Page 1

User Manual

For Authorized Service Technicians

AEROTOP T Air-Water Heat Pump

with LOGON B WP61

12/2012 Art. 420010520000

Page 2

Table of Contents

2

Table of Contents ………………………………………………………………… 2

Product Overview …………………………………………………………………. 3

Basic Information ………………………………………………………………….. 4

Product Description AEROTOP T.................................................................... 5

Setup and Connection Safety, Transport and Installation..................................... 7

Hydraulic Connections, Condensate Drain....................... 8

Electrical Connection General………………………………………………………. 9

Unit Design, Terminal Assignment……………………….. 10

Switch box…………………………………………………… 13

Checklist Correct Installation of an Air-Water Heat Pump................ 16

Initial Startup Requirements, Parameterization, Upkeep........................ 17

Fan Speed Setting

AEROTOP TC: Setting of the Integrated Thermal Valve… 18

Indoor Installation Corner Setup…….............................................................. 19

Corner Setup with Noise Dampers..................................... 20

Corner Installation…….……………………………………. 21

Cutout Insulation Installation............................................. 22

Parallel Setup with Rigid Duct........................................... 24

Parallel Setup with Rigid Duct (with Noise Damper)….. 25

General Duct Installation Information................................ 26

Flexible Air Intake.............................................................. 27

Flexible Air Outlet............................................................. 28

Controller Unit Installation................................................. 29

Outdoor Installation Special Conditions, Installation Location.......................... 30

Base/Pedestal Plan........................................................... 31

Duct and Cable Bushing………........................................... 32

Controller Unit…………………………………………......... 33

Troubleshooting AEROTOP T LOGON B WP61 Troubleshooting.............. 34

Initial Startup AEROTOP T Checklist...................................................... 37

System Sensor Characteristics NTC1, NTC10.............................. 39

Technical Data AEROTOP T07(C)-T16..................................................... 40

AEROTOP T20-T35.......................................................... 41

AEROTOP T07(C)X-T10(C)X........................................... 42

AEROTOP T07R-T16R..................................................... 43

AEROTOP T20R-T35R..................................................... 44

AEROTOP T07RX-T10RX................................................ 45

Conformity Declaration .......................................................................................... 46

Notes .......................................................................................... 51

Page 3

Product Overview

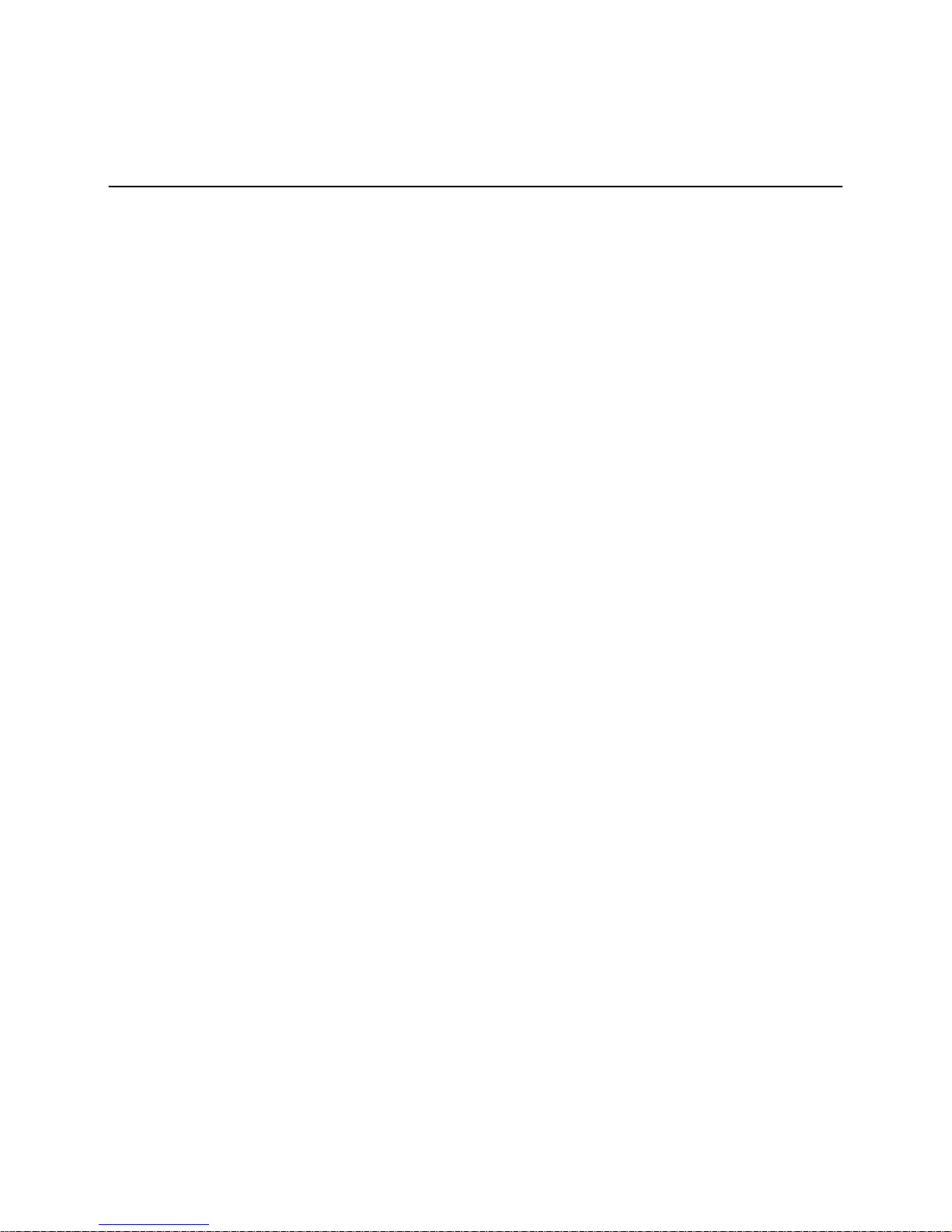

AEROTOP T

The air-water heat pump

AEROTOP T is available

in the following models:

AEROTOP T..C

The designation AEROTOP T..C includes

the following models:

• AEROTOP T..C

• AEROTOP T..CX

AEROTOP T..

The designation AEROTOP T.. includes

the following models: :

• AEROTOP T07-T35

• AEROTOP T..X

• AEROTOP T..R

• AEROTOP T..RX

3

Compact models ..C..

Up to models AEROTOP T12C and AEROTOP T10CX

the heat pumps are compact design with integrated

buffer tank, electrical resistance, expansion vessel

and circulation pump.

Single-phase models ..X..

Up to modesl AEROTOP T10X and T10CX single-phase

versions are also available.

All other models are three-phase

Reversible models ..R..

The reversible heat pumps can be used, as well as for heating,

even for the active cooling

Model for outdoor installation

With the right accessories the AEROTOP T are also suitable for

outdoor installation (not T.. C..).

Page 4

Basic information

Legal guidelines

Warranty conditions

Receiving inspection

General information

• The calculations, sizing, installa-

installations and putting into service related to the products described in this document may only be

carried out by qualified specialists

• Comply with the requirements of

local law, which may differ from the

information contained herein

• Subject to change.

These instructions are for aproper installation, adjustment and maintenance of the

machine. It is therefore necessary to read

carefully the instructions given below and

to install, test and maintain the heat pump

by technicians qualified by specific training.

At the end of the warranty period, the manufacturer assumes no responsibility for

mechanical, hydraulic or electrical changes.

In the case of operations not expressly

authorized, executed in violation of these

instructions, the warranty will become void

with immediate effect.

During the installation must meet the specific safety statements. Check that your

mains supply correspond to the data of the

heat pump (nameplate).

These instructions and the wiring diagram

of the heat pump should be stored with due

care and, if necessary, be made available

to the personnel responsible .

The manufacturer declines any responsibility for damage to persons or property caused directly or indirectly from failure to follow these instructions.

The housing may only be opened by a qualified technicians.

Limitations and Guidelines

The construction and the manufacture of

heat pump meets all the requirements of

European standards. (See EC Declaration

of Conformity).

The electrical connection of the heat pump

must be performed in compliance with the

applicable ASE, EN and IEC. Should also

observe the connection conditions of the

local energy supply

Warranty Conditions

Our performance guarantee shall lapse

for damage due to:

• misuse or non standard use

• installation or commissioning

incorrect by the purchaser or

from other.

• Use of the system with pressure

excessive or outside the factory

values

• Failure to follow directions in the

instructions for use

The warranty for heat pumps for

heating is 24 months from the date

of delivery.For the rest, the conditions of sale, delivery and warranty

in accordance with the order confirmation.

Control Input

The units are delivered on a wooden

pallet with an adequate protective

packaging.

Upon delivery, check the unit for

shipping damage and that the budget is complete.

If damage is found, they must be

reported immediately to the transport

document with a warning:

"Acceptance qualified as a result of

blatant corruption."

Given that overloading can cause

serious damage to heat pump and

plant heat source side, it is forbidden

to operate the heat pump if the following conditions exist:

• drying of the construction.

• plant is not completed

(building shell).

• windows and exterior doors

are not finished and closed.

In these cases it is necessary to provide a heating pipeline. A functional

heating or heat pump ready pose in

according to the DIN EN 1264 should

be only taking into account the above

conditions. Furthermore, keep in

mind that after the sizing of the heat

pump for normal operation may not

be possible to generate all the necessary thermal power.

Observe the following guidelines:

• Comply with the regulations

and requirements of the manufacturer of mortars for screed coat!

• Correct operation is only pos-

sible with a system installed in

a workmanlike manner (the

hydraulic, electrical, settings)!

Otherwise, the screed coat

may be damaged!

Low energy consumption use of

the heating with heat pump

The decision to opt for a heating

system with heat pump is a valuable

contribution to protecting the environment by reducing emissions and

reduced use of primary energy. In

order for the new heating system will

work efficiently, note the following

points:

L

The heating system with heat pump

must be sized and installed with care.

L

The lower is the flow temperature of

the heating water side, the more

efficient is the operation of the heat

pump.

L

Give preference to a short-term intensive aeration of the premises.

Compared to the windows always

open in the tilted position, this immediate ventilation reduces the consumption of energy.

4

Page 5

Product Description

AEROTOP T

5

High Degree of Efficiency and

Optimized Defrosting

Thanks to the correspondingly dimensioned air heat exchanger as well

as the unique defrosting system, the

AEROTOP T heat pump is especially

efficient and a cost-saver. This heat

pump always exceeds the required

degree of efficiency (coefficient) of

3.0 (COP at A2W35).

Frost forms on the air exchanger, the

evaporator, if the exterior temperature

is less than 5°C. This results in ice

formation and as a consequence

reduced the heat exchange and with

that the efficiency of the heat pump.

The evaporator must be defrosted to

remove this frost or ice. However, the

defrosting process, carried out by the

AEROTOP T by reversing the cooling

circuit, is cumbersome since the heat

pump does not yield any energy during

the defrosting process but still uses

electricity. However, this is frequently

unnecessary since frost formation

depends on the humidity in the air.

Instead of the unnecessary defrosting

at timed intervals, the AEROTOP T

determines the correct time to defrost

the unit using a progressive and well

thought out logic with different performance parameters in the cooling

circuit. Thanks to this procedure, the

unit rarely requires any defrosting

during winter, if any at all, which is a

great advantage.

Cooling with AEROTOP TR

The purpose of heat pumps is primarily

to supply a building with heat. However,

the technology can also be used to

cool a building in the summer.

This involves actively generating the

cooling energy through a process

reversal of the heat pump. In case of

distributor systems specifically

designed for cooling (fan coil or similar), the cooling capacity of the heat

pump can be transferred optimally to

the building. Cooling ceilings also

have a good cooling capacity and

comfort level. Floor heaters, however,

are only partially suited and provide a

limited cooling effect. Radiator heaters

are unsuitable.

Cascade

Thanks to the new heat pump controller

LOGON B WP61, it is possible to link

and operate several heat generators of

a system in a cascade arrangement.

Cascades with up to 4 heat pumps, or

a bivalent operation in combination with

fossil heat generators are feasible.

When using a cascade formation, the

heat generators switch on or off

depending on the current energy

demand: If the currently running heat

pump cannot satisfy the energy

demand within a specific time, an

additional heat pump/heat generator

switches on.

Quiet Operation

Regardless whether installed indoors

or outdoors, the air-water heat pump

AEROTOP T is characterized by

comparatively very low noise

emissions. This is possible thanks to

the high-performance fan, the very

advantageous air routing, the

noise--dampening insulation of the

cladding, as well as the

multi-dampened support of the cooling

circuit. Additional noise insulation

elements are available for most

variants to reduce sound emissions

further. AEROTOP T heat pumps are

quiet and efficient. However, incorrectly

integrating constructional components

may result in undesired noise increases

if the conditions are unfavorable.

Flexible and Space-Saving

Some air-water heat pumps are

relatively bulky due to the required

cross-sections for the air ducts or

application options are severely limited.

Thanks to the clever utilization of the

geometric properties of the radial fan,

AEROTOP T are among the most

flexible, space saving air-water heat

pumps.

Especially noteworthy is the fact that

the heat pump can be placed into the

left or right corner of the utility room

when not using the air ducts.

The exhaust opening is easily moved

on-site from the left to the right and

even to the top without having to use

any additional tools. The intake opening

can also be selected as desired without

special accessories. AEROTOP T heat

pumps are also suitable for outdoors

installation when using the corresponding accessories.

Page 6

Product Description

AEROTOP T

6

Enclosure and Special Components

The enclosure consists of a frame that

is completely free of thermal bridging,

sound dampened, and specifically

developed for use with heat pumps.

The cladding and panels feature a

high-grade insulation to sound-dampen

and thermally insulate the unit.

A pedestal or base is not required

since the feet of the unit feature a

vibration-dampening design.

All panels can be detached for easy

access to the internal elements of the

unit and for control or configuration

tasks.

The high-performance radial fan

ensures the unit runs efficiently and

quietly.

The high performance cooling circuit

is mounted on a vibration-dampened

support and features a thermostatic

expansion valve, filter dryer, inspection

glass, high-pressure pressure controller

with manual reset, and a low-pressure

pressure controller with automatic

reset function. The hermetic scroll

compressor is mounted on a double

vibration-dampened support.

The evaporator consists of a large-area

finned tube heat exchanger made from

aluminum and copper; the condenser

consists of a welded chromium steel

high performance plate heat exchanger. The environmentally friendly

refrigerant R407C is used as the

working medium. A flow monitor on

the consumer side ensures trouble-free

cooling for reversible heat pumps.

Operating the heat pump is prohibited if

the following conditions exist:

• Construction drying

• System/unit used in unfinished

buildings

• Windows or exterior doors

unfinished and locked.

These cases require the use of a

specific construction heating system.

Functional heating or surface-ready

heating with the heat pump acc. to

DIN EN 1264 is only permitted when

complying with these conditions.

Furthermore, it must be noted that the

design of the heat pump concerning

its standard operation may not yield the

full extent of the required heat output.

The following notes must be observed

as well:

• Comply with the corresponding

standards and rules of the floor/

screed manufacturer!

• Proper function is only ensured

with a correctly installed system

(hydraulics, electrical, settings)!

Deviations may damage the floor/

screed!

Brief Description of the LOGON B

WP61 Controller

Plain text display unit, control and

protection of the cooling circuit, defrost

logic, malfunction display and diagnostics, control of a sliding or mixed

heating circuit, service water heating,

storage tank charging, control of the

electrical auxiliary heater, expandable

for several mixed heating circuits.

LPB system bus with up to 15 heating

circuits per segment, bivalent operation

with additional heat generator (oil/gas),

cascade of several HPs. cooling

function, improved solar function

(heating support, pool, PWH), pool

function, controlling the multi-phase

electrical heating elements.

Selectable Connections

The connections for heater flow and

return, condensate drain, and electrical

connections can be placed on the left

or right side during the on-site installation and even directed towards the

bottom when installed outdoors.

Page 7

Setup and Connection Instructions

Safety, Transport and Installation

7

Transport

To avoid transport damages, the heat

pump must remain packaged and on

the wooden pallet and transported to

its final installation location with a hand

lift, pushcart, or similar equipment.

• Make sure the heat pump does

not slip on the equipment used for

transport.

• Components and piping of the

cooling circuit, the heater side, and

the heat source side may never be

used for transport purposes.

• Note the weight of the heat pump.

• Make sure the water hoses and

electrical lines are not damaged

during transport.

• Only lift and transport the heat

pump at and with the unit's bottom

panel.

Safety Information

• Compliance with all rules and

instructions of all documentation,

labels, type plates, and associated

documents of the unit is

mandatory.

Transport

• When receiving the shipment, the

heat pump must be checked for

completeness as per order

confirmation .In case of damaged

or missing material, the carrier

must be informed in writing

immediately.

• Care and due diligence are

required during transport, setup,

preparation, or when handling

heavy materials that may damage

the heat pump.

• Make sure that towing ropes, belts,

or chains used for transport or

installation do not damage the heat

pump. Do not allow the heat pump

to swing back and forth when lifting

it up. Never tilt the heat pump more

than 15° from its vertical axis.

• The heat pump is affixed to a pallet

at the factory for transport and

covered with a protective film to

protect the unit from scratches. Do

not remove the packaging until the

heat pump is positioned at its final

location.

Setup

• Setup must be carried out carefully

and accurately.

• AEROTOP T heat pumps can be

installed on a level interior floor

without pedestal or base.

If installed outdoors, a pedestal or

base is required unless the

substrate is very firm and can

support the load.

• The installation room must have at

least one exterior wall. Rooms with

high humidity are unsuitable as

installation locations for

AEROTOP T heat pumps. A

condensate drain must be

available.

• The heat pump must be set up on

a level ground and aligned with the

adjustable feet. Make sure there is

sufficient space to access the

control panel and at the sides for

inspections and maintenance.

• Make sure the ground is able to

support the load of the heat pump

and all accessories. The floor or

ground must be free of dust and

other foreign particles. If installing

in the basement, make sure the

selected installation position

cannot be flooded.

• The heat pumps may not be placed

on floating floorings.

• Once moved to its final location,

the heat pump must be carefully

unpacked and removed from the

pallet. Protect heat pump from

impact and other damaging forces!

Installation

• The safety regulations and

schemes/diagrams must be strictly

observed.

• The accessories and additional

equipment must be installed by a

trained service technician (heating

contractor) as per the enclosed

assembly and installation

instructions.

• The noise emissions of the

AEROTOP T heat pump are very

low thanks to the sound-absorbing

materials used to mount the mobile

parts and the insulating cladding.

The effective noise value depends

also on the size of the installation

room, the noise-absorbance or

reflection of the materials in the

room, as well as the possibility of

the noise to spread and transfer

via solid bodies, among others.

• Air ducts, pipes, and electrical lines

must be attached to the masonry

and not the heat pump.

• All of these connections must be

established using flexible

connections so that they can swing

freely, especially when the

compressor or evaporator starts

up. Only then is it possible to avoid

transference of sound from solid

bodies to the building structure as

well as line breakages.

Observe the checklist notes when

selecting the installation site for the

correct setup of an air-water heat

pump

Page 8

Setup and Connection Instructions

Hydraulic Connections, Condensate Drain

8

Heating System Hydraulic

Connections

AEROTOP T heat pumps can be

connected in any desired layout.

The hydraulic connections require

flexible ducts to avoid noise transference from pipe openings and solid

bodies to the distributor network and

from there to the heating elements

such as radiators, etc. The ducts can

be directed from the right or left and

are connected to the inside of the heat

pump.

The ductwork must be carried out in

such a way that pressure drops at the

nominal volume flow do not exceed

the available pressure since this would

result in a reduction of the heat pump

output. This means that ducts cannot

have elbows that are too narrow.

Pipes and ducts must also be sufficient

insulated to prevent unnecessary heat

loss and the formation of condensate,

which could damage the pipe and duct

system or the installation location.

Dimensions

Heater flow Ø 1” (T07-T16),

Ø 1 1/4” (T20-T35),

flexible. Heater return Ø 1” (T07-T16),

Ø 1 1/4” (T20-T35), flexible,

Condensate Drain Ø 25/31mm, flexible.

For each heat pump we offer hydraulic

standard schemes. The integration of

these variants guarantee a safe and

faultless operation.

The system must be thoroughly

flushed before connecting to the heat

pump.

Residues in the heat pipes lead to

damages on the heat exchangers und

to malfunction of the heat pump.

Especially if there is no buffer storage

it is recommended to a dirt trap in the

heating return flow.

The water filled into the heating system

must be handled in accordance with the

rules and regulations of the relevant

professional associations.

It is important to ventilate the heating

system. If not the correct operation of

the heat pump is affected. Therefore

an exhauster must be provided. The

compact heat pumps have an

exhauster installed in the flow.

Condensate Drain

The condensate drain should be as

close to the heat pump connection as

possible. To prevent room air or

canalization waste air from being

sucked into the heat pump, the

condensate drain must be connected

airtight to the heat pump using a

siphon with a min. height of 100 mm.

The condensate drainage pipe cross-section may not be reduced and must

be at a continuous 2% incline to ensure

water can be sufficiently drained.

Changing the Hydr. and Electr.

Connections

Lines are connected at the left side of

the unit by default. If the right side is

preferred, the panels (1 and 2) can be

switched with the panels from the left

side. Ducts and cables are pulled to

the other side inside of the unit and

through the opening in panel 1.

1 2

Page 9

Electrical Connections

General

9

Cable Entry Point

1 Entry point for load cable 3 x 400V

2 Entry point for low voltage/sensor

cable

3 Fastening screws

Detach screws (3) and push cover

plate towards front. This makes it easier

to pull through the low voltage cables (2).

After inserting the cables, push cover

back into place and refasten the

screws (3).

1

2

3

Electrical Connections and Control

Information

The electrical connections must be

established in compliance with local

rules and regulations. The current feed

may exhibit a max. tolerance of 2%

with this power intensity when a voltage

of 10% exists. Do not connect the heat

pump if the phase difference exceeds

more than 2%. (EN 60439-1)

Operating the equipment

outside of the listed limit values will void

the warranty. If necessary, please

contact your local electricity company

or utility. The internal wiring of the heat

pump is carried out at the factory as

listed on the electrical diagram included

with the unit.

The heat pump is equipped with an

electrical supply box containing the

components listed below.

• An automatic cutout switch or a

3 phase, slow-blow fuse with

neutral conductor must be provided

externally in compliance with the

technical requirements.

• The low voltage cables (control)

may not be placed in the same

cable conduits or ducts as the

supply cables.

• The exterior temperature sensor of

the controller must be attached to

the outside wall of the building in a

location protected from the after noon sun and other heat sources

(open windows, chimneys, etc.).

Northern and northeastern

exposures are preferred.

• If the room impact is to be

activated for a remote control, this

control unit must be placed in a

reference room (e.g. living room)

where it cannot be influenced by

an external heat source (e.g.

stoves, heaters, air flow, etc.).

Main Power

Heat Pump Models

(Also applies to same models in reversible (R) designs.

Ext.-Fuse Cross-section

terminal board

[A] [mm

2

]

AEROTOP T07CX (X)+ Electrical Heating Element R25 (6kW) 1x50 16

AEROTOP T10CX (X)+ Electrical Heating Element R25 (6kW) 1x63 16

AEROTOP T07C/T10C/T12C+Electrical Heating Element R25 (6kW) 20 4

AEROTOP T07/T10/T12+Electrical Heating Element R25 (6kW) 20 6

AEROTOP T14/T16 +Electrical Heating Element R25 (6kW) 25 6

AEROTOP T20 25 10

AEROTOP T26 32 10

AEROTOP T32-35 40 10

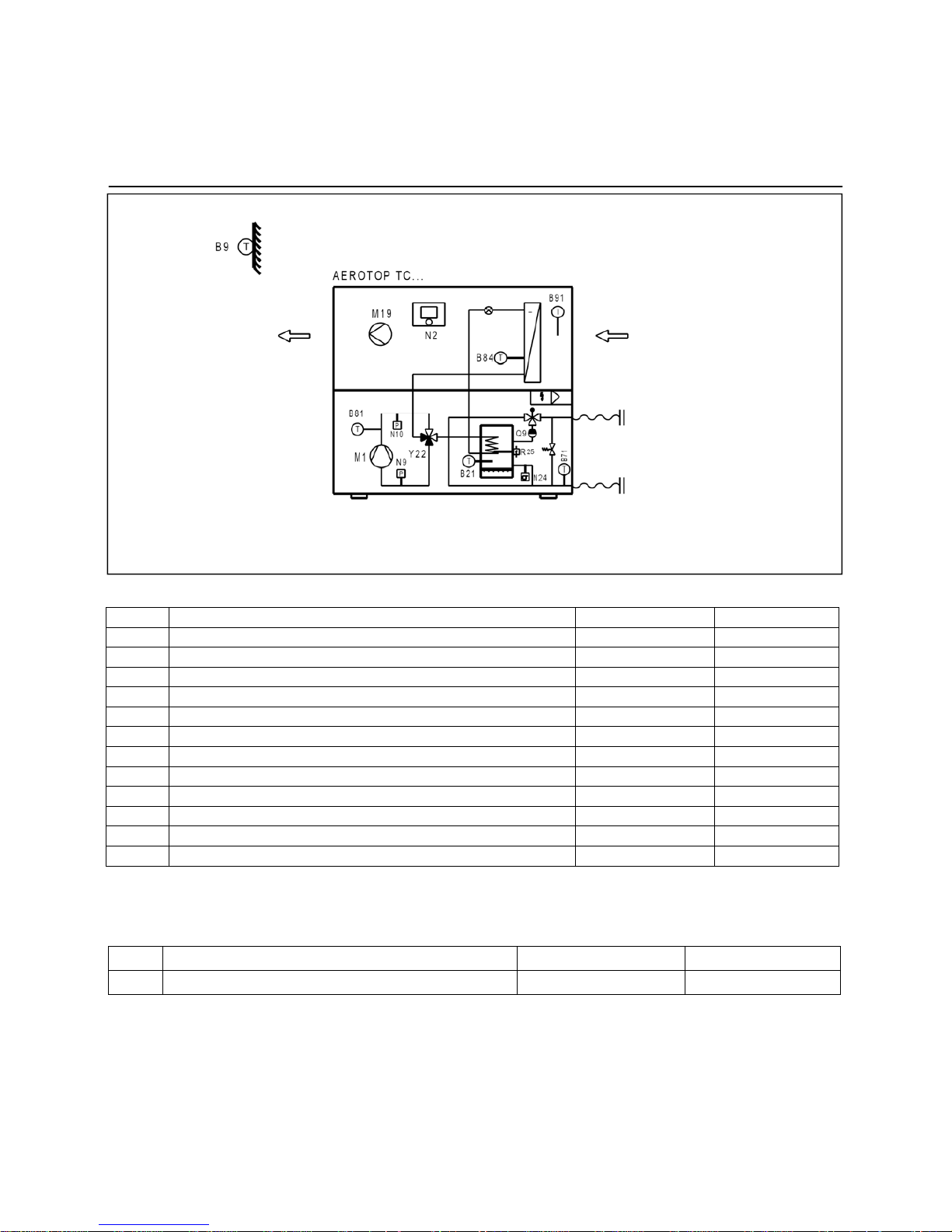

Page 10

Air in

Air out

AEROTOP T..C..

Electrical Connections

Unit Design, Terminal Assignment

Description RVS61 Slot RVS61 Output

N9

Low pressure K E9

N10

High pressure K E10

Y22

Process reversal valve Y22 W QX1

R25

Electrical heater element 1 flow W QX2

B81

Hot gas temperature sensor 1 f B81

B21

Heat pump flow temp. sensor n B21

B71

Heat pump return temp. sensor q B71

B91

Source intake temp. sensor r B91

B84

Evaporator temp. sensor s B84/B92

M19

Fan z UX

N24

Flow monitor consumer P EX3

Q9

Condenser pump V Q9

Controller terminal assignment of components wired at the factory:

Description RVS61 Slot RVS61 Output

B9

Outdoor temperature sensor k B9

Other important components to be wired in the system

Please consult the electrical diagram of the heat pump for complete terminal assignments and electrical connections.

10

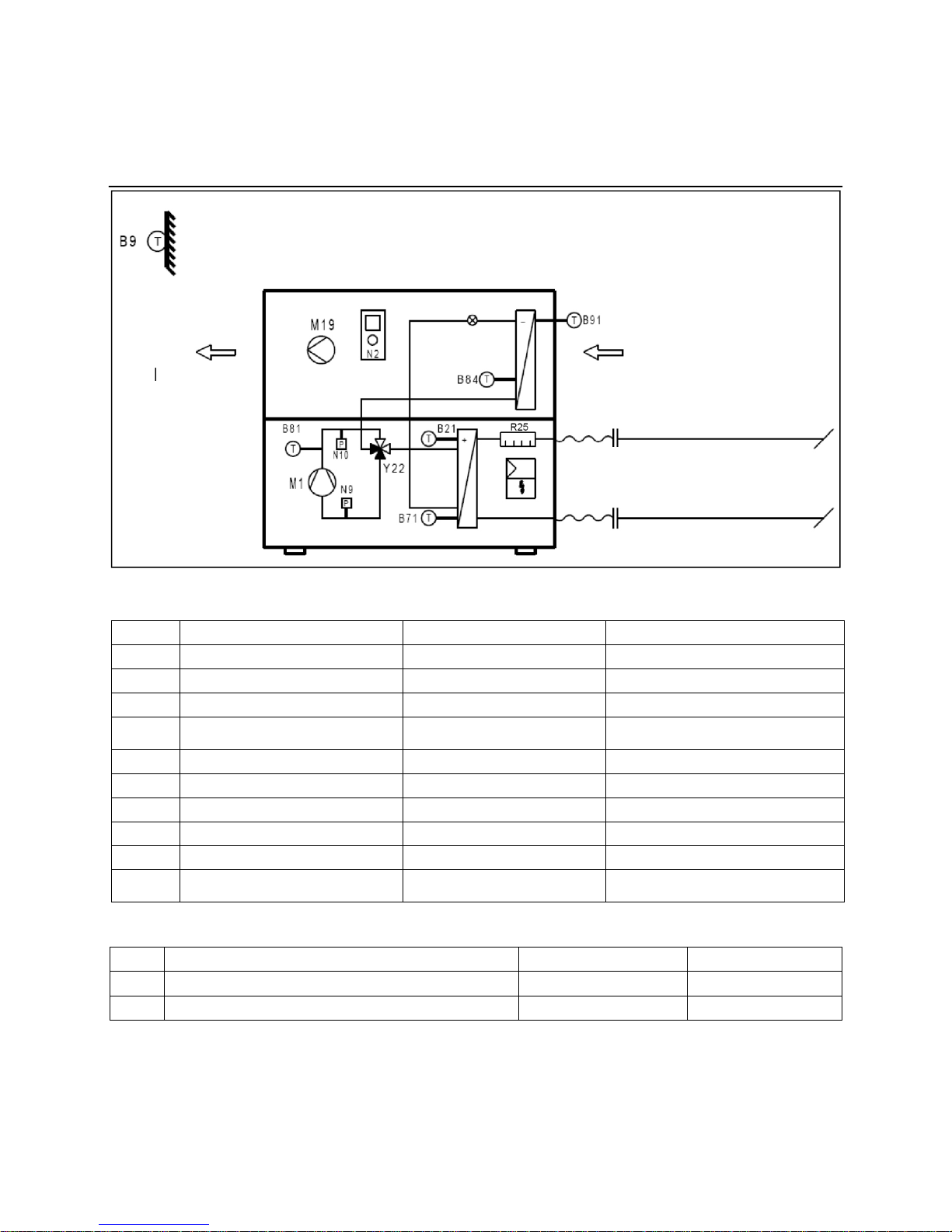

Page 11

Air in

Flow sensor

Return sensor

Air out

Electrical Connections

Unit Design, Terminal Assignment

AEROTOP T..

Description RVS61 Slot RVS61 Output

N9

Low pressure K E9

N10

High pressure K E10

Y22

Process reversal valve Y22 W QX1

R25

Electrical heater element 1 flow

(only with AEROTOP T07 to T16)

W QX2

B81

Hot gas temperature sensor 1 f B81

B21

Heat pump flow temp. sensor n B21

B71

Heat pump return temp. sensor q B71

B91

Source intake temp. sensor r B91

B84

Evaporator temp. sensor s B84/B92

M19

Fan z (AEROTOP T07-T16)

U (AEROTOP T20-T35)

UX (AEROTOP T07-T16)

Q8-K19 (AEROTOP T20-T35)

Controller terminal assignment of components wired at the factory:

Please consult the electrical diagram of the heat pump for complete terminal assignments and electrical connections.

Description RVS61 Slot RVS61 Output

Q9

Condenser pump V Q9

B9

Outdoor temperature sensor k B9

Other important components to be wired in the system

11

Page 12

Electrical Connections

Unit Design, Terminal Assignment

Air in

Air out

Flow sensor

Return sensor

Description RVS61 Slot RVS61 Output

N9

Low pressure K E9

N10

High pressure K E10

N24

Flow monitor consumer P EX3

R25

Electrical heater element 1 flow (only with AEROTOP T07 to T16) W QX1

Y22

Process reversal valve Y22 W QX2

B81

Hot gas temperature sensor 1 f B81

B21

Heat pump flow temp. sensor n B21

B71

Heat pump return temp. sensor q B71

B91

Source intake temp. sensor r B91

B84

Evaporator temp. sensor s B84/B92

B83

Liquid refrigerant sensor B83 y BX5

M19

Fan z UX

Controller terminal assignment of components wired at the factory:

Description RVS61 Slot RVS61 Output

Q9

Condenser pump V Q9

B9

Outdoor temperature sensor k B9

Other important components to be wired in the system

Please consult the electrical diagram of the heat pump for complete terminal assignments and electrical connections.

12

Page 13

13

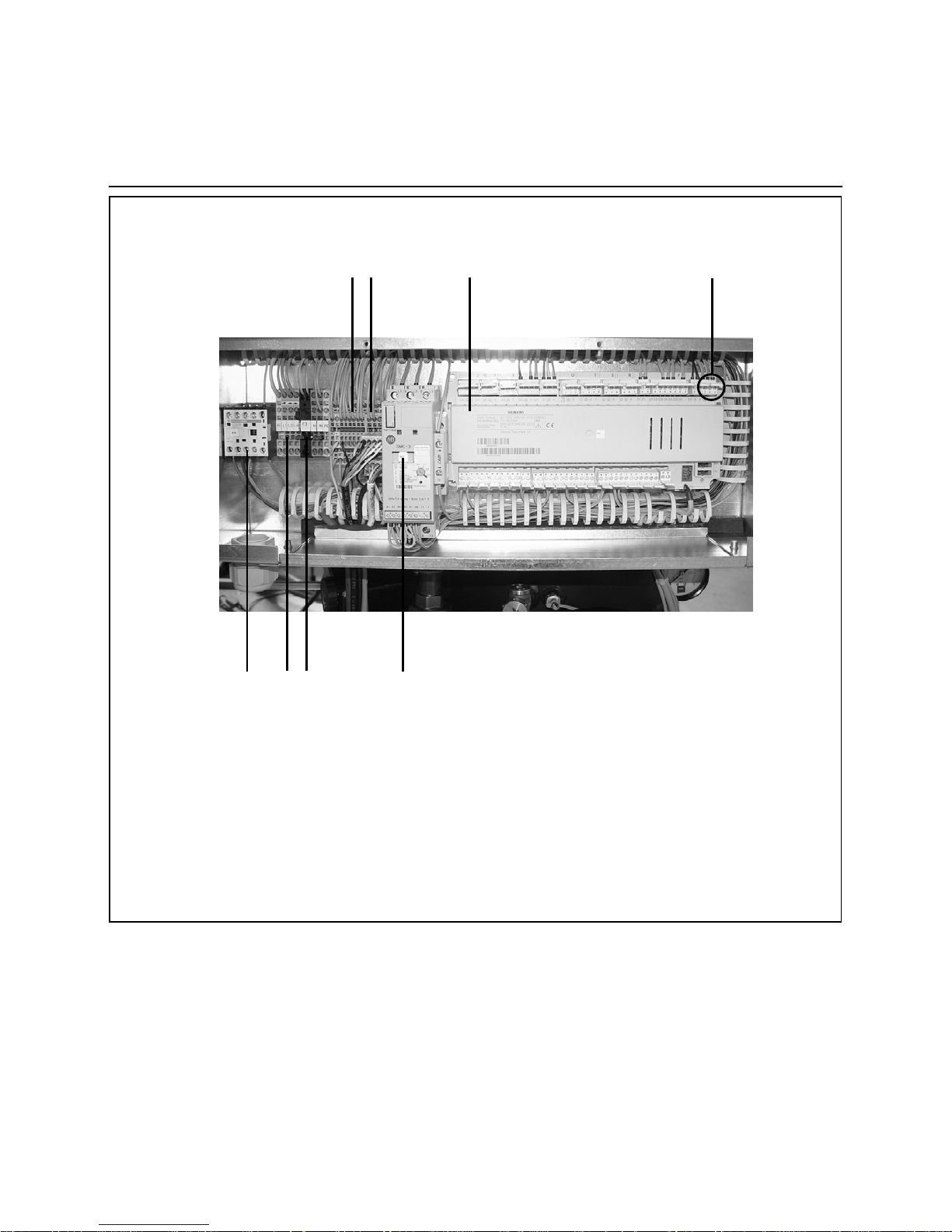

AEROTOP T..C

5 Contactor electric heating element

6 Main incoming supply 3*400V

7 Fan fuse / control fuse (F3)

8 Soft-starter and rotary current relay

Electrical Connection

Switch box

1 2 3 4

5 ....6 7 8

Legenda:

1 Terminal strip consumer, power

station blockage

2 Terminal strip Fan Contactor / oil

sump heater

3 Heat pump controller

LOGON B WP61

4 Mains supply plug:

Mains connector phase AC 230 V

Main connector neutral connector

Page 14

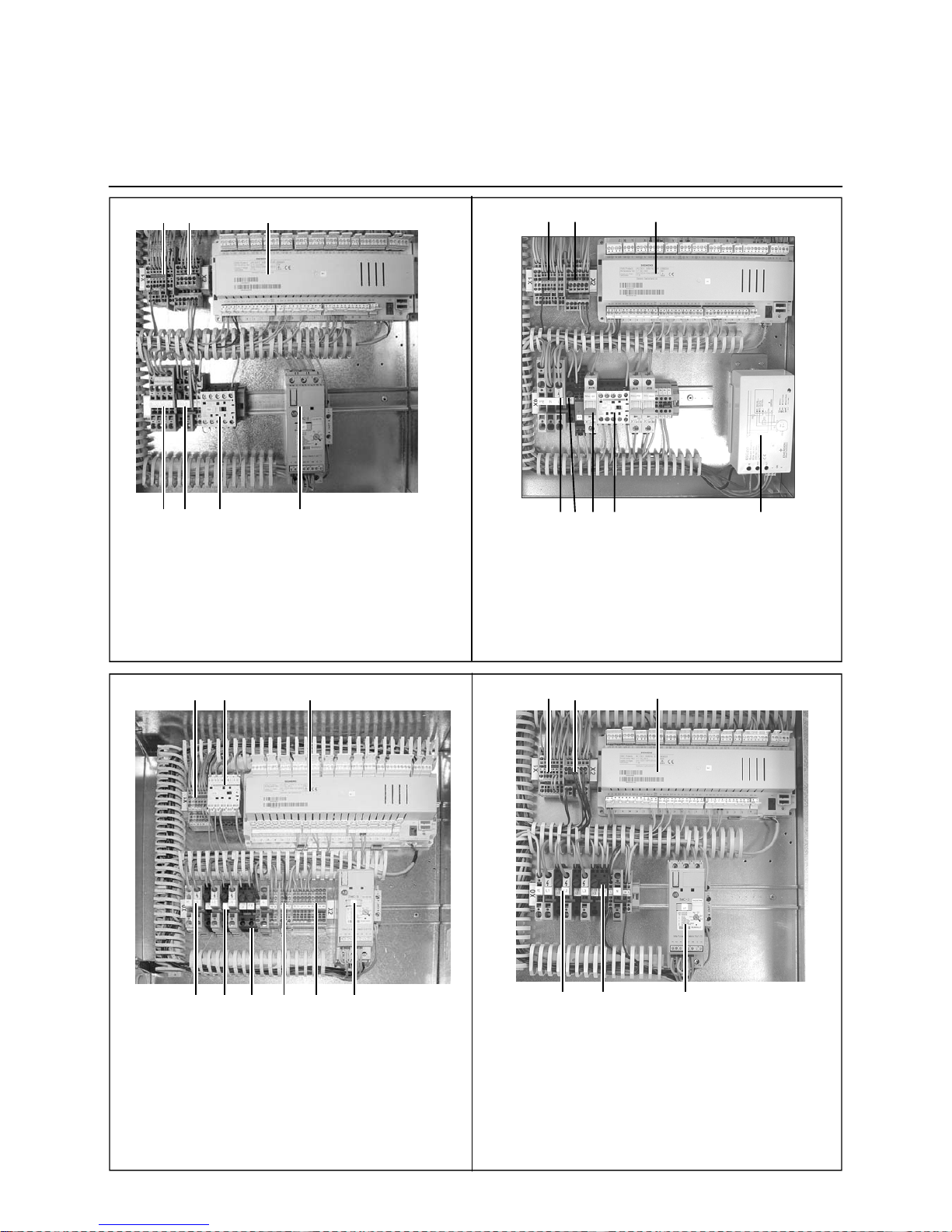

Electrical Connection

Switch box

10 7 6 3 4

11 5 9 1 2 8

AEROTOP T..CX

5 Contactor electric heating element

6 Main incoming supply 3*400V

7 Fan fuse / control fuse (F3)

8 Soft-starter and rotary current relay

9 Fan Contactor

10 Electr. heater element fuse

F6.1/F6.2/F6.3

11 Compressor fuse

Legenda:

1 Terminal strip consumer, power

station blockage

2 Terminal strip Fan Contactor / oil

sump heater

3 Heat pump controller

LOGON B WP61

4 Mains supply plug:

Mains connector phase AC 230 V

Main connector neutral connector

14

Page 15

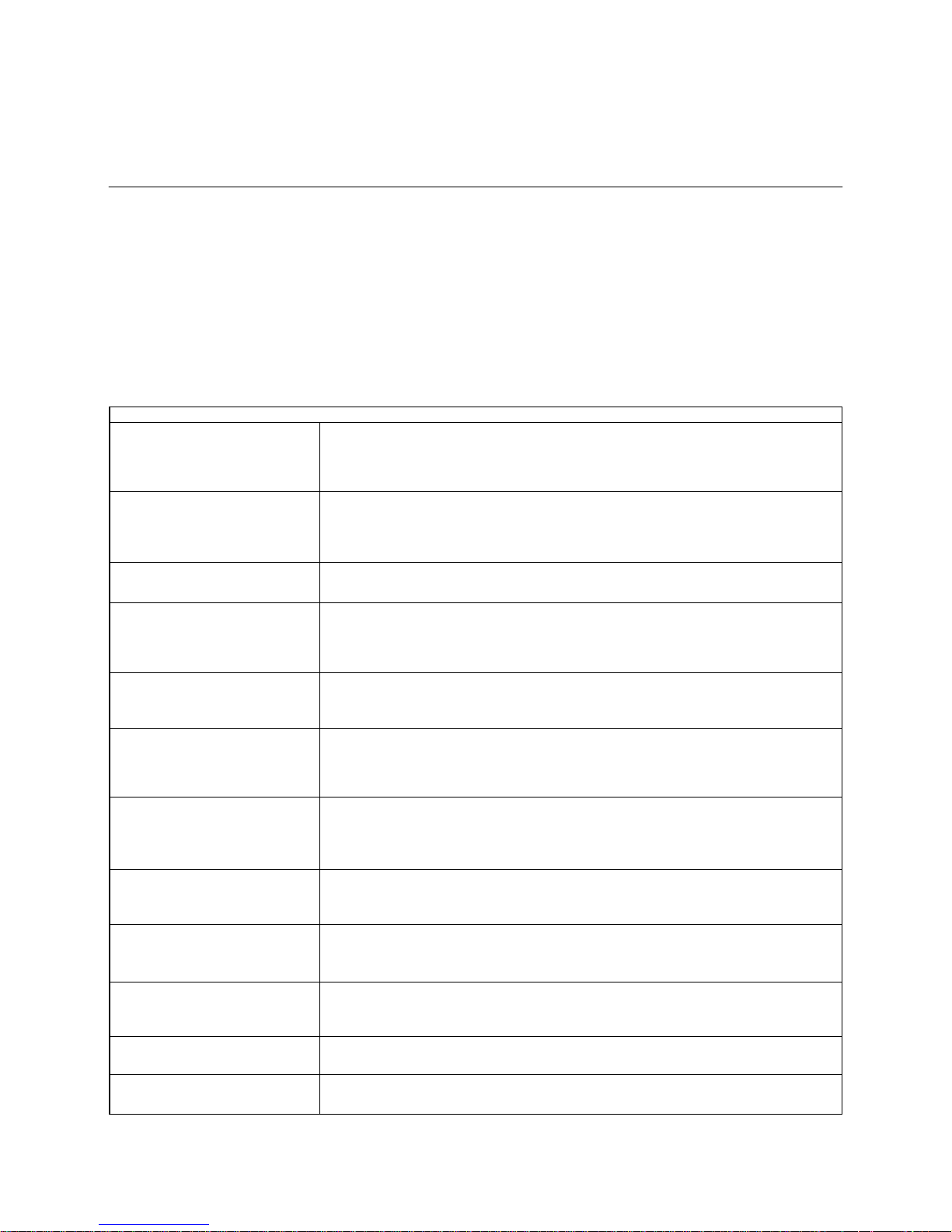

15

Electrical Connection

Switch box

Electrical Box AEROTOP T20-T35 with LOGON B WP61

1 Terminal block consumer (EC block / source flow monitor)

2 Terminal block foil sump heater

3 Terminal block Fan contactor

4 Heat pump controller RVS61

5 Main incoming supply 3*400V (L1, L2, L3)

6 Fan fuse (F19-1-2-3)

7 Control fuse (F3)

8 Soft-starter and rotary current relay

9 Fan contactor K19

Electrical Box AEROTOP T07-T16 with LOGON B WP61

1 Terminal block consumer (EC block / source flow

monitor)

2 Terminal block fuse fan / oil sump heater

3

Heat pump controller RVS61

4 Main incoming supply 3*400V

5 Fan fuse / control fuse

6 Soft-starter and rotary current relay

7 Contactor electric heating element

1 9 4

5 6 7 2 3 8

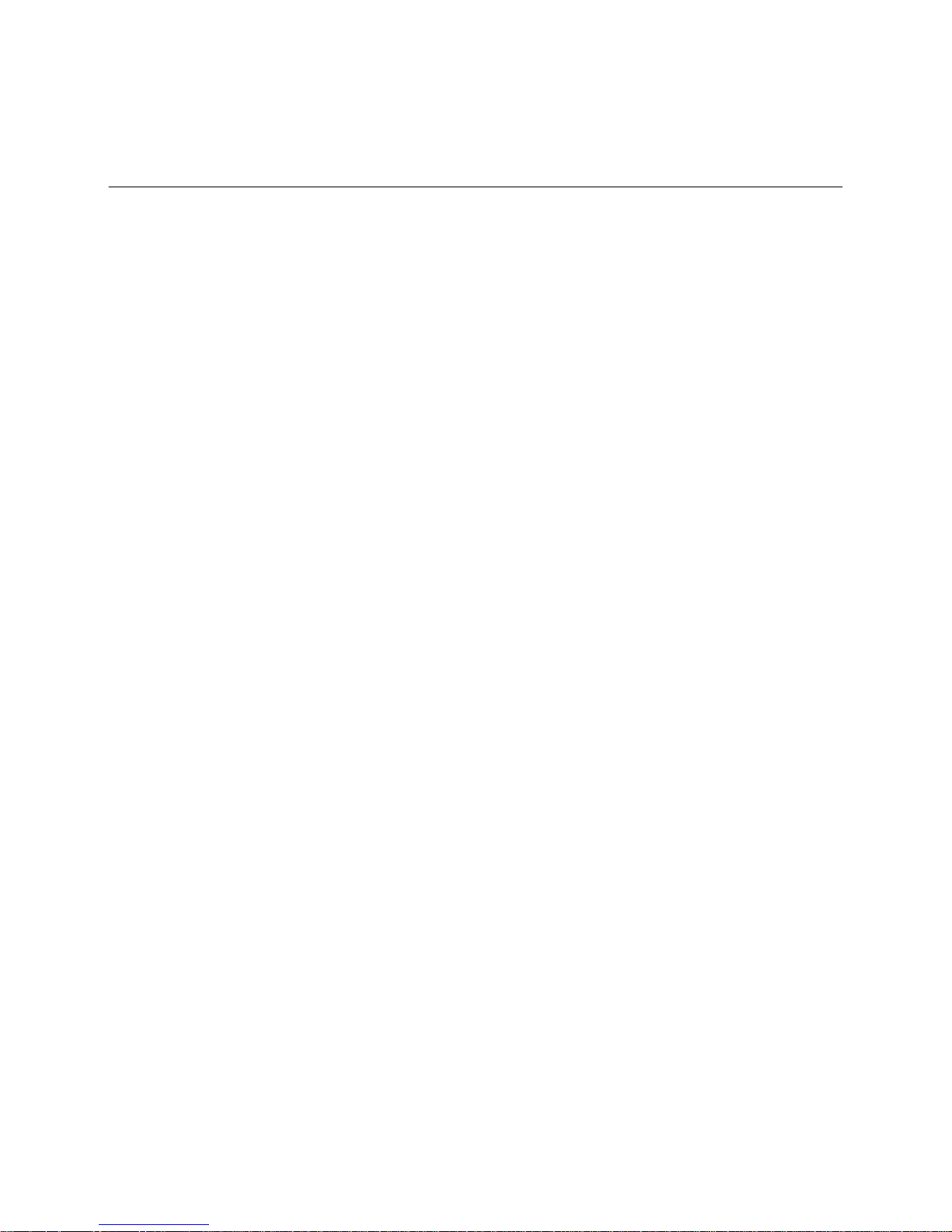

Electrical Box AEROTOP T20R-T35R with LOGON B WP61

1 Terminal block consumer (EC block / source flow

monitor)

2 Terminal block fuse fan / oil sump heater

3

Heat pump controller RVS61

4 Main incoming supply 3*400V

5 Fan fuse / control fuse

6 Soft-starter and rotary current relay

Electrical Box AEROTOP TX e TRX with LOGON B WP61

1 Terminal block consumer (EC block / source flow

monitor)

2 Terminal block fuse fan / oil sump heater

3 Heat pump controller RVS61

4 Main incoming supply 3*400V

5 Fan fuse / control fuse

6 Soft-starter and rotary current relay

7 Contactor electric heating element

8 Compressor Fuse

1 2 3

4 5 8 7 6

1 2 3

4 5 7 6

1 2 3

4 5 6

Page 16

Checklist

Correct Installation of an Air-Water Heat Pump

AEROTOP T heat pumps are quiet

and efficient. However, incorrectly

integrating constructional components

may result in undesired noise increases if the conditions are unfavorable.

A careful assessment of the noise

emissions is required when planning

the installation of heat pump systems.

Noise reduction measures considered

early on in the development process

result in the fewest additional costs.

Subsequent measures usually are

extremely expensive and cumbersome

to implement. [Heat Pump Manual,

Federal Energy Agency, Switzerland]

The following points apply to the

interior and exterior installation of

air-water heat pumps.

16

To be considered when installing an air-water heat pump

Each reflecting surface doubles

the noise (acoustic power).

One wall increases this value by

+3dB, one corner by +6dB.

one corner by +6dB.

Avoid solid-borne noise transmission by avoiding reflecting surfaces. Never route air

intake or outlet into closed or partially closed spaces such as a corner, foyer, entrance

area, covered patio, etc.

Rooms with reverberant or

sound-reflecting floor coverings

and walls increase the noise

level.

Avoid rooms with reverberant or sound-reflecting floor coverings and walls. When

installing the heat pump in a room with reverberant or sound-reflecting floor coverings

and walls, reflections may increase the sound level. Cover one or two walls with

noise-absorbing material if this is the case.

Adherence with the min.

clearances reduces noise

reflection and air short-circuits

and improves airflow near the fan.

Make sure the min. distances and clearances to the air intake and outlet as well as the

min. size of the light wells are applied. Avoid walls or flow barriers around the

circumference of the heat pump to ensure air can reach the fan evenly.

Less pressure losses = low peripheral speed = reduction of the fan noise.

Construction measures can

reduce noise, plants cannot.

Use constructional measures to interrupt the flow of noise from the heat pump

(direct noise propagation). Use solid walls, fences, palisades, etc. to reduce noise

levels. Plants, however, do not reduce noise.

Consider different noise

sensitivity levels.

Avoid placing the heat pump where it may cause problems due to its noise emission

(bedrooms, living rooms, neighbors, etc.). Position heat pumps in areas where noise is

less likely to be an annoyance. If installed indoors, do not install underneath or next to

living or sleeping quarters.

Sound absorbing materials

reduce noise.

Additional sound absorbing materials or measures must be planned for and used in

cases where extreme noise reductions are desired or when installing model Forever

GREEN 20C or later. Use only original accessories and spare parts. in extreme cases,

it may be advisable to consult a noise expert.

Separation from the structure

minimizes structure-borne

sounds.

Always use flexible connections throughout: Flexible hoses and tubes for heat

distribution, flexible electrical connections, sound isolation of the air ducts by using

elastic sleeves or Compriband products.

Correct installation of pedestal

or base reduces structure-borne

sounds.

The base or ground must be level or made level and able to support the load of the

equipment. Use the adjustable feet of the heat pump to level the equipment after

installation.

Correct installation of the ducts

reduces air and structure-borne

noise transference.

All wall openings and ducts must be equipped with the corresponding noise-absorbing

materials. Comply with the specified cross-sections and dimensions.

Avoid air short-circuits and airflow

barriers.

Air intakes and outlets cannot be installed next to each other without using a

separating wall. Avoid any airflow obstacles that favor an air short-circuit.

Always comply with all rules,

regulations, and applicable laws.

Germany: Technical Instructions on Noise

Switzerland: Noise Protection Ordinance

Be careful with dropping the

washing

Dropping the washing from lived-in rooms to the place of installation of the heat pump

can lead to noise transmission when unfavourably positioned.

Page 17

Initial Startup

Requirements, Parameterization, Upkeep

17

Requirements for Initial Startup

(Commissioning)

The initial startup of the AEROTOP T

heat pump must be carried out by our

qualified technicians or the warranty will

become void.

Operating the heat pump is prohibited if

the following conditions exist:

• Construction drying

• System/unit used in unfinished

buildings

• Windows or exterior doors

unfinished and locked.

These cases require the use of a

specific construction heating system.

Functional heating or surface-ready

heating with the heat pump acc. to

DIN EN 1264 is only permitted when

complying with these conditions.

Furthermore, it must be noted that the

design of the heat pump concerning its

standard operation may not yield the

full extent of the required heat output.

The following notes must be observed

as well: The corresponding rules and

regulations of the floor/screed manufacturer! Proper function is only ensured

with a correctly installed system

(hydraulics, electrical, settings)!

Deviations may damage the floor/screed!

Ensure the following points are implemented and checked before the initial

startup of the heat pump:

• The control box is installed and

completely connected.

• The heat pump is professionally

and completely installed (hydraulics

and electrical).

• All external system components

required for operating the heat

pump (circulation pumps, three-way

valves, sensors, etc.) are completely

and professionally connected.

• The hydraulic connections have

been established completely and

professionally.

• All sensors are professionally

installed, shielded, and positioned

in the correct locations as outlined

by the respective system scheme.

• The heating system is profes-

sionally installed and has been

flushed, charged, vented, and

checked for leaks as per rules and

regulations.

• The electrical voltage meets the

requirements listed on the type

plate of the heat pump.

• All fittings are in operational position.

The following persons must be

present to carry out the initial startup

process:

• The planer; he or she must indicate

the operational parameters.

• The installer; he or she is responsi-

ble for the functionality and settings

of the hydraulic system.

• The system maintainer (customer

or representative); he or she will

be instructed in the operation and

functions of the system.

If an initial startup is requested without

all of these conditions having been met,

ELCO rejects any responsibility for

system malfunctions or other operational problems. In this case, the

system is operated at the risk and responsibility of the owner.

Parameterization

The heat pump and the entire system is

controlled with the integrated LOGON B

WP61 controller. Please consult the

system documentation for the correct

parameter settings.

After the Initial Startup

After the initial startup is finished, the

AEROTOP T heat pump does not

require any additional interventions or

adjustments to the controller.

Any desired heating temperature

adjustments can be made in accordance with the enclosed user

manual for the LOGON B WP61

controller.

Controller Function

Different temperature sensors and

measuring elements in the heat pump,

at the exterior air, in the system, in the

storage tank, in the hot water tank, and

possibly also in the living quarters are

used by the controller.

If and as needed, the controller passes

a heat demand signal to the heat pump.

The input of a heating curve is used

to control and adjust heating temperatures. The heat pump as well as the

system is controlled automatically.

The system-relevant parameters are

entered when commissioning the

climate-based controller.

Heat Pump Upkeep

The AEROTOP T heat pump does not

require any special upkeep. However,

it is important to keep the system clean

and in good working order.

The specified leak checks must be

carried out as well. From an energetic

viewpoint, it is also recommended, especially in case of a new construction,

to have the heating parameters

checked and optimized by a service

technician during the second winter

after the initial startup since the initial

humidity has now evaporated from the

building and the required heating

output is less than initially.

Primary focus should be on keeping air

intake and outlet free of dust and other

foreign particles or objects. The air

intake and outlet openings must be

kept free of obstructions (e.g. leaves,

vehicles, debris).

Only trained and authorized service

technicians are permitted to service

AEROTOP T heat pumps.

The warranty becomes null and void if

the system or heat pump is serviced

by other persons or companies that are

not authorized to do so.

Error Messages

AEROTOP T heat pumps function

without problems as long as the different parameters do not deviate from

the intended or specified values. If one

or several of these parameters exceed

the limit values, the controller depicts

the corresponding error in plain text

and stops the heat pump if required to

protect the different components.

The different error messages are

described in the LOGON B WP61 user

manual. The heat pump is released

again with some errors (automatic

acknowledgement) once the intended

status has been reached again. It is

also usually possible to release the

heat pump manually.

In order to ensure reliable

functionality of your system, we

recommend purchasing a maintenance/service contract.

Page 18

Initial Startup

Fan Speed Setting

AEROTOP TC: Setting of the Integrated Thermal Valve

AEROTOP T A Value B Value

T35(R)

64 % 69 %

T32(R)

56 % 61 %

T26(R)

72 % 77 %

T20(R)

60 % 65 %

T16(R)

55 % 60 %

T14(R)

50 % 55 %

T12(R) / T12C

42 % 47 %

T10(X+R+RX) / T10C(X)

70 % 75 %

T07(X+R+RX) / T07C(X)

50 % 55 %

Fan Speed Settings

The fan speed of the air-water

AEROTOP T heat pumps can be

directly adjusted on the LOGON B

WP61 controller (parameter 3010).

The following table serves as a reference for setting the fan speed based

on the most important setup variants:

• A values refer to outdoor and

corner setup.

• B values refer to setups with air

duct on air intake and outlet

(KWI + KFS) or with rigid air ducts

(KSL).

Notes:

The setting must be increased by 5% if sound dampers are installed on the heat

pump. This applies usually to the AEROTOP T20 to T35 models.

Please contact the technical support if you have any additional questions.

AEROTOP TC Heat Pump:

Integrated Thermal Mixing Valve

The thermal mixing valve integrated

into the compact heat pump routes a

part of the flow water back to the buffer

storage tank only if the flow temperature is below +30°C. This means the

storage is heated immediately and the

energy depot is available for the defrosting process of the evaporator.

This upkeep function ensures a

continuous defrosting process and the

system can be operated even when

the heating system is cold.

Settings of the Integrated Thermal

Mixing Valve of the Heat Pumps

- AEROTOP T07C (manually

adjustable valve with scale):

The factory setting of this valve is set

with the scale to minimum (scale at 0)

= crank completely closed

Important: The line marking for the

adjustment is on the rear side of the

valve.

- AEROTOP T10-12C (not manually

adjustable, must use key):

The following applies to correctly adjust

the setting: Open completely and then

close with 3½ turns. Important: Set like

this at the factory.

18

Page 19

19

Indoor Installation

Corner Setup

AEROTOP T07...35 Corner Setup

If the heating or utility room has two

exterior walls, a space-saving corner

installation is ideal with the heat pump

being placed into the left or right corner.

Air ducts are not needed.

Required Accessories:

- WAI wall setup, suction side

- WAO wall setup, output side

Left corner setup

Right corner setup

1) The compliance with acoustic limit

values must be clarified by

customer.

2) Necessary outside insulation by

customer, minimal clearance of

light well must not be gone below.

3) Possible air short-circuit to be

prevented by customer.

4) Statistics to be checked by

Customer

5) Distance from wall: min 20 mm,

max 40 mm

finished floors.

• Statistics to be checked by

customer If necessary wall must be

reinforced with PUR- insulation

elements. This must be considered

for the cutouts

The indicated cutouts apply only to the

accessories AIR IN and OUTLET wall

setup. The dimensions apply after all

tasks have been completed and refer to

AEROTOP T

Width

Widt

h

Heigh

Dimensions Of Both Cutouts,

Without Insulation

Recommended Dimensions,

Light Well

a b c a2 c2 d2 e2 x a3 c3 a4 c4

T07C, T07 995 1525 650 950 600 640 860 60 1200 600 800 600

T10C, T10 1095 1575 750 1050 700 640 910 60 1200 600 1000 600

T12C, T12, T14, T16 1195 1675 750 1150 700 640 1010 60 1200 600 1000 600

T20, T26 1195 1695 880 1150 830 740 930 60 1400 800 1200 800

T32, T35 1295 1905 1000 1250 950 740 1140 60 1400 800 1200 800

• Possible air short-circuit to be

prevented by customer

• Necessary outside insulation to be

installed by customer

Page 20

Indoor Installation

Corner Setup with Noise Dampers

20

AEROTOP T20-35 Corner Setup

The dimensions of the noise dampers

must be considered in addition when

placing AEROTOP T07 to T35 heat

pumps into a corner.

The heat pump can be placed in the

right or left corner. Air ducts are not

needed.

Required Accessories:

- WAI wall setup, suction side

- WAO wall setup, output side

- SI nose damper

- SO noise damper

1) The compliance with acoustic limit

values must be clarified by

customer.

2) Necessary outside insulation by

customer, minimal clearance of

light well must not be gone below.

3) Possible air short-circuit to be

prevented by customer.

4) Statistics to be checked by

Customer

5) Distance from wall: min 20 mm,

max 40 mm

AEROTOP T

Width Width Heigh

Dimensions With

Noise Dampers

Dimensions Of Both Cutouts,

Without Insulation

Minimal Dimensions,

Light Well

a b c A C a2 c2 d2 e2 x a3 c3 a4 c4

T07C, T07 995 1525 650 1570 1225 950 600 640 860 635 1200 600 800 600

T10C, T10 1095 1575 750 1670 1325 1050 700 640 910 635 1200 600 1000 600

T12, T14,

T16

1195 1575 750 1770 1325 1150 700 640 1010 635 1200 600 1000 600

T20, T26 1195 1675 880 1770 1455 1150 830 740 930 635 1400 800 1200 800

T32, T35 1295 1695 1000 1870 1575 1250 950 740 1140 635 1400 800 1200 800

• Statistics to be checked by

customer If necessary wall must

be reinforced with PUR- insulation

elements. This must be considered

for the cutouts

The indicated cutouts apply only to the

accessories AIR IN and OUTLET wall

setup. The dimensions apply after all

tasks have been completed and refer

to finished floors.

• Possible air short-circuit to be

prevented by customer

• Necessary outside insulation to

be installed by customer

Page 21

Indoor Installation

Corner Installation

21

Installation Notes

- Insulate cutout with the self adhesive insulation elements (2).

The elements are cut to fit the

size of the cutout opening. The

width (400 mm) can be adjusted

to match the wall thickness.

Use a sharp knife to cut the

elements to size. The installation

of the cutout insulation boards is

described in detail below.

- Attaching the compression belt

(1) around the outer frame of the

enclosure at air intake and outlet.

Important: The belt must be

attached all the way around the

entire frame without any gaps.

- As indicated on pages 19 and 20,

the heat pump must push against

the wall up to a distance of 40

mm - with irregular walls the dis

tance is reduced to 20 mm, how

ever, the heat pump should in no

way touch the wall.

Make sure there are no uninsu lated wall areas within the airflow

path (thermal bridge). If this is the

case, e.g. if the cutout was in correctly done, this wall area

must be insulated separately.

- Mount air intake cover grating (3)

on exterior wall. Select either a

mesh or protective grating.

Additional noise dampers SI and

SO must be integrated for

AEROTOP T20 to T35!

The defrosting sensor must be positioned in the airflow. Never place the

sensor in between the plates of the

evaporator.

2

1

3

3

2

1

AEROTOP T20-T35 (optional for AEROTOP T16)

AEROTOP T07-T35

Page 22

Indoor Installation

Cutout Insulation Installation

22

Cutout Insulation

The cutout insulation kit is needed to

insulate the air intake and output

cutouts. The kit includes the following:

• 4 star screws

• 4 insulating boards: Length and

width dependent on heat pump

size

• 1 bottle of assembly foam adhesive

to attach insulating boards (only

included in air intake kit)

How to Install the Cutout Insulation

• Prepare insulating board

• Apply adhesive foam onto outside

(wall side) of insulating board.

The wall side is the side where the

leg of the metal section is shorter.

Installation in the Cutout

Take note of the correct placement

of the cutout parts!

Press insulating boards against cutout

walls as indicated in illustration.

Fig. (A): The front side remains free,

i.e. no sheet metal in this side.

Fig. (B): Setup insulating boards.

The sheet metal is attached to the

rear side.

Fig. A

Fig. B

Protective grating Heat pump

Page 23

Indoor Installation

Cutout Insulation Installation

1

Fastening with Star Screws

Use the star screws to additionally fix

the insulation boards in place.

One star screw per insulation element.

Steps

• Align in center of cutout insulation

• Drill hole diameter is 8.5 Ø.

• Wall opening is 4 cm.

• Screw in star screws.

Installation of Mesh or Protective

Grating

The protective grating is installed at

the rear at the sheet metal frame of the

insulation using sheet metal screws.

Finished Installation with Cutout

Insulation and Mesh

23

Page 24

Indoor Installation

Parallel Setup with Rigid Duct

24

Required Accessories:

• AIR IN wall setup kit

• AIR OUT parallel installation with

rigid duct.

All dimensions refer to a

finished floor and completed

walls/masonry.

Light well dimension

a3 a4 c3 c4

T07C, T07 1200 800 600 600

T10C, T10 1200 1000 600 600

T12C, T12, T14, T16 1200 1000 600 600

AEROTOP T

Rigid Duct

Dimension

Cutouts without Insulation

Distance between

Cutouts

Partition Wall

e1 c1 a2 c2 d2 e2

k1 without

partition

wall

k1 with

partition

wall

Height k2 Width k3

T07C, T07 800 520 950 600 640 860 1500 630 1500 1000

T10C, T10 850 620 1050 700 640 910 1500 630 1500 1000

T12C, T12, T14, T16 950 620 1150 700 640 1010 1800 630 1700 1200

Light well

Light well

1) The compliance with acoustic

limit values must be clarified by

customer.

2) Necessary outside insulation by

customer, minimal clearance of

light well must not be gone below.

• Attach flex sleeve (A) to inside

frame of unit.

• Attach sealing tape to sheet metal

duct on the side that is attached

to the sleeve.

• Insert the sheet metal duct into

the cutout. The sheet metal duct

may not touch the wall in the cutout

at any side. This can be achieved

by placing a piece of insulation into

the center of the cutout.

• Use the enclosed screws to affix

sheet metal duct to the sleeve.

Attach the section clips (included

in installation kit) along all sides

between sheet metal duct and

sleeve. This ensures a tight

connection.

• Use insulating foam in between

the gaps of the cutout and the

sheet metal duct from the outside

of the cutout. An opening in the

sheet metal duct makes it possible

to insert the nozzle of the spray

can. Completely fill the area

between duct and cutout with foam.

• Mount air intake cover grating

on exterior wall. Select either a

mesh, protective grating, or a

sound-dampening protective

3) Possible air short-circuit to be

prevented by customer; for the

short duct (KSK) it is necessary

to apply a partition wall.

5) Noise level of AIR OUT and AIR IN

must be considered separately

Page 25

25

Indoor Installation

Parallel Setup with Rigid Duct (with Noise Damper)

Required Accessories:

• AIR IN wall setup kit

• AIR OUT parallel setup with rigid

Duct

• SI Noise damper

• SO Noise Damper

1) The compliance with acoustic

limit values must be clarified by

customer.

2) Necessary outside insulation by

customer, minimal clearance of

light well must not be gone below.

3) Possible air short-circuit to be

prevented by customer; for the

short duct (KSK) it is necessary

to apply a partition wall.

5) Noise level of AIR OUT and AIR IN

must be considered separately

AEROTOP T

Rigid Duct

Dimension

Cutouts without Insulation

Distance between

Cutouts

Partition Wall

e1 c1 f1 a2 c2 d2 e2

k1 without

partition

wall

k1 with

partition

wall

Height

k2

Width

k3

T07C, T07 800 520 575 950 600 640 860 1500 630 1500 1000

T10C, T10 850 620 575 1050 700 640 910 1500 630 1500 1000

T12C, T12, T14, T16 950 620 575 1150 700 640 1010 1800 630 1700 1200

T20, T26 870 750 575 1150 830 740 930 2000 630 1700 1200

T32, T35 1080 870 575 1250 950 740 1140 2200 630 1700 1500

Light well

Light well

Light well dimension

a3 a4 c3 c4

T07C, T07 1200 800 600 600

T10C, T10 1200 1000 600 600

T12C, T12, T14, T16 1200 1000 600 600

T20, T26 1400 1200 800 800

T32, T35 1400 1200 800 800

Page 26

Indoor Installation

General Duct Installation Information

26

The cause for condensate formation is

due to the interplay between the room

air temperature and the room's humidity

level. These two components may

result in the formation of condensate.

The following factors promote the formation of condensate:

• High building moisture during first

year of operation

• Low room temperatures in installa-

tion location

• Some laundry rooms/bathrooms

nearby or even integrated

• Little ventilation in installation

location

Condensate always collects at the

coldest spots in a room. In our case,

this is the outgoing air side of the duct.

Measures to minimize the problem:

Avoid Thermal Bridges

No contact between masonry/walls and

airflow or air duct incl. cover plate

Correctly Establishing the Opening

for the Air Duct through the Wall

(Prevent cooling of wall.) The duct must

be pulled through the exterior wall at

least beyond the exterior insulation.

The wall opening (or gap between wall

and air duct) must be filled or sealed

with foam (e.g. PU foam) or insulation

(Sagex/Armaflex).

Air Duct Insulation

The air duct must be insulated

throughout (min. thickness of 25 mm).

The flexible canvas sleeve (prevents

noise transference) must also be

insulated.

Duct System

Sealing tape must be used between

the individual connectors of the air

ducts. (Included in installation kit.)

Use section clips to seal the frame

connections as well. (Included in installation kit.)

Correct Incorrect

Thermal bridges

Join cutout insulation tightly in corners

(for wall installation without ducts).

Page 27

Indoor Installation

Flexible Intake

27

• Insulate cutout with the insulation

elements (1).

• Attach intake box (2) to heat pump.

To avoid thermal bridges, use the

enclosed sealing tape to seal the

space between bracket, intake box,

and enclosure frame.

• Attach oval duct plate (3) to intake

box.

• Attach round duct plate (4) to wall.

The plate must be centered over

the cutout.

• Attach duct (5) to duct plates.

Adjust duct length if needed. Use

a wire cutter to shorten the duct.

• Fasten duct to the connection

plates with the enclosed cable clips

(5). The duct must be fastened

tightly to avoid leaks.

• Mount air intake cover grating (6)

on exterior wall. Select either a

mesh or protective grating.

4

3

1

2

5

6

GMO

G

W

O

Page 28

Indoor Installation

Flexible Air Outlet

28

• Insulate cutout with the insulation

elements (1).

• Attach air outlet panel (2) to heat

pump.

• The can be done on the left, right,

or the top of the heat pump as

needed.

• Make sure the opening of the

sheet metal is attached to the side

of the fan so that the airflow is not

blocked.

• Attach oval duct plate (3) to air

outlet panel.

• Attach round duct plate (4) to wall.

The plate must be centered over

the cutout.

• Attach duct (5) to duct plates.

Adjust duct length if needed.

Use a wire cutter to shorten the

duct.

• Fasten duct to the connection

plates with the enclosed cable clips

(5). The duct must be fastened

tightly to avoid leaks

• Mount air intake cover grating (6)

on exterior wall. Select either a

mesh or protective grating.

6

1

3, 2 5

4

GMO

G

W

O

Page 29

Indoor Installation

Controller Unit Installation

29

The controller unit is to be snapped

into the provided opening of the

controller panel. Then connect the

ready-to-use cable to the controller unit.

The controller panel with integrated

control unit is pressed into the slot

opening (1) at the heat pump enclosure. Finally, snap the Plexiglas cover

(2) into the provided tabs (3) at the

bottom side of the panel.

1

1

3 3

2

Page 30

Outdoor Installation

Special Conditions, Installation Location

30

Special Rules for Outdoor Installations

Please observe the general setup, installation, and connection instructions.

Place the heat pump on a level and

solid surface with the necessary bearing

capacity. If not available, provide a

cement base, acc. to the snow height,

so that the feet of the outdoor unit

cannot be covered with snow. The heat

pump must be aligned with the adjustable feet.

Heater flow and return must be as short

as possible and well insulated to prevent

heat losses. The condensate drain must

be insulated and protected from frost

and have a siphon with a min. height of

100 mm routed into a closed drain.

The drain line must not have any crosssection reductions and must be sufficiently suitable to ensure problem-free

drainage.

The controller unit must be installed

inside of the building (temperature range

of +5°C to +40°C). The wall openings

for heater flow and return as well as the

electrical cables must be carried out

according to the rules and regulations.

Especially the flexible electrical cables

as well as the low voltage (230 or 400V)

and the extra-low voltage (sensor and

controller cable) must be shielded from

one another.

Selecting the Installation Site

Air intake and outlet must be kept

clean, unobstructed, and free of snow,

leaves, plants, machinery, etc. Comply

with min. clearances as specified for

air intake, outlet, misc. ducts, and

maintenance (see previous page).

Avoid an air short-circuit at all costs.

Use both sides for the air outlet if

strong winds, for example, may cause

an air short-circuit. The air intake must

be protected from aggressive or corrosive substances such as ammonia,

chlorinated substances, etc.

The AEROTOP T heat pump is very

quiet. However, since noise is perceived differently by different people,

the heat pump should not be installed

near windows, sleeping or living

quarters (porch, edge of pool, etc.).

The distance to neighboring houses

should be sufficient as well. It is not

advised to install the heat pump in

recesses (possible echo or air short-circuit). Local rules and regulations

apply.

Observe the checklist notes when

selecting the installation site for the

correct setup of an air-water heat

pump.

1 EC block 2-pin Ø 5 mm

1 x malfunction 2-pin Ø 5 mm

1 x controller unit 3-pin Ø 7 mm

1 x room sensor 2-pin Ø 5 mm

7 x sensor 2-pin Ø 35 mm

= Ø 57 mm

(conduit min. 70 mm)

1 x electr. feed 3 x 400 V 3-pin Ø 12 mm

= Ø 57 mm

(conduit min. 70 mm)

1 x condenser pump 3-pin Ø 7 mm

1 x heating circuit pump 3-pin Ø 7 mm

1 x mixing valve 3-pin Ø 7 mm

1 x storage charge pump 3-pin Ø 7 mm

1 x heating circuit pump 3-pin Ø 7 mm

1 x mixing valve 4-pin Ø 10 mm

Heating Circuit 2

Information about Cables in Conduits (Min. Ø 70 mm)

1

7

1

3

2

7

a

b

1 Heater flow

Hydraulic and electrical connections

are at the bottom side of the heat

pump.

2 Heater return

3 Condensate drain Ø 25/31 mm

4 Air intake

5 Air outlet

6 Internal electrical panel

7 Hydraulic and electrical connections,

electr. low voltage cable shielded

from 380V and 230V

8 Adjustable, noise-dampened feet

9 Protective cover

10 Base or pedestal, recommended height

of 200 mm, consider local snow

levels.

12 Wall opening slanted towards inside

with seal (in PE, inner diameter of 300

mm)

13 Controller unit for wall mounting

(included in delivery)

.

12

Ø 300mm

13

Page 31

31

Outdoor Installation

Base/Pedestal Plan

Cutouts in Base/Pedestal for

AEROTOP T07-T35

The base or pedestal should project

beyond each side of the heat pump for

about 50 mm and be approx. 300 mm

high (adjust to local snow conditions

as needed). A conduit (NW 250) must

be installed between building and heat

pump for the installation lines (electrical,

hydraulic, and condensate).

Setup Base/Pedestal

AEROTOP T a1 c1 h1

T07

1095 750 300

T10

1195 850 300

T12, T14, T16

1295 850 300

T20, T26

1295 980 300

T32, T35

1395 1100 300

Min. 800mm

min. 500 mm

c1

a1

242 mm

242 mm

min. 50 mm

Ø 175

Min. 800mm

min. 500

AEROTO T07-T16

AEROTO T20 - T35

Ø 175 mm

Page 32

Installation

Duct and Cable Bushing

32

Please take note of the base/pedestal

plan with the required cutout.

The prepunched cover can be lifted

with a screwdriver or detached with

sheet metal nippers.

Prepunched Opening for Outdoor

Installation of an Air-Water Heat

Pump

A prepunched opening (1) for the lines

routed from the rear of the enclosure

into the ground is provided in the unit

bottom behind the electrical panel.

We recommend routing the lines this

way for the heat pump installed

outdoors. This involves pulling the

heating lines, condensate connection,

and the electrical cables through the

opening.

1

Water-proof conduit (plastic pipe)

installed 800 to 1000 mm on-site underground with 2% tilt towards building.

Use only 45° elbows.

Upper edge of ground

to upper edge of base

min. 30 cm

Upper edge of base to

upper edge of conduit

min. 3 cm

Push conduit

against HP insulation

to protect from insects

Condensate drain also possible

via seepage pit.

Drain pipe insulation min. 3 cm

Seepage pit size min.

H = 50 cm

W = 50 cm

D = 50 cm

Page 33

Installation

Controller Unit

1

1

4

5

3

2

Control unit (3), switch panel (1),

control unit bracket and Plexiglas unit

cover (2) are supplied with Heat

pump in the case of outdoor installation.

33

The control unit must be mounthed on a internal wall

of the building

Page 34

Troubleshooting/Fault Remedy

AEROTOPT LOGON B WP61 Troubleshooting/Fault Remedy

34

Problem Cause Remedy, Action

107: Hot gas compressor Hot gas temperature (B81) too high

A Not enough coolant

B Compressor leak

C Filter dryer dirty

D Defective non-return valve

E 4-way valve leaking

F Injection valve not working

A Top off coolant

B Replace compressor

C Check the difference in temperature between the filter

drier inlet and outlet (∆T max = 3)

D Temperature at the compressor inlet and outlet is

practically identical. Sounds could be heard at the

non-return valve.

E Check the temperature difference between the 4-way

valve input inlet and outlet (∆T max=5K)

F Check injection valve, check position of capillary sensor

The refrigerant technician must be called in such cases.

146: Sensor control

element configure tion

A The connected sensors are not suitable

for the given function of the programmable

inputs/outputs.

A Check sensor assignment

A1 Check programmed function at Qx outputs

A2 Check system configuration by means of control numbers

204: Fan overload Affects E14 (EX4).

A Parameter set incorrectly on LOGON B WP

B Fan is defective

A Check the setting of the parameter 5700 (should

correspond with the diagram number of an air-water

HP, >= 20)

B Check the input voltage on terminal E14 (rest contact)

B1 For load shedding check electric wiring.

Check connections

B2 Replace fan

222: High pressure

during HP operation

Affects contact E10 at the LOGON B WP61.

High-pressure problem during operation of heat

pump. High-pressure pressure controller

triggered in cooling circuit. No heat can be

emitted.

A In heating mode

A1 Insufficient flow rate

A2 Valve closed, non-return valves don’t close

A3 Heating or potable water circulation pump

not running

A4 Overflow valve missing or set incorrectly

A5 Heating curve set too steep

The module switches the particular unit to the

safety mode when a malfunction or error occurs.

A1 Check hot water flow (∆T =5-10 K)

A2 Open slide valve. Check non-return valves and 3-way

switching valves

A3 Check whether pump is working, restore function, replace

pump if necessary

A4 Install overflow valve, repeat setting procedure

A5 Set heating curve lower

B If A can be precluded, the amount of coolant could be

too high.

The refrigerant technician must be called in this case.

223: HP when starting

HC

Affects contact E10 at the LOGON B WP61.

High-pressure problem when the heat pump is

started.

A Water in system is too cold (below 10°C).

For compact HP:

B Upkeep valve does not open

(is set to 30°C, DO NOT ADJUST).

A Below 10 °C: Raise temperature in system with electric

heating element.

B Vent system at buffer storage.

224: HP when starting

potable water

heating

Affects contact E10 at the LOGON B WP.

High pressure problem when starting potable

water mode.

A Potable water charging pump not running

B Three-way valve opens too slowly or not at

all

C Water volume too low

D Air in the system

E Slide valve closed

F Heat exchanger surface in storage too

small or heat pump too large

G Sensor positioned incorrectly/too low in

storage

A Unblock or replace pump

B Check three-way valve, replace if needed. Extend flow

time of condenser pump (Parameter 2802)

C Check temperature difference between flow and

return (∆T =approx. 5-8 K)

D Vent system

E Open slide valve, check non-return valve

F Heat exchange area (in m

2

) = heating output HP at 20°C

air and 50°C water x 0.3. E.g. 10 kW x 0.3= 3.0 m

2

.

HP output, consult technical data for corresponding

source temperature.

G Install sensor correctly. Check position of potable

water sensor

Page 35

Troubleshooting/Fault Remedy

AEROTOPT LOGON B WP61 Troubleshooting/Fault Remedy

35

Problem Cause Remedy, Action

225: Low pressure

problem

Low pressure problem

Affects contact E9 at the LOGON B WP61.

Low pressure switch in the cooling circuit

triggered.

A Insufficient flow of air through evaporator

A1 Ice formation

A2 Evaporator dirty

A3 Duct dirty/plugged

A4 Protective grating dirty

A5 Protective grating iced

A6 Fan not running or not running enough

A7 Pressure loss in ducts too great

B Plugged filter

C Injection valve defective, frozen or clogged

D Incorrect amount of coolant

E Leak in cooling circuit

A1 Check thawing function (check sensor)

A2 Clean evaporator

A3 Clean duct dirty/remove obstacles from opening

A4 Clean grating

A5 Check size of mesh (use only one grating)

A6 Check speed, adjust, check voltage

A7 Check length of ducts

If everything in A can be excluded:

B Measure temperature difference between filter dryer input

and output (∆T max 3 K)

C Check, set or replace injection valve

D Empty and refill in accordance with type plate

E Oil residue in the unit is another indication of a leak in

the cooling circuit.

The refrigerant technician must be called in such cases.

226: Winding protection

compressor

Affects contact E11 at the LOGON B WP61.

A Phase interruption (compressor gets hot)

B Phase reverse (incorrect rotary field)

C Phase loss

D Phase asymmetry

E Short circuit

A Check all three phases (wait until the winding protection

has cooled, can take several hours).

B Check electrical connection.

C Check whether oil sump heater is working.

D Make sure the rotation is right.

E Eliminate short circuit

247: Thawing problem After the fourth thawing attempt, the evaporator

sensor on the cooling circuit (B84) still has not

reached the evaporator temperature

(Para. 2954) set at the LOGON B WP61.

A Sensor B91 positioned incorrectly

B Sensor B84 defective/no longer in the

required position

C Not enough energy for thawing

(water temperature in heating circuit too low)

D Flow rate to the condenser too low

A Position sensor properly, replace sensor if defective

B Check sensor position. Check function (measure actual

temperature in all injection pipes and compare with

B84 value)

C Switch on electric heating element until the minimum

water temperature is reached. Close part of heating circuit.

D Check pumps for functions, check return and switch valves

358: Soft starter Softstarter problem

Actions in relation to the LOGON B WP61’s E25

(EX5) contact.

356:

Flow monitor

consumer

Flow monitor consumer

Affects contact N24 at the LOGON B WP61.

Page 36

Troubleshooting/Fault Remedy

AEROTOPT LOGON B WP61 Troubleshooting/Fault Remedy

Problem Cause Remedy, Action

Pre-heating for thawing Following a pre-maturely interrupted thawing

attempt (see “maximum thawing time”), the hot

water is pre-heated during “disabled thawing” (message on the control unit “pre-heating for

thawing”). If there is an electric heating element

in the flow line or in the buffer/combination storage, it will be switched on for support. Afterwards, thawing mode will be switched to automatically.

Check the electric heating element connection

Electric heating element should be configured in the programming menu

Heat pump disabled Info about Parameter 8006 status HP

1. Disabled, outdoor temperature

2. Disabled, external

External disablement on the part of the

power supply company / of the electric

utility company. Input voltage E6 has

dropped.

3. Disabled, eco-mode

1. Outdoor temperature too low

2. Utility/power station blockage

No problem, HP continues to run when the disablement is

over. Check the functioning of the phase monitoring relay:

The green LED on the phase monitoring relay must be