Elba PXDO 906 DF, PBKDO 906 DF Instructions For Use - Installation Advice

TWIN OVEN

DUAL FUEL

COOKER

PXDO 906 DF

PBKDO 906 DF

GB

Instructions for use - Installation advice

KEEP IN A SAFE PLACE

2

Read the instructions carefully before installing and using the appliance.

CAUTION: this apparatus must only be installed in a permanently ventilated room in

compliance with the applicable regulations.

Dear Customer,

Thank you for having purchased and

given your preference to our product.

The safety precautions and

recommendations reported below are

for your own safety and that of others.

They will also provide a means by

which to make full use of the features

offered by your appliance.

Please preserve this booklet

carefully. It may be useful in future,

either to yourself or to others in the

event that doubts should arise relating

to its operation.

This appliance must be used only

for the task it has explicitly been

designed for, that is for cooking

foodstuffs. Any other form of usage

is to be considered as inappropriate

and therefore dangerous.

The manufacturer declines all

responsibility in the event of damage

caused by improper, incorrect or

illogical use of the appliance.

IMPORTANT INSTRUCTIONS AND

ADVICE FOR THE USE OF

ELECTRICAL APPLIANCES

The use of any electrical appliance

requires the compliance with some basic

rules, namely:

– do not touch the appliance with wet or

damp hands (or feet)

– do not use the appliance whilst in bare

feet

– do not allow the appliance to be

operated by children or unqualified

persons without supervision.

The manufacturer cannot be deemed

responsible for damages caused by

wrong or incorrect use.

AFTER SALES SERVICE

If you require After Sales Service contact

the MASTERCARE Domestic Appliance

Helpline Telephone 08701 565550.

This cooker has been designed, constructed and marketed in compliance with:

- safety requirements of EEC Directive “Gas” 90/396;

- safety requirements of EEC Directive “Low voltage” 73/23;

- protection requirements of EEC Directive “EMC” 89/336;

- requirements of EEC Directive 93/68.

Important:

This appliance is designed and manufactured solely for the cooking of domestic

(household) food and is not suitable for any non domestic application and therefore

should not be used in a commercial environment.

The appliance guarantee will be void if the appliance is used within a non domestic

environment i.e. a semi commercial, commercial or communal environment.

3

FIRST USE THE OVEN

It is advised to follow these instructions:

– Clean the interior of the oven with

cloth soaked in water and detergent

(neutral) then dry carefully.

– Furnish the interior of the oven by

placing the wire racks as described

at chapter “Cleaning and

maintenance”.

– Insert shelves and tray.

– Empty the oven and close the door.

Heat the oven at the maximum

temperature setting for around two

hours to eliminate the odour of

grease and fumes from the

manufacturing process. Make sure

that the kitchen is well ventilated and

do not remain in the room during this

process.

IMPORTANT PRECAUTIONS

AND RECOMMENDATIONS

After having unpacked the appliance,

check to ensure that it is not damaged

and that the oven doors close correctly.

In case of doubt, do not use it and

consult your supplier or a professionally

qualified technician.

Packing elements (i.e. plastic bags,

polystyrene foam, nails, packing straps,

etc.) should not be left around within

easy reach of children, as these may

cause serious injuries.

● ATTENTION: Model PXDO 906 DF

Please peel plastic cover of both

sides and front before use.

● Do not attempt to modify the technical

characteristics of the appliance as

this may cause danger to users.

● Do not carry out cleaning or

maintenance operations on the

appliance without having previously

disconnected it from the electric

power supply.

● If you should decide not to use this

appliance any longer (or decide to

substitute another model), before

disposing of it, it is recommended that

it be made inoperative in an

appropriate manner in accordance to

health and environmental protection

regulations, ensuring in particular that

all potentially hazardous parts be

made harmless, especially in relation

to children who could play with

unused appliances.

● After use, ensure that the knobs are

in off position.

● Do not allow children or other

unqualified people to use the

appliance without your supervision.

● During and after use of the cooker,

certain parts will become very hot. Do

not touch hot parts.

● Keep children away from the cooker

when it is in use.

● Some appliances are supplied with a

protective film on steel and aluminium

parts. This film must be removed

before using the appliance.

● Fire risk! Do not store flammable

material in the oven and in the

storage compartment.

● Make sure that electrical cables

connecting other appliances in the

proximity of the cooker cannot come

into contact with the hob or become

entrapped in the oven doors.

● Do not line the oven walls with

aluminium foil. Do not place baking

trays or the drip tray on the base of

the oven chamber.

● The manufacturer declines all liability

for injury to persons or damage to

property caused by incorrect or

improper use of the appliance.

● The various components of the

appliance are recyclable. Dispose of

them in accordance with the

regulations in force in your country. If

the appliance is to be scrapped,

remove the power cord.

4

1 - COOKING HOB

Fig. 1.1

2345

6

1

COOKING HOB

1. Double-ring burner (PB) 3,45 kW

2. Semi-rapid burner (SR) 1,90 kW

3. Rapid burner (R2) 2,95 kW

4. Auxiliary burner (A) 1,00 kW

5. Semi-rapid burner (SR) 1,90 kW

6. Auxiliary burner (A) 1,00 kW

5

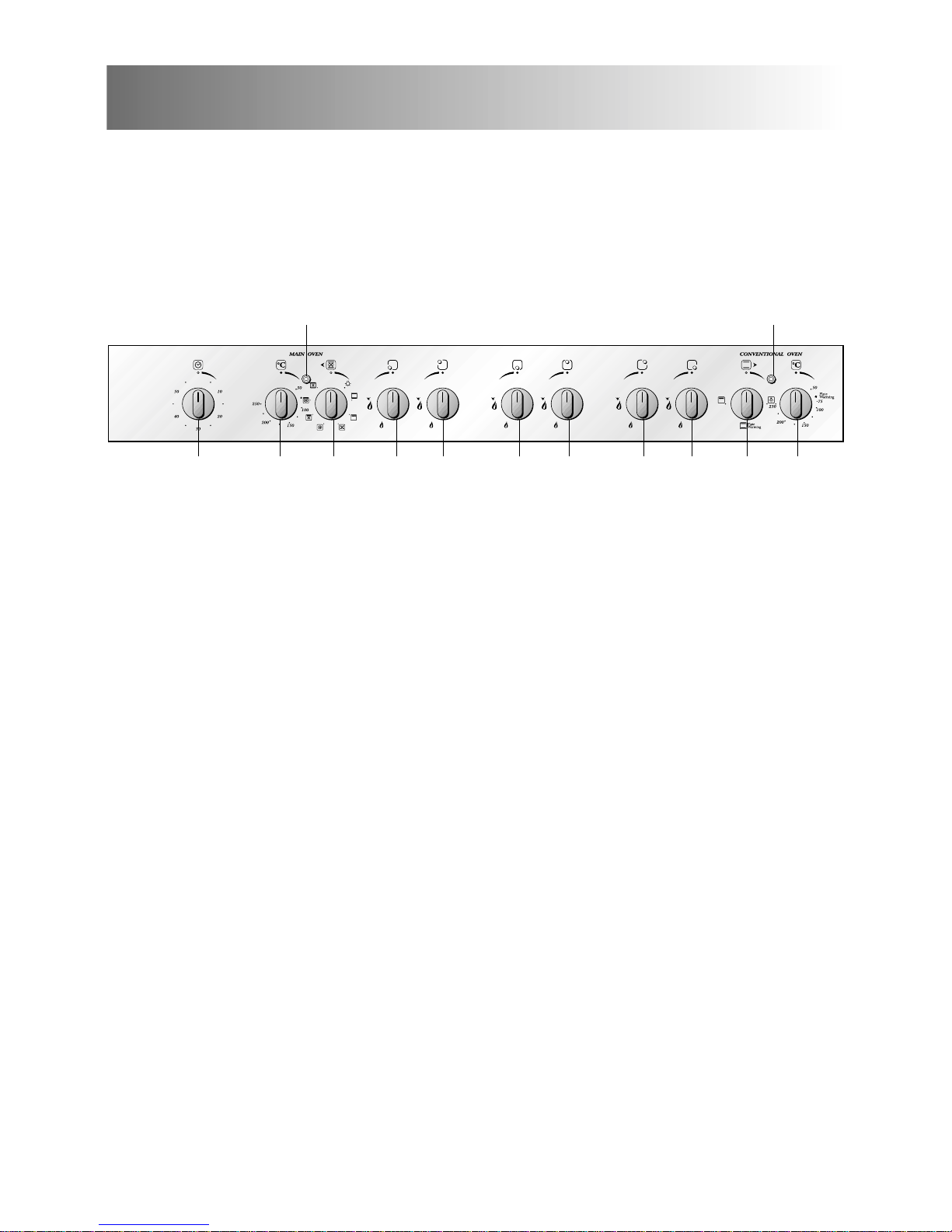

2 - CONTROL PANEL

Fig. 2.1

98 65 10321117

1312

CONTROL PANEL - Controls description

1. Front right burner control knob

2. Rear right burner control knob

3. Rear central burner control knob

4. Front central burner control knob

5. Rear left burner control knob

6. Front left burner control knob

7. Multifunction main oven switch knob

8. Multifunction main oven thermostat knob

9. Minute counter (60 minutes)

10. Conventional oven thermostat knob

11. Conventional oven switch knob

Pilot lamps:

12. Main oven thermostat indicator light

13. Conventional oven thermostat indicator light

4

6

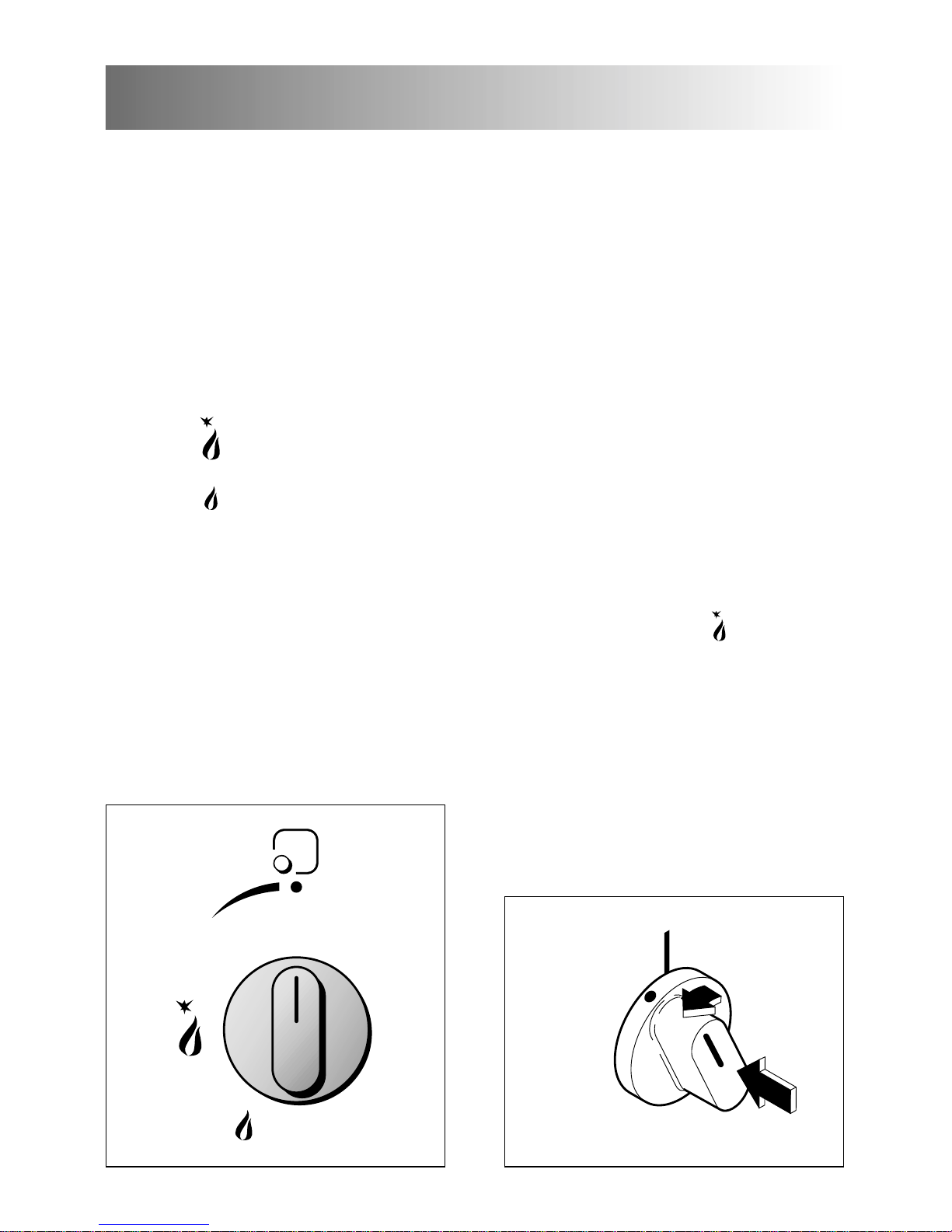

3 - USE OF COOKING HOB

GAS BURNERS

Each burner is controlled by a gas tap

assuring the opening and the closing of

the gas supply.

Make the lever of the knob match with

the indicator on the control panel to

obtain:

– symbol

● : off

– symbol : full on (nominal rate)

– symbol : reduced rate

To reduce the gas flow to minimum,

rotate the knob anti-clockwise to point

the lever towards the small flame

symbol.

Fig. 3.1

The maximum aperture position permits

rapid boiling of liquids, whereas the

minimum aperture position allows slower

warming of food or maintaining boiling

conditions of liquids (simmering).

Other intermediate operating

adjustments can be achieved by

positioning the lever between the

maximum and minimum aperture

positions, and never between the

maximum aperture and off positions.

LIGHTING THE BURNERS

To ignite the burner, the following

instructions are to be followed:

1) Lightly press and turn the knob anticlockwise, and position the knob

indicator to the symbol printed on the

control panel (fig. 3.2).

2) Press the knob to operate the electric

ignition; or, in the case of a mains

failure light the burner with a match or

lighted taper.

3) Adjust the burner according to the

setting required.

Fig. 3.2

7

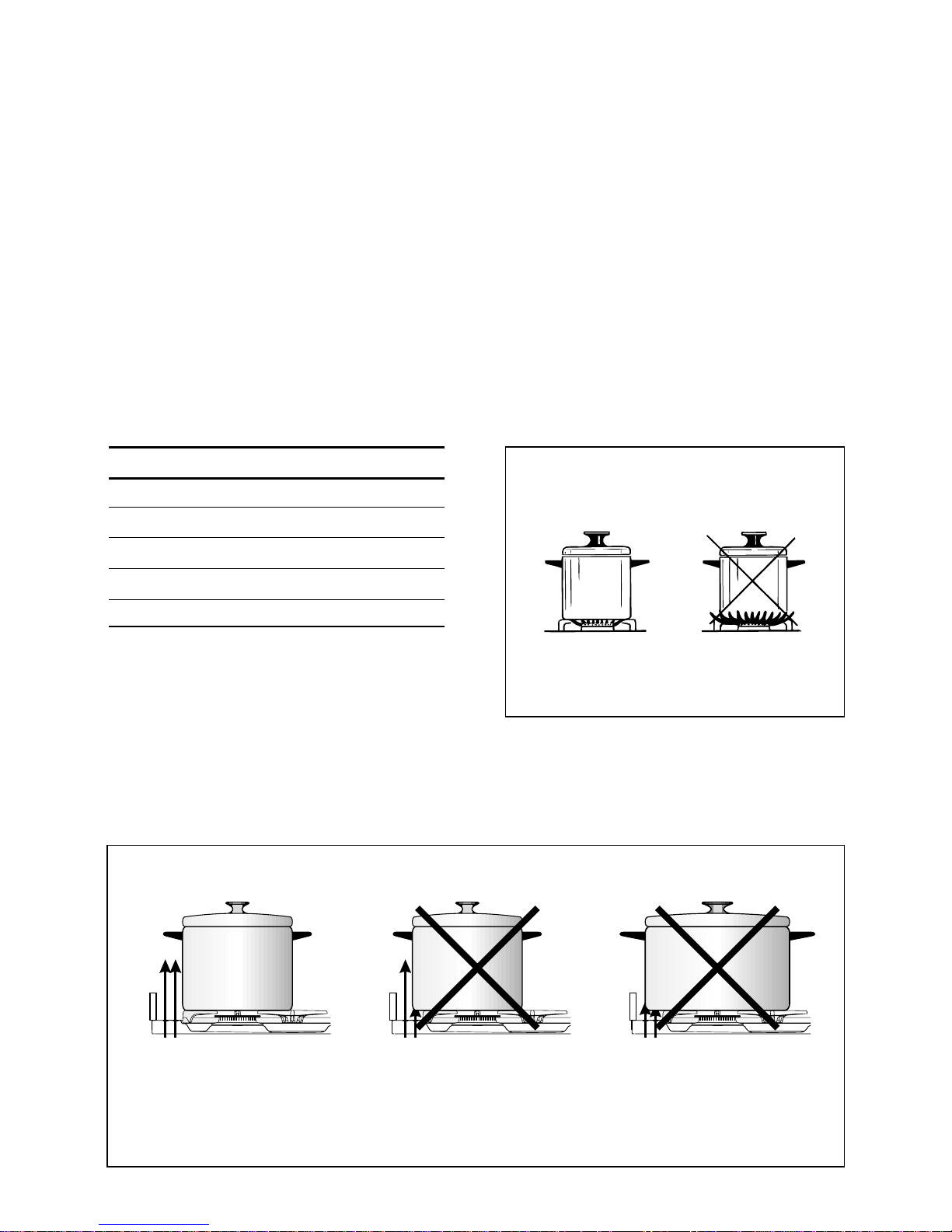

CHOICE OF THE BURNER

On the control panel, near every knob,

there is a diagram that indicates which

burner is controlled by that knob.

The suitable burner must be chosen

according to the diameter and the

capacity used.

As an indication, the burners and the

pots must be used in the following way:

It is important that the diameter of the

pot be suitable to the potentiality of the

burner so as not to compromise the high

output of the burners and therefore

energy waste.

A small pot on a large burner does not

give you a boiling point in a shorter

amount of time since the capacity of

heat absorption of a liquid mass

depends on the volume and the surface

of the pot.

Fig. 3.3a

BURNERS POT DIAMETER

Auxiliary 12 - 16 cm

Semi-rapid 16 - 22 cm

Rapid 24 - 24 cm

Double-ring up to 30 cm

do not use pans with concave or convex bases

AIR FLOW

(cooling fan)

AIR FLOW

(cooling fan)

AIR FLOW

(cooling fan)

CORRECT USE OF RAPID BURNER

Fig. 3.3b

8

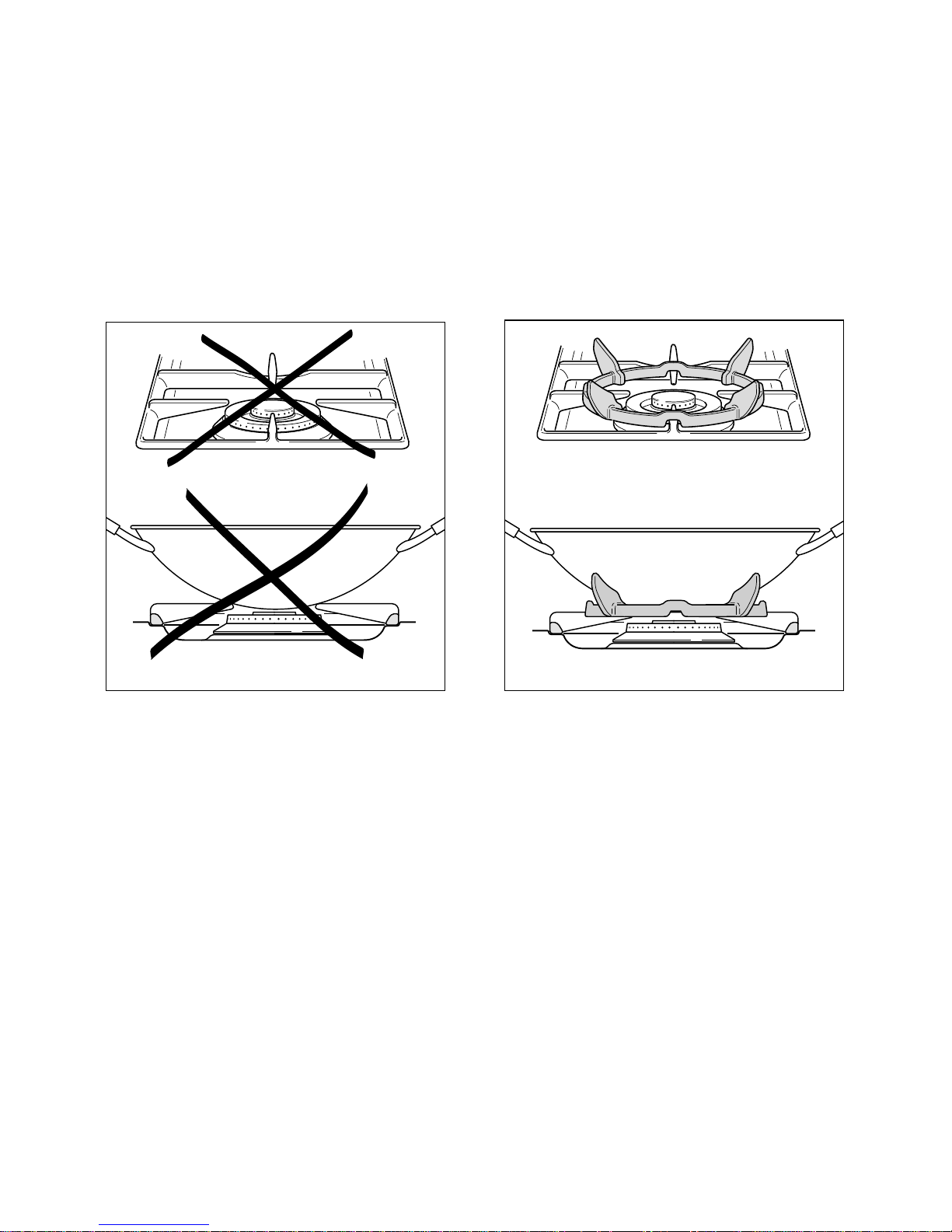

Fig. 3.4b

Fig. 3.4a

WRONG

CORRECT

CORRECT USE OF DOUBLE-RING BURNER

The flat-bottomed pans are to be placed directly onto the pan-support.

When using a WOK you need to place the supplied stand in the burner to avoid any faulty

operation of the double-ring burner (Fig. 3.4a - 3.4b).

9

Attention: the oven door

becomes very hot during operation.

Keep children away.

GENERAL FEATURES

As its name indicates, this is an oven

that presents particular features from an

operational point of view.

In fact, it is possible to insert 7 different

programs to satisfy every cooking need.

The 7 positions, thermostatically controlled, are obtained by 4 heating elements which are:

– Bottom element 1400 W

– Top element 1000 W

– Grill element 2000 W

– Circular element 2500 W

NOTE:

Upon first use, it is advisable to operate the

oven for 30 minutes in the position and

for another 30 minutes at the maximum

temperature (thermostat knob on position

250) in the positions

and

, to eliminate possible traces of grease on the heating elements.

Clean the oven and accessories with warm

water and washing-up liquid.

WARNING:

The door is hot, use the handle.

OPERATING PRINCIPLES

Heating and cooking in the MULTIFUNCTION oven are obtained in the following ways:

a. by normal convection

The heat is produced by the upper and

lower heating elements.

b. by forced convection

A fan sucks in the air contained in the

oven muffle, which sends it through

the circular heating element and then

sends it back through the muffle.

Before the hot air is sucked back

again by the fan to repeat the

described cycle, it envelops the food in

the oven, provoking a complete and

rapid cooking.

It is possible to cook several dishes

simultaneously.

c. by semi-forced convection

The heat produced by the upper and

lower heating elements is distributed

throughout the oven by the fan.

d. by radiation

The heat is irradiated by the infra red

grill element.

e. by radiation and ventilation

The irradiated heat from the infra red

grill element is distributed throughout

the oven by the fan.

4 - MULTI-FUNCTION MAIN OVEN

10

Fig. 4.1 Fig. 4.2

FUNCTION SELECTOR KNOB

Rotate the knob clockwise to set the

oven for one of the following functions:

OVEN LIGHT

By turning the knob onto this setting we

light the oven cavity (15 W).

The oven remains alight while any of the

functions is on.

THERMOSTAT KNOB

To turn on the heating elements of the

oven, set the switch knob on the desired

program and the thermostat knob onto

the desired temperature.

To set the temperature, it is necessary to

make the knob indicator meet the chosen

number.

The elements will turn ON or OFF automatically according to the energy need

which is determined by the thermostat.

TRADITIONAL CONVECTION

COOKING

The upper and lower heating elements

are switched on. The heat is diffused by

natural convection and the temperature

must be regulated between 50° C and

250° C with the thermostat knob.

It is necessary to preheat the oven

before introducing the foods to be

cooked.

RECOMMENDED USE:

For foods which require the same cooking temperature both internally and

externally, i. e. roasts, spare ribs,

meringue, etc.

11

GRILLING

The infra-red heating element is switched

on. The heat is diffused by radiation.

Use with the oven door closed and the

thermostat knob to position 225°C for

max 15 minutes, then to position 175°C.

For correct use see chapter “USE OF THE

GRILL”.

Note: It is recommended that you do not

grill for longer than 30 minutes at any one

time.

Attention: the oven door becomes very

hot during operation. Keep children away.

For correct use see chapter “USE OF

THE GRILL”.

RECOMMENDED USE:

Intense grilling action for cooking with the

broiler; browning, crisping, “au gratin”,

toasting, etc.

DEFROSTING FROZEN FOODS

Only the oven fan is on.

To be used with the thermostat knob on

“●” because the other positions have no

effect. The defrosting is done by simple

ventilation without heat.

RECOMMENDED USE:

To rapidly defrost frozen foods; 1 kilogram requires about one hour.

The defrosting times vary according to

the quantity and type of foods to be

defrosted.

HOT AIR COOKING

The circular element and the fan are on.

The heat is diffused by forced convection

and the temperature must be regulated

between 50° and 250 °C with the thermostat knob.

It is not necessary to preheat the oven.

RECOMMENDED USE:

For foods that must be well done on the

outside and tender or rare on the inside,

i. e. lasagna, lamb, roast beef, whole

fish, etc.

VENTILATED GRILL COOKING

The infra-red ray grill and the fan are on.

The heat is mainly diffused by radiation

and the fan then distributes it throughout

the oven.

The temperature must be regulated between

50° and 175 °C for max 30 minutes, with

the thermostat knob.

Leave to warm up for approximately 5

minutes with the door closed.

It is recommended that you do not

grill for longer than 30 minutes at any

one time.

Attention: the oven door becomes

very hot during operation.

Keep children away.

For correct use see chapter “GRILLING

AND “AU GRATIN”.

RECOMMENDED USE:

For grill cooking when a fast outside

browning is necessary to keep the juices

in, i. e. veal steak, steak, hamburger,

etc.

Loading...

Loading...