elco AEROTOP G Installation, Operation And Maintenance Manual

Installation, operation and maintenance

manual

AEROTOP G Air-Water Heat Pump

for installation outdoors

06/2015 Art. No. 420010405804

Table of Contents

TABLE OF CONTENTS………………………….………………………………………………………….............................. 2

GENERAL INFOMATION…………………...................................................................................................................... 3

Safety wornings………………………………………............................................................................................ 4

Legal guidelines, warranty conditions, checks on delivery................................................................................ 6

Product Overview………………………………………………………………………………………………...…….. 7

Equipment……….………………………………………………………………………………………………...…….. 8

TECHNICAL DATA…………………………………………………………………………………………………………….….. 9

AEROTOP G07-10, G12, G07-14M………....................................................................................................... 9

AEROTOP G07(X)-10(X)……………................................................................................................................ 12

Performance chart AEROTOP G07(X)………................................................................................................... 15

Performance chart AEROTOP G10(X)………................................................................................................... 16

Performance chart AEROTOP G12………………………………………….…..……........................................... 17

Performance chart AEROTOP G07-14M (Nominal Capacity)…………………………………………….............. 18

Performance chart AEROTOP G07-14M (Maximum Capacity)…………………………………………............... 19

Operational limits …………………..................................................................................................................... 20

Device dimensions ……………………………………………………………………………………………............. 21

Delivery pressure circulating pump YONOS PARA RS 25/7.5……………………………………...…................. 22

Delivery pressure circulating pump STRATOS PARA 25/1-9........................................................................... 23

INSTALLATION………………………………………………………………………………………………………………..….. 24

Transportation, General installation notes………………………………………………………………………..….. 24

Pedestal………………………………………………………………………………………………………..………… 25

Pipeline, Condensate drain pipe……………………………………………………………………………….……… 26

Checklist for correct set-up…………………………………………………………………………………..………… 27

Delivery to installation site................................................................................................................................. 28

Hydraulic connections....................................................................................................................................... 30

Hydraulic connections, assembly instructions................................................................................................... 31

Notes……………………………………………………………………………………………………………….…….. 32

Electrical Connection ……………………………………….………………………………………………………….. 34

Instruction for the installation of control unit…………………………………………………………………...…….. 35

Electrical panel AEROTOP G………………………………………………………………………………….……… 37

Electrical panel AEROTOP G..X………………………………………………………………………………..…….. 38

Electrical panel AEROTOP G07-14M………………………………………………………………………….……… 39

Cabled components AEROTO G..(X)……………………………………………………………………………….... 40

Cabled components AEROTO G07-14M……………………………………………………………………….…….. 41

COMMISSIONING………………………………………………………………………………………………………...……… 42

Requirements and parameterization…………………………………………..……………………………...……… 42

Washing and filling, Water quality……………................................................................................................... 43

Checklist............................................................................................................................................................ 44

Sensor characteristic curves…………………………………………………………............................................... 46

MAINTENANCE……………………………………………………………………………………………………………..……. 49

General, cleaning.............................................................................................................................................. 49

Troubleshooting................................................................................................................................................. 50

PRODUCT FICHES ERP…………………………………………………………………………………………………….…. 53

PRODUCTS INFORMATION ERP ……………………………………………………………………………………….……. 54

CONFORMITY DECLARATION..................................................................................................................................... 56

NOTES………………………………………….................................................................................................................. 57

General notes.................................................................................................................................................... 3

2

General information

General notes

•

All calculations, sizing, installations

and commissioning linked to the

products described in this document can be carried out only by

qualified experts.

•

Please comply with local legal instructions, which may differ from

the directions given in this document.

•

Reserving the right to make

amendments.

Low energy consumption

The decision of opting for heat pump

heating is a significant contribution to

the protection of the environment

through the reduction of emissions

and the reduced use of primary energy.

In order for your new heating system

to function efficiently, please observe

the following:

The heat pump system must

be sized and installed with

great care.

Avoid excessively high inlet

temperatures. The lower the

inlet temperature on the heating water side, the more efficient the heat pump's operation.

Please comply with the correct setting up of the regulator, which must match the

heating system installed.

Preference should be given

to intense and short airing of

rooms, as opposed to always

open windows in the tilted

position; quick and immediate

airing reduces energy consumption.

3

General information

Safety warnings

Legend

The following general safety notes

are used in these operating instructions:

Please observe notes about

the function and mode of

operation.

Please do not fail to observe

the safety information.

Reference to the operating

instructions LOGON B WP61

controller

It is essential to read the instructions

carefully before installing the heat

pump. This is for your own safety and

that of others.

Keep this manual and keep it available .

For any questions related to the safety or if the assembly instructions are

not clear , please contact your local

sales office ELCO

Keep the work area clean and free of

obstructions

Ensure appropriate lighting of your

workplace .

Unauthorized persons , children and

pets should be kept away from work

areas .

Keep antifreeze or heat transfer fluid

away from children and pets .

Do not insert objects through the air

grate devices .

Use only suitable components for

system ELCO.

In general , use only original spare

parts Elco . Check that materials and

components, before being used, comply with the laws, regulations , directives and national regulations .

Do not make unauthorized changes .

This can cause danger to personal

safety and damage to the plant . If

damage is evident that the machine

can not be operated

Personnel Requirements

Positioning, installation, connection

and commissioning of the heat pump

must be carried out by a specialised

expert in compliance with national

appliance regulations and with the

instructions for use.

Any work on the cooling circuit can

only be carried out by skilled personnel trained and experienced in the

risks linked to the use of coolants.

Observe the national standards for

the use of F-Gas , as well as EU directives CE 303/2008 and CE

842/200.

Workwear

Wear protective clothing, safety glasses , safety shoes and helmet dring

assembly works .

Use clothes that can not get caught in

moving parts. The same applies to

accessories, such as chains .

If your eyes come in contact with Refrigerant fluid , rinse eyes thoroughly

with running water and go immediately to a doctor.

Before opening the appliance, make

sure you disconnect all electrical circuits.

Fire protection .

In particular

- When passing through ceilings and

walls

- ( Observe local regulations ) In

rooms with special requirements for

fire prevention measures;

comply exactly the rules of fire safetyregulations and the applicable building regulations .

Take extra precautions when dealing

with open flames .

The appliance is not designed

to be used by individuals

(including children) whose

physical, sensory or mental

capabilities are reduced, or

lacking expertise or

knowledge, unless they have

been supervised or instructed

on how to use the appliance

by a person in charge of their

safety.

Please supervise children to

ensure they don't play with

the appliance.

4

General information

Safety warnings

Area of use

The AEROTOP G heat pump

is designed exclusively for

heating and the production of

potable hot water.

The heat pump can be integrated in newly installed or

existing heating systems by

complying with the operational limits.

In order to ensure trouble-free

operation

of the heat pump, we recommend that

you set up a service contract.

The setup, installation, configuration, and commissioning of

the heat pump system must

be carried out by a qualified

technician in observance of

the relevant statutory rules,

regulations, and guidelines,

as well as the operating instructions.

The use of the heat pump

must be registered with the

local power supply company.

Do not tilt the heat pump more

than 15° when transporting.

Avoid exposing the heat pump

to any type of moisture or humidity. Protect the heat pump

against damage and dirt during all stages of assembly.

The components and the pipes

of the cooling circuit should

never be used for transport

purposes.

The heat pump is fastened to

the transport pallet.

All electric circuits must be

de-energized before opening

the unit.

All work on the cooling circuit

must be carried out by trained

technicians who are familiar

with and trained in the use and

handling of the coolant.

Never use abrasive, acidic or

chlorine containing cleansers

on the surface of the equipment.

For cleaning , it’s recommended using a damp cloth.

The manufacturer declines all

responsability for the misuse

of the heat pump

5

General information

Legal guidelines, warranty conditions,

checks on delivery

General indications

The sizing, installation, commissioning and maintenance of

the products described in this

document can only be carried

out by qualified specialists.

Please comply with local legal

instructions, which may differ

from the directions given in this

document.

These instructions are necessary to

correctly install, adjust and maintain

the appliance. It is therefore essential

to read the following instructions carefully and to have the heat pump installed, tested and maintained by

qualified technicians with specific

training.

At the end of the period of warranty,

the manufacturer declines all responsibility for mechanical, hydraulic or

electrical modifications. In the event

of explicitly unauthorised interventions, carried out in breach of these

instructions, the warranty shall be

forfeit with immediate effect.

During installation, the specific operating safety regulations must be complied with. Please check that the properties of the power supply match the

heat pump details (identification tag).

These instructions and the heat

pump's electrical system must be

stored with due care and attention

and, if necessary, made available to

the relevant personnel.

The manufacturer declines all

responsibility for damages to

individuals and property

caused, directly or indirectly, by

failure to comply with these

instructions.

The appliance body can only be

opened by a qualified technician.

Binding indications and directives

The construction and manufacture of

the heat pump complies with all European regulation directives (see EC

declaration of conformity).

The power connection of the

heat pump must be carried out

in compliance with national

appliance regulations. In addition, it is necessary to comply

with the connection conditions

of the local energy provider.

Additional indications and instructions.

Functional or surface-ready heating

with the heat pump according to DIN

EN 1264 is only possible if taking into

account the aforementioned conditions.

After sizing the heat pump for normal operations, it may not be possible to generate all heating neces-

sary.

Please comply also with the following

instructions:

•

Comply with regulations and instructions issued by the screed

manufacturer of the screed mortar!

•

Correct operations are possible

only with a system that has been

installed up to standards

(hydraulics, electrical components,

settings)! Otherwise the screed

could be damaged!

Because overloading could

cause serious damages, it is

forbidden to activate the heat

pump if the following conditions

apply:

•

construction drying out;

•

System temperature < 25 °

C . It is recommended to

heat with the use of electrical

resistance installed

•

unfinished system

(raw construction);

•

external doors and windows

not completed and closed.

In these cases, it is necessary

to make provisions for site

heating.

Warranty terms

The warranty for heat pumps is valid

for 24 months from the day of delivery. For everything else, the sale,

provision and warranty conditions

apply on the basis of the order confirmation.

Our warranty provisions shall be forfeit for damages as a result of:

•

improper use, misuse or noncompliant use

•

incorrect installation or commissioning by the purchaser or third

parties

•

addition of parts from other manufacturers

•

usage of the system with excessive pressure or pressure outside

the indicated factory levels

•

failure to comply with the instructions contained in the manual

Checks on delivery

The appliances are delivered on a

wooden pallet, packed in cardboard.

At the time of delivery, please check

that the appliance wasn't damaged in

transport and that the equipment is

complete.

If you do find any damage, this

must be reported immediately on

the transport document with the

following wording: «Delivery accepted with reserved due to obvious damages».

The utmost care has been used in

manufacturing the heat pump.

However, during the manipulation of

the evaporator, it isn't possible to exclude a slight bending of the single

blades during production. This does

not constitute a defect in the product.

For more information, please see

product description: high-efficiency

visible evaporator.

6

General information

Product Overview

Models available

The AEROTOP G heat pumps are

available in the following models, all

powered by electricity.

400V/3ph/50Hz

AEROTOP G07

AEROTOP G10

AEROTOP G12

AEROTOP G07-14M

230V/1ph/50Hz

AEROTOP G07X

AEROTOP G10X

Construction/Functions

•

Air-water heat pump for external installation.

•

Adjustable power (only Aerotop

G07-14M)

•

For the production of hot water

for heating systems and domestic water supply.

•

Inlet temperature up to 65 °C.

•

High-efficiency circulation pump.

•

Low noise emission thanks to

the ELCO-NRS system (Noise

Reduction System).

•

Cycle-inversion defrosting function, with high efficiency as

based on actual demand.

•

Multiple-stage emergency heating element.

Structure

•

Stainless steel or plastic covering (colored Stainless steel)

•

Completely soundproofed and

thermally isulated

•

Easy removal of all panels for

ease of handling.

•

The machine itself stands on

rubber buffers.

Compressor

• Hermetic scroll with low level

noise and vibrations.

•

Speed control via inverter to

adjust heat to the actual demand in all conditions, both for

heating and optimal production

of hot domestic water

(AEROTOP G07-14M).

Condenser

•

High-efficiency plate heat exchanger in stainless steel.

•

Water cooling on heating side.

•

Fully thermally insulated.

Evaporator

•

Heat exchanger with wide passage surface, with optimised air

flow, built with copper pipes with

aluminium fins.

•

The fins have a hydrophilic cover for better down flow of condensation and optimised defrosting.

Cooling circuit

•

Hermetically sealed, loaded at

the factory and tested against

leaks.

•

Ecologic coolant R407C.

•

The coolant complies with the

Kyoto protocol requirements.

Fan

•

Low noise Axial fan.

•

Variable speed.

•

Low power consumption.

Control

•

Front mounted LOGON® E

WP61 heating regulator.

•

Management of PV panels.

•

Complies with the requirements

of the SG-ready label.

•

Easy configuration menu with

pre-configured hydraulic

schemes.

•

Management of the generator

block.

•

1 direct heating circuit, up to 2

mixing circuits (accessories

required) and domestic hot water loading.

•

Backlit display with easy to read

text and display of statuses and

functions.

•

Predefined setpoints and heating programmes.

•

Automatic change from summer

operation to winter operation

and vice versa.

•

Dedicated programmes for every heating circuit and hot water.

•

Zone control can be connected

for every mixed circuit.

•

Legionella protection circuit for

thermal disinfection of drinking

water.

•

Multi-function outputs programmable for solar energy, domestic

hot water, room heating, circulating pump for hot water.

•

Control of a second heat generator.

•

Swimming pool integration.

•

Integration of a combustion fuel

boiler.

•

Storage tank management.

•

Cascade control.

Electrical panel

•

Internal wiring in compliance

with current directives.

•

Equipped with all safety components necessary:

•

Possibility of installing additional

expansion modules.

•

Circuit breaker 400V and 230V.

7

General information

Equipment

11

1

2

3

6

8

9

The following components are

included with the delivery of the heat

pump:

1 1 control unit bracket

2 1 switch panel

3 1 control unit to the controller

4 1 outdoor sensor

5 4 vibration absorbent adjustable

feet

6 4 hose seals

7 1 set of documentation

8 2 vibration absorbent hoses

9 4 transport aids (L-sections)

10 8 M10 bolts for securing the

transport aids

11 1 base

12 1 Flat cable

2

7

3

1

12

6

4

5

9

10

8

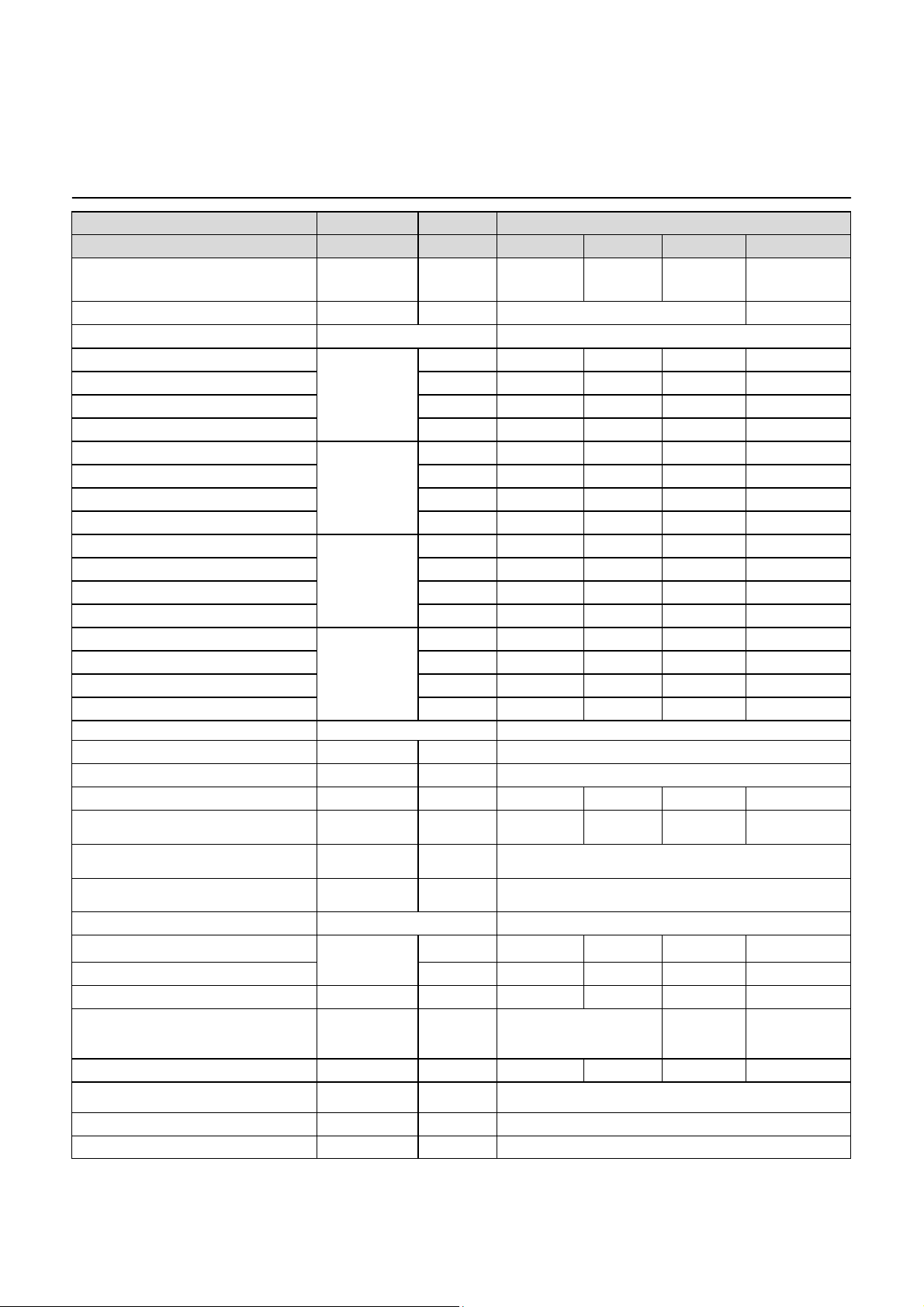

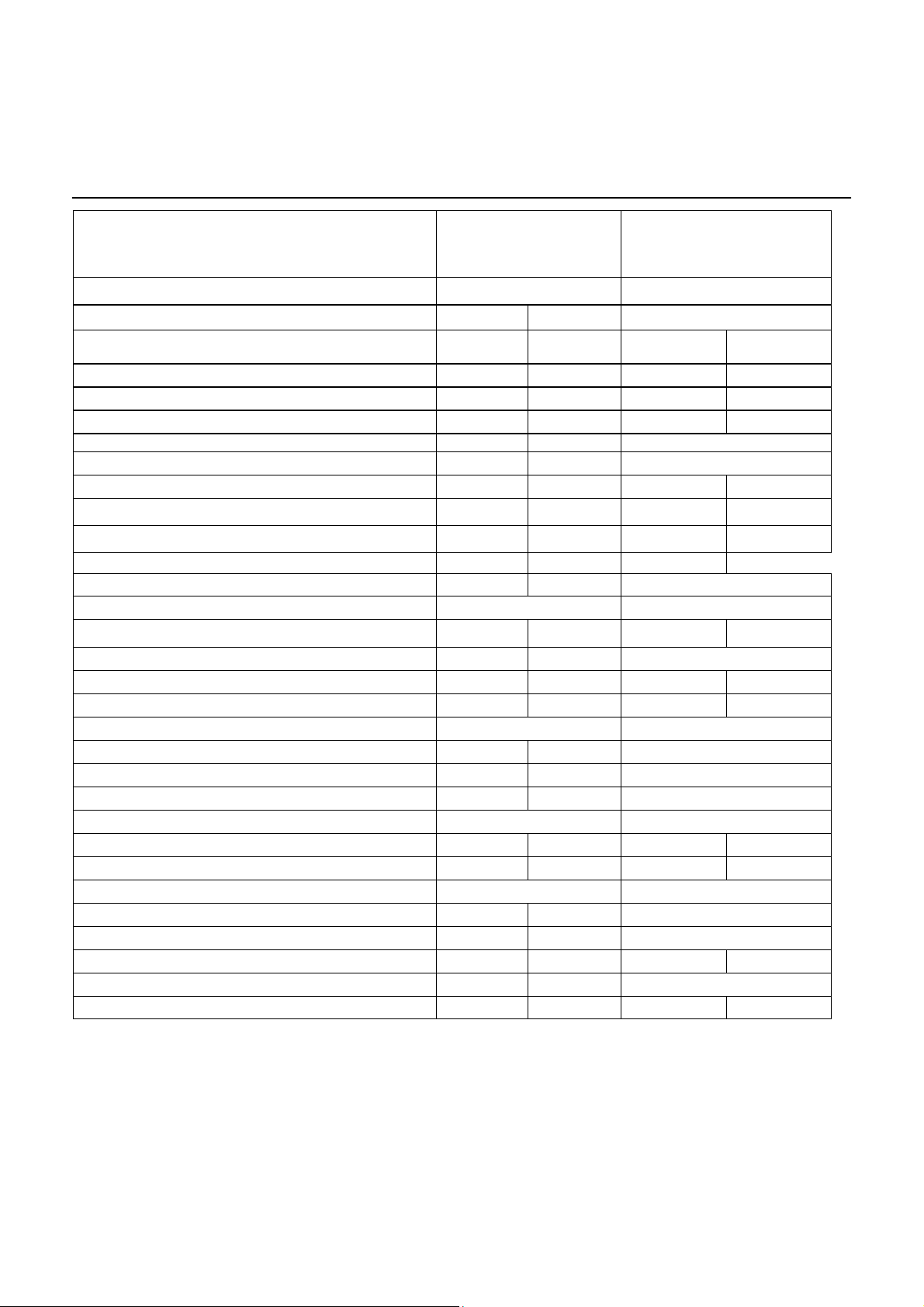

Technical Data

AEROTOP G07 / G10 / G12 / G07-14M

Series

Model

Energy efficiency category, average

climate, W55/W351)

Power regulation

Heating

Capacity range min-max

Nominal heating capacity [kW] 8.64 12.52 14.1 11.0

Nominal power input [kW] 1.85 2.69 3.33 2.2

COP 4.65 4.65 4.23 5.0

Capacity range min-max

Nominal heating capacity [kW] 6.36 9.22 11.8 10.0

Nominal power input [kW] 1.72 2.5 3.24 2.6

COP 3.69 3.69 3.64 3.8

Capacity range min-max

Nominal heating capacity [kW] 5.30 7.60 10.30 10.7

Nominal power input [kW] 1.70 2.50 3.10 3.6

COP 3.10 3.10 3.30 2.9

Capacity range min-max

Nominal heating capacity [kW] 5.00 7.30 9.80 10.8

Nominal power input [kW] 2.40 3.50 4.40 5.7

COP 2.10 2.10 2.20 1.9

Evaporator, air side

Evaporator Grooved copper pipes and fins in hydrophilic aluminium

Fan Axial

Air flow min-max [m³/h] 3500 4000 4600 2800-5200

(2)

A7/W35

A2/W35

A-7/W35

A-7/W55

G07 G10 G12 G07-14M

A++/A++ A++/A++ A++/A++ A++/A++

[kW] 8.64 12.52 14.1 4,7 - 17,5

6.36 9.22 11.8 3,6 - 15,2

5.30 7.60 10.30 2.9 - 12.7

2,9 - 12,8

AEROTOP G

No Yes

Available static pressure (without Pa 47 45 41 34-55

Min external air temperature in hea- [°C] -18

Max external air temperature in hea- [°C] 35

Condenser, water side

Nominal water flow (dT=5K)

Nominal pressure drop (dT=5K) [mbar] 128 218 350 250

Minimum water flow [m³/h] 0.76 1.08 1.37 0.97

Circulator model YONOS PARA 25/7.5

Available pressure head [mbar] 576 370 254 382

3-way water valve integrated No

Max operating pressure [bar] 3

Plate heat exchanger material AISI 316

1) Note on the energy efficiency category: This information complies with the official requirements for room heaters (EU regulation no. 811/2013) that will

be mandatory as of September 2015, based on the data for heating heat pumps as per EN 14511 and EN 14825.

2) According to EN 14511, EN 14825According to EN 14511, EN 14825

(2)

A2/W35

[m³/h] 1.52 2.09 2.80 1.93

STRATOS

PARA 25/1-

9

YONOS PARA

25/7.5

9

Technical Data

AEROTOP G07 / G10 / G12 / G07-14M

-18°C / 45°C

Operating limits air / water (heating)

Electrical data

Voltage supply

Current consumption max

@A35Wmax

(without heating element)

Nominal current consumption

@A2W35

Inrush current VSA [A] 13 20.5 25.3 < 6

Starting current with locked rotor LRA [A] 32 51.5 64 -Max starts per hour max. 3

Restart delay after power off [Sec] 60-120

I max. [A] 5.2 8.2 10.1 16.5

I [A] 3.1 4.8 5.9 6.7

[°C]

-7°C / 57°C

-4°C / 60°C

35°C / 60°C

3/N/PE 400 V/50 Hz

External fuse (without heating element)

External fuse heating element (6 kW) [A] C16A 3-polig

Control voltage supply 230V/50Hz

Power input data

Heat pump max power input

(without heating element)

Heating element power input PE [kW] 2/4/6 selectable

Fan power input min-max PV [W] 30 40 50 10-60

Circulator power input min-max PP [W] 4-75 4-75 3.5-90 4-75

Dimensions

Height [mm] 1140-1290

Width [mm] 960

Depth [mm] 1470

Weights

Stainless steel version [kg] 248 260 262 255

Plastic version [kg] 233 245 247 240

Refrigerant circuit

Compressor Hermetic scroll

Refrigerant R407C

Refrigerant charge [kg] 3.8 4.0 5.5 4.6

Lubricant Ester oil

Lubricant quantity l 1.5 1.9 1.9 0.9

[A] C13A 3-polig

PHP [kW] 3.17 5.28 6.16 8.20

C16A 3-

polig

C20A 3-

polig

C20A 3-

polig

C25A 3-

polig

C20A 3-polig

C25A 3-polig

10

Technical Data

AEROTOP G07 / G10 / G12 / G07-14M

Sound measurements

Sound power level Lwa 3)

(nominal power)

Sound power level Lwa 3)

(nominal power, silence mode)

Sound pressure level Lpa, free field

( at 1 m )

Sound pressure level Lpa free field

( at 1 m; silence mode )

Controller

Model LOGON B WP 61

Connections

Water inlet DN25 (IG 1) DN25 (IG 1) DN25 (IG 1) DN25 (IG 1)

Heating water outlet DN25 (IG 1) DN25 (IG 1) DN25 (IG 1) DN25 (IG 1)

Condensation discharge DN25 (IG 1) DN25 (IG 1) DN25 (IG 1) DN25 (IG 1)

Power supply 1 x 35mm 1 x 35mm 1 x 35mm 1 x 35mm

A7 / W35 dB(A) 57 59 61 55

A7 / W35 dB(A) 49 51 53 47

53 55 57

45 47 49

3) Sound power level Lwa according to EN 12102

11

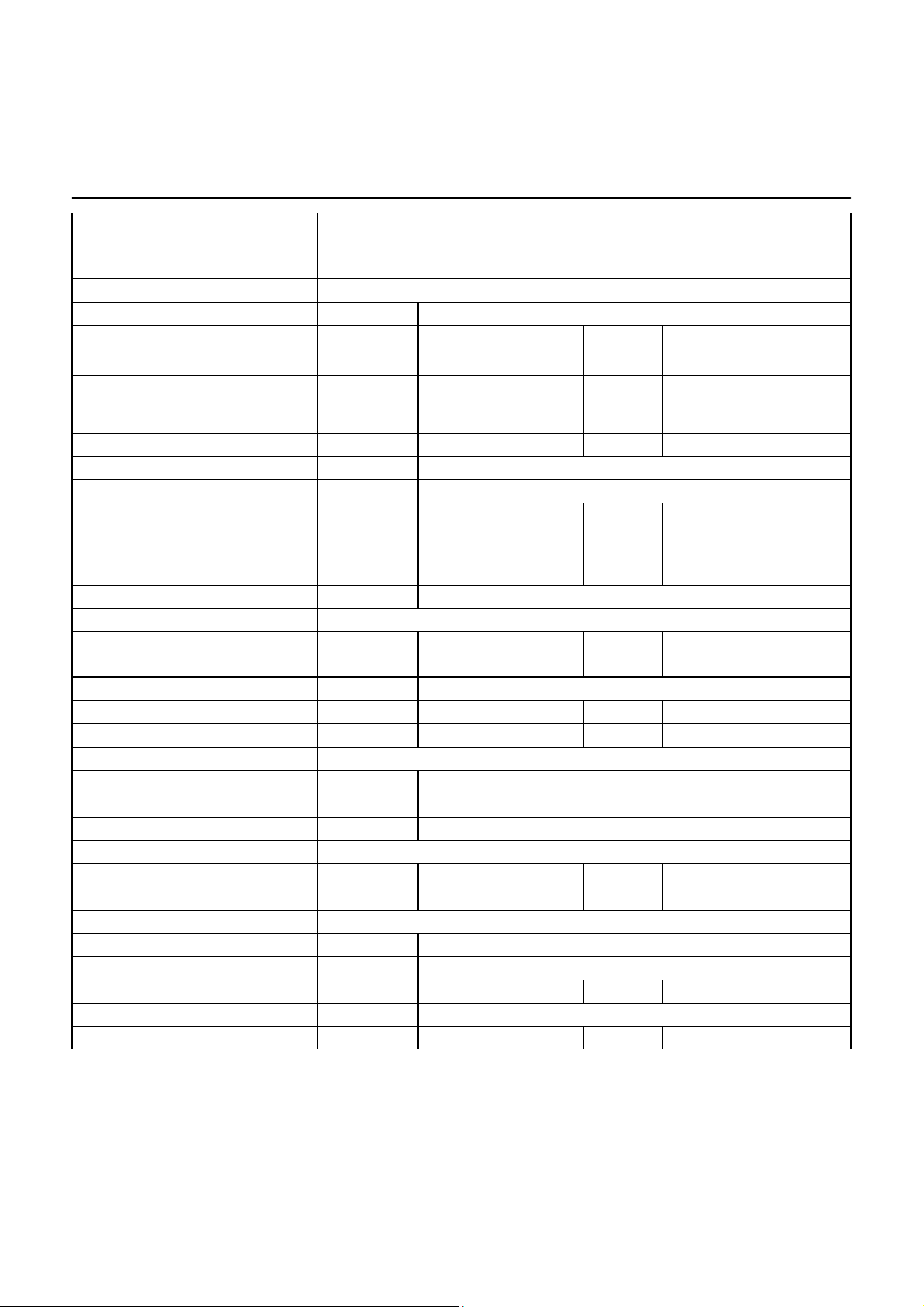

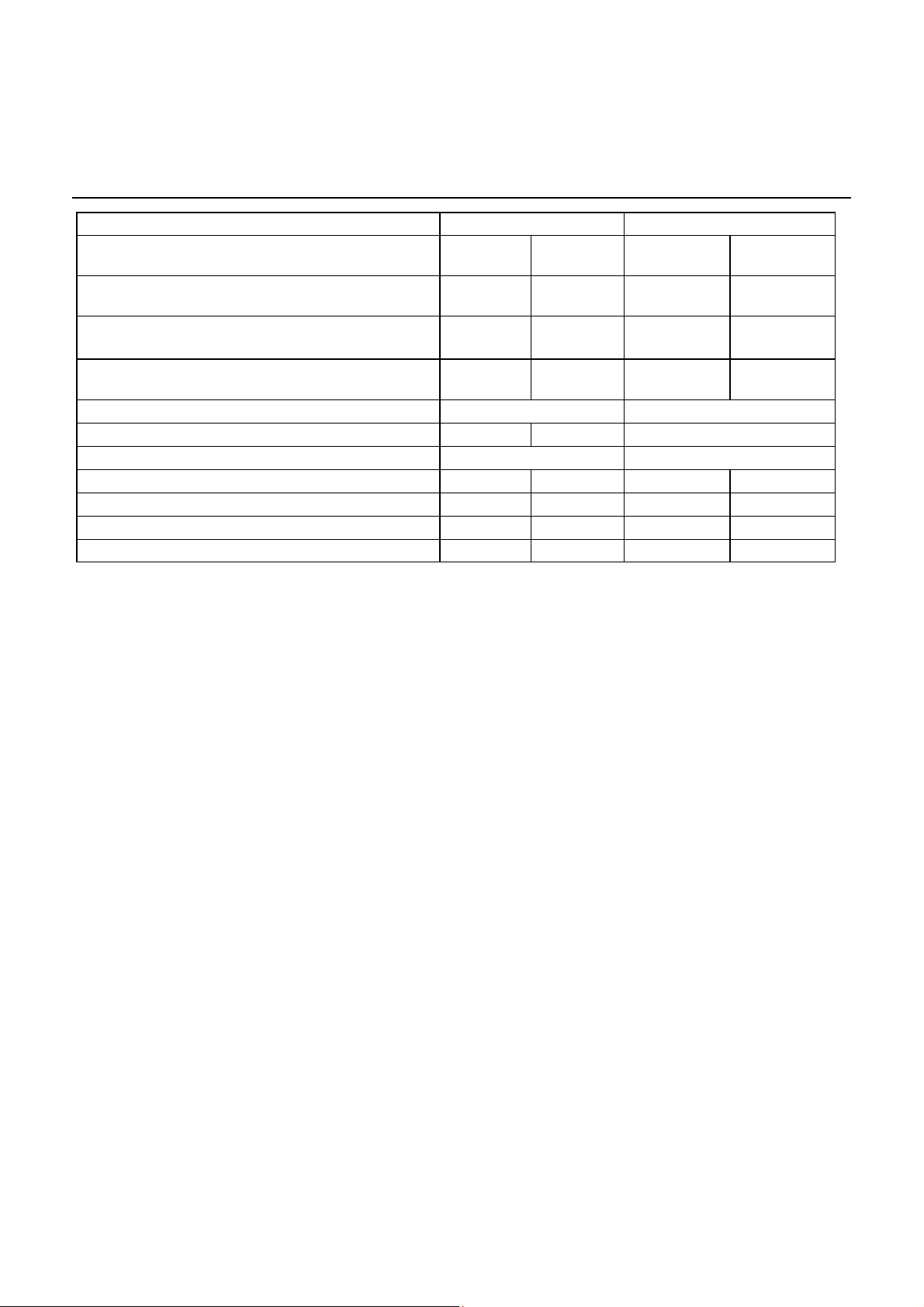

Technical Data

AEROTOP G07X / G10X

Series

Model

Energy efficiency category, average climate, W55/

W351)

Power regulation No

Heating

Capacity range min-max

Nominal heating capacity [kW] 8.64 12.52

Nominal power input [kW] 1.85 2.69

COP 4.65 4.65

Capacity range min-max

Nominal heating capacity [kW] 6.36 9.22

Nominal power input [kW] 1.72 2.5

COP 3.69 3.69

Capacity range min-max

Nominal heating capacity [kW] 5.30 7.60

Nominal power input [kW] 1.70 2.50

COP 3.10 3.10

Capacity range min-max

Nominal heating capacity [kW] 5.00 7.30

Nominal power input [kW] 2.40 3.50

COP 2.10 2.10

Evaporator, air side

Evaporator

Fan axial

Air flow min-max [m³/h] 3500 4000

Available static pressure (without ducts) Pa 47 45

Min external air temperature in heating [°C] -18

Max external air temperature in heating [°C] 35

Condenser, water side

Nominal water flow (dT=5K)

Nominal pressure drop (dT=5K) [mbar] 128 218

Minimum water flow [m³/h] 0.76 1.08

Circulator model YONOS PARA 25/7.5

Available pressure head [mbar] 576 370

3-way water valve integrated No

(2)

(2)

A++/A++ A+/A++

[kW] 8.64 12.52

A7/W35

6.36 9.22

A2/W35

5.30 7.60

A-7/W35

A-7/W55

Grooved copper pipes and fins in

A2/W35

[m³/h] 1.52 2.09

AEROTOP G

G07X G10X

hydrophilic aluminium

Max operating pressure [bar] 3

Plate heat exchanger material AISI 316

1) Note on the energy efficiency category: This information complies with the official requirements for room heaters (EU regulation no. 811/2013) that will

be mandatory as of September 2015, based on the data for heating heat pumps as per EN 14511 and EN 14825.

2) According to EN 14511, EN 14825According to EN 14511, EN 14825

12

Technical Data

AEROTOP G07X / G10X

-18°C / 45°C

Operating limits air / water (heating)

Electrical data

Voltage supply 3/N/PE 400 V/50 Hz

Current consumption max @A35Wmax

(without heating element)

Nominal current consumption @A2W35 I [A] 16.2 25

Inrush current VSA [A] 40.5 75

Starting current with locked rotor LRA [A] 76 108

Max starts per hour max. 3

Restart delay after power off [Sec] 60-120

External fuse (without heating element) [A] C13A 1-polig C16A 1-polig

External fuse heating element (2kW) C32A 1-polig C40A 1-polig

I max. [A] 5.2 8.2

-7°C / 57°C

-4°C / 60°C

35°C / 60°C

External fuse heating element (4 kW) C40A 1-polig C50A 1-polig

External fuse heating element (6 kW) [A] C50A 1-polig C63A 1-polig

Control voltage supply 230V/50Hz

Power input data

Heat pump max power input (without heating element) PHP [kW] 3.17 5.3

Heating element power input PE [kW] 2/4/6 selectable

Fan power input min-max PV [W] 30 40

Circulator power input min-max PP [W] 4-75 4-75

Dimensions

Height [mm] 1140-1290

Width [mm] 960

Depth [mm] 1470

Weights

Stainless steel version [kg] 248 260

Plastic version [kg] 233 245

Refrigerant circuit

Compressor Hermetic scroll

Refrigerant R407C

Refrigerant charge [kg] 3.8 4.0

Lubricant Ester oil

Lubricant quantity l 1.5 1.9

13

Technical Data

AEROTOP G07X / G10X

Sound measurements

Sound power level Lwa 3)

(nominal power)

Sound power level Lwa 3)

(nominal power, silence mode)

Sound pressure level Lpa, free field ( at 1 m ) A7 / W35

Sound pressure level Lpa, free field ( at 1 m; silence

mode )

Controller

Model

Connections

Water inlet

Heating water outlet

Condensation discharge

Power supply

A7 / W35 dB(A)

LOGON B WP 61

DN25 (IG 1) DN25 (IG 1)

DN25 (IG 1) DN25 (IG 1)

DN25 (IG 1) DN25 (IG 1)

1 x 35mm 1 x 35mm

57 59

53 55

dB(A)

49 51

45 47

3) Sound power level Lwa according to EN 12102

14

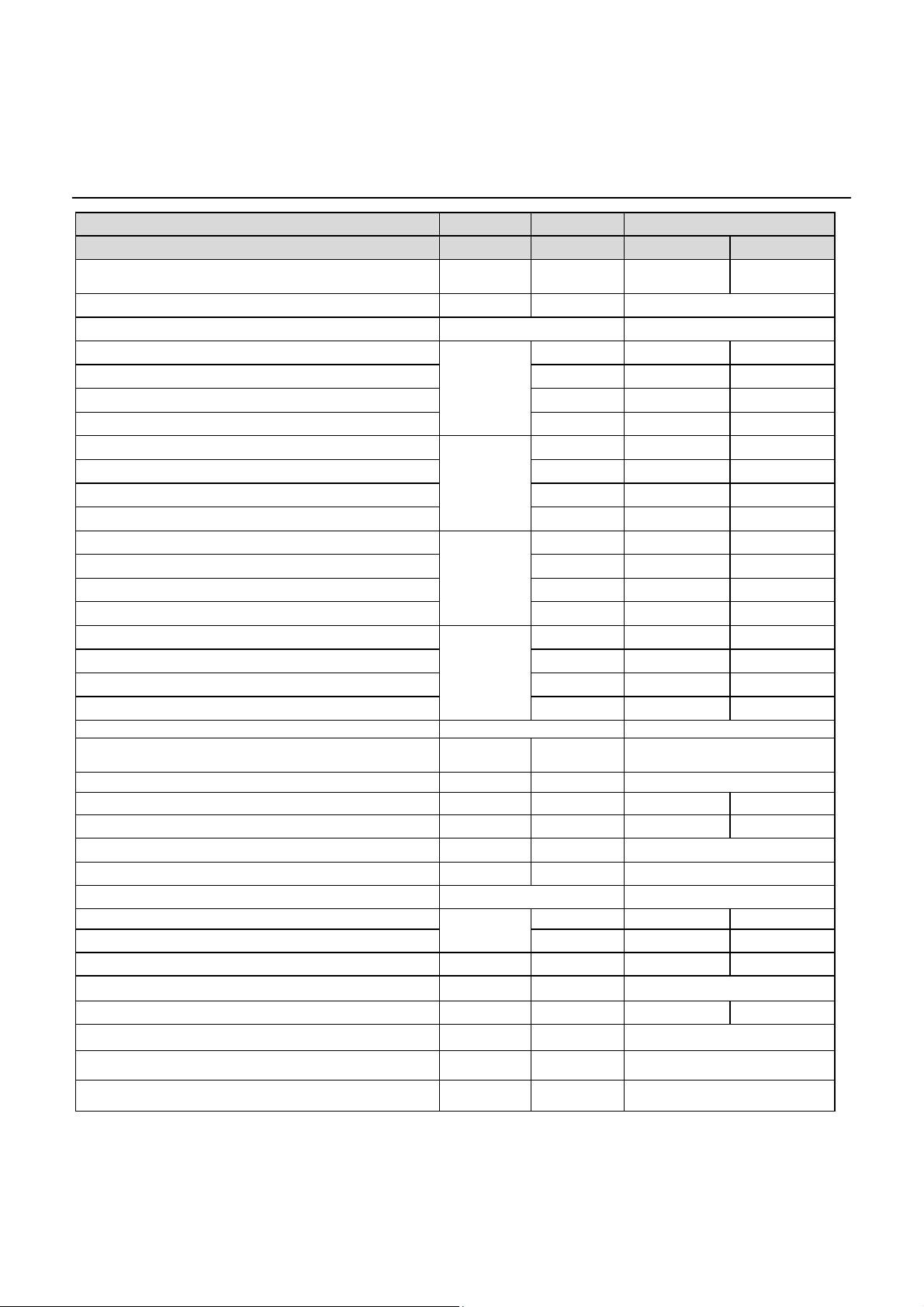

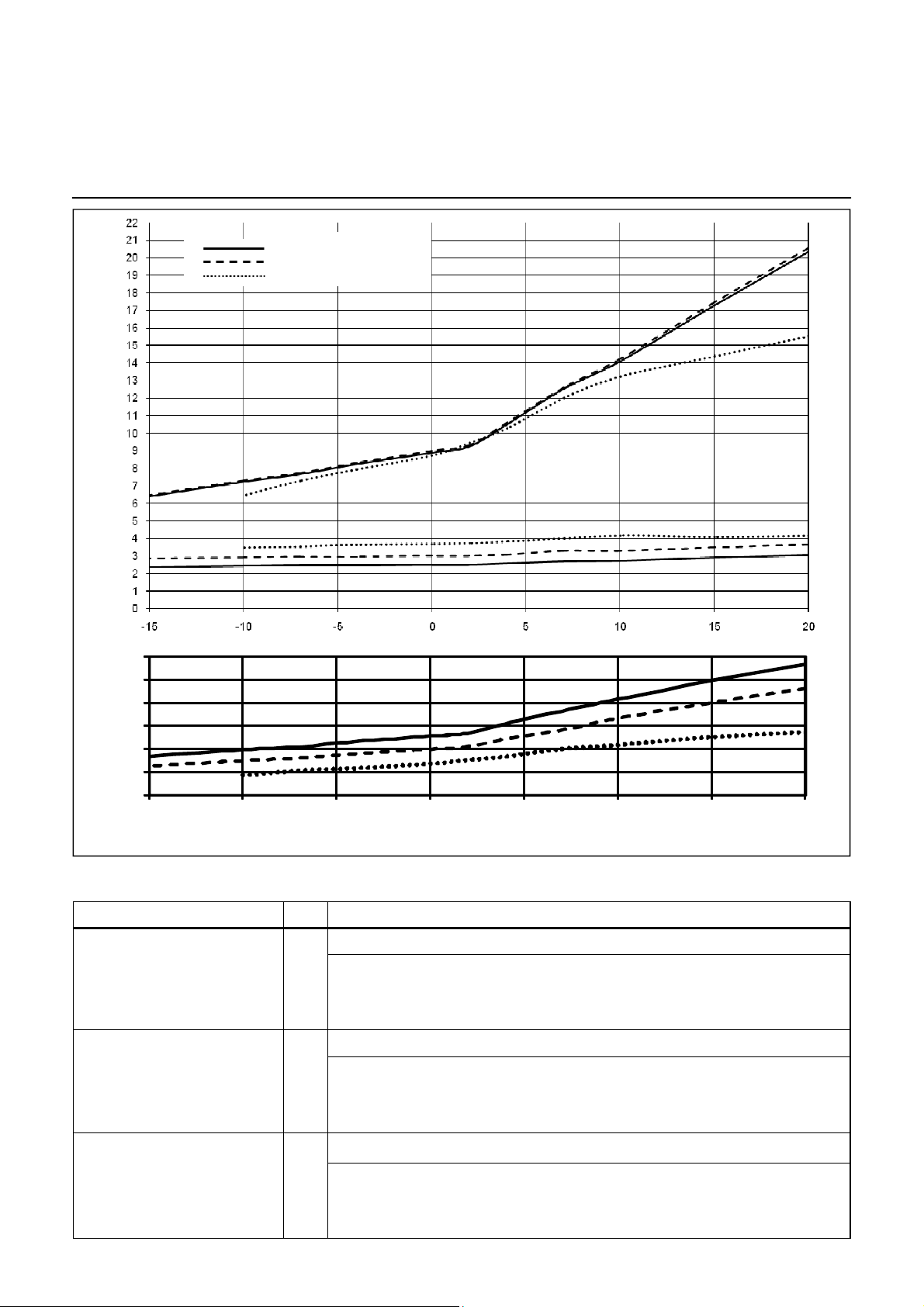

Technical Data

Performance chart AEROTOP G07(X)

Flow temperature 35°C

Flow temperature 45°C

Flow temperature 55°C

Q

h

P

Power consumption and heating capacity in kW Performance rating in heating mode

7

b

6

e

i

r

t

e

b

5

z

i

e

H

4

m

i

l

3

h

a

z

s

2

g

n

u

t

s

1

i

e

L

-15 -10 -5 0 5 10 15 20

Lufteintrittstemperatur (°C)

Air inlet temperature (°C)

HEATING CAPACITY

External air temperature °C -15 -10 -7 2 7 10 15 20

Outlet water temperature °C

35

Heating capacity kW 4.41 4.98 5.28 6.36 8.64 9.73 11.91 14.03

Power consumption kW 1.64 1.67 1.70 1.72 1.86 1.89 2.00 2.10

COP 2.69 2.98 3.10 3.69 4.66 5.16 5.96 6.68

el

Outlet water temperature °C

45

Heating capacity kW 4.45 5.03 5.33 6.43 8.70 9.82 12.03 14.17

Power consumption kW 1.97 2.01 2.05 2.07 2.27 2.26 2.40 2.52

COP 2.26 2.51 2.61 3.11 3.83 4.34 5.02 5.62

Outlet water temperature °C

55

Heating capacity kW - 4.45 5.03 6.51 8.27 9.13 9.92 10.71

Power consumption kW - 2.38 2.43 2.57 2.75 2.86 2.82 2.86

COP - 1.87 2.07 2.53 3.01 3.19 3.52 3.74

15

Technical Data

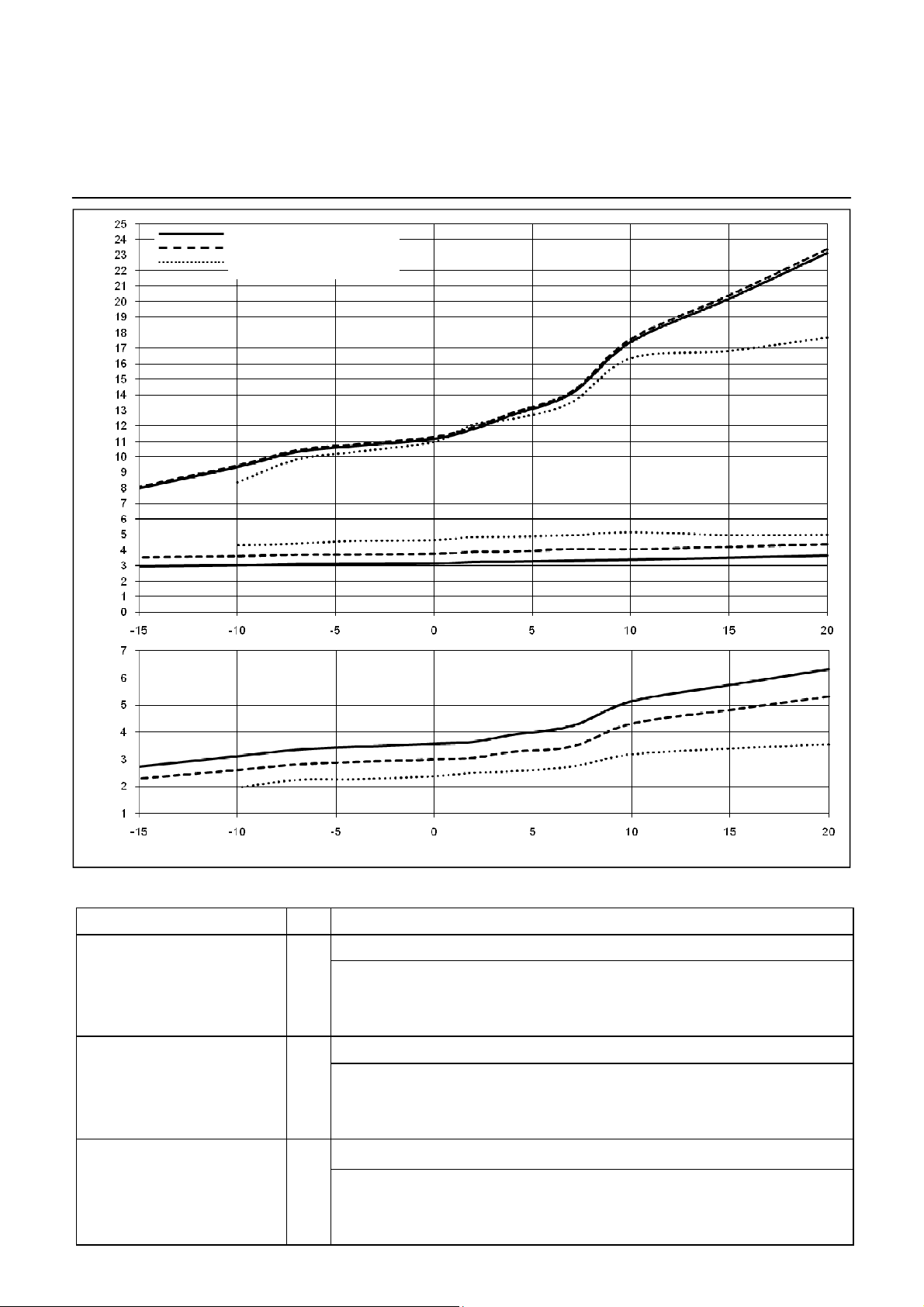

Performance chart AEROTOP G10(X)

Flow temperature 35°C

Flow temperature 45°C

Flow temperature 55°C

Q

h

Power consumption and heating capacity in kW Performance rating in heating mode

7

6

5

4

3

2

1

-15 -10 -5 0 5 10 15 20

Lufteintrittstemperatur (°C)

Air inlet temperature (°C)

External air temperature °C -15 -10 -7 2 7 10 15 20

Outlet water temperature °C

Heating capacity kW 6.39 7.22 7.65 9.22 12.52 14.10 17.27 20.34

Power consumption kW 2.37 2.42 2.47 2.50 2.69 2.73 2.90 3.05

COP 2.69 2.98 3.10 3.69 4.65 5.16 5.96 6.68

HEATING CAPACITY

35

P

el

Outlet water temperature °C

Heating capacity kW 6.45 7.29 7.73 9.32 12.60 14.24 17.44 20.54

Power consumption kW 2.85 2.91 2.96 3.00 3.29 3.28 3.48 3.66

COP 2.26 2.51 2.61 3.11 3.83 4.34 5.02 5.62

Outlet water temperature °C

Heating capacity kW - 6.45 7.29 9.44 11.99 13.23 14.38 15.52

Power consumption kW - 3.45 3.52 3.72 3.99 4.15 4.08 4.15

COP - 1.87 2.07 2.53 3.01 3.19 3.52 3.74

16

45

55

Technical Data

Performance chart AEROTOP G12

Flow temperature 35°C

Flow temperature 45°C

Flow temperature 55°C

Q

h

Power consumption and heating capacity in kW

Performance rating in heating mode

External air temperature

Outlet water temperature

Heating capacity

Power consumption

COP

Outlet water temperature

Heating capacity

Power consumption

COP

Outlet water temperature

Heating capacity

Power consumption

COP

Air inlet temperature (°C)

HEATING CAPACITY

°C -15 -10 -7 2 7 10 15 20

°C

kW 7.99 9.36 10.32 11.80 14.10 17.40 20.19 23.14

kW 2.94 3.01 3.09 3.24 3.33 3.39 3.52 3.66

2.72 3.11 3.35 3.64 4.23 5.13 5.74 6.32

°C

kW 8.07 9.45 10.43 11.92 14.20 17.57 20.39 23.37

kW 3.52 3.61 3.70 3.89 4.08 4.07 4.22 4.39

2.29 2.61 2.82 3.07 3.48 4.32 4.83 5.32

°C

kW - 8.36 9.84 12.08 13.51 16.33 16.82 17.67

kW - 4.28 4.40 4.83 4.94 5.15 4.96 4.98

- 1.95 2.24 2.50 2.73 3.17 3.39 3.54

35

45

55

P

el

17

Technical Data

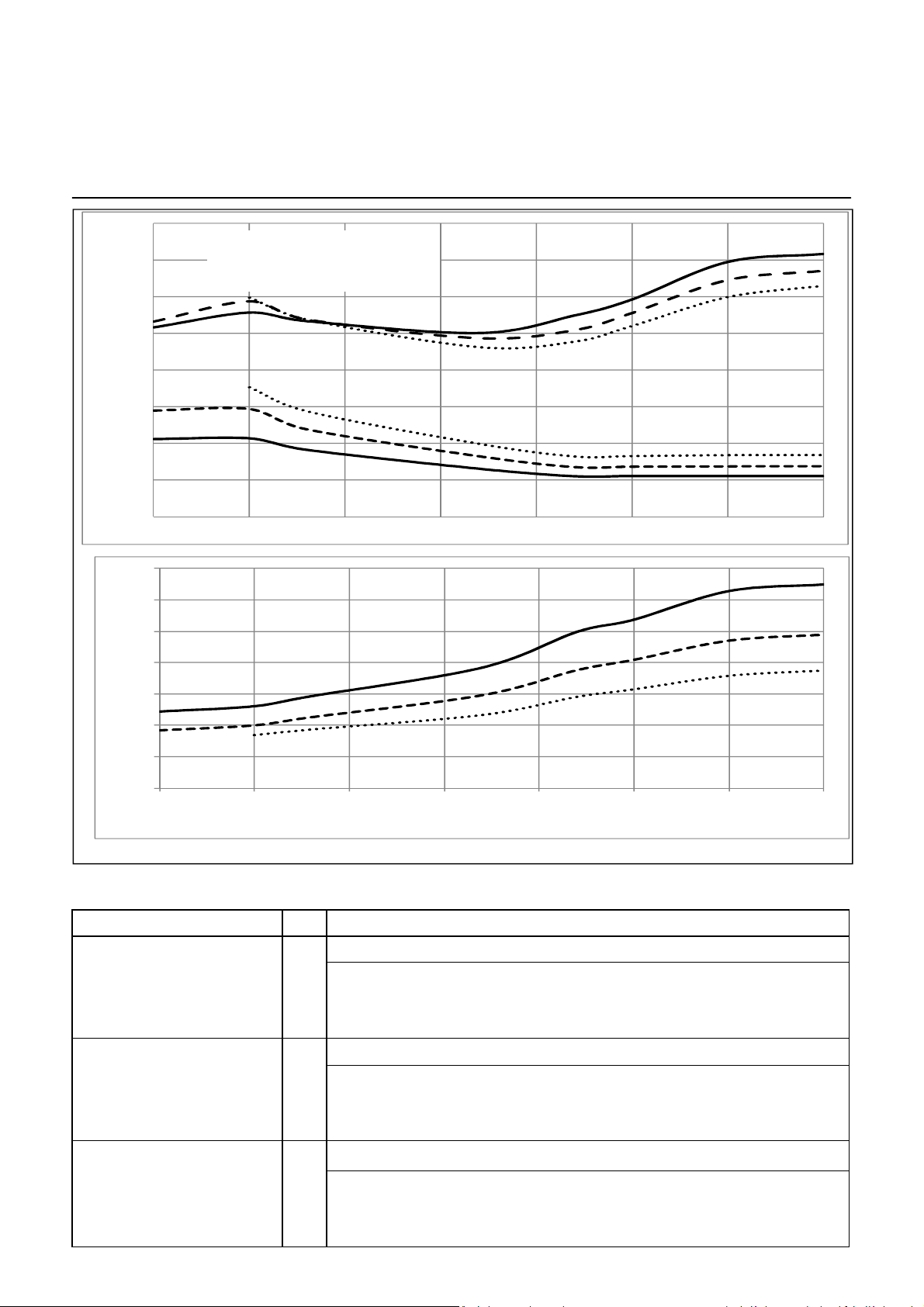

Performance chart AEROTOP G07-14M (Nominal Capacity)

16

14

12

10

————

- - - - - - …………..

8

6

Flow temperature 35°C

Flow temperature 45°C

Flow temperature 55°C

Q

h

4

Potenza assorbita e potenza termica (kW)

2

Power consumption and heating capacity in kW

0

-15 -10 -5 0 5 10 15 20

7

6

5

4

3

2

1

Coefficiente di rend. regime riscaldamento

0

Performance rating in heating mode

-15 -10 -5 0 5 1 0 15 20

Air inlet temperature (°C)

Temperatura ingresso aria (°C)

External air temperature °C -15 -10 -7 2 7 10 15 20

NOMINAL CAPACITY

P

el

Outlet water temperature °C

35

Heating capacity kW 10.33 11.14 10.67 10.02 10.98 11.85 13.90 14.34

Power consumption kW 4.23 4.27 3.64 2.61 2.20 2.21 2.21 2.21

COP 2.44 2.61 2.93 3.84 4.98 5.37 6.28 6.49

Outlet water temperature °C

Heating capacity kW

10.65 11.75 10.76 9.74 10.18 11.11 12.91 13.42

45

Power consumption kW 5.79 5.87 4.76 3.29 2.70 2.72 2.74 2.75

COP 1.84 2.00 2.26 2.96 3.76 4.09 4.7 4.89

Outlet water temperature °C

Heating capacity kW

- 11.96 10.76 7.65 9.55 10.40 11.98 12.60

55

Power consumption kW - 7.06 5.75 3.33 3.28 3.30 3.35 3.36

COP - 1.69 1.87 2.30 2.91 3.15 3.58 3.75

18

Loading...

Loading...