Page 1

© 2016 EL-CELL GmbH

User Manual

Rel ease 2.02

Electrochemical Test Cell

ECC-PAT-Core

November 2016

Page 2

Page 2 of 17

User Manual ECC-PAT-Core – Release 2. 02

The information in this manual has been carefully checked and believed to be accurate;

however, no responsibility is assumed for inaccuracies.

EL-CELL GmbH maintains the right to make changes without further notice to products

described in this manual to improve reliability, function, or design. EL -CELL GmbH does

not assume any liability arising from the use or application of this p roduct.

EL-CELL GmbH

Tempowerkring 8

21079 Hamburg - Germany

phone: +49 40 79012-737

fax: +49 40 79012-736

e-mail: in fo @e l- ce ll.com

web: www.el-cell.com

Page 3

Page 3 of 17

User Manual ECC-PAT-Core – Release 2. 02

Content

1 Product Description ............................................................................................ 4

2 Features ........................................................................................................... 6

3 Safety Precautions ............................................................................................. 6

4 Unpacking ......................................................................................................... 6

5 Cell Assembly .................................................................................................... 8

6 Different Test Cases .......................................................................................... 10

7 PAT-Core Components ....................................................................................... 11

9 Disassembly and Cleaning .................................................................................. 14

10 Consumables ................................................................................................... 14

11 Spare Parts ..................................................................................................... 15

12 Technical Support ............................................................................................ 16

13 Warranty ........................................................................................................ 17

Page 4

Page 4 of 17

User Manual ECC-PAT-Core – Release 2. 02

12

12,2

12,4

12,6

12,8

13

13,2

13,4

13,6

13,8

14

0 200 400 600 800 1000

SPRING FORCE APPLIED ON CELL STACK / N

THICKNESS OF UPPER ELECTRODE / MICRONS

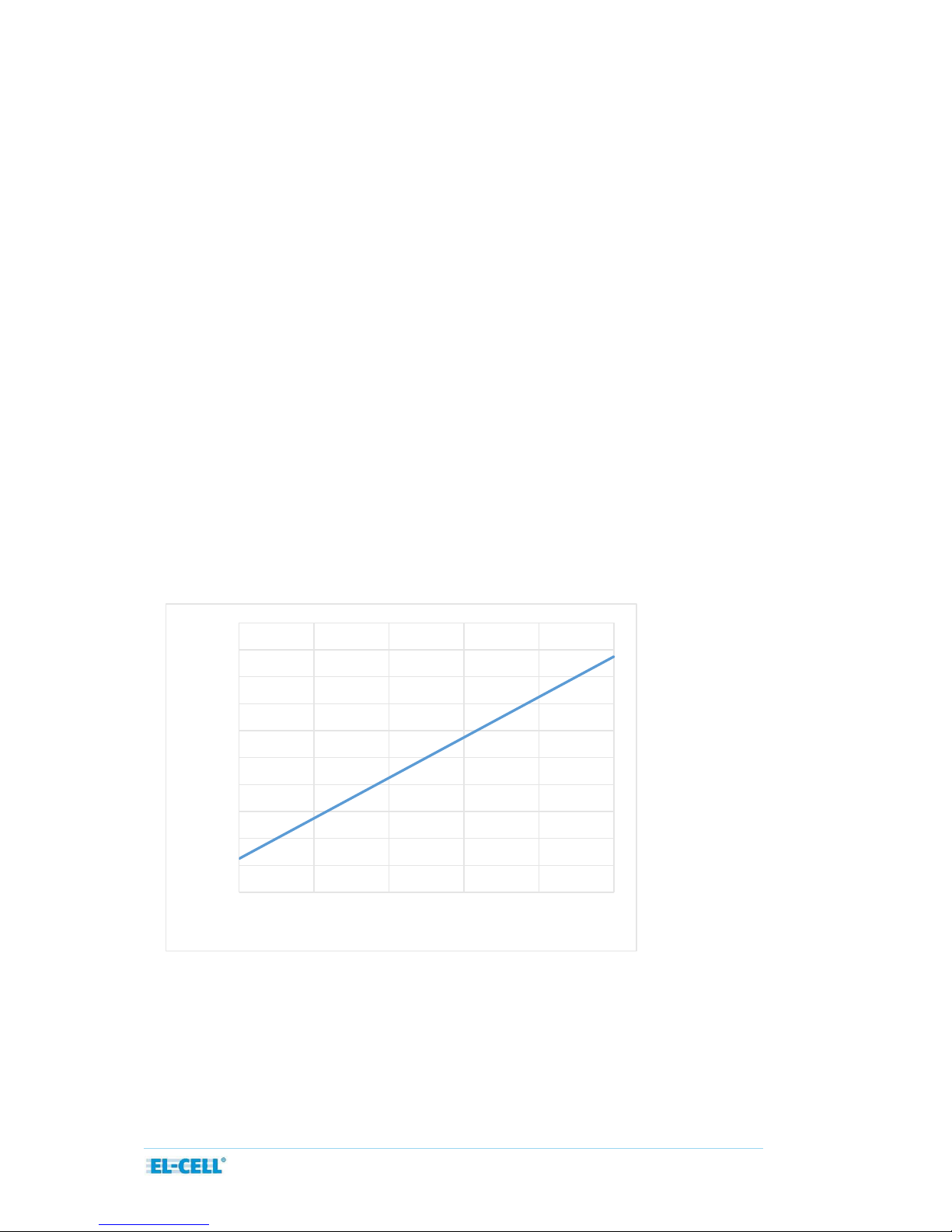

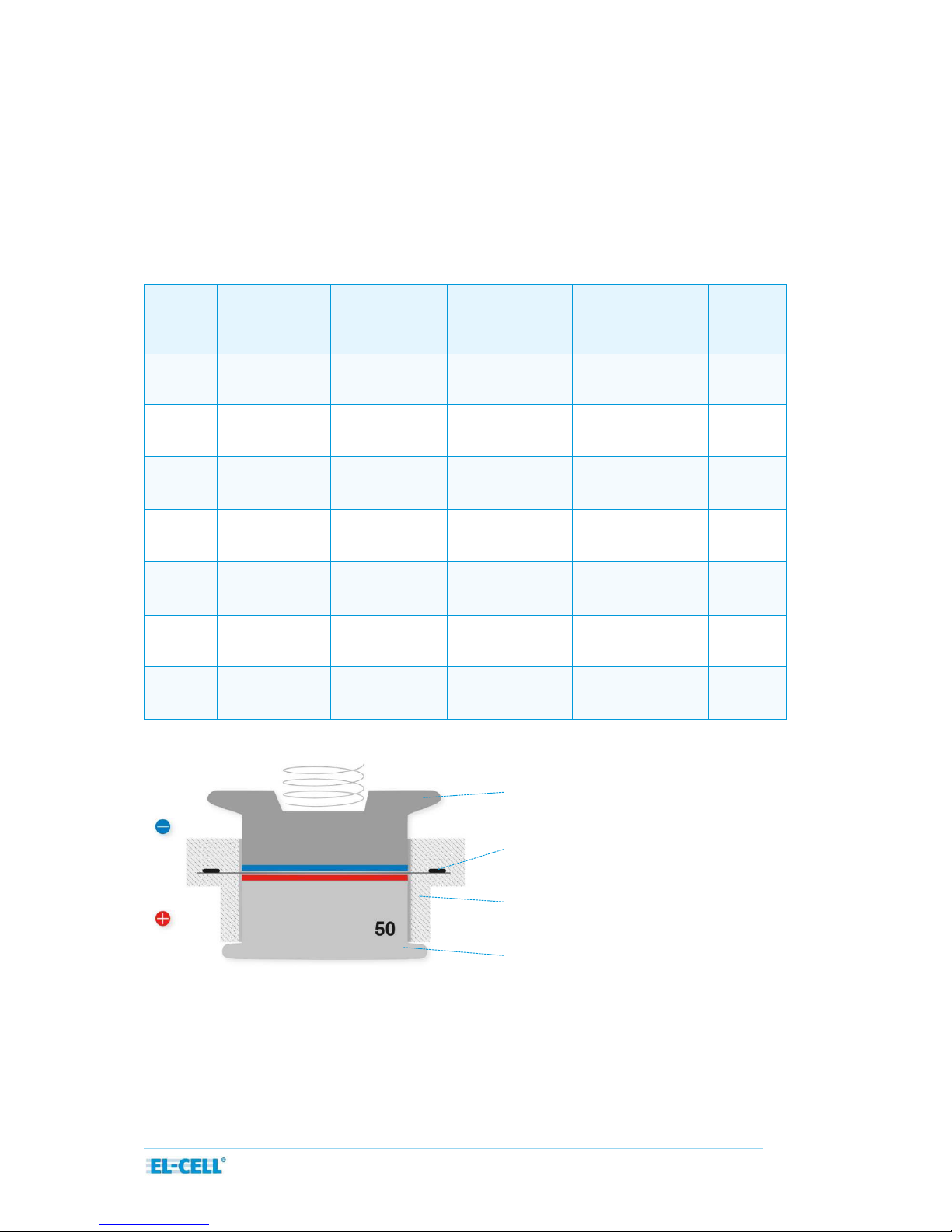

1 Product Description

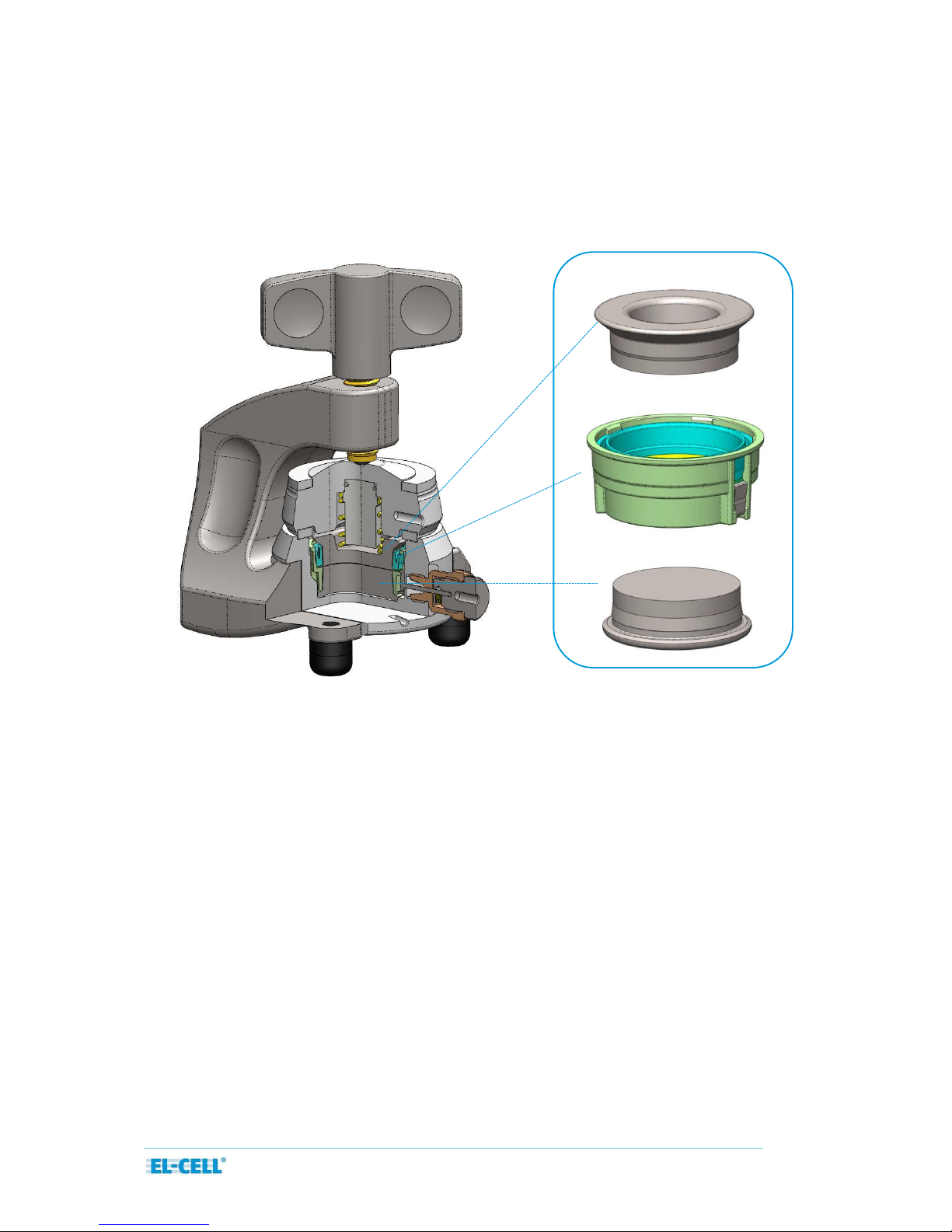

The ECC-PAT-Core is the latest test cell of the ECC series, which allows the application

of the novel PAT-Core. The PAT-Core is comprised of three components:

1. Insulation sleeve: The polypropylene insulation sleeve with a ring -shaped

reference electrode and a separator, both pre-installed at the factory, sealed and

ready for use in the glovebox. Several other versions are available for special

purposes. The insulation sleeve is also available in the disassembled state, so that

the customer can use his own separator or reference .

2. Lower plunger: The lower plunger serves as the positive current collector.

Different gap sizes are available to match electrodes and separators with different

thicknesses. When using the proper gap size, the lower electrode ca n have a

maximum thickness of 800 µm.

3. Upper plunger: The upper plunger serves as the negative current collector. The

maximum thickness of the upper electrode is 800 µm. Note that the spring force

applied on the cell stack will depend slightly on the thickness of the upper

electrode.

4.

Spring force in relation to the thickness of the upper electrode:

Compression sp ring

FED9015

Page 5

Page 5 of 17

User Manual ECC-PAT-Core – Release 2. 02

The insulation sleeve is a single -use component, which has to be disposed after use. In

contrast, the plungers are available as both single -use components (made of battery

grade copper and aluminium) and as reusable components (made of stainless steel

316 L/ 1.4404).

Ins ulation sle eve

Upp er plunger

Low er plunger

PAT -Core

ECC-PAT-Core

Page 6

Page 6 of 17

User Manual ECC-PAT-Core – Release 2. 02

2 Features

The ECC-PAT-Core is a test cell to accurately characterize aprotic lithium-ion battery

materials over long periods of times. The standard PAT-Core is composed if a lithium

metal ring and a a separator (either glass fiber or a nonwoven polyester pasted with

Al2O3). Both the reference and the separator are pre-installed in a single-use insulation

sleeve. This concept has got several advantages:

Ability for conducting long-term mea surements with a reliable reference electrode

over more than one thousand hours of battery operation .

Ability for measuring half cell impedance spectra throughout the battery’s life

time.

Less mistakes that may result from corrosion or cross-contamination.

Increase of testing productivity by single -use concept.

No need for cleaning or drying cell components.

Fast assembly and dismantling lowers lead times of experiments.

Easy and reliable electrolyte filling upon assembly (defined electrolyte volume

dow n to 0.05 cm³).

Reliable leakage-proof sealing with PE-Seal and double cutting ring.

Reproducible a nd homogeneous mechanical pressure on electrodes .

High precision 18 mm diameter sa ndwich geometry with a concentricity better

than 0.1 mm (electrode and separator dimensions are compatible with other test

cells of the ECC series).

The ECC-PAT-Core is designed for use in the temperature range from -20 to +70°C.

3 Safety Precautions

Use proper safety precautions when using hazardous electrode materials and

electrolytes. Wear protective glasses and gloves to protect you against electrolyte

that may accidentally spill out during disassembly. Upon cell disassembly, dispose all

materials properly. Metallic lithium and some insertion compounds may decompose

hea vily in contact with water and other solvents, and can cause fire.

4 Unpacking

Check the contents of the packages against the list given below to verify that you

have received all of the required components. Contact EL-CELL, if anything is missing

or damaged. NOTE: Damaged shipments must remain within the original packaging for

freight company inspection .

Page 7

Page 7 of 17

User Manual ECC-PAT-Core – Release 2. 02

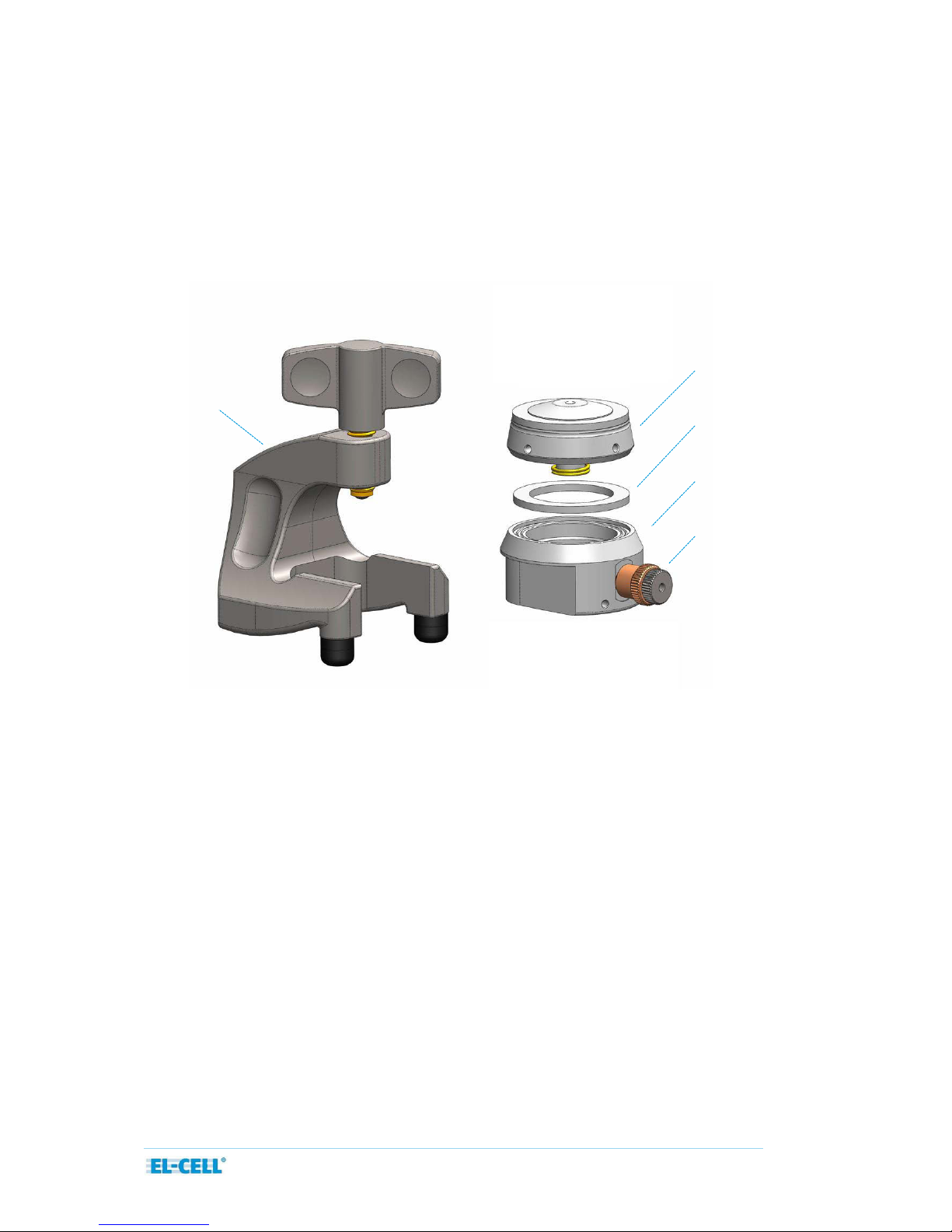

List of Components:

ECC-PAT-Core test cell without PAT-Core

Note: The components of the PAT-Core (insulation sleeves and plungers) must be

purchased separately.

Lid

PE-Se al

Cell Base

Feed wire assy

Bra cket

Page 8

Page 8 of 17

User Manual ECC-PAT-Core – Release 2. 02

5 Cell Assembly

This section describes, how the ECC-PAT-Core has to be assembled in order to

conduct proper battery tests. Please note that the assembly has to take place under

the protective atmosphere in a glove box.

1. Put the insulation sleeve (5) onto the worktop with the smaller side pointing

upwards. Different insulation sleeves are available for different test purposes, see

chapters 6 and 7.

2. Insert the lower electrode ( 6) into the sleeve with the active layer facing

dow nwards.

3. Attach the lower plunger (7). The lower plunger is available in different gap

sizes in order t o account for the thickness of the electrodes and separator used,

see chapters 6 and 7.

4. Turn the assembly upside down.

5. Align the contact spring of the sleeve with the horizontal contact pin inside the

cell base (9). Then insert the assembly into the cell base .

6. Eve nly dispense 100 µL of electrolyte (4) on top of the separator with a pipette.

Note: The optimum amount of electrolyte will depend on the thickness and porosity of

the separator and the electrodes used.

7. Insert the upper electrode ( 3) into the insulation sleeve with the active layer

facing downwards.

8. Attach the upper plunger (2).

9. Mount the PE-Seal (8) on the cell.

10. Put the lid (1) (with integrated spring) on top .

11. Hold the lid down and push the cell into the bracket (11).

12. Turn the wing nut (10) to close the cell.

A video showing the assembly of the ECC-PAT-Core in detail, can be found here.

Page 9

Page 9 of 17

User Manual ECC-PAT-Core – Release 2. 02

Lid

Upper plunger

Upper electrode

Ele ctr olyte

Insulation sle eve

Low er electrode

Low er plunger

PE-Se al

Cell base

Bra cket

Win g nut

Further recommended tools for working with the ECC-PAT-Core:

ECC1-02-0005-A ECC-LiPunch 18 mm

ECS1-00-0100-A EL-Cut Cutting Pliers 18 mm

1

3 4 5 6 7 8 9

10

11

2

Page 10

Page 10 of 17

User Manual ECC-PAT-Core – Release 2. 02

6 Different Test Cases

The PAT-Core may be used for many different battery and capacitor types . The table

below summarizes some of the most common test cases. In general, we recommend

sleeves with built-in glass fiber separator rather the n thin technical separators (such as

Viledon or Celgard) when lithium metal is used as the negative electrode, and when

measuring half cell impedances.

Battery

Type

Lower electrode

(+)

Upper electrode

(-)

Lower plunger

single-use/re-use

Upper plunger

single-use/re-use

Separator

Li-metal

LCO, NCA, NCM or

LFP

Li

Al/SS

Cu/SS

GF

Li-metal

Graphite or silicon

Li

Cu/SS

Cu/SS

GF

Li-metal

LTO

Li

Al or Cu/SS

Cu/SS

GF

Li-ion

LCO, NCA, NCM,

or LFP

Graphite

Al/SS

Cu/SS

GF or thin

Li-ion

LFP

LTO

Al/SS

Al or Cu/SS

GF or thin

EDLC

AC

AC

Al/SS

Al/SS

GF or thin

Li-ion cap

AC

Lithiated graphite

Al/SS

Cu/SS

GF or thin

The lower electrode can have a thickness of up to 800 µm provided that the proper gap

size of the lower plunger is chosen. The maximum thickness of the upper electrode is

800 µm.

Upp er plunger

Ring-shaped re ference electrode

Ins ulation sle eve

Low er plunger

Page 11

Page 11 of 17

User Manual ECC-PAT-Core – Release 2. 02

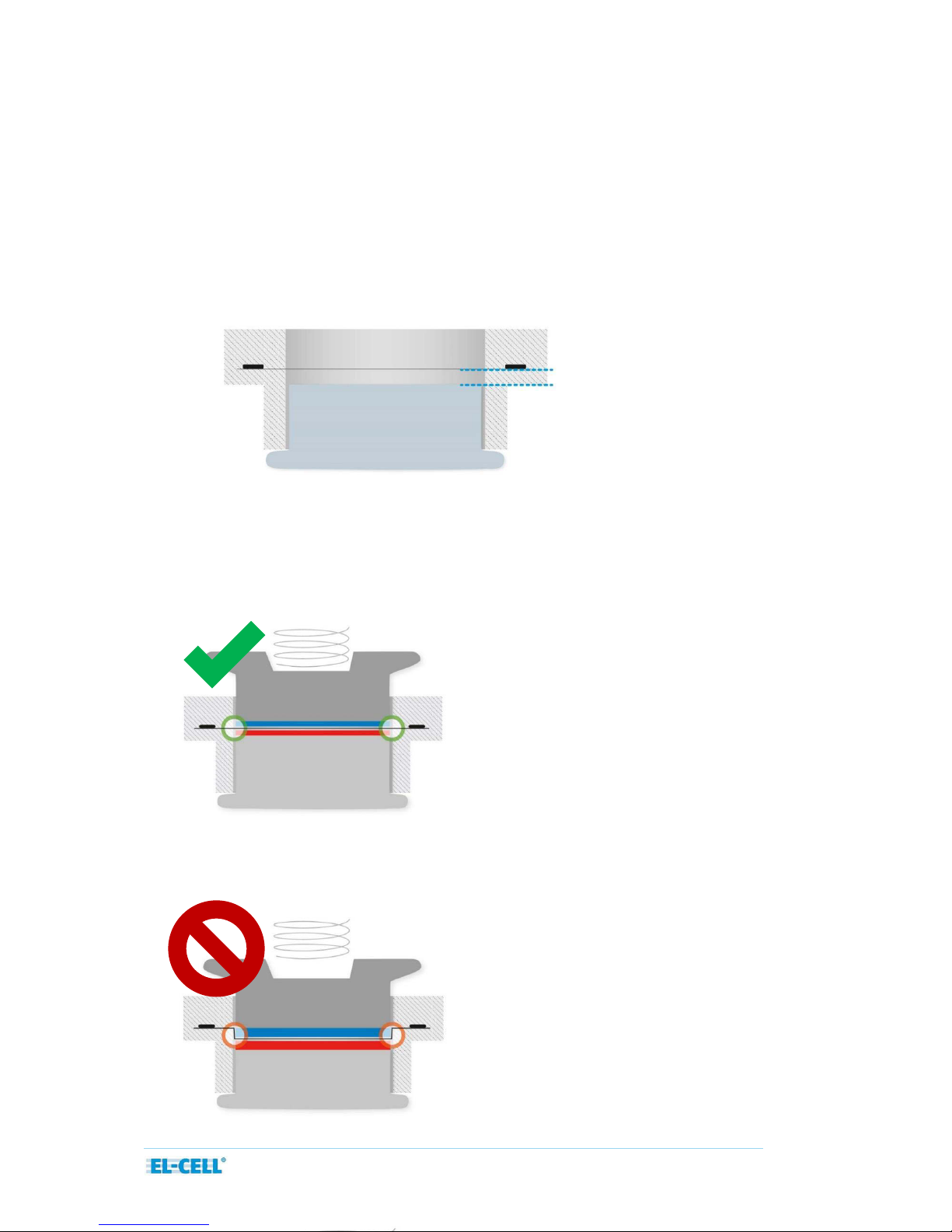

7 PAT-Core Components

Lower Plunger:

The lower plunger is available in different materials (SS 1.4404, Al 99.5%, Cu 99.9%)

and with different gap sizes. The different gaps are necessary in orde r to account for

the different thicknesses of the lower electrode and the separator used. The term ‘ gap’

refers to the distance between the lower face of the built -in separator (thought of as

having zero thickness) and the upper face of the lower plunger when attached to the

insulation sleeve, see sketch below.

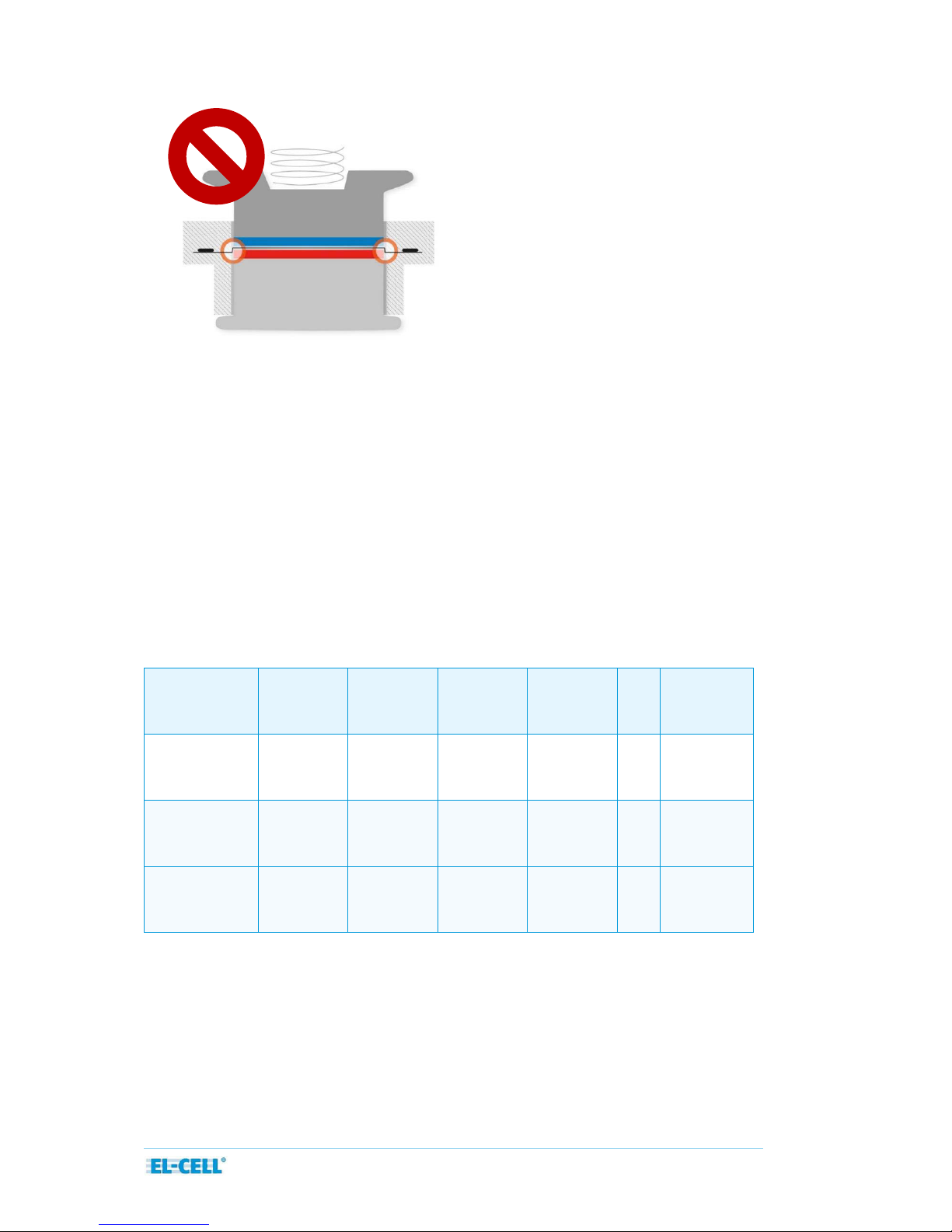

If you use a wrong plunger gap, you may get trouble with your battery test. The below figures

illustrate this point.

Good case: No bending of

built-in separator; reference

ring is in plane with

separator.

Gap

Gap too large: Excessive

dow nward bending of built-in

separator; reference ring is out

of plane with separator.

Page 12

Page 12 of 17

User Manual ECC-PAT-Core – Release 2. 02

Available lower plungers:

The lower plunger is available with gap sizes between 50 and 800 in steps of 50 µm. For

ordering, just append the step size to the article code, see table below.

For lower electrodes having a thickness of around 100 µm, we recommend a gap size of 100

when using thin separators such as Viledon or Celgard, and a gap size of 200 when using our

standard glass fiber separator. In general, for glass fiber, the gap size must be approx. 100 µm

larger than the electrode thickness because of the compression of the built-in separator.

Gap of

lower plunger

(in µm)

50

100

150

200

..

800

Article code

lower plunger

(SS)

ECC1-010027-C_50

ECC1-010027-C_100

ECC1-010027-C_150

ECC1-010027-C_200

ECC1-010027-C_800

Article code

lower plunger

(Al)

ECC1-010027-A_50

ECC1-010027-A_100

ECC1-010027-A_150

ECC1-010027-A_200

ECC1-010027-A_800

Article code

lower plunger

(Cu)

ECC1-010027-B_50

ECC1-010027-B_100

ECC1-010027-B_150

ECC1-010027-B_500

ECC1-010027-B_800

Gap too small: Excessive

upward bending of built-in

separator; reference ring is

out of plane with separator.

Page 13

Page 13 of 17

User Manual ECC-PAT-Core – Release 2. 02

Upper Plunger:

The upper plunger is available in different materials: Stainless steel 1.4404, Al 99.5% and Cu

99.9%. Other materials on request.

type of utilization

(single-use vs. reusable)

Art-No. upper plunger

copper

Cu 99.9

(E-CU 58)

single-use

ECC1-01-0026-A

aluminium

Al 99.5

(EN-AW- 1050)

single-use

ECC1-01-0026-B

stainless steel

316L

(1.4404)

reusable

ECC1-01-0026-C

Insulation sleeve:

The insulation sleeve is available with and without a ring-shaped lithium metal reference ring,

and with two different types of separator: borosilicate glass fiber separator (Whatman GF/A)

having a thickness of 260 µm, and nonwoven polyester pasted with Al2O3 (Freudenberg Viledon

FS 3005-25) having a thickness of 25 µm. Other separators and customized solutions are

available on request. Furthermore, the sleeve is available in the disassembled state, either with

or without the lithium reference ring. The table below comprises the four standard versions

only.

Art-No.

type of testing

(2 or 3 electrodes)

Insulation sleeve

with lithium metal ring reference,

with glass fiber separator (260 µm)

ECC1-00-0210-O/x

3 electrodes

Insulation sleeve

with lithium metal ring reference,

with Viledon separator (25 µm)

ECC1-00-0210-A/x

Insulation sleeve

with glass fiber separator (260 µm)

ECC1-00-0210-P/x

2 electrodes

Insulation sleeve

with Viledon separator (25 µm)

ECC1-00-0210-B/x

Page 14

Page 14 of 17

User Manual ECC-PAT-Core – Release 2. 02

9 Disassembly and Cleaning

After disassembly, dispose all single-use components and electrodes properly. If the

cell base has got contaminated with electrolyte, clean it with plenty of water and dry with

compressed air. Use less electrolyte for subsequent tests. Plungers made of stainless

steel have to be cleaned with plenty of water. If necessary, remove persistent dirt with

aqueous nitric acid (20%, 2 hours at room temperatu re). All other cell components are

for immediate re-use without cleaning.

10 Consumables

Plunger (single-use):

Upper plunger (Al) ECC1-01-0026-B

Upper plunger (Cu) ECC1-01-0026-A

Lower plunger (Al), gap x = 50 to 800 ECC1-01-0027-A_x

Lower plunger (Cu), gap x = 50 to 800 ECC1-01-0027-B_x

Insulation sleeves (single-use):

Insulation sleeve with Li-reference ring and Viledon separator

ECC1-00-0210-A/x

Insulation sleeve with Viledon separator only

ECC1-00-0210-B/x

Insulation sleeve with Li-reference ring and glass fiber separator

ECC1-00-0210-O/x

Insulation sleeve with glass fiber separator only

ECC1-00-0210-P/x

Seals (single-use):

Ferrule 1.0 ECC1-00-0029-B

PE-Seal (lid)* ECC1-00-0053-A

* W e recomm end r eplacement of the PE-Seal after every u se.

Page 15

Page 15 of 17

User Manual ECC-PAT-Core – Release 2. 02

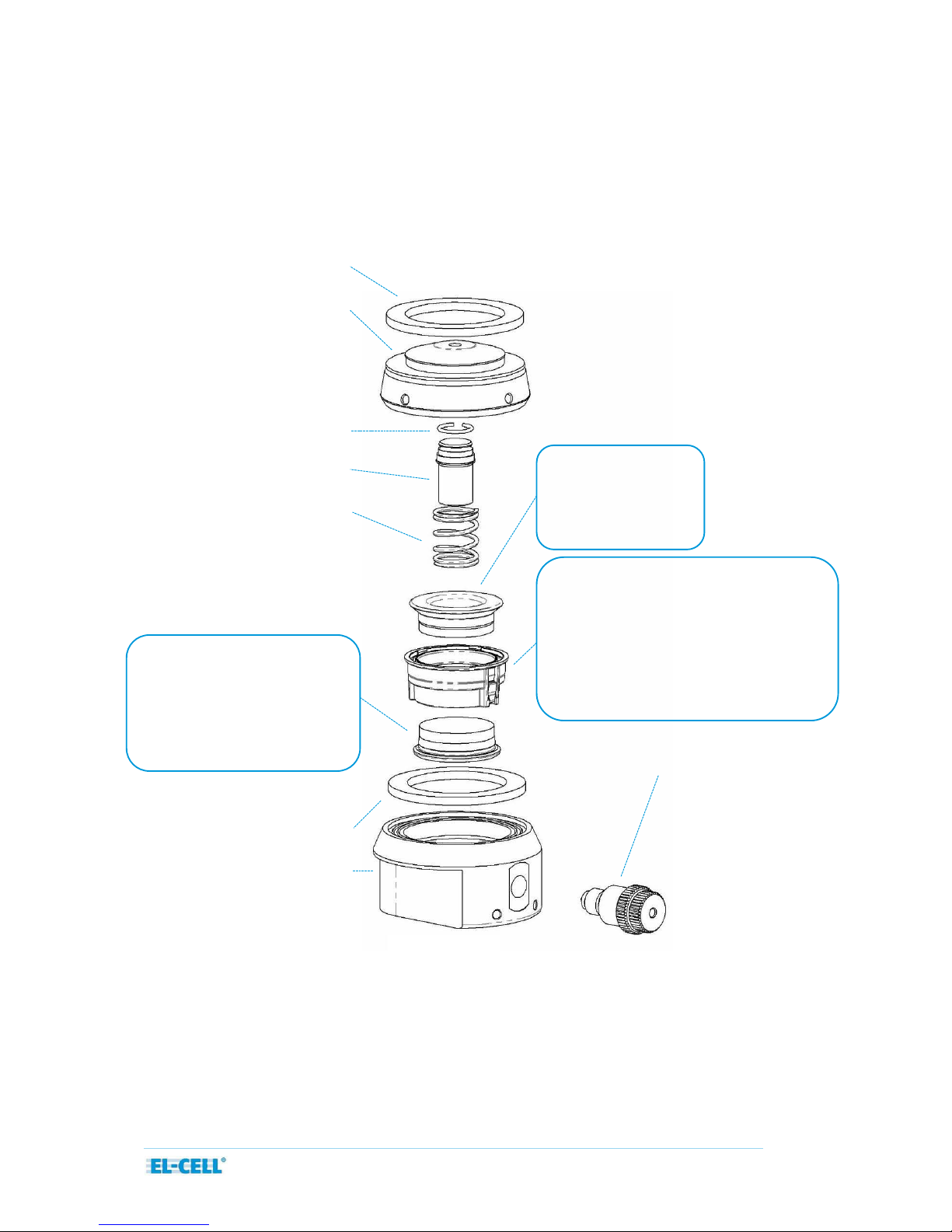

11 Spare Parts

Components:

PE-Se al

ECC1-00-0053-A

Lid (ECC-PA T-Core)

ECC1-00-0057-M

Sha ft ring

FED9029

Dead volume adapter (ECC- PAT-Core)

ECC1-00-0224-A

Com pre ssion sp rin g (Au)

FED9015

Low er plunger (SS)

ECC1-01-0027-C_x

or Lower plunger (Al)

ECC1-01-0027-A_x

mor e versions see chapter 7

PE-Se al

ECC1-00-0053-A

Cell base

ECC1-00-0056-M

Upper plunger (SS)*

ECC1-01-0026-C

or Upper plunger (Cu)*

ECC1-01-0026-A

Insulation sleeve with bu ilt-in G F

sep arator and wit h Li-ref erence ring

ECC1-00-0210-O/ x

or Insulation sle eve with built-in G F

sep arator (no ref erence)

ECC1-00-0210-P/x

mor e versions see chapter 7

Feed wire assy ( ECC -PAT- Core)

ECC1-00-0010-M

Page 16

Page 16 of 17

User Manual ECC-PAT-Core – Release 2. 02

Plunger (reusable):

Upper plunger (SS)

ECC1-01-0026-C

Lower plunger (SS), ), gap x = 50 to 800 (steps of 50)

ECC1-01-0027-C_x

12 Technical Support

Technical support for this product is exclusively provided by EL-CELL GmbH.

EL-CELL GmbH

Tempowerkring 8

21079 Hamburg - Germany

phone: +49 40 79012-737

fax: +49 40 79012 -736

e-mail: in fo @e l- ce ll.com

web: www.el-cell.com

Page 17

Page 17 of 17

User Manual ECC-PAT-Core – Release 2. 02

13 Warranty

For a period of one year from the date of shipment, EL-CELL GmbH (hereinafter Seller)

warrants the goods to be free from defect in material and workmanship to the original

purchaser. During the warranty period, Seller agrees to repair or replace defective

and/or nonconforming goods or parts without charge for material or labor, or, at the

Seller’s option, demand return of the goods and tender repayment of the price. Buyer’s

exclusive remedy is repair or replacement of defective and nonconforming goods, or, at

Seller’s option, the repayment of the price.

Seller excludes and disclaims any liability for lost profits, personal injury, interruption of

service, or for consequential incidental or special damages arising out of, resulting

from, or relating in any manner to these goods.

This Limited Warranty does not cover defects, damage, or nonconformity resulting from

abuse, misuse, neglect, lack of reasonable care, modification, or the attachment of

improper devices to the goods. This Limited Warranty does not cover expendable items.

This warranty is void when repairs are performed by a non-authorized person or service

center. At Seller’s option, repairs or replacements will be made on site or at the factory.

If repairs or replacements are to be made at the factory, Buyer sha ll return the goods

prepaid and bear all the risks of loss until delivered to the factory. If Seller returns the

goods, they will be delivered prepaid and Seller will bear all risks of loss until delivery

to Buyer. Buyer and Seller agree that this Limited Warranty shall be governed by and

construed in accordance with the laws of Germany.

The warranties contained in this agreement are in lieu of all other warranties expressed

or implied, including the warranties of merchantability and fitness for a particular

purpose.

This Limited Warranty supersedes all prior proposals or representations oral or written

and constitutes the entire understanding regarding the warranties made by Seller to

Buyer. This Limited Warranty may not be expanded or modified except in writing sig ned

by the parties hereto.

Loading...

Loading...