Page 1

R600

Operation and Installation manual

for authorized technicians only

Betriebsanleitung

für die autorisierte Fachkraft

Bedienings- en Installatiehandleiding

alleen voor bevoegde vakmensen

Notice d’installation et d’emploi

réservée à l’usage des techniciens agréés

Istruzioni per l'uso

solo per il tecnico autorizzato

07/2010 DOC3070 / 12099579

Page 2

Page 3

Operation and Installation manual

for authorized technicians only

R 600

07/2010 DOC3070 / 12099579

Page 4

Contents

2

Contents .................................................................. 2

Safety General regulations ................................... 3

Application ................................................. 3

Norms and regulations .............................. 3

Construction Layout of boiler .......................................... 4

Operating principle .................................... 4

Technical data .................................................................. 5

Extent of delivery Standard boiler .......................................... 7

Accessories ............................................... 7

Installation Boiler transport .......................................... 8

Removing the casing ................................. 9

Boiler installation ....................................... 10

Connecting the boiler ................................ 11

Commissioning Water and hydraulic system ...................... 13

Gas supply ................................................ 14

Condensate connection ............................. 14

Flue and air intake connections ................. 14

Prepare boiler for first startup .................... 15

Combustion analysis ................................. 16

Check water flow ...................................... 17

Check functionality of safety devices ........ 18

Gas tightness check .................................. 18

Boiler shut down ........................................ 18

Commissioning protocol ............................ 19

Operating instructions Controls .................................................... 20

Display / Programming .............................. 21

Overview of main functions ....................... 22

Maintenance Checklist .................................................... 23

Replacing the electrodes ........................... 23

Cleaning the condensate receptacle ......... 24

Cleaning and refilling the syphon .............. 24

Inspection of combustion chamber ............ 24

Water pressure and quality ....................... 25

Water flow rate .......................................... 25

Combustion analysis ................................. 25

Gas pressure ............................................. 25

Gas tightness check .................................. 25

Safety devices ........................................... 25

Maintenance protocol ................................ 26

Lockouts .................................................................. 27

Sensor values .................................................................. 30

Declaration of Conformity .................................................................. 31

Page 5

Safety

General regulations

Application

Norms and regulations

3

General regulations

This documentation contains important

information, which is a base for safe

and reliable installation, commissioning

and operation of the R600 boiler. All

activities described in this document

may only be excecuted by authorized

companies.

Changes to this document may be effected without prior notice. We accept

no obligation to adapt previously delivered products to incorporate such

changes.

Only original spare parts may be used

when replacing components on the

boiler, otherwise warranty will be void.

Application

The R600 boiler may be used for heating and hot water production purposes

only. The boiler should be connected to

closed systems with a maximum temperature of 100ºC (high limit temperature), maximum setpoint temperature is

90ºC.

Norms and regulations

When installing and operating the

boiler, all applicable norms (european

and local) should be fulfilled:

Local building regulations for install-

ing combustion air and flue gas systems;

Regulation for connecting the boiler to

the electrical appliance;

Regulations for connecting the boiler

to the local gas network;

Norms and regulations according to

safety equipment for heating systems;

Any additional local laws/regulations

with regard to installing and operating

heating systems.

Additional national standards

Germany:

RAL - UZ 61 / DIN 4702-8

Switzerland:

SVGW

EKAS-Form. 1942: Flüssiggas-

Richtlinie Teil 2

Vorschriften der kantonalen Instanzen

(z.B. Feuerpoilizeivorschriften)

Netherlands:

GASKEUR BASIS

GASKEUR SV

GASKEUR HR107

Belgium:

HR TOP

The R600 boiler is CE approved and

applies to the following European

standards:

92 / 42 / EEC

Boiler efficiency directive

2009 / 142 / EEC

Gas appliance directive

73 / 23 / EEC

Low voltage directive

2004 / 108 / EEC

EMC directive

EN 656

Gas-fired central heating boilers –

Type B boilers of nominal heat input

exceeding 70 kW but not exceeding

300 kW

EN 15420

Gas-fired central heating boilers Type C boilers of nominal heat input

exceeding 70 kW, but not exceeding

1000 kW

EN 15417

Gas-fired central heating boilers Specific requirements for condensing

boilers with a nominal heat input

greater than 70 kW but not exceeding

1000 kW

EN 13836

Gas fired central heating boilers Type B boilers of nominal heat input

exceeding 300 kW, but not exceeding

1000 kW

EN 15502-1

Gas-fired central heating boilers Part 1: General requirements and

tests

EN 55014-1 (2000)

Electromagnetic compatibility - Requirements for household appliances,

electric tools and similar apparatus Part 1: Emission

EN 55014-2 (1997)

Electromagnetic compatibility - Requirements for household appliances,

electric tools and similar apparatus Part 2: Immunity - Product family

standard

EN 61000-3-2 (2000)

Electromagnetic compatibility (EMC) Part 3-2: Limits - Limits for harmonic

current emissions (equipment input

current 16 A per phase)

EN 61000-3-3 (2001)

Electromagnetic compatibility (EMC) Part 3-3: Limitation of voltage

changes, voltage fluctuations and

flicker in public low-voltage supply

systems, for equipment with rated

current 16 A per phase and not subject to conditional connection

EN 60335-1 (2002)

Household and similar electrical appliances - Safety - Part 1: General requirements

EN 60335-2-102 (2006)

Household an similar electrical

appliances: Particular requirements

for gas, oil and solid-fuel burning appliances having electrical connections

Page 6

Construction

Layout of boiler

Operating principle

4

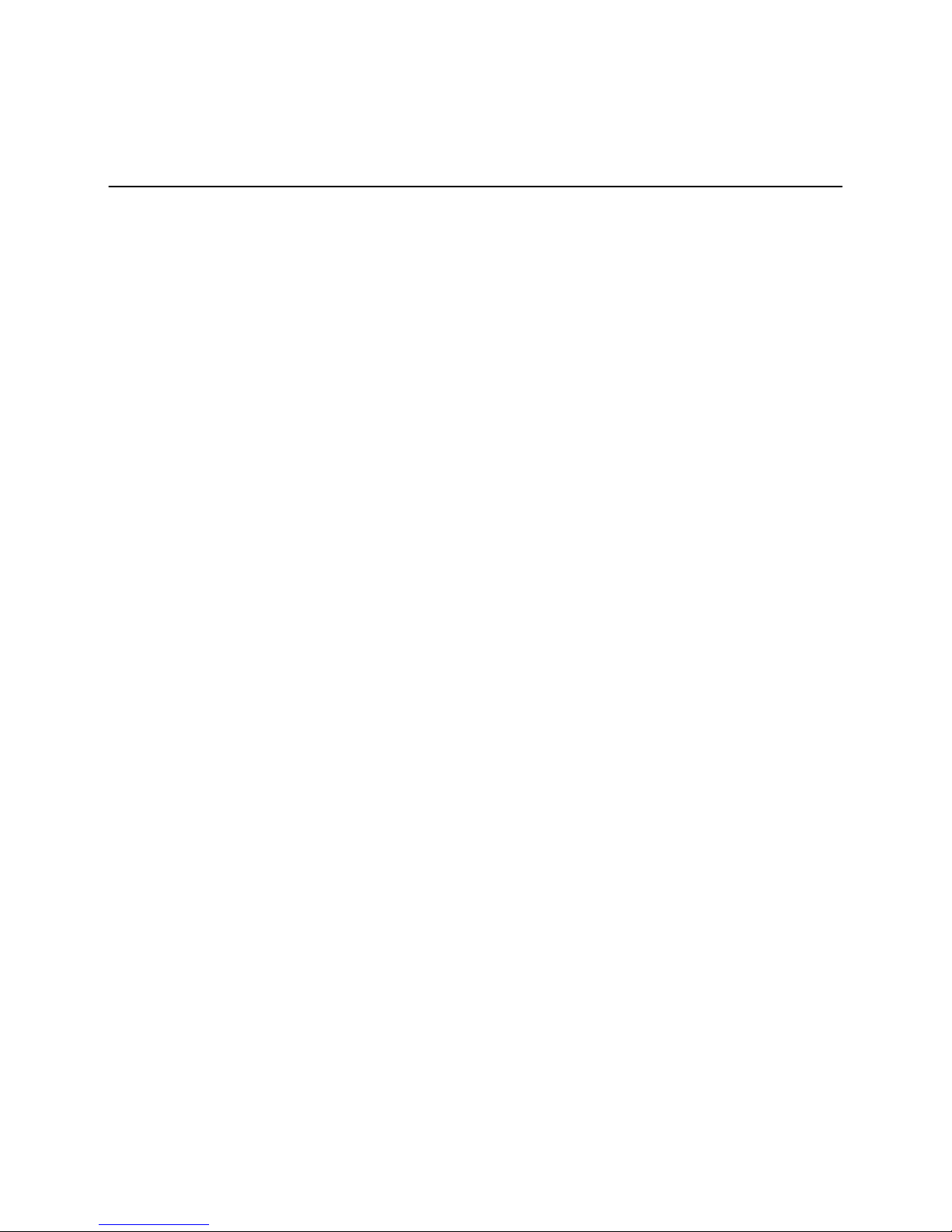

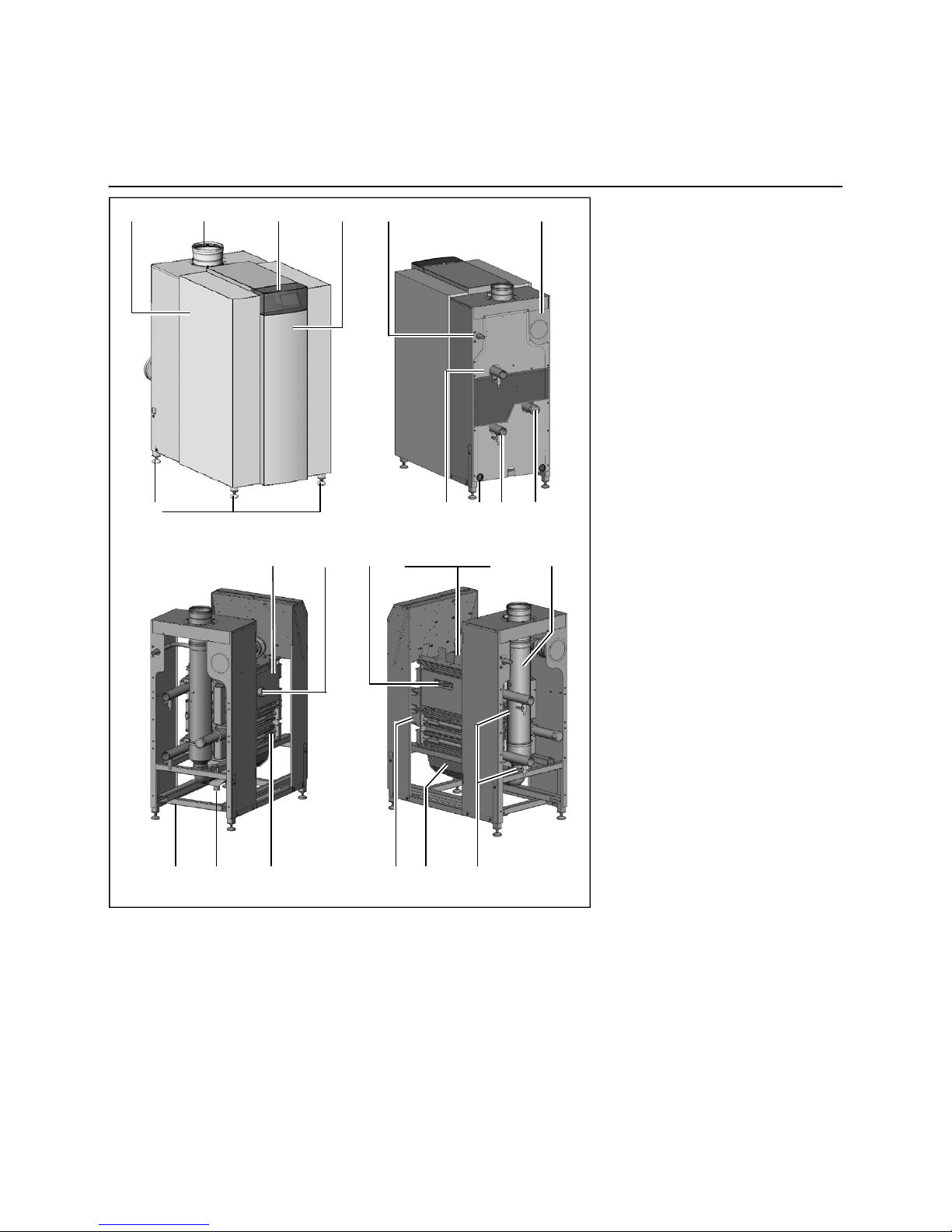

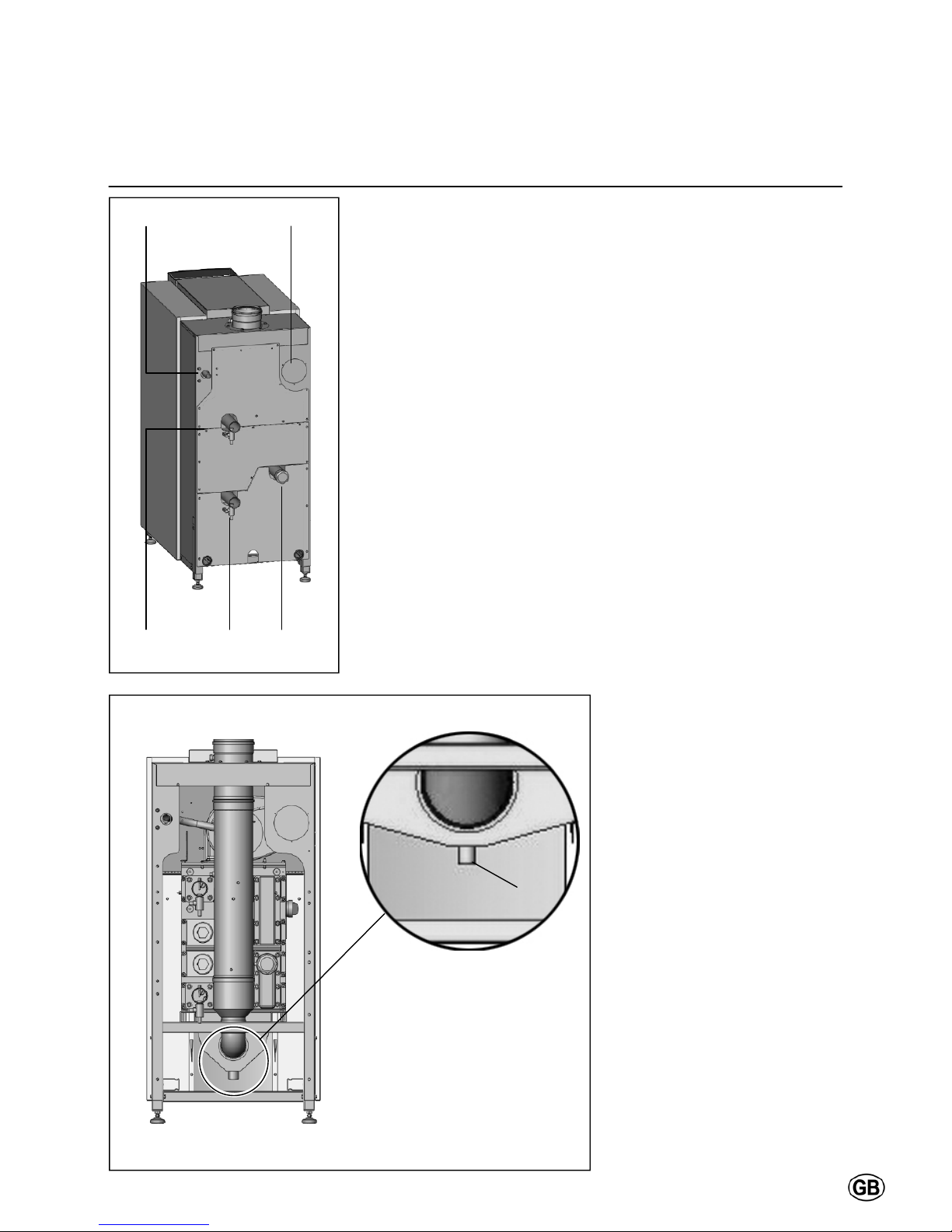

Layout of boiler

The R600 boiler consists of the following main components:

1 Casing

2 Front panel

3 Adjustable feet

4 Control panel (below cover)

5 Flue gas connection

6 Air intake connection

(under casing)

7 Gas connection

8 Flow water connection

9 Return water connection

10 2nd (hot) return water connection

(for split system use)

11 Filling/draining valve

12 Electrical input connections

13 Frame

14 Burner/1st heat exchanger

assembly

15 2nd/3rd heat exchanger assembly

16 Water headers

17 Condensate receptacle

18 Whirlwind gas/air mixing system

19 Fan

20 Gas valve

21 Gas pressure switch

22 Inspection opening

23 Ignition and ionisation electrodes

24 Syphon

25 Removable flue gas adapter

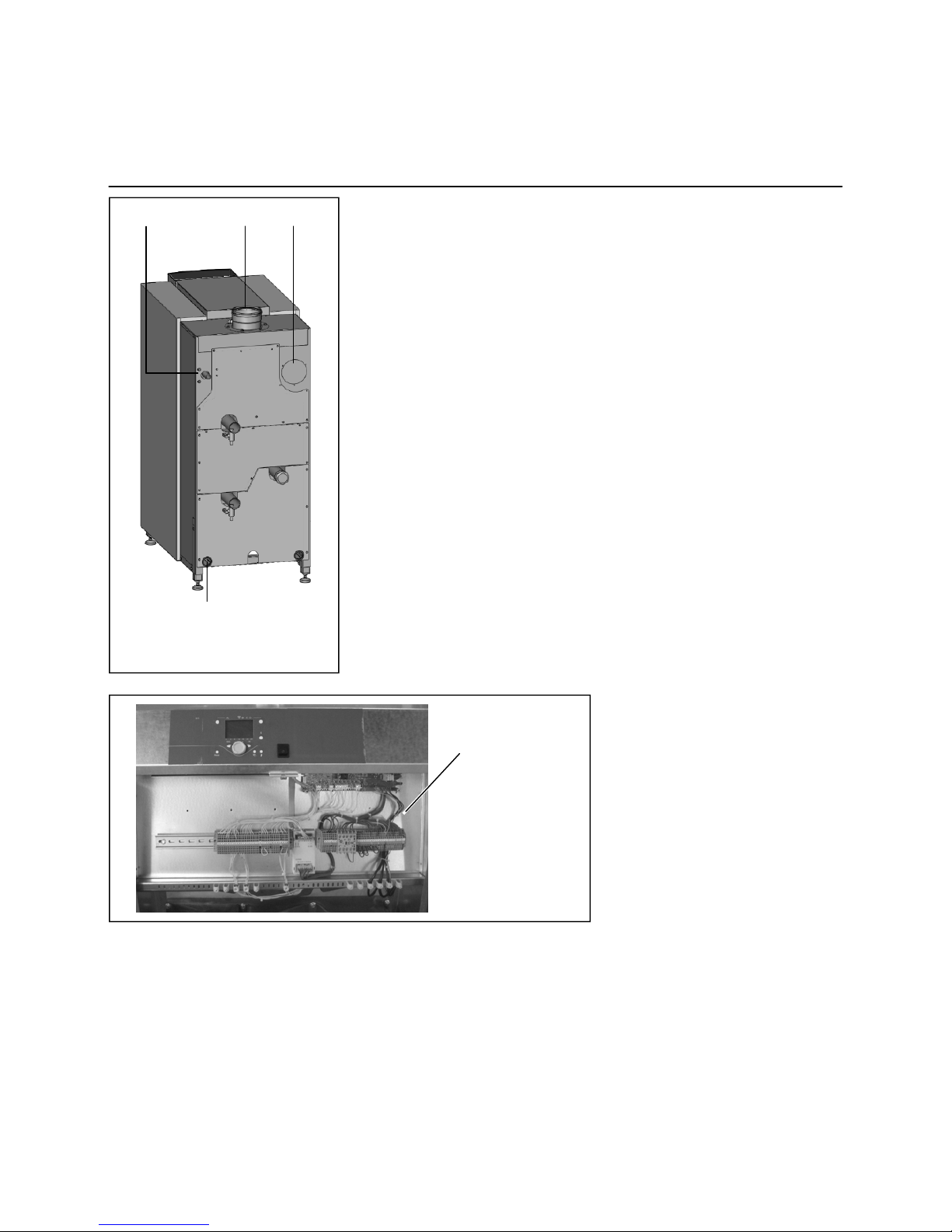

Operating principle

The R600 is a fully modulating boiler.

The control unit of the boiler adapts the

modulation ratio automatically to the

heat demand requested by the system.

This is done by controlling the speed of

the fan. As a result, the Whirlwind mixing system will adapt the gas ratio to

the chosen fan speed, in order to maintain the best possible combustion figures and therewith the best efficiency.

The flue gases created by the combustion are transported downwards

through the boiler and leave at the back

side into the chimney connection.

The LMS14 control unit can control the

boiler operation based on:

Boiler control (stand alone operation);

weather compensated operation

(with optional outdoor sensor);

with 0-10V external influence

(temperature or capacity) from a building management system.

The return water from the system enters the boiler in the lower section,

where is the lowest flue gas temperature in the boiler. In this section condensation takes place. The water is

being transported upwards through the

boiler, in order to leave the boiler at the

top (burner) section. The cross flow

working principle (water up, flue gas

down) ensures the most efficient combustion results.

1 5 4 2 7 6

3 8 12 9 10

14 22 23 18, 19, 20, 21 25

13 24 15 16 17 11

Page 7

Technical data

5

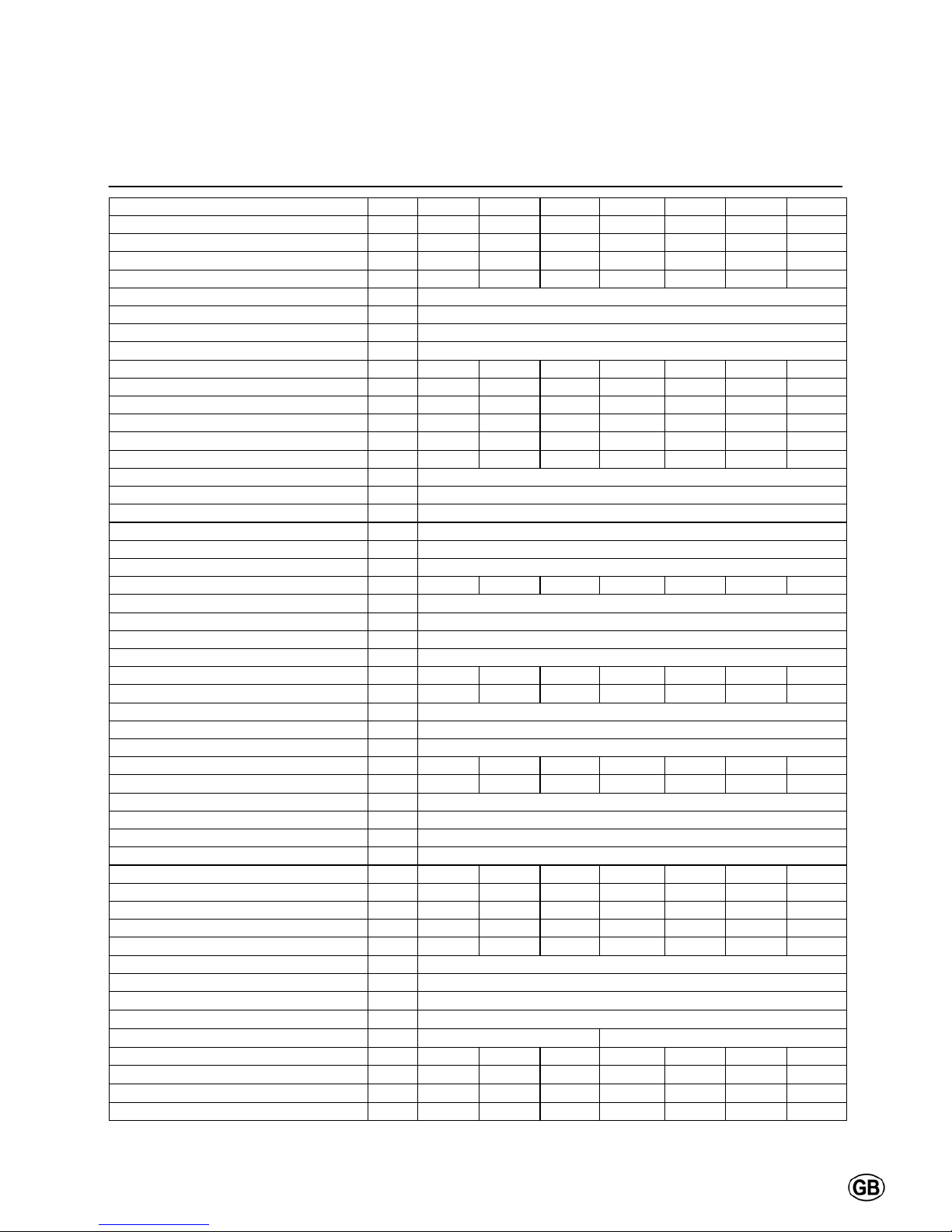

R601 R602 R603 R604 R605 R606 R607

Nominal heat output at 80/60ºC max/min*

kW 142.1/23.3 190.1/39.5 237.2/39.5 285.2/39.5 380.2/76.6 475.3/76.6 539.0/76.6

Nominal heat output at 75/60ºC max/min*

kW 142.2/23.5 190.3/39.5 237.4/39.5 285.5/39.5 380.6/76.6 475.8/76.6 539.6/76.6

Nominal heat output at 40/30ºC max/min*

kW 150.7/26.7 201.6/45.2 251.4/45.1 302.3/45.2 403.1/87.7 503.9/87.7 571.5/87.7

Nominal heat input Hi max/min*

kW 145.0/24.5 194.0/41.5 242.0/41.5 291.0/41.5 388.0/80.5 485.0/80.5 550.0/80.5

Efficiency at 80/60ºC

% 98.0

Efficiency at 40/30ºC % 103.9

Annual efficiency (NNG 75/60ºC)

% 106.8

Annual efficiency (NNG 40/30ºC)

% 110.4

Standstill losses (T

water

= 70ºC) % 0.21 0.18 0.17 0.16 0.15 0.14 0.13

Max. condensate flow

l/h 11 15 19 22 30 37 42

Gas consumption H-gas max/min (10,9 kWh/m

3

) m3/h 13.3/2.3 17.8/3.8 22.2/3.8 26.7/3.8 35.6/7.4 44.5/7.4 50.5/7.4

Gas consumption L-gas max/min (8,34 kWh/m

3

) m3/h 17.4/2.9 23.2/5.0 29.0/5.0 34.9/5.0 46.5/9.7 58.2/9.7 66.0/9.7

Gas consumption LL-gas max/min (8,34 kWh/m

3

) m3/h 17.4/2.9 23.2/5.8 29.0/5.8 34.9/5.8 46.5/11.2 58.2/11.2 66.0/11.2

Gas consumption LPG. max/min (12,8 kWh/kg)

kg/h 11.3/1.9 15.2/3.2 18.9/3.2 22.7/3.2 30.3/6.3 37.9/6.3 43.0/6.3

Gas pressure H-gas

mbar 20

Gas pressure L/LL-gas

mbar 25

Gas pressure LPG

mbar 30/50

Maximum gas pressure

mbar 100

Flue gas temperature at 80/60ºC max/min

ºC 78/61

Flue gas temperature at 40/30ºC max/min

ºC 56/30

Flue gas quantity max/min*

m

3

/h 238/40 318/69 397/69 477/69 636/134 795/134 901/134

CO

2

level natural gas H/E/L/LL max/min % 10.2/9.4

CO

2

level liguid gas P max/min % 11.9/10.0

NOx level max/min

mg/kWh 35/15

CO level max/min

mg/kWh 14/8

Max. permissible flue resistance max/min

Pa 160/10 160/10 200/10 200/10 200/10 250/10 250/10

Water volume

l 27 31 35 61 68 75 82

Water pressure max/min

bar 8/1

Max. water temperature (High limit thermostat)

ºC 100

Maximum temperature setpoint

ºC 90

Nominal water flow at dT=20K

m

3

/h 6.1 8.1 10.2 12.2 16.3 20.4 23.1

Hydraulic resistance at nominal water flow

kPa 10 18 28 15 27 42 55

Electrical connection

V 230/400

Frequency

Hz 50

Mains connection fuse

A 16

IP class

- IP20

Power consumption boiler max/min (excl. pump)

W 158/43 200/35 230/35 260/35 470/61 650/61 770/61

Power consumption 3-step pump (optional)

W 170/90 190/120 380/210 380/210 530/300 720/380 1150/600

Power consumption speed controlled pump (opt)

W 180/10 180/10 435/25 435/25 450/25 800/35 800/35

Power consumption bypass pump (optional)

W 55/35 85/65 170/90 170/90 190/120 460/225 470/280

Weight (empty)

kg 295 345 400 465 535 590 650

Noise level at 1 meter distance dB(A) 59

Ionisation current minimum µA 6

PH value condensate - 3.2

CE certification code - CE-0063BS3840

Water connections

- R2" DN65 PN16

Gas connection

- R3/4" R1" R1" R1" R1.1/2" R1.1/2" R1.1/2"

Flue gas connection

mm 150 150 200 200 250 250 250

Air intake connection (for room sealed use)

mm 130 150 150 150 200 200 200

Condensate connection

mm 40 40 40 40 40 40 40

* min load on gasses H/L/LPG. For type R602-R607 on gasses LL-Gas min value is 15% higher.

Page 8

Technical data

6

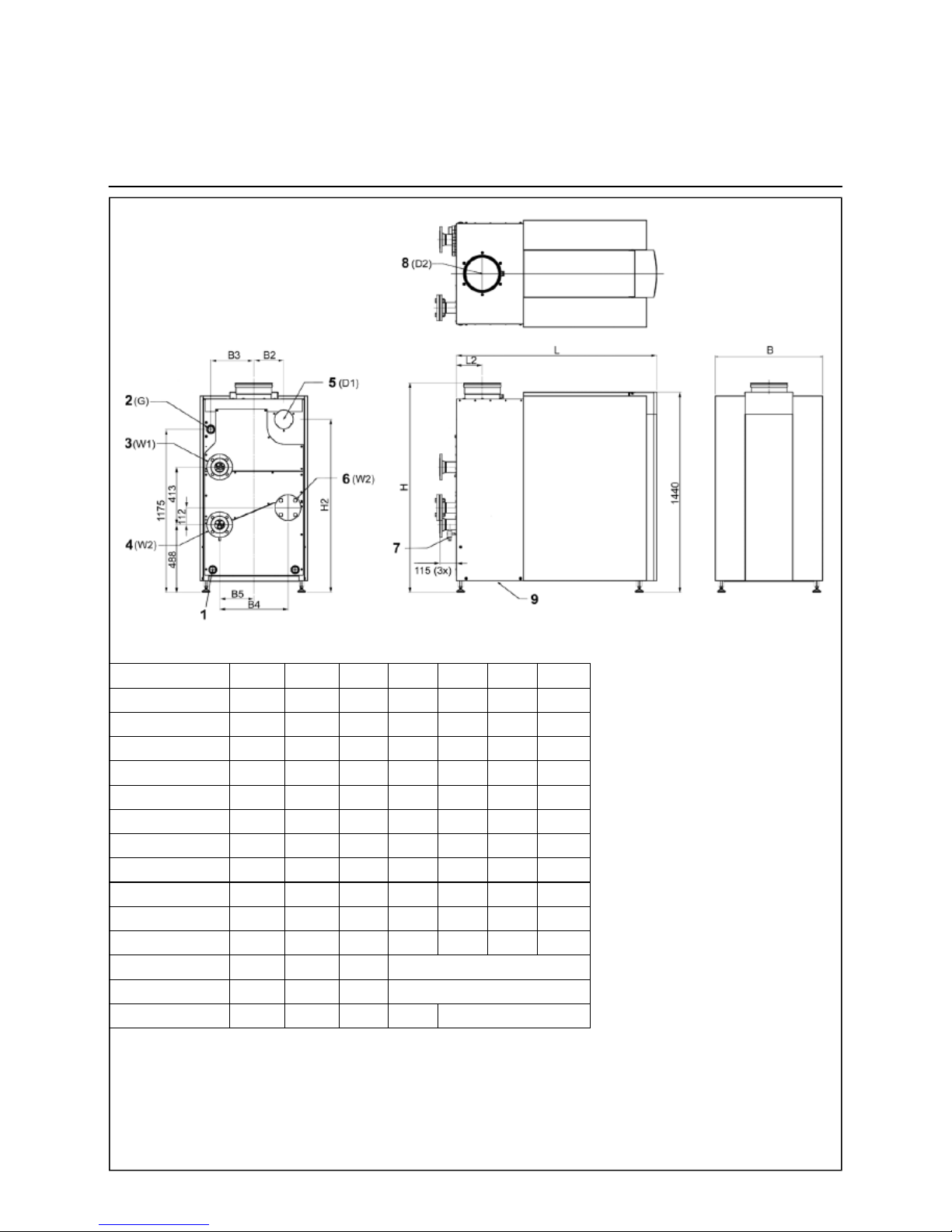

Dimension R601 R602 R603 R604 R605 R606 R607

L mm 1105 1260 1470 1220 1435 1585 1735

L2 mm 127.5 127.5 137.5 137.5 187.5 187.5 187.5

H mm 1480 1480 1500 1500 1500 1500 1500

H2 mm 1120 1130 1130 1150 1245 1245 1245

B mm 670 670 670 770 770 770 770

B2 mm 225 235 235 235 215 215 215

B3 mm 260 260 260 310 310 310 310

B4 mm 260 260 260 490 490 490 490

B5 mm 130 130 130 245 245 245 245

D1 mm (Diam.) 130 150 150 150 200 200 200

D2 mm (Diam.) 150 150 200 200 250 250 250

W1 R" / DN R2" R2" R2" DN65 PN16

W2 R" / DN R2" R2" R2" DN65 PN16

G R R 3/4" R 1" R 1" R 1" R 1 1/2"

1 Electrical connections

2 Gas supply

3 Water supply

4 Water return (Cold)

5 Air Intake (under casing)

6 Water 2nd return (Hot)

7 Boiler water drain valve 1/2"

8 Flue gas Outlet

9 Condensate drain

flexible hose 25mm diam.

Page 9

Extent of delivery

Standard boiler

Accessories

7

Standard boiler

A boiler delivery package contains the

following components:

The above accessories are specially

designed for the R600 boiler and therewith easy to install (plug and play). By

choosing a combination of the kits mentioned above, you can create your own

complete system solution. Ask your

supplier for more detailed information.

Extension module AVS75 for heating

zone control or external gas valve

and/or room fan control.

For each boiler a maximum of 3

AVS75 modules (2x heating zone, 1x

ext. gas valve / room fan) can be integrated in the boiler;

Additional RVS63 heating zone con-

troller, when controlling more than 2

zones (incl. wall hung box, all necessary sensors and sockets and connection material for bus communication).

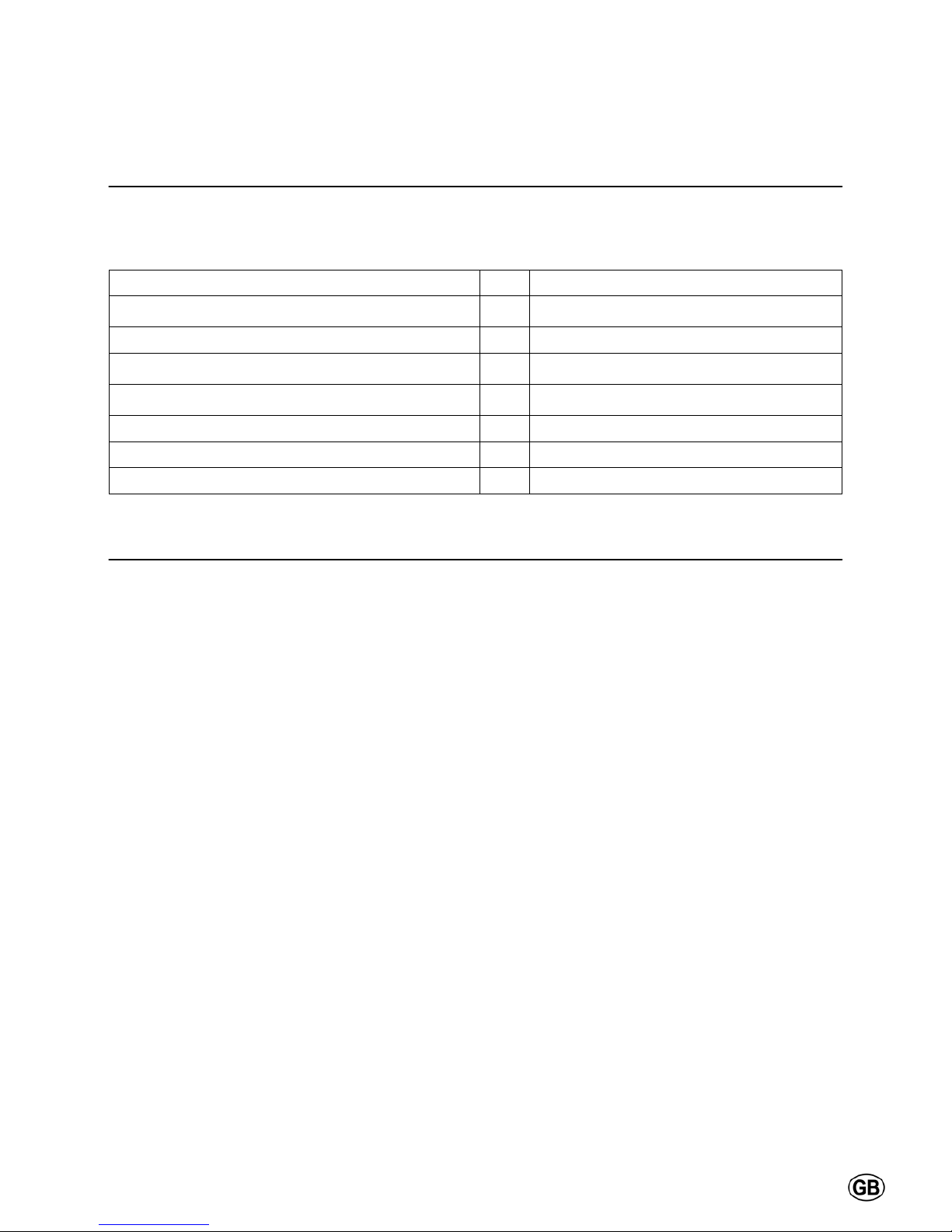

Component Pcs. Package

Boiler fully assembled and tested 1 Mounted on wooden blocks with wooden border,

sealed in PE foil

Adjustable feet 4 Mounted on frame of the boiler

Syphon for condensate connection 1 Cardboard box on top of heatexchanger

(under casing)

Conversion kit for natural gas L and propane incl. instruction 1 Cardboard box on top of heatexchanger

(under casing)

Operation and Installation manual 1 Map attached to back panel of the boiler

Spare parts list 1 Map attached to back panel of the boiler

Wiring diagram 1 Map attached to back panel of the boiler

Accessories

Additional to the boiler, the following

accessories can be ordered:

Standard 3-step pump incl. connec-

tion kit;

Speed controlled pump incl. connec-

tion kit;

Safety valve, manometer and de-

aerator (3,4,5 or 6 bar) incl. connection kit;

2x max. water pressure switch and 1

external high limit thermostat incl.

connection kit;

Gas filter incl. connection kit;

Max. gas pressure switch;

External high limit thermostat incl.

connection kit;

Gas valve leakage tester (not possi-

ble for R601);

Controlled bypass (incl. pump) incl.

connection kit;

Plate heat exchanger (dT=10K/15K or

dT=20K) incl. connection kit;

Low velocity header, suitable for

dT=10K/15K and dT=20K incl. connection kit;

Duo header for connecting 2 boilers

in cascade (excl. connection kit);

Page 10

Installation

Boiler transport

8

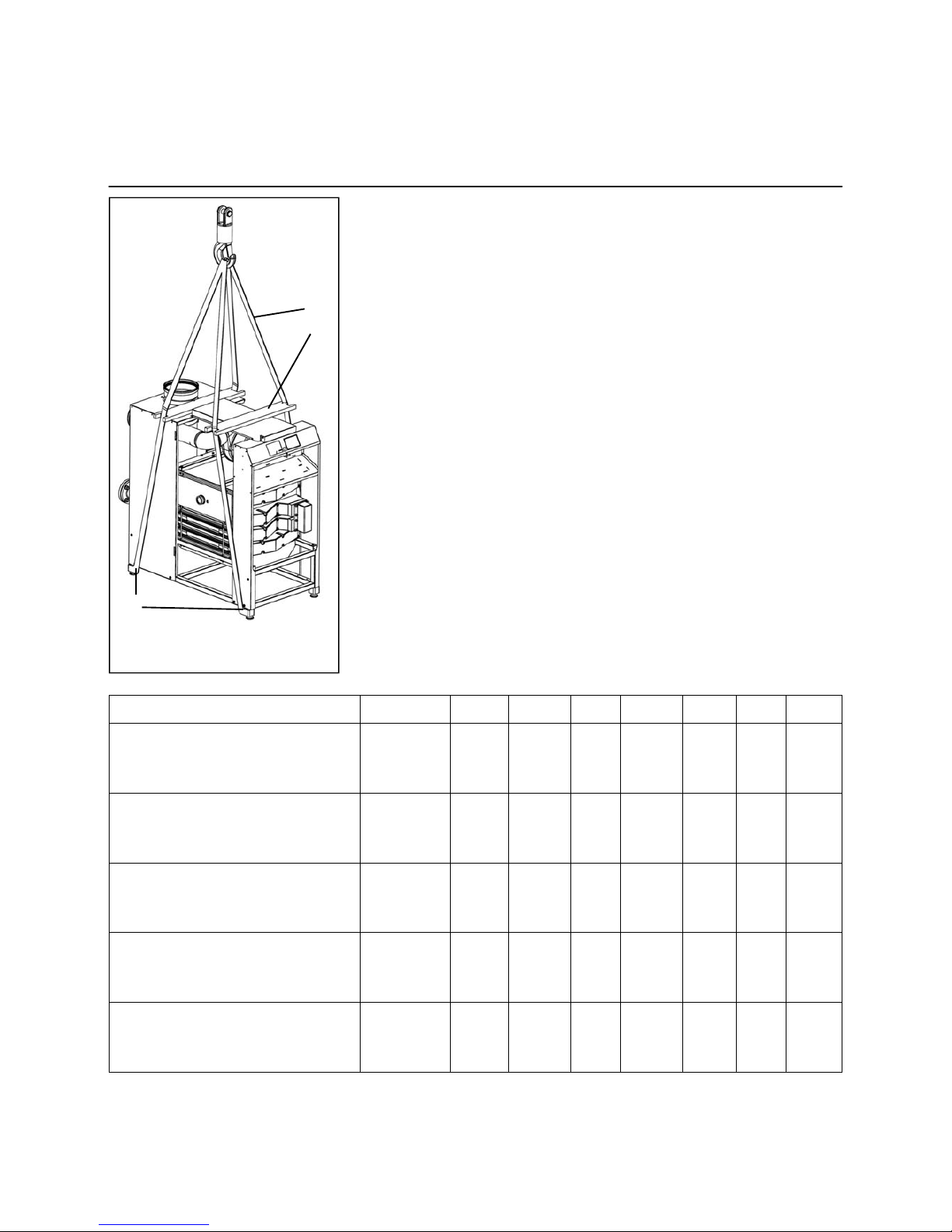

Boiler transport

The R600 boiler will be supplied as a

complete unit being fully assembled

and pre-tested. The maximum width is

670mm for models R601-R603 and

770mm for models R604-R607, which

makes it possible to transport all models through a normal door in one piece. The boiler can be transported with a

pallet truck, entering either from the

front or from the side.

Whenever necessary, the boiler can be

dismantled into smaller parts for easier

transport inside the building. The table

below shows the main dismantled parts

with their weight and dimensions.

When the boiler has to be transported

with a crane, it is necessary to remove

the casing before connecting the boiler

to the crane. Always connect the crane

to the frame of the boiler by using

straps.

Component R601 R602 R603 R604 R605 R606 R607

Burner/1st heat exchanger assembly Weight [kg]

Length [mm]

Width [mm]

Height [mm]

86

735

400

321

100

885

400

321

112

1035

400

321

135

735

680

321

158

885

680

321

181

1035

680

321

198

1185

680

321

2nd/3rd heat exchanger assembly Weight [kg]

Length [mm]

Width [mm]

Height [mm]

90

735

400

244

103

885

400

244

116

1035

400

244

150

735

680

244

170

885

680

244

198

1035

680

244

219

1185

680

244

Condensate receptacle

Weight [kg]

Length [mm]

Width [mm]

Height [mm]

7

589

385

225

9

739

385

225

10

889

385

225

11

589

665

225

12

739

665

225

13

889

665

225

15

1039

665

225

Frame

Weight [kg]

Length [mm]

Width [mm]

Height [mm]

15

990

624

335

16

1140

624

335

17

1350

624

335

17

1100

724

335

18

1320

724

335

19

1470

724

335

21

1620

724

335

Front U-frame with electronic board Weight [kg]

Length [mm]

Width [mm]

Height [mm]

11

628

1304

202

11

628

1304

202

11

628

1304

202

12

728

1304

202

12

728

1304

202

12

728

1304

202

12

728

1304

202

1 Hoisting belt (4x)

2 Wooden retaining beam (2x)

3 Hoisting belt position (4x)

1

2

3

Page 11

Installation

Removing the casing

9

Boiler transport

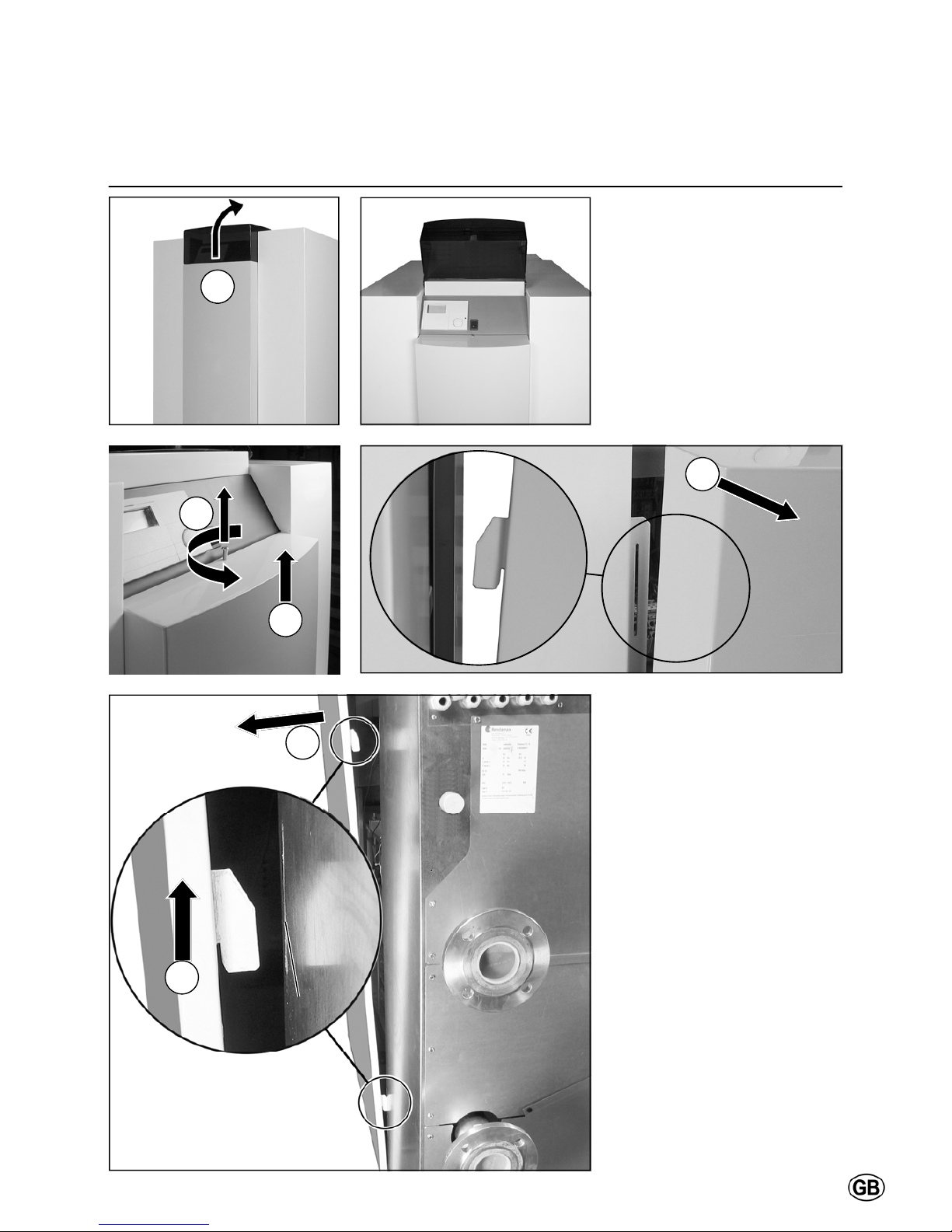

Remove the casing before transporting

the boiler, in order to avoid damage to

the casing parts during transportation.

Removing the casing is done as follows:

1.

2.

3.

4.

5.

6.

Page 12

Installation

Boiler installation

Boiler installation

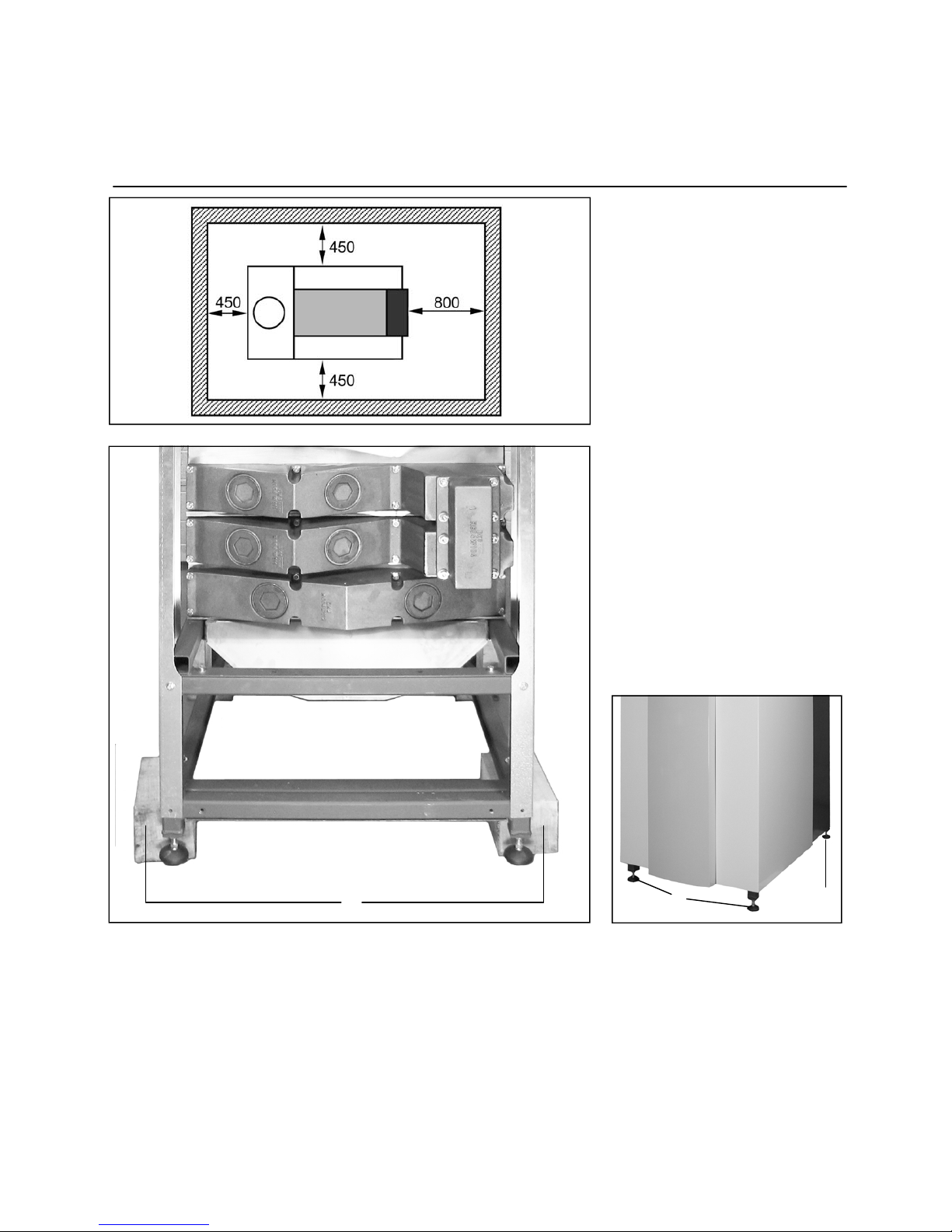

The boiler should be positioned in a

frost-proof boiler room. If the boiler

room is on the roof, the boiler itself may

never be the highest point of the installation.

When positioning the boiler, please

note the recommended minimum clearance in the picture. When the boiler is

positioned with less free space, maintenance activities will be more difficult.

Once the boiler is in the correct position, the wooden blocks (1) should be

removed and the adjustable feet (2)

(with vibration absorption dampers)

should be adjusted to the right height.

Water and gas connections should be

done after mounting the feet, as they

affect the exact height of all connections.

10

1

2 2

Page 13

Installation

Connecting the boiler

11

Connecting the boiler

This chapter will explain how to make

all connections to the boiler with regard

to:

Hydraulic connections

Condensate drain connection

Gas connection

Flue gas connection

Air intake connection

(under casing)

Electrical connection

The boiler should always be connected

in such a way, that the system applies

to all relevant standards and regulations (European, national and local). It’s

the responsibility of the installer to ensure that all standards and regulations

are respected.

Hydraulic connections

The boiler should always be connected

in such a way, that water flow through

the boiler can be ensured at all times.

Connect the flow (4) and return (5) connection of the system tension free to

the boiler connections. If the boiler is

used in a system with two return circuits, the common return becomes the

low temperature return, the 2nd return

connection (6) is the high temperature

return (remove cap/flange before connecting).

The (optional) accessory kit with safety

valve, manometer and deaerator

should be mounted on the flow connection (4) of the boiler, before connecting

to the system.

The (optional) pump kit should be

mounted directly to the return connection (5) of the boiler, before connecting

to the system.

Condensate connection (8)

After filling with water, the syphon

(included in delivery) should be installed to the connection at the bottom

of the condensate receptacle. Lead the

hose under the frame at the back of the

boiler and connect it to the draining

system in the boiler room. The connection to the draining system should always be done with an open connection,

in order to avoid a flooding of the boiler

in case of a blocked drain.

8

1 3

4 5 6

Page 14

Installation

Connecting the boiler

12

Gas connection (1)

The gas connection must be made by

an authorized installer in accordance

with the applicable national and local

standards and regulations.

Connect the gas line from the system

tension free to the gas connection (1) of

the boiler. A gas cock should be mounted directly behind the boiler.

A gas filter can be mounted directly on

the gas connection of the boiler.

Flue gas connection (7)

Regulations for the construction of flue

gas systems are very different for each

country. It should be ensured that all

national regulations with regard to flue

gas systems are respected.

Connect the flue gas system to the flue

gas connection (7) of the boiler, use

fluegas systems with seamless connections only. It’s not necessary to make a

separate condensate drain for the flue

gas system, as the condensate will be

drained via the syphon of the boiler.

Please note the following issues:

It’s recommended to use stainless

steel or PPS fluegas systems

The diameter of the flue gas system

must be chosen by calculation according to the national regulations

Construct the flue gas system as

short as possible (for maximum

length see planner documentation)

Construct horizonal ways with a mini-

mum angle of 3º

Air intake connection (3)

The air intake can be connected in case of room sealed installation. The cover (3) must be disassembled in order

to connect the air intake piping to the

connector inside the boiler. The diameter should be calculated according to

the national regulations, together with

the flue gas system. The total resistance of both systems should never overcome the maximum permissible resistance of the fan inside the boiler (see

also chapter: Technical data).

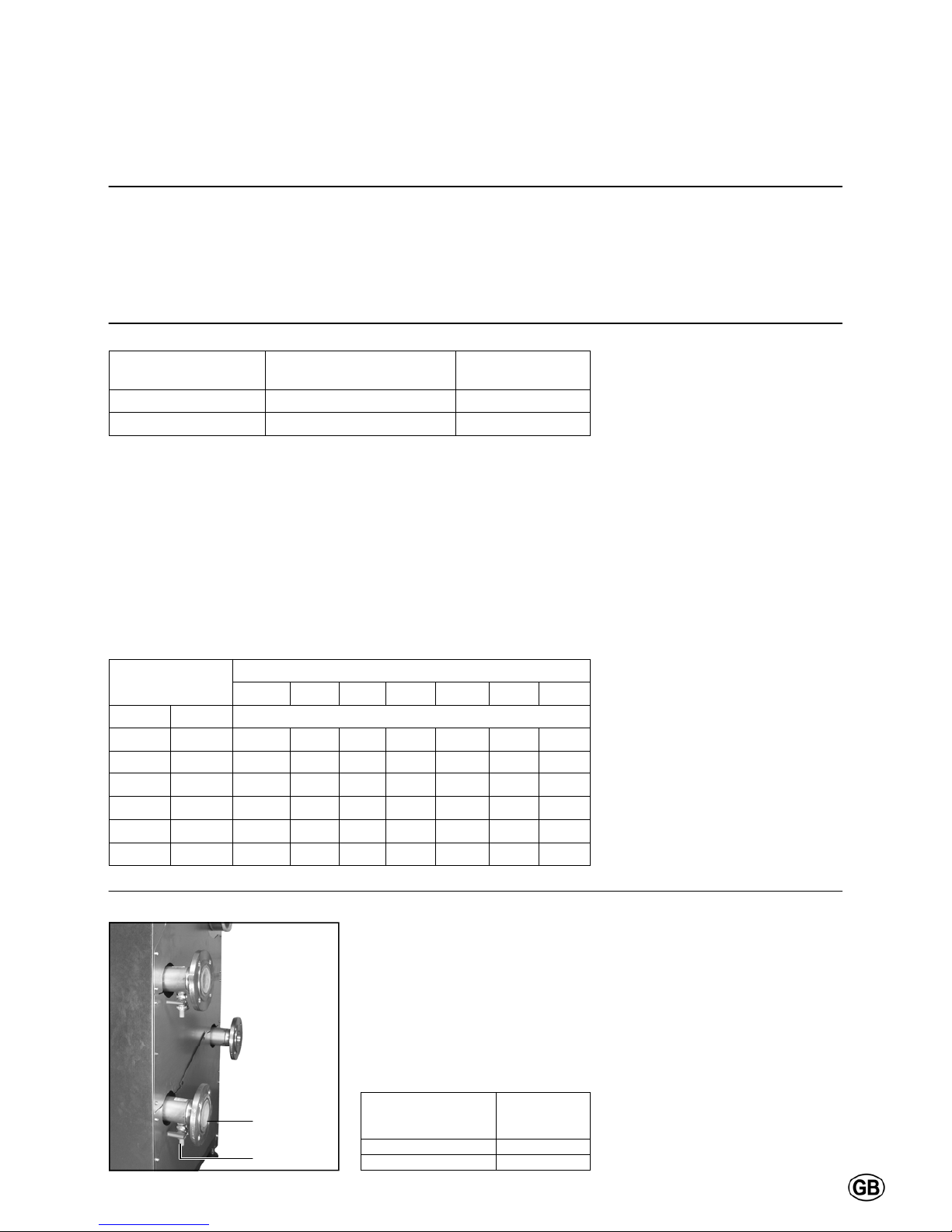

Electrical connection

The electrical connection must be made by an authorized installer in

accordance with the applicable national

and local standards and regulations.

For the power supply it’s necessary to

use a mains isolator switch with a contact opening of at least 3 mm

within the boiler room. This switch can

be used to switch off the power supply

for maintenance purposes.

All cables should be lead through the

cable glant (2) from the back of the

boiler boiler into the electro panel

(11).

Connect all wires to the terminals

according to the wiring diagram of the

boiler (enclosed in map attached to

back panel of the boiler).

1 7 3

2

11

Page 15

Commissioning

Water and hydraulic system

13

Water quality

The system should be filled with water

with a PH value between 8,0 and 9,5.

The chloride value of the water should

not exceed 50 mg/l. Entry of oxygene

by diffusion should be prevented at all

times. Damage to the heat exchanger

because of oxygene diffusion will not

be taken under warranty.

Boiler output

[kW]

Max. sum of alkaline earths

[mol/m3]

Max. total hardness

[dºH]

50 - 200 2.0 11.2

200 - 600 1.5 8.4

Concentrate

Ca(HCO3)2

Capacity of installation Q (kW)

150 200 250 300 400 500 600

mol/m

3

dºH Maximum water (re)fill volume V

max

[m3]

≤0.5 ≤2.8 - - - - - - -

1.0 5.6 - - - - - - -

1.5 8.4 3 4 5 6 8 10 12

2.0 11.2 3 4 5 6 6.3 7.8 9.4

2.5 14.0 1.9 2.5 3.1 3.8 5.0 6.3 7.5

≥3.0 ≥16.8 1.6 2.1 2.6 3.1 4.2 5.2 6.3

Minimum operating

pressure

[bar]

Flow tempe-

rature

[ºC]

> 1.5 90

> 1.0 80

Water pressure

Open the valves to the system. Check

the water pressure in the system. If the

water pressure is too low (see table

below), increase the pressure up to at

least the minimum required water

pressure in the table.

Filling can be done via the fill and drain

valve (2) on the return connection (1) of

the boiler.

1

2

Hydraulic system

Check if the boiler is hydraulically connected to the system in such way, that

water flow can be secured at all times

during burner operation. The water flow

is supervised by the water flow switch

in the boiler and a lack of flow will lead

to a direct burner stop and lockout of

the boiler.

Commissioning of the boiler should be

carried out by authorized personnel

only. Failure to respect this condition

makes the guarantee void. A protocol

of the commissioning should be filled

out (see end of this chapter for example

of commissioning protocol).

This chapter explains the commissioning of the boiler with the standard boiler controller. When an additional system controller is installed, please refer

to its manual for commissioning the

controller.

In installations with higher water volumes, it’s necessary to respect the maximum filling and additional volumes with

corresponding hardness values as stated in the german VDI2035 standard. In

the table you can find the nominal values for filling and additional water for

the R600 according to the the VDI2035.

The table at the left gives an indication

of the relation between the water quality and the maximum water filling volume during the lifetime of the boiler.

Consult the original text of the VDI2035

for more detailed information.

Page 16

Commissioning

Gas supply

Condensate connection

Flue and air intake connections

14

Gas supply

Check the gas supply connection to the

boiler for tightness. If any leakage is

found, reseal the leakage before starting the boiler!

Remove any air between the gas valve

and the gas line. This can be done at

the test point (1) at the gas pressure

switch. Don’t forget to close the test

point afterwards!

Check the gas type and values with the

local gas company, in order to know for

which gas type the boiler should be

commissioned.

Consult the conversion kit instruction if

the boiler is to be installed with natural

gas L or LPG.

Condensate connection

Remove the syphon (2) from the condensate connection. Fill it with water

and place it back in the original position. Make sure the syphon is filled

before starting the boiler, in

order to prevent flue gases discharging through the condensate connection!

Flue and air intake connections

Check whether the flue and air intake

systems are made according to the

national and local regulations. Installations which don’t comply with the regulations, are not allowed to be commissioned.

Make sure that all connections are free.

The size of flue gas and air intake connections may not be reduced.

1

2

Page 17

Commissioning

Prepare boiler for first startup

15

1

M

H

B C D E F

I

L

G

A

Legend:

A On/off switch

B Return (ESC)

C Room temperature control

D Confirmation (OK)

E Manual mode

F Chimney sweeper mode

G Info mode

H Reset button

I Operation mode heating zone(s)

L Display

M Operation mode DHW

Preparation for first startup

Open the gas supply;

Enable the power supply to the boiler;

Switch on the boiler with the on/off

switch (1);

Make sure the boiler is in standby

mode (K);

Check the pump operation: make

sure the pump runs in the right

direction;

Release all air from the pump motor.

It‘s recommended to put the boiler on

50% load after the first startup, as this

is the best starting point to do a proper

combustion analysis. This can be done

with the following procedure:

Push button I >3 Sek, the boiler goes

into controller Stopp mode.

Push the Info button (G), the actual

boiler load (%) appears in the display;

Choose „set up“ (confirm with OK

button), now the boiler load can be

changed by rotating the wheel (C)

and confirming the 50% setting with

the OK button.

After checking the combustion values

(see next page), the controller Stopp

mode can be stopped by pushing the

control mode button (I) >3 Sek.

Page 18

Commissioning

Combustion analysis

16

Combustion settings

for natural gas G20 / G25

R601-R607

CO

2, max

% 10.2 ± 0.2

CO

max

ppm < 30

Combustion settings

for LPG G31

Convert boiler before operation

(see coversion kit instruction)

R601-R607

CO

2, max

% 11.9 ± 0.2

CO

max

ppm < 30

Combustion check at full load

Start the boiler in controller stop mode

and go to 50% load. Now the boiler

operates at 50% load. Allow the boiler

to stabilise the combustion for 3

minutes. Then increase the boiler load

step by step up to 100%. Check the

gas pressure on the inlet of the gas

valve while increa-sing the boiler load:

the gas pressure should never go

below the minimum required value

see technical data. Set the minimum

gas pressure switch (1) at 75% of the

required gas pressure.

Check the combustion settings via the

test point in the chimney connection(3).

If necessary, correct the settings with

the flat adjustment screw on the outlet

of the gas valve (2).

Combustion settings

for natural gas G20 / G25

R601-R607

CO

2, min

% 9.4 ± 0.2

CO

min

ppm < 30

Combustion settings

for LPG

G31

Convert boiler before operation

(see coversion kit instruction)

R601-R607

CO

2, min

% 10.0 ± 0.2

CO

min

ppm < 30

Combustion check at minimum load

Switch the boiler to minimum load (0%).

Check the combustion settings the

same way as described for full load. If

necessary, correct the settings with the

allen key adjustment screw on either

side of the gas valve (4).

Combustion check at 50% load

An additional reference check of combustion values at 50% load is recommended in order to check if the gas

valve is set in such way, that the modulating behaviour is normal. The CO

2

value should be in between the settings

of full load and minumum load. CO

value should be equal to full load and

minimum load values.

Make sure that the boiler is set to automatic operation and controller stop mode is disabled after the combustion test

is finished.

2

4

R601

R602 - R607

1

2

4

3

Page 19

Commissioning

Check water flow

17

q

actual

= (∆T

nominal

/ ∆T

measured

) * q

nominal

[m3/h]

Water flow data

R601 R602 R603 R604 R605 R606 R607

Nominal flow rate [m

3

/h] 6.1 8.1 10.2 12.2 16.3 20.4 23.1

∆T at nominal flow rate [ºC] 20

∆p at nominal flow rate [kPa] 10 18 28 15 27 42 55

Check water flow

The water flow through the boiler can

be checked with two different methods

shown below.

∆T measurement

Check the temperature difference over

the boiler (∆T flow-return) when the

boiler is running on 100% load. The

nominal ∆T is 20K and must be at least

between 15K and 25K for secure boiler

operation. An indication of the actual

flow rate can be found with the following calculation (see table below for

nominal data):

q

actual

= √(∆p

measured

/ ∆p

nominal

) * q

nominal

[m3/h]

∆p measurement

Check the pressure difference over the

boiler (∆p flow-return) when the boiler

pump is running (burner on is not required). The nominal ∆p for each boiler

type can be found in the table below,

actual ∆p must be within:

0.35*Δp

nom

≤ ∆P ≤ 1.75*∆p

nom

. An

indication of the actual flow rate can be

found with the following calculation (see

table below for nominal data):

Page 20

Commissioning

Check functionality of safety devices

Gas tightness check

Boiler shut down

18

5

4

6

Flow temperature sensor (1)

Disconnect the plug from the sensor

while the boiler is switched on. This

should result in a lockout no. 20.

The lockout should disappear as soon

as the plug is placed back in position,

the boiler will restart.

Return temperature sensor (2)

Disconnect the plug from the sensor

while the boiler is switched on. This

should result in a lockout no. 40.

The lockout should disappear as soon

as the plug is placed back in position,

the boiler will restart.

Flue gas temperature sensor (3)

Disconnect the plug from the sensor

while the boiler is switched on. This

should result in a lockout no. 28.

The lockout should disappear as soon

as the plug is placed back in position,

the boiler will restart.

.

Minimum gas pressure switch (5)

Close the gas cock when the boiler is in

standby position (

K). Open the test

point on the gas line (4) while measuring the gas pressure on the test point

of the gas pressure switch (5).

The boiler will go in lockout no. 2 when

the switch off setting is achieved. Close

both test points and open the gas cock.

Check functionality of safety devices

All safety devices have to be checked

on good functioning. Safety devices on

a standard boiler are a water flow temperature sensor, fluegas temperature

sensor, water flow switch minumum

gas pressure switch and ionisation

electrode. These devices can be

checked as described below.

Ionisation electrode (6)

Remove electrical connection from the

ionisation electrode while the boiler is

running, the boiler will go in lockout no.

128. The boiler will try to restart. With

the electrical connection removed, the

restart will result in lockout no. 133.

When the connection is already

mounted, the restart will be successful.

Measuring the ionisation current can

be done by mounting a multi-meter (set

to µA) in between the ionisation electrode and its electrical connection. The

ionisation current should always be

above 1.2 µA, in normal conditions it

will be 6 µA and above.

Gas tightness check

Check the gas tightness of all sealed

connections with an approved soap or

electronic gas analyzer, for example:

Test points

Bolt connections

Gaskets of mixing system, etc.

Boiler shut down

When the boiler will not be used for

longer periods, shut down the boiler by

following procedure:

Switch the boiler in standby operation

(K)

Switch off the boiler with the on/off

switch (7)

Disable power supply to the boiler by

deactivating the mains isolator switch

in the boiler room

Close the gas supply to the boiler.

7

1 2 3

Page 21

Commissioning

Commissioning protocol

19

Commissioning Protocol R600

Project

Boiler type Project

Serial number Address

Year City

Nominal load (Hi) [kW] Date

Nominal output (Hi) [kW] Engineer

System

Water pressure [bar] Installati-

on:

Roof top

Water pH [-] Ground floor

Water hardness [dºH] Basement

Water chloride [mg/l] Other: .........................

Water ∆T full load [ºC] Hydrau-

lics:

Low velocity header

Water ∆p

boiler

[kPa] Plated heat exchanger

Water flow [m

3

/h] Bypass boiler

Pump setting [-] Other: .........................

Safety devices

High limit setting [ºC] Water flow sensor checked

Temp. limiter setting [ºC] Fluegas sensor checked

Min. gas pressure switch setting [mbar] Water flow switch checked

Ignition time burner [sec]

Combustion analysis

100% load 50% load Min. load

Gas consumption [m

3

/h] [m3/h] [m3/h]

Gas pressure [mbar] [mbar] [mbar]

CO

2

[%] [%] [%]

O

2

[%] [%] [%]

CO [ppm] [ppm] [ppm]

NOx [ppm] [ppm] [ppm]

T

atmospheric

[ºC] [ºC] [ºC]

T

fluegas

[ºC] [ºC] [ºC]

T

water, flow

[ºC] [ºC] [ºC]

T

water, return

[ºC] [ºC] [ºC]

Ionisation current [µA] [µA] [µA]

p

fan

[mbar] [mbar] [mbar]

p

top panel

[mbar] [mbar] [mbar]

p

combustion chamber

[mbar] [mbar] [mbar]

Remarks

Page 22

Operating instructions

Controls

20

Confirmation (OK) (D)

Return (ESC) (B)

These buttons are used for programming in combination with the wheel.

By pressing the ESC button it‘s possible

to go back one level, changed values

are not taken over by the controller.

By pressing the OK button it‘s possible

to arrive in the next level or confirm

changed values.

Manual mode (E)

This button is used for switching the

boiler into manual mode. In manual

mode all pumps will run and the mixing

valves are no longer controlled, the burner setpoint is 60°C (indicated by spanner symbol).

On/off switch (A)

Position 0:

Boiler and connected electrical components are no powered. Frost protection

is not secured.

Position I

The boiler and connected electrical

components are powered and standby

for operation.

Operation mode DHW (M)

For switching on the DHW operation

(indication in display below DHW symbol)

Operation mode heating zone(s) (I)

For setting 4 different heating modes:

Auto (clock): Automatic operation by

time programm

Comfort (sun): 24/7 heating in comfort

mode

Reduction (moon): 24/7 heating in reduced mode

Standby: heating off, frost protection

activated.

Display (L)

Info mode (G)

Display possibility of following info

without influence on boiler control:

temperatures, operation mode

Heating / DHW, error code.

Room temperature control (C)

for changing room comfort tempe-

rature

for changing settings when pro-

gramming.

Deaeration mode (E)

By pressing the manual mode button

longer than 3 seconds, the automatic

hydraulic deaeration is activated. During

deaeration the system is put in standby

mode

The pumps are switched on and off for

several times.

After deaeration, the boiler automatically

returns to normal operation.

Chimney sweeper mode (F)

Used for combustion analysis. By pressing the button once again, or automatically after 15 minutes, the chimney sweeper mode will be deactivated (indicated

by spanner symbol).

Reset button (H)

By shortly pressing the reset button a

burner lockout can be cancelled.

M

H

B C D E F

I

L

G

A

Legend:

A On/off switch

B Return (ESC)

C Room temperature control

D Confirmation (OK)

E Manual mode

F Chimney sweeper mode

G Info mode

H Reset button

I Operation mode heating zone(s)

L Display

M Operation mode DHW

Page 23

21

Operating instructions

Display / Programming

- gewünschtes Menü

auswählen

- mit Taste OK bestätigen

- mit Taste ESC zurück

zur Grundanzeige

- gewünschte Benutzer-Ebene auswählen

- mit Taste OK bestätigen

- gewünschtes Menü auswählen

- mit Taste OK bestätigen

- mit Taste ESC zurück zur Grundanzeige

DHW mode selection

Heating operation mode selection

(Controller Stopp mode when

pressing > 3 sec.)

Display

Info button

Confirm

Manual mode

(Deaeration mode when pressing

> 3 sec.)

Chimney sweeper mode

Enduser

- choose menu

- confirm with OK button

- choose parameter

- confirm with OK button

- change value + - with wheel

- confirm with OK button

- return to main menu with ESC button

Commissioning Expert

- choose user level

- confirm with OK button

- choose menu

- confirm with OK button

- choose parameter

- confirm with OK button

- change value + - with wheel

- confirm with OK button

- return to main menu with ESC button

Programming

Select

(turn left/right)

Quit menu

Reset

Press OK (1x)

Press OK (1x)

Press INFO (4 sec.)

Default mode

(buttons)

Heating to comfort setpoint Info level activated

Heating to reduced setpoint Programming activated

Heating for frost protection setpoint Heating temporarily

switched off

Process running – please weit ECO function active

Burner operating (only oil / gas boiler)

Error messages

Info level activated

Programming activated

Heating temporarily switched off

ECO function active

Holiday function active

Reference to heating circuit

Maintenance / special operation

Parameter number

Page 24

22

Operating instructions

Overview of main functions

Button Action Procedure Display / Function

Set room temperature

Zone 1 and zone 2

Actuate wheel left/right

Turn wheel

Confirm with OK button

or wait 5 sec.

or press

Comfort setpoint with blinking temperature

Blinking temperature in 0,5 °C steps from 10 to 30 °C

Comfort setpoint saved

Comfort setpoint cancelled

- after 3 sec. Main menu appears

Set room temperature for

zone 1 or zone 2

Zone 2 independent from zone 1

Actuate wheel left/right

Confirm with OK button

Actuate wheel left/right

Confirm with OK button

or wait 5 sec.

or press

Choose heating zone

Heating zone is chosen

Blinking temperature in 0,5 °C steps from 10 to 30 °C

Comfort setpoint saved

Comfort setpoint cancelled

- after 3 sec. Main menu appears

Switch on /off DHW operation

Press button DHW mode on / off

(see indication below DHW symbol)

- On: DHW mode by time programm

- Off: no DHW operation

- Safety functions activated

Change heating operation

mode

Factory setting

Press button 1x

Press button 1x again

Press button 1x again

Automatic mode on, with:

- Heating by time programm

- Temperature setpoint by heating programm

- Safety functions activated

- Summer/Winter automatic switching activated

- ECO-functions activated

(see indication below operation symbol)

Continuous COMFORT heating on, with:

- Heating without time programm by comfort setpoint

- Safety functions activated

Continuous REDUCED heating on, with:

- Heating without time programm by reduced setpoint

- Safety functions activated

- Summer/Winter automatic switching activated

- ECO-functions activated

Safety mode on, with:

- Heating off

- Temperature by frost protection

- Safety functions activated

Controller Stop mode Press button > 3 sec.

Press button > 3 sec. again

304: Controller Stopp mode insert setpoint

after 3 sec. Main menu appears

Info display

Press button 1x

Press button 1x again

Press button 1x again

…..

Press button 1x

INFO Segment displayed

- Status Boiler - room temperature

- room temperature minimum

- Status DHW - room temperature maximum

- Status zone 1 - outside temperature

- Status zone 2 - outside temperature minimum

- outside temperature maximum

- Time / Date - DHW temperature 1

- Error indication - Boiler temperature

- Maintenance indication - Flow temperature

(Info display depends on configuration)

Back to main menu; INFO Segment disappears

Operation by manual

setpoint

Change factory setting

boiler temperature

Press button 1x

Press button

Press button

Turn wheel -/+

Press button

Press button

Press button

Manual mode on (spanner symbol appears)

- Haeting by fixed setpoint

(factory setting = 60 °C)

301: Manual mode insert setpoint?

blinking temperature

set value

Status boiler

Manual mode off (spanner symbol disappears)

Deaeration Press button > 3 sec.

Press button > 3 sec. again

312: Deaeration on

Deaeration off

Activate chimney sweeper

mode

Press button (< 3 sec.)

Press button again (< 3 sec.)

Chimney sweeper mode on

Chimney sweeper mode off

Temporary reduction of

reduced temperature on

QAA75

Press button

Press button again

Heating by reduced setpoint

Heating by comfort setpoint

RESET Reset button Press button (< 3 sec.)

Press button again > 3 sec.

Boiler manually blocked, no release

Boiler released, Alarm symbol disappears

= confirmation

= cancel, return to main

menu

Page 25

Maintenance

Checklist

Replacing the electrodes

23

Maintenance of the boiler should be

carried out by authorized personnel

only.

In order to ensure continued good and

safe operation of the boiler, it should be

inspected at least once per year. A

maintenance protocol should be filled

out (see end of this chapter for example

of maintenance protocol).

Checklist

The following activities must be carried

out, see following paragraphs for an

extensive description of the main activities:

Replace the ignition and ionisation

electrodes;

Clean the condensate receptacle;

Clean and refill the syphon;

Inspect the combustion chamber,

clean if necessary;

Check the water pressure of the sys-

tem;

Check the water quality of the system

water as well as supply water;

Check the water flow rate through the

boiler;

Check/correct the combustion values

at full and mimimum load with a combustion analyzer;

Check the gas pressure to the boiler;

Check the tightness of all sealed con-

nections and test points;

Check the functionality of all safety

devices;

Fill out a maintenance protocol.

Replacing the electrodes

The electrodes are positioned on the

right hand side of the boiler. Replace

the ignition elektrode (1) and ionisation

eclectrode (2) as shown on the picture.

2

1

Page 26

Maintenance

Cleaning the condensate receptacle

Cleaning and refilling the syphon

Inspection of combustion chamber

24

5

6

7

Cleaning the condensate receptacle

Disconnect the plug of the fluegas

temperature sensor (1);

Remove the internal fluegas pipe (2)

of the boiler in order to create access

to the condensate receptacle;

Clean the receptacle (3);

Mount the fluegas pipe back in positi-

on when the cleaning is finished;

Connect the plug of the fluegas tem-

perature sensor.

Inspection of combustion chamber

The inspection opening is positioned on

the left hand side of the boiler.

Remove the radiation panel (5) from

the heat exchanger;

Remove the cover (6) from the in-

spection opening;

Inspect the combustion chamber (7),

clean if necessary;

Mount the cover and radiation panel

back in original position.

Cleaning and refilling the syphon

Remove the syphon (4) from the con-

densate connection;

Clean and fill it with fresh water;

Mount the syphon back in the original

position.

4

1

3

2

Page 27

Maintenance

25

Water pressure and quality

Check if the water pressure and quality

meet the requirements. Consult the

chapter “commissioning: water and

hydraulic system” for more detailed

information.

Water flow rate

Check if the water flow rate through the

boiler is within the limits. Consult the

chapter “commissioning: check water

flow” for more detailed information.

Combustion analysis

Check the combustion at full load and

minumum load, correct the settings if

necessary. An additional reference

check at 50% load is recommended.

Consult the chapter “commissioning:

combustion analysis” for more detailed

information.

Gas pressure

Check the dynamic pressure of the gas

supply to the boiler, when the boiler is

running at full load. In case of a boiler

cascade, all boilers should be running

at full load. See technical data for required values.

Gas tightness check

Check the tightness of all sealed connections with an approved soap or

electronic analyzer, for example:

Test points;

Bolt connections;

Gaskets of mixing system, etc.

Safety devices

Check the functionality and the settings

of all safety devices connected. Consult

the chapter “commissioning: Check

functionality of safety devices” for more

detailed information.

Page 28

Maintenance

Maintenance Protocol

26

Maintenance Protocol R600

Project

Boiler type Project

Serial number Address

Year City

Nominal load (Hi) [kW] Date

Nominal output (Hi) [kW] Engineer

System

Water pressure [bar]

Water pH [-]

Water hardness [dºH]

Water chloride [mg/l]

Water ∆T full load [ºC]

Water ∆p

boiler

[kPa]

Water flow [m

3

/h]

Pump setting [-]

Safety devices

High limit setting [ºC] Water flow sensor checked

Temp. limiter setting [ºC] Fluegas sensor checked

Min. gas pressure switch setting [mbar] Water flow switch checked

Ignition time burner [sec]

Combustion analysis

100% load 50% load Min. load

Gas consumption [m

3

/h] [m3/h] [m3/h]

Gas pressure [mbar] [mbar] [mbar]

CO

2

[%] [%] [%]

O2 [%] [%] [%]

CO [ppm] [ppm] [ppm]

NOx [ppm] [ppm] [ppm]

T

atmospheric

[ºC] [ºC] [ºC]

T

fluegas

[ºC] [ºC] [ºC]

T

water, flow

[ºC] [ºC] [ºC]

T

water, return

[ºC] [ºC] [ºC]

Ionisation current [µA] [µA] [µA]

p

fan

[mbar] [mbar] [mbar]

p

top panel

[mbar] [mbar] [mbar]

p

combustion chamber

[mbar] [mbar] [mbar]

Remarks

Page 29

27

In case of a lockout, a warning symbol ( ) and a flashing error code appears on the display. The cause of a fault should first

be determined and eliminated before the boiler is being reset. The table below shows all possible lockouts with indication of

possible cause.

Lockouts

Error

code

Description of error

0 No error

10 Outside temperature sensor error

20 Boiler temperature 1 sensor error

26 Common flow temperature sensor error

28 Flue gas temperature sensor error

30 Flow temperature 1 sensor error

32 Flow temperature 2 sensor error

38 Flow temperature primary controller sensor error

40 Return temperature 1 sensor error

46 Return temperature cascade sensor error

47 Common return temperature sensor error

50 DHW temperature 1 sensor error

52 DHW temperature 2 sensor error

54 DHW primary controller sensor error

57 DHW circulation temperature sensor error

60 Room temperature 1 sensor error

65 Room temperature 2 sensor error

70 Buffer storage tank temperature 1 sensor error

71 Buffer storage tank temperature 2 sensor error

72 Buffer storage tank temperature 3 sensor error

73 Collector temperature 1 sensor error

74 Collector temperature 2 sensor error

82 LPB address collision

83 BSB wire short-circuit

84 BSB address collision

85 BSB RF communication error

91 EEPROM error lockout information

98 Extension module 1 error (collective error)

99 Extension module 2 error (collective error)

100 2 clocktime masters (LPB)

102 Clocktime master without reserve (LPB)

103 Communication error

105 Maintenance message

109 Boiler temperature supervision

110 STB lockout

111 TW cutout

121 Flow temperature 1 (HC1) supervision

122

Flow temperature 2 (HC2) supervision

125 Pump supervision error

126 DHW charging supervision

127 Legionella temperature not reached

128 Loss of flame during operation

129 Fan error or LP error

130

Flue gas temperature limit exceeded

131

Burner fault

132 GP or LP error

133 No flame during safety time

146 Configuration error collective message

Page 30

Lockouts

28

Error

code

Description of error

151 Internal error

152 Parameterization error

153 Unit manually locked

160 Fan error

162 LP error, does not close

164 Error heating circuit flow switch

166 LP error, does not open

171 Alarm contact H1 or H4 active

172 Alarm contact H2 (EM1, EM2 or EM3) or H5 active

173 Alarm contact H6 active

174 Alarm contact H3 or H7 active

178 Limit thermostat heating circuit 1

179 Limit thermostat heating circuit 2

183 Unit in parameterization mode

193 Pump supervision error after flame on

216 Fault boiler

217 Fault sensor

241 Flow sensor solar sensor error

242 Return sensor solar sensor error

243 Swimming pool temperature sensor error

270 Limit function

317 Mains frequency outside permissible range

320 DHW charging temperature sensor error

324 BX same sensors

325 BX / extension module same sensors

326 BX / mixing group same sensors

327 Extension module same function

328 Mixing group same finction

329 Extension module / mixing group same function

330 Sensor BX1 no function

331 Sensor BX2 no function

332 Sensor BX3 no function

333 Sensor BX4 no function

334 Sensor BX5 no function

335 Sensor BX21 no function (EM1, EM2 or EM3)

336 Sensor BX22 no function (EM1, EM2 or EM3)

337 Sensor BX1 no function

338 Sensor BX12 no function

339 Collector pump Q5 not available

340 Collector pump Q16 not available

341 Solar Collector sensor B6 not available

342 DHW sensor B31 not available

343 Solar integration not available

344 Solar controlling element buffer K8 not available

345 Solar controlling element swimming pool K18 not available

346 Solid fuel boiler pump Q10 not available

347 Solid fuel boiler comparison sensor not available

348 Solid fuel boiler address error

Page 31

29

Lockouts

Error

code

Description of error

349 Buffer return valve Y15 not available

350 Puffer address sensor

351 Primary controller / system pump address error

352 Pressureless header address error

353 Common flow sensor B10 not available

371 Flow temperature 3 (heating circuit 3) supervision

372 Limit thermostat heating circuit 3

373 Extension module 3 error (collective error)

349 Buffer return valve Y15 not available

350 Puffer address sensor

351 Primary controller / system pump address error

352 Pressureless header address error

353 Common flow sensor B10 not available

371 Flow temperature 3 (heating circuit 3) supervision

372 Limit thermostat heating circuit 3

373 Extension module 3 error (collective error)

386 Fan speed has lost valid range

388 DHW error no function

426 Feedback flue gas damper

427 Configuration flue gas damper

431 Sensor primary heat exchanger

432 Functional earth not connected

433 Temperature primary heat exchanger to high

Page 32

Sensor values

The diagrams show the sensor values

for all boiler sensors and optional sensors available in accessory kits.

The diagrams contain average values,

as all sensors are liable to tolerances.

When measuring the resistance values,

the boiler should always be switched

off. Measure close to the sensor, in

order to avoid value deviations.

30

0

5000

10000

15000

20000

25000

30000

35000

40000

45000

50000

55000

60000

-10 0 10 20 30 40 50 60 70 80 90 100 110

Temperature [ºC]

Resistance [Ohm]

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

-20-100 10203040

Temperature [ºC]

Resistance [Ohm]

NTC 1kΩ temperature sensor

(outdoor sensor)

NTC 10kΩ temperature sensor

(flow, return, flue gas, DHW and header sensor)

Page 33

Declaration of Conformity

31

Declaration of Conformity

Rendamax BV, Hamstraat 76, 6465 AG Kerkrade (NL),

Declares that the product

R600

Is in conformity with the following standards:

EN 298

EN 656

EN 15420

EN 55014-1 / -2

EN 61000-3-2 /-3

EN 60 335-1/ -2

And in accordance with the guidelines of directives:

92 / 42 / EEC (boiler efficiency directive)

2009 / 142 / EEC (gas appliance directive)

73 / 23 / EEC (low voltage directive)

2004 / 108 / EEC (EMC directive)

This product is designated with CE number:

CE – 0063BS3840

Kerkrade, 22-04-2010

ing. G.A.A. Jacobs

Managing Director

Page 34

Page 35

Betriebsanleitung

für die autorisierte Fachkraft

R 600

07/2010 DOC3070 / 12099579

Page 36

Inhalt

2

Inhalt .................................................................. 2

Sicherheitsbestimmungen Allgemeine Bestimmungen

...................... 3

Verwendungszweck ................................. 3

Normen und Vorschriften .......................... 3

Konstruktion Produktbeschreibung ................................ 4

Funktionsbeschreibung ............................. 4

Technische Daten .................................................................. 5

Lieferumfang Standard Ausführung ............................... 7

Zubehör .................................................... 7

Installation Transport ................................................... 8

Installation ................................................. 9

Anschlüsse ................................................ 11

Inbetriebnahme Wasser- und Hydrauliksystem .................. 13

Gasversorgung

........................................ 14

Kondensatanschluss

................................ 14

Abgas- und Zuluftanschlüsse

................... 14

Vorbereitung für 1. Inbetriebnahme

......... 15

Verbrennungswerte

.................................. 16

Wasserdurchsatz prüfen

.......................... 17

Sicherheitseinrichtungen prüfen

............... 18

Gasdichtheitsprüfung

............................... 18

Kessel außer Betrieb setzen

.................... 18

Inbetriebnahme Protokoll

......................... 19

Bedienung

Bedienelemente

....................................... 20

Beschreibung Display / Programmierung . 21

Kurzübersicht über die Hauptfunktionen ... 22

Wartung Checkliste

.................................... 23

Ersetzen der Elektroden

.......................... 23

Reinigung der Kondensatwanne

.............. 24

Reinigen und Auffüllen des Siphons

........ 24

Inspektion der Verbrennungskammer

...... 24

Wasserdruck und -qualität

....................... 25

Wasserdurchsatz

..................................... 25

Verbrennungswerte

.................................. 25

Gasdruck

.................................................. 25

Gasdichtheitsprüfung

............................... 25

Sicherheitseinrichtungen

.......................... 25

Wartungsprotokoll

.................................... 26

Störungen .................................................................. 27

Fühlerkennwerte .................................................................. 30

Konformitätserklärung .................................................................. 31

Page 37

Sicherheitsbestimmungen

Allgemeine Bestimmungen

Verwendungszweck

Normen und Vorschriften

3

Allgemeine Bestimmungen

Diese Dokumentation enthält wichtige

Hinweise bezüglich Sicherheit und Zuverlässigkeit von Installation, Inbetriebnahme und Betreibung des R600 Kessels. Alle beschriebenen Tätigkeiten

sind ausschließlich durch die autorisierte Fachkraft auszuführen.

Es dürfen nur Original Bauteile des

Kesselherstellers verwendet werden,

ansonsten schließen wir unsere Gewähr- und Garantieleistungsbedingungen aus.

Verwendungszweck

Der R600 Heizkessel ist ausschliesslich

für geschlossene Warmwasserheizungsanlagen zu verwenden. Die maximale Temperatur des Kesselsollwerts

beträgt 90ºC, sowie 100ºC des Systems (Sicherheitstemperatur Limit).

Normen und Vorschriften

Bei Installation und Betreibung des

R600 Kessels müssen alle maßgebenden Normen (europäische und nationale) eingehalten werden:

Lokale Gebäudevorschriften über die

Installation von Heizungsanlagen und

Abgassysteme

Vorschriften über den Anschluss an

das elektrische Versorgungsnetz

Vorschriften der lokalen Gasversor-

gungsunternehmen

Normen und Vorschriften betreffend

Sicherheitseinrichtungen für Heizungsanlagen

Zusätzliche lokale Gesetze/Vorschrif-

ten bezüglich Installationen und

Betreibung von Heizungsanlagen.

Der R600 Kessel ist CE geprüft und

beinhaltet die folgenden europäischen Normen:

92 / 42 / EEC (Wirkungsgrade von

Warmwasserheizungsanlagen)

2009 / 142 / EEC

(Gasverbrauchseinrichtungen)

73 / 23 / EEC (Sicherheit von elektri-

schen Betriebsmitteln)

2004 / 108 / EEC (EMV Verträglich-

keit)

EN 656 (Anforderungen an Gasfeue-

rungsanlagen – Type B Kessel 70 kW

– 300 kW)

EN 15420 (Anforderungen an Gas-

feuerungsanlagen – Type C Kessel

70 kW – 1000 kW)

EN 15417 (Spezielle Anforderungen

für kondensierende Gasheizkessel 70

kW – 1000 kW)

EN 13836 (Anforderungen an Gas-

feuerungsanlagen – Type B Kessel

300 kW – 1000 kW)

EN 15502-1 (Anforderungen an Gas-

feuerungsanlagen – Part 1: allgemeine Anforderungen und Tests)

EN 55014-1 (2000) EMV – Anforde-

rungen an Haushaltgeräte, elektrische Werkzeuge und ähnliche Apparate – Teil 1: Emissionen

EN 55014-2 (1997) EMV – Anforde-

rungen an Haushaltgeräte, elektrische Werkzeuge und ähnliche Apparate – Teil 2: Sicherheit - Produktefamilienstandard

EN 61000-3-2 (2000) Elektromagneti-

sche Kompatibilität (EMC) - Teil 3-2:

Rahmenbedingungen - Rahmenbedingungen für Stromschwankungen

(Stromaufnahme 16 A pro Phase)

EN 61000-3-3 (2001) Elektromagneti-

sche Kompatibilität (EMC) - Part 3-3:

Rahmenbedingungen für Spannungsschwankungen, Spannungsverluste

und –Flicker in öffentlichen Niederspannungsnetzen, für Equipment mit

Nennstrom 16 A pro Phase, die keiner Sonderanschlussbedingung unterliegen.

EN 60335-1 (2002) Haushalt und

ähnliche elektrische Geräte - Sicherheit-Teil 1: Allgemeine Anforderungen

EN 60335-2-102 (2006) Haushalt und

ähnliche elektrische Geräte - Sicherheit: Besondere Anforderungen für

Gas, Öl und Festbrennstoff gefeuerte

Geräte mit elektrischen Anschlüssen

Darüber hinaus sind die nationalen

Normen zu beachten:

Deutschland:

RAL - UZ 61 / DIN 4702-8

Schweiz:

SVGW

EKAS-Form. 1942: Flüssiggas-

Richtlinie Teil 2

Vorschriften der kantonalen Instanzen

(z.B. Feuerpoilizeivorschriften)

Holland:

GASKEUR BASIS

GASKEUR SV

GASKEUR HR107

Belgien:

HR TOP

Page 38

4

Konstruktion

Produktbeschreibung

Funktionsbeschreibung

Der R600 Heizkessel beinhaltet nachfolgende Hauptkomponenten:

1 Kesselverkleidung

2 Frontabdeckung

3 Höhenverstellbare Füße

4 Schaltfeld

5 Abgasanschluss

6 Luftzufuhranschluss

(unter Verkleidung)

7 Gasanschluss

8 Vorlauf Anschluss

9 Rücklauf Anschluss

10 HT Rücklauf Anschluss

(bei Bypasssystem)

11 Befüll-/Entleerhahn

12 Öffnung für Elektrokabel

13 Tragkonstruktion

14 Brenner/1. Wärmetauscheraufbau

15 2./3. Wärmetauscheraufbau

16 Wasserverteilstücke

17 Kondensatwanne

18 Verbundregelung

19 Gebläse

20 Gasventil

21 Gasdruckwächter

22 Inspektionsöffnung

23 Zünd- und Ionisationselektroden

24 Siphon

25 Abgasrohr (demontierbar)

Funktionsbeschreibung

Der R600 ist ein modulierender Brennwertheizkessel. Der Feuerungsmanager passt die Modulation automatisch

dem aktuellen Wärmebedarf des Heizsystems an. Dies geschieht indem der

Feuerungsmanager die Gebläsedrehzahl laufend anpasst. Hierbei passt die

Verbundregelung die Gasmenge der

gewählten Gebläsedrehzahl an, um

eine optimale Verbrennung und somit

die bestmögliche Effizienz zu erzielen.

Die entstandenen Abgase werden abwärts durch den Heizkessel geleitet,

und auf der Rückseite in den Kaminanschluss geführt.

Mit dem Feuerungsmanager LMS14

können folgende Regelungsvarianten

realisiert werden:

Kesselregelung (stand alone);

Witterungsgeführte Regelung;

(mit zusätzlichem Aussenfühler);

Externe Sollwertführung 0-10V

(Temperatur oder Leistung) von einem Gebäudeleitsystem.

Der Rücklaufanschluss ist im unteren

Bereich des Heizkessels angeordnet,

dort wo die tiefste Abgas/Kesseltemperatur im Heizkessel auftritt. In diesem

Bereich tritt Kondensation auf. Das

Wasser wird aufwärts durch den ganzen Heizkessel transportiert, wo es

oben im Brennerbereich wieder austritt

(Vorlaufanschluss). Somit kann eine

höchstmögliche Wärmeabgabe an das

System erfolgen. Dieses Prinzip bewirkt

eine bestmögliche und äußerst effiziente Verbrennung.

1 5 4 2 7 6

3 8 12 9 10

14 22 23 18, 19, 20, 21 25

13 24 15 16 17 11

Page 39

Technische Daten

5

R601 R602 R603 R604 R605 R606 R607

Nennwärmeleistung 80/60ºC max/min * kW 142.1/23.3 190.1/39.5 237.2/39.5 285.2/39.5 380.2/76.6 475.3/76.6 539.0/76.6

Nennwärmeleistung 75/60ºC max/min * kW 142.2/23.5 190.3/39.5 237.4/39.5 285.5/39.5 380.6/76.6 475.8/76.6 539.6/76.6

Nennwärmeleistung 40/30ºC max/min * kW 150.7/26.7 201.6/45.2 251.4/45.1 302.3/45.2 403.1/87.7 503.9/87.7 571.5/87.7

Feuerungswärmeleistung max/min * kW 145.0/24.5 194.0/41.5 242.0/41.5 291.0/41.5 388.0/80.5 485.0/80.5 550.0/80.5

Wirkungsgrad 80/60ºC % 98.0

Wirkungsgrad 40/30ºC % 103.9

Normnutzungsgrad 75/60ºC % 106.8

Normnutzungsgrad 40/30ºC

% 110.4

Bereitschaftsverluste (T Wasser = 70ºC) % 0.21 0.18 0.17 0.16 0.15 0.14 0.13

Max. anfallendes Kondensat l/h 11 15 19 22 30 37 42

Gasverbrauch H-Gas (G20) max/min (10,9 kWh/m

3

) m3/h 13.3/2.3 17.8/3.8 22.2/3.8 26.7/3.8 35.6/7.4 44.5/7.4 50.5/7.4

Gasverbrauch L-Gas (G25) max/min (8,34 kWh/m

3

) m3/h 17.4/2.9 23.2/5.0 29.0/5.0 34.9/5.0 46.5/9.7 58.2/9.7 66.0/9.7

Gasverbrauch LL-Gas (G25) max/min (8,34 kWh/m

3

) m3/h 17.4/2.9 23.2/5.8 29.0/5.8 34.9/5.8 46.5/11.2 58.2/11.2 66.0/11.2

Gasverbrauch F-Gas (G31) max/min (12,8 kWh/kg) kg/h 11.3/1.9 15.2/3.2 18.9/3.2 22.7/3.2 30.3/6.3 37.9/6.3 43.0/6.3

Gasdruck H-Gas (G20) mbar 20

Gasdruck L/LL_Gas (G25) mbar 25

Gasdruck F_Gas (G31) mbar 30/50

Maximaler Gasdruck mbar 100

Abgastemperaturen bei 80/60ºC max/min ºC 78/61

Abgastemperaturen bei 40/30ºC max/min ºC 56/30

Abgas Durchsatz max/min m

3

/h 238/40 318/69 397/69 477/69 636/134 795/134 901/134

CO

2 Wert Erdgas H/E/L/LL max/min % 10.2/9.4

CO

2 Wert Flüssiggas P max/min % 11.9/10.0

NOx Wert max/min mg/kWh 35/15

CO Wert max/min mg/kWh 14/8

Förderdruck des Gebläses max/min Pa 160/10 160/10 200/10 200/10 200/10 250/10 250/10

Wasser Inhalt l 27 31 35 61 68 75 82

Wasserdruck max/min bar 8/1

Sicherheitsthermostat ºC 100

Maximaler Sollwert

ºC 90

Nominaler Wasser Durchsatz bei dT=20K m

3

/h 6.1 8.1 10.2 12.2 16.3 20.4 23.1

Druckverlust Kessel kPa 10 18 28 15 27 42 55

Elektrischer Anschluss V 230/400

Frequenz Hz 50

Elek. Absicherung A 16

IP Klasse - IP20

El. Leistungsaufn. Kessel max/min (o.Pumpe) W 158/43 200/35 230/35 260/35 470/61 650/61 770/61

El. Leistungsaufn. Pumpen 3-stufig max/min W 170/90 190/120 380/210 380/210 530/300 720/380 1150/600

El. Leistungsaufn. Pumpen drehzahlgesteuert

W 180/10 180/10 435/25 435/25 450/25 800/35 800/35

El. Leistungsaufn. Pumpen Bypass max/min W 55/35 85/65 170/90 170/90 190/120 460/225 470/280

Gewicht (ohne hydr. Zubehör) kg 295 345 400 465 535 590 650

Schallpegel in 1m Abstand dB(A) 59

Min. Ionisationsstrom µA 6

PH Wert des Kondensates - 3.2

CE Nr.

- CE-0063BS3840

Wasser Anschlüsse - R2" DN65 PN16

Gas Anschluss - R3/4" R1" R1" R1" R1.1/2" R1.1/2" R1.1/2"

Abgas Anschluss mm 150 150 200 200 250 250 250

Zuluft Anschlüsse (raumluftunabhängig) mm 130 150 150 150 200 200 200

Kondensat Anschluss

mm 40 40 40 40 40 40 40

* Min. Belastung für H / L / F-Gas. Für Typen R602-R607 mit LL-Gas ist die min. Belastung 15% höher

Page 40

Technische Daten

6

R601 R602 R603 R604 R605 R606 R607

L mm 1105 1260 1470 1220 1435 1585 1735

L2 mm 127.5 127.5 137.5 137.5 187.5 187.5 187.5

H mm 1480 1480 1500 1500 1500 1500 1500

H2 mm 1120 1130 1130 1150 1245 1245 1245

B mm 670 670 670 770 770 770 770

B2 mm 225 235 235 235 215 215 215

B3 mm 260 260 260 310 310 310 310

B4 mm 260 260 260 490 490 490 490

B5 mm 130 130 130 245 245 245 245

D1 mm (Diam.) 130 150 150 150 200 200 200

D2 mm (Diam.) 150 150 200 200 250 250 250

W1 R" / DN R2" R2" R2" DN65 PN16

W2 R" / DN R2" R2" R2" DN65 PN16

G R R 3/4" R 1" R 1" R 1" R 1 1/2"

1 Öffnung für Elektrokabel

2 Gasanschluss

3 Vorlauf Anschluss

4 Rücklauf Anschluss

5 Luftzufuhranschluss

(unter Verkleidung)

6 HT Rücklauf Anschluss

7 Befüll-/Entleerhahn

8 Abgasanschluss

9 Kondensatwanne / Siphon

Page 41

Lieferumfang

Standardausführung

Zubehör

7

Standard Ausführung

Der Lieferumfang eines Heizkessels

enthält die folgenden Komponenten:

Zubehör

Folgendes Zubehör kann bestellt werden:

Standard 3-stufige Pumpe

inkl. Stecker;

Drehzahlgeregelte Pumpe

inkl. Stecker;

Sicherheitsventil, Manometer und

Entlüfter (3,4,5 oder 6 bar) inkl.

Anschlusskit;

2x max. Wasserdruckwächter und 1

externer Sicherheitsthermostat inkl.

Anschlusskit;

Gasfilter inkl. Anschlusskit;

Max. Gas Druckwächter;

Externer Sicherheitsthermostat inkl.

Anschlusskit;

Gas Dichtheitsprüfgerät (nicht erhält-

lich für R601);

Kontrollierter Bypass (inkl. Pumpe)

inkl. Anschlusskit;

Plattenwärmetauscher (dT=10K/15K

oder dT=20K) inkl. Anschlusskit;

Hydraulische Weiche, erhältlich für

dT=10K/15K und dT=20K inkl.

Anschlusskit;

Duo Weiche für Anschluss von 2

Heizkesseln in Kaskade (exkl. Anschlusskit);

Erweiterungsmodul AVS75 für

Ansteurung von einem gemischten

Heizkreis oder Steuerung von einem

Zulufventilator und/oder externen

Gasventil. Pro Kessel sind maximal 3

AVS75 Module einzubauen (2x Heizkreis, 1x Zuluftventilator/Gasventil);

Zusätzliches Regelgerät RVS63 bei

mehr als 2 gemischten Heizkreisen,

(inkl. Wandgehäuse, allen notwendigen Sensoren und Steckern sowie

das notwendige Material für die

Buskommunikation).

Die aufgeführten Zubehörteile sind speziell für den R600 Heizkessel konstruiert oder ausgesucht worden und

sind somit sehr einfach zu installieren

(plug and play). Wählen sie aus dem

aufgeführten Zubehör ihre Kombination, und sie können ihre eigene, vollumfängliche Systemlösung zusammenstellen. Für Details und Preise wenden sie

sich an den Elco Vertrieb.

Komponenten

Verpackungsart

Heizkessel vollständig montiert und geprüft 1 Auf Holzpalette mit Holzrahmen, eingewickelt in

PE Folie

Höhenverstellbare Füße 4 Am Kesselrahmen montiert

Siphon für Kondensatanschluss 1 In separatem Karton auf dem Wärmetauscher