elco Low-NOx N10.12000.37 G-EU2, Low-NOx N10.14000.37 G-EU2, Low-NOx N10.12000.30 G-EU2, Low-NOx N10.14000.45 G-EU2 FQ, Low-NOx N10.16000.45 G-EU2 FQ Operation Manual

Page 1

Operation manual

for the authorized specialist

Gas forced draught burner Low-NO

x

N10... G-EU2

12/2011 14 072 205

Page 2

2

Inhalt

Overview Contents ................................................................................................................ 2

Important information Warranty, safety instructions .............................................. 3

Safety instructions Installation, start-up, maintenance .......................................... 4

Technical data .............................................................................................................................. 5

Important components, burner description ............................................................ 6

Operation fields ..................................................................................................... 7

Operation fields ..................................................................................................... 8

Gas pressure loss burner head Gas pressure loss gas butterfly .......................... 9

Dimensional drawing ........................................................................................... 10

Installation conditions .......................................................................................... 11

Installation Mounting to boiler Electrical connection Presetting ............................................ 12

Burner head settings ........................................................................................... 13

Gas connection ................................................................................................... 14

Gas train description ........................................................................................... 15

Start-up Checking procedure ............................................................................................ 17

Disassembling firing head ................................................................................... 18

Gas start-up mode Gas operating mode General safety function ....................... 19

Fuel-air compound control .................................................................................. 20

Electronic burner controller ................................................................................. 21

Servo motor type SAD 15 ................................................................................... 22

Electrical actuator STM 40 .................................................................................. 22

Flame sensor ...................................................................................................... 23

Gas pressure switch Air pressure switch ............................................................ 24

Adjustment Combination controls CG 15 -30 ...................................................... 25

Exhaust gas test .................................................................................................. 27

Servicing instructions Burner maintenance ............................................................................................ 29

Fan impeller ........................................................................................................ 30

Trouble shooting instructions Cause and removal of disturbance ..................................................................... 31

Manufacturer’s declaration ............................................................................................................................ 33

Overview

Contents

12/2011 14 072 205

Page 3

3

Overview

Important information

Warranty, safety instructions

General information

These operating instructions are a fixed

component of the system which should

be displayed in a prominent location at

the point of installation of the heat generator and should include the address

and telephone number of the nearest

customer service centre.

They are directed solely at authorised

expert personnel.

These operating instructions cont ain

the most important information for

installing, commissioning and maintaining the burner safely and must

be observed by any personnel who

work on the system.

Important information

The burners are designed in accordance with the specification in the Technical data section (alternative fuels on

request).

The burners should be installed and

taken into operation carefully by qualified personnel. The work should be

done in accordance with the applicable

regulations and guidelines.

Only a duly authorised specialist should

be entrusted with the installation of the

gas system, and all applicable directives and regulations must be observed.

Any repair work on monitors, limiters

and automatic furnace controllers and

on the other safety facilities are allowed

to be done on the single items only by

the manufacturers themselves or specialists authorized by them.

Original parts should only be exchanged by a duly qualified specialist.

Standards and regulations

The following standards should be

observed in the interest of a safe, easyon-the-environment and energy-saving

operation of the burner:

The operator must, in accordance with

country-specific standards and legislation, be given instruction on how the

heating installation operates.

National requirements and building regulations must be taken into consideration during installation of a gas-fired

system.

Screwed unions of metal used in gas

lines should be fitted with approved

sealing elements.

Prior to taking the burner into operation

make sure to vent the gas line, but this

should in no case be done through the

furnace chamber.

Place of installation

The burner must not be operated in

rooms containing corrosive vapours

(e.g. spray, perchloroethylene, hydrocarbon tetrachloride, solvent, etc.) or

tending to heavy dust formation or high

air humidity.

Adequate ventilation must be provided

at the place of installation of the furnace

system to ensure a reliable supply with

combustion air.

Maintenance

The furnace system should be serviced

at least once a year by an authorized

specialist. It is recommended to conclude a maintenance agreement to this

effect.

Guarantee

The guarantee does not cover damage resulting from:

- failure to commission and maintain the

burner in accordance with the operating instructions;

- damage or loss arising from incorrect

installation;

- damage or loss arising from incorrect

adjustment;

- damage or loss arising from unauthorised tampering and

- damage or loss arising from improper

operation (e.g. operating the system

at excessive pressure).

Subject to change without notice due to

ongoing technical developments.

EN 676 Gas burners with

blowers

Safety instructions

The burner has been built and tested to

applicable standards and directives and

recognised rules of technical safety

and, depending on the burner type, has

either been type tested (see declaration

of conformity in the Technical data

section) or must be tested individually

(see manufacturer's declaration in the

Technical data section). Risks to

persons or property may arise if the

burner is not operated correctly or used

for its intended purpose.

To eliminate these risks, the burner

may only be installed and operated

• in accordance with its intended

purpose

• in a technically safe condition

• in compliance with all guidelines and

information contained in these

operating instructions

• in compliance with all inspection and

maintenance guidelines, as specified

in the operating instructions or

components documentation, or as

defined by applicable national

legislation, standards or requirements.

Safety measures and rules of

conduct

1. Burner only to be operated in an

undamaged, defect-free and

technically safe condition.

2. Assembly, commissioning /

adjustments, repair and maintenance

carried out only by experts trained and

authorised for the work concerned.

This also applies to work on the

electrical system and the gas/oil

supply.

3. All safety devices of the system must

be checked on a regular basis as

specified by applicable regulations.

4. Protective clothing must be worn

while work is being carried out on the

system.

5. The information in the operating

instructions must be observed as well

as the applicable requirements or

regulations of accident prevention and

relevant national construction and

safety regulations, requirements,

standards and legislation.

6. The markings on the system must be

maintained in a clearly readable

condition and restored if necessary.

12/2011 14 072 205

Page 4

4

Overview

Important information

Safety instructions

Installation, start-up, maintenance

7. Equipment to be operated only with

safety devices activated and in good

working order.

8. The system must be checked

annually – or more frequently if

necessary, depending on system

conditions - for externally visible

damage and for the correct operation

of safety devices.

9.Safety functions and safety times

must not be impaired, rendered

inoperational or modified by additional

external wiring.

Tasks carried out on the electrical system

• All tasks involving the electrical

system must be carried out by expert

electricians.

• Before any work is carried out, the

system must be disconnected from

the power supply and secured against

unexpected reconnection.

• Work on live systems may only be

carried out under the supervision of a

second person who would be able to

disconnect the power supply in the

event of danger.

• The electrical system must be

routinely checked as part of

maintenance. Damage of any kind

(e.g. loose connections, damaged

cable insulation) must be rectified

immediately.

Safety instructions for assembly

Always disconnect the system from

the power supply!

Before assembly work begins, switch

off the master and emergency switches

and secure them against the possibility

of being switched back on.

Danger! Failure to comply could result

in a harmful or fatal electrical shock.

Risk of severe injury and danger of

death.

Safety instructions for initial

commissioning

The initial commissioning of the heating

installation must only be carried out by

the constructor, manufacturer or

another of the experts described. All

regulating, control and safety devices

must be checked for correct operation

and – where adjustment is possible –

for correct adjustment.

Before initial commissioning, it is

necessary to check electrical circuits for

correct fusing, and the measures for

protection against accidental contact

with electrical equipment and wiring.

Safety instructions for

maintenance

• The operator must be informed of all

work to be carried out before it begins.

• Assembly, commissioning /

adjustments, repair and maintenance

carried out only by experts trained and

authorised for the work concerned.

This also applies in particular to work

on the electrical system and the gas/

oil supply.

• Protective clothing must be worn while

work is being carried out on the

system.

• Specified adjustment, maintenance

and inspection work must be carried

out at the specified intervals.

• Before any work is carried out on the

system, the system must be

disconnected from the power supply

and secured against unexpected

reconnection.

• The fuel supply must be closed before

work is carried out on the system.

• All safety devices of the system must

be checked on a regular basis as

specified by national requirements,

regulations, standards and legislation.

• Damaged system parts must be

replaced immediately. If parts are to

be replaced, it is only permitted to use

genuine parts, or replacement parts

that have been approved or

authorised by the manufacturer.

• The installation of additional

components that were not subjected

to model series or individual testing at

the same time as the system is not

permitted.

• Do not modify the system or fit

attachment or conversion parts

without the authorisation of the

manufacturer.

• Loose connections must be checked

for firm seating after they have been

reconnected.

• If seal connections are opened, the

sealing surfaces must be cleaned

thoroughly at the time of reassembly.

Ensure a perfect connection;

damaged seals must be replaced with

new ones. Check for leaks once

reassembly is complete.

• Repairs to limiting devices, automated

equipment, flame monitoring

equipment and other safety devices

must only be carried out by the

manufacturer or its appointed

representatives. The expert charged

with carrying out maintenance work

must replace complete components or

assemblies with those of the same

type.

• Safety devices must be checked for

correct operation following their

replacement or repair and after any

maintenance work has been

completed.

• Only use the burner with furnaces that

are suitable for the flame dimension

concerned, i.e. in which the flame may

burn out unhindered.

• Any change to the furnace pressure

(e.g. as a consequence of

modifications to the flue system), and

any modification that would result in a

change in the supply of air to the

burner (e.g. a retrofitted

soundproofing shroud), requires

reconfiguration of burner regulation.

• Persons present in the proximity

during burner operation must be

equipped with suitable measures for

protection against harmful noise

levels.

After all maintenance and repair

work:

1. Function test.

2. At all load points, check O

2

- (CO2-) /

CO -/ NOx- values, soot emissions

and exhaust gas losses.

3. Create a measurement report, leave

a copy with the system.

12/2011 14 072 205

Page 5

5

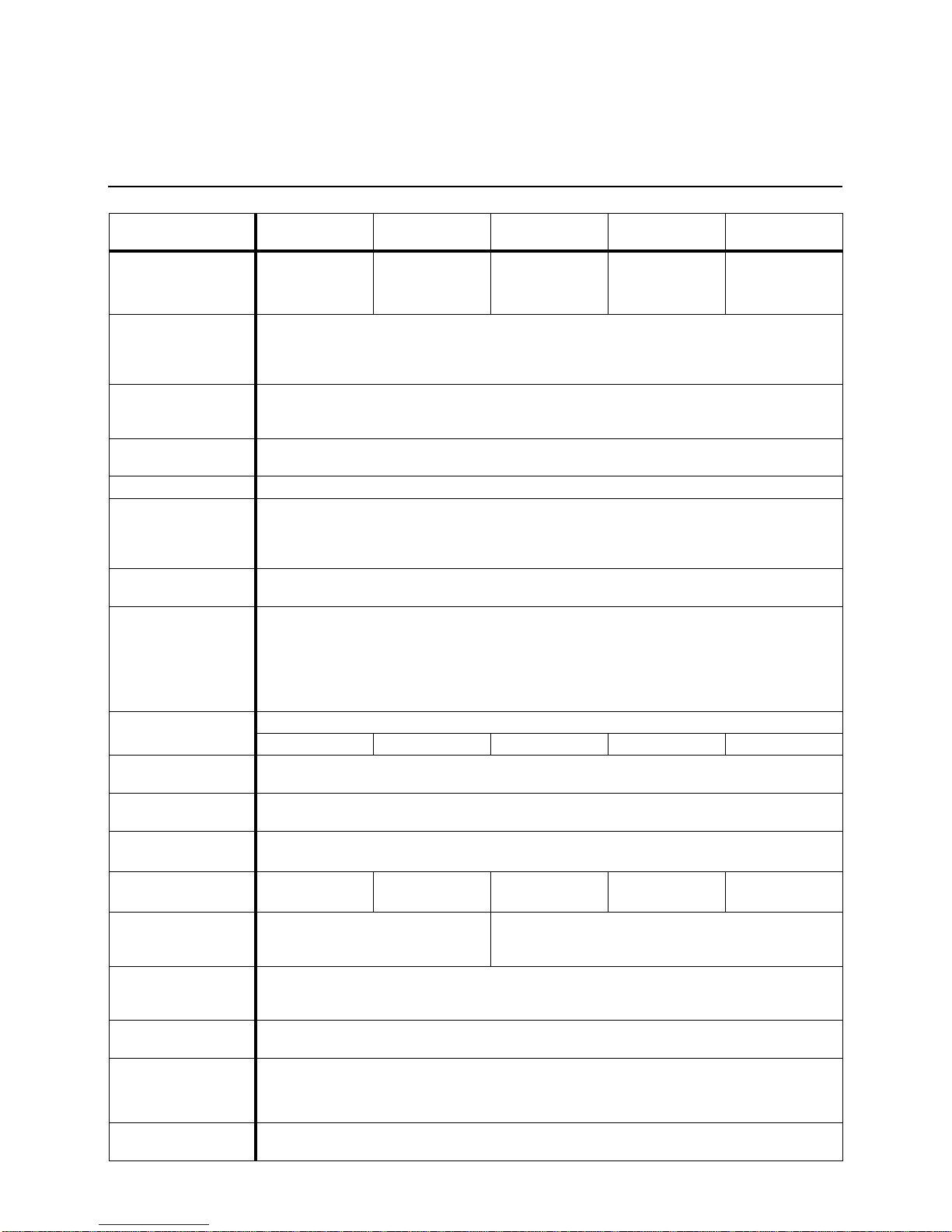

Technical data

Burner type

N10.12000.30

G-EU2

N10.12000.37

G-EU2

N10.14000.37

G-EU2

N10.14000.45

G-EU2 FQ

N10.16000.45

G-EU2 FQ

Combustion power

output

(*FQe=frequency converter

for motor externally)

1.500* - 12.000 kW

*(1.750 kW without

FQe or Natural gas

LL)

1.500* - 12.000 kW

*(1.750 kW without

FQe or Natural gas

LL)

1.750* - 14.000 kW

*(2.000 kW without

FQe or Natural gas

LL)

1.750 - 14.000 kW 2000 - 16.000 kW

Max. control ratio 1:8 for Natural gas E and with FQe

1:7 without FQe or Natural gas LL

Deviating values on request

(N.B.: the lower operating point must also be within the working field.)

Boiler furnace

pressure

Selection of the nominal burner capacity within the nominal capacity area marked in the working

field. Deviating nominal capacities on request. At burners with FQ higher furnace back pressure by

rise of the motor frequency to > 50 Hz up to the max. capacity limit.

Fuels Natural gas E, LL

Operation type Continuously modulating

Electronic air-fuel-

compound-control,

automatic firing

device

Etamatic OEM or BCS 300 on burner

Alternative electronic burner controls in separate cabinet

Electrotechnical

equipment

Attached to the burner is an IP54 control cabinet that contains the terminal block and, where applicable, the combustion manager and other components

Optional electrotechnical equipment

BCS or Etamatic OEM as burner controller

Power controller with protection, soft start or Y-D start externally in a separate control cabinet

Power regulation by external 4-20 mA nominal value input

Frequency converter externally in a separate control cabinet

Preparation for controller-specific O

2

regulation, probe fitted externally

Profibus DP, Modbus RT, Ethernet

Fan motor 400/690 V, 50/ 60 Hz / 2950 U/min, IP55

30 kW 37 kW 37 kW 45 kW 45 kW

Gas connection DN100, PN16, Natural gas E p

min

=250 mbar, Natural gas LL p

min

=300 mbar

Protection class IP40, IP54 as option

NOx-emissions Emission class 3 according EN 676, 70-150mg/kWh (0% O

2

acc. EN 676)

Precise values on request.

Flame length max. at

3% O

2

6,0 m 6,0 m 6,4 m 6,4 m 6,8 m

Flame diameter

min. 1,3 - 1,6 m

(depending on combustion output

and NOx requirements)

min. 1,4 - 1,75 m

(depending on combustion output and NOx requirements)

Acoustic

Emissions, Sound

Pressure

< 97 dB(A) (average value on enveloping surface at 1 m distance)

Site Closed rooms or weatherproof on site; non-aggressive atmosphere

Ambient temperature

(including impact of heat

radiation)

0°C - 60°C with BCS or Etamatic on burner,

-10°C - 60°C with alternative electronic burner controls in switch cabinet,

relative humidity max. 60% (special corrosion protection on request)

Burner weight Approx. 550 kg plus 100 kg for transport rack

12/2011 14 072 205

Page 6

6

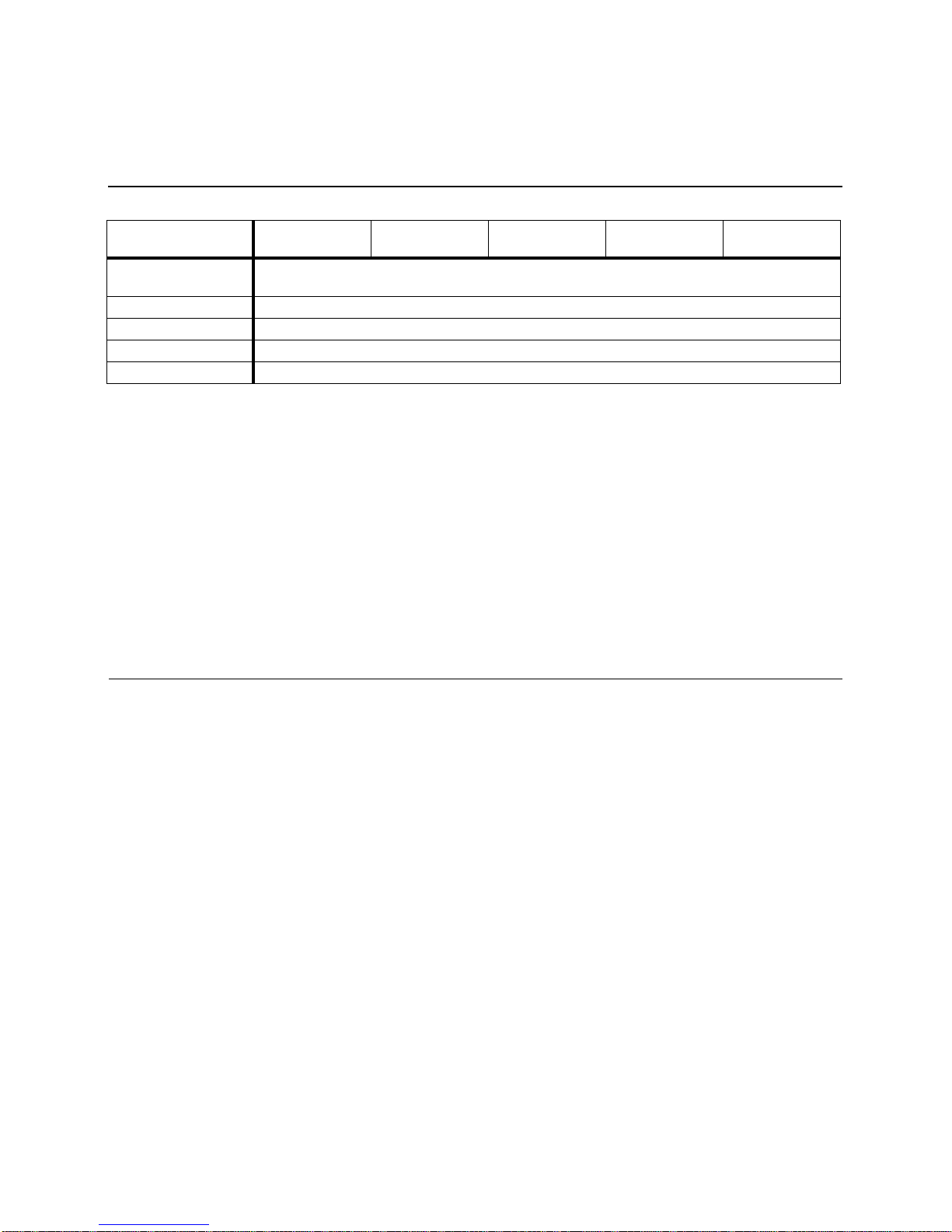

Technical data

Important components, burner description

important

components:

Flame monitor QRA 2, QRA 53 / FFS 06

Ignition transformer EBI

Servo motor SAD15 / STM 30/40

Air pressure switch DL 50 A

Burner type

N10.12000.30

G-EU2

N10.12000.37

G-EU2

N10.14000.37

G-EU2

N10.14000.45

G-EU2 FQ

N10.16000.45

G-EU2 FQ

Operating mode

The burner is designed as an automatic

controllable gas blast burner to EN 437

Gasfamily 2. It is tested according to

EN 676 and fitted with a delta burner

head, a system for the low NO

x

combu-

stion of fuel.

Application

The burners are applicable for the operation at heating boilers, steam boilers

and air heater with 3-pass, draft or

reverse furnace.

Design

The burner is supplied with connection

leads fixed to a terminal block ready for

connection to the boiler system.

BCS and Etamatic OEM design

The burner is equipped with an electronic burner control system (automatic

furnace controller, electronic compound

controller, gas valve leak detector).

Other electronic burner controller

Electronic burner control (automatic furnace controller, electronic compound

controller, gas valve leak detector) is

placed in the separated switch cabinet.

Combustion air

An overpressure fan impeller with a

steep characteristic is provided to

ensure a high pressure build-up. This

ensures a pulsation-free and steady

combustion behaviour also on boilers

with a high exhaust gas resistance.

Control

The fuel-air ratio is controlled by an

electronic compound controller with

actuators provided for positioning the

following control elements:

- air damper,

- gas damper.

- event. frequency inverter.

Sensors

A flame sensor and an approved automatic furnace controller are provided for

flame monitoring. An differential pressure switch is fitted for fan air monitoring. A speed monitor is installed if an

automatic speed control system is

used.

Ignition

Electrical high voltage ignition of the

enclosed ignition burner.

Heat capacity of the ignition flame

< 10% of the main flame.

Internal exhaust gas return

As a primary precaution to minimize the

generation of nitric oxides, the delta

burner head will internally extract combustion gases from the furnace chamber and feed them to the fuel mixture.

This concept does away with the equipment otherwise required for the external

return of the exhaust gases.

12/2011 14 072 205

Page 7

7

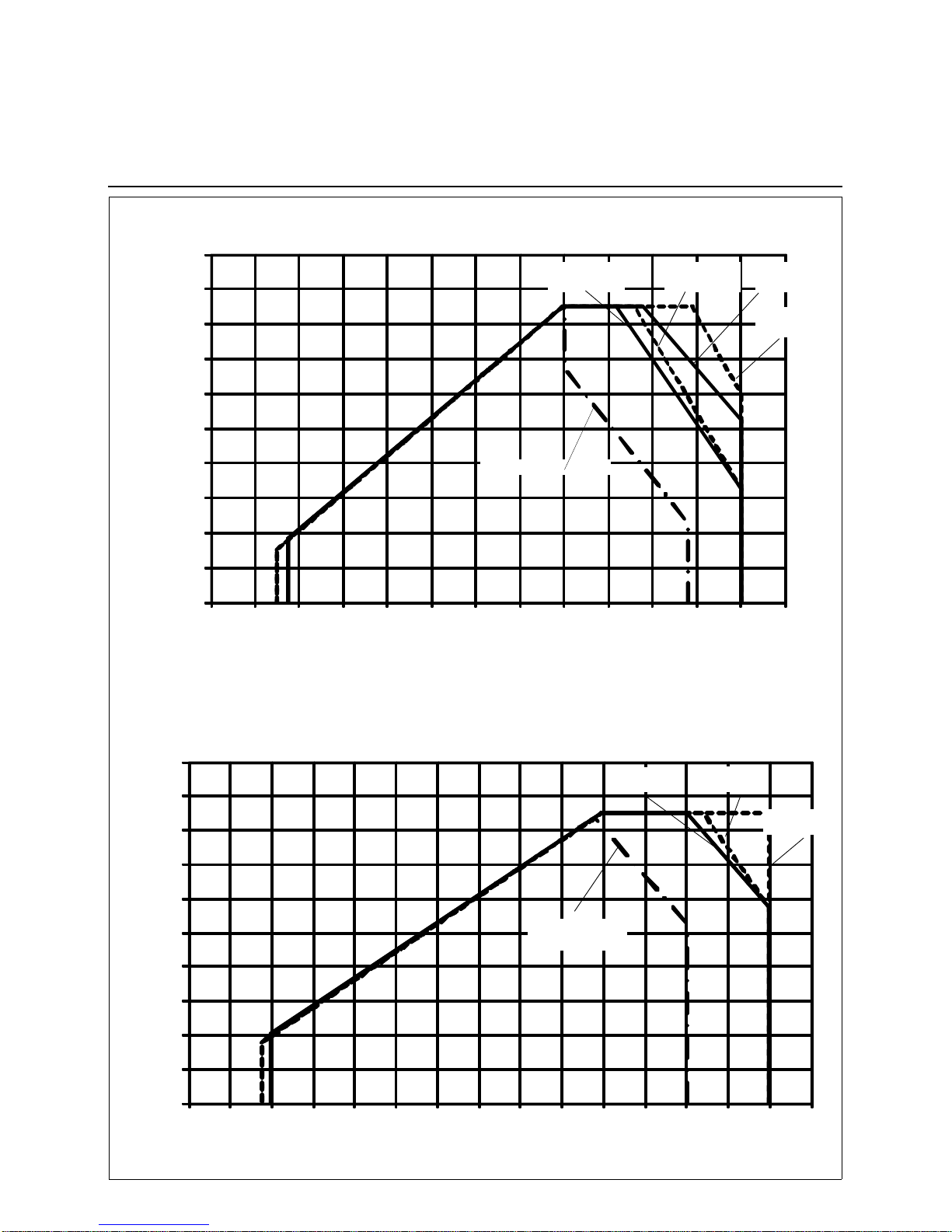

Technical data

Operation fields

0

4

8

12

16

20

24

28

32

36

40

012345678910111213

A rbei tsfel der N10.12000 G- EU2 nach EN 676

0

4

8

12

16

20

24

28

32

36

40

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Arbeitsfelder N10.14000 G-EU2 nach EN 676

Combustion power output [MW]

Limit full load range

Boiler furnace pressure [mbar]

Operation fields N10.12000 G-EU2 according EN 676

Operation fields N10.14000 G-EU2 according EN 676

Combustion power output [MW]

Boiler furnace pressure [mbar]

FQe=frequency converter for motor externally

FQe=frequency converter for motor externally

N10.14000.45

G-EU2 FQe

N10.14000.37

G-EU2 FQe

Limit full load range

N10.14000.37

G-EU2

N10.12000.30

G-EU2

N10.12000.30

G-EU2 FQe

N10.12000.37

G-EU2

N10.12000.37

G-EU2 FQe

12/2011 14 072 205

Page 8

8

0

5

10

15

20

25

30

35

40

45

50

55

01234567891011121314151617

Arbeitsfeld N10.16000.45 G-E FQ

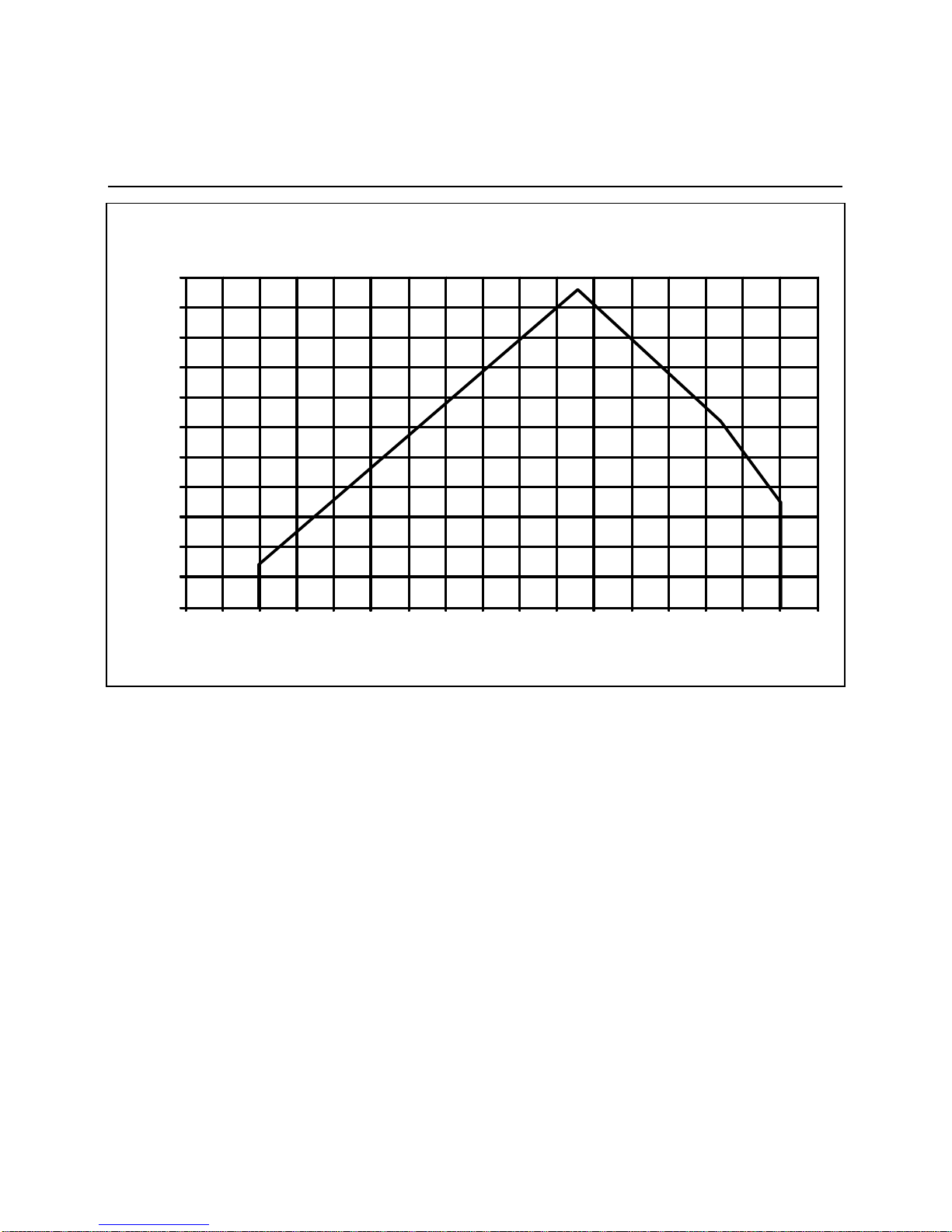

Operation fields N10.16000 G-EU2 FQe according EN 676

Technical data

Operation fields

Combustion power output [MW]

Boiler furnace pressure [mbar]

FQe=frequency converter for motor externally

12/2011 14 072 205

Page 9

9

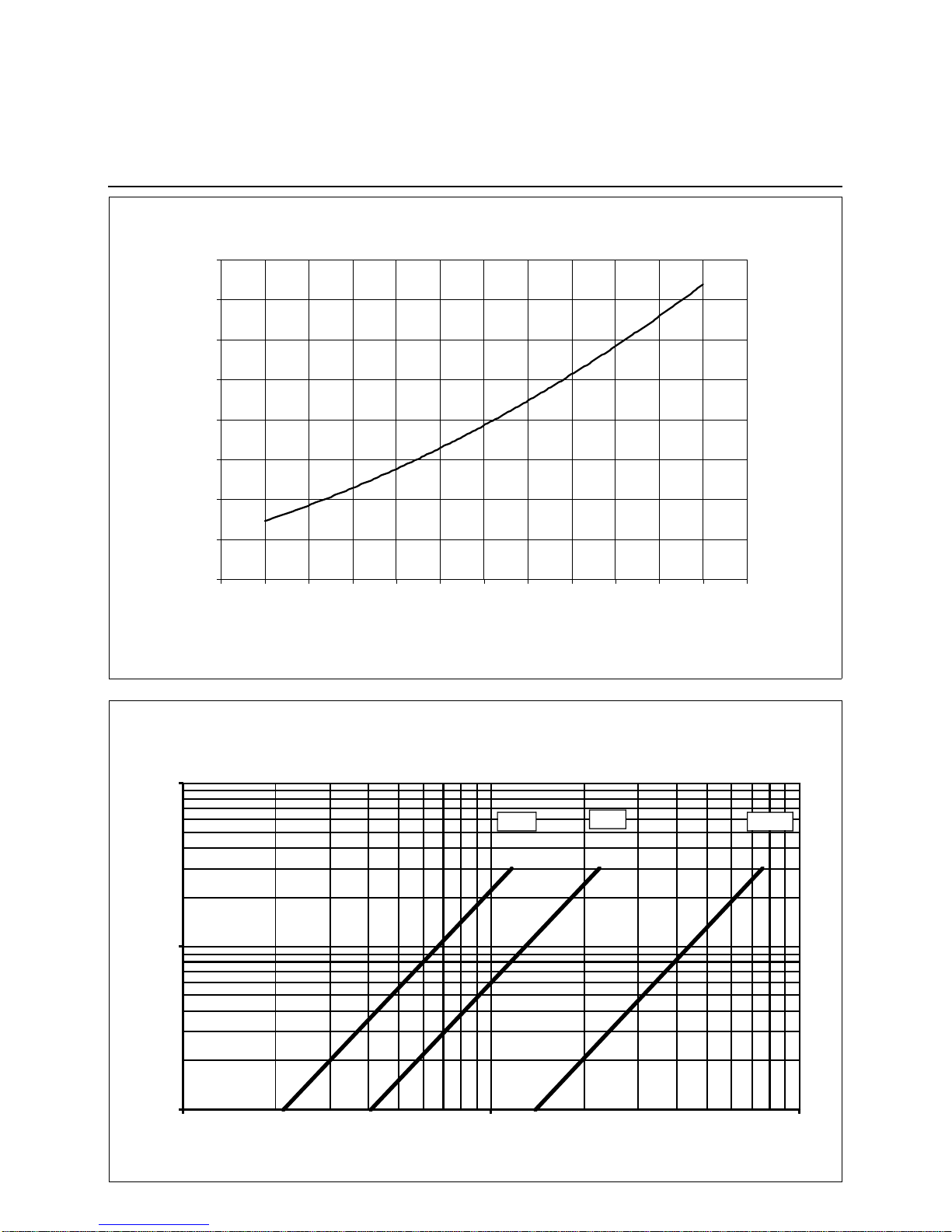

Technical data

Gas pressure loss burner head

Gas pressure loss gas butterfly

Druckverluste G as Mischeinrichtung E10 G-EU 2

0

20

40

60

80

100

120

140

160

700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900

Volumenstrom Erdgas [m³ /h], 15° C, 1013 mbar, dv 0,61

Druckverl u st [ m bar]

Operation volume flow natural gas [m3/h], t=15°C, 1013 mbar, dv=0,61

p p

diagr

T

288

----------

1013

p

-------------

dv

061,

-------------

=

Pressure loss [mbar]

Pressure loss gas mixed unit N10 ... G-EU2

1

10

100

100 1000 10000

D

r

u

c

k

v

e

r

l

u

s

t

[

m

b

a

r

]

Vol um enst r om V [m ³ /h ], Erdgas, 15 ° C, 1013 mbar, dv = 0,62

Druckverlust b ei voll geöffneter Gasklappe DN 100 Typ DKG / BVG

Ø 100 Ø 65

Ø 80

Pressure loss gas butterfly (full open) DN 100 type DKG/BVG

Operation volume flow natural gas [m3/h], t=15°C, 1013 mbar, dv=0,62

Pressure loss [mbar]

12/2011 14 072 205

Page 10

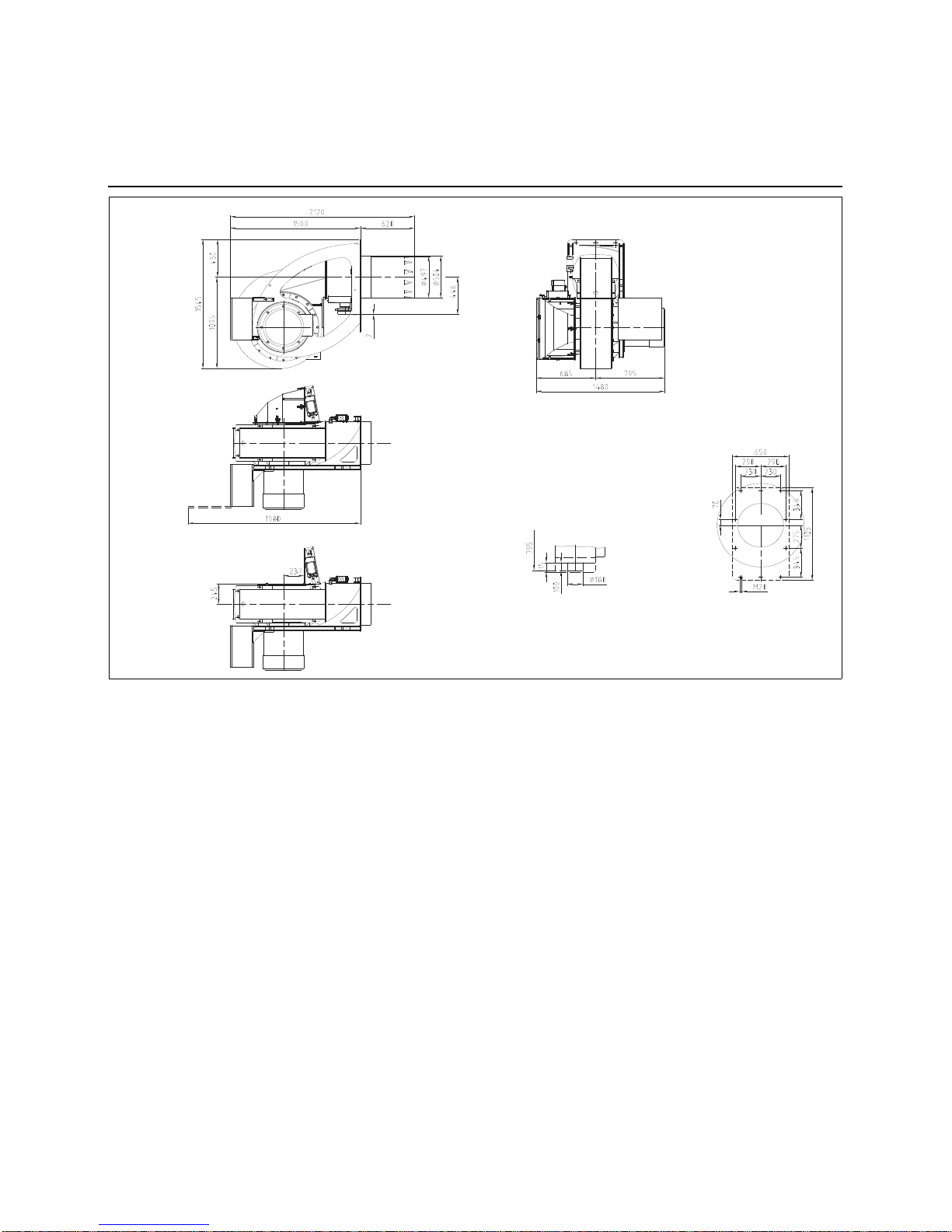

10

Technical data

Dimensional drawing

N 10... G-EU2

The cover of motor is

removable in case of opening boiler door for revision

Motor with disassembled protection grid

Drilling Template

Air intake box cover with

dismantled home

12/2011 14 072 205

Page 11

11

Technical data

Installation conditions

ad 1) Boiler lining

D = 497

D

1

= 525

DF= combustion chamber

diameter

T

1

= 150-250

A = 620

(option: extensions

of 100 and 200 mm)

The burner lining must be installed at

right angles to the burner tube.

Possible trimming work (bevelling, rounding) as is required for reversing boilers, for example, should done at a

diameter not below 70 % of the combustion chamber diameter.

The space between the flame pipe of

the burner and the boiler lining should

be lined with heat resistant material,

such as Cerafelt.

This space is not allowed to be lined

with brickwork.

Minimum distance on double

flame tube boilers

ad 3)

Note:

In special cases, the air infake box can

be mounted in a way that the opening

shows to another direction. The dimensioned drawing will the differ slightly.

The air intake box can be rotated in

steps of 22,5 °..

3)

1)

2)

12/2011 14 072 205

Page 12

12

Installation

Mounting to boiler

Electrical connection

Presetting

Check before burner installation

Check the mixing unit for correct setting; see dimensioned drawing.

Deviations from the burner head adjustment data may be acceptable following

a type test or individual testing by

arrangement with the test authority in

order to adapt the burner to the boiler

and flue gas system. However, these

deviating adjustments must be carried

out by an authorised expert and all

modified dimensions must be documented in the adjustments and measurements log containing the flue gas

measurement and combustion stability

evaluation. This must be handed over

to the test authority on request.

- Set the ignition electrodes according

to the sketch.

- Check the burner pipe mounting

according to Section “Boiler lining for

burners” and the boiler manufacturer’s

specifications.

Electric connection:

The electric connection including all

installation materials as well as joints

and earth terminals must be made in

accordance with the applicable regulations. For the electrical installation of the

burner reference should be made to the

circuit diagram of the furnace system.

The electric connection of the burner

and gas valves and instruments is allowed to be entrusted to authorized specialists only.

Burner installation

For mounting the burner to the boiler

make sure the connection plate is prepared in accordance with the dimensions given in the technical datasheets.

• Install the stud bolts in the connection

plate.

• Put the insulating base and burner in

place and fasten with bolts.

Arrangement of sealing tape on

the boiler (1)

- Evenly stick on self-adhesive tape (2)

according to Figure.

- Adapt the flat gasket by cutting to the

boreholes in the area of the four. vertically arranged boiler fastening holes.

(3)

- In case of butt joints make sure the

bordering is fitting closely. (4)

Attention:

After the completion of the electric connection work make a check of the wiring

of the burner electric system. This includes a check for the direction of rotation

of the burner motor (fan).

Boiler inspection glass cooling

For cooling and cleaning the boiler

inspection glass, a cooling line (e.g. a

hose) may be installed from the burner

to the inspection glass. A connection

piece is provided on the burner for this

purpose.

Burner plate with gasket strip

12/2011 14 072 205

Page 13

13

Installation

Burner head settings

N 10.... G-EU2

Burner ABC D D1EXY

N10.12000 G-EU2 620 155 118 491/497 375 65 30 10

N10.14000 G-EU2 620 155 118 491/497 338 65 30 10

N10.16000 G-EU2 620 155 118 491/497 338 65 30 10

Adjustment electrical Ignition Operation Gas ignition burner ZB 2

Ignition burner gas pressure [mbar]

Blower pressure p [mbar]

12/2011 14 072 205

Page 14

14

Installation

Gas connection

Gas connection

The gas lines and valves and instruments group should be installed and

taken into operation in accordance with

the applicable engineering standards

and regulations.

The connection between the gas distribution network and the gas ramp must

be done by authorised persons.

The section of the pipings must be calculated so that the loss of load doesn’t

exceed 5% of the distribution pressure.

A quarter turn manual valve (not supplied) must be provided for upstream of

the gas ramp and the filter.

The filter must be installed on a horizontal nozzle with the cover in the vertical position to enable cleaning.

The threaded unions used must be in

conformity with present standards

(tapered male thread, straight female

thread with sealing provided in the

thread).

Gas properties

Prior to any installation work make sure

to obtain the following data from the gas

supply company:

1. type of gas

2. calorific value Hu

n

=kW/m³ (kJ/m³)

3. maximum CO

2

content of exhaust

gas

4. gas connection pressure and rest

pressure

Type of gas test

Prior to mounting the burner to the gas

feed line check the available type of gas

and burner type against the data given

on the burner nameplate (attached to

burner). Be sure the description of the

burner and the type of gas are the

same as indicated on the nameplate.

Gas connection pressure

A minimum connection pressure must

be available upstream of the burner gas

valve to ensure the proper functioning

of the burner.

For the installation of the valves and

instruments group take care to observe

the mounting instructions supplied by

their manufacturers (these are packed

with the equipment).

The gas line installed to the burner

must be dimensioned in accordance

with the throughput rate and the available pressure.

For selecting the nominal bore „DN“ of

the gas valves and instruments group

care should be taken to observe the

flue resistance of the boiler and the

gas pressure loss of the burner and

valves and instruments group.

Caution!

The absence of impurities and foreign

bodies must be checked before installation and commissioning of the gas

ramp, the lever valves and unions.

Gas valves and instruments

group

The gas valves and instruments group

can be connected directly to the gas

feed line.

T a ke care to observe the

correct order of installation and

direction of flow (arrow on housing).

Check the valves and instruments and

connection pieces for absence of dirt

particles and foreign matter before

installation and initial operation.

T o provide effective conditions for start-up

make sure the distance between the

burner and the gas stop valve is as

short as possible.

Leak test

The gas line upstream of the burner gas

valves and instruments group must be

installed in accordance with the applicable regulations, checked for absence of

leaks, vented and certified accordingly

by the gas installation company. The

screwed unions and flanged joints must

be checked for proper tightness (by

making a pressure test). The leak test

must be made under pressure using

approved foaming agents which do not

cause corrosion. For steam boiler furnaces the result of the leak test must be

duly certified.

Venting

Caution! Prior to taking the burner into

operation or after any repair work make

sure to vent the complete gas feed line

and the gas valves and instruments

group into the open atmosphere (e.g.

by means of a hose) taking care to

avoid any hazards.

In no case should the gas line be

vented into the heating or furnace

chambers.

Make use of a test burner to check the

gas-carrying spaces are free from an

inflammable gas mixture.

Support

The valves and instruments group must

be supported with at least one telescopic jacking member or similar during

and after installation (e.g. on filter and

valve).

Joint

It is recommended to provide an easyto-disconnect joint (with planar sealing

faces) to facilitate repair work on the

boiler (furnace) and allow the boiler

door to be swivelled out if required.

12/2011 14 072 205

Page 15

15

Installation

Gas train description

The burner's scope of delivery may

include a gas train. In this case, the burner and the gas train are issued with a

CE Declaration of Conformity. If the gas

train is not delivered with the burner, the

conformity of the burner is valid only if

the gas fittings and instruments and the

design of the gas train satisfy the burner test specified by EN 676 and meet

the Pressure Equipment Directive. Individual testing will be necessary where

this is not the case.

The gas train delivered has its own

documentation including operating

instructions and a spare parts list.

There follows a general description of

the gas train.

Gas trains with a double valve are

intended for the supply, main shut-off,

gas filtration, gas pressure regulation

and monitoring of the gas supply. They

are compatible for use with gases conforming to the specifications of the gas

fittings and instruments. They are built

in accordance with EN 676. All function

parts have been individually tested and

awarded the CE marking and number

of the Notified Body. The preassembled

gas train is checked for leaks in the factory.

Low- and high-pressure gas

trains

If the outlet side of the regulator, i.e.

individual fittings and instruments

downstream of the gas pressure regulator, has not been designed to be compatible with the maximum supply

pressure that occurs in the event of a

fault, the gas train must be equipped

with a safety shut-off valve (SSV) and a

safety relief valve (SRV) in accordance

with EN 676. This equipment is generally required for maximum supply pressures of >360 mbar and > 500 mbar

respectively. These are known as highpressure gas trains.

If all fittings and instruments of the gas

train have been designed/approved for

the maximum supply pressure that

occurs in the event of a fault, the gas

train is known as a low-pressure gas

train. This is the case, depending on

component selection, for maximum

supply pressures of 360 and 500 mbar.

101

100 Burner

101 Impulse pipe gas pressure

120 Air flap

141 Ball valve

142 Gas filter

150 Gas control butterfly

151 Gas double valve (Siemens system illustrated)

155 Ignition unit

313 Min. gas pressure switch

314 Gas pressure switch for valve leak check or valve leak

checker

349 Actuator

Options in accordance with country-specific requirements:

143 Pressure gauge with pushbutton valve

147 Test burner with pushbutton valve

148 Compensator

154 Gas safety valve (additional)

313a Max. gas pressure switch

Gas train to EN 676, low pressure

12/2011 14 072 205

Page 16

16

Installation

Gas train description

Gas valves and instruments

group

The gas trains must be dimensioned to

suit the throughput required and the

available gas pressure. The gas valves

and instruments group is defined on a

system-specific basis.

The following must be taken into consideration:

• Burner output,

• Combustion chamber counterpres

sure,

• Gas pressure loss in the burner head,

• Gas pressure losses in the gas fit

tings and instruments.

The total drop in gas pressure must

always be lower than the available gas

flow pressure.

100 Burner

101 Impulse pipe gas pressure

120 Air flap

141 Ball valve

142 Gas filter

144 Gas pressure regulator

145 Safety shut-off valve (SSV)

148 Safety relief valve (SRV)

150 Gas control butterfly

151 Gas double valve with integrated gas pressure

regulator (Siemens system illustrated)

155 Ignition unit

313 Min. gas pressure switch

314 Gas pressure switch for valve leak check or valve

leak checker

349 Actuator

Options in accordance with country-specific requirements:

143 Pressure gauge with pushbutton valve

147 Test burner with pushbutton valve

148 Compensator

154 Gas safety valve (additional)

313a Max. gas pressure switch

Gas train to EN 676, high pressure

12/2011 14 072 205

Page 17

17

Start-up

Checking procedure

Check the following prior to the

initial operation of the boiler system:

• Take care to observe the operating

instructions supplied by the boiler

manufacturer. The boiler must be

mounted ready for operation.

• Ensure that the heating system is

filled with water to capacity.

• Check the complete system for correct electrical wiring.

• Check the burner motor for correct

direction of rotation.

• Check for the proper setting of the

temperature and pressure controllers,

limiters, safety switches and electrical

limit switches.

• Check the gas connection pressure.

• Make a test of the all gas-carrying elements for absence of leaks.

• Bleed the fuel-carrying lines (make

sure they are free of air).

• Check the exhaust gas ports are opened and adequate fresh air intake is

ensured.

• With burner in starting position check

that air damper is in „CLOSED“ position.

• Check that automatic furnace controller is unlocked and that it is in original

position.

Gas butterfly valve:

The position indicator can be altered on

the system without the use of tools. As

a result, the position indicator is not

always a definitive indication of flap

position. The position of the gas flap is

always determined by the pin that forms

a positive connection with the valve

shaft and is arranged at a 90° angle to

the position of the valve.

Gas start-up

• Connect the measuring instruments

for the gas head pressure on the test

connection downstream of the gas

damper and the air pressure on the

burner test connection.

• Open the gas shut-off valve before the

gas-armatures and test the gas pressure on the pressure gauge.

Prior to the initial fuel feed start

make a functional test of the burner

program flow:

• Shortly open the gas shut-off valve in

the valve group until pressure is available and close again.

• Start burner and check program flow

for correct start-up sequence:

1. Valve tightness check.

2. Fan.

3. Pre-ventilation damper.

4. Check air pressure.

5. Partial-load damper.

6. Ignition.

7. Valves open (disconnected valve

remains closed).

8. Shut-off upon trouble after expiry

of safety period (see automatic

furnace controller) or shut-off

because of gas supply failure.

• Reset the Electronic Burner Controller

12/2011 14 072 205

Page 18

18

Start-up

Disassembling firing head

• Isolate the system from power

source. Set the main switch to

„OFF“.

• Close all shut-off valves upstream

of the burner.

To disassemble the combustion head,

the cover on the housing must be removed. In order to make it easier to

disassemble the combustion head, it is

recommended that the air intake box is

removed.

Disassembling the air intake box

(Image 1):

Only a few steps are required to disassemble the air intake box:

- Detach the hose (1) from the air pressure switch on the pressure tap located on the air intake box

- Open the manual locking system

- Remove the cover

Removing and closing the casing

cover

(Figure 2)

The casing cover is removed as follows:

- Screw out the screws (8) to (13).

- Remove the casing cover.

When closing the casing cover do the

following steps:

- Screw in the screws (8) to (13) by

doing only a few turns.

Tighten the screws beginning with the

screws (8) and (9), followed by the

screws (10) and (11) and finally by the

screws (12) and (13).

3

4

7

6

5

1

Figure 1

Figure 1

1

2

9

11

13

8

10

12

Figure 2

Removal of the firing head

(Figure 3 and 4)

For replacing and adjusting the baffle

plate and ignition system make sure to

remove the complete gas head from the

burner according to the following procedure:

- Withdraw the flame sensor (14) after

loosening the screw (15).

- Disconnect ignition cable (16).

- Loosen nut (17) and remove the gas

pilot burner.

- Screw out the gas head fastening

screws (18), lift up the gas head (19)

from the locking pins (20) and take it

out backwards. Make sure the gasket

(21) is not damaged.

- Prior to reassembly, check the gasket

(21) and replace it if required.

- Reassemble in reversed order.

16

17

14

15

Figure 3

19

20

21

18

Figure 4

12/2011 14 072 205

Page 19

19

Start-up

Gas start-up mode

Gas operating mode

General safety function

Gas starting function

If there is a demand for heat by the furnace system the burner control circuit

will be closed and the program flow

started. At the end of the program flow

the burner will start.

Prior to any burner start and after

burner stop the gas valve will be

automatically tested for proper tightness. The necessity results from the

legal provisions that apply to the

heating system.

The air damper will be closed at burner stop.

The electric actuator will move the closed air damper into its full-load position

so that the burner ventilates the furnace

and the exhaust ducts with the specified air flow rate. Shortly after pre-ventilation start the air failure cut-out must

change over to working position, i.e. the

preset minimum air pressure must be

reached and maintained until the burner

is turned off. After the expiry of the preset pre-ventilation time the air damper

and the gas control damper are set to

their partial-load positions.

The ignition transformer is commissioned. Following the pre-ignition

period, the ignition gas solenoid valves

are opened and gas flows into the pilot

burner. The ignition gas is ignited by the

ignition electrodes on the pilot burner.

The UV radiation of the pilot light is now

monitored by the flame sensor (1st

safety period), and the safety shut-off

valves are opened. The gas is supplied

to the gas nozzles by way of the gas

control butterfly, the combustion air by

the ventilator. Both media are thoroughly mixed in the mixing unit and

ignited by the pilot light.

The ignition gas solenoid valves then

close and the pilot light goes out. By the

end of the 2nd safety period, the radiation of the main flame must have been

detected by the flame sensor.

Gas operating function

After flame formation, the burner will

shortly remain in the separately set ignition load und is then run at minimum

output.This brings the burner to its operating position. The controller will now

automatically control the burner between its partial-load and full-load positions.

Depending on the heat demand the output controller will actuate the electronic

compound controller which in turn will

control the actuators of the gas control

damper and air control dampers and

increase or decrease the flow rates

according to a specific program.

The stepless control makes it possible

to operate the burner at any desired

stage between its partial-load and fullload positions.

For turning off the burner this must

always be in its partial-load position.

The air damper will be closed when the

burner is in its off position so as to prevent cold air from flowing through the

furnace chamber, heat exchanger and

chimney. The interior cooling losses will

be greatly minimised.

Attention:

If there are shut-off dampers in the flue

gas tract they must be complete open.

Otherwise there will be a high danger of low-speed detonation or

explosion!

The open-position of the

shut-oft damper can be assured by the

integration of the opening contact of the

shut-off damper in the safety chain of

the heat generator.

General safety functions

In case a flame does not develop when

starting the burner (fuel release), the

burner controller will shut off at the end

of the safety period (shut-off on trouble).. A shut-off on trouble will also

occur in the case of flame failure during

operation, air flow failure during the preventilation phase and pressure failure

during the whole period of burner operation. Any failure of the flame signal at

the end of the safety period and a flame

signal during the pre-ventilation phase

(external light control) will result in a

shut-off on trouble with the automatic

furnace controller being locked. The

trouble is indicated by the trouble signal

lamp lighting up. The automatic furnace

controller can be unlocked immediately

after a shut-off on trouble by pressing

the unlocking key. The program unit will

return to its starting position and proceed with the restart of the burner. A

voltage failure will result in a regular

shut-off of the burner.

After voltage recovery, the burner can

be automatically restarted unless

another interlock is active, e.g. one

caused by the safety circuit. In any

case, the fuel oil supply will be immediately stopped upon occurrence of a

trouble.

When using the burner control system

(electronic compound control) all operational and fault messages may be indicated in plain text on an optionally

available operating and display module.

12/2011 14 072 205

Page 20

20

Start-up

Fuel-air compound control

Fuel-air compound control

This compound pneumatic control

system with precision-adjustment capability has been designed to allow the

fuel and air flow rates to be steadily

varied in sliding mode for an adjustment

of the fuel-air ratio over the whole control range.

In the stepless control mode the load

will be controlled at any point within the

control range depending on the heat

demand.

Electronic compound control

The air flap and the gas flap are each

fitted with a servomotor that controls

the position of these servo components.

At the factory, the air curve of the compound controller is configured in such a

way that the air flap is closed at the

minimum setting and open at the maximum setting.

As part of burner commissioning, the

servo components for the fuel and air

are assigned permanently defined positions in relation to burner output. During

burner operation, the servo components move into these positions with

great accuracy. This precision is a fundamental prerequisite for permanently

ensuring low-emission combustion.

The gas pressure should be corrected

at the gas pressure regulator if necessary.

Please note!

The gas outlet pressure (gas regulating

pressure) must always be less than the

gas inlet pressure but higher than the

total pressure loss of the system.

Proceed in accordance with the commissioning instructions for the electronic compound control system

when making gradual adjustments to

the load points (fuel flow rate, air

flow rate).

Where possible, a combustion measurement should be carried out at each

point.

Equipment option: speed control

The burners can be equipped with a

speed controller as an option.

During long burner operating periods in

the partial load range in particular, the

reduction in blower speed helps to conserve electrical energy and reduce

noise emissions from the burner blower

itself.

The speed of the blower is measured

by a Namur sensor

and controlled to the programmed reference value for the current output level.

Equipment option:

O

2

control / CO control

To improve the efficiency of the system,

the combustion manager can be

equipped with residual oxygen or CO

control (CO control available only with

the use of a Lamtec burner controller).

The residual oxygen is measured in the

flue gas of the heating system by an O

2

measuring probe with zirconium oxide

sensor and sent to the combustion

manager as a correction factor. Thanks

to O2 control, it is possible to eliminate

variations in ambient conditions (e.g.

combustion air temperature and humidity, calorific value fluctuations, etc.) and

significantly reduce the air surplus

required for calibration. Reference

value deviations are controlled by corrections to the blower speed or the air

flap position. With the use of CO control

(only possible with gas operation), the

CO content is measured in addition to

the residual oxygen. The air surplus is

reduced to the “CO edge” by a correction to the blower speed or the air flap

position. The correction factors are

determined in a system-specific “learning process” and stored temporarily in

the combustion manager. This makes it

possible to maximise the system's heating efficiency across the entire output

range and optimally manage the combustion process. For further information, please refer to the manufacturer's

documentation for the electronic combustion manager.

1a Gas damper with actuator

1b Air dampers with actuators

2Burner

3Boiler

4 Comustion air fan

4

Luf

t

G

as

1

b

1a

3

2

M

M

M

Gas

Air

12/2011 14 072 205

Page 21

21

Start-up

Electronic burner controller

Description

The electronic burner controller is a

programmable automatic combustion

control unit with an integrated electronic

coupled controller. There may be additional functions, depending on the

equipment and model.

The following burner-specific controllers

are used:

Additionally, some burners are delivered without a controller and all components are connected to a terminal

block. The burner controller in this case

does not form part of the burner's scope

of delivery.

Commissioning

Commissioning must be carried out by

trained and expert personnel only. For

the wiring of the system, the relevant

electrical diagram for the burner and all

local standards and legal regulations

must be observed.

The procedure described in the relevant

operating instructions for the burner

controller must be observed.

The burner controller has a burner-specific factory setting. At the time of initial

commissioning, it must be checked

whether the parameters have been

appropriately configured to meet the

requirements of the system. The actuators must similarly be chekked for correct adjustment.

During the I/O test, the manual gas

shut-off valves must be kept closed at

all times. It is not permitted to extend

fixed safety times using external circuitry.

Burner controller BCS 300 Etamatic OEM

Manufacturer Dungs Lamtec

Technical Data

Operating voltage: 230 VAC Operating voltage: 230 VAC

Frequency: 50/ 60 Hz Frequency: 50/ 60 Hz

Power consumption: <16,5 VA Power consumption: ca. 50 VA

Ambient temperature Ambient temperature:

during operation: 0-60°C during operation: 0-60°C

Storage: -20-70°C Storage: -25-60°C

Mode of operation:

Continuous operation

Mode of operation:

Continuous operation

Components and integrated

functions

Flame monitor module FLW05

for connecting various

flame sensors

Actuator STM 30/40

Actuator SAD15 Customer interface

integrated power regulator integrated power regulator

integrated valve leak check integrated valve leak check

optional equipment Operating and display module Programming unit

Expansion module EM1 for speed

regulation and O

2

-regulation

Installation kit for speed control

O

2

-regulation

12/2011 14 072 205

Page 22

22

Start-up

Servo motor type SAD 15

Electrical actuator STM 40

The electronic compound control

system type BCS makes use of digitally

activated servomotors type SAD 15

These consist of a stepping motor with

electronic trigger and power pack.

A driver with digital feedback via encoder disk is provided for monitoring the

function and direction of rotation.

Take care to observe the instruction for

operation for the burner control system

type BCS 300.

The connection is documented in the

wiring diagram for burners.

NOTE: Check the zero position of the

servomotors prior to start-up.

Technical documentation:

BCS 300, Dungs

P3 P2 closed

N L PE

P 1

The STM 40 servomotor is used in conjunction with various electronic compound control systems. Priority with

products supplied by “Lamtec” (Etamatic, Etamatic OEM, VMS, FMS).

With some types of burner, the motor is

also used as a servomotor for other

servo components independently of the

compound control system (e.g. nozzle

linkage safety adjustment). Please refer

to the appropriate section of the operating instructions.

The electrical diagram for the burner

shows how to establish the servomotor's electrical connection.

Observe the documentation issued by

the manufacturer.

T e chnical data:

Voltage: 230 V AC

Frequency: 50 Hz

Angle of rotation: 90°

Running time: 40 sec. for 90°

Torque: 15 Nm

Static holding

moment: 8 Nm

Dimensions

(a x b x c): 93 mm x 144 mm x 149 mm

Potentiometer

(integrated): 5 k

12/2011 14 072 205

Page 23

23

Start-up

Flame sensor

The flame sensor is a component of the

flame monitoring system.

In interaction with the automatic combustion control unit, it suppresses stray

flame during burner start-up and monitors the presence of flame during bur-

ner operation.

Depending on the requirements of the

burner and fuels, the flame sensor may

be an optical sensor that monitors light

radiation in the ultraviolet, infrared or

visible spectrum emitted by the flame.

In some gas burners, flame monitoring

is achieved by means of ionisation. In

this case, no optical flame sensor is

present.

The flame sensors used are listed in the

table below.

Table: Flame sensor

The appropriate type of flame sensor is

selected based on the spectral range of

the flame radiation, the mode of operation required and the burner controller

used.

For the electrical connection, please

refer to the electrical diagram and the

supplementary information for the individual flame sensors contained in the

manufacturer's documentation.

N.B.:

The flame sensors must be regularly

inspected for dirt and cleaned as

necessary. The sensor windows of the

optical flame sensors must be kept free

of dust. The ionisation rods must be

checked for burn-up and replaced if

necessary.

Name Spectral

range

Area of use Connection Mode of

operation

Producer Note

D-LX 100 EK-S (IR) IR oil, gas, dual fuel

burner

BCS continuous

service

Durag LED display for settings

and operating status,

sensitivity setting

FFS 06 IR oil, gas, dual fuel

burner

EVR of the

firm Lamtec

(Etamatic,

Etamatic

OEM)

continuous

service

Lamtec Sensitivity setting

FFS 06 UV-1 UV oil, gas, dual fuel

burner

F 150 and

Etamatic

continuous

service

Lamtec Senisitivity setting

QRA-2 KPL UV gas-, dual fuel

burner

BCS, LFL1,

LFE1

intermittent Siemens

QRA-53 C 27 UV gas, dual fuel

burner

BCS, LGK,

LGI

continuous

service

Siemens

RAR-7 light oil burner BCS, LAL,

LAE1, LOK 16,

LAE10

continuous

service

Siemens

12/2011 14 072 205

Page 24

24

Start-up

Gas pressure switch

Air pressure switch

Gas pressure switch GW...A5/A6

The pressure switch can be used to

monitor either falling pressure (min.) or

increasing pressure (max.).

Types GW...A5/A6 are EC-type-tested

and certified in accordance with the EC

Gas Appliances Directive and EC Pressure Equipment Directive. Class “S” as

defined by EN 1854 and TÜV-tested as

a pressure switch of special type for

use in heating installations of steam

and hot-water boilers in accordance

with TRD 604 and VdTÜV information

sheet pressure 100/1.

The nominal value (switch point) is

adjusted using an adjustment wheel

with scale.

Use:

GW ... A5 for dual solenoid valves

GW ... A6 for individual solenoid or

motor valves

Verbundregler für EK

Gas pressure switch A5

Verbundregler für EU

Gas pressure switch A6

T e chnical data:

Type of gas:

Gases according to DVGW Worksheet

G 260/1, gas families 1, 2, 3

Degree of protection: IP 54

Ambient temperature: -15°C to +60°C

Mounting position: any

Operating pressure up to:

GW 50/150 A5A6 500 mbar

GW 500/ A5/A6 600 mbar

Adjusting range:

GW 50 A5/ A6 5-50 mbar

GW 150 A5/ A6 10-150 mbar

GW 500 A5/ A6 100-500 mbar

Air pressure switch

The air pressure switch is provided for

monitoring the pressure of the combustion air fan.

The pressure switch DL 50A has been

designed for switching on, off or over an

electric circuit in the case of changes of

the actual pressure levels from the setpoint setting. The pressure switch DL

50A can be used as overpressure,

vacuum or differential pressure monitor

for air and non-aggressive gases but

not for gases according to DVGW

Worksheet G 260/l.

Determining the differential preflushing pressure and adjusting the

differential pressure switch

• Burner in the pre-aeration phase.

• Measure pressure on test

connection (2).

• Measure vacuum on test

connection (3).

• Add the measured pressures.

• Set the scale to 90% of the calculated

value.

Certification

The pressure switch is registered by

CE/DIN-DVGW.

Switch function test

Test buttons are provided to check the

switch functions for proper operation

(with safety cut-out and interlock). The

burner is normally run in partial-load

condition when testing the safety

functions. On pressing button (4) the

vacuum will be removed which causes

the differential pressure to drop below

the required level. If it is necessary to

test the pressure switch functions under

full-load conditions this may be done by

pressing button (1).

12/2011 14 072 205

Page 25

25

Start-up

Adjustment

Combination controls CG 15 -30

Combination controls CG 15-30

Complete with strainer,

two safety valves (Class A) and servogovemor für maximum control

accuracy

Application

The combination controls are typetested and certitied pursuant to the Gas

Appliance Directive (90/396/EEC) in

conjunction with

EN 126 and EN 12067-1.

Function

The incorporated, power-saving linear

compressor increases the inlet gas

pressure level for opening and controlling the valves. In conjunction with

the servogovernor, this results in a high

control accuracy over a wide inlet press

ure range up to 360 mbar at low control

pressures and with only slight pressure

difference between inlet

and outlet pressure.

The first valve can be controlled separately (e.g. in conjunction with a pilot

gas supply connection in the intermediate space).

Features

CG ... D1 with constant governor

General technical data

Type of gas: natural gas, propane and

butane gas.

Inlet pressure range: 10 to 360 mbar.

Ambient temperature: -15 to +60°C.

Storage temperature: -20 to +80°C.

Threaded connection: Rp to ISO 7-1 .

Pressure test points at the inlet downstrearn of the strainer and at the outlet.

Housing parts: AlSi.

Diaphragms: Perbunan.

Strainer: plastic.

Option:

- With four connections and screw

plugs on both first and second valve

(e.g. for connection of a pressure

switch or pilot gas).

- May also be supplied prepared for

tightness control TC 1 .

Connections on

1st valve: 1/8"

2nd valve: on CG 15,20: 1/8",

on CG 25,30: 1/4".

Safety vatves (Class A) with springloaded vatve disc, normaIty closed

(when de-energsed).

Switching frequency: any.

Persistence time: approx. 0.5 seconds.

Full opening time: max. 10 seconds.

Glosing time: >

1 second.

Mains voltage:

230 V AG, +10/-15 %,50/60 Hz,

24 VAG, +10/-15 %, 50/60 Hz.

The electrical power is the same on

switch-on and in continuous operation:

20 VA, 17 W. CG for TC 1: 22 VA, 19W.

Duty cycle: continuous duty (100 %).

Enclosure IP 54 to lEG 529.

Fusing: max. 6.3 A slow-blow.

Electrical connection:

ISO 4400 plug with connection type:

Pg 11.

Installation

Fitting position:

CG..D1, D2, Z (Fig. 5)

in ver1ical pipework: any,

in horizontal pipework: tilted up to max.

90° to left/right, not upside down.

12/2011 14 072 205

Page 26

26

Start-up

Adjustment

Combination controls CG 15 -30

Adjustment

After fitting, the governor must bechekked for proper functioning in conjunction with the gas consuming

installation, because the governorsetpoint set at the factory might notbe the

same as the setpoint requiredfor the

gas consuming installation.

- The scale readings are approximate.

- All adjustments are to be carriedout

with a 2.5 mm!

Governor CG..D1

The gas outlet pressure pG can beset

from

1 to 20 mbar (standard) or

4 to 50 mbar (CG..-50),being pre-set at

the factory to: p

G

=10 mbar.

Pre-setting:

• Measure gas pressure p

G

at testpoint

B.

• Set gas pressure at p

G

in accord-ance

with the burner manufacturer’sspecifications and flue gas analysis.

• Set pressure switch for gas (seebelow).

• Close off all test points.

Testing contol capacity

Set burner to high fire.

Measure gas pressure at A and B.

Slowly close manual valve up-stream of

the combination controluntil the gas

inlet pressure at Adrops by 2 mbar.

- The gas outlet pressure at Bshould

not drop by more than10%. Otherwise, the settingshould be re-checked

and ad-justed.If the control capacity is

insuffi-cient, the device may not

beoperated.

- Open manual valve.

12/2011 14 072 205

Page 27

27

Start-up

Exhaust gas test

Exhaust gas test

To ensure an economically efficient and

trouble-free operation of the system it

will be necessary to adjust the burner

specifically in accordance with the furnace system. This is achieved by means

of a fuel-combustion air compound control unit which adjusts the burner to

ensure a proper combustion. Exhaust

gas tests are required for this purpose.

The percentage CO

2

and O2 and the

exhaust gas temperature will have to be

measured to determine the efficiency

and combustion quality.

Prior to any measurement make sure to

check the boiler and exhaust gas system

for absence of leaks.

Secondary air will falsify the measured results

Check that the exhaust gases have a

residual oxygen (O

2

) content as low as

possible and a carbon dioxide (CO

2

)

content as high as possible.

The carbon monoxide content of the

exhaust gases must be below the currently applicable specifications in all load

stages.

In the fuel oil combustion mode the permissible soot number in the exhaust

gas is not allowed to be exceeded.

Determining the volumetric gas flow

rate

The thermal furnace output of a boiler

(Q

F

) is the amount of heat supplied with

the gas in a unit of time.

When taking the burner into operation

the volumetric fuel flow rate should be

selected according to the nominal thermal capacity of the boiler.

Example:

Nom. thermal output

QN

1000 kW

Boiler efficiency

nK

0,88

Calorific value of gas

H

u

9,1 kWh/m³

Gas pressure p

u

100 mbar

Barometer reading

p

amb

980 mbar

Gas temperature

t

gas

15 °C

Standard pressure

p

n

1013 mbar

Q

F

Q

N

n

K

-------

1000

088

----------- -

1136kW===

Ratio between O2 - and CO2- for

natural gas H (CO

2max

=11,86%)

Ratio between O

2

- and CO2 -

for light oil EL (CO

2

max=15,40%)

Mean barometer readings

%O

2

%CO2 %O2 %CO2

0,00 11,86 3,00 10,16

0,10 11,80 3,10 10,10

0,20 11,75 3,20 10,04

0,30 11,69 3,30 9,99

0,40 11,63 3,40 9,93

0,50 11,58 3,50 9,87

0,60 11,52 3,60 9,82

0,70 11,46 3,70 9,76

0,80 11,41 3,80 9,70

0,90 11,35 3,90 9,65

1,00 11,29 4,00 9,59

1,10 11,24 4,10 9,53

1,20 11,18 4,20 9,48

1,30 11,12 4,30 9,42

1,40 11,07 4,40 9,36

1,50 11,01 4,50 9,31

1,60 10,95 4,60 9,25

1,70 10,90 4,70 9,19

1,80 10,84 4,80 9,14

1,90 10,78 4,90 9,08

2,00 10,73 5,00 9,02

2,10 10,67 5,10 8,97

2,20 10,61 5,20 8,91

2,30 10,55 5,30 8,85

2,40 10,50 5,40 8,80

2,50 10,44 5,50 8,74

2,60 10,38 5,60 8,68

2,70 10,33 5,70 8,63

2,80 10,27 5,80 8,57

2,90 10,21 5,90 8,51

O221

CO

2max

CO

2gem

–

CO

2max

-----------------------------------------------

%==

% O2 % CO2 % O2 % CO2

0,00 15,40 3,00 13,19

0,10 15,33 3,10 13,12

0,20 15,25 3,20 13,04

0,30 15,18 3,30 12,97

0,40 15,11 3,40 12,89

0,50 15,03 3,50 12,82

0,60 14,96 3,60 12,75

0,70 14,88 3,70 12,67

0,80 14,81 3,80 12,60

0,90 14,74 3,90 12,53

1,00 14,66 4,00 12,45

1,10 14,59 4,10 12,38

1,20 14,52 4,20 12,31

1,30 14,44 4,30 12,23

1,40 14,37 4,40 12,16

1,50 14,29 4,50 12,08

1,60 14,22 4,60 12,01

1,70 14,15 4,70 11,94

1,80 14,07 4,80 11,86

1,90 14,00 4,90 11,79

2,00 13,93 5,00 11,72

2,10 13,85 5,10 11,64

2,20 13,78 5,20 11,57

2,30 13,71 5,30 11,49

2,40 13,63 5,40 11,42

2,50 13,56 5,50 11,35

2,60 13,48 5,60 11,27

2,70 13,41 5,70 11,20

2,80 13,34 5,80 11,13

2,90 13,26 5,90 11,05

Sea

level

[m]

Mean

barometer

[mbar]

Aachen 205 991

Berlin 50 1009

Dresden 120 1000

Erfurt 315 978

Frankfurt/M. 104 1004

Hamburg 22 1011

Cologne 45 1009

Leipzig 130 998

Magdeburg 79 1005

Munich 526 955

Nuremberg 310 980

Rostock 4 1013

Stuttgart 297 984

Schwerin 59 1010

Ulm 479 960

600

700

800

900

1000

0 1000 2000 3000 4000 5000

Höhe in m.ü.M.

Mittlerer Luftdruck in mbar

45

0

96

0

1013,2

5

Mean atmospheric pressure in mbar

Altitude in m above sea level

Volumetric gas flow rate at STP:

Volumetric gas flow rate in

operating condition:

V

Bn

Q

N

HUnK

------------------ -

1000

91 088

---------------------- -

125m

3

h===

V

BBVBn

T

273

-------- -

p

n

p

ambpu

+

----------------------

m

3

h==

125

273 15+

273

-------------------- -

1013 25

980 100+

----------------------- -

123 9m3h==

12/2011 14 072 205

Page 28

28

Start-up

Exhaust gas test

Flue gas loss

Flue gas loss caused by free heat

arises as a consequence of the temperature difference between the fuel-air

mixture entering the combustion chamber and the gases that leave it. The

higher the air surplus and thus the

greater the flue gas volume, the higher

the loss.

It is calculated as follows:

q

A

= flue gas loss in %

t

A

= flue gas temperature in °C

t

L

= combustion

air temperature in °C

CO

2

= carbon dioxide

content in %

Examples:

Measured values in natural gas operation:

CO

2

content of the flue gases10.8 %

Flue gas temperature 195 °C

Air intake temperature 22 °C

Flue gas loss is calculated thus:

Measured values in fuel-oil operation:

CO

2

content of the flue gases12.8 %

Flue gas temperature 195 °C

Air intake temperature 22 °C

Flue gas loss is calculated thus:

q

A

tAtL–

A

1

CO

2

-----------

B+

=

Fuel oil ELFuel oil SNatural

gas

City gas Liquid

gas

A

1

= 0,50 0,490 0,370 0,350 0,420

B = 0,007 0,007 0,009 0,011 0,008

qAf195 22–

037

10 8

----------- -

0 009+

7 48pr==%q

Af

195 22–

049

12 8

----------- -

0007+

783pr==

%

12/2011 14 072 205

Page 29

29

Servicing instructions

Burner maintenance

To ensure a high operational readiness, functionality, safety and economic efficiency, the user should

have the boiler system inspected by

an authorized person of the manufacturer or other specialist once a

year. The whole system must be

checked for proper operation and

faults detected should be rectified

without delay. It is advisable however to make another inspection of

the system in addition to the one

specified herein. The inspection

should comprise the following work:

1. Inspect the boiler internals and

insulating packages and replace

by new ones if required. Check

boiler for possible accumulation of

dirt.

2. Remove the nozzle, check it and

replace it by new one if required.

3. Clean the ignition electrodes.

4. Check the ignition electrode and

spark functions and readjust if

required.

5. Clean the burner interior and

exterior.

6. Clean the fan impeller.

7. Check the fan impeller for possible deformation and cracks.

8. Clean the UV flame sensor.

9. Clean the filters and screens.

10. Check the electrical connections.

11. Check the burner head setting.

Check the flat sealing between

gas head and burner tube for

absence of leaks.

12. Check the gas valves and instruments group for absence of leaks.

13. Check the gas valves for absence

of leaks and clean condition.

14. Check the control equipment for

proper operation, setting and

safety period.

15. Check the pressure switch for

proper setting and operation.

16. Clean the air damper and check

for smooth operation.

17. Check the combustion process

and make exhaust gas tests:

• Fuel throughput rate adjustment

• Heating chamber temperature

(intake temperature)

• Exhaust gas temperature

• Pressure in combustion

chamber and exhaust gas pipe

•CO

2

and O2 contents of exhaust

gases

• CO test, soot test

• UV sensor current measurement

18. Enter measured data in test

record.

N.B.: Before maintenance and adjustment work

- switch off the power supply to the sys-

tem. Master switch to "OFF".

- Close all shut-off valves upstream of

the burner.

12/2011 14 072 205

Page 30

30

Servicing instructions

Fan impeller

Note:

Prior to removing the fan impeller, the

shaft or the fan impeller must be marked on the edge of the suction funnel so

that the fan impeller is in the same position when reassembling, or the same

overlapping of the suction funnel

(dimension in Fig.) can be readjusted

as initially. An axial displacement of the

impeller on the shaft may result in a

lower efficiency, thus having a reduced

air flow.

Prior to removing the bush from the

disk, the position of the bush in the disk

must be marked so that a rotating

against one another can be prevented.

Rotating the bush deteriorates the

balance of the fan impeller.

To demount the impeller, remove the

screws (1) and (2), screw in one of

them as separating screw into the hole

(3) having half a thread in the bush and

tighten it.

This causes the bush to loosen. Open

the bush by means of a wedge if required. Remove the loose impeller ran without striking a blow and without

damage by hand.

- Clean and degrease all bright-finished

surfaces. A requirement for achieving

a high slipping moment is always a

clean and fat free surface of all parts

to be fitted into one another.

- For reassembly: Place the disk and

the bush into their initial position (without rotating) into one another, make

sure that the holes are congruent.

- Screw the bush into or out from the

disk until about 2..3 mm of the bush

are protruding.

- For new installation: Mark the dimen-

sion x on the inside of the fan impeller.

- Mount the fan impeller onto the shaft.

For this, open the bush by means of a

wedge if required. Adjust the position

to maintain the dimension x using the

marking(s).

- Align the two opposing screws (1) and

(2) and tighten them evenly step by

step. In doing so, start with the first

step of the torque (max. 10 Nm) by

tightening one screw, then rotate the

fan impeller by half a rotation and tighten the other screw with the same torque, afterwards rotate the fan impeller

to the initial position. Increase the torque by one step and proceed until the

specified torque is reached as described above. The torque steps should

not be larger than 10 Nm.

- check the dimension X.

The following torques must be

followed:

SM 25, Bushes No. 2517 – centre bore

42 and 48 mm: