Page 1

Operating Instruc tions

Only for Authorized Service Technicians

Brine-Water a nd Water-Water

Heat Pumps

AQUA TOP TC

02/2008 Art. No. 11 051 525

Page 2

2

Table of Contents

Table of Contents …………………………………………………....... 2

Basic Information Safety Information…………………….................. 3

General Info................................................ ....... 4

Legal Guidelines, Rules...................................... 5

Warranty Terms............................. ..................... 5

Receiving Inspection............................................ 5

Installation and

Connection Instructions Delivery Scope..................................................... 6

Transport and Setup........................................... 7

Hydraulic Connections........................................ 8

Heat Reclamation Connection............................ 9

Heater-Side Connection...................................... 11

Condensate and Safety Line.............................. 13

Electrical Connection General.............................................................. 14

Wiring Diagram and Terminal Assignment......... 15

Assembly Control Panel....................................................... 16

Charging

Geothermal Heating Systems Problems and Issues........................................... 18

Incorrect Brine Concentration............................. 18

Flushing.............................................................. 18

Charging with Antifreeze..................................... 19

Correctly Charging a Geothermal Heating System 19

Initial Startup Heat Pump Controller LOGON B RVS51........... 21

Quickstart........................................................... 22

LOGON B RVS51.843, Control Elements.......... 22

Basic Display..................................................... . 24

Parameterization.................................................. 27

Troubleshooting

Troubleshooting AQUATOP LOGON WP........... 35

System Characteristic Curve of Sensor NTC 1 k............ 38

Characteristic Curve of Sensor NTC 10 k.......... 38

Equipment Dimensions AQUATOP T05C+T06C, T08C-T14C,

T07C-HT, T11C-HT, T19C................................. 39

Technical Data AQUATOP T05C-T10C...................................... 40

AQUATOP T12C-T19C...................................... 42

AQUATOP T07C-HT, T11C-HT......................... 44

Initial Startup Lo g ........................................................................... 46

Notes ........................................................................... 47

Page 3

3

Basic Information

Safety Notes

E

Components and piping of the cooling

circuit may never be used for transport.

E

The heat pump is fastened to the

transport pallet.

E

All electric circuits must be de-energized

before opening the unit.

E

All work on the cooling circuit must be

carried out by trained technicians who

must be familiar with and trained in the

use and handling of the coolant.

L

Never us harsh, abrasive, acidic or

chlorine-containing cleansers on the

surface of the equipment.

Safety Notes

The following notes and information are

generally used in the operating

instructions:

L Comply with information about

function and operation.

E Always comply with and

observe all safety notes and

safety information.

Information about the operating

instructions of the controller

LOGON B WP

E

Setup, installation, configuration, and

initial startup of the heat pump system

must be carried out by a qualified

technician applying the relevant

statutory rules, regulations, and guidelines, as well as the operating

instructions.

E

The use of the heat pump must be

reported to the local utility or electric

company.

E

Do not exceed a tilt of 30° when transporting the heat pump. Avoid exposing

the heat pump to any type of moisture

or humidity.

Protect the heat pump from damage

and dirt during all construction phases.

Page 4

Basic

Information

General

4

General

Usage Range

The heat pump is designed only for

heating as well as generating service

water.

The heat pump can be utilized in newly

installed or existing heating systems

by complying with the usage limits as

defined by the AQUATOP planning

document.

E

Setup

The heat pumps can be set up on a

smooth, level, and plane surface

without the need of a base or pedestal.

The installation room must be dry and

frost-free. Rooms with much humidity

such as laundry rooms, etc. are not

very suitable for installing the heat

pump. The min. clearances must be

adhered with for all equipment to

ensure access in case of maintenance

and control tasks.

Function Principle of the

Brine-Wat er/Water-Wat er Heat Pump

The heat pump converts the heat

contained in the soil or rock

(groundwater) with a low temperature

into heat with a higher temperature.

This is achieved by routing the brine

liquid through a heat exchanger in the

soil (groundwater) and a pump to the

evaporator. The liquid working medium

in the evaporator boils and evaporates

at a low temperature and low pressure.

The evaporation heat required is drawn

from the brine liquid and returned to

the heat exchanger.

The evaporated working medium is

suctioned by the compressor and

compressed to a higher pressure.

The compressed, gaseous working

medium is fed to the condenser where

it is condensed at a high pressure and

high temperature.

The condensation heat is transferred

to the heating water and the temperature of that water increases.

The energy transferred to the heating

water corresponds with the energy

previously extracted from the soil

(groundwater) plus the small amount

of electrical energy required for

compressing the working medium.

Energy-Saving Use of the Heat

Pump System

Your decision to obtain a heat pump

heating system is an important contribution to saving the environment by

having lower emissions and reduce

your primary energy use.

Please observe the following points to

ensure your new heating system

functions efficiently:

L

The heat pump heating system must

be carefully dimensioned and installed.

L

Avoid unnecessarily high flow temperatures. The lower the flow temperature

on the heating side the more efficient

the heat pump is working. Make sure

the controller is set correctly and

properly.

L

Rush airing (several windows open at

once for short period) is to be preferred

over continuously leaving a small gap

open. Rush airing reduces the energy

consumption.

Page 5

5

Basic Information

Legal Guidelines, Rules,

Warranty Terms,

Receiving Inspection

General Information

These operating instructions serve the

correct installation, adjustment, and

maintenance of the equipment.

The following information must therefore be read carefully and the heat

pump must be installed, inspected, and

maintained by correspondingly trained

technicians.

The manufacturer is not liable for

mechanical, hydraulic, or electrical

modifications after the warranty

expires. The warranty becomes null

and void in case of not explicitly

authorized actions carried out contrary

to or in violation of these operating

instructions.

All applicable safety standards must

be observed during installation. Check

whether the properties of the power

supply system match those of the heat

pump (type plate).

These operating instructions and the

electrical scheme (diagram) of the heat

pump must be stored carefully and

made available to the operating personnel if needed.

E

The manufacturer is not liable for personal injury or property damage, direct

or indirect, caused by noncompliance

with these instructions.

The equipment may be opened only

by qualified personnel.

Legal Guidelines and Rules

All guidelines based on CE standards

were observed during design and

manufacture of the heat pump.

(See CE Conformity Declaration.)

Compliance with the corresponding

SEV, EN, and IEC standards is

required for the electrical connection

of the heat pump. The connection

specifications of the local utility or

electric company must be complied

with as well.

E

Explanations Concerning Our

Warranty Terms

Our warranty does not cover damages

caused by or due to the following

reasons:

- Unsuitable or improper use or

operation,

- Incorrect setup, adjustment, or

incorrect initial startup by buyer

or third parties

- Installation of third party parts

- Operating the equipment under

overpressure or in excess of the

specifications indicated by the

factory

- Noncompliance with the notes

and information of the operating

instructions

The heat pumps have a warranty

period of 24 months after the day of

delivery. The sales, delivery, and

warranty terms and conditions according to the order confirmation apply

in all other instances.

Receiving Inspection

The equipment is shipped on a

wooden pallet and a corresponding

protective cover.

The equipment must be checked for

completeness and transport damage

upon receipt.

E

If damages are detected, the corresponding damage must be noted

immediately on the shipping document

and identified with the following

phrase: "Conditional acceptance due

to obvious damage."

Page 6

Installation and Connection Instructions

Delivery Scope

6

1

2

3

4

5

6

7

8

Preattached tubes in rear of unit

Additional items enclosed in accessory bag

The following components are included

with the heat pump:

1 1 Plexiglas cover

2 1 controller receptacle

3 1 front panel

4 1 LOGON B WP controller

5 1 exterior sensor

6 4 vibration dampening rubber

pads

7 4 tube seals

8 1 set of documentation

9 4 vibration-dampening tubes

Page 7

7

Installation and Connection Instructions

Transport and Setup

Transport

Before every transport, make sure the

lifting or transport equipment has the

lifting power needed to transport the

respective equipment weight. All of the

tasks described here must be carried

out based on the relevant safety

standards. This applies to tasks associated with the equipment as well as

the process or procedure of each task

itself.

Transport with Forklifts, Lifting

Platform or Similar Equipment

Insert forks lengthwise under the

wooden pallet.

When lifting, make sure the weight is

equally distributed. Never tilt the heat

pump beyond max. 30

º

(in any direction)

when transporting it. Avoid exposing

the heat pump to any type of moisture

or humidity.

(Also applies to setup and installation!)

Never stack objects on the heat pump or

hang up wet clothes over it.

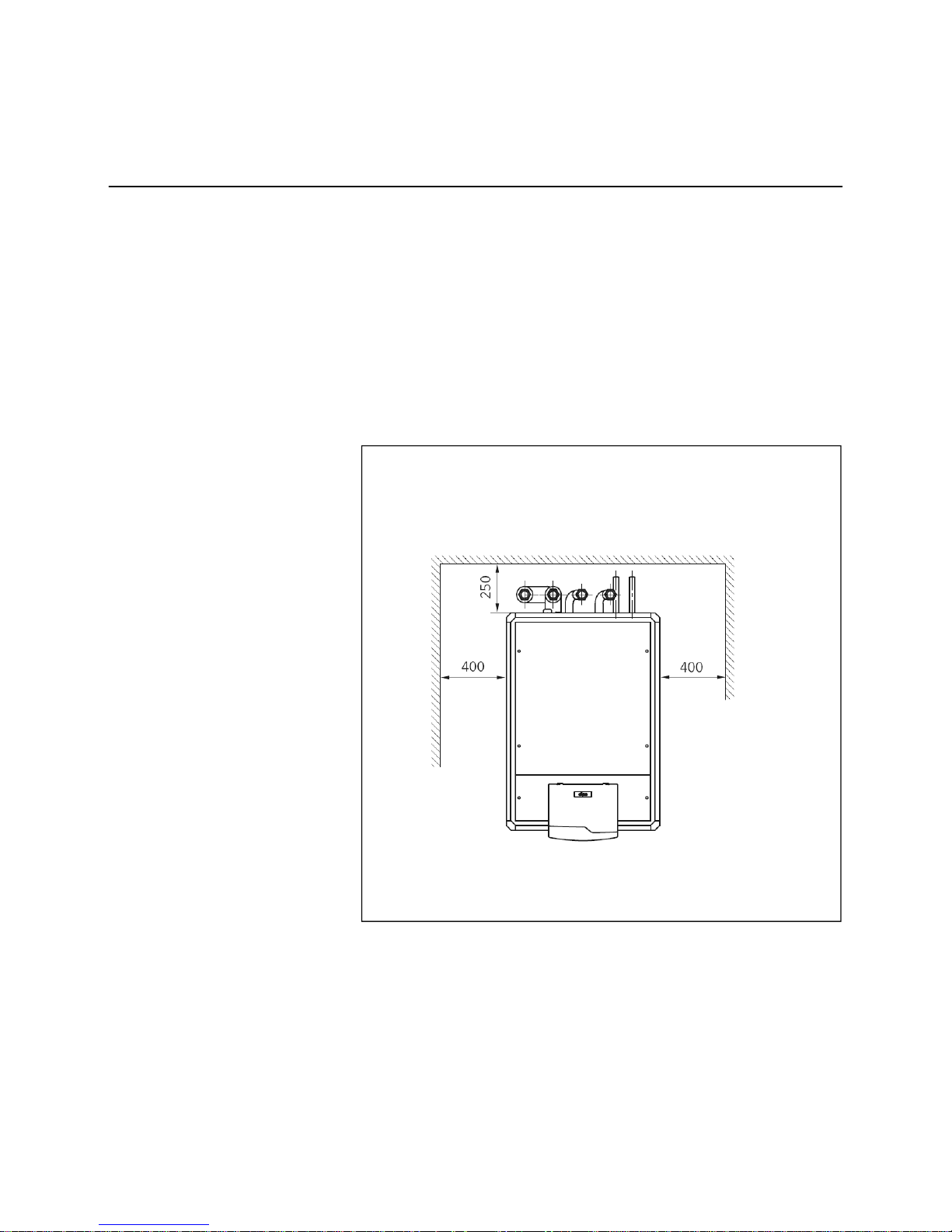

Setup

The heat pump is designed to be set

up in an interior location (IPXO, i.e.

only dry rooms). The base frame must

be set up on a smooth, level, and plane

surface.

The heat pump must be setup in a way

that allows servicing the pump without

access problems. This is ensured

when complying with the wall

clearances depicted below.

Control station

Plan view with min. clearances

After moving the unit to the installation

location, remove the transport

protection and safety elements and

attach the vibration dampening rubber

pads included with the equipment into

the now exposed threaded openings

at the bottom of the unit.

These pads are also adjustable to

ensure the heat pump is level.

Page 8

8

Installation and Connection Instructions

Transport and Setup

Hydraulic Connections

After the unit is placed into position,

make sure to check for visible damage.

Properly dispose off the packaging

material.

Transport safety device

The flexible connection tubes and

hoses included in the delivery scope

are attached to the rear of the

AQUATOP TC.

The heating and the heat reclamation

sides are connected to the rear as

well (hold on to nut when tightening

cap nut to prevent twisting the flexible

connection lines).

Page 9

9

Connections

Connection pipes and distributor

Delivery/installation by

ELCO/ installation company

On-site

Trenches and openings

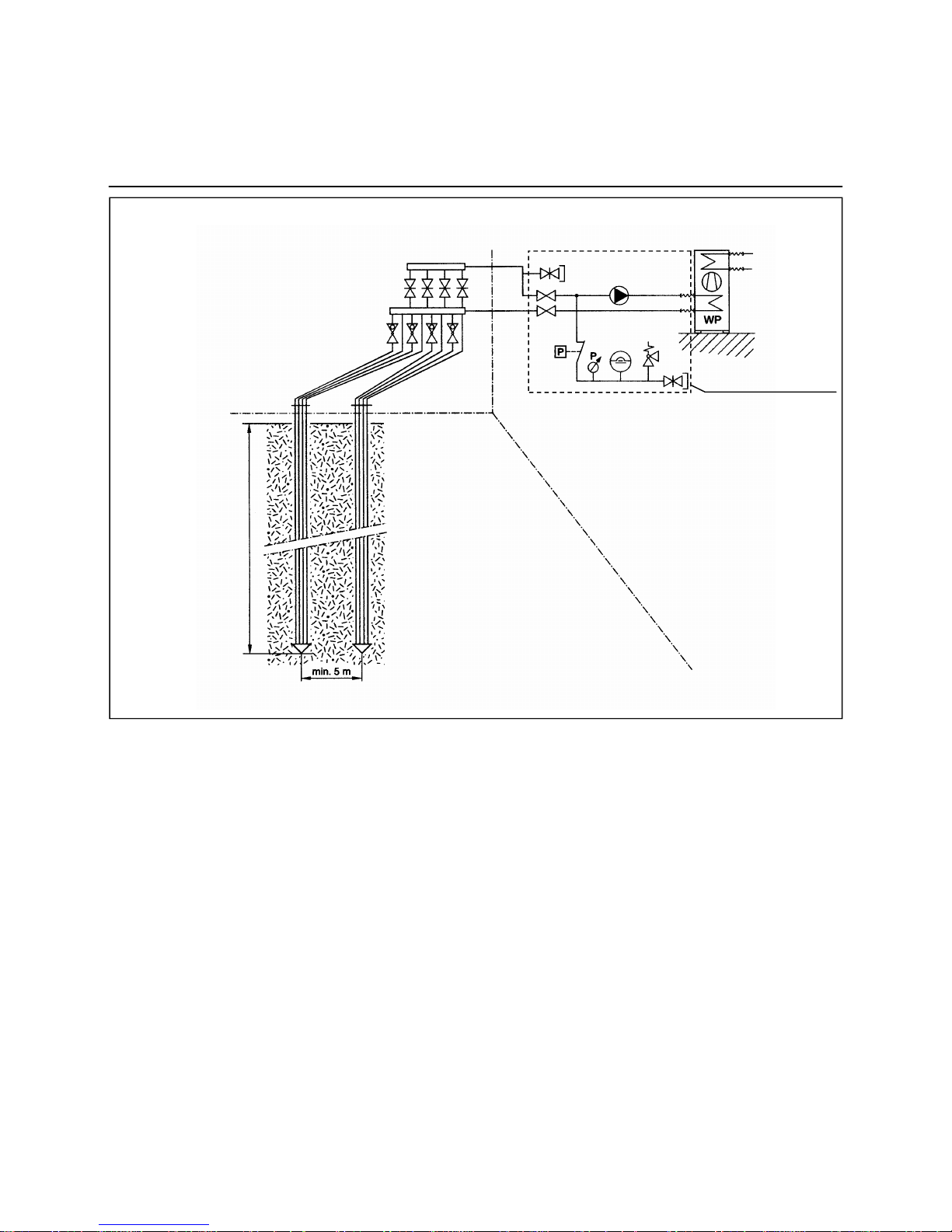

Geothermal Heating System

Boreholes for geothermal heating

systems/installation and backfill

Delivery/installation by

ELCO/ drilling company

On-site

sludge trough

Recommended: 8 m

Heat Pump Connection

Heat source booster pump and

safety devces, connection lines,

insulation, heat carrier fill

Delivery/installation by

ELCO/ installation company

Probe depth

Installed in compact

heat pumps

Installation and Connection Instructions

Heat Reclamation Connection

The general schematic also applies to

geothermal tube collectors.

L

Brine-side circulating pump, expansion

vessel, manometer, charging element,

and safety valve are already installed

into the AQUATOP TC unit.

L

Lead safety line at an incline into

suitable collection container.

Geothermal Heating System / Geotherma l Tube Collector

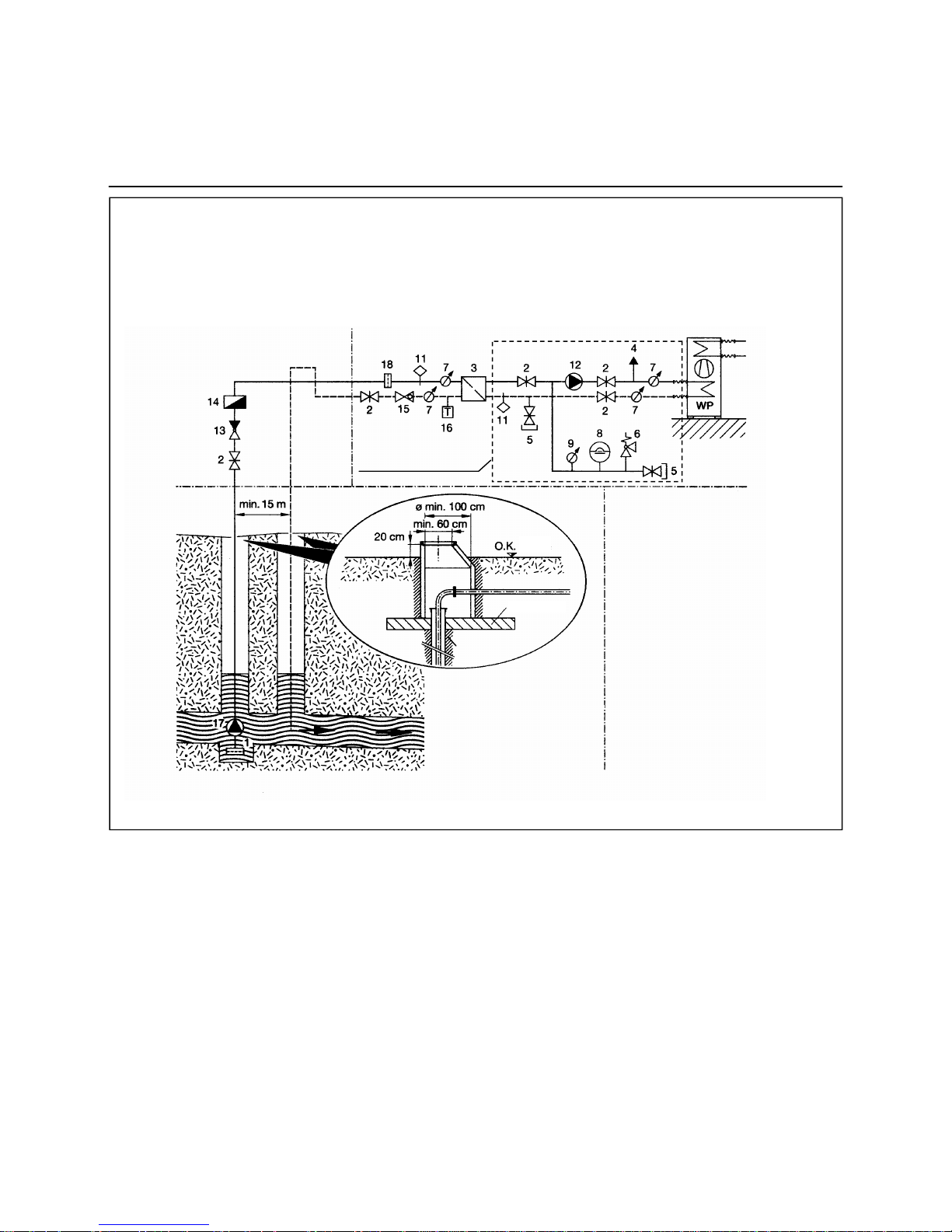

Page 10

10

Installation and Connection Instructions

Heat Reclamation Connection

Connections

• Tapping and return lines

• Trenches and opening

Delivery/installation by installation

company or builder

Intermediate Circuit

• Poss. groundwater pump

• Establishing intermediate

circuit incl. heat carrier fill

Delivery/installation by installation company

Heat Pump

Bank

Terrain

Brine concrete

Sealing

borehole

Heat Source Systems

• Establishing tapping

and return wells

• Poss. groundwater

pump

• Delivery/installation by

installation company

or drilling company

Key

1 Poss. filter

2 Slide valve

3 Intermediate exchanger

4 Manual air exhauster

5 Filling and draining valve

6 Safety valve

7 Thermometer

8 Expansion vessel

9 Manometer

11 Flow monitor

12 Circulating pump

13 Return valve

14 Poss. flow rate meter

15 Flow control valve

16 Antifrost thermostat

17 Submerged pump

18

Fine filter, mesh size

= 280 – 350 my

Installed in compact

heat pumps

L

When using groundwater or well water

as heat source, the following must be

observed:

- Min. temperature > = 7°C

- Filtered, clean water; provide water

filter in pressure line

L

Brine-side circulating pump, expansion

vessel, manometer, charging element,

and safety valve are already integrated

into the AQUATOP TC.

L

Lead safety line at an incline into

suitable collection container.

Water (with intermediate circuit)

Page 11

11

Installation and Connection Instructions

Heater-Side Connection

Key

1 Heating water outlet, inside thread

2 Heating water inlet, inside thread

3 Heat source outlet, inside thread

4 Heat source inlet, inside thread

5 Electrical feed

6 Sensor cable

7 Safety valve outlet

Page 12

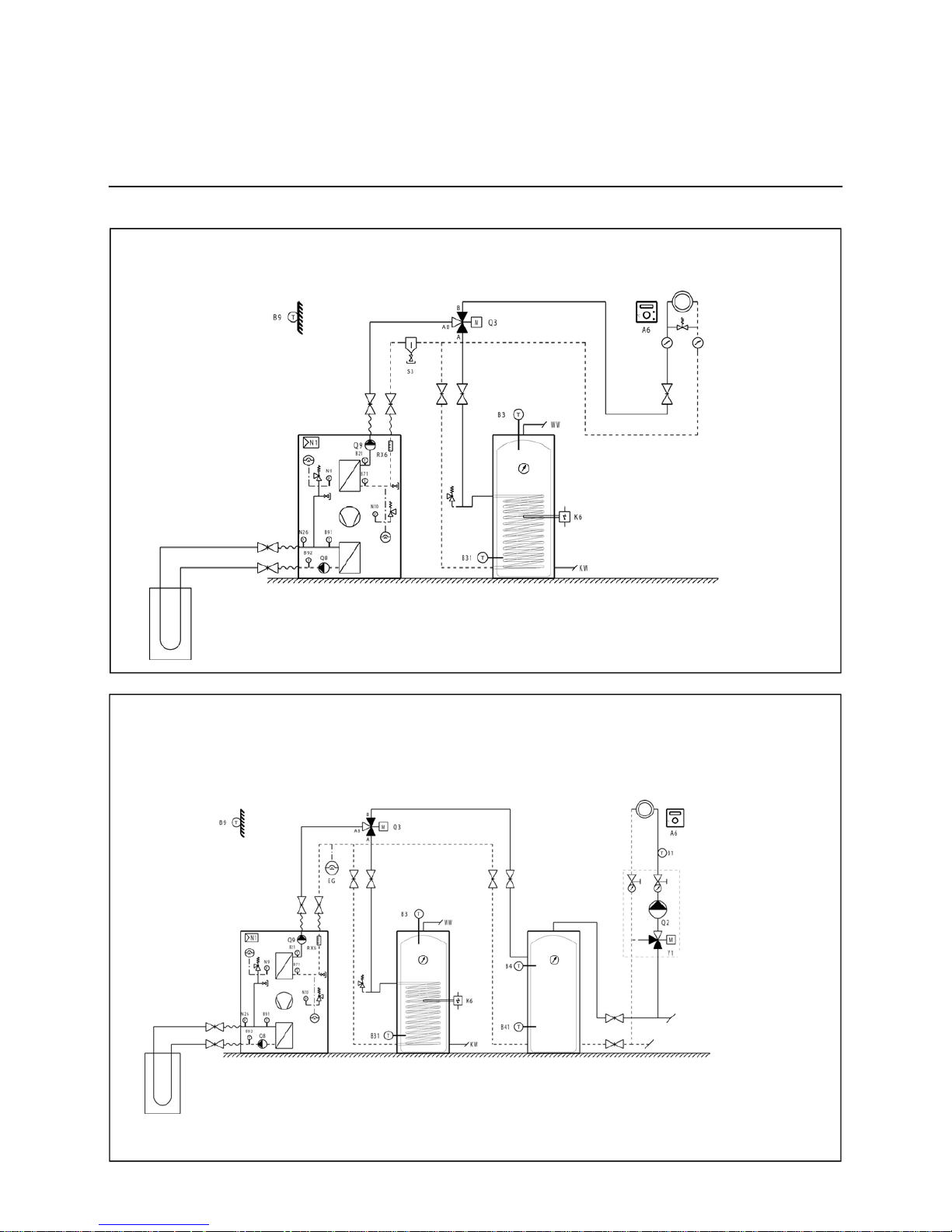

12

Installation and Connection Instructions

Heater-Side Connection

Two different basic concepts exist:

a) Direct connection, without buffer storage, comply with min. circulating water volume requirement

The coil area of the service water storage

must be adjusted to the heat pump capacity.

b) Indirect connection, with buffer for hydraulic decoupling

The coil area of the service

water storage must be

adjusted to the heat pump

capacity.

Page 13

13

Installation and Connection Instructions

Condensate and Safety Line

The condensate line and the safety

line of the heating side must be installed

freely visible and at an incline towards

the building drainage system.

L

The safety line of the heat reclamation

side (heat gain with brine) must be

installed freely visible and at an incline,

leading into a suitable collection

container.

Page 14

14

Electrical Connection

General

E

Compliance with the corresponding SEV,

EN, IEC, as well as the corresponding

VDE standards is required for the

electrical connection of the heat pump.

The connection specifications of the

local utility or electric company must be

complied with as well.

E

The power supply to the equipment must

be interrupted before each electrical

connection or service or maintenance

work. The upper cover on the equipment

must be removed for the electrical

connection. This requires unscrewing

four hexagonal screws on the rear

upper cover plate of the unit and removing the cover by pulling towards

the top.

The power supply is carried out via the

inlet of the cable connection at the rear

side of the heat pump. All other necessary control connections such as flow

monitor, frost protection, thermostat,

and temperature sensor are also at the

rear of the heat pump.

E

Power Supply to the Switchbox

The power supply for the heat pump

must feature

a main switch or all-pole

cut-off switch with a contact distance

of at least 3 mm, as well as a 3-pole

circuit breaker with shared trigger for all

outer conductors. See technical data or

type plate on rear of heat pump for the

tripping current! The power cables must

have a cross-section that meets the

equipment output as well as locally

applicable rules and standards.

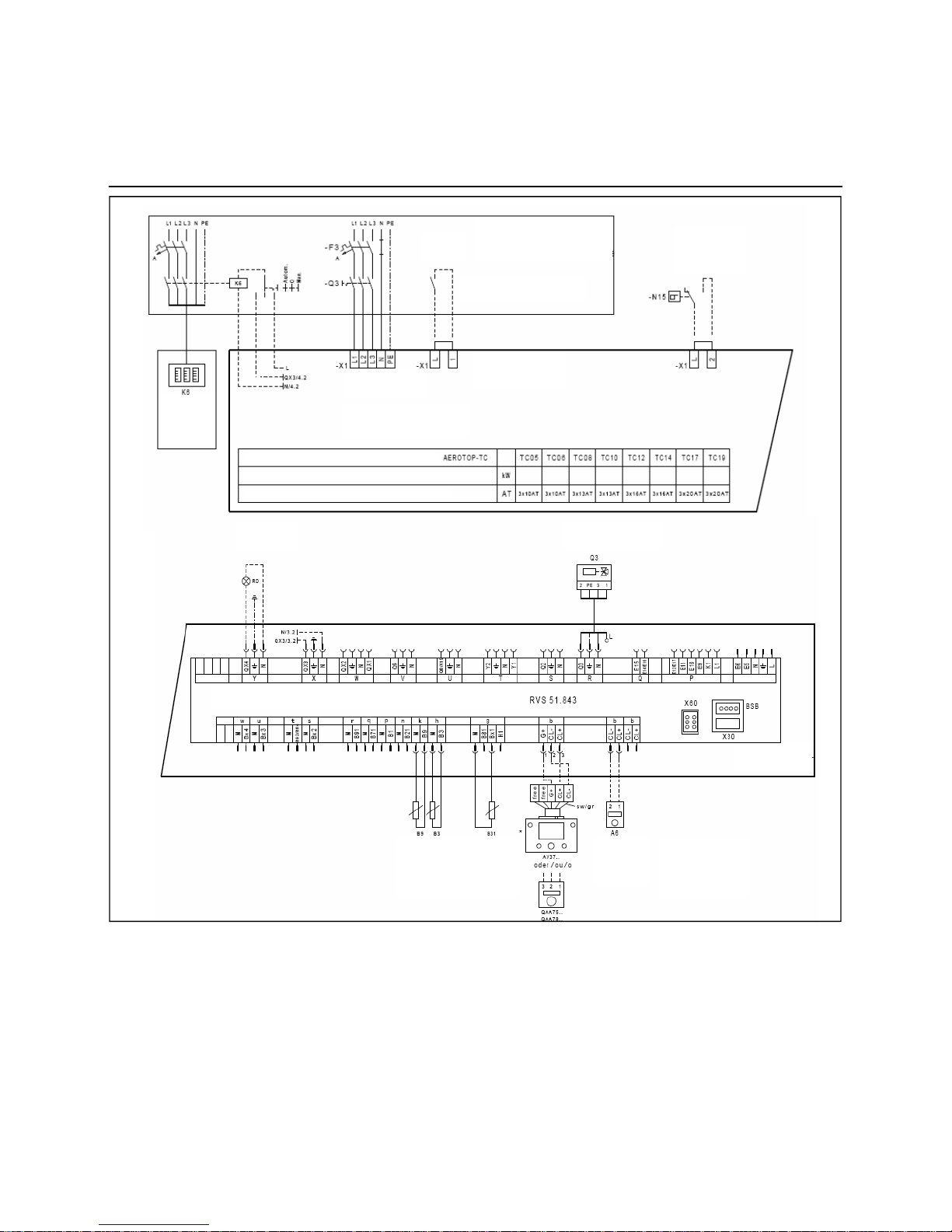

Page 15

15

Electrical Connectio n

Wiring Diagram and Terminal Assignment

L

The sensors, pumps, mixing valves, etc.

to be connected may vary depending

on the system configuration and are

listed in the corresponding standard

documentation.

L

Depending on the technical connection

requirements (TCR) of the electric

company, a separate input of power

element (compressor) and control

element (control, pumps) may be

needed. Comply with the corresponding

connection scheme (diagram)!

L

Hot cables and sensor cables must be

installed separately!

Electric

company

block

On-site setup

Contact closed – HP released

Flow monitor

HP supply

Terminals in HP

Heat pump

Heat pump

Power consumpti on

Ext. fuse

Load

(optional)

Malfuncti on

Switching valve

Heizungsregler

Heat pump

Exterior - Service- Service

sensor water - water

sensor sensor

Remote

control

Control unit

(optional)

Page 16

16

Assembly

Control Panel

The front cover, the controller case, and

the control panel are to be assembled

in the following order:

Connection P l u g to Control Panel 1

Insert the connection plug to the control

panel through the opening in the front

upper cover plate.

Connection Plug to Control Panel 2

Insert Controller Receptacle into

Upper Front Cover Plate

The controller receptacle is inserted

into the 4 lengthwise grooves of the

upper front cover panel.

Make sure the connection plug is

threaded through the opening for the

control panel.

Insert Connection Plug into

Control Panel

Page 17

17

Assembly

Control Panel

Insert Control Panel into

Controller Case

Attach Front Cover

Insert the front cover panel into the

controller case from bottom to top

while holding at a slant.

Snap Front Cover into Place

Snap front cover into the provided

lengthwise grooves.

Page 18

18

Charging Geothermal Heating Systems

Problems and Issues

Incorrect Brine Concentration

Flushing

Problems

Problems with charging a geothermal

heating system (GHS) with antifreeze

may occur occasionally and result in a

reduced capacity of the system or even

total system failure. Most problems are

as follows:

Dirt in the Circ ui t

Drilling companies generally strive to

fill only clean water into geothermal

heating systems. However, dirt may

reach the probe due to inattention.

This dirt can damage the circulating

pump or the evaporator of the heat

exchanger.

Insufficiently Mixed Brine Solution

If the correctly calculated antifreeze

volume is charged directly as a concentrate without corresponding mixing

device, individual probes may jam or

become completely disconnected due

to the viscosity of the concentrate.

Water without the required glycol

content circulates in the remaining

probes. Without the required glycol

content, the heat pump may freeze

already upon initial startup, which may

destroy the associated evaporator.

Incorrect Brine Concentration

In some cases, the detected glycol

concentration differed greatly from the

calculation.

This was mostly due to a lack of the

proper equipment to prepare the

mixture correctly. If the concentration

is too high, the heat pump's capacity is

reduced and works less efficiently.

The heat pump may also overheat.

An insufficient concentration (<20%)

may cause corrosion and frost damage.

Correctly Charging the GHS with the

Help of a Mixing Tank, Mixing

Equipment with Filter

All of the problems listed previously

can be avoided by properly charging the

GHS circuit. The right equipment can

make all the difference as well.

Use a mixing and charging tank to

charge the GHS circuit according to

the following requirements:

- Clean mixture

- Correct concentration:

- Homogeneous mixing

Flushing

Use filtered potable water and pressure to flush first the circulating pump

of the GHS circuit and the evaporator

and remove pollutants such as welding

beads, little stones, and dirt.

After closing a slider in the heat pump

circuit, each circuit of the GHS is

flushed one after the other.

A pressure of 2 bar is used to flush

a 140-m long ø 32 mm probe for

6 minutes as depicted below.

Min. Flushing

Time for 32-mm Probe

10

9

8

7

6

5

4

3

2

1

0

0 50 100 150 200

Probe length

Duration in minutes

2 bar pressure

3 bar pressure

Charging hose

Excess pressure

valve 2.5 bar

Mixing

tank

120 l

Jet pump.

e.g. Grundfos

max. 5 m

3

/h

max. 5 bar

GHSs

Brine circulat ing pump

Heat pump

Expansion vessel

GHS circuit

Drain hose

Filter

Page 19

19

Charging Geothermal Heating Systems

Charging with Antifreeze

Correctly Charging a Geothermal Heating System Circuit

Charging with Antifreeze

After flushing, the entire geothermal

heating system circuit is to be filled

with clean tap water. Follow the steps

below to prepare the required concentration of antifreeze with a 100%

concentrate. For example:

The required antifreeze concentration

is 25% (ideal range is 25-30%) with a

140-m Duplex® ø 32 mm BHE.

(Content per meter = 4 pipes x 10 dm,

length x 0.13 dm,

inner radius

2

x rr = 2.12 l/m.)

Correctly Charging a Geothermal

Heating System in 14 Steps

1. Flush the GHS circuit as described

on page 18.

2. Calculate the probe volume acc. to

table above. One GHS (GHS

ø 32 mm) has 2.12 l/m content per

meter. This yields the following

GHS content for our example:

140 m x 2.12 l/m = 296.8 liters

(297 l). Do not forget the content of

the connection lines up to the heat

pump, 30 liters in our example.

This results in a total system content

of 297 liters + 30 liters = 327 liters.

3. Required volume of 100% anti freeze concentrate:

25% of 327 liters = 82 liters.

4. Close the sliders to the heat pump.

Remove the drain hose from the

tank and place in drain.

5. Open the sliders of the GHS – if

several probes have been

installed, one slider after the other

is opened during charging.

6. Fill the mixing tank with an approx.

mixture of 1:1 of antifreeze

concentrate and fresh water.

Depending on tank size, not all of

the 82 liters of concentrate fit into

the tank (see calculation, item 3).

7. Switch the feed pump on.

As soon as the tank begins to

empty, continuously fill in the

remaining antifreeze concentrate

and additional fresh water into the

mixing tank at a ratio of approx.

1:1. Make sure that always at least

40 liters of mixed reserve remains

in the tank. Volume markers can

be attached to the edge of the

tank to help you determine its

volume.

8. The feed pump is allowed to run

until the entire antifreeze

mixture – except for the 40 liters

reserve – are filled in and then is

switched off at once. Excess tap

water drains from the drain hose

into the drain.

9. Now insert the drain hose into the

tank, turn the feed pump back on,

and allow it to run until glycol and

water are thoroughly mixed. This

takes about 6-times to 8-times as

long as it takes for flushing (see

diagram, item flushing).

10. Close charging valves at drain

hose and then those at the

geothermal heating system

distributor. The excess pressure

valve (2.5 bar) routes the excess

mixture back into the tank. Shut off

feed pump. About 40 liters remain

in the tank. Some of the mixture

was absorbed by the expansion

of the geothermal heating system.

11. In case of relatively long geo thermal heating systems and

insufficiently mixed mixture, the

excess pressure valve at the tank

is triggered and thereby intensifies

mixing.

12. If several GHSs are combined into

one system, the second, third, etc.

GHS is first flushed and then

charged individually until all have

been processed.

13. Once all geothermal heating

systems are charged, the eva porator and the brine circulating

pump must be charged next.

All sliders to the geothermal

heating systems are closed for

this purpose and the sliders to the

evaporator are opened.

The remaining mixture is now

carefully pumped via the slider at

the filling hose. Allow water in the

circuit to escape via the drain

hose. As soon as the glycol

mixture emerges as the drain hose

(color change), close the corre sponding valve and allow the

pump pressure to charge the

expansion vessel (2.5 bar). Then

close the valve at the filling hose.

The system is now charged with

the correct concentration and

correct operating pressure without

introducing pollutants to the

system.

14. Now carry out a pressure test.

This test should be performed

over an extended period to avoid

the hassle of finding leaks later on.

Note: Antifreeze mixtures are

more likely to result in leaks earlier

than water alone!

Geothermal heating

system (probe)

diameter

Content per

meter

25 mm 1,31 l/m

32 mm 2,12 l/m

40 mm 3,34 l/m

Page 20

20

Charging Geothermal Heating Systems

Charging with Antifreeze

Correctly Charging a Geothermal Heating System Circuit

Heating and Brine Charging Valves

L

The brine circuit is to be charged with

a charging pressure of 1 bar

(diaphragm-type expansion vessel

initial pressure) + 0.3 bar as brine

header = total of

1.3 bar

.

L

The temperature difference during

this operation should not exceed 4 K

between sole inlet and outlet.

Flushing and charging (heating side).

The heating side must be flushed and

charged as well.

The initial pressure in the diaphragmtype expansion vessel (heater, factoryset at 1 bar) must be adjusted to meet

local requirements. (Static height in

m 0.1

bar.).

The charging pressure should be as

follows while cold: initial pressure

diaphragm-type expansion vessel

+ 0.2 bar (water header).

L

The Aquatop TC 19 and the

AQUATOP TC 11 HT are equipped

with 2 heater-side expansion vessels.

L

Important: Comply with water quality,

VDI 2035

L

Charging must be carried out in

accordance with DIN EN 1717.

Page 21

21

Initial Startup

Heat Pump Controller LOGON B RVS51

R

E

S

E

T

1

4

5

7

2

3

6

8

9

Control Based on Atmospheric

Conditions, Featuring the Following:

• lluminated display, status and

function indicators in plain text.

• Standard program default setting,

setpoints, date, time.

• Automatic switching

between summer/winter time.

• Preset standard timed programs

for heating and hot water heating.

• Complete control and monitoring

of the HP incl. 2 heating circuits

and potable water heating, buffer

in one unit.

• Highly flexible application options

due to wireless transfer to room

controller and exterior sensor

(optimal for renovations).

• Vacation program.

• Info key for quickly querying the

most important temperatures and

system states.

• Floor drying function.

• Room temperature control with

accessory QAA75 and QAA78.

• Demand-based heater

shut-off.

• Easy initial startup of

system due to sensor self-detection

or presetting to specific scheme.

• Adjustable min. and max.

flow temperatures.

• Pump overrun.

• Integrated operating hours counter.

• Thermal disinfection of hot water

with electrical immersion heater in

PWH tank can be enabled in

addition.

• 2-lead bus interface for

controller accessories.

• Trend logging

(data logging function).

Key:

1 Operating mode key service

water

Switches on potable water heating.

(Bar in display below water faucet.)

2 Select heating operation

Sets 4 different heating operating

modes.

3 Info key

Displays information without

affecting control.

4 Service plug (BSB)

2-wire connection.

5 Return key ESC

6 Confirmation key OK

These two keys are needed

together with the large rotary knob

(7) for programming and confi guring the controller. Settings not

adjustable with the control

elements are programmed into the

control unit.

Press the ESC key to jump one

step back. Set or adjusted values

are not applied.

7 Room temperature control knob,

navigation, and settings

- Changes the

comfort setting of the room.

- Use this rotary knob to select

and adjust settings during

programming.

8 Cooling key

Cooling cycle key activates passive

cooling via the heat source for type

AQUATOP T units in combination

with the corresponding accessories.

9 HP Reset and HP defrosting key

The reset key triggers a reset of

the heat pump.

Page 22

22

Initial Startup

Quickstart

LOGON B RVS51.843, Control Elements

Control Units

Control Panel AVS37.294/309

Control unit installation variations:

Snapped into HP front panel (interior

HP setup) or inside the building, with

the help of the wall mounting plate,

attached to wall (exterior HP setup).

Room Controllers QAA75...

QAA75.611 /301:

Room controller, wired.

Operating Options

Using control panel "plain text"

(Additional room controller optional)

A Basic unit RVS...

C Room controller QAA75...

D Exterior temp. sensor AVS13...

E Control panel AVS37.294 (plain text)

The room controller should be placed

in the primary occupancy room after

considering the following items:

• Select the placement location in

such a way that the sensor is able

to obtain accurate room temperature

readings and is not affected by

direct sunlight or another heat or

cold source (approx. 1.5 above

floor level).

• When mounting to wall, there

must be sufficient room to slide unit

in and out.

If the unit is removed from its base, it is

no longer functional.

Select potable water operation

Select heating operation

Display information

Apply setting

Reset / defro s t key

Exit setting

Service plug (BSB)

Cooling key

Adjust room comfort setpoint

Navigation and settings

Select heating operation

Select potable water operation

Exit setting

Apply setting

Adjust room comfort setpoint

Navigation and settings

Presence key

Cooling key

Display information

Page 23

23

Initial Startup

Quickstart

LOGON B RVS51.843

Heat to comfort setpoint

Heat to reduced setpoint

Heat to frost protection setpoint

Cool

Process running – please wait

Replace battery

Vacation function activated

Refers to heat circuit

Maintenance/special function

Error messages

Info level activated

Setting level activated

Heater temporary shut off

ECO function active

Basic Display

(Key Level)

Press OK (1x)

End user

• Select desired setting

• Confirm with OK

• Use ESC to return to basic display

Press OK (1x)

Press INFO (3 seconds)

Initial startup / Service technician

• Select desired user level

• Confirm with OK

• Select desired setting

• Confirm with OK

• Use ESC to return to basic display

Page 24

24

Initial Startup

Basic Display

Key Action How To Display/Function

Change operating

mode or cycle

Factory setting:

- Press key 1x

- Press key again

- Press key again

Automatic Mode ON

The automatic operating mode adjusts

the room temperature as set with the

timer program.

Continuous operation

D or C

Keeps the room temperature at the

selected operating level.

D Heat to comfort setpoint ON

• Heating operation without timer

program to comfort setpoint

• Protective functions active

C Heat to reduced comfort setpoint

ON

• Heating operation without timer

program to reduced setpoint

• Protective functions active

• Su/Wi automatic switching (ECO

functions and automatic day heating

limit inactive with continuous

operating with comfort setpoint

Protective mode K ON

While in protective mode, the heater is

switched off but remains protected from

frost (frost-protection temperature).

Adjust room comfort

setpoint

- Use rotary knob left/right.

- Confirm with OK

or:

- Press ESC

Changes the heating comfort setpoint

during the active heating cycle.

Comfort setpoint D applied

Comfort setpoint not applied

- The basic display is depicted after

3 seconds

Press OK

- Select control side heating circuit

and:

- Set the "reduced comfort setpoint"

Reduced comfort setpoint

C applied

Tip: Wait for at least 2 hours after changing settings so that the room temperature

can adjust.

Switch potable water

operation ON or Off

- Press key 1x

Potable water operation ON/OFF

(Bar under potable water symbol visible/hidden)

- ON: Potable water is prepared according to the

selected switching program.

- OFF: No potable water preparation, protective function

is active

Page 25

25

Initial Startup

Basic Display

Key Action How To Display/Function

Cooling operation

Switch ON or Off

- Press key 1x

Cooling operation ON/OFF

(Bar under cooling cycle symbol visible/

hidden)

Passive cooling via HP switched ON/

OFF.

The "cooling" operating mode adjusts the

room temperature as set with the timer

program.

Cooling mode characteristics:

- Manual cooling mode

- Cooling operation acc. to timer

program

- Temp. setpoint acc. to

- "Cooling comfort setpoint"

- Protective functions active

- Su/Wi automatic switching active

Presence key:

(If you are leaving the

rooms for a short time

during the comfort

period, use this key to

lower the temperature

temporary to save

heating or cooling

energy.)

In heating mode:

- Press key 1x

- Press key again

Switching from comfort setpoint to

reduced comfort setpoint

Switching from reduced comfort

setpoint to comfort setpoint

In cooling mode:

- Press key 1x

- Press key again

Switching from comfort setpoint to

OFF.

Switching from cooling OFF to

comfort setpoint.

! The presence function only works while in automatic mode.

! The current selection is active until the next switching acc. to heating program.

Displays various

information.

- Press key 1x

- Press key

again

- Press key

again

- …

- Press key

INFO segment is displayed

1. Use the info key to query and display

various information.

2. The display may depict one of the following

symbols as well:

Error message

If this symbol is depicted, a system malfunction has occurred.

Press the info key for additional information.

Maintenance

If this symbol is depicted, a service message or a special

operating mode has occurred. Press the info key for

additional information.

Back to basic display, INFO segment is turned off

- Room temperature - Heat ci rcuit status

- Room setpoint - Potable water status

- Exterior temperature - Heat pump status

- Potable water temperature - Solar status

- Buffer storage temp. - Buffer storage status

- Puffer storage setpoint - Floor function

- HP setpoint - Date & time

- HP flow temp. - Customer service phone

- HP return temp.

- Inlet/outlet temp . of source

- …

Page 26

Initial Startup

Basic Display

26

Key Action How To Display/Function

Reset and defrost

function

- Press key 1x and less than

3 seconds

Triggers reset

Any pending heat pump error messages,

counters, and other resettable parameters are reset all at one when

pressing this key.

The preset switching-on delay in case

of malfunctions is thereby bridged.

Do not use this function during normal

operation!

RESET

Page 27

27

Initial Startup

Parameterization

Initial startup (sometimes referred to as "commissioning") involves the following tasks:

• The correct assembly, setup, and electrical installation are prerequisites.

• Make all system-specific adjustments. The "configuration" control side is particularly important. Select the

corresponding control level as follows:

• On the room controller, use OK to switch to programming.

• Keep the info depressed for at least 3 seconds and use the rotary knob to select the "initial startup" control level.

Then press OK. Perform function check. Reset the damped exterior temperature.

(Control side "Diagnose consumer," control line damped exterior temperature 8703)

• Basic display "room temperature"

• Press 1 x OK

• Press INFO > 5 seconds

• Use +/- rotary knob to select "initial startup or technician" level, for example

• Press 1 x OK

• Use +/- rotary knob to select "parameter 1612 reduced setpoint," for example from potable water menu

• Press 1 x OK

• Use +/- rotary knob to change current value

• Press 1 x OK -> value is saved

• Press 2 x ESC to return to basic display

Overview of Initial Startup Parameters

Parameter lines E (end user) and I (initial startup) are displayed in the initial startup level.

The complete parameter list (with lines E, I and F) is displayed in the technician level.

Time and date 1 E

Hours/Minutes

hh:mm 00:00 23:59 -

2 E

Day/Month

dd.mm 1.01 31.12 -

3 E

Year

yyyy 2004 2099 -

4 F

Summer time start

dd.mm 1.01 31.12 25.03

5 F

Summer time end

dd.mm

1.01 31.12 25.10

Control unit 20 E

Language

-

Deutsch, English, Francais, Italiano, Nederlands

Deutsch

40 I

Unit address

-

Room controller 1, room controller 2, HMI,

service unit

Room controller 1

42 I

Room contr. 1 assignment

-

Heating circuit 1, heating circuit 1 and 2

Heating circuit 1

44 I

Operation HC2

-

Together with HC1, independent

Together with HC1

46 I

Operation HCP

-

Together with HC1, independent

Together with HC1

48 I

Presence key active duration

-

None, heating circuit 1, heating circuit 2, together

Heating circuit 1

500 E

Preset value

-

Mon - Sun, Mo - Fri, Sat - Sun, Mon, Tue, Wed,

Thu, Fri, Sat, Sun

Mon - Sun

501

E

1. phase ON

hh:mm 00:00 24:00 06:00

502 E

1. phase OFF

22:00

503 E

2. phase ON

- - . - -

504 E

2. phase OFF

- - . - -

505 E

3. phase ON

- - . - -

506 E

3. phase OFF

- - . - -

516

E

Default values

-

Yes No No

Timer program

heating

circuit 1

Control line

Control level Function

Unit Min Max

Factory

settings

F = Function E = End User I = Initial Startup

Page 28

28

Initial Startup

Parameterization

Timer program

heating circuit 2

520 . . . 536 (same as timer program heating circuit 1)

Timer program

3 / HCP

540 E

Preset value

-

Mon - Sun, Mo - Fri, Sat - Sun, Mon, Tue,

Wed, Thu, Fri, Sat, Sun

Mon - Sun

541 E

1. phase ON

hh:mm 00:00 24:00 06:00

542 E

1. phase OFF

22:00

543 E

2. phase ON

- - . - -

544 E

2. phase OFF

- - . - -

545 E

3. phase ON

- - . - -

546 E

3. phase OFF

- - . - -

556 E

Default values

-

Yes No

No

Timer program

4 / PWH

560 E

Preset value

- Mon - Sun, Mo - Fri, Sat - Sun, Mon, Tue, Wed,

Thu, Fri, Sat, Sun

Mo - So

561 E

1. phase ON

hh:mm 00:00 24:00 00:00

562 E

1. phase OFF

05:00

563 E

2. phase ON

- - . - -

5 64 E

2. phase OFF

- - . - -

565 E

3. phase ON

- - . - -

566 E

3. phase OFF

- - . - -

5 76 E

Default values

-

Yes No

No

Vacation heating

circuit 1

642 E

Vacation period 1 HC1:

First day

dd.mm 1.01 31.12 --.--

643 E

Vacation period 1 HC1:

Last day

dd.mm 1.01 31.12 --.--

648 E

Vacation operating level 1

HC1

-

Frost protection Reduced Frost protection

Vacation heating

circuit 2

652 . . . 658 (same as vacation heating circuit 1)

Vacation heating

P

662 . . . 668 (same as vacation heating circuit 1)

Heating circuit 1 710 E

Comfort setpoint

°C

Value from control

line 716

Value from control

line 713

20

712 E

Reduced setpoint

°C

Value from control

line 714

Value from control

line 710

19

714 E

Frost protection setpoint

° C 4

Value from control

line 712

10

720 E

Slope of the characteristic

- 0.1 4 0.8

730 E

Summer/winter

switching temperature

°C - - - / 8 30 20

740 I

Min. flow setpoint

°C 8

Value from control

line 741

8

741 I

Max. flow setpoint

°C

Value from control

line 741

95 50

850 F

Floor drying function

-

OFF, function heating, ready for covering

heating, function/surface ready, manual

OFF

851 F

Floor setpoint, manual

°C 0 95 25

855 E

Floor setpoint, current

°C 0 95 0

856 E

Floor, current day

- 0 32 0

Control line

Control level Function Unit Min Max Factory

settings

F = Function E = End User I = Initial Startup

Page 29

29

Initial Startup

Parameterization

Cooling

circuit 1

901 E

Operating mode

-

OFF

902 E

Comfort setpoint

°C

Value from control

line 710

907 E

Release

- 24h/day, timer program heating circuit,

timer program 3/HCP,

timer program 4/PWH

24h/day

908 I

Flow setpoint at ExT 25°C

°C 8 35 20

909 I

Flow setpoint at ExT 35 °C

°C 8 35 16

912 E

Cooling limit at ExT

°C 8 35 24

923 I

Min. flow setpoint at ExT 25°C

°C 8 35 18

924 I

Min. flow setpoint at ExT 35°C

°C 8 35 18

945 I

Mixing valve in heating mode

-

Opened Closed Opened

Heating

circuit 2

1010 . . . 1156 (same as heating circuit 1)

Heating

circuit P

1300 E Operating mode heating circuit P - Protective mode, automatic, reduced, comfort Automatic

1310 . . . 1456 (same as heating circuit 1)

Potable water 1610 E

Potable water temperature,

rated setpoint

°C

Value from control

line 1612

TempBwMax 55

1612 E

Reduced setpoint

°C 8

Value from control

line 1610

40

1620 I

Potable water release

-

24h/day, timer program, heating circuit, timer program 4

Timer program 4

1630 I

Load priority

-

Absolute, sliding, none, MC sliding, PC absolute

Absolute

1640 F

Legionella function

-

OFF, periodic, fixed day of week

OFF

Heat pumps

2800 I

Frost protection condens. pump

-

OFF ON ON

2802 I

Flow time condens. pump

s 0 240 10

2803 I

Overrun time condens. pump

s 0 240 10

2815 I

Source temp. min. water

HP (B92)

°C - - - / -20 30 3

2816 I

Source temp. min. brine

HP (B91)

°C - - - / -30 50 -5

2817 I

Switching diff. source protect.

°C 1 10 3

2818 I

Increase source protection temp.

°C 0 10 2

2819 I

Flow time, source

s 0 240 40

2820 I

Overrun time, source

s 0 240 10

2840 I

Switching diff. return temp.

°C 1 20 4

2842 I

Compressor run time, min.

min 0 120 10

2843 I

Compressor standstill time, min.

min 0 120 20

2844 F

Switch off temp. max.

°C 8 100 57

2860 F

Block level 2 at PWH

-

OFF ON OFF

2861 F

Release level 2 below ExT

°C -30 30 -5

2886 F

Compensation heat deficit

-

OFF ON ON

2951 I

Source temp. defrost release

°C 5 20 12

2958 I

No. of defrost cycles, max.

- 0 10 4

2962 I

Duration defrost block

min 0 100 15

2963 I

Time until forces defrost

min 60 600 150

2964 I

Defrost duration, max.

min 1 42 15

2965 I

Evaporator drip time

min 0 10 0

3000 I

Switch off temp. max. cooling

°C 20

60 35

Control line Control level Function Unit Min Max

Factory

settings

F = Function E = End User I = Initial Startup

Page 30

30

Initial Startup

Parameterization

Solar 3810 F Temp. diff. ON exchanger 1 °C Value from control line 3811 8

3811 F Temp. diff. OFF exchanger 1 °C 0 4

3812 F Load temp. min. exchanger 1 °C - - - / 8 30

3830 F Collector start function min - - - / 5 10

3831 F Min. run time collect. pump s 5 31

3840 F Collector frost protection °C - - - / -20 - - 3850 F Collector overheat protection °C - - - / 30 90

3860 F Evapor. heat carriers °C - - - / 60 110

Buffer storage 4709 I Forced loading heating - None, forced loading setpoint heating, index

pointer setpoint heating

None

4710 I Forced loading setpoint

heating

°C 20 80 50

4711 I Forced loading point in time hh:mm - - - / 00:00 23:50 02:00

4712 I Max. forced loading duration h 1

20 4

Potable water

storage

5056 F Re-cooling generator/HC - OFF ON OFF

5057 F Re-cooling collector - OFF, summer, always Always

5060 F Electr. immersion heater

operating mode

- Auxiliary, summer, always Auxiliary

5061 F Electrical immersion heater

release

- 24h/day, potable water release, timer program

4/PWH

Potable water release

5090 F With buffer storage - No Yes No

Configuration 5700 I System scheme, preset

values

- - - - / 1 16 - - -

5710 I Heating circuit 1 - OFF ON ON

5711 I Cooling circuit 1

OFF, 4-conductor system, 2-conductor system OFF

5712 I Using mixing valve 1 None, heating, cooling, heating and cooling Heating and cooling

5731

I Potable water actuator Q3 - None, charge pump, reversing valve Charge pump

5800 I Heat source - Brine, water, air Water

5801 I HC spread at ExT -10°C °C 0 20 7

5870

I Combination storage - No Yes No

5890 I Relay output QX1 - None, compressor 2 K2,

electrical immers. heater flow K26,

electrical immers. heater buffer K16

None

5891 I Relay output QX2 -

None, circulating pump Q4, electrical immersion

heater PWH K6 alarm output K10, heating circuit

pump HCP Q20, H1 pump Q15, 2. pump level HC1

Q21, 2. pump level HC2 Q22, pump level HCP Q23,

directional valve cooling Y21, process reversal valve

Y22, collector pump Q5

None

5892 I Relay output QX3 -

None, circulating pump Q4, electrical immersion

heater PWH K6 alarm output K10, heating circuit

pump HCP Q20, H1 pump Q15, 2. pump level HC1

Q21, 2. pump level HC2 Q22, pump level HCP Q23,

directional valve cooling Y21, process reversal valve

Y22, collector pump Q5

None

5894 I Relay output QX4 -

None, circulating pump Q4, electrical immersion

heater PWH K6 alarm output K10, heating circuit

pump HCP Q20, H1 pump Q15, 2. pump level HC1

Q21, 2. pump level HC2 Q22, pump level HCP

Q23, directional valve cooling Y21, process reversal

valve Y22, collector pump Q5

Alarm output K10

5930

5931

5932

5933

I Sensor input BX1, BX2,

BX3, BX4

-

None, buffer storage sensor B4, buffer storage sensor

B41, collector sensor B6, potable water sensor B31,

hot gas sensor B82, coolant sensor fluid B83

None

5950 I

Function input H1 -

Operating mode switching HCs+PWH, operating mode

switching HCs, operating mode switching HC1,

operating mode switching HC2, operating mode

switching HCP, error /alarm message, minimal flow

setpoint, heat demand, dew point monitor, flow

setpoint increase hygro

Operating mode

switching HCP

Control line

Control level Function

Unit Min Max

Factory

settings

Page 31

31

Initial Startup

Parameterization

Configuration 5951 I

Operating action contact H1

-

Normally closed contact (NCC), normally

open contact (NOC

NOC

5952 I

Min. flow setpoint H1

°C 8 120 40

5954 I

Heat demand 10V H1

°C 5 130 60

6007 F

Operating action input

E14, E16

-

NCC NOC NCC

6020 I

Function expansion module 1

-

No function, heating circuit, cooling circuit 1 Heating circuit

6110 F

Time constant, building

h 0 50 10

6120 F

System frost protection

-

OFF ON ON

6200 I

Save sensor

-

No Yes No

6201 F

Delete sensor

-

No Yes No

6204 F

Save parameter

-

No Yes No

6205 F

Reset parameter

-

No Yes No

6212 I

Control number generator 1

- 0 199999 0

6213 I

Control number generator 2

- 0 199999 0

6215 I

Control number storage

- 0 9 19999 0

6217 I

Control number heating

circuits

- 0 199999 2

Failure 6710 I

Reset alarm relays

-

No Yes No

6711 I

Reset heat pump

-

No Yes No

6740 F

Flow temperature 1 alarm

min - - - / 10 240 - - -

6741 F

Flow temperature 2 alarm

min - - - / 10 240 - - -

6800

-

6819

F

Time stamp and error

code, error history 1-18

0 255 Only displays:

Date, time, error code,

error type

Maintenance

Service

7070 I

HP time interval Months

- - - / 1 240 - - -

7071 I

HP time since maintenance Months

0 240 0

7072 I

Max starts compr1 / op hours

- - - - / 0.1 12 - - -

7073 I

Act starts compr1 / op hours

- 0 12 0

7074 I

Max starts compr2 / op hours

- - - - / 0.1 12 - - -

7075 I

Act starts compr2 / op hours

- 0 12 0

7076 I

Spread condens max/week

- - - - / 1 250 - - -

7077 I

Act spread condens max/week

- 0 250 0

7078 I

Spread condens min/week

- - - - / 1 250 - - -

7079 I

Act spread condens min/week

- 0 250 0

7080 I

Spread evap max/week

- - - - / 1 250 - - -

7081 I

Act spread evap max/week

- 0 250 0

7082 I

Spread evap min/week

- - - - / 1 250 - - -

7083 I

Act spread evap min/week

- 0 250 0

7090 I

PWH storage time interval Months

- - - / 1 240 - - -

7091 I

PWH storage since maintenance

Months

0 240 0

7092 I

PWH charge temp HP min

°C 8 80 40

7093 I

Act. PWH charge temp. HP

°C 8 80 -

7141 E

Emergency operation

-

OFF ON OFF

7142 F

Emergency operation function

type

-

Manual Automatic Manual

7150 I

Exterior temp. simulation

°C - - - / -50 50 - - -

7181 I

Customer service phone

Digits 0 16

Control l ine

Control level Function Unit Min Max

Factory

settings

Page 32

32

Initial Startup

Parameterization

Input/output test

7700 I

Relay test

- No test, all off, source pump Q8,

fan K19, condenser 1 K1,

condensate pump Q9,

potable water pump Q3, heat circuit pump Q2,

heat circuit mixing valve open Y1,

heat circuit mixing valve closed Y2,

relay output QX23 module 1,

relay output QX21 module 1,

relay output QX22 module 1,

relay output QX1, relay output QX2,

relay output QX3, relay output QX4

No test

7730 I

Exterior temperature B9

°C -50 50 -

7732 I

Flow temperature B1

°C 0 140 -

7750 I

B3 potable water temperature

°C 0 140 -

7770 I

Flow temperature HP B21

°C 0 140 -

7771 I

Return temperature HP B71

°C 0 140 -

7772 I

Hot gas temperature B81

°C 0 140 -

7775 I

Source input temp. B91

°C -50 50 -

7777 I

Sensor temperature B92, B84

°C -50 50 -

7820 I

Sensor temperature BX 1

°C -28 350 -

7821 I

Sensor temperature BX 2

°C -28 350 -

7822 I

Sensor temperature BX 3

°C -28 350 -

7823 I

Sensor temperature BX 4

°C -28 350 -

7830 I

Sensor temperature BX21

module 1

°C -28 350 -

7840 I

Voltage signal H1

Volt 0 10 -

7841 I

Contact status H1

-

Opened Closed

-

7885 I

Low rate E5

- 0 V 230 V -

7886 I

HP block E6

- 0 V 230 V -

7889 I

Low pressure monitor E9

- 0 V 230 V -

7890 I

High pressure monitor E10

- 0 V 230 V -

7891 I

Coil guard compressor 1 E11

- 0 V 230 V -

7895 I

Pressure/flow source E15

- 0 V 230 V -

7896 I

Signal input E12, E17

- 0 V 230 V -

7897 I

Signal input E14, E16

- 0 V

230 V -

Status 8000 I Status heating circuit 1 -

Different status messages

8001 I Status heating circuit 2 -

8002 I Status heating circuit P -

8003 I Potable water status -

8006 I Heat pump status -

8007 I Solar status -

8010 I Buffer storage status -

8050

-

8069

I Time stamp and status

code, error history 1

Control line

Control level Function

Unit Min Max

Factory

settings

Page 33

33

Initial Startup

Parameterization

8400 I

Compressor 1 K1

-

OFF ON

-

8401 I

Compressor 2 K2

-

OFF ON

-

8402 I

Electr. immers. heater flow K26

-

OFF ON

-

8403 I

Source pump Q8 / fan K19

-

OFF ON

-

8405 I

Condenser pump Q9

-

OFF ON

-

8410 E

Return temperature HP

°C 0 140 -

8411 E

HP setpoint

°C 0 140 -

8412 E

Flow temperature HP

°C 0 140 -

8415 I

Hot gas temperature 1

°C 0 140 -

8416 I

Hot gas temperature max

°C 0 140 -

8417 I

Hot gas temperature 2

°C 0 140 -

8420 I

Coolant temperature, liquid

°C 0 140 -

8425 I

Temp. spread condenser

°C -50 140 -

8426 I

Temp. spread evaporator

°C -50 140 -

8427 E

Source input temperature

°C -50 50 -

8428 I

Source input min

°C -50 50 -

8429 E

Source output temperature

°C -50 50 -

8430 I

Source output min

°C -50 50 -

8440 I

Rest level 1 standstill time min

min (0) 1 255 ---

8441 I

Rest level 2 standstill time min

min (0) 1 255 ---

8442 I

Rest level 1 run time min

min (0) 1 255 ---

8443 I

Rest level 2 run time min

min (0) 1 255 ---

8444 I

Rest time limit source temp min

min (0) 1 65535 ---

8445 I

Rest time auto reset

h (0) 1 255 ---

8446 I

Compressor sequence

- 1-2, 2-1 ---

8450 F

Op hours compressor 1

h 0 65535 0

8451 F

Start counter compressor 1

- 0 199999 0

8470 I

Fan K19

-

OFF ON

---

8471 I

Process reversal valve Y22

-

OFF ON

---

8475 I

Evaporator temperature

°C -50 50 0

8477 I

Temp. diff. defrost actual value

°C -50 50 0

8478 I

Temp. diff. defrost setpoint

°C -50 50 0

8480 I

Rest time defrost block

min 0 255 0

8481 I

Rest time forced defrost

h/min 00:00 07:00 00:00

8485 I

No. of defrost cycles

- 0 10 0

8510 I

Collector temperature 1

°C -28 350 -

8511 I

Collector temperature 1 max

°C -28 350 200

8512 I

Collector temperature 1 min

°C -28 350 -28

8513 I

dT collector 1 / PWH

°C -28 350 0

Generator

diagnosis

Control line

Control level Function Unit Min Max Factory

settings

Page 34

34

Initial Startup

Parameterization

Consumer

diagnosis

8700 E

Exterior temperature

°C -50 50

8701 E

Exterior temperature min

°C -50 50

8702 E

Exterior temperature max

°C -50 50

8703 I

Exterior temperature damped

°C -50 50

8704 I

Exterior temperature mixed

°C -50 50

8730 I

Heating circuit pump Q2

°C

OFF ON

8731 I

Heating circuit mixing valve open Y1

-

OFF ON

8731 I

Heating circuit mixing valve open Y2

-

OFF ON

8740 E

Room temperature 1

°C 0 50

8741 E

Room setpoint 1

°C 4 35

8743 E

Flow temperature 1

°C 0 140

8744 E

Flow setpoint 1

°C 0 140

8751 I

Cooling circuit pump Q24

- 0 1

8752 I

Cooling circuit mixing valve open Y2

- 0 1

8753 I

Cooling circuit mixing valve close Y2

- 0 1

8754 I

Directional valve cooling Y21

- 0 1

8756 E

Flow temperature cooling 1

°C 0 140

8757 E

Flow setpoint cooling 1

°C 0 140

8760 I

Heating circuit pump Q6

-

OFF ON

8761 I

Heating circuit mixing valve open Y5

-

OFF ON

8762 I

Heating circuit mixing valve open Y6

-

OFF ON

8770 E

Room temperature 2

°C 0 50

8771 E

Room setpoint 2

°C 4 35

8773 E

Flow temperature 2

°C 0 140

8774 E

Flow setpoint 2

°C 0 140

8800 E

Room temperature P

°C 0 50

8801 E

Room setpointP

°C 4 35

8803 E

Flow setpoint P

°C 0 140

8820 I

Potable water pump Q3

-

OFF ON

8821 I

Electrical immersion heater PWH K6

-

OFF ON

8830 E

Potable water temperature 1

°C 0 140

8831 E

Potable water setpoint

°C 8 80

8832 I

Potable water temperature 2

- 0 140

8970 I

Electrical immersion heater buffer

K16

-

OFF ON

8980 E

Buffer storage temperature 1

°C 0 140

8981 E

Puffer storage nominal value

°C 0 140

8982 E

Buffer storage temperature 2

°C 0 140

9031 I

Relay output QX1

- 0 1

9032 I

Relay output QX2

- 0 1

9033 I

Relay output QX3

- 0 1

9034 I

Relay output QX4

- 0 1

-

Control line

Control level Function Unit Min Max Factory

settings

Page 35

35

Troubleshooting

T roubleshooting A QUATOP LOGON WP

Malfunction

Cause

Remedy, Action

106: Source temperature too

low B-W HP

Brine output temperatures too low (parameter

2816, -5°C)

A1 Low volume flow

A2 Geothermal heating system badly charged

A3 Geothermal heating system comp. not in order

A4 Slider closed

A5 Pump not running

A1 Check pump output

A2 Vent geothermal heating system

A3 Set flow control

A4 Open slider

A5 Check thermo relays, phases and relays

106: Source temperature too

low W-W HP

While the HP is running and the groundwater

return temperature at thermostat, built in

downstream of HP, is less than 3°C

(parameter 2815, corresponding setting 3°C),

switching to frost protection.

A Frost protection thermostat incorrectly set

or defective.

B Groundwater volume flow too low.

The module switches the respective unit to

the safety state when a malfunction or error

occurs.

A Check frost protection thermostat for function

or not properly set, replace if needed.

B With too low groundwater output

temperatures, the system cannot be operated.

Min. water temperatures were not determined.

B1 Check filter for dirt

B2 Check evaporator for dirt

B3 With existing intermediate circuit, check function

of intermediate circuit, check plate exchanger

for dirt

B4 Check flow switch setting (triggers too late)

B5 Check water level in well and check its

dropping during operation.

107: Hot gas compressor (B 81) A Too little coolant

B Compressor leak

A Top off coolant

B Replace compressor

The cooling technician must be called in these cases.

222: HP at HP operation, high

pressure malfunction

High pressure compressor

High-pressure pressure controller triggered in

cooling circuit. No heat.

A In heating mode

A1 Insufficient flow rate

A2 Slider closed

A3 Heating circulation pump not running

A4 Overflow valve incorrectly set

A5 Heating curve set too steep

B High-pressure pressure controller actuated

too early

The module switches the respective unit to the

safety state when a malfunction or error occurs.

A1 Check flow heating water (

O

T =3-5 K)

A2 Open slider. Check flap valves

A3 Make heating circuit pump functional

again/replace pump.

A4 Repeat overflow valve setting procedure

A5 Set heating curve lower

B If A can be precluded, check at which heating

water output temperature from the heat pump

the high-pressure pressure controller is actuated.

If the switching point is significantly below 65°C,

it is possible that

B1 The switching point of the pressure controller is

too low (the pressure controller setting has

changed)

B2 The amount of coolant is too high

The cooling technician must be called in these

cases.

Page 36

36

Troubleshooting

T roubleshooting A QUATOP LOGON WP

Malfunction

Cause

Remedy, Action

223: HP when starting HC

High pressure malfunction

when starting heating circuit.

A Water in system too cold. A Below 10 °C: Increase temperature in system

with electr. immersion heater.

224: HP when starting potable

water heating

High pressure malfunction

when starting PWH.

Service water operation.

A Boiler charging pump/3-way valve not running

B Air in system

C Slider closed

D Heat exchanger too small

E Sensor positioned incorrectly (too low)

A Unblock pump/3-way valve or replace

B Vent system

C Open slider, check flap valve

D Check with retailer

E Mount sensor correctly

226: Coil guard compressor A Phase interrupt (compressor is getting hot) A Check all three phases (wait until

coil guard has cooled down, this may take

several hours).

225: Low pressure malfunction Low pressure compressor E9

Low pressure pressure controller triggered in

cooling circuit.

A Insufficient flow of brine-water in evaporator

B Leak in cooling circuit

C Pressure controller defective

D Plugged filter

E Defective or blocked injection valve

F Incorrect amount of coolant

A

A1 Blocked brine pump, make brine pump

function again

A11 Defrost thickened brine in evaporator

(remove insulation, use hairdryer to melt or let

sit for 1 day)

A2 In case of inhomogeneous brine mixtures, the

brine may become thickened in the evaporator.

A21 Better mixing of brine

B If all items above have been checked and of the

compressor switches to low pressure malfunction

within a few seconds after being started, then the

cooling circuit has a leak.

Oil residues in the unit are another indicator of a

leak in the cooling circuit (do not mistake oil for

brine).

B1 In case of a leak in the cooling circuit,

the cooling service technician must be called.

C Check switching point (important: depends on

coolant type)

D Measure temperature upstream and downstream

of filter (AT max 2 K)

E Check or replace injection valve

Check and insulate sensor

F Empty and recharge acc. to type plate.

Page 37

37

Troubleshooting

T roubleshooting A QUATOP LOGON WP

Malfunction

Cause

Remedy, Action

228: Flow controller water source A W-W heat pump

No flow

A1 Checker whether corresponding sliders are

opened

A2 Check function flow switch (while keeping

groundwater pump running, check switching

point of flow switch by slowly closing/opening

slider)

A3 Check function of groundwater pump

229: Pressure monitor

GHS/geothermal probe/tube

collector system

A B-W heat pump

Brine pressure too low

The module switches the respective unit to

the safety state when a malfunction or error

occurs.

A1 Check brine pressure with manometer

A2 Check function of brine pressure monitor

A3 Recharge brine

A4 Check expansion vessel when recharging brine

(if pressure increases quickly when recharging

brine, expansion vessel malfunction)

A5 If occurring several times, check brine circuit for

leaks

230: Thermo relays

230: Thermo relays brine pump Brine pump / groundwater pump

A Pump failure

A1 Pump blocked

A2 Motor protection was triggered

A3 Defective pump

The module switches the respective unit to the

safety state when a malfunction or error occurs.

A1 Eliminate pump block, determine cause of

block

A2 Check why motor protection was triggered

A21 Check power consumption of pump (ampere)

A22 Check trigger value of motor protection

A23 Check motor protection for defects

A3 Replace pump if defective

Electric company block active External block by utility or electric company No malfunction, HP continues to run once block

period is over.

Page 38

38

System

Characteristic Curves NTC 1 k

Characteristic Curves NTC 10 k

T [°C] R[Ohm] T [°C] R[Ohm] T [°C] R[Ohm]

-30.0 13'034 0.0 2'857 30.0 827

-29.0 12'324 1.0 2'730 31.0 796

-28.0 11'657 2.0 2'610 32.0 767

-27.0 11'031 3.0 2'496 33.0 740

-26.0 10'442 4.0 2'387 34.0 713

-25.0 9'889 5.0 2'284 35.0 687

-24.0 9'369 6.0 2'186 36.0 663

-23.0 8'880 7.0 2'093 37.0 640

-22.0 8'420 8.0 2'004 38.0 617

-21.0 7'986 9.0 1'920 39.0 595

-20.0 7'578 10.0 1'840 40.0 575

-19.0 7'193 11.0 1'763 41.0 555

-18.0 6'831 12.0 1'690 42.0 536

-17.0 6'489 13.0 1'621 43.0 517

-16.0 6'166 14.0 1'555 44.0 500

-15.0 5'861 15.0 1'492 45.0 483

-14.0 5'574 16.0 1'433 46.0 466

-13.0 5'303 17.0 1'375 47.0 451

-12.0 5'046 18.0 1'320 48.0 436

-11.0 4'804 19.0 1'268 49.0 421

-10.0 4'574 20.0 1'218 50.0 407

-9.0 4'358 21.0 1'170

-8.0 4'152 22.0 1'125

-7.0 3'958 23.0 1'081

-6.0 3'774 24.0 1'040

-5.0 3'600 25.0 1'000

-4.0 3'435 26.0 962

-3.0 3'279 27.0 926

-2.0 3'131 28.0 892

-1.0 2'990 29.0 859

Characteristic Curve NTC 1K for Exterior Temperature Senso r B9

T [°C] R[Ohm] T [°C] R[Ohm] T [°C] R[Ohm]

-30.0 175203 50.0 3605 130.0 298

-25.0 129289 55.0 2989 135.0 262

-20.0 96360 60.0 2490 140.0 232

-15.0 72502 65.0 2084 145.0 206

-10.0 55047 70.0 1753 150.0 183

-5.0 42158 75.0 1481 155.0 163

0.0 32555 80.0 1256 160.0 145

5.0 25339 85.0 1070 165.0 130

10.0 19873 90.0 915 170.0 117

15.0 15699 95.0 786 175.0 105

20.0 12488 100.0 677 180.0 95

25.0 10000 105.0 586 185.0 85

30.0 8059 110.0 508 190.0 77

35.0 6535 115.0 443 195.0 70

40.0 5330 120.0 387 200.0 64

45.0 4372 125.0 339

Characteristic Curves NTC 10 k

for Sensors B1, B3, B4, B21, B41, B71, B81, B91, and B92

Page 39

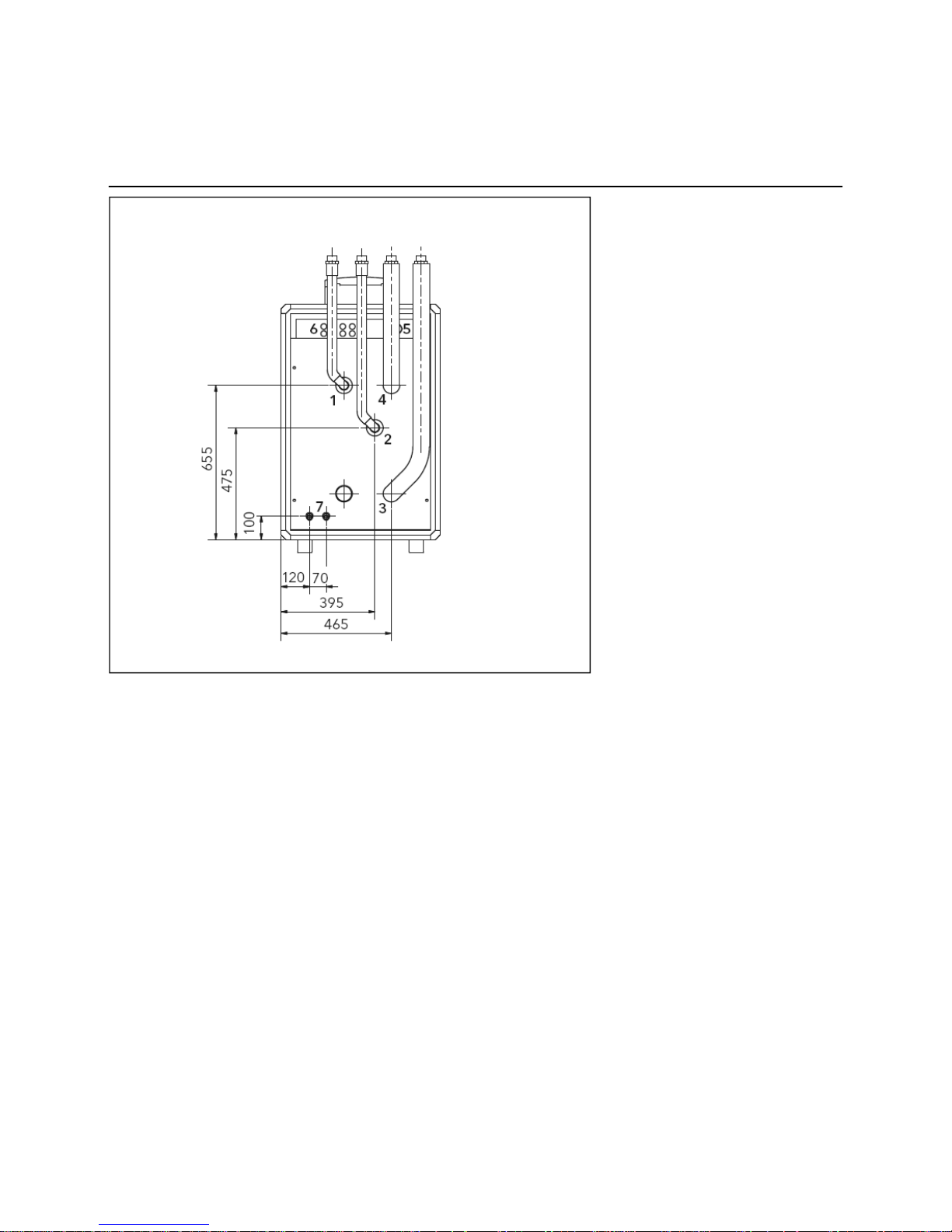

39

Equipment Dimensions

AQUATOP

T05C+T06C, T08C-T14C,

T07C-HT, T11C-HT, T19C

AQUATOP T05C+T06C T08C-T14C

T07C-HT

T11C-HT

T19C

1

Heating water Outlet Internal thread 1" 1" 1"

2

Heating water Inlet Internal thread 1" 1" 1"

3

Heat source Outlet Internal thread 1" 1¼" 1½"

4

Heat source Inlet Internal thread 1" 1¼" 1½"

5

Electrical feed PG 13,5 + PG 29

6

Sensor cable

7

Safety valve Outlet Brine and heater

8

Controller

9

Controller cover

10

Front panel holding plate

11

Vibration dampening rubber pads Diameter

Height

ø Screws

40 mm

30 mm

M8x23mm

ø 15/21 mm

Dimensional Drawing

Front view Right view Left view

(control side)

Plane view with min. clearances

Control station

Page 40

40

Technical Data

AQUATOP T05C-T10C

Heat Pump Type AQUATOP T05C T06C T08C T10C

Model Type Compact Heat Pumps

Standard Data Hea t Pu mps Brine

W35 W50 W35 W50 W35 W50 W35 W50

Heating capacity (Qh) B0 kW 5.4 5.0 6.5 6.1 8.2 7.7 9.6 9.0

Cooling capacity (Qo) B0 kW 4.2 3.3 5.0 4.0 6.3 5.0 7.4 5.9

El. power consumption 1) (Pe) B0 kW 1.2 1.8 1.5 2.1 1.9 2.7 2.2 3.1

Performance rating 1) (COP) B0 (-) 4.5 2.8 4.3 2.7 4.4 2.8 4.5 2.9

Standard Data Hea t Pumps Water

Heating capacity (Qh) W10 kW 7.1 6.7 8.7 8.1 11.0 10.2 12.9 12.0

Cooling capacity (Qo) W10 kW 5.9 4.9 7.2 6.0 9.1 7.5 10.8 8.9

El. power consumption 1) (Pe) W10 kW 1.2 1.8 1.5 2.1 1.9 2.7 2.2 3.1

Performance rating 1) (COP) W10 (-) 5.9 3.8 5.8 3.7 5.9 3.8 6.0 3.8

Coolant R 407 c

Oil Ester oil

Oil charge l 1.0 1.1 1.1 1.1

Charge volume coolant kg 1.4 1.7 1.85 2.0

Geothermal heating system length

(50 W/m acc. to AWP)

DN 32 m 84 100 126 2 x 74

Evaporator, Brine Side

Water content WT l 1.5 1.9 1.9 2.4

Volume flow (3.0 K Δt with B0/W35) l/h 1326 1584 1992 2352

Volume flow intermediate circuit

(3.0 K Δt with W10/W35)

l/h 1863 2281 2877 3433

Pressure loss (3.0 K Δt with B0/W35) kPa 11 6 15 10

Pressure loss (3.0 K Δt with W10/W35) kPa 22 12 31 21

Medium water/ethylene glycol % 75/25

Installed brine pump RS 25/7 RS 25/7 Top S 25/10 Top S 25/10

Residual pressure with SO/W35 kPa 46 50 95 102

Residual pressure with W10/W35 kPa 31 35 77 83

Condenser Heating Side

Water content WT l 1.8 1.8 1.8 2.0

Volume flow (10 K Δt) l/h 666 798 1008 1182

Pressure loss (10 K Δt) kPa 2 5 6 6

Medium water % 100

Installed heat pump RS 25/4 RS 25/4 RS 25/4 RS 25/4

Pressure loss 10 K Δt kPa 33 27 24 22

Usage Range

Heat source temperature min./max. °C -8 / +20 -8 / +20 -8 / +20 -8 / +20