The ATLANTIS

Dishwashe

r

Brandt Customer Services

TRAINING

TECHNICAL

wsh

A

C

C

H

H

SET

THE ATLANTIS DISHWASHER

Technical Training

CONTENTS

- 3 -

LA3-ATLANTIS-002UK-04/04

1 - INTRODUCTION ......................................................................................................................................................5

2 - THE ENERGY LABEL..............................................................................................................................................7

2.1. - What you must know.........................................................................................................................................7

2.2. - Consumption level of the main appliances* ......................................................................................................7

3 - THE DISHWASHER .................................................................................................................................................8

3.1. - The customer's expectations ............................................................................................................................8

3.2. - The advantages of the dishwasher...................................................................................................................8

3.3. - The sound level.................................................................................................................................................8

3.4. - The drying .........................................................................................................................................................8

3.5. - Operating principle ............................................................................................................................................9

4 - THE WATER...........................................................................................................................................................10

4.1. - The noxious effects of limestone ....................................................................................................................10

4.2. - The effects of too soft a water ........................................................................................................................10

4.3. - The water softening : a vital function ..............................................................................................................11

4.4. - The regeneration.............................................................................................................................................11

4.5. - The pH (hydrogen potential) ...........................................................................................................................12

5 - THE DETERGENTS ...............................................................................................................................................13

5.1. - The products ...................................................................................................................................................13

6 - THE ATLANTIS DISWASHER ...............................................................................................................................14

6.1. - Presentation ....................................................................................................................................................14

6.2. - Identification of the reference .........................................................................................................................16

6.3. - Fitting ..............................................................................................................................................................17

6.4. - Adjusting the water softener ...........................................................................................................................18

6.5. - Setting of the rinsing agent dispenser ............................................................................................................19

6.6. - Use of the sensors in new wash recipes classified A A A ..............................................................................20

6.7. - Other possibilities offered by the electronics ..................................................................................................21

6.8. - Intuitive internal arrangement .........................................................................................................................21

6.9. - Low sound level ..............................................................................................................................................21

6.10. - Filtering 100% efficient throughout the cycle and easy to access ..................................................................21

6.11. - Hydraulic diagram ...........................................................................................................................................22

6.12. - The filling of the Atlantis dishwasher with flow meter .....................................................................................23

6.13. - The filling with Atlantis dishwasher without flow meter ...................................................................................23

6.14. - The "floating" regeneration .............................................................................................................................25

6.15. - The drying .......................................................................................................................................................26

6.16. - The different components ...............................................................................................................................28

6.17. - The washing programmes ..............................................................................................................................36

6.18. - Synoptic ..........................................................................................................................................................39

6.19. - The block diagram of the Atlantis dishwasher with electronic access ............................................................40

6.20. - The block diagram of the Atlantis dishwasher with mechanic access without flow meter..............................41

7 - OPERATION SERVICE ..........................................................................................................................................42

7.1. - The diagnosis assistance programme (DAP) .................................................................................................42

7.2. - Checks and measurements possible at power board terminal strips .............................................................44

7.3. - The electronics-controlled safety devices.......................................................................................................47

7.4. - Water height in tank from pressure controller switching .................................................................................48

THE ATLANTIS DISHWASHER

Technical Training

INTRODUCTION

- 5 -

LA3-ATLANTIS-002UK-04/04

1 - INTRODUCTION

The objective is simple : the matter is to make the dirty dishes clean. The quantity, nature, dirt level of

the dishes, the cleaning product used, or even the water hardness may act against the expected result.

So far, all these parameters have been left to the assessment of the consumer, who alone assumed

the responsibility for poor wash. Increasingly, the new ATLANTIS dishwasher consider all these

factors.

The intelligent use of some sensors enables the electronics to adapt the run of its auto-programs,

in order to guarantee the result while trying to save water, energy and time, and this, whatever the load

or dirt rate is.

The new ATLANTIS dishwasher provides reduction in water, energy consumption, and cycle times

while assuring A level in washing and drying.

To perform the dishwasher maintenance, the technician has to identify the cause(s) at the origin of the

consumer's claim. To do so, he has to make a precise diagnostic in order to adopt the appropriate for

the encountered problem.

The new ATLANTIS dishwasher proposes a programme of aid to diagnostic intended for the

after-sales department. Only the rigorous and systematic implementation of this programme can

definitely assure the action reliability.

A properly performed after-sales action should favour the development of customer’s loyalty to the

sales outlet, to the sign and also to the trademark concerned.

THE ATLANTIS DISHWASHER

Technical Training

ENERGY

- 7 -

LA3-ATLANTIS-002UK-04/04

2 - THE ENERGY LABEL

2.1. - What you must know

Washing machine, dryer and dishwasher are three

appliances likely to weigh heavy on the electricity invoice if

you choose model poorly classified from the energetic

point of view. Washing machine and dishwasher each

consume about 250 kWh a year. For a few years, the

manufacturers have made efforts on the water

consumption, which has a direct effect on the power

consumption at the moment of the heating.

Initiated by the European Community, this labelling is now

compulsory in France for most household electrical

appliances. The classification from A (the most

economical) to G (the most avid on electricity), enables the

consumer to locate at a glance, the various models

proposed.

For washing machines, an additional indication concerning

the wash and spin, complements the information

concerning the power consumed.

This mention must appear compulsorily on all the

dishwashers marketed from the 1

st

of January 2000.

The “Bio” programme is selected to laboratory tests.

2.2. - Consumption level of the main appliances*

Dryer (150 uses)

Electric hob

Dishwasher

(220 uses)

Chest freezer

Electrical oven

Washing machine

(200 uses)

Refrigerator

Television

Microwave oven 800W

Iron

Vacuum cleaner

A good use of the deferred start you to benefit by off-peak periods

and, therefore, to save electricity.

Dishwasher

Energy

Manufacturer

Model

More efficient

Less efficient

Washing performance

(dB(A) re 1 pW)

Noise

Further information is contained

in product brochures

Norm EN 60456

LOGO

Energy consumption

Actual energy consumption will

depend on how the appliance is used

kWh/cycle

A: higher G: lower

Capacity (place settings)

Water consumption

1 2 3A B C

Dishwasher label Directive

Drying performance

A: higher G: lower

(In accordance with programme

recomanded by the manufacturer)

THE ATLANTIS DISHWASHER

Technical Training

THE DISHWASHER

- 8 -

LA3-ATLANTIS-002UK-04/04

3 - THE DISHWASHER

3.1. - The customer's expectations

• Perfectly clean dishes

• Dry dishes

• Sparkle of glasses and stainless steel

• Respect of delicate dishes

• Rapidity

• Easy to use

• Low sound level

• Low consumption (water, electricity and products)

3.2. - The advantages of the dishwasher

A family of four persons devotes 55 minutes a day on average to do dishes, against 20 minutes when

it has a dishwasher.

The cost of a dishwasher is written off in only 3 years and its estimated lifetime is approximately 10 years.

Washing up in machine is much more hygienic because dishes are perfectly washed and dried

without contact with external elements (towels, hands or work surface), which often convey a number

of bacterias.

ATLANTIS 0,25 €€€€ DISHES DONE BY AND 0,88 €€€€

Water (12 litres) 0,03 € Water (70 litres) 0,18 €

Energy (0.75 kWh) 0,08 € Energy (4,8 kWh) 0,53 €

Detergent product 0,10 € Detergent 0,14 €

Rinsing product 0,01 € Accessories 0,03 €

Salt 0,03 €

Annual cost 91,25 €€€€ Annual cost 321,20 €€€€

3.3. - The sound level

Noise remains a selection criterion essential despite the fact that indicating it on the "Energy Label" is

not compulsory.

For the ATLANTIS dishwasher, the level is comprised between 45 and 51 decibels (dB). It must be

known that a variation by 3 decibels multiplies by two the sound volume and this is only below 50

decibels that the dishwasher can be operated late at night.

To achieve this result, several improvements have been made to the ATLANTIS dishwasher :

• PTC and double auxiliary winding for certain asynchronous cycling pumps

• Reinforced acoustics (double-thickness bitumen, felts, phonic seals)

• Passage of the entire spraying circuit in the tank.

3.4. - The drying

The drying result is an important point that appears on the "Energy Label".

The ATLANTIS dishwasher proposes 3 marks for the drying (A/B/C), according to the dishwasher level

of equipment.

THE ATLANTIS DISHWASHER

Technical Training

THE DISHWASHER

- 9 -

LA3-ATLANTIS-002UK-04/04

3.5. - Operating principle

Dirt adheres to dishes with a certain energy that is to be overcome to get rid of it. It is, therefore,

necessary to implement the following actions:

The mechanical action (aspersion)

Its purpose is to project the detergent bath onto dishes to remove and drag the dirt.

The ATLANTIS dishwasher is provided with 4 spraying levels:

• Two that spray the lower and upper baskets

• A third one, multidirectional (small shower) attached to the tank ceiling prevents residues from

depositing on the tank ceiling and falling during drying

• A fourth one, carried out using a rotary nozzle assembled to the lower winch in certain models, is

used to better clean the bottom of saucepans (it is associated to a specific program).

Spraying the dishes is performed by the winches, which turn simultaneously or not (alternate spraying)

under action of the water pressure in spraying nozzles. The water thus projected onto dishes falls in

the tank bottom where it is purified by flowing through four filters. These filters perform continuous

recycling of the detergent solution until cycle end.

The water is then returned, pressurised, by the circulation pump (approximately 50 litres / minute) into

the spraying arms. Such a circulation and the low volume of the cycling unit volume (1.85 litres) are

used to have a total water consumption relatively low (12 litres), as each piece of dishes is washed by

only one volume of water (approximately 4 litres).

After wash, the wastewater is evacuated, the clear water, cold for the first rinse rinses dishes, and

then a second rinse, hot, precedes the drying.

The thermal action

The progressive temperature rise and the achievement of an enzymatic dwell at 50°C are used to

obtain the best conditions of elimination of all the types of dirt. Actually, the action of the various

components of detergent products varies according to the bath temperature.

The chemical action

When dishes are done in machine, the mechanical action is limited (as compared with dishes done by

hand), and must therefore be compensated for by a more powerful chemical action.

To the mechanical and thermal energy of the machine are added the physical-chemical and biological

actions of the detergent.

As the nature of dirt is very varied, it is not always eliminated in the same way.

This is the reason why detergents contain very different components and, in particular, enzymes.

The duration.

All is not as simple. If we detail the operation, we remark that an essential element is missing : the

water. Actually, without water, there is no wash! The water will, with the support of active principles of

the detergent, destroy, eradicate, dissolve and emulsify the dirt present on dishes.

It will do so all the better since the machine will water the dishes and heat the water.

The wash result depends, therefore, simultaneously on 4 factors :

• The washing product

• The water

• The temperature

• The mechanics

A good wash result can, therefore, only be obtained if all these conditions are respected.

Spraying arms project onto dishes (mechanical action) a solution of detergent

products (chemical action) progressively heated by a resistor (thermal action)

THE ATLANTIS DISHWASHER

Technical Training

THE WATER

- 10 -

LA3-ATLANTIS-002UK-04/04

4 - THE WATER

The water covers, in the nature, a cycle due to its continuous evaporation under the action of the sun

heat; this vapour is condensed into fine droplets to produce clouds, which are transformed into rain

when they meet a cold air draft.

It is possible to assert practically that this is from the moment where the rain starts falling that it begins

to lose its purity. Actually, during its fall, the rain meets in the atmosphere a certain number of

impurities of variable nature, among which carbon gas with which it is combined to make up very

slightly acid soft water.

This water, when it arrives on earth, flows by streaming and infiltrates the cracks to reach the

groundwater tables and artesian tables that feed sources and wells. In both cases, this water dissolves

and carries with it a part of the mineral salts it meets (limestone, magnesium, etc.); this is this last

process, which causes its mineralisation. The more the water is mineralised, the harder it is !

The water hardness is expressed in degrees TH.

1 French degree TH corresponds to 10 mg of CO

3

Ca per litre of water.

from 0° to 5° TH very soft water

from 5° to 15° TH soft water

from 15° to 30° TH half-hard water

from 30° to 45° TH hard water

More than 45° TH very hard water

4.1. - The noxious effects of limestone

Any water contains traces of minerals, mainly limestone, magnesium and iron originating from the

ground. The higher the content is, the harder the water is. These minerals reinforce the dirt catch to

fabric fibres, and the eliminated one tends to be fastened again to them. Limestone reduces the

efficiency of the washing product, makes the laundry rough, makes whites turn grey, fades colours and

accelerates the laundry wear.

4.2. - The effects of too soft a water

Too soft a water also reduces the washing efficiency (reduction in mechanical action), causes foam

overflows, leaks and accelerates the appliance ageing (the water is more aggressive).

THE ATLANTIS DISHWASHER

Technical Training

THE WATER

- 11 -

LA3-ATLANTIS-002UK-04/04

4.3. - The water softening : a vital function

The system water contains soluble calcium hydrogen carbonate. Hot, the calcium hydrogen carbonate

decomposes and gives insoluble calcium carbonate (fur).

The water softening is, therefore, a vital function.

This is the reason why all dishwashers are fitted, from the origin, with water softeners.

Softening is, in fact, the substitution of calcium ions contained in the system water by sodium ions

contained in the salt.

To perform this substitution, the water is circulated in the heart of the softener that contains small

balls of synthetic resin.

Combined with sodium, this resin sets the limestone particles (calcium or magnesium) contained in

the system water. To do so, the resin exchanges its sodium ions for the calcium ions.

After a certain number of fillings, resins are more or less saturated with limestone and start becoming

ineffective to soften the water. It is then necessary to regenerate them.

4.4. - The regeneration

To regenerate the resins, it is necessary to eliminate the limestone from them with sodium (salt).

This regeneration, automatic and "floating" on "all electronic" ATLANTIS dishwashers, is initiated by

the board according to the adjustment performed on the putting into service and to the number of filling

baths already performed.

SOFTENER

Resin

Water

+

Calcium &

magnesium

Softened

water

+

sodium

Saturated resin

Water

+

Calcium (Ca)

and

magnesium

SALT

Water

WATER

+

S

ALT

W

ater+Ca

THE ATLANTIS DISHWASHER

Technical Training

THE WATER

- 12 -

LA3-ATLANTIS-002UK-04/04

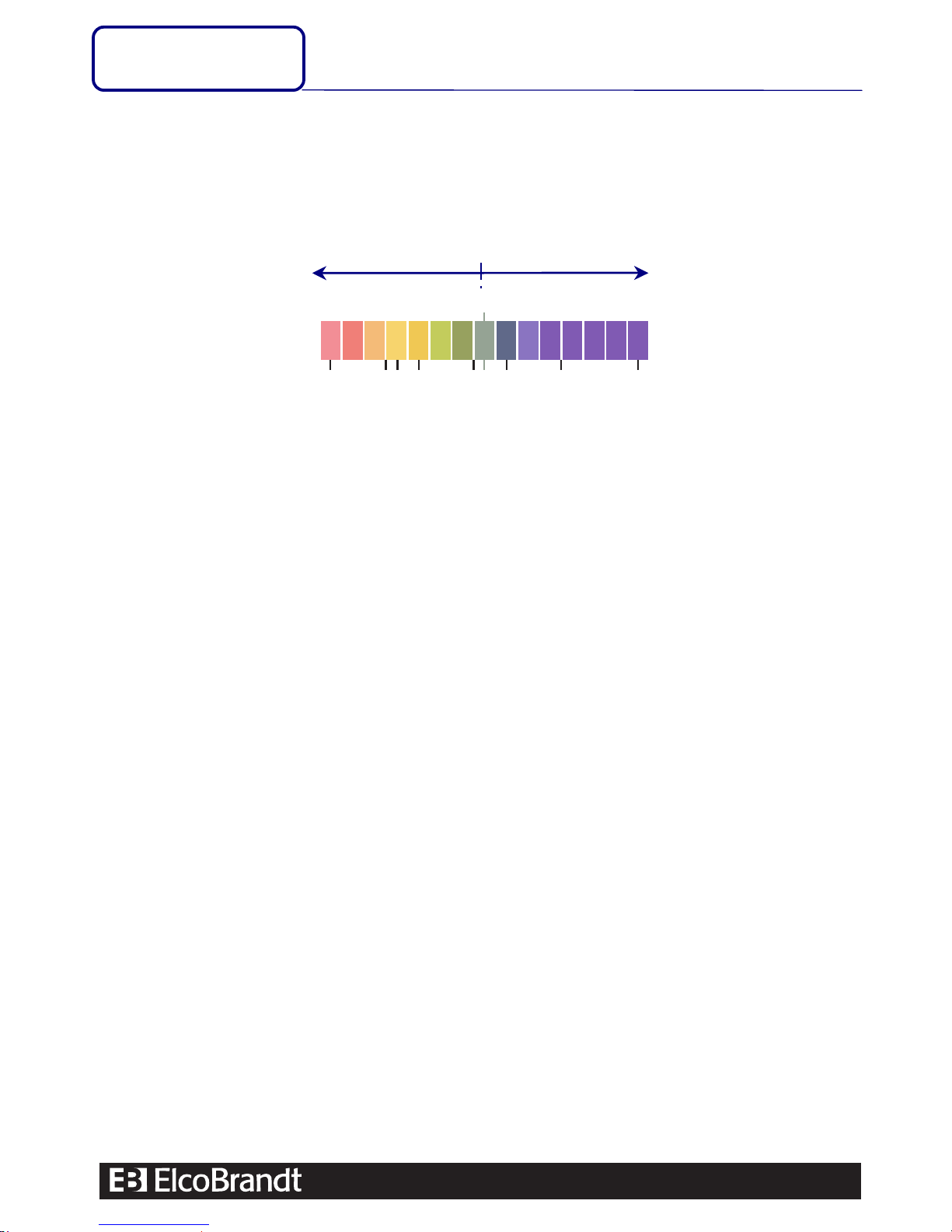

4.5. - The pH (hydrogen potential)

Maybe, you have already remarked on labels of cleaning products or drinks the pH indication followed

by a number. Maybe, you know that the pH is related to the acidity of a solution, sometimes verifiable

by its taste. If you taste successively lemon juice, coffee and water, you will be able without any

difficulty to rank these three liquids by level of acidity.

10141312111098765432

Acid Neutral Basic

Chlorydric acid

Coca-cola

Vinegar

Beer

Milk

Sea water

Concentrated

Bleach

Sink caustic

cleaner

Tape water

The pH paper is used for approximate, simple and rapid determination of the pH of a solution.

This paper, which does not provide exact determination of a value of pH, rather gives an idea of the

pH range of the solution, namely:

• Acid for a pH smaller than 7

• Neutral for a pH equal to 7

• Basic or alkaline for a pH greater than 7

Water, mineralised or not (and, therefore, salt water) has a pH very close to 7.

A few acids

• Vinegar (acetic acid)

• Aspirin (acetylsalicylic acid)

• Lemon juice (citric acid)

• Coffee

• Vitamin C (ascorbic acid)

• Dishwasher rinsing product

A few bases

• Household cleaning products (ammonia)

• Soap (potassium hydroxide)

• Concentrated bleach

• Sink caustic cleaner (sodium hydroxide)

• Detergent products for washing machine and dishwasher

Alkaline pH is necessary for the washing bath to ensure maximum efficiency.

4.5.1. - Analysis of traces or deposits on dishes

Replacing a component supposed defective does not constitute the essentials of the maintenance of

a dishwasher. A dishwasher, for which the consumer signals a bad wash result, cannot be repaired so

easily. Actually, to solve this type of claim, it will always be necessary to precisely identify the nature

of the trace or residue present on the piece of dishes. Only this precise identification can indicate us

the probable cause at the origin of the defect.

The matter is not to precisely measure the pH but simply to detect the origin of the white traces or of

the residues.

So, when the paper turns red we are in the presence of an acid solution (rinsing product for example),

if it turns blue, then it is an alkaline solution (washing product).

Red Blue

Green

THE ATLANTIS DISHWASHER

Technical Training

THE DETERGENTS

- 13 -

LA3-ATLANTIS-002UK-04/04

5 - THE DETERGENTS

5.1. - The products

5.1.1. - The detergents

Contrary to many received ideas, all detergents are not identical. They contain specific ingredients.

So each type of detergent has its own features and will be particularly suited to such or such type of

wash or of dishes.

• Detergent products are alkaline.

• They have, therefore, a pH comprised between 9 and 11.

• They are classified IRRITATING.

The powder

It is perfectly efficient under difficult wash conditions (very hard water or very dirty dishes) and is

suitable for washing silver and decorated glasses.

The tabs

The dosage ease certainly explains the development of their market share. The dissolution time can

vary from 10 seconds to over 10 minutes. When selecting a fast or short program, it's better to use

powder.

The liquids

It is particularly more suitable for fragile dishes and respects the decoration.

5.1.2. - The rinsing product

It enables water to flow more rapidly and more completely from dishes, so preventing the formation of

traces during drying. It neutralises alkaline residues of the detergent during the final rinse and favours

the drying of dishes. Its acid pH is comprised between 1 and 3. It must be compatible with the

detergent (it is preferable to keep the same product trademark).

5.1.3. - The regenerating salt

It is used to regularly regenerate the water softener resins. It protects the appliance and dishes from

layers of sediment. Its pH is neutral and equal to 7.

5.1.4. - The "all-in-one" products

New products integrate in one and the same dose the 3 functions essential to the right operation of

the dishwasher:

• The wash function

• The salt function

• The rinse function

In cases of hard and very hard water (hardness greater than 35°TH), it is indispensable to use

regenerating salt. Some manufacturers specify that the wash must be done at 50°C maximum under

penalty of freeing too early the various actions of the product and altering the final result, or even

damaging some pieces of dishes.

THE ATLANTIS DISHWASHER

Technical Training

THE RANGE

- 14 -

LA3-ATLANTIS-002UK-04/04

6 - THE ATLANTIS DISWASHER

6.1. - Presentation

The ATLANTIS frame proposes a large choice of models: free-standing with rounded design or flat

design with frame decor, or built-in and also many options (alternate spraying, saucepan nozzle,

insulation, fan, condenser, turbidimeter, mezzanines …).

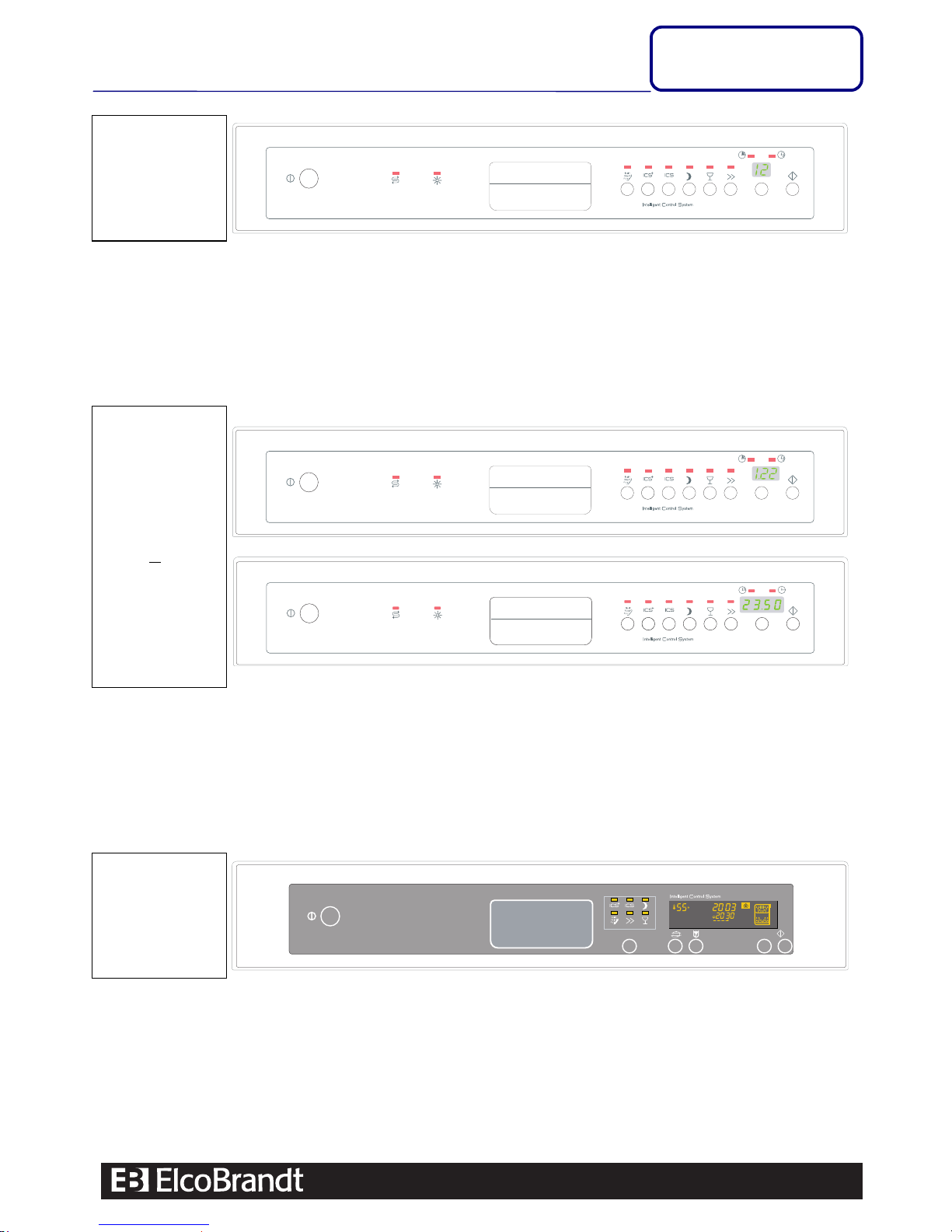

5 levels of electronics exist, defined by the type of access

:

3 ‘all electronic’ models, from L0 to L3, and 1 ‘mechanical access’ model, Lm.

Lm

Mechanical access

• Salt light

• Rinsing light

• Washing light

• End of programme light

• Start/Cancel button

• Programmes Knob

L0

Multi-LED display

wshA

C

C

3

h

wshA

6

h

• Delayed start button

• Programme buttons

• Start/Cancel button

• Salt light

• Rinsing light

• On/Off button

THE ATLANTIS DISHWASHER

Technical Training

THE RANGE

- 15 -

LA3-ATLANTIS-002UK-04/04

L1

Display 2 digits

wshA

C

• On/Off button

• Salt light

• Rinsing light

• Programme buttons

• Display

• Delayed start

• Start/Cancel button

L2

Display 2 digits

or

Display 3 digits

(clock)

wshA

C

wshA

C

• On/Off button

• Salt light

• Rinsing light

• Programme buttons

• Display

• Delayed finish

• Start/Cancel button

L3

LCD display

46,6

Axe Bouton

wsh

A

C

C

H

H

SET

• On/Off button

• Programme buttons

• Display LCD

• Delayed finish

• Start/Cancel button

THE ATLANTIS DISHWASHER

Technical Training

IDENTIFICATION

- 16 -

LA3-ATLANTIS-002UK-04/04

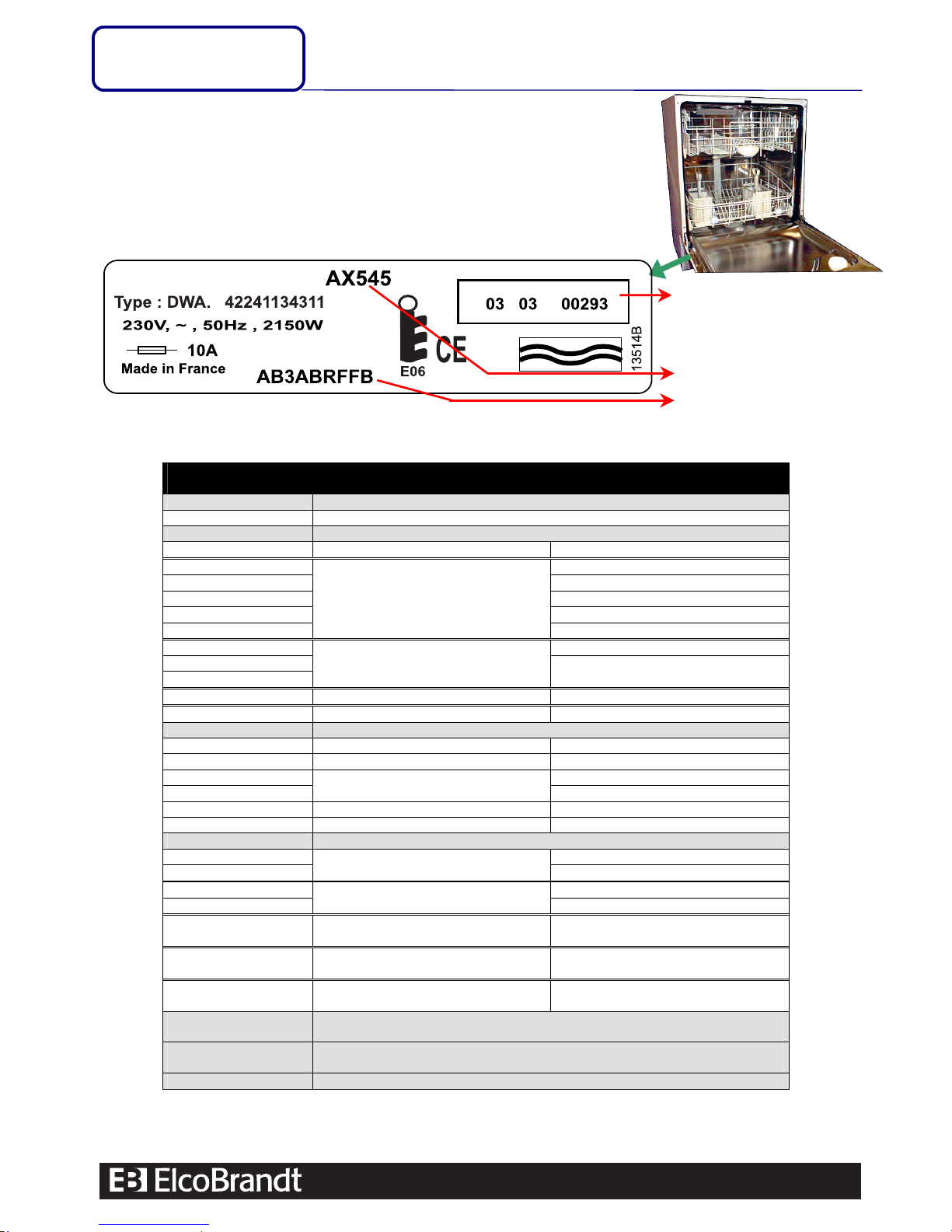

6.2. - Identification of the reference

The identification plate is on the right hand side of the double door.

Interpretation of the factory reference :

FACTORY

REFERENCE

REMARK

1

ist

characteristic Chassis

A

ATLANTIS

2nd characteristic Type of installation

A / B / C Free-standing with entasis

E Not cabinet

F Cabinet

G Cabinet & Cooker top

H Not cabinet & Cooker top

I

Free standing

Cabinet & raised element

K Cabinet & raised element

L

M

Can be encased

Not cabinet & raised element

O Integrate model raised element

Q Fully integrated model raised element

3rd characteristic Level

0 L0 Display Leds

1 L1 Display 2 digits

2 Display 3 digits

3

L2

Display 4 digits

4 L3 Display LCD

8 or 9 Lm Buttons and/or Programmes knob

4th characteristic Equipment

A With dirt sensor

B

- With flap-valve (alternated spaying)

– Air drying

Without dirt sensor

F With dirt sensor

G

- With flap-valve (alternated spaying)

– Drying by condensation

Without dirt sensor

H

- Without flap-valve

- Drying by condensation

Without dirt sensor

L

- With flap-valve (alternated spaying)

– Natural drying

Without dirt sensor

M

- Without flap-valve

- Natural drying

With dirt sensor

5th and 6th

characteristic

Brandt code

7th and 8th

characteristic

Country code

9th characteristic Index

Trademark

Serial number :

- Year

- Week

- Number of order

Commercial reference

Factory reference

THE ATLANTIS DISHWASHER

Technical Training

FITTING

- 17 -

LA3-ATLANTIS-002UK-04/04

6.3. - Fitting

6.3.1. - Levelling by adjusting the feet

The dishwasher must be well balanced ad stable. The four feet can

be adjusted, so adjust them if the necessary using a screwdriver. If

the feet are poorly adjusted, this decentres the door and makes the

dishwasher wobble, causing leaks. For dishwashers that can be

built-in, fitted with rear feet adjustment via two knurled knobs on the

base of the machine, at the front, use a screwdriver.

For better noise insulation, install the flap supplied with the

dishwasher.

6.3.2. - Water connections

Lenght of the water supply pipe

: 1.50m

Flow

: 10l/min. minimum

Tap

: with threaded end, 20/27mm

Pressure

: 1 bar to 10 bars

Connecting the hot water

: Check that the original hose is designed for

connection to the hot water supply.

6.3.3. - Electrical connection

• Mains voltage : 220-240V

• Fuse : 10A, 13A or 16A

The socket outlet must be grounded to earth. The machine must be installed so that the socket

remains accessible. Do not use an electrical extension, a double socket or an electrical timer.

The installation must comply with the country’s prevailing norms.

6.3.4. - Draining away the waste water

Connect the drain hose :

• To a ventilated siphon

• To a sink U-bend

• Directly to a sink

6.3.5. - Built-in unit and faceable units

• Remove the top board

• Adjust the height of the feet, if necessary

• Fix the dishwasher to the worktop

• Cut a laminated panel to the following dimensions (in mm) 595 x 585 with a maximum thickness

of 4mm.

• Adjust the tension on the springs, if required

6.3.6. - Dishwasher with built-in hob

The dishwasher combines two functions, which means that it must be connected to the wall so that it is

completely safe to use. This is to prevent a child, who may accidentally lean on the door while the

loading or unloading the dishes , from causing a hot (boiling) pan resting on the hob to fall, resulting in

severe burns or scads. It is essential that these instructions be observed.

Remove the

stopper form t he

-

THE ATLANTIS DISHWASHER

Technical Training

FITTING

- 18 -

LA3-ATLANTIS-002UK-04/04

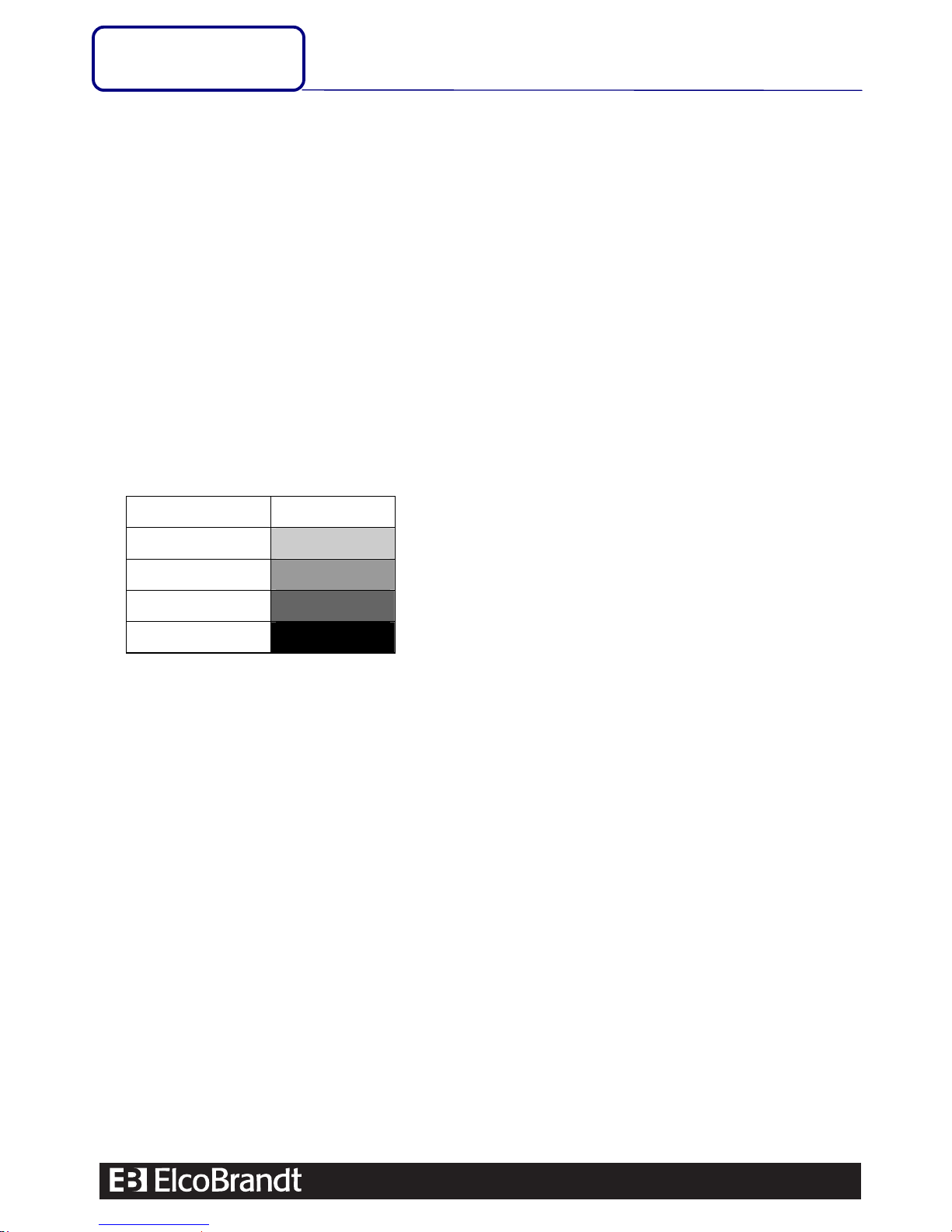

6.4. - Adjusting the water softener

Measuring the water hardness

After checking the hardness of the water from the tap,

either with the help of the small strip provided with the

appliance, or with the AQUA-TEST, adjust the

softener on the position which corresponds to the

degree of hardness you have measured. It is very

important to respect the setting recommended, as

follows :

Water which is insufficiently softened (> 15° F) will

leave traces of lime on the glasses.

Water which is too well softened (< 5° F) could bring

about an irreversible opalescence of the glassware.

Testing strip

Water

hardness

Setting

Salt

required

0 à 10°TH

0

No

10 à 18°TH

1

Yes

18 à 25°TH

1

Yes

25 à 40°TH

2

Yes

40 à 55°TH

3

Yes

55 à 70°TH

4

Yes

> à 70°TH

5

Yes

Setting on the control panel (L0, L1, L2 and L3)

Using the keys of the control panel following the explanatory notes in the appliance's Instructions for use.

On these models, the distributor's cursor is held at position 4 and the regeneration does not occur with

each cycle, but sequentially, when the resins are saturated.

The microprocessor counts and holds in memory the number of fillings carried out, and according to the

hardness programmed when the setting was effected, it sets off a regeneration at the appropriate time.

The adjustment of the hardness is done with the help of a combination of keys (see Instructions).

The visualisation of the adjustment, depending on the model, is done

• either with the help of the programme indicator lights,

• with the digital display.

When the machine is first switched on, the setting is 10-25°F.

• the display shows d1

• the “drenching” light permanently lit

For water which is extremely hard (> 70°F), you need to replace the cursor to regulate

the softener on the MAXI position (number 5).

Adjustment via the cursor inside the tub (Nm)

The setting of the softener is done by a cursor which is found inside the tub, on

the left hand side.

2

3 4

1

THE ATLANTIS DISHWASHER

Technical Training

FITTING

- 19 -

LA3-ATLANTIS-002UK-04/04

Filling the regenerating salt reservoir

In order for the softener to work correctly, when the machine is first put to use the salt container

should be filled with water (after the regenerative salt has been poured in). Be sure to screw the salt

container's lid down securely. Failure in doing this or in screwing it properly on its threads will result in

an abnormal consumption of salt and traces of salt on the dishes.

6.5. - Setting of the rinsing agent dispenser

Fill the rinsing agent dispenser, pouring in at least the whole of the sample provided. This rinsing agent

is essential as it contributes to drying, makes glassware shine more and prevents the formation of

streaks and traces of spots on the dishes.

Hold 120 ml (approximately one glassful).

The dispenser comes with a visual gauge and, depending on the model, with an indicator light

(ballcock controlled by ballcock and ILS).

The original setting is in the middle (Medium position : setting 2).

Do not use

kitchen salt

THE ATLANTIS DISHWASHER

Technical Training

FUNCTION

- 20 -

LA3-ATLANTIS-002UK-04/04

Cold rinse Rinse +

If excess of foam : R+

Filling duration

cold rinse / hot rinse

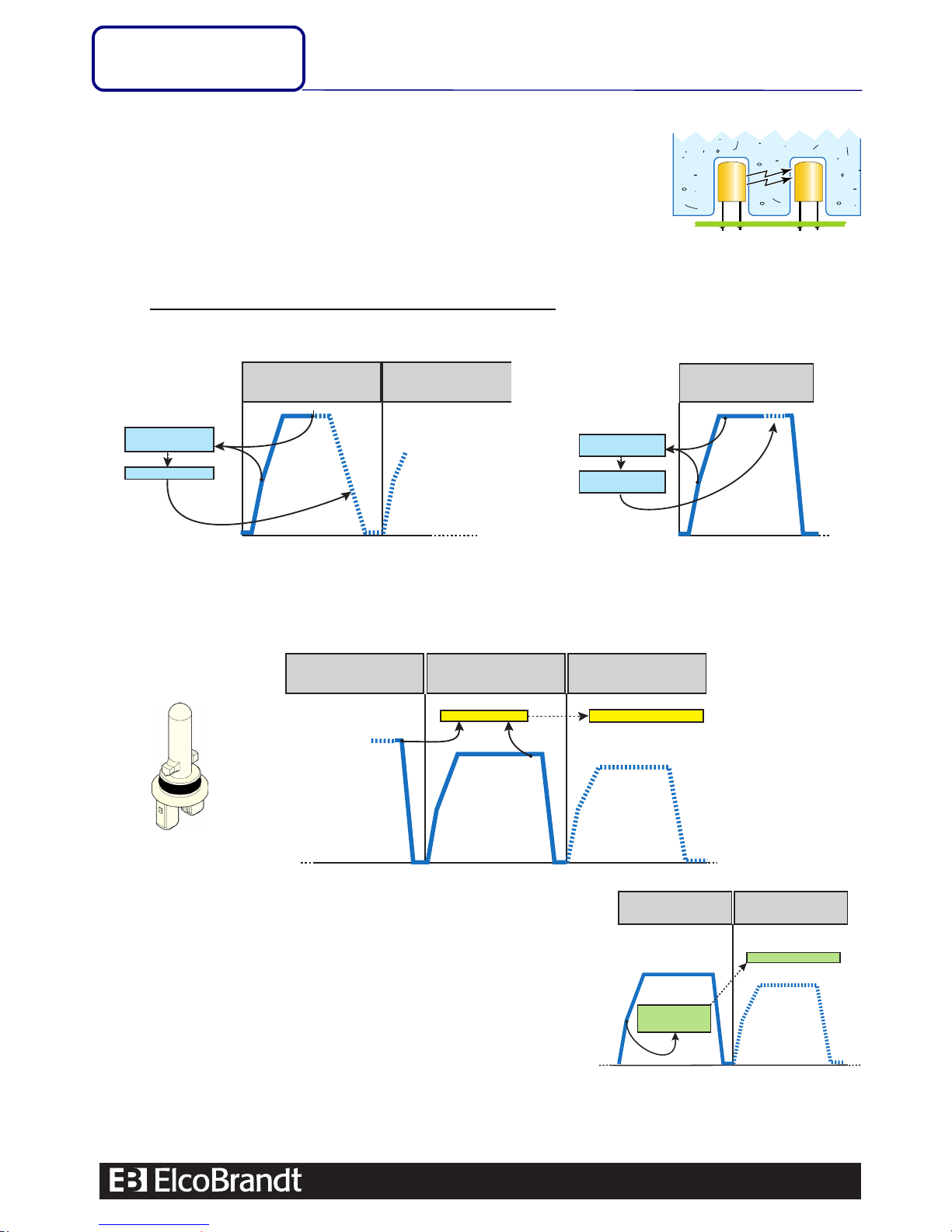

6.6. - Use of the sensors in new wash recipes classified A A A

The intelligent use of some sensors enables the electronics to adapt the

run of its auto-programs, in order to guarantee the result while trying to

save water, energy and time, and this, whatever the load or dirt rate is.

A turbidimeter (sensor consisting of an infrared emitter and a phototransistor used to assess the

state assess the state of turbid liquid) is located on the transparent duct of the spraying valve.

It enables the printed circuit board to assess the dirt level

from the cycle start. This measurement is

used to optimise the cycle duration (prewash possible or lengthening of the wash duration) and,

therefore, the water consumption, according to the dirt level of dishes.

Cold prewash

Possible correction

Hot washing

Measurement

of dirt level

Hot washing

Measurement

of dirt level

Lengthening of

wash duration

The NTC enables the printed circuit board to estimate the quantity of dishes. Because, this board

measures the water temperature rise at the first cold rinse, and compares it to the water

temperature at the very first filling. This temperature rise, which is due to the heat stored up by

dishes during the previous hot wash, enables the board to know the type of load. This allows to

perform an additional cold rinse in the case of a significant amount of dishes and, therefore, of dirt.

Hot washing Cold Rinse Rinse +

NTC measurement

R+ if large amount of dishes

The pressure controller enables the printed circuit board to

know if dirt remains on wash completion, in order to initiate, if

necessary, the additional cold rinse.

Because, if there is much dirt and not enough detergent

during the wash, there is a risk of emulsion, which causes an

excess of dirty foam difficult to evacuate. Draining will then

be incomplete and the time to reach the high level on next

filling will be shorter. The board compares this time to that

recorded during filling for the last hot rinse (that of the

previous cycle is stored in memory).

NTC

47 kΩ

Ω Ω

Ω at 25°C

THE ATLANTIS DISHWASHER

Technical Training

FUNCTION

- 21 -

LA3-ATLANTIS-002UK-04/04

3

2

1

6.7. - Other possibilities offered by the electronics

Display of savings achieved on completion of a cycle

This display of achieved energy and time savings depends on what the sensors have detected.

It only takes place on completion of models with automatic programs.

Memorisation of the most used cycle from the last 5 cycles.

Children safety device : the access (except "Start" button) is locked from the start of a cycle.

Pause : 1 short pressure on "Start" button is used to stop or restart the current cycle.

"Demo" mode for levels of programming with LCD screen :

To enter this mode, press 5 times the "Start" button within less than 5’’ and one time "Cyclone"

button. To exit the "Demo" mode, press the "Cyclone" button for 10’’.

Enzymatic dwell at 50°C, in order to strengthen the action of the detergent (except for "fast"

and "fragile" programs).

6.8. - Intuitive internal arrangement

The internal dishwasher arrangement has been optimised and, in particular, the upper basket, in order

to facilitate the loading and drying of stemmed glasses. Other points are also to be mentioned :

• Mezzanine shelf to accommodate long place settings or silver

• Upper basket with adjustable height

• Folding pins of the lower basket

6.9. - Low sound level

In order to meet a significant demand from consumers, many technical changes are used to obtain a

low sound level :

• Asynchronous cycling pump with PTC

• Reinforced acoustics

• Internal spraying circuit

• Alternate spraying

6.10. - Filtering 100% efficient throughout the cycle and easy

to access

A filtering in suction over four levels ensures perfect recycling of

the detergent bath throughout the program. Moreover, it requires

less water than a pulsed filter, and the components making it up

are easily accessible by the consumer for servicing.

- 1 : main filter

- 2 : two-part waste filter

- 3 : micro-filter

Dishwashers with 4-digit display (programming L2) and models

with LCD screen (programming L3) recall the user that it is necessary to perform the filter servicing.

Display

appears then once every 25 cycles.

No counter reset to 0 is necessary.

THE ATLANTIS DISHWASHER

Technical Training

FUNCTION

- 22 -

LA3-ATLANTIS-002UK-04/04

6.11. - Hydraulic diagram

• Horizontal and onboard draining pump :

gain in noise and dead volumes

• Internal cycling ducts:

gain in noise, dead volumes and energy

• Alternate spraying on certain models :

gain in noise and water consumption

• Heating tunnel :

quickness of heating and water saving

• Suction filters :

gain in water consumption

Small shower

Condenser *

EV1

EV2 *

EVS *

Pressure switch

N1 / Overflow

Distributor

Upper spray

Lower spray

Leakage control

Flow-meter

Draining

pump

Resin tray

Filters

Heating

tunnel

Base plate

Compression chamber

And droplets sensor

Flap-valve

EVR

Draining

hose

Tank

Circulation pump

I II III IV

V

* depending on the model

Non-return

valve

THE ATLANTIS DISHWASHER

Technical Training

FUNCTION

- 23 -

LA3-ATLANTIS-002UK-04/04

EV1

P

N1

N1'

t1 ⇒⇒⇒⇒ t2

6.12. - The filling of the Atlantis dishwasher with flow meter

The association of a pressure controller with a flow-meter is used to perfectly control the quantity of water

admitted during each filling and to announce a total consumption of 12 litres on certain models.

The flow-meter is a component that measures very precisely the quantity of water admitted by filling

solenoid valve EV1. The more or less quick passage of the water drives a magnetised turbine that acts

on a semiconductor supplied from the board.

6.13. - The filling with Atlantis dishwasher without flow meter

Filling controlled by pressure switch and checking of the absorbed current by water pump.

On some models, especially new products with mechanical access, a new process of the power card

enables to get a very accurate and adapted filling of water according to :

- Water pump and hydraulic circuit

- Level of loading and nature of dish

- Inlet water pressure and flow even if

the value is < 2l/mn

The filling is carried out as follow :

• Time « T1 » measurement to

reach the level 1 of the pressure

switch (1.85L). The normal time of

this static filling is 20s.

• Second static filling during

arround 13s (time « T2 » =

0.68xT1) to approach the working

level (3.2L) To avoid any

overflow, « T2 » time limit is 42s.

•

Hydraulic

unit

Tank

N1 level mark

Additional filling

from 1,7 to 2,95l

EV1

Distributor

Compression

chamber

Droplets

sensor

Pressure

switch

Flow-meter

Filters

THE ATLANTIS DISHWASHER

Technical Training

FUNCTION

- 24 -

LA3-ATLANTIS-002UK-04/04

• Water pump supplying and stand by of water valve 1 supplying.

As soon as the pump is working, the different spraying circuits fill themselves, switching down the

contact to low level of the pressure switch.

• Control of the current absorbed by the pump and supplying of EV1, as soon as current is not

stabilised during 6 or 9.6s (according to the programme). It enables to get the right water level

whatever the situation (bowl turned upside down)

A security cut the supplying of EV1 if the level 1 of pressure switch is reached again and remains

during 10s, to prevent any risk of overflow.

In case of opening/closing of the door or power shut down during current measurement phases,

a 5s break of measurement is carried out to avoid any disturbance of this measurement.

• Checking of current going through the pump during the following 5 min and completed filling

of water if needed.

As soon as current is stabilised during 1 min, EV1 is shut down. The completed filling of water

cannot exceed 1mn to avoid any security status of the pressure switch in case of :

- Failure of water pump

- Excessive foam into the tank

EV1

P

I

a

t

Ia unstable ⇒⇒⇒⇒ EV1 supplied

Ia stable ⇒⇒⇒⇒ EV1 shut down

EV1

P

N1

THE ATLANTIS DISHWASHER

Technical Training

FUNCTION

- 25 -

LA3-ATLANTIS-002UK-04/04

•

6.14. - The "floating" regeneration

The regeneration controlled by the electronics is not necessarily performed during each cycle.

It is said "floating", as it can be integrated in masked time into the program (the total cycle duration is

the same with or without regeneration). It can be performed during soaking, cold or hot prewash, wash

or first cold rinse. It never takes place during hot rinse before drying; on the other hand an anticipated

regeneration can take place if the additional cold rinse is initiated (detection of foam and/or significant

load during automatic programs). The objective is to guarantee the best possible water quality before

wash heating and especially before drying.

The complete regeneration phase is as follows

:

• 3 minutes of regeneration valve supply (EVR) to leave the 4 containers

of the distributor push the brine from the salt pot to resins (step 1)

• 3 seconds of filling solenoid valve supply (EV1) and 15 seconds of

pause to stir up the resins (step 2)

• 3 x (7 seconds of EV1 + 20 seconds of pause) to activate the salt work

(step 3)

• Complete draining to eliminate the salt and limestone (step 4)

Model with electronic access (L0 to L3)

The regeneration initiation will depend, of course, on the setting performed during appliance putting

into service (factory setting to 1), but also on the number of baths (L1 of pressure controller), and not

on the number of programs carried out. Below is the threshold (number of baths) initiating the

regeneration.

Setting

0 1 2 3 4 5

Number of baths

before

regeneration

No

regeneration

16 8 5 4 4

The regeneration phase systematically integrates a rinse of resins without cycling, in order not to send

the resin-cleaning residue (chlorides) onto dishes and risk to throw it towards dishes by heating it.

Because, this cleaning residue is very calcareous (more than from tap) and salty. Moreover, if the

regeneration is to be made before hot wash, then a second static rinse of resins is performed.

Model with mechanical access (Lm)

The dishwasher with mechanical access (Lm) does not allow adjusting the regeneration from the front

strip (no access board). It is actually necessary to adjust the cursor located in tank. The regeneration

will thus be partly performed (association of containers I to V) and during each cycle.

12 34

THE ATLANTIS DISHWASHER

Technical Training

FUNCTION

- 26 -

LA3-ATLANTIS-002UK-04/04

6.15. - The drying

The ATLANTIS dishwasher presents three levels of drying, depending on the model :

• Level 1 "C" (natural drying)

During the rinse process, the temperature of the dishes is taken up to 73°C. At the end of the

programme, a drying phase of about 15 minutes enables the dishes, well drained through the action of

the rinsing agent, to evaporate the residual film of humidity by restoring part of the heat accumulated.

The steam thus created is partially evacuated by being exposed to air through the exchanger situated

in the distributor.

• Level 2 "B" (drying by condensation)

In this system a V2 control valve with a low-level output (0.25l/min) supplies several threads of cold

water to the rear wall of the tub, enabling almost all the steam to be condensed, which leads to

optimum drying and to an avoidance of there being a cloud of steam when the door is opened.

• Level 3 "A" (Air drying)

The hot (65°C) and humid air given off by dishes is evacuated to outside the tank through a fan.

This air is first mixed with the ambient air to avoid the formation of steam at the dishwasher outlet.

A 1st

wax actuator partly opens a valve that leaves only approximately 20% of the tank air go to the

outside. This first phase lasts approximately 10 minutes. Then, the 2nd wax actuator completely opens

the valve, thus allowing the evacuation of all the humid air from the tank. This second phase lasts

approximately 15 or 30 minutes depending on the program selected.

Only the "fast 30’" does not propose ventilated drying.

The evacuation of humid air is performed at the bottom for 'free standing' models (through a plastic

duct coming out between front panel and plinth). On the other hand, it is performed directly at the top

(under front strip) for built-in dishwashers and square ‘free standing’ ones.

This type of drying cannot be fitted to ‘full built-in’ models as a result of the presence of a complete

wood panel on the front. Products must neither be installed in a cupboard.

Thermo-activator n°1

Thermo-activator n°2

Exit

Moto

r

Turbine

THE ATLANTIS DISHWASHER

Technical Training

FUNCTION

- 27 -

LA3-ATLANTIS-002UK-04/04

6.15.1. - The extra drying option

Mechanical access model (Nm)

- Consultation of setting

1 : the programmes knob must be adjusted to « 0 » position

2 : Turn the programmes knob to the option desired

3 : The light « washing » or « end of programme » will first of all flash and then go out

- the washing light flashes: EXTRA DRYING ACTIVED

- the end of programme light flashes: EXTRA DRYING NOT ACTIVED

- To activate the option

1 : hold down the « start » button

2 : turn the programmes knob to the right

- the washing light flashes: EXTRA DRYING ACTIVED

- To alter the option

1 : hold down the « start » button

2 : turn the programmes knob to the left

- the end of programme light flashes: EXTRA DRYING NOT ACTIVED

THE ATLANTIS DISHWASHER

Technical Training

THE COMPONENTS

- 28 -

LA3-ATLANTIS-002UK-04/04

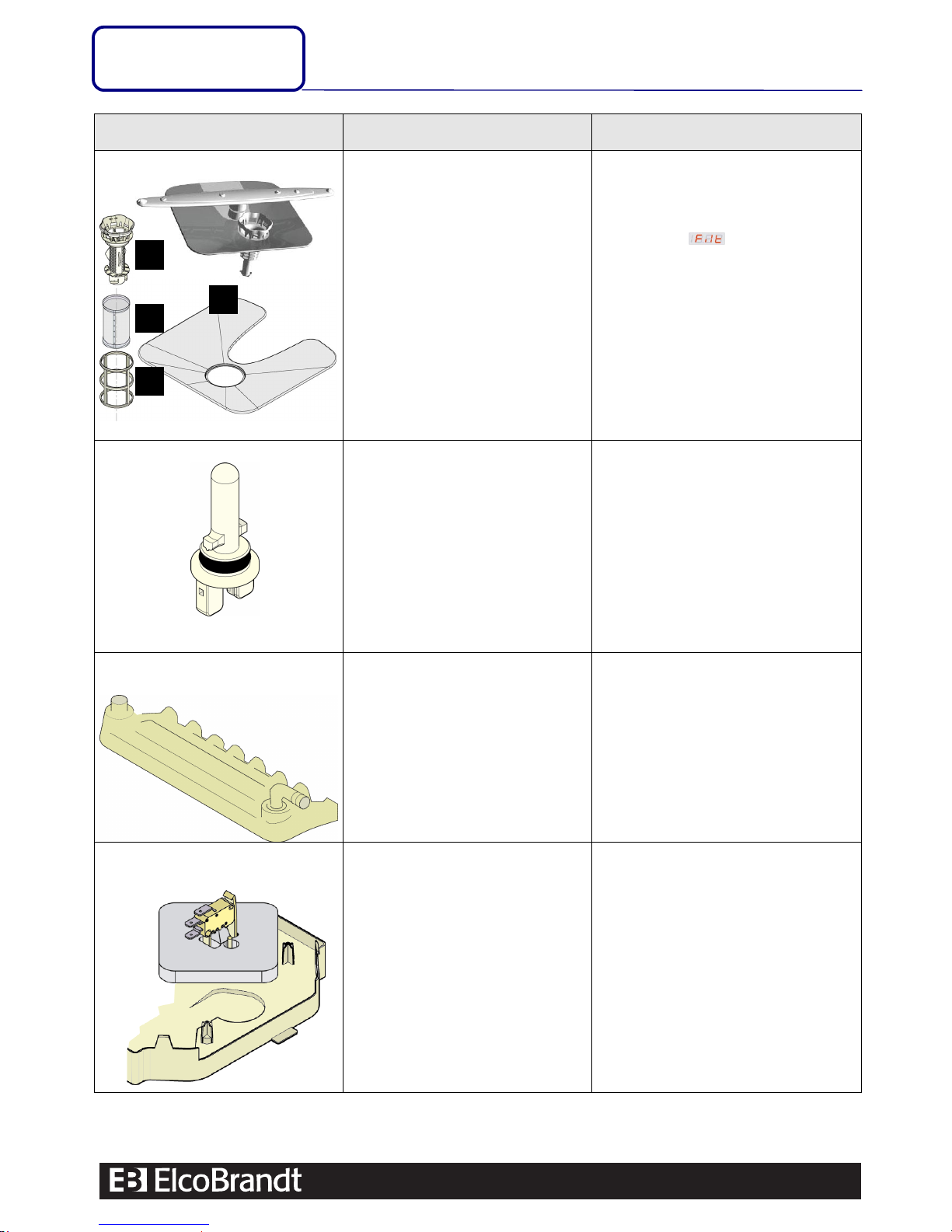

6.16. - The different components

Designation Function Characteristics

Water supply pipe

"Aqua stop". The supply pipe is

equipped with a control valve to the tap

which cuts off the water supply in the

event of the leak control being triggered

(by a leak under the machine or an

overflow from the tub).

"Burst proof". A supply pipe with

double casing would act, in the event of

a burst in the main pipe, either to shut off

a mechanical valve to the tap, or to set

off the "aqua stop" by means of the leak

control, channelling the water down to

the base plate.

Or by the supply pipe reinforced with a

plaited metal casing, which would avert

any risk of the pipe

Water valve

Used to fill the dishwasher.

• 1 or 2 way

• EV1 5 l/min

• EV2 0,25 l/min

• 220/240V~ (brown coil)

• 115V~ (grey coil)

• 3,5 kΩ or 1kΩ

• Water feed pressure 0,2 to 10 bar

1

2

3

EV1

EV1 + EV2

THE ATLANTIS DISHWASHER

Technical Training

THE COMPONENTS

- 29 -

LA3-ATLANTIS-002UK-04/04

Designation Function Characteristics

Distributor

Ensures the water distribution for wash

and regeneration.

Ensures evacuation of the steam

contained in the tank, in particular during

drying, for dishwashers with natural

drying (marked C).

Water distribution for filling with soft water

(system to distributor, and then distributor to

resins and resins to tank).

Soft-water reserve of the system for the

regeneration (Distributor to salt pot).

‘All electronic’ dishwashers L0 to L3

:

4 containers (1 to 4) of hard water empty at

the regeneration moment (i.e., 165 ml).

The brine in salt pot (in chassis bottom) is

thus pushed into the resin pot.

If hardness is greater than 70°TH, then it is

necessary to replace the decorative strip of

the distributor initially locked in position 4,

and set it to the maximum, position 5, so

that the 5 containers of the distributor empty

(i.e., 250 ml).

Dishwasher with ‘mechanical access’, Lm

:

Containers (1 to 5) of hard water empty at

the regeneration moment and according to

the position of the adjustable cursor of the

decorative strip, located in the tank.

Tap > (EVS) > EV1 > Flow-meter

Resins

Sal

t

Resins

Tank

cursor

- cursor held at 4 (L0 to L3)

- cursor adjusted to 1 at 5 (Lm)

1 2 3 4 5

Hard water

Soft water

THE ATLANTIS DISHWASHER

Technical Training

THE COMPONENTS

- 30 -

LA3-ATLANTIS-002UK-04/04

Designation Function Characteristics

Softener

It consists of a salt container and a resin

tray joined by a pipe into which the

regeneration control valve (EVR) is

inserted.

When the machine is filling, the water

goes through the resin and discharges

the calcium and magnesium salts, which

remain on the resin: the water is

softened.

When all the calcium-magnesium ions

have replaced the sodium ions, the resin

is saturated and no longer softens the

water: it has to be regenerated.

• Salt compartment 1,4 Kg

• Resin tray 0,60 L

Regeneration valve

It leaves the 4 containers of the

distributor push the brine from the salt

pot to resins.

• 220/240V~

• 4,5 kΩ

Draining pump

Evacuate wastewater.

The synchronous pump can turn

clockwise or counter-clockwise.

To reach its synchronism rate, the

turbine must have a freedom degree of

approximately 180° with respect to the

rotor.

The synchronism rate is reached very

easily when loaded (with water),

the off-load start is, as for it, very

irregular (the rotation direction may be

reversed several times).

• 220/240V~

• 250Ω.

• 30 W

• 15 l/min

• Synchronous

Salt

Resins

ILS

Full Empty

THE ATLANTIS DISHWASHER

Technical Training

THE COMPONENTS

- 31 -

LA3-ATLANTIS-002UK-04/04

Designation Function Characteristics

Pressure switch

Compression chamber

Droplets sensor

The water level is controlled by a

compression chamber in the hydraulic

unit and a pressure switch.

To obtain a greater precision in the

filling, the pressure switch’s detection

occurs at the level of the upper part of

the hydraulic unit at the point where the

section is weakest.

A complement of water is effected by a

flow-meter.

• Low level : 11/12

• High level : 11/13 (1,85 litres)

• Safety : 21/23

Flow-meter

The flow-meter measures very precisely

the quantity of water admitted by filling

EV1.

Heating element

Performs heating of the detergent bath.

• 220 / 240 V~

• 2040 W

• 25 Ω

• Safety thermostat at 98°C

• Thermal fuse at 206°C

Red

down

THE ATLANTIS DISHWASHER

Technical Training

THE COMPONENTS

- 32 -

LA3-ATLANTIS-002UK-04/04

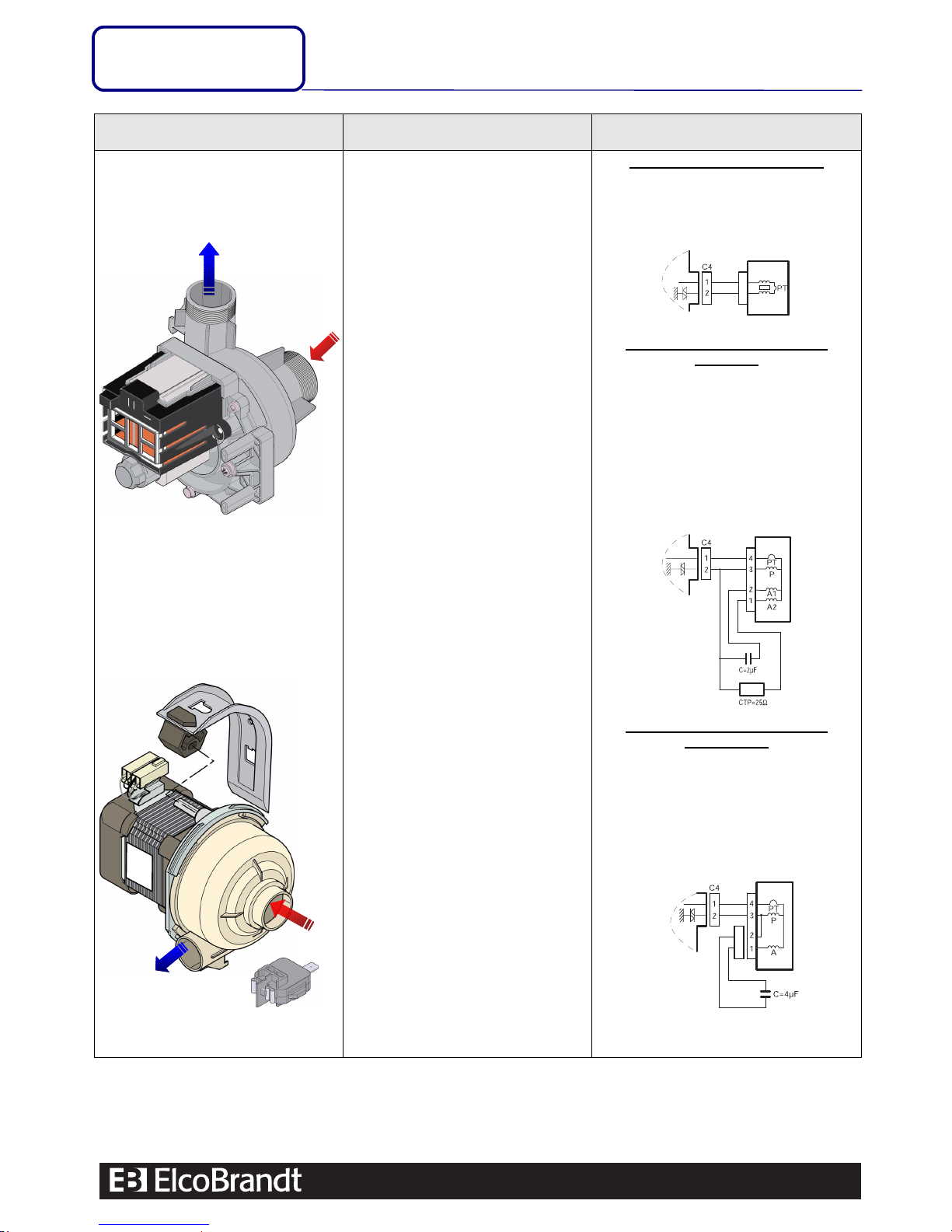

Designation Function Characteristics

Cycling pump

Synchronous motor

Asynchronous motor

The pump pulses the water to the lower

winch and upper winch, ceiling small

shower and product box.

A pump internal mechanical system

enables the synchronous motor to drive

the curved-vane turbine in the right

direction

Some models are fitted with

asynchronous pump with double

auxiliary winding switched off by the

PTC after motor start. This process is

used to reduce the pump sound level.

Synchronous circulation pump

• 50 l/min

• 220 / 240 V~

• 110 W

• 44Ω

Asynchronous circulation pump

with P.T.C

• 50 l/min

• 220 / 240 V~

• 90 W

• 2µF

• P.T.C : 25 Ω at 20°C

• Principal coil (3-4) : 102Ω

• Auxiliary coil 1 (2-4) : 215Ω

• Auxiliary coil 2 (1-4) : 25Ω

Asynchronous circulation pump

without P.T.C

• 50 l/min

• 220 / 240 V~

• 100 W

• 4µF

• Principal coil (3-4) : 62Ω

• Auxiliary coil (1-4) : 92Ω

PTC

Asynchronous motor + PTC

Synchronous motor

Asynchronous motor

THE ATLANTIS DISHWASHER

Technical Training

THE COMPONENTS

- 33 -

LA3-ATLANTIS-002UK-04/04

Trough for tablets

Powder and

liquid

compartment

Designation Function Characteristics

Alternated spraying

flap valve

This system is used to both save water

and reduce the sound level of ATLANTIS

dishwashers.

The micro motor of the back-geared

motor drives a disc with alternately

obstructs the way to the lower spray

(240mbar) or the way to the upper spray

(140mbar) .

Turbidimeter :

The Turbidimeter (dirt sensor) consists

of an infrared emitter and a

phototransistor used to assess the state

assess the state of turbid liquid.

It is located on the transparent duct of

the spraying valve.

Rinsing agent compartment

Filling with rinsing agent is done when

the dishwasher door is opened and

closed.

The command for the introduction of the

rinsing agent is done electronically

through a thermo-activator.

The value of this product is to improve

the drying out of the contents of the

dishwasher, by breaking down the

surface tension of the water and

preventing the deposit of spot marks.

The rinsing agent is introduced into the

tank when the desired water

temperature has been reached.

A level detector (ballcock and ILS) or an

indicator light (near the cap)

demonstrate to the user the need to add

more rinsing agent (see instructions).

• 220/240V~

• 2 kΩ.

• Reserve 130ml

- Position 1 : 2 cm

3

- Position 2 : 3,5 cm3

- Position 3 : 5 cm

3

Detergent compartment

The hydraulic unit, fixed onto the upper

rack for easy access, simplifies the

measuring of the detergent.

It will take all types of detergent. It has a

compartment for powder or gel, and a

special place to put the tablets in.

A return spring facilitates the fastening.

The off-take of the detergent (powder or

liquid) occurs when water flows directly

into the compartment and overflows.

The tablets will dissolve through the

spraying action of the middle spray.

• powder (40 gr.)

• tablet (1)

• liquid (130 mil)

Upper spray Lower spray

H

B

C

Disc

position

Turbidimeter

Lower spray

Upper spray

THE ATLANTIS DISHWASHER

Technical Training

THE COMPONENTS

- 34 -

LA3-ATLANTIS-002UK-04/04

Designation Function Characteristics

Filters

Ensures perfect recycling of the

detergent bath throughout the program

- main filter (1)

- food waste filter and particles filter (2

and 3)

- micro-filter (4)

The filters are located in the middle of the

tub and must be cleaned regularly to ensure

optimum washing results.

Approximately every month the dishwasher

(L2 and L3) advises the user to proceed to

clean the filters

NTC

The NTC informs the microprocessor on

printed circuit board.

• 47 kΩ at 25°C

Condenser

EV2 control valve with a low-level output

(0.25l/min) supplies several threads of

cold water to the rear wall of the tub.

Micro-switch

leakage detection

This system cuts off the water supply if a

leak is detected under the machine.

1

2

4

3

THE ATLANTIS DISHWASHER

Technical Training

THE COMPONENTS

- 35 -

LA3-ATLANTIS-002UK-04/04

Designation Function Characteristics

Drying fan

Ensure evacuation of the steam

contained in the tank

Motor

• 220/240V~

• 380 Ω.

Thermo activator

• 220/240V~

• 1 kΩ.

Access board

The access board manages

• the programme management

• the temperature

• the water level

• the safety devices

• the D.A.P.

• the power card

The visualisation is realised by

• indicator lights

• digital display

• LCD screen

The access cards are thus specific of each

model.

Power board

This card, which is situated at the front

of the frame, controls the different

components by means of bi-directional

triode thyristors or relays (heating), and

receives information from the various

sensors (pressure switch, door security,

NTC…)

Up

THE ATLANTIS DISWASHER

Technical Training

PROGRAMMATION

- 36 -

LA3-ATLANTIS-002UK-04/04

6.17. - The washing programmes

DRENCHING :

• Cold pre-wash

INTENSIVE :

• Washing at 65°C

• Rinse

• Hot rinse

• Drying

ICS + : Auto-programme adapted to the amount of items and levels of residue.

• Cold pre-wash

• Washing at 70°C

• Rinse

• Hot rinse

• Air drying or drying by condensation

ICS : Auto-programme adapted to the amount of items and levels of residue.

• Washing at 60°C

• Rinse

• Hot rinse

• Air drying or drying by condensation

NORMAL :

• Washing at 55°C

• Rinse

• Hot rinse

• Drying

ECO :

• Washing at 45°C

• Rinse

• Hot rinse

• Drying

ECO WASH :

• Cold pre-wash

• Washing at 50°C

• Rinse

• Hot rinse

• Air drying

FRAGILE :

• Washing at 45°C

• Rinse

• Hot rinse

• Natural drying

RAPID :

• Washing at 40°C

• Rinse

• Hot rinse

• Natural drying

THE ATLANTIS DISWASHER

Technical Training

PROGRAMMING

- 37 -

LA3-ATLANTIS-002UK-04/04

6.17.1. - Programmes

DRENCHING

Hot pre-wash

ECO WASHNORMALICS

Cold pre-wash Hot washing Cold rinse Rinse + Hot rinse Drying

Alternated

Alternated Alternated

Alternated Alternated Alternated

Alternated

AlternatedAlternatedDown

Alternated

Alternated

55 C

Air drying

or drying

by condensation

Air drying

S : Dirt level detection

C : Quantity of dishes detection

M

:

Foam d

etection

THE ATLANTIS DISWASHER

Technical Training

PROGRAMMING

- 38 -

LA3-ATLANTIS-002UK-04/04

ICS+

Air drying or

drying by

condensation

Natural drying

Natural drying

Alternated Alternated Alternated

Alternated Alternated Alternated

Alternated Alternated Alternated Alternated Down

70 C

S : Dirt level detection

C : Quantity of dishes detection

M

:

Foam detection

THE ATLANTIS DISWASHER

Technical Training

SYNOPTIC

- 39 -

LA3-ATLANTIS-002UK-04/04

6.18. - Synoptic

Is the access that differentiates the five levels of programming ‘All electronic’ dishwashers L0 to L1 are

fitted with access printed circuit boards. ‘Mechanical access’ models are fitted with selectors and are

not provided with access boards in front strip.

On/Off

Door

switch

N

L

Cycling

pump

Draining

pump

Heating

element

N.T.C.

Anti-

leak

Power board

Rinsing

distributor

EVR

EV1

Microprocessor

EEPROM

N1

Overflow

EV2

Dirt sensor

Micro-motor

flap valve

Switch

thermo-

activator

+

Drying fan

Flow-meter

Life

Neutral

Info

L1

L0

L2 L3

Lm

C

H

H

THE ATLANTIS DISHWASHER

Technical Training

BLOCK DIAGRAM

- 40 -

LA3-ATLANTIS-002UK-04/04

6.19. - The block diagram of the Atlantis dishwasher with electronic access

THE ATLANTIS DISHWASHER

Technical Training

BLOCK DIAGRAM

- 41 -

LA3-ATLANTIS-002UK-04/04

6.20. - The block diagram of the Atlantis dishwasher with mechanic access without flow meter

THE ATLANTIS DISHWASHER

Technical Training

OPERATION SERVICE

- 42 -

LA3-ATLANTIS-002UK-04/04

7 - OPERATION SERVICE

7.1. - The diagnosis assistance programme (DAP)

Complete DAPs are used to control all the appliance functions and give a certain number of codes

used to know the faulty function.

Positions, names of Leds and buttons differ according to the product and the programming level.

Consultation of faults

• Access L1, L2 and L3

(display 3 or 4 digits or LCD display)

If there is a failure, a fault code may appear during the DAP.

FAULT

CODES

FUNCTION AND/OR COMPONENT TO CHECK STEP

Filling >>> EV1 + EVS + Pressure switch

Draining >>> Draining pump + Pressure switch

Heating >>> Heating element (Thermal fuse + safety thermostat) + door safety SP2

NTC

Flow-meter

Dry sensor

Leakage >>> Leakage detection switch (this fault cancels the current programme)

All steps

Cycling >>> Cycling pump (with or without capacitor and PTC)

• Access L0 and Lm (muti-leds display)

During the DAP, a quick blinking of one or two Leds means the function is faulty.

To go from one step to the next

Press the « Start »

key

For the steps which are underlined: the step point must be reached to allow you to go on the next step.

Checking during the DAP

It is possible to disconnect the appliance during the DAP, in order to check the faulty circuit, and then

to connect it again to continue the DAP.

To exit test programme

Press the « Start »

key for 2 seconds

Preliminary steps

• Remove the plinth

to found the DAP

• Remove the left pannel

to check the draining of the distributor regeneration containers

• Take the transparent door

31x5364 to check that the agitator rotates freely

• Connect if possible an ammeter to dishwasher power supply

• Check that the tap is open

• Hold down the « Start »

button or turn the programmes knob Lm to an other position 0.

THE ATLANTIS DISHWASHER

Technical Training

OPERATION SERVICE

- 43 -

LA3-ATLANTIS-002UK-04/04

Action Step Run Remarks

The Leds and the digits light + « Bip »

(according to model) ?

Launching

NO

You are not in the Test programme

Press the “start”

key

5 times within 5

seconds

0

YES

You are in the Test programme

Access check

1 Led lights or blinks ?

NO

Access defective or not connected.

Press the

« start » key

Pressing one key or rotating the button lights or blinks

appropriate Led

YES

To go from one step to the next

1 or 2 Leds light up ?

NO

No any led lighted

:

Connexion boards HS - Locked fault.

1 or 2 leds flashing

:

N.T.C. and/or turbidimeter defective.

Fault code

: N.T.C defective.

Fault code

: Turbidimeter defective.

Press the

« start » key

NTC check

+

Turbidimeter check

+

Connexion check

power board / access board

YES

To go from one step to the next

N0 level check

Is level N0 reached before 30’’ ?

(led flashed if N1 and lighted if N0)

NO

1 Led quick blinks

or Fault code :

Pressure switch or draining pump defective.

Locked fault.

Press the

« start » key

Supply

- draining pump

- EV2 or thermo-activator n°1 of the extractor

(according to model)

YES

To go from one step to the next

EV1 and N1 level check

Is level 1 reached ?

(1 led blinking if N0 and lighting if N1)

NO

Fault code

: or Led quick blinks

Anti-leakage safety or overflow actived.

Locked fault.

Fault code

or Led quick blinks

N1 non détecté - Locked fault..

Press the

« start » key

Supply

- EV1

! IF ANTI-LEAKAGE SAFETY ACTIVED

- EV1shut down + supply draining pump

- P.A.D. bloqué → contrôle N1 non réalisé

YES

To go from one step to the next

Additional filling check

Is additional filling ?

(led blinks during filling

led lights up : complément débimètrique atteint)

NO

Fault code

or led blinks :flowmeter defective.

Automatically

switches top

step 6

Additional filling

by flow meter or chronometric filling 15’’ (according to

model)

Supply

- EV1

YES

To go from one step to the next

Cycling check

Are the agitators rotating freely ?

(leds blinking)

NO

- agitator blocked, pump or aspersion valve HS

- led quick blinks

: Cycling pump defective.

Press the

« start » key

or

aucune action

selon modèle

Supply

- cycling pump

- alternate motorised aspersion valve (according to model)

quick rate :

• 15’’ in lower position

• 19’’ in rotation (passing low → up)

• 15’’ in upper position

• 5’’ in rotation (passing up → low)

YES

To go from one step to the next

Heating check

Current consumption?

(led blinks during heating

led lights up if heating OK after 5 min)

NO

Fault code

led quick blinks :

No heating after 5 min

Press the

« start » key

Supply

- cycling pump

- heating element

YES

To go from one step to the next

Regeneration check

Are the distributor regeneration containers draining ?

(led blinking)

NO

Regeneration valve defective .

Press the

« start » key

Supply

- regeneration valve EVR

YES

To go from one step to the next

Rinse aid distribution check

Is the product discharging on the inner door ?

(led blinking)

NO

Thermo-activator defective

Press the

« start » key

Supply

- rinse aid distribution thermo-activator

YES

To go from one step to the next

Draining check

Is level N0 reached before 30’’ ?

(led flashed if N1 and lighted if N0)

NO

led quick blinks

or fault code :

Pressure switch or draining pump defective

Locked fault.

Press the

« start » key

Supply

- cycling pump during 10 sec

- draining pump

- EV2 or thermo-activator n°2 of the extractor (according to

model)

YES

To go from one step to the next

Press the

« start » key

or power shut

down

End of the DAP.

THE ATLANTIS DISHWASHER

Technical Training

OPERATION SERVICE

- 44 -

LA3-ATLANTIS-002UK-04/04

PHE

0V

1

3

1

3

SP

1

2

C7A

C7B

PHP

PHP

PHP

PHP

MOT. CLAP.

POS. CLAP.

0V/TURB

-5.1V

SIGNAL

C4

CYCLAGEC6NIV 1

NI 2

EV2

EV1

C5

C3

RINC

VID

REGE

VENT

CLAPET VENT

C8

C1

C2

DEBI.

0V

-5V

PHE

0V

-5V

DATA

CLOCK

C1-3

C1-2

CTN

123

321

321

1

2

3

4215

123

21

4

3

2

1

12345

7.2. - Checks and measurements possible at power board terminal strips

To test most of the components in the operating dishwasher, therefore with door closed, you just have

to remove the plinth and move the power board forward on the left-hand side. The access board is

checked with the DAP (step 01).

7.2.1. - The Atlantis dishwasher with electronic access (L0 to L3)

On the voltmeter

CAUTION

: The reference is J1/3 (neutral).

Mark

Components position Connector Voltage

Cycling pump 2 C4

Alternated spraying flap valve motor 3 C7A

Thermo-activator N°1 2 C3

Thermo-activator N°2 4 C6

Drying fan 1 C3

EV2 1 C3

EV1 5 C6

Rinse aid distribution thermo-activator 1 C5

EVR 3 C5

Draining pump 2 C5

Heating element 1 J2

0 V~ : Components powered

or

230V~ : Components not powered

THE ATLANTIS DISHWASHER

Technical Training

OPERATION SERVICE

- 45 -

LA3-ATLANTIS-002UK-04/04

On the ohmmeter

CAUTION

: All the measurements are made with connectors disconnected from the power

board.

Components Mark Values Remark

N.T.C C1/1 Blue C1/3 Blue

47 kΩ

At 25°C

Dry sensor C7B/1 or 2 Flat cable C7B/3 Black - Not measurable

Draining pump J3/2 Grey C 5 /2 Green

250 Ω

-

Pressure switch N0 (11-12 closed) J3/2 Grey C6/2 White

0 Ω

Empty tank

EV2 J3/2 Grey C6/4 Green

3,5 kΩ

Drying by condenser

Drying fan J3/1 Violet C3/1 Orange

380 Ω

Air drying

Thermo activator n°1 J3/1 Violet C3/2 White

1 kΩ

Air drying

EV1 J3/2 Grey C6/5 Red

3,5 kΩ 2 kΩ if EVS

Pressure switch N1 (11-13) J3/2 Grey C6/2 White Infinity Full tank

Flow-meter C8/1 or 2 Red C8/3 Red Signal Not measurable

Asynchronous circulation pump

with PTC and capacitor (2 µF)

C4/1 Black C4/2 Orange

28 Ω

Asynchronous circulation pump

with capacitor (4 µF)

C4/1 Black C4/2 Orange

60 Ω

-

Synchronous circulation pump C4/1 Black C4/2 Orange

44 Ω

-

Alternated spraying flap valve motor C7A/3 Brown C7A/4 Brown

6 kΩ

Alternated spraying flap valve

position switch

C7A/1 Black C7/2 Black

0 Ω or infinity 0 Ω (position B) or infinity

Heating element J2/1 Red/Green J2/3 Orange

25 Ω

Door closed

EVR J3/2 Grey C5/3 White

4,5 kΩ

Rinsing agent distributor J3/1 Violet C5/1 Red

2 kΩ

Door closed

Thermo activator n°2 J3/1 Violet C6/4 Green

1 kΩ

Air drying

Pressure switch overflow (21-23) C6/1 Orange C6/3 Orange

0 Ω

Overflow

Micro-switch leakage detection J3/2 Grey C6/3 Orange

0 Ω

Leakage

PTC On capacitor 2 µF

25 Ω

At 20°C

THE ATLANTIS DISHWASHER

Technical Training

OPERATION SERVICE

- 46 -

LA3-ATLANTIS-002UK-04/04

7.2.2. - The Atlantis dishwasher with mechanical access (Lm)

The Atlantis dishwasher with mechanical access (Lm) are not all fitted with flow meter.

On the voltmeter

CAUTION

: The reference is J1/3 (neutral).

Mark

Components Position Connector Voltage

Cycling pump 2 C4

EV1 5 C6

Rinse aid thermo-activator 1 C5

EVR 3 C5

Draining pump 2 C5

Heating element 1 J2

0 V~ : Components powered

or

230V~ : Components not powered

THE ATLANTIS DISHWASHER

Technical Training

OPERATION SERVICE

- 47 -

LA3-ATLANTIS-002UK-04/04

On the ohmmeter

CAUTION

: All the measurements are made with connectors disconnected from the power

board.

Components Mark Values Remark

Position "drenching" C2/6 Orange C2/5 (T1) Orange

0 Ω

Position "0" or "stop" C2/6 Orange C2/1 à C2/6 Orange Infinity Position "1" C2/6 Orange C2/4 (T2) Orange

0 Ω

Position "2" C2/6 Orange C2/3 (T3) Orange

0 Ω

-

Programmes

knob position

Position "3" C2/6 Orange C2/2 (T4) Orange

0 Ω

Key "Start" C2/6 Orange C2/1 (START) Orange

0 Ω

on

Draining pump J3/2 Grey C5/2 Orange

250 Ω

-

Pressure switch N0 (11-12

closed)

J3/2 Grey C6/2 White

0 Ω

Empty tank

EV1 J3/2 Grey C6/5 Red

3,5 kΩ 2 kΩ if EVS

Pressure switch N1 (11-13

closed)

J3/2 Grey C6/2 White Infinity Full tank

Asynchronous circulation pump

with PTC and capacitor (2 µF)

C4/1 Black C4/2 Orange

28 Ω

-

Asynchronous circulation pump

with capacitor (4µF)

C4/1 Black C4/2 Orange

60 Ω

-

Synchronous circulation pump C4/1 Black C4/2 Orange

44 Ω

-

Heating element J2/1 Red/Green J1/1 Orange

25 Ω

-