User Guide

Elcometer 510 Model S

Automatic Adhesion Tester

en

R

www.elcometer.com

1

Gauge Overview

10

Reviewing Batch Data

2

Box Contents

11

Verifying the Gauge Calibration

3

Using the Gauge

12

Menu Structure

4

Getting Started

13

Downloading Data & Upgrading Your Gauge

5

Securing the Dolly

14

Spares & Accessories

6

Attaching the Gauge to the Dolly

15

Adhesives

7

Performing the Test

16

Technical Specification

8

Assessing the Results

17

Legal Notices & Regulatory Information

9

Batching

en

R

www.elcometer.com

For the avoidance of doubt, please refer to the original English language version.

Gauge Dimensions: 260 x 100 x 66mm (10.3 x 3.9 x 2.6").

Gauge Weight: With 10mm, 14.2mm & 20mm Standard Dolly Skirt: 2.9kgs (6.4lbs); With 50mm Standard Dolly Skirt: 3.1kgs (8.3lbs)

Note: Compliance can only be assured if approved accessories are used with this product.

© Elcometer Limited 2014. All rights reserved. No part of this document may be reproduced, transmitted, transcribed, stored (in a retrieval system or otherwise) or translated into any

language, in any form or by any means (electronic, mechanical, magnetic, optical, manual or otherwise) without the prior written permission of Elcometer Limited.

TMA-0595 Issue 02 - Text with cover 24603

Pb

Hg

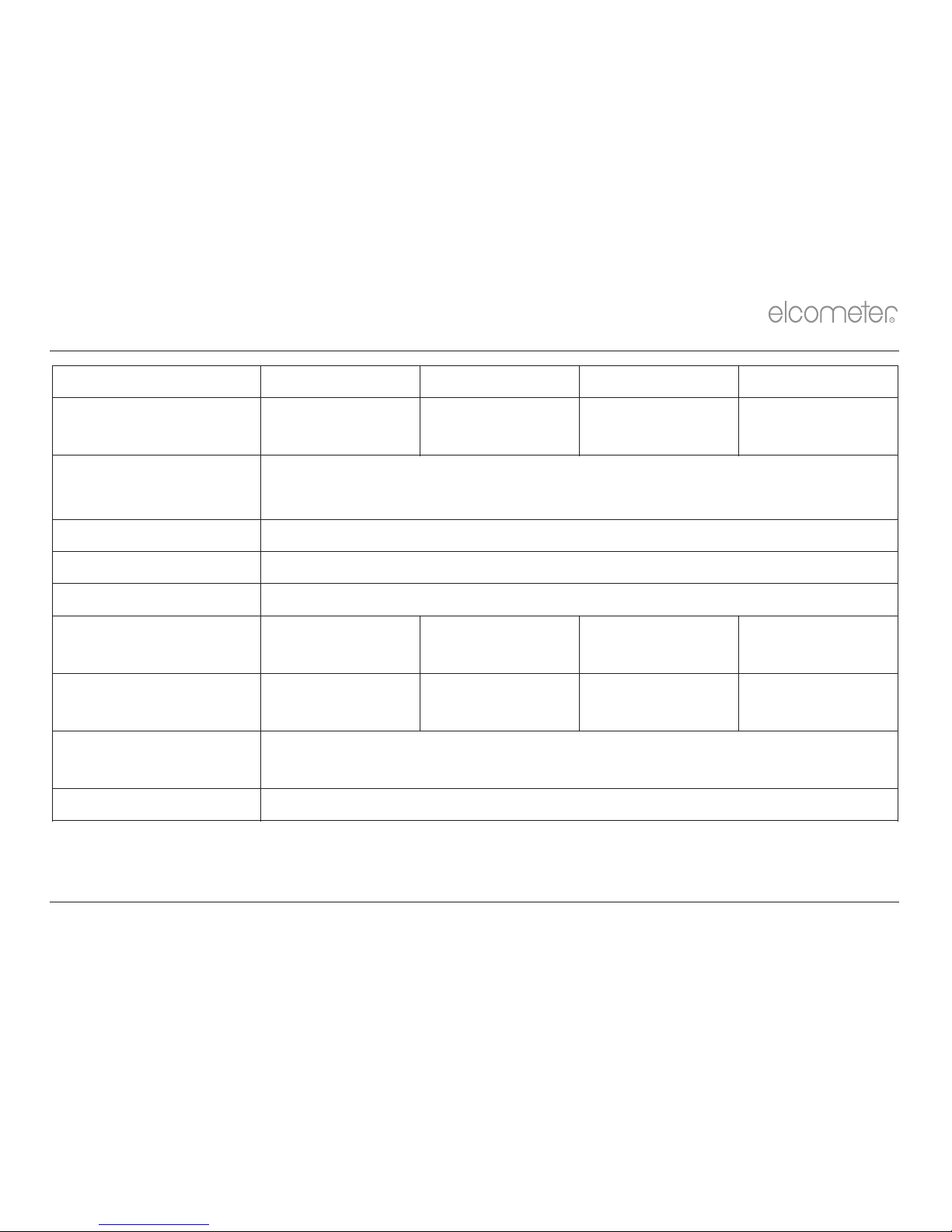

CONTENTS

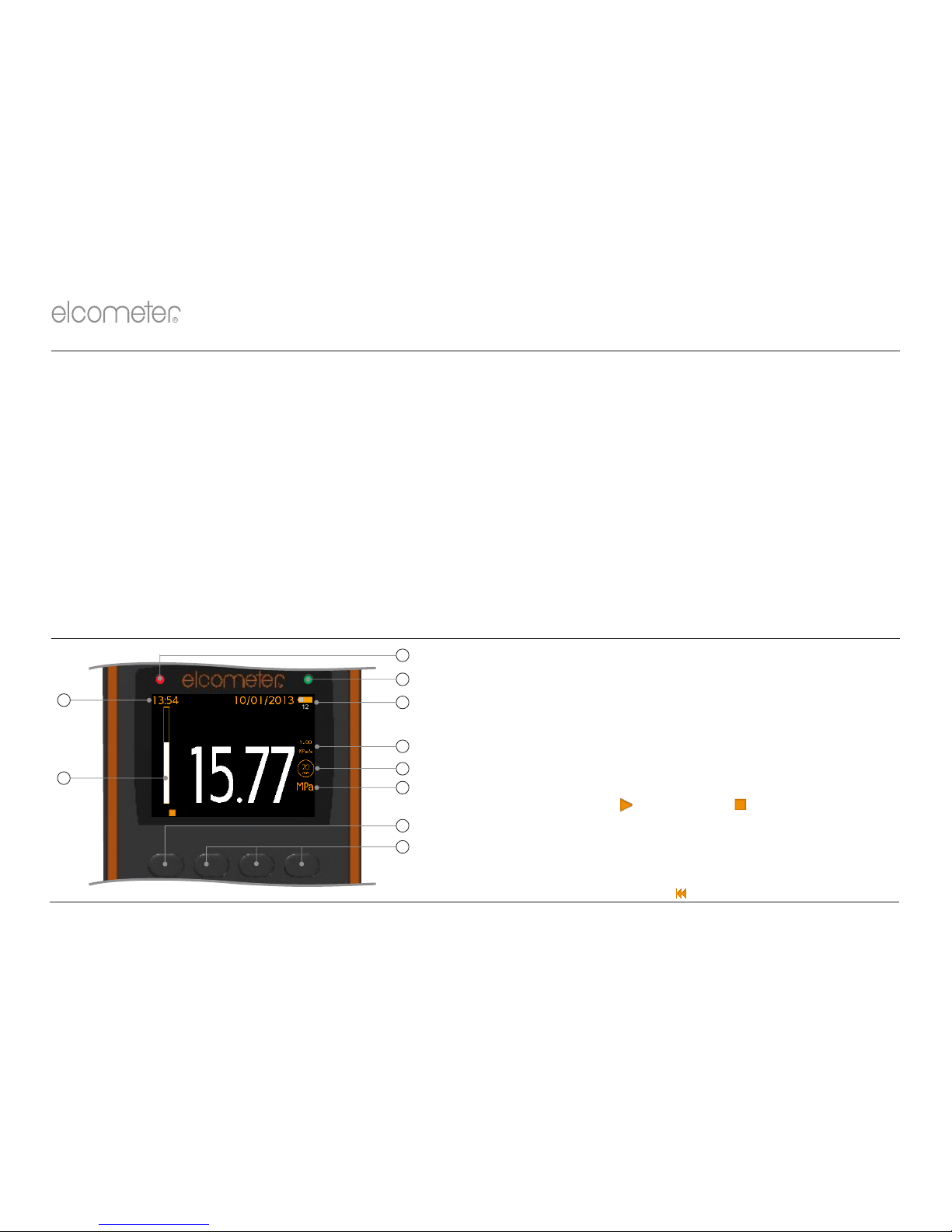

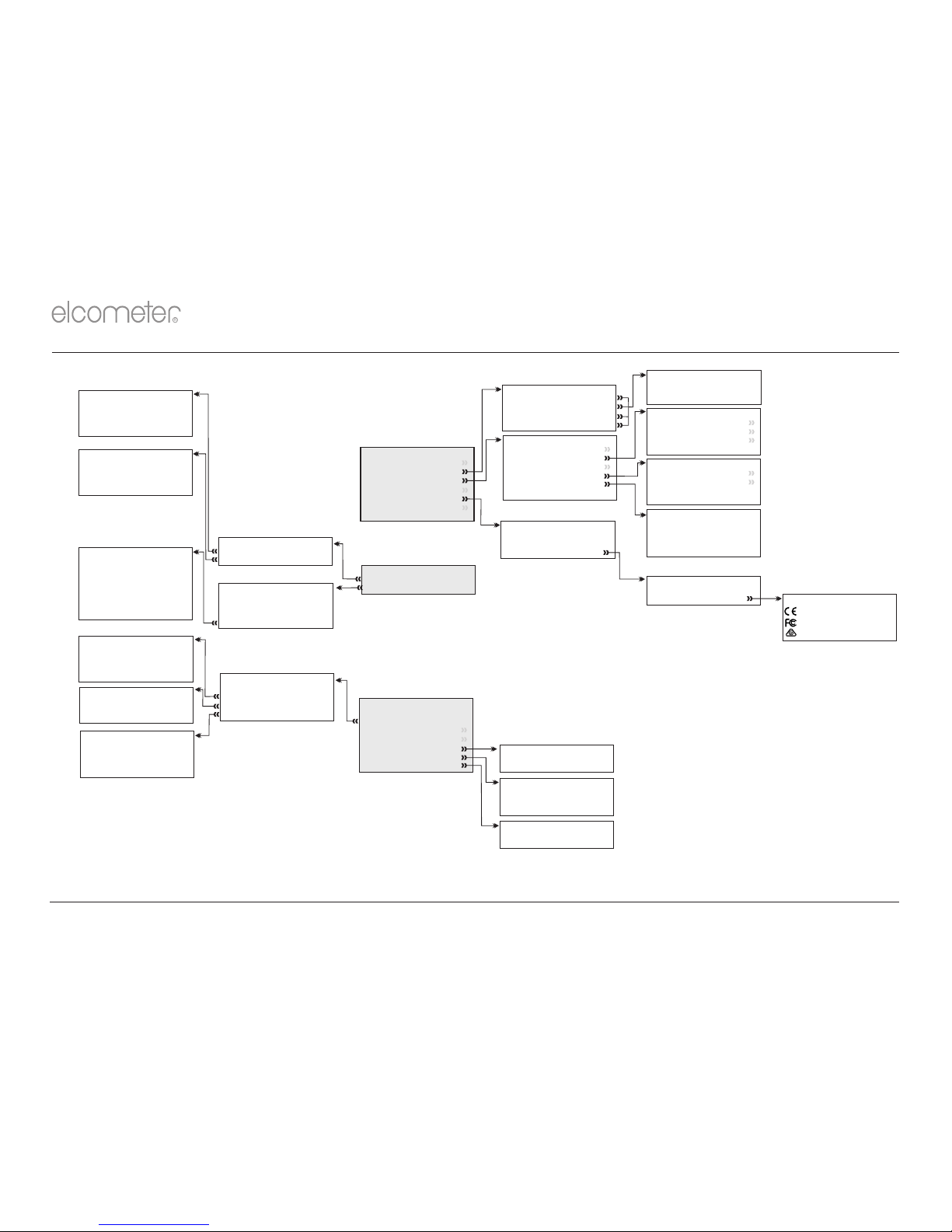

1 GAUGE OVERVIEW

www.elcometer.com

2

en

R

a

The Standard Actuator Skirt for 20mm dollies is illustrated above. Skirts for other dolly sizes and thin substrates are also available - see Section 14.3 - “Dolly Skirts” on

page 20 for details.

1 Actuator

2 Lanyard Ring

3 Shoulder Strap Connections

4 Battery Compartment

5 LED Indicators - Red (left), Green (right)

6 Multifunction Softkeys

2

1

3

4

5

6

7

8

7 On/Off Key

8 USB Data Output Socket (below cover)

9 LCD Display

a

10 Actuator Skirt

11 Quick Connect Coupling

9

10

11

<

Elcometer 510 Adhesion Tester

<

Actuator Lanyard

<

Standard Epoxy Adhesive (2x15ml tubes)

<

ElcoMaster™ 2.0 Software & USB Cable

<

Abrasive Pad

<

Carry Case

<

16 x AA Rechargeable Batteries

<

Calibration Certificate

<

8 Cell Battery Charger

<

User Guide

<

Shoulder Harness

Additional items in 20mm Kit:

Additional items in 50mm Kit:

<

20mm Dollies (x10)

<

50mm Dollies (x6)

<

20mm Dolly Standard Skirt

<

50mm Dolly Standard Skirt

<

20mm Dolly Cutter & Handle

<

50mm Dolly Cutter with Drill Arbor

2 BOX CONTENTS

www.elcometer.com3

en

R

3 USING THE GAUGE

a

Red LED

b

Green LED

c

Power: Batteries (including battery life indicator &

number of pulls remaining)

d-2Pull Rate - MPa/s, psi/s, N/s, Nmm /s

e

Dolly Size - 10mm, 14.2mm, 20mm, 50mm

f

-2

Measurement Units - MPa, psi, Newtons, Nmm

g

b b

Start Test ( ) ; Stop Test ( ) ; Menu Softkey

h

Softkeys

i

Load Bar

j

Date & Time (when enabled and not in batching)

a

g

h

b

is displayed when the gauge is rewinding.

i

j

b

c

d

e

f

3 USING THE GAUGE (continued)

en

R

www.elcometer.com

4

k

Batching On

l

Last Reading (> [greater than] symbolizes ‘Did Not Fail’)

m

Actuator Load Value

n

User Selectable Statistics - 4 rows

o

Batch Name (when in batching)

p

Run Chart - last 20 readings (user selectable)

q

Power: USB

k

n

l

m

o

p

q

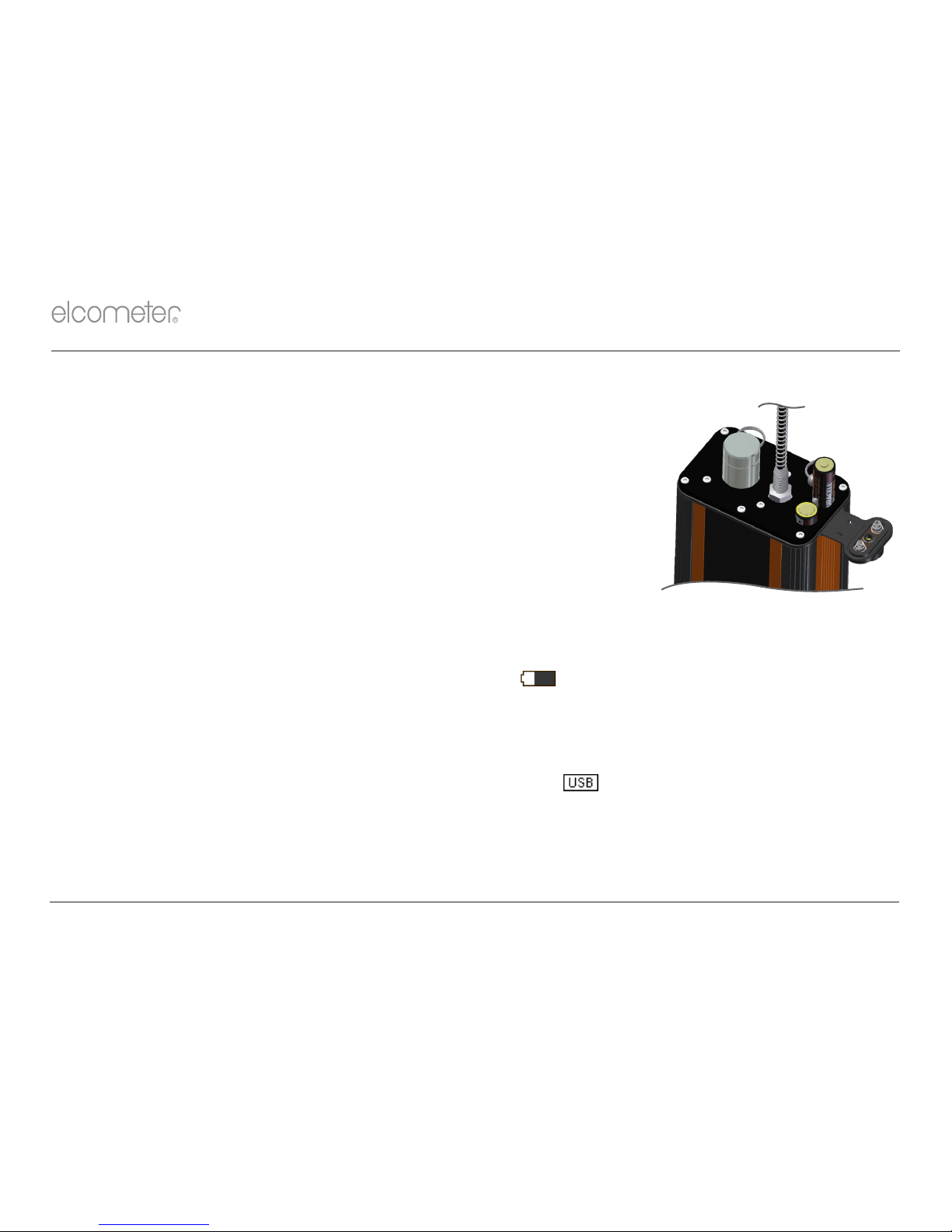

4 GETTING STARTED

4.1 FITTING THE BATTERIES

Each gauge is supplied with 16 x AA NiMH rechargeable batteries and battery charger.

To insert or replace the batteries:

1 Unscrew the battery cap (turning anti-clockwise) and remove the

battery cover.

2 Insert 8 batteries taking care to ensure correct polarity.

3 Refit the cover and tighten the battery cap.

Each fully charged set of batteries last for approximately will

200 pulls up to 25MPa (3600psi) at 1MPa/s ( psi/s) using a 20mm dolly.145

The battery charger supplied can re-charge a set of 8 cells in approximately 5 hours. Care should be

taken to ensure the correct polarity when fitting the batteries into the charger.

The battery condition is indicated by the battery symbol at the top right of the display. When ( )

there is insufficient charge remaining to perform >100 tests, an indication of the approximate number

of tests remaining - based on pulls to 25MPa (3600psi), using a 20mm dolly - is also displayed below

the battery symbol.

The LCD display can be powered via USB. When connected, is displayed at the top right of the

display allowing various functions to be undertaken including batch setup, review and transfer of data

to PC or mobile device. Pull tests can not be performed using USB as it does not provide suf ficient

power to run the adhesion gauge motor.

en

R

www.elcometer.com5

-

+

+

-

4 GETTING STARTED (continued)

4.2 SELECTING YOUR LANGUAGE

1 Press and hold the ON/OFF button until the Elcometer logo is displayed.

é

2 Press Menu/Setup/Language and select your language using the softkeys.

ê

3 Follow the on screen menus.

To access the language menu when in a foreign language:

1 Switch the gauge OFF.

2 Press and hold the left softkey and switch the gauge ON.

é

3 Select your language using the softkeys.

ê

4.3 SETTING UP THE DISPLAY

A number of screen settings can be defined by the user via Menu/Setup/Screen Settings including:

Ÿ Screen Brightness; This can be set to ‘Manual’ or ‘Auto’ - the brightness is adjusted

automatically using the gauge’s ambient light sensor.

Ÿ Screen Timeout; The display will dim if inactive for more than 15 seconds and will go ‘black’ if

inactive for the period defined. Press any key, or tap the gauge to awaken it. The gauge will also

switch off automatically after 5 minutes of inactivity if ‘Gauge Auto Off’ is enabled via Menu/Setup.

Ÿ Screen Rotation; Using the internal accelerometer, the gauge rotates the display to allow the

user to easily read the pressure value at 0° or 180° orientation (‘Auto Display Rotation’).

en

R

www.elcometer.com

6

The colour LCD display is split into two halves; Top Display and Bottom Display. The user can define

what information is displayed in each half including:

Ÿ Selected Stats; As defined by the user via Display/Statistics/Select Statistics. The user can

choose to view only those selected or view all.

Ÿ Run Chart; A line trend graph of the last 20 measurements which is updated automatically after

each reading.

Ÿ Readings; The last reading is displayed under the current pressure reading and is only updated

when the current reading is saved.

To setup the display:

1 Press Display/Setup Display/Top Display (or Bottom Display as required).

é

2 Use the softkeys to highlight the required option and press ‘Select’.

ê

If ‘None’ is selected for one half and ‘Readings’ or ‘Run Chart’ for the other half, the readings or run

chart will fill the whole the screen. If any other combination of options is selected; the data will be

shown in the top or bottom display as specified.

4.4 SELECTING THE MEASUREMENT UNITS

-2

The Elcometer 510 Model S can display pull test results in MPa, psi, Newtons or Nmm . To select the

measurement units, press Menu/Setup/Units.

4.5 SELECTING THE DOLLY SIZE & PULL RATE

Prior to performing an adhesion test, the appropriate dolly size and pull rate must be selected. The

Elcometer 510 can be used with 10mm, 14.2mm, 20mm and 50mm dollies. As the pull rate is

determined by the dolly size, the dolly size must be selected first.

4 GETTING STARTED (continued)

en

R

www.elcometer.com7

4 GETTING STARTED (continued)

To set the dolly size and pull rate:

1 Press Menu/Dolly Size & Pull Rate.

é

2 Use the softkeys to highlight the required dolly size and press ‘Select’. The ‘Pull Rate’

ê

screen will now appear.

é

3 Use the softkeys to set the pull rate as required and press ‘Ok’ to set.

ê

en

R

www.elcometer.com

8

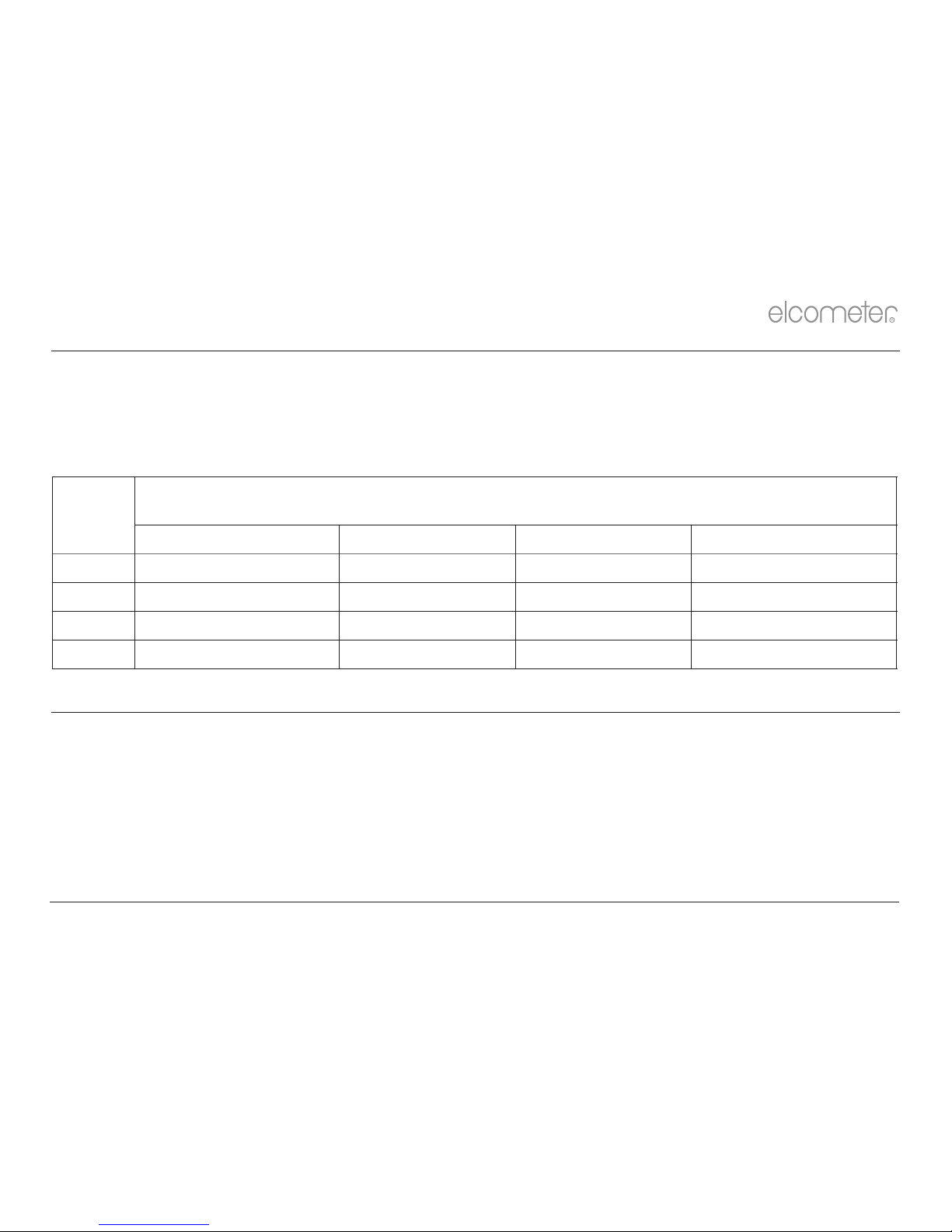

Dolly Size

Pre-defined Pull Rates

(Only the pull-rates listed below are available for selection)

MPa/s

psi/s

N/s

-2

Nmm /s

10mm

1.00, 2.00, 3.00, 4.00, 5.00

125, 200, 400, 600, 725

80, 160, 235, 315, 395

1.00, 2.00, 3.00, 4.00, 5.00

14.2mm

0.40, 0.70, 1.40, 2.00, 2.50

60, 100, 200, 300, 360

65, 110, 220, 315, 395

0.40, 0.70, 1.40, 2.00, 2.50

20mm

0.20, 0.30, 0.70, 1.00, 1.20

30, 50, 100, 150, 180

65, 95, 220, 315, 380

0.20, 0.30, 0.70, 1.00, 1.20

50mm

0.04, 0.08, 0.12, 0.16, 0.20

5, 8, 16, 24, 30

80, 160, 235, 315, 400

0.04, 0.08, 0.12, 0.16, 0.20

5 SECURING THE DOLLY

5.1 USING 10mm, 14.2mm OR 20mm DOLLIES

1 Prepare the surface of the dolly and the coating where the dolly is to be applied by roughening with

the abrasive pad. Then de-grease and clean both surfaces using a suitable solvent and allow to dry.

®

2 Mix equal quantities of the two part Araldite adhesive and apply a thin, even layer to the prepared

surface of the dolly.

4

®

Araldite adhesive is supplied by Elcometer however, other adhesives can be used - see Section 15

‘Adhesives’ on page 21.

3 Press the dolly firmly onto the prepared test surface and apply pressure to squeeze out excess

adhesive which should then be wiped clean.

en

R

www.elcometer.com9

4 Allow the adhesive to cure - see Section 15 ‘Adhesives’ on page 21.

If testing on vertical surfaces, you may wish to tape the dolly in place during cure.4

5 If required, score the coating around the dolly using the dolly cutter provided.

5.2 TESTING COATINGS ON CONCRETE USING 50mm DOLLIES

When testing coatings on concrete using 50mm dollies, scoring of the coating

down to, or into, the surface of the concrete may be required.

1 If testing on coatings thicker than 0.5 mm (20 mils) use the 50mm dolly cutter and

arbor (mounted in a drill press or hand drill) to cut a “ring” into the concrete.

Ensure that the scoring is perpendicular to the coating and that the test area is not 4

subjected to twisting or torque. To minimise heat and suppress dust, water lubrication

may be required.

2 Follow steps 1-4 in Section 5.1, making sure the dolly is positioned inside the cut

“ring”.

To score coatings thinner than 0.5 mm (20 mils), a sharp knife may be sufficient to carefully score around

the dolly once it has been secured in place by adhesive.

5 SECURING THE DOLLY (continued)

Concrete Substrate

6 ATTACHING THE GAUGE TO THE DOLLY

c

1 Pull up the quick connect coupling, place the actuator (with skirt fitted ) over the

dolly then release the coupling to grip the dolly.

4 The quick connect coupling is not a bayonet fitting. Do not attempt to push the actuator on to

the dolly without lifting the quick connect coupling.

c

Skirts for 10mm, 14.2mm, 20mm and 50mm dollies and thin substrates are available - see Se etails.ction 14.3 ‘Dolly Skirts’ on page 20 for d

en

R

www.elcometer.com

10

6 ATTACHING THE GAUGE TO THE DOLLY (continued)

When testing at height or on vertical surfaces, in order to prevent damage to the surrounding coating or harm to

the user, it may be necessary to use the Magnetic Anchor Clamp accessory, part number T99923797. This

connects to the lanyard ring on the top of the actuator to prevent the actuator from falling when the dolly is pulled

from the substrate.

1 Press and hold the ON/OFF button to switch the gauge on.

2 Ensure that the measurement units, dolly size and pull rate are set as required, see section 4.

3 Press the start softkey (4) to begin the test. Load is applied at the rate defined, displayed

numerically on the screen and illustrated on the load bar.

4 The load continues to increase at the defined rate until either:

a) the dolly pulls off;

b) the gauge maximum pull load / pressure has been reached (eg. 25MPa for a 20mm dolly)

At this point, the gauge re-winds to ‘zero’ and the user is asked if they wish to save the reading.

4 ‘---’ indicates a reading outside of range

4 If the maximum pull load / pressure has been reached, the gauge will not re-wind to ‘zero’ until the default

hold time of 0.5 seconds has elapsed.

4 The gauge re-winds to ‘zero’ at a set rate of 1.5MPa/s or equivalent.

5 Pull up the quick connect coupling to release the dolly and assess the results, see Section 8.

The stop softkey (<) can be pressed at any time during the test. If pressed, the user is asked if they

wish to save the reading and the gauge re-winds to ‘zero’. If saved, the “stopped” reading is included

in the statistics.

Dollies can be reused after cleaning until either the top of the dolly (where it is held in position by the

quick connect coupling) is severely deformed or the dolly surface is no longer flat. Additional dollies

are available from Elcometer or your local supplier - see Section 14.1 - ‘Dollies’ on page 18 for

details.

7 PERFORMING THE TEST

8.1 EXAMINING THE DOLLY

a) Cohesive Failure: The coating fails within the body of a

coating layer leaving the same coating on the surface and on

the dolly face.

b) Adhesive failure: Is a failure at the interface between layers

(intercoat) where one pulls away from the other. The

“coating” on the dolly face will not be the same as that on the

test area.

c) Glue failure: When no coating is present on the dolly it must be

recorded as a failure of the glue. This is normally due to

incorrect or insufficient mixing of the component parts of the

adhesive, incompatibility between the adhesive, the coating,

the dolly, and / or the test surface - see Section 5 - ‘Securing

the Dolly’ on page 8 for more information.

8 ASSESSING THE RESULTS

en

R

www.elcometer.com11

Dolly Face

Substrate

a) 100% Cohesive Failure

b) 100% Adhesive Failure Between Two

Layers

c) Glue Failure

Layer 2

Substrate

Glue

Dolly Face

Key

Layer 1

Layer 3

Many National and International Standards including ISO 4624 & ASTM D4541, require the user to

record not only the pull-off force but also the nature of the fracture by examining the bottom of the dolly

and assessing the adhesive / cohesive failure.

en

R

www.elcometer.com

12

8 ASSESSING THE RESULTS (continued)

8.2 EXAMINING THE DOLLY (COATINGS ON CONCRETE)

When testing coatings on concrete it is common for the adhesive bond

between the coating and the concrete to exceed the strength of the

concrete itself. In this case concrete will be removed from the surface

and will be seen on the coating on the dolly face.

Observing the test area will give additional information about the type of

failure; adhesion and cohesion between different layers of the coating.

Adhesive

Failure

Partial Coating

Failure

Concrete

Failure

Coating

Failure

9 BATCHING

9.1 BATCH FUNCTIONS

The Elcometer 510 Model S gauge can store up to 60 readings in one batch and has the following

batching functions:

Ÿ Batch/New Batch; Create a new batch - see Section 9.2 for further information.

Ÿ Batch/Open Existing Batch; Open an existing batch.

Ÿ Batch/Edit Batch/Clear Batch; Clear all readings within the batch - but leaving all batch header

information.

Ÿ Batch/Review Batch; Review the readings, statistics and batch information - see Section 10 for

further information.

Ÿ Batch/Edit Batch/Delete Batch; Delete the batch entirely from the gauge.

en

R

www.elcometer.com13

9 BATCHING (continued)

Ÿ Batch/Deleted Reading/Delete without Tag; Delete the last reading entirely.

Ÿ Batch/Deleted Reading/Delete with Tag; Delete the last reading but mark it as deleted in the

batch memory.

9.2 CREATING A NEW BATCH

Many Standards require the user to record not only the pull-off force and the nature of the fracture but

also details of the test equipment used; if a support ring was used and its dimensions, if, and by what

means, the coating was cut around the dolly.

This additional information is recorded within the batch header and can be transferred to PC to be

included on any report within ElcoMaster. For further information on ElcoMaster™ 2.0, visit

www.elcometer.com.

To create a new batch select Batch/New Batch and add the following criteria as required:

Ÿ Dolly Size & Pull Rate; (Batch/New Batch/Dolly Size & Pull Rate)

Ÿ Cutting Device; the type of cutting device used, if any, to score the coating around the dolly;

(Batch/New Batch/Cutting Device)

Ÿ The dolly skirt type; (Batch/New Batch/Skirt Type)

- Select ‘20mm Standard’ for Standard Skirt for 10, 14.2 and 20mm dollies;

- Select ‘50mm Standard’ for Standard Skirt for 50mm dollies;

- Select ‘14.2mm Thin Substrate’ for Thin Substrate Skirt for 14.2mm dollies;

- Select ‘20mm Thin Substrate’ for Thin Substrate Skirt for 20mm dollies;

Note: A new batch can not be created if a batch already exists. The existing batch must be deleted first.

en

R

www.elcometer.com

14

9 BATCHING (continued)

Note: The Elcometer 510 dolly skirt has an integrated support ring, therefore

identifying the dolly skirt used records the use of a support / bearing ring as

required by some standards, together with the support ring dimensions - see

Section 14.3 ‘Dolly Skirts’ on page 20 for dimensions.

These details can be added and amended until the first reading has

been stored in the batch after which no changes can be made.

This information is saved in the batch header and can be viewed at any

time via Batch/Review Batch/Batch Information.

Batch Information

Batch 1

Created

Date Last Verified

Time Last Verified

Pull Rate

Dolly Size

Cutting Device

Skirt Type

Back

15:31

28/11/2013

25/11/2013

12:49

1.00 MPa/s

20 mm

Dolly Cutter

20 STD

é

é

10.1 BATCH STATISTICS (Batch/Review Batch/Statistics)

Displays statistical information for the batch including:

Ÿ Number of readings in the batch ( )

Ÿ Average reading for the batch ( )

Ÿ Lowest reading in the batch ( )

Ÿ Highest reading in the batch ( )

Ÿ Range ( ); the difference between the highest and lowest reading

in the batch

Ÿ Standard Deviation ( )

Ÿ Coefficient of Variation ( )

10 REVIEWING BATCH DATA

Statistics

Batch 1

Back Zoom+

6

4.01

5.99

32.9

7.592

10.00

2.498

en

R

www.elcometer.com

15

Note: The calculation of standard deviation is based on the distribution of individual fracture strength values being

normal, that is forming a normal curve when plotted as a frequency chart. If adhesion values for pulls that are not

completed are included in the calculation, i.e. pulled to a limit value or maximum and not to fracture, the

distribution will not be normal and the standard deviation calculation will not be mathematically correct. For the

purpose of assessing the distribution of values in this case, however, the calculation will be included as though all

the dollies were pulled to coating failure and it should be noted that the resulting calculation is for guidance only .

10.2 BATCH READINGS (Batch/Review Batch/Readings)

Displays all measurement data for each individual reading within the batch including:

Ÿ The reading value;

Ÿ Date and time stamp for each test;

Ÿ Test duration.

Note: The test duration includes the hold time but does not include the time it takes for the gauge to re-wind to ‘zero’.

é

Press the softkeys to scroll through the readings and è to move to the next information screen.

ê

10 REVIEWING BATCH DATA (continued)

Readings

Batch 1

1

2

3

4

5

6

Back

10.02 MPa

5.17 MPa

7.86 MPa

4.01 MPa

8.51 MPa

10.00 MPa

é

é

é

Readings

Batch 1

1

2

3

4

5

6

Back

14:00:39

14:01:06

14:02:05

14:03:57

14:06:33

14:08:41

10/01/14

10/01/14

10/01/14

10/01/14

10/01/14

10/01/14

é

é

é

Readings

Batch 1

1

2

3

4

5

6

Back

31.25 Seconds (s)

31.42 Seconds (s)

30.90 Seconds (s)

32.14 Seconds (s)

31.83 Seconds (s)

31.19 Seconds (s)

é

é

é

15

en

R

www.elcometer.com

16

The Elcometer 510 is factory calibrated. The calibration of the gauge can be verified in

the field using the Elcometer Adhesion Verification Unit (AVU), part number

T99923924C and the Elcometer 510 Verify Calibration wizard, Menu/Verify Calibration.

To verify the calibration:

é

1 Select Menu/Verify Calibration and use the softkeys to highlight the

ê

required the dolly size; 20mm or 50mm. Press ‘Ok’ to select.

2 Switch on the Elcometer AVU and ensure that the appropriate dolly

adaptor is fitted and the measurement units are the same as the

Elcometer 510 (refer to the instructions supplied with the Elcometer AVU).

3 Connect the Elcometer 510 actuator (with skirt fitted) to the Elcometer

AVU dolly adaptor.

4 Press ‘Ok’ on the Elcometer 510 when connected. The Elcometer 510

automatically starts to apply pressure until the first test load is reached.

5 Compare the test load with the reading on the Elcometer AVU display. If the

Elcometer AVU reading is within the acceptable range, displayed in brackets

underneath the test load, press ‘Ok’ to proceed to the next test pressure and

repeat step 4. (If outside the acceptable range, re-calibration is

recommended. Press ‘Escape’ to exit the calibration verification procedure

and contact Elcometer or your local supplier for further information).

6 , if it When the final test load has been reached is within the acceptable range, press ‘Verify’ to update

the gauge or ‘Escape’ to cancel. The date and time of the last verification procedure is recorded against

each batch and can be viewed via Batch/Review Batch/Batch Information.

Note: The acceptable range is based on the ‘system’ accuracy - the accuracy of the Elcometer 510 and Elcometer AVU

unit combined. Measurement verification points: 20mm Dolly; 5, 15 & 25MPa, 50mm Dolly; 0.8, 2.4 & 4.0MPa (or

equivalent units)

11 VERIFYING THE GAUGE CALIBRATION

Verify Calibration

5.00 MPa

(4.72 - 5.28 MPa)

Press Escape To Cancel

Ok To Continue

Escape Ok

en

R

www.elcometer.com17

12 MENU STRUCTURE

Menu

Delete Last Reading

Dolly Size / Pull Rate

Setup

Verify Calibration

About

Reset

Emergency Light

Setup

Language

Time and Date

Beep Volume

Screen Settings

Units

Gauge Auto Off

Time and Date

Set Time

Set Date

Set Format

Display Time and Date

○

Screen Settings

Screen Brightness

Screen Timeout

Opening Screen

Screen Rotation

○

○

Units

MPa

psi

Newtons

2

N/mm

○

○

○

○

○

About

Gauge Information

Contact

Legal

Legal

Legal Notices

Regulatory

Display

Setup Display

Statistics

Setup Display

Top Display

Bottom Display

Top Display

None

Selected Stats

Run Chart

Readings

○

○

○

○

Statistics

Clear Statistics

View Selected

View All

Select Statistics

○

○

○

Select Statistics

Number of Readings

Mean

Lowest Reading

Highest Reading

Range

Standard Deviation

Coefficient of Variation

○

○

○

○

○

○

○

Batch

Memory Free xx.x%

New Batch

Open Existing Batch

Exit Batching

Edit Batch

Review Batch

Deleted Reading

New Batch

Open Batch n

Dolly Size & Pull Rate

Cutting Device

Skirt Type

Dolly Size

10 mm

14.2 mm

20 mm

50 mm

○

○

○

○

Cutting Device

None

Dolly Cutter

Knife

○

○

○

Skirt Type

Standard 20 mm

Standard 50 mm

Thin Substrate 14.2 mm

Thin Substrate 20 mm

○

○

○

○

Edit Batch

Clear Batch

Delete Batch

Review Batch

Statistics

Batch Information

Readings

Deleted Reading

Delete With Tag

Delete Without Tag

○

○

Dolly Size

10 mm

14.2 mm

20 mm

50 mm

○

○

○

○

Pull Rate

x.xx

MPa/s

Regulatory

xxxxx

xxxxx

xxxxx

Bottom Display

None

Selected Stats

Run Chart

Readings

○

○

○

○

R

www.elcometer.com

18

en

13.1 DOWNLOADING DATA USING ELCOMASTER™ 2.0

Using ElcoMaster™ 2.0 - supplied with each gauge, and available as a free download at

elcometer.com - gauges can transmit readings via USB to a PC for archiving and report generation.

For more information on ElcoMaster™ 2.0 visit www.elcometer.com

13.2 UPGRADING YOUR GAUGE

Gauge firmware can be upgraded to the latest version by the User via ElcoMaster™ 2.0, as they

™

become available. ElcoMaster 2.0 will inform the User of any updates when the gauge is connected

to the PC with an internet connection.

13 DOWNLOADING DATA & UPGRADING YOUR GAUGE

14 SPARES & ACCESSORIES

14.1 DOLLIES

The Elcometer 510 can be used with a range of dollies, also referred to as test elements or stubs.

d

10, 14.2, 20 and 50mm diameter dollies are available to purchase as an optional accessory .

10mm: ideal for testing up to 100MPa (14400psi) on very small surface areas.

14.2mm: ideal for testing on small surface areas, for measurements over 25MPa (3600psi) and

suitable for use on some curved surfaces.

20mm: suitable for use on a variety of coatings / substrates.

50mm: Coatings on concrete, cementitious layers and uneven surfaces can be tested more

effectively with the larger 50mm dolly. Our 50mm dollies are also available in stainless

steel as required for testing in accordance with DIN 1048 part 2 and BS EN 12636.

d

Please ensure the appropriate dolly skirt is fitted. See Section 6 - ‘Attaching the Gauge to the Dolly’ and Section 14.3 - ‘Dolly Skirts’ on pages 9 and 20 for

further information.

en

R

www.elcometer.com19

14 SPARES & ACCESSORIES (continued)

Description Sales Part Number

Aluminium Dolly 10mm (x10) T5100010AL-10

Aluminium Dolly 10mm (x100) T5100010AL-100

Aluminium Dolly 14.2mm (x10) T9990014AL-10

Aluminium Dolly 14.2mm (x100) T9990014AL-100

Aluminium Dolly 20mm (x10) T9990020AL-10

Aluminium Dolly 20mm (x100) T9990020AL-100

Aluminium Dolly 50mm (x4) T9990050AL-4

Stainless Steel Dolly 50mm (x4) T9990050SS-4

14.2 DOLLY CUTTERS

Standards or test methods will determine if the Inspector should cut / score around the dolly prior to

test to separate the test area from the rest of the coating; information which should be recorded with

the results.

The Elcometer 510 is supplied with a dolly cutter and handle appropriate for the dolly size included in

the kit. Spare / replacement cutters are available to purchase using the sales part numbers below.

Description For Dolly Sizes (mm) Sales Part Number

Dolly Cutter 14.2mm T9990014CT

Dolly Cutter 20mm T9990020CT

Dolly Cutter 50mm T9990050CT

Dolly cutter handles must be ordered separately - a handle is not supplied with the dolly cutter

accessory.

R

www.elcometer.com

20

en

Description For Dolly Cutter Sales Part Number

Dolly Cutter Handle T9990014CT / T9990020CT T9991420H

Dolly Cutter Arbor T9990050CT T9990050H

14.3 DOLLY SKIRTS

Standard skirts are available for 10mm, 14.2mm and 20mm dollies as well as 50mm dollies. Special

skirts are also available for testing on thin substrate to even out the load, as using a standard skirt on a

thin substrate may cause the substrate to bend or flex during test.

14 SPARES & ACCESSORIES (continued)

Description For Dolly Sizes (mm) Integrated Support Sales Part Number

Ring Dimensions

† ‡

I/D O/D

Standard Skirt 10mm, 14.2mm & 20mm 30mm 40.4mm T999101420S

Thin Substrate Skirt 14.2mm T9990014T16.3mm 40.4mm

Thin Substrate Skirt 20mm T9990020T21mm 40.4mm

Standard Skirt 50mm T9990050S52mm 72mm

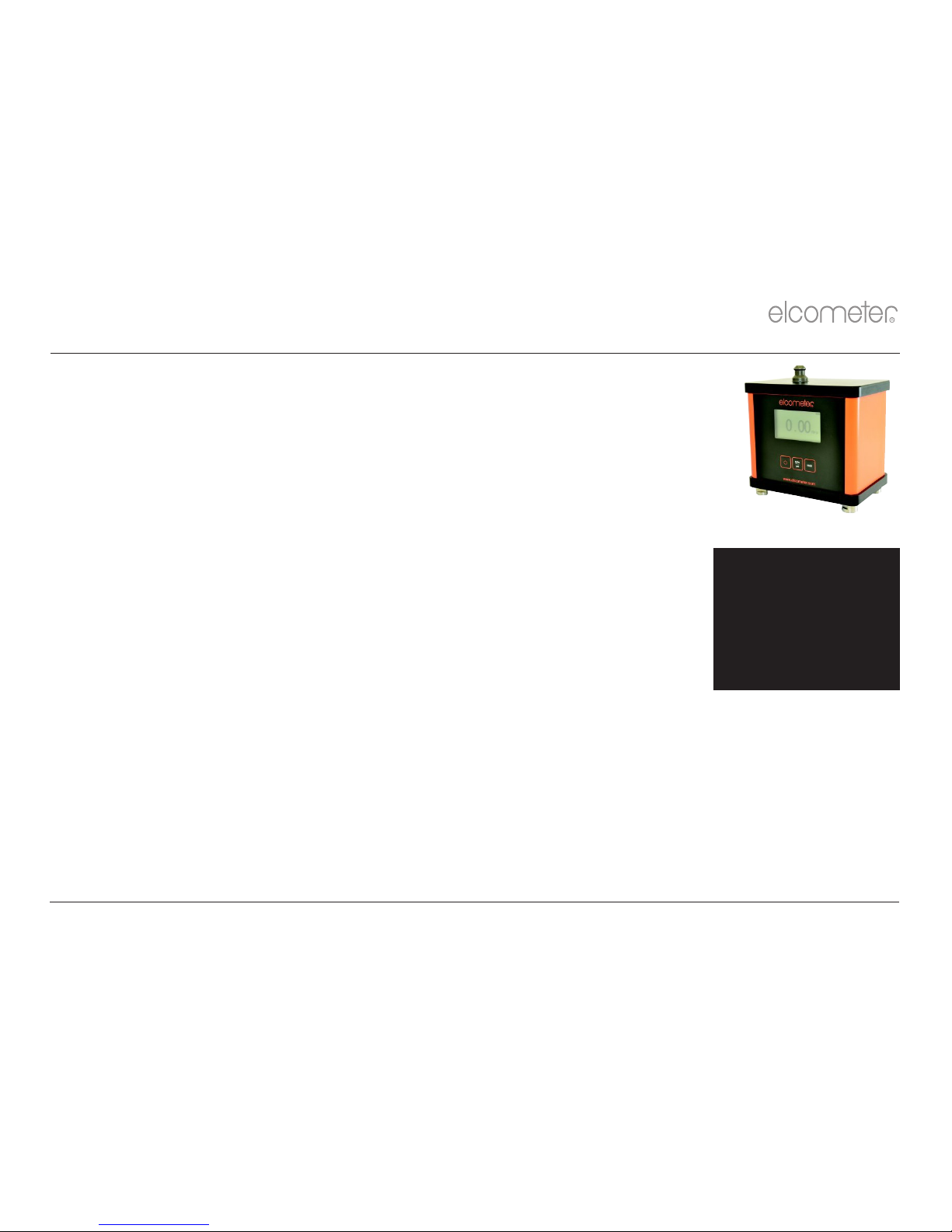

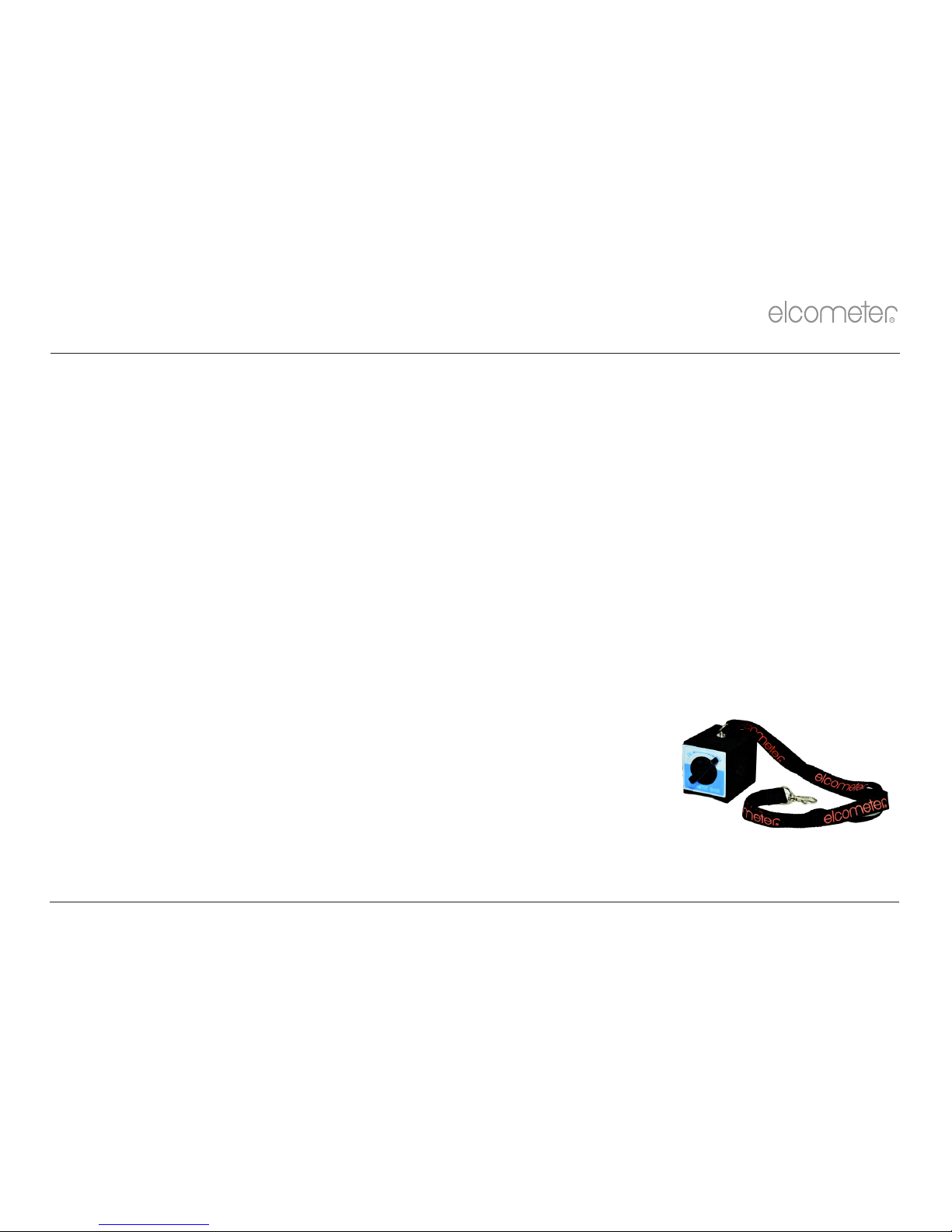

14.4 MAGNETIC ANCHOR CLAMP

Ideal when testing at height or on vertical surfaces to prevent damage to

the surrounding coating or harm to the user, the magnetic anchor clamp

connects to the lanyard ring on the top of the actuator to prevent the

actuator from falling when the dolly is pulled from the substrate.

Description Sales Part Number

Magnetic Anchor Clamp Accessory T99923797

† ‡

I/D: Inner Diameter O/D: Outer Diameter

en

R

www.elcometer.com21

15 ADHESIVES

The adhesive supplied with the Elcometer 510 is Araldite Standard, a two-pack epoxy paste which is

®

mixed from approximately equal volumes of the two components. Measurement by eye is sufficient.

When mixed it should be used within one hour. Curing Times: 24 hours at 25°C (77°F);

3 hours at 60°C (140°F)

Araldite is suitable for warm and hot environments. Lower temperatures can require extended curing

®

times of up to 3 days or more. The expiry date of the adhesive should be checked before use.

Adhesive which has expired should not be used.

Unused adhesive must be disposed of as special waste unless it has been fully cured. To dispose of

excess adhesive at the end of its shelf life simply mix the remaining material and allow it to cure before

disposal.

Description Sales Part Number

Araldite Standard Two Part Epoxy Adhesive; 2x15ml Tubes T99912906

®

A Material Safety Data Sheet for adhesive supplied by Elcometer can be downloaded via our website:

Araldite Standard Two Part Epoxy Adhesive: www.elcometer.com/images/MSDS/araldite_epoxy_adhesive.pdf

®

Note: Other suitable adhesives include Loctite Hysol 907 and 3M™ Scotch-Weld™ Epoxy Adhesive.

® ®

The suitability of any adhesive should be determined by the user. Some coatings can be adversely affected by

adhesives. Some adhesives can be contaminated by coating environments, solvents etc.

en

R

www.elcometer.com

22

Dolly Diameter

10mm

14.2mm

20mm

50mm

Operating Range

8 - 100MPa

(1200 - 14400psi)

4 - 50MPa

(600 - 7200psi)

2 - 25MPa

(300 - 3600psi)

0.3 - 4.0MPa

(50 - 580psi)

Operating Temperature

Range

-10 to 50°C (14 to 122°F); Humidity: 0 - 95% RH

Pressure Rating

26MPa (3800psi)

Pressure Resolution

0.01MPa (1psi)

Pressure Accuracy

±1% of full scale

Pull Rate Range

1.0 - 5.0MPa/s

(125 - 725psi/s)

0.4 - 2.5MPa/s

(60 - 360psi/s)

0.2 - 1.2MPa/s

(30 - 180psi/s)

0.04 - 0.20MPa/s

(5 - 30psi/s)

Pull Rate Setting

Resolution

0.1MPa/s

(1psi/s)

0.1MPa/s

(1psi/s)

0.1MPa/s

(1psi/s)

0.01MPa/s

(0.1psi/s)

Pull Rate Display

Resolution

0.01MPa (1psi)

Pull Rate Accuracy

± (2.5% + 0.3 seconds) over time of test

16 TECHNICAL SPECIFICATION

en

R

www.elcometer.com23

Dolly Diameter

10mm

14.2mm

20mm

50mm

Gauge Memory

Up to 60 readings in one batch

Power Supply

e

8 x AA NiMH batteries

Battery Life

200 pulls per charge up to 25MPa (3600psi) at 1MPa/s (150psi/s)

Instrument Weight

2.9kg (6.4lb)

2.9kg (6.4lb)

2.9kg (6.4lb)

3.1kg (8.3lb)

Kit Weight

n/a

n/a

6.1kg (13.5lb)

7.3kg (16.1lb)

Instrument Length

260mm (10.3")

Actuator Height

85mm (3.4")

(10mm skirt fitted)

85mm (3.4")

(14.2mm skirt fitted)

85mm (3.4")

(20mm skirt fitted)

110mm (4.3")

(50mm skirt fitted)

Can be used in accordance with:

ASTM C1583, ASTM D4541, ASTM D7234-12, AS/NZS 1580.408.5, BS 1881-207, DIN 1048-2, EN 1015-12,

EN 12636, EN 13144, EN 1348, EN 1542, EN 24624, ISO 16276-1, ISO 4624, NF T30-606, NF T30-062

16 TECHNICAL SPECIFICATION (continued)

e

The numbe r of pulls rema ining with a ba ttery charge is calculated using the NiHM batteries supplied. Alternative AA batteries (alkaline for example), can be

used but will affect battery performance and the accuracy of the “pulls remaining” indication.

en

R

www.elcometer.com

24

This product meets the Electromagnetic Compatibility Directive

The product is Class B, Group 1 ISM equipment according to CISPR 11

Group 1 ISM product: A product in which there is intentionally generated and/or used conductively coupled radio-frequency energy which is necessary for the internal

functioning of the equipment itself.

Class B product are suitable for use in domestic establishments and in establishments directly connected to a low voltage power supply network which supplies buildings

used for domestic purposes.

The USB is for data transfer only and is not to be connected to the mains via a USB mains adapter.

The ACMA compliance mark can be accessed via: Menu/About/Legal/Regulatory

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will

not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

-- Reorient or relocate the receiving antenna.

-- Increase the separation between the equipment and receiver.

-- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

-- Consult the dealer or an experienced radio/TV technician for help.

Modifications not expressly approved by Elcometer Limited could void the user's authority to operate the equipment under FCC rules.

This Class B digital apparatus complies with Canadian ICES-003.

is a registered trademark of Elcometer Limited, Edge Lane, Manchester, M43 6BU. United Kingdom

All other trademarks acknowledged.

R

17 LEGAL NOTICES & REGULATORY INFORMATION

en

R

www.elcometer.com25

Loading...

Loading...