DELETE ALL GRIDS

2. Press ENTER and then OK to confirm (or ESC to cancel).

The data logger memory is erased - all files are deleted.

14 GAUGE SETUPS

Your gauge contains 64 configurable preset locations in which you can store custom gauge setups,

each one optimised for a specific measuring application.

These gauge setups can save time when conducting routine inspections of the same job or project.

This feature also helps to eliminate error between two or more users during the setup and

calibration process.

The setups store:

• Measurement mode

• Transducer type

• Gain setting

• Scan mode setting

• Alarm settings

• Display type setting

As well as storing the setups in your gauge, you can also store the setups on a computer and

transfer them bi-directionally using the PC interface software included with the gauge.

The factory supplied setups stored in the gauge cover some of the more typical applications

commonly used with this type of instrument and may be modified freely by the user.

The PC interface software includes a default setup file that can be uploade d to the gauge at any

time to restore factory settings. However, you should consider saving modified setups to an empty

location rather than overwriting the factory setups in your gauge.

19

14.1 OPENING A SETUP

1. Select MENU/SETUP/OPEN and press ENTER to display the SETUP

LIST BOX.

2. Scroll through the list of setups until the required setup is highlighted.

3. Press ENTER to activate the confirmation screen.

4. Press OK to load the setup from memory.

5. Press MEAS to return to the measurement screen.

14.2 SAVING AND EDITING A SETUP

Once the parameters and features have been adjusted for an application,

you can save these setting to a specific setup location for future use.

It is sometimes necessary to rename a previously saved setup, or add

additional comments about a particular setup. The other comments about the project may also be

required for additional documentation purposes.

The following procedures outline the necessary steps for saving and editing a setup:

1. Select MENU/SETUP/SAVE and press ENTER to display the SAVE SETUP EDIT BOX.

2. Scroll to NAME and then press ENTER to edit its value:

• When you have finished, press OK to enter the value.

3. If you want to add a note, repeat step 2 for NOTE.

4. When you have finished, scroll to SAVE SETUP and press ENTER.

The setup list screen is displayed.

5. Scroll through the list of setups until the required location to save the

setup is highlighted.

6. Press OK to activate the confirmation screen.

7. Press OK to save the SETUP, or ESC to cancel.

en

Note: The Name and Note parameters of a Setup can be edited at any time

by repeating the Save Setup routine described above. Therefore, the Save

Setup function can also be considered an Edit Function.

14.3 USING THE DEFAULT SETUP

Your gauge includes a default setup which you can use (as a last resort) if

there are no other setups stored in the gauge. This gives you the ability to

load and modify a basic setup as follows:

1. Select MENU/SETUP/DEFAULT SETUP and press ENTER to activate the confirmation

screen.

2. Press OK to confirm.

3. Press OK again to confirm.

15 DATA TRANSFER SOFTWARE

Software is available which allows data to be transferred from your gauge to a PC. Presently

Elcometer supplies ElcoMaster 2.0™ software for this purpose.

To set-up other types of communications software:

1. Start the communications software.

2. Configure the software using the following parameters:

Data Bits - 8, Parity - None, Stop Bits - 1, Baud Rate 1200 (to print a report), or 9600 to

transfer data file.

Note: A report can be printed to a communications program (i.e. HyperTerminal), or printed to

a serial printer using A4 or 8.5" x 11" paper.

20

en

3. Set the communications software COM port to the port number that the gauge is connected to.

15.1 TRANSFERRING MEASUREMENT DATA TO YOUR COMPUTER

15.1.1 RS-232 Connector

The RS-232 connector, located on the bottom end cap of the gauge, is a 2 pin female Lemo

connector. It is designed to connect directly from the gauge to a standard AT serial port on a PC. A

Lemo to 9 pin serial cable is supplied with the gauge.

Note: This connector is also used to upgrade the gauge with the latest version of firmware.

15.1.2 USB to Serial Converter

Some newer laptop computers do not have standard serial ports. In this case, use the USB to Serial

converter supplied with the gauge.

15.1.3 Computer System Requirements

ElcoMaster 2.0™ is compatible with any Windows computer system running Windows XP or above.

15.1.4 Using the XFER menu

The XFER menu of your gauge is used in conjunction with the ElcoMaster 2.0™ PC software. The

steps below outline the procedure for accessing the XFER menu and basic operation as fo llows:

1. Scroll to the XFER section of the main menu.

2. Press the ENTER key to activate the option selected.

3. Once the Backup or Restore function has been completed, press the MEAS key once to return

to the menu items, or twice to return to the measurement mode.

16 STORAGE

Your gauge has a Liquid Crystal Display. If the display is heated above 50°C (120°F) it

may be damaged. This can happen if the gauge is left in a car parked in strong sunlight.

Always store the gauge in its case when it is not being used.

If the gauge is to remain unused for long periods of time, remove the batteries and store

them separately. This will prevent damage to the gauge in the event of malfunction of

the batteries.

17 MAINTENANCE

You own one of the finest corrosion gauges in the world. If looked after, it will last a lifetime.

17.1 FAULTS

Your gauge is designed to give many years reliable service under normal operating and storage

conditions. The gauge does not contain any user-serviceable components. In the unlikely event of

a fault, the gauge should be returned to your local Elcometer NDT supplier or directly to Elcometer

NDT. The warranty will be invalidated if the instrument has been opened.

17.2 TRANSDUCER

The transducer will wear with repeated use. To extend transducer life, always set the transd ucer

down so that it is perpendicular to the panel surface. Dragging the transducer along the surface will

reduce the life of the transducer. Replacement transducers are available from your local Elcometer

NDT supplier or directly from Elcometer NDT.

21

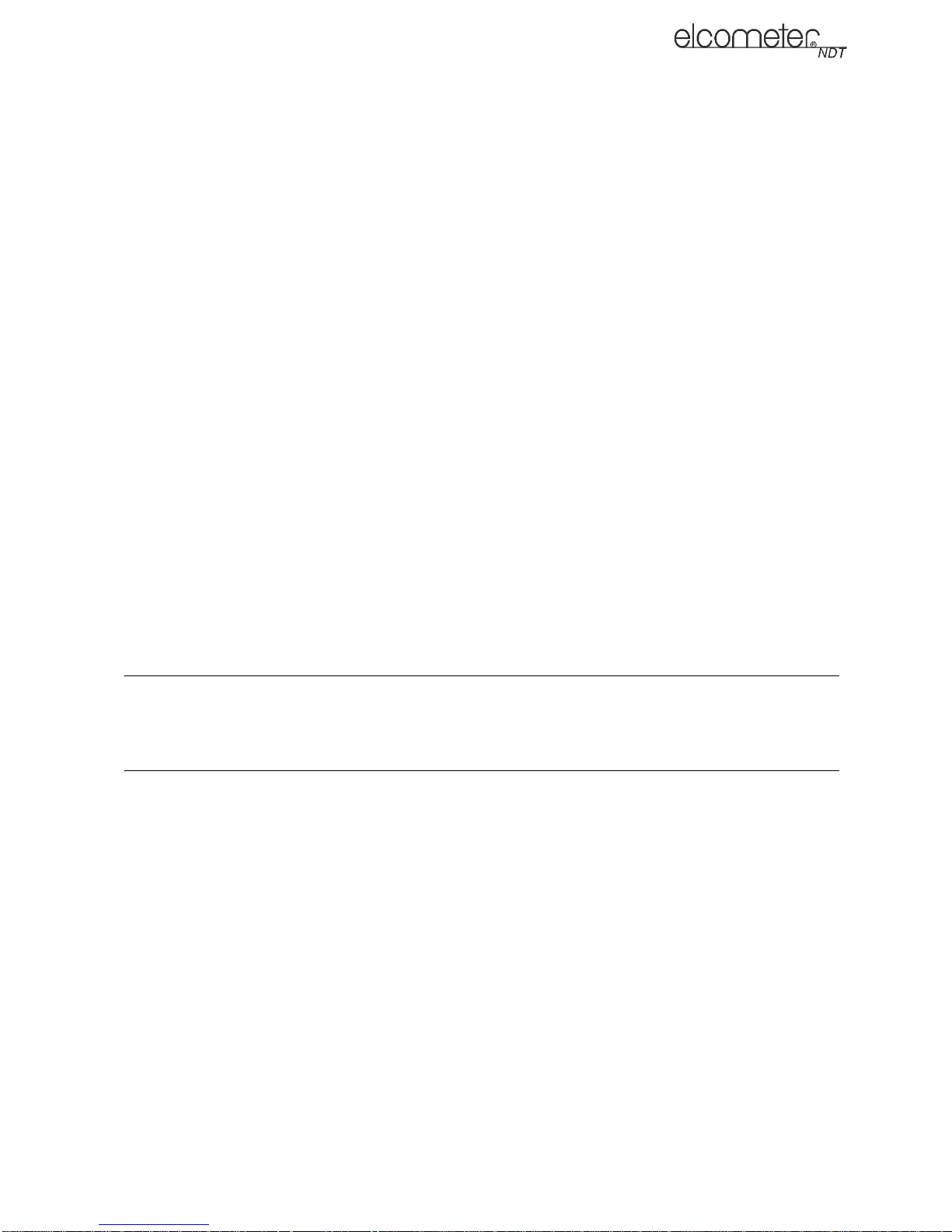

18 TECHNICAL SPECIFICATION

en

Measurement Rate

Manual 4 readings per second

Scan mode 32 readings per second

a

Measuring Range

- Sound Velocity

Measuring Range Thickness

Measurement Resolution

Pulse-Echo

P-E

Echo-Echo

E-E

Sound

Velocity

1250 m/s to 10000 m/s (0.0492 in/µs

in/µs)

0.63 mm to 254 mm (0.025” to 9.999”)

2.54 mm to 102 mm (0.1” to 4.0”)

Range will vary +/- depending on the coating.

1 m/s (0.0001 in/µs)

Thickness 0.01 mm (0.001")

Velocity Calibration Range

1250 m/s to 10000 m/s (0.0492 in/µs

in/µs)

Weight (including batteries) 380 g (13.5 oz)

Dimensions (W x H x D)

63.5 mm x 165 mm x 31.5 mm (2.5” x 6.5” x

1.24”)

Gauge Operating Temperature -10°C to 60°C (14°F to 140°F)

Case

Aluminium case with gasket sealed end caps and

waterproof membrane keypad

to 0.3930

to 0.3937

PC Connection

RS232 serial port. Windows PC interface

software

Backlit VGA greyscale display (240 x 160 pixels).

Display

Viewable area 62 mm x 45.7 mm (2.4” x 1.8”). EL

backlit (on/off/auto).

Three 1.5V AA alkaline or 1.2V rechargeable

cells. Typically operates for 200 hours on alkaline

and 120 hours on rechargeable cells (charger not

included.)

Power Source

Note: Alkaline batteries must be disposed of

carefully to avoid environmental contamination.

Please consult your local environmental authority

for information on disposal in your region. Do not

dispose of any batteries in fire.

a. Measuring Range depends on material, surface conditions and the transducer selected.

19 WARRANTY

Elcometer NDT warrants your gauge against defects in materials and workmanship for a period of

two years from receipt by the end user.

Additionally, Elcometer NDT warrants transducers and accessories against such defects for a

period of 90 days from receipt by th e end user. If Elcometer NDT receives notice of such defects

during the warranty period, Elcometer NDT will either, at its option, repair or replace products that

prove to be defective. The warranty will be invalidated if the instrument has been opened.

22

en

19.1 EXCLUSIONS

The above warranty shall not apply to defects resulting from: improper or inadequate maintenance

by the customer; unauthorised modification or misuse; or operation outside the environmental

specifications for the product.

Elcometer NDT makes no other warranty, either express or implied, with respect to this product.

Elcometer NDT specifically disclaims any implied warranties of merchantability or fitness for a

particular purpose. Some states or provinces do not allow limitations on the duration of an implied

warranty, so the above limitation or exclusion may not apply to you. However, any implied warranty

of merchantability or fitness is limited to the two-year duration of this written warranty.

This warranty gives you specific legal rights, and you may also have other rights, which may vary

from country to country, state to state or province to province.

19.2 OBTAINING SERVICE DURING WARRANTY PERIOD

If your hardware should fail during the warranty period, contact Elcometer NDT and arrange for

servicing of the product. Retain proof of purchase in order to obtain warranty service.

For products that require servicing, Elcometer NDT may use one of the following methods:

• Repair the product

• Replace the product with a re-manufactured unit

• Replace the product with a product of equal or greater performance

• Refund the purchase price.

19.3 AFTER THE WARRANTY PERIOD

If your hardware should fail after the warranty period, contact Elcometer NDT for details of the

services available, and to arrange for non-warranty service.

20 SPARES & ACCESSORIES

20.1 TRANSDUCERS

Elcometer NDT gauges are not

separately.

The transducers listed below are the most commonly used however, Elcometer NDT offer a wide

range of other transducers to suit various applications.

Further information on the transducers available and their applications can be found on the

Elcometer NDT Knowledge Centre on www.elcometerndt.com.

Description Sales Part No.

2.25 MHz 1/4” Potted Side Transducer TX2M25CP-2

5 MHz 1/4” Potted Side Transducer TX5M00CP-4

5 MHz 1/4” P otted Side High Damped Transducer TX5M00CP-10

7 MHz 1/4” P otted Side High Damped Transducer TX7M50CP-6

10 MHz 1/4” Potted Side Transducer TX10M0CP-4

Dual Lemo to Single Microdot Transducer Cable TL-24030-8

2.25 MHz 1/4” Microdot Side Mini Angle Beam Transducer, 45 Degree TF2M25C45M

5 MHz 3/8” Microdot Side Mini Angle Beam Transducer, 60 Degree TF5M00D60M

10 MHz 3/16” Microdot Side Mini Angle Beam Transducer, 70 Degree TF10M0B70M-1

supplied with a transducer as standard - this must be ordered

20.2 CALIBRATION BLOCKS

Elcometer NDT offer a comprehensive range of calibration blocks to suit a wide range of

applications and standards.

23

Selecting the correct calibration block for the application is essential to ensure accurate evaluation.

The form, shape and material of the calibration block should be appropriate for the material being

inspected. Any artificially induced flaw should closely resemble that of the actual flaw being tested

for.

The calibration blocks listed below are a selection of those available - details of the full range can

be found on www.elcometerndt.com

Description Sales Part No.

Calibration Block: 8 Step; 1 - 8mm TW-24005-*

Calibration Block: 10 Step; 2 - 20mm TW-24006-*

Calibration Block: 10 Step; 2.5 - 25mm TW-24007-*

Replace * with S1018 = 1018 Steel Block; A = Aluminium Block; SS = Stainless Steel Block;

T = Titanium Block.

20.3 ULTRASONIC COUPLANT

Each gauge is supplied with a 120ml (4oz) bottle of standard ultrasonic couplant. Replacement

bottles and couplant for high temperature applications are available from your local Elcometer NDT

supplier or directly from Elcometer NDT.

Description Sales Part No.

Ultrasonic Couplant, 120 ml (4 oz) TC-24034-1

Ultrasonic Couplant, 360 ml (12 oz) TC-24034-2

Ultrasonic Couplant, High Temperature 343°C (650°F), 120 ml (4 oz) TC-24034-4X

Ultrasonic Couplant, High Temperature 482°C (900°F), 120 ml (4 oz) TC-24034-5X

en

Note: A wide range of other transducers and accessories is available - see www.elcometerndt.com

for details.

21 CONDITION AND PREPARATION OF SURFACES

Further information can be found on the Elcometer NDT Knowledge Centre on

www.elcometerndt.com.

22 APPLICATION

Further information can be found on the Elcometer NDT Knowledge Centre on

www.elcometerndt.com.

24

en

23 SOUND VELOCITIES OF COMMON MATERIALS

Material

Aluminium 6350 0.250 Paraffin 2210 0.087

Bismuth 2184 0.086 Platinum 3962 0.156

Brass 4394 0.173 Plexiglas 2692 0.106

Cadmium 2769 0.109 Polystyrene 2337 0.092

Cast Iron 4572 0.180

Constantan 5232 0.206 PVC 2388 0.094

Copper 4674 0.184 Quartz Glass 5639 0.222

Epoxy Resin 2540 0.100

German Silver 4750 0.187 Silver 3607 0.142

Glass, Crown 5664 0.223 Steel 5918 0.233

Glass, Flint 4267 0.168 Steel, Stainless 5664 0.223

Gold 3251 0.128 Stellite 6985 0.275

Ice 3988 0.157 Teflon 1422 0.056

Iron 5893 0.232 Tin 3327 0.131

Lead 2159 0.085 Titanium 6096 0.240

Magnesium 5791 0.228 Tungsten 5334 0.210

Mercury 1448 0.057 Water 1473 0.058

Nickel 5639 0.222 Zinc 4216 0.166

Nylon 2591 0.102

Sound velocity

(m/s) (in/µs) (m/s) (in/µs)

(Approx.)

(Approx.)

(Approx.)

Material

Porcelain 5842 0.230

Rubber, Vulcanised

Sound velocity

(Approx.)

2311 0.091

(Approx.)

24 THE MENU COMMANDS

Note : Certain menu commands are not accessible on some CG70 models

Menu Function Description

PRB

(PROBE)

ZERO

TRANSDUCER

Zeros your gauge in much the same way that a mechanical

micrometer is zeroed. If your gauge is not zeroed correctly,

all of the measurements made may be in error by some

fixed value.

TYPE Use this function to select the type of transducer being

used from a chart of transducer types. This provides

increased linearity between transducers.

FLAW MODE Activates the flaw detection mode and view. This feature is

for use with single element angle beam transducers and

used as a general prove-up flaw inspection mode.

PULSE Your gauge has adjustable pulse width for both high

penetration and resolution applications. The pulse width

refers to the duration of time the pulser is on. The options

are SPIKE, THIN, and WIDE.

25

Menu Function Description

en

CAL

(CALIBRATION)

DISP

(DISPLAY)

MATERIAL Select the material velocity from a chart of basic material

types when a known sample thickness, or material velocity

cannot be obtained.

ONE-POINT Performs a single point calibration. This function allows you

to automatically calculate the velocity by entering a known

sample thickness.

TWO-POINT Performs a two-point calibration. This function allows you to

automatically calculate the velocity by entering a second

known sample thickness.

UNITS Toggle between Metric (millimetres) or English (inches)

units.

VELOCITY This function calibrates your gauge by setting the velocity

to a known material velocity.

VIEW Choose between RF wave, RECT (rectified) wave, BSCAN

(cross section), and DIGITS (large digits) views.

DELAY

(B-START)

RANGE

(B-DEPTH)

Adjust where the left side of the display window starts

according to thickness, in inches or millimetres.

Set the overall depth of the viewable measurement area. It

functions a lot like a zoom on a camera.

CONTRAST Adjusts the contrast of the display

BACKLIGHT Select backlight option of OFF, ON or AUTO. In AUTO

mode the backlight is only switched on when the gauge is

making a measurement.

TUNE POLARITY The gauge operates on a zero crossing detection principle.

This feature toggles which stroke of the cycle the crossing

detection uses, either positive or negative.

GAIN Increases or decreases the overall amplitude of the signal.

Gain is similar to the volume control on a stereo receiver.

AGC When operating in E-E mode, the gauge adjusts the gain

automatically. Alternatively, the AGC can be manually

controlled.

GATE GATE 1 Sets the start of the gate, according to time/distance.

GATE 2 Set the start position of gate 2 (E-E mode only)

MEASURE

Select the measurement mode.

MODE

SET UP OPEN Displays a list of factory and user-defined setups currently

stored in memory. These setups can be recalled and used

at any time.

SAVE Save a custom setup that you have modified or created.

DEFAULT

SETUP

Loads a basic default setup. Use only as a last resort if the

setups in your gauge have been corrupted and a computer

is not accessible.

LANGUAGE Select the menu language

26

en

Menu Function Description

DATA NEW Creates a new alpha numeric grid. You can customise the

grid file according to your requirements.

EDIT Modify the parameters of grid files previously saved.

Note: Predefined coordinates cannot be changed once they

have been created.

OPEN Recalls existing grids files from gauge memory.

UTIL

(UTILITIES)

XFER

(TRANSFER)

DELETE ONE

Deletes a selected grid file from memory.

GRID

DELETE ALL

Deletes all files currently stored in memory.

GRID

AUTO FIND Automatically locates the detection point if the

measurement is out of the viewable display area.

SCAN MODE Enables a high speed scan mode that increases the overall

sample rate from 24 to 50 measurements per second,

depending on the current measurement mode used.

ALARM

Toggles alarm mode ON, OFF, or AUDIBLE.

STATUS

ALARM HIGH Sets the HI limit parameter. If the measurement exceeds

this value, a red light will illuminate and the alarm will

sound.

ALARM LOW Sets the LOW limit parameter. If the measurement falls

below this value, a red light will illuminate and the alarm will

sound.

BACKUP

SETUPS

RESTORE

SETUPS

Allows you to backup the setups currently stored in your

gauge to a computer via the RS232 port.

Allows you to restore setups saved on a computer to your

gauge via the RS232 port.

BACKUP GRID Allows you to backup grids files stored in your gauge to a

RESTORE

GRID

ABOUT Provides Elcometer NDT contact information and your

27

computer via the RS232 port.

Allows you to restore grids files saved on a computer to

your gauge via the RS232 port.

gauge software version.

Refer to the help section of your gauge NDT Link software

for a complete electronic manual covering data transfer.

26 INDEX

A

Adjusting the Gates 14

Alarm 15

Auto Find 14

B

Batteries 5

B-SCAN Measurement Screen 8

C

Calibration 11

Calibration One Point 12

Coating Calibration 12

Couplant 13

Cut/Boost 15

D

Data logger 17

Default Setup 20

Delay 9

Deleting readings 18

Digits Measurement Screen 8

Display 6

E

Echo - Echo (E-E) 10

F

Flaw Mode 16

G

Gates 10

Gauge Setups 20

Grid Log 17

O

One Point calibration 11

P

Packaging 4

Peak 17

Polarity 15

Probe Zero 11

Pulse - Echo (P-E) 10

Pulse Width 15

Pulse-Echo Coating (PECT) 10

R

RECT A-Scan Measurement Screen 8

Reset 20

RF A-Scan Measurement Screen 8

S

Saving Data 17

Scan Mode 15

Selecting menu language 6

Spike Pulse 16

Stability Indicator 7

stability indicator 13

Switching On/Off 5

T

Thin Pulse 16

Threshold 10

ThruPaint™ 10

Transducer 5

Transducer delay line 13

Tuning 15

Two Point Calibration 11

H

High Speed Scan 14

K

Known Material Calibration 12

M

Measurement Modes 10

Measurement Procedure 13

Measurement Screens 7

Memory 17

28

V

Viewable Range 8

Viewing Readings 18

W

Wide Pulse 16

Z

Zeroing 11

Loading...

Loading...