ELCI EKM PRO/3000 Service Manual

A/C Recovery Recycling Recharge Machine

Service Manual

EKM pro/3000

www.elcielektronik.com 2/55

Contents

Technical Specifications ......... 4

Safety Warning ....................... 5

Diagnosis ................................ 11

Setting ..................................... 12

Setting ................................ 12

Owner information ............. 14

Software update ................. 15

Database update ................ 16

Send Error Log ................... 17

Add Users ................................ 18

Service .................................... 21

Calibrations ........................ 22

Vacuum calibrations .......... 23

Pressure calibrations ......... 25

Pressure zeroing ................ 27

Scale calibrations ................ 28

Scale zeroing ....................... 29

New Oil calibrations............ 30

New Oil zeroing .................. 32

UV Oil calibrations .............. 33

UV Oil zeroing ..................... 35

Used Oil calibrations ........... 36

Used Oil zeroing .................. 38

Valve Tests .............................. 39

Scales ...................................... 40

Sensors .................................... 41

Change filter ............................ 42

Change Vacuum pump oil ....... 43

Remote ................................... 44

Doesn’t Absorb gas ................. 46

Doesn’t press gas .................... 48

Gaz be out of the tank............. 49

Not able to fill .............................. 50

Don’t vacuuming ........................ 51

Vacuum pump not work ........... 52

Compressor not working ............ 53

Compressor test procedures ....... 54

Do not weigh the load cell ........... 55

Grounding .................................... 56

Power and Socket ........................ 57

troubleshooting .......................... 60

Warranty ..................................... 62

warranty terms .............. 62

warranty certificate ....... 65

suggestion ................................... 67

About Us ..................................... 68

Muniments ................................. 70

www.elcielektronik.com 3/55

Technical Specifications

Model ....................................................... EKM PRO

Refrigerant type ....................................... R134a, R1234yf

Power supply ........................................... 220 V ±10% / 50Hz

Display ...................................................... 7" touch screen, 1024x600 resolution

Storage tank capacity .............................. 15 kg (optional 25 kg)

Scale resolution........................................ ±5 gr for refrigerant, ±1 gr for oils

Compressor .............................................. 1/3 HP 12 cc hermetic

Recovery rate ........................................... 400 gr/min maximum

Filter capacity ........................................... 100 kg

Vacuum pump .......................................... 7.68 m3/h (optional 10.2 m3/h)

Operating range ....................................... 8°C to 49°C

Low pressure gauge ................................. 15 bar

High pressure gauge ................................ 30 bar

Hose length .............................................. 180 cm (optional 250 cm & 300 cm)

Dimensions .............................................. 55 cm x 58 cm x 113 cm

Weight...................................................... 95 kg

Refrigerant Analyzer ................................ optional

www.elcielektronik.com 4/55

Safety warning

Read this manual carefully and understand all the procedures outlines in this manual before operating the

unit. Failure to follow these procedures could result in personal injury or property damage.

Allow only qualified personnel to operate this unit. The operator must have basic knowledge of air

conditioning and refrigeration systems, including potential hazards associated with the handling of refrigerants

and systems under high pressure.

Always wear safety goggles and appropriate protective clothing. Avoid contact of liquid refrigerant with the

eyes and prolonged skin exposure.

Pressurized tank contains liquid refrigerant.

Never fill the refrigerant tank to more than 80% of its maximum capacity.

Hoses may contain refrigerant under pressure.

Make sure to use a properly grounded AC outlet.

Do not operate the unit with a damaged cord or plug. Extension cords should not be used unless absolutely

necessary.

Disconnect unit from power supply before removing any protective cover.

Do not expose the unit to wet environment.

Only use the correct refrigerants.

Avoid breathing in refrigerant vapors. Use only in well ventilated areas.

The unit must be transported in a vertical position.

The refrigerant scale must be fixed in place before transport.

www.elcielektronik.com 5/55

Safety warning

Makinede Kullanılan Güvenlik Etiketlerinin Açıklaması

Be careful.

Wear safety goggles.

Grounding protection.

Risk of electric shock.

Danger of explosion.

Read the instructions carefully .

www.elcielektronik.com 6/55

Safety warning

UYARILAR: Kişisel yaralanmaları önlemek için,

ALLOW ONLY QUALIFIED PERSONNEL TO OPERATE THE MACHINE. Before operating the

machine, read and follow the instructions and warnings in this manual. The operator must be

familiar with air conditioning and refrigeration systems, refrigerants, and the dangers of

pressurized components. If the operator cannot read this manual, operating instructions and

safety precautions must be read and discussed in the operator’s native language.

PRESSURIZED TANK CONTAINS LIQUID REFRIGERANT. Do not overfill the internal storage vessel

(ISV), because overfilling may cause explosion resulting in personal injury or death. Do not

recover refrigerants into nonrefillable containers; use only type-approved refillable containers

that have pressure relief valves.

HOSES MAY CONTAIN LIQUID REFRIGERANT UNDER PRESSURE. Contact with refrigerant may

cause personal injury, including blindness and frozen skin. Wear protective equipment, including

goggles and gloves. Disconnect hoses using extreme caution. Ensure the phase has been

completed before disconnecting the machine to prevent the release of refrigeration to the

atmosphere.

www.elcielektronik.com 7/55

Safety warning

DO NOT BREATHE REFRIGERANT AND LUBRICANT VAPOR OR MIST. Refrigerant reduces the

oxygen available for breathing, resulting in drowsiness and dizziness. Exposure to high

concentrations of refrigerant causes asphyxiation, injury to the eyes, nose, throat, and lungs, and

can affect the central nervous system. Use the machine in locations with mechanical ventilation

that provides at least one air change per hour. If accidental system discharge occurs, ventilate

the work area before resuming service.

DO NOT DISPERSE THE REFRIGERANT INTO THE ENVIRONMENT. Such a precaution is necessary

to prevent the possible presence of refrigerant in the working environment.

TO REDUCE THE RISK OF FIRE:

Do not use an extension cord. An extension cord may overheat and cause fire. If you must

use an extension cord, use the shortest possible cord with a minimum size of 14 AWG.

Do not use the machine in the vicinity of spilled or open containers of gasoline or other

flammable substances.

Do not use the machine in the vicinity of flames and hot surfaces. Refrigerant decomposes at

high temperatures, freeing toxic substances to the environment which are noxious to the

user.

Do not use the machine in environments containing explosive gases or vapors.

www.elcielektronik.com 8/55

Safety warning

DO NOT USE COMPRESSED AIR TO PRESSURE TEST OR LEAK TEST THE MACHINE OR VEHICLE

AIR CONDITIONING SYSTEM. Mixtures of air and refrigerant can be combustible at elevated

pressures. These mixtures are potentially dangerous and may result in fire or explosion causing

personal injury and / or property damage..

HIGH VOLTAGE ELECTRICITY INSIDE THE MACHINE HAS A RISK OF ELECTRICAL SHOCK. Exposure

may cause personal injury. Disconnect the power before servicing the machine.

DO NOT MODIFY THE PRESSURE RELIEF VALVE OR CHANGE THE CONTROL SYSTEM SETTINGS.

Using the machine in a manner for which it was not designed will compromise the machine and

nullify the protections provided.

www.elcielektronik.com 9/55

Diagnosis

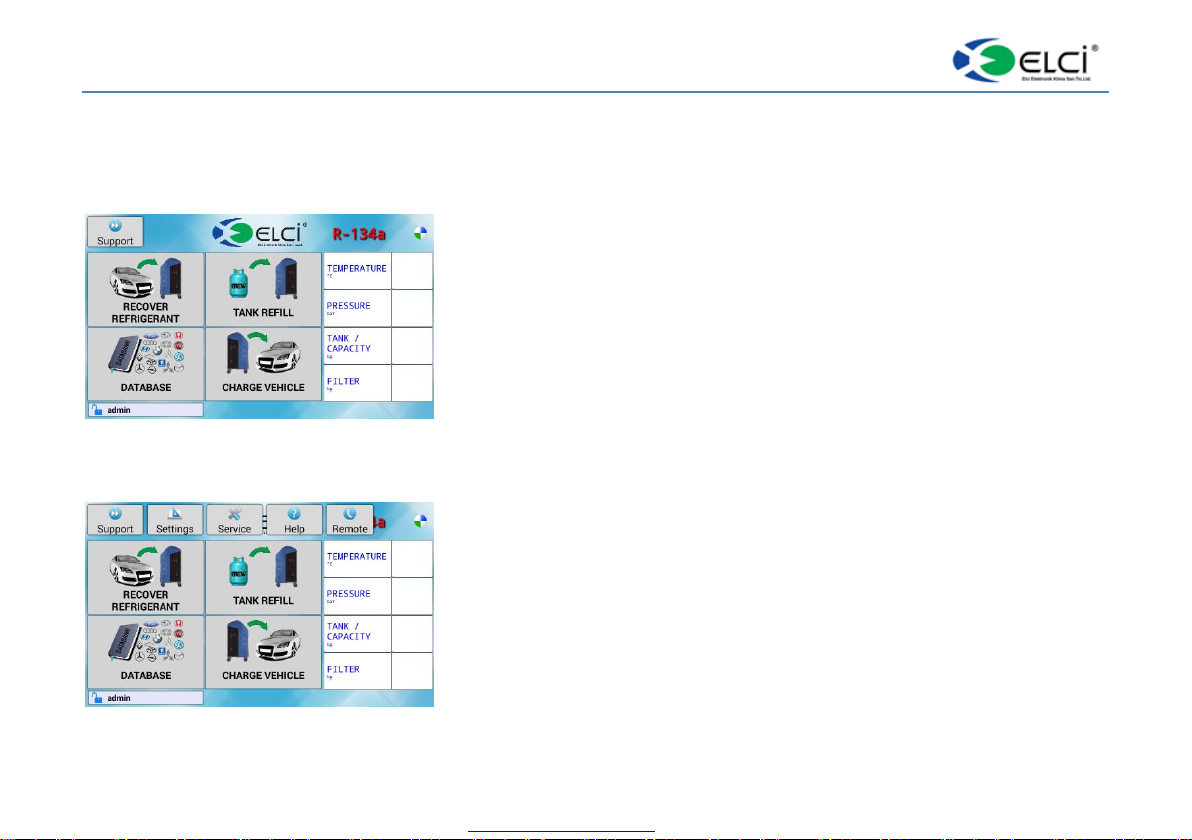

Service Center Menu Options

These are the Service Options at the time of printing this service manual. Some options may be

added or deleted in future circuit board and software updates and revisions.

Do not change the default settings unless they are removed from the factory. Otherwise the unit

may not work properly.

Do not provide programming or service codes to customers.

www.elcielektronik.com 10/55

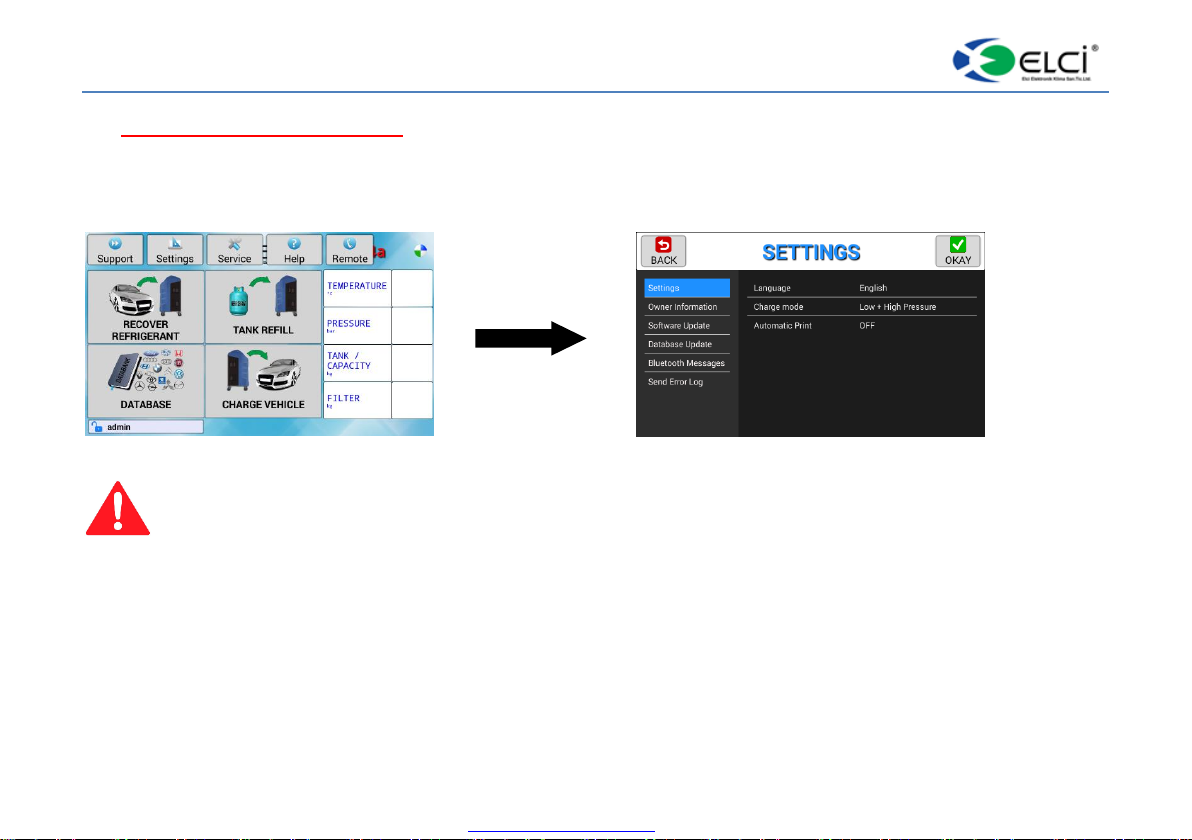

Setting

Select the setting menu.

You need to change the tablet language to change the language of program.

If you select the languages that are not loaded in the program of the gas filling device from the

tablet, the gas filling program will automatically be in Turkish. If the gas filling device is not in the

program, you need to contact the manufacturer.

www.elcielektronik.com 11/55

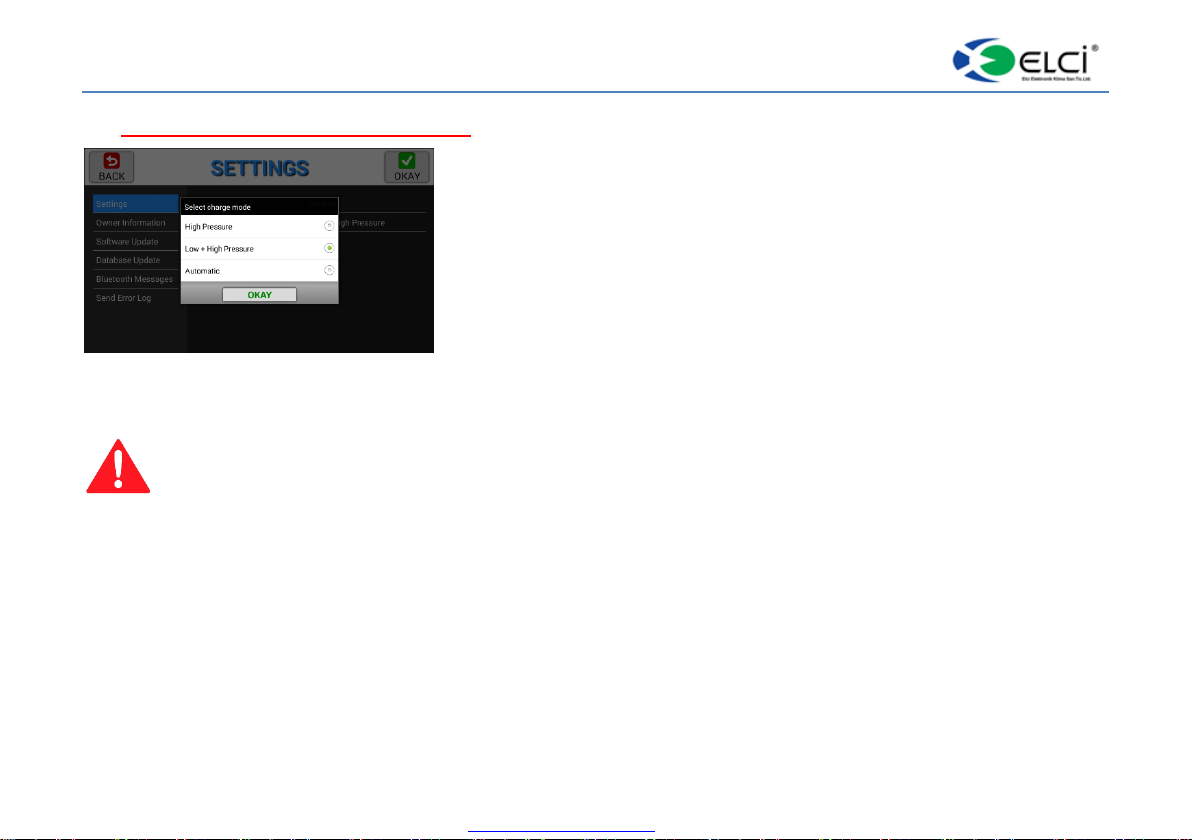

Setting

Select the gas fill mode menu.

1. High Pressure.

2. Low + High Pressure.

3. Automatic.

The user can change it according to his request. You can do whatever gas filling process you

want.

www.elcielektronik.com 12/55

Setting

Select the Owner Information.

In this option, the information of the user company is available.

Company Name

Company Official

Company Address

Company Phone

Software Update.

By connecting to the Internet, new software versions according to the model of your device will

be found in this section.

www.elcielektronik.com 13/55

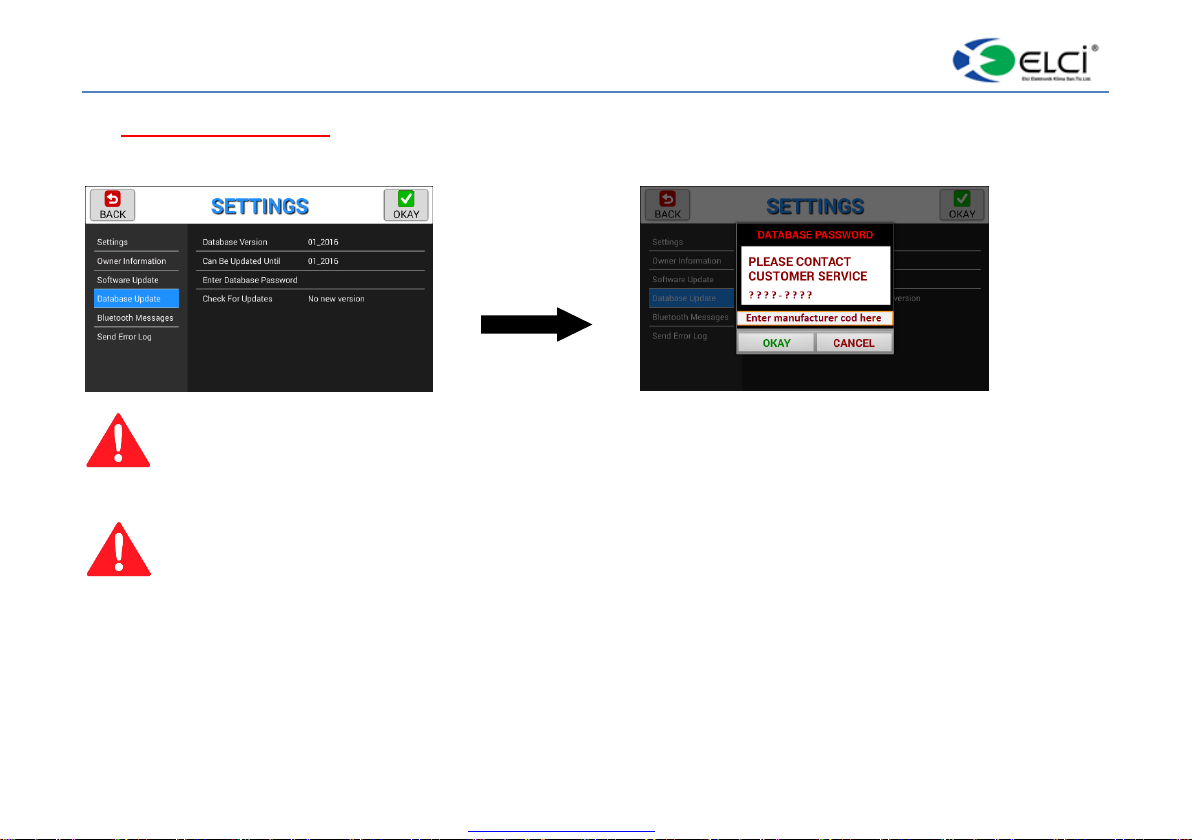

Setting

Database Update.

Databank updates must be made by the manufacturer once a year.

In order to perform the update, a password is obtained from the vendor. In order to be able to

contact the vendor, you need to send the eight-digit code shown on the screen to the vendor.

Updating will be performed by typing the code from blank to the empty field.

www.elcielektronik.com 14/55

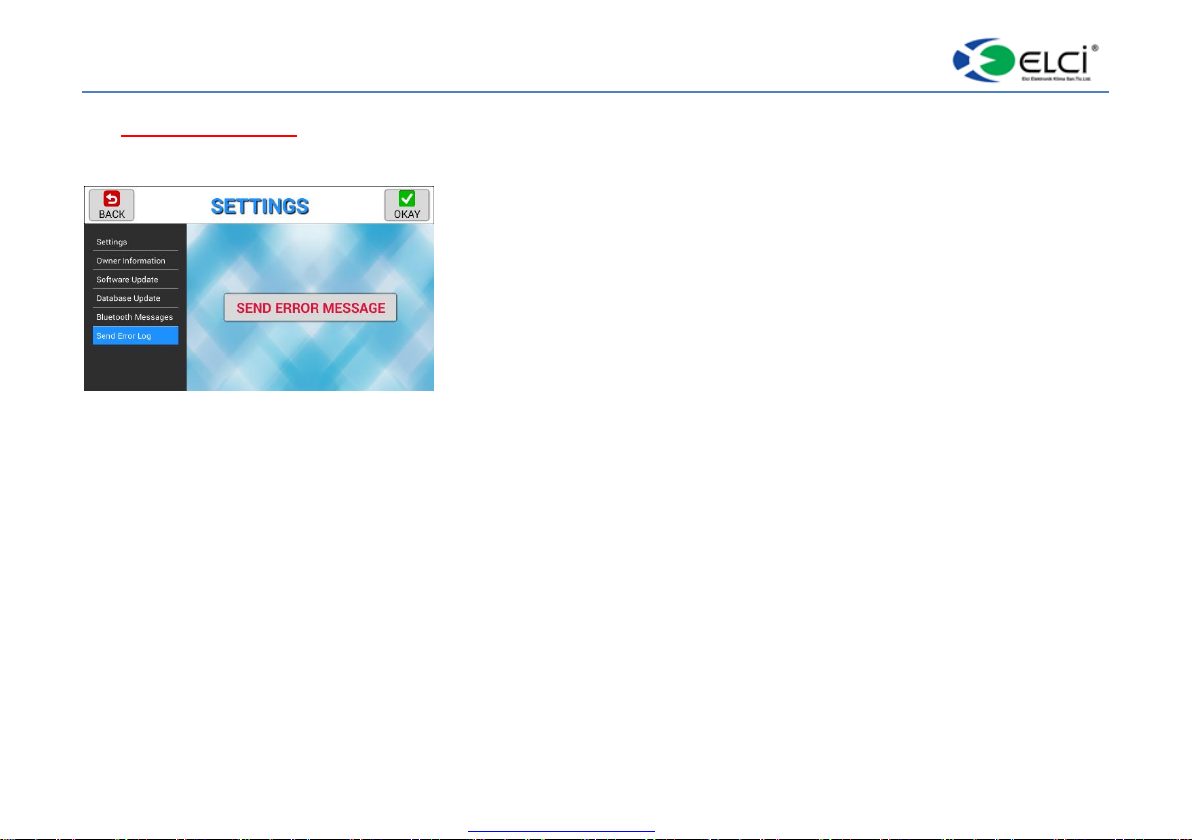

Setting

Send Error Log.

Select the Send Error Log.

By connecting to the internet, user can send the error which is occurred in the device by selecting

(SEND ERROR MESSAGE)

www.elcielektronik.com 15/55

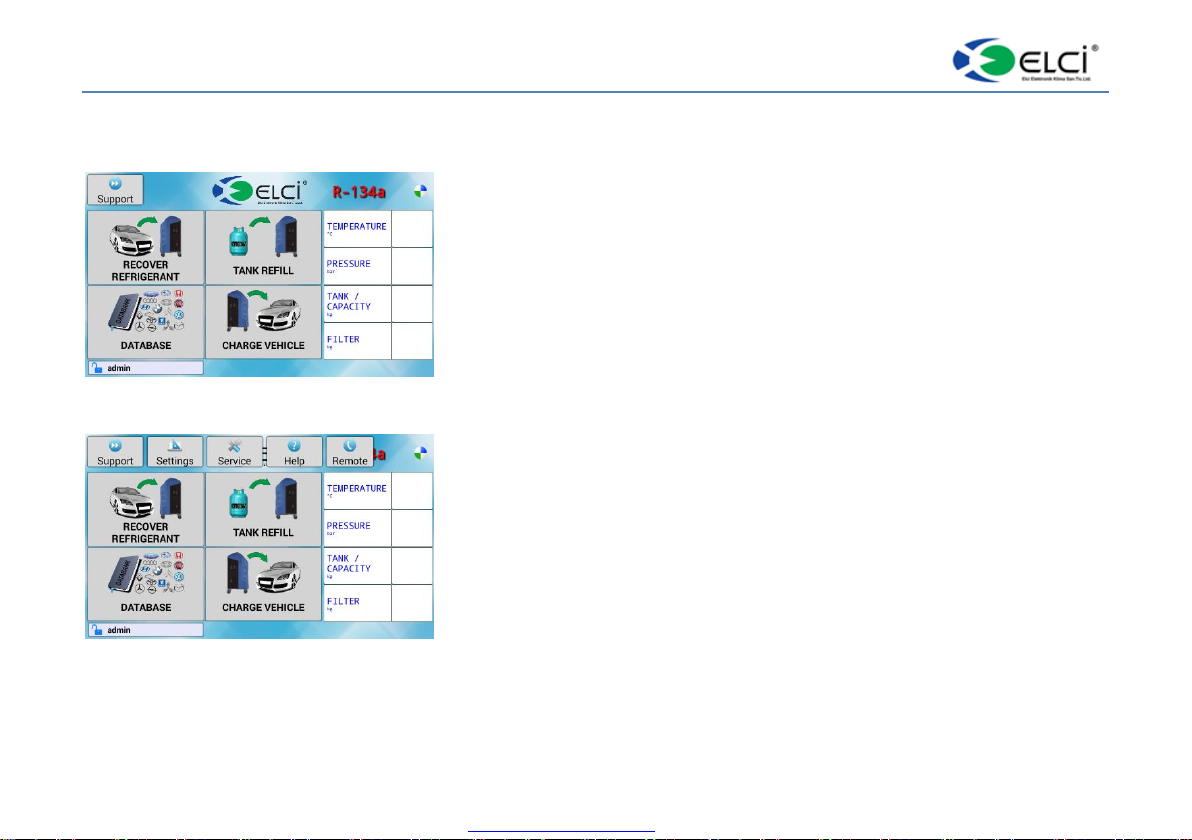

Add Users

1. Turn on the machine and allow it to run through the boot sequence.

2. Select the support menu.

3. Select service nemu.

www.elcielektronik.com 16/55

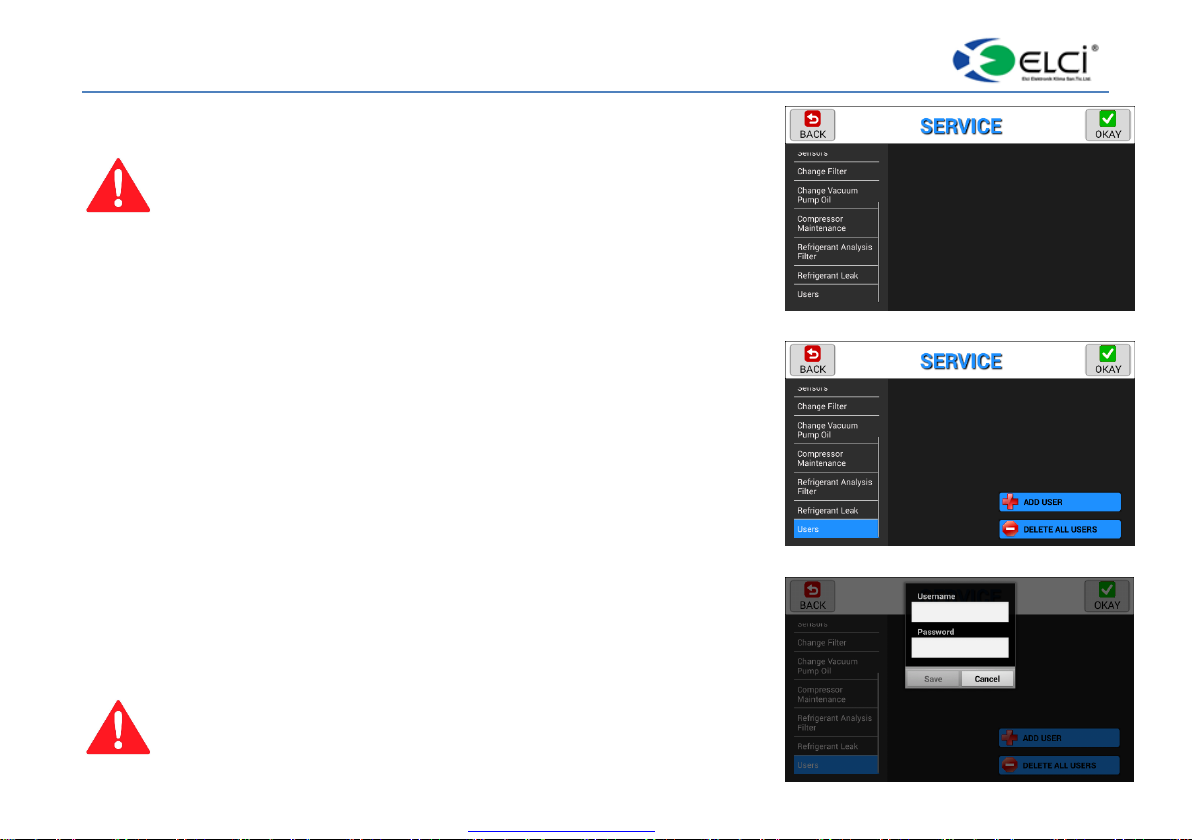

Add Users

4. Select Users.

it locates in the lowest part of the list .

5. Select ADD USERS.

6. Create a custom username and password for you.

The admin user's password is 5588.

www.elcielektronik.com 17/55

Service

The following four steps are required to start all operations on the service menu.

1. Select Support menu.

2. Select service nemu.

Loading...

Loading...