Page 1

R

User Guide

Elcometer 224

Surface Profile Gauge

www.elcometer.com

Page 2

Section

Page

1

Gauge Overview

en-2

2

Box Contents

en-2

3

Using the Gauge

en-3

4

Getting Started

en-4

5

Taking a Reading

en-6

6

Calibrating & Testing the Gauge Calibration

en-7

7

Batching - Model T

en-9

8

Displaying Graphs

en-9

9

Menu Structure - Model B

en-10

10

Menu Structure - Model T

en-11

11

Downloading Data & Upgrading Your Gauge

en-12

12

Technical Specification

en-13

13

Elcometer 224 Separate Probes

en-13

14

Legal Notices & Regulatory Information

en-14

CONTENTS

R

Pb

These operation instructions are a short User Guide only. A copy of both this Instruction Manual and an English

language extended version are available for download on our website elcometer.com. For the avoidance of doubt,

please refer to the original English language version.

Gauge Dimensions: Integral: 168 x 73 x 37mm (6.61 x 2.87 x 1.46")

Separate: 141 x 73 x 37mm (5.55 x 2.87 x 1.46")

Gauge Weight: Integral: 218g (7.69oz) including batteries

Separate: 161g (5.68oz) including batteries

Applicable Patents: GB2505193, US9261345

© Elcometer Limited 2012 - 201 . All rights reserved. No part of this document may be reproduced, transmitted, 9

transcribed, stored (in a retrieval system or otherwise) or translated into any language, in any form or by any

means (electronic, mechanical, magnetic, optical, manual or otherwise) without the prior written permission of

Elcometer Limited.

en-1

Hg

www.elcometer.com

Page 3

1 GAUGE OVERVIEW

<

Elcometer 224 Surface Profile Gauge

<

Calibration Test Foils; Nominal Values 125 & 500µm and

a

Glass Zero Tile (Integral gauges)

<

a

Probe Protection Cap (Integral gauges)

<

Wrist Harness

<

Protective Case (Model B)

<

Transit Case (Model T)

<

1 x Screen Protector

<

2 x AA Batteries

<

®

USB Cable & ElcoMaster Software (Model T)

<

Test Certificate

<

User Guide

1 LED Indicators -

Red (left), Green (right)

R

9

2 Colour Screen

3 Multifunction Softkeys

4 On/Off Key

5 Separate Probe

Connection

6 Internal Probe

7 Wrist Strap Connection

8 Battery Compartment

(¼ turn open/close)

9 USB Data Output Socket

(below cover)

1

2

8

3

7

6

4

5

2 BOX CONTENTS

a

For separate gauges, the test foils, glass zero tile and probe protection cap are supplied with the

separate probe.

www.elcometer.com

en-2

Page 4

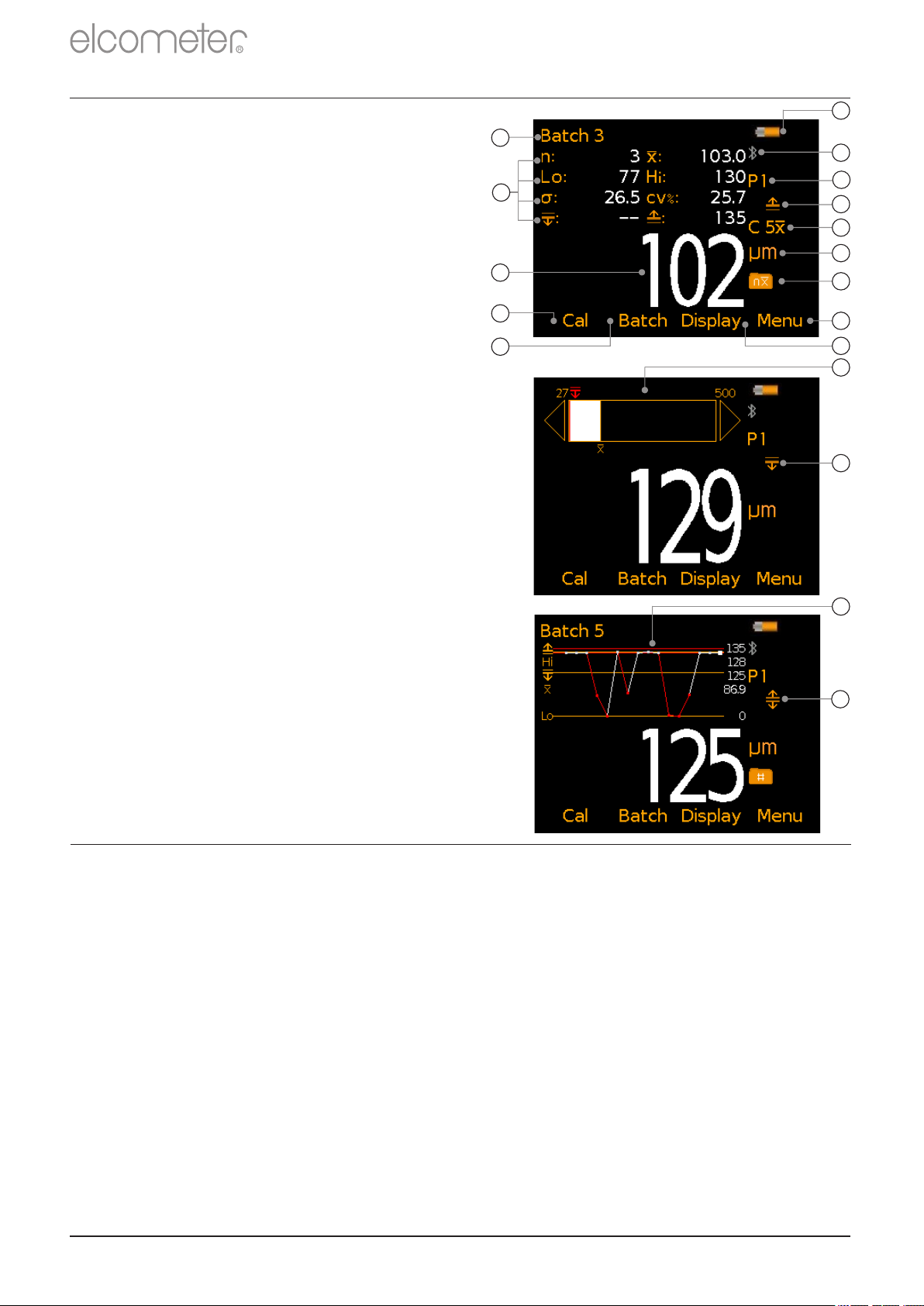

Model

a

Battery Life Indicator

BT

b

Bluetooth On - Grey: not

connected; Orange: connected

T

c

Probe Scale

BT

d

Upper Limit On

T

e

#

Measurement Mode

BT

f

Units of Measurement -

µm, mils, mm, inch

BT

g

Batch Type -

normal, counted average

T

h

Menu Softkey

BT

i

Display Softkey

BT

j

Batch Softkey

BT

k

Calibration Softkey

BT

l

Reading Value

BT

m

User Selectable Statistics -

4 rows

BT

n

Batch Name (when in Batching)

T

o

Bar Graph - highest, lowest &

average reading

BT

p

Lower Limit On

T

p

Run Chart - last 20 readings

TrUpper & Lower Limits On

T

R

3 USING THE GAUGE

a

n

b

m

l

c

d

e

f

g

k

j

h

i

o

p

q

r

4 GETTING STARTED

4.1 ENSURING YOUR GAUGE HAS THE LATEST FIRMWARE &

UPGRADING YOUR GAUGE

To ensure that your gauge has the most up-to-date gauge firmware,

allowing you to benefit from the latest features and functionality, we

recommend that the gauge is connected to ElcoMaster on a regular

basis and before first use.

Simply connect the gauge via USB to an internet connected computer

running ElcoMaster using the ‘Connect Gauge’ feature. If a later

version of the gauge firmware is available, ‘Update Gauge’ will be

displayed to the right of the gauge details. Click ‘Update Gauge’ to

install the latest firmware.

#

The icon displayed depends on the measurement mode selected. If ‘Immediate’ mode is selected, no

icon is displayed. See Section 4.4 ‘Selecting the Measurement Mode’ on page en-4 for further

information.

en-3

®

®

www.elcometer.com

Page 5

4 GETTING STARTED (continued)

Icon Displayed

Measurement Mode

None

continued...

Immediate: Allows the users to take single measurements

which are displayed on the gauge (Model B & T) and saved

into the batch memory (Model T only).

Note: This mode allows gauges to be used and measurements to be taken

in the same way as older Elcometer 224 models.

4.2 SELECTING YOUR LANGUAGE

1 Press and hold the / button until the Elcometer logo is ON OFF

displayed.

2 Select your language using the softkeys.

é

ê

3 Follow the on screen menus.

To access the language menu when in a foreign language:

1 Switch the gauge .OFF

2 Press and hold the left softkey and switch the gauge .ON

3 Select your language using the softkeys.

é

ê

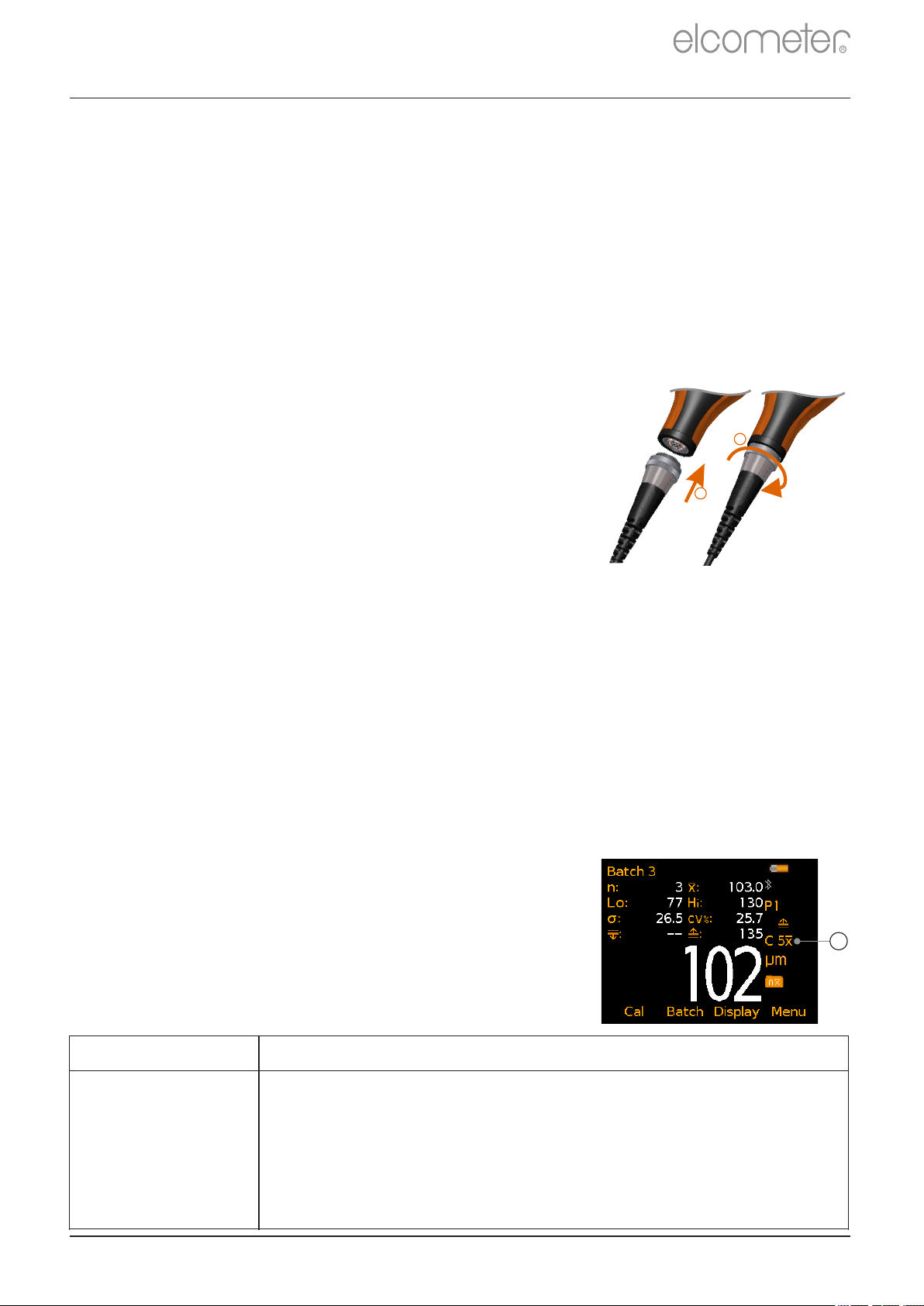

4.3 CONNECTING THE PROBE -

R

SEPARATE GAUGES ONLY

1 Rotate the probe plug to align the pins.

2

2 Screw in the collar - clockwise.

1

See Section 13 ‘ Elcometer 224 Separate Probes’

on page en-13 for details of the probes available.

4.4 SELECTING THE MEASUREMENT MODE

The Elcometer 224 has a choice of three measurement modes;

‘Immediate’, ‘Custom’ and ‘Standards’ - see the table below for an

explanation of the different modes available. The mode selected

depends on which International Standard the user is working in

accordance with.

To select the measurement mode:

1 Press Menu/Setup/Measurement Mode or when in batching

(Model T only), Batch/New Batch/Measurement Mode.

2 Use the softkeys to select the required measurement mode.

é

ê

The measurement mode selected and in use, is

indicated by the icon shown on the right of the

display (a). If no icon is displayed, ‘Immediate’

Mode is in use.

www.elcometer.com

a

en-4

Page 6

R

Icon Displayed

Measurement Mode

C 5x, C 10x

C 5H, C 10H

C 5L, C 10L

Custom: The user can choose to take either 5 or 10

readings and can choose to display on the gauge

(Model B & T) and save into the batch memory (Model T

only), the mean/average, highest or lowest measurement

of each set of readings.

Standards:

Select from AS 3894.5, ASTM 4417-B or SANS 5772

AS

AS 3894.5 (Australian Standard):

The user is prompted to take 10 readings. The lowest 5 readings are

discarded and the mean/average measurement of the remaining 5

readings is displayed on the gauge (Model B & T) and saved into the

batch memory (Model T only).

ASTM x

ASTM H

ASTM 4417-B (American Society for Testing & Materials):

The user is prompted to take 10 readings and can choose to display

on the gauge (Model B & T) and save into the batch memory

(Model T only), the mean/average or highest measurement of each

set of 10 readings.

SANS

SANS 5772 (South African National Standard):

The user is prompted to take 5 readings and the mean/average

measurement of each set of 5 readings is displayed on the gauge

(Model B & T) and saved into the batch memory (Model T only).

Note: When using ‘Custom’ or ‘Standards’ mode, only the mean/average, highest or lowest

measurement as specified for each set of 5 or 10 readings is saved in the batch

memory. The individual readings are not stored. This also applies when using ‘Live

®

Readings’ mode in ElcoMaster to transmit readings from a gauge to a PC to be

®

stored in a batch within ElcoMaster .

4 GETTING STARTED (continued)

When ‘Custom’ or ‘Standards’ measurement mode is selected:

4 The circles indicate the number of readings

out of the set of predefined readings which

a

are to be taken (a). In this example, 3 out of

the 10 readings have been taken.

4 The value of the last reading taken is

b

displayed on screen in grey, below the

reading circles (b).

4 When the last of the predefined number of

readings has been taken, the

c

mean/average, highest or lowest

measurement (as selected by the user) is

en-5

displayed (c).

www.elcometer.com

Page 7

ü

DO

•

Hold the probe by the probe sleeve.

•

Firmly place the probe onto the surface

•

Allow the sleeve to make contact with the surface - to improve

accuracy.

û

DO NOT

•

Drag the probe over the surface

•

Bang the probe down hard onto the surface

•

Swing the probe by its cable

5 TAKING A READING

1 Hold the probe by its sleeve

2 To take a reading, bring the probe down onto the surface whilst

holding it perpendicular

3 For subsequent readings, lift the probe off and then replace it

onto the surface

R

4 To accurately assess the surface profile 5-10 readings should be

taken over a surface area of 150mm (6 sq. in.). The average of

2

these readings will indicate the surface profile peak-to-valley

height of that area.

4 When using ‘Immediate’ mode, users can pre-define the number of readings

using the counted average function. When in batching (Model T), press

Batch/New Batch/Batch Type, select “Counted Average” and set the number of

readings as required. The average of this pre-defined number will be saved into

the batch, but the individual readings within the counted average are not saved.

When not in batching (Model B & T), press Display/Statistics/Counted Average

and set the number of readings as required. When using counted average, the

gauge switches between displaying statistics based on individual readings to

statistics based on the counted average, as each set of reading are taken.

4 The display will dim if inactive for more than 15 seconds and will go ‘black’ if

inactive for the period defined in Menu/Setup/Screen Settings/Screen Timeout.

Press any key or tap the gauge to awaken it.

4 The gauge will switch off automatically after 5 minutes of inactivity.

4 - - - indicates reading outside range of probe.

www.elcometer.com

en-6

Page 8

R

6 CALIBRATING AND TESTING THE GAUGE CALIBRATION

6.1 CALIBRATING THE GAUGE

Adjusting the calibration of the gauge is the process of zeroing the

gauge on a smooth glass zero tile. Calibration foils can be used to

check the accuracy of the gauge across its measurement range.

The Elcometer 224 Model T has a choice of calibration methods as

detailed below. The Elcometer 224 Model B uses the Zero calibration

method.

4 Zero Calibration: A simple method for calibrating on the smooth

glass zero tile. Simply place the probe on the glass tile and the

gauge will adjust the calibration accordingly.

4 2 Point Calibration: This is a more accurate method of calibrating

the gauge than the Zero method as it requires the user to

calibrate the gauge using a foil and the smooth glass zero tile.

4 Tip Change Calibration: The precision manufactured probe tip will

wear after continued use. Re-calibration is required after a tip

replacement to ensure the continued accuracy of the gauge - see

Section 6.2 on page en-8 for further information.

To calibrate the gauge:

1 Press the Cal softkey.

2 Use the softkeys to select the required calibration method

é

ê

(Model T only).

3 Follow the on-screen instructions.

After continued use, the surface of the glass zero tile will begin to

wear. If a repeatable zero can not be obtained the tile should be

replaced.

Description Part Number

Glass Zero Tile T22420072

en-7

www.elcometer.com

Page 9

6 CALIBRATING AND TESTING THE GAUGE CALIBRATION

6.2 CALIBRATING THE GAUGE AFTER PROBE TIP REPLACEMENT

The precision manufactured probe tip will wear after continued use.

This is a consumable item which can be replaced by the user.

Description Part Number

Replacement Probe Tips (x2) with Fixing Tool T22420053

Replacement Probe Tips (x5) T22420095

Re-calibration is required after a tip replacement to ensure the

continued accuracy of the gauge.

To re-calibrate after tip replacement:

1 Press the Cal softkey.

2 Select “Tip Change Calibration” (Model T only).

R

3 Follow the on-screen instructions.

6.3 TESTING THE GAUGE CALIBRATION (MODEL T)

The calibration can be checked at any time without affecting any

statistics or batch memory by following the procedure below and

comparing the reading value displayed with the glass zero or

measured foil value.

To test the gauge calibration:

1 Press the Cal softkey.

2 Select “Test Calibration” and follow the on-screen instructions.

3 When prompted, either place the probe on to the glass zero tile or

on the centre of the foil resting on the glass tile, making sure the

pin goes through the hole in the centre of the foil.

www.elcometer.com

90°

en-8

Page 10

R

7 BATCHING - MODEL T

1 To use the Batching memory facility, press the Batch softkey

2 Select “New Batch” or “Open Existing Batch” to add readings

3 Copy and review batch data

4 Select “Edit Batch” to rename, clear readings from or delete a

batch

5 Fixed Batch Size allows users to pre-define the number of

readings to be stored in a batch.

Once all readings have been taken the gauge automatically

opens a new batch with a link

to the original batch name. For Example NewBatch_1 becomes

NewBatch_2, NewBatch_3, etc.

4 Save each reading into memory or store the average of a pre-defined number of

readings using the Counted Average function.

8 DISPLAYING GRAPHS

8.1 BAR GRAPH (MODEL B & T)

The Bar Graph displays an analogue

representation of the thickness value

together with the highest, lowest and

average reading as measurements are

taken. To display the Bar Graph:

1 Press the Display softkey and select

“Readings & Bar Graph”

4 If a reading is outside set limits, the white bar and the reading value turn red.

8.2 RUN CHART (MODEL T)

To display the Run Chart of the last 20

readings:

1 Press the Batch softkey

2 Select “New Batch” or “Open Existing

Batch”

3 Press the Display softkey and select

“Readings & Run Chart”.

4 Red points signify a reading outside the batch’s limits (if set).

en-9

www.elcometer.com

Page 11

8 DISPLAYING GRAPHS (continued)

8.3 BATCH GRAPH (MODEL T)

To display the Batch Graph:

1 Select the appropriate batch name

from Batch/Review Batch

2 Select “Batch Graph”.

4 Red columns signify a reading outside the

batch’s limits (if set).

4 Press the Zoom softkey followed by ç or è to

review individual readings as required.

R

9 MENU STRUCTURE - MODEL B

Menu

Display

Data

Last Five Readings

Calibration

¡

¡

¡

Clear Statistics

View Selected

View All

Select Statistics

Counted Average

Number of Readings

Mean

Lowest Reading

Highest Reading

Standard Deviation

Coefficient of Variation

Statistics

Select Statistics

Delete Last Reading

Setup

About

Reset

Emergency Light

Clear Statistics

Readings Only

Readings & Selected Stats

Readings & Bar Graph

Statistics

50.5 µm

52.3 µm

51.0 µm

51.8 µm

¡

¡

¡

¡

¡

¡

51.5 µm

Escape Delete Ok

Pressing the Cal Softkey

starts the calibration process

Measurement Mode

Units

Language

Beep Volume

Screen Settings

Gauge Auto Off

Gauge Information

Probe Information

Contact

Legal

Setup

About

Measurement Mode

Immediate

Custom

Standards

¡

µm

mm

mils

inch

Screen Brightness

Screen Timeout

Auto Display Rotation

Opening Screen

Patents

Legal Notices

Regulatory

Units

Screen Settings

Legal

¡

¡

¡

¡

¡

¡

¡

¡

¡

www.elcometer.com

en-10

Page 12

R

10 MENU STRUCTURE - MODEL T

¡¡¡

Measurement Mode

Immediate

Custom

Standards

Setup

Measurement Mode

Units

Language

Units

Time and Date

¡¡¡

mmµminch

Beep Volume

¡

mils

¡

Screen Settings

Gauge Auto Off

Time and Date

Set Time

Set Date

¡

Set Limits

Set Upper

Enable Limits

Set Lower

¡

Set Format

Display Time and Date

Set Nominal

¡

¡

Screen Settings

Screen Timeout

Screen Brightness

Opening Screen

Auto Display Rotation

¡

Bluetooth

Bluetooth ID xxxxxx

Enable Bluetooth

Bluetooth Code xxxxxx

A

¡¡¡

Legal

Patents

About

Contact

Probe Information

Legal

Gauge Information

¡

Legal Notices

Regulatory

New Batch

Open Batch 1

Rename Batch 1

Calibrate

¡¡¡

Measurement Mode

Custom

Immediate

Batch Type

Batch Limits

Measurement Mode

Batch Type

Standards

Edit Batch

Fixed Batch Size

¡

Normal

Rename Batch

¡

Counted Average

Review Batch

Delete Batch

Clear Batch

¡

Batch Limits

Set Upper

Set Lower

Enable Limits

Batch 1

Statistics

Batch Information

Calibration Information

¡

Set Nominal

Readings

Graph

¡

¡

Deleted Reading

Delete With Tag

Delete Without Tag

Menu

Delete Last Reading

Setup

Set Limits

Bluetooth

Reset

About

Emergency Light

Display

Clear Statistics

Readings Only

Readings & Selected Stats

Readings & Run Chart

Readings & Bar Graph

Batch Graph

Statistics

Statistics

Batch

Memory Free

Exit Batching

New Batch

Open Existing Batch

Counted Average

View Selected

Select Statistics

Clear Statistics

View All

Select Statistics

Calibration

Review Batch

Deleted Reading

Copy Batch

Edit Batch

¡¡¡¡¡

Mean

Number of Readings

Lowest Reading

¡¡¡

¡¡¡

Number Below Limit

Coefficient of Variation

Low Limit Value

Highest Reading

Standard Deviation

High Limit Value

Nominal Value

Number Above Limit

Tip Change Calibration

Zero Calibration

2 Point Calibration

Calibration Lock

Test Calibration

en-11

www.elcometer.com

Page 13

11 DOWNLOADING DATA & UPGRADING YOUR GAUGE

11.1 USING ELCOMASTER

1 Using ElcoMaster - supplied with the Elcometer 224 Model T,

®

®

and available as a free download at elcometer.com - all gauges

R

can transmit readings to a PC for archiving and report

generation. Data can be transferred via Bluetooth (Model T) or

USB. For more information on ElcoMaster visit

®

®

www.elcometer.com.

2 All Elcometer 224 gauge firmware can be upgraded to the latest

versions, as they become available. Elcometer 224 B & T models

can be upgraded by the User via ElcoMaster .

3 ElcoMaster will inform you of any updates when the gauge is

®

®

connected to the PC with an internet connection.

11.2 USING ELCOMASTER MOBILE APPS (MODEL T)

®

Ideal when out in the field or on-site, live readings can be stored

directly onto a mobile device and saved into batches. Inspection data

can be transferred from mobile to PC for further analysis and

reporting.

Compatible with smart phones

and tablets running Android 2.1

or above. To install, download

via www.elcometer.com or using

the Google Play™ Store app,

and follow the on screen

instructions.

Made for iPhone 6 Plus, iPhone

6, iPhone 5s, iPhone 5c, iPhone

5, iPhone 4s, iPhone 4, iPad Air

2, iPad mini 3, iPad Air, iPad mini

2, iPad (3rd and 4th generation),

iPad mini, iPad 2, and iPod touch

(4th and 5th generation). To

install, download via

www.elcometer.com or the App

www.elcometer.com

Store, and follow the on screen

instructions.

en-12

Page 14

Battery

Type

2 x AA batteries, rechargeable batteries

can also be used

Operating

Temperature

-10 to 50°C (14 to 122°F)

Relative

Humidity

0 to 95%

Gauge

Dimensions

Separate: 14.1 x 7.30 x 3.70cm (5.55 x 2.87 x 1.46")

Integral: 16.8 x 7.30 x 3.70cm (5.61 x 2.87 x 1.46")

Gauge Weight

(with supplied

batteries)

Integral: 218g (7.69oz)

Separate: 161g (5.68oz)

Can be used in accordance with:

ASTM D 4417-B, SANS 5772, US Navy NSI 009-32,

US Navy PPI 63101-000

R

12 TECHNICAL SPECIFICATION

13 ELCOMETER 224 SEPARATE PROBES

A choice of flat or convex surface profile

probes, ideal for measuring profile on

external curved surfaces such as pipelines

etc, are available for Elcometer 224

Separate Gauges, with either standard or

armoured metal reinforced heavy duty

cables.

All Elcometer 224 Surface Profile Probes have an accuracy of ±5% or

±5μm (±0.2mil) and are supplied with a glass zero plate, calibration

test foils; nominal values 125μm (5.0mils) & 508μm (20mils) and an

Elcometer test certificate.

Description Part Number

Flat Surface Probe; Standard Cable T224C500US

Flat Surface Probe; Armoured Cable T224C500UARM

Convex Surface Probe ; Standard Cable T224C500UX

Convex Surface Probe ; Armoured Cable T224C500UXARM

˄

˄

˄

Applicable Patents: GB2505193, US9261345

en-13

www.elcometer.com

Page 15

14 LEGAL NOTICES & REGULATORY INFORMATION

Declaration of Conformity:

Elcometer 224 Model B complies with the requirements of the following EU Directives:

2014/30/EU Electromagnetic Compatibility

2011/65/EU Restriction of the use of certain hazardous substances

Elcometer 224 Model T complies with the requirements of the following EU Directives:

2014/53/EU Radio Equipment

2011/65/EU Restriction of the use of certain hazardous substances

Declarations of Conformity are available to download via:

Model B: www.elcometer.com/images/stories/PDFs/Datasheets/Declaration_of_Conformity/English/DoC_224C_B.pdf

Model T: www.elcometer.com/images/stories/PDFs/Datasheets/Declaration_of_Conformity/English/DoC_224C_T.pdf

Operational Frequency Band: 2,402 - 2,480 MHz

Maximum Transmitted Power: <4 dBm

This product is Class B, Group 1 ISM equipment according to CISPR 11.

Class B product: Suitable for use in domestic establishments and in establishments directly connected to a low voltage power

supply network which supplies buildings used for domestic purposes.

Group 1 ISM product: A product in which there is intentionally generated and/or used conductively coupled radio-frequency

energy which is necessary for the internal functioning of the equipment itself.

The USB is for data transfer only and is not to be connected to the mains via a USB mains adapter.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may

not cause harmful interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

The ACMA compliance mark can be accessed via: Menu/About/Legal/Regulatory

Elcometer 224 Model T: The Giteki mark, its product identification code, the FCC ID and Bluetooth SIG QDID can be

accessed via: Menu/About/Legal/Regulatory

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

-- Reorient or relocate the receiving antenna.

-- Increase the separation between the equipment and receiver.

-- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

-- Consult the dealer or an experienced radio/TV technician for help.

To satisfy FCC RF Exposure requirements for mobile and base station transmission devices, a separation distance of 20 cm

or more should be maintained between the antenna of this device and persons during operation. To ensure compliance,

operation at closer than this distance is not recommended. The antenna(s) used for this transmitter must not be co-located or

operating in conjunction with any other antenna or transmitter.

Modifications not expressly approved by Elcometer Limited could void the user’s authority to operate the equipment under

FCC rules.

This device complies with Industry Canada license exempt RSS standard(s). Operation is subject to the following two

conditions: (1) this device may not cause interference, and (2) this device must accept any interference, including interference

that may cause undesired operation of the device.

This Class B digital apparatus complies with CAN ICES-3 (B)/NMB-3(B).

R

and ElcoMaster are registered trademarks of Elcometer Limited, Edge Lane,

Manchester, M43 6BU. United Kingdom

are trademarks owned by Bluetooth SIG Inc and licensed to Elcometer Limited.

Elcometer 224 Model T: Made for iPhone 6 Plus, iPhone 6, iPhone 5s, iPhone 5c, iPhone 5, iPhone 4s, iPhone 4, iPad Air 2,

iPad mini 3, iPad Air, iPad mini 2, iPad (3rd and 4th generation), iPad mini, iPad 2, and iPod touch (4th and 5th generation).

“Made for iPod,” ”Made for iPhone,” and “Made for iPad” mean that an electronic accessory has been designed to connect

specifically to iPod, iPhone, or iPad, respectively, and has been certified by the developer to meet Apple performance

standards. Apple is not responsible for the operation of this device or its compliance with safety and regulatory standards.

Please note that the use of this accessory with iPod, iPhone, or iPad may affect wireless performance.

iPad, iPhone, and iPod touch are trademarks of Apple Inc., registered in the U.S. and other countries.

App Store is a trademark of Apple Inc., registered in the U.S. and other countries.

Google Play is a trademark of Google Inc.

All other trademarks acknowledged.

®

R

The Elcometer 224 is packed in a cardboard package. Please ensure that all packaging is disposed of in an environmentally

sensitive manner. Consult your local Environmental Authority for further guidance.

Head-Office: Elcometer Limited, Edge Lane, Manchester, M43 6BU, United Kingdom.

www.elcometer.com

en-14

Page 16

R

TMA-0523 Issue 08 - Text with cover 23302

Loading...

Loading...