Page 1

09/2005 - Art. Nr. 13 019 533A

Operating instructions

for authorized experts

Light oil burners

EK4...L-ZA

Designs:

Basis

CEN

DIN

Page 2

09/2005 - Art. Nr. 13 019 533A

2

Survey

Table of contents

General information

Table of contents Page

Survey Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Performance charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Burner functions Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Functional diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Functional sequence LAL 1 . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation Mounting the burner to the heat generator . . . . . . . . . . . . . . . . . . . 7

Zero point adjustment (flame cup) . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Oil connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Oil pressure regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Adjustments Burner head setting dimensions . . . . . . . . . . . . . . . . . . . . . . . . 9

Air regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Service instructions Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General information

The EK4...L-ZA series of ELCO light oil

burners, featuring monobloc design and

fully automatic two-stage operation, are

suitable for the combustion of extralight fuel oil. Design and performance of

the burners comply with currently appli

cable guidelines and regulations.

Burner installation and start-up must be

performed by a qualified expert who is

responsible for the proper execution of

these tasks.

The burner complies with the standards

EN 267

DIN 4787

Observe the following standards to

ensure safe, environmentally friendly

and energy-saving operation of the

burner.

DIN 4755

Oil-burning installations in heating

systems.

DIN 4789

Connection of atomizing oil burners and

blower gas burners to heat generators.

EN 60335-1

Safety of electrical appliances for

domestic use

Site of installation

The burner must not be operated in

rooms with aggressive fumes (e.g.

hairspray, tetrachloroethylene, carbon

tetrachloride), dust-laden air or high

atmospheric humidity (e.g. laundry

rooms).

ELCO rejects all warranty claims for

damage resulting from one of the

following reasons:

–

Improper use

–

Inexpert installation or mainten

ance by the purchaser or third

persons, including the installation

of parts other than genuine parts

supplied by the manufacturer.

Start-up

Initial start-up of the oil burning installa

tion must be performed by the installer,

manufacturer, or by another expert

designated by them.

Delivery and operating instructions

At the time of delivery at the latest, the

company installing the oil burner must

supply the user with a set of Operating

and Service Instructions. These should

be kept in the room where the heat

generator is installed.

The address and telephone number of

the nearest service representative must

be entered in the Instructions.

Note for the user

The system should be serviced by an

expert at least once a year. To ensure

maintenance at regular intervals, we

recommend you to conclude a service

contract.

Scope of delivery

Each burner is delivered in a separate

packing case. The following compo

-

nents are included in delivery:

–

Burner with burner head

–

Movable mounting flange and insula

-

ting base

–

Two oil tubes

–

Automatic burner control unit with

plug-in socket

–

Document folder

Page 3

09/2005 - Art. Nr. 13 019 533A

3

Survey

Technical data

Performance charts

Burner type EK 4.100 L-ZA EK 4.160 L-ZA

Technical data

Thermal output . . . . . . . . . . . . min. 360 kW 580 kW

Thermal output . . . . . . . . . . . . max. 1070 kW 1660 kW

Oil flow . . . . . . . . . . . . . . . . min. 31 kg/h 49 kg/h

Oil flow . . . . . . . . . . . . . . . . max. 90 kg/h 140 kg/h

Fuel oil . . . . . . . . . . . . . . . . Extra Light, DIN 51603 Extra Light, DIN 51603

Hydraulic system/standard . . . . . . 2-stage, 2 nozzles/CEN 2-stage, 2 nozzles/DIN

Air regulation . . . . . . . . . . . . . suction side Air cut-off valve Air cut-off valve

Air regulation . . . . . . . . . . . . . pressure side in burner head in burner head

Control ratio . . . . . . . . . . . . . max. 60/100% 60/100%

Voltage . . . . . . . . . . . . . . . . 230/400 V, 50/60 Hz 230/400 V, 50/60 Hz

Power consumption . . . . . . . . . 2.5 kW 2.5 kW

Weight approx. . . . . . . . . . . . . 83 kg 98 kg

Burner equipment

Electric motor 2800 min.–1 2.2 kW 2.2 kW

Automatic burner control unit LAL 1.25 LAL 1.25

Flame monitor QRB 1 QRB 1

Ignition transformer ZM 20/10 ZM 20/10

Solenoid valves Nozzle control 2-way on pump 2-way

Solenoid values 3-way 3-way

Air damper drive hydraulic hydraulic

Oil pressure pump A2L95D, 110 l/h at 18 bar RSA 125

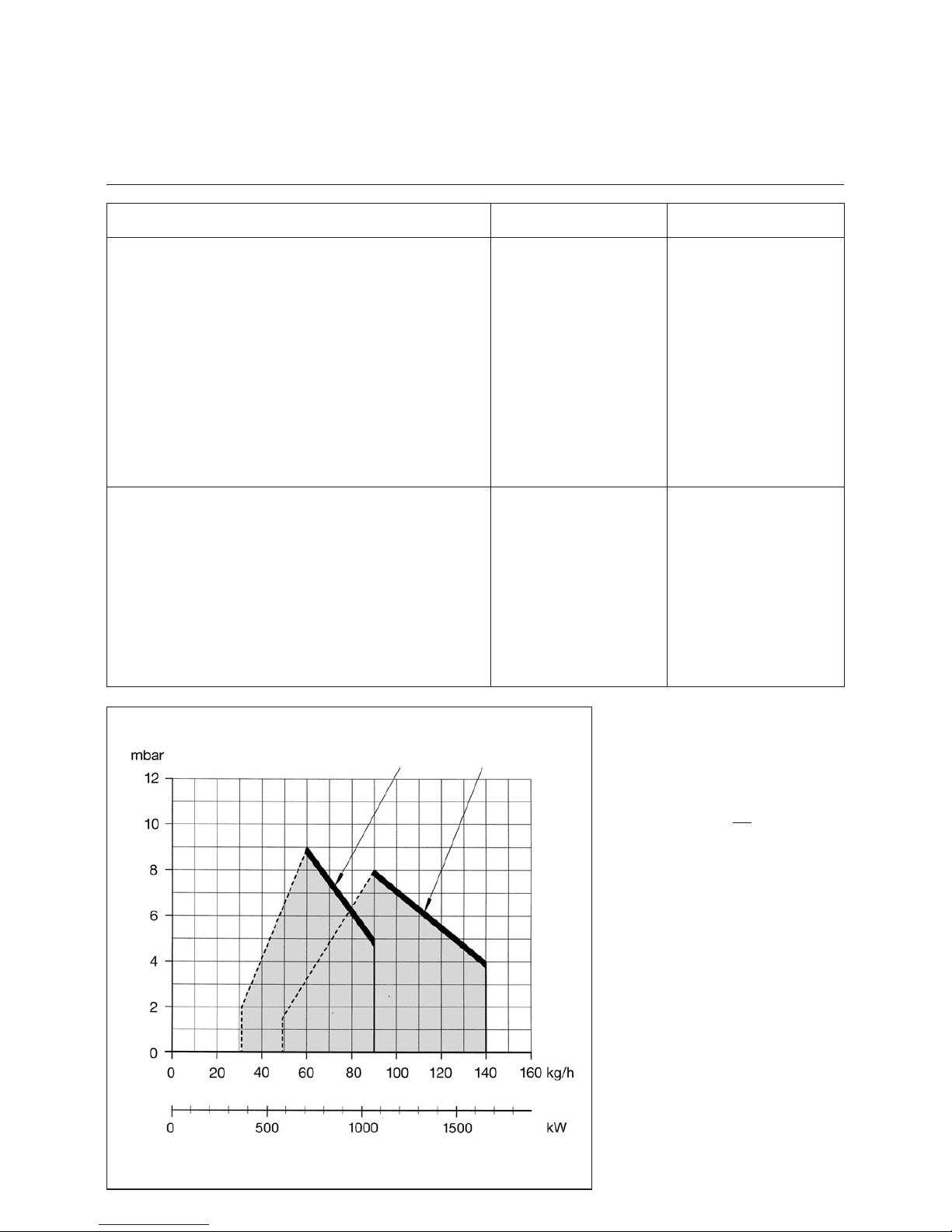

Performance charts

The performance charts reflect

the values approved during official

homologation.

Determining the required thermal output

Q

Q

K

F

N

=

h

Q

F

= Thermal output (kW)

Q

N

= Rated boiler capacity (kW)

h

K

= Boiler efficiency (%)

Thermal output Q

F

Oil throughput

Furnace pressure

EK4.100 L-ZA EK4.100 L-ZA

Page 4

09/2005 - Art. Nr. 13 019 533A

4

Survey

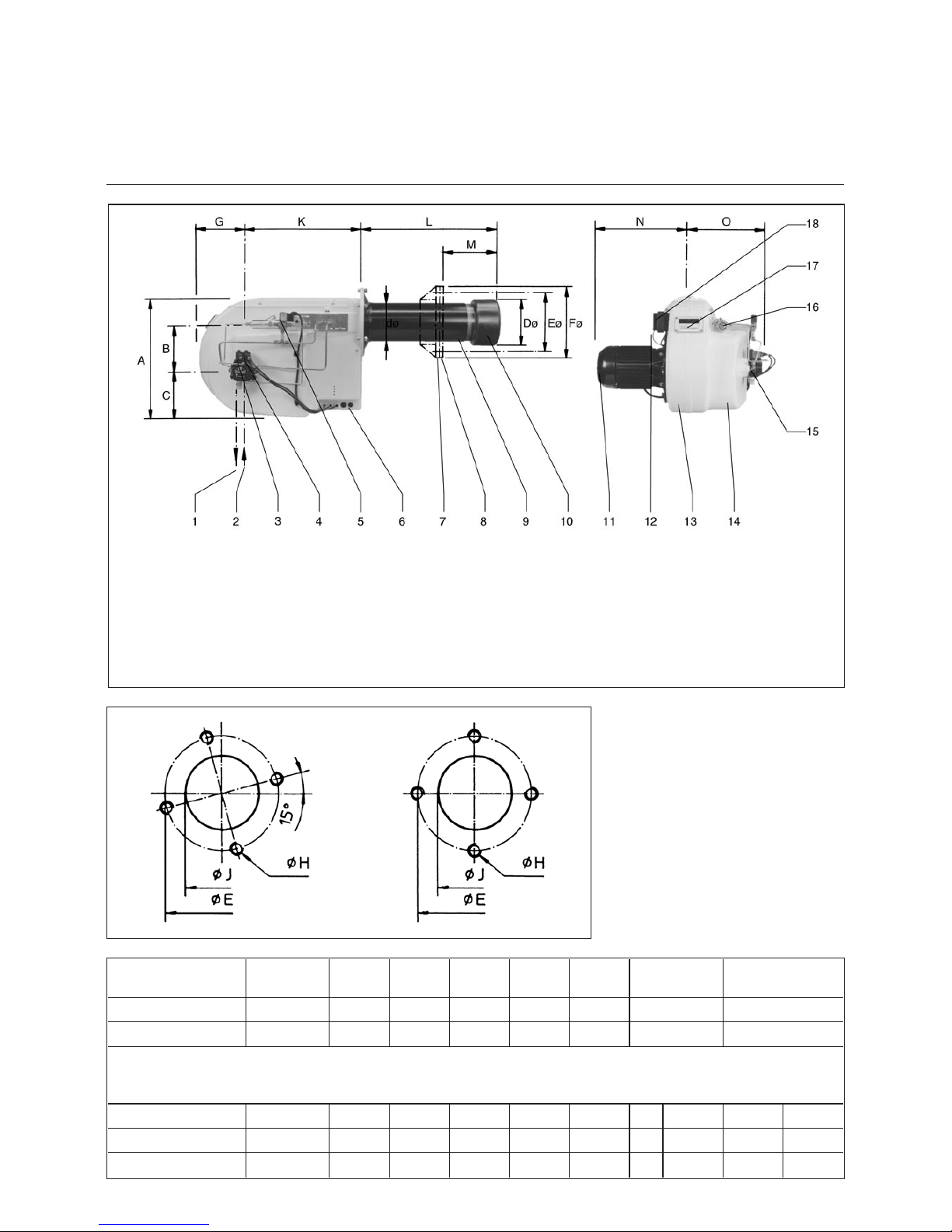

Dimensions

Key

EK = Manufacturer

4 = Size

160 = Performance rating

L = Fuel oil Extra Light

Z = Two-stage

A = Automatic burner control unit

1 Return line connection

2 Suction line connection

3 Solenoid valve, nozzle 2

4 Solenoid valve, nozzle 1

5 Solenoid valve for hydraulic air

damper drive

6 Switch box with automatic burner

control unit, switch, protective

motor switch and connecting

terminals

7 Connecting flange

8 Insulating base

9 Burner tube

10 Flame cup

11 Electric motor

12 Flame monitor

13 Burner housing

14 Air suction box

15 Oil pressure pump

16 Hydraulic air damper drive

17 Inspection glass

18 Ignition transformer

Burner type Thermal

output kW

A B C dø Dø Eø* Type No.

EK 4.100 L-ZA 360–1070 455 176 179 159 190 240–300* BN19787/89

EK 4.160 L-ZA 580–1660 455 176 179 185 220 280 BN19787/89

Customized designs and voltages on request.

* Long holes in burner connecting flange, graduated circle from … to …

Burner type F ø Fig. G H J K L M N O

EK 4.100 L-ZA 330 1 222 M12 200 430 520 120–406 382 307

EK 4.160 L-ZA 310 2 222 M12 230 430 535 125–380 382 332

Holes in the boiler connecting plate

Fig. 1 Fig. 2

Page 5

09/2005 - Art. Nr. 13 019 533A

5

Burner Functions

Functional Description

Functional Diagram

Starting function

The automatic burner control unit auto

matically starts the burner when heat is

required by the system.

–

The motor starts, the ignition is

switched on.

–

The air damper drive 6a switches the

air damper 5 to the low-load position (

in ”Basis” design, the air damper is in

the low-load position when the burner

is idle)

–

Preventilation

–

The solenoid valve 2 opens nozzle 1

–

The flame is formed (low load is in

operation).

Switching over to full load

If required by the system, the automatic

burner control unit switches the burner

to full load.

–

The solenoid valve 3 opens nozzle 2

–

At the same time, the solenoid valve

7 switches from passage b–c to

a–b

–

The hydraulic air damper drive 6

switches the air damper 5 to full load

(full load is in operation).

–

The ignition is switched off again

upon activation of full load.

Functional diagram

A Supply oil connection

B Return oil connection

C Combustion air inlet

D

1

Nozzle 1

D

2

Nozzle 2

1 Oil pressure pump with pressure

regulator

2 Solenoid valve for nozzle 1

3 Solenoid valve for nozzle 2

4 Nozzle rod with two nozzles

5 Air damper

6 Hydraulic air damper drive

6a Hydraulic air damper driver for air

cut-off

7 Solenoid valve for air damper drive

8 Combustion air blower

9 Safety solenoid valve (with design

”DIN”)

Safety functions

A fault shutdown is effected if:

–

a flame signal occurs during

preventilation (extraneous light moni

-

toring)

–

no flame occurs within 5

secondsafter starting the burner

(initial oil release)

–

the flame is extinguished during

operation.

A fault shutdown is indicated by the

flashing lamp in the reset button.

The program timer stops and the

location of the malfunction is indicated

(see Service Instructions, Malfunctions).

After eliminating the malfunction, press

the reset button to start the burner

again.

A controlled shutdown is effected if:

–

the medium temperature or pressure

is reached

–

the power supply fails.

The burner starts again automatically

as soon as the operating conditions

have returned to normal.

Basis

CEN/ DIN

Page 6

09/2005 - Art. Nr. 13 019 533A

6

Burner functions

Functional sequence of burner control units LAL 1...

The burner control units LAL 1... are

designed for controlling and monitoring

burners with multi-stage or modulating

control systems. For a detailed functio

nal description of the burner control

units, including technical data and

planning information, refer to

Technical Documentation

LAL 1 L&G 7153 D

Functional diagram, 2-stage

A = Start command

A–B = Interval for flame formation

B = Burner in operating position

B–C = Burner operation

(heat generation)

C = Controlled shutdown

t1 Pre-venting time

t2 Safety time

t3 Preignition time, short

t30 Preignition time, long

t3n Post-ignition time

t4 Interval between voltage on

terminals 18 and 19

t6 Post-venting time

t7 Interval between Start command

and voltage on terminal 7

t11 Opening time of air damper

t12 Closing time of air damper

t13 Admissible after-burning time

t16 Interval until OPEN command

for air damper

G Blower motor

R Temperature or pressure controller

Z Ignition transformer

BV Fuel valve(s)

FS Flame signal

LR Load controller

LK Air damper

Page 7

09/2005 - Art. Nr. 13 019 533A

7

Installation

Mounting the burner to the heat generator

Zero point adjustment

Electrical connection

Mounting the burner to the heat

generator

To mount the burner connecting flange

to the heat generator, prepare the con

-

necting plate according to the dimen

sions given on page 4. The connecting

flange 4 with the insulating base 3 have

been factory-mounted to the front of the

burner tube.

·

Set the desired burner tube length in

the furnace by moving the flange on

the burner tube

·

Insert the burner into the opening of

the heat generator and secure it.

Inspection glass cooling

To keep the boiler inspection glass cool

and clean, a cooling line may be

connected to connection 12 R

1/4”.

The cooling line can be either a hose or

a copper pipe.

A hose union is enclosed with the

burner.

To connect a copper pipe, a suitable

clamping ring connection is required.

Zero point adjustment, flame cup

Before the burner is operated for the

first time, the zero point must be

checked and adjusted, if necessary, so

that the zero mark on the scale corre

sponds to the zero position in the

burner head. Adjustment is made by

displacing the flame cup after releasing

the screw 1.

Electrical connection

Electric wiring must be carried out by

an authorized electrician according to

the enclosed wiring diagram.

The connecting terminals are located in

the built-in switch box.

For cable connection, ensure the

following:

·

Connect to terminal strip 8.

·

Provide sufficient length of cable so

that the burner and the boiler door

can be opened.

·

Do not install the sensor lead in the

multi-conductor cable.

The electric module can be removed for

connection, replacement or adjustment

of components.

5 Lock nut for electric module

6 Pushbutton, stage 1 - stage 2

7 Pushbutton On/Off

8 El. connecting terminals

9 Overload relay

10 Protective motor switch

11 Automatic burner control unit with

reset button

12 Connection for inspection glass

cooling

Disassembling the electric module

·

Set the main switch to off, remove

the fuse

·

Release the lock nuts 5

·

Carefully remove the electric module.

Caution!

Never apply voltage to the electric

module after disassembly.

After making the connections, check all

system components for correct wiring.

Then start the motor for a short time to

check its sense of rotation.

Page 8

09/2005 - Art. Nr. 13 019 533A

8

Installation

Oil connection

Oil pressure regulation

Start-up

Oil connection

Hoses are used for connecting the

oil pipes and the valve system. The

hoses must be properly installed

(suspended if possible) to avoid kinking

and the risk of fracture. For the dimen

sions of the supply and return pipes

from the valve system to the tank,

please consult the relevant technical

data sheets.

Mounting options

–

Direct single-pipe installation

–

Single pipe installation with vent

filter

–

Two-pipe installation

Filters

To protect the burner pump and the

hydraulic system, suitable filters must

be installed upstream of the burner.

Conversion from two-pipe to singlepipe installation

The burners are delivered with the

pumps fitted for two-pipe installation.

Conversion

·

Remove the bypass plug from the

return line connection and close the

return line R with the screw supplied

with the burner.

Attaching the measuring

instruments

·

Suction line vacuum gauge to con

-

nection 3

·

Oil pressure gauge to connection 4

Oil pressure regulation

The oil pressure is regulated by the

pressure regulator incorporated in the

pump. The correct setting is approx.

15–20 bar, depending on the burner

capacity.

The pressure regulator is actuated by

turning the screw 6.

Vacuum test (suction line)

The maximum permissible vacuum is

0.4 bar. A higher vacuum will cause the

heating oil to vaporize and may cause

malfunctions.

Pump type for EK4.160 L-ZA

R Return line connection

S Suction line connection

1 Solenoid valve, nozzle 2 (full load)

2 Connection, nozzle 2

3 Vacuum gauge connection

(suction line)

4 Pressure gauge connection

(oil pressure)

5 Screws for pump cover

6 Oil pressure regulator

7 Connection, nozzle 1

8 Connection, hydraulic air damper

drive

9 Solenoid valve, nozzle 1 (low load)

10 Pressure output

Start-up and ventilation

Switch on the burner for a short while

and check whether the sense of

rotation is correct. Loosen the oil pipe

union at the pressure output (7 or 10),

switch on the burner and run the burner

until bubble-free oil emerges. Then

reconnect the oil pipe.

Important!

The hydraulic system has been filled

with test oil at the factory. This may

cause ignition problems when starting

the burner for the first time.

Adjustment sequence

·

Start the burner

·

Adjust the oil pressure (15–20 bar)

·

Provisionally adjust low load

·

Switch over to full load

·

Finally adjust full load

·

Switch back to low load

·

Finally adjust low load

Pump type for EK4.100 L-ZA

Page 9

09/2005 - Art. Nr. 13 019 533A

9

Start-up

Burner head setting dimensions

The setting dimensions are standard

values which refer to 80% of the

maximum burner capacity. They can be

readjusted depending on operating con

-

ditions, flue gas analysis and combu

-

stion behaviour.

Important!

Check the settings by means of the

table before starting the burner for the

first time. Remove the nozzle connec

-

tion for this purpose.

Ignition electrodes

The ignition electrodes are directed to

nozzle 1.

Spare ignition electrodes must be bent

for replacement (at an angle of approx.

30° to the nozzle).

Burner head

1 Oil connection, minimum low load

1a Oil connection, maximum full load

2 Ignition electrode

3 Flame cup

4 Nozzle rod

5 Baffle plate holder

6 Nozzle

7 Baffle plate

Burner type Standard settings

ACDEHKL

Baffle plate/

nozzle rod

Electrode/axis

Electrode/

nozzle rod

Electrode gap

Baffle plate/

flame cup

max. longitudi-

nal adjustment

Oil filler neck/

scale plate 0

EK 4.100 L-ZA

27 7 20 3 20 50

EK 4.160 L-ZA

27 7 20 3 20 50

View Z

Page 10

09/2005 - Art. Nr. 13 019 533A

10

Start-up

Air regulation

Design ”Basis”

Low load

·

Release the lock nut 1

·

Use the screw 2 to adjust the

low-load air

·

Tighten the lock nut after

adjustment.

Full load

·

Release the lock nut 3

·

Use the screw 4 to adjust the

full-load air

·

Tighten the lock nut after

adjustment.

Air regulation, suction side

The combustion air is adjusted on the

hydraulic air damper drive.

Design ”CEN”/”DIN”

The closed air damper position is

adjusted by means of the screw 6

(standard factory setting).

Low load

· Release the plug screw 5. The screw

behind it is now accessible for

adjusting the low-load air.

· Retighten the plug screw.

Full load

·

Release the lock nut 3

·

Use the screw 4 to adjust the

full-load air

· Tighten the lock nut after

adjustment.

Important!

Make sure that you do not turn the stops

of the hydraulic drive forcefully towards

each other, i.e. adjust the stop screws

only as long as the air dampers move

synchronously. Violent and excessive

turning will destroy the pinion.

1 Lock nut

2 Air regulator, low load (Basis)

3 Lock nut

4 Air regulator, full load

5 Air regulator, low load (CEN)

6 Air regulator, air damper closed

(CEN)

7 Locking screws for longitudinal

nozzle rod adjustment

8 Fixing screw, nozzle rod

Air regulation, pressure side

Moving the nozzle rod changes the

available sectional area F in the flame

cup.

Adjusting the nozzle rod

·

Release the screws 7

·

Adjust the nozzle rod

·

Tighten the screws after adjustment.

The ideal position of the nozzle rod

is determined by analyzing the combustion

quality at low and full load.

To disassemble the nozzle rod, release

the screw 8.

Page 11

09/2005 - Art. Nr. 13 019 533A

11

Service instructions

Maintenance

Troubleshooting

Maintenance

Burner installations should be serviced

once a year. The combustion and

emission values should be checked and

readjusted, if necessary. All mechanical

and hydraulic functions should also be

checked and wearing parts should be

replaced, if necessary.

Any maintenance and repair jobs

may be carried out by authorized

experts only.

Check for operating ability

If a malfunction occurs, check first

whether all requirements for troublefree

operation have been met.

1. Check fuel level

2. Check power supply

3. Check if all control and safety

features, such as thermostat, safety

limiter, low-water cutout, electric

limit switches etc. are operative and

properly adjusted

Burner malfunction, electric

Burner malfunctions are indicated by a

malfunction lamp. The automatic burner

control unit LAL 1 is equipped with a

malfunction indicator that is very useful

for locating the cause of a malfunction.

Malfunction control program and

malfunction indicator

Automatic burner control unit LAL 1; for

detailed information, see L and G 7153.

Basically, the program timer and the

malfunction indicator stop whenever a

malfunction occurs. The symbol

displayed above the reading mark

indicates the type of malfunction:

w

No Start, e.g. because the

CLOSED signal from limit

reversing switch ”Z” (or from

auxiliary switch ”M”) is missing on

terminal 8, or because a contact

is open between terminals 4 and

5.

x

Start aborted because the OPEN

signal from limit reversing switch

”A” is missing on terminal 8.

Terminals 6, 7 and 15 remain

energized until the fault is

eliminated!

Burner malfunction, general

In the event of any burner malfunction

whose cause is not immediately identifi

able, check the program sequence by

means of the applicable wiring diagram

and the hydraulic system description

until you locate the fault.

z

Fault shutdown because the

flame supervising circuit is

defective.

v

Start aborted because the

position signal from auxiliary

switch ”M” for the small flame

position is missing on terminal 8.

Terminals 6, 7 and 15 remain

energized until the fault is

eliminated!

1 Fault shutdown because no flame

signal is present upon expiry of

the safety time.

F

Fault shutdown because the

flame signal has failed during

burner operation.

w

Fault shutdown on or after

completion of the control

program because of extraneous

light (e.g. flame not extinguished,

leaky fuel valves or shutoff

elements in the nozzle rod,

defective flame supervising

circuit, etc.).

a–b Starting program

b–b’ ”Blank spaces”

(no contacts actuated)

b(b’)–a Post-venting program

The automatic control unit can be reset

immediately after a fault shutdown.

After resetting (as well as after a power

failure or after eliminating a malfunction

which caused a fault shutdown), the

program timer will always returns to its

starting position, supplying voltage to

terminals 7, 9, 10 and 11 only, as deter

mined by the control program. Only

then will the control unit initiate another

starting sequence of the burner.

Note:

Operate the reset button for 20

seconds at the most.

Page 12

09/2005 - Art. Nr. 13 019 533A

12

Fabriqué en EU. Made in EU. Hergestellt in der EU.

Document non contractuel. Non contractual document. Angaben ohne Gewähr.

Adresse Service-Hotline

ELCO Austria GmbH

Aredstr.16-18

2544 Leobersdorf

0810-400010

ELCO Belgium n.v./s.a.

Pontbeeklaan-53

1731 Zellik

02-4631902

ELCOTHERM AG

Sarganserstrasse 100

7324 Vilters

0848 808 808

ELCO GmbH

Dreieichstr.10

64546 Mörfelden-Walldorf

0180-3526180

ELCO France

18 rue des Buchillons

74106 Annemasse

0450877624

ELCO-Rendamax B.V.

Amsterdamsestraatweg 27

1410 AB Naarden

035-6957350

NL

FR

DE

BE

AT

CH

Loading...

Loading...