Page 1

Operation and Installation manual

THISION WH

02/2011 DOC3078 / 12103187

Page 2

Page 3

Contents

Contents .................................................................. 3

General regulations ................................... 5

Application ................................................. 5

Norms and regulations .............................. 5

Construction Layout of water heater ............................... 7

Operating principle .................................... 7

Technical data ................................................................. 10

Water heater Installation .......................... 12

Connecting the water heater .................... 12

Commissioning Water and hydraulic system ...................... 17

Gas supply ................................................ 18

........................... 18

Flue and air intakeconnections ................. 18

Prepare water heater for first startup ........ 19

Combustion analysis ................................. 20

........... 21

Gas tightness check .................................. 21

Water heater shut down ............................ 21

Maintenance Checklist .................................................... 25

Replacing the electrodes ........................... 25

Cleaning the condensate receptacle ......... 26

Cleaning and refilling the syphon .............. 26

Inspection of the combustion chamber ...... 26

Water pressure and quality ....................... 27

Combustion analysis ................................. 27

Gas pressure ............................................. 27

Gas tightness check .................................. 27

Safety devices ........................................... 27

Maintenance Protocol ................................. 28

Loc

kouts

.................................................................. 22

Safety Provisions ...................................... 6

Thision WH principle ................................. 7

Unvented Applications .............................. 14

Cylinder diagnosis & controls .................... 19

Commissionign protocol ............................. 29

3

Condensate connections

Check functionality of safety devices

Cylinder venting .........................................

17

Page 4

Page 5

Safety

General regulations

Application

Norms and regulations

5

General regulations

This documentation contains important

information, which is a base for safe

and reliable installation, commissioning

and operation of the THISION L boiler.

All activities described in this document

may only be excecuted by authorized

companies.

Changes to this document may be effected without prior notice. We accept

no obligation to adapt previously delivered products to incorporate such

changes.

Only original spare parts may be used

when replacing components on the

boiler, otherwise warranty will be void.

Applic

ation

The THISION water heater may be

used for hot water production purpo-

ses only.

Norms and regulations

When installing and operating the

boiler, all applicable norms (european

and local) should be fulfilled:

Local building regulations for installing combustion air and flue gas systems;

Regulation for connecting the water

heater to the electrical appliance;

Regulations for connecting the water

heater to the local gas network;

Norms and regulations according to

safety equipment for heating systems;

Any

additional local laws/regulations

with regard to installing and operating

heating systems.

Additional national standards

Germany:

RAL - UZ 61 / DIN 4702-8

Switzerland:

SVGW

EKAS-Form. 1942: Flüssiggas-

Richtlinie Teil 2

Vorschriften der kantonalen Instanzen

(z.B. Feuerpoilizeivorschriften)

Netherlands:

GASKEUR BASIS

GASKEUR SV

GASKEUR HR107

Belgium:

HR TOP

The THISION L boiler is CE approved

and applies to the following European standards:

92 / 42 / EEC

Boiler efficiency directive

2009 / 142 / EEC

Gas appliance directive

2006 / 95 / EEC

L

ow voltage directiv

e

2004 / 108 / EEC

EMC directive

EN 483

Gas-fired central heating boilers Type C boilers of nominal heat input

not exceeding 70 kW

EN 15420

Gas-fired central heating boilers Type C boilers of nominal heat input

exceeding 70 kW, but not exceeding

1000 kW

EN 15417

Gas-fired central heating boilers Specific requirements for condensing

boilers with a nominal heat input

greater than 70 kW but not exceeding

1000 kW

EN 50165

Electrical equipment of non-electri

c

appliances for household and similar

purposes - Safety requirements

EN 15502-1

Gas-fired central heating boilers Part 1: General requirements and

tests

EN 55014-1 (2000)

Electromagnetic compatibility - Requirements for household appliances,

electric tools and similar apparatus Part 1: Emission

EN 55014-2 (1997)

Electromagnetic compatibili

ty - Requirements for household appliances,

electric tools and similar apparatus Part 2: Immunity - Product family

standard

EN 61000-3-2 (2000)

Electromagnetic compatibility (EMC) Part 3-2: Limits - Limits for harmonic

current emiss

ions (equipment input

current 16 A per phase)

EN 61000-3-3 (2001)

Electromagnetic compatibility (EMC) Part 3-3: Limitation of voltage

changes, voltage fluctuations and

flicker in public low-voltage supply

systems, for equipment with rated

current 16 A per phase and not subject to conditional connection

EN 60335-1 (2002)

Household and similar electrical appliances - Safety - Part 1: General requirements

EN 60335-2-102 (2006)

Household an similar electrical

appliances: Particular requirements

for gas, oil and solid-fuel burning appliance

s having electrical connections

Page 6

Safety Provisions

Conditions

It is a statutory requirement that all gas appliances are installed in accordance with the manufactures instructions and

all current regulations in force, all instructions should be fully read before installing or using the appliance.

All installations should be carried out by competent persons as described in the Gas Safety (Installation & Use)

Regulations. i.e. GasSafe registered and holding current certification.

The work must be carried out by a competent person as described in the I.S. 813 Domestic Gas Installations with

reference to the following codes of practices.

The Manufacturers instructions MUST NOT be taken in any way as overriding statutory obligations.

This boiler has been tested and certified to comply with all necessary European directives, latest building regulations

and efficiency requirements for the SEDBUK scheme and as been approved with an efficiency band rating of A and

is CE marked and

complies with

92

/42/EEC Efficiency of Hot Water Boilers Directive

90/396/EEC Gas Appliance Directive

93/68/EEC Low Voltage Directive (was 73/23)

92/31/EEC Electromagnetic compatibility Directive

I.S. 813 Domestic Gas Installations

The Thision WH should be installed in compliance with

The building regulations (Scotland-consolidated)

Building Regulations (Northern Ireland)

Building Regulations

Water fittings regulations or water bylaws in Scotland

Local water company bylaws

The boiler should not be modified in any way. Any modifications will invalidate the gas approval and invalidate the warranty.

ATTENTION: High Voltage

Before opening the boiler casing for maintenance or servicing the 230VAC main supply to the boiler must be

disconnected!!

5

6

Page 7

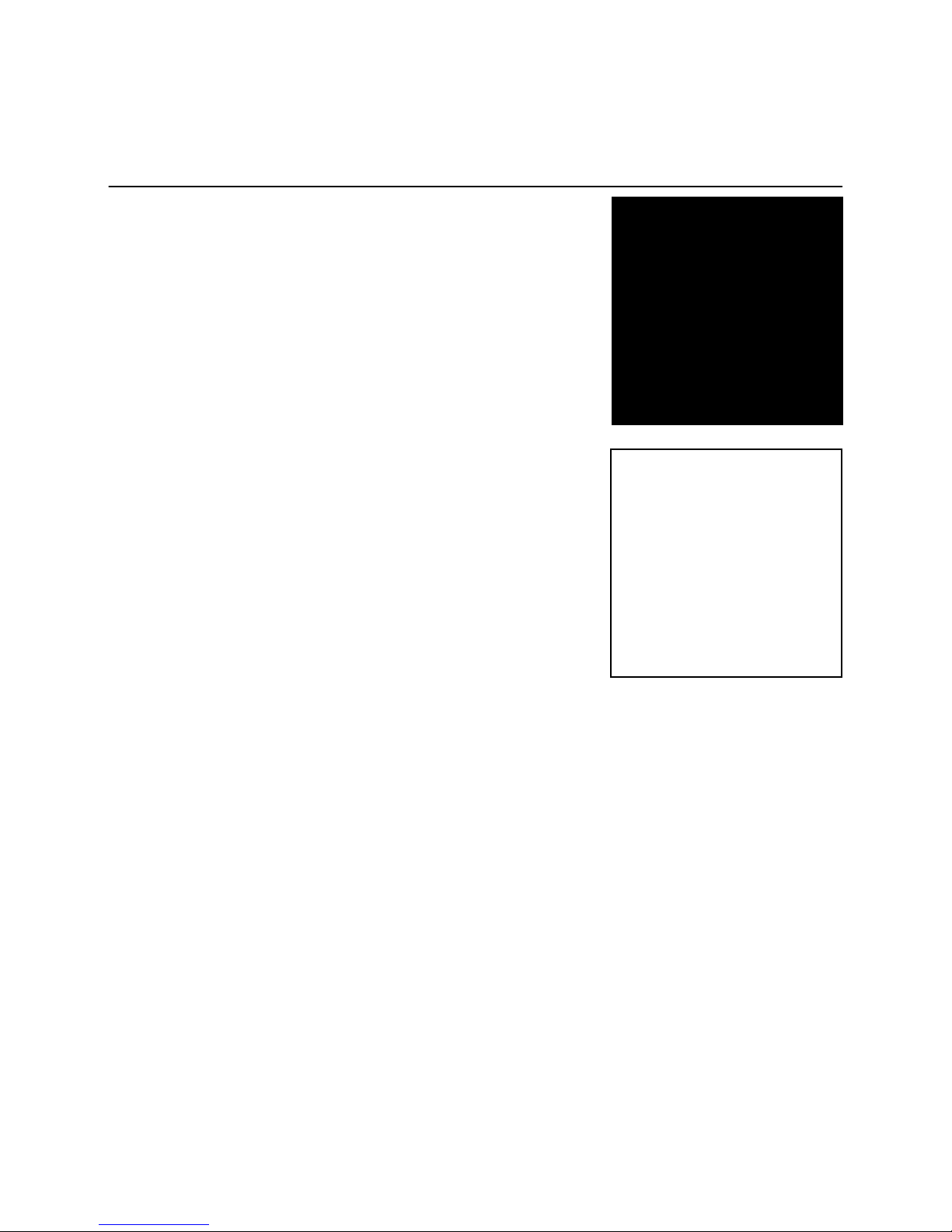

Construction

Layout of water heater

Operating principle

Layout of water heater

The THISION water heater consists

following main components:

1 Casing

2 Control panel

3 Flue gas connection (+ test point)

4 Air intake connection (+ test point)

5 Flow water connection

6 Return water connection

7 Gas connection

8 Syphon

9 Input for wiring

10 Connection for safety valve

11 Connection for fill/drain valve

12 Manometer

13 Fan

14 Gas valve

15 Ignition and ionisation electrodes

16 Heat exchanger

17 Inspection window

18 Ignition transformer

19 Electrical input connections

20 Controller

21 Condensate receptacle

Operating p

rinciple

The THISION WH is a fully modulating

water heater. The control unit of the

water heater adapts the modulation

ratio automatically to the heat demand

required. This is done by controlling the

speed of the fan. As a result, the whirlwind mixing system will adapt the gas

ratio to the chosen fan speed, in order to

maintain the best possible combustion

figures and therewith the best efficiency.

The flue gases created by the combustion

are transported downwards through the

heat exchanger and leave the boiler at

the top into the

chimney connection.

The return water from the system enters the boiler in the lower section,

where is the lowest flue gas temperature in the boiler. In this section condensation takes place. The water is

being transported upwards through the

heat exchanger, in order to leave the

boiler at the flow connection. The cross

flow working principle (water up, flue

gas down) ensures the most efficient

combustion results.

2

4

1

3

6 5

8 7

9

10 11

12

13

14

15

16

17

18

19

20

21

2

7

of the

Page 8

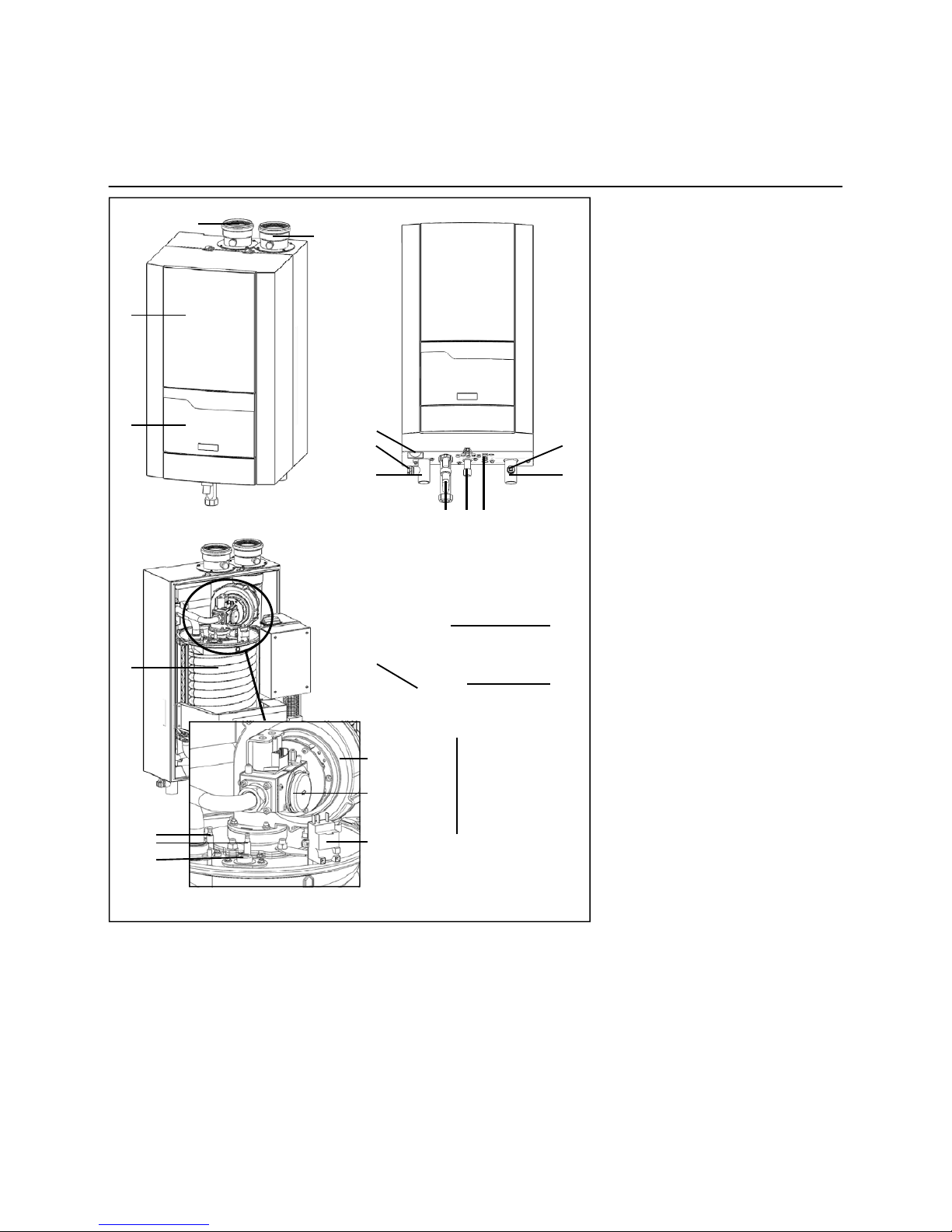

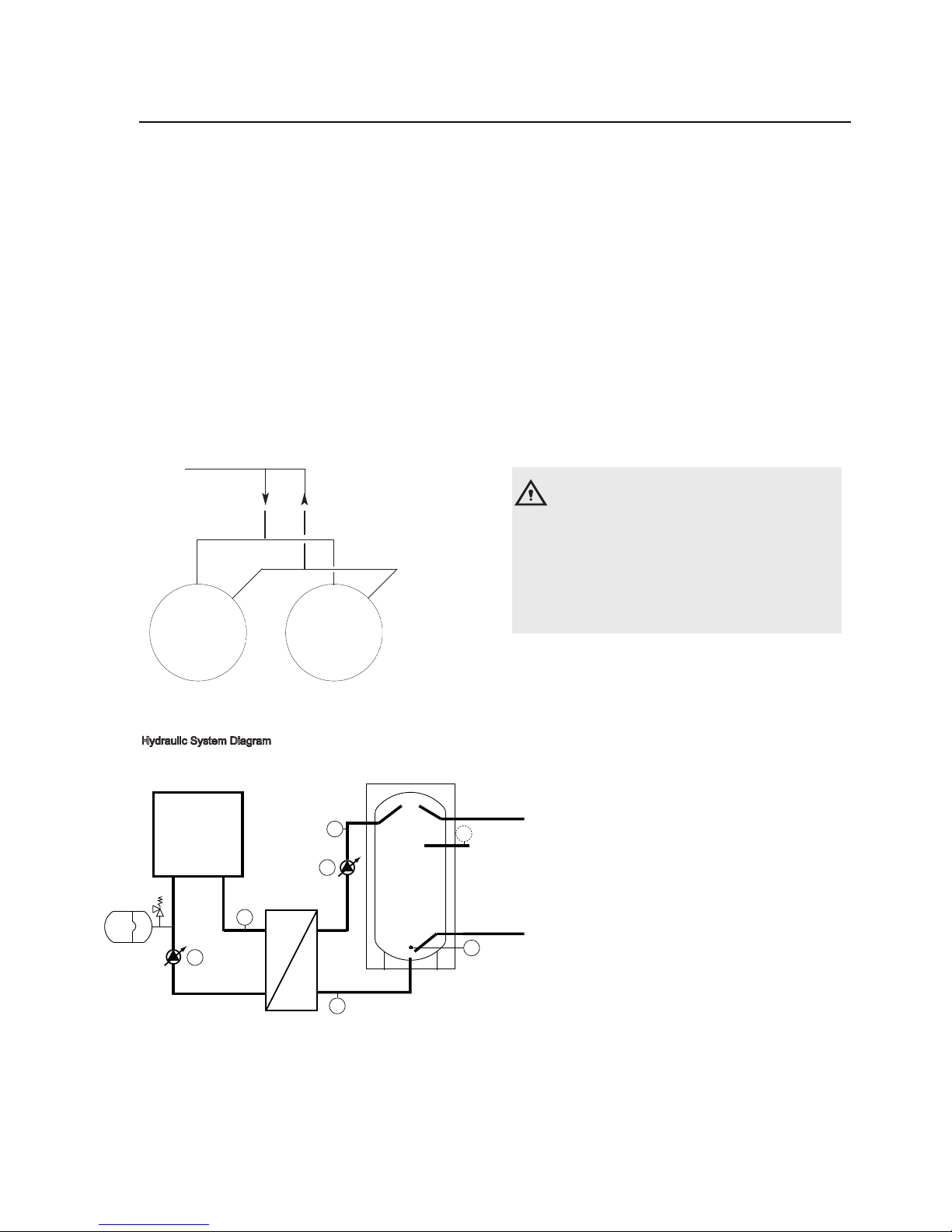

The Thision WH is a standalone DHW charging system that

consists of a buffer tank, plate heatexchanger and a boiler.

The System is suitable for use in any building with

medium to large water usage, such as swimming pools,

gyms , sports clubs, fitness centres etc.

Hydraulic System Diagram

The Thision WH is a standalone unit that functions exceptionally.

Where there is a high demand for hot water there is an option

to connect two units together in parallel. It is essential that the

units are connected such that flow is distributed evenly through

both units

Caution!

The capacity of the built in water recirculation pump is

600 l/hr at the 20 kPa setting. The maximum loss of the

flow and recirculation system occurs at 65°C flow and

60°C return (3.kw). A greater loss will cause a lower

return temperature and therefore a longer loading

period.

Legend:

P1: Loading Pump

P2: Boiler Pump

T1: Loading Temperature Sensor

T2: Start Temperature Sensor

T3: Shut Down Temperature Sensor

T4: Primary Flow Temperaure Sensor

T5: Secondary Return Temperature Sensor

(optional sensor required)

Ensure that pipework is equal from both units to the

secondary flow and secondary return connection.

Thision Thision

Plan View of two Thisions in parallel

The Thision WH has been designed for ease of installation. For

the unit to provide DHW a minimum of the following is

required to be installed from the system to the unit:

1. 230Vac electrical supply

2. Mains cold water supply

3. DHWS secondary flow pipework

4. DHWS secondary return pipework

5. Gas supply pipework

6. Condense drain pipework

7. Flue gas outlet & Air intake pipework

8

Thision WH

Installing 2 Thision WH in parallel

T2

T5

T3

T4

T1

P1

P2

Secondary Return

Connection

Page 9

Technical data

9

65

THISION L

85

THISION L

120

Nominal heat output at 80-60ºC max/min

kW 60.8/10.1 81.1/13.4 111.6/18.7

Nominal heat output at 75-60ºC max/min

kW 60.9/10.1 81.3/13.4 111.8/18.7

Nominal heat output at 40/30ºC max/min

kW 63.9/11.1 85.3/14.8 120.0/20.6

Nominal heat input Hi max/min

kW 62.4/10.4 83.3/13.8 114.3/19.2

Efficiency at 80/60ºC

% 97.4 97.4 97.6

Efficiency at 40/30ºC % 102.4 102.4 105.0

Annual efficiency (NNG 75/60ºC)

% 106.2 106.2 106.2

Annual efficiency (NNG 40/30ºC)

% >110 >110 >110

Standstill losses (T

water

= 70ºC) % 0.20 0.20 0.20

Max. condensate flow

l/h 3.5 4.8 7.7

Gas consumption H-gas max/min (10,9 kWh/m

3

) m3/h 5.7/1.0 7.6/1.3 10.5/1.8

Gas consumption L-gas max/min (8,34 kWh/m

3

) m3/h 7.5/1.2 10.0/1.7 13.7/2.3

Gas consumption LPG. max/min (12,8 kWh/kg)

kg/h 4.9/0.8 6.5/1.1 8.9/1.5

Gas pressure H-gas

mbar 20 20 20

Gas pressure L-gas

mbar 25 25 25

Gas pressure LPG

mbar 30/50 30/50 30/50

Maximum gas pressure

mbar 50 50 50

Flue gas temperature at 80/60ºC max/min

ºC 76/63 76/63 76/63

Flue gas temperature at 40/30ºC max/min

ºC 55/39 55/39 55/39

Flue gas quantity max/min

m

3

/h 119/19 159/25 213/35

CO

2

level natural gas H/E/L max/min % 8.5/8.5 8.5/8.5 8.7/8.5

CO

2

level liguid gas P max/min % -/- -/- -/-

NOx level

mg/kWh 39 39 39

CO level max/min

mg/kWh 98/7 98/7 98/7

Max. permissible flue resistance max/min

Pa 150/15 150/15 200/15

Water volume

l 3.5 4.8 7.7

Water pressure max/min

bar 6/1 6/1 6/1

Max. water temperature (High limit thermostat)

ºC 100 100 100

Maximum temperature setpoint

ºC 90 90 90

Nominal water flow at dT=20K

m

3

/h 2.6 3.4 4.8

Hydraulic resistance at nominal water flow

kPa 16 29 22

Electrical connection

V 230 230 230

Frequency

Hz 50 50 50

Mains connection fuse

A 10 10 10

IP class

- IPX4D IPX4D IPX4D

Power consumption boiler max/min (excl. pump)

W 98/26 167/38 228/36

Power consumption 3-step pump (optional)

W 150 205 210

Power consumption speed controlled pump (opt)

W 124 124 130

Weight (dry) with 250L cylinder

Noise level at 1 meter distance dB(A) - - -

-

Water connections

- R1.1/4" R1.1/4" R1.1/2"

Gas connection

- R3/4" R3/4" R1"

Flue gas connection

mm 100 100 100

Air intake connection (for room sealed use)

mm 100 100 100

Condensate connection

mm 22 22 22

CE-0063CM3576

kg

CE certification code

PH value condensate

Ionisation current minimum

-

µA 3 3 3

3.2 3.2 3.2

Weight (dry) with 500L cylinder kg

160

168 190

170 178 200

THISION L

Weight (wet) with 250L cylinder kg

Weight (wet) with 500L cylinder kg

413.5

422.8 447.7

673.5 682.8 707.7

Page 10

Technical data

65

THISION L

85

THISION L

120

10 min peak output at 60ºC (250L storage)

L 424 481 568

L 1292 1640 2163

THISION L

1st hour continous output at 60ºC (250L storage)

Continuous operation at 60ºC

1st hour continous output at 60ºC (500L storage)

10 min peak output at 60ºC (500L storage) L 674 731 818

L 1542 1890 2413

L 1042 1390 1913

10

Electrical Data

Maximum Power Consumption

Electrical Supply

Fuse Rating

W

A

328 397 458

10

V

Frequency

Hz

50

50 50

230 230 230

DHW Performance Data

10

10

Page 11

Technical data

Dimensions

W mm

B1 mm

B2 mm

D mm

H mm

C1 BSP

C2 BSP

E mm

F mm

Thision WH

250 - 65/85

W

Thision WH

500 - 65/85

Thision WH

250 - 120

Thision WH

500- 120

585 750 585 750

140 140 140 140

H

2015 1879 2015 1879

B2

380 380 480 480

D

1516134614231248

C1

C2

C3 BSP

C3

G mm

E

F

G

1578

1061

323

1483

1082

352

1578

1061

323

1483

1082

352

1 1/4 “ 1 1/4 “

1 1/4 “ 1 1/4 “

3/4 “ 3/4 “ 3/4 “ 3/4 “

1 1/2 “

1 1/2 “ 1 1/2 “

1 1/2 “

W

B195

D

H1

H1 mm

1952 1821

1952 1821

11

J

K

L

M

N

mm

mm

mm

mm

mm

J

K

L

M

N

1100

1000

800

700

600

1100

1000

800

700

600

DHW Flow

DHW

Secondary

Return

CW

Inlet

1000

900

450

350

250

1000

900

450

350

250

Cable Gland

Cable Gland

Condense Waste

Gas

PRV Drain

O

P

Q

O

mm

1578

1578

1483

1483

P

mm

1215

1215

1122

1122

Q

mm

323

323

352

352

C4

C4 BSP 3/4 “ 3/4 “

3/4 “ 3/4 “

C5 BSP 1 “ 1 “

1 “ 1 “

C4

C4

C5

Page 12

Installation

Water heater installation

Connecting the water heater

Water heater installation

The boiler should be positioned in a

frost-proof boiler room. If the boiler

room is on the roof, the boiler itself may

never be the highest point of the installation.

When positioning the boiler, please

note the recommended minimum clearance in the picture. When the boiler is

positioned with less free space, maintenance activities will be more difficult.

Connecting the

water heater

This chapter will explain how to make

all connections to the boiler with regard

to:

Hydraulic connections

Condensate drain connection

Gas connecti

on

Flue gas connection

Air intake connection

Electrical connection

The boiler should always be connected

in such a way, that the system applies

to all relevant standards and regulations (European, national and local). It’s

the responsibility of the installer to ensure that all standards and regulations

are respected.

Hydraulic connections (1,2,3,4)

Condensate connection (5)

After filling with water, the syphon

(included in delivery) should be

installed to the connection (5) at

the bottom of the water heater.

Connect the hose to the draining

system in the boiler room. The

connection to the draining system

should always be done with an open

connection, in order to avoid flooding

the boiler in case of a blocked drain.

Gas connection (6)

The gas connection must be made by

an authorized installer in accordance

w

ith the applicable national and local

standards and regulations.

Connect the gas line from the system

tension free to the gas connection (6) of

the boiler. A gas cock should be mounted directly behind the boiler.

5 6

3 4

The Thision WH should be connected to

the mains water supply, The concentration

of chloride in the water supply should be

less than 200mg/l. Should the hardness be

measured at more than 14°dH then a

softener should be installed to bring the

hardness down to between 6°dH and 8°dH.

Caution!

When installing the Thision WH a mains water kit must be used.

The DHWS flow connection should be protected against

a vacuum by use of an anti-vacuum valve.

1000mm

100mm

500mm

200mm

12

Page 13

Installation

Connecting the water heater

Flue gas connection (7)

Regulations for the construction of flue

gas systems are very different for each

country. It should be ensured that all

national regulations with regard to flue

gas systems are respected.

Connect the flue gas system to the flue

gas connection (7) of the water heater,

use flue gas systems with seamless

connections only. It’s not necessary to

make a separate condensate drain for

the flue gas system, as the condensate

will be drained via the syphon of the

boiler.

Please note the following issues:

It’s recommended to use stainless

steel or PPS fluegas systems

The diameter of the flue gas system

must be chosen by calculation according to the national regulations

Construct the

flue gas system as

short as possible (for maximum

length see planner documentation)

Construct horizonal ways with a minimum angle of 3º

Air intake connection (8)

The air intake can be connected in case of room sealed installation. The diameter should be calculated according

to the national regulations, together

with the flue gas system. The total re

-

sistance of both systems should never

overcome the maximum permissible

resistance of the fan inside the boiler

(see also chapter: Technical

data).

Elec

trical connection

The electrical connection must be

made by an authorized installer in

accordance with the applicable

national and local standards and regulations.

For the power supply it’s necessary

to use a mains isolator switch with a

contact opening of at least 3 mm

within the boiler room. This switch

can be used to switch off the power

supply for maintenance purposes.

8

7

13

Page 14

The Thision WH can be fed directly from the mains supply to the property without

the need for seperate feed cisterns or vent pipes. It is supplied complete with all its

necessary inlet and safety controls, thermal cut out and two port motorised valve.

Schematic installation details for unvented applications

PRESSURE REGULATING VALVE

c/w NON RETURN VALVE

T&P RELIEF

VALVE

PRIMARY

FLOW &

RETURN

DRAIN COCK

(NOT SUPPLIED)

DISCHARGE

PIPE

TUNDISH

SECONDARY RETURN

TAPPING

TO HOT

OUTLETS

MAINS

WATER

SUPPLY

EXPANSION VALVE

EXPANSION VESSEL

Thermal

cut out

Examples of acceptable discharge arrangements are;

i. Ideally below a fixed grating and above the water seal in a trapped gully.

ii. Downward discharges at low level; i.e. up to 100mm above external surfaces such

as car parks, hard standings, grassed areas etc. are acceptable providing that where

children may play or otherwise come into contact with discharges a wire cage or

similar guard is positioned to prevent contact, whilst maintaining visibility.

iii. Discharges at high level; e.g. into a metal hopper and metal downpipe with the end of the

discharge pipe is clearly visible (tundish visible or not) or onto a roof capable of withstanding high

temperature discharges of water and 3m from any plastic guttering systems that would collect such

discharges (tundish visible).

iv. Where a single pipe serves a number of discharges, such as in blocks of flats, the number served

should be limited to not more than 6 systems so that any installation discharging can be traced

reasonably easily. The single common discharge pipe should be at least one pipe size larger than the

largest individual discharge pipe (D2) to be connected. If unvented hot water storage systems are

installed where discharges from safety devices may not be apparent i.e. indwellings occupied by blind,

infirm or disabled people, consideration should be given to the installation of an electronically operated

device to warn when discharge takes place.

Note: The discharge will consist of scalding water and steam. Asphalt, roofing felt and non metallic

rainwater goods may be damaged by such discharges.

Unvented Applications

14

Page 15

Valve outletsize Minimumsizeof

discharge pipe D2

Minimumsizeof

fromtundish

Maximum

res is tance

allowed,

expressed as a

length of straight

pipe (i.e. no.

elbowsor bends)

createdbyeach

elboworbend

G1/2 15mm

22mm

28mm

35mm

up to 9m

up to 18m

up to 27m

0.8m

1.0m

1.4m

G3/4 22mm

28mm

35mm

42mm

up to 9m

up to 18m

up to 27m

1.0m

1.4m

1.7m

G1 28mm

35mm

42mm

54mm

up to 9m

up to 18m

up to 27m

1.4m

1.7m

2.3m

Fixed grating

Discharge below

fixed grating

(Building Regulation

G3 section 3.9d gives

alternative points

of discharge)

Trapped

gully

Discharge pipe (D2)from tundish,

with continuous fall. SeeBuilding

Regulation G3 section 3.9d i-iv,

Table4and worked example

300mm

minimum

500mm maximum

Metal discharge pipe (D1) from

Temperature relief valve to tundish

Tundish

Safety device

(e.g. Temperature

relief valve)

Sizing of copper discharge pipe (D2) for common T&P relief valve sizes

Schematic discharge pipe arrangement

Unvented Applications

Worked example of discharge pipe sizing.

The example below is for a G1/2 temperature relief valve with a discharge pipe (D2) having 4 No. elbows and length of

7m from the tundish to the point of discharge.

From Table 1:

Maximum resistance allowed for a straight lenght of 22mm copper discharge pipe (D2) from a G1/2 temperature relief

valve is 9.0m.

Subtract resistance of 4 No. 22mm elbows at 0.8m each = 3.2m

Therefore permitted length equates to 5.8m.

5.8m is less than the actual length of 7m therefore calculate the next largest size.

Maximum resistance allowed for straight lenght of 28mm copper discharge pipe (D2) from a G1/2 temperature relief

valve equates to 18m.

Subtract resistance of 4 No. 28mm elbows at 1.0m each = 4.0m

Therefore the maximum permitted length equates to 14m.

As the actually length is 7m, a 28mm (D2) copper pipe will be satisfactory.

15

Resistance

discharge pipe D2

Page 16

16

Cylinder Controls

Electrical Connections

Page 17

Commissioning

Water and hydraulic system

17

Commissioning of the water heater should

be carried out by authorised personnel only.

Failure to respect this condition makes the

guarantee void. A protocol of the commissioning should be filled out (see end of this

manual for example of commissioning protocol).

This chapter explains the commissioning

of the water heater with the standard

water heater controller. When an additional controller is installed, please refer to

its manual for commissioning the controller.

Filling and venting the domestic hot water system

Step 1:Open the furthest outlet from unit

Step 2:Open the mains cold water supply

until all the air has been eliminated

from the outlet

Step 3:Open the valve on the reciculation circuit,

when all of the air has been eliminated

close the outlet

Step 4:Check pipework for leaks

Further Commissioning

Once the system has been completely filled and vented

the unit can be connected to the electrical supply.

All DHWS settings are pre-set.

Ensure the following are operating correctly.

The recirculation pump should operate continuously,

ensure the pump is running

The load pump will operate intermittently, ensure

the pump turns freely

The boiler should operate when the loading pocess

has started

The loading process will stop when the sytem has

reached the required temperature

During the loading process the pumps speed will be

altering this can lead to a pulsing sound from the pumps

but is not damaging to their operation

Display codes during use:

The display will show various codes during operation

including the unit flow temperature.

Temperature Setting

The Thision WH is factory set at 65 C DHW flow and 60

DHW return, the temperature can only be adjsuted using

specialist equipment.

Page 18

Commissioning

Gas supply

Condensate connection

Flue and air intake connections

Gas supply

Check the gas supply connection to the

boiler for tightness. If any leakage is

found, reseal the leakage before starting the boiler!

Remove any air between the gas valve

and the gas line. This can be done at

the test point (1) at the gas pressure

switch.

Don’t forget to close the test

point afterwards!

Check the gas type and values with the

local gas company, in order to know for

which gas type the boiler should be

commissioned.

Condensate connection

Remove the syphon (2) from the condensate connection. Fill

it with water

and place it back in the original position. Make sure the syphon is filled before starting the boiler, in

order to prevent flue gases discharging

through the condensate connection!

Flue and air intake connections

Check whether the flue and air intake

systems are made according to the

national and local regulations. Installations which don’t comply with the regulations, are not allowed to be commissioned.

Make sure that all connections are free.

The size of flue gas and air intake con-

nections may not be reduc

ed.

1

2

18

Page 19

Commissioning

Prepare water heater for first startup

19

M

H

B C D E F

I

L

G

A

Legend:

A On/off switch

B Return (ESC)

C Room temperature control

D Confirmation (OK)

E Manual mode

F Chimney sweeper mode

G Info mode

H Reset button

I Operation mode heating zone(s)

L Display

M Operation mode DHW

Preparation for first startup

Open the gas supply;

Enable the power supply to the boiler;

Switch on the boiler with the on/off

switch (1);

Make sure the boiler is in standby

mode (K );

Check the pump operation: make

sure the pump runs in the right

direction;

Release all air from the pum

p

motor.

It‘s recommended to put the boiler on

50% load after the first startup, as this

is the best starting point to do a proper

combustion analysis. This can be done

with the following procedure:

Push button I >3 Sek, the boiler goes

into controller Stopp mode.

Push the Info button (G), the actual

boiler load (%) appears in the display;

Choose „set up“ (confirm with OK

button), now the boiler load can be

changed by rotating the wheel (C)

and confirming the 50% setting with

the OK button.

After checking the combustion values

(see

next page), the controller Stopp

mode can be stopped by pushing the

control mode button (I) >3 Sek.

1

Cylinder Diagnosis

It is possible to view the operational data of each of

the Thision WH i.e. temperatures, this is achieved by

holding the button on the cylinder controller for

approximately 5 seconds. The diagnosis number is

shown for 1 second then the value for 3 seconds.

The diagnosis setting can be exited by holding the button for

5 seconds or if the button is not depressed for 10 minutes.

So software version

D0 Operating Status

D1 Current T1 temperature

D2 Current T2 temperature

D3 Current T3 temperature

D4 Current T4 temperature

D5 N/A

D6 Load pump P1 speed (rpm)

D7 Required temperature

Temperature Setting

The Thision WH is factory set for 60 C DHW flow and can

be adjusted by 5 C by switching the unit off and back on

whilst holding the control button on the P CB.

º

º

Page 20

Commissioning

Combustion analysis

Combustion check at full load

Start the water heater in controller stop

mode

and go to 50% load. Now the

boiler operates at 50% load. Allow the

boiler to stabilise the combustion for 3

minutes. Then increase the waterheater

load step by step up to 100%. Check the

gas pressure on the inlet of the gas

valve while increasing the water heater

load: the gas pressure should never go

below the minimum required value

see technical data. When an (optional)

minimum gas pressure switch is connected, this must be set to 75% of the

required gas pressure.

Check the combustion settings via the

test point in the chim

ney connection

(1). If necessary, correct the settings

with the small adjustment screw at the

top of the gas valve (2).

Combustion check at minimum load

Switch the water heater to minimum load

(0%). Check the combustion settings the

same way as described for full load. If

necessary, correct the settings with the

large adjustment screw at the top of the

gas valve (3).

Combustion check at 50% load

An additional reference check of combustion values at 50% load is recommended in order to check if the gas

valve is set in such way, that the modulating behaviour is norma

l. The CO

2

value should be in between the settings

of full load and minumum load. CO

value should be equal to full load and

minimum load values.

Make sure that the boiler is set to automatic operation and controller stop mode is disabled after the combustion test

is finished.

1

Combustion settings max. load

for natural gas G20 / G25

TH-L 100-145

CO

2, max

% 8.7±0.2

CO

max

ppm < 70

TH-L 65-85

CO

2, max

% 8.5±0.2

CO

max

ppm < 70

Combustion settings max. load

for LPG G31

Convert boiler before operation

(see coversion kit instruction)

TH-L 100-145

CO

2, max

% -

CO

max

ppm -

TH-L 65-85

CO

2, max

% -

CO

max

ppm -

Combustion settings min. load

for natural gas G20 / G25

TH-L 65-145

CO

2, min

% 8.5 ± 0.2

CO

min

ppm < 30

Combustion settings min. load

for LPG

G31

Convert boiler before operation

(see coversion kit instruction)

TH-L 65-145

CO

2, min

% -

CO

min

ppm -

2

3

20

Page 21

Commissioning

Check functionality of safety devices

Gas tightness check

Water heater shut down

Flow temperature sensor (1)

Disconnect the plug from the sensor

while the water heater is switched on.

This should result in a lockout no. 20.

The lockout should disappear as soon

as the plug is placed back in position,

the water heater will restart.

Return temperature sensor (2)

Disconnect the plug from the sensor

while the water heater is switched on.

This should result in a lockout no. 40.

The lockout should disappear as soon

as the plug is placed back in position.

The water heater will restart.

Flue gas temperature sensor (3)

Disconnect the plug from the sensor

while the water heater is switched on.

The should result in a lockout no. 28.

The lockout should disappear as soon

as the plug is placed back in position,

the boiler will restart.

Ionisation electrode (4)

Remove electrical connection from the

ionisation electrode while the water heater

is running, the water heater will go to lockout no. 128. The water heater will try to

restart. With the electrical connection removed, the restart will result in lockout no. 133.

When the connection is remade the restart

will be successful.

Measuring the ionisation current can

be done by mounting a multi-meter (set

to µA) in between the ionisation electrode and its electrical connection. The

ionisation current should always be

above 1.2 µA, in normal conditions it

w

ill be 6 µA and above.

Check functionality of safety devices

All safety devices have to be checked

on good functioning. Safety devices on

a standard water heater are a water

flow temperature sensor, water return

temperature sensor, flue gas temperature sensor and ionisation electrode.

These devices can be checked as

described below.

Gas tightness check

Check the gas tightness of all sealed

connections with an approved soap or

electronic gas analyzer, for example:

Test points;

Bolt connections;

Gaskets of mixing system, etc.

Water heater shut down

When the water heater will not be used

for longer periods, shut down the boiler

by following procedure:

Switch the boiler in standby operation

(K );

Switch off the boiler with the on/off

switch (5);

Disable power supply to the boiler by

deactivating the mains isolator switch

in the boiler room;

Close the gas supply to the boiler.

1

2

3

4

5

21

Page 22

22

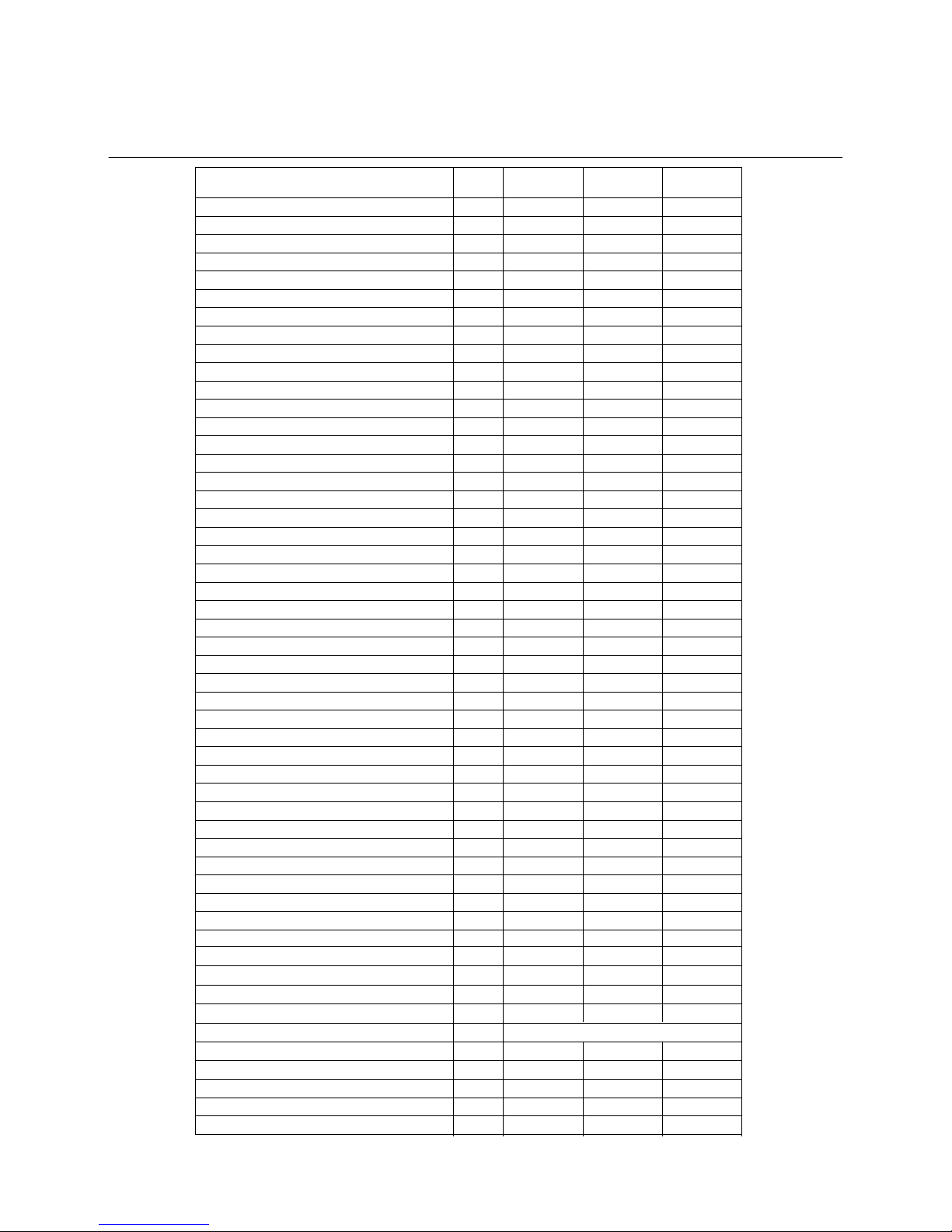

In case of a lockout, a warning symbol ( ) and a flashing error code appears on the display. The cause of a fault should first

be determined and eliminated before the boiler is being reset. The table below shows all possible lockouts with indication of

possible cause.

Lockouts

Error

code

Description of error

0 No error

10 Outside temperature sensor error

20 Boiler temperature 1 sensor error

26 Common flow temperature sensor error

28 Flue gas temperature sensor error

30 Flow temperature 1 sensor error

32 Flow temperature 2 sensor error

38 Flow temperature primary controller sensor error

40 Return temperature 1 sensor error

46 Return temperature cascade sensor error

47 Common return temperature sensor error

50 DHW temperature 1 sensor error

52 DHW temperature 2 sensor error

54 DHW primary controller sensor error

57 DHW circulation temperature sensor error

60 Room temperature 1 sensor error

65 Room temperature 2 sensor error

70 Buffer storage tank temperature 1 sensor error

71 Buffer storage tank temperature 2 sensor error

72 Buffer storage tank temperature 3 sensor error

73 Collector temperature 1 sensor error

74 Collector temperature 2 sensor error

82 LPB address collision

83 BSB wire short-circuit

84 BSB address collision

85 BSB RF communication error

91 EEPROM error lockout information

98 Extension module 1 error (collective error)

99 Extension module 2 error (collective error)

100 2 clocktime masters (LPB)

102 Clocktime master without reserve (LPB)

103 Communication error

105 Maintenance message

109

Boiler temperature supervision

110 STB lockout

111 TW cutout

121 Flow temperature 1 (HC1) supervision

122

Flow temperature 2 (HC2) supervision

125 Pump supervision error

126 DHW charging supervision

127 Legionella temperature not reached

128 Loss of flame during operation

129 Fan error or LP error

130

Flue gas temperature limit exceeded

131

Burner fault

132 GP or LP error

133 No flame during safety time

146 Configuration error collective message

Page 23

Lockouts

Error

code

Description of error

151 Internal error

152 Parameterization error

153 Unit manually locked

160 Fan error

162 LP error, does not close

164 Error heating circuit flow switch

166 LP error, does not open

171 Alarm contact H1 or H4 active

172 Alarm contact H2 (EM1, EM2 or EM3) or H5 active

173 Alarm contact H6 active

174 Alarm contact H3 or H7 active

178 Limit thermostat heating circuit 1

179 Limit thermostat heating circuit 2

183 Unit in parameterization mode

193 Pump supervision error after flame on

216 Fault boiler

217 Fault sensor

241 Flow sensor solar sensor error

242 Return sensor solar sensor error

243 Swimming pool temperature sensor error

270 Limit function

317 Mains frequency outside permissible range

320 DHW charging temperature sensor error

324 BX same sensors

325 BX / extension module same sensors

326 BX / mixing group same sensors

327 Extension module same function

328 Mixing group same finction

329 Extension module / mixing group same function

330 Sensor BX1 no function

331 Sensor BX2 no function

332 Sensor BX3 no function

333 Sensor BX4 no function

334 Sensor BX5 no function

335 Sensor BX21 no function (EM1, EM2 or EM3)

336 Sensor BX22 no function (EM1, EM2 or EM3)

337 Sensor BX1 no function

338 Sensor BX12 no function

339 Collector pump Q5 not available

340 Collector pump Q16 not available

341 Solar Collector sensor B6 not available

342 DHW sensor B31 not available

343 Solar integration not available

344 Solar controlling element buffer K8 not available

345 Solar controlling element swimming pool K18 not available

346 Solid fuel boiler pump Q10

not available

347

Solid fuel boiler comparison sensor not available

348 Solid fuel boiler address error

23

Page 24

24

Lockouts

Error

code

Description of error

349 Buffer return valve Y15 not available

350 Puffer address sensor

351 Primary controller / system pump address error

352 Pressureless header address error

353 Common flow sensor B10 not available

371 Flow temperature 3 (heating circuit 3) supervision

372 Limit thermostat heating circuit 3

373 Extension module 3 error (collective error)

349 Buffer return valve Y15 not available

350 Puffer address sensor

351 Primary controller / system pump address error

352 Pressureless header address error

353 Common flow sensor B10 not available

371 Flow temperature 3 (heating circuit 3) supervision

372 Limit thermostat heating circuit 3

373 Extension module 3 error (collective error)

386 Fan speed has lost valid range

388 DHW error no function

426 Feedback flue gas damper

427 Configuration flue gas damper

431 Sensor primary heat exchanger

432 Functional earth not connected

433 Temperature primary heat exchanger to high

Cylinder Lockouts

Error

code

Description of error

01 TT1 sensor fault

02 TT2 sensor fault

03 TT3 sensor fault

04 TT4 sensor fault

05 TT5 sensor fault

06 Low temperature for extended time

07 Frost protection active

08 Boiler fault

09 No communication with boiler

Page 25

Maintenance

Checklist

Replacing the electrodes

25

Maintenance of the water heater

should be carried out by authorized

personnel

only.

In order to ensure continued good and

safe operation of the water heater, it sh-

ould be inspected at least once per year.

A maintenance protocol should be filled

out (see end of this chapter for example

of maintenance protocol).

Checklist

The following activities must be carried

out, see following paragraphs for an

extensive description of the main activities:

Replace the ignition and ionisation

electrodes;

Clean the condensate receptacle;

Clean and refill the syphon;

Inspect the

combustion chamber,

clean if necessary

(DON'T use water !);

Check the water pressure of the system;

Check the water quality of the system

water as well as supply water;

Check/correct the combustion values

at full and mimimum load with a combustion analyzer;

Check the gas pressure to the water

heater;

Check the tightness of all sealed connections and test points;

Check the functionality of all safety

devices;

Fill out a maintenance protocol.

Replacing the electrodes

The electrodes are positioned on the

top side of the boiler. Replace the

ignition electrode (1) and ionisation electrode (2) as shown on the picture.

2

1

Page 26

Maintenance

Cleaning the condensate receptacle

Cleaning and refilling the syphon

Inspection of combustion chamber

Cleaning the condensate receptacle

Disconnect the plug of the fluegas

temperature sensor (1);

Remove the condensate receptacle

(2);

Clean the receptacle;

Mount the condensate receptacle;

Connect the plug of the fluegas tem-

perature sensor.

Cleaning and refilling the syphon

Remove the syphon (3) from the condensate connection;

Clean and fill it with fresh water;

Mount the syphon back in the original

position.

Inspection of combustion chamber

For inspection of the combustion chamber the mixing system and burner must

be disassembled.

Switch off the boiler and close the gas

supply;

Remove the electrical connection

from the fan and gas valve

(4);

Remove the electrical connection

from the electrodes (5);

Undo the gas connection at the inlet

of the gas valve (6);

Disassemble the top plate incl. mixing

system (7);

Remove the burner from the

combustion chamber (8);

Inspect the combustion chamber and

clean it with a vacuumcleaner if

necessary;

Assemble all components in opposite

order;

Open the gas su

pply and check all

connections for gas leakage;

Switch on the boiler.

1

2

5

4

6

7

8

3

26

Page 27

Maintenance

27

Water pressure and quality

Check if the water pressure and quality

meet the requirements. Consult the

chapter “commissioning: water and

hydraulic system” for more detailed

information.

Combustion analysis

Check the combustion at full load and

minumum load, correct the settings if

necessary. An additional reference

check at 50% load is recommended.

Consult the chapter “commissioning:

combustion analysis” for more detailed

information.

Gas pressure

Check the dynamic pressure of the gas

supply to the boiler, when the water

heater is ru

nning at full load.

Gas tightness check

Check the tightness of all sealed connections with an approved soap or

electronic analyzer, for example:

Test points;

Bolt connections;

Gaskets of mixing system, etc.

Safety devices

Check the functionality and the settings

of all safety devices connected. Consult

the chapter “commissioning: Check

functionality of safety devices” for more

detailed information.

It is possible to clean out the cylinder using

fresh mains cold water if so desired. To

carry out this operation isolate and disconnect

all water supplies and ensure all electrical

supplies are isolated. Run a drain hose from

the drain valve to an operating drain, then

connect a controlled mains water supply to the

unit, drain the unit fully and then slowly

supply water to the unit at the rate of drainage.

carry on at this rate until the water running

out of the bottom of the cylinder runs clear, then

carry out two full fills and drains.

Reconnect and re-commission.

Draining and cleaning the cylinder

Page 28

Maintenance

Maintenance Protocol

Maintenance Protocol THISION L

Project

tcejorP epyt relioB

sserddA rebmun laireS

ytiC raeY

etaD ]Wk[ )iH( daol lanimoN

reenignE ]Wk[ )iH( tuptuo lanimoN

System

]rab[ erusserp retaW

]-[ Hp retaW

]Hdº[ ssendrah retaW

]l/gm[ edirolhc retaW

Water ∆ ]Cº[ daol lluf T

Water ∆p

boiler

]aPk[

m[ wolf retaW

3

/h]

]-[ gnittes pmuP

Safety devices

aW ]Cº[ gnittes timil hgiH ter flow sensor checked

dekcehc rosnes sageulF ]Cº[ gnittes retimil .pmeT

Min. gas

pressure switch setting [mbar] Water flow switch checked

]ces[ renrub emit noitingI

Combustion analysis

100% load 50% load Min. load

m[ noitpmusnoc saG

3

m[ ]h/

3

/h] [m3/h]

]rabm[ ]rabm[ ]rabm[ erusserp saG

CO

2

]%[ [%] [%]

O

2

]%[ [%] [%]

]mpp[ OC [ppm] [ppm]

]mpp[ xON [ppm] [ppm]

T

atmospheric

]Cº[ [ºC] [ºC]

T

fluegas

]Cº[ [ºC] [ºC]

T

water, flow

]Cº[ [ºC] [ºC]

T

water, return

]Cº[ [ºC] [ºC]

Ionisation current [µA] [µA] [µA]

p

fan

]rabm[ [mbar] [mbar]

p

top panel

]rabm[ [mbar] [mbar]

p

combustion chamber

]rabm[ [mbar] [mbar]

Remarks

28

Page 29

Commissioning

Commissioning protocol

29

Commissioning Protocol THISION L

Project

tcejorP epyt relioB

sserddA rebmun laireS

ytiC raeY

etaD ]Wk[ )iH( daol lanimoN

reenignE ]Wk[ )iH( tuptuo lanimoN

System

[ erusserp retaW bar] Installati-

on:

Roof top

roolf dnuorG ]-[ Hp retaW

tnemesaB ]Hdº[ ssendrah retaW

......................... :rehtO ]l/gm[ edirolhc retaW

Water ∆ -uardyH ]Cº[ daol lluf T

lics:

Low velocity header

Water ∆p

boiler

[kPa] Plated heat exchanger

Water flow [m

3

/h] Bypass boiler

Pump setting [-] Other: .........................

Safety devices

High limit setting [ºC] Water flow sensor checked

Temp. limiter setting [ºC] Fluegas sensor checked

Min. gas pressure switch setting [mbar] Water flow switch checked

Ignition time burner [sec]

Combustion analysis

100% load 50% load Min. load

Gas consumption [m

3

m[ ]h/

3

/h] [m3/h]

]rabm[ ]rabm[ ]rabm[ erusserp saG

CO

2

]%[ [%] [%]

O

2

]%[ [%] [%]

]mpp[ OC [ppm] [ppm]

]mpp[ xON [ppm] [ppm]

T

atmospheric

]Cº[ [ºC] [ºC]

T

fluegas

]Cº[ [ºC] [ºC]

T

water, flow

]Cº[ [ºC] [ºC]

T

water, return

]Cº[ [ºC] [ºC]

Ionisation current [µA] [µA] [µA]

p

fan

]rabm[ [mbar] [mbar]

p

top panel

]rabm[ [mbar] [mbar]

p

combustion chamber

]rabm[ [mbar] [mbar]

Remarks

Page 30

Service:

ELCO GmbH

D - 64546 Mörfelden-Walldorf

ELCO Austria GmbH

A - 2544 Leobersdorf

ELCOTHERM AG

CH - 7324 Vilters

ELCO Netherlands / Rendamax B.V.

NL - 6465 AG Kerkrade

ELCO Belgium n.v./s.a.

B - 1731 Zellik

ELCO Italia S.p.A.

I - 31023 Resana

ELCO UK / MHS Boilers ltd.

UK - Basildon, Essex, SS15 6SJ

ELCO France / Chaffoteaux SAS

F - 93521 Saint-Denis Cedex

Loading...

Loading...