Page 1

USER MANUAL

Version 1.0

Keep this manual for future needs !

© Copyright

Reproduction prohibited !

COLOR SPO T 150

Page 2

2

Table of contents

1. Safety instructions......................................................................................................... 3

2.Operating determina tions ..............................................................................................4

3.Description of the device............................................................................................... 5

4.Inst alla tio n....................................................................................................................... 6

4.1Fitting/Exchanging the lamp.......................................................................................6

4.2Lamp adjustment........................................................................................................ 6

4.3 Inserting/Exchanging rotating gobos......................................................................... 7

4.4 Rigging ...................................................................................................................... 8

4.5 Connection to the mains..........................................................................................10

4.6 DMX- 512 connection, master/sl ave connect ion ..................................................... 11

5. DMX Protocol-16 bit..................................................................................................... 12

6. DMX Protocol-8 bit....................................................................................................... 14

7.Controller mode............................................................................................................ 16

7.1 DMX addressing ..................................................................................................... 16

7.2 Remotely controllable functions .............................................................................. 16

8. Stand - alone mode...................................................................................................... 17

9. Functions of the control panel....................................................................................18

9.1 Addressing.............................................................................................................. 18

9.2 Slave control ........................................................................................................... 19

9.3 Fixture informations................................................................................................. 19

9.4 Personality options..................................................................................................20

9.5 T es t sequences........................................................................................................ 23

9.6 Stand-alone setting ................................................................................................. 24

9.7 Reset function ......................................................................................................... 25

9.8 Special functions..................................................................................................... 2 5

10. Error and information messages.............................................................................. 27

11.T echnical specifications ............................................................................................ 28

12. Maintenance and cleaning ........................................................................................ 30

13. Appendix .................................................................................................................... 31

COLOR SPO T 150

Page 3

3

CAUTION!

Keep this device away from rain and moisture!

Unplug mains lead before opening the housing!

FOR YOUR OWN SAFETY, PLEASE READ THIS USER MANUAL CAREFULLY

BEFORE YOU INITIAL S TART - UP!

1. Safety instructions

Caution ! Be careful with your operations.With a dangerous voltage you can suffer

a dangerous electric shock when touching the wires

This device has left our premises in absolutely perfect condition. In order to maintain this condition and to ensure

a safe operation, it is absolutely necessary for the user to follow the safety instructions and warning notes written

in this manual.

Important:

Damages caused by the disregard of this user manual are not subject to warranty. The dealer will not accept

liability for any resulting defects or problems.

If the device has been exposed to drastic temper ature fluctuation (e .g. after transportation), do not switch it on

immediately . The arising condensation water might damage your de vice. Lea ve the device s witched off until it has

reached room temperature.

This device falls under protection-class I. The power plug must only be plugged into a protection class I outlet.

Never let the power-cord come into contact with other cables! Handle the power-cord and all connections with the

mains with particular caution!

Make sure that the available voltage is not higher than stated on the rear panel.

Make sure that the power-cord is never crimped or damaged by sharp edges. Check the device and the power-

cord from time to time.

Always disconnect from the mains, when the device is not in use or before cleaning it. Only handle the power-cord

by the plug. Never pull out the plug by tugging the power-cord.

During the initial start-up some smoke or smell may arise. This is a nor mal process and does not necessar ily

mean that the device is defective.

Caution: During the operation, the housing becomes very hot.

Do not switch the device on and off in short intervals as this would reduce the lamp’ s life.

HEALTH HAZARD!

Never look directly into the light source,as sensitive persons may suffer

an epileptic shock

( especially meant for epileptics) !

Please consider that damages caused by manual modifications to the device are not subject to w arranty.

Keep aw ay children and amateurs !

Page 4

4

2.Operating determinations

This device is a moving-head spot f or creating decorativ e eff ects and w as designed f or indoor use only.

This device is designed for professional use, e.g. on stages, in discotheques, theatres etc.

Lighting effects are not designed for permanent operation. Consistent operation breaks will ensure that the device

will serve you for a long time without defects.

Never run the device without lamp!

Do not shake the device. Avoid brute force when installing or operating the de vice .

Never lift the fixture by holding it at the projector-head, as the mechanics may be damaged. Always hold the

fixture at the transport handles.

When choosing the installation-spot, please make sure that the device is not exposed to extreme heat, moisture

or dust.There should not be any cables lying around. Y ou e ndanger your own and the saf ety of others!

The minimum distance between light-output and the illuminated surface must be more than 0,8 meter .

Make sure that the area below the installation place is blocked when rigging, derigging or servicing the fixture.

Always fix the fixture with an appropriate saf ety-rope. Fix the safety-rope at the correct holes only .

Only operate the fixture after having checked that the housing is firmly closed and all screws are tightly fastened.

The lamp must never be ignited if the objective-lens or any housing-cover is open, as discharge lamps may

explose .

The maximum ambient temperature ta must never be exceeded.

CAUTION!

The lens has to be replaced when it is obviously damaged,

so that its function is impaired, e. g. due to cracks or deep scratches!

Operate the device only after having familiarized with its functions. Do not permit operation by persons not

qualified for operating the device. Most damages are the result of unprofessional operation!

CAUTION!

The lamp has to be replaced when it is damaged

or deformed due to the heat!

Please use the original packaging if the device is to be transported.

Please consider that unauthorized modifications on the device are forbidden due to safety reasons!

Never remove the serial barcode from the device as this would make the guarantee void.

If this device will be operated in any way different to the one described in this manual, the product may suffer

damages and the guarantee becomes void. Furthermore, any other operation may lead to dangers like shortcircuit, burns, electric shock, lamp explosion, crash etc.

Page 5

5

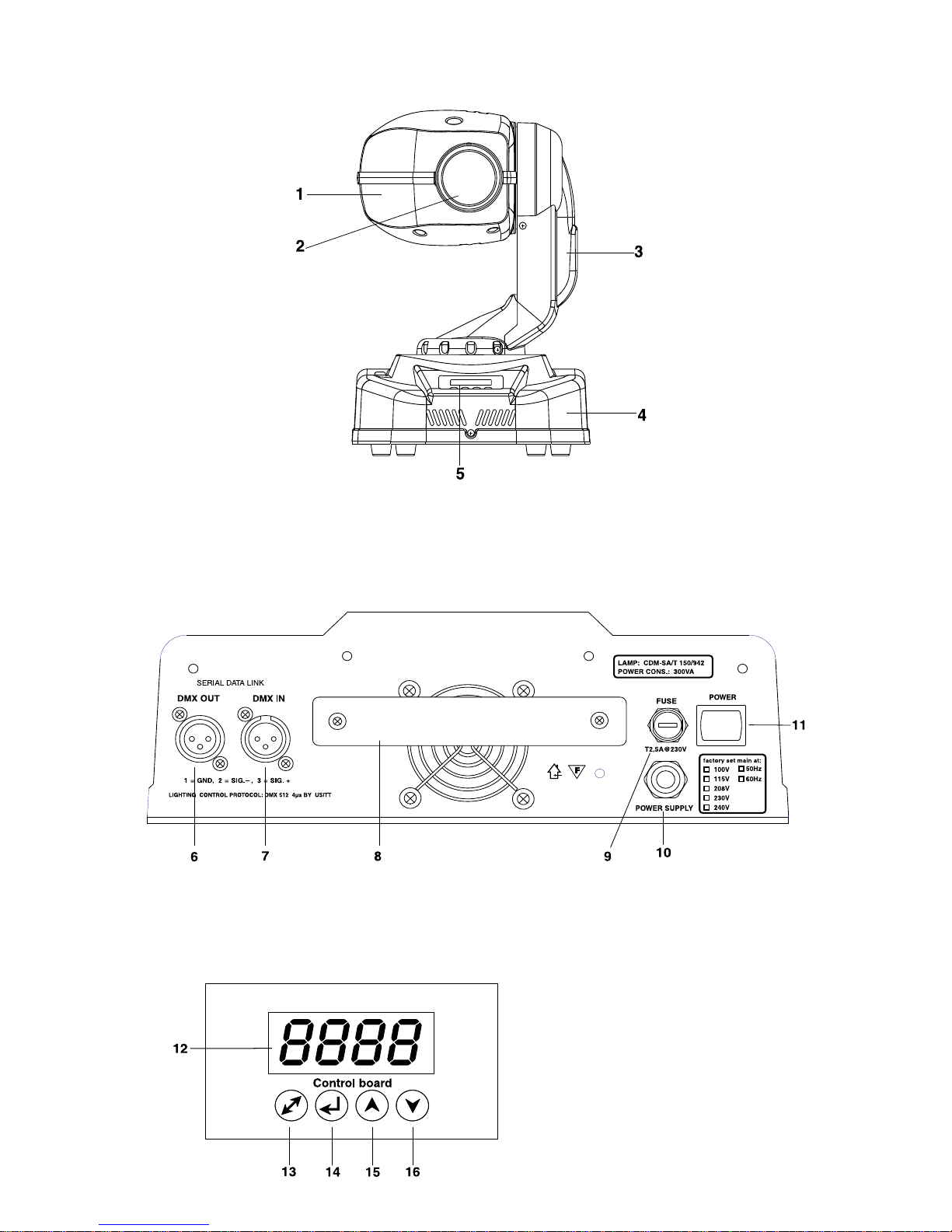

3.Description of the device

Rear panel of the base

12 - Display

13 - Mode-button

14 - Enter-button

15 - Up-button

16 - Down-button

6 - DMX output 9 - Fuseholder

7 - DMX input 10 - Pow ercord

8 - T ransport handle 11 - Power-switch

Control panel

1 - Projector-head 4 - Base

2 - Objective 5 - Control panel

3 - Arm

Page 6

6

4.Installation

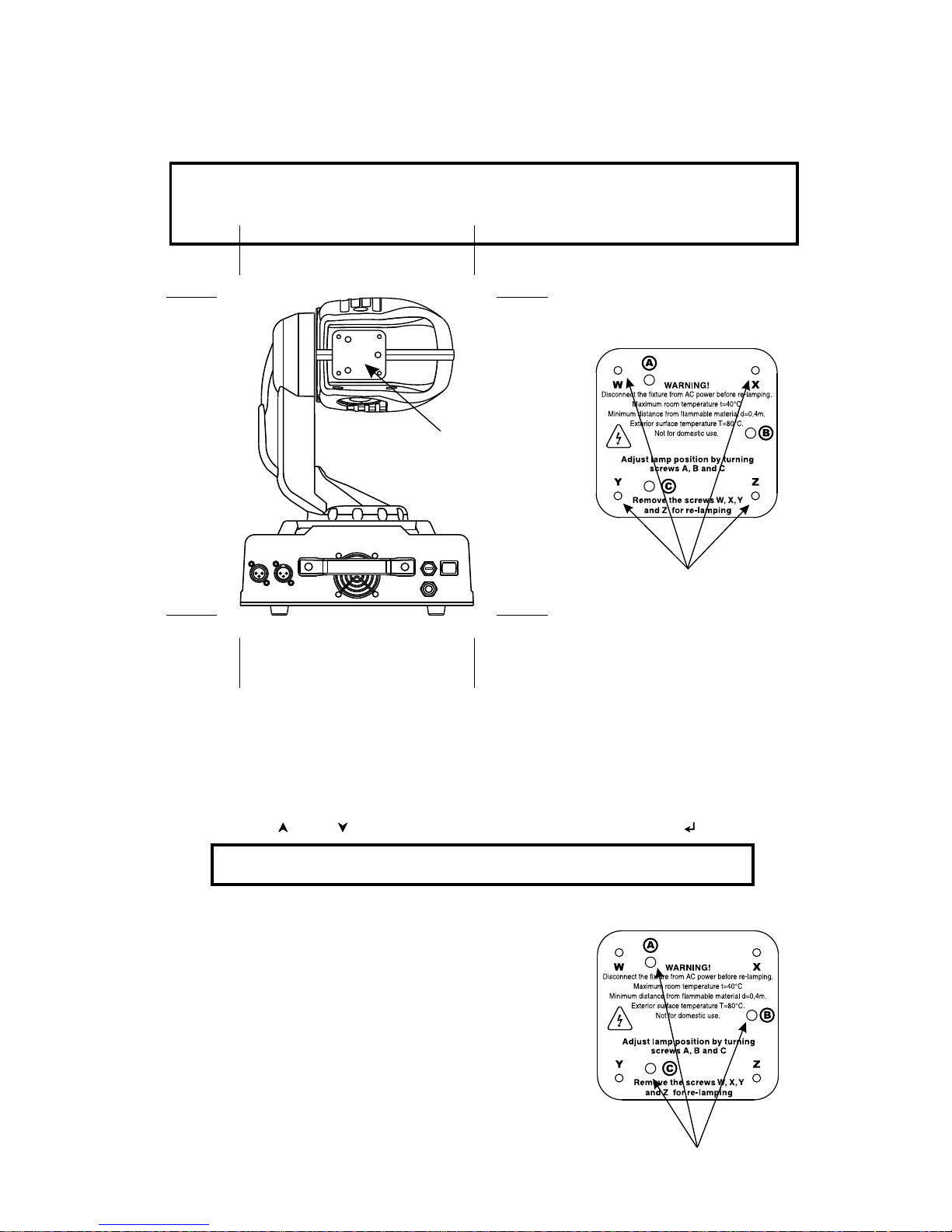

4.1Fitting/Exchanging the lamp

DANGER !

Install the lamp with the device switched off only.

Unplug from mains before !

To insert the lamp CDM-SA/T 150/942 open the small lamp cover at the rear of the head (see the drawing) by

loosening the 4 screws „W, X,Y, Z,” on the lamp cover.

Gently pull out the lamp assembly.

If changing the lamp, remov e the old lamp from the soc ket. Insert the lamp to the socket.

Do not install a lamp with a higher wattage! A lamp like this generates temperatures the device is not designed

for.

Damages caused by non-observance are not subject to warranty. Please f ollow the lamp manuf acturer‘s notes!

Do not touch the glass-bulb bare hand during the installation! Make sure that the lamp is installed tightly into the

lamp holder system.

Reinsert the lamp assembly and tighten 4 screws again.

Before striking the lamp, reset the "LAti/rSEt" and "LASt/rSEt"counters in the "InFO" menu on the control

panel, by pressing the [ ] and [ ] buttons in one time and then confirming with the [ ] button.

Do not operate this fixture with opened housing-cover!

4.2Lamp adjustment

The COLOR SPOT 150 lampholder is aligned at the factor y.

Due to differences between lamps, fine adjustment may improve

light performance.

Strike the lamp, cancel all effects, open the shutter and set

the dimmer intensity onto 100 % and focus the light on a flat

surface (wall) or use function "LAAd" in the Special

functions .

Center the hot-spot (the brightest part of the beam) using the 3

adjustment screws „A, B, C”.Turn one screw at a time to dra g

the hot-spot, diagonally across the projected image. If you cannot

detect a hot -spot, adjust the lamp until the light is even.

screws "X,Y ,Z W"

Lamp cover:

screws "A, B, C"

Page 7

7

To reduce a hot-spot, pull the lamp in by turning all three screws „A, B, C” cloc kwise 1/4-turn at a time until the

light is evenly distributed.

If the light is brighter around the edge than it is in the center, or if light output is low , the lamp is too far back in the

reflector. „Push” the lamp out by turning the screws „A, B, C” counterclockwise 1/4-turn at a time the light is bright

and evenly distributed.

4.3 Inserting/Exchanging rotating gobos

DANGER!

Install the gobos with the device switched off only.

Unplug from mains before!

To insert the gobos open the top co ver of the head b y loosening the 2 scre ws .

If you wish to use other forms and patterns as the standard-gobos, or if gobos are to be exchanged,remove the

fixation-ring with an appropriate tool. Remove the gobo and insert the new gobo. Press the fixation-ring together

and insert it in front of the gobo.

CAUTION!

Never unscrew the screws of the rotating gobo

as the ball bearing will otherwise be opened!

go b o fixation-ring

Page 8

8

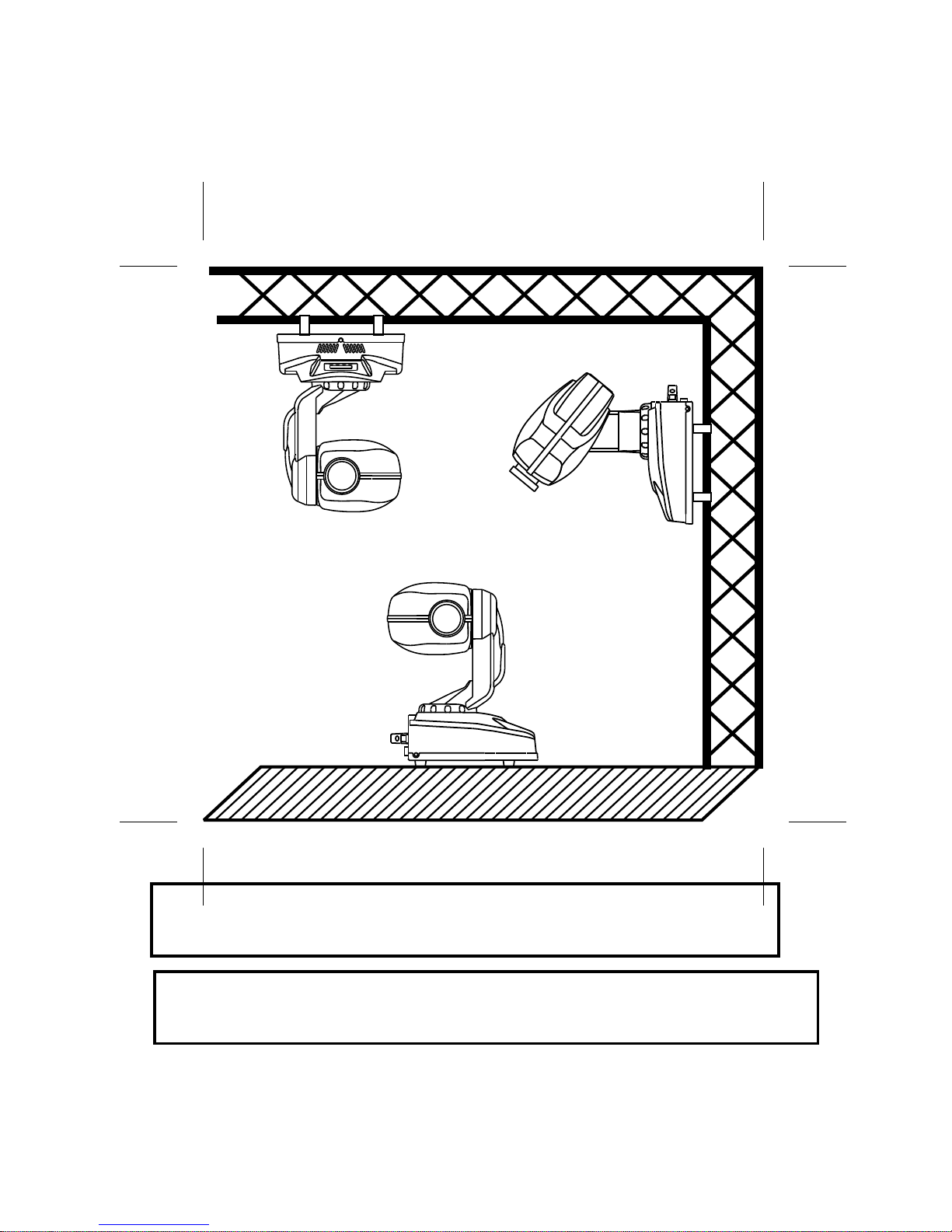

4.4 Rigging

DANGER T O LIFE!

Please consider the respective national norms during the installation!

Theinstallation must only be carried out by an authorized dealer!

The installation of the projector has to be built and constructed in a way that it can hold 10 times the weight for 1

hour without any harming deformation.

The installation must always be secured with a secondary safety attachment, e.g. an appropriate catch net. This

secondary safety attachment must be constructed in a way that no part of the installation can fall down if the

main attachment fails.

When rigging, derigging or servicing the fixture staying in the area below the installation place, on bridges, under

high working places and other endangered areas is forbidden.

The operator has to make sure that safety-relating and machine-technical installations are appro ved by an e xpert

before taking into operation for the first time and after changes before taking into operation another time.

The operator has to make sure that safety-relating and machine-technical installations are appro ved by an e xpert

after every four year in the course of an acceptance test.

The operator has to make sure that safety-relating and machine-technical installations are approved by a skilled

person once a year .

The projector should be installed outside areas where persons may walk by or be seated.

IMPORTANT! OVERHEAD RIGGING REQUIRES EXTENSIVE EXPERIENCE, including (but not limited to)

calculating working load limits, installation material being used, and periodic safety inspection of all installation

material and the projector. If you lack these qualifications, do not attempt the installation y ourself, but instead use

a professional structural rigger . Improper installation can result in bodily injury and.or damage to property .

The projector has to be installed out of the reach of people.

If the projector shall be lowered from the ceiling or high joists, profession al trussing systems have to be used. The

projector must never be fixed swinging freely in the room.

Caution: Projectors may cause severe injuries when crashing down! If you have doubts concerning the safety of

a possible installation, do NOT install the projector!

Before rigging make sure that the installation area can hold a minimum point load of 10 times the projector’s

weight.

Danger of fire !

When installing the device, make sure there is no highly inflammable

material (decoration articles, etc.) in between a distance of min. 0,4 m.

CAUTION!

Use 2 appropriate clamps to rig the fixture on the truss.

Follow the instructions mentioned at the bottom of the base.

Make sure that the device is fixed properly! Ensure that

the structure (truss) to which you are attaching the fixtures is secure.

Page 9

9

The moving-head can be placed directly on the stage floor or rigged in any orientation on a truss without altering

its operation characteristics .

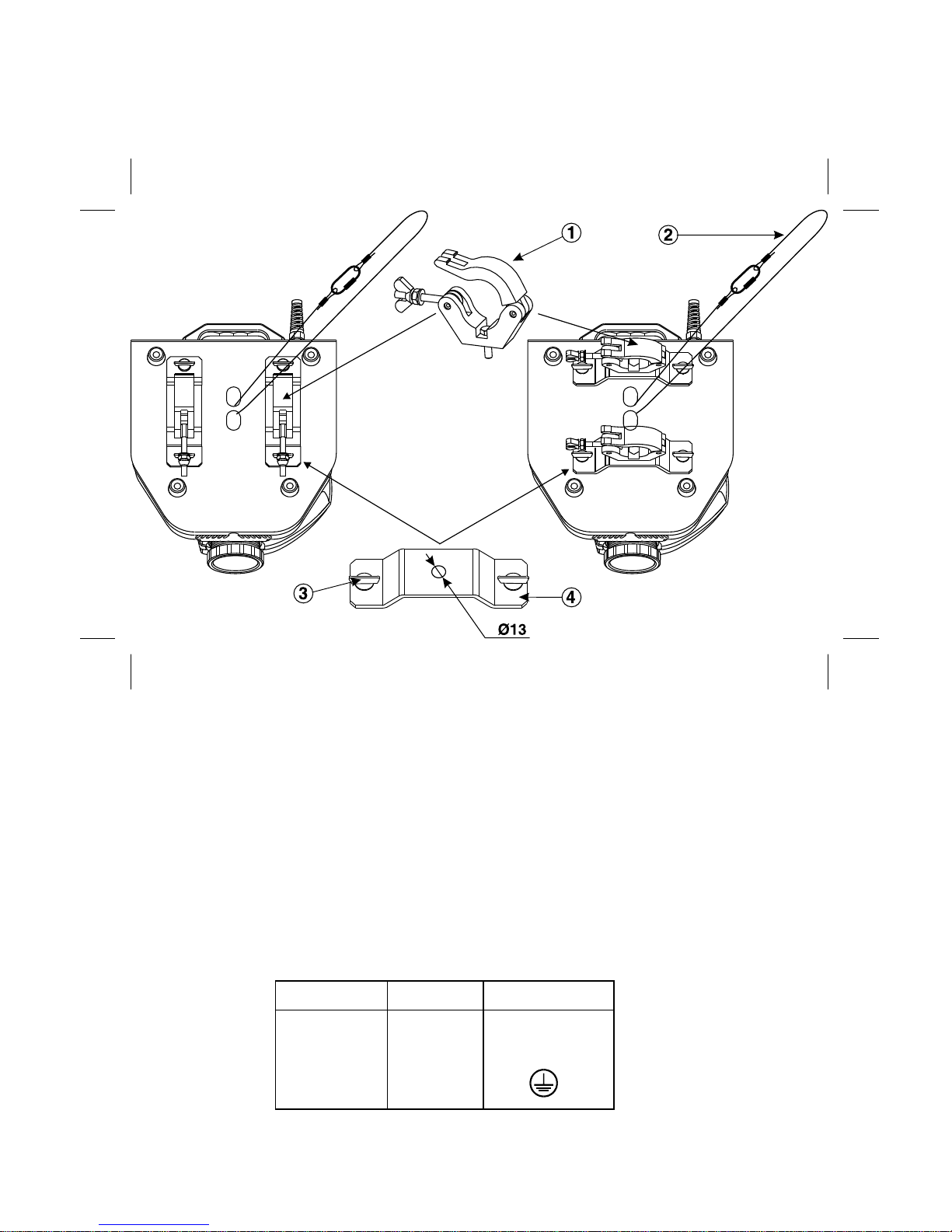

There are two possibility how to fix the COLOR SPOT 150 on a truss via the Omega holders -see the drawing

below .Use the rigging clamps (not included) with screws M12.

For overhead use , alwa ys install a saf ety-rope that can hold at least 10 times the w eight of the fixture. You must

only use safety-ropes with screw-on carabines. Pull the safety-rope through the two apertures on the bottom of

the base and over the trussing system etc. Insert the end in the carabine and tighten the fixation screw .

When installing fixtures side-by-side,

avoid illuminating one fixture with another!

DANGER T O LIFE!

Before taking into operation for the first time,the installation has to be

approved by an expert!

Page 10

10

Fixation via the Omega holders

1. Scre w each clamp (1) to the included Omega holders (4) with M12 bolt and nut through the hole in the holder .

2. Insert both quick-lock fasteners (3) into the holes of the base and tighten fully clockwise.Install the second

clamp.

3. F asten the saf ety-rope (2) through the two apertures on the bottom of the base and over the trussing system.

1-Clamp

2-Safety-rope

3-Quick-lock fastener

4-Omega holder

4.5 Connection to the mains

Connect the fixture to the mains with the enclosed power-plug.

The earth has to be connected!

The occupation of the connection-cables is as follows:

Cable Pin International

Brown Live L

Light blue Neut ral N

Y ello w/Green Earth

Page 11

11

4.6 DMX- 512 connection, master/slave connection

The wires must not come into contact with each other , otherwise

the fixtures will not work at all, or will not work properly.

Only use a stereo shielded cable and 3-pin XLR-plugs and connectors in order to connect the controller with the

fixture or one fixture with another.

Occupation of the XLR-connection:

DMX - output DMX-input

XLR mounting-socket: XLR mounting-plug:

Building a serial DMX-chain:

If you are using the standard controllers, you can connect the DMX-output of the controller directly with the DMXinput of the first fixture in the DMX-chain. If you wish to connect DMX-controllers with other XLR-outputs, you

need to use adapter-cables.

Connect the DMX-output of the first fixture in the DMX-chain with the DMX-input of the next fixture. Always

connect output with the input of the next fixture until all fixtures are connected.

Caution: At the last fixture, the DMX-cable has to be terminated with a terminator. Solder a 120 Ohm resistor

between Signal (–) and Signal (+) into a 3-pin XLR-plug and plug it in the DMX-output of the last fixture.

Building a master/slave-chain:

Connect the DMX-output of the master fixture in the data-chain with the DMX-input of the first slave. Always

connect output with the input of the next slave until all slaves are connected (up to 9 fixtures).

Caution:It’s necessary to insert the XLR termination plug (with 120 Ohm) into the input of the master fixture and

into the output of the last slave fixture in the link in order to ensure proper transmission on the data link.

1 - Ground

2 - Signal (-)

3 - Signal (+)

1 - Ground

2 - Signal (-)

3 - Signal (+)

Master/slave operation

Controller operation

Page 12

12

5. DMX Protocol-16 bit

Mode 1 Mode 2 Value Function Type of control

Channel Channel

1 1 Pan

0- 25 5 Pan mov ement by 530° prop ortio nal

2 3 Tilt

0- 2 55 Tilt movement by 280° prop ortio na l

3 2 Pan fine

0- 25 5 Fine control of pan movement prop ortio nal

4 4 Tilt fine

0- 2 5 5 Fine control of tilt movement prop o rtio na l

5 5 Speed of P AN/TIL T movement

0 Max. speed (tracking mode) step

1- 24 9 From max. speed to min.speed (vector mode) prop ortio nal

250-252 Max. speed(track.mode),black-out while step

color or gobo changes

253-255 Max. speed(v ector mode),black-out while PAN/TILT step

moving or colour or gobo changes

6 6 Colours

0 Open/white proportional

10 Turquoise propor tio nal

21 Red proportional

32 Cyan proportional

42 Light green proportional

53 Magenta proportional

64 Light Blue proportional

74 Yellow proportional

85 Green proportional

96 Pink proportional

106 Blue proportional

117 Orange proportional

128-189 Forwards rainbow effect from fast to slow prop orti o n al

190-193 No rotation pr op o rtiona l

194-255 Backwards rainbow effect from slow to fast prop orti o nal

7 7 Rotating gobos

0-11 Open position (hole) step

12-23 Gobo 1 st ep

24-35 Gobo 2 step

36-47 Gobo 3 step

48-59 Gobo 4 step

60-71 Gobo 5 step

72-83 Gobo 6 step

84-95 Gobo 7 step

96-235 Shaking gobos with variable speed

96-115 Gobo 1 proportional

116-135 Gobo 2 pr o p o rtio n a l

136-155 Gobo 3 pr o p o rtio n a l

156-175 Gobo 4 pr o p o rtio n a l

176-195 Gobo 5 pr o p o rtio n a l

196-215 Gobo 6 pr o p o rtio n a l

216-235 Gobo 7 pr o p o rtio n a l

236-255 Gobo wheel rotation from slow to fast prop ortio na l

Page 13

13

Channel Channel

8 8 Rotating gobo rotation

0-127 Gobo rotation proportional

128-189 Forwards gobo rotation from fast to slow prop ortional

190-193 No rotation step

194-255 Backwards gobo rotation from slow to fast prop ortional

9 9 Shutter,Strobe,Reset

0 Shutter closed step

1-63 Light intensity from 0 to 100% proportional

64-95 Shutter open step

96-127 Strobe-effect from slow to fast (max 8 flashes/s) proportional

128-139 Reset ,shutter closed step

140-159 Shutter closed step

160-175 Pulse-effect in sequences with increasing speed prop o rtional

176-191 Pulse-effect in sequences with decreasing speed prop o rti onal

192-223 Random strobe effect with increasing speed prop o rti o nal

224-255 Shutter open step

Mode 1

Mode 2 Value Function Type of control

Page 14

14

Mode 3 Mode 4 Value Function Type of control

Channel Channel

1 1 Pan

0- 25 5 Pan mov ement by 530° prop ortio nal

2 2 Tilt

0- 2 55 Tilt movement by 280° prop orti on al

3 Speed of P AN/TILT movement

0 Max. speed (tracking mode) step

1- 24 9 From max. speed to min.speed (vector mode) prop ortio nal

250-252 Max. speed(track.mode),black-out while step

color or gobo changes

253-255 Max. speed(v ector mode),black-out while PAN/TILT step

moving or colour or gobo changes

4 3 Colours

0 Open/white proportional

10 Turquoise propor tio nal

21 Red proportional

32 Cyan proportional

42 Light green proportional

53 Magenta proportional

64 Light Blue proportional

74 Yellow proportional

85 Green proportional

96 Pink proportional

106 Blue proportional

117 Orange proportional

128-189 Forwards rainbow effect from fast to slow prop o rti o nal

190-193 No rotation pro po rtion a l

194-255 Backwards rainbow effect from slow to fast proportional

5 4 Rotating gobos

0-1 1 Open position (hole) step

12-23 Gobo 1 step

24-35 Gobo 2 step

36-47 Gobo 3 step

48-59 Gobo 4 step

60-71 Gobo 5 step

72-83 Gobo 6 step

84-95 Gobo 7 step

96-235 Shaking gobos with variable speed

96-115 Gobo 1 proportional

116-135 Gobo 2 proportional

136-155 Gobo 3 proportional

156-175 Gobo 4 proportional

176-195 Gobo 5 proportional

196-215 Gobo 6 proportional

216-235 Gobo 7 pro p o rti onal

236-255 Gobo wheel rotation from slow to fast proportional

6 5 Rotating gobo rotation

0-127 Gobo rotation proportional

128-189 Forwards gobo rotation from fast to slow prop ortional

190-193 No rotation step

194-255 Backwards gobo rotation from slow to fast prop ortional

6. DMX Protocol-8 bit

Page 15

15

Channel Channel

7 6 Shutter,Strobe,Reset

0- Shutter closed step

1-63 Light intensity from 0 to 100% proportional

64-95 Shutter open step

96-127 Strobe-effect from slow to fast (max 8 flashes/s) proportional

128-139 Reset ,shutter closed step

140-159 Shutter closed step

160-175 Pulse-effect in sequences with increasing speed prop o rtional

176-191 Pulse-effect in sequences with decreasing speed prop o rti onal

192-223 Random strobe effect with increasing speed prop o rti o nal

224-255 Shutter open step

Mode 3 Mode 4 Value Function Type of control

Page 16

16

The COLOR SPOT 150 can be operated with a controller in controller mode or without the controller in stand-

alone mode.

Both modes are described in the texts below .

7.Controller mode

The fixtures are individually addressed (001-504) on a data link and connected to the controller.The fixtures

respond to the DMX signal from the controller.

7.1 DMX addressing

The control panel on the front side of the base allows you to assign the DMX fixture address, which is defined as

the first channel from which the COLOR SPOT 150 will respond to the controller .

If you set, for ex ample, the address to channel 5, the COLOR SPOT 150 will use the channel 5 to 13 f or control.

Please, be sure that you don’t have an y overlapping channels in order to control each COLOR SPOT 150 correctly

and independently from any other fixture on the DMX data link.

If two, three or more COLOR SPO T 150 are addressed similarly, they will work similarly .

For address setting, please refer to the instructions under "Addressing"(menu "A001").

Controlling:

After having addressed all COLOR SPOT 150 , y ou may no w start operating these via your lighting controller .

Note:After switching on, the COLOR SPO T 150 will automatically detect whether DMX 512 data is receiv ed or

not.If there is no data received at the DMX-input, the display will start to flash "A001" with actually set address.

This situation can occur if:

- the 3 PIN XLR plug (cable with DMX signal from controller) is not connected with the input of the COLOR SPOT

150

- the controller is switched off or defective, the cable or connector is defective or the signal wires are swap in the

input connector.

Note:It’s necessary to insert the XLR termination plug (with 120 Ohm) to the last fixture in the link in order to

ensure proper transmission on the DMX data link.

7.2 Remotely controllable functions

Colour - wheel

The COLOR SPOT 150 contains a colour wheel with 12 colour positions - 11 of these with dichroic colours and

the last one white. The colour-wheel can be positioned between two adjacent colours in any position. It is also

possible to rotate the colour- wheel continuously at different speeds("Rainbow effect“ in both directions).

Rotating gobo wheel

The rotating gobo-wheel includes 3 metal gobos, 3 glass gobos and 1 multicolor dichroic gobo rotating in both

directions. All gobos are interchangeable.The metal gobos have an outside diameter of 27 mm and an image

diameter of 22,5 mm.The glass and dichroic gobos have an outside diameter of 26,8 mm and an image diameter

of 22,5 mm.

Shutter/Dimmer/Strobe

The dimming (0-100%) is provided by the simple mechanical shutter unit. This unit may also be used f or strobe

effect (1 - 8 flashes per second).

Page 17

17

8. Stand - alone mode

The fixtures on a data link are not connected to the controller but can execute pre-set programs which can be

different for e very fixture.To set the program to be play ed,see the "Stand-alone setting" ( menu "St.AL.").

"Stand-alone operation" can be applied to the single fixture (the fixture may be set to the master /slave mode or

controller mode ) or to multiple fixtures operating synchronously.

Synchronous operation of multiple fixtures requires that they must be connected on a data link and one of them

is set as a master (master mode) and the rest as the slaves (slave mode).The slaves are assigned to SLA1SLA9 and on the certain slave address can be connected only one fixture.To set the fixture as the master or

slave , see the "Addressing" (menu "A001").

If the master fixture runs a reset or plays test(program) ,all slaves will e xecute these acts too.

You can't play or edit any programs on the slaves by their control panels if the master is switched on and

connected to the master/slave chain.

The master fixture starts simultaneous program start in the other s lave fix tures.All fixtures have a definite,

synchronized starting point when playing back their prog rams.The number of running program is the same in all

slaves and depends on the master's choice (menu "St.AL." ).Every fixture runs its program repeatedly ,starting

the program step No.1 when requested b y the master .

For example:

If the slave fixture has a shorter program length, it will continously repeat its program until the master fixture

finishes its own program and restarts its program running (slave 1- prog.step 3 will not be finished).

If the slave fixture has a longer program length, it will restart at prog. step 1 bef ore it completes all its prog.steps

(slave 2 - prog.step 5 will not be pla yed)- see the picture bellow.

Note:Disconect the fixtures from the DMX controller before master/slave operating ,otherwise data collisions can

occur and the fixtures will not work properly!

It’s necessary to insert the XLR termination plug (with 120 Ohm) into the input of the master fixture and into the

output of the last slave fixture in the data link in order to ensure proper transmission on the data link.

From the master's control panel is possib le to control any sla v e in a master/sla v e chain.

Starting point

Restart

Page 18

18

9. Functions of the control panel

The control panel situated on the front side of the base offers several features. You can simply set the DMX

address,master/slave mode, read the number of lamp or unit hours, run test, make a reset and also use many

functions for setting and service purposes.

The main menu of the control panel is accessed by pressing the [ ] button - press this one so many times until

the display shows message "A001" (with actually stored address). Browse through the menu by the pressing [

] or [ ] buttons - the display shows step by step these messages: A001,SLCt,InFO,PErS,tESt, StAL,rESE,

SPEC. Press [ ]if you wish to select one of them. The functions are described in the following sections and the

function hierarchy is shown belo w .

9.1 Addressing

By this menu you can set the DMX address or address the fixture as a master/slave.

- DMX addressing

1. Press the [ ]- button so many times until the display shows message "A001" (with actually stored address).

2. Press [ ]-button and use the [ ] and [ ] buttons to select"dM.Ad."-menu.

3. Press[ ]-button(the letter "A" flashes) and by [ ] and [ ] buttons select required address (001 -

504), press [ ]-button to confirm.

4. Select "M.ASL."-menu,press[ ]-button and use [ ] and [ ] buttons to select "d.AbL."(no master or

slave),press [ ]-button to confirm.

5. Press the [ ]- button.Choosen address is sho wn on the displa y.

If message "A001" (with actually stored address) flashes-no DMX data received at the DMX-input.

- Master/slave adressing

1. Press the [ ]- button so many times until the display shows message "A001" (with actually stored

address).

2. Press [ ]-button and use the [ ] and [ ] buttons to select "MA.SL."-menu.

3. Press [ ]-button(display flashes) and select"MASt"(to set the fixture as the master in a chain of multiple

fixtures) or "SLA.1"-"SLA.9" (to set the fixture to be the slave in a chain of multiple fixtures) and press [ ]

to confirm. If you want address no master or slave, select "d.AbL.".

4. Press the [ ]- button.Choosen address is sho wn on the displa y.

If message "MASt." fast flashes-DMX signal is received at the DMX-input- disconnect DMX controller!

Only one fixture may be the master. Up to the 9 slaves may be connected to the master and on the certain

address can be connected only one slave fixture (SLA1-SLA9).

Page 19

19

Note:Disconect the fixtures from the DMX controller before master/slave operating ,otherwise data collisions can

occur and the fixtures will not work properly!

If the fixture is set as the master and DMX signal is connected to its input,the error massage "MAEr" will appear

on its display and the fixture's address will be set to its DMX address in order to respond to DMX signal from the

controller.

For example:

The master fixture has this address setting:"dM.Ad."-menu.........A010

"MA.SL."-menu........MASt (is displayed)

The DMX signal is connected to the master fixture.The message "MAst" starts fast flashing and after 20s error

massage "MA.Er" appears on its display and the fixture automatically will be switched to its DMX address

(master address is disabled).

Now the fixture has the address setting: "dM.Ad."-menu.........A010 ("A010"/" MA.Er"blinks )

"MA.SL."-menu.........d.AbL.

If the fixture is set as the slave and DMX signal is connected to its input,the fixture will respond to DMX signal

from the controller (in dependence on the fixture's DMX address).

9.2 Slave control

This function allows you to control the slaves from the master's control panel in a master/slave operation.

Select this function from the main menu and press [ ]-button.Browse the list of all connected slaves ("SL.C.1"

- "SL.C.9") by pressing [ ] and [ ] bottons.Select the desired slave and press [ ]-button.The slave's control

panel is available from the master's control panel.

If no slave is connected to the master ,massages "SL.C.1","SL.C.2","SL.C3"..."SL.C.9" still round repeat.

Note:This function is ava ilable from the master fixture only.

9.3 Fixture informations

The menu allows you to read an useful information about the fixture as the lamp life,head temperature,software

version, etc.

Press [ ] and [ ] buttons to select the desired option and press [ ] to see the value or next submenu.

Power On time

-By this option you can read the total number of the operation hours since the

COLOR SPOT 150 has been fabricated. Press [ ] or [ ] to return to the

menu.

Page 20

20

- The number of the hours that the COLOR SPO T 150 has been po wered On since the

counter wa s last reset.Press [ ] or [ ] to return to the menu.In order to reset

this counter to 0, you have to hold the [ ] and [ ]-button and press the [ ]-

button.

Lamp On time

- This option enab les you to read the total number of the operation hours with the lamp

on since the COLOR SPOT 150 has been f abricated.Press [ ] or [ ] to

ret ur n to the menu.

- The number of hours that the lamp has been po wered On since the counter was last

reset.Press [ ] or [ ] to return to the menu. In order to reset this counter to 0,

you have to hold the [ ] and [ ]-button and press the [ ]-button.

Lamp strikes

- By this option you can read the total number of the lamp strikes since the COLOR

SPOT 150 has been f abricated.Press [ ] or [ ] to return to the menu.

-The number of the lamp strikes since the counter was last reset.Press [ ]

or [ ] to return to the menu. In order to reset the counter to 0, you have to hold the

[ ] and [ ]-button and press the [ ]-button.

- DMX values

Readout DMX values of each channel received by the fixture. Use the [ ] and [ ] buttons to select desired

channel and press [ ] to read its value coming to the fixture or [ ] to cancel and return to the menu.

- Software version

By this function you can read the software version of the display module. Press [ ] to read its value or [ ]

to return to the menu.

9.4 Personality options

These options allow you to modify COLOR SPO T 150 operating behavior .

Press [ ] and [ ]buttons to select the desired option and press [ ] to set the value or to see next submenu.

Page 21

21

- Pan reverse

This function allows you to invert the pan movement. Use the [ ] or [ ] buttons to select "On" if you wish this

feature or "Off" if you don’t wish this feature and press [ ] to confirm or [ ] to cancel and return to the menu.

- Tilt reverse

This function allows you to inv ert the tilt movement. Use the [ ] or [ ] buttons to select "On" if you wish this

feature or "Off" if you don’t wish this feature and press [ ] to confirm or [ ] to cancel and return to the menu.

- DMX presetting

The function makes possible to select from the 4 DMX- channels settings (including 8 or 16 bit movement

resolution). Use the [ ] or [ ] buttons to select desired channel settings ("Mod.1,Mod.2,Mod.3,Mod.4") and

press [ ] to confirm or [ ] to cancel and return to the menu.

List of the channels settings:

Chan nel Mode 1 Mode 2 Mode 3 Mode 4

1 Pan Pan Pan Pan

2 Tilt Fine P an Tilt Tilt

3 Fine Pan Tilt Speed Colours

4 Fine Tilt Fine Tilt C olou rs R .gob os

5 Speed Spee d R.gobos Gobo rotation

6 Colours Colours Gobo rotation Dimmer

7 R. gobos R.gobos Dimmer

8 Gobo rotation Gobo rotation

9 Dimmer Dimmer

Please refer to the chapter "DMX- protocol" for detail description.

If the Mode 4 is selected,the speed of pan/tilt movement is set onto maximum.

- Display adjusting

This function allows you to adjust the display settings:

Page 22

22

- Display -intensity

With this function you can adjust the display intensity from 20% to 100% . Use the [ ] or [ ]

buttons to select the level of the display intensity and press [ ] to confirm or [ ] to cancel

and return to the menu.

- Display-reverse

With this function, you can rotate the display by 180°. Use the [ ] or [ ] buttons to select "normal

display" or "display turned by 180°" and press [ ] to confirm or [ ] to cancel and return to the

menu.

- Display-On

This function allows you to keep the display on or to turn off automatically 2 minutes after last

pressing any button on the control panel. Use the [ ] or [ ] buttons to select "On" if you wish to

keep the display on or "Off" if you wish to turn off automatically 2 minutes after last pressing any

button on the control panel and press [ ] to confirm or [ ] to cancel and return to the menu.

- Blackout during movement correction

The function executes the blackout during the head movement correction (the moving head has lost its right pan/

tilt-position for a short moment). Use the [ ] and [ ] buttons to select "On" if you w ant to execute the b lackout

or "Off" if you don’t and press [ ] to confirm or [ ] to cancel and return to the menu.

- PAN/TILT-feedback

This function allows to return the mowing head to the required pan/tilt position after changing the position by

external force (e.g.by stroke). Use the [ ] and [ ] buttons to select "On" if you wish to enable this function

or "Off" if you wish not to return the mowing head to the required position and press [ ] to confirm or [ ] to

cancel and return to the menu.

Note: If the feedback was switched off ,the pan/tilt-position is changed by an external force and the feedback is

switched on again,the moving head might not to be synchronized with the DMX signal.You hav e to make a reset

in order to synchronize the moving head with the DMX signal.

- Microphone -sensitivity

With this function you can adjust the microphone sensitivity from 1(maximum) to 20(minimum) . Use the [ ] or

[ ] buttons to select the level of the microphone sensitivity and press [ ] to confirm the chosen level or [

] to cancel and return to the menu.

Example:

underexited right level overexited

(upper segment blinks by the bass rhythm)

- Default settings

Press [ ] to reset all fixture personalities (not the adjusting functions) to the default values. On the display will

appear "rSt" meaning that the fixture makes the reset. See the table of personality setting and their default

positions.

Page 23

23

9.5 Test sequences

This function allows you to run a special demo-test sequences without an external controller , which will show you

some possibilities of using COLOR SPOT 150. Press [ ] or [ ] keys to select the "Mod1" or "Mod2"

sequences. The "Mod1" is suitable for projections on the w all, ceiling or ground without any head-mov ement, the

"Mod2" uses all COLOR SPOT 150 functions and therefore is good f or a complete introduction of the fixture.Select

"Mod1" or "Mod2" by [ ] or [ ] buttons and press [ ]-button to confirm the choice.If the test program is

running,messages "run/test" blink on the display .

If you want to pause the runnnig program in the required position, press the [ ]-button(messages"PAUS"/" test"

blink ).T o c ontinue the program running,press the [ ]-button again.

Perso nal ity Display Default values

(SHADED)

Pan rev erse

Tilt reverse

Display intensity

Display- reverse

Displaypermanent

On

DMX

presetting

Blackout during

mov . correction

Pan/Tilt feed back

Microphone

sensitivity

Music trigger

Page 24

24

9.6 Stand-alone setting

This menu offers options for stand-alone mode as a selection of the playing program,programming and modifying

current programs.

- Music trigger

The COLOR SPOT 150 enab les the sound control of the running programs via the built-in microphone.Use the [

] or [ ] buttons to select "On" if you wish this feature or "Off" if you don’t wish this feature and press [ ] to

confirm or [ ] to cancel and return to the menu.

-Presetting playback

This function allows you to select the the program which will be played in the stand-alone mode after switching

the fixture On.Use the [ ] or [ ] buttons to select desired program ("tESt"- bilt-in program) or "OFF" if you don't

want trigger any program after switching the fixture On and press [ ] to confirm or [ ] to cancel and return to

the menu.Selected program will be play ed continuously in a loop as long as it appears on the displa y.

This option should be set "OFF" for all slav es in the master/sla ve chain by reason of the right program starts.

For example: You hav e selected program "PrG.3" in this menu and:

this fixture is set as a single fixture (master/slave or controller operating)- the fixture will run its program "PrG.3".

this fixture is set as a master in a data chain- the fixture will run its program "PrG.3".

this fixture is set as a slave in a data chain- the fixture will run its program according to the master (i f the ma s te r

runs its own program "PrG.1", the slave will run its own program "PrG.1"also).

Note:If the fixture operates in the controller mode ( DMX controller is connected) and any program from this menu

is selected ,in this case the fixture will not respond to the DMX controller after switching On and will play selected

program.

- Playing program

This function allows you to run a bilt-in program "tESt" and the 3 freely-programmable programs

"PrG.1,PrG.2,PrG.3" .Press [ ] or [ ] buttons to select the desired program and press [ ] to run the program

which will be played continuously in a loop.

If you want to pause the runnnig program in the required position, press the [ ]-button(messages"PAUS"/"

program No."blink ).To continue the program running,press the [ ]-button again.

Note:If the fixture operates in the controller mode ( DMX controller is connected) and any program from this

function is selected in this case the fixture will not respond to the DMX controller and will play selected program.

You can't play programs on the slave fixtures from their control panels if the master fixture is switched On and

connected to the slaves (playing is forced by the master).

Page 25

25

- Editing program

This menu item allows you to select a program to edit or create.The COLOR SPOT 150 has one b uilt-in program

("tESt") and the 3 free programs,each up to 99 steps.Each program step has a dynamic part(fade time) and

static part(step time).

Fade time-the time,during which effects mo ve to the programmed position.

Step time-the time,during which effects last in the current step.

If the fixture is set as a master ,then you may edit any program in the slav es.You can't edit programs on the slav e

fixtures from their control panels if the master fixture is switched on and connected to the slaves (editing is

possible by the master control panel only).

Procedure:

1. Press [ ] or [ ]-button to select the program you want to edit ("PrG.1" - "PrG.3") and press [ ].

2. Press [ ] or [ ]-button to select the desired fixture ("MASt." - "SLA.9") and press [ ]-button.

3. Press [ ] or [ ]-button to select the desired program step ("St.01" - "St.99") and press [ ]-button.

4 Press [ ] or [ ]-button to select the desired item and press [ ]-button.Now you can edit by [ ] or [ ]

buttons the DMX value for selected item:

"P .End." - a total number of the program steps,value 1-99 .This value you must set before start

programming(e.g. if you want to create program with the 10 steps,set the value onto 10).

"PAn" - a pan,value 0-255

"tilt" - a tilt,value 0-255

"F.PAn" - a fine pan, value 0-255

"F.tilt" - a fine tilt,value 0-255

"SPEd" - a speed of P AN/TILT movement,value 0-255

"Colo." - a colour , value 0-255

"r.Gob." - a rot.gobo,value 0-255

"G.rot." - a gobo rotation,value 0-255

"dimr" - a dimmer, v alue 0-255

"S.tim." - a step time,value 0,1-25,5 seconds

"F.tim." - a fade time,value 0,1-25,5 seconds

"COPY ." - a copying the current prog. step to the next prog. step .If the last prog.step is copied to the

next prog. step ,parameter "P.End" is increased about 1 automatically (except step 99).

5. Press [ ]-button to confirm adjusted value .

6. Press [ ]-button,select next prog. step and repeat this procedure (steps 4 and 6).

The editting programs "PrG.1,PrG.2,PrG.3" are saved in the current modified fixture (master or slave1-9).

9.7 Reset function

Press [ ] button to run a reset. This option enables the COLOR SPOT 150 to index all eff ects (functions) and

return to their standard positions.

9.8 Special functions

Use the [ ] or [ ] buttons to browse through the special functions and select the one by pressing [ ]-button.

Page 26

26

- Manual control of effects

The function allows you to control manually the channel functions of the fixture. Use the [ ] or [ ] buttons to

select desired function and press [ ] to adjust the effect or [ ] to cancel and return to the menu.

- Lamp adjustment

This function can be used when you make the fine adjustment of the lamp.If you select "LAAd" pressing by [

]-button ,all effects will be canceled,shutter will be opened and the dimmer intensity will be set onto 100%.By

using the options "P An, tilt," you can focus the light on a flat surf ace (wall) and perf orm the fine lamp adjustment.

-- Fixture code

The option contains identification code (1-9999) for the fixture, which is used for the master/slave operation.

- Adjusting the default positions of the colour and gobo wheels

By this function you can calibrate and adjust the colour and gobo wheels to their standard/right positions. Use the

[ ] and [ ] buttons to browse through the adjusting menu - the display shows step by step these messages:

"PAn, tilt,FP An,FTilt,SPEd,Colo,rGob,Gr ot, dimr, FCAL" by which you can adjust the fixture to the required/

desired position (0-255) before the function calibration. Then when the positioning is finished use the last "F .CAL."

function (Fixture calibration).

Page 27

27

1. Calibration via the control panel

Press [ ] and the [ ] or [ ] buttons in order to display the following messages: "Colo, rGob," for very smooth

function calibration. Select one of them, press [ ] and use the [ ] and [ ] buttons in order to adjust their right

value from 0 to 255. Then press [ ] to confirm or [ ] to cancel and return to the menu. This can be repeated f or

each calibration parameter if it is required. When the calibration is finished, it is necessary to use the "A.rES."

function in order to write the calibration values to the memory (EPROM) and to make a reset in order to check the

newly adjusted positions of the colour and gobo wheels. When the reset of the fixture is finished, the displa y will

show the "F .CAL." message . Press [ ] to repeat the calibration or [ ] to return to the "AdJ." menu.

2. Calibration via the external controller

Connect the DMX controller, press [ ] and the [ ] or [ ] buttons in order to display the follo wing messages:

"Colo, rGob," - calibration parameters. Select one of them and press [ ].

Now you can calibrate the colour and rotating gobo wheel by your controller. The DMX calibration protocol is

described in the table mentioned below.

DMX Calibration protocol:

After having calibrated required functions press [ ] to confirm (or [ ] to cancel and return to the menu without

reset by the "A.rES." function) and use the "A.rES." function in order to write the calibration values to the

memory (EEPROM) and to make a reset in order to check the new adjusted positions of the colour and gobo

wheels.

10. Error and information messages

M.b.Er.

This messsage informs you that the main PCB does not communicate correctly with the Control P anel.

Co.Er.

(Colour -wheel error)This messsage will appear after the reset of the fixture if the magnetic-indexing circuit

malfunctions (sensor failed or magnet missing) or the stepping-motor is defective (or its driver circuit on the main

PCB).The color-wheel is not located in the default position after the reset.

r.GEr.

(Rotating gobo-wheel error) This message will appear after the reset of the fixture if the magnetic-indexing circuit

malfunctions (sensor failed or magnet missing) or the stepping-motor is defective (or its driver circuit on the main

PCB).The rotating gobo-wheel is not located in the default position after the reset.

Po.Er .

This message will appear if the fixture was shortly disconnect from the main.

PA.Er.

(Pan-yok e movement error) This message will appear after the reset of the fixture if the yoke’ s magnetic-inde xing

circuits malfunction (sensors failed or magnet missing) or the stepping motor is defective. (Or its driving IC on the

Page 28

28

main PCB).The yoke is not located in the default position after the reset.

ti.Er .

(TIL T-head mov ement error) This message will appear after the reset of the fixture if the head’ s magnetic-indexing

circuit malfunctions (sensor failed or magnet missing) or the stepping motor is defective. (Or its driving IC on the

main PCB).The head is not located in the default position after the reset.

MA.Er.

(Master error) The message informs you that the fixture was addressed as a master and DMX signal is connected

to its input.Disconnect the DMX controller from fixture's input and address the fixture as the master again.

11.Technical specifications

Power supply:

V oltage: 100/115/208/230/240V AC, 50/60Hz ~

Fus e: T 5,0A @ 115V

Power consumption: 300 V A

Lamp:

CDM-SA/T 150/942 , base G12

Optical System:

- High luminous-efficiency parabolic system and 3 elements- objective

-All lenses are anti-reflection coated

-19° beam angle

Beampath:

Colours:

- 11 dichroic-filters plus white

- Colour-wheel with variable rotation speed

Rotating gobos:

-3 metal gobos, 3 glass gobos and 1 dichroic gobo rotating in both directions at different speeds

- Gobo rotation

- Rotating gobo-wheel cont. rotation

- Metal gobos: outside diameter 27 mm, image diameter 22,5 mm

-Glass and dichroic gobos:outside diameter 26,8 mm, image diameter 22,5 mm

-All gobos are interchangeable

Focus:

- 19°-wide angle objective with the manual focus

Strobe:

- Strobe effect with variable speed (1 - 10 flashes per second)

Beam opening (m)

Distance (m)

Diameter (m)

Page 29

29

Shutter/Dimmer:

- Simple dimmer from 0 - 100 %

Motors:

- 5 high quality stepping-motors controlled by microprocessors

Fans:

- Two axial fans - one in the projector head and one in the base.

Electronics:

- built-in microphone

- Digital serial input DMX-512

- 4 DMX channel-presettings (8 or 16 bit protocols):

Chan nel Mode 1 Mode 2 Mode 3 Mode 4

1 Pan Pan Pan Pan

2 Tilt Fine Pan Tilt Tilt

3 Fine Pan Tilt Speed Colours

4 Fine Tilt Fine Tilt Colo urs Rot.gobo s

5 Spee d Speed Rot. gobos Gobo rotation

6 Colours Colours Gobo rotation Dimmer

7 Rot. gobos Rot. gobos Dimmer

8 Gobo rotation Gobo rotation

9 Dimmer Dimmer

Pan/Tilt:

-Pan movement r ange 530°

-Tilt movement range 280°

-Automatic P an / Tilt position correction

-Maximum PAN-movement 530° in 3.0 s

-Maximum TILT-movement 280° in 1.9 s

Rigging:

-Stands directly on the floor

-Mounts horizontally or vertically with 2 clamps

-2 truss orientation

-Safety chain/cord attachment point

Temperatures:

-Maximum ambient temperature

t

a

: 40° C

-Maximum housing temperature

t

B

(steady state): 80° C

Minimum distances:

-Min.distance from flammable surfaces: 0,4m

-Min.distance to lighted object: 0,8m

Dimensions:

-Width: 292 mm

-Length of base :378 mm

-Height (head horizontal):415 mm

Weight (net):

12,5 kg

Shipping weight:

18,5 kg

Page 30

30

12. Maintenance and cleaning

The operator has to make sure that safety-relating and machine-technical installations are inspected b y an expert

after every four years in the course of an acceptance test.

The operator has to make sure that safety-relating and machine-technical installations are inspected by a skilled

person once a year .

The following points have to be considered during the inspection:

1) All screws used for installing the de vices or parts of the device hav e to be tighly connected and must not

be corroded.

2) There must not be any deformations on housings, fixations and installation spots (ceiling, suspension,

trussing).

3) Mechanically moved p arts like axles, ey es and others must not sho w any traces of w earing (e.g. material

abrading or damages) and must not rotate with unbalances.

4) The electric power supply cables must not show any damages, material fatigue (e.g. porous cables) or

sediments. Further instructions depending on the installation spot and usage have to be adhered by a

skilled installer and any safety problems have to be removed.

DANGER T O LIFE !

Disconnect from the mains before starting

maintenance operation!

It is absolutely essential that the fixture is kept clean and that dust, dirt and smoke-fluid residues must not build

up on or within the fixture. Otherwise, the fixture‘s light-output will be significantly reduced. Regular cleaning will

not only ensure the maximum light-output, but will also allow the fixture to function reliably throughout its life.

Please use a moist, lint-free cloth. Never use alcohol or solvents!

The front objective lens will require weekly cleaning as smoke-fluid tends to building up residues, reducing the

light-output very quickly. The cooling-f ans should be cleaned monthly.

The gobos may be cleaned with a soft brush. The interior of the fixture should be cleaned at least annually using

a vacuum-cleaner or an air-jet.

The dichroic colour-filters, the gobo-wheel and the internal lenses should be cleaned monthly .

T o ensure a proper function of the gobo-wheel we recommend lubrication in six month intervals. The quantity of

oil must not be excessive in order to avoid that oil runs out when the gobo-wheel rotates.

There are no serviceable parts inside the device except for the lamp and the fuse. Maintenance and service

Page 31

31

operations are only to be carried out by authorized dealers.

Please refer to the instructions under "Fitting/Exchanging the lamp".

Replacing the fuse

If the lamp burns out, the fine-wire fuse of the device might fuse, too . Only replace the fuse b y a fuse of same type

and rating.

Before replacing the fuse, unplug mains lead.

Procedure:

Step 1: Unscrew the fuseholder on the rear panel of the base with a fitting screwdriver from the housing (anti-

clockwise).

Step 2: Remove the old fuse from the fuseholder .

Step 3: Install the new fuse in the fuseholder.

Step 4: Replace the fuseholder in the housing and fix it.

Should you need any spare parts, please use genuine parts.

If the power supply cable of this device will be damaged (cable firmly connected with the device), it has to be

replaced by authorized dealers only in order to avoid hazards.

If the power supply cable of this device will be damaged (replaceable cable), it has to be replaced by a special

power supply cable av ailable at your dealer .

Should you hav e further questions, please contact your dealer.

13. Appendix

We hope you will enjoy y our COLOR SPOT 150. We can assure you that you will enjo y this device f or years if you

follow the instructions given in this manual.

Should you hav e further questions, do not hesitate to contact your local dealer .

Please note: Every information is subject to change without prior notice.

Loading...

Loading...