elco THISION L Evo 60, THISION L Evo 70, THISION L Eco 70, THISION L Eco 100, THISION L Evo 100 System Manual

...Page 1

Flue Gas System Guide

Flue systems for wall hung condensing boilers from 33kW to 1040kW in cascade

Page 2

Index

1. Flue Systems

1.1

1.2

1.3

1.4

1.5

Flue information and guidelines…………....

Open flue system…………………….…….…

Room sealed system…………….………….

Examples of flue gas systems……………...

Available flue systems per boiler……….……

3

3

4

5

6

2. Design and sizing information

2.1

2.2

2.3

2.4

2.5

Boiler maximum flue lengths…….……..…...

Thision S Plus………………………...

Thision L Evo……………….…………

Thision L Eco……………….……….…

Safe flue termination………………………….

IGEM-UP 10…………………………………...

BS6644 – 70kW to 1.8MW………..…………..

BS5440 – Up to 70kW………………..………

6

6

7

7

8

9

10

11

3. Flue components

3.1

3.2

3.3

3.4

3.5

3.6

Available flue components……………..……..

Thision S Plus flue components……..……….

Concentric flue……………..…..……..

Two pipe flue system……………..……

Thision L Evo flue components……….…..…

Concentric flue……….…………..……

Two pipe flue system………………..

Thision L Eco flue components………..……

Concentric flue………………..….…..

Two pipe flue system………..……….

Flexible flue components…………..….………

Cascade flue components……..……………

13

14

14

14

15

15

15

16

16

16

17

18

4. Flue component dimensions

4.1

4.2

4.3

4.4

4.5

Concentric flue parts dimensions...…………

PPs flue parts dimensions…………………….

Cascade flue dimensions………..…………..

Flexible flue dimensions…………..…………

Cascade flue dimensions…………………….

20

23

24

25

27

Page 2 of 33

Page 3

1. Flue Systems

1.1 Flue information and guidelines

Requirements and regulations

Regulations for the construction of flue gas systems are very different for each country. It should

be ensured that all national regulations with regards to flue gas systems are respected.

Pay attention to the following recommendations when dimensioning a flue gas system.

The flue gas system must be properly calculated to ensure safe operation of the system.

Flue gas system components should be removable for maintenance purposes.

Horizontal flue sections must have an incline of no less than 3° back towards the boiler.

Only materials which are heat resistant, resistant to flue gases and aggressive condensate

and also CE approved may be used.

It is the responsibility of the installer to ensure the integrity of the flue and/or chimney

system before commissioning the boiler.

Any terminal that is less than 2 metres above finished floor or ground level must be

guarded. This also applies when terminals are positioned above flat roofs and balconies to

where there is regular unimpeded access. Please see IGEM-UP10 section for more

information on termination.

Please contact Elco UK office for more information for configurations.

1.2 Open flue systems

Open flue systems can be designed where the combustion air supply

is taken from the room or from the surrounding area where the boiler

is installed.

The flue combustion gases are taken from the boiler and terminated

at a higher level to the air intake or a different termination location to

avoid contaminating the air supply with the flue gas. Elco recommend

that single wall plastic flue pipe (PPs) be used for open flue systems.

When designing a flue gas pipe, please ensure that the horizontal

lengths have a 3° fall towards the boiler to aid in any condensate

draining. It is not necessary to make a separate condensate drain in

the flue gas system as the condensate will be drained via the boiler

syphon.

In addition to this, we also recommend that flue brackets are used at 1 metre increments to support

the flue pipe installation. The flue pipe should also be designed to be as straight as possible to

utilise the maximum length of the flue that the boiler can run. If a bend is unavoidable, we advise

that 90° bends not be installed directly one after another.

Page 3 of 33

Page 4

Open flue systems continued…

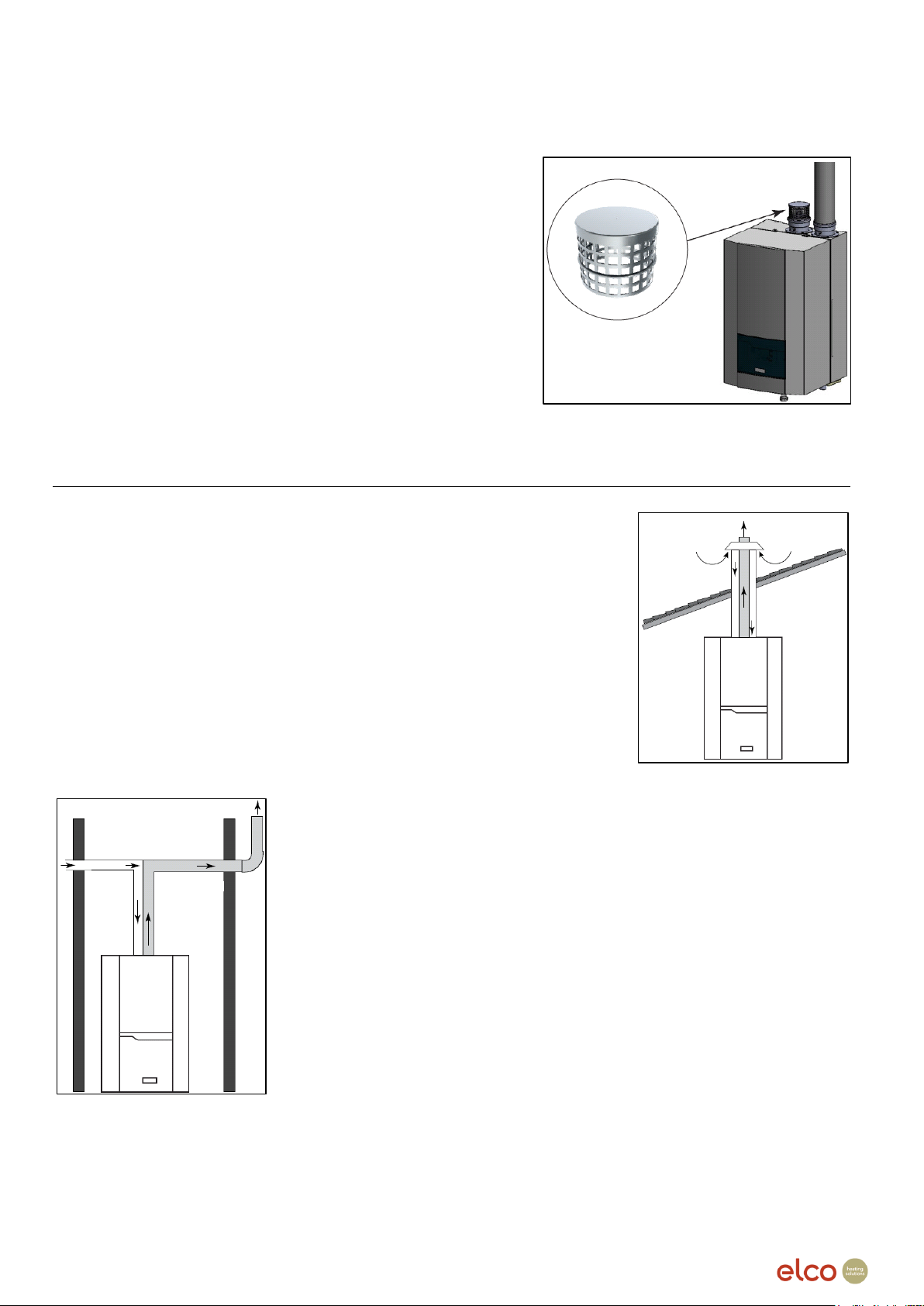

When using an open flue system, Elco recommends that

an air inlet cover or air filter must be fitted on the air inlet

connection on the boiler, to stop any debris entering the

air supply and causing issues with the boilers

combustion. The flue system must be fitted with flue

pipes that have seamless connections only to avoid

leaks.

The maximum temperature of the flue gas for the wall

hung boiler range that we supply is 77°C so no protective

measures or clearances towards combustible objects

needs to be taken.

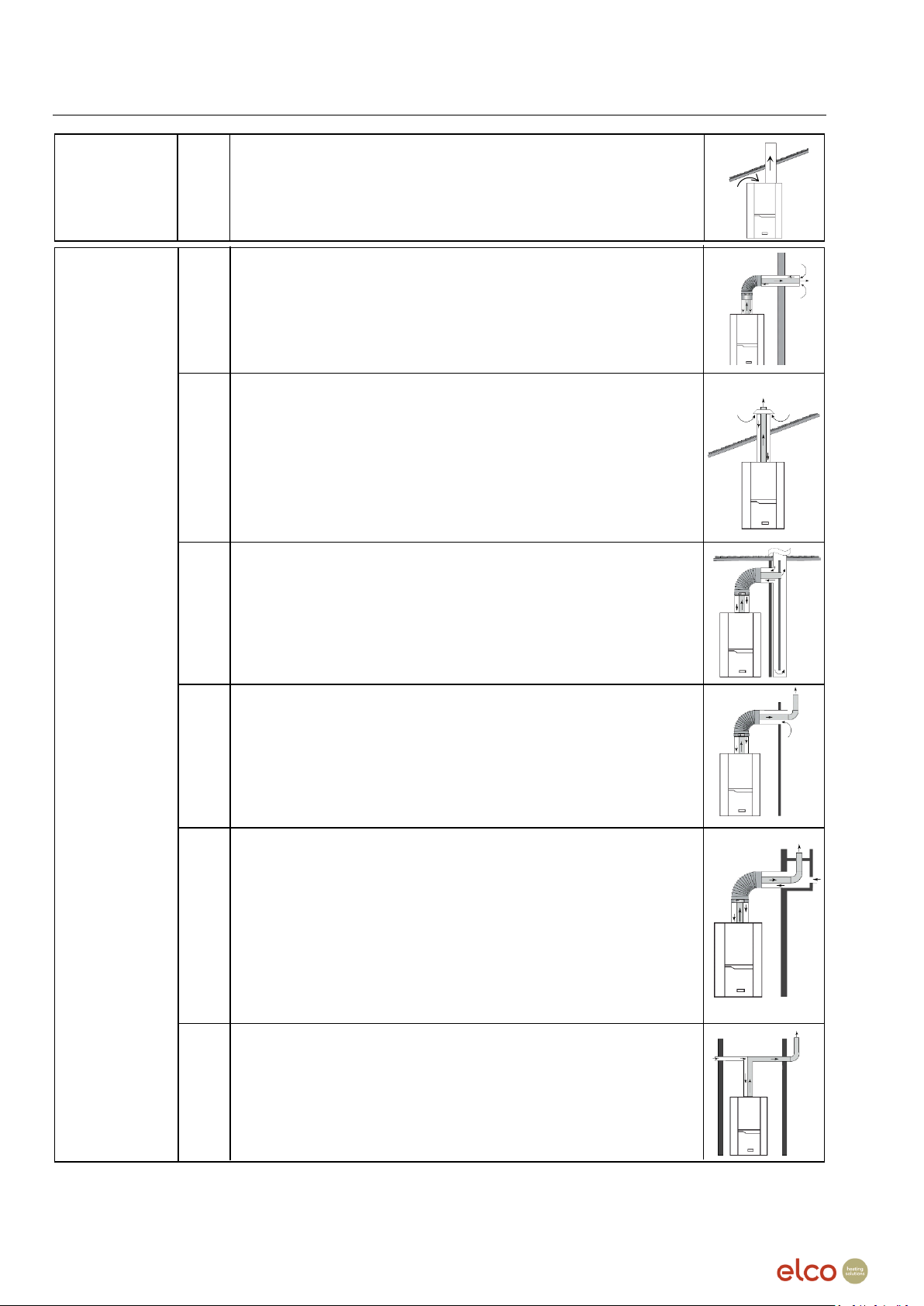

1.3 Room sealed flue systems

Room sealed flue can be constructed with either concentric flue pipe

or single pipe plastic flue (PPs). These type of systems are defined

by taking the combustion air supply from outside the room the boiler

is located.

With concentric flue pipe the combustion air is supplied and the flue

gas extracted through one concentric coaxial pipe. The combustion

air is supplied through the gap between the external painted

aluminium air pipe and the internal plastic flue pipe. Flue gases are

extracted through the internal plastic pipe (PPs).

When designing a room sealed system please ensure that the

horizontal lengths must have a 3° fall towards the boiler to aid in any

condensate draining. It is not necessary to make a separate

condensate drain in the flue gas system as the condensate will be

drained via the boiler syphon.

In addition to this, we also recommend that flue brackets be used at 1

metre increments to support the flue pipe installation. The flue pipe

should also be designed to be as straight as possible to utilise the

maximum length of the flue that the boiler can run. If a bend is

unavoidable then they must not be installed directly one after another.

The maximum temperature of the flue gas for the wall hung boiler

range that we supply is 77°C so no protective measures or

clearances towards combustible objects needs to be taken.

Page 4 of 33

Page 5

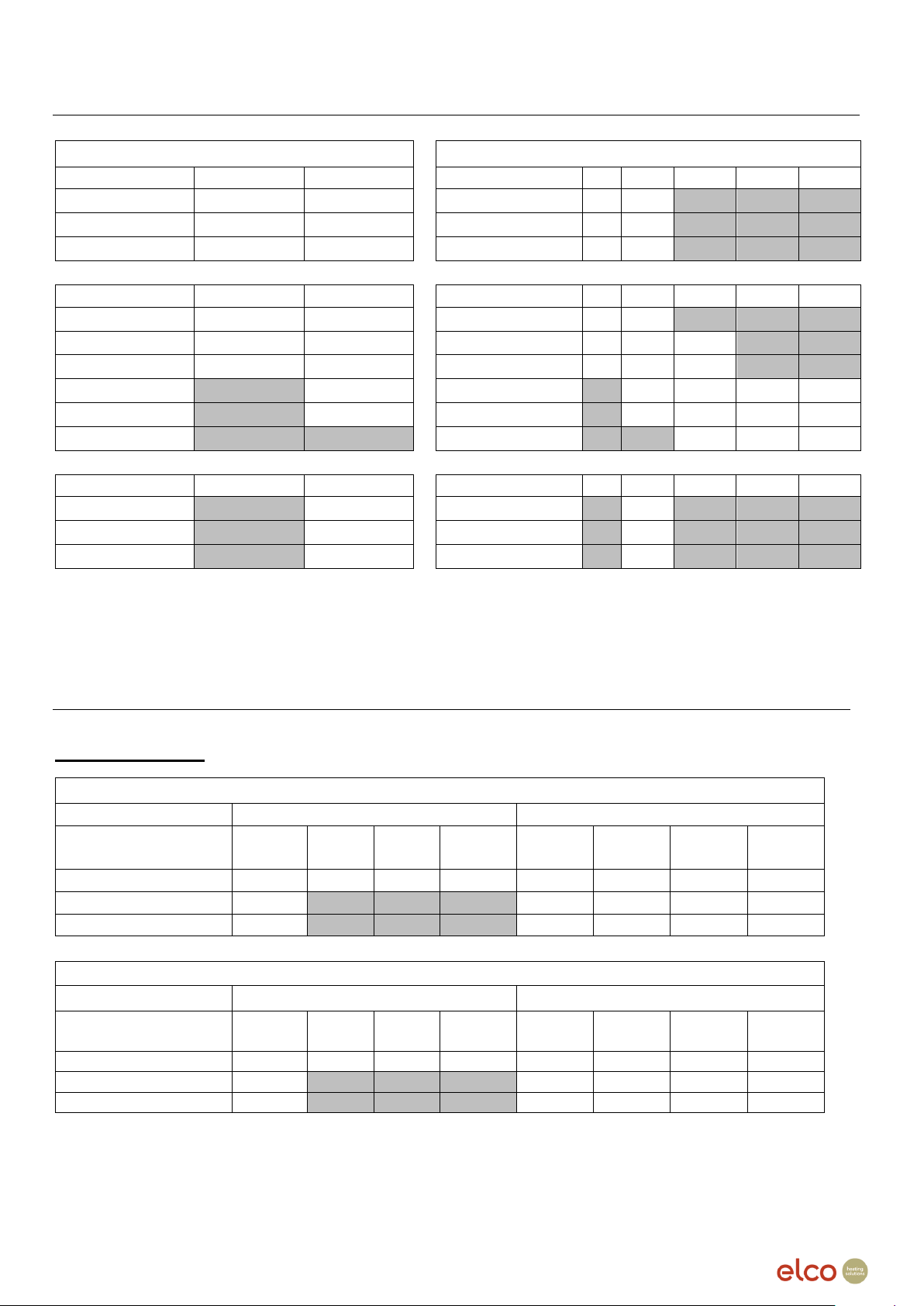

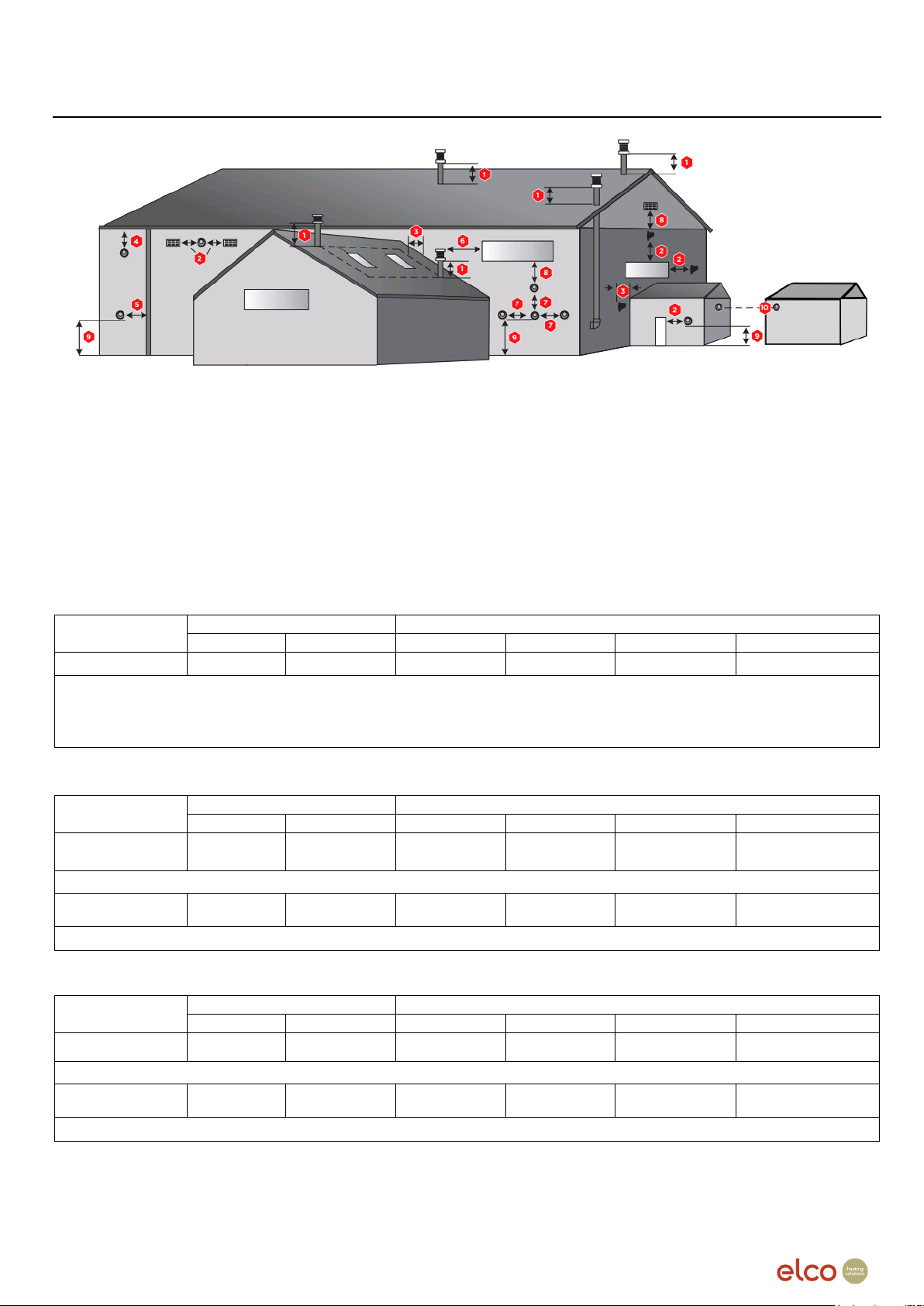

1.4 Examples of flue gas systems

B23

C13

Air/exhaust gas routing through outside wall in the same pressure

and 100 cm with a heat input from 70 up to 100 kW.

C33

C43

C53

C63

Air and exhaust connection to separate tested and supplied

building.

C83

Combustion air

Combustion air

drawn from the

room

External flue gas exhaust. Air drawn from the room.

range.

Exhaust gas/fresh air supply system through outside wall.

The Terminal outlets from separate combustion and air supply circuits

shall fit inside a square of 50 cm for boilers with a heat input to 70 kW

Flue gas exhaust and air suction duct from outside with roof terminal

in the same range of pressure.

The Terminal outlets from separate combustion and air supply circuits

shall fit inside a square of 50 cm and distance between the planes of

the two orifices shall be less than 50cm for boilers with a heat input

below 70 kW.

A square of 100 cm and distance between the planes of the two

orifices shall be less than 100 cm with a heat input above 70 kW.

drawn from

outside

Individual or shared flue gas exhaust and air suction through flue

ducting built into the building

Flue gas exhaust leading outside and air suction duct through external

wall not in the same range of pressure.

air/exhaust pipes.

Basement / floor installation.

Air and exhaust venting via exterior wall.

Exhaust venting through heat insulated exhaust pipe or moisture

resistant pipe.

Exhaust line (standing air layer) at exterior wall.

The terminals for the supply of combustion air and for the evacuation

of combustion products shall not be installed on opposite walls of the

Flue gas exhaust through individual or shared flue ducting built into

the building. Air suction through external wall.

Page 5 of 33

Page 6

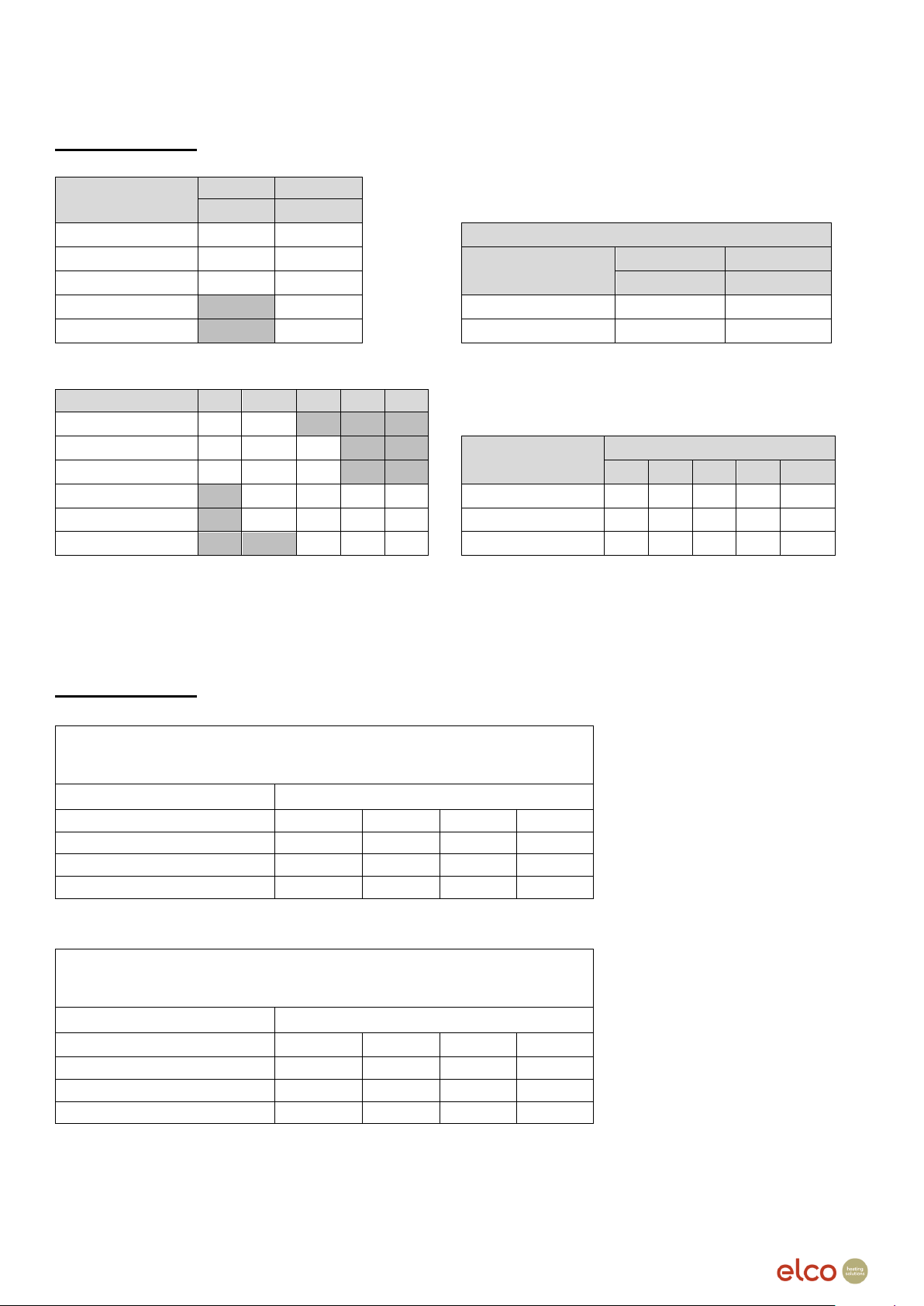

1.5 Available flue systems per boiler

Concentric Flue (mm)

Plastic Single Pipe Flue (PPs) (mm)

Thision S Plus

80/125

100/150

Thision S Plus

80

100

110

125

130

34

34

46

46

54

54

Thision L Evo

80/125

100/150

Thision L Evo

80

100

110

125

130

60

60

70

70

80

80

100

100

120

120

140

140

Thision L Eco

80/125

100/150

Thision L Eco

80

100

110

125

130

70

70

100

100

120

120

Maximum length in metres for concentric room sealed installations

80/125

100/150

Changes of

direction

0 2 3 4 0 2 3

4

34

25

13.6

7.9

2.2

40

34.2

31.3

28.4

46

12 30

19.4

14.1

8.8

54

11 30

15.4

8.1

0.8

Maximum length in metres for single pipe open or room sealed installations

80mm

100mm

Changes of

direction

0 2 3 4 0 2 3

4

34

30

22

18

14

80

77.1

75.7

74.3

46

12 55

49.9

47.3

44.7

54

11 50

42.9

39.3

35.8

2. Design and sizing information

2.1 Boiler maximum flue lengths

Thision S Plus

Page 6 of 33

Page 7

2.1 Boiler maximum flue lengths continued…

Thision L Evo

80/125

100/150

(m)

(m)

60

14

38 Equivalent length in m

70

12

33

Concentric flue

Bend R = D

Bend R = D

80

7

23

gas system

90°/87°

45°/43°

100

11 80/125

1.5

1

120

7 100/150

1.5

1

Thision L Evo

80

100

110

125

130

60

17

62

70

13

52

65 Twin pipe flue

Equivalent length in m

80

7

36

47 gas system

80

100

110

125

130

100

13

23

56

88

Straight Pipe

1 1 1 1 1

120

8 13

43

65

90°/87° Bend

1.5

1.8

2

2.2

2.2

140

5

14

23

45°/43° Bend

0.8

0.9 1 1

1

Maximum length in metres for

concentric room sealed installations

100/150

Changes of direction

0 2 3

4

70

25

22

20

18

100

15

12

10

8

120

8 5 3

1

Maximum length in metres for single pipe

open or room sealed installations

100mm

Changes of direction

0 2 3

4

70

63

59

57

55

100

35

31

29

27

120

12 8 6

4

Thision L Evo

*Please be advised that we do not offer concentric flue for the Thision L Evo 140 boiler.

**Please be advised that we do not supply 130mm PPs flue.

Thision L Eco

Page 7 of 33

Page 8

2.2 Safe flue termination

In this section we aim to advise which laws and guidance are to be used in which situation. This

document will not cover every regulation but it will provide guidance as to which regulation

applies to certain situations.

The guide will look at the more common standards used to advise the requirements for flue and

ventilation installations and is not to be used as a standalone reference for regulations relating

to flue.

Please also refer to the installation and planning manuals for the specific boiler were there may

be specific information relating to flue installation standards.

When dealing with domestic installations that have a net input up to 70kW, these will be covered

by BS5440.

If the same appliance under the 70kW limit was to be installed in a commercial property then

this now needs to meet the requirements of IGE UP10 & BS6644.

However if a boiler is installed in a cascade arrangement and then exceeds the total input of

70kW then it falls under the commercial flue and ventilation requirements.

What is mandatory and what is just guidance?

British Standards (such as BS5440) are a mandatory requirement and have to be adhered

to. The approved documents offer guidance on how to comply and are only legally binding if

they are stipulated in the manufacturers installation manual. It is important to follow the

guidelines as they may be used in a court of law as the minimum expectation of a

competent person when installing a safe heating system.

The Clean Air Act is a mandatory requirement set out in Government legislation. It was

introduced in 1956 to reduce air pollution reacting to the Great Smog of London in 1952, in

that it helped the development of laws to help protect the environment.

This act targeted areas in major towns and cities, in these areas only fuels that produced

smokeless fuels could be used, also moving power stations away from main cities and

making it so that the height of certain chimneys being increased to avoid low level

contamination.

Nowadays smog is not as much of an issue as it was, but amendments of the Clean Air Act

have maintained control of emissions and the height of flue systems being more conscious

of pollution at lower levels.

Gas Safe (Gas Safety Installation and Use Regulations) is now mandatory and is there to

set out the requirements for safe installations and for working on gas installations.

IGE/IGEM is a guidance in a similar fashion to the British Standards but these are used by

industry experts as a current best practice and are in line with international and national

legislation and standards. The most relevant being IGEM UP 10 – Installation of flued gas

appliances in industrial and commercial premises.

On the following page is an extract from IGEM UP10 in relation to termination positions for

appliances over 70kW net input.

Page 8 of 33

Page 9

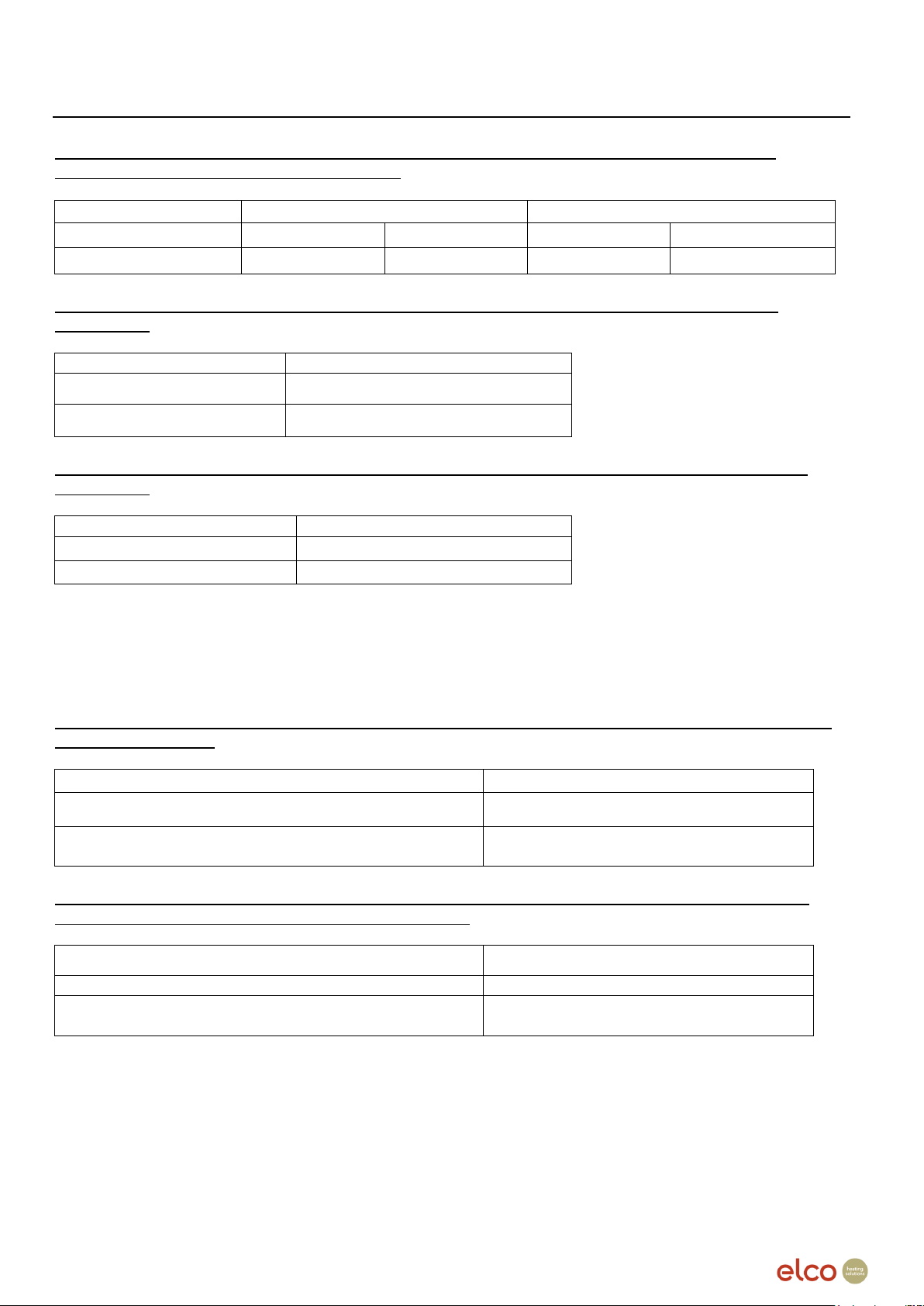

2.3 IGEM-UP 10

Single pipe flue minimum height of termination above a roof relating to number 1

Boiler Model

Thision L Eco Boilers

Thision L Evo Boilers

L Eco 100

L Eco 120

L Evo 80

L Evo 100

L Evo 120

L Evo 140

Above Roof

475mm

605mm

335mm

420mm

505mm

590mm

For other appliances use the calculation: Distance = 4.5675 (net heat input) - 19.723

For all sloped roofs over a 20° pitch the terminal must be 1.5 metres away.

If the flue terminates within 2.5 metres of an adjacent structure, the heights will apply to above the adjacent structure.

Elco concentric roof terminals terminates 700mm above roof level and therefore the above need not apply.

Minimum termination distances relating to numbers 2, 3 & 6

Boiler Model

Thision L Eco Boilers

Thision L Evo Boilers

L Eco 100

L Eco 120

L Evo 80

L Evo 100

L Evo 120

L Evo 140

Open Flue

1865mm

2135mm

1565mm

1740mm

1925mm

2105mm

For other open flue fan draught appliances use the calculation: Distance = 9.5156 x (net heat input) + 833.91

Room Sealed

875mm

1085mm

650mm

785mm

925mm

1060mm

For other room sealed fan draught appliances use the calculation: Distance = 7.232 x (net heat input) + 93.708

Minimum horizontal termination to opposing flat surfaces/terminals relating to number 10

Boiler Model

Thision L Eco Boilers

Thision L Evo Boilers

L Eco 100

L Eco 120

L Evo 80

L Evo 100

L Evo 120

L Evo 140

Flat Surfaces

3115mm

3775mm

2395mm

2825mm

3265mm

3705mm

For other appliances use the calculation: Distance = 23.126 x (net heat input) + 618.84

Terminals

2735mm

3285mm

2135mm

2490mm

2860mm

3225mm

For other appliances use the calculation: Distance = 19.32 x (net heat input) + 647.59

Termination positions for appliances over 70kW net input

Key to Diagram:

1 – Minimum termination height for ridged and flat roofs

2 – Minimum horizontal termination distance from openings e.g. doorways, windows, ventilation grilles, etc.

3 – Minimum horizontal termination distance from adjacent walls or obstructions

4 – Minimum distance to be 200mm for fan assisted appliances, 300mm for room sealed natural draught appliances. See BS5440.

5 – Minimum distance to be 150mm, see BS5440

6 – Minimum termination distance from openings e.g. doorways, windows, ventilation grilles, etc.

7 – Minimum distance between the flue terminals is to match the flue centres of our boilers when mounted on a cascade frame.

8 – Minimum distance below terminal or opening – 2.5 metres

9 – Minimum termination 2000mm above ground and a terminal guard must be fitted if less than 3000mmm.

10 – Opposing a terminal or flat surface.

Page 9 of 33

Page 10

2.4 BS6644 – 70kW to 1.8MW

Flue type

Ventilation direct to outside air

Ventilation to an internal space

Open flue Type B

5 cm²

10 cm²

Not permitted

Not permitted

Room sealed Type C

5 cm²

5 cm²

10 cm²

10 cm²

Open flue Type B

Ventilation direct to outside air

Low Level (Free Area / kW)

4 cm²

High Level (Free Area / kW)

2 cm²

Room sealed Type C

Ventilation direct to outside air

Low Level (Free Area / kW)

2 cm²

High Level (Free Area / kW)

2 cm²

System Type & Operational Time Grille Location

Ventilation direct to outside air

Low Level Inlet (m3/h / kW)

2.8

High Level Extract (m3/h / kW)

(Difference Between Inlet and Extract Air)

2.07 +/- 0.18

System Type & Operational Time Grille Location

Ventilation direct to outside air

Low Level Inlet (m3/h / kW)

2.6

High Level Extract (m3/h / kW)

(Difference Between Inlet and Extract Air)

1.35 +/- 0.18

Open Flued Type B and Room sealed Type C Appliances Installed within an Enclosure (Natural

ventilation requirements direct to Outside Air.)

Open Flued Appliances Installed within a Boiler Room (Natural ventilation requirements direct to

Outside Air.)

Balanced Flued Appliances Installed within a Boiler Room (Natural ventilation requirements direct to

Outside Air.)

Room sealed appliances with an Maximum Operating Pressure not exceeding 100 mbar in ventilated

occupied spaces with an air change rate exceeding 0.5 air changes per hour do not require additional

ventilation. If the air changes rate is below 0.5 per hour, 2 cm 2 kW -1 ventilation at high and at low level

shall be required.

Open Flued Appliances Installed with a Draught Diverter (Mechanical ventilation flow rate requirements

direct to Outside Air.)

Open Flued Appliances Installed without a Draught Diverter (With or without stabilizers) (Mechanical

ventilation flow rate requirements direct to Outside Air.)

Where high level discharge openings are not mechanically assisted, the free area must be calculated as

detailed above. All air inlet and extract fans must be fitted with automatic controls (interlocks) causing

safety shut-down or lockout of the installed gas burning appliances in the event of an inlet or extract air

flow failure.

Page 10 of 33

Page 11

2.5 BS5440 – Up to 70kW

Ventilation Route

Grille Location

Ventilation to room or internal space.

(The internal space ventilated into must be

ventilated as detailed above to outside air.)

Ventilation direct to outside air

Low Level (Free Area/kW)

20 cm²

10 cm²

High Level (Free

Area/kW)

10 cm²

5 cm²

Ventilation Route

Grille Location

Ventilation to room or internal space.

Ventilation direct to outside air

Low Level (Free Area/kW)

10 cm²

5 cm²

High Level (Free

Area/kW)

10 cm²

5 cm²

Air Vent Position

Appliance Input

(kW)

Fanned Draught

Distance (mm)

A

Above a

Terminal

0 to 7

300

>7 to 14

300

>14 to 32

300

>32

300

B

Below a

Terminal

0 to 7

300

>7 to 14

300

>14 to 32

300

>32

300

C

Horizontally to

a Terminal

0 to 7

300

>7 to 14

300

>14 to 32

300

>32

300

Open Flued Appliances installed within a Room (Natural ventilation requirements direct to Outside Air.)

Total rated net input not in excess of (70 kW – 7 kW) x 5cm² = Ventilation opening free area Open Flued

Open Flued appliances Installed within a compartment (Natural ventilation requirements.)

Balanced Flued Appliances Installed within an Enclosure (Natural ventilation requirements)

Page 11 of 33

Page 12

2.5 BS5440 – Up to 70kW continued…

If the chimney penetrates the dotted area,

and distance A is less than 1500mm, then

distance B shall not be less than 600mm.

Examples of the structure referred to above

include a parapet, dormer window or

chimney stack.

No part of the chimney outlet shall be less

than 1500mm measured horizontally to the

roof surface or 600mm above the ridge.

Page 12 of 33

Page 13

3. Flue Components

21

9

Available Flue Parts:

1. Wall Terminal

2. 2000mm Concentric Pipe

3. 500/1000mm Concentric Pipe

4. 90° Concentric Bend

5. 45° Concentric Bend

6. Vertical Adaptor

7. Roof Terminal

8. Flat Roof Flashing

9. Pitched Roof Flashing

10. Wall Bracket

11. Concentric Increaser

12. 2000/1000/500mm PPs Pipe

13. 90° PPs Bend

14. 45° PPs Bend

15. Plume Kit

16. PPs Increaser

17. Bird Mesh Stainless Steel Guard

18. Air Filter

19. Concentric to Parallel Adaptor

20. Air Inlet Cover

21. Parallel to Concentric Adaptor

22. PPs Reducer

*Products supplied may differ from image

1

3

2

13

12

14

15

8

16

17

18

7

11

10

6

5

4

19

20

22

3.1 Available Flue Components

Page 13 of 33

Page 14

3.2 Thision S Plus Flue Components

Concentric Flue Systems

Item

Flue Component

80/125

100/150

2

1950mm Length

3791646

3791303

3

1000mm Length

3791641

3791304

3

500mm Length

3791642

3791305

4

87°/93° Bend

3791643

3791306

5

45° Bend

3791644

3791307

1

Wall Terminal

3791645

3791308

1 + 4

Wall Terminal Kit *

FLUE-B-WALL

FLUE-B-EVOWALL

7

Roof Terminal

3791640

3791309

8

Flat Roof Slate

3791613

3791617

9

Pitched Roof Slate

3791614

3791618

10

Flue Bracket

3791612

3791616

15

Plume Kit

3791639

3791480

*Wall terminal kit includes wall terminal and 87°/93° bend

Single/Two Pipe Flue Systems

Item

Flue Component

80mm

100mm

UV Resistant 80mm

12

1950mm Length

3791584

3791297

12

1000mm Length

3791573

3791299

3791577

12

500mm Length

3791585

3791594

3791578

13

87°/93° Bend

3791574

3791300

3791579

14

45° Bend

3791575

3791301

3791580

17

Mesh Terminal

3791582

3791607

3791582

10

Flue Bracket

3791576

3791302

3791581

15

Plume Kit

3791639

3791480

3791639

Accessories

Item

Flue Component

Part Code

11

80/125 to 100/150 Concentric Increaser

3791570

16

80mm to 100mm Single Pipe Increaser

3791662

19

80/125 Concentric to Parallel Adapter

3791658

Page 14 of 33

Page 15

Elco do not supply 130mm PPs flue, if this is required then please contact a specialist flue supplier.

3.3 Thision L Evo Flue Components

Concentric Flue Systems

Item

Flue Component

80/125

100/150

110/150

2

1950mm Length

3791646

3791303

3

1000mm Length

3791641

3791304

3791621

3

500mm Length

3791642

3791305

3791622

4

87°/93° Bend

3791643

3791306

3791623

5

45° Bend

3791644

3791307

3791624

1

Wall Terminal

3791645

3791308

3791768

1 + 4

Wall Terminal Kit *

FLUE-B-WALL

FLUE-B-EVOWALL

FLU-110/150-WALL

7

Roof Terminal

3791640

3791309

3791625

8

Flat Roof Slate

3791613

3791617

3791617

9

Pitched Roof Slate

3791614

3791618

3791618

10

Flue Bracket

3791612

3791616

3791616

15

Plume Kit

3791639

3791480

*Wall terminal kit includes wall terminal and 87°/93° bend

Single/Two Pipe Flue Systems

Item

Flue Component

80mm

100mm

110mm

125mm

UV Resistant

80mm

12

1950mm Length

3791584

3791297

3791345

3791609

12

1000mm Length

3791573

3791299

3791595

3791608

3791577

12

500mm Length

3791585

3791594

3791578

13

87°/93° Bend

3791574

3791300

3791596

3791610

3791579

14

45° Bend

3791575

3791301

3791597

3791611

3791580

17

Mesh Terminal

3791582

3791607

3791607

3791619

3791582

10

Flue Bracket

3791576

3791302

3791626

3791612

3791581

15

Plume Kit

3791639

3791480

3791639

8

Flat Roof Slate

3791613

9

Pitched Roof Slate

3791614

20

Air Inlet Cover

452002280

Accessories

Item

Flue Component

Part Code

21

100/100 to 80/125 Concentric Adaptor

3791648

21

100/100 to 100/150 Concentric Adaptor

3590656

21

100/100 to 110/150 Concentric Adaptor

3791653

21

130/130 to 110/150 Concentric Adaptor

3791647

22

100mm to 80mm Reducer

3791650

16

100mm to 110mm Increaser

3590307

16

100mm to 125mm Increaser

FLUE0039AA000

22

130mm to 125mm Reducer

3590308

20

130mm Air Inlet Cover

452002300

Page 15 of 33

Page 16

3.4 Thision L Eco Flue Components

Concentric Flue System

Item

Flue Component

100/150

2

1950mm Length

3791303

3

1000mm Length

3791304

3

500mm Length

3791305

4

87°/93° Bend

3791306

5

45° Bend

3791307

1

Wall Terminal

3791308

1 + 4

*Wall Terminal Kit

FLUE-B-EVOWALL

7

Roof Terminal

3791309

8

Flat Roof Slate

3791617

9

Pitched Roof Slate

3791618

10

Flue Bracket

3791616

15

Plume Kit

3791480

*Wall terminal kit includes wall terminal and 87°/93° bend

Single/Two Pipe Flue System

Item

Flue Component

100mm

12

1950mm Length

3791297

12

1000mm Length

3791299

12

500mm Length

3791594

13

87°/93° Bend

3791300

14

45° Bend

3791301

17

Mesh Terminal

3791607

10

Flue Bracket

3791302

15

Plume Kit

3791480

18

Air Filter

3905046

20

Air Inlet Cover

452002280

Page 16 of 33

Page 17

The image on the left is an example

installation of a flexible flue solution where the

air is being taken in via the chimney cover and

then down through the chimney into the

150mm connection on the wall plate, where it

will then be taken into the boiler via concentric

flue pipe.

The flue gas is being taken from the boiler

through concentric flue pipe to the wall plate,

where it is connected to the flexible flue and

taken out through the flexible pipe to the

termination at the chimney cover.

This solution allows the boiler to operate as a

room sealed device taking combustion air from

the brick chimney which is ventilated to allow

air to be taken from outside. We recommend

that the chimney is swept prior to installation to

reduce the risk of dirt to be drawn into the

boiler.

This is mostly used in older buildings where

modification of the building is prohibited.

3.5 Flexible Flue Components

Flue Component

80mm

110mm

12.5m Flexible Flue Liner

FLUEBRECAA500

15m Flexible Flue Liner

FLUECRECAA600

25m Flexible Flue Liner

FLUEBREDAA600

FLUECREDAA600

Rigid to Flexible Adaptor

FLUEBREMAA600

FLUECREMAA700

Flexible to Flexible Adaptor

FLUEBREFAA600

FLUECREFAA600

Flexible to Rigid Adaptor

FLUEBREGAA700

FLUECREGAA700

Bracing Brackets (Pack of 5)

FLUEBREJAA500

FLUECREJAA500

Chimney Cover c/w Flex to Rigid Adaptor

FLUEBRCTAA500

FLUECRCTAA500

Chimney Support Bend

FLUEBKCRAA000

FLUECKCRAA000

Starter Kit

BRFY.AA.000

CRJEAA000

100-110 Increaser

FLUE113795

Mesh Terminal

FLUE173121

FLUE173121

Mesh Terminal

FLUE173121

Chimney Cover

FLUECRCTAA500

Bracing Brackets

FLUECREJAA500

15m Flexible Flue Liner

FLUECRECAA600

Chimney Support Bend

FLUECKCRAA00

100/150 Wall Plate

FLUECBDDAA600

100 to 110 Increaser

FLUE113795

At Elco Heating Solutions we can offer a flexible flue solution for when the flue

gas system needs to be routed through an existing chimney/void such as in listed

buildings where amendments to the building layout cannot be made.

We have a simple starter kit that has been assembled to make it easier when

selecting the required items. The starter kit includes a chimney cover, bottom

bend and support, 5 spider brackets, flexible and rigid couplings and the

installation tool.

Adding this kit to the appropriately sized flexible flue liner and the concentric/PPs

flue from the boiler, this gives you a kit that will allow you to take the flue gas to

the desired termination location as per the image.

Example of a 110mm Flexible Flue Installation

Page 17 of 33

Page 18

3.6 Cascade Flue Components

Thision L Evo

Flue Component

DN150

DN200

2 Boilers In-Line Cascade Flue

452001320

452001420

3 Boilers In-Line Cascade Flue

452001340

452001440

4 Boilers In-Line Cascade Flue

452001360

452001460

5 Boilers In-Line Cascade Flue

452001380

452001480

6 Boilers In-Line Cascade Flue

452001400

452001500

3 Boilers Back to Back Cascade Flue

452001520

452001640

4 Boilers Back to Back Cascade Flue

452001540

452001660

5 Boilers Back to Back Cascade Flue

452001560

452001680

6 Boilers Back to Back Cascade Flue

452001580

452001700

7 Boilers Back to Back Cascade Flue

452001600

452001720

8 Boilers Back to Back Cascade Flue

452001620

452001740

Thision L Eco

Flue Component

DN150

DN200

2 Boilers In-Line Cascade Flue

452004325

452004350

3 Boilers In-Line Cascade Flue

452004330

452004355

4 Boilers In-Line Cascade Flue

452004335

452004360

5 Boilers In-Line Cascade Flue

452004340

452004365

6 Boilers In-Line Cascade Flue

452004345

452004370

3 Boilers Back to Back Cascade Flue

452004375

452004405

4 Boilers Back to Back Cascade Flue

452004380

452004410

5 Boilers Back to Back Cascade Flue

452004385

452004415

6 Boilers Back to Back Cascade Flue

452004390

452004420

7 Boilers Back to Back Cascade Flue

452004395

452004425

8 Boilers Back to Back Cascade Flue

452004400

452004430

We currently do not do cascade flue for the Thision S

Plus. If you wish to install a cascade flue system for

the Thision S Plus range, please contact a specialist

flue supplier.

Elco only supply the cascade flue header as pictured,

the flue pipe exiting the cascade flue header will need

to be sourced via a flue specialist. The air intake

header will be need to be sourced by a flue specialist.

Please see the relative boiler operation and

installation manual for the information regarding

cascade flue system lengths and diameters.

Page 18 of 33

Page 19

3.4 Cascade Flue Components continued…

Thision L Evo Cascade Flue Accessories

Flue Component

Part Code

Cover for Combustion Air Inlet 100mm

For L Evo 60 – 120 Models

452002280

Cover for Combustion Air Inlet 130mm

For L Evo 140 Model

452002300

Cascade Flue System Adaptor for Thision L Evo 140

452001760

Thision L Eco Cascade Flue Accessories

Flue Component

DN150

DN200

2 Boiler In-Line Cascade Flue Fixation Rail

452004435

452004435

3 Boiler In-Line Cascade Flue Fixation Rail

452004440

452004440

4 Boiler In-Line Cascade Flue Fixation Rail

452004445

452004445

5 Boiler In-Line Cascade Flue Fixation Rail

452004450

452004450

6 Boiler In-Line Cascade Flue Fixation Rail

452004455

452004455

3 & 4 Boiler Back to Back Cascade Flue Fixation Rail

452004435

452004435

5 & 6 Boiler Back to Back Cascade Flue Fixation Rail

452004440

452004440

7 & 8 Boiler Back to Back Cascade Flue Fixation Rail

452004445

452004445

Air Filter

3905046

Cover for Combustion Air Inlet 100mm

452002280

*A cover for the air intake is supplied with the cascade flue set for the Thision L Eco

boilers

Page 19 of 33

Page 20

4. Flue Component Dimensions

Concentric Wall Terminal

1

Part

Part Code

D1

D2

D3

L1

X1

80/125

3791635

80

125

220

955

800

2

100/150

3791309

100

150

230

870

690

110/150

3791768

110

150

230

870

690

3

Concentric Roof Terminal

Part

Part Code

D1

D2

D3

D4

L1

L2

X1

80/125

3791635

80

125

140

190

1150

250

600

4

Concentric Roof Terminal

Part

Part Code

D1

D2

D3

L1

X1

100/150

3791633

100

150

175

1195

420

110/150

3791659

110

150

175

1195

420

1 2 4

3

4.1 Concentric flue parts dimensions

Page 20 of 33

Page 21

4.1 Concentric flue parts dimensions continued…

1

Concentric 90° Bend

Part

Part Code

D1

D2

L1

L2

X1

80/125

3791643

80

125

130

120

80

100/150

3791306

100

150

130

145

95

110/150

3791623

110

150

145

130

95

2

Concentric 45° Bend

Part

Part Code

D1

D2

L1

L2

X1

80/125

3791644

80

125

90

90

40

100/150

3791307

100

150

110

120

70

110/150

3791624

110

150

120

110

70

3

1000mm Concentric Straight Length

Part

Part Code

D1

D2

L1

X1 80/125

3791641

80

125

1000

950

100/150

3791304

100

150

1000

944

110/150

3791621

110

150

1000

950

500mm Concentric Straight Length

Part

Part Code

D1

D2

L1

X1

80/125

3791642

80

125

500

450

100/150

3791305

100

150

500

450

110/150

3791622

110

150

500

450

4

1950/2000mm Concentric Straight Length

Part

Part Code

D1

D2

L1

X1

80/125

3791646

80

125

1950

1890

100/150

3791297

100

150

1950

1945

4

2

1

3

Page 21 of 33

Page 22

4.1 Concentric flue parts dimensions continued…

1

80/125 to 100/150 Concentric Increaser

Part

Part Code

D1

D2

D3

D4

L1

X1

80/125

3791664

80

125

100

150

165

110

80/125 to 110/150 Concentric Increaser

Part

Part Code

D1

D2

D3

D4

L1

X1

80/125

3791659

80

125

110

150

165

115

2

100/100 to 80/125 Concentric Adaptor

Part

Part Code

D1

D2

D3

L1

L2

X1

X2

100/100

3791648

100

80

125

65

145

305

180

130/130 to 110/150 Concentric Adaptor

Part

Part Code

D1

D2

D3

L1

L2

X1

X2

130/130

3791647

130

110

150

65

145

305

180

3

100/100 to 100/150 Adaptor

Part

Part Code

D1

D2

D3

L1

L2

X1

X2

100/100

3590656

110

100

150

80

179

284

148

4

100/100 to 110/150 Adaptor

Part

Part Code

D1

D2

D3

L1

L2

X1

X2

100/100

3791653

100

110

150

52

163

320

175

1 2 3

4

Page 22 of 33

Page 23

4.2 PPS flue parts dimensions

1

2000mm PPs Straight Length

Part

Part Code

D1

L1

X1

80

3791584

80

1950

1895 100

3791593

100

1945

1890 110

3791345

110

1950

1895 125

3791609

125

2075

2000

1000mm PPs Straight Length

Part

Part Code

D1

L1

X1

80

3791573

80

100

945 100

3791299

100

995

940

110

3791595

110

1000

945 125

3791608

125

1075

1000

500mm PPs Straight Length

Part

Part Code

D1

L1

X1

80

3791585

80

500

445 100

3791594

100

495

440

1000mm UV Resistant PPs Straight Length

Part

Part Code

D1

L1

X1

80

3791577

80

100

945

500mm UV Resistant PPs Straight Length

Part

Part Code

D1

L1

X1

80

3791578

80

500

445

2

90° Bend PPs and UV Resistant PPs

Part

Part Code

D1

L1

L2

X1

80

3791574

80

130

120

75

100

3791300

100

145

130

90

110

3791596

110

120

110

60

125

3791610

125

145

150

70

3

45° Bend PPs and UV Resistant PPs

Part

Part Code

D1

L1

L2

X1

80

3791575

80

90

90

45

100

3791301

100

110

120

75

110

3791597

110

90

85

35

125

3791611

125

100

100

35

2 1 3

Page 23 of 33

Page 24

4.3 Accessory parts dimensions

1

Stainless Steel Mesh Terminal

Part

Part Code

D1

L1

X1

90mm

AT-3791582

90

125

47

120mm

AT-3791607

120

130

60

160mm

AT-3791619

160

140

60

200mm

AT-3791620

200

140

60

2

Flat Roof Flashing

Part

Part Code

D1

D2

X1

80/125

AT-3791613

135

410

100

100/150

AT-3791617

170

450

100

3

Pitched Roof Flashing

Part

Part Code

D1

L1

α (°)

80/125

AT-3791614

142

500

25° - 45°

100/150

AT-3791618

172

500

25° - 45°

4

PPs Increaser

Part

Part Code

D1

D2

L1

X1

80 to 100

3791662

80

100

165

110

80 to 110

3791651

80

110

140

85

100 to 110

3791652

100

110

160

105

5

80/125 to 80/80 PPs Adaptor

Part

Part Code

D1

D2

D3

D4

L1

L2

L3

X1

X2

80/125

3791658

80

80

80

125

175

150

255

130

120

6

Plume Kits

Part

Part Code

D1

80mm

AT-3791639

80

100mm

AT-3791480

100

4 1 2 35

6

Page 24 of 33

Page 25

4.4 Flexible flue dimensions

1

80mm Flexible Flue Liner

Part

Part Code

D1

L1

X1

12.5m

AT-3791586

80

12.5m

1490

25m

AT-3791587

80

25m

1490

110mm Flexible Flue Liner

Part

Part Code

D1

D2

X1

15m

AT-3791598

110

15m

1490

25m

AT-3791599

110

25m

1490

2

Chimney Support Bend

Part

Part Code

D1

L1

L2

L3

L4

X1

80mm

AT-3791591

80

120

130

212

390

80

110mm

AT-3791605

110

120

110

230

390

65

3

100mm to 110mm Increaser

Part

Part Code

D1

D2

L1

X1

100-110

AT-3791652

100

110

160

105

4

Flexible Flue Brackets (5 Pack)

Part

Part Code

D1

D2

L1

80mm

AT-3791589

80

40

400

110mm

AT-3791602

110

40

400

5

100mm to 110mm Increaser

Part

Part Code

D1

L1

X1

X2

110mm

AT-3791601

110

190

50

50

1

2

3 4 5

Page 25 of 33

Page 26

4.4 Flexible flue parts dimensions continued…

1

Chimney Cover for Flexible Flue

Part

Part Code

D1

D2

L1

80mm

FLUEBRCTAA500

48

246

188

110mm

FLUECRCTAA500

72

246

188

2

Flex to Flex Adaptor

Part

Part Code

D1

L1

X1

80mm

FLUEBREFAA600

80

187

87

110mm

FLUECREFAA600

110

187

87

1

2

Page 26 of 33

Page 27

4.5 Cascade flue dimensions

Thision L Eco DN150 In-Line Cascade Flue

Thision L Eco DN200 In-Line Cascade Flue

The cascade flue kits that are supplied for the Thision L Eco boilers are built from individual kits and then

multiplied dependant on how many boilers is in the installation. For example, if you have 4 boilers on an

in-line cascade frame then the kit will come with 4 sections of cascade flue and so on.

So the overall length of the cascade flue will be the individual kits multiplied by the number of boilers.

Each individual section comes with a vertical single skin pipe to be used to take the flue gas into the

cascade flue header. This section will be supplied in a 500mm length. To achieve the 3° incline back to

the boilers this length will need to be cut down to facilitate this requirement.

Page 27 of 33

Page 28

4.5 Cascade flue dimensions continued…

Thision L Eco DN150 Back to Back Cascade Flue

Page 28 of 33

Page 29

4.5 Cascade flue dimensions continued…

Thision L Eco DN200 Back to Back Cascade Flue

Page 29 of 33

Page 30

4.5 Cascade flue dimensions continued…

DN150 In-Line Cascade Flue

603mm

1493mm

205mm Centre to Centre

285mm

DN150

100mm

100mm

621mm

362mm

DN200 In-Line Cascade Flue

1493mm

205mm Centre to Centre

DN200

100mm

100mm

The cascade flue kits that are supplied for the Thision L Evo boilers is a 2 boiler version of the casade

header, however further additional extension kits and are added on depending on how many boilers is in

the installation. For example, if you have 4 boilers on an in-line cascade frame then the kit will come with

one 2 boiler in-line cascade flue set and 2 additional extension kits of cascade flue.

The overall length of the cascade flue will be the 2 boiler cascade header plus the individual extension kits

multiplied by the number of boilers.

Each extension kit comes with a vertical single skin pipe to be used to take the flue gas into the cascade

flue header. This section will be supplied in a 500mm length. To achieve the 3° incline back to the boilers

this length will need to be cut down to facilitate this requirement and this information can be found in the

cascade installation manual for the Thision L Evo boiler.

Page 30 of 33

Page 31

4.5 Cascade flue dimensions continued…

DN200 Back to Back Cascade Flue

DN150 Back to Back Cascade Flue

100mm

100mm

100mm

100mm

100mm

100mm

100mm

100mm

DN200

439mm

684mm

1422mm

149mm Centre to Centre

149mm Centre to Centre

685mm

488mm

149mm Centre to Centre

149mm Centre to Centre

1401mm

Page 31 of 33

Page 32

4.5 Cascade flue dimensions continued…

DN150 In-Line Cascade Flue Extension

100mm

DN150

689mm

DN200 In-Line Cascade Flue Extension

100mm

715mm

DN200

DN150 Back to Back Cascade Flue Extension

DN200 Back to Back Cascade Flue Extension

100mm

100mm

DN150

690mm

100mm

100mm

710mm

DN200

Page 32 of 33

Page 33

Elco Heating Solutions

3 Juniper West, Fenton Way, Southfields Business Park,

Basildon, Essex, SS15 6SJ

Tel: 01268 546700 Fax: 01268 888250

www.elco.co.uk

This publication is issued subject to alteration or withdrawal without notice. The

illustrations and specifications are not binding in detail. All offers and sales are subject

to the Company’s current terms and conditions of sale.

Page 33 of 33

Loading...

Loading...