EL BJORN A155F, A155HW User Instructions

User instructions

WARNING!

400V

VARNING!

FÅR EJ ÖVERTÄCKAS

OBS!

BYT FILTER

REGELBUNDET

Drying room dehumidier

A155F/A155HW

Table of contents ........................................................ 2

Introduction ........................................................ 3

Technical data ........................................................ 3

Safety instructions ........................................................ 4

Description ....................................................................... 5-9

Installation ....................................................................... 10-13

Drying ....................................................................... 14-15

Maintenance ....................................................................... 16-17

Spare parts/accessories ........................................................ 18

TABLE OF CONTENTS

- 2 -

4

INTRODUCTION

TECHNICAL DATA

- 3 -

Technical data, dehumidier

Width: 470 mm

Height: 1498 mm

Depth: 370 mm

Noise level: 66dB

Weight: 70 kg

Electrical connection: 3N~400V

Fuse: 10 A slow

Rated power (A 155F): 5400W

Rated power (A 155HW): 1200W

Auxiliary heating: 3990W

Operating range, temp.: 15-35ºC

Operating range, RH: 35-99%

Dehumidication capacity: Max. 3 l/h

Refrigerant, type: R134a

Refrigerant, amount: 870g

The A 155 dehumidier is designed for the high

capacity drying of laundry in large drying rooms, for

example in apartment / multi occupancy buildings

or on site Portacabins. An optional pipe system

for hanging laundry on can be ordered with the

dehumidier. See web site for more information

This instruction manual covers the free-blowing

dehumidiers A 155F (standard electric) and the

155HW (hot water), model designed for district

heating.

The manual contains detailed instructions for use,

maintenance and inspection of the dehumidier with

or without a pipe system. It includes instructions for

insuring maximum safety and information on the

design and use of the safety features.

NOTE: All persons using or repairing the

dehumidier should carefully read the section

on safety.

This manual contains instructions on use of the

product and maintenance that can be carried out by

the operator.

More detailed servicing or troubleshooting may only

be performed by the manufacturer’s service staff or

representative.

The user instructions describe all the necessary safety

features.. The rst thing the user should do following

delivery, is to read the instruction manual carefully.

This should be done before connecting to the

electricity supply.

The manufacturer reserves the right to make

modications.

Various symbols and warning signs are shown in

this manual and displayed on the dehumidier.

They are listed on the next page.

If any of the warning signs on the dehumidier

are damaged in any way, a new one must be

ordered and attached immediately to ensure

maximum safety during use of the dehumidier.

The dehumidier may only be used for the

applications described in this user manual.

The manufacturer reserves the right to make any

modications.

5

SAFETY INSTRUCTIONS

- 4 -

Warning signs on the dehumidier

Read the instruction manual carefully

before using the dehumidier.

Warning of high voltage if the hatch is

opened before the power supply to the

dehumidier has been turned off.

The manufacturer’s guarantee that this

product meets the safety provisions of

the Low Voltage Directive.

Safety during installation

Electrical connection of the dehumidier and its peripheral

equipment should be carried out by a qualied electrician.

Safety during use

The dehumidier’s air intake and air outlet must never

be covered during operation. It is strictly forbidden

to remove the protective hoods or cover plates during

operation.

Safety during maintenance

The power supply to the machine must be cut off

before performing maintenance on the dehumidier.

This can be done by pulling the connector out of

the power socket, or by breaking the current with the

circuit breaker.

All maintenance of the electrical system must be

performed by a qualied electrician.

All maintenance of the refrigeration system must be

performed by a qualied refrigeration technician.

When cleaning the condenser and evaporator, use

gloves to avoid cutting injuries.

Caution! and Note:

The following boxes are shown in this instruction

manual where appropriate.

CAUTION!

These boxes warn of injury or

damage to people or objects.

The caution boxes are shown in front

of the procedure they refer to.

NOTE:

These boxes contain special

instructions and information on how

to make specic procedures easier.

The lter should be

replaced 1–2 times per

year. Also see under

“Maintenance”.

The dehumidier’s air

intake and air outlet

must never be covered.

Warning signs in these user instructions

Read the instruction manual carefully

before using the dehumidier.

Caution! The dehumidier may be

dangerous. Careless or incorrect use

could result in serious or even fatal

injury.

The manufacturer’s guarantee that this

product meets the safety provisions of

the Low Voltage Directive.

VARNING!

400V

• The product may not be used by persons (including

children) with physical or mental disabilities,

unless they have received information or instruction

on safe use of the product from a person with

responsibility for their safety.

• However, the product is suitable for use in

environments where there are persons (including

children) with physical or mental disabilities or

impaired judgement.

• If children have access to the product, they must be

instructed not to use the product for playing with.

1-2 times / year

604503

DESCRIPTION

- 5 -

WARNING!

400V

VARNING!

FÅR EJ ÖVERTÄCKAS

OBS!

BYT FILTER

REGELBUNDET

1

2

16

AEV

9

LP

M2

10

12

K2

K1

X

S1

GT3

GT2

GT5

1 Ceiling mounting with suspension bars.

2 Side bar

3 Drying pipes

4 Base pipe

5 End plate

6 Inner telescopic tube

7 Outer telescopic tube

8 Anti-tip device

9 Drain water connection, for copper pipe Ø15 mm

10 Adjustable foot

12 Type plate

13 Sticker “Replace lter regularly”

14 Filter cassette (inside door)

15 Sticker “Do not cover”

16 Hanger (accessory)

B1 Overcurrent relay

AEV Evaporator. (Also see next page).

E Auxiliary heating 3990 W. (1330x3)(See next page or

water condenser A 155HW

FT Dryer lter. (See next page).

GT1 Thermostat for control of heating coil

GT2 Overheating protector, manual reset (x 2).

GT3 Overheating protector, automatic reset GT4

Thermocontact switch in fan (not shown).

GT5 Low pressure control

GT6 Overload protection device, compressor

GT7 Overload protection device, compressor

K1 Contactor for fan

K2 Contactor for compressor

K3 Contactor for heating coil

KD Capacitor. (See next page).

M1 Fan. (See next page).

M2 Compressor

S1 Timer, 2 options

X Terminal block

SD Capillary tube, throttle (see next page).

LP Low pressure control

GT1

B1

K3

3

5

4

6

7

8

15

13

14

Fig 1. A 155 with pipe system

Fig 1. A 155 with pipe system

GT6/GT7

DESCRIPTION

- 6 -

Function

Dehumidier A 155

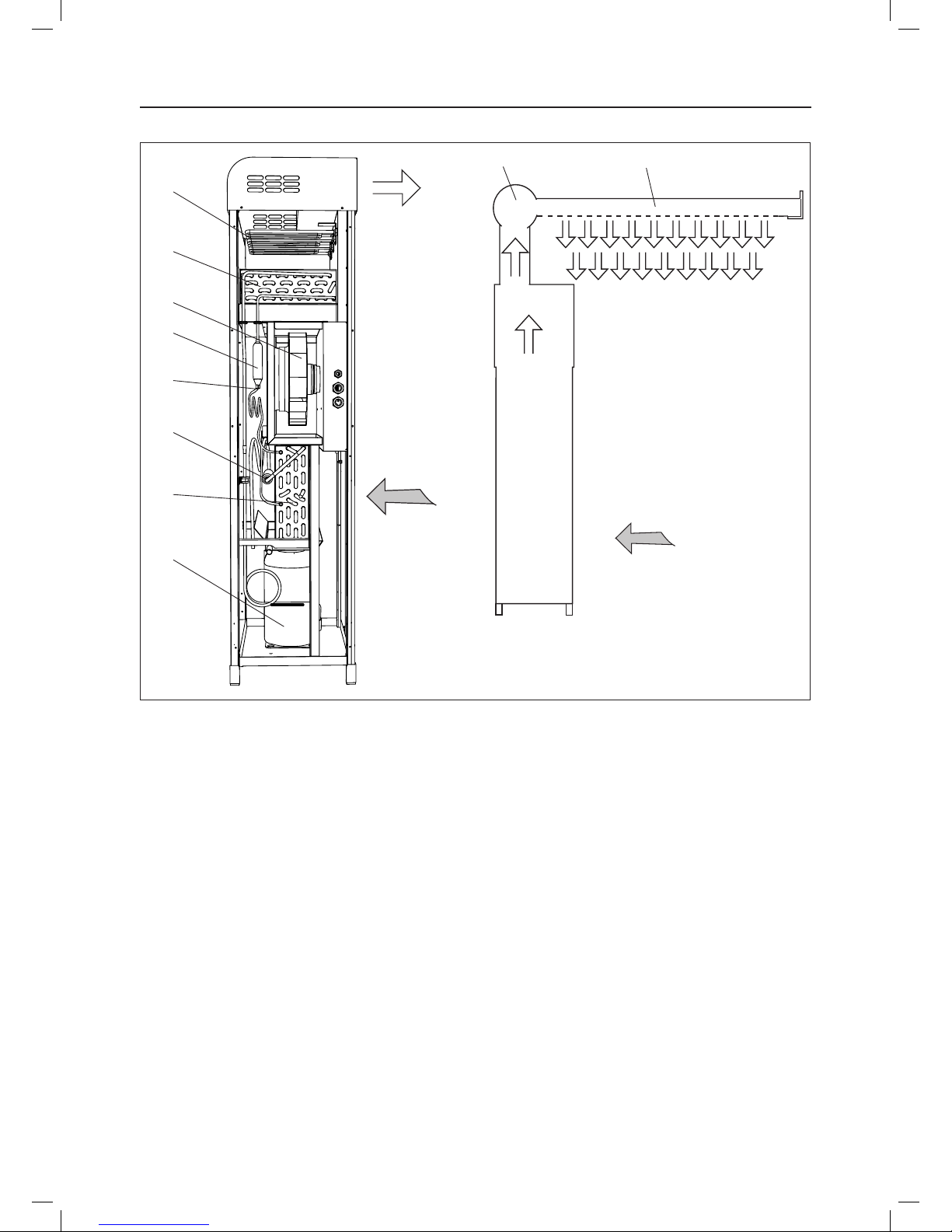

The A 155 is a condensation dehumidier, and is

based on the principle that air moisture condenses on

cold surfaces.

The cold surfaces are created on the evaporator

(AEV) when the compressor (M2) transfers heat from

the evaporator to the condenser (KD).

The dehumidier is equipped with a fan (M1) that

transports the air through the dehumidier.

The air rst passes through the evaporator (AEV),

where the moisture condenses and is deposited on the

evaporator.

The condensate collects in a trough located

underneath the evaporator, is transported away.

The air then passes through the fan (M1) and the

condenser (KD). In the condenser, the air is warmed

up and the condenser is simultaneously cooled.

After this, the air can be heated by the auxiliary

heating system (E) before being released from the

dehumidier.

Pipe system

The pipe system has two functions: it distributes the

air and is used for hanging washing on. The diameter

of the drying pipes is(Ø60 mm) (3) prevents clothes

from creasing whilst drying.

Dry air from the dehumidier is blown into the pipe

system and distributed to the drying pipes (3) via the

base pipe (4).

Dry air is blown downwards through holes in the

drying pipes, and is distributed between the items of

laundry.

This dries the laundry evenly, even in the places that

are least exposed.

All tubes are made of extruded, anodised aluminium,

making them highly durable and corrosion-resistant.

E

KD

M1

FT

SD

A

AEV

M2

Moist air

4 3

Moist air

Dry air

Dry air

Fig 3. A 155F (left) and A 155 with pipe system

Loading...

Loading...