Page 1

10/2010 - Art. Nr. 4200 1030 6900A

N6.2400 G-R

N6.2900 G-R

N7.3600 G-R

N7.4500 G-R

Operating instructions

For specialist installation engineers

Gas burners ........................................... 2-25

e

n

de, fr ..................................... 4200 1030 7000

it, nl ...................................... 4200 1031 9200

............................................. 4200 1028 8600

Page 2

10/2010 - Art. Nr. 4200 1030 6900A2

Overview

Contents

We accept no responsibility for

damage arising from:

- inappropriate use.

- incorrect installation and/or repair on

the part of the buyer or any third party,

including the fitting of non-original

parts.

Final delivery and instructions for

use

The firing system fitter must supply the

operator of the system with operating

and maintenance instructions on or

before final delivery. These instructions

should be displayed in a prominent

location at the point of installation of the

heat generator, They should include the

address and telephone number of the

nearest customer service centre.

Notes for the operator

The system should be inspected by a

specialist at least once a year.

Depending on the type of installation,

shorter maintenance intervals may be

necessary! It is advisable to take out a

maintenance contract to guarantee

regular servicing.

Overview Contents.................................................................... 2

Important information................................................2

Burner description..................................................... 3

Operation Gas start-up mode, gas operating mode ..................4

General safety functions........................................... 4

Fuel-air compound control........................................ 5

Gas valves and instruments group ...........................5

Automatic furnace controller LFL 1.../LGK... ............6

Gas valve VGD with SKP regulator .......................... 7

Gas valve MBC-SE...................................................7

Assembly Boiler lining for G-R burner, burner assembly...........8

Gas connection.........................................................9

Checking, assembling the combustion components10

Gas connection, electrical connection .................... 11

Checks before commissioning................................ 11

Commissioning Burner power adjusting sequence .......................... 12

Mechanical compound, electrical actuator.............. 13

Limit switch setting.................................................. 13

Monitoring of the flame by ionisation ...................... 14

Sensor current measurement ................................. 14

Gas pressure switch, air pressure switch ............... 15

Gas valves and instruments group

Description.............................................................. 16

Basic construction.............................................. 17-19

Gas valve leakage controller................................... 20

Servicing Maintenance ..................................................... 21-22

Exhaust gas test, trouble shooting instructions..23-24

Operating trouble .................................................... 25

Declaration of conformity

for gas burners

We,

Elco Burners GmbH, HerbertLiebsch-Straße 4a, 01796 Pirna,

Germany,

declare under our sole responsibility

that the products

N6.2400 G-R

N6.2900 G-R

N7.3600 G-R

N7.4500 G-R

conform to the following standards

EN 50165

EN 12953-7

EN 12952-8

EN 61000-6-2

EN 61000-6-4

EN 676

These products bear the CE mark in

accordance with the stipulations of the

following directives

2006/42 /EC Machinery directive

2004/108/EC EMC directive

2006/95/EC Low voltage directive

2009/142/EC Gas appliances

Directive

97/23/EC Pressure Equipment

Directive

Pirna, 26th May 2010

D. HOFFMANN

Important information

N6 and N7 G-R burners are designed for

the combustion of natural gas. The

design and function of the burners meet

standard EN 676. They are suitable for

use with all heat generators complying

with standard within their respective

performance range. Any other type of

application requires the approval of

ELCO.

Installation, start-up and maintenance

must only be carried out by authorised

specialists and all applicable guidelines

and regulations must be complied with.

Burner description

N6 and N7 G-R burners are progressive

mechanical fully automatic monoblock

devices.

Emissions values may differ, depending

on combustion chamber dimensions,

combustion chamber load and the firing

system (three-pass boilers, boilers with

reverse firing). For specifying warranty

values, the conditions for the measuring

equipment, tolerances and humidity

must be observed.

Packaging

The burner is supplied packaged in

three boxes on a pallet:

- Burner body with:

- integrated switch cabinet

- flange seal and securing screws

- operating instructions, circuit

diagram and spare parts list

- Combustion head

- Compact gas train with integrated or

external filter

The following standards should be

observed in order to ensure safe,

environmentally sound and energyefficient operation:

EN 226

Connection of fuel oil and forceddraught gas burners to a heat generator

EN 60335-1, -2-102

Specification for safety of household

and similar electrical appliances,

particular requirements for gas burning

appliances

Gas lines

When installing the gas lines and trains,

the general directives and guidelines, as

well as the following national

regulations, must be observed:

CH: - G1 instruction text from SSIGE

- EKAS form no. 1942,

liquefied gas directive, part 2

- Cantonal authority guidelines

(e.g. directives for the pilot valve)

DE: - DVGW-TVR/TRGI

Installation location

The burner must not be used in rooms

with aggressive vapours (e.g. hair spray,

tetrachloroethylene, carbon

tetrachloride), high levels of dust or high

air humidity (e.g. laundry rooms).

If no connection to an air exhaust

system is provided for the air supply,

there must be a supply air inlet

measuring:

DE: up to 50 kW: 150 cm

2

per additional kW: : + 2.0 cm

2

CH: QF [kW] x 6= ...cm2; but at least

200cm2.

Variations may arise as a result of local

regulations.

Page 3

10/2010 - Art. Nr. 4200 1030 6900A 3

Overview

Burner description

2 Power controller (option)

5 Housing

6 Gas inlet flange

8 Burner flame tube

10 Integrated electrical cabinet

11 Burner fixing flange

13 Air intake box

14 Mechanical compound

19 Hoisting eyes

F6 Air pressure switch

M1 Blower motor

Y10 Actuator for air and gas dampers

e

n

Page 4

10/2010 - Art. Nr. 4200 1030 6900A4

Gas start-up mode

As soon as the furnace system is

required to supply heat, the burner

control circuit will close and the program

flow started. When the program has

come to its end, the burner will be turned

on.

An automatic test is made for the

tightness of the gas valves prior to

each burner start.

The air damper is in its closed

position when the burner is out of

operation.

The electric actuator will open the closed

air damper to its full-load position so that

the burner will ventilate the furnace and

the exhaust hoods with the specified air

rate. Shortly after the pre-ventilation

process has been started the lack-of-air

cut-out must change over to operating

position within a certain time, i.e. the

minimum air pressure setting must be

reached and maintained until the burner

is turned off. At the end of the specified

pre-ventilation time the air damper will

be moved into its partial-load position in

a linked control concept with the gas

damper.

The ignition transformer is activated.

After the pre-ignition time, the main gas

valves are open and the gas comes out

from injectors where it is mixed in the

combustion head with air coming from

the fan. The ignition of the gas air

mixture is done directly by a high voltage

spark on a gas injector. During the

safety time, a stable flame is formed and

is monitored by an ionisation sensor.

The ignition is stopped before the end of

the safety time and the burner operates

at its minimum power. The start-up

programme is completed.

Gas operating mode

After the flame has developed the load

regulator will be enabled which brings

the burner into its operating position.

The load regulator will now control the

burner automatically between its partialload and full-load stages. Depending on

the heat demand, the electric actuator of

the compound control system will be fed

with the OPEN or CLOSE command via

the regulator and thus increase or

decrease the gas and air flow rates. This

compound control system will vary the

positions of the gas control valve and air

damper and thus regulate the gas flow

rate in a linked concept with the air flow

rate. The burner can either be controlled

by a 2-stage sliding or, if a respective

controller is provided, a stepless control

concept. The stepless control will allow

the burner to be operated at any desired

stage between its partial-load and fullload positions. The burner will always be

turned off out of its partial-load position.

The air damper will be closed when the

burner is out of operation and will thus

prevent cold air flowing through the

burner chamber, heat exchanger and

chimney. The interior cooling losses will

thus be greatly minimized.

Attention:

If there are shut-off dampers in the flue

gas tract they must be complete open.

Otherwise there will be a high danger of

low-speed detonation or explosion! The

open-position of the shut-off damper can

be assured by the integration of the

opening contact of the shut-off damper

in the safety chain of the heat generator.

General safety functions

In case a flame does not develop when

starting the burner (fuel release), the

burner controller will shut off at the end

of the safety period (shut-off on trouble).

A shut-off on trouble will also occur in

the case of flame failure during

operation, air flow failure during the preventilation phase and pressure failure

during the whole period of burner

operation. Any failure of the flame signal

at the end of the safety period and a

flame signal during the pre-ventilation

phase (external light control) will result in

a shut-off on trouble with the automatic

furnace controller being locked.

The trouble is indicated by the trouble

signal lamp lighting up. The automatic

furnace controller can be unlocked

immediately after a shut-off on trouble

by pressing the unlocking key. The

program unit will return to its starting

position and proceed with the restart of

the burner.

A voltage failure will result in a regular

shut-off of the burner. After voltage

recovery, the burner can be

automatically restarted unless another

interlock is active, e.g. one caused by

the safety circuit. In any case, the fuel oil

supply will be immediately stopped upon

occurrence of a trouble.

The control unit will stop at the same

time causing also the trouble location

indicator to stop. The symbols will

indicate the kind of trouble.

Operation

Gas start-up mode

Gas operating mode

General safety functions

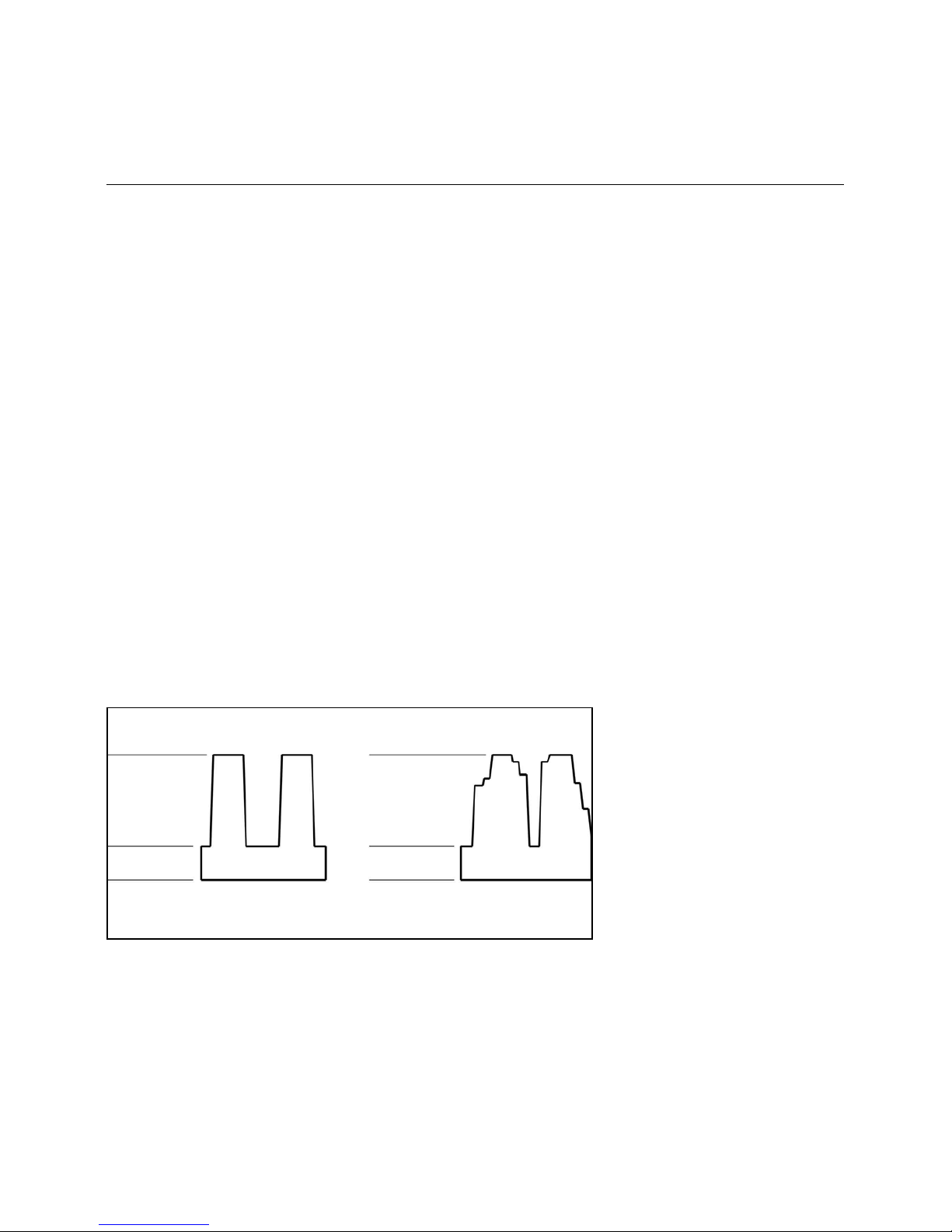

Full load

Operating position

Load regulator

Release

Partial load

Ignition/Gas valves

Gas control:

2-stage sliding Stepless

ON OFF

ON OFF

Full load

Operating position

Load regulator

Release

Start load

Partial load

Ignition/Gas valves

Page 5

10/2010 - Art. Nr. 4200 1030 6900A 5

Operation

Fuel-air compound control

Gas valves and instruments group

e

n

Fuel-air compound control

This compound control system with

precision-adjustment capability has

been designed to allow the fuel and air

flow rates to be steadily varied in sliding

mode for an adjustment of the fuel-air

ratio over the whole control range.

In the two-stage sliding control concept

the partial-load and full-load positions

are within the control range. Depending

on the heat demand these two load

points will be selected in sliding mode. A

larger fuel feed will not be suddenly

turned on or off. In the stepless control

mode the load will be controlled at any

point within the control range depending

on the heat demand. The two-stage

sliding and the stepless control concepts

are different only in the control systems

used with the burners. The same mode

of operation is used for both versions.

Mechanical compound control:

The compound control system will be

operated by the steplessly reversible

electric drive unit in dependence of the

heat requirement. The air damper and

the gas damper will be controlled by the

same system.

To ensure an optimum air-to-fuel

adjustment over the full control range, it

will be possible to vary the position of the

air damper by means of stud bolts

incorporated in the compound controller.

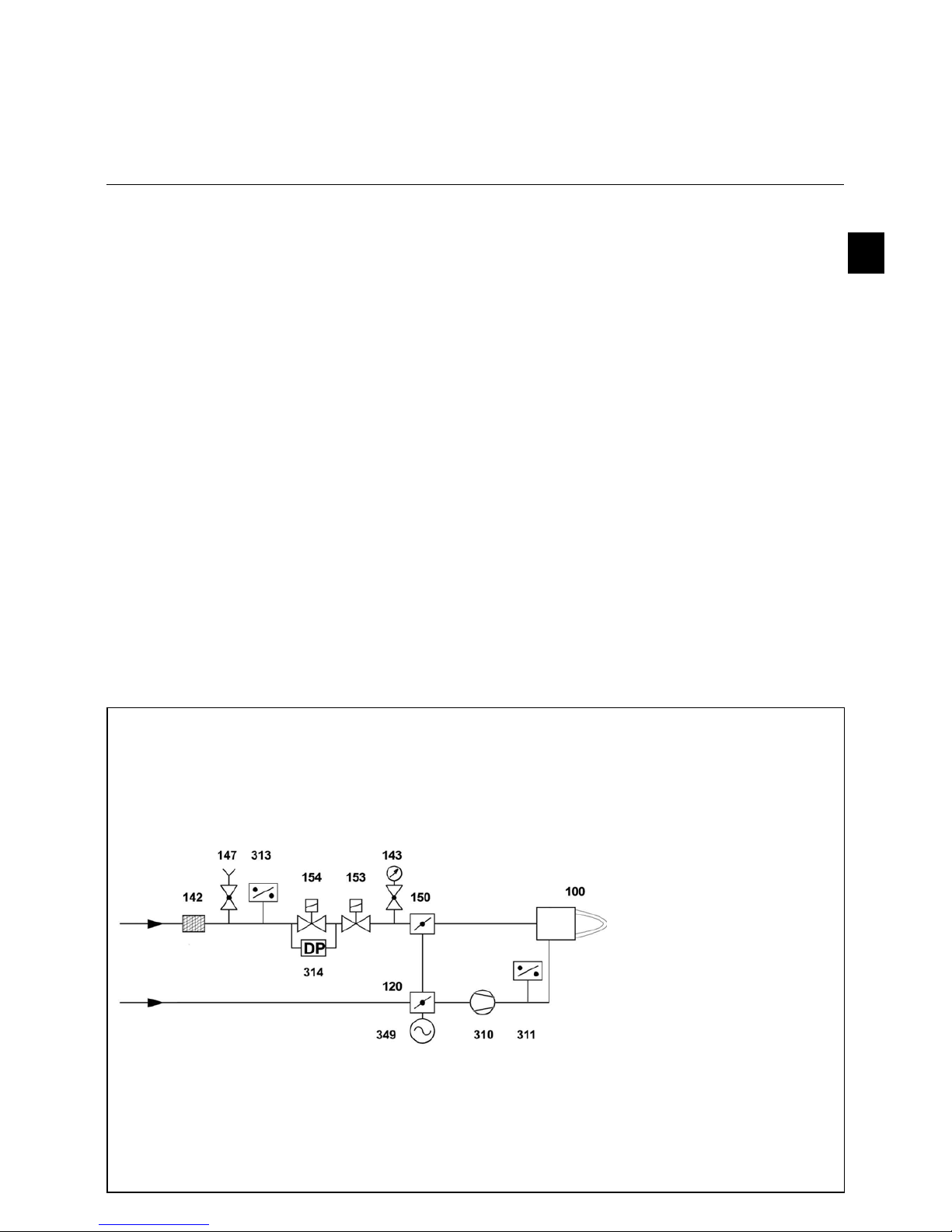

Gas valves and instruments group

The gas valves and instruments group

used with the furnace will be selected

according to the specific requirements to

be met by a burner system.

The following factors must be taken into

account:

• burner output

• furnace back pressure

• gas pressure loss of the burner head

• gas pressure losses of the gas valves

and instruments group

The total gas pressure loss must always

be smaller than the available gas flow

pressure.

NOTE: Use should only be made of gas

valves and instruments that have been

approved in accordance with the burner

test specifications.

100 Burner

120 Air damper

141 Ball valve

142 Gas filter

143 Pressure gauge with stop valve

147 Test burner with stop valve

(optional)

150 Gas damper

153 Main gas solenoid valve

154 Safety solenoid valve

310 Blower

311 Minimum air pressure switch

313 Minimum gas pressure switch

314 Leak test

349 Actuator

Page 6

10/2010 - Art. Nr. 4200 1030 6900A6

O peration

Autom atic furnace contro ller LFL 1.../LG K ...

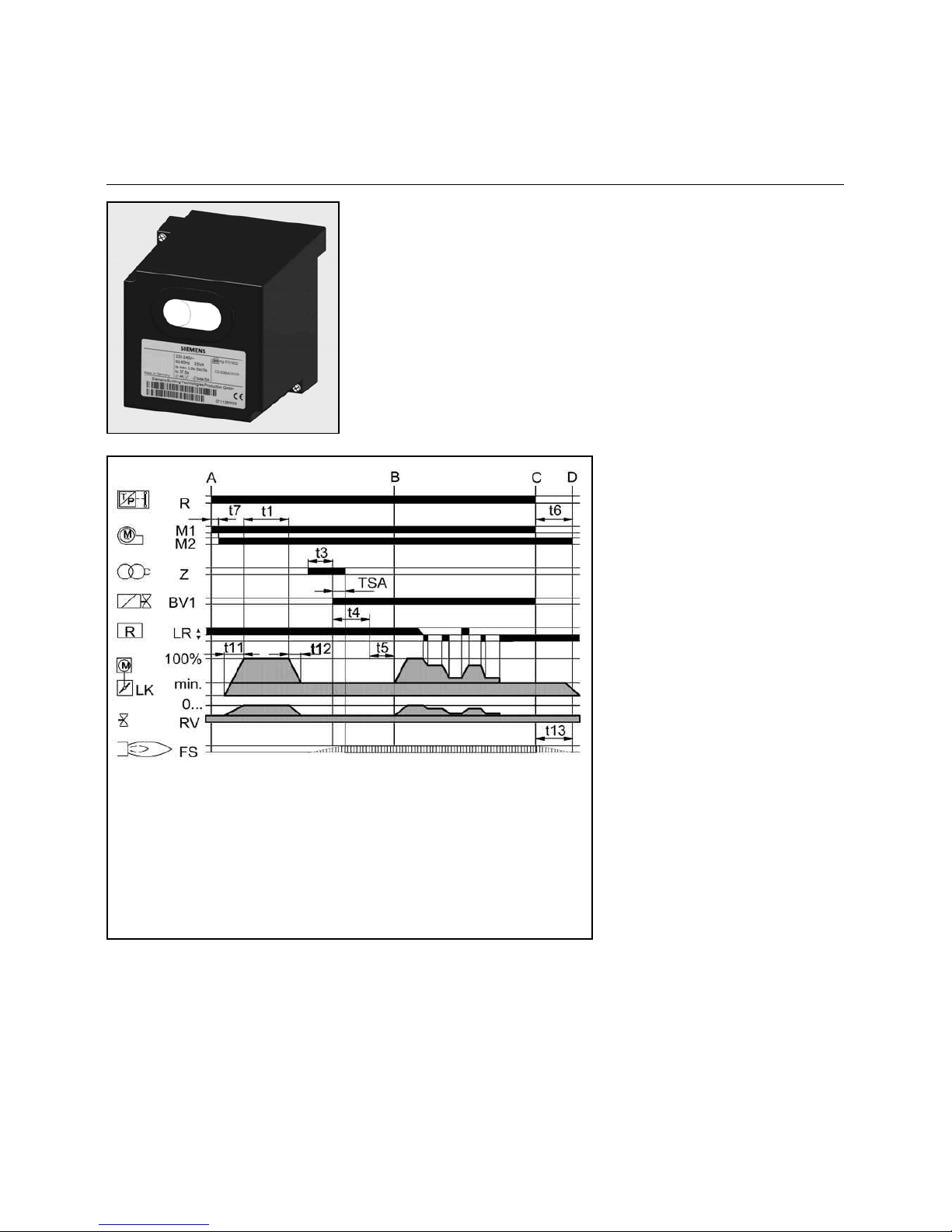

The LFL 1…/LGK... type controller is

designed to control and monitor burners

working according to a stepwise or

modulating principle. A detailed

functional description with technical data

and project planning information with

respect to the automatic combustion

controllers can be found in the annex

and in the documents:

LFL 1...-7451/LGK...

Functional diagram

LFL 1.../LGK...

A = Starting type interval

A-B= Flame development interval

B = Burner has reached operating

position

B-C= Burner operation

(heat generation)

C-D= regular shut-off

t1 Pre-ventilating time

t2 Safety time

t3 Pre-ignition time

t4 Fuel valve enable

t5 Load regulator enable

t11 „OPEN“ run time of air damper

t12 „CLOSE“ run time of air damper

R = Temperature or pressure

controller

M = Fan motor

Z = Ignition transformer

BV= Fuel valve(s)

LR= Load regulator

LK= Air damper

RV= Steadily adjustable fuel valve

FS= Signal of flame

Page 7

10/2010 - Art. Nr. 4200 1030 6900A 7

O peration

G as valve VG D with SKP actuator

G as valve M BC-SE

Technical data

Input pressure 360 mbar max.

Ambient temperature -15 to +50°C

Voltage 230 V/ 50 Hz max.

Protection rating IP 54

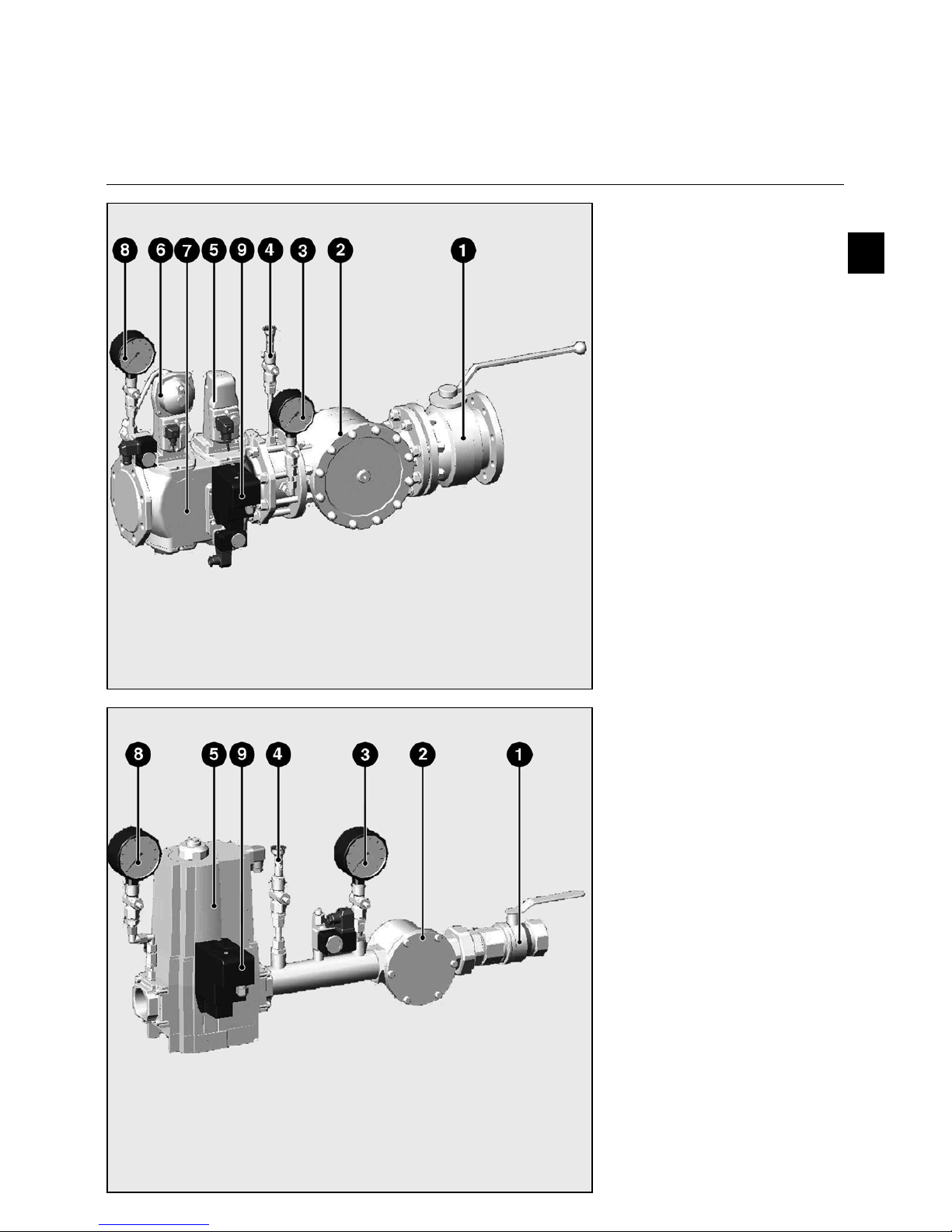

1 Gas ball valve (option)

2 Filter (under the cover)

3 Gas manometer with push button

(upstream) (option)

4 Test burner with push button

(option)

5 Actuator SKP 15

6 Actuator SKP 25

7 Gas main valve VGD..

8 Gas manometer with push button

(downstream) (option)

9 Gas tightness control unit

e

n

Technical data

Input pressure 360 mbar max.

Ambient temperature -15 to +50°C

Voltage 230 V/ 50 Hz max.

Absorbed output (in operation)

250 W max

Protection rating IP 54

1 Gas ball valve (option)

2 Filter (under the cover)

3 Gas manometer with push button

(upstream) (option)

4 Test burner with push button

(option)

5 Compact gas train (safety valve +

main valve)

8 Gas manometer with push button

(downstream) (option)

9 Gas tightness control unit

Page 8

10/2010 - Art. Nr. 4200 1030 6900A8

Assembly

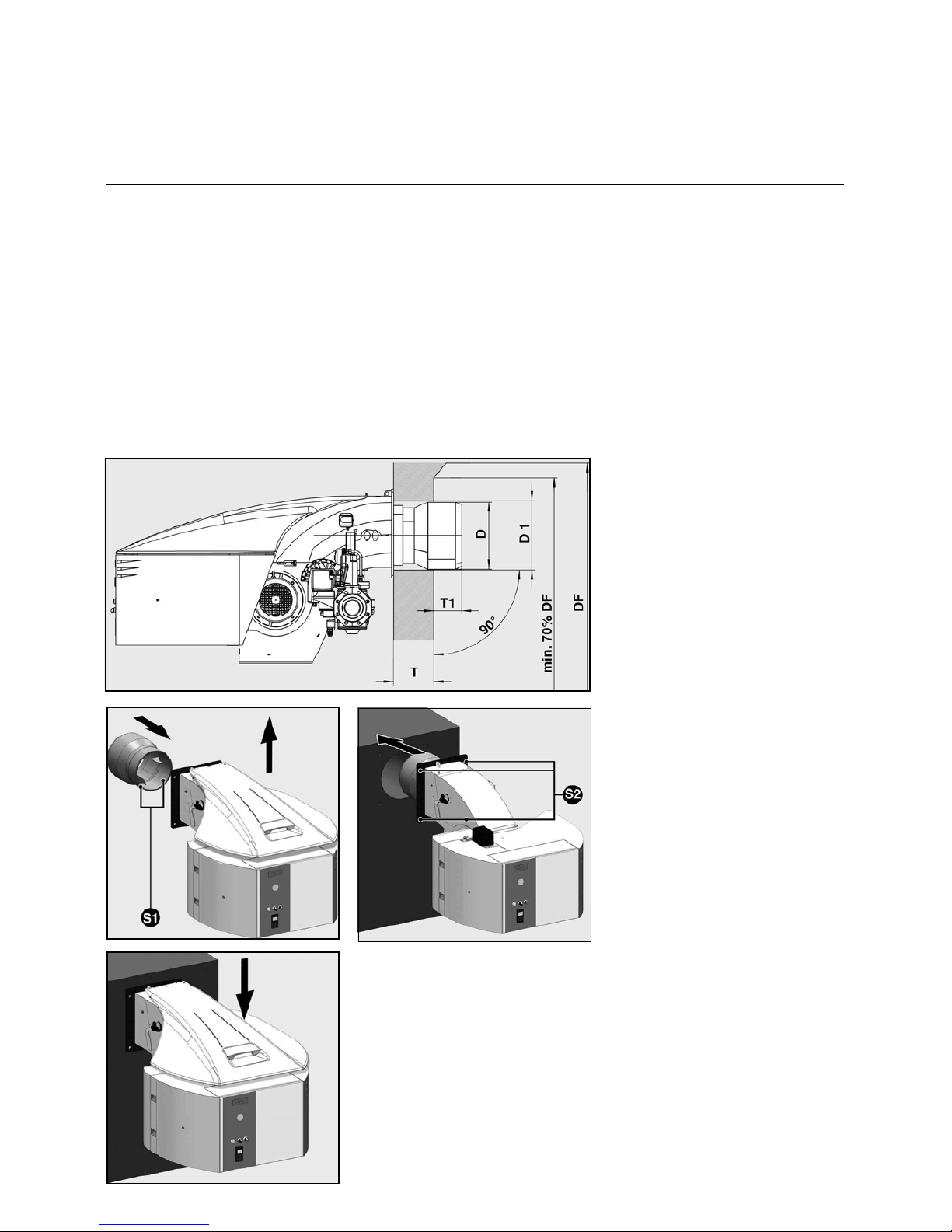

Boiler lining for G-R burner

Burner assembly

Boiler lining

The burner lining must be installed rightangled to the burner tube. Possible

trimming work (bevelling, rounding) as

required for reverse boilers, for example,

should be done at a diameter not below

70% of the combustion chamber

diameter. The space between the flame

pipe of the burner and the boiler lining

should be lined with heat resistant

material, such as Cerafelt.

This space is not allowed to be lined

with brickwork

Note for reverse flow boilers!

For reverse flow boilers the dimension

T1 is only a recommended value.

Depending on type of boiler the burner

head must stand at least 50 mm ahead

the opening for flue gas turning back.

D = see dimensioned drawings

D1 = see dimensioned drawings

DF = combustion chamber diameter

T1 > 80 mm

T = depth of boiler lining

(option: extensions: see technical data)

Burner assembly

• Take the burner tube (delivered in a

separate box).

• Fit it on burner body.

• Remove cover.

• Tighten the 2 fixing screws S1.

• Lift the burner, using the 2 hoisting

eyes 19 (see page 3) and fasten to the

boiler.

• Tighten the 4 fixing screws S2.

• Place cover back on.

Page 9

10/2010 - Art. Nr. 4200 1030 6900A 9

Assembly

Gas connection

Gas connection

The gas lines and valves and

instruments group should be installed

and taken into operation in accordance

with the applicable engineering

standards and regulations.

The connection between the gas

distribution network and the gas ramp

must be done by authorised persons.

The section of the pipings must be

calculated so that the loss of load

doesn’t exceed 5% of the distribution

pressure.

A quarter turn manual valve (not

supplied) must be provided for upstream

of the gas ramp and the filter.

The filter must be installed on a

horizontal nozzle with the cover in the

vertical position to enable cleaning.

The threaded unions used must be in

conformity with present standards

(tapered male thread, straight female

thread with sealing provided in the

thread).

Provide for sufficient space to access

the gas pressure switch adjustment.

Gas properties

Prior to any installation work make sure

to obtain the following data from the gas

supply company:

1. type of gas

2. calorific value H

un

=kW/m³ (kJ/m³)

3. maximum CO2 content of exhaust gas

4. gas connection pressure and rest

pressure

Type of gas test

Prior to mounting the burner to the gas

feed line check the available type of gas

and burner type against the data given

on the burner nameplate (attached to

burner). Be sure the description of the

burner and the type of gas are the same

as indicated on the nameplate.

Gas connection pressure

A minimum connection pressure must

be available upstream of the burner gas

valve to ensure the proper functioning of

the burner.

For the installation of the valves and

instruments group take care to observe

the mounting instructions supplied by

their manufacturers (these are packed

with the equipment).

The gas line installed to the burner must

be dimensioned in accordance with the

throughput rate and the available

pressure.

For selecting the nominal bore „DN“ of

the gas valves and instruments group

care should be taken to observe the

flue resistance of the boiler and the

gas pressure loss of the burner and

valves and instruments group.

Caution!

The absence of impurities and foreign

bodies must be checked before

installation and commissioning of the

gas ramp, the lever valves and unions.

Gas valves and instruments group

The gas valves and instruments group

can be connected directly to the gas

feed line. Take care to observe the

correct order of installation and

direction of flow (arrow on housing).

Check the valves and instruments and

connection pieces for absence of dirt

particles and foreign matter before

installation and initial operation. To

provide effective conditions for startup make sure the distance between

the burner and the gas stop valve is

as short as possible.

Leak test

The gas line upstream of the burner gas

valves and instruments group must be

installed in accordance with the

applicable regulations, checked for

absence of leaks, vented and certified

accordingly by the gas installation

company. The screwed unions and

flanged joints must be checked for

proper tightness (by making a pressure

test). The leak test must be made under

pressure using approved foaming

agents which do not cause corrosion.

For steam boiler furnaces the result of

the leak test must be duly certified.

Venting

Caution! Prior to taking the burner into

operation or after any repair work make

sure to vent the complete gas feed line

and the gas valves and instruments

group into the open atmosphere (e.g. by

means of a hose) taking care to avoid

any hazards.

In no case should the gas line be

vented into the heating or furnace

chambers. Make use of a test burner to

check the gas-carrying spaces are free

from an inflammable gas mixture.

Support

The valves and instruments group must

be supported with a telescopic jacking

member or similar during and after

installation (e.g. on filter and valve).

Joint

It is recommended to provide an easytodisconnect joint (with planar sealing

faces) to facilitate repair work on the

boiler (furnace) and allow the boiler door

to be swivelled out if required.

e

n

Page 10

10/2010 - Art. Nr. 4200 1030 6900A10

Assembly

Checking / assembling the combustion components

Burner A B

N6.2400 G-R 19 203

N6.2900 G-R 0 185

N7.3600 G-R 50

234.5

N7.4500 G-R 10

Assembling the combustion

components

• Check that the O-Ring J1 is in the

correct position in the gas elbow.

• Check the adjustment settings of the

ionisation probe and of the ignition

electrode as per the diagrams.

• Insert the combustion components

into the head, tighten the mounting

screws S3.

• Connect the ionisation cable IK and

the ignition cable ZK on the

combustion head.

• Connect the ignition cable ZK on the

ignition transformator T1.

Important

If there is a change to the type of gas

used, for example H or E natural gas

(G20) to L or LL gas ( G25) or vice versa,

the burner settings should be

completely overhauled.

It is not necessary to modify the

combustion head in any way.

Page 11

10/2010 - Art. Nr. 4200 1030 6900A 11

Assembly

Gas connection

Electrical connection

Checks before commissioning

Checks before commissioning

The following must be checked before

initial commissioning:

• That the burner is assembled in

accordance with the instructions given

here.

• That the burner is pre-set in

accordance with the values in the

adjustment table.

• Setting the combustion components.

• The heat generator must be ready for

operation, and the operating

regulations for the heat generator

must be observed.

• All electrical connections must be

correct.

• The heat generator and heating

system must be filled with water and

the circulating pumps must be in

operation.

• The temperature regulator, pressure

regulator, low water detectors and any

other safety or limiting devices that

might be fitted must be connected and

operational.

• The exhaust gas duct must be

unobstructed and the secondary air

system, if available, must be

operational.

• An adequate supply of fresh air must

be guaranteed.

• The heat request must be available.

• Sufficient gas pressure must be

available.

• The fuel supply lines must be

assembled correctly, checked for

leaks and bled.

• A standard-compliant measuring point

must be available, the exhaust gas

duct up to the measuring point must

be free of leaks to prevent anomalies

in the measurement results.

General regulations applying to the

gas connection

• The gas train must only be connected

to the gas mains by a recognised

specialist.

• The cross-section of the gas line

should be of a size designed to

guarantee that the gas flow pressure

does not drop below the specified

level.

• A manual shut-off valve (not supplied)

must be fitted upstream of the gas

train.

• In Germany, a thermally triggered

shut-off valve (to be installed by the

customer side) must be fitted as

specified by the draft combustion

ordinance.

It is the responsibility of the fitter or his

representative to obtain approval for the

system at the same time as the burner is

commissioned. Only the fitter or his

representative can guarantee that the

system meets applicable standards and

regulations. The fitter should be in

possession of the corresponding official

permit, and should carry out the

corresponding sealing tests and purge

the system of air.

All electrical installation and

connection work must only be carried

out by a suitably qualified electrician.

The applicable guidelines and

directives must be observed,

as well as the electrical circuit

diagram supplied with the

burner!

Electrical connection

• Check to ensure that the power supply

is as specified (230V, 50 Hz single

phase with neutral and earth)

Boiler fuse: 10 A

Electrical connection

It must be possible to disconnect the

burner from the mains using an

omnipolar shutdown device complying

with the standards in force.

Burner motor connection

The burner is delivered for a power

supply of 400V - 50Hz of triphase

current with neutral and earth.

Connect the burner motor cable to the

terminals in the electrical cabinet.

Check the direction of rotation of the

ventilation motor manually with the

burner contactor.

Connecting the gas train

Connect the gas train to the plugs on the

burner.

e

n

Page 12

10/2010 - Art. Nr. 4200 1030 6900A12

Commissioning

Burner power adjusting sequence

SQM actuator switch assignment

Description Pre setting Function

I 125° Max. power

(air and gas)

II 5° Closed flaps

(air and gas)

III 20° Gas min.

power

IV - Not used

V - Not used

Setting sequence (short description)

• In electrical cabinet, set switch on

"local control / hand" position or

• Adjust min. power switch (minimum

flame power), for example on 20°

• Adjust max. power switch (maximum

flame power) for example on 125°

• Check air shut-off switch (0°)

• Switch burner on

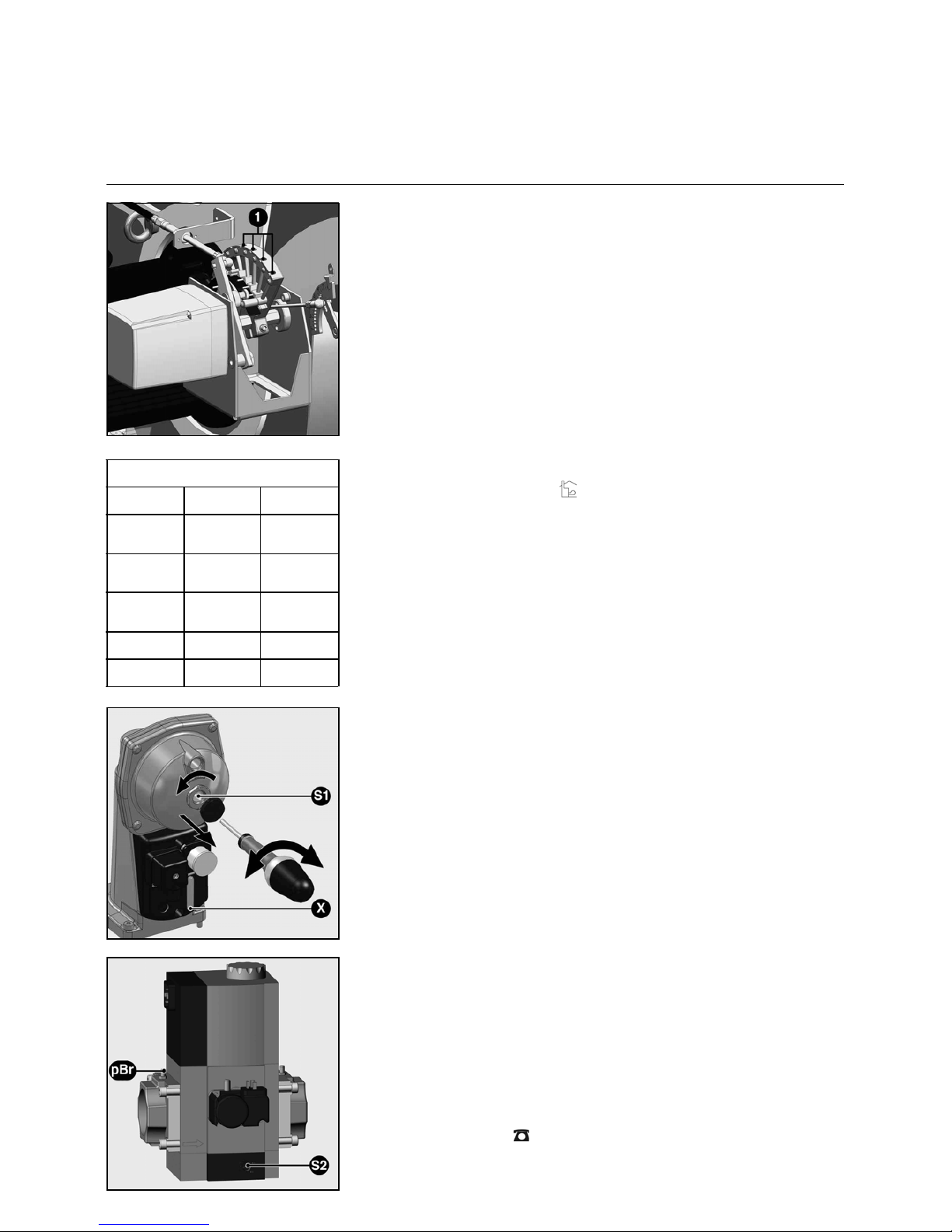

• Air flow-rate setting (min. power).

Screws (Pos. 1) allow the combustion

air flow-rate setting. Rotation to the

left : less air. Rotation to the right :

more air.

• Increase power gradually up to max.

power, either using "higher - lower"

"+/-" switch, either by disengaging the

actuator. During adjustment,

continuously check emissions of CO,

CO

2

and soot!

• Adjustment of max. power by setting

the air flow-rate and adjusting the gas

pressure. Adjust the max. power

switch again. Burner power should

never exceed the max. heat generator

allowed flame power.

(see chapter entitled ’’Exhaust gas test’’)

• Decrease power gradually down to

min. power using "higher - lower" "+/-"

switch, while accurately refining the air

flow according to the new defined gas

pressure.

• Register in a measurement report the

main data (flow rates, power, gas

pressure, air pressure, combustion

values) for at least three power levels

(min. power, intermediate power,

max. power).

• Adjust min. power switch (minimum

flame power) on the desired min.

power.

• Switch burner off

• Set switch on "automatic operation /

remote control" position .

• If fitted : go on with the electrical

modulating power controller setting

Gas pressure setting

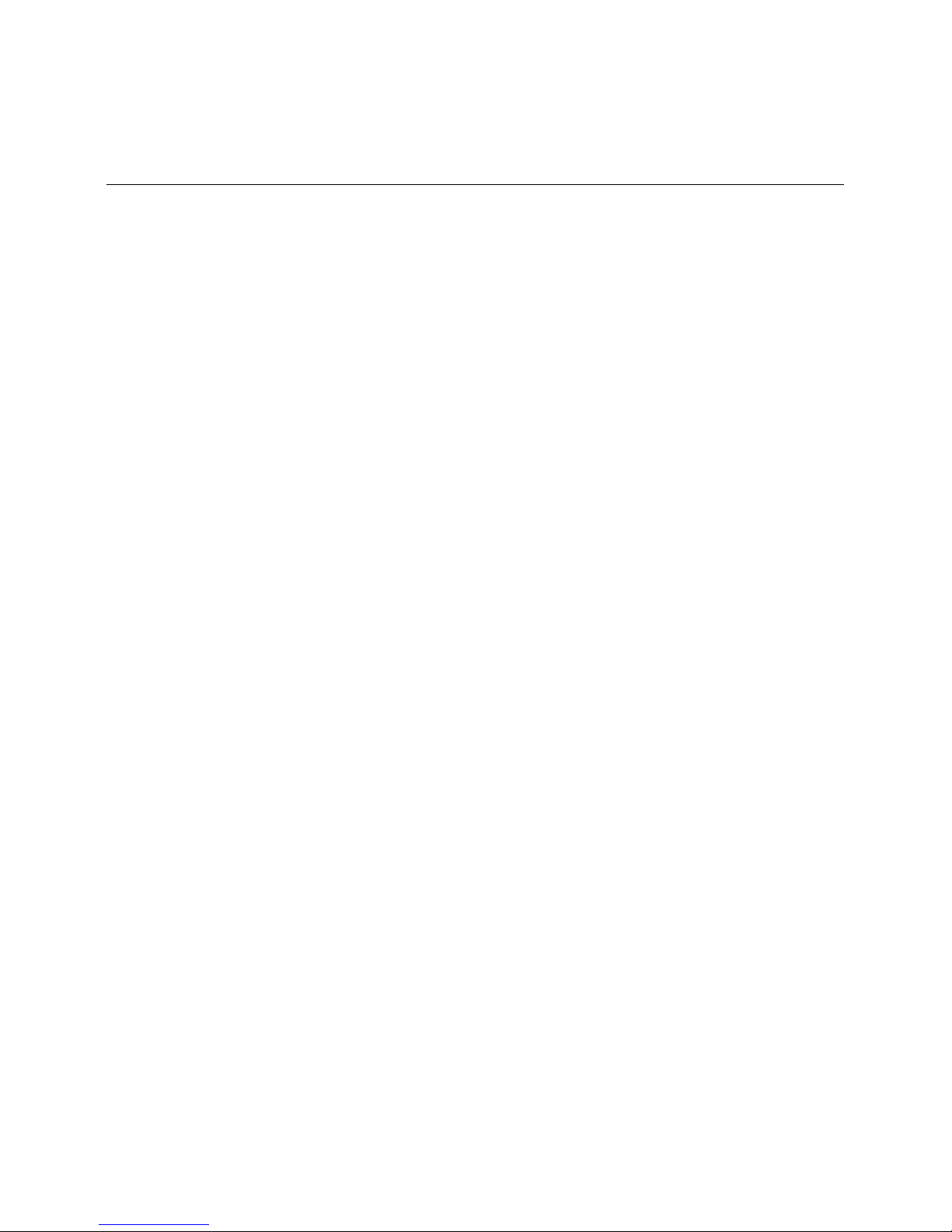

Gas train VGD

• Remove protection cap on SKP25

• Set gas pressure pBr using screw S1

(hidden by the cap)

• Check setting : position of the index in

relation with the scale X

Gas train MBC

• Set gas pressure pBr using screw S2

Caution!

Gas output pressure (regulator output

pressure) must be adjusted lower than

the input pressure, but higher than the

total gas pressure loss of the heating

plant.

Q

·

F

Q

·

N

η

--------

=

VGD ..

.

MBC ...

Page 13

10/2010 - Art. Nr. 4200 1030 6900A 13

e

n

Commissioning

Mechanical com pound

Electrical actuator

Limit sw itch setting

Technical data SQM actuator

Voltage 230 V -15%

50 / 60 Hz

240 V +10%

50 / 60 Hz

Power input 9 VA

Max. contact load250 V 10 (3) A

Mounting positionas required

Ambient

temperature -20°C + 50°C

Protection

classification IP 54, DIN 40050

Weight 1,7 kg

SQM10/11 SQM20/21

Running time at

130° turning

angle

42 Sec. 66 Sec.

Torque 10 Nm 20 Nm

Description

The SQM actuator is intended for use

with two-stage sliding or modulating oil,

gas or dual-fuel burners. The reversible

actuator is fitted with a synchronous

motor which drives a shaft via a

gearbox. The shaft end carries a

coupling to drive the fuel and

combustion air controlling element.

The SQM actuator has been designed

for dual-wire control by controller or

switching units with change-over

contacts. Potentiometers can be

installed for a range of applications on

customer's request.

The 60 Hz frequency will reduce the

running times by approx. 17 %.

Limit switch factory setting

Description Pre setting Function

I 125° Max. power

(air and gas)

II 5° Closed flaps

(air and gas)

III 20° Gas min.

power

IV - Not used

V - Not used

The limit and auxiliary switches are set

by means of manually adjustable

latching cam plates. Scales are fitted

between the disks to facilitate the

selection of the switching points.

The cam plates are provided with a

small pointer for indicating the switching

point of a scale between the setting

ranges.

An additional scale fitted to the end of

the cam roller serves to indicate the

position of the actuator.

The drive unit may be disconnected from

the controlling element by changing over

a rocker arm mounted to the gearbox.

This will allow any desired position of the

controller plate to be selected by hand.

Drive and output will be coupled in the

vertical position of the rocker arm.

The fuel-air curve should be set over the

full range of the cam plate so that

operating safety will be retained also

when the limit switch is overrun.

Positions

1 Terminals

2 Cam setting key

3 Scales for switching point setting

4 Rocker arm for uncoupling

5 Scale for actuator position

6 Actuator position indicator

7 Shaft end to fit a return

potentiometer

8 Power supply

Important

A l'issue du réglage des manostats,

ceux-ci doivent être protégés contre tout

dérèglement. Ceci peut par exemple

être réalisé par le marquage, à l'aide

d'un vernis, d'au moins une vis sur le

couvercle de protection des appareils.

A l'issue de la mise en service du

brûleur, il est nécessaire de vérifier le

fonctionnement correct des systèmes

de sécurité du brûleur. De même, après

la mise en service, il est nécessaire de

vérifier le fonctionnement correct de la

chaîne de sécurité de la chaudière par

rapport à la réglementation en vigueur.

Cette vérification doit avoir lieu en

accord avec l'exploitant.

Page 14

10/2010 - Art. Nr. 4200 1030 6900A14

Commissioning

M onitoring of the flam e by ionisation

Sensor c u rre n t m easurem ent

Ionisation monitoring

Detection of the flame using an

ionisation device. Flame detection is

achieved using the conductivity and the

rectification effect of the hot flame

gases. An alternating voltage is applied

to the sensor (in refractory material),

which is dipped into the flame. When a

flame is present, the current (ionisation

current) circulates and forms the flame

signal. This signal is transmitted to the

input of the flame signal amplifier. The

flame signal amplifier is designed to

react only to the continuity of the flame

signal. This eliminates the possibility for

confusion of a potential short-circuit

between the sensor electrode and earth

with a flame signal (as an alternating

current would be used in this scenario).

Use a microammeter to measure the

signal (take into account the

measurement range). This device is

placed between the control box and the

ionisation electrode. Make sure the

polarity of the device is observed (see

connection examples for the control box

LFL 1…/LGK...).

During ionisation monitoring, it is

important that the signal is transmitted

without wastage. The connection cable

must not lie adjacent to a multicore

cable. A soiled sensor electrode bracket

or faulty ceramics encourage leakage

currents, which reduce the flame signal.

The burner (as a counter electrode)

must be earthed in conformity with the

directives. If this is not the case, an

ionisation current cannot flow. Earthing

of the boiler only is often inadequate.

The ionisation current must be

monitored when the burner is set to

ensure combustion hygiene, i.e. when

switching from partial load to full load.

The ionisation current must not fall

below the minimum monitoring current

required. A large drop in the ionisation

current indicates either a lack or an

excess of air. These malfunctions must

be corrected using appropriate

methods. A consistently high ionisation

current indicates a stable flame and the

correct combustion hygiene.

Sensor currents

* See technical data for automatic

furnace controller LFL 1.../LGK...

Automatic

controller

Minimum

required

Maximum

possible

* LFL 1...

LGK...

6 µA-µA

Recommended instrument range:

0 - 150 µA

Page 15

10/2010 - Art. Nr. 4200 1030 6900A 15

e

n

Commissioning

Gas pressure switch

Air pressure switch

Determining the differential preflushing pressure and adjusting the

differential pressure switch

• Burner in the pre-aeration phase.

• Measure pressure on test

connection (2).

• Measure vacuum on test

connection (3).

• Add the measured pressures.

• Set the scale to 90% of the calculated

value.

Switch function test

• Test buttons are provided to check the

switch functions for proper operation

(with safety cut-out and interlock). The

burner is normally run in partial-load

condition when testing the safety

functions. On pressing button (4) the

vacuum will be removed which causes

the differential pressure to drop below

the required level. If it is necessary to

test the pressure switch functions

under full-load conditions this may be

done by pressing button (1).

Gas pressure switch A6

Technical data:

Type of gas:

Gases according to DVGW Worksheet

G 260/1, gas families 1, 2, 3

Degree of protection: IP 54

Ambient temperature: -15°C to +50°C

Mounting position: any

Operating pressure up to:

GW 50/150 A5A6 500 mbar

GW 500/ A5/A6 600 mbar

Gas pressure switch GW...A5/A6

The gas pressure switch is designed to

monitor the gas flow pressure. It can be

used for monitoring either falling

pressure (minimum) or rising pressure

(maximum, specified for equipment

according to TRD 604).

The types GW...A5/A6 may be used as

pressure switches of specific design

according to VdTÜV Leaflet "Pressure

100/1" for application in furnace systems

complying with TRD 604. The setpoint

(switching point) may be selected by

means of a setting disk with scale.

Air pressure switch

The air pressure switch is provided for

monitoring the pressure of the

combustion air fan.

The pressure switch „Dungs“ LGW...

has been designed for switching on, off

or over an electric circuit in the case of

changes of the actual pressure levels

from the setpoint setting. The pressure

switch LGW... can be used as

overpressure, vacuum or differential

pressure monitor for air and nonaggressive gases but not for gases

according to DVGW Worksheet G 260/l.

Certification

The pressure switch has been tested in

accordance with DIN 3398 Part 2 and is

registered by CE/DIN-DVGW. It has

been registered in other important gas

consumption countries.

Important

Once the pressure switches have

been set, they must be protected to

prevent settings from being altered.

For example, this can be done by

placing a spot of varnish on at least

one of the screws on the equipment's

protective cover.

Gas pressure switch A5

Setting the min. gas pressure switch

• Remove the protective cover.

• At the rated output, measure the gas

flow pressure and calculate the

switch-off pressure by reducing by

approximately 20%.

• Adjust the graduated disc to the

desired switch-off pressure opposite

the arrow (the graduations are

approximate values).

• Operate the burner at minimum power.

• Close the gas cut-off valve slowly to

obtain the desired switch-off pressure.

• Turn the graduated disc until the

burner switches off.

• Refit and screw down the protective

cover.

Max. gas pressure switch

• Remove the protective cover.

• At the rated output, measure the gas

flow pressure and calculate the

switch-off pressure by increasing by

approximately 20% (no more than

30% under any circumstances).

• Adjust the graduated disc to the

desired switch-off pressure opposite

the arrow (the graduations are

approximate values).

• Operate the burner at minimum power.

If the max. gas pressure switch

switches off the burner, increase the

adjustment value but not to more than

130% of the flow pressure at the rated

output.

Page 16

10/2010 - Art. Nr. 4200 1030 6900A16

Specifications for the design,

construction and safety features of gas

furnace systems in heating installations

are contained in DIN 4756 and TRD 412.

Heating installations with higher

operating pressures are subject to the

DVGW Worksheets G 460 and G 461.

The gas pipes must meet the

specifications of DVGW-TRGI in the

case of installations with operating

pressures up to 100 mbar or higher

than100 mbar.

Gas connection pressure

To ensure the proper functioning of the

burner, a minimum connection pressure

must be available.

The gas feed pipe to the burner must be

dimensioned according to the

throughput rate and the available

pressure.

The nominal bore (DN) of the gas valves

and instruments group must be selected

on the basis of the resistance of the

boiler on its flue-gas side and the gas

pressure loss of the burner and

valves and instruments group.

Gas valves and instruments group

The gas valves and instruments group

may be connected directly to the gas

supply line. Care should be taken to

install the valves and instruments in the

specified order and according to the

direction of flow (arrow on housing).

Prior to installation and operation, check

the valves and instruments and the

connecting elements for possible

accumulated dirt particles and foreign

matter. To ensure proper conditions

for start-up, the distance between the

burner and the gas shut-off valve

must be as low as possible.

On completion of installation the gas

valves and instruments group must be

subjected to a leak test in accordance

with DVGW Worksheet G 600 and G

490 in the furnace system.

Gas valves and instruments group

Description

Gas valves and instruments group type

VGD

Technical data:

Types of gas:

Gas types of gas families 1, 2 and 3

according to DVGW Worksheet

G 260/1

Max. inlet pressure:

500 mbar

Electrical connection: 230-240V, 50Hz

Protection classification: IP 54

Ambient temperature:

-15°C to +50°C

Description

The gas valves and instruments groups

type VGD (screwed and flanged valves)

are provided for gas supply, main shutoff, gas filtration and gas supply

pressure control and monitoring. They

can be used for all types of gases in the

gas families 1, 2 and 3 according to

Worksheet G 260/1. The valves and

instruments groups are constructed as

specified by EN 676 and DIN 4788, Part

2. All functional parts have been

checked by individual tests and

approved by a CE and DIN-DVGW

registration number.

A detailed description of the valves and

instruments used is contained in the

Technical Datasheet for the Gas Valves

and Instruments Groups Type VGD.

The premounted gas valves and

instruments group is subjected to a leak

test at the manufacturer's works.

For the installation and start-up of the

gas pipes take care to observe the rules

and regulations set forth by DVGW,

especially DVGW-TRGI and TRF.

Page 17

10/2010 - Art. Nr. 4200 1030 6900A 17

e

n

Gas valves and instruments groups

Basic construction

100 Burner

101 Impulse pipe gas pressure

120 Air flap

141 Ball valve

142 Gas filter

150 Gas control butterfly

151 Gas double valve (Siemens system illustrated)

155 Ignition unit

313 Min. gas pressure switch

314 Gas pressure switch for valve leak check or valve leak

checker

349 Actuator

Options in accordance with country-specific requirements:

143 Pressure gauge with pushbutton valve

147 Test burner with pushbutton valve

148 Compensator

154 Gas safety valve (additional)

313a Max. gas pressure switch

The burner's scope of delivery may

include a gas train. In this case, the

burner and the gas train are issued with

a CE Declaration of Conformity. If the

gas train is not delivered with the burner,

the conformity of the burner is valid only

if the gas fittings and instruments and

the design of the gas train satisfy the

burner test specified by EN 676 and

meet the Pressure Equipment Directive.

Individual testing will be necessary

where this is not the case.

The gas train delivered has its own

documentation including operating

instructions and a spare parts list. There

follows a general description of the gas

train.

Gas trains with a double valve are

intended for the supply, main shut-off,

gas filtration, gas pressure regulation

and monitoring of the gas supply. They

are compatible for use with gases

conforming to the specifications of the

gas fittings and instruments. They are

built in accordance with EN 676. All

function parts have been individually

tested and awarded the CE marking and

number of the Notified Body. The

preassembled gas train is checked for

leaks in the factory.

Low- and high-pressure gas trains

If the outlet side of the regulator, i.e.

individual fittings and instruments

downstream of the gas pressure

regulator, has not been designed to be

compatible with the maximum supply

pressure that occurs in the event of a

fault, the gas train must be equipped

with a safety shut-off valve (SSV) and a

safety relief valve (SRV) in accordance

with EN 676. This equipment is

generally required for maximum supply

pressures of >360 mbar and > 500 mbar

respectively. These are known as

highpressure gas trains.

If all fittings and instruments of the gas

train have been designed/approved for

the maximum supply pressure that

occurs in the event of a fault, the gas

train is known as a low-pressure gas

train. This is the case, depending on

component selection, for maximum

supply pressures of 360 and 500 mbar.

Page 18

10/2010 - Art. Nr. 4200 1030 6900A18

Gas valves and instruments groups

Basic construction

100 Burner

101 Impulse pipe gas pressure

120 Air flap

141 Ball valve

142 Gas filter

144 Gas pressure regulator

145 Safety shut-off valve (SSV)

148 Safety relief valve (SRV)

150 Gas control butterfly

151 Gas double valve with integrated gas pressure

regulator (Siemens system illustrated)

155 Ignition unit

313 Min. gas pressure switch

314 Gas pressure switch for valve leak check or valve

leak checker

349 Actuator

Options in accordance with country-specific requirements:

143 Pressure gauge with pushbutton valve

147 Test burner with pushbutton valve

148 Compensator

154 Gas safety valve (additional)

313a Max. gas pressure switch

Gas valves and instruments group

The gas trains must be dimensioned to

suit the throughput required and the

available gas pressure. The gas valves

and instruments group is defined on a

system-specific basis.

The following must be taken into

consideration:

• Burner output,

• Combustion chamber counterpressure,

• Gas pressure loss in the burner head,

• Gas pressure losses in the gas fittings

and instruments.

The total drop in gas pressure must

always be lower than the available gas

flow pressure.

Page 19

10/2010 - Art. Nr. 4200 1030 6900A 19

Gas valves and instruments groups

Basic construction

Installation and mounting of the gas

filter

The gas filter may be installed in any

desired position. Take care only to

observe the direction of flow of the gas

(arrow on filter housing). Make sure

there is adequate clearance to facilitate

the removal of the cover and

replacement of the filter cartridge.

Filter replacement

The filter cartridge should be replaced

by a new one as soon as a high pressure

drop is noticed. If a new filter cartridge is

not at hand it will be possible to wash the

filter mat in 40°C water adding some

light-duty detergent. Allow the mat to dry

before reinstallation.

NOTE: For the installation of the filter

mat take care to observe the marking or

sticker.

e

n

Test burner

Depending on the country-specific

requirements, when installing steam

boilers it may be necessary to fit a test

burner to the gas train (e.g. in line with

directive TRD 412). This is used to vent

the gas pipes. The gas supply is

switched on by pressing the button (1).

The flow of gas brings in the required

amount of combustion air via the hole in

the body (3). The gas/air mixture is

routed towards the burner head (4) and

ignited manually at its opening. Gas is

supplied for as long as the button is

pressed and cut off when it is released.

Technical features:

• Types of gas:

Gas in accordance with sheet G 260/1

of the DVGW, gas families 1, 2, 3

• Ambient temperature: -15°C to +70°C

• Assembly position: vertical, facing

upwards

• Operating pressure up to: 500 mbar

Page 20

10/2010 - Art. Nr. 4200 1030 6900A20

Gas valves and instruments group

Gas valve leakage controller

Leakage controller VPS 504 S02

Working principle :

Prior to each burner start-up, the

controller checks for possible leaks

between safety and main valves by

increasing distribution pressure.

Electrically, the leakage controller is

serially connected between the

thermostatic circuit and burner control

and safety unit.

Installation :

Directly on valve.

Program stages :

On stoppage, safety and main valves

are closed.

On thermostat stoppage, the leakage

controller is turned on and booster

increases distribution pressure by

20mbar.

After no more than 30 seconds

operation :

- If leakage test is OK; yellow light

comes on and current is released to

feed the burner’s control and safety

unit, which then starts its cycle.

- If leakage test is NOK; red light comes

on and no power is fed to the control

and safety unit.

Control cycles have to be restarted

manually. Change valve if defect

persists.

Setting :

The controller requires no on-site

setting.

Working test :

While controller is working :

• Open pa pressure take-off. Leak

caused prevents superpressure from

building up and safety unit locks after

30 seconds.

• Reclose pa pressure take-off.

• Release controller safety by pressing

red indicator light.

Leakage test restarts and, after 30

seconds, yellow indicator lights up and

powers up the control and safety unit,

which begins its cycle.

1 Wieland 7P socket

3 Filter element

4 O-ring Ø10.5x2.25

5 Fuse T6.3 250V Ø 5x20

6 Yellow indicator On :

Leakage test OK

7 Red indicator On :

Leakage test NOK

Manual clear

8 Spare fuses

9 pa (p2) pressure take-off Ø 9

pe + 20mbar

10 pe (p1) pressure take-off Ø 9

i nlet pressure (distribution)

Page 21

10/2010 - Art. Nr. 4200 1030 6900A 21

Servicing

Maintenance

Burner and boiler servicing must only

be carried out by a professionally

qualified heating engineer. The system

operator is advised to take out a

maintenance contract to guarantee

regular servicing. Depending on the

type of installation, shorter

maintenance intervals may be

necessary.

1. Turn off the power supply and protect

the system from accidental start-up.

2. Cut the gas supply.

3. Make sure there is no residual power in

the system and that the actions in points

1 and 2 have been completed.

4. Before opening the burner casing,

ensure that the fan motor has stopped

completely.

Failure to observe any of these

instructions will result in the risk of

death or injury!

• Use original spare parts.

Work recommended as part of annual

burner maintenance:

- Burner test run, input measurement in

the boiler room

- Clean the combustion components

and replace defective parts if

necessary

- Clean the fan wheel and the blower

- Clean the gas filter; replace it if

necessary

- Visual inspection of the burner's

electrical components; eliminate

malfunctions if necessary

- Check burner start characteristics

- Leakage test

- Burner safety devices function check

(air pressure/gas pressure switches)

- Flame monitor and automatic

combustion control unit function check

- Commissioning the burner

- Check the gas flow

- Correct the adjustment values if

necessary

- Draw up a measurement report

General checks

- Emergency stop button function check

- Visual inspection of gas lines in the

boiler room

Checking the combustion

components

• Loosen the 2 screws S to remove the

burner hood.

• Remove the 7 screws W to remove the

combustion components access

cover.

• Remove the combustion components.

• Check the ignition electrodes and the

ignition cable; replace if necessary.

• Clean the baffle plate.

• Check adjustments and settings

during assembly.

Cleaning the fan

• Disconnect the motor by unplugging it

from the power supply.

• Remove the motor.

• Thoroughly clean the fan.

• Do not use pressurised materials.

• Reassemble.

e

n

Page 22

10/2010 - Art. Nr. 4200 1030 6900A22

Servicing

Maintenance

Filter replacement

• The filter element of the must be

checked at least once a year and

replaced if clogged.

• Loosen the screws of the filter cap.

• Remove the filter element and clean its

housing.

• Do not use any pressurised cleaning

products.

• Replace the filter element with a new

element.

• Screw the cover back into place.

• Reopen the manual shut-off valve.

• Check it is airtight.

• Check the combustion values.

Cleaning the cover

• Do not use abrasive products or

products containing chlorine.

• Clean the cover with water and a

suitable cleaning product.

• Refit the cover.

Precautions

After any operation: check the

combustion performance under real

operating conditions (doors shut,

cover fitted etc.). Record the results

in the relevant documents.

Important

Once the pressure switches have

been set, they must be protected to

prevent settings from being altered.

For example, this can be done by

placing a spot of varnish on at least

one of the screws on the equipment's

protective cover.

Following maintenance on the

burner, and after its safety system

settings have been modified (e.g. the

pressure switches), the burner's

safety systems must be checked to

ensure they are operating correctly.

Likewise, following burner

maintenance, it is necessary to check

that the boiler's safety chain is

operating correctly in accordance

with the regulations in force. This

check must be carried out with the

user's agreement.

Checking the flue gas temperature

• Check the flue gas temperature at

regular intervals.

• Clean the boiler if the flue gas

temperature is more than 30 °C above

the value measured at the time of

commissioning.

• Use a flue gas temperature gauge to

make the check easier.

Page 23

10/2010 - Art. Nr. 4200 1030 6900A 23

Servicing

Exhaust gas test

Trouble shooting instructions

Exhaust gas loss

Exhaust gas loss by way of free heat will

occur as a result of the temperature

difference between the fuel-air mixture

entering the furnace chamber and the

gases discharged. Any increase in the

excess of air and the resultant higher

exhaust gas volume will cause the

exhaust gas loss to rise. The exhaust

gas loss can be calculated as follows:

q

A

= exhaust gas loss in %

t

A

= exhaust gas temperature in °C

t

L

= combustion air temperature in °C

CO

2

= volumetric content of carbon

dioxide in %

O

2

= volumetric content of oxygen

in %

q

A

tAt

L

∠()

A

1

CO

2

------------B+

⋅=

In any case of trouble proceed with

checking the basic conditions for a

proper operation of the boiler

system:

1. Is electric power available?

2. Is ther any gas pressure?

3. Are the shut-off valves opened?

4. Are all control and safety instruments

such as boiler thermostat, water

supply failure cut-out, limit switches,

etc. properly set?

1. Ignition failure

Cause Remedy

Ignition

electrode short

circuit.

Adjust

electrodes.

Wide ignition

electrode

spacing.

Adjust

electrodes.

Dirty and wet

electrodes.

Clean

electrodes.

Cracked

insulator.

Replace

insulator.

Defective

ignition

transformer.

Replace

transformer.

Defective

automatic

furnace

controller.

Replace

controller.

Burnt ignition

cable.

Replace cable;

search for cause

and eliminate.

Pilot burner

failure.

Adjust ignition

gas pressure

Ignition gas

valve does not

open.

Search for cause

and eliminate

Defective

solenoid.

Replace

2. Motor running failure

Cause Remedy

Motor protection

relay and fuses.

Check and

replace if

required.

Air pressure

switch not

changed over or

defective.

Check and

replace if

required.

Defective motor. Replace motor.

Defective power

contactor.

Replace

contactor.

Air fan motor

starts but stops

after 20-25 secs.

Check for

solenoid leaks

Air fan motor

starts, but stops

after about 10

secs in preventilating mode.

Air pressure

switch fails to

change over;

replace switch if

defective; clean

switch if dirt has

accumulated;

check electrical

connections.

3. No response to flame by

automatic furnace controller

with flame sensor

Cause Remedy

Dirty flame

sensor.

Clean flame

sensor.

Burner fails to

start.

Check

connection of

automatic

furnace

controller.

Trouble lamp

lights; flame

trouble.

Unlock and

search for cause

Ionisation

current too

weak.

Check

combustion

setting.

Burner starts

without flame

formation.

Solenoid valve

fails to open.

Defective coil or

rectifier.

Check

connection.

Lack of gas or

gas pressure too

low.

Check gas

pressure

controller, gas

valve, gas filter.

Is the equipment

gas cock open?

Example:

Data measured in natural gas mode:

CO

2

content of exhaust gases 10,8%

Exhaust gas temperature 195°C

Air intake temperature 22°C

The exhaust gas loss can be calculated

as follows:

Natural

gas

Town

gas

L.P.G.

A

1

= 0,370 0,350 0,420

B = 0,009 0,011 0,008

e

n

Page 24

10/2010 - Art. Nr. 4200 1030 6900A24

Servicing

Exhaust gas test

Trouble shooting instructions

6. Cleaning and lubricating

instructions

Depending on the amount of dirt

introduced by the combustion air it will

be necessary to clean the fan impeller,

ignition electrodes, flame sensors and

air dampers as required.

For burner with mechanical compound

controller:

Lubricate the compound controller

setting screws with grease.

The bearing points of the burner moving

parts require no maintenance. Damages

of ball bearings should be detected and

eliminated at an early stage to avoid

greater subsequent trouble. Listen to the

motor bearing noise to identify possible

irregularities.

4. Mixing unit gives poor

combustion data

Cause Remedy

Incorrect

settings.

Correct settings.

Incorrect mixture

ignition unit.

Replace unit.

High or low

combustion air

flow rate.

Readjust burner.

Furnace

chamber not

sufficiently

ventilated.

Furnace

chamber to be

ventilated

through a nonclosed opening

with a cross

section of min.

50 % of all

chimney cross

sections of the

furnace system.

Take care to

observe the

application

regulations.

5. Solenoid valve fails to open

Cause Remedy

Defective coil or

SKP actuator.

Replace coil or

SKP actuator.

Defective

automatic

furnace

controller.

Replace

automatic

furnace

controller.

Valve does not

close tightly; dirt

accumulated on

sealing surfaces.

Open valve;

remove foreign

matter; replace

valve if required.

Page 25

10/2010 - Art. Nr. 4200 1030 6900A 25

Servicing

Operating trouble

In case of operating trouble it should

be checked whether the system is in

proper working order.

Make a check for the following:

1. Availability of fuel. Availability of gas

in the line at sufficiently high

pressure. Availability of fuel oil in the

tank (for dual fuel burner). Correct

position of fuel selector switch.

2. Availability of electric power in the

burner system.

3. Proper functional order and setting of

all control and safety instruments

such as temperature controller,

safety limiter, water failure cut-out,

electrical limit switches, etc. If the

trouble is not found to be due to any

of the above-mentioned points it will

be necessary to test the burner

functions very carefully.

Prevailing conditions:

The burner will be found to be out of

operation and in faulty and interlocked

position.

Proceed with searching for the cause of

the trouble and eliminate it. Unlock the

automatic furnace controller by pressing

the fault eliminate key and start the

burner.

Do not press the fault eliminate key

longer than 10 seconds.

The start-up program will be initiated

and should be carefully monitored.

The possible cause of the fault may be

quickly found by reference to the fault

indicator of the automatic furnace

controller and watching the start-up and

operating program.

Control program in the case of

trouble and fault indicator LFL 1... /

LGK...

a - b Starting program.

b-b' In a number of time versions; idle

steps of the program unit to selfstop after burner start-up

(b' = operating position of program

unit).

b(b')-aAfter-flushing program after

regular stop. In the starting

position „a“ the program unit will

automatically stop or initiate an

immediate restart of the burner,

e.g. after a fault has been

eliminated.

• Duration of the safety period for

single-tube burners.

•• Duration of the safety period for

burners with ignition gas valve.

Basically, any type of trouble will

result in the immediate stop of the

fuel supply. At the same time, the

program unit and consequently the fault

indicator will stop. The type of trouble

can be identified by the symbol opposite

to the reading mark of the indicator:

No start, e.g. because the

„CLOSED“ signal from the „Air

Damper CLOSED“ limit switch is

missing or a contact is not closed

between terminals (12) and (4) or

(4) and (5); or the contacts of all

control and safety units in the

controlled system are not closed

(e.g. gas pressure or air pressure

switches, temperature or pressure

switches, temperature or pressure

regulators).

Operating stop because the

„OPEN“ signal from the „Air

Damper OPEN“ limit switch is

missing. Check and adjust the limit

switch concerned.

Shut-off on trouble because

there is not air pressure signal at

the beginning of the air pressure

check. Any air pressure failure

after this time will also lead to a

shut-off on trouble.

I Shut-off on trouble because of a

fault in the flame monitoring circuit.

Operating stop because the

position signal of the „Partial Load“

limit switch (air damper in „Partial

Load“ position) is not available on

terminal (8). Check and adjust the

limit switch concerned.

1 Shut-off on trouble because a

flame signal is not available on the

expiry of the (1st) safety time.

Any failure of the flame signal on the

expiry of the safety time will also lead

to a shut-off on trouble.

2 Shut-off on trouble because the

flame signal has not occurred on

the expiry of the (2nd) safety time

(flame signal of main flame with

burners having an ignition gas

valve).

Shut-off on trouble because the

flame signal failed during burner

operation or a lack of air has

occurred.

Shut-off on trouble during or after

the control program flow due to

external light (e.g. by flame not

extinguished, leaking fuel valves)

or a faulty flame signal (e.g. fault in

flame monitoring circuit, or similar);

see flame monitor.

If the shut-off on trouble occurs at

any other time between start and preignition that is not identified by a

symbol as above, this will normally

be due to an early flame signal which

is considered to be a faulty flame

signal.

The automatic furnace controller may

be unlocked immediately after a shut-

off on trouble using the unlock button

with integrated fault signal lamp or an

external switch. After it has been

unlocked (and after a defect with

resultant operating stop has been

eliminated and after a voltage failure),

the program unit will in any case return

to its starting position with voltage being

only supplied to terminals 7, 9, 10 and

11 as preset by the control program. It is

only at this stage that the program of the

automatic furnace controller will restart

the burner.

LFL 1.../LG K ...

e

n

Page 26

10/2010 - Art. Nr. 4200 1030 6900A26

Page 27

10/2010 - Art. Nr. 4200 1030 6900A 27

Page 28

10/2010 - Art. Nr. 4200 1030 6900A28

Made in EU.

Non contractual document.

www.elco.net

Hotline

ELCO Austria GmbH

Aredstr.16-18

2544 Leobersdorf

0810-400010

ELCO Belgium nv/sa

Z.1 Researchpark 60

1731 Zellik

02-4631902

ELCOTHERM AG

Sarganserstrasse 100

7324 Vilters

0848 808 808

ELCO GmbH

Dreieichstr.10

64546 Mörfelden-Walldorf

0180-3526180

ELCO Italia S.p.A.

Via Roma 64

31023 Resana (TV)

800-087887

ELCO Burners B.V.

Amsterdamsestraatweg 27

1411 AW Naarden

035-6957350

OOO «Ariston Thermo RUS LLC»

Bolshaya Novodmitrovskaya

St.bld.14/1 office 626

127015 Moscow -Russia

+7 495 783 0440

Loading...

Loading...