Elcold PRO 60, PRO 21, PRO 41, PRO 11, PRO 31 User guide

Elcold Frysere Hobro ApS

Løgstørvej 81 Hørby 9500 Hobro Denmark

Phone +45 9657 2222 Fax +45 9852 4685

Email elcold@elcold.com www.elcold.com

i.c. graphics cph

User Instructions

Pro* Frost

Low Temperature Freezers Model PRO/XLT

SAFETY INFORMATIONS

The PRO/XLT freezers contains environmentally friendly but flammable refigerants. It means

danger of explosion if for any reason the refigerants are allowed to escape from the system.

The refigeration system must never be accessed by unauthorized personal.

When transporting and installing the unit, ensure that no part of the tubing system is damaged.

If the tubing is damaged and leak occurs, avoid any ignition sources and naked flames near

the unit, and ventilate the room immediately.

In order to avoid formation of flammable gas/air mixtures an case of a leak from the refigera

tion system, the room where the unit is placed must have a volume of minimum 40 m3 cor

-

responding to a surface area of approx. 4 m2 in a room with normal ceiling height.

WARNING!!!

The ventilation openings must never be covered or blocked.

Never use a stream or water cleaning device during cleaning or defrosting in order to avoid

short circuits in the electrical system.

Do not place any electrical devices in the freezer.

Products containing flammable gasses and explosives must not be stored in the freezer.

-

User Instructions Low Temperature Freezers Model PRO/XLT

2

USER INSTRUCTIONS

Congratulations on your new low temperature freezer. We trust that it will serve you

for many years to come. In order to gain

optimum benefit from your freezer, please

read the following instructions thoroughly

and act accordingly. The low-temperature

freezers are used for freezing and long-term

storing of food products, medical preparations ( vaccines, blood plasm, ect.) and

other biological products.

1. Environmental protection and disposal.

The packaging is designed to protect the

appliance and its components during

transportation, and it is made of recyclable

materials.

• Please return the packaging to an

official collection point for recycling.

• Old appliances contain reusable

materials and should not be disposed

of together with household refuse.

• Remove the spring-action hinges from

the appliance, in order to prevent

children from being entrapped in the

appliance.

• Ensure that no part of the refrigeration

tubing is damaged as the refrigerant

in the appliance risks escaping to the

environment.

• Information about refrigerant type

and amount will be found on the type

plate on the rear of the appliance

(Fig. 1).

2. Safety instructions.

• In order to prevent injuries and or

damage to the appliance, it should

be unpacked and set up by min. two

people.

• If upon unpacking the appliance is

found damaged, do not connect to

the mains, but contact the supplier.

•

Interference with or repair to the

appliance should only be carried out

by authorized personnel, in order to

avoid any injuries. (contact the sup plier for further information).

• Never put naked flames or other igni tion sources inside the appliance.

• Never touch the freezers interior or

GB

products in the freezer when the

freezer is operating. Use gloves or alike

in order to avoid injuries (frost-bite).

• Keep the key to the appliance away

from the appliance and out of the

reach of children.

3. IMPORTANT NOTE !!!

• The type of refrigerant in the –60°C

freezers, is a mixture of different

flammable hydrocarbons.

These freezers are designed and

tested according to the EN 378 stan dard, under clause A3 room and L3

refrigerants, this means that the

volume of the room where the freezers

is placed must have a volume of mini mum 40m

4m

height.

4. Connection to the mains.

• For safety reasons the appliance must

be earthed. If you are in any doubt,

please contact an authorized electri

cian.

• The appliance should be left for 5

hours before it is connected to the

mains. If the appliance is connected

before that, there is a risk of damaging

the compressor.

• If for any reason the appliance is

disconnected from the mains, please

wait 10 minutes before re-connecting.

The electronic starting device needs

this time to cool down, before a safe

re-start can be made.

5. Before use.

• Before use, the interior of the appli ance should be cleaned with a mild

soap solution, and wiped off with a dry

clean cloth. Never use any kind of

solvent or other chemicals.

3

corresponding to approx.

2

in a room with a normal floor

User Instructions Low Temperature Freezers Model PRO/XLT

3

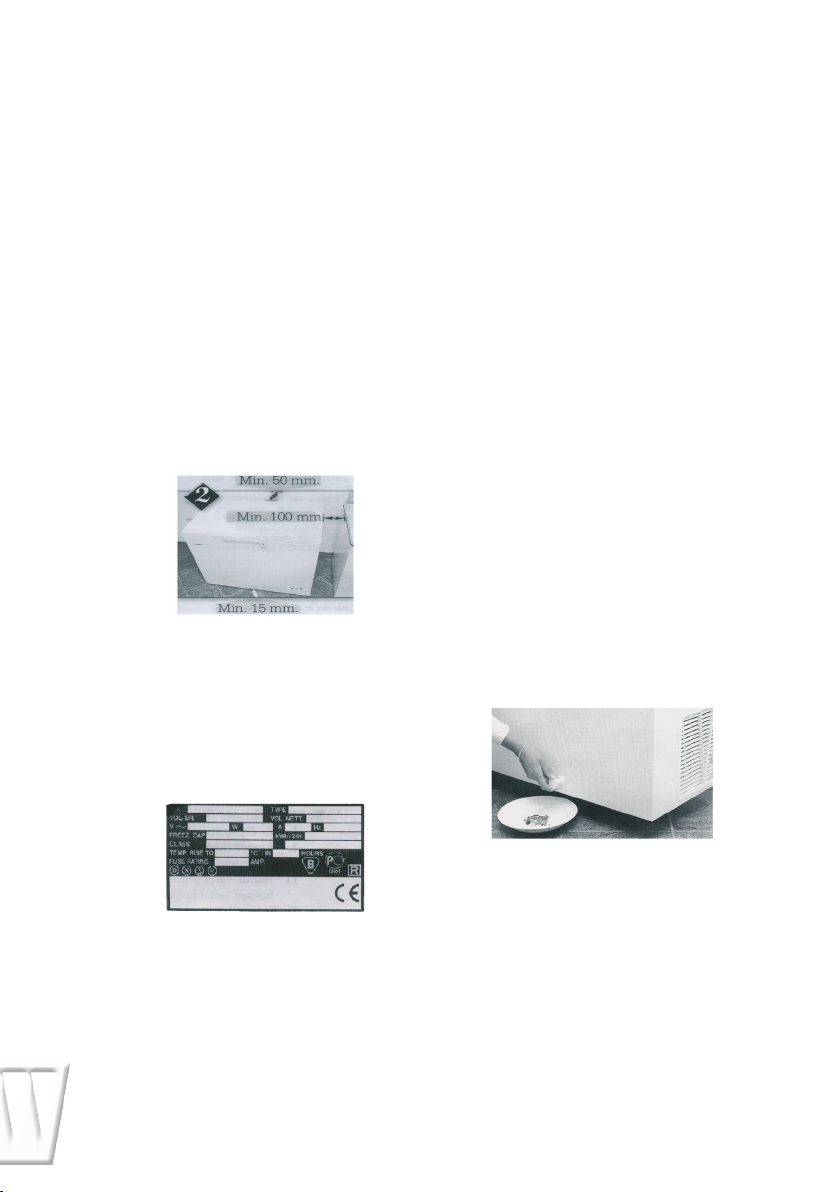

6. Setting up the freezer.

The freezer should not be placed where it

might be splashed with water, in extreme

high humidity or in direct sunlight. Any of

these factors may lead to a reduction in

performance and shorten the life span of

the components. The freezer should be

placed on a horizontal level, and should

not be placed close to a heating appliance

or heating tubes. Allow a minimum of 50mm

(2”) clearance on the side and the back.

The side with the ventilation grill should have

a clearance of at least 100 mm (4”) in order

to allow the heat from the compressor

motor to dissipate. Underneath the appli

ance there should be a gap of 15 mm ap

-

prox. (1⁄2”). On a soft surface, e.g. carpet,

it may be necessary to ensure the correct

distance by means of spacers.

7. Electrical supply.

The electrical supply should always be in

accordance with the rating plate on the

back of the freezer.

The supply must always be in accordance

with the law and regulations regarding

electrical safety, if any doubts contact your

supplier.

there is an electricity supply to the plug or if

the fuse is blown. If not please go to trouble

shooting page 6. 18.

9.Operating the freezer

The empty freezer should be switched on

for at least 5-6 hours prior to loading of the

freezer. The freezer should not be loaded

above the inside walls which is also the load

line limit.

Please note: After the lid has been opened,

there will be a vacuum created inside the

freezer due to the low temperatures. Wait a

few minutes before trying to reopen the lid

otherwise the handle could be damaged.

10.Defrosting.

In order for the freezer to work to its maxi

mum efficiency the cabinet should be de

-

frosted when a approx. 2mm thick ice layer

has formed inside the cabinet.

The ice layer is easily removed with a plastic

or wooden scraper.

Never use a sharp metal

object which might will cause damage to

the inner liner.

The defrosting frequency is determined

mainly by two factors the usage pattern

(number of lid openings) and the relative

humidity. Excess water can be drained out

by using the drain water outlet on the front

of the freezer.

Fig. 1

8. Starting Up.

In case the compressor does not start when

the freezer has been plugged in, the electri

cal supply may not be in order. Check if

User Instructions Low Temperature Freezers Model PRO/XLT

11.Cleaning.

Cleaning should be done when needed.

When used in a dirty environment it might

be necessary to remove the compressor

compartment grill, and clean the compres

sor compartment eventually with a vacuum

cleaner.

If the cleaning process is neglected there

is a risk that the performance of the freezer

will be effected, and even damage to the

4

-

compressor could occur due to overheating.

12. Storage.

If the freezer is stored for a period of time,

the lid should be kept open for free circula

tion of air inside the cabinet in order to

avoid corrosion of the inner liner.

13. Temperature control PRO/XLT- freezers.

The temperature inside the freezer is con

trolled by the electronic controller in the

front grill. The controller has a digital readout

of the temperature inside the cabinet. and

the option of changing the temperature

inside the cabinet.

14. External voltage and temperature alarm.

Optionally the freezer can be equipped with

a battery operated alarm box with connections for external alarm for voltage failure

and temperature alarm. The battery should

be exchanged every two years.

Please note! When commissioning the

freezer, the battery must be turned into its

correct position.

15.Dixell controller.

16. Functions.

How to see the set point:

1.Press and immediately release the SET key,

the display will now show the set point value.

2.Press and immediately release the SET key

or wait for 5 seconds to display the probe

value again.

How to lock and unlock the keyboard

1.Press the up and down keys simultaneously

for more than 3.seconds.

How to change the set point

1.Press the SET key for more than 3.seconds

to change the set point value.

2.The set point value will be displayed and

the LED starts flashing.

3.To change the set point value, push the up

or down arrow.

4. To memorise the new setting press the SET

key again or wait 15 seconds for the controller to return to normal display of the probe

temperature.

17. Setting the controllers offset value

The LAB/ULT freezer is designed for long time

and safe storage of sensitive products.

In some situations the PRO/XLT freezer is also

used for other applications like in laboratories for different low temperature test.

Depending on the actual situation it might

be necessary to change the controllers off

set value in order to get a correspondence

between the reading on the display and the

actual temperature inside the cabinet.

The factory setting is an offset of 2 dgr.C.

The offset can be adjusted in the following

way.

Unlock the keyboard.

Enter the programming mode by pressing

the SET and arrow down keys for 3 seconds.

Select the parameter “Opb” by pressing

arrow up or down key.

Press the SET key to display its value.

Use arrow up or down to change its value.

The offset can be adjusted to +/- 12 dgr .C

Press SET to store the new value.

Press SET + arrow up or wait 15 seconds

without pressing any key. The new value will

now be stored.

For more detailed information about

programming the Dixell controllers please

consult the attached manuals.

User Instructions Low Temperature Freezers Model PRO/XLT

5

Loading...

Loading...