Page 1

Operation Manual

For the authorized specialist

Dual-fuel Duoblock Burner

RPD 30 - 100 GL-R / GS-R

03/2005 102.877.8447

Page 2

2

Inhalt

General Information .............................................................3

Technical Data Sheet ..........................................................4

Burner Construction ..........................................................10

Mounting the Burner to the Boiler ......................................11

Combustion Air Fan Drive Modes .....................................12

Dimensioned Drawing for RPD Burner 20 - 100 ...............13

Burner scheme Gas train ..................................................15

Hydraulic Scheme .............................................................17

Hydraulic Scheme .............................................................18

Mounting Position Leak Test Ignition Gas Connection

Ignition Burner Type ZT0 ...................................................20

Ignition Gas Solenoid Valve ..............................................24

Oil Connection Fuel Oil Supply .........................................25

Oil Connection ...................................................................26

Medium pressure screw pumps ........................................27

Burner Pump Assembly Electrical Connection ..................29

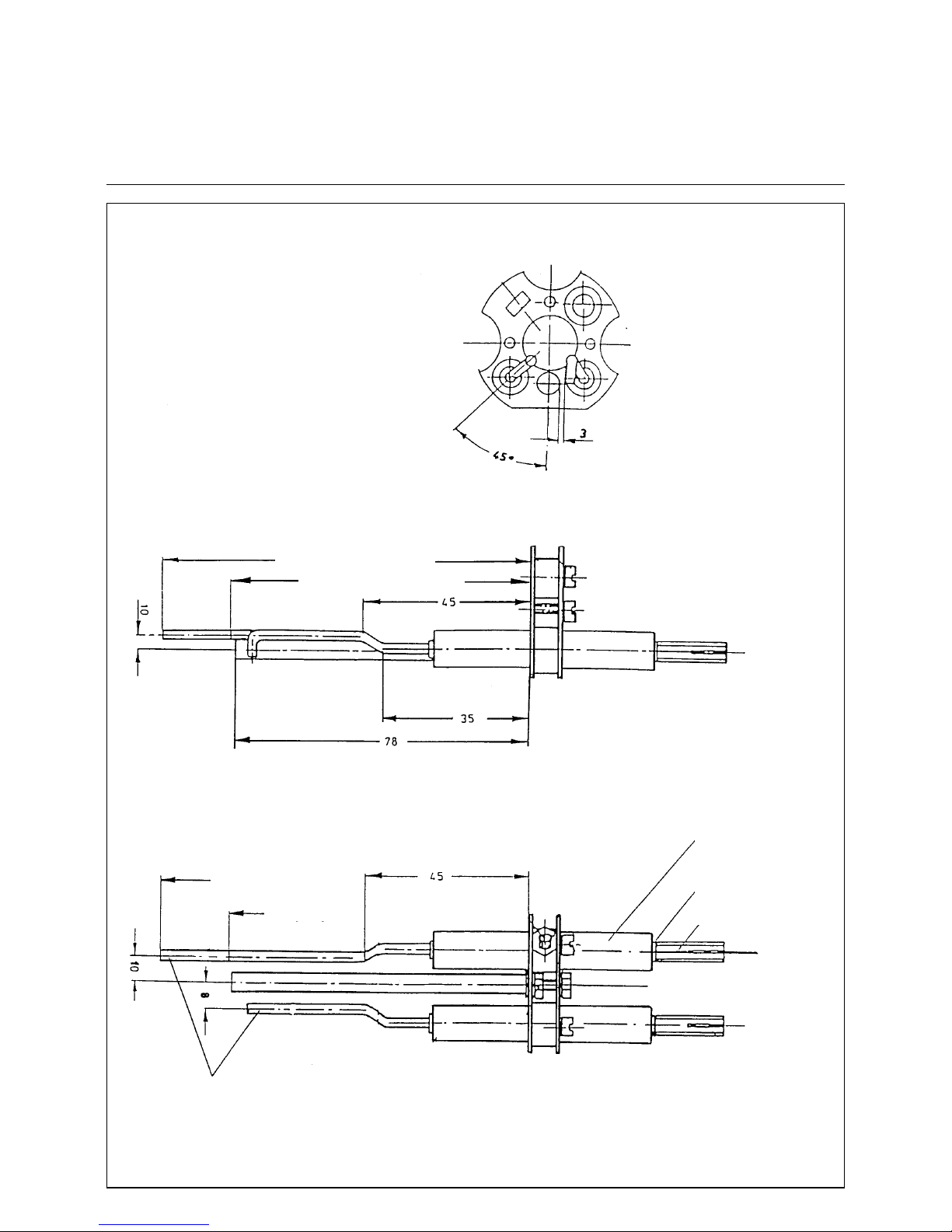

Return Nozzle Rod DG 75 .................................................30

Return Nozzle Rod MAT ...................................................31

Throughput Rate Charakteristics Light Fuel Oil ................32

Throughput Rate Charakteristics Heavy Fuel Oil ..............40

Dimensions of the Mixing Unit ...........................................49

Draw-out and Swing Mechanism .......................................50

Air Flow Adjustment

Oil Flow and Gas Rate Adjustment ...................................51

Mechanical Compound Controller .....................................52

Pressure Setting ................................................................53

Removal and Replacing the Shaft Seal

of the Return Flow Nozzle Assembly DG 75 .....................54

Oil Pressure Switch Air Pressure Switch ...........................55

Setting Pressure Switches and Control System ................56

Automatic Furnace Controller LFL 1... / LGK 16... ............57

Flame Monitor Sensor Current Measurement ...................58

Actuator Type ARIS, 4, 4a, 5 .............................................59

Solenoid Safety Valves .....................................................60

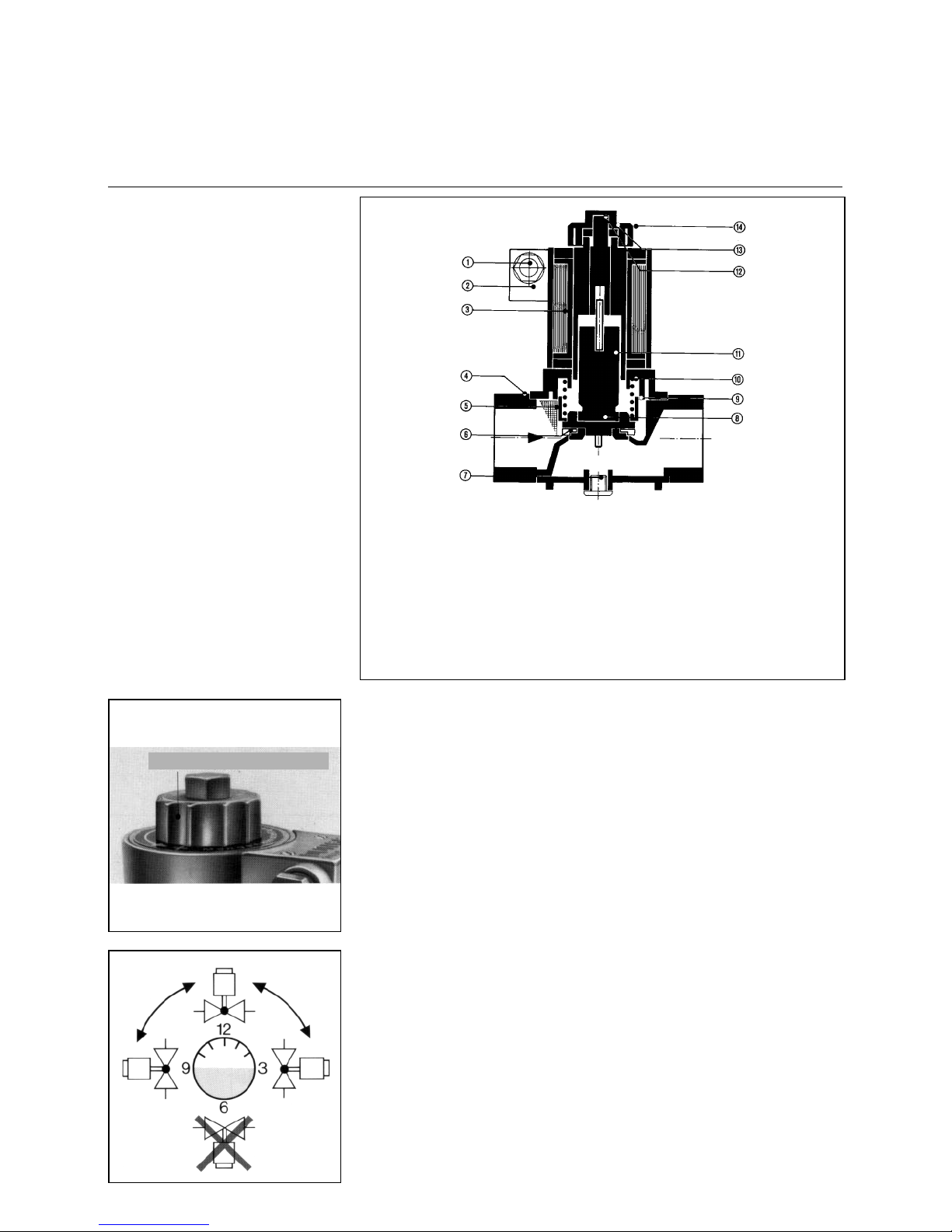

2/2 Way Valve Type MK 15 ...............................................62

2/2 Way Valve Type MK 20 ...............................................64

Pipe spring - Glycerine - Manometer

Bimetal - Pointer - Temperature controller ........................66

Flushing and Oil Feed Start Thermostat ATH 22 .............67

Gas Connection .................................................................68

Gas Motor Valve VK ..........................................................69

Gas Pressure Regulator ....................................................71

Gas Pressure Regulator ....................................................72

Gas Filter Safety Vent Valve .............................................74

Diagram Pressure Loss .....................................................75

Discharge Speed, Gas Nozzles ........................................76

Preoperational Checks Functional Flow Gas Start-up ......78

Start-up Light Oil ...............................................................79

Start-up Heavy Oil .............................................................80

Viscosity as a Function of Oil Temperature .......................81

Oil Start-up Burner Shutdown

Measures in Case of Trouble ............................... ...... .......82

Exhaust Gas Test ..............................................................83

SO2-content i n Exhaust Gas

from Light Oil and Heavy Oil Combustion .........................84

O2, CO2, Lambda Conversion Table ................................85

O2, CO2, Lambda Conversion Table ................................86

O2, CO2, Lambda Conversion Table ................................87

O2, CO2, Lambda Conversion Table ................................88

Trouble Shooting Instruction s .............. ...... ........................89

Contents

Page 3

3

General Information

Important information

The burners of type RPD 30...100GL/

GS-E.../R... have been desig ned for the

combustion of natural gas or fuel oil.

The burners should be installed and

taken into opera tion by qualifi ed pers onnel only who will be responsible for the

proper performance of this work in

accordance with the applicable regulations and guidelines.

Only duly authorized specialists should

be entrusted with the installation of the

gas system.

Any repair work on monitors, limiters

and automatic furnace controllers and

on the other safety facilities are allow ed

to be done only by the manufacturers

themselves or specialists authorized by

them. Original parts should only be

exchanged by a duly qualified specialist.

Standards and regula tions

The following standards should be

observed in the interest of a safe, easyon-the-environment and energy-saving

operation of the burner:

According to EN 676 and EN 267, the

user must be instruc ted in the operati on

of the burner and according to DIN 4755

and DIN 4756, the user must be introducted in to gas firing system.

For the installation of a gas furnace

system, care should be taken to

observe DIN 4756, TRGI (Technical

Regulation on Gas Installations), the

Worksheets of DVGW (German Association of the Gas and Water Sector)

and the local furnace construction regu lations applicable in the country.

Screwed unions of metal used in gas

lines should be fitted with approved

sealing elements.

Prior to taking the burner into operation

make sure to vent the gas line, but this

should in no case be done through the

furnace chamber.

For the installation of an oil furnace

system, care should be taken to

observe DIN 4755, TRbF (Technical

Regulation on Combustib le Liquids) and

the local furnace construction regulations applicable in the country.

Start-up

The furnace system should be started

initially by the installer, manufacturer or

other specialized personnel. Prior to

taking the furnace system into operation, make a test of all automatic control, safety and control facilities for

proper functional order and check them

for correct setting if of adjustable type.

Furthermore, check the control circuits,

fans, etc. for proper fuse rating, and

whether suitabl e precaution s have bee n

taken to prevent accidental contact.

Inspection and Maintenance

The furnace system should be inspected and serviced at least once a y ear by

an authorized special ist of the inst al le r

to ensure its proper functional order,

operational safety and energy-saving

operation. Check the system for

absence of leaks and functional order.

For the combustion anal ysis proceed as

described in the section entitled

„Exhaust Gas Test“. It is recommende d

to conclude a maintenance agreement

to this effect.

Warranty

Manufacturer will not accept any warranty if the operating instructions have

not been duly observed in the start-up

and maintenance of the burner and

damages have been caused by improper installation, incorrect adjustment,

unauthorized interference or operating

errors.

Burner installation and

accessories

Boiler lining

The boiler lining should be made of

heat-resistant materials (temperature

resistance >1400°C). T ake care that the

burner flame tube is covered by the

boiler lining over its full length.

The open space between the burner

flame tube and the boiler lining should

be packed with mineral wool.

Checks prior to burner installation

1 Check the mixing ignition unit

according to the boiler output.

2 Oil nozzles and mixing ignition

unit.

3 Pilot burner setting.

4 See dimensioned drawing for set-

ting dimensions of mixing ignition

unit.

5 Check the air cylinder for proper

function (po ssible damage in

transport).

6 Check the air damper setting

according to flame p attern and fur-

nace chamber geometry.

EN 676/

DIN 4788

Gas burners with bl ower

EN 267/

DIN 4787

Oil atomizer burners

VDE 0116 Electrical Equipment of

furnace

Page 4

4

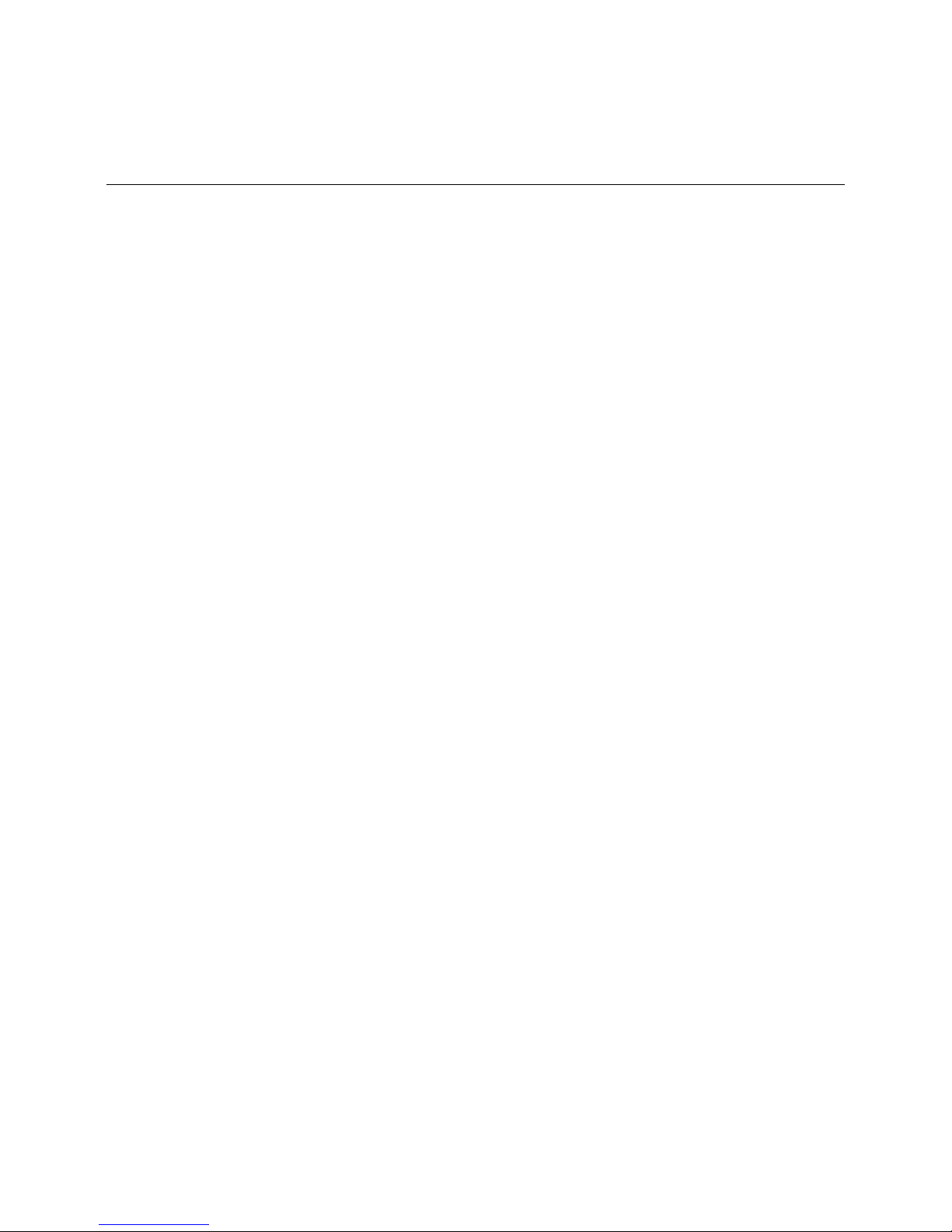

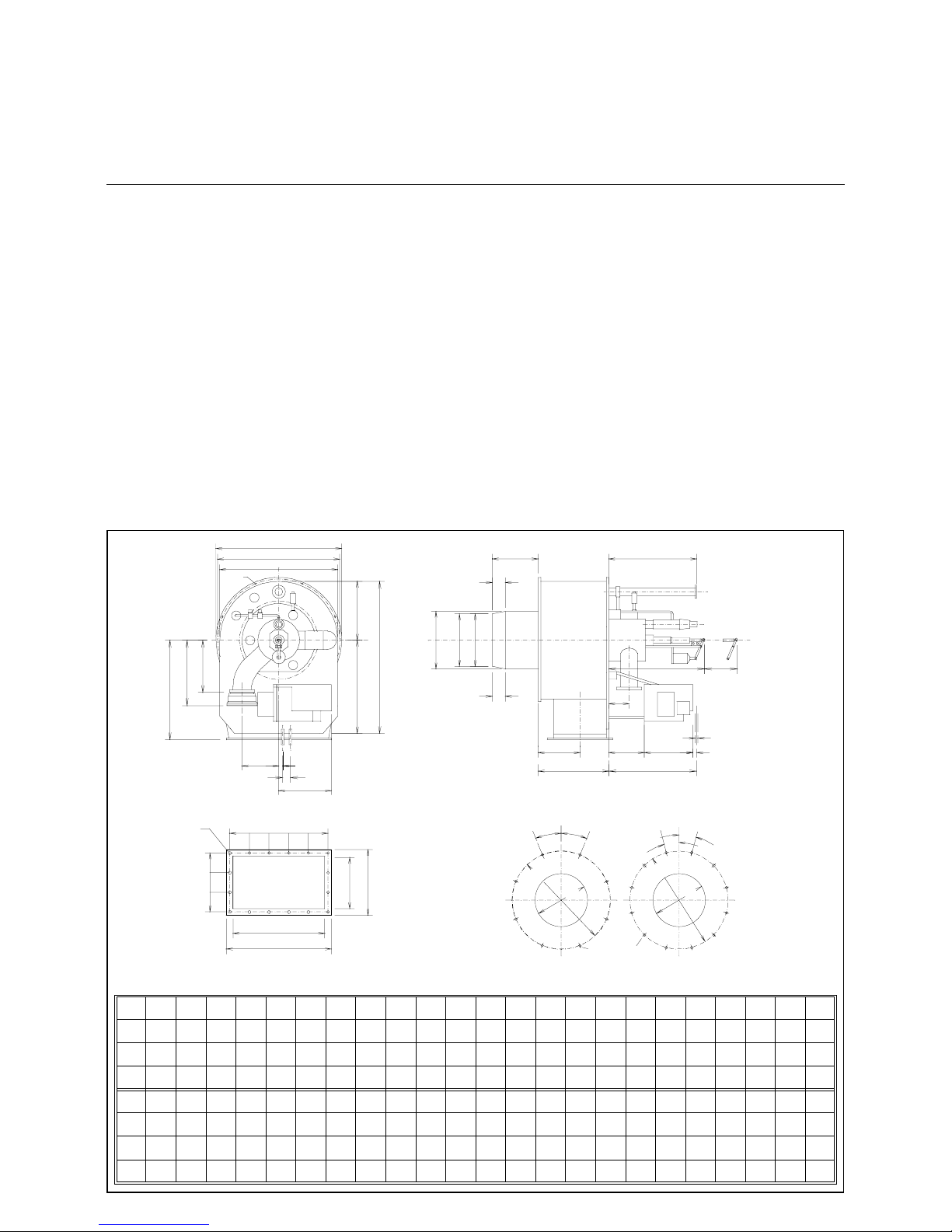

Technical Data Sheet

Duoblock Dual Fuel Burner

Feld52:

RPD 30 / 40 / 50 GL-R / GS -R

6042

8230

1116 0

954

110 0

1400

0

2000

4000

6000

8000

10000

12000

RPD 30 RPD 40 RPD 50

kW

Technical Data

Fuel flow rate (light oil)

Gas flo w rat e

Operating mode

Fuel ty p e

Automatic burner controller

Flame sensor

Ignition burner

Ignition transformer

Pump output at 35 bar

MAT oil control block

Oil connection

Nozzle rod

Nozzle

Actuator

Gas conn ection

We ight

Pre ssure loss i n mixing uni t

Gas contr ol organ

Burner output

Output range

954 - 6042 kW

RPD 30

81 - 513 kg/h

95 - 604 m³/h

fully modulating

Light oil / heavy oil / natura l gas / special fuels

LFL 1., LGK 16 or other approved models

QRA 2, QRA 53 o r other approved models

MAT / Hegwein ZNVL (ZT0)

D-52 L5 KV

Z112 K5

1200 l/h

SRB 19000/30

R 3/4" / 22 mm

MAT / DG 75

MAT - MK 27

WA N 4

R 3"

430 kg

30 mbar or according to diagram

accordi ng to gas pressure

(MAT ignition burner)

(Hegwein ignition burne r)

1100 - 8230 kW

RPD 40

98 - 694 kg/h

110 - 823 m³/h

1850 l/h

SRB 19000/40

R 3/4" / 22 mm

MAT / DG 75

MAT - MK 27

WA N 4

R 3"

450 kg

1400 - 11160 kW

RPD 50

118 - 941 kg/h

140 - 1116 m³/h

2400 l/h

SRB 19000/50

R 3/4" / 22 mm

MAT / DG 75

MAT - MK 27

WA N 4

R 5"

600 kg

Technical Data Sheet

Duoblock Dual Fuel Burner

RPD 30, 40 & 50 GL-R / GS - R

Page 5

5

RPD 30, 40 & 50 GL-R / GS - R

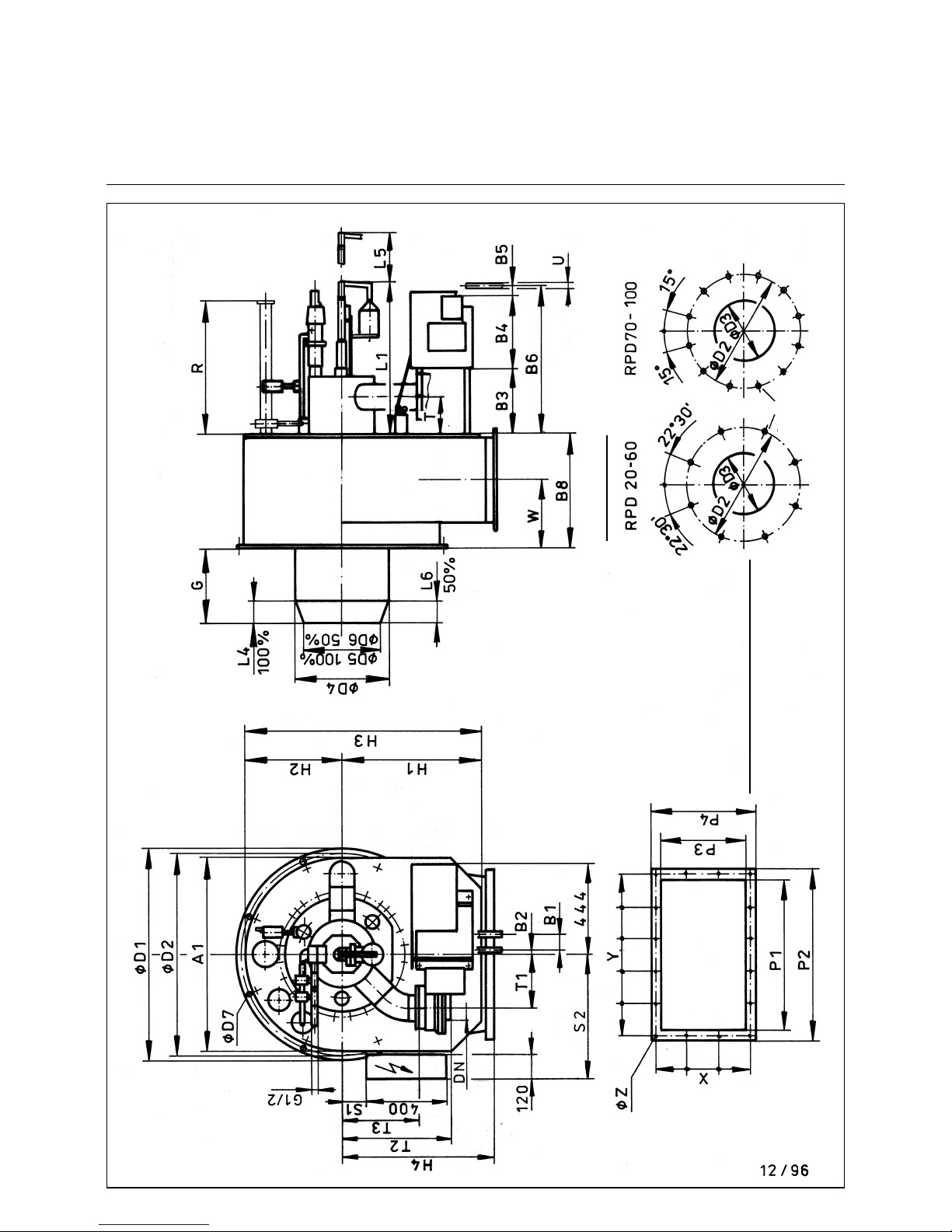

Description

Dimensions

Operating mode

Fully automatic for ced drau ght dual fuel

burner, safety equipment according to

EN 267 and EN 676, especially designed for high turn down ratios.

Electric design

Burner pre-wired and ready to connect. All burner components wired to

the burner terminal rail. Burner control

box supplie d loose for installation in

separate contr ol panel. Separate fitted

oil pump assembly.

Combustion air

Separate combustion air blower with

stable and p ulsation-free characterist ics

also on appli ances with a high flue gas

resistance. The combustion air volume

is divided into a primary and a secon-

dary stream. The flame shape may be

adapted by adjustable twist dampers.

Control systems

oil side: adjustable by means of return

flow system with compound controller

and spill back nozzle.

gas side : fuel throughput controlled by

compound controller with adjustable

cam disc and gas inlet butterfly valve.

air side : by means of compound controller with adjustable cam discs for primary air (air dampers) and secondary

air (air cylinder).

Monitoring system

Flame monitoring by means of flame

sensor and tested burner control box.

Combustion air monitoring achieved

through differential air pressure switch,

resp. speed control switch in cas e of

burner with speed control regulation.

Ignition

Direct electric high voltage ignition,

5000 V, by means of an inbuilt ignition

burner.

G

D2

22,5 °

P

4

P

3

X

P1

P2

Y

Z

B1

T1

444

B2

RPD 20 - 60

H

2

H

3

H

1

D1

H

4

T

2

T

3

V

D7

A1

D2

D

4

D

5

1

0

0

%

D

6

5

0

%

L6 50%

L4 100%

B3 B4 B5W

RPD 70 - 100

D2

Gewinde

Länge K

Stift M

D3

D3

Bohrungen Kesselplatte

B6

22,5 °

B8

15°

15°

L5L1

T

U

R

RPDA1B1B2B3B4B5B6B8D1D2D3D4D5D6D7GH1H2H3H4 K L1L4

30 745 78 19 260 375 70 705 416 830 790 385 371 2 90

323,5

17,5 317 620 373 993 650 30 700 124

40 745 78 19 260 375 70 705 416 830 790 423 409 3 40 367 17,5 442 620 373 993 650 30 700 95

50 950 78 19 315 375 70 760 535 1030 990 470 456 380 410 17,5 370 675 475 1150 740 30 770 110

RPD L5 L6 M P1 P2 P3 P4 R T T1 T2 T3 U V W X Y Z LB C FI F2 F3

30 1350 62 12 580 670 320 410 1265 160 192 491 346

22x1,5

3" 248

4x92 5x126

10-----

40 1425 50 12 580 670 320 410 1265 160 192 491 346

22x1,5

3" 248

4x92 5x126

10-----

50 1620 55 12 740 830 416 506 1743 181 250 530 376

22x1,5

5" 319

3x152 5x156

10-----

set screw M

length K

Details of boiler front plate

Page 6

6

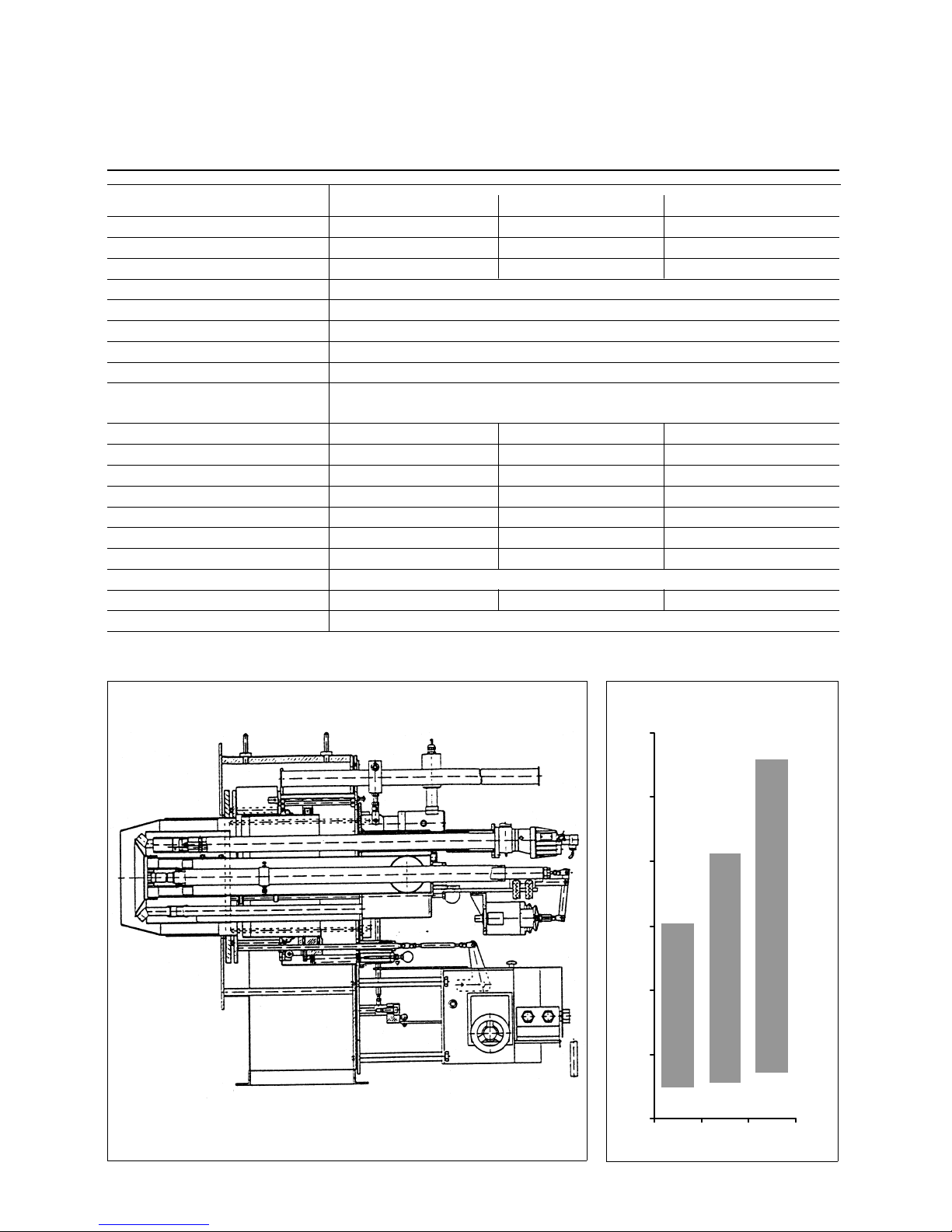

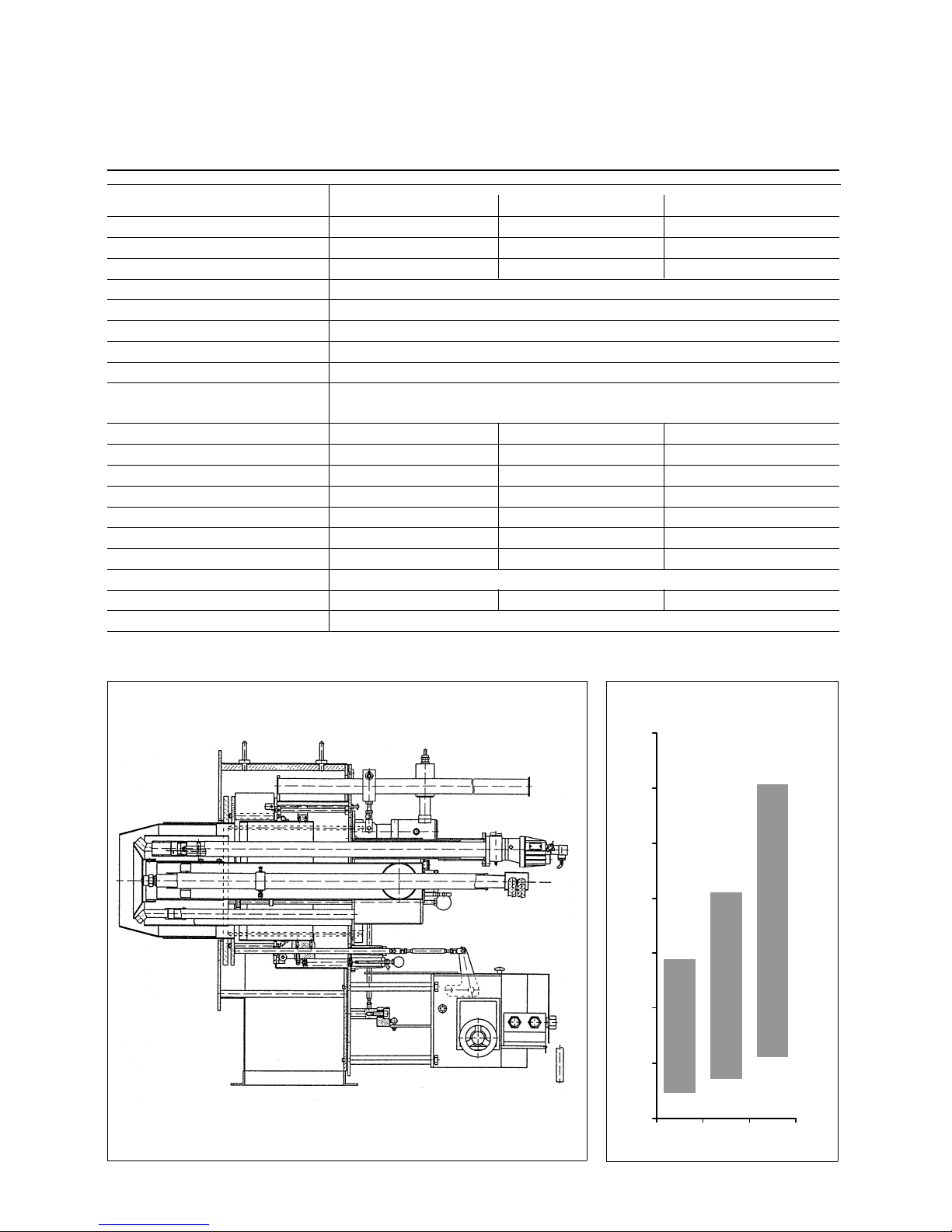

Technical Data Sheet

Duoblock Dual Fuel Burner

Feld52:

RPD 60 / 70 / 80 GL-R / GS -R

145 11

20470

30350

2232

3590

5500

0

5000

10000

15000

20000

25000

30000

35000

RPD 60 RPD 70 RPD 80

kW

Technical Data

Fuel flow rate (light oil)

Gas flo w rat e

Operating mode

Fuel ty p e

Automatic burner controller

Flame sensor

Ignition burner

Ignition transformer

Pump output at 35 bar

MAT oil control block

Oil connection

Nozzle rod

Nozzle

Actuator

Gas conn ection

We ight

Pre ssure loss i n mixing uni t

Gas contr ol organ

Burner output

Output range

2232 - 14511 kW

RPD 60

188 - 1223 kg/h

223 - 1451 m³/h

fully modulating

Light oil / heavy oil / natura l gas / special fuels

LFL 1., LGK 16 or other approved models

QRA 2, QRA 53 o r other approved models

MAT / Hegwein ZNVL (ZT0)

D-52 L5 KV

Z112 K5

3100 l/h

SRB 19000/60

R 3/4" / 22 mm

MAT

MAT - MK 50

WA N 4

R 5"

640 kg

30 mbar or according to diagram

accordi ng to gas pressure

(MAT ignition burner)

(Hegwein ignition burne r)

3590 - 20470 kW

RPD 70

303 - 1726 kg/h

359 - 2047 m³/h

4000 l/h

SRB 19000/70

R 3/4" / 22 mm

MAT

MAT - MK 50

WA N 4 A

R 5"

900 kg

5500 - 30350 kW

RPD 80

465 - 2559 kg/h

550 - 3035 m³/h

6400 l/h

SRB 19000/80

R 1" / 28 mm

MAT

MAT - MK 50

WA N 4 A

R 8"

1200 kg

Technical Data Sheet

Duoblock Dual Fuel Burner

RPD 60, 70 & 80 GL-R / GS - R

Page 7

7

D

4

L6 50%

G

L4 100%

RPD 20 - 60

P1

P2

Y

B1

444

X

Z

T1

B2

P

4

P

3

H

2

D1

H

3

H

4

T

2

T

3

V

D7

A1

D2

D

5

1

0

0

%

D

6

5

0

%

H

1

B3 B4 B5W

15°

D2

D3

15°

B6

D2

Stift M

Gewinde

Länge K

D3

B8

Bohrungen Kesselplatte

22,5 °

22,5 °

RPD 70 - 100

U

L1

R

T

L5

RPDA1B1B2B3B4B5B6B8D1D2D3D4D5D6D7 G H1H2H3H4 K L1L4

60 994 78 19 315 375 70 760 622 1080 1040 520 506 420

455,5

18 312 700 497 1197 825 30 735 125

70 1160 78 19 315 375 75 765 731 1240 1200 640 626 520

565,5

18 469 780 580 1360 900 30 740 170

80 1350 75 19 315 375 75 765 860 1450 1400 740 710 597 646 18 600 820 675 1495 1000 30 700 185

RPD L5 L6 M P1 P2 P3 P4 R T T1 T2 T3 U V W X Y Z LB C FI F2 F3

60 1695 62,5 12 750 840 470 560 1760 181 270 555 401

22x1,5

5" 379

4x129 5x160

10 - - - - -

70 1995 85 12 936 1026 600 690 2010 181 365 610 450

28x1,5

5" 410

5x128 7x140

10 - - - - -

80 2285 92 12 1102 1192 700 790 2320 187 310 707 495

28x1,5

8" 489

6x125 9x128

10 - - - - -

RPD 60, 70 & 80 GL-R / GS-R

Description

Dimensions

Operating mode

Fully automatic for ced drau ght dual fuel

burner, safety equipment according to

EN 267 and EN 676, especially designed for high turn down ratios.

Electric design

Burner pre-wired and ready to connect. All burner components wired to

the burner terminal rail. Burner control

box supplie d loose for installation in

separate contr ol panel. Separate fitted

oil pump assembly.

Combustion air

Separate combustion air blower with

stable and p ulsation-free characterist ics

also on appli ances with a high flue gas

resistance. The combustion air volume

is divided into a primary and a secondary stream. The flame shape may be

adapted by adjustable twist dampers.

Control systems

oil side: adjustable by means of return

flow system with compound controller

and spill back nozzle.

gas side : fuel throughput controlled by

compound controller with adjustable

cam disc and gas inlet butterfly valve.

air side : by means of compound controller with adjustable cam discs for primary air (air dampers) and secondary

air (air cylinder).

Monitoring system

Flame monitoring by means of flame

sensor and tested burner control box.

Combustion air monitoring achieved

through differential air pressure switch,

resp. speed control switch in cas e of

burner with speed control regulation.

Ignition

Direct electric high voltage ignition,

5000 V, by means of an inbuilt ignition

burner.

set screw M

length K

Details of boiler front plate

Page 8

8

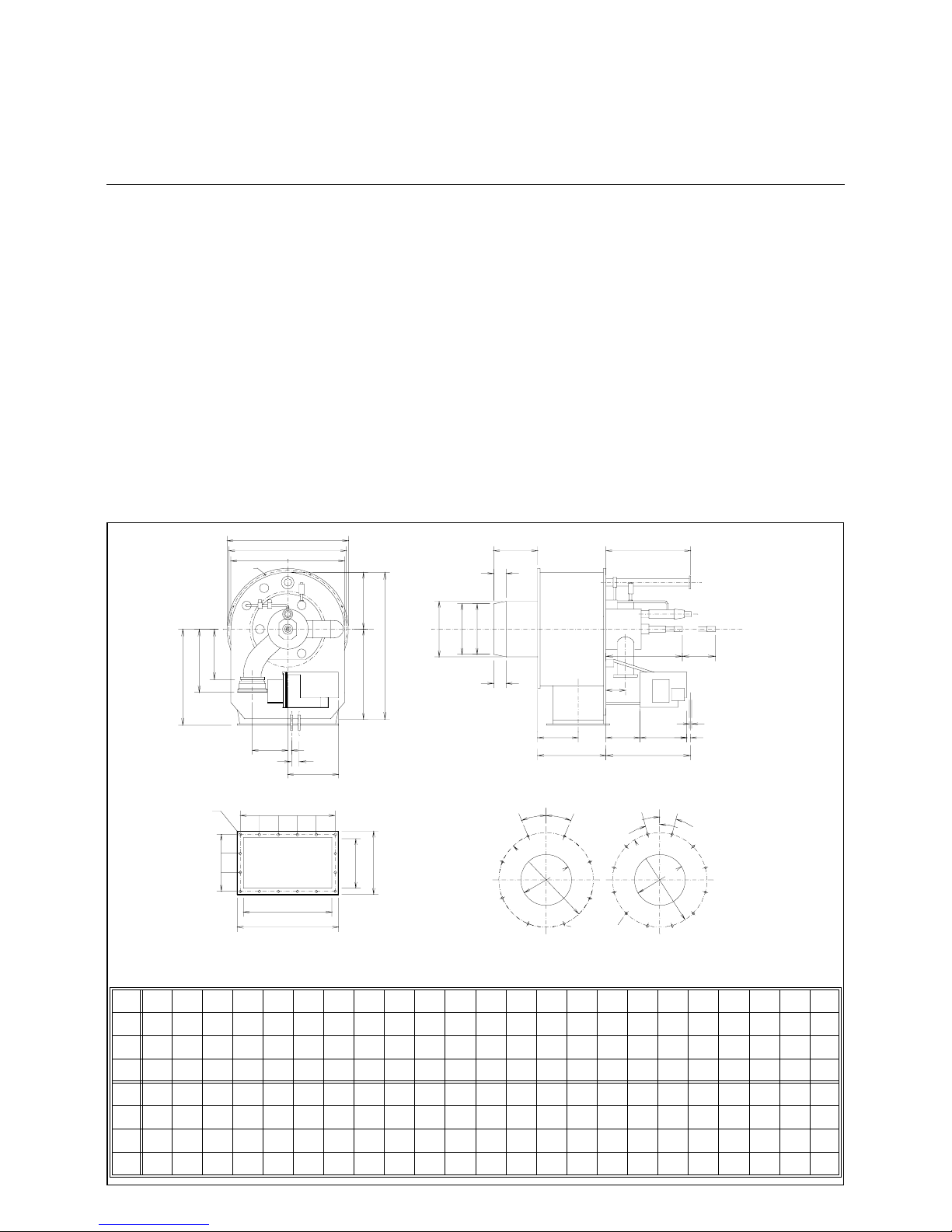

Technical Data Sheet

Duoblock Dual Fuel Burner

Feld52:

RPD 90 / 100 GL-R / GS-R

42000

45000

7000 7000

0

5000

10000

15000

20000

25000

30000

35000

40000

45000

50000

RPD 90 RPD 100

kW

Technical Data

Fuel flow rate (light oil)

Gas flow rate

Operating mode

Fuel type

Automatic burner cont roller

Flame sensor

Ignition burner

Ignition transformer

Pump output at 35 bar

MAT oil control block

Oil connection

Nozzle rod

Nozzle

Actuator

Gas connection

Weight

Pressure loss in mixing unit

Gas control organ

Burner output

Output range

7000 - 42000 kW

RPD 90

590 - 3540 kg/h

700 - 4200 m³/h

fully modulating

Light oil / heavy oil / natural gas / special fuels

LFL 1. , LGK 16 or other approved models

QRA 2, QRA 53 or other approved models

MAT / Hegwein ZNVL (ZT0)

D-52 L5 KV

Z112 K5

8900 l/h

SRB 19000/90

R 1" / 28 mm

MAT

MAT - MK 50

WAN 5 A

R 8"

1400 kg

30 mbar or according to diagram

according to gas pressure

(MAT ignition burner)

(Hegwein ignition burner)

7000 - 45000 kW

RPD 100

590 - 3800 kg/h

700 - 4500 m³/h

9500 l/h

SRB 19000/90

R 1"/ 28 mm

MAT

MAT - MK 50

WAN 5 A

R 8"

1450 kg

Technical Data Sheet

Duoblock Dual Fuel Burner

RPD 90 & 100 GL-R / GS-R

Page 9

9

RPD 90 & 100 GL-R / GS-R

Description

Dimensions

Operating mode

Fully automatic for ced drau ght dual fuel

burner, safety equipment according to

EN 267 and EN 676, especially designed for high turn down ratios.

Electric design

Burner pre-wired and ready to connect. All burner components wired to

the burner terminal rail. Burner control

box supplie d loose for installation in

separate contr ol panel. Separate fitted

oil pump assembly.

Combustion air

Separate combustion air blower with

stable and p ulsation-free characterist ics

also on appli ances with a high flue gas

resistance. The combustion air volume

is divided into a primary and a secondary stream. The flame shape may be

adapted by adjustable twist dampers.

Control systems

oil side: adjustable by means of return

flow system with compound controller

and spill back nozzle.

gas side : fuel throughput controlled by

compound controller with adjustable

cam disc and gas inlet butterfly valve.

air side : by means of compound controller with adjustable cam discs for primary air (air dampers) and secondary

air (air cylinder).

Monitoring system

Flame monitoring by means of flame

sensor and tested burner control box.

Combustion air monitoring achieved

through differential air pressure switch,

resp. speed control switch in cas e of

burner with speed control regulation.

Ignition

Direct electric high voltage ignition,

5000 V, by means of an inbuilt ignition

burner.

D

4

L6 50%

G

L4 100%

RPD 20 - 60

P1

P2

Y

B1

444

X

Z

T1

B2

P

4

P

3

H

2

D1

H

3

H

4

T

2

T

3

V

D7

A1

D2

D

5

1

0

0

%

D

6

5

0

%

H

1

B3 B4 B5W

15°

D2

D3

15°

B6

D2

Stift M

Gewinde

Länge K

D3

B8

Bohrungen Kesselplatte

22,5 °

22,5 °

RPD 70 - 100

U

L1

R

T

L5

RPDA1B1B2B3B4B5B6B8D1D2D3D4D5D6D7 G H1H2H3H4 K L1L4

90 1700 75 3 420 375 75 870 890 1800 1750 883 870 675 - 18 810 905 850 1755 1100 30 745 190

100 1700 75 3 420 375 75 870 890 1800 1750 935 922 830 - 18 810 905 850 1755 1100 30 745 190

RPD L5 L6 M P1 P2 P3 P4 R T T1 T2 T3 U V W X Y Z LB C FI F2 F3

90 2585 - 12 1300 1390 742 832 2720 224 310 832 620

28x1,5

8" 494

6x132

10x135

10 - - - - -

100 2585 - 12 1300 1390 742 832 2720 224 310 832 620

28x1,5

8" 494

6x132

10x135

10 - - - - -

set screw M

length K

Details of boiler front plate

Page 10

10

Burner Construction

1 Secondary air pressure switch

2 Ignition gas valve group

4 Inspection glasses

5 Terminal box

6 Gas flow rate control damper

7 Secondary air connection

11 Primary air damper

12 Sleeve

13 Combustion air for ignition burner

14 Flame monitor

15 Gas feed pipes

16 Air guide valve

17 Gas nozzles

18 Nozzle

19 Turbulator

20 Flame tube

21 Burner tube

23 Secondary air control valve

24 Extracting assembly

26 Burner housing

27 Ignition burner

28 Nozzle rod

29 Oil pressure switch

30 Oil flow rate controller

32 Electric actuator

Combustion air connection

The combustion air connecti on (Item 7)

may be mounted at intervals of 45° for

the RPD 30-60 version and 30° for the

RPD 70-90 ver s ion. The burner equipment plate with control block and all valves and instruments will be retained in

the vertical position in any case.

13 2 1 14 19 18 20 21 23 26 24 28 27

12

11

4 17 16 15

5 6 29,30 7 32

Page 11

11

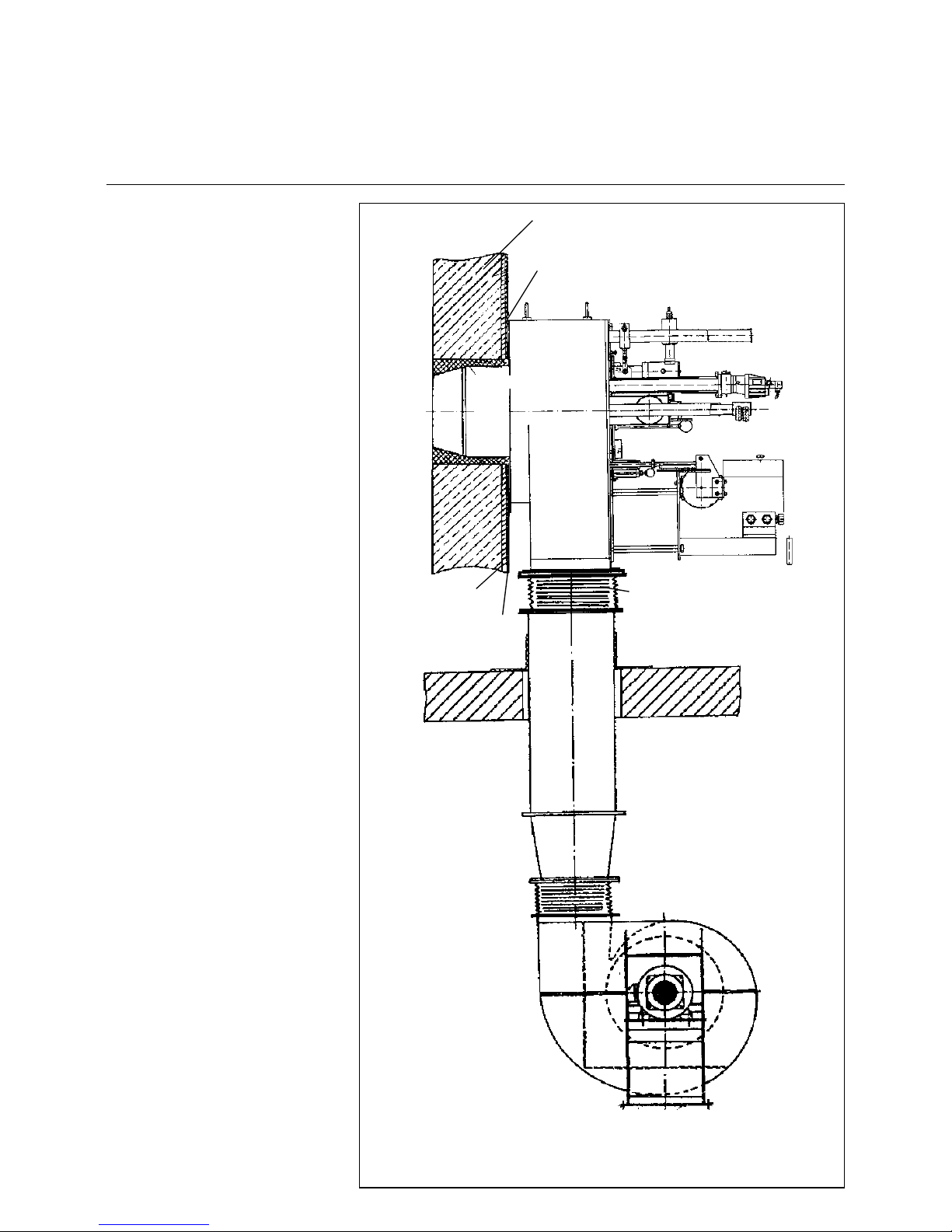

Mounting the Burner to the Boiler

The burner plate of the boiler must be

fabricated to the specified dimensions.

Mount the burner to the boiler with its

insulation backing. Apply a layer to graphite or similar lubri cant to the bo lts and

tighten by equal amounts. Mixing ignition units extended in length are available for boilers requiring a specifi c

installation depth of the burner flame

tube.

Refer to the drawing for the mounting

dimensions of the burner and air duct

and exhaust gas connection, if any.

Boiler lining

The boiler lining must consist of heatresistant materials (temperature resistance >1400°C).

Take care that the burner flame tube is

covered by the boiler lining over its full

lenght.

The space between the burner flame

tube and lining is packed with mineral

wool.

Burner mounting inspection

1. Check the mixing ignition unit

according to the boiler output.

2. Adjust the pilot burner.

3. Refer to the dimensioned drawing

for adjusting the mixing ignitio n

unit.

Boiler lining

Burner flange sealing

Mineral wool

Burner

Insulation

Boiler plate

Mounting bracket

Textile compensator

Air duct

Combustion air fan

Baseframe to anti-vibration mounting

Page 12

12

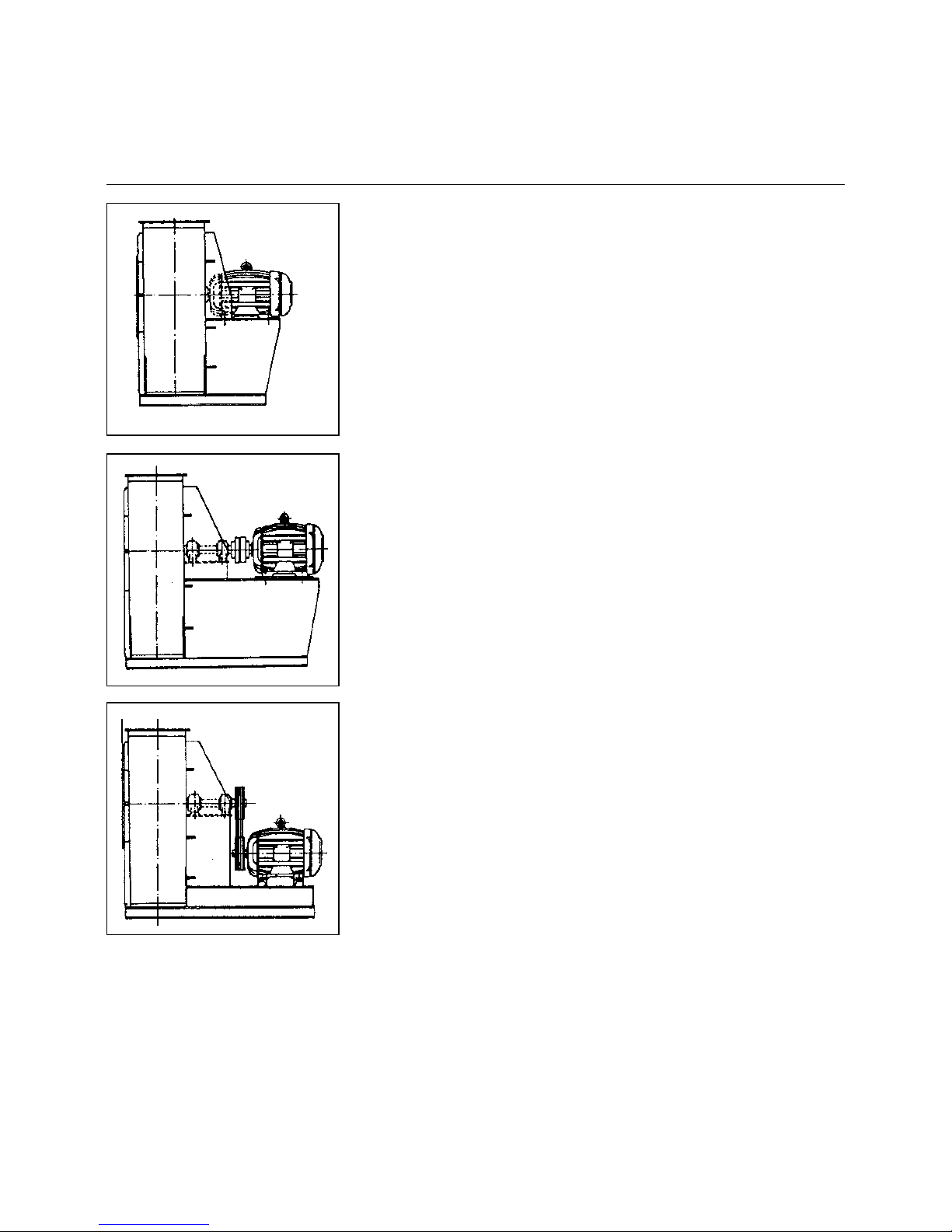

Combustion Air Fan

Drive Modes

1. Direct dr ive

In this concept the motor is coupled

directly to the fan impeller. The fan

impeller is mounted directly on the

motor shaft end. The speeds used are

those of the drive motors only. The bearing of the motor shaft must be specifically designed for the fan impeller used.

Recommendation: up to 10 MW output

2. Drive via flexible coupling

The fan impeller is mounted on its own

shaft by means of a bea rin g sp ec ific al ly

designed for the purpose. The powe r is

transmitted from the drive motor via a

torsionally flexible coupling. The speeds

used are those of the drive motor.

3. V-belt drive

The fan impeller is mounted on its own

shaft by means of a bea rin g sp ec ific al ly

designed for the purpose. The powe r is

transmitted from the drive motor via Vbelts which can provide practically any

desired speed.

Air duct and fan

Baseframe: Pre-mount exactly.

Do not prestress for

mounting.

Direction of rotation: Check for proper

direction of

rotation.

Fans with V-belt drive should be chekked for V-belt tension after about 12

hours of operation and the V-belts

retensioned if necessary. If the V-belts

are not properly tensioned this will

cause slip with resultant lower speed

and a considerably reduced service life.

Mount the air ducts in a way to ensure

an accurate and reliable fixing of the

fan. Connect the air duct by mean s of a

compensator to avoid transmission of

stress. The air ducts are made from 3-4

mm metal sheet.

Page 13

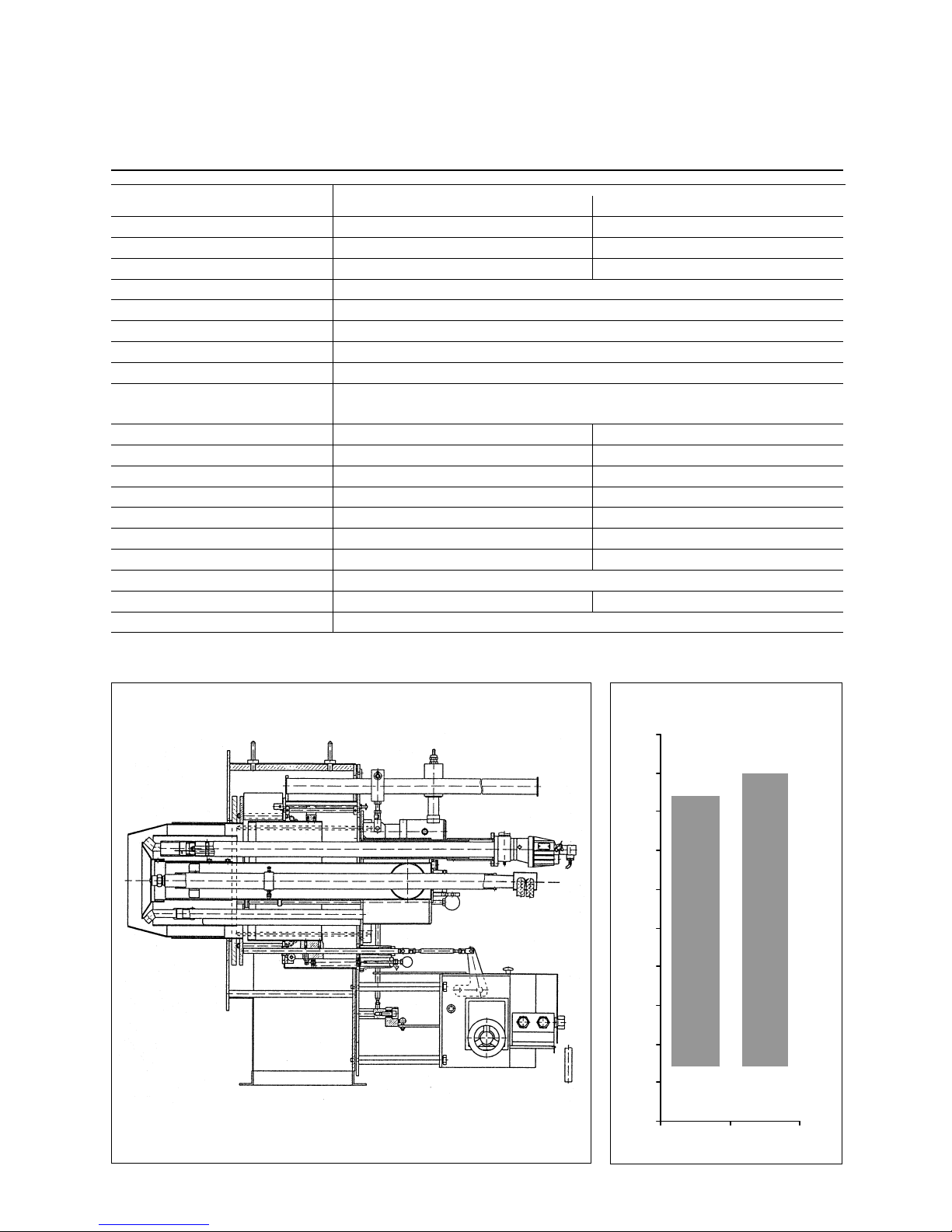

13

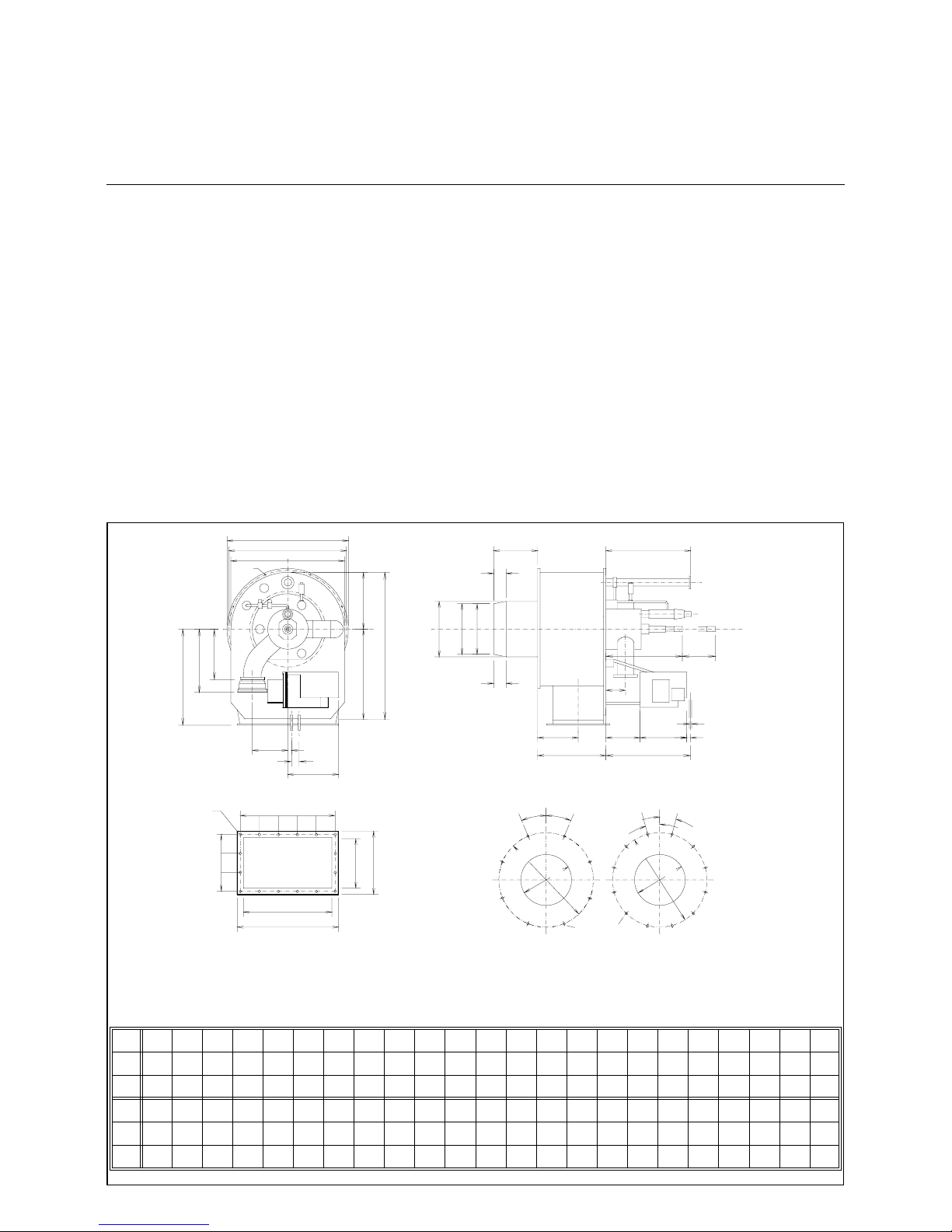

Dimensioned Drawing for RPD Burner 20 - 100

Oil, Gas and Dual-fuel Burners

(without external exhaust gas return)

Boilerplate holes

Set screw M

Lenght K

Attention for burners type U

Mixing unit see on separate

sheet

Page 14

14

Dimensions of RPD Burner 20 - 100

Oil, Gas and Dual-fuel burners

(without external exhaust gas return)

*) Note: If longer flame tubes are used, the extended lenght must be

added to the dimensiones G, R, L5

**) D4 = burner tube outside diameter

***) Flange acc. to DIN 2631 for RPD 20 to 70, and acc. to DIN 2633 for RPD 80, 90 and 100

RPDA1B1B2B3B4B5B6B8D1D2D3D4D5D6D7 G H1H2H3H4 K L1 L4L5

**)

100% 50%

*)

MAT

RDG

1250

10 0% *)

20

530 53 29 90 314 91 560 325 530 500 270 260 210 - 12 250 385 265 650 425 30 465 - 68 780

30

745 78 19 260 375 70 705 416 830 790 385 371 290 323 17,5 317 620 373 993 650 30 550 700 124 1350

40

745 78 19 260 375 70 705 416 830 790 423 409 340 367 17,5 442 620 373 993 650 30 550 700 95 1425

50

950 78 19 315 375 70 760 535 1030 990 470 456 380 410 17,5 370 675 475 1150 740 30 600 770 110 1620

60

994 78 19 315 375 70 760 622 1080 1040 520 506 420 455 18 312 700 497 1197 825 30 650 735 125 1695

70

1160 78 19 315 375 75 765 731 1240 1200 640 626 520 565 18 469 780 580 1360 900 30 740 - 170 1995

80

1350 75 19 315 375 75 765 860 1450 1400 740 710 597 646 18 600 820 675 1495 1000 30 700 - 185 2285

90

1700 75 3 420 375 75 870 890 1800 1750 883 870 675 - 18 810 905 850 1755 1100 30 745 - 190 2585

100

1700 75 3 420 375 75 870 890 1800 1750 945 922 830 - 18 810 905 850 1755 1100 30 745 - 190 2585

RPD L6 M P1 P2 P3 P4 R S1 S2 T T1 T2 T3 U DN W X Y Z

50% *) ***)

20

- 10 430 510 236 316 - - - 112 150 240 -

18x1,5

50 190

2x1 43 4x1 20

10

30

62 12 580 670 320 410 1265 140 497 160 192 491 346

22x1 ,5

80 248

4x92 5x1 26

10

40

50 12 580 670 320 410 1265 140 497 160 192 491 346

22x1 ,5

80 248

4x92 5x1 26

10

50

55 12 740 830 416 506 1743 115 595 181 250 530 376

22x1 ,5

125 319

3x1 52 5x1 56

10

60

62 12 750 840 470 560 1760 195 622 181 270 555 401

22x1 ,5

125 379

4x1 29 5x1 60

10

70

85 12 936 102 6 600 690 2010 270 705 181 365 610 450

28x1 ,5

125 410

5x1 28 7x1 40

10

80

92 12 1102 1192 700 790 2320 310 800 187 310 707 495

28x1 ,5

200 489

6x1 25 9x1 28

10

90

- 12 1300 1390 742 8 32 2720 240 845 224 310 832 620

28x1 ,5

200 494

6x1 32 10x 135

10

100

- 12 1300 1390 742 8 32 2720 240 845 224 310 832 620

28x1 ,5

200 494

6x1 32 10x 135

10

Page 15

15

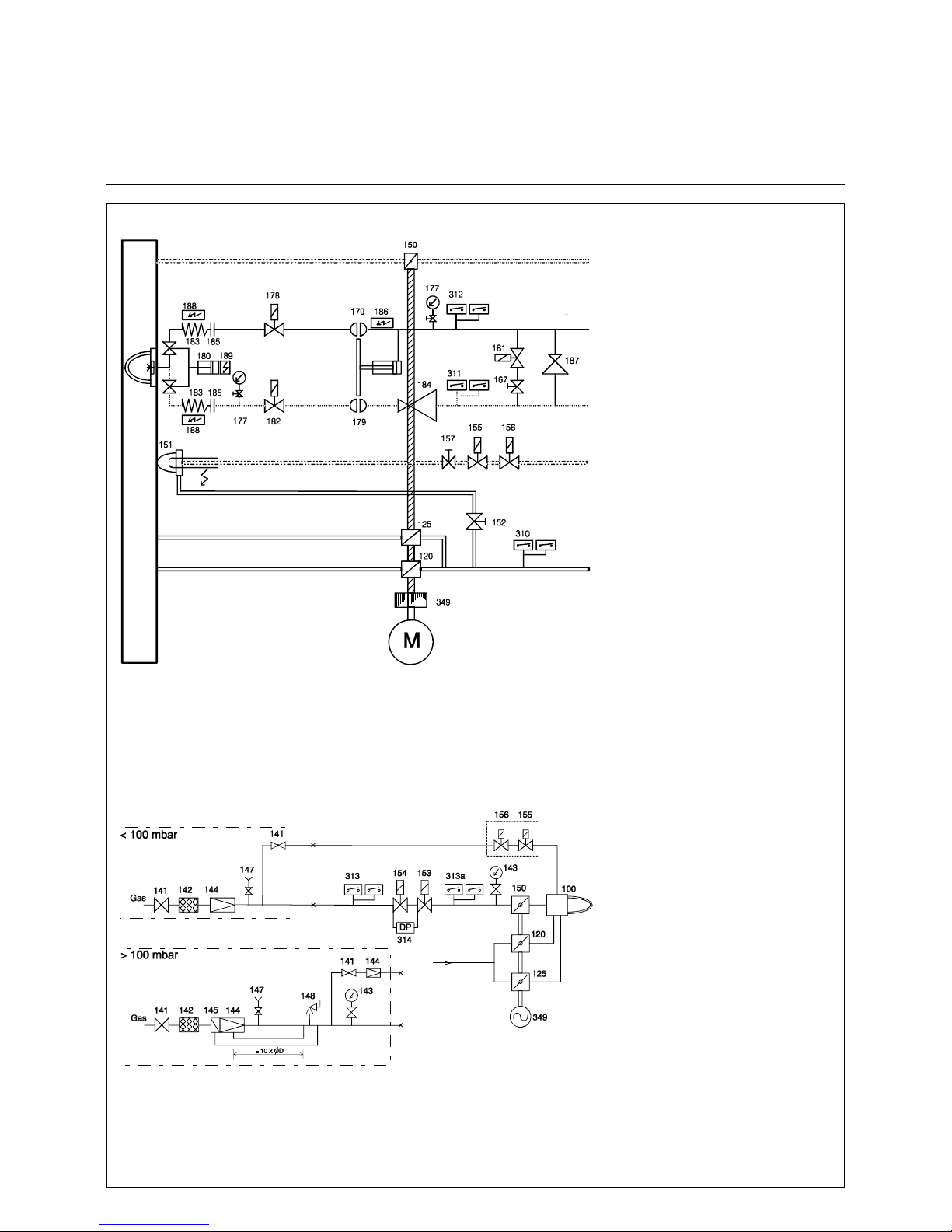

Burner scheme

Gas train

RPD 30, 40 and 50 GL - R / GS - R

TRD 604 - 72 hr :

The 310, 311,312, 313, 313a pressure switches are approved in dual mode or under the

code of "special construction requirements",

the solenoid valve RL (182) in the return line

is required.

TRD 604 - 24 hr :

The 310, 311, 312, 313, 313a pressure switches are designed in single mode. The solenoid valve RL (182) is built in if the return

flow pressure / ring line pressure exeeds 1

bar.

EN :

The 310, 311, 312, 313 pressure switches

are designed in single mode.

The 313a max. pressure switch is not available. The solenoid valve RL (182) is required.

Electrical heating cartridges for the oil bloc,

the nozzle rod and the hoses are used with

heavy oil burner versions only.

Always 1x178 und 1x182 electrical connected

in-line

100 Burner

120 Secondary air cylinder

125 Primary air damper

141 Ball valve

142 Gas filter

143 Pressure gauge with manual valve

144 Pressure governor

145 Safety shutt-off valve

147 Test burner w. push button valve

148 Safety blow off valve

150 Gas butterfly valve

151 Ignition burner lance

152 Air regulating valve

153 Main gas solenoid valve

154 Safety shutt-off solenoid valve

155 Ignition gas solenoid valve

156 Ignition gas solenoid valve

157 Gas regulating valve

167 Ball valve

177 Pressure gauge with manual valve

178 Oil solenoid valve, feed line(115 V)

179 Hydraulic shut-off valve

180 Nozzle assembly with shut-off valve

181 Solenoid valve, oil circulation

182 Solenoid valve, return line (115 V)

183 Oil hoses

184 Pressure regulator return line

185 Coupling

186 Electrical cartridge heater, oil bloc

187 Pressure regulator feed line

188 Trace heating, oil hoses

189 Trace heating, nozzle rod

310 Air pressure switch

311 Oil pressure switch, return line

312 Oil pressure switch, feed line

313 Gas pressure switch, low

313a Gas pressure switch, high

314 Gas leakage control

349 Mechanical compound controller

Burner scheme TRD 604 - 72 h

gas

oil feed line

ignition electrodes

oil return line

air

primary air

secondary air

ignition gas

Gas train TRD 604 - 72 h

air

secondary

primary

Page 16

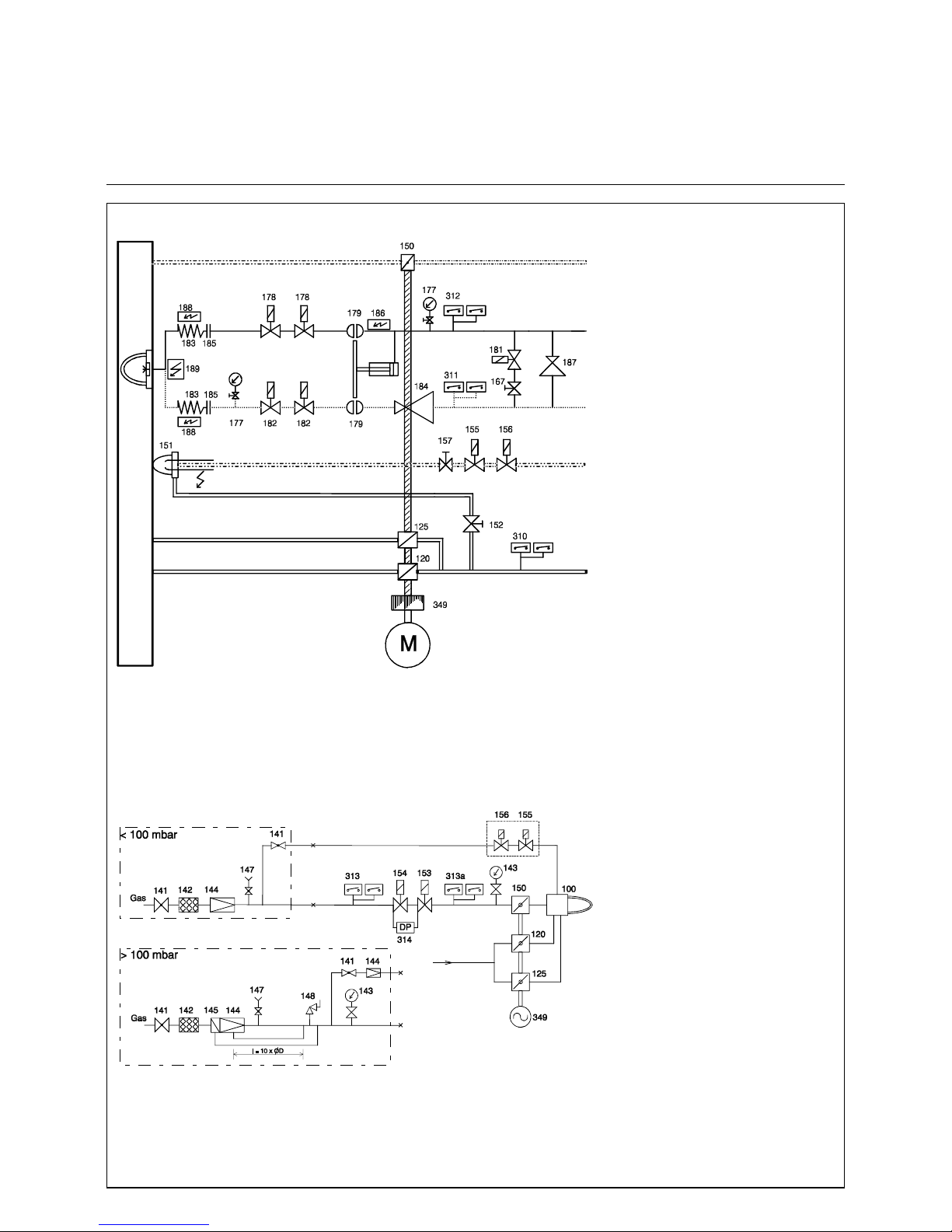

16

Burner scheme

Gas train

RPD 60 - 100 GL - R / GS - R

TRD 604 - 72 hr :

The 310, 311,312, 313, 313a pressure switches are approved in dual mode or under the

code of "special construction requirements",

the second solenoid valve RL (182) in the

return line is required.

TRD 604 - 24 hr :

The 310, 311, 312, 313, 313a pressure switches are designed in single mode. The

second solenoid valve RL (182) is built in if

the return flow pressure / ring line pressure

exeeds 1 bar.

EN :

The 310, 311, 312, 313 pressure switches

are designed in single mode. The 313a max.

pressure switch is not available. Both solenoid valves RL (182) are required.

Electrical heating cartridges for the oil bloc,

the nozzle rod and the hoses are used with

heavy oil burner versions only.

Always 1x178 und 1x182 electrical connected

in-line

100 Burner

120 Secondary air cylinder

125 Primary air damper

141 Ball valve

142 Gas filter

143 Pressure gauge with manual valve

144 Pressure governor

145 Safety shutt-off valve

147 Test burner w. push button valve

148 Safety blow off valve

150 Gas butterfly valve

151 Ignition burner lance

152 Air regulating valve

153 Main gas solenoid valve

154 Safety shutt-off solenoid valve

155 Ignition gas solenoid valve

156 Ignition gas solenoid valve

157 Gas regulating valve

167 Ball valve

177 Pressure gauge with manual valve

178 Oil solenoid valve, feed line (115 V)

179 Hydraulic shut-off valve

181 Solenoid valve, oil circulation

182 Solenoid valve, return line (115 V9

183 Oil hoses

184 Pressure regulator return line

185 Coupling

186 Electrical cartridge heater, oil bloc

187 Pressure regulator feed line

188 Trace heating, oil hoses

189 Trace heating, nozzle rod

310 Air pressure switch

311 Oil pressure switch, return line

312 Oil pressure switch, feed line

313 Gas pressure switch, low

313a Gas pressure switch, high

314 Gas leakage control

349 Mechanical compound controller

Burner scheme TRD 604 - 72 h

gas

oil feed line

ignition electrodes

oil return line

air

primary air

secondary air

ignition gas

Gas train TRD 604 - 72 h

air

secondary

primary

Page 17

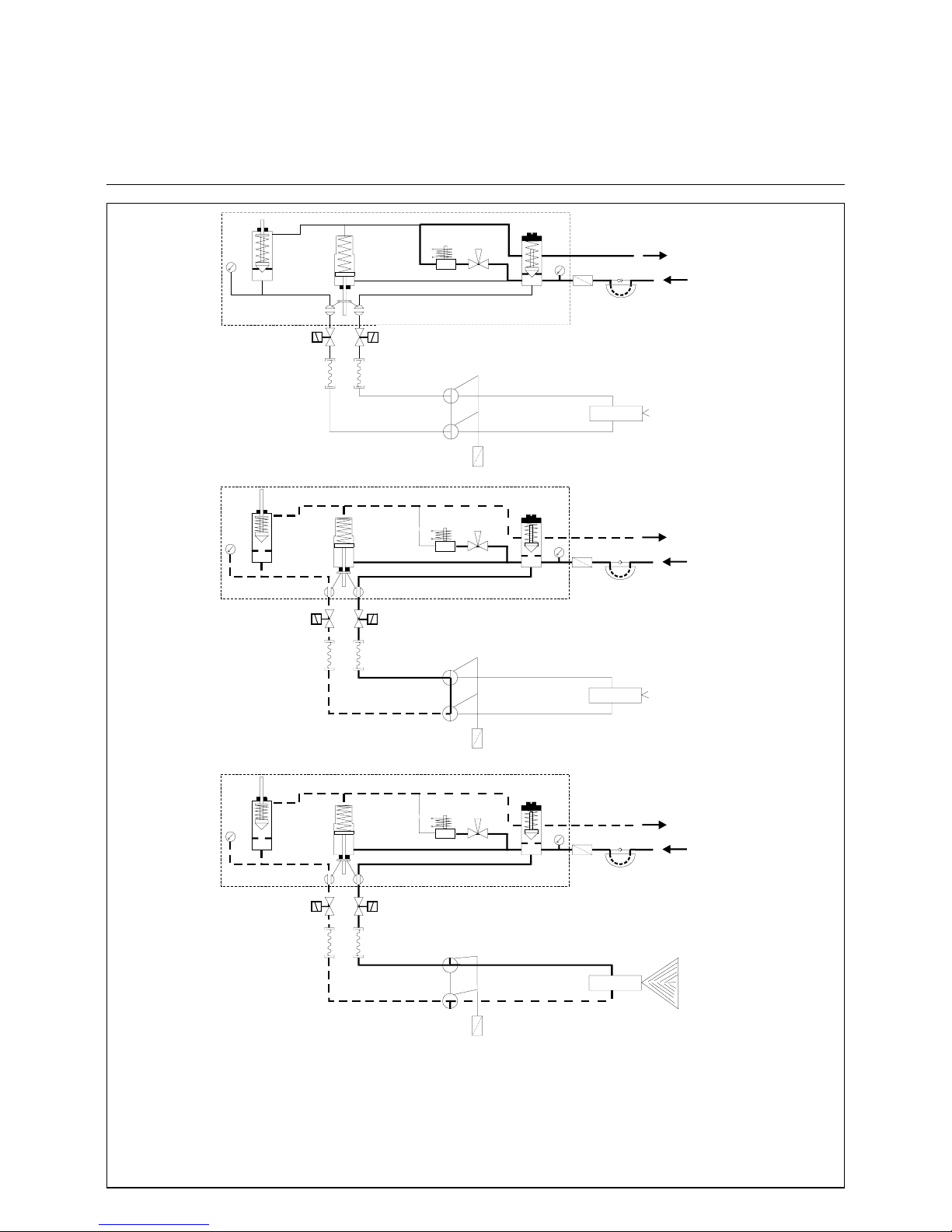

17

Hydraulic Scheme

RPD 30 -50

Oil Control Block and Nozzle Rod DG 75

11

12

12

14

14

16

16

13

15

8

10

9

7

6

5

4

3

2

1

11

12

12

14

14

16

16

13

15

8

10

9

7

6

5

4

3

2

1

11

12

12

14

14

16

16

13

15

8

10

9

7

6

5

4

3

2

1

Oil circuit at burner stand by

(Zirkulation)

Oil circuit at burner pre-purge

Oil circuit at burner operation

1. Oil pressure pump

2. Safety valve

3. Oil filter

4. Pressure gauge (feed line)

5. Oil regulating valve

6. Manual valve (for bleeding)

7. Circulating valve

9. Hydraulic cylinder for ball valves

10. Oil regulating valve, return line

11. Pressure gauge (return line)

12. Ball valve

13. Inner nozzle oil line assembly

14. Solenoid valves

15. Return nozzle

16. Pressure hoses

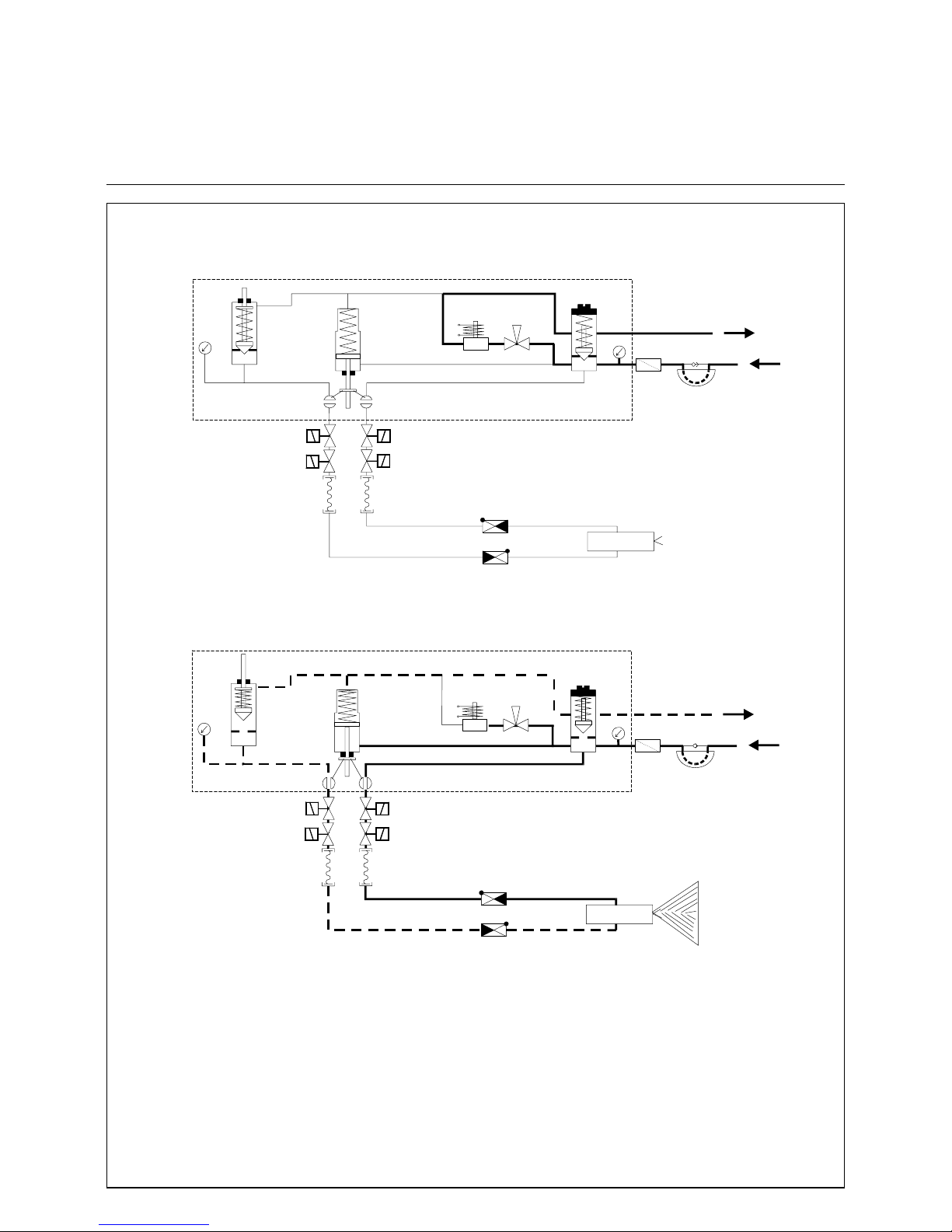

Page 18

18

Hydraulic Scheme

RPD 30 -100

Oil Control Block and Nozzle Rod MAT

11

12

12

14

14

14

14

16

16

15

17

17

17

17

13

10

9

7

6

5

4

3

2

1

11

12

12

10

9

7

6

5

4

3

2

1

14

14

14

14

1616

15

13

Oil circuit at burner stand by

(Zirkulation)

Oil circuit at burner operation

1. Oil pressure pump

2. Safety valve

3. Oil filter

4. Pressure gauge (feed line)

5. Oil regulating valve

6. Manual valve (for bleeding)

7. Circulating valve

9. Hydraulic cylinder for ball valves

10. Oil regulating valve, return line

11. Pressure gauge (return line)

12. Ball valve

13. Inner nozzle oil line assembly

14. Solenoid valves

15. Return nozzle

16. Pressure hoses

17. Non-return valves

Page 19

19

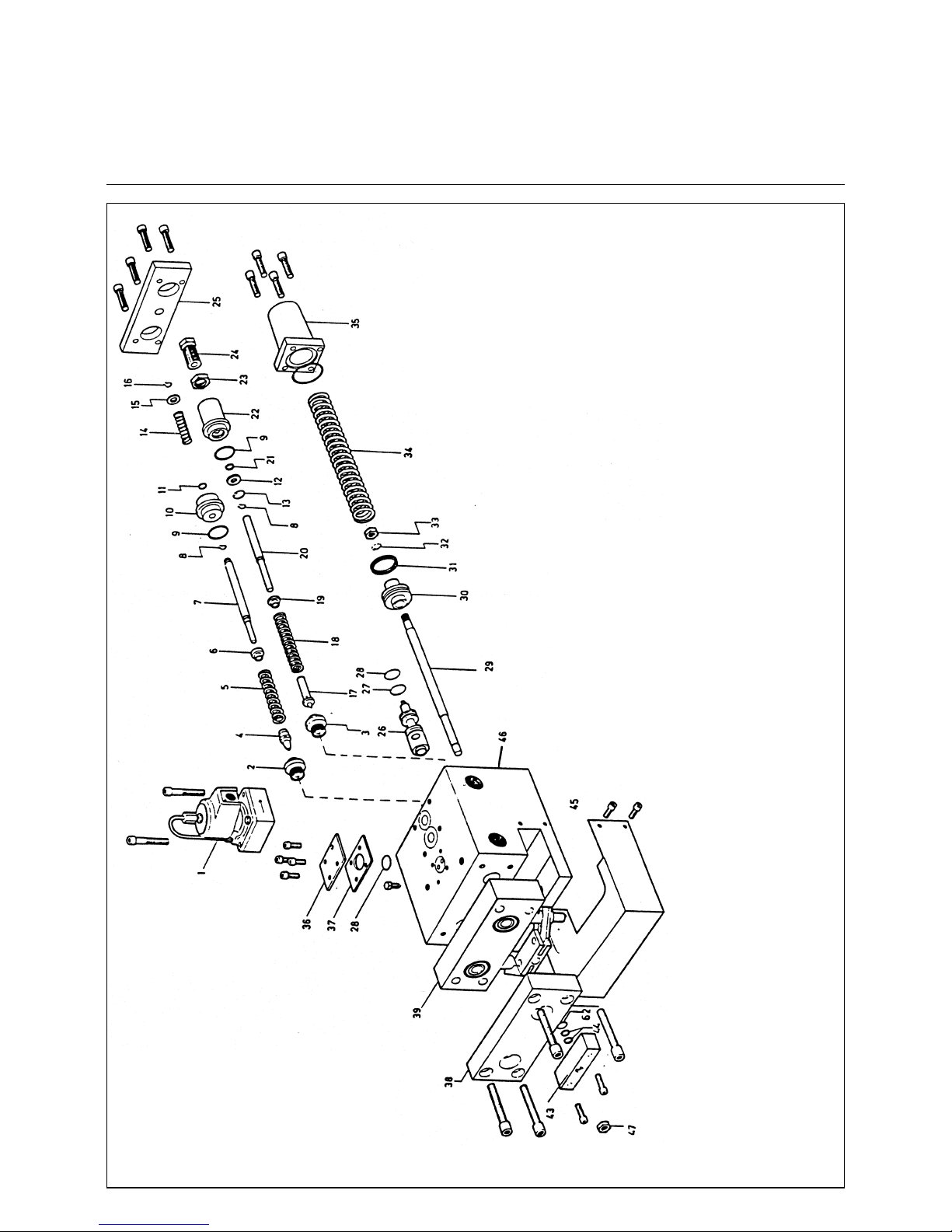

1. oil solenoid valve circulation

2. oil regulating valve return flow

3. oil regulating valve bloc inlet pressure

4. regulating needle

5. spring

6. washer

7. shaft

8. surclip

9. O- ring seal N. 19

10. bush gland

11. gasket

12. washer

13. surclip

14. spring

15. washer

16. surclip

17. regulating needle

18. spring

19. washer

20. shaft

21. gasket

22. bush gland

29. shaft

30. piston

31. gasket

32. lock washer

33. nut M8

34. spring

35. spring cover

36. cover plate

37. aluminum washer

38. valve flange

39. double blocking valve

40. outer shaft ring

41. washer

42. fixing ring

43. valve cover

44. O ring gasket

45. cover

46. block body

47. nut M8

Oil Control Block

Page 20

20

Mounting Position

Leak Test

Ignition Gas Connection

Ignition Burner Type ZT0

Mounting position

Gas pressure regulator s and valves can

be mounted in vertical lines in any position within the 360° range. In horizontal

lines they must not be mounted overhead and only 180° in the upper se cto r.

The ball valve and filter can be mou nted

in any desired position. Take care that

the housing does not m ake c ont act w ith

the wall and is clear by minimum 20

mm. Do not use the spring bolt of the

regulator and the solenoid elements of

the valves as levers.

Leak test

Check the screwed joints and flanged

connections for absence of leaks. The

leak test of the joints should be made

under pressure using only foaming

agents approved by DVGW and not

causing corrosion.

Electrical wiring of gas valves

Check that the data given on the nameplate of the gas valves agree with the

mains voltage.

Open the terminal box of the valve.

Feed the connection cable through the

screwed union (condui t thr ead Pg 13 .5)

and connect the terminals marked

accordingly.

L = phase

N = zero conductor

= protective conductor

(green-yellow)

Disconnectable joint

An easy-to-disconnect joint with flat

sealing (e.g. compensator) should be

provided to allow the boiler door to be

swivelled out if required for maintenance work on the boiler (furnace

chamber). Th is compensator should

also be designed to accommodate the

axial or lateral expansion and absorb

vibrations.

Ignition gas connection

An ignition burner is used to ignite the

main gas flame. The ignition gas line is

branched out of the gas control group

between the two gas valves and installed to the ignit ion bu rner on the s hortes t

possible way. In the case of oil and

dual-fuel burners the burner is ignited

with propane supplied through a separate R „ propane connection. The ignition gas flow rate may be adjusted on

the volumetric flow control valve of the

ignition gas valve or directl y on the ign ition gas burner. The required gas pressure for the ignition gas burner is 50150 mbar . It is ad vis ab le to ins t all a gas

pressure regulator upstream of the ignition gas burner . Th e air pres sure for the

ignition gas burner should be between

10 and 30 mbar. The boi ler back pressure shall not be taken into account.

The air pressure should be adjusted in

accordance with the gas pressure to

ensure an undelayed ignition and a

good flame pat tern.

1 Transformer unit with bui lt-i n

ignition transformer

2 Electrical angular plug connector

3 Gas connection, may be

connected on either side right and

left with gas test socket

4 Air connection, mounted to

transformer unit

5 Air test socket

6 Igniter tube, mounted to air flange

7Spacer ring

8 Ignition electrode connection rods

9 Gas tube

10 Ignition electrode connection rods

11 Gas nozzle for natural gas or

propane

12 Mixing chamber

* The outside diameter will be 50 mm for

tube lengths above 4000 mm and for all

high-grade steel tubes.

Mounting f lange

View A

Gas RP1/2

normally left

Air Rp1

Ignition Burner Type ZT0

Page 21

21

Ignition Burner Type ZT0

Technical Data

Construction according to sectional

drawing

The igniter consists mainly of the transformer unit (Item 1) housing the ignition

transformer , the ignit er tube with a ir and

mounting flange (Item 6 ), a gas tub e (9)

with nozzle (11) and the electrode carrier ring (10). The igniter tube with the

Rp1 air connection is bolted to the

transformer unit. After the 4 bolts (Item

4) have been unscrewed it may be

removed or turned by 90° if required by

the position of the air connection. When

turning the tubes care must be taken

not to change the position of the inner

supporting rings and rods because this

might lead to operational trouble.

The gas supply may be connected either to the left-hand or right-hand opening. The opening not used is closed

with a screw plug which al so car ries the

screw-in gas test socket (3). The electrode support ring (Item 10) is mounted

to the end of the gas tube.

The ionization electrode and ignition

electrode are extended with conn ec tin g

rods (Item 8). These rods are installed

through the bottom of the transformer

housing in 2 ceramic insulators and carried by intermediate supporting rings

(Item 7) spaced at 300 mm.

Flame moni tor

An ionization electrode is provided for

flame monitoring. The flame signal is

generated by d.c. current which due to

the ionization effect and the rectifier

effect of the flame is caused to flow from

the igniter tube earth via the flame to

the ionization electrode and via the connecting rod to the amplifier in the automatic furnace controller. The ionization

electrode and ignition electro des ar e

adjusted in accordance with the dra wing.

When installing new electrodes these

must be bent, cut to len gth and adjusted

as required.

The internal resistance of the ionization

system amounts to some megohms.

Such a high resistance ensures a good

insulating capacity of the electrodes and

connecting rods. In a dust-laden combustion air environment it is therefore

important to clean t he ins ulators a t shorter intervals. Humidity should be kept

out. See also electrical function.

The ceramic insulator of the ionization

electrode must not be allowed to heat

up above 500 °C because this could

lead to shutdown on tro ubl e. Therefore,

a minimum air flow rate (10-20 % of the

full-load rate) should be allowed to flow

if this temperature is likely to be reached by radiation or convection with the

furnace chamber in hot condition and

the burner flame turned off.

Technical data of ignition gas burner type ZT0

Fuel gases according to G 260

Flame power max. 120 kW

Flame length max. 600 mm

Gas connection Rp 1/2 right or left

Air connection Rp 1, may be turned by 4x90°

Air flow rate max. 50 m³/h

Air index 0.3-0.5; remaining air rate must be available from furnace chamber

Max. ambient

temperature 500°C in tube; if temperature is higher, keep combustion air

connected partly as cooling air; 0°C to +60°C in transformer unit

Transformer unit

Connection voltage 230 V, 50 Hz

Connector type plug connector

Power input ignition transformer 100 VA, 20% duty cycle (with thermal winding shield)

ignition 5 kV (2-3 seconds via automatic furnace controller)

Ambient temperature 0°C to +60°C

Degree of protection IP 54

Electrical connection

Cl. 1 (Mp)

Cl. 8 (Ph) ignition transfer, primary Use shielded cable Z 912 F 00 for flame feedback.

Cl. 10 ionization signal NOTE: The shield must not make contact with earth.

Page 22

22

Ignition Burner Type ZT0

Gas Pressure Adjustment

Parts List

Gas pressure adjustment

In standard version the igniters are suitable for a working range 50-150 mbar.

If a higher gas pressure is required in

the customer's order, the two threaded

gas inlet connections will be fitted with

restrictors by the manufacturer already.

The igniter will in this way be adjusted

to the pressure above 150 mbar.

If the higher inlet pressu re is recogniz ed

at a later stage only, a restriction to

maximum 150 mbar can also be achieved by means of a ball valve, for

example.

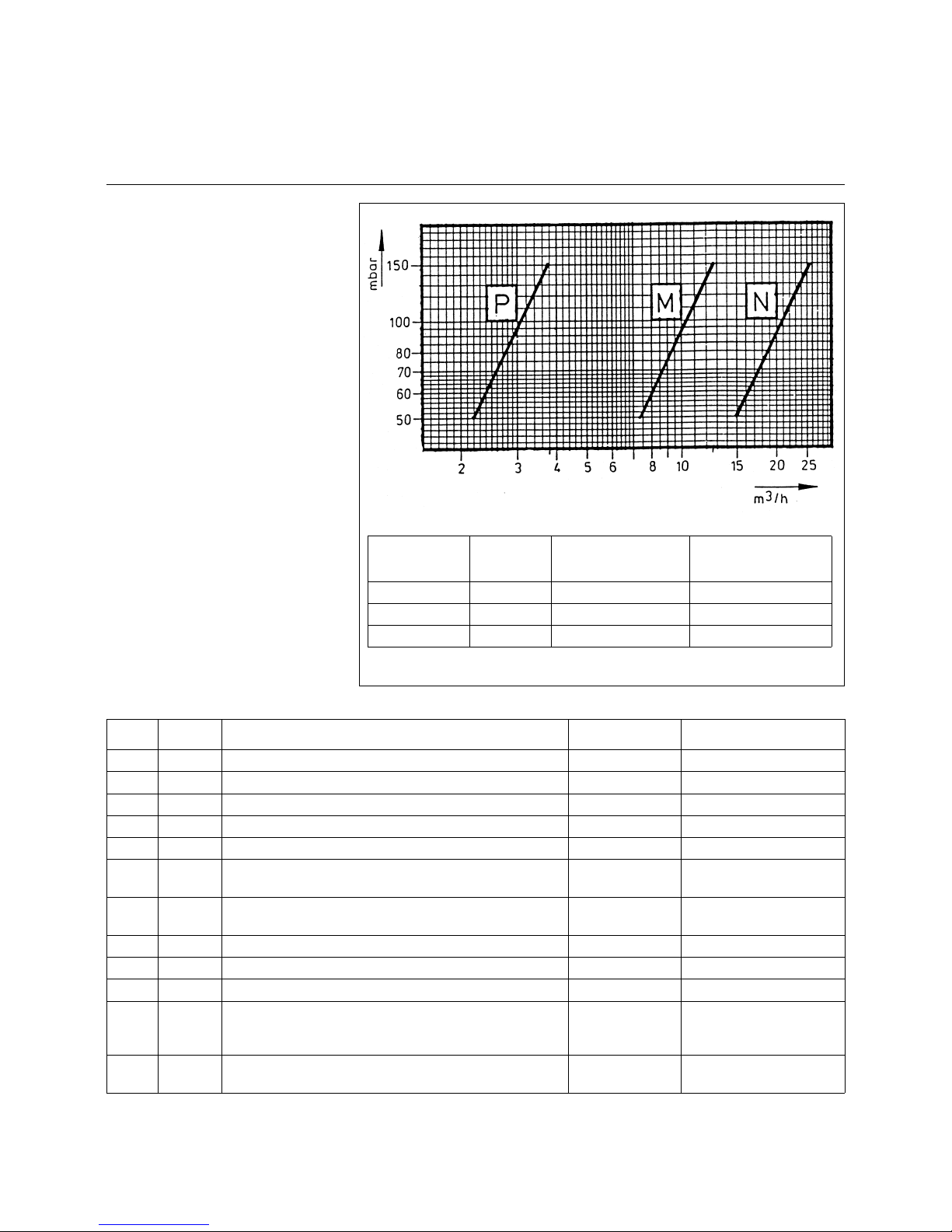

Characteristic

line Gas type Nozzle holes Flame length

P Propane 1x2,5 + 6x1,0 approx. 600 mm

M Natural gas 1x4,0 + 6x1,3 approx. 500 mm

N City gas 1x5,0 + 8x2,3 approx. 500 mm

Parts list

Item. Qty. Description Part No. Material

1 1 Transformer unit Z 112 K 5 Housing of GAL

2 1 Right-angle plug with 2 unions A 5 Z 1 10-pole, max. 2.5

3 1 Gas test socket Z 138 Z 2 Ms 58

4 4 Hexagon socket head screw W 826 F 10

5 1 Air test socket Z 138 Z 1 Ms 58

6 1 Igniter tube with rolled-in mixing chamber and mounting

flange with Rp1 air inlet thread

Z 1050 Z...** GAL / steel

7 * Intermediate supporting ring with 2 ceramic insulators Z

545 F11

Z 960 K 4 St VII 23

8 2 Connecting rods Z 781 F...** Zinc-plated steel

9 1 Gas tube Z 521 F...** St 35

10 1 Electrode carrier ring Z 960 K 13 St VII 23

11 1 Gas nozzle Natural gas

Propane

City gas

Z 330 F 4013

Z 330 F 2510

Z 985 F 1

High-grade steel 1. 4104

High-grade steel 1. 4104

High-grade steel 1. 4104

12 - Mixing chamber with mixing ring Included in

Item 6

High-grade steel,

heat-resistant

* Quantity depends on pipe length: 3 intermediate rings per metre of tube length.

** Additional data according to type (tube length).

Page 23

23

Ignition Burner Settings

Electrode Carrier Ring

Front

view

Side view

110 mm for natural gas

90 mm for propane

Top view

Natural gas

Propane

Electrodes Z 707 F 3

Ceramic Z 545 F 11

Ring W 715F 101

Bush Z 789F 10

Preset amount of bend and adjustment

Cut ionization electrode to length according to gas type.

Page 24

24

Ignition Gas Solenoid Valve

Type MVD 505 / 5 single-stage

Technical data:

Nominal bore: R1/2“

Max. operating

pressure: 500 mbar

Opening time: < 1 sec

Closing time : < 1 sec

Ambient temperature:-15°C to +60°C

Mounting position: solenoid in upright

position vertical to

horizontal

Voltage/frequency: (AC) 230 V

(+10% -15%)

Duty factor: 100% CD

Degree of protection: IP 54, IP 65

Power rating: 15 VA

Main flow rate adjuster

type series MVD

Unscrew the prot ective cap a nd remove

the lock nut to allow the main flow rate

to be adjusted. The main flow rate adjuster is supplied ex works in fully opened

position.

Turning clockwise will reduce the gas

flow rate.

Turning counterclockwise will increase

the gas flow rate.

After having adjusted the flame control

on the gas burner make sure to tighten

the lock nut again. Screw on the protective cap again.

Installation

When installing the valve in the pipeline

take care to observe the arrow on the

valve housing and the required mounting position. For screwing the pipeline

into the valve housing do not use the

magnet as a lever but apply a suitable

tool against the valve housing.

After installati on ma ke a test for

absence of leaks and proper operation.

Solenoid replacement

type series MV, MVD

Disconnect the electrical termina ls ;

remove the screw cap; lift off the solenoid. For install ation proc eed in reve rse

order.

Electrical connection

Feed in the cable through cable union

(conduit thread Pg 11). Make the electrical connection by me ans of the screw

terminals in the termi nal bo x of the sole noid housing.

Take care to observe the connection

diagram.

1 Cable union

2 Electric terminal box

3 Solenoid

4Housing

5Screen

6 Valve seat

7 Connector for

earthing contact K01/1

8 Valve disk

9 Mud guard

10 Closing compression spring

11 Anchor

12 Main flow rate adjuster

13 Lock nut

14 Protective cap

Protective cap

Not

acceptable

Page 25

25

Oil Connection

Fuel Oil Supply

Oil connection

For the installation of a furnace system

care should be taken to observe the

applicable rules and regulations. When

installing an oil burner be sure to follow

the recommendations outlined for oilfired furnace systems (DIN 4787,

DIN 51603 Parts 1&2, TRD 411). DIN

4736 Parts 1 &2 describes the safety

requirements applicable to the oil supply systems of oil burners. DIN 4755

Part "Oil furnaces in heating installations (safety requirements)" outlines the

safety recommendations for oil furn ac e

systems of steam boilers.

The installer has the duty to inform

himself of the regulations applic able to

gas and oil furnace systems.

Fuel oil supply

Complete oil feeding groups are

available for the supply of the furnace systems with fuel oil. A fuel oil

supply unit may consist of ball stop

valve, suction filter , pressure gauge,

pump with coupling and threephase rnotor. All units are all finished ready for connection and

mounted with anti-vibration elements on an oil collecting tray.

The oil supply lines must be slelected in accordance with the technical

instruction sheets and installed in

line with the applicable specifications. The total pipeline length is

understood to be the length of all

horizontal and vertical lines and

bends. The maximum permissible

vacuum at the suction port of the

pump may be -0.6 bar. A higher

vacuum will lead to the escaps of

gas resulting in an unsteady delivery and damage to the pump.

All connections must be tightened

to avoid leaks. The sealing rings

used should be of copper, aluminium or plastic. In no case should

hemp or similar sealing material be

used. The pipelines must be cleaned before they are connected to

the pump.

Ring line operation

lf several burners and storage t anks are

installed in a system o r if t here is a large

distance between the burner and the

storage tank, a ring line system with

gas-air separater will be needed for

supplying the burners.

NOTE: In case of pressurized oil feed,

the suction press ure of the p ump shoul d

not exceed 5 bar. All lines must be

fixedly installe d, welded to oil-tight s tandards or connected with oil-tight unions

or flanges.

Flexible tubes are allowed only as connecting pieces between the fixed line

and the burner . The flexi ble tubes

should be installed properly (in hanging

position) and free of sharp bends.

For the installation of the flexible

tubes take care these do not get

twisted. They should not be subject

to torsional stress neither at the

stage of installation nor during subsequent movernents.

Oil pressure pump filling

Prior to initial oparation make sure to fill

the oil pressure pump and oil feed line

with oil to prevent the pump from dry

running and getting seized.

Oil filter

lt is recommended to install a filter

directly upstream of the pump to separate dirt particles contained in the oil or

any other foreign matter produced

during installat ion. When a fuel oil uni t is

mounted this will be fitted with an oil filter already.

Starting the oil pump

- Make sure all stop valves are

open.

- Check the pump for direction of

rotation.

- The safety overflow valve in the

pump is preset at 40 bar and may

be readjusted by duly authorized

specialists only.

Pressure atomizer

The oil throughput rate of the nozzle

and thus the burner output is controlled

by an oil regulator valve installed in the

return line and coupled to the actuator

and compound controller.

The oil throughput rates and oil flow

pressures downstre am of the nozzle ro d

must be set according to the applicable

nozzle characteristic.

As the oil control valve is closed or opened the oil through put rate of th e n ozzle

will be increased or reduced, respectively.

The oil pressure up stre am of th e nozz le

rod must be set at 28 bar to 30 bar.

Depending on the version this can be

can be adjusted either on the fuel oil

station or on the oil control block of the

burner.

Page 26

26

Oil Connection

Fuel Oil Supply

Oil connection

For the installation of a furnace system

care should be taken to observe the

applicable rules and regulations. When

installing an oil burner be sure to follow

the recommendations outlined for oilfired furnace systems (DIN 4787,

DIN 51603 Parts 1&2, TRD 411). DIN

4736 Parts 1&2 describes the safety

requirements applicable to the oil supply systems of oil burners. DIN 4755

Part „Oil furnaces in heating installations (safety requirements)“ outlines the

safety recommendations for oil furn ac e

systems of steam boilers.

The installer has the duty to inform

himself of the regulations applic able to

gas and oil furnace systems.

Fuel oil supply

The operational reliability of a burner

system depends greatly on the oil supply conditions.

Oil supply lines must be determined

according to the technical instruction

sheets and inst a lled b y strict adhe rence

to the applicable regulations.

All joints must be mounted with due

care to ensure they are absolute ly tight.

The sealing rings used must be made

from copper, aluminium or plastic. In no

case should hemp or a similar material

be used. Make sure to remove any dirt

from the pipelines before mounti ng

them to the pump.

Normally, a ring pipe system will be

used.

In addition to the electri c tracing l ines, a

ring pipe system for heavy oil installations comprises the following major components:

oil delivery pump,

oil filter ,

gas-air vent, and

pressure control valves.

The electric tracing lines and the tank

heaters will ensure that th e fuel oil to be

delivered is kept in a pumpable state.

An oil filter must be installed in the feed

line upstream of each burner to avoid

that dirt particles and other impurities

possibly left behind after pipe installation cannot damage the solenoid and

pressure control valves.

Steam trac ing or hot-wa ter trac ing

systems can be used instead of the

electric tracing lines.

T o av oid burner troub le due to entrain ed

air, a gas-air vent must be provided at

the uppermost position of the ring pipe

system.

The ring pipe pressure must be controlled in dependence of the fuel oil temperature.

As can be seen from the chart below,

the static pressure of the oil at 130°C

must be minimum 3 bar, for example.

Oil pressure in dependence of

operating temperature

The fuel oil withdrawn from the ring pipe

or gas-air vent is pumped to an oil preheater and on to the b urner by means of

a high-pressure pump. The return oil

from the burner is fed into the ring pipe

in any case and not directly into the

tank.

Oil pressure pump filling

Prior to initial operation make sure to fill

the oil pressure pump and oil feed line

with oil to prevent the pump from dry

running and getting seized.

Oil filter

It is recommended to install a filter

directly upstream of the pump to separate dirt particles contained in the oil or

any other foreign matter produced

during installat ion. When a fuel oil uni t is

mounted this will be fitted with an oil filter already.

Starting the oil pump

- Make sure all stop valves are

open.

- Check the pump for direction of

rotation.

- The safety overflow valve in the

pump is preset at 40 bar and may

be readjusted by duly authorized

specialists only.

Pressure atomizer

The oil throughput rate of the nozzle

and thus the burner output is controlled

by an oil regulator valve installed in the

return line and coupled to the actuator.

The oil throughput rates and oil flow

pressures downstre am of the nozzle ro d

must be set according to the applicable

nozzle characteristic.

As the oil control valve is closed or opened the oil through put rate of th e n ozzle

will be increased or reduced, respectively.

The oil pressure up stre am of th e nozz le

rod must be set at 28 bar to 30 bar.

Depending on the version this can be

can be adjusted either on the fuel oil

station or on the oil control block of the

burner.

0

1

2

3

4

5

100 110 120 130 140 150 160

Temperatur °C

Druck bar

Temperature °C

Pressure bar

Page 27

27

Medium pressure screw pumps

Installation

Commissioning

Maintenance

Medium pressure screw pumps

General

Screw pumps are rotating positive displacement pumps with strong suction,

which can be used with self-lubricating

agents.

1. Application guidelines

1.1 Shaft seals for normal versions

1.2 Pressure relief valve

This valve protects the pump against

overloading and should not be used as

a pressure control valve. This is absolutely necessary if a shut-off device is fitted in the pressure pipe. Standard

pressure setting unless otherwise required at the time of ordering. Low pressure pumps (type N) approx. 6 bar,

medium pressure pumps (type M)

approx. 40 bar or 10% above the specified operating pressure, as with Ctypes. By turning the adjustment sc rew

in a clockwise direction = pressure

increase.

2. Installation

2.1

Clean any plant parts (ensure no dirt or

loose particles in the pipes) and fi t pipes

(flange) without any stress. Observe

direction of flow as well as any possible

heat expansion of the pipes.

2.2

Ensure stress-free fitti ng of th e pump or

base frame.

2.3 Coupling

Motor and pump shafts must be aligned. Axial play between the Coupling

halves approx. 1.5 mm. It should be

possible to turn the whole unit of pump

shaft-Coupling-Motor shaft by hand.

Installation of the coupling halves: Sliding on (tapping not permitted) in heated condition (min. 100°C); Press p lastic

couplings home in cold condition.

2.4

Check direction of rotation of the motor

and the pumps a nd pro tect the moto r by

means of a motor protection switch.

3. Commissioning

3.1

The pump must not be allowed to run

dry!

Before initial commissioning of the

pump fill the pump with operating

medium and open suction and shut-off

devices on the pressure side. The

medium must be free from solids.

3.2

With hot medium (above 100°C) heat

the pump before s t art ing (pump heating

facility). ATTENTION! The medium in

the pump and pipes must be able to

expand freely during heating (development of unauthorized pressures with

enclosed medium).

3.3

Viscous mediu m, whic h can only be

pumped after heating, must be heated

first in the pump and pipes (pump heating as well as secondary heating for

pipes). ATTENTION! Heat expansion of

the medium (see above).

When pumping heavy heating oil it is

essential that cold starting of the pump

is avoided (use pu mp heating prov ided),

as this could also damage the shaft

seal.

3.4

Vent the pressure pipe during initial

starting of the pump.

3.5

Switching off the pump: Residual static

pressure in the pressure pipe must no

exceed that of the permissible supply

pressure. If necessary, de-pressurize

the pump through the non-return valve,

as this pressure pressurizes the shaft

seal which in turn could damage the

seal. The same applies to parallel operation of several pumps.

4. Maintenance

Special maintenance of the screw

pumps is not required. In case of

damage to the pump of the inst allation it

is possible that medium will leak out. In

order to avoid subsequent damage it is

recommended that respective warning

devices are fitted.

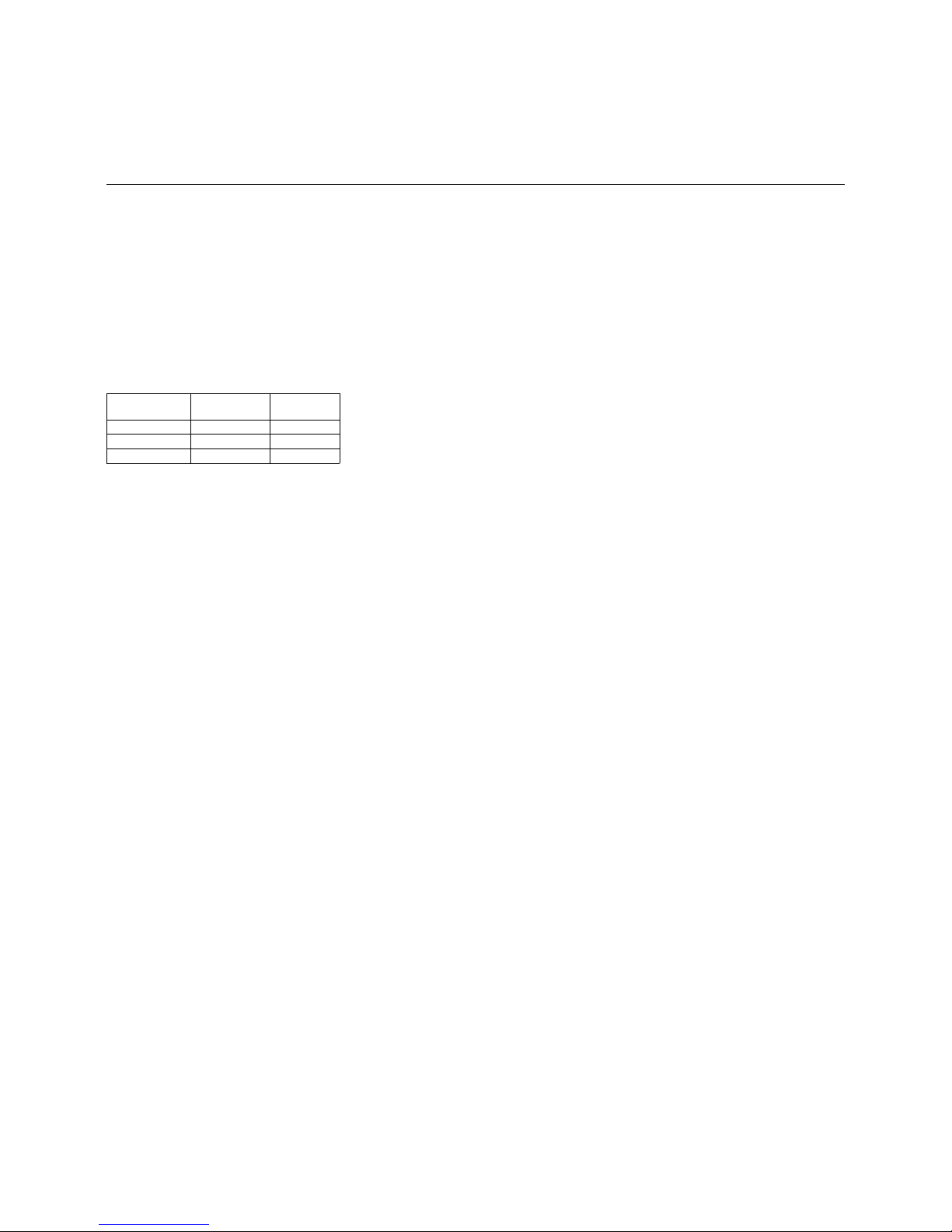

Type of seal Max. supply

pressure

Max.

Temperature

Rotary shaft 0,5 bar 80°C

Packing rings 3 bar 150°C

Axial face seal 5 bar 150°C

Page 28

28

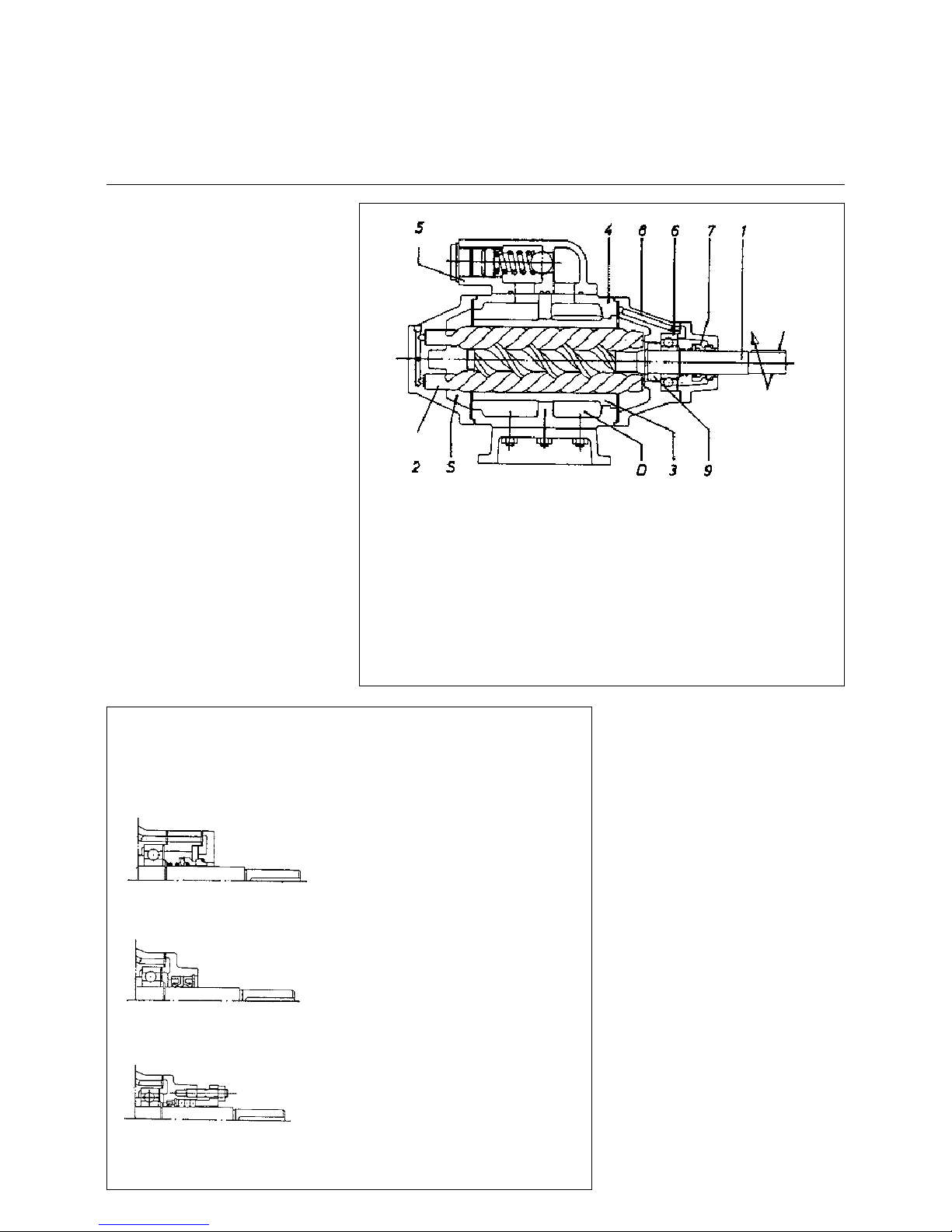

Medium pressure screw pumps

Technical specifications

Function

Versions

Technical specifications

Function

Screw pumps have three rotating spindles, of which the main spindle supplies

the hydraulic power and the auxiliary

spindles, which run free, have only a

rotating function. The two-speed main

and auxiliary spindles crea te sup pl y

chambers within the enclosed housing,

which move constantly from the suction

to the pressure side. Due to this principle the screw pump s ca n also o perate

under high pressures, revolutions and

provide strong suction, they are extremely quiet and almost pulse-free.

Safety valve

All types of medium pressure pumps

can be supplied on request with or without a spring-loaded pressure control

valve. The valve is installed to protect

the pump and/or installation against

excess pressure, but cannot be used

solely as a control valve.

Materials

Supply spindles Nitrided steel

Housing Grey cast iron

(M55 to M210) Nodular graphite

iron

Operating housing Al-Si alloy *

Cover plate Al-Si alloy *

* Guarantees the best emergency

running characteristics and long

service life

Flow rate Approx. 3 - 420 l/min

Operating pressure Max. 40 bar

Supply pressure See under versions

Operating temp. See under versions

Viscosity 1.0 E (6 cSt) to

100 E (758 cSt)

and greater

Direction of rotation Right, viewed from

drive

Heating Supplied on request

1. Main spindle

2. Auxiliary spindle

3. Enclosed housing

4. Pump housing

5. Safety valve (adjust a ble )

6. Main spindle bearing

7. Seal

8. Compensating bore

9. Compensating piston

S Suction chamber

D Pressure chamber

The axial forces acting on the feed

screws are balanced (compensated)

by the compensating piston (9) and

compensating bores (8).

Versions

Medium pressure sc rew pump s, as shown on the follo wing p ages, a re suppli ed in

various constructions. Depending on the application, the following types of seal

are available:

Rotary shaft sealing ri ngs

Normal packing and rotary shaft seal

Temperature: Max. 150 °C (above

150°C on request)

Supply pressure: Max. 5 bar (above 5

bar on request)

Temperature: Max. 80°C

Supply pressure: Max. 0.5 bar

Temperature: Max. 80°C

Supply pressure: Max. 0.5 bar

Axial face seal

Page 29

29

Burner Pump Assembly

Electrical Connection

Burner pump assembly

The installation material and all electrical connections and earthing points

must be in accordance with the

VDE 0116 specifications and the local

regulations. The electrica l connection o f

the burner must be made as shown in

the circuit diagram att ached hereto. The

electrical control lines are installed

through the screwed cable joints and

connected to the numbered terminal

strip in accordance with the circuit diagram. Control boxes related to the burner must also be connected in

accordance with the enclosed circuit

diagram and VDE 0116 and taking into

account the local regulations. After the

electrical connections have been completed a check must be made for the

correct wiring of all items of the equipment.

Also the direction of rotation of the air

fan and of the pump should be checke d.

1 Electrical terminal box

2 Plug connector

3Terminal strip

4 Cable bushings

Electrical connection

1Stop valve

2 Pressure/vacuum gauge

3 Ball valve

4 Oil pressure pump

(volumetric)

5Drip tray

6 Oil filter

7 Ball valve

8 Flange connection

9 Pump bracket

10 Pump-end coupling

11 Motor-end coupling

12 Electric motor

Page 30

30

Return Nozzle Rod DG 75

Functional description

Pre-flushing

The oil delivered by the burner pump

will enter the feed pipe (Item 2) via the

connection block (Item 1). Then it flows

through the feed pipe to the closing

taper plug of the regulating piston (Item

4). The plug is permanently pressed

against the nozzle head (Item 7) by a

cylindrical pressure spring (Item 5) so

that the feed pipe is kept in closed position. At the same time, pressure is applied to the connecting rod (Item 8) by a

spring (Item 6) so that the valve needle

(Item 12) is pressed against the return

opening of the nozzle head (Item 7),

thus keeping the latter in closed position.

In this position the oi l may only enter the

return pipe (Item 9) through the o pened

flushing hole (Item 13 ) an d wi ll return to

the gas-air separator and finally to the

fuel tank. This will give an effect ive flush

up to the nozzle.

Operating function

After the air pre-flushing period, an

electromagnet will be operated and

apply a tensile force via an arm (Item

10) to the connecting rod (Item 8). As

the valve needle and the regulating

piston are connected to one another,

the feed pipe and return pipe will be

opened at the same time so that the oil

can flow to the nozzle through the hole

of the nozzle head.

At the same time the regulating piston

(Item 4) will shut off the flushing hole

(Item 13) to the retur n pipe. T his causes

the oil to be forced to the nozzle with

part of the oil flowing back through the

return opening of the nozzle (Item 11)

and the nozzle rod. The return oil flow

rate is controlled in dependence of the

pressure by means of an output pressure regulating valve i n accordance wi th

the required load.

When the burner is stopped the solenoid actuator will be turned off so that

through the action of the pressure

springs in the feed and return pipes the

valve needle and the regulating piston

will shut off the return pipe and feed

pipe, respectively.

For the adjustment of the transmission

arm (Item 10) it should be ensured that

the solenoid actuator (Item 14) is deenergized. Care sho uld also be tak en to

avoid any mechanical loads. Pull out

the anchor (Item 15) to the stop, unscrew the lock nut (Item 16) and turn the

anchor (Item 15). When the solenoid

actuator is de-energized there should

be a noticeable backlash in the transmission linkage. When operated electrically, the solenoid actuator should

produce and audible noise when

making contact with the mechanical

stop. The valve needle (Item 12) must

be operated over its full travel of 4 mm.

Tighten the lock nut (Item 16).

Lift

Lift

Flushing nozzle rod DG-75 (complete)

Description of items

1. Connection block

2. Feed pipe

3. Rod block

4. Regulating piston

5. Feed pressure spring

6. Return pressure spring

7. Nozzle head

8. Connecting rod

9. Return pipe

10. Arm

11. Return feed

12. Valve needle

13. Flushing hole

Transmission arm

Mount for arm

Feed Return

Page 31

31

Return Nozzle Rod MAT

Functional description

The oil delivered by the burner pump will enter the feed pipe

(9) via the connection block (10).

Then it flows through t he feed pipe (9) at the pre-s et pressure

directly to the return nozzle. Part of the oil delivered will be

returned through the return flow pipe (6) via the return flow

hole of the nozzle.

The return flow rate is controlled according to the required

output using an output pressure control valve.

Approved shut-off valves are installed directly upstream of

the inlet to the nozzle rod in the oil feed and oil return lines.

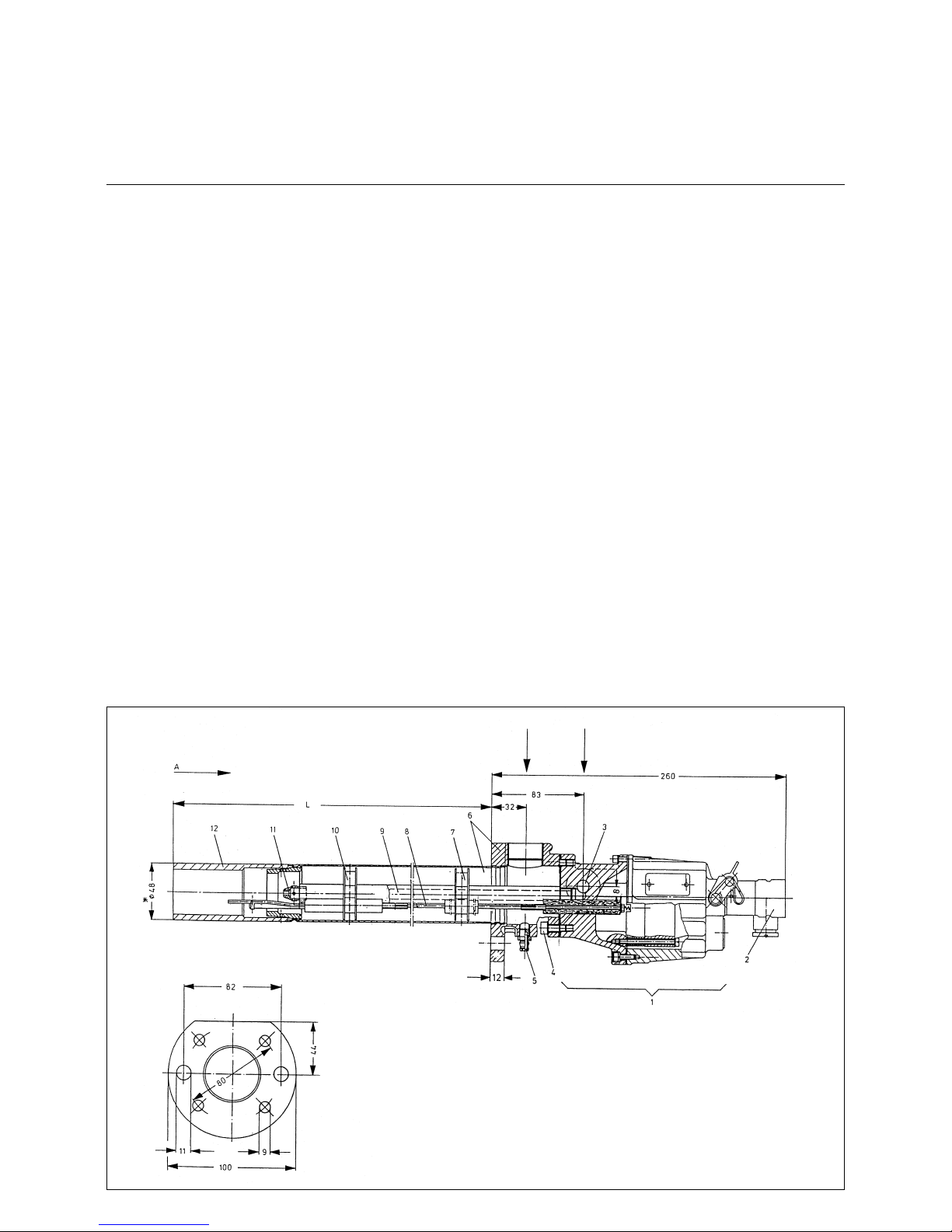

1. Union nut

2. Nozzle plate

3. Intermediate plate

4. Swirl chamber

5. Nozzle rod

6. Return pipe

7. Feed flow

8. Return flow

9. Feed pipe

10. Connection block

Page 32

32

Throughput Rate Charakteristics

Light Fuel Oil

Return Nozzle MK 27

Article-No.: 145.513.5899

Oil [kg/h]

m

·

2 alpha [°]

p return [bar]

T est cond ition s:

Page 33

33

Throughput Rate Charakteristics

Light Fuel Oil

Return Nozzle MK 27

Article-No.: 145.513.5902

Oil [kg/h]

m

·

2 alpha [°]

p return [bar]

T est cond ition s:

Page 34

34

Throughput Rate Charakteristics

Light Fuel Oil

Return Nozzle MK 27

Article-No.: 145.513.5913

Oil [kg/h]

m

·

2 alpha [°]

p return [bar]

T est cond ition s:

Page 35

35

Throughput Rate Charakteristics

Light Fuel Oil

Return Nozzle MK 27

Article-No.: 145.513.5924

Oil [kg/h]

m

·

2 alpha [°]

p return [bar]

Test conditions:

Page 36

36

Throughput Rate Charakteristics

Light Fuel Oil

Return Nozzle MK 50

Article-No.: 145.513.5946

Oil [kg/h]

m

·

2 alpha [°]

p return [bar]

T est cond ition s:

Page 37

37

Throughput Rate Charakteristics

Light Fuel Oil

Return Nozzle MK 50

Article-No.: 145.513.5957

145.513.5968

Oil [kg/h]

m

·

2 alpha [°]

p return [bar]

T est cond ition s:

Page 38

38

Throughput Rate Charakteristics

Light Fuel Oil

Return Nozzle MK 50

Article-No.: 145.513.5979

Oil [kg/h]

m

·

2 alpha [°]

p return [bar]

T est cond ition s:

Page 39

39

Throughput Rate Charakteristics

Light Fuel Oil

Return Nozzle MK 50

Article-No.: 145.513.6007

145.513.5991

Oil [kg/h]

m

·

2 alpha [°]

p return [bar]

Test conditions:

Page 40

40

Throughput Rate Charakteristics

Heavy Fuel Oil

Return Nozzle MK 27

Article-No.: 145.513.5899

Oil [kg/h]

m

·

2 alpha [°]

p return [bar]

Test conditions:

Page 41

41

Throughput Rate Charakteristics

Heavy Fuel Oil

Return Nozzle MK 27

Article-No.: 145.513.5902

Oil [kg/h]

m

·

2 alpha [°]

p return [bar]

Test conditions:

Page 42

42

Throughput Rate Charakteristics

Heavy Fuel Oil

Return Nozzle MK 27

Article-No.: 145.513.5913

Oil [kg/h]

m

·

2 alpha [°]

p return [bar]

Test conditions:

Page 43

43

Throughput Rate Charakteristics

Heavy Fuel Oil

Return Nozzle MK 27

Article-No.: 145.513.5924

Oil [kg/h]

m

·

2 alpha [°]

p return [bar]

Test conditions:

Page 44

44

Throughput Rate Charakteristics

Heavy Fuel Oil

Return Nozzle MK 50

Article-No.: 145.513.5946

Oil [kg/h]

m

·

2 alpha [°]

p return [bar]

Test conditions:

Page 45

45

Throughput Rate Charakteristics

Heavy Fuel Oil

Return Nozzle MK 50

Article-No.: 145.513.5957,

145.513.5968

Oil [kg/h]

m

·

2 alpha [°]

p return [bar]

Test conditions:

Page 46

46

Throughput Rate Charakteristics

Heavy Fuel Oil

Return Nozzle MK 50

Article-No.: 145.513.5980

Oil [kg/h]

m

·

2 alpha [°]

p return [bar]

Test conditions:

Page 47

47

Throughput Rate Charakteristics

Heavy Fuel Oil

Return Nozzle MK 50

Article-No.: 145.513.5979

Oil [kg/h]

m

·

2 alpha [°]

p return [bar]

Test conditions:

Page 48

48

Throughput Rate Charakteristics

Heavy Fuel Oil

Return Nozzle MK 50

Article-No.: 145.513.5991

145.513.6007

Oil [kg/h]

m

·

2 alpha [°]

p return [bar]

Test conditions:

Page 49

49

Dimensions of the Mixing Unit

(standard versions)

RPD 30 - RPD 80

Page 50

50

Draw-out and Swing Mechanism

Burner Settings

Draw-out and swing mechanism

The duobloc burners type RPD are

equipped with a draw-out and swing

mechanism. This makes it possible to

pull out and swing away the complete

central tube for maintenance access to

the mixing head and for adjusting the

mixing and ignition units.

Prior to this, the fastening bolts of the

central tube must be unscrewed. The

baseplate of the cen tral tub e carries t he

ignition burner, flame detector, nozzle

rod assembly (only for oil and dual-fuel

burners) and primary air connection.

After the central tube has been remo-

ved, the air damper in the burner housing will also be accessible.

NOTE: Before removing and swinging

away the central tube take care to