Elastec MediBurn30 Operation & Service Manual

OPERATION & SERVICE MANUAL

www.elastec.com

MEDIBURN30

MEDIBURN30 D-115 Rev 010

www.elastec.com

MEDIBURN30 2 D-115 Rev 010

TABLE OF CONTENTS

www.elastec.com

Introduction, Contact Information ..................................................................... 4

Product Description ............................................................................................ 5

General Information ............................................................................................ 6

Control Panel ....................................................................................................... 7

How it Works ....................................................................................................... 8

Butterfly Assembly ........................................................................................... 10

Door Lock Motor Assembly ............................................................................. 11

Surge Protector Assembly ............................................................................... 12

Burnables .......................................................................................................... 13

Safety Instructions ............................................................................................ 14

Preparing for Disposal ...................................................................................... 15

Cycle Completion .............................................................................................. 17

Ash Removal ..................................................................................................... 17

Error Codes ....................................................................................................... 18

Troubleshooting Guide ..................................................................................... 19

Installing Gauge, Setting Fuel Pressure ......................................................... 23

Maintenance ...................................................................................................... 24

Storage ............................................................................................................... 24

Fuse Identification ............................................................................................ 25

Controller Parts List.......................................................................................... 26

Chamber Parts List #1 ...................................................................................... 27

Chamber Parts List #2 ...................................................................................... 28

Chamber Brick Assemblies .............................................................................. 30

Chamber Brick Assembly Parts List ............................................................... 31

Burner Drawing, Parts List ............................................................................... 32

Under Air Parts List .......................................................................................... 33

Spare Parts List ................................................................................................. 33

Warranty ............................................................................................................ 34

Items Not Covered by Warranty ....................................................................... 35

MEDIBURN30 3 D-115 Rev 010

INTRODUCTION

www.elastec.com

This manual contains information on the Elastec MediBurn30, manufactured

by Elastec, Inc. All data in this publication is based on the latest product

information.

Elastec reserves the right to make changes at any time without notice and

without incurring any obligations. If a problem is encountered, or if you have

questions about your Elastec equipment, please call one of our consultants at

+1 (618) 382-2525.

Elastec products are USA-designed and built to provide safe and dependable

service when operated according to instructions. Please remember that

working with an incineration device can be dangerous. Read and understand

this manual before operating this system. Failure to do so may result in

personal injury and/or equipment damage.

Your MediBurn30 serial number is _________________________________

SERIAL NUMBER MUST BE INCLUDED WHEN ORDERING PARTS.

CONTACT INFORMATION

Elastec, Inc. Telephone: +1 (618) 382-2525

1309 West Main Street Fax: +1 (618) 382-3610

Carmi, IL 62821 E-mail: elastec@elastec.com

USA Website: www.elastec.com

MEDIBURN30 4 D-115 Rev 010

1

PRODUCT DESCRIPTION

www.elastec.com

The Elastec MediBurn30 is a portable, small batch medical waste incinerator.

It enables small hospitals, clinics and laboratories to dispose of medical waste

in a safe and efficient manner. The MediBurn30 is designed to be easily and

safely operated by existing personnel with minimal training. The MediBurn30

can be used at any convenient location on existing property. Before using the

MediBurn30, the operator should read and follow the instructions in this

manual.

FUEL AND POWER CONSUMPTION

Incinerates up to 30 kg per hour

Modulating burners & under-air technology provide up to 50%

fuel savings.

Ready to use upon delivery

Updated electronic control system with multiple languages

available

Dual chamber combustion & high exhaust temperatures in

excess of 1000 degrees C

Safety features such as door lock and sensor.

Replaceable ceramics

SPECIFICATIONS

Length:

Width:

Height:

Weight:

Fuel Tank Capacity:

Primary Chamber Volume:

Suggested Load Volume:

FUEL AND POWER CONSUMPTION

Electric:

Fuel:

MEDIBURN30 5 D-115 Rev 010

79” (201 cm)

34” (86 cm)

82” (208 cm) without stack

100” (254 cm) with stack

2,440 lbs (approx. 1,107 kg)

40 gallons (151 litres)

13 cu ft (.37 cu m)

10.5 cu ft (.30 cu m)

Variable

2-3 gallons/hour (7-11 litres/hour)

GENERAL INFORMATION

www.elastec.com

CAUTION: Operators must wear gloves and safety glasses while operating unit.

CAPACITY

One MediBurn30 is capable of disposing of 10.5 cubic feet (.030 cubic meters)

of medical waste per load. Since there is a broad range of densities in waste

materials, the actual amount may vary. The waste is reduced to approximately

5% of its original volume. Ash is removed by means of a special rake (supplied

with the unit) and can be emptied directly into appropriate containers.

HOOK-UP

Electrical: In some cases, plugs may have to be installed on the end of the wires

extending from the unit to be compatible with local electrical fittings.

Fuel: There are two options for the supply of diesel to the unit:

Gravity-fed system: A large fuel tank supplies the unit. The bottom of the

tank should be higher than the top of the burner on the secondary chamber.

Mounted tank: Fuel supply is mounted under the unit with a fuel pump and

return line.

CONTROL PANEL OPERATION

The burn times are adjusted using the UP and DOWN arrows on the controller

located on the control panel (see Page 7). When the cycle time is chosen, push

the START button and the MediBurn30 will begin its operating cycle. To change

the cycle time, push the STOP button and change the cycle time. Then restart

the unit.

COMPLETE CYCLE

Unit is switched on, burn chamber door will lock and the 30-second purge

begins (fans only).

7-minute pre-heat (secondary chamber burner fires and begins the pre-heat

process).

Burn cycle begins.

After the firing cycle is complete, blowers in both primary and secondary

chambers blow cool air until the temperature of the unit is 300 degrees

Celsius. If the temperature rises again, blowers will be activated cyclically

until the temperature remains below 300 degrees Celsius.

OPERATING TEMPERATURES

Temperature readouts are visible on the control panel. The unit is designed to

preheat the secondary chamber for 7 minutes before incineration begins in the

primary chamber. Exhaust temperatures are automatically controlled to range

from 1000 degrees Celsius to 1025 degrees Celsius during the burn cycle.

Lower temperatures noted during operation indicate that the materials in the

batch load have been incinerated.

MEDIBURN30 6 D-115 Rev 010

CONTROL PANEL

www.elastec.com

Stop

Start

Upper

Temperature

Indicator light is red

when burner is on.

Burn time

adjustment

Upper Burner

Reset Button

Lower Burner

Reset Button

Lower

Temperature

Maintenance

Information

MEDIBURN30 7 D-115 Rev 010

Burn

Time

Language

HOW IT WORKS

www.elastec.com

Under-Air

Blower

Under-Air

Piping

MEDIBURN30 8 D-115 Rev 010

HOW IT WORKS

www.elastec.com

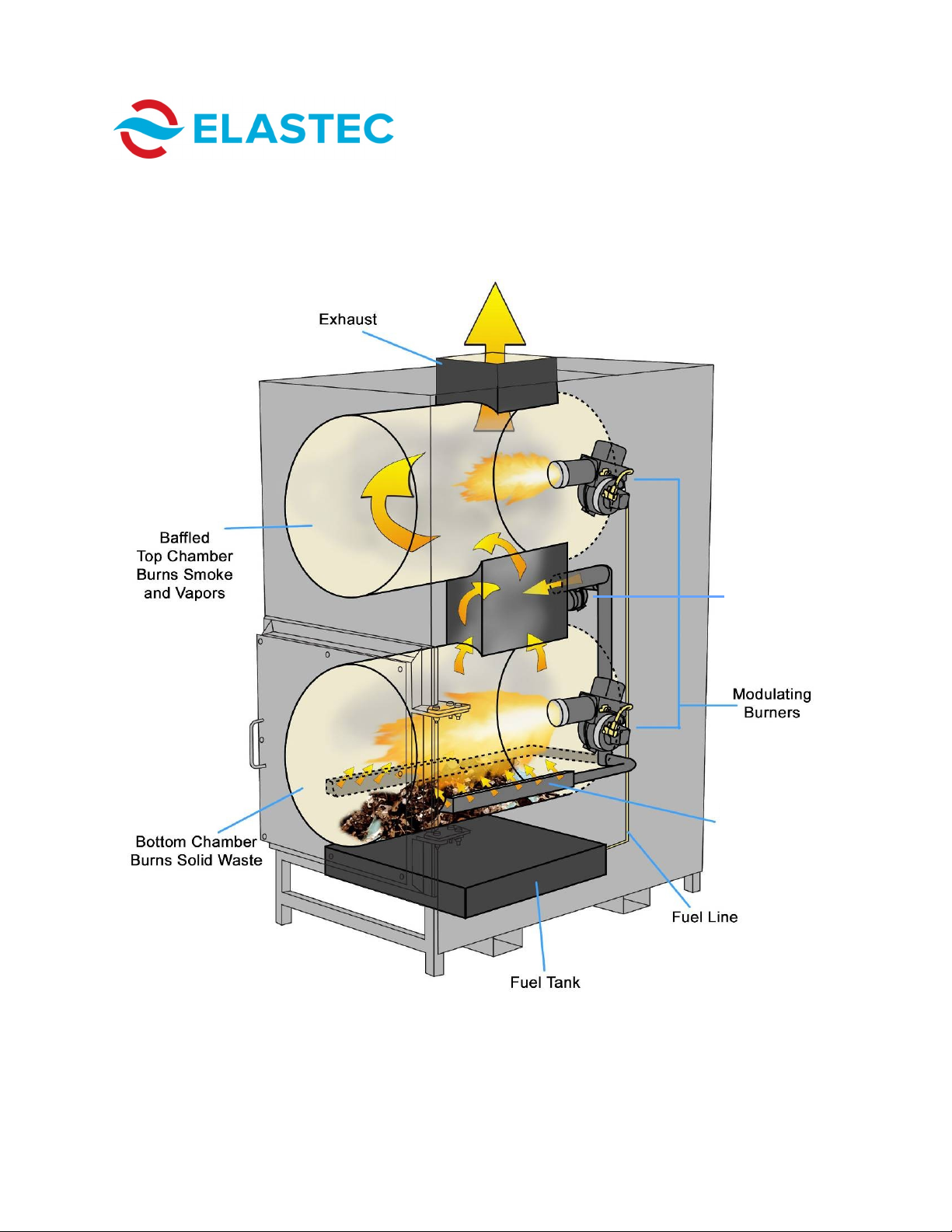

The operating functions of the burners on the MediBurn30 differ from those of

the original MediBurn in that the 30 has two-stage pumps which oscillate based

on temperature, rising and falling during normal burn operation. As the unit

starts its burn cycle and the temperature climbs, the pumps decrease fuel

usage at specified temperatures. This lowers the heat output of the burners.

However, the temperature continues to rise as the under-fired air in the

primary chamber raises the load temperature by increasing the flame of the

burning material. This process increases temperature to a preset point where

the lower burner can shut off, further reducing fuel usage. The upper burner

also oscillates fuel usage as it works to keep the stack temperature at or above

1000 degrees Celsius.

The MediBurn30 incorporates two 24-volt continuous stall motors. One of

these motors is used to operate and maintain the automatic door lock, which is

activated when the START button is pushed. The other 24-volt motor is used to

open and close the under-fired air bypass.

All of these components are controlled by temperature through the system

controller. Should you as the owner or system user have problems with these

components, please refer to the Troubleshooting Guide found on Pages 19-22

or call Elastec at (618) 382-2525.

MEDIBURN30 9 D-115 Rev 010

BUTTERFLY ASSEMBLY

www.elastec.com

The butterfly assembly, located just above the lower burner, is used to open

and close an air bypass. This motor function should be checked on a regular

basis to ensure that it is working properly. In the top of the motor bracket,

there is a small hole that will allow you to view the shaft coupler set screw.

This set screw will turn and disappear out of sight when the motor is activated.

This process can be easily viewed when the lower chamber temperature is

between 600° Celsius and 1000°

Celsius (1112° Fahrenheit and 1832°

Fahrenheit).

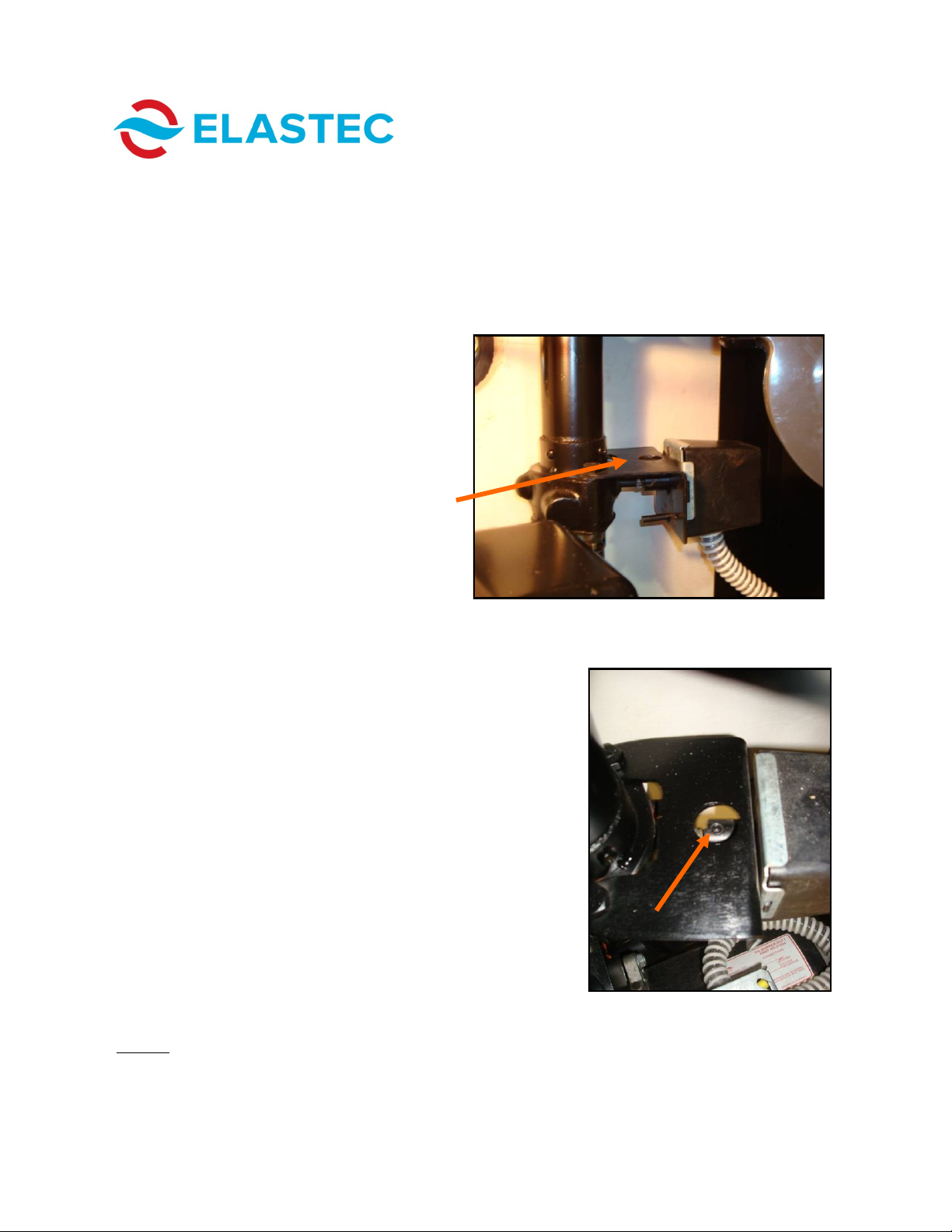

The picture to the right shows the set screw

(arrow) as it appears when the MediBurn30 is in

idle. This set screw will rotate out of view when the

temperature climbs above 600° Celsius (1112°

Fahrenheit), indicating the butterfly valve has

opened, allowing air to bypass into the under-air

system. When the lower chamber temperature

reaches 1000° Celsius (1832° Fahrenheit), the

butterfly valve will close and the set screw will

again be visible. It can also be felt by using your

finger. This bracket rarely gets very hot, due to the

cold air that passes through the tubing and

butterfly valve, making it possible to check this by

hand as well as sight. Should you have to replace

this motor, be sure to orient the set screw so that it

can be viewed through the view hole.

NOTE: It is important to maintain this motor in good working condition, as it is

instrumental in the process of fuel savings.

MEDIBURN30 10 D-115 Rev 010

DOOR LOCK MOTOR ASSEMBLY

www.elastec.com

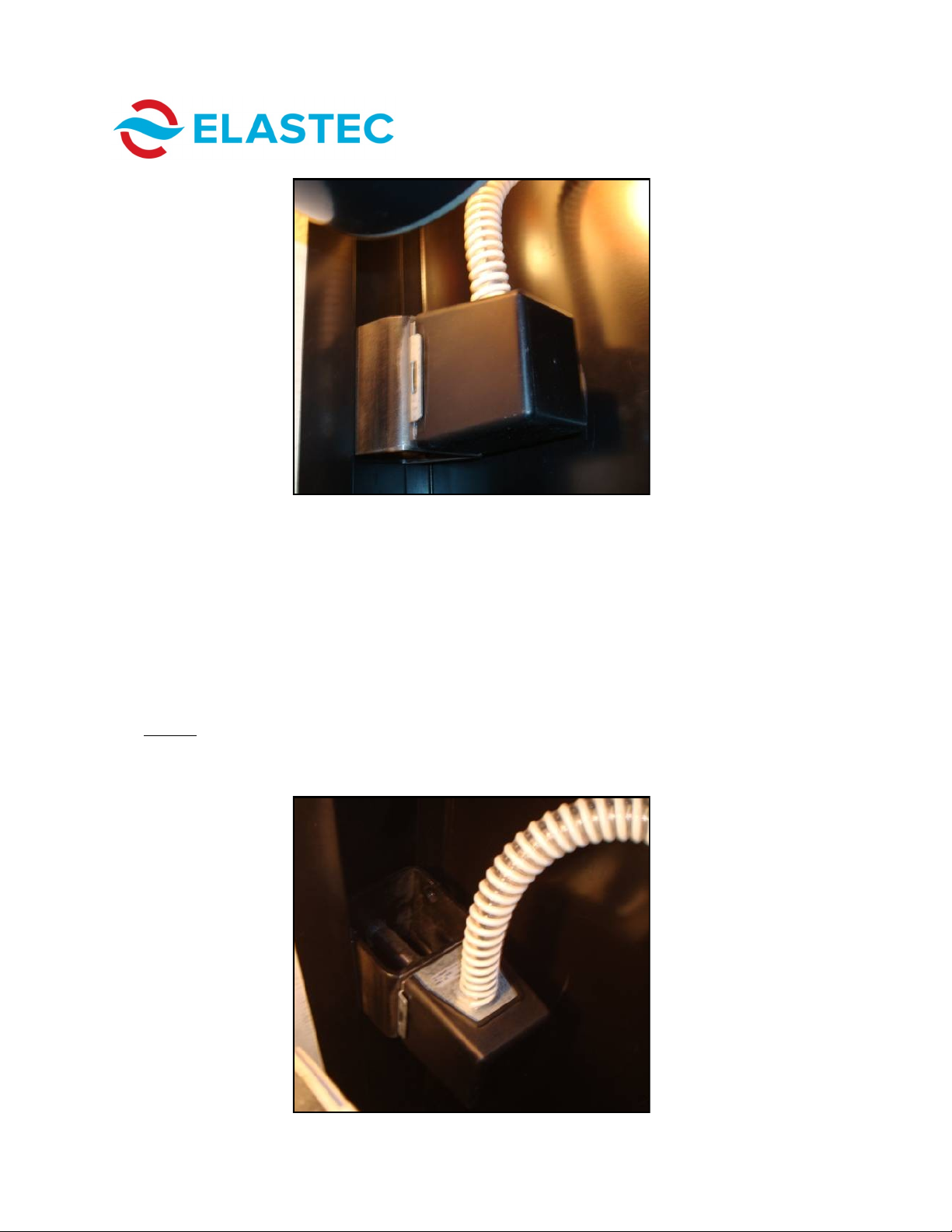

The door lock motor assembly is located on the right side of the burner

compartment. It is designed to lock the burn chamber door as soon as the

START button is pushed. The door-locking system is designed as a safety

feature and is built in such a way that, if tampered with, the MediBurn30 will not

start. When the burn chamber door is open, the controller scrolls “door open,”

and if the burn chamber door is opened during the burn cycle, the unit will

automatically cycle into cool mode and the unit will have to cool to 300C before

restart can begin.

NOTE: The MediBurn30 must always be cooler than 300° Celsius (572°

Fahrenheit) before trying to load unit.

MEDIBURN30 11 D-115 Rev 010

Loading...

Loading...