EXPRESSO

DED400XP1

SERVICING AND MAINTENANCE

SERVICE INSTRUCTION

1/04

FILTER HOLDER GROUP HEAD (O-RING)

PAGE 1-7

Problem :

Liquid drips over the side of filter holder leaking out from between filter holder and filter

holder group head during coffee infusion.

2/04

FILTER HOLDER (O-RING)

PAGE 8-14

Problem :

During coffee infusion, liquid drips out of the side of the filter holder leaking out of the area

between filter holder base and where the spouts are screwed on.

3/04

THERMOSTAT

PAGE 15-20

Problem :

Water for brewing coffee or water for hot beverages from the water (or dry steam) wand is

not delivered at the desired temperature. The cause may be that one of the two safety

thermostats on the heat exhangers defective.

4/04

STOPS - BLOCKING

PAGE 21-27

Problem :

The dual function of the drawer handle is not working properly. When the drawer is pulled

out, the whole appliance slides forward out of its housing because the blocking mechanism

is not working.

5/04

CABLE SLACK

PAGE 28-31

Problem :

The appliance (cable) that sits between the panel wall of the machine housing and the back

panel of the espresso machine on the left-hand side, should form a loup, so that the

espresso machine can be glided smoothly out of the housing. However, it is causing an

obstruction and the espresso machine does not sit flush in the built-in cabinet, the safety

switch cannot engage and thus the machine has no power supply.

6/04

COFFEE GRINDER

Problem :

PAGE 32-41

The coffee grinder is not delivering coffee even though the sound of the motor can be

heard.

7/04

SENSORS

PAGE 42-61

Problem :

Brewing and beverage water (or steam) does not reach the prescribed temperature. The

reversible thermostats on both heat exchangers for coffee and/or hot beverages are

repeatedly triggered after being manually reset, even though there appears to be no

problem with the water supply and in-let system.

8/04

CIRCUIT BOARD REPLACEMENT

PAGE 62-74

Problem :

Semi-automatic processes are not functioning, which are normally engaged by pressing the

corresponding pad on the front control panel. Problems may include :

- Grinder

- Water for coffee - not delivered

- Steam / Water - not delivered

- By pressing on/off switch - no reaction

- By pressing one or two cups of coffee - no reaction

9/04

WATER PUMP /WATER PIPE

PAGE 75-86

Problem :

The water pump is very noisy (running without water) and hot water and brewing water are

being delivered slowly because there is a problem with water flow between the water

container and the heat exchanger.

SAFETY ADVICE FOR SERVICE ENGINEERS

PAGE 87

IDRAULIC LAYOUT DIAGRAM

PAGE 88

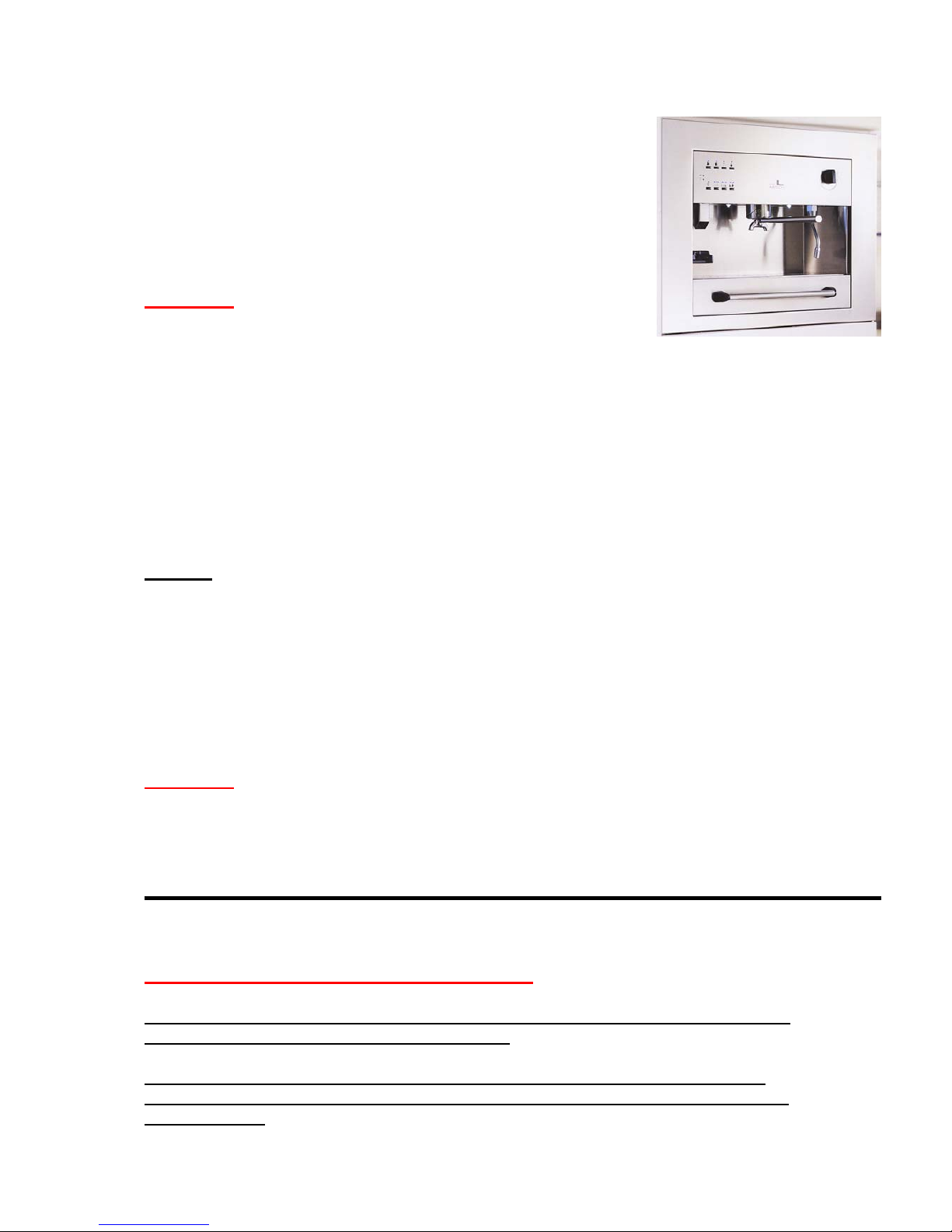

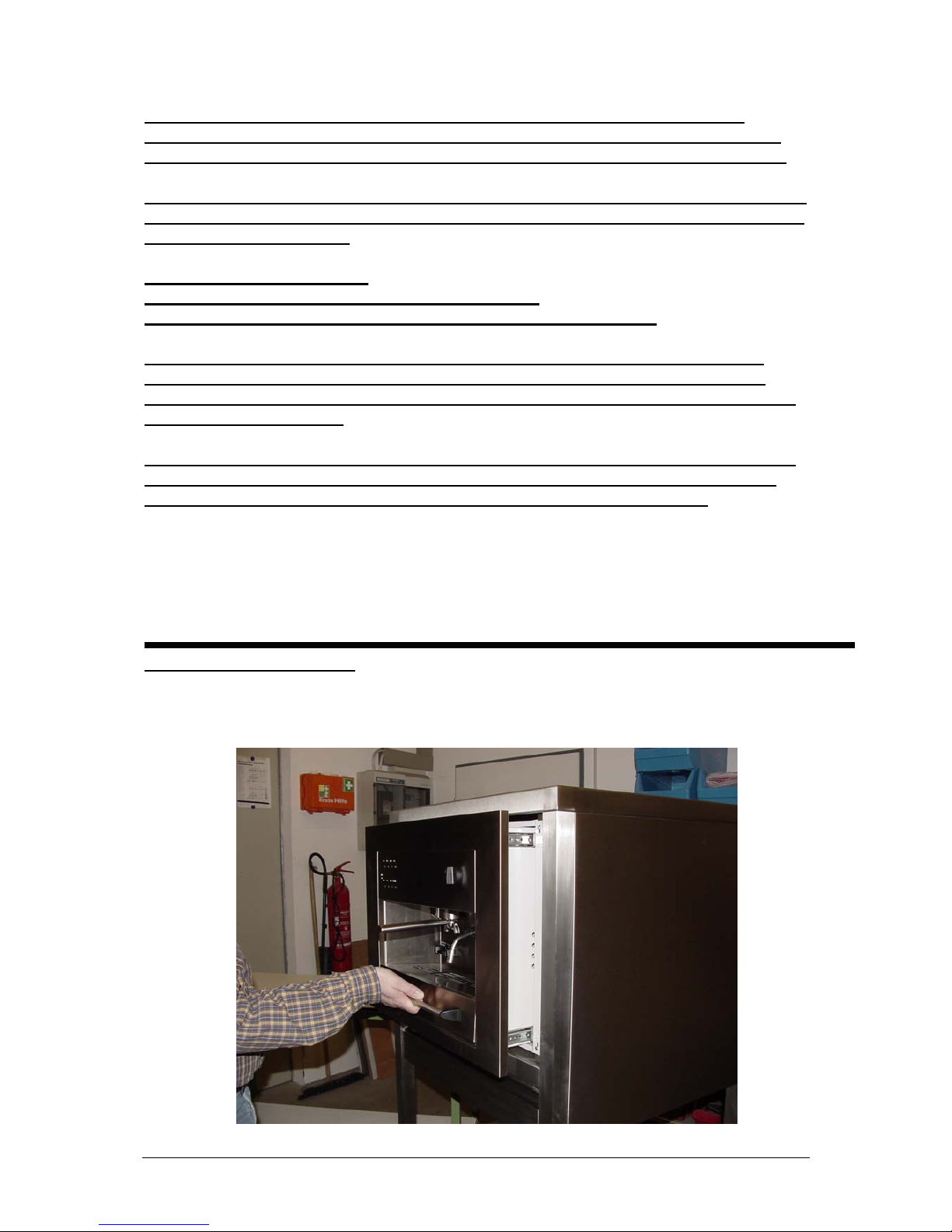

PRODUCT : SEMI-AUTOMATIC BUILT-IN COFFEE MACHINE

MODEL : SUPREME

1

Servicing and Maintenance

Product: Espresso-Machine

Model: Semi-automatic, Built-in

Service-Instruction: 1/04 Filter holder group head

(O-Ring)

Problem:

Liquid drips over the side of filter holder leaking out from between

filter holder and filter holder group head during coffee infusion.

coffee-brew should only flow out of the spouts on the lower part of the filter

holders.

Cause:

In the upper part of the group head there is the flange from which heated water

under pressure is forced through the tampered coffee during brewing. The flange

makes sure that the inner diameter of diffuser and filter holder group matches

the outer diameter of the filter holder. It is approximately 8-10 mm thick and has

a groove running around the outer edge which houses a gasket or seal made out

of heat-resistant, rubber-like material (O-ring) which normally prevents liquid

from leaking out between group head and filter holder. When the “O-Ring” is

defective or the wrong size, this can lead to the problem described above.

Solution:

The old gasket should be replaced with a new one following these

step-by-step instructions.

Safety Advice for Service Engineers

Attention: Before commencing any work on the appliance, it should be “disconnected”

from the electricity supply. This can be done by:

either removing the appliance plug from the mains socket or by isolating electricity

supply to socket through safety circuit-breaker or by turning off electricity completely

at mains switch.

As an authorised Service Engineer, you should comply with all European testing

standards and the relevant safety regulations for electrical appliances, in order not to

endanger yourself or other people and to prevent any other kind of hazards and risks.

2

For this electrical appliance, due to various systems that contribute to the working of the

machine, it is important that you observe and take note of the technical specifications of

the machine which include:

Power supply: 240 Volt mains

Heat exchanger and operating pressure up to 15 bar

Water containers and water conducting pipes (some under pressure)

Only authorised Customer Service Engineers are allowed to carry out work on this

Espresso machine (the opening of parts of the machine that are secured by screws).

European testing and safety regulations should always be complied with when carrying

out work on the appliance.

The appliance manufacturer and the Servicing firm shall not be liable for work carried

out that is not conformant with test an safety regulations and, likewise, tampering or

work carried out by unqualified servicing firms and local service engineers.

Step-by-Step procedure:

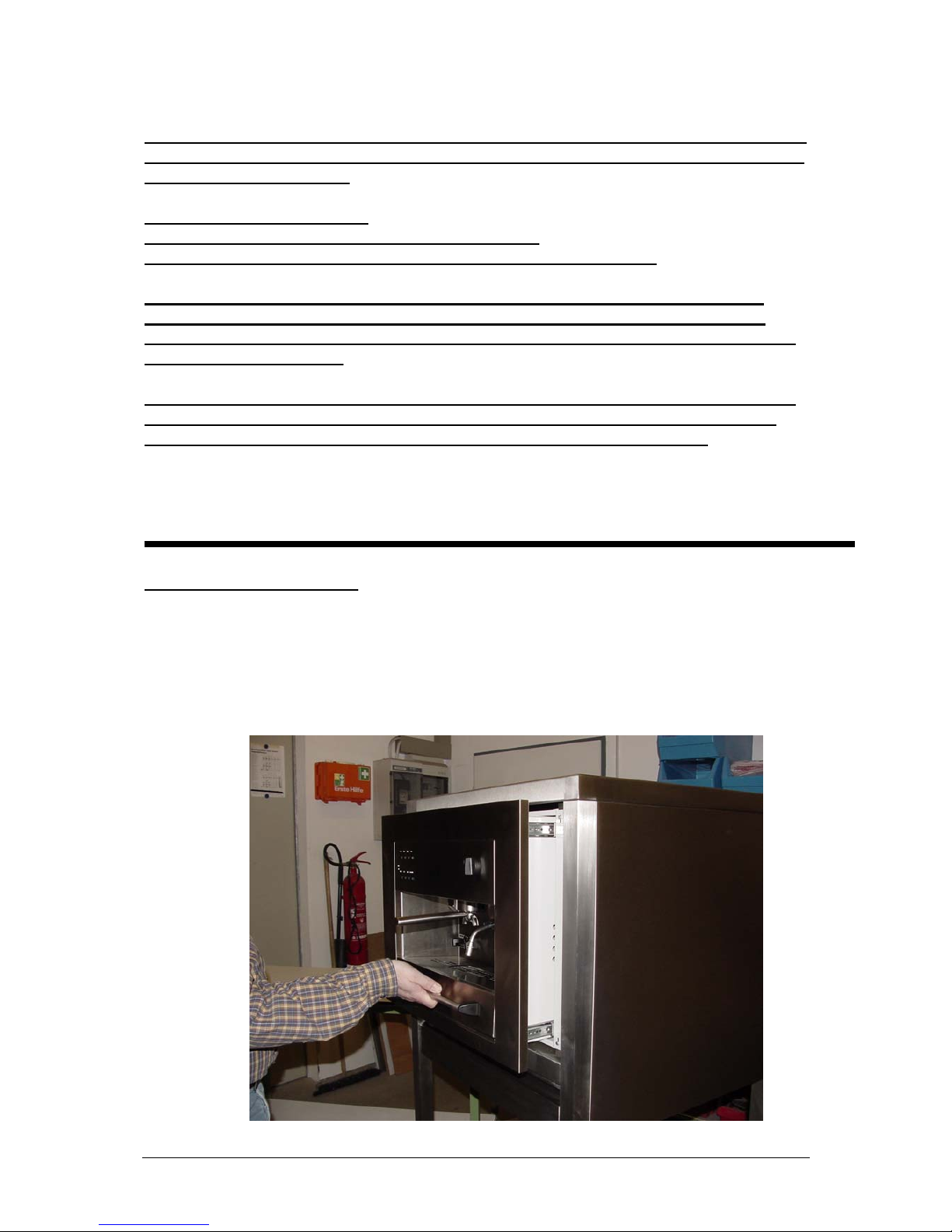

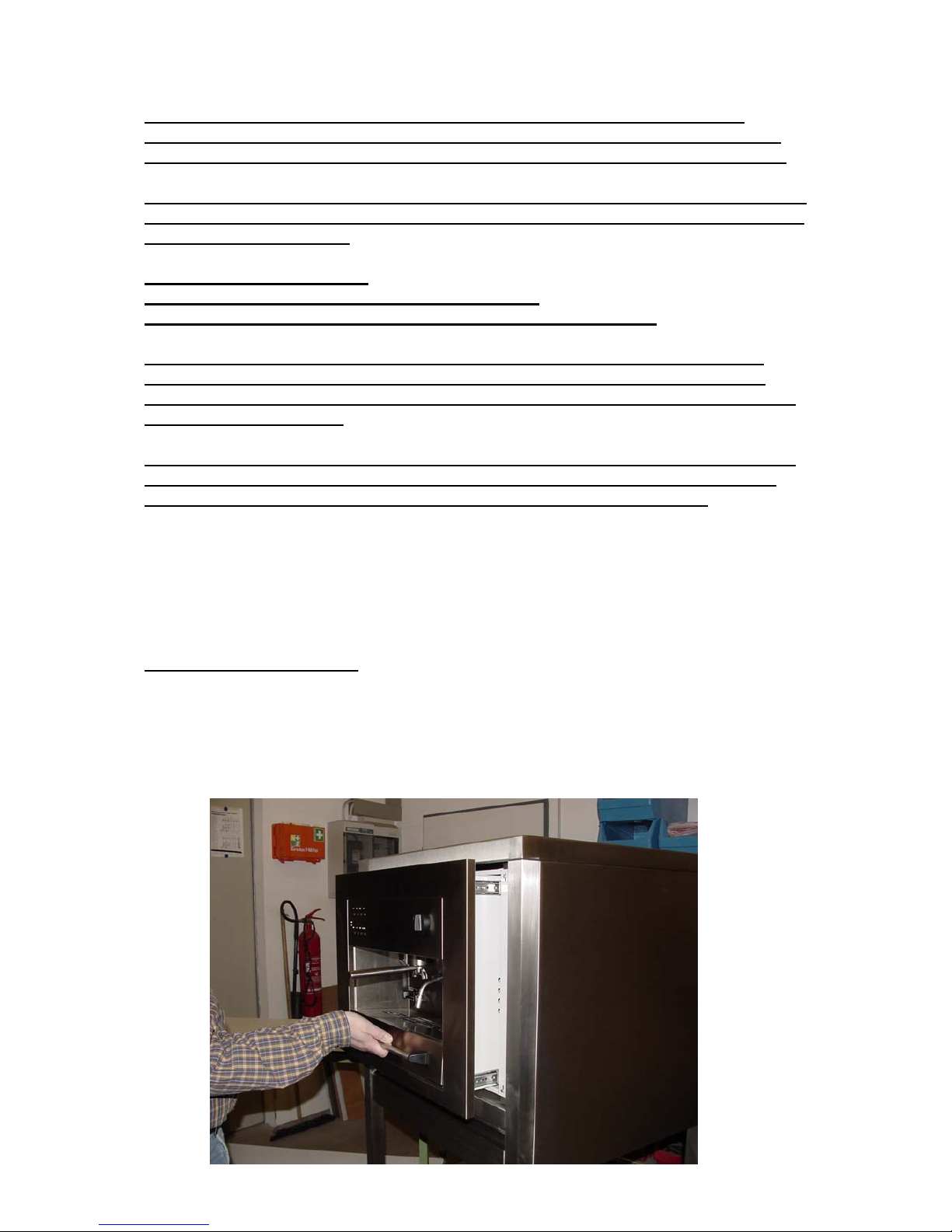

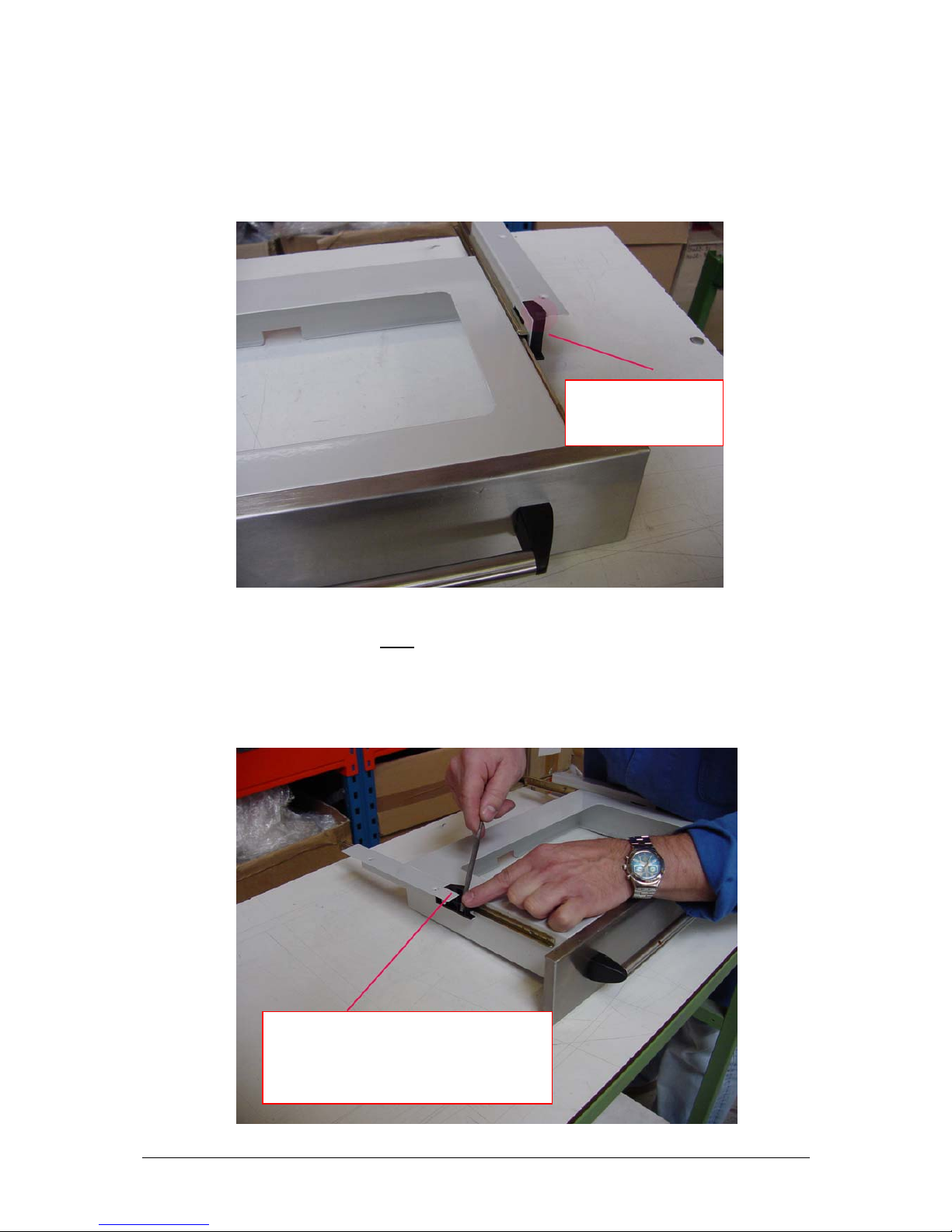

1. Firmly clutch the handle on the spill-tray drawer, and gently slide the Espresso

machine out of its housing towards you. (Opening as for water and coffee refilling

or replacing the grinder).

3

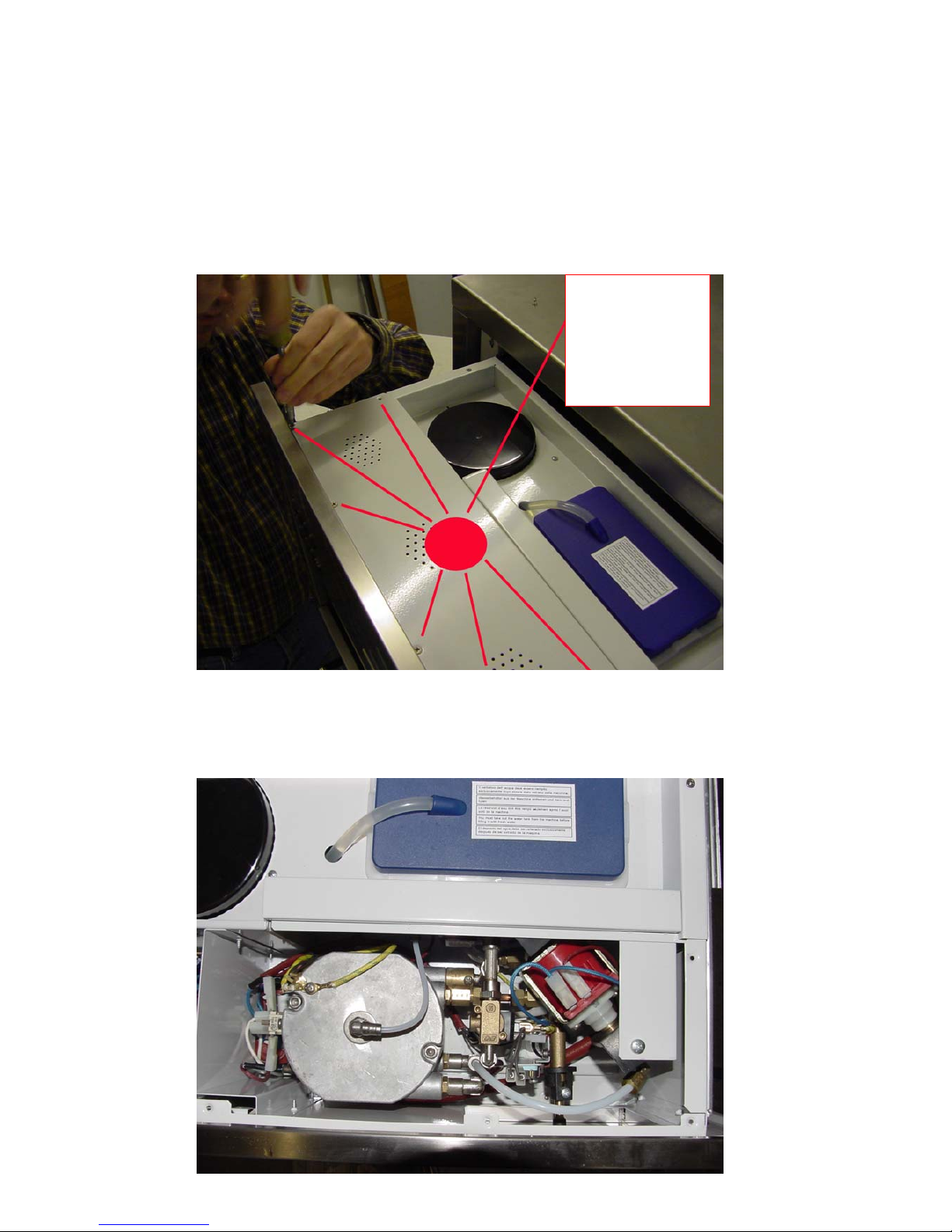

2. The upper front cover is screwed down with 6 countersunk screws. Unscrew and

remove all screws and take cover off.

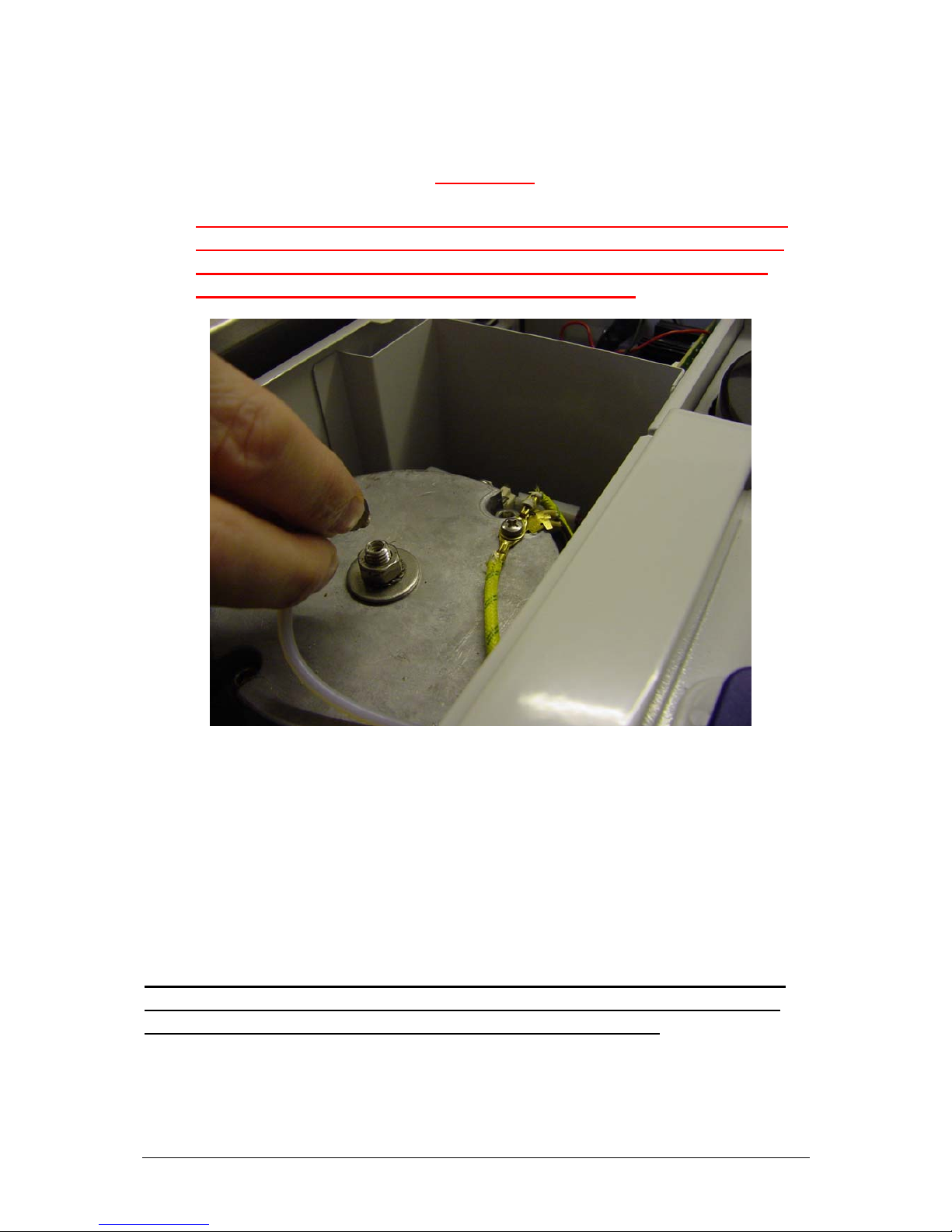

3. Using a >>M10 spanner<< and a >>M13 spanner<< proceed to loosen the nuts

on the water in-let base arrangement located on the ALU-heat exchanger.

Unscrew the six

countersunk screws

on the cover.

Then remove cover.

First, loosen the

hexagonal “M10” nut,

then remove L-bend

element holding the

flexible water in-let tube.

Next, loosen the hexagonal

“M13” corner nut. Then,

remove the top and inner metal

plates. Finally the freed water

in-let group can be removed

from below.

4

4. Firstly, using the >>M 10 spanner<< carefully loosen the nut at the base of the Lbend element by >>turning anti-clockwise<<.

Attention: There is a threaded connection attaching the L-bend element to the water

in-let group. This thread is small and delicate. On the outer thread of the L-bend

element there is a mini seal that should not be lost. It is essential that this seal is

replaced when the part is screwed back in later.

Take out element with plastic pressurised in-let tube and place it temporarily to one

side.

5. Next, using the >>M 13 spanner<< remove the water in-let assembly

Once the M13 nut has been

removed, do the same thing with

the top and lower metal plates.

Finally, the sunken group can be

pushed out below by following

the instructions in this section

5

Attention: Provided the filter holder (bayonet coupling) is locked in place, then

the upper (M13) nut can be removed from the water in-let group without any

problem.

If the filter holder is not locked in place, and when the M13 nut is finally ready to

be removed, a hand should be placed under the filter holder group head to catch

the diffuser as it is released.

6. Removal of the diffuser

After having unscrewed and removed the water in-let assembly and the (M13)

nut and, likewise removed the top and lower metal plates on the top of the heat

exchanger, the diffuser and the insert screen can be glided out from below. You

will see that there is a groove on the outer perimeter of the diffuser that houses

the gasket (large O-Ring) that needs to be replaced.

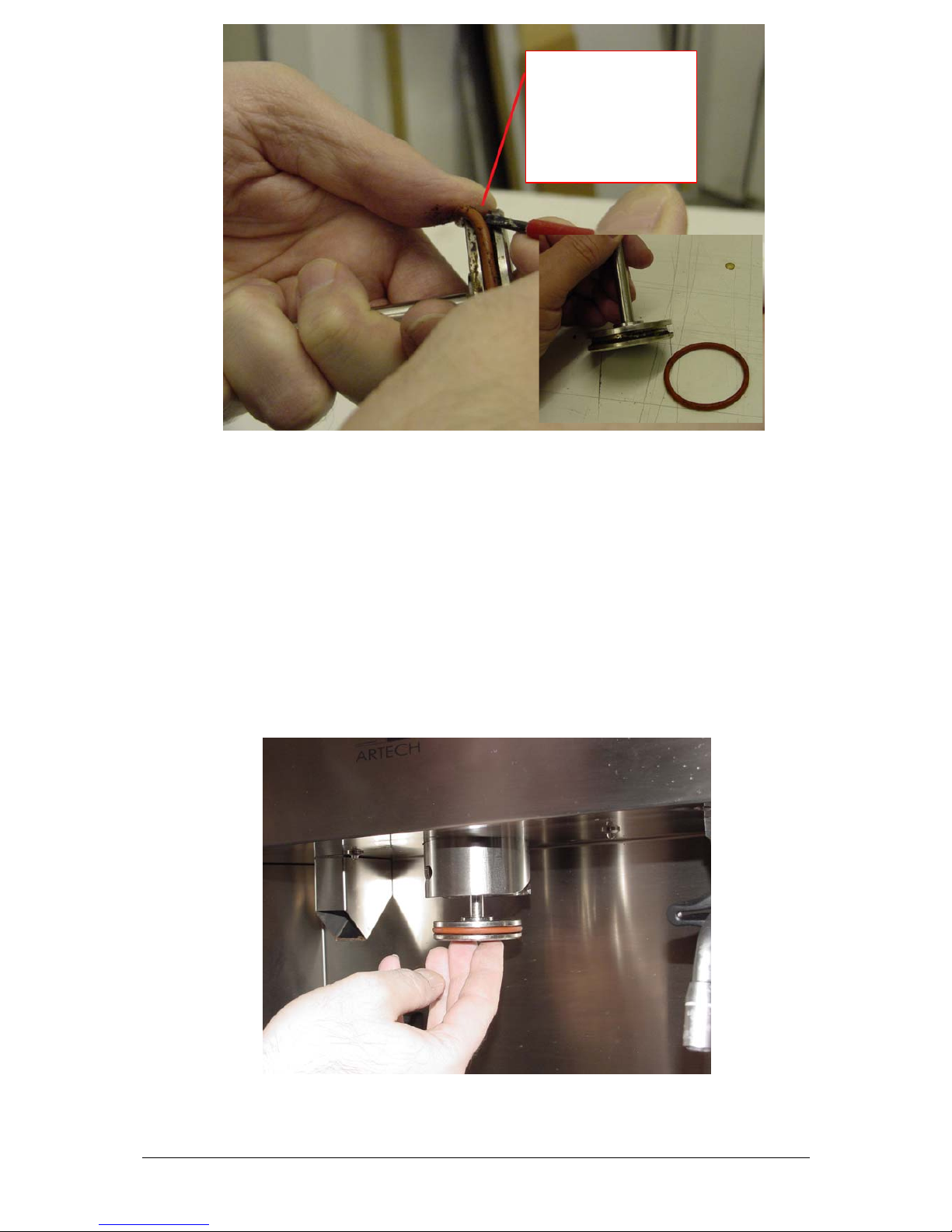

7. Removing the gasket (O-Ring)

The description in the next section will show you how to remove the gasket.

Please avoid damaging or scratching the diffuser when removing the gasket

(use a small flat-headed screwdriver) and the delicate outer and inner thread

on the upper side.

6

Insert new gasket (large O-Ring) inside out.

After the O-Ring has been removed, a new gasket can be inserted, making sure it

goes into the groove inside out. Clean the screen, the groove (where the gasket

will sit) and the group of any residual deposits (coffee, etc.) before inserting the

new O-Ring.

After performing this operation, reassemble the entire group in reverse order:

1. Replace the diffuser by inserting it into the filter holder group head from

below and push up until it reaches the top position and the threaded part once

again protrudes out of the heat exchanger. Reposition the low and top plates

and position and tighten the (M13) nut.

Tighten the nut by turning in a clockwise direction using a >>M 13

spanner<< .

Remove the gasket from

its groove with the aid

of a small flat headed

screwdriver

7

Once the >>M 13 nut<< has been tightened, reposition the water in-let L-bend

element very carefully onto the inner thread of the water in-let arrangement on

the heat exchanger and then tighten up the M 10 nut by turning in a clockwise

direction making sure that it is >>securely<< fastened.

Remember to check that the mini seal has been replaced around the

outer thread of the L-bend element before reassembling it. Without

this seal the machine cannot be restarted up. Additional seals and

gaskets are available from the service department.

Once the water in-let tube has been reattached, the cover can be repositioned and

screwed into place using the six countersunk screws.

Finally, reposition the machine in its housing and reconnect electricity supply. Then,

switch the espresso machine back on and, after following normal start-up procedure, the

espresso machine is ready for use.

Carry out 2-3 test runs (espresso) to check whether the replacement of the gasket has

been successful.

Espresso should only be delivered from the spouts under the filter holder.

No liquid should drip out of where the filter holder group head meets the

filter holder nor should any sputtering or spraying be seen.

8

Servicing and Maintenance

Product: Espresso-Machine

Model: Semi-automatic, built-in

Service-Instruction: 2/04 Filter holder (O-Ring)

Problem:

During coffee infusion, liquid drips out of the side

of the filter holder leaking out of the area between

filter holder base and where the spouts are screwed on.

coffee-brew should only flow out of the spouts on the lower part of the filter

holders.

Cause:

Inside the filter holder there is a spring mechanism and a gasket or sealing ring

which, during coffee brewing, should prevent coffee brew from dripping over the

sides. The sealing ring in the filter holder has an almost limitless working life and

is resistant to damage due to high temperatures but a fault in the material from

which it is made may mean that it is defective.

Solution:

The old sealing ring should be replaced with a new one following

these step-by-step instructions.

Safety Advice for Service Engineers

Attention: Before commencing any work on the appliance, it should be “disconnected”

from the electricity supply. This can be done by:

either removing the appliance plug from the mains socket or by isolating electricity

supply to socket through safety circuit-breaker or by turning off electricity completely

at mains switch.

As an authorised Service Engineer, you should comply with all European testing

standards and the relevant safety regulations for electrical appliances, in order not to

endanger yourself or other people and to prevent any other kind of hazards and risks.

9

For this electrical appliance, due to various systems that contribute to the working of the

machine, it is important that you observe and take note of the technical specifications of

the machine which include:

Power supply: 240 Volt mains

Heat exchanger and operating pressure up to 15 bar

Water containers and water conducting pipes (some under pressure)

Only authorised Customer Service Engineers are allowed to carry out work on this

Espresso machine (the opening of parts of the machine that are secured by screws).

European testing and safety regulations should always be complied with when carrying

out work on the appliance.

The appliance manufacturer and the Servicing firm shall not be liable for work carried

out that is not conformant with test an safety regulations and, likewise, tampering or

work carried out by unqualified servicing firms and local service engineers.

Step-by-Step procedure:

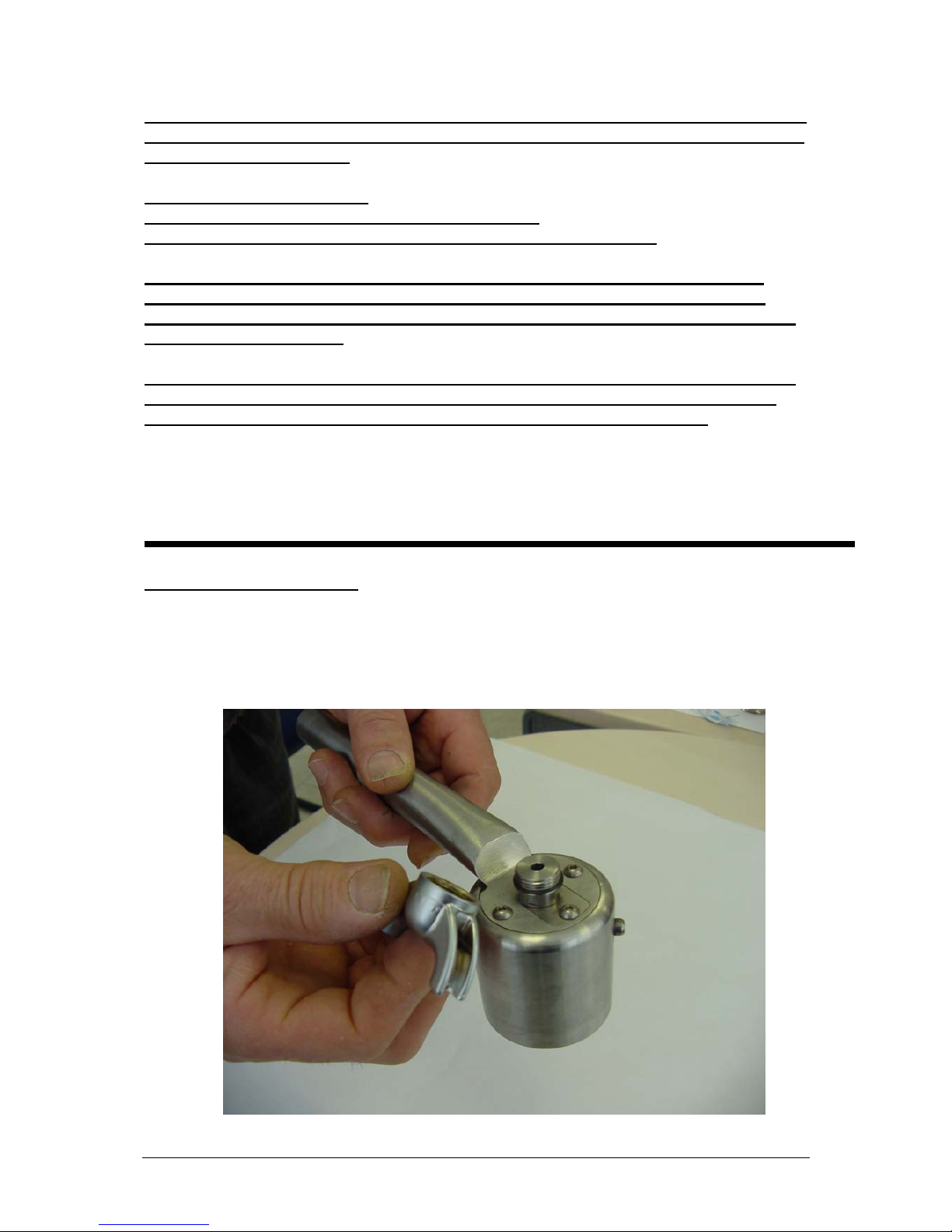

1. Unlock the filter holder from the filter holder group head with a clean sideways

movement of the handle to the left. Working on a clear work surface, turn the

filter holder upside down and unscrew the spout.

10

2. Using a small hex key (2,5 mm), unscrew the three socket head screws which fix

the two-part filter holder base to the filter holder basket.

3. Now, remove the check plate with the aid of the hex key.

11

4. Turn the threaded centre pin on the filter holder so that the spanner surfaces

(notches) are exactly parallel to the elongated straight-cut edges of the base plate

cavity of the filter holder. Please see photo below!

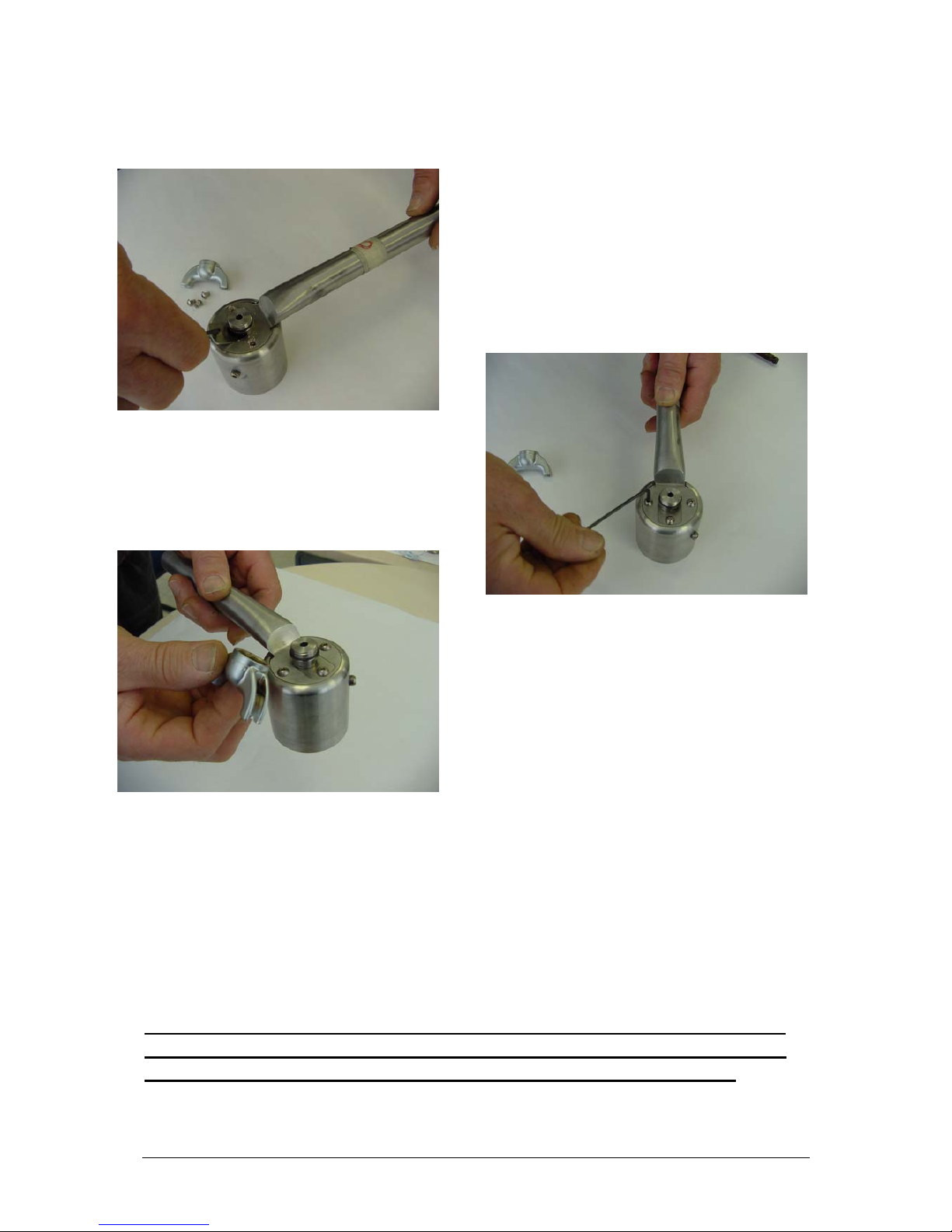

5. With the aid of a round object (for example a sturdy glass, as show in the photo)

that fits into the filter holder basket, place the filter holder over the glass pressing

down firmly until the filter holder spring is under tension.

12

5. Using the handle, jiggle the base place out of its seating and over the threaded

centre pin.

6. The filter basket with the O-Ring (sealing ring) which is part of the centre

threaded pin assembly, and, likewise, the coiled-up spring can now be eased out

from below. The old O-ring can be replaced with a new one at this point.

13

7. Once the O-rings have been exchanged, reassemble the group following the

disassembly instructions in reverse order: The >broader< Spiral side must point

in the direction of the basket base.

Then, once again with the help of a round object (base of a glass), recoil the

spring and reassemble the base plate on the filter holder following the photo

sequence below:

1.

2.

3.

14

8. Reposition the check plate in its seating and then reposition socket screws and

tighten with the hex key. Then, screw the spout back on and tighten.

1.

2.

3.

Finally, lock the filter holder back under its group head and switch electricity back on.

Switch the machine on and, after following normal start-up procedure, the espresso

machine is once again ready for use.

Carry out 2-3 test runs (espresso) to check whether the replacement of the seal has been

successful.

Espresso should only be delivered from the spouts under the filter holder.

No liquid should drip out of the area where the threaded centre pin meets

the filter holder base nor should any sputtering or spraying be seen.

15

Servicing and Maintenance

Product: Espresso-Machine

Model: Semi-automatic, built-in

Service-Instruction: 3/04 (Thermostat)

Problem:

Water for brewing coffee or water for hot beverages from the water

(or dry steam) wand is not delivered at the desired temperature. The

cause may be that one of the two safety thermostats on the heat

exchangers defective.

Under correct working conditions, the electrical connections in the thermostats are closed and power

is delivered. In the case of a fault (for example the heat exchanger runs dry causing subsequent

overheating of the heat exchanger), the reverse circuit breaker is activated to prevent the heating

elements from burning out.

Cause:

The heat exchangers on the machine are positioned one on top of the other. Each

heat exchanger is equipped with a safety thermostat. The sensors establish the

maximum and minimum temperature of water in the heat exchanger. The safety

thermostats are activated when there is no water flowing into the heat exchanger

or when defective sensors signal abnormally high temperatures. In theses

instances, the relative thermostat is activated breaking the circuit and it

subsequently needs to be reset manually (reversible).

Solution:

The machine needs to be opened up and the upper cover removed

following the relative service instruction thus making access possible

to the two thermostats.

Safety Advice for Service Engineers

Attention: Before commencing any work on the appliance, it should be “disconnected”

from the electricity supply. This can be done by:

either removing the appliance plug from the mains socket or by isolating electricity

supply to socket through safety circuit-breaker or by turning off electricity completely

at mains switch.

16

As an authorised Service Engineer, you should comply with all European testing

standards and the relevant safety regulations for electrical appliances, in order not to

endanger yourself or other people and to prevent any other kind of hazards and risks.

For this electrical appliance, due to various systems that contribute to the working of the

machine, it is important that you observe and take note of the technical specifications of

the machine which include:

Power supply: 240 Volt mains

Heat exchanger and operating pressure up to 15 bar

Water containers and water conducting pipes (some under pressure)

Only authorised Customer Service Engineers are allowed to carry out work on this

Espresso machine (the opening of parts of the machine that are secured by screws).

European testing and safety regulations should always be complied with when carrying

out work on the appliance.

The appliance manufacturer and the Servicing firm shall not be liable for work carried

out that is not conformant with test an safety regulations and, likewise, tampering or

work carried out by unqualified servicing firms and local service engineers.

Step-by-Step procedure:

1. Firmly clutch the handle on the spill-tray drawer, and gently slide the Espresso

machine out of its housing towards you. (Opening as for water and coffee refilling

or checking the grinder).

17

2. The upper front cover is screwed down with 6 countersunk screws. Unscrew and

remove all screws and take cover off.

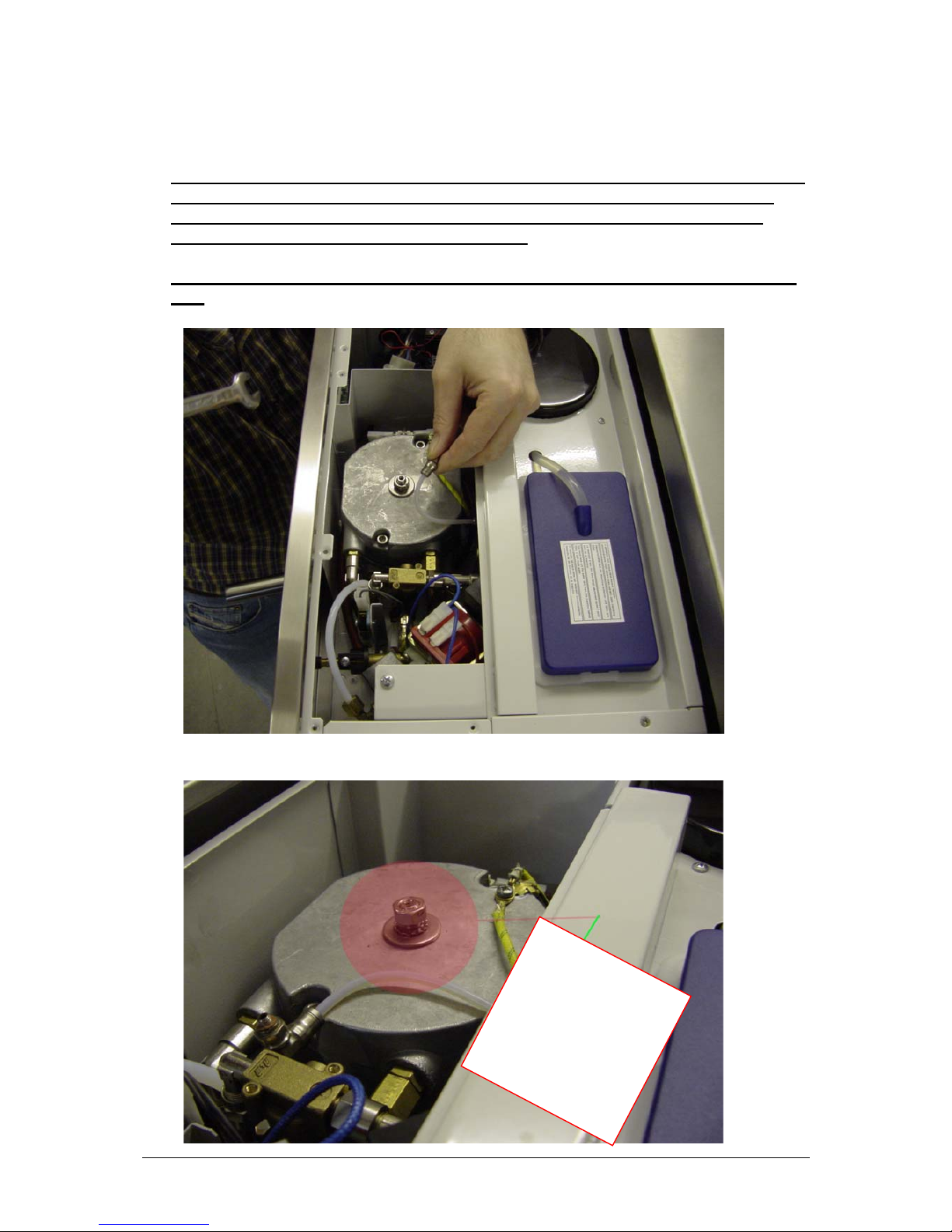

3. With the cover removed, the next photo shows the view of the inside layout from

above.

Unscrew the six

countersunk screws

on the cover.

Then remove cover.

18

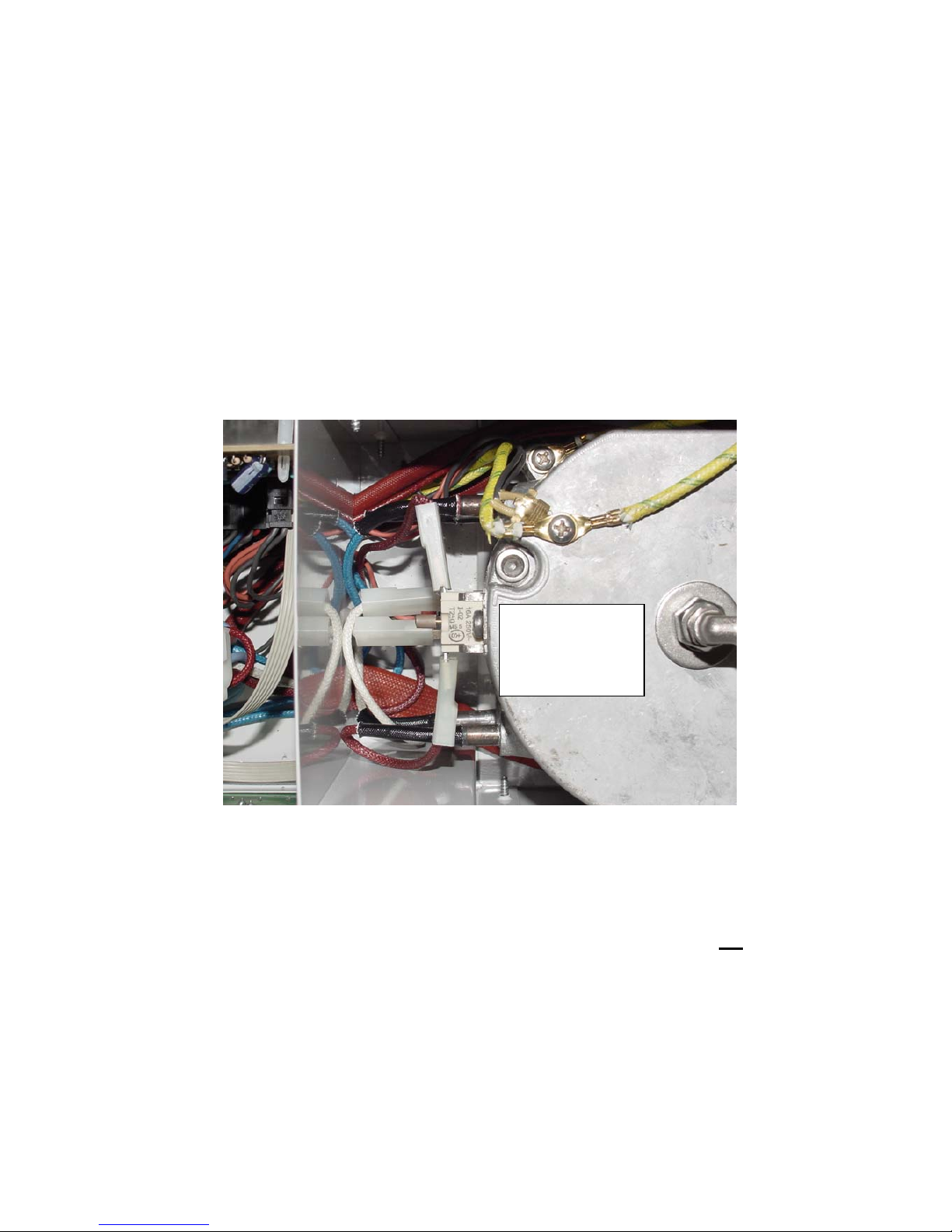

4. The following picture shows the top-positioned heat exchanger seen from above.

In the centre of the heat exchanger there is the water in-let pipe assembly

through which heated water under pressure is forced through the tampered

coffee during brewing . Top left >>at 10 O’clock<< there is the earth connection

with a brass seal under which the temperature sensor (Minimum-Maximum

operating temperatures) can be found.

5. On the left side >>at 9 O’clock<< there is the reversible thermostat. In the

middle, between the two electrical connections, the reverse push button can be

seen (grey-brown). This push button must be in the pushed-in position.

6. After the reverse push button has been set in the pushed-in position, close the

machine for testing. (do not reassemble the top front cover!); switch the machine

on following normal start-up procedure. Wait until the top left and top right leds

(showing brewing water and hot water/steam temperature) remain alight. For

testing purposes, turn the knob on the front panel and check whether hot water is

delivered from the wand. In the event that the thermostat should cut out again,

then the fault could be with the thermostat. In this case, disconnect power supply

to machine and open it up. Follow the procedure outlined below:

a. With the aid of a very short screwdriver for phillips head screws (if available use

a rachet ), unscrew the top screw on the upper thermostat. Remove both AMP

casings and unscrew the lower Phillips screw. Remove the thermostat and apply

a small amount of heat conducting adhesive to the back of the new thermostat,

On the left, the

thermostat. Centre

the reverse push

button.

19

stick into position and screw tight using upper and lower screws. Put AMP

casings back on.

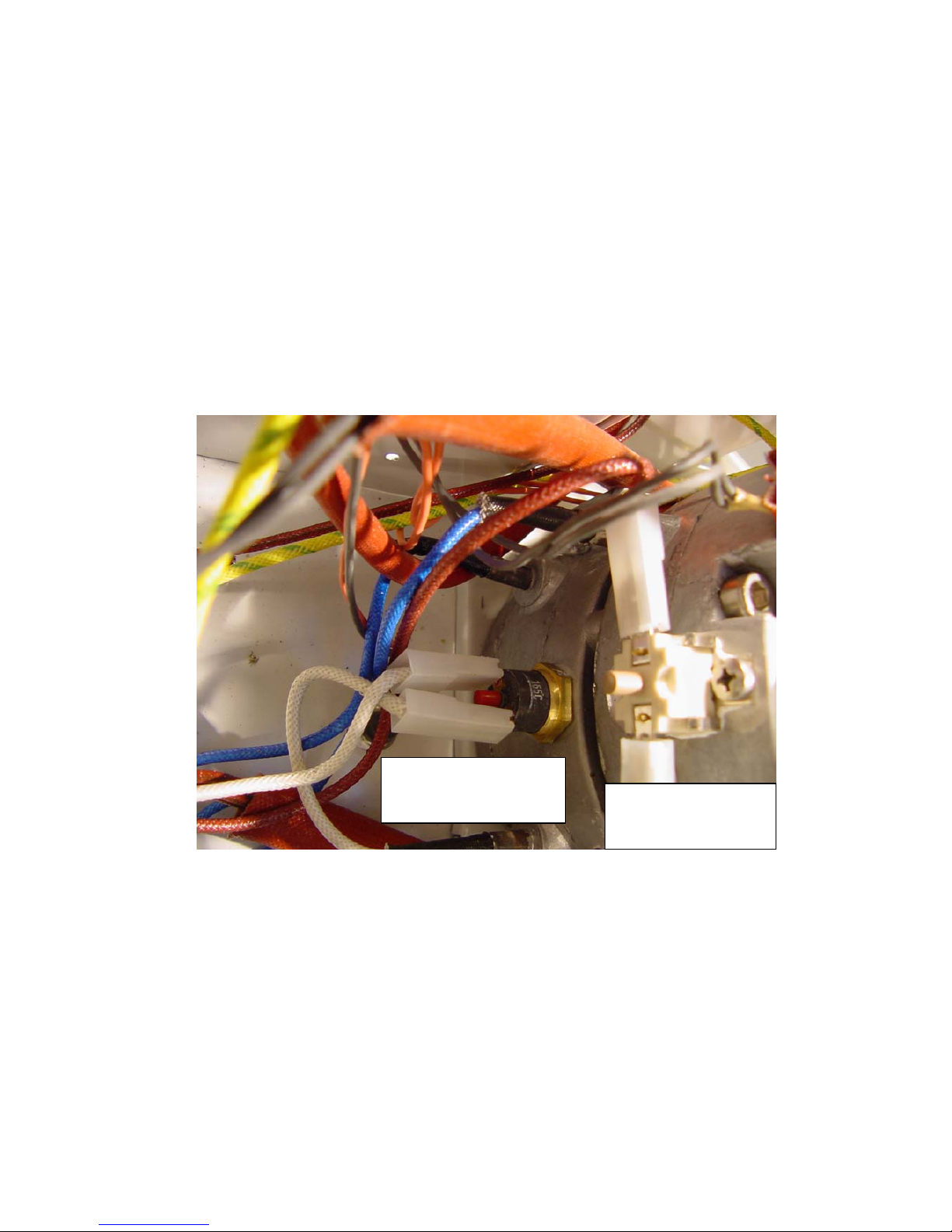

b. When the top-positioned thermostat has been unscrewed, the lower one becomes

visible and can be accessed. In the same way as before, to test the thermostat

push in the reverse (red) push button. If during the water and steam test, this

thermostat cuts out, then this could mean that it is also defective. In the case that

the bottom thermostat needs to be replaced, follow the procedure outlined for the

top thermostat. To unscrew the bottom thermostat use a suitable screwdriver.

Before doing this remove the AMP casings. The bottom thermostat makes

contact with the metal of the lower heat exchanger using a thin probe (fixed by a

screw). After the defective thermostat has been removed, apply thermal

conducting adhesive to the back of the new one, install and screw tightly into

position.

7. After having reversed (reset) the thermostat buttons and/or replaced the

thermostats, close up the machine ( do not yet screw the upper cover in place)

and test run the machine. When both brewing water and hot water/steam are

delivered from the wand at the right temperature, the repair has been carried out

successfully and the upper cover can now be screwed back into place.

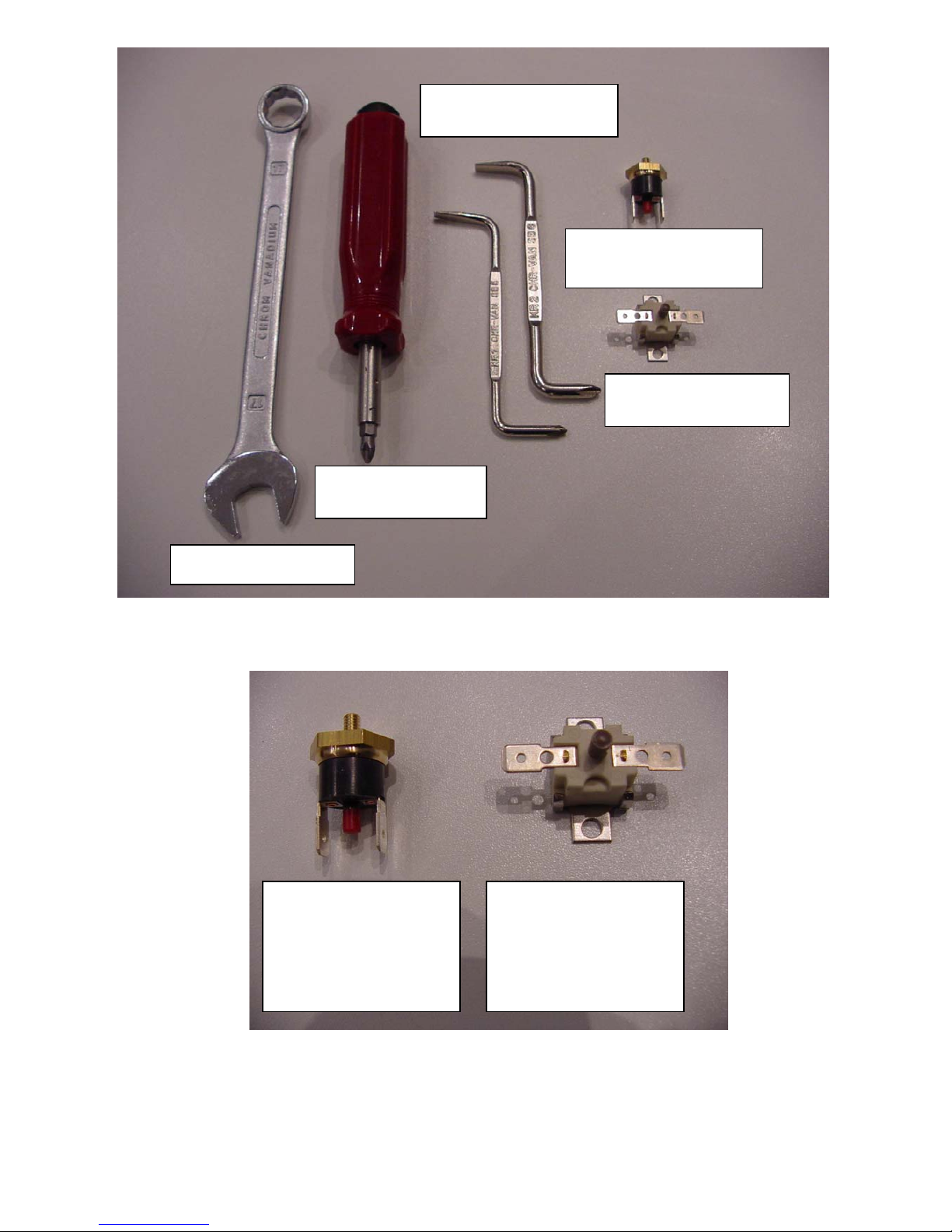

8. The following photos shows the hand tools and spare parts that are essential for

carrying out this service repair. Together with the routine delivery of thermostat

spare parts for the Espresso machine, for installing two thermostats you will also

need to order a quantity of thermal conductive adhesive. This conductive paste

must be applied to the back surface in contact with the heat exchanger of the new

thermostats to be installed.

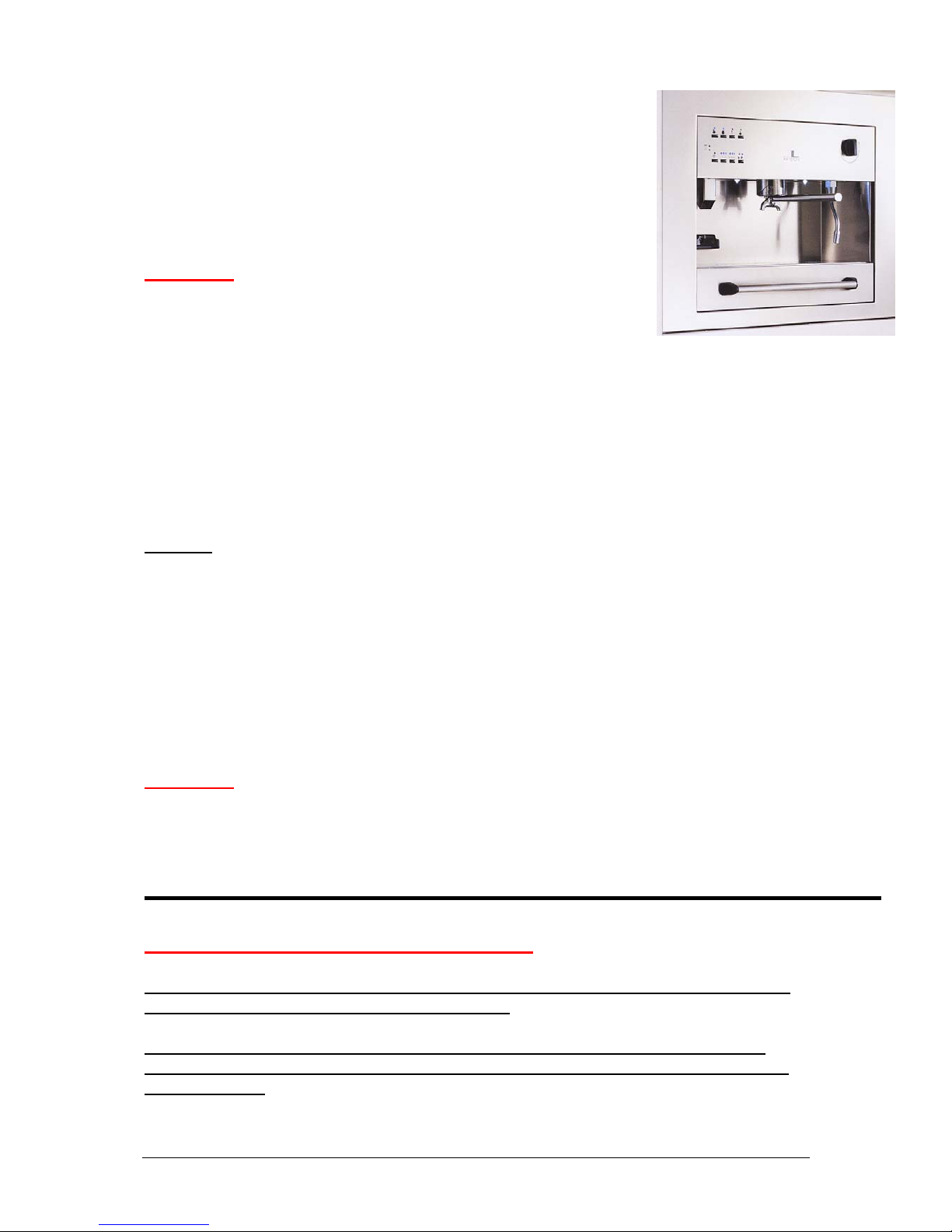

Here above, the

thermostat for the bottom

heat exchanger

Here above, the

thermostat for the top

heat exchanger

20

No 17 spanner

Phillips head

screwdriver

Phillips head rachet

Rev-Thermostat

bottom heat exchanger

Rev-Thermostat

Top heat exchanger

Bottom heat exchanger

thermostat

( Coffee brewing water)

165 ° C

nut size

no. 17 spanner

red reverse breaker

Top heat exchanger

thermostat

(Hot water + steam)

195 ° C

Screw holdfast plates X 2

Phillips head screws

brown reverse breaker

21

Servicing and Maintenance

Product: Espresso-Machine

Model: Semi-automatic, built-in

Service Instruction: 4/04 Stops - blocking

Problem:

The dual function of the drawer handle is not

working properly. When the drawer is pulled out,

the whole appliance slides forward out of its housing because the

blocking mechanism is not working.

Only when the drawer handle is lifted and pulled should the appliance come out

of its housing. By simply pulling the drawer handle, only the drawer should come

out.

Cause:

The movement required to slide the appliance out of its housing is for the handle

to be grasped and lifted slightly upwards; when this mechanism is working

correctly the stops blocking the appliance on the right and left sides of the

machine are released, so that the appliance slides along the glides and can be

pulled forward. Sometimes a production defect means that these stops are not

locked into position behind the corresponding groove (they do not fall into

position) so that the appliance is pulled forward out of its housing every time the

drawer is opened.

Solution:

The plastic stops need to be filed down so that they engage with the

grooves on the glide frames on the housing of the appliance.

Safety Advice for Service Engineers

Attention: Before commencing any work on the appliance, it should be “disconnected”

from the electricity supply. This can be done by:

either removing the appliance plug from the mains socket or by isolating electricity

supply to socket through safety circuit-breaker or by turning off electricity completely

at mains switch.

22

As an authorised Service Engineer, you should comply with all European testing

standards and the relevant safety regulations for electrical appliances, in order not to

endanger yourself or other people and to prevent any other kind of hazards and risks.

For this electrical appliance, due to various systems that contribute to the working of the

machine, it is important that you observe and take note of the technical specifications of

the machine which include:

Power supply: 240 Volt mains

Heat exchanger and operating pressure up to 15 bar

Water containers and water conducting pipes (some under pressure)

Only authorised Customer Service Engineers are allowed to carry out work on this

Espresso machine (the opening of parts of the machine that are secured by screws).

European testing and safety regulations should always be complied with when carrying

out work on the appliance.

The appliance manufacturer and the Servicing firm shall not be liable for work carried

out that is not conformant with test an safety regulations and, likewise, tampering or

work carried out by unqualified servicing firms and local service engineers.

Step-by-step procedure:

1. Clasp the drawer handle and lift so that the Espresso coffee machine glides

forward (opening as for water and coffee filing or checking the grinder).

23

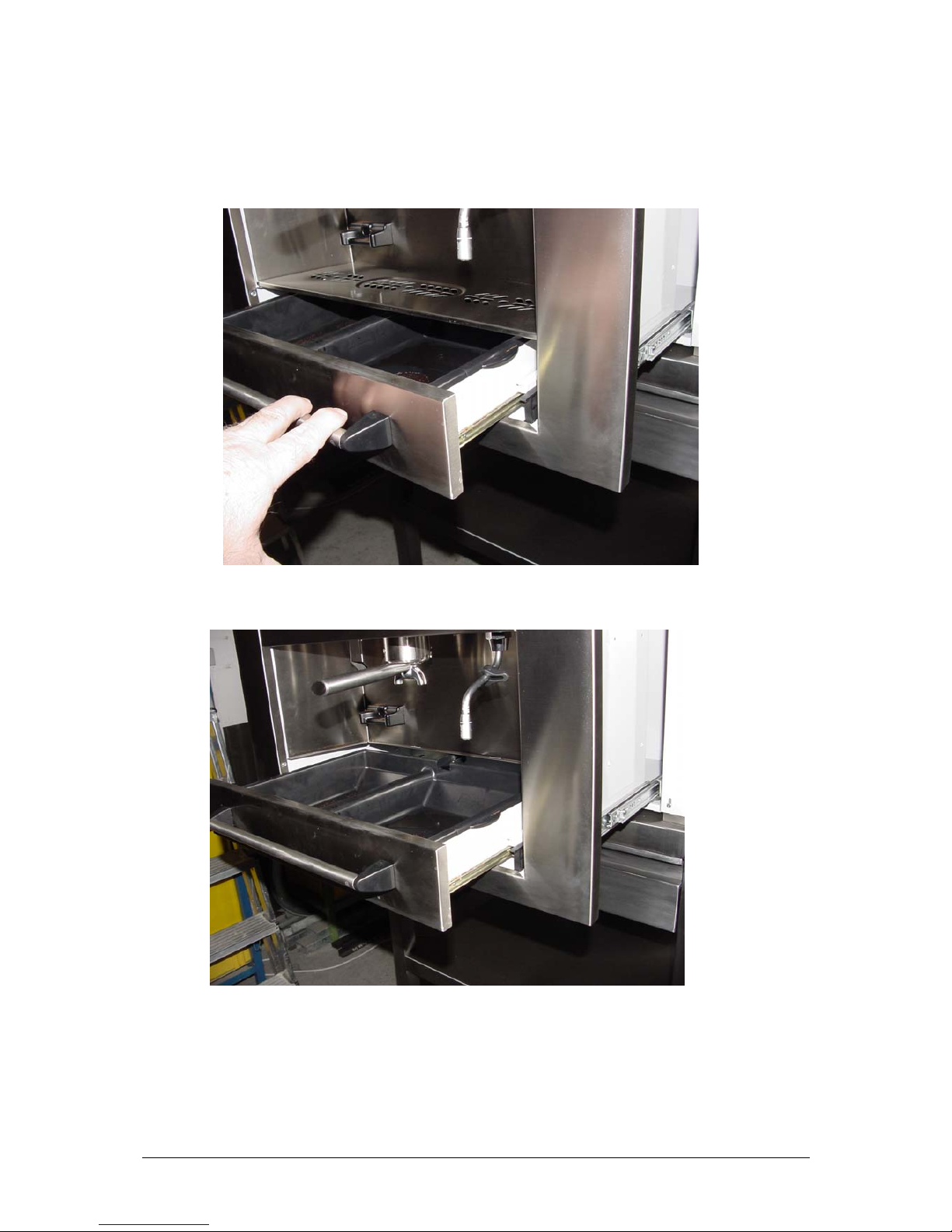

2. After the machine has been pulled out, now pull at the drawer out until it reaches

its most forward position. Remove the top spill plate.

3. Remove the double-partition drawer liner.

The next photo shows one of the two (black) stops that need to be worked on.

24

Disassemble the whole drawer to make it easier to access the two stops from which

you will need to file off a small layer of plastic.

4. The whole drawer assembly is fixed underneath with four counter-sunk screws.

These screws can be accessed easily from below and need to be unscrewed.

Unscrew these four screws

25

5. Unscrew all 4 screws from below. This frees the whole drawer assembly which

can now be taken out.

6. You will find easier to work if you place the whole drawer assembly upside down

on a table. Now the corners of glide notches can be worked on comfortably.

After having taken out the 4 screws,

remove the whole drawer assembly

including the glide system and

place it upside down on a table

.

26

7. Now you need to file away about 2mm of material from the sloping surface of

the small, approximately 5 x 5 mm plastic components. It is better to >>file off a

bit more rather than a bit less<< , otherwise when you have re-assembled the

drawer, you will not have obtained the desired result, and this will mean having

to repeat the whole procedure one more time.

8. The small surfaces on both plastic components need to be filed down. These

surfaces should maintain the existing sloping edge, so that later, when they have

been re-assembled that can >>glide<< more easily behind the housing frame.

After final re-assembly, the drawer, after the appliance has been reinstalled in its

housing, should descend slightly (4-5 mm) and engage.

You will need to file off

about 2 mm of plastic from

the upper corner of this stop

using a small file.

File off about 2 mm from the top corner of the small

(approx. 5 x 5 mm) sloping surface only. In normal use the

draw should engage on this sloped surface. The appliance

should not glide out of its housing when the handle is lifted,

otherwise when the stops are lowered and engaged on the

drawer should slide out.

27

Only after lifting the drawer handle should the appliance glide out of its housing.

When the drawer handle is simply pulled, only the drawer should pull out.

Reassemble in reverse order:

1.

2.

3.

FINISHED!

28

Servicing and Maintenance

Product: Espresso-Machine

Model: Semi-automatic, Built-in

Service Instruction: 5/04 Cable slack

Problem:

The appliance (cable) that sits between the panel wall of the machine

housing and the back panel of the espresso machine on the left-hand

side, should form a loop, so that the espresso machine can be glided

smoothly out of the housing. However, it is causing an obstruction

and the espresso machine does not sit flush in the built-in cabinet, the

safety switch cannot engage and thus the machine has no power

supply.

Under correct working conditions, when the machine has been pulled out, the

power cord should lay in a straight line between the strain relief device at the

back, on top, on the outer housing and the cord feed-in point in between the two

panels. There should be no cord slack between the appliance and the outer

housing panel wall.

Cause:

The cord is not sitting in the prescribed way, that is, entering from behind and

running along the top in the fixed strain relief clamp on the outer housing and in

a straight line to the entry point on the appliance that is positioned in about the

centre of the machine in between the two wall panels, but it is forming a loop of

slack. When the machine is pushed into its housing cabinet, the length of the cord

(of varying size) forms a loop of slack in between the two wall panels. A red

plastic runner can be found at the back that supports the cord ensuring that the

movement of the cord is smooth between the two wall panels.

Solution:

Taking the cord >>between two fingers<< push it a far to the right as

possible between the two wall panels and check that cable moves

smoothly on the >>free side<< (between appliance and cabinet back

wall panel). If this is not the case, >>bend<< the cord into the correct

shape. The loop in the cord should only be formed inside the two wall

panels. No loop or slack should be formed on the >>free<< side,

otherwise it will form an obstruction between the appliance back

panel and the fixed (screwed to the cabinet) housing back panel.

29

Safety Advice for Service Engineers

Attention: Before commencing any work on the appliance, it should be “disconnected”

from the electricity supply. This can be done by:

either removing the appliance plug from the mains socket or by isolating electricity

supply to socket through safety circuit-breaker or by turning off electricity completely

at mains switch.

As an authorised Service Engineer, you should comply with all European testing

standards and the relevant safety regulations for electrical appliances, in order not to

endanger yourself or other people and to prevent any other kind of hazards and risks.

For this electrical appliance, due to various systems that contribute to the working of the

machine, it is important that you observe and take note of the technical specifications of

the machine which include:

Power supply: 240 Volt mains

Heat exchanger and operating pressure up to 15 bar

Water containers and water conducting pipes (some under pressure)

Only authorised Customer Service Engineers are allowed to carry out work on this

Espresso machine (the opening of parts of the machine that are secured by screws).

European testing and safety regulations should always be complied with when carrying

out work on the appliance.

The appliance manufacturer and the Servicing firm shall not be liable for work carried

out that is not conformant with test an safety regulations and, likewise, tampering or

work carried out by unqualified servicing firms and local service engineers.

Step-by-step procedure:

1. Photos 1 and 2 show the machine that has been pulled completely out to the front

and the running of the cable from the side round to the back (to the strain relief

clamp). When the cable is positioned correctly it should form a loop between he

two panel walls. The small red plastic runner should be fixed firmly to the narrow

corner edge at the back preventing the cord from chaffing with the metal.

30

Photo 1 Photo 2

2. Photo 3 shows the cable after the side panel has been unscrewed, and how it

should run correctly behind the side panel. The cable should be placed as far to

the right as possible behind the panel. This can be done by taking the cable

between two fingers

and pushing it from left to right into the gap inside the

panel. The cable should not form a loop of

slack at the back of the housing but should

run fairly taught from the upper strain relief

device to the red plastic support clip.

The cable slack should only run in the gap behind

the two panels, as shown.

The next two photos show the red plastic support

clip (cable protection) and how the cable should run

from in between the two panels and behind and up

to the strain relief device.

Photo 3

At this point, the cable should run

diagonally upwards. When the machine

is repositioned inside its housing the

cable should not form any slack. Slack

cord between the back panel of the

machine (that needs to be moved in and

out of out of its housing) and the back

panel of the housing (screwed to the

cabinet) will create an obstruction and

prevent proper closing and engagement.

As a result, the limit switch cannot

engage, the machine does not work and

the espresso machine comes out of its

housing every time the drawer is

opened.

Photo 4

31

Photo 5

Check that the red plastic

protective clip is always fixed to

the narrow curved edge of the

back outer panel!!!

32

Servicing and Maintenance

Product: Espresso-Machine

Model: Semi-automatic, Built-in

Service-Instruction: 6/04 Coffee Grinder

Problem:

The coffee grinder is not delivering coffee even

though the sound of the motor can be heard.

In correct working conditions, the coffee grinder should deliver ground coffee

from the hopper. The degree of the desired coffee grind can be set individually

when the machine is moved out of its housing (dual function of the front drawer

handle - to pull out machine lift handle and pull). On the left-hand side of the

machine there is the grind selector for choosing the desired grind of coffee.

Cause:

a. This could that the grinder has been set wrongly. The grind is set too

fine, so that the milling wheels of the grinder are so close together that

coffee beans cannot pass between them.

b. Because the grind selection has been set to >>very fine<< the milling

wheels have already come into direct contact with each other and this

has caused damage to the plastic milling wheels that are housed in the

gear motor part of the appliance. The gears have been permanently

damaged.

Solution:

To a.

Pull the machine out of its housing. Remove coffee bean hopper cover

and empty. At the back of the machine, on the left-hand side, feel for

the safety switch and manually press and hold. At the front of the

machine control panel, activate grinder (you should hear the sound of

the motor) and look into the hopper to see whether the milling wheel

is turning. If the milling wheel is turning, then the grinder has not

been damaged. In this case follow this procedure:

Using the grind selector, turn the dial at least ten times in the

direction of >>coarse<<. Fill hopper with coffee beans and start

grinder. If the coffee hopper delivers ground coffee, then the problem

is a question of grind selection and can be solved by carefully

selecting the desired grind by turning the dial back and forth.

Remember to read the operating instructions (and not select a very

fine grind!!)

33

To b.

When the milling wheels in the grinder are not turning, but the sound

of the motor can be heard, this means that the grinder is damaged

and a new grinder must be installed following this service and repair

instruction procedure.

Safety Advice for Service Engineers

Attention: Before commencing any work on the appliance, it should be “disconnected”

from the electricity supply. This can be done by:

either removing the appliance plug from the mains socket or by isolating electricity

supply to socket through safety circuit-breaker or by turning off electricity completely

at mains switch.

As an authorised Service Engineer, you should comply with all European testing

standards and the relevant safety regulations for electrical appliances, in order not to

endanger yourself or other people and to prevent any other kind of hazards and risks.

For this electrical appliance, due to various systems that contribute to the working of the

machine, it is important that you observe and take note of the technical specifications of

the machine which include:

Power supply: 240 Volt mains

Heat exchanger and operating pressure up to 15 bar

Water containers and water conducting pipes (some under pressure)

Only authorised Customer Service Engineers are allowed to carry out work on this

Espresso machine (the opening of parts of the machine that are secured by screws).

European testing and safety regulations should always be complied with when carrying

out work on the appliance.

The appliance manufacturer and the Servicing firm shall not be liable for work carried

out that is not conformant with test an safety regulations and, likewise, tampering or

work carried out by unqualified servicing firms and local service engineers.

34

Step-by-step procedure:

1. When the machine has been pulled out, both upper covers need to be unscrewed and

removed.

2. First remove the cover at the front. Look at the following photos as a guide:

Photo 2/1

Photo 2/2

Unscrew the six

countersunk screws

on the cover.

Then remove cover.

35

3. Next remove the back cover. First, remove the cover on the water container and coffee

container. Remove the round plastic filter holder on the end of the water tube and slide

the tube out of the opening in the cover, remembering first to use a felt-tipped pen to

mark the position of the tube in the water container so that it can be replaced in the same

position. This is important as you will see later. Place both covers to one side. Observe

the following photos:

Photo 3/1 Photo 3/2

Photo 3/3 Photo 3/4

4. The water container mounting now needs to be disassembled. To do this, the

stops on the thin side walls for the front dividing panel must be pushed as far

back as possible so that the mounting can be pushed up to the top and removed.

The base of the mounting is sprung. So please be careful that this spring is not

lost. When re-assembling the mounting, position the base horizontally and

reinsert the side plates in the corresponding >>slots << . (See the following

photos)

36

Photo 4/1

Photo 4/2 Photo 4/3

5. In photo 4, looking in a diagonal direction from above, you can see the grinder motor

below. You can also see the wiring. The two AMP – plug connections for the power

supply can be disconnected. You should trace the earth wiring through the housing

opening and into the front section of the machine. The plug is positioned on the front

water valve and must be disconnected.

The safety tabs

must be bent so

that the container

can be pushed up.

37

6. After having loosened the earth wire on the front water valve (see photo), you can now

get to work on disassembling the grinder.

7. You are looking down into the empty coffee bean hopper. You will see two socket

screws that should be unscrewed and removed. Detach the transparent hopper

from the grinder and remove. Remember that the mark on the rim of the

transparent hopper should positioned later on the left-hand side.

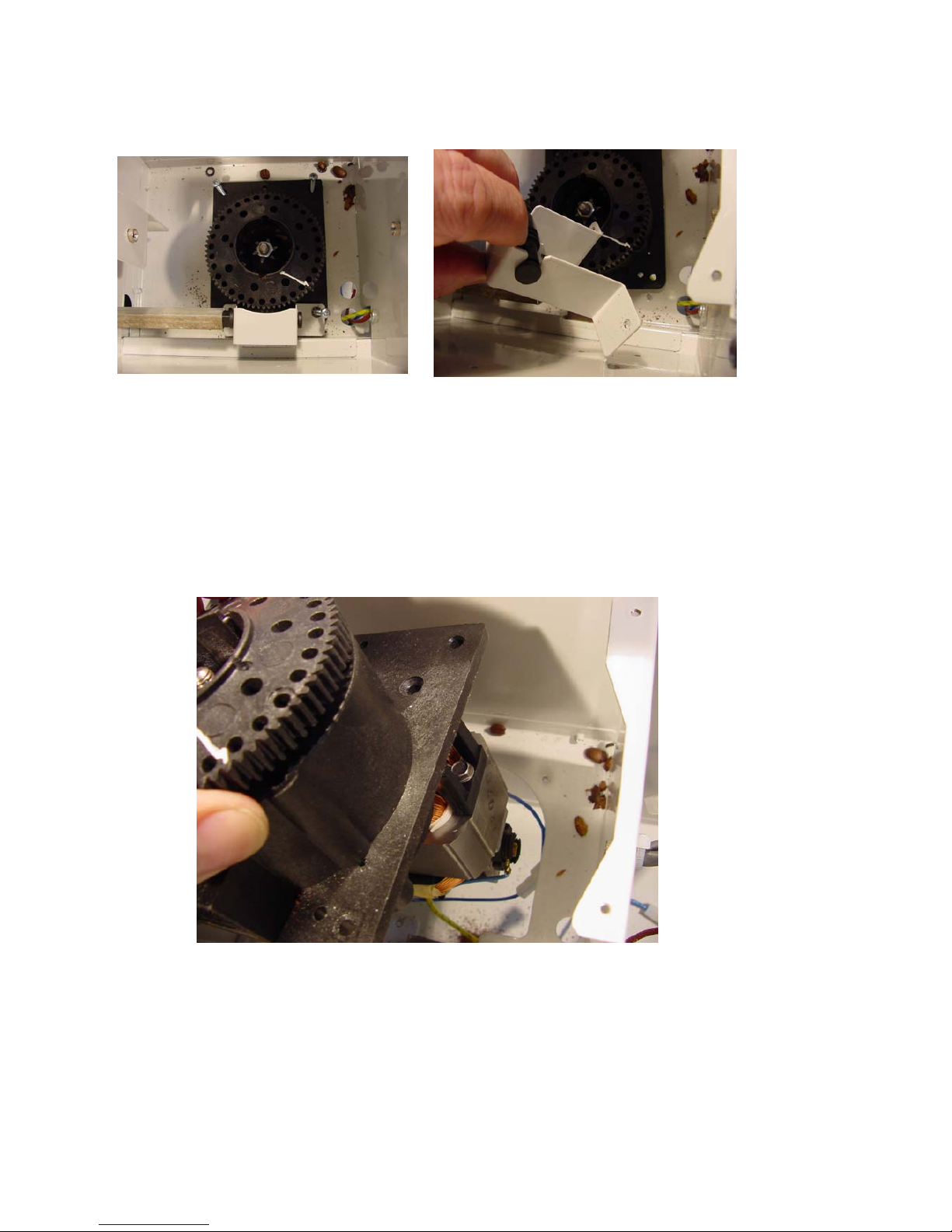

8. Now, it is the turn for the grinder to be disassembled. First unscrew the four

socket head screws (see photo on the next page) The front screw on the left is not

easy to access and is partially hidden by the axel arrangement of the grind

selector. Once all four screws have been removed, the small transmission worm

38

screw (behind the white cover) can be removed and by jiggling the whole grinder

slightly the square axel can be uncoupled ; remove the worm screw!

Photo 8/1 Photo 8/2

9. Now the entire grinder assembly consisting of motor and gearbox containing the

milling wheels can carefully be taken out. During this operation, manually pull

the two electrical wires and the long earth wire through the housing shaft

opening.

Photo 9/1

39

10. You should now prepare the new gear motor assembly so that all plug connections

have unmistakable >>male<< and >>female << terminals and so that the

electrical connections that will be set up will work correctly. Now, working in

reverse order, firstly replace the gear motor into its corresponding shaft and

roughly position. Then connect up the blue and brown wires using suitable plugs

and insert the earth wire through the corresponding gap in the housing so that it

comes out into the front section of he machine and, there, reconnect it to the

water valve.

Photo 10/1

11. Now the worm screw forming part of the angled transmission on the grind

selector should be positioned so that it engage with the teeth of the gear motor

wheels. At the same time, the coffee outlet on the grinder must be positioned so

that it is matches that of the coffee hopper at the front and connection in the

square hole set up.

12. Now reposition plates that were previously removed carefully over the holes and

insert socket screws and tighten.

13. Next, reposition the transparent water holde , remembering to >>carry out<<

suitable tap connection and fix the container using the two black screws.

40

14. When re-assembling the mounting for the water container, remember that the

sprung base plate should be engaged in the appropriate holes in the side panels.

After the mounting assembly has been reinserted, bend the safety latches slightly

outwards so that the mounting for the water container is secured.

15. Now, replace the back upper cover. The tube that delivers water from the flow

gauge to the container must be put back into position very carefully.

It should be re-inserted into the round opening on the back upper cover. When

replacing the cover, make sure that the tube running between the water gauge and

the hole in the cover has no kinks, which would cause major problems to the water

flow system.

16. Now, insert the tube through the opening in the blue cover of the water container

remembering to position it as it was positioned before with the aid of the felt pen

marking. Then push the transparent filter into the end of the tube.

17. Replace water container in its mounting and replace cover. Check that the tube

lies flat against the cover so that, when the machine is pushed back into its

housing, it will not be obstructed or get caught up.

18. Screw the upper back cover down and then replace the front cover and screw back

into place.

41

19. A general note needs to be made regarding the replacement of the grinder on the

Espresso machine and concerns the pre-setting of the new built-in grinders. The

manufacturer has used two markings for recognising the pre-setting that can be

found on the moving teeth component of the gear motor and the apparently slowmoving casing.

Please look at the following photos. This pre-setting should not be changed under any

circumstances, otherwise delivery of the right coffee grind will become lengthy and

difficult. The markings are covered in the section >>selection settings<< for the coffee

grind in the User’s Guide.

This pre-setting will allow the individual grind preferences - coarse or fine – to be

selected by simply turning the grind selector.

42

Servicing and Maintenance

Product: Espresso-Machine

Model: Semi-automatic, built-in

Service-Instruction: 7/04 Sensors

Problem:

Brewing and beverage water (or steam) does not reach the prescribed

temperature. The reversible thermostats on both heat exchangers for

coffee and/or hot beverages are repeatedly triggered after being

manually reset, even though there appears to be no problem with the

water supply and in-let system.

Under correct working conditions, each sensor monitors the temperatures of the

coffee-brewing water heat exchanger and the hot water/steam heat exchanger

and regulates the minimum and maximum temperatures, which are different for

each heat exchanger. So long as the temperature is above the minimum, a

corresponding led (on the top left or right) of the espresso machine front control

panel will flash on and off. The led will stop flashing and will remain on when the

temperature falls to the minimum. The relative sensor will switch the heater off

when the maximum temperature is reached. When temperature exceeds the

maximum limit (sensor error/fault?), the safety thermostat is triggered

(reversible).

Cause(s):

a. The sensor may be faulty or defective. The corresponding blue led on

the diagnostics panel remains permanently on, or the reverse safety

thermostat is repeatedly triggered.

b. It may be caused by an obstruction in the water flow system (a kink in

tubes running between the water container and flow gauge) or, a

general >>furring up<< of the system leading to a lack of water in the

heat exchangers, resulting in overheating and the safety thermostats

being activated.

Solution:

to: a.

The sensor need to be replaced following this detailed Service

Instruction.

to: b.

The water flow system needs to be checked. This should include water

flow to the Espresso brewing head (top left function pad = press

deliver coffee) and to wand >>hot water/steam<< - >>hot water<< or

>>dry steam<<, following the relative operating instructions. During

this operation the >>water pump<< should function silently ensuring

43

that sufficient water is forced out of the taps. To be checked:

(Caution

: this should only be carried out by a service engineer if

required during servicing!!!) The movement required is like that for

coffee or water servicing, pull out the machine (lift up and pull

forward) and on the left-hand side, behind, manually activate the

safety switch so that the machine is electrified. Next, (place a

container under the water taps!). Press the top left pad (brew coffee)

and look into the back section between the blue water cover and the

entry hole and check whether water is flowing. See photo! Carefully

jiggle the tube left and right to eliminate any kinks that might be

along the tube (which cannot be seen because it is behind the casing).

Safety Advice for Service Engineers

Caution: Before commencing any work on the appliance, it should be “disconnected”

from the electricity supply. This can be done by:

either removing the appliance plug from the mains socket or by isolating electricity

supply to socket through safety circuit-breaker or by turning off electricity completely

at mains switch.

Caution: For the purpose of simply carrying out testing and checking of the machine,

the Service Engineer may leave the machine connected to the mains power supply when

there the approved electrical safety breaker device installed at the back, in the left-hand

bottom corner of the machine (that cuts out power supply in all directions between

appliance socket and appliance electrical circuit) is manually activated and cuts out

mains power to the machine.

As an authorised Service Engineer, you should comply with all European testing

standards and the relevant safety regulations for electrical appliances, in order not to

endanger yourself or other people and to prevent any other kind of hazards and risks.

44

For this electrical appliance, due to various systems that contribute to the working of the

machine, it is important that you observe and take note of the technical specifications of

the machine which include:

Power supply: 240 Volt mains

Heat exchanger and operating pressure up to 15 bar

Water containers and water conducting pipes (some under pressure)

High temperatures in water conducting system and heat exchangers

Only authorised Customer Service Engineers are allowed to carry out work on this

Espresso machine (the opening of parts of the machine that are secured by screws).

European testing and safety regulations should always be complied with when carrying

out work on the appliance.

The appliance manufacturer and the Servicing firm shall not be liable for work carried

out that is not conformant with test an safety regulations and, likewise, tampering or

work carried out by unqualified servicing firms and local service engineers.

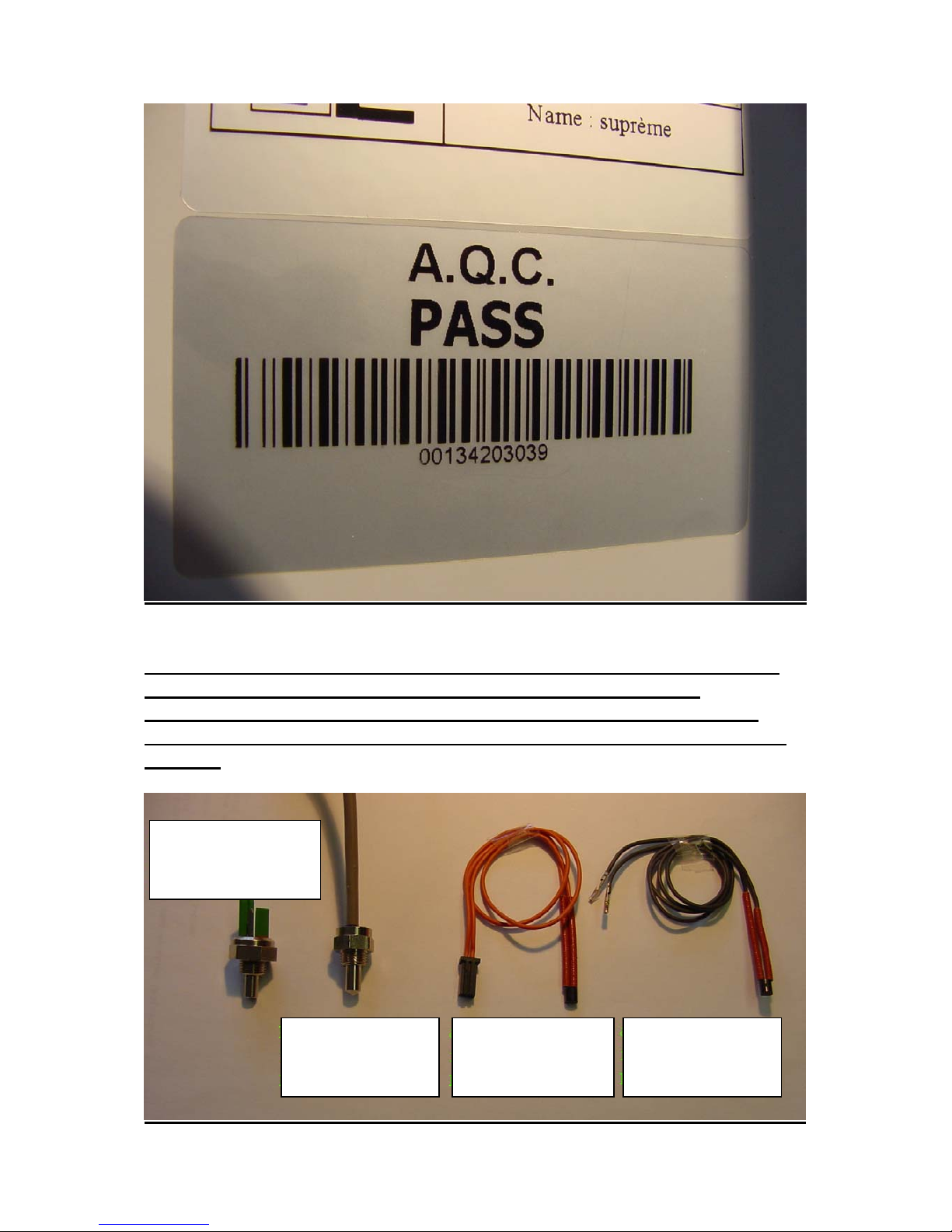

Important information on manufacturing coding

AQ PASS – Serial number

Artech – Espresso machine

000/0/00/00/000

Day – serial number

Year – (last two digits)

Production week in year

Day (1-7) of corresponding week

Customer reference number

Shown above is the previous coding system used up to week 47/2003. The 1

st

and 2nd digit groups were not

used.

After week 47, the coding shown below was introduced and is now the valid coding system.

00/00/000

Serial number

Year – (last two digits)

Production week of year

45

There are two different types of temperature sensors currently in use. As

from Wk 42-2003, the new, larger sensors were introduced. The

instructions that follow are valid for both types. The procedure for the

older type of sensor will be described first, and then the procedure for the

new one.

New sensor for bottom

heat exchanger

New sensor for top

heat exchanger

Old sensor for bottom

heat exchanger

Old sensor for top

heat exchanger

46

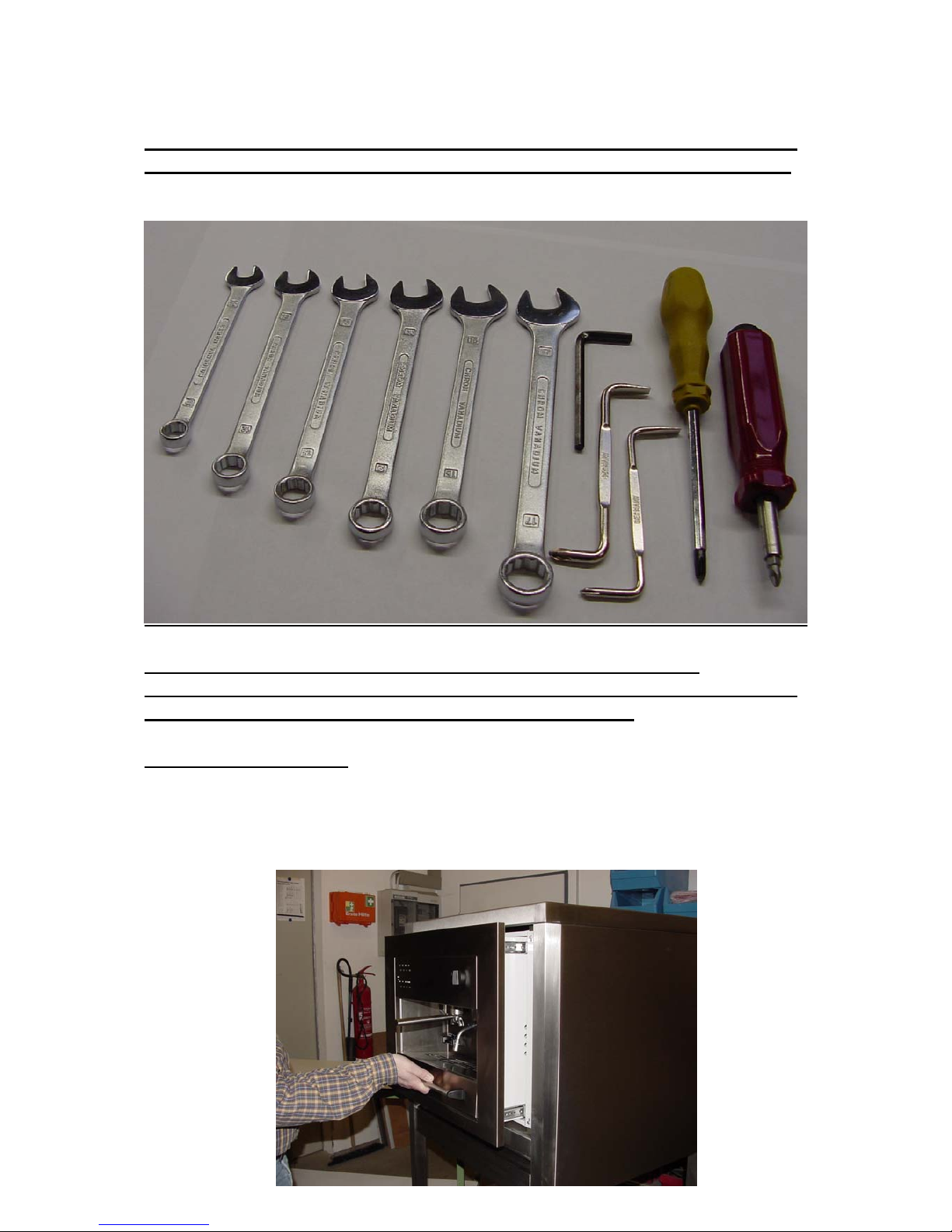

The hand tools that are essential for carrying out servicing on the Espresso

Machine are shown below and should always be part of your servicing kit.

In addition to screw key and two rachets, you will also need two

screwdrivers (one normal one and one with interchangeable bits) as well as

spanners for a range of widths: 10, 12, 13, 14, 15 and 17.

Step-by-step procedure

1. Firmly clutch and lift the handle on the spill-tray drawer, and gently slide the

Espresso machine out of its housing towards you. (Opening as for water and

coffee refilling or checking the grinder).

47

2. The upper front cover is screwed down with 6 countersunk screws. Unscrew and

remove all screws and take cover off.

3. With the cover removed, the next photo shows the view of the inside layout from

above.

Unscrew the six

countersunk screws

on the cover.

Then remove cover.

48

4. The following picture shows the top-positioned heat exchanger seen from above.

In the centre of the heat exchanger there is the water in-let pipe assembly

through which heated water under pressure passes. Top left >>at 10 O’clock<<

there is the earth connection with a brass seal under which the temperature

sensor (Minimum-Maximum operating temperatures- older installation layout)

can be found.

5. On the left side >>at 9 O’clock<< there is the reversible thermostat. In the

middle, between the two electrical connections, the reverse push button can be

seen (beige-brown). Test the thermostat by pushing in the button. Wait to see

what happens!

6. After the reverse push button has been set in the pushed-in position, close the

machine for testing (do not reassemble the top front cover!). Switch the machine

on following operating instructions. Wait until the top left and top right leds

(showing brewing water and hot water/steam temperature) remain alight. For

testing purposes, turn the knob on the front panel and check whether hot water is

delivered from the wand. In the event that the thermostat should be triggered

again, then the fault could be with the sensor on the corresponding heat

exchanger. In this case, disconnect power supply to machine and open it up.

7. Follow the photo sequence and explanation in the next section to replace sensor.

This procedure is for the >>old<< type of sensors.

T

op left, the top

thermostat. In the

centre there is the

beige-bown pushbutton

T

he sensor is

under the earth

cable

49

8. Unscrew the earth cable connection

9. Move both earth cables, the earth connection assembly, screw, and earth seal to

one side, and use the short insulation wires to take the defective sensor out of the

hole in the heat exchanger.

10. Now find a >>clear working space<< as the diagnostics and settings panel needs

to be disassembled. The panel is fixed on the outside by two screws underneath

on the right and on the left. First, remove knob on the right, then unscrew right

screw underneath and then left screw. See photos!

10/1 10/2

50

10/3

11. Now, inside the electronics panel, at the front on the far left remove the multiterminal plug and carefully lift it up as far as the wire will allow it to be lifted.

Now, make room in the lower area for the main circuit board. Look at the view

of the circuit board after the large plug has been removed:

Here you can see the plug (on the right, black wire) of the sensor that has just been

freed. From the front, carefully put your hand into the opening that has been created in

the housing and remove this plug and wire with the sensor attached through the gap,

lifting it >>over and out<< of the heat exchanger zone and into the electronic one (or,

alternatively, pull the wire into the heat exchanger zone).

If this does not resolve the problem, you need to >>make room<<for the next parts to be

disassembled. Remove the top cover. In detail, this entails removing the cover from the

coffee container, the filter at the end of the water tube and taking the tube out of the

cover (first, mark the tube so that it can be repositioned in its old position later). Now,

remove the water container and loosen all cover screws and remove cover. Empty the

coffee container. Remove transparent coffee container after having loosened both black

screws. Later, using the marking (on the left) replace.

51

See the following step-by-step photos:

Loosen all screws

Remove cover

Empty coffee storage container and after having loosened

the two screws, take it out. Now, the back screw fixing the

metal plate separating the heat exchanger and electronic

zones can be accessed. The front screw can be accessed

after having removed the switch cover. Loosen screws!

Multi-terminal plug has already been loosened.

Remove the two earth connections and the two primary

line wires (brown and blue) lying on L and N and the two

secondary line wires lying on 1 and 2. Take out the

dividing plate.

Now, it is possible to track the sensor connections that

need to be loosened to the electronic zone, loosen them

and lay a new one.

52

Plug socket for the two black

wires (adapter box) of the hot

water sensor

Plug socket for flatband connection

between main circuit board and front

switch circuit board.

Plug socket for the two red

wires (adapter box) of the

coffee brewing water sensor

53

12. If it was clear at the start of the repair that the sensor in the bottom heat exchanger

(responsible for Espresso coffee temperature) may also have a problem, then at this step

of the repair, the bottom sensor (old installation layout) should be replaced in any case.

This means that the top heat exchanger has to be completely disassembled, following the

procedure in the next section.

a. Disassemble the central water in-let pipe. Next, remove the flexible tube from the

elbow union (press ring on the union in the

direction of union and slide out tube in

opposite direction).

b. Work carefully when disassembling and reassembling the elbow union.

The thread on the elbow union is very delicate and can easily be ruined by over tightening. When reassembling, apply >>Loctite<< sealant to thread and tighten

>>gently<<.

Press ring in direction of elbow union

and slide out tube

First loosen top hex

nut using a >>SW 10<<

spanner turning

anti-clockwise.

Then loosen >> M8<<

nut and remover top

and under plates

54

Proceed with disassembly as follows

Remove the elbow union

Loosen M8 nut, remove

base plates

Place a hand under the

filter holder group

head and catch

diffuser as it drops

down

12. Now, it is time to disassemble the top heat exchanger. First, the two water

connections on the right-hand side need to be loosened. Both can be found on the

top heat exchanger. The back connection is made up of a brass fitting

arrangement, while the front one, under a curved connection, is a chrome union

fitting arrangement.

In the case of the brass fitting union, use the left large nut for support and loosen

the smaller right nut. In the case of the chrome union, the nut which is under the

elbow union should be loosened from the front through the window.

The photos show this procedure.

55

12/1 12/2 12/3

Photo 12/1 shows the loosening of the brass nut on the coffee heat exchanger water inlet.

Photo 12/2 and photo 12/3 show the loosening of the inbus screw (5th INBUS)

Photo 12/4 shows a front view through the window of the chrome union with the 180°

copper pipe elbow union.

Now that all connections have been unfastened, the top water heat exchanger can be

carefully removed.

Next, the bottom heat exchanger (for coffee brewing water) sensor can be changed that

is likewise in a „10 O’clock position“ under the earth screw.

Loosen the earth screw that holds the three incoming earth connections and take the

sensor with its two red wires out of the hole in the heat exchanger. Trace the connection

back to the main circuit board of the corresponding plug (on the left, red connection)

and remove.

T

his chrome union needs to be loosened

56

13/1 13/2

13/3

13. Photos 13 / 1 to 13/3 show the removal of the top heat exchanger and the freeing

of the bottom sensor connection. The sensor with the red wires is under the

insulation next to the earth screw.

57

14. Apply a quantity of heat conducting adhesive to the sensor with the red wire and,

likewise, fill the hole with a quantity of adhesive and push the sensor back into

the hole. Replace and press the insulation securely around both wires right up to

the black sensor casing (no direct contact should be made between the wire and

the heat exchanger shell or the earth wires and/or the earth screw). Both wires

should not be allowed to move around (short circuit).

15. Collect all earth connections using the short insulation band into the earth screw

and screw firmly into place. The sensor should be in a secure position and fixed

so that it is insulated. Next, lay the red wires in the direction of the electronic

circuit board and plug the AMP- plug into third plug slot (see photo).

Now check whether the reverse button is engaged on the bottom reversible safety

thermostat.

16. Next you need to completely reassemble the top heat exchanger. Follow this

procedure:-

a. Place the heat exchanger in the correct position and position both inbus

screws and screw up tight.

b. Reconnect water connections. Tighten well so that afterwards the pressure

connections are also sealed.

c. Replace the central tube with upper filter holder (check gasket and

carefully clean off any dried coffee deposits that may be on the filter and

in the gasket groove. Insert the rod with the threaded part at the top up

through the filter holder group head. Next, replace under plate and top

plate and tighten the M8 nut by hand. The secure, using the correct size

spanner secure.

Next, with the aid of >>Loctite 542<< sealant,

carefully place the elbow union on the inner thread

of the pipe and turn 1-1/2 times by hand. Then apply

a little >>Loctite 542<< and give it a few seconds to

take, then using a spanner carefully, >>gently<<

tighten. Do not force the thread!

Re-insert the tube in the elbow union. It will automatically be clasped in place by a

mechanical clipping mechanism.

58

Position the new >>hot water sensor<< with black wires, together with both earth wires

and the earth seal under the insulating tape. Caution: rub a quantity of conducting paste

on to this sensor and around the hole in the heat exchanger. When repositioning, push to

squeeze any excess adhesive and carefully wipe away. Next, insulate he single wires up to

the sensor casing and position so that no contact can be made between them and no

contact with the metal is possible.

17. The next section will explain how to replace the new sensors that were introduced

commencing from Wk 42 in 2003 with a view to making the disassembly and reassembly procedure to replace sensors easier.

The position and the type of sensors were changed. The hot water and steam

sensor is now positioned on the right-hand side near the top, on the top heat

exchanger in a „2 O’clock position“

59

18. Loosen the sensor using a suitable size spanner and screw out. Next remove the

plug from the main electronic circuit board (both size and position have been

changed) and pull out the whole cable in the direction of the sensor.

19. Lay the cable of the new sensor behind the heat exchanger, plug in AMP – miniplug to the corresponding plug slot in the main circuit board and using

conductive paste screw the new sensor back into the heat exchanger and tighten.

20. The coffee sensor (bottom heat exchanger) is likewise on the right-hand side of

the heat exchanger. It is however positioned below, at the front on the right, at „5

O’clock“ and in the current production series is somewhat difficult to access (in

the future, the “window” on the bottom right of the housing will be made larger,

to make handling easier).

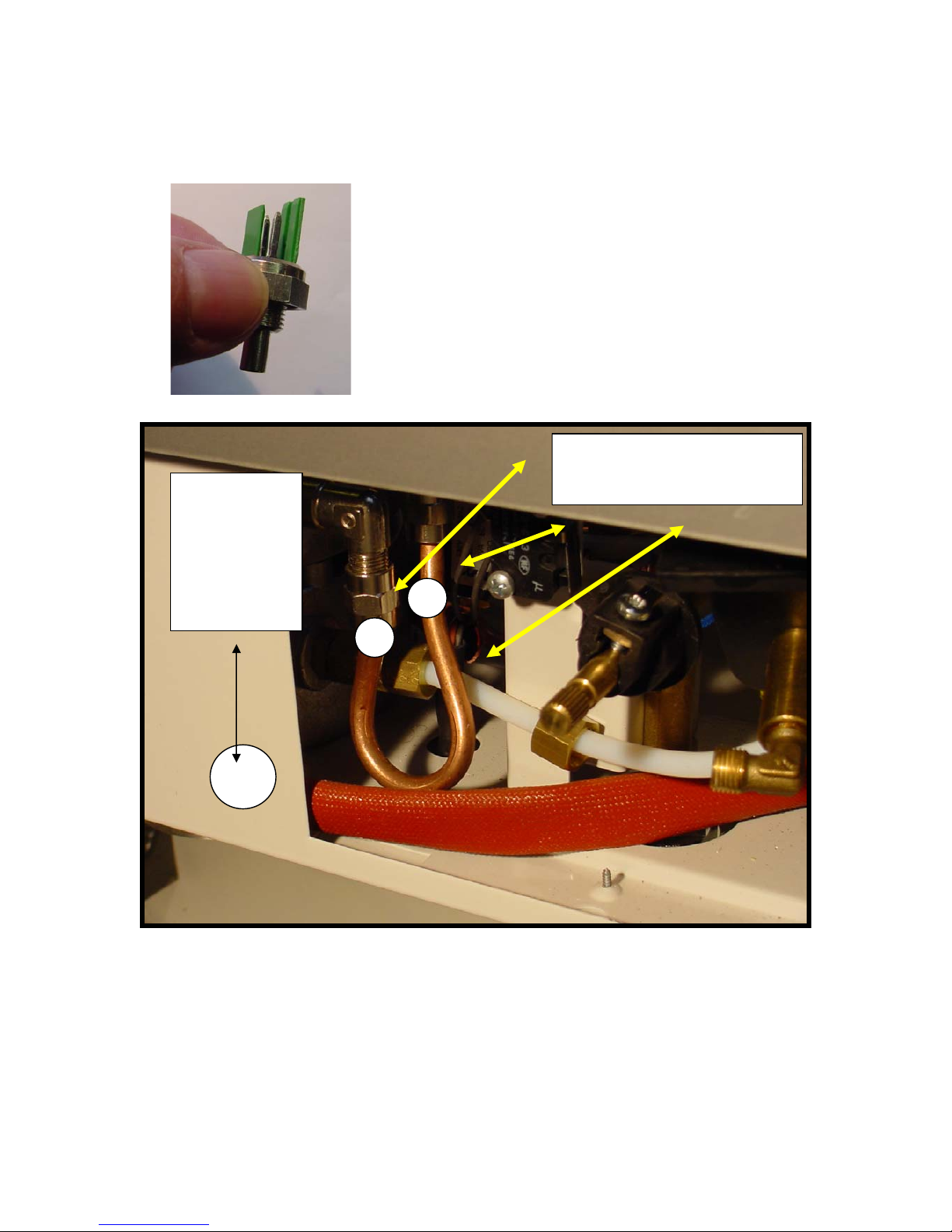

The yellow two-headed

arrow shows the hot water

sensor. Loosen using a

suitable size spanner!

Shown is the sensor

for coffee water

temperature. In the

event that the nut

cannot be reached

with the spanner,

loosen the copper

elbow union at the

front and displace

to the right, thereby

creating room for

the sensor to be

accessed.

60

21. The photo on the next pages shows the view from the front looking on to the heat

exchangers. The bottom sensor must be loosened

with a spanner and screwed out. Both connecting

wires (slack running in front of the heat exchanger)

must be disconnected from the old defective sensor

and connected up to the connecting plugs of the new

sensor. With the aid of conducting paste position

the new sensor and screw firmly into place. Finally,

reposition the copper elbow union in its original

place and tighten up nut.

22. After the new sensors have been installed, (old and new procedure), the machine

can now be re-assembled:

a. Position the dividing plate with fitted filter (against electromagnetic

interference). All connecting wires that run between the heat exchanger

compartment and the electronics compartment must be carefully placed

in the gaps under the metal plate so that the metal plate can sit cleanly

underneath on the floor. Screw in the black screws in the grinder

compartment and on the front side fixing this plate in position.

Loosen nut (1) and (2) work

loose, displacing copper pipe

to the right.

Sensor

T

he sensor lies

behind this plate,

where the white

circles is, and

can be accessed

when the copper

pipe has been

displaced to the

ri

g

ht

1

2

61

b. Plug in both the primary line wires (brown and blue that run out of the

left side of the casing wall) to the L and N connection terminal. Plug in

both secondary line wires, brown from the circuit board to connection

terminal 1 and blue from the multi-terminal plug to connection terminal

2.

c. Plug in the flat band-cable connection from the switch circuit board to the

main circuit board in the red connecting strip.

d. Reposition the multi-terminal plug.

e. Position the front panel and screw in place with the two screws from

below.

f. Replace the knob on its pin and set in zero position.

g. Reposition the transparent coffee container on the grinder and screw in

place with the two black screws. Refill with coffee beans!

h. Refill water container and reposition. Provisionally dip water tube into

water.

i. Reconnect machine to mains for testing purposes and disengage the safety

switch (at the back, bottom left) with the aid of a piece of styrene, wood

or cardboard so that the machine is electrified.

j. Caution: Now do NOT touch any parts inside the machine! Keep people

away from the machine! All connections and plugs are under 230 volt

voltage. Electric shock hazard!

k. Switch machine on at front panel. A number of leds should be

permanently on. The leds top left and top right should now start to flash

and after approximately two minutes should likewise remain permanently

lit up.

l. Proceed following operating instructions and, after the previously flashing

leds are likewise permanently lit up, deliver both water and steam to the

wand and hot water to the brewing station.

m. During all processes, check again that all water connections which have

been loosened during this repair are >>tight<<. Should a problem be

found, immediately engage the safety switch and disconnect machine from

mains supply. Look into problem.

62

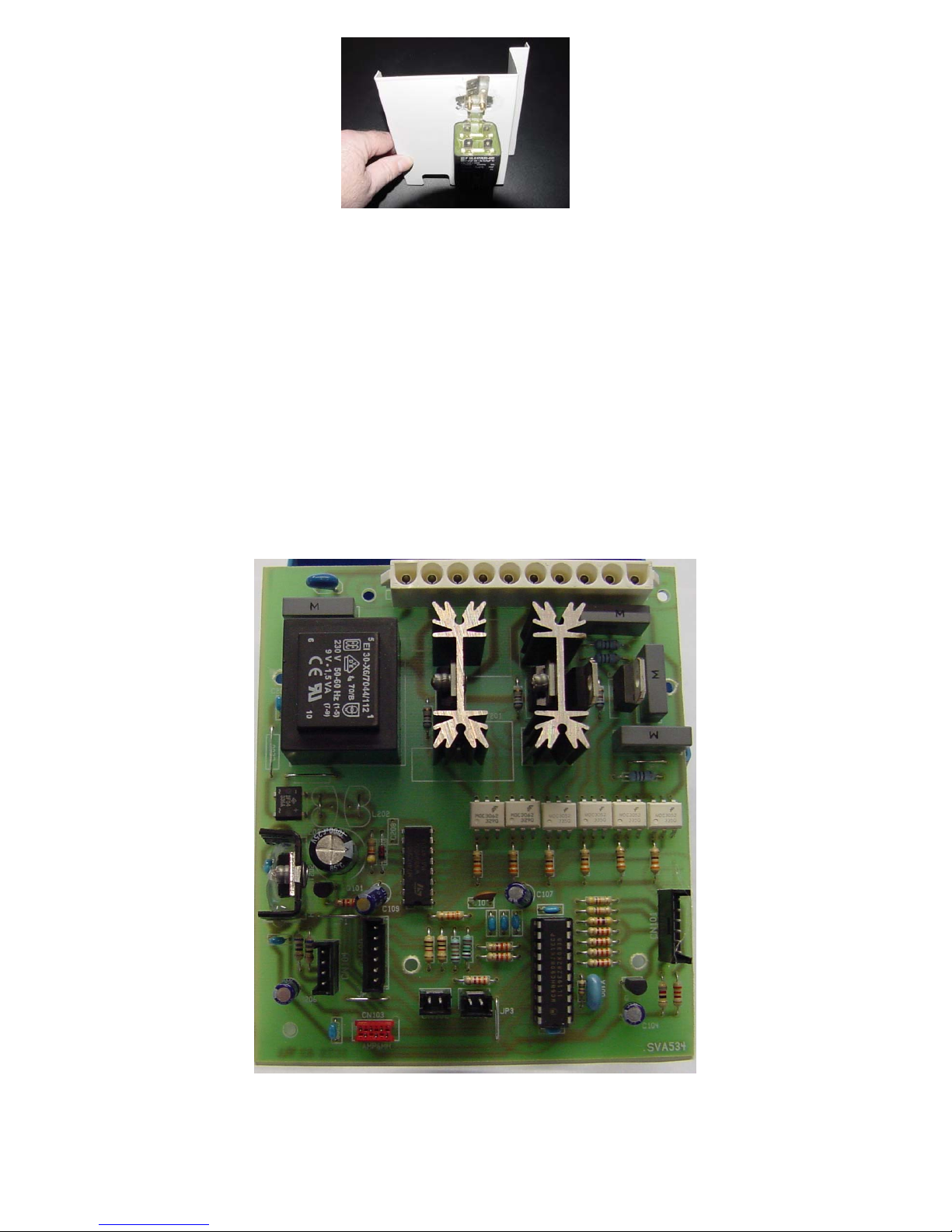

Servicing and Maintenance

Product: Espresso-Machine

Model: Semi-automatic, Built-in

Service Instruction: 8/04 Circuit Board replacement

Problem:

Semi-automatic processes are not functioning, which are normally

engaged by pressing the corresponding pad on the front control

panel. Problems may include:

● After pressing the grinder switch there is no reaction

● In spite of pressing the >>brew coffee<< pad, no water is delivered

to the brewing station ( water pump not working = no pump noise)

● When switch for >>steam<< and/or >>Water<< is pressed, there is

no reaction

● No reaction from the main on-off switch (First, move machine out

of its housing and manually activate safety switch. This switch can be

found at he back of the machine, bottom left-hand side) Further,

check whether the machine’s safety fuse system is o.k. It is positioned

on the side, top left)

● There is no reaction after having pressed >>one cup or two cups<<

pad and, likewise, >>short-medium-long Espresso<<

In correct working conditions, all function pads on being pushed should

immediately perform their relative tasks. The pre-set or individually set functions

should always be performed and delivered repeatedly in the same, standardised

way. If problems arise concerning these functions, which are not being delivered

in a standard way each time, or they are not working at all, then the following

checks should be carried out in the order given below:

● check the flat cable connection between die switch circuit board and main

circuit board, next check

● switch circuit board and, if the problem cannot be solved here, and the fault

still persists, then check

●the main circuit board

and replace with a new one. This instruction will illustrate how to replace both

circuit boards and the procedures will be described separately.

63

Cause:

a. The switch and/or relative indicator led may be defective. In this case

the circuit board needs to be replaced.

You can assume that the fault lies with the switch circuit board when

individual leds do not work (switch or led fault) or when no leds on the

circuit board light up (which however may also be due to no contact being

made with safety switch located at the back on the bottom left of the

machine or the machine safety fuse system being faulty – for example, due

to the grinder being overtaxed; attention, in this case, first look to see

whether any foreign bodies are obstructing the grinder movement!!) In the

above mentioned cases, you should concentrate on replacing the switch

circuit board, but first check to make sure that the flat-cable connection

running between the switch circuit board and the main switch board is

plugged in correctly.

b. The fault could be due to normal wear and use of the circuit boards; the

relative maintenance instruction highlights the importance of changing the

main circuit.

Before changing the main circuit board, check that the fault is not due to

the switch circuit board.

Solution:

To a.

The switch circuit board needs to be disassembled following the

procedure illustrated further on. However, first check that that the

cable on the circuit board is plugged in correctly and (when you have

checked) proceed to disassemble the switch circuit board from its

frame on the machine.

To b.

Please check that it is absolutely necessary to replace the main circuit

board as, in order to access it, an entire sector of the machine has to

be >>disassembled<<.

Before carrying out the required work procedures, please read the

following general notes and recommendations, and especially the

safety advice notes for service engineers, remembering to follow them

at all times.

64

Safety Advice for Service Engineers

Caution: Before commencing any work on the appliance, it should be “disconnected”

from the electricity supply. This can be done by:

either removing the appliance plug from the mains socket or by isolating electricity

supply to socket through safety circuit-breaker or by turning off electricity completely

at mains switch.

Caution: For the purpose of simply carrying out testing and checking of the machine,

the Service Engineer may leave the machine connected to the mains power supply when

there the approved electrical safety breaker device installed at the back, in the left-hand

bottom corner of the machine (that cuts out power supply in all directions between

appliance socket and appliance electrical circuit) is manually activated and cuts out

mains power to the machine.

As an authorised Service Engineer, you should comply with all European testing

standards and the relevant safety regulations for electrical appliances, in order not to

endanger yourself or other people and to prevent any other kind of hazards and risks.

For this electrical appliance, due to various systems that contribute to the working of the

machine, it is important that you observe and take note of the technical specifications of

the machine which include:

Power supply: 240 Volt mains

Heat exchanger and operating pressure up to 15 bar

Water containers and water conducting pipes (some under pressure)

High temperatures in water conducting system and heat exchangers

Only authorised Customer Service Engineers are allowed to carry out work on this

Espresso machine (the opening of parts of the machine that are secured by screws).

European testing and safety regulations should always be complied with when carrying

out work on the appliance.

The appliance manufacturer and the Servicing firm shall not be liable for work carried

out that is not conformant with test an safety regulations and, likewise, tampering or

work carried out by unqualified servicing firms and local service engineers.

65

Important production series information:

AQ PASS – Serial number

Artech – Espresso machine

000/0/00/00/000

Day – serial number

Year – (last two digits)

Production week in year

Day (1-7) of corresponding week

Customer reference number

Shown above is the previous coding system used up to week 47/2003. The 1

st

and 2nd digit groups were not

used.

After week 47, the coding shown below was introduced and is now the valid coding system.

00/00/000

Serial number

Year – (last two digits)

Production week of year

Please always quote the appliance number when dealing with our service

department!!!!!!!!

66

The hand tools that are essential for carrying out servicing on the Espresso

Machine are shown below and should always be part of your servicing kit.

In

addition to 5 mm screw key ( for disassembling the heat exchanger)and two

rachets, you will also need two screwdrivers (one normal one and one with

interchangeable bits) as well as spanners for a range of widths: 10, 12, 13,

14, 15 and 17.

General procedure:

1. Firmly clutch the handle on the spill-tray drawer, and gently slide the Espresso

machine out of its housing towards you. (Opening as for water and coffee refilling or

grinder selection).

67

2. The upper front cover is screwed down with 6 countersunk screws. Unscrew and

remove all screws and take cover off.

3. With the cover removed, the next photo shows the view of the inside layout from

above:

4. The following picture shows the top-positioned heat exchanger seen from above. In

the centre of the heat exchanger there is the water in-let pipe assembly through

which heated water under pressure passes. Top left >>at 10 O’clock<< there is the

Unscrew the six

countersunk screws

on the cover.

Then remove cover.

68

earth connection with a brass seal under which the temperature sensor (MinimumMaximum operating temperatures) can be found.

5. On the left side >>at 9 O’clock<< there is the reversible thermostat. In the middle,

between the two electrical connections, the reverse push button can be seen (beigebrown). This push button must be in the pushed-in position.

Wait and see what happens! If the thermostat is working correctly, go directly to

point 8 of this section (changing the circuit board).