elco N6.2400 GL-RZ3/LFL, N6.2900 GL-RZ3/LFL, N7.3600 GL-RZ3/LFL, N7.4500 GL-RZ3/LFL Operating Instructions Manual

Page 1

09/2011 - Art. Nr. 4200 1040 7900A

N6.2400 GL-RZ3/LFL

N6.2900 GL-RZ3/LFL

N7.3600 GL-RZ3/LFL

N7.4500 GL-RZ3/LFL

............................................. 4200 1035 0600

Operating instructions

For specialist installation engineers

Dual fuel burners

de ......................................... 4200 1035 0500

fr ........................................... 4200 1040 8000

it ........................................... 4200 1041 4900

nl .......................................... 4200 1041 5000

Page 2

09/2011 - Art. Nr. 4200 1040 7900A2

General information

Contents

General information Contents ............................................................................................................................ 2

Important notes .................................................................................................................3

Burner description ............................................................................................................. 4

Installation General information regarding burner assembly ............................................................... 5

Boiler lining for GL-RZ3/LFL burner ..................................................................................6

Burner assembly................................................................................................................7

Burner head setting data GL-RZ3/LFL ..............................................................................8

Gas train

Gas train description .............................................................................................. 9

Basic design....................................................................................................... 10

Description of gas train with MBC... .....................................................................11

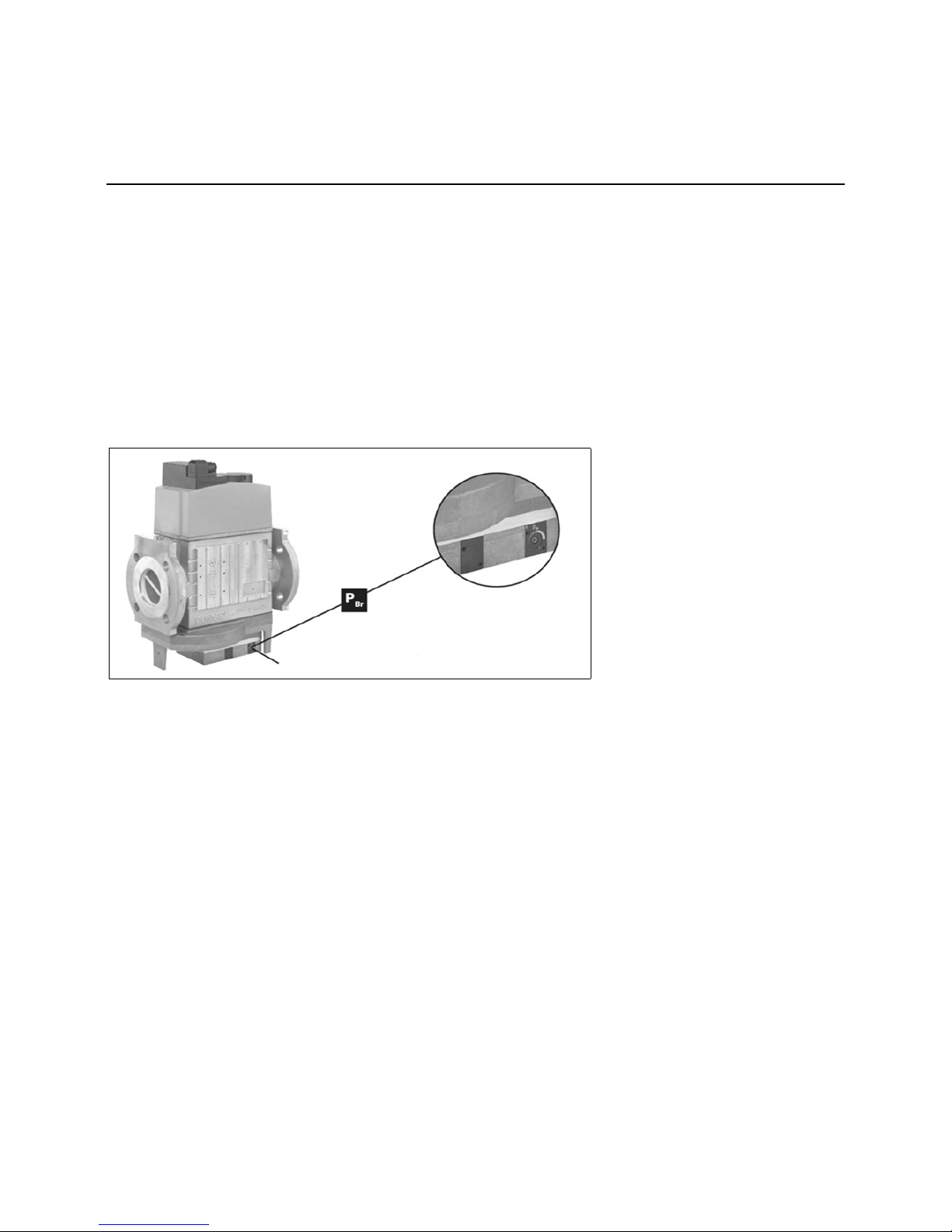

Description of Dungs MBC double gas valve... (gas multiblock)..........................12

Changing MBC-300-700-1200 filter ..................................................................... 13

Setting MBC-300-700-1200-SE pressure regulating component ....................... 13

Setting MBC-1900-5000-SE pressure regulating component .............................14

Description of double gas valve VGD... with servomotors SKP ........................... 15

Gas filters ............................................................................................................ 16

Gas/air pressure switch...................................................................................... 17

Leakage controller, test burner............................................................................ 18

Hydraulics

General information regarding fuel oil system, fuel oil hydraulics diagram ......... 19

Fuel oil pressure switch ....................................................................................... 20

General information regarding fuel oil system .....................................................21

Pump...............................................................................................................22-25

Nozzle line 3-stage..........................................................................................26-27

Commissioning Control and safety unit LFL 1.../LGK... ............................................................................ 28

Electrical servomotor..................................................................................................29-30

Flame monitor, probe current measurement .............................................................31-32

Connecting the gas train, electrical connection, checks before commissioning.............. 33

Gas connection................................................................................................................ 34

Fuel-air coupler control....................................................................................................35

Design of switch cabinet door.......................................................................................... 36

Dual fuel load regulator ..............................................................................................37-38

Control .............................................................................................................................39

Preventilation................................................................................................................... 40

Fuel oil start-up mode, fuel oil operating mode ............................................................... 41

General safety functions..................................................................................................41

Gas start-up mode, gas operating mode......................................................................... 42

General safety functions..................................................................................................42

Servicing Maintenance ..............................................................................................................43-45

Checking, assembling the combustion components ....................................................... 45

Setting for ignition electrodes .......................................................................................... 46

Exhaust gas analysis..................................................................................................47-48

Diagnosing and remedying faults ...............................................................................49-50

Faults .............................................................................................................................51

Declaration of conformity ...........................................................................................52-53

Page 3

09/2011 - Art. Nr. 4200 1040 7900A 3

Important information

Burners

N6 and N7 GL-RZ3/LFL

are

designed for the combustion of natural

gas and light oil. The design and

function of the burners comply with

EN676 and EN 267. They are designed

for use with systems that are approved

for the use of burners in accordance with

EN 676 and EN 267.. To use the burner

with heat generators in conformity with

Pressure Equipment Directive 97/23/

EU, special burner components are

required (not supplied with standard

equipment). Before using the burner

with equipment of this type, the

equipment characteristics must be

checked. Burners that comply with

Pressure Equipment Directive 97/23/EU

come with a declaration of conformity to

this effect and are labelled on the identification plate. Any other type of application requires the approval of ELCO. The

burner may only be used in accordance

with the instructions set out in this documentation and the relevant technical

data. If not used properly, it could cause

damage to property and the environment and personal injury. Furthermore,

the burner would no longer be CE compliant. Installation, commissioning and

maintenance may only be carried out by

authorised specialists and all applicable

guidelines and regulations must be

complied with.

Burner description

The burners

N6 and N7 GL-RZ3/LFL

are

progressive, fully automatic mechanical

monoblock-type burners for gas and 3stage for fuel oil. Emissions rates may

differ, depending on combustion

chamber dimensions, combustion

chamber load and the furnace (threepass boilers, boilers with reverse firing).

For specifying warranty values, the conditions for the measuring equipment, tolerances and humidity must be observed.

Scope of delivery

The burner is supplied packaged in

three boxes on a pallet:

- Burner with:

- integrated switch cabinet

- flange seal and securing screws

- operating instructions, circuit

diagram and spare parts list

- Burner head

- Compact gas train with gas filter

Before commissioning, a check must be

carried out to ensure that the product

delivered complies with the scope of

delivery.

The following standards should be

observed in order to ensure safe, environmentally sound and energy-efficient

operation:

EN 226

Connection of fuel oil and forceddraught gas burners with fan to a heat

generator

EN 60335-1, -2-102

Specification for safety of household

and similar electrical appliances, particular requirements for gas burning appliances

DIN EN 60204-1

Safety of machinery. Electrical

equipment of machines

DIN EN 50156-1

Electrical equipment for furnaces

Gas lines

When installing the gas lines and trains,

the general directives and guidelines, as

well as the following national regulations, must be observed:

CH: - SVGW-Gasleitsätze G1

- Vorschriften der kantonalen

Instanzen (SVGW Gas Direc tives G1 - Cantonal specifi cations) (e.g. fire authority

specifications)

DE: - DVGW-TVR/TRGI

Installation location

The burner must not be used in rooms

with aggressive vapours (e.g. hair spray,

tetrachloroethylene, carbon tetrachloride), high levels of dust or high air

humidity (e.g. laundry rooms). The limitations of use set out in the technical

data must be complied with.

Adequate provision must be made for

the supply of combustion air. Given

standard conditions, the combustion air

requirement may be calculated as

follows:

Vl [Nm³/h] = QF [kW] *1.25 [Nm³/(h*kW)]

We can accept no warranty liability

whatsoever for loss, damage or injury

caused by any of the following:

- inappropriate use

- incorrect installation and/or repair on

the part of the buyer or any third party,

including the fitting of non-original

parts

Final delivery and instructions for

use

The furnace fitter must supply the

operator of the system with operating

and maintenance instructions on or

before final delivery. These instructions

should be displayed in a prominent

location at the point of installation of the

heat generator. They should include the

address and telephone number of the

nearest customer service centre.

Notes for the operator

The system should be inspected by a

specialist at least once a year. It is

advisable to take out a maintenance

contract to guarantee regular servicing.

Warning:

When in operation, the burner produces

an electromagnetic field. In certain circumstances, this field could affect

medical implants (e.g. pacemakers).

Before working with the machine,

anyone who has a medical implant

should consult their doctor and the manufacturer of the medical implant in order

to reduce the risk of serious or fatal

injury.

Transport \ packaging \ storage

Safety measures

The burner and accessories must be

transported and stored using suitable

lifting equipment, means of transport

and tools. The safety instructions must

be complied with.

Transport

Depending on the size and weight of

packaging, burners and accessories

must be transported manually or with the

use of suitable aids. The transport

instructions on the packaging must be

complied with. The burner must be

properly secured for transport. If

measures to secure the burner have not

been taken at the factory, suitable

measures to secure it during transportation must be taken.

Packaging

The burner and accessories are placed

on a wooden pallet and shrink-wrapped.

When unpacking the product, suitable

lifting equipment and tools must be used

to remove the screw connections and

clamping devices between the burner

and the packaging. Suitable protective

clothing must be worn (gloves, safety

shoes).

Storage

In order to protect the burner from environmental influences, it must be placed

in a dry, locked room when stored temporarily. For the maximum storage temperatures, please refer to the technical

data sheet.

Disposal

The current local legislation must be

complied with without

fail.

General information

Important notes

Page 4

09/2011 - Art. Nr. 4200 1040 7900A4

General information

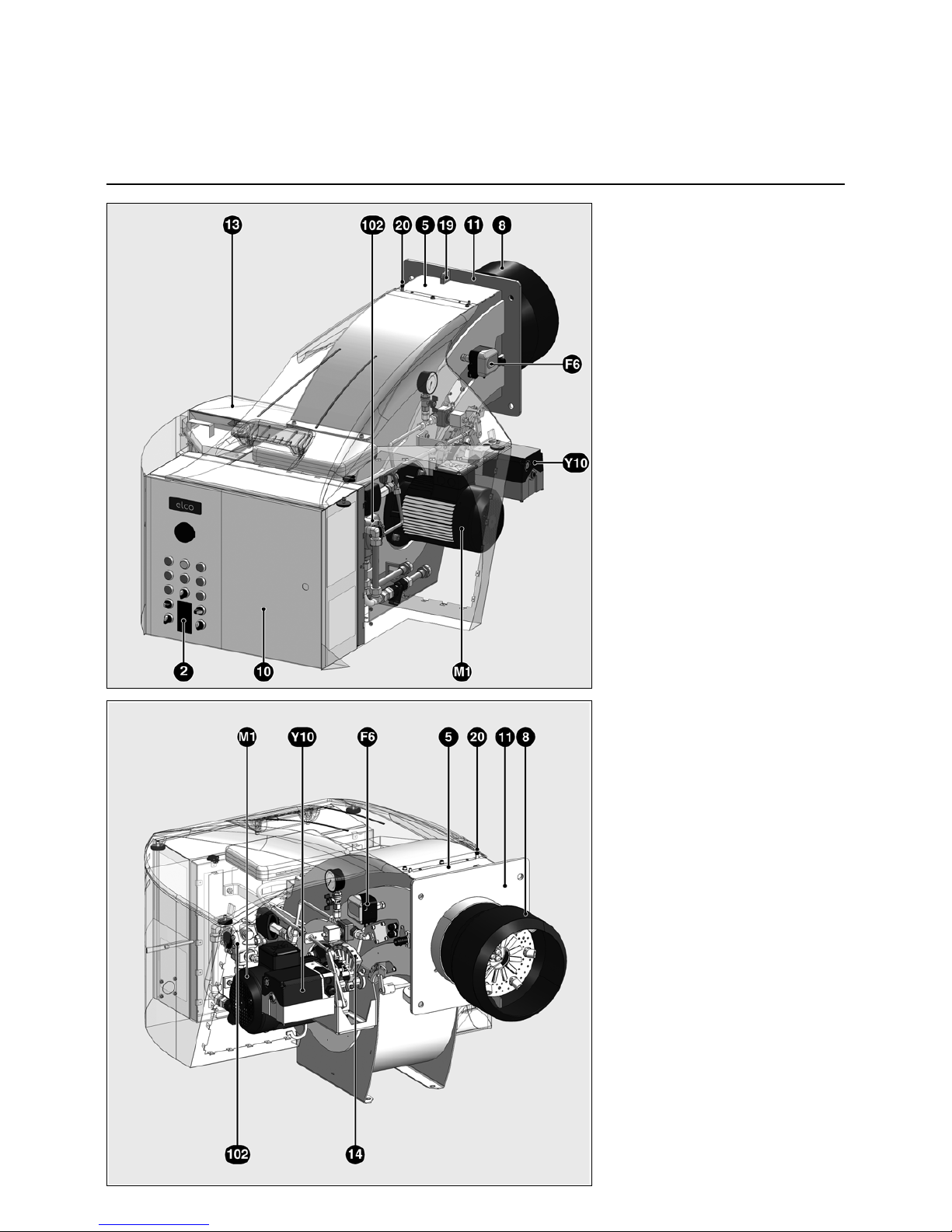

Burner description

2 Load regulator (option)

5 Body

6 Gas inlet flange

8 Burner tube

10 Integrated switch cabinet

11 Burner fixing flange

13 Air intake box

14 Mechanical coupler

19 Hoisting eyes

20 Connector for inspection glass

cooling

F6 Air pressure switch

M1 Fan motor

Y10 Servomotor for air and gas flaps

102 Pump

Page 5

09/2011 - Art. Nr. 4200 1040 7900A 5

Installation

General information regarding burner assembly

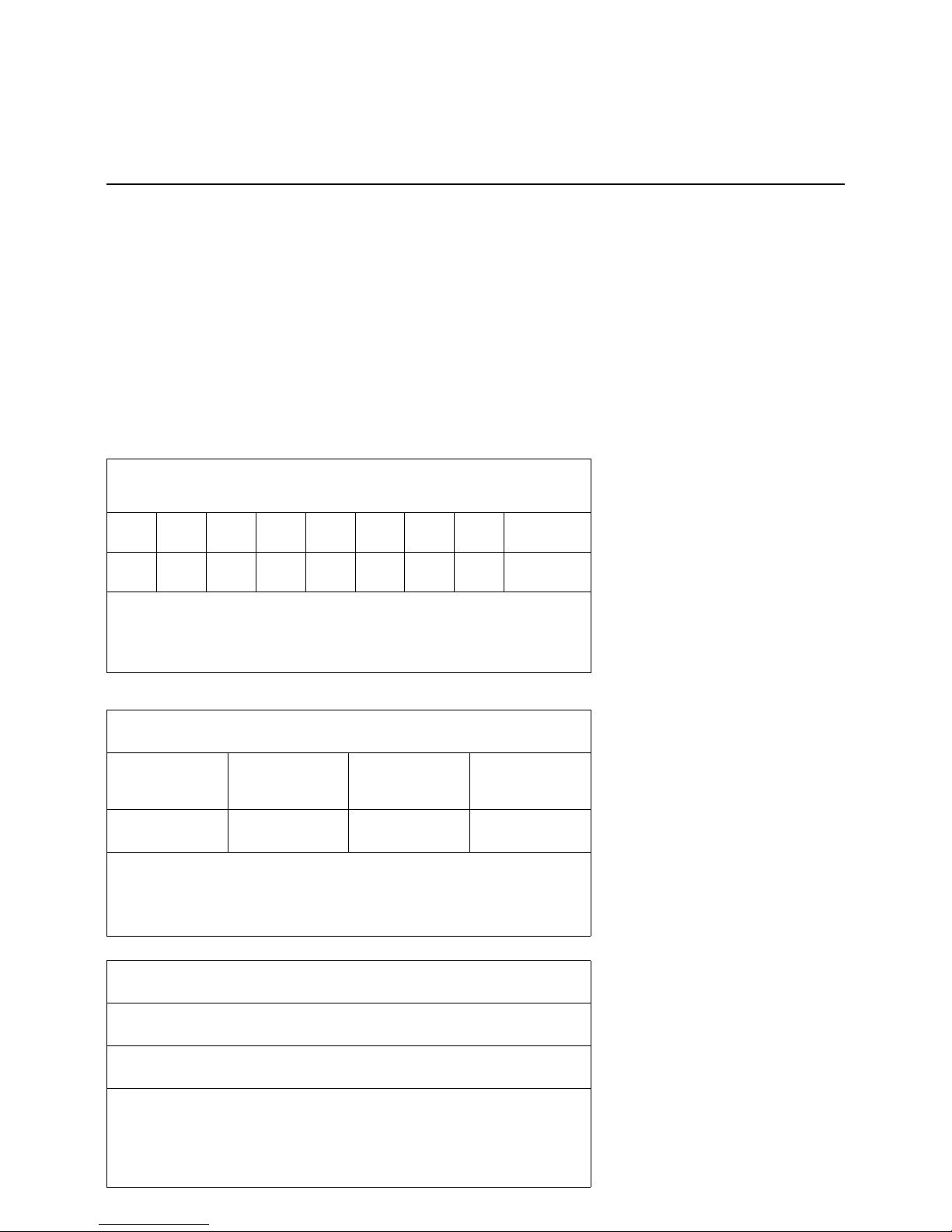

Tightening torques

During installation, commissioning and

maintenance, the following torques for

unions must be complied with.

Recommended tightening torques

Standard unions

M4 M5 M6 M8 M10 M12 M16 M20

2 6 10 25 48 85 210 415 Nm

N.B.:

In general, the correct tightening torques have been applied when the unions are

tightened hand-tight using a screwdriver (ISO 272) or angled Allen key.

Tightening torques for root connector for fan impeller

SM16 (Ø28)

No.: 1615

SM20 (Ø38 and 42)

No.: 2012

SM25 (Ø42 and 48)

No.: 2517

Bushing

20 30 50 Nm

N.B.:

For more information regarding installation/dismantling of the fan impeller, please

refer to the relevant chapter in the operating instructions.

Tightening torque for gas train flange connector

M16 / DN 65 - DN 125

Max. 50 Nm

N.B.:

The unions must be tightened crosswise. The union must be checked to ensure it

is tight. If it is not sufficiently tight, the fitting must be removed and checked (tightening surfaces).

Page 6

09/2011 - Art. Nr. 4200 1040 7900A6

Installation

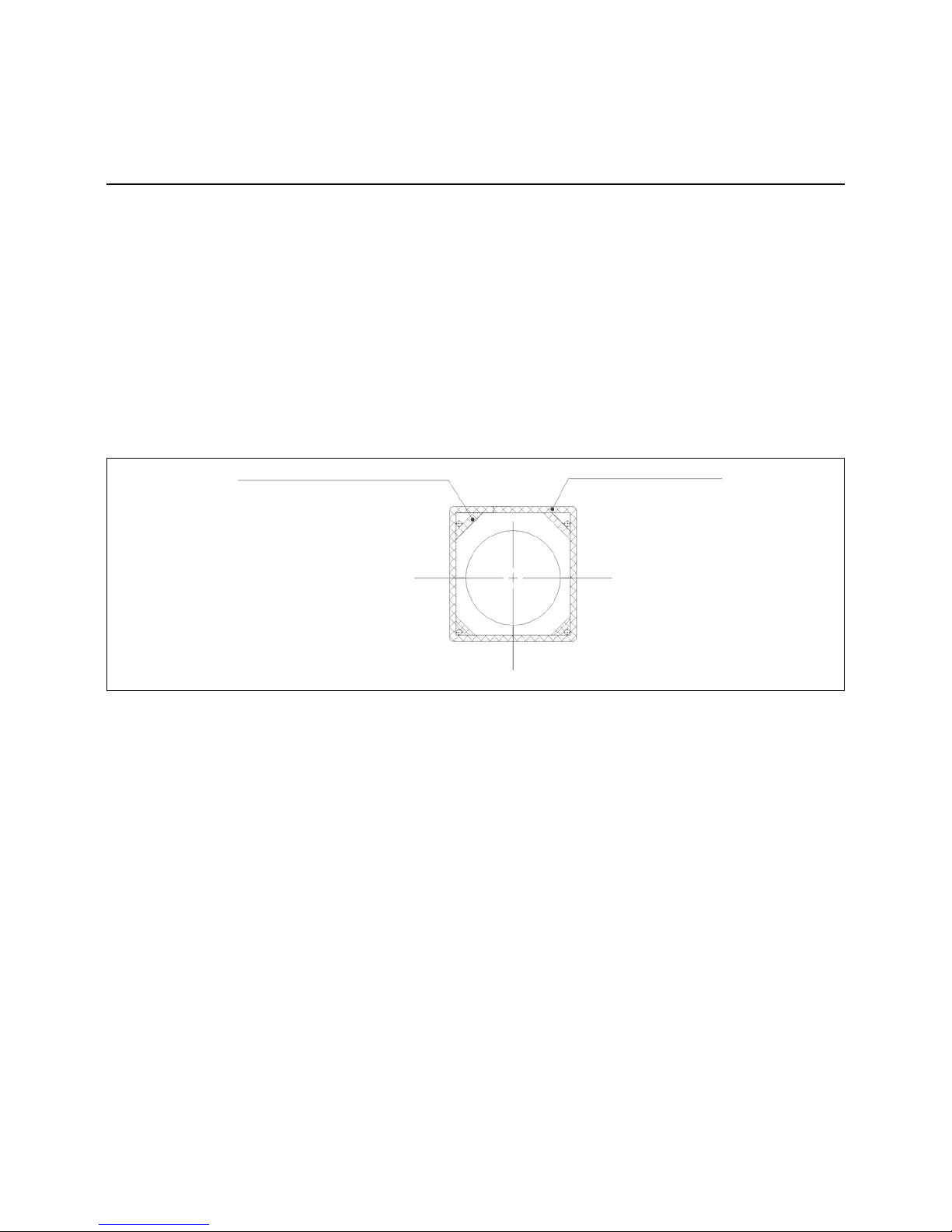

Boiler lining for GL-RZ3/LFL burner

Boiler lining

The burner lining must be installed rightangled to the burner tube. Possible

trimming work (bevelling, rounding) as

required for reverse boilers, for example,

should done at a diameter not below

70% of the combustion chamber

diameter. The space between the flame

tube of the burner and the boiler lining

should be lined with heat resistant

material, such as Cerafelt.

This space is not allowed to be lined

with brickwork

Sealed area

must cover the

entire

circumference

Seal corners with

sealing tape

Warning!

Owing to the fibre diameter, the mineral

fibre tightness thermocord may cause

reversible mechanical irritation to the

eyes and skin. In the event of high dust

concentrations, the upper respiratory

tract may suffer mechanical irritation.

When working with the tightness thermocord, the operator should wear loosefitting, long-sleeved clothing. In the

event of high fibre dust concentrations,

the operator should wear an FFP1 mask

and well-sealed protective goggles

(when carrying out overhead work too).

Page 7

09/2011 - Art. Nr. 4200 1040 7900A 7

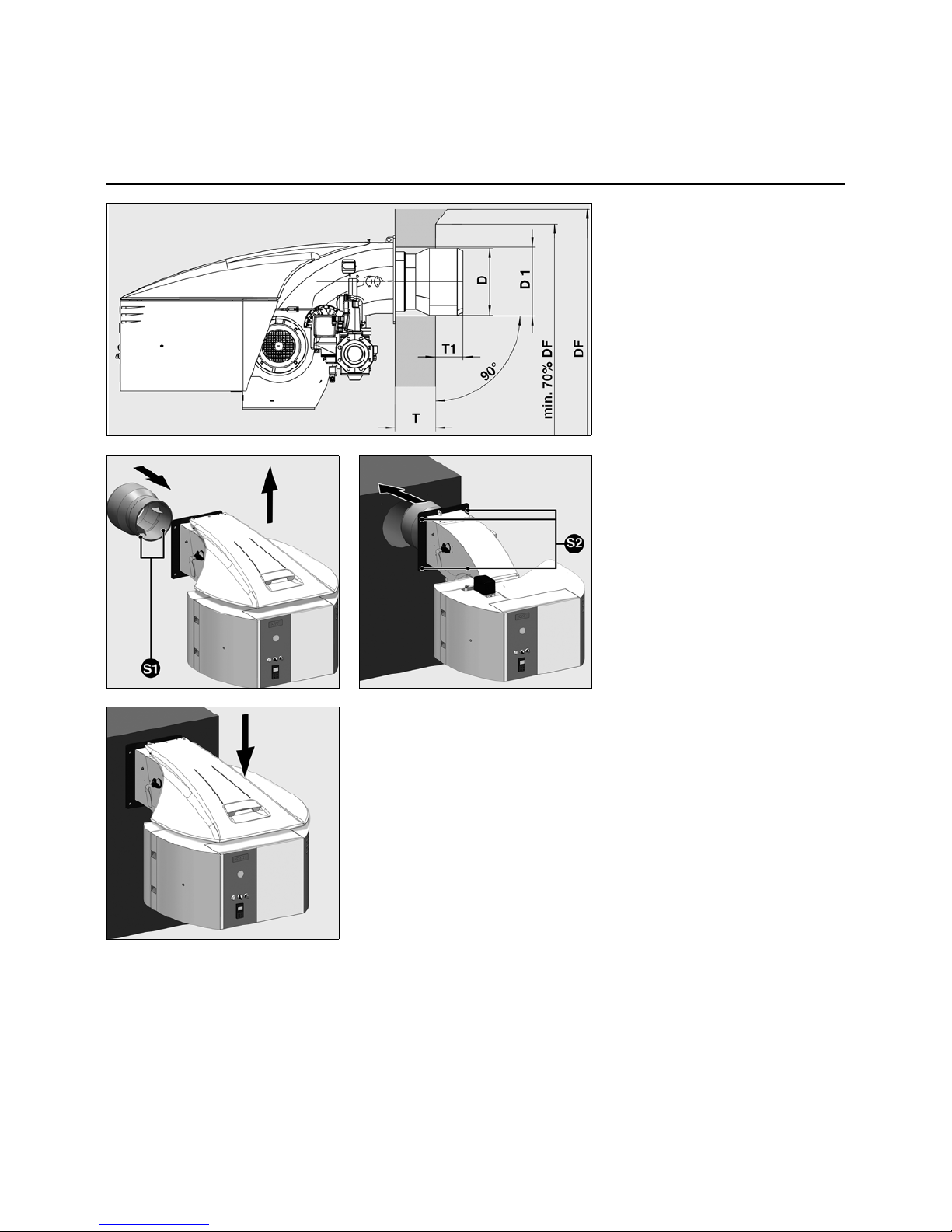

Burner assembly

• Remove cover.

• Take the flame tube (delivered in a

separate box).

• Fit it on the burner body.

• Tighten the 2 fixing screws S1.

• Fit the boiler seal to the burner.

• Raise the burner with the aid of

hoisting eyes 19 and fix it to the

boiler.*

• Tighten the 4 fastening screws S2

(comply with tightening torques).

• Place cover back on.

* Alternatively a forklift truck may be

used for fixing it if the burner is fixed

to the transport pallet supplied with it.

Provision must be made for adequate

transport safety. It may be necessary

to use suitable materials for transportation (lashing straps).

The burner boiler must be tested while in

operation to ensure it is leak-proof.

Every effort must be made to ensure that

exhaust gases cannot leak in harmful

amounts. Poorly sealed burner boiler

connections may result in combustion

problems

D = see dimensioned drawings

D1 = see dimensioned drawings

DF = combustion chamber diameter

T1 = 70 to 200 mm

T = standard muffle depth

(option : extensions: see technical

data)

Note for reverse flow boilers!

For reverse flow boilers, the dimension

T1 is only a recommended value.

Depending on type of boiler the burner

head must stand at least 70 mm ahead

the opening for exhaust gas turning

back.

Installation

Burner assembly

Page 8

09/2011 - Art. Nr. 4200 1040 7900A8

Installation

Burner head setting data GL-RZ3/LFL

Ø a Ø b Ø c d e f g

X

min max

N6.2400 320 270 240 29 121 60.5 380 148 137

N6.2900 320 270 240 29 121 60,5 380 148 137

N7.3600 320 270 240 40 150 60 425 202 182

N7.4500 340 270 240 30 150 60 425 195 130

Page 9

09/2011 - Art. Nr. 4200 1040 7900A 9

Installation

Gas train

Gas train description

Gas train installation

To install the gas train supplied in the

burner, the unions and seals intended

for this must be used (supplied with the

product).

Warning: in order to prevent injury, heavy

gas train components should only be fitted

using suitable aids and lifting equipment

(crane, cable slings, assembly supports).

The max. tightening torques must be

complied with (see chapter on Installation/

tightening torques). The unions must be

tightened crosswise and evenly. The union

must be checked to ensure that it is tight.

For further information, please refer to the

chapter on commissioning the gas connection.

Gas valve group selection

The gas trains must be dimensioned to suit

the throughput required and the available

gas pressure. The gas valve group is

defined on a system-specific basis.

The following must be taken into consideration:

• Burner output,

• Combustion chamber counterpressure,

• Gas pressure loss in the burner head,

• Gas pressure losses in the gas fittings.

The total drop in gas pressure must always

be lower than the available gas flow

pressure.

The burner's scope of delivery may include a

gas train. In this case, the burner and the gas

train are issued with a CE Declaration of Conformity. If the gas train is not delivered with

the burner, the conformity of the burner is

valid only if the gas fittings and the design of

the gas train satisfy the burner test specified

by EN 676 and meet the Pressure Equipment

Directive. Individual testing will be necessary

where this is not the case. The gas train

delivered has its own documentation

including operating instructions and a spare

parts list. There follows a general description

of the gas train.

Gas trains with a double gas valve are

intended for the supply, main shut-off, gas filtration, gas pressure regulation and monitoring of the gas supply. They are compatible for

use with gases conforming to the specifications of the gas fittings. The design complies

with EN 676. All function parts have been

individually tested and awarded the CE mark

and number of the notified body. The prefitted

gas train is subjected to a leak test at the

manufacturer's works.

Low- and high-pressure gas trains

If the outlet side of the regulator, i.e. individual

fittings and instruments downstream of the

gas pressure regulator, has not been

designed to be compatible with the maximum

supply pressure that occurs in the event of a

fault, the gas train must be equipped with a

safety shut-off valve (SSOV) and a safety

relief valve (SRV) in accordance with EN 676.

This equipment is generally required for

maximum supply pressures of >360 mbar

and > 500 mbar respectively. These are

known as high-pressure gas trains. If all

fittings and instruments of the gas train have

been designed/approved for the maximum

supply pressure that occurs in the event of a

fault, the gas train is known as a low-pressure

gas train. This is the case, depending on

component selection, for maximum supply

pressures of 360 and 500 mbar.

Page 10

09/2011 - Art. Nr. 4200 1040 7900A10

Installation

Gas train

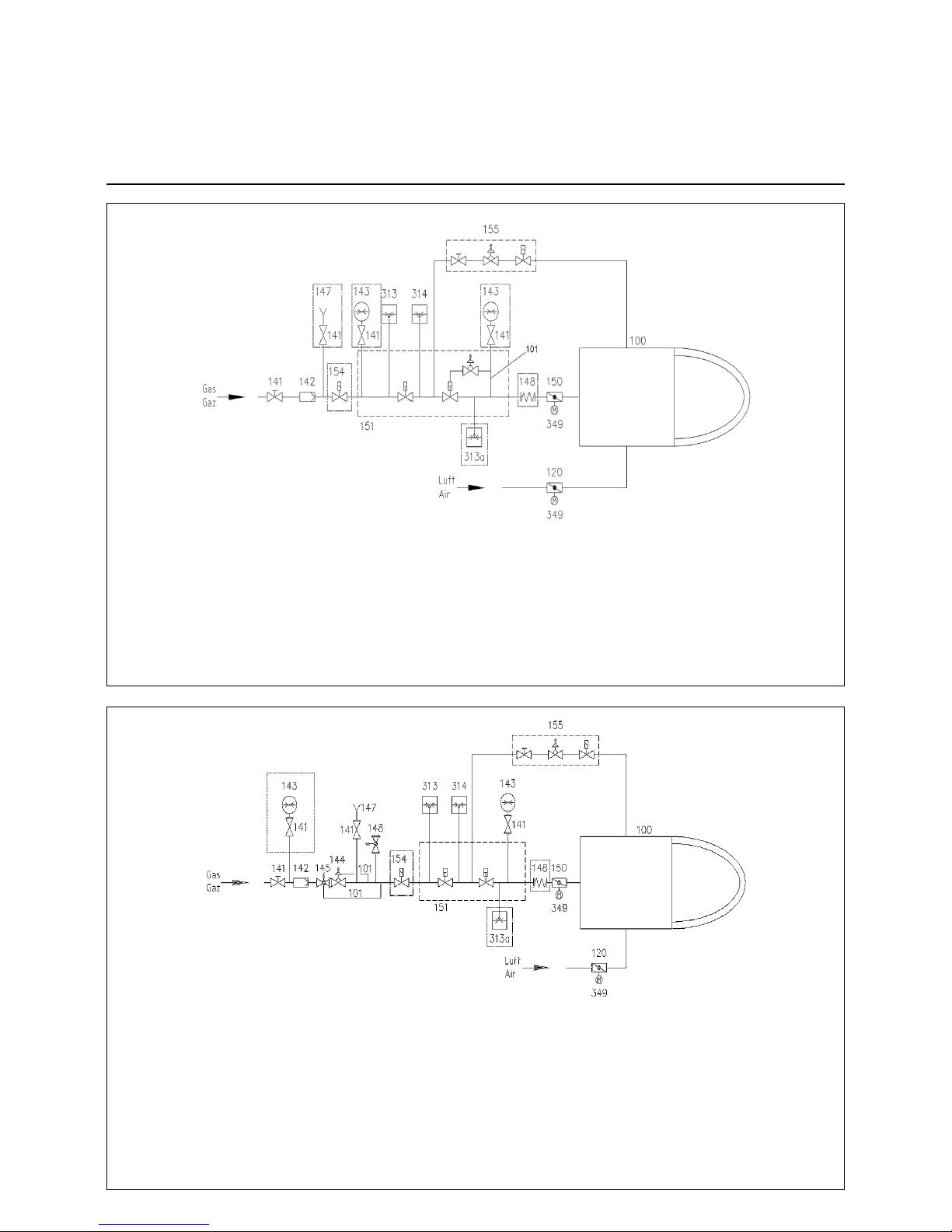

Basic design

100 Burner

101 Gas pressure impulse pipe

120 Air flap

141 Ball valve

142 Gas filter

144 Gas pressure regulator

145 Safety gate valve (SGV)

148 Safety relief valve (SRV)

150 Gas control butterfly

151 Double gas valve or 2 single valves

155 Ignition unit

313 Min. gas pressure switch

314 Gas pressure switch for checking valve tightness

349 Servomotor

Options in accordance with country-specific requirements:

143 Pressure gauge with pushbutton valve

147 Test burner with pushbutton valve

148 Compensator

154 Gas safety valve (additional)

313a Max. gas pressure switch

High pressure

100 Burner

101 Gas pressure impulse pipe

120 Air flap

141 Ball valve

142 Gas filter

150 Gas control butterfly

151 Double gas valve with integrated regulation

(Siemens VGD system shown)

155 Ignition unit

313 Min. gas pressure switch

314 Gas pressure switch for checking valve seals or valve

tightness control device

349 Servomotor

Options in accordance with country-specific requirements:

143 Pressure gauge with pushbutton valve

147 Test burner with pushbutton valve

148 Compensator

154 Gas safety valve (additional)

313a Max. gas pressure switch

Low pressure

Page 11

09/2011 - Art. Nr. 4200 1040 7900A 11

Description

The gas trains with Dungs MBC ...

double gas valves MBC... are used for

gas supply, as the main isolation valve,

for gas filtering, gas pressure regulation

and monitoring of the gas supply. They

can be used for all gases in the 1, 2, 3

gas families in accordance with DVGW

worksheet G 260/1 and/or EN 437. The

design complies with EN 676. All the

functional components have been

tested individually and awarded the CE

mark and number of the Notified Body.

The premounted gas valve group is

subjected to a leak test at the manufacturer's works.

Minimum scope of delivery for

gas trains

in accordance with

EN 676:

- 1 Ball valve

- 1 Gas filter

- 1 Double gas valve with spring 580 mbar

- 1 Min. gas pressure switch

- 1 Leakage controller or 1 gas pressure

switch for valve leak test

Options:

- Springs for other outlet pressures

- Test burner with pushbutton valve

- Pressure gauge with pushbutton valve

- Compensator

- Max. gas pressure switch

- Gas meter

- Pipe parts and connection parts

- Ignition gas device

- Installation support

- High-pressure regulator with safety

shut-off valve (SSOV)

- Settling section with pulse lines for

high-pressure regulator

- Safety relief valve (SRV)

- Additional gas safety valve

Low and high-pressure gas trains

If the outlet side of the regulator, i.e.

individual fittings and instruments downstream of the gas pressure regulator,

has not been designed to be compatible

with the maximum supply pressure that

occurs in the event of a fault, the gas

train must be equipped with a safety

shut-off valve (SSOV) and a safety relief

valve (SRV) in accordance with EN 676.

This equipment is generally required for

maximum supply pressures of

>360 mbar and > 500 mbar respectively. These are known as highpressure gas trains. If all gas train

fittings and equipment have been

designed and/or approved for the

maximum supply pressure that occurs in

the event of a fault, the gas train is

known as a low-pressure gas train. This

is the case, depending on component

selection, for maximum supply

pressures of 360 and 500 mbar.

Gas valve group

The gas valve group is defined on a

system-specific basis.

The following must be taken into consideration:

• Burner output

• Furnace counterpressure

• Gas pressure loss in the burner head

• Gas pressure losses in the gas fittings

The total drop in gas pressure must

always be lower than the available gas

flow pressure.

The section of the pipings must be calculated so that the loss of load doesn’t

exceed 5% of the supply pressure.

Warning!

With burners that have the CE mark,

only the use of gas fittings that have

been approved on the basis of burner

type-testing is permitted.

If alternative gas fittings are used, the

burner must undergo individual testing

by the relevant testing body.

Subject to change without notice due

to ongoing technical developments.

Gas train with MBC

Technical data:

Types of gas:

Gas types of gas families 1, 2 and 3

according to DVGW Worksheet

G 260/1

Max. inlet pressure:

MBC700-1200 with CG15 ignition gas

fittings: 360 mbar

without ignition gas fittings: 360 mbar

MBC1900-5000 with CG15 ignition

gas fittings: 360 mbar

MBC1900-5000 with FRS 505/ MVD

505 ignition gas fittings: 500 mbar

without ignition gas fittings: 500 mbar

Elect. connection: AC 220-240 V,

50 Hz

Protection level: IP 54

Ambient temperature:

-15 °C to +60 °C

Installation

Gas train

Description of gas train with MBC...

Page 12

09/2011 - Art. Nr. 4200 1040 7900A12

Technical data

Gas multiblock MBC-.../SE:

Type of gas:

Gases in accordance with DVGW

worksheet

G 260/1, gas families 1, 2, 3

Electrical data:

230 V -15% + 10%, other voltages on

request

50...60 Hz

Protection level: IP 54

Ambient temperature:

-15C to +60C

Installation position:

MBC-300-1200: magnet vertically

upright or magnet horizontal

MBC-1900-5000: magnet vertically

upright

Max. operating pressure:

MBC-300-1200: 360 mbar

MBC-1900-5000: 500 mbar

The MBC...SE gasmultibloc integrates

the filter, valves and servo pressure

regulator into one compact unit:

- Dirt trap: fine filter (MBC-300-1200

only)

- 2 solenoid valves up to 360 mbar in

accordance with DIN EN 161 Class A

Group 2 fast-closing, fast-opening

(MBC-300-1200)

- 2 solenoid valves up to 500 mbar in

accordance with DIN EN 161 Class A

Group 2 fast-closing, fast-opening

(MBC-300-1200)

- Servo-pressure regulation component

in accordance with DIN EN 88 Class A

Group 2, EN 12067-1

- Outlet pressure: 0 - 300 mbar (MBC300-1200), 4 - 300 mbar (MBC-1900-

5000)

- Sensitive adjustment of the outlet

pressure with the SE version for

optimum outlet pressure sensitivity

- Sensitive adjustment of the gas and

air pressure ratio with the VEF version

- Flanged connections with pipe

threads in accordance with ISO 7/1 or

NPT (MBC-300-1200)

- Flanged connections in accordance

with EN 1097-1 / ISO 7005 (MBC1900-5000)

1, 2, 3

Seal plug G 1/8

4, 5, optional

Connection system accessories (optional)

6, 7

Seal plug G 1/4

8, 9, optional

Seal plug G 1/2 (optional)

10

Impulse line p

Br

(integrated)

11

Breather plug G 1/8

Installation

Gas train

Description of Dungs MBC double gas valve... (gas multiblock)

Pressure switches

MBC-300/

700...

MBC-1200...

1, 2, 3, 4, 5

Seal plug G 1/8

MBC-...-SE 1900-5100

Pressure switches

Page 13

09/2011 - Art. Nr. 4200 1040 7900A 13

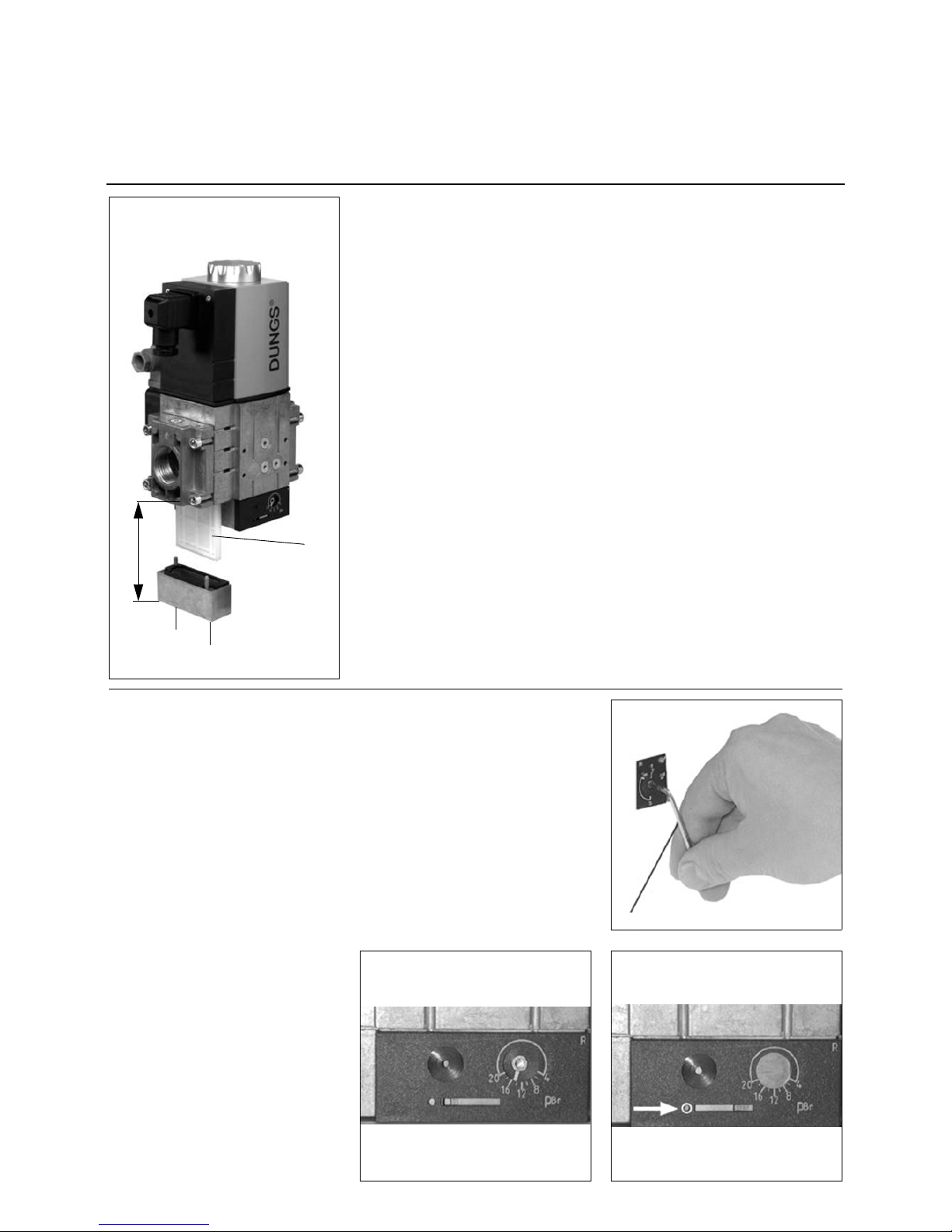

Filter inspection must be carried out

at least once a year

Replace filter if p between pressure

port 1 and 2 > 10 mbar.

Replace filter if p between pressure

port 1 and 2 is twice as high as the last

measurement.

1. Interrupt gas supply: close ball valve.

2. Unscrew screws 1-2.

3. Replace fine-filter element 3.

4. Screw in and gently tighten screws 1-

2.

5. Carry out a function test

and a test to check the water tightness

p

max.

= 360 mbar.

Space required for filter replacement:

MBC-300-...: 150 mm

MBC-700-...: 170 mm

MBC-1200-...: 230 mm

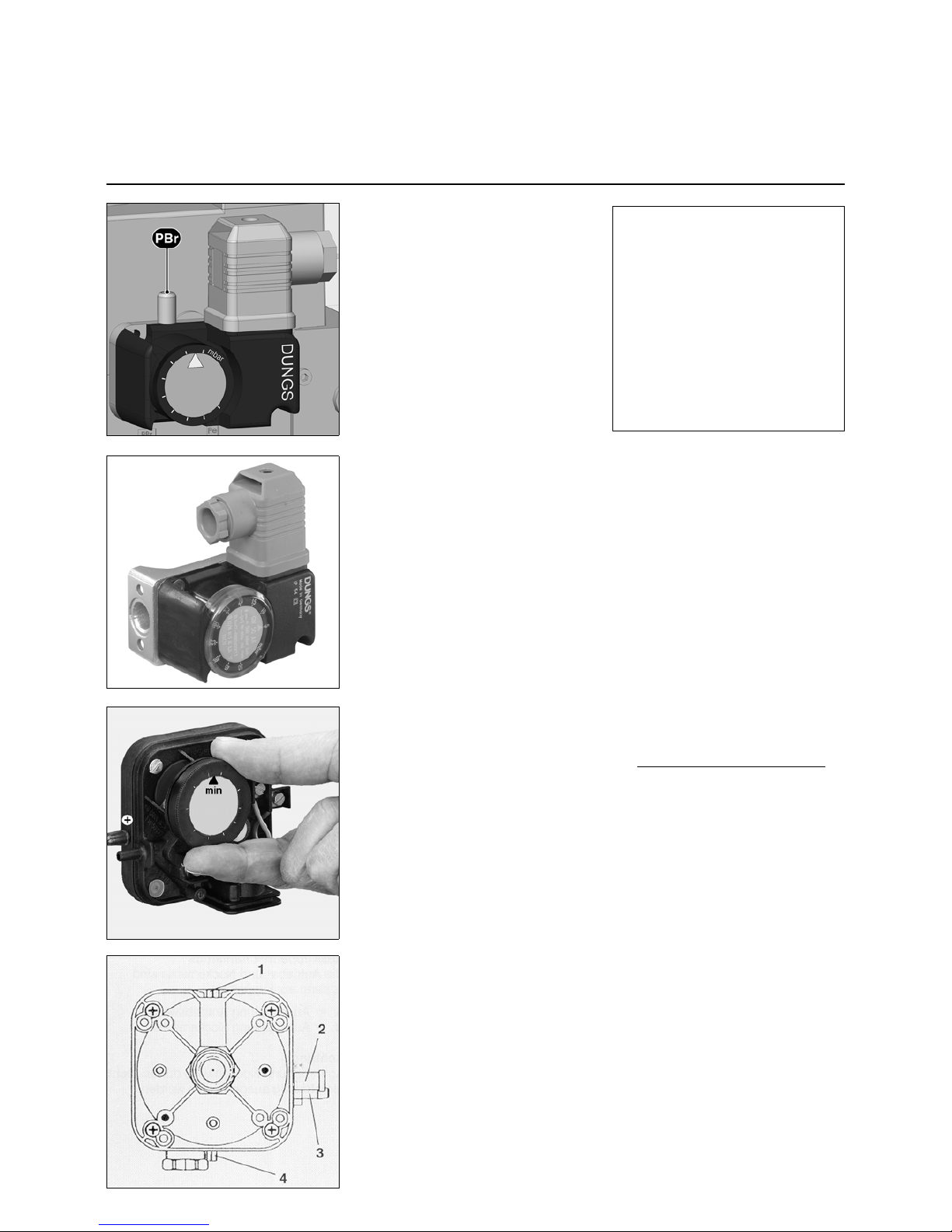

Adjusting the MBC-300-700-1200-SE

pressure regulating component

1. Open the slide.

2. Start the burner, correction of set

values possible while burner in

operation (fig. 1).

3. Check ignition safety of the burner.

4. If necessary repeat the setting steps.

Check intermediate values.

5. Apply a security seal to the adjusting

screw, see right.

Optimum combustion and ignition

safety must be ensured.

Security seal

After you have set the desired nominal

pressure value:

1. Close the slide.

2. Secure the slide in closed position

using the screw (fig. 3).

Installation

Gas train

Changing MBC-300-700-1200 filter

Setting the MBC-300-700-1200-SE pressure regulating component

3

1

2

1

Allen key no. 2.5

Open2Closed

3

Page 14

09/2011 - Art. Nr. 4200 1040 7900A14

Installation

Gas train

Setting the MBC-1900-5000-SE pressure regulating component

Allen key no. 2.5

Adjusting the MBC-1900-5000-SE

pressure regulating component

1. Open the protective caps.

2. Start the burner, correction of set

values possible while burner in

operation (see figure).

3. Check ignition safety of the burner.

4. If necessary repeat the setting steps.

Check intermediate values.

5. Apply a security seal to the adjusting

screw (see below).

Optimum combustion and ignition

safety must be ensured.

Page 15

09/2011 - Art. Nr. 4200 1040 7900A 15

Installation

Gas train

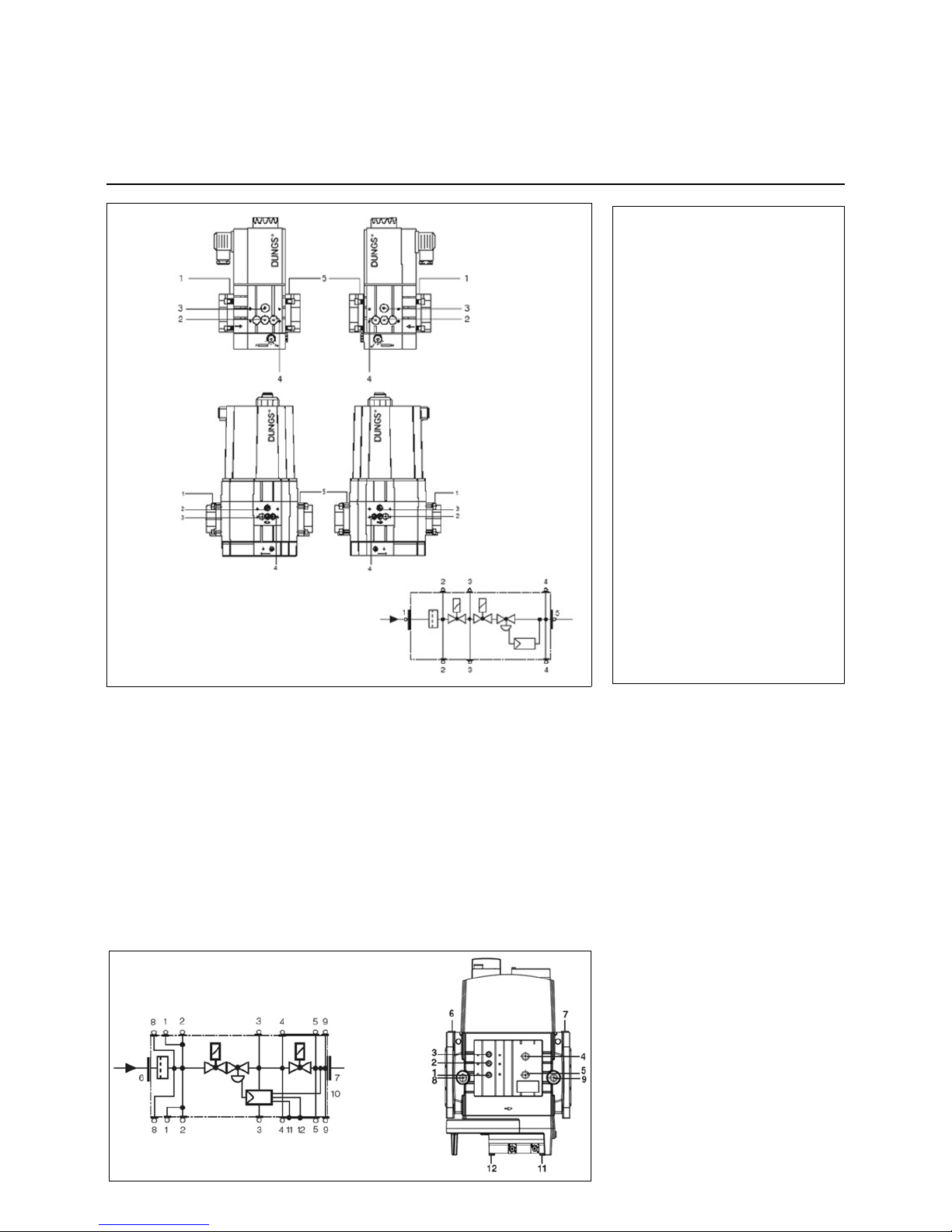

Description of double gas valves VGD... with servomotors SKP

VGD 20

VGD 40

SKP 15

SKP 25

SKP 75

Technical data

Double gas valves VGD with servomotors SKP:

Type of gas:

Gases in accordance with DVGW

worksheet

G 260/1, gas families 1, 2, 3 and

biogas (H

2

S-content 0.1 Vol.% max.),

H

2

Electrical data:

220 V -15%...240 V +10%

100 V -15%...110 V +10%

50 to 60 Hz

Protection level: IP 54

Media temperature :-15°C to +60°C

Ambient temp.: -10°C to +60°C

Installation position:

Magnet vertically upright or on its side,

magnet horizontal

Max. operating pressure:

VGD20: 500 mbar

VGD40: 700 mbar (DN 40 and DN 50

to 1000 mbar)

Double gas valve VGD with

servomotors SKP

The combined servomotor and valve

perform the following functions:

• safety shut-off valve Class A Group 2

in accordance with EN 161 (SKP15...)

• safety shut-off valve Class A Group 2

in accordance with EN 161 with gas

pressure regulator (SKP25...,

SKP55..., SKP75...)

The electrohydraulically operated servomotors with valve are designed for

gases of families I to III and air, and are

intended mainly for use in gas-fired

furnaces.

They are slow-opening and fast-closing.

The servomotor can be combined as

desired with any of the valves and

nominal widths specified above.

The servomotor can be supplied with a

limit switch (closed position signalling).

Valve dimension information is provided

on the "Throughput diagram" in the

relevant valve datasheet.

The SKP25... operates as a constantpressure regulator with setpoint spring.

It is mainly intended for use with forced

draught burners

- with mechanical coupler;

- with electronic coupler.

The SKP75... operates as a constantratio pressure regulator and regulates

gas pressure in proportion to the

pressure of the combustion air. This

keeps the gas/air ratio constant across

the entire load range. It is intended

mainly for use with modulating forced

draught gas burners with pneumatic

coupler.

System accessories available for the

double gas valve include the VPS 504

leak testing system and the GW...A5

pressure switch.

Page 16

09/2011 - Art. Nr. 4200 1040 7900A16

Installation

Gas train

Gas filter

Installation and mounting of the gas

filter

The gas filter may be installed in any

desired position. Take care only to

observe the direction of flow of the gas

(arrow on filter housing). Make sure

there is adequate clearance to facilitate

the removal of the cover and replacement of the filter cartridge.

Filter replacement

The filter cartridge should be replaced

with a new one as soon as a high

pressure drop is noticed. If a new filter

cartridge is not at hand it will be possible

to wash the filter mat in 40°C water

adding some light-duty detergent. Allow

the mat to dry before reinstallation.

Warning: when installing the filter mat,

comply with the marking or adhesive

label.

Page 17

09/2011 - Art. Nr. 4200 1040 7900A 17

Installation

Gas train

Gas/air pressure switch

Determining the differential preflushing pressure and adjusting the

differential pressure switch

• Burner in the pre-aeration phase.

• Measure pressure on test

connection (2).

• Measure vacuum on test

connection (3).

• Add the measured pressures.

• Set the scale to 90% of the calculated

value.

Switch function test

• Test buttons are provided to check the

switch functions for proper operation

(with safety cut-out and interlock). The

burner is normally run in part-load

condition when testing the safety functions. On pressing button (4) the

vacuum will be removed which causes

the differential pressure to drop below

the required level. If it is necessary to

test the pressure switch functions

under full-load conditions this may be

done by pressing button (1).

Technical data:

Type of gas:

Gases according to DVGW Worksheet

G 260/1, gas families 1, 2, 3

Protection level: IP 54

Ambient temp.: -15°C to +50°C

Installation position: any

Operating pressure up to:

GW 50/150 A5A6 500 mbar

GW 500/ A5/A6 600 mbar

Gas pressure switch GW...A5/A6

The gas pressure switch is designed to

monitor the gas flow pressure. It can be

used for monitoring either falling

pressure (minimum) or rising pressure

(maximum, specified for equipment

according to TRD 604).

The types GW...A5/A6 may be used as

pressure switches of a specific construction according to VdTÜV leaflet

"Pressure 100/1" for application in

furnaces complying with TRD 604.

The setpoint (switching point) may be

selected by means of a setting disk with

vessel.

Air pressure switch

The air pressure switch is provided for

monitoring the pressure of the combustion

air fan.

Pressure switch LGW... is suitable for

switching an electrical circuit or for

switching it on or off if the actual pressure

values

are changing vis-a-vis the setpoint.

The pressure switch LGW... can be used

as overpressure, vacuum or differential

pressure switch for air and non-aggressive

gases but not for gases according to

DVGW Worksheet G 260/l.

Certification

The pressure switch has been tested in

accordance with EN1854 and is CE/DIN-

DVGW-registered. It has been registered

in other important gas consumption countries.

N.B.(Gas and air pressure switches)

The pressure switches must be set in

accordance with the specifications.

Furthermore, each time they are set, a

function test must be carried out. Noncompliance could result in personal

injury or damage to property!

Once the pressure switches have been

set, they must be protected to prevent

settings from being altered. For

example, this can be done by placing a

spot of varnish on at least one of the

screws on the equipment's protective

cover.

Setting the min. gas pressure switch

Remove the protective cover. At the

rated output, measure the gas flow

pressure and calculate the switch-off

pressure by reducing by approximately

20%. Adjust the graduated disc to the

desired switch-off pressure opposite the

arrow (the graduations are approximate

values). Operate the burner at minimum

power. Close the gas shut-off valve

slowly to obtain the desired switch-off

pressure. Turn the graduated disc until

the burner switches off. Refit and screw

down the protective cover.

Max. gas pressure switch

Remove the protective cover. At the

rated output, measure the gas flow

pressure and calculate the switch-off

pressure by increasing by approximately

20% (no more than 30% under any circumstances). Adjust the graduated disc

to the desired switch-off pressure

opposite the arrow (the graduations are

approximate values). Operate the

burner at minimum power. If the max.

gas pressure switch switches off the

burner, increase the adjustment value

but not to more than 130% of the flow

pressure at the rated output.

Gas pressure switch A5

Gas pressure switch A6

Page 18

09/2011 - Art. Nr. 4200 1040 7900A18

Gas train

Leakage controller

Test burner

1 Wieland 7P socket

3 Filter element

4 O-ring Ø10.5x2.25

5Fuse

T6.3 250V Ø 5x20

6 Yellow indicator On :

Leakage test OK

7 Red indicator On :

Leakage test NOK

Manual clear

8 Spare fuses

9 pa (p2) pressure switch Ø 9

pe + 20mbar

10 pe (p1) pressure switch Ø 9

inlet pressure (distribution)

Leakage controller VPS 504 S02

Working principle :

Prior to each burner start-up, the controller checks for possible leaks between

safety and main valves by increasing

supply pressure.

Electrically, the leakage controller is

serially connected between the thermostatic circuit and burner control and

safety unit.

Installation :

Directly on valve.

Program stages :

On stoppage, safety and main valves

are closed.

On thermostat stoppage, the leakage

controller is turned on and booster

increases supply pressure by 20 mbar.

After no more than 30 seconds

operation :

- the leakage test has been passed; the

yellow light comes on and current is

released to feed the burner’s control

and safety unit, which then starts its

program cycle.

- If the leakage test is not passed; the

red light comes on and the power

supply to the control and safety unit for

the burner is not released. Control

cycles have to be restarted manually.

Change valve if fault persists.

Setting :

The controller requires no on-site

setting.

Working test :

While controller is working :

• Open pa pressure switch. The precip-

itated leak prevents superpressure

from building up and safety unit locks.

• Reclose pa pressure switch.

• Release controller safety by pressing

red indicator light.

The leakage test is restarted; after 30

seconds, yellow indicator lights up and

powers up the burner's control and

safety unit, which then starts its program

cycle.

Test burner

Depending on the country-specific

requirements, when installing steam

boilers it may be necessary to fit a test

burner to the gas train (e.g. in line with

directive TRD 412). This is used to vent

the gas pipes.

The gas supply is switched on by

pressing the button (1). The flow of gas

brings in the required amount of combustion air via the hole in the burner tube

(3). The gas/air mixture is routed

towards the burner head (4) and ignited

manually at its opening. Gas is supplied

for as long as the button is pressed and

cut off when it is released.

Technical data:

• Type of gas:

gases in accordance with DVGW

worksheet G 260/1, gas families 1, 2, 3

• Ambient temp.: -15°C to +70°C

• Installation position: vertical, facing

upwards

• Operating pressure to: 500 mbar

Page 19

09/2011 - Art. Nr. 4200 1040 7900A 19

Installation

Hydraulics

General information regarding fuel oil system

Fuel oil hydraulics diagram

100 Burner

101 Fan

118 Nozzle

120 Air flap

143 Pressure gauge (optional)

175 Filter

176 Pump

178 Solenoid valve, supply line

349 Servomotor

Page 20

09/2011 - Art. Nr. 4200 1040 7900A20

Installation

Hydraulics

Fuel oil pressure switch

Fuel oil pressure switch

Fuel oil pressure switches are used to

monitor burners to ensure that they do

not exceed or fall below specific fuel oil

pressures.

Depending on the burner variant,

pressure switches may be specified for

backflow only

or for backflow and the supply line. The

shut-off pressure in question is set

depending on the system parameters

(ring line pressure, fuel oil nozzle etc.).

Fuel oil pressure damping

To reduce fluctuations in fuel oil

pressure, a throttle screw (2) or a

capillary tube may be screwed into the

connection nozzle.

Adjustment of switching pressure

To adjust the switching pressure, the

adjustment button (1) can be pulled

upward and reinserted the opposite way

around.

Setting the fuel oil pressure switch

min.:

The shut-off pressure is the fuel oil

supply pressure at full load, minus

approx. 20%.

Setting the fuel oil pressure switch

max. (only for burners with a return

nozzle):

The shut-off pressure is the ring line

pressure with a full load plus approx.

2...3 bar.

The set shut-off pressure should also

take cognisance of the set switch difference.

When the setting procedure is complete,

the setting button must be returned to its

original orientation

for safety.

A seal must be applied to the pressure

switch to secure the setting (Item 4).

Switching difference

The switching difference may be set at

the limits of the pressure switch in

accordance with the values in the table.

To do this, the set screw must be rotated

in the adjusting screw (3) for the

switching point. 1 turn modifies the

switching difference by approx. 20% of

the total switching difference range.

Model Adjustment

range

Switching

difference

Application

DSB 158 F ... 0-25 bar 1.0... 7.5 bar

Standard EN 267 supply line

and backflow

Page 21

09/2011 - Art. Nr. 4200 1040 7900A 21

Installation

Hydraulics

General information regarding fuel oil system

Fuel oil connection

Hoses are used to make a connection to

the fuel oil tubes or the gate valves. To

prevent kinks and therefore any risk of

rupture, the hoses must be fed correctly

(no tension or distortion). When installing the fuel oil tubes or the gate valves,

care must be taken to ensure that the

lines terminate as close to the burner as

possible and that they are positioned in

such a way that the boiler door and the

burner can be swivelled out without

obstruction.

Gate valve

In the fuel supply feed line, manual gate

valves must be fitted before the burner

(supply line and backflow). These must

be installed in such a way that they are

easily accessible. The manual gate

valves are not included in the scope of

delivery.

Gas and air separators

Air or gas In the fuel supply line could

cause noise and operational problems.

In order to avoid this, a suitable gas air

separator must be fitted in the fuel

supply line.

Fuel oil filter

To protect the oil pressure pump and the

hydraulic system, a filter must be

installed before the pump.

A filter with ≤ 200 µm is recommended.

Installation options

• Two-line installation (separate supply

line and return line with no delivery

pump)

• Ring line system (with delivery pump

and gas-air separator)

Fuel oil pressure regulator (supply

line)

The supply pressure is regulated by the

pressure regulator fitted in the pump

and, depending on the burner output

and make of nozzle, it is set to 1015 bar. The pressure regulator is

actuated by rotating screw 3.

Before commissioning, the pump must

be filled with fuel oil.

Venting

With the ring line, if any, in operation,

open the supply line and return gate

valves. Reduce the oil pressure on the

pressure regulation valve. Switch on the

pump by depressing the contactor.

Check whether the direction of rotation

is correct, the pump is supplying fuel oil

and the fuel oil hydraulics system is

leak-proof. Vent the pump, e.g. at the

pressure gauge connector. When commissioning the burner, the oil pressure

must be increased slowly until it reaches

the operating value.

Pressure regulation (fuel oil intake

pressure)

The maximum possible vacuum is

0.2 bar. If the vacuum pressure is

greater than this, gas emissions are

produced from the fuel oil and this could

cause problems.

In the case of ring line operation, the oil

pressure at the pump must not exceed

the maximum permissible pressure. For

the maximum pressure, please refer to

the technical data.

Connecting test devices

Before setting the burner, test pressure

gauges must be fitted to determine

supply pressure 1 and possibly intake

pressure 2.

N.B.:

When commissioning is complete, the

pressure gauges must be removed and

the connections must be duly sealed.

If the pressure gauges are left on the

burner, they must all be shut off with

shut-off valves.

Oil hoses for burner connection

Burner type DN Length [mm] Connection on

both sides

Minimum bending radii R

[mm]

N6.2400 20 1500 R 1/2" 145

N6.2900 20 1500 R 1/2" 145

N7.3600 20 1500 R 3/4" 145

N7.4500 20 1500 R 3/4" 145

Connection to the test point

Burner Test point for

intake

pressure

Test point for

pump pressure

(at pump)

Test point for pump pressure (bef. 1st safety valve)

N6.2400 G1/2 G1/4 Ø10 pipe connector acc. to DIN EN ISO 8434-1*

N6.2900 G1/2 G1/4 Ø10 pipe connector acc. to DIN EN ISO 8434-1*

N7.3600 G1/4 G1/4 Ø10 pipe connector acc. to DIN EN ISO 8434-1*

N7.4500 G1/4c G1/4 Ø10 pipe connector acc. to DIN EN ISO 8434-1*

*In order to be able to use the test components, a cutting ring in acc. with DIN EN ISO 8434-1 is

required.

If the pressure gauge is not left on the burner, a union nut in acc. with DIN EN ISO 8434-1 is also

required.

N6

N7

Page 22

09/2011 - Art. Nr. 4200 1040 7900A22

Installation

Hydraulics

Pump type J7

Areas of application

- Light, medium-grade oil

- Two-line system.

- Generally connected to the solenoid

valve in the nozzle line

Description of Functions

The gearbox draws the fuel oil from the

tank through the built-in filter and

supplies it under pressure to the valve

which controls the oil pressure for the

nozzle line.

In the case of two-line installations, fuel

oil which exceeds the nozzle capacity

flows back to the tank through the valve

via the return opening.

Description of how the integrated valve

works: a flat section on the pressure regulation piston assists drainage of the fuel

oil*. If rotation of the gearbox is

increased when pumping commences,

all the fuel oil flows to the backflow via

the flat section and the hydraulic valve

remains closed. It is only when a specific

rotational gearbox speed is reached that

the fuel oil can no longer be returned via

the flat section. The pressure before the

control piston increases rapidly and

opens the valve as soon as it is higher

than the force of the valve springs.

When switched off, the valve closes as

soon as the gearbox capacity is lower

than the outflow via the flat section on

the piston on account of the lower rotational speed.

Opening and closing of the valve

depends on the size of the gearbox and

the set pump pressure.

Venting

In the two-line system, venting is carried

out automatically. However, venting can

be speeded up by opening the pressure

connection.

*In the J 1002 models, the bypass hole

in the nozzle plug prevents shut-off. For

shut-off, a separate solenoid valve must

be installed in the nozzle line.

Pumping capacity

Pump power requirements

Capacity (l/hr)

Power (W)

Pressure (bar)

Pressure (bar)

Viscosity = 5 cSt - pump speed = 2850 rpm

Allowance has already been made for gearbox wear in the

curves shown. In selecting the gearbox capacity, you

should therefore ensure that the pump is not over-dimensioned.

Viscosity = 5 cSt - pump speed = 2850 rpm

Page 23

09/2011 - Art. Nr. 4200 1040 7900A 23

Installation

Hydraulics

Pump type J7

General

Attachment Flange attachment as per EN 225.

Model 1000 Model 1001/1002

Connections Conical Cylindrical in acc. with ISO 228/1

Supply line and backflow 1/4" NPTF G 1/2

Nozzle outlet 1/8" NPTF G 1/4

Pressure test connection 1/8" NPSF G 1/8

Vacuum test connection 1/4" NPTF G 1/2

Valve function Pressure regulation and shut-off (apart from J 1002).

Filter Filter area: 45 cm²

Mesh size: 170 µm

Shaft Ø 11 mm in acc. with EN 225.

Bypass-plug Installed in the return opening

For two-line installaiton

Weight 4 kg

Hydraulic data

Pressure range C : 10 - 21 bar

E : 10 - 30 bar

Pressure setting

when delivered

12 bar

Viscosity range 2 - 75 mm²/s (cSt)

Fuel oil temperature 0 - 90°C in the pump

Supply pressure 1.5 bar max.

Return pressure 1.5 bar max.

Intake height 0.45 bar max. vacuum in order to avoid air separation

Rotational speed 3600 rpm max.

Torque (at 45 rpm) 0.30 Nm

Fuel oil under vacuum

Fuel oil under

pressure

Excess fuel oil

returned to the tank

or to the section side

Supply

Vacuum test

connection

Gearbox

Pressure

regulation

To the nozzle

Bypass

plug

screwed down

firmly

Pressure test

connection

Backflow

TWO-LINE

INSTALLATION

Page 24

09/2011 - Art. Nr. 4200 1040 7900A24

Installation

Hydraulics

Pump type TA3

Areas of application

- Domestic oil and heavy-grade oil (for

use with kerosene, please contact

SUNTEC)

- Two-line system.

Description of Functions

The gearbox draws the fuel oil from the

tank and supplies it under pressure to

the valve which controls the oil pressure

for the nozzle line.

In the case of two-line installations, fuel

oil which exceeds the nozzle capacity

flows back to the tank through the valve

via the return opening.

Venting

Pump venting is speeded up by opening

a pressure connection.

Note:

All TA pumps supplied are for two-line

installation (bypass plug screwed into

the vacuum connection).

To convert to single-line operation, the

bypass plug must be removed and the

return opening must be sealed off with a

gasket and metal plug.

Pumping capacity

Pump power requirements

Capacity (l/hr)

Power (W)

Pressure (bar)

Pressure (bar)

The values specified in the curves apply to new pumps

(with no evidence of wear)

The values specified in the curves apply to new pumps

(with no evidence of wear)

Viscosity

Viscosity

- Rotational pump speed = 2850 rpm

- Rotational pump speed = 2850 rpm

Page 25

09/2011 - Art. Nr. 4200 1040 7900A 25

Installation

Hydraulics

Pump type TA3

General

Attachment Flange attachment

Connections Cylindrical in acc. with ISO 228/1

Supply line and backflow G 1/2

Nozzle outlet G 1/2

Pressure test connection G 1/4

Vacuum test connection G 1/4

Shaft Ø 12 mm

Bypass-plug Used in the vacuum connection

for two-line installaiton

Weight 45.4 kg (TA2) - 5.7 kg (TA3)

6 kg (TA4) - 6.4 kg (TA5)

Hydraulic data

Pressure range 30 : 7 - 30 bar

40 : 7 - 40 bar

Pressure setting

when delivered

30 bar

Viscosity range 3 - 75 mm²/s (cSt)

(Fuel oil with a higher viscosity may be used if the fuel oil is supplied under pressure and is heated in such a way

that the viscosity falls below 75 cSt. For use with kerosene, please contact SUNTEC)

Fuel oil temperature 0 - 150°C in the pump

Supply pressure Light oil operation: vacuum 0.45 bar max.

in order to avoid air separation

Heavy-grade oil operation: 5 bar max.

Return pressure Light oil operation : 5 bar max.

Heavy-grade oil operation: 5 bar max.

Rotational speed 3600 rpm max.

Torque (at 40 rpm) 0.30 Nm

Selecting the heating element

Heating cartridge Ø 12 mm

Thread connection In acc. with EN 50262

Power 80-100 W

Fuel oil under vacuum

Fuel oil under pressure

Excess fuel oil

returned to the tank

or to the section side

Supply

Pressure

control

To the nozzle

Bypass

plug

screwed down

firmly

Backflow

TWO-LINE

INSTALLATION

Vacuum or

boost pressure

test connection

Pressure test

connection

Page 26

09/2011 - Art. Nr. 4200 1040 7900A26

Installation

Hydraulics

Nozzle line, 3-stage

3-stage nozzle line

The nozzle line consists of three pipes

each of which carries the fuel oil to a

nozzle. The flow of the fuel oil is controlled by the upstream fuel oil safety

valves. These are normally closed. Each

of the three valves controls a nozzle in

the fuel line. When the valves are

engaged, load stages 1, 2 and 3 are

implemented. In load stage 3, i.e. at

maximum burner output, all the valves

are open and all the nozzles are

operating simultaneously. To the front of

the nozzle line there is a nozzle plate

designed to hold the nozzles.

The table (see below) lists the standard

fuel oil nozzles for the lowest and

highest output range. Intermediate gradations are possible. The nozzle configuration selected must ensure that the

burner output falls within the specified

working field (see technical data). It

must not fall below or exceed this.

It is essential to have stable, hygienic

and reliable combustion. The fuel oil

pressure set must be taken into account

when selecting the nozzle.

Valve block

The valve block collects the oil and distributes it to the three fuel oil valves fitted

directly onto the block.

The fuel oil is supplied through the fuel

oil pump on the burner. Before it reaches

the fuel oil block, the fuel oil first passes

through the first fuel oil safety valve. The

valve block is fixed to the rear of the

nozzle line with two screws. In this way,

the entire burner head can be dismounted along with the nozzle line and

valve block.

The connections to be unscrewed

have been kept to a minimum.

The nozzles for the 3-stage nozzle line

are selected so as to meet the maximum

performance requirements of the boiler

with the best possible control range and

high combustion quality overall.

This means that in selecting the nozzles,

not only is the nominal capacity of the

relevant boiler crucial, so is the minimum

performance and the quality of combustion during each load stage.

The nozzle for the first stage must be

selected in such a way that it is within the

range of the permissible working field of

the burner. For the working field and the

minimum permissible outputs, please

refer to the technical data.

All the Monarch and Steinen nozzles

have permanent labels containing the

following information (subject to change

and based on CEN standards):

- Flow (in USGPH at 100 Psi = 6,895

bar)

- Manufacturer's code

- Spray angle

- Nozzle series ID

- Manufacturer's logo

Standard configuration for fuel oil nozzles for domestic fuel oil

Burner 1st stage 2

nd

stage 3rd stage

Model Size Model Size Model Size Fuel oil

pressure

supply line

[basic load]

N6.2400 min. Steinen SS60° 15.0 GPH Monarch PLP 60° 15.5 GPH Monarch PLP 60° 19.5 GPH 11.5 bar

N6.2400 max. Steinen SS60° 18.0 GPH Monarch PLP 60° 21.5 GPH Monarch PLP 60° 24.0 GPH 11 bar

N6.2900 min. Steinen SS60° 18.0 GPH Monarch PLP 60° 19.5 GPH Monarch PLP 60° 21.5 GPH 10 bar

N6.2900 max. Steinen SS60° 18.0 GPH Monarch PLP 60° 19.5 GPH Monarch PLP 60° 24.0 GPH 12 bar

N7.3600 min. Steinen SS60° 22 GPH Monarch PLP 60° 30 GPH Monarch PLP 60° 30 GPH 12 bar

N7.3600 max. Steinen SS60° 24 GPH Monarch PLP 60° 30 GPH Monarch PLP 60° 30 GPH 13.5 bar

N7.4500 min. Steinen SS60° 22 GPH Monarch PLP 60° 30 GPH Monarch PLP 60° 30 GPH 14 bar

N7.4500 max. Steinen SS60° 26 GPH Monarch PLP 60° 35 GPH Monarch PLP 60° 40 GPH 16 bar

Page 27

09/2011 - Art. Nr. 4200 1040 7900A 27

Installation

Hydraulics

Nozzle line, 3-stage

Oil throughput with pump pressure in bar

STEINEN

Oil through-

put at 7 bar

Kg/hr

Pressure in bar

GPH1012141820

10.00 38.28 41.93 45.29 51.36 54.14

11.00 42.11 46.13 49.82 56.50 59.56

12.00 45.94 50.32 54.36 61.64 64.98

13.00 49.77 54.52 58.89 66.77 70.40

14.00 53.6 58.71 63.42 71.91 75.81

15.00 57.43 62.91 67.95 77.05 81.23

16.00 61.26 67.10 72.48 82.19 86.65

17.00 65.08 71.29 77.00 87.31 92.05

18.00 68.91 75.48 81.53 92.45 97.47

20.00 76.57 83.87 90.60 102.7 108.3

22.00 84.23 92.27 99.66 113 119.14

24.00 91.88 100.7 108.7 123.27 129.96

26.00 99.54 109.04 117.8 133.5 140.8

28.00 107.2 117.4 126.8 143.8 151.6

Fuel oil, standard: 3.4 cst viscosity, .84 voluminal mass @ 20° C EN 293

Nozzle size Flow in l/hr at a pressure of (bar):

MONARCH

7 8.8 10.4 12.2 14

10.5 39.7 44.3 48.8 52.6 56.4

12 45.2 50.7 55.6 60.2 64.3

13.5 51.1 57 62.6 67.8 72.5

15.5 58.66 65.6 71.7 77.8 82.8

17.5 66.2 74.2 81 87.8 93.9

19.5 73.9 82.5 90.5 97.6 104.5

21.5 81.4 90.9 99.9 107.5 115

24 90.9 101.4 111.3 120.4 128.7

28 106 118.5 129.8 140 149.9

30 113.5 127.2 139.3 150.3 160.9

35 132.5 148 162.4 175.2 187.4

40 151.4 169.2 185.5 200.6 213.8

45 170.3 191 209 225.2 241.1

50 189.2 211.6 232 250.2 267.6

55 208.2 232.8 255.1 275.2 294.1

Page 28

09/2011 - Art. Nr. 4200 1040 7900A28

Commissioning

Control and safety unit LFL 1.../LGK...

LFL 1.../LGK... is designed for controlling and monitoring burners that operate

on the basis of a stepped or modulating

principle.

The following control and safety units

are installed as standard:

• Hot water applications - LFL 1.333

series 02

• Steam and hot water applications LGK 16.333A27

The safety times for these control and

safety units are listed in the table below.

Before commissioning, a check must be

carried out to determine whether the

safety times comply with national and

regional regulations. Other control and

safety unit variants can be obtained on

request.

N.B.

Do not press the reset button for

more than 10 sec!

R Reset button

R = Temperature or pressure

controller

M = Fan motor

Z = Ignition transformer

BV= Fuel valve(s)

LR= Load regulator

LK= Air flap

RV= continually adjustable fuel valve

or load stage valve

FS= Signal of flame

A = Starting type interval

A-B= Flame development interval

B = Burner has reached operating

position

B-C= Burner operation (heat genera-

tion)

C-D= regular shut-off

Functional diagramLFL 1.../LGK... Safety times

(sec)

t1 Pre-ventilating time 31,5

t3 Pre-ignition time 6

t4 Fuel valve enable 11.5

t5 output regulation release LR 11.5

t6 Post-ventilation time 17

t7 Interval between start command and voltage on terminal 7 3

t11 "OPEN" run time of air flap any

t12 "CLOSE" run time of air flap any

t13 Permissible post-combustion time 17

TSA Start-up safety time 3

Page 29

09/2011 - Art. Nr. 4200 1040 7900A 29

Commissioning

Electrical servomotor

Field of application

The SQM5... series servomotors are

designed for driving gas and air flaps in

medium to high output fuel oil and gas

burners. It is primarily designed for use

in the regulation of gas and combustion

airflow depending on the load.

• In conjunction with regulation with 3point or continuous (e.g. 4 ... 20 mA)

control signals or by the control and

safety units directly.

Technical documentation

SQM5... L&G 7815 D

Limit switches

The limit switches are actuated by

control cams which are set to a basic

position in the factory.

Disengaging mechanism

The drive shaft and camshaft can be disengaged separately.

A = Disengaging of drive shaft

N = Disengaging of camshaft

Warning!

The drive shaft and camshaft must not

be disengaged at the same time.

Page 30

09/2011 - Art. Nr. 4200 1040 7900A30

Commissioning

Electrical servomotor

Technical data SQM servomotor

Voltage 230 V -15%

50 / 60 Hz

240 V +10%

50 / 60 Hz

Power input 20 VA

Max. contact load 250 V 7.5 (3) A

Installation position as required

Ambient temperature- 20°C + 60°C

Protection level IP 54

Weight 3.3 kg

SQM 50.381A2

Duration with

130° rotation angle

22 sec

Torque 10 Nm

Description

The "SQM" servomotor is designed

for use in fuel oil, gas or two-stage

burners that operate in accordance with

the sliding or modulating principle. The

reversible servomotor comes with a synchronous motor which drives a shaft via

a gearbox. The shaft end carries a

coupling to drive the fuel and combustion air actuator.

The SQM servomotor has been

designed for dual-wire control by controller or switching units with changeover contacts.

Suitable potentiometers can be fitted for

a very wide range of applications.

The 60 Hz frequency will reduce the

running times by approx. 17 %.

Limit switch factory setting

The limit and auxiliary switches are set

by means of manually adjustable

latching cam plates. Scales are fitted

between the disks to facilitate the

selection of the switching points.

The cam plates are provided with a

small pointer for indicating the switching

point of a scale between the setting

ranges.

An additional scale fitted to the end of

the cam roller serves to indicate the

position of the servomotor.

The drive unit may be disengaged from

the controlling element by changing over

a rocker arm mounted to the gearbox.

This will allow any desired position of the

controller plate to be selected by hand.

Drive and output will be coupled in the

vertical position of the rocker arm.

The fuel-air curve must be set over the

entire adjustment range of the cam disk

so that safe operation can still be guaranteed even if the limit switch is overridden.

SQM servomotor, standard configuration of limit switch

Limit switch Function Standard setting [°]

1

Full load setting, gas,

Pre-ventilation setting gas/fuel oil

120

2

Basic load, gas,

Zero setting if burner is shut down, gas/fuel

oil

18

3 Ignition position, gas 20*

4

Air flap position, stage 1. Fuel oil

release stage 1, fuel oil

45

5 Fuel release stage 2, fuel oil 60

6 Air flap position, stage 2. Fuel oil 78

7 Fuel release, stage 3, fuel oil 90

8 Air flap position, stage 3. Fuel oil 120

9 Vessel, red part for anti-clockwise, black part for clockwise

P Potentiometer kit for further control functions (optional)

* The angle of limit switch 3 must be set a little higher than that of limit switch 2

Page 31

09/2011 - Art. Nr. 4200 1040 7900A 31

Commissioning

Flame monitor

Probe current measurement

Using a UV probe for flame monitoring

For the monitoring method, the UV

radiation from hot flame gases is used to

create the flame signal. A radiation

detector is a UV-sensitive tube with two

electrodes to which voltage is constantly

applied. When illuminated with light from

the 190...270 nm range of the spectrum,

it fires and applies current to the flame

signal amplifier. The UV tube does not

react to the after-glow of fireclay in the

furnace, sunlight, daylight or the lighting

used to illuminate the boiler room. The

tubes have a service life of approx.

10,000 hours at ambient temperatures

of up to 50°C; higher ambient temperatures reduce the service life considerably.

Burners used for constant or intermittent

operation for more than 24 hours without

a break (e.g. boiler sequence control) or

burners used in conjunction with steam

boilers must be fitted with control and

safety unit LGK 16... and the self-monitoring flame monitoring circuit (QRA

5...).

UV current measurement with QRA 5

In order to carry out accurate UV current

measurement, we recommend the use

of test device KF 8832. For UV current

measurements with normal test

equipment (microammeter) we

recommend that the measurement be

carried out as shown in the diagram. A

suitable capacitor must be integrated

into the test circuit (for details see the

table entitled "Probe currents and test

devices").

Connect the test device between the

control and safety unit and the UV flame

probe QRA 5... (terminals 22 (-) and 5

(+)).

Flame probe current test device KF8832

must not be left in constant use because

self-monitoring is not guaranteed during

the test process.

Ensure that the polarity is correct!

Flame probe current test device

KF8832 must not be left in constant

use because self-monitoring is not

guaranteed during the test process.

Alignment of UV probe QRA 5...

The movable connecting flange on the

probe tube facilitates precise alignment

of the probe window with the direction of

incidence of UV radiation.

Please note!

The terminal (22) must always be

earthed.

Cleaning the probe

The UV probe window must be regularly

inspected for dirt and cleaned. The

probe window must be kept free of dust.

If this measure proves unsuccessful, the

tubes must be replaced.

Test circuit for probe

current measurement

QRA2…, QRA10…,

QRA5… series D and

QRA5… series G

QRA2.

QRA5.

QRA2.

QRA5.

Page 32

09/2011 - Art. Nr. 4200 1040 7900A32

Commissioning

Flame monitor

Probe current measurement

Probe currents and test equipment

Min. required or max. achievable probe current in µA (DC)

QRA2 Ionisation

QRA5x.C...

QRA5x.E…

QRA5x.D...

QRA5x.G…

Automatic control unit min max min max min max min max

LFL1… 70 700 6 200 - - - -

LGK16… - - 12 100 35 50 120 270

Test

equipment

Recommended Tester KF 8832

Alternative

M1 - microammeter Ri max. 5000 Ω;

0 - 1000 µA

C - electrolyte capacitor 100...470 µF;

DC 10...25 V

-

M1 - microammeter Ri max.

5000 Ω; 0 - 1000 µA

C - electrolyte capacitor 470 µF; DC 25

V

Page 33

09/2011 - Art. Nr. 4200 1040 7900A 33

Commissioning

Gas train connection

Electrical connection

Checks before commissioning

Checks before commissioning

The following must be checked before

initial commissioning:

• That the burner is assembled in

accordance with the instructions given

here.

• That the burner is pre-set in accordance with the values in the adjustment

table.

• Setting the combustion components.

• The heat generator must be ready for

operation, and the operating regulations for the heat generator must be

observed.

• All electrical connections must be

correct.

• The heat generator and heating

system must be filled with water and

the circulating pumps must be in operation.

• The temperature regulator, pressure

regulator, low water detectors and any

other safety or limiting devices that

might be fitted must be connected and

operational.

• The exhaust gas duct must be unobstructed and the secondary air

system, if available, must be operational.

• An adequate supply of fresh air must

be guaranteed.

• The heat request must be available.

• Sufficient gas pressure must be available.

• The fuel supply lines must be

assembled correctly, checked for

leaks and bled.

• A standard-compliant measuring point

must be available, the exhaust gas

duct up to the measuring point must

be free of leaks to prevent anomalies

in the measurement results.

All electrical installation and connection work must only be carried out by

a suitably qualified electrician.

The applicable guidelines and direc-

tives must be observed, as

well as the electrical circuit

diagram supplied with the

burner!

Before connecting the burner,

it is essential to ensure that the entire

burner has reached the ambient temperature. Otherwise, there is a risk

that condensation will form on electronic components resulting in

damage to property and personal

injury!

Gas train connection

The connectors on the burner must be

used for connecting the gas train. Cognisance must be taken of the equipment

labelling and the electrical circuit

diagram.

Electrical connection

The electrical connections, i.e. the

installation materials and all the connectors and earth/ground connections, must

be installed in compliance with the specifications.

The electrical installation of the burner

must be carried out in accordance with

the circuit diagram drawn up for the

furnace.

The electrical connection of the burner

may only be performed by authorised

professionals.

Please note:

When installing the connection cable,

the cable loops selected must be large

enough to allow the boiler door to swivel

open.

When electrical connection work is

complete, the wiring for the burner

electrics must be checked.

This includes checking the direction of

rotation of the fan or the fuel oil pump

motor.

Page 34

09/2011 - Art. Nr. 4200 1040 7900A34

Commissioning

Gas connection

Gas connection

The gas lines and valve groups should

be installed and taken into operation in

accordance with the applicable engineering standards and regulations.

The connection between the gas distribution network and the gas ramp must

be done by authorised persons.

All the gas ramp components must be

fitted and installed without bending or

distortion or any other form of mechanical stress.

The section of the pipings must be calculated so that the loss of load doesn’t

exceed 5% of the supply pressure.

A quarter turn manual valve (not

supplied) must be provided for

upstream of the gas ramp and the filter.

The max. operating pressure for the

shut-off device must be 1.5 times the

max. connection pressure. Ease of

access must be guaranteed. Precautions must be taken to prevent unintentional actuation. The operating position

of the gate valve must be quite obvious.

The manually operated valve should

have fixed stops in the "OPEN" and

"SHUT" positions.

The filter must be installed on a horizontal nozzle with the cover in the vertical

position to enable cleaning.

Depending on the current specification,

a thermally triggered gate valve must be

provided for on site (not supplied).

All the gas ramp components must be

protected against condensation and if

necessary, a condensate trap (not

supplied) must be provided for on site.

The threaded unions used must be in

conformity with present standards

(tapered male thread, straight female

thread with sealing provided in the

thread).

Sufficient space must be provided for

setting and maintaining the gas ramp

components (gas pressure switch,

valves, pressure regulator, gas filter,

test burner etc.) (see technical data).

Gas properties

Prior to any installation work make sure

to obtain the following data from the gas

supply company:

1. Type of gas

2. Calorific value Hu

n

= kWh/m3 (kJ/m3)

3. Max. CO

2

content of exhaust gas

4. Gas connection pressure and rest

pressure

Type of gas test

Prior to mounting the burner to the gas

feed line check the available type of gas

and burner type against the data given

on the burner nameplate (attached to

burner).

Be sure the description of the burner

and the type of gas are the same as

indicated on the nameplate.

Gas connection pressure

A minimum connection pressure must

be available upstream of the burner gas

valve to ensure the proper functioning of

the burner.

For the installation of the valves and

instruments group take care to observe

the mounting instructions supplied by

their manufacturers (these are packed

with the equipment). The gas line

installed to the burner must be dimensioned in accordance with the throughput rate and the available pressure.

For selecting the nominal bore "DN" of

the gas valve group care should be

taken to observe the flue resistance

of the boiler and the gas pressure

loss of the burner and valve group.

Warning!

The absence of impurities and foreign