EL1056AC/EL1056C

Monolithic High-Speed Pin Driver

EL1056AC/EL1056C March 1993 Rev A

Features

# Wideg12V output levels

# 250 ps dispersion

# 3 ns delay times

# 1V/ns slew rateÐadjustable

# Low overshoot and aberrations in

50X systems

# 3-state output

# Power-down mode reduces

output leakage to nanoamperes

# Overcurrent sense flag available

to protect internal output devices

# Buffered analog inputs

# Differential logic inputs are

compatible with ECL, TTL, and

CMOS

Applications

# Memory testers

# ASIC testers

# Functional board testers

# Analog/digital incoming

component verifiers

# Logic emulators

Ordering Information

Part No. Temp. Range Package Outline

EL1056CM 0§Ctoa75§C 24-Lead MDP0027

EL1056ACM 0§Ctoa75§C 24-Lead MDP0027

Thermal SOL

Thermal SOL

General Description

The EL1056 is designed to drive high-quality test signals into

close or terminated loads. It has a dispersion of 250 ps or less Ð

whether due to signal size or direction of edge. It can output a

very wide 24V output span, encompassing all logic families as

well as analog levels. The EL1056 is fabricated in Elantec’s oxide isolated process, which eliminates the possibility of latch-up

and provides a very durable circuit.

The output can be turned off in two ways; the OE pins allow

the output to be put in a high-impedance state which makes the

output look like a large resistance in parallel with 3 pF, even for

back-driven signals with as much as 2.5V/ms slew rate. The E

pins put the output in an even higher impedance state, guaranteed to 150 nA leakage in the EL1056A. This allows accurate

measurements on the bus without disconnecting the EL1056

with a relay.

The EL1056 incorporates an output current sense which can

warn the system controller that excessive output current is

flowing. The trip point is set by two external resistors.

Connection Diagram

24-Lead Thermal SOL Package

Ý

*and Heat-spreader

Note: All information contained in this data sheet has been carefully checked and is believed to be accurate as of the date of publication; however, this data sheet cannot be a ‘‘controlled document’’. Current revisions, if any, to these

specifications are maintained at the factory and are available upon your request. We recommend checking the revision level before finalization of your design documentation.

©

1993 Elantec, Inc.

Top View

1056– 1

EL1056AC/EL1056C

Monolithic High-Speed Pin Driver

Absolute Maximum Ratings

V

S

b

V

a

B

b

B

I

SR

V

SR

Shunt

Shunt

Data, Data

OE, OE

Important Note:

All parameters having Min/Max specifications are guaranteed. The Test Level column indicates the specific device testing actually

performed during production and Quality inspection. Elantec performs most electrical tests using modern high-speed automatic test

equipment, specifically the LTX77 Series system. Unless otherwise noted, all tests are pulsed tests, therefore T

Test Level Test Procedure

Voltage between Vaand V

Supply Voltage

Supply Voltage V

Supply Voltage Vbto V

Input Current 0 mA to 3 mA

Input Voltage,

Power-Down Mode

a

Input Voltage (Ba)b5V to B

b

Input Voltage Bbto (Bb)a5V

Input Voltages Vbto Vaor

Input Voltages Vbto Vaor

I 100% production tested and QA sample tested per QA test plan QCX0002.

II 100% production tested at T

III QA sample tested per QA test plan QCX0002.

IV Parameter is guaranteed (but not tested) by Design and Characterization Data.

V Parameter is typical value at T

T

MAX

and T

ba

g

g

A

per QA test plan QCX0002.

MIN

e

(T

25§C)

A

33V

b

to V

INH

b

0.3V toa6V

6V Differential

E, E

18V

a

Sense Output Voltage V

INL

V

INH

V

INL

I

OUT

T

J

a

T

A

T

ST

P

D

6V Differential

e

25§C and QA sample tested at T

e

25§C for information purposes only.

A

Input Voltages Vbto Vaor

g

6V Differential

b

to V

Input Voltage V

Input Voltage Bbto V

Output Current

b

0.3V to B

INL

INH

b

60 mA toa60 mA

a

0.3V

Junction Temperature 150§C

Operating Ambient Temperature

Range

Storage Temperature

Power Dissipation (T

(See Curves) 3.1W

e

25§C,

A

e

25§C)

A

b

b

65§Ctoa150§C

e

e

T

J

C

0§Ctoa75§C

TA.

a

a

DC Electrical Characteristics

e

T

25§C, VaeBae15V, VbeB

A

b

0.8V. I

SR

e

800 mA. V

INH

e

Parameter Description Min Typ Max

I

S

(Va)a(Ba), (Vb)a(Bb) Supply Currents 52 60 I mA

IS, dis (Va)a(Ba), (Vb)a(Bb) Supply Currents, Disabled 17 25 I mA

I

VINH

I

VINL

I

DATA

I

OE

I

E

V

SR

I

SHUNT

V

SHUNT

I

SENSE

V

OS

a

a

,I

SHUNT

,V

SHUNT

OE Input Current

E Input Current

Voltage at ISRPin 0 20 40 I mV

b

Sense Threshold at Shunts 160 200 250 I mV

b

Sense Output Currents 1 1.5 2 I mA

Output Offset, Data High, V

5V, V

beb

INL

eb

10V, R

1.6V

Data Low, V

SHUNT

INH

INL

e

e

e

a

0V, V

0V, V

R

SHUNT

INL

INH

e

6.5X, no load. Data, E, and OE fromb1.6V to

b

b

b

20

320 I mA

b

20 2 20 I mA

b

30b15 30 I mA

b

30b14 30 I mA

b

20 7 20 I mA

47 I mA

eb

e

1.6V

5V

b

50 50 I mV

b

100 100 I mV

Test

Level

Units

TDis 2.7in

2

EL1056AC/EL1056C

Monolithic High-Speed Pin Driver

DC Electrical Characteristics

e

T

25§C, VaeBae15V, VbeB

A

b

0.8V. I

SR

e

800 mA. V

INH

e

Parameter Description Min Typ Max

Eg Gain Error Data High, V

Data Low, V

NL Gain Nonlinearity Data High, V

PSRR Power Supply Rejection Ratio of V

a,Bb

to B

, Shunta, or ShuntbPotential

Ro, en Output Resistance, Enabled, Il

Ro, dis Output Resistance, Output Disabled, V

Io, dis Output Current, Output, Disabled, V

Io, off Output Leakage, E Low, (Shut-Down), V

beb

5V, V

INL

INH

INH

Data Low, V

eb

from 0V to 5V, V

e

Ð Contd.

10V, R

SHUNT

e

R

a

SHUNT

1.6V

eb

5V, V

INH

e

INH

OUT

e

g

20 mA 4.5 6 7.5 I X

O

INL

fromb5V to 0V, No Load

INL

from 0V to 10V, V

5V, V

INL

INL

fromb10V to 0V, No Load 0.06 V %

with Respect

eb

1.6V tob5V, EL1056C 20K 100K

O

e

0V

e

0V, EL1056C

O

EL1056AC

e

6.5X, no load. Data, E, and OE fromb1.6V to

b

1.6V, No Load

eb

1.6V, No Load 0.04 V %

b

1.5b0.6 0 I %

b

1.5b0.6 0 I %

2.2 V mV/V

EL1056AC 100K 200K

b

20 5 20 I mA

b

20 20 I mA

b

150 150 I nA

Test

Level

AC Electrical Characteristics

e

T

25§C, VaeB

A

included at output. Data E, and OE from

b

1.6V, CMOS swing defined by V

Parameter Description Min Typ Max

T

PD

Dis Propagation Delay Dispersion

SR Output Slew Rate, CMOS Swing, 20% –80% 0.8 1 1.2 I V/ns

SR

sym

TR Output Rise Time, ECL Swing, 20% –80% 2.2 V ns

OS Output Overshoot

T

dis

T

en

Co, dis Output Capacitance in Disable 3 V pF

T

off

T

on

Co, off Output Capacitance in Power-Down 50 V pF

T

sense

aea

15V, VbeB

INH

beb

b

1.6V tob0.8V. I

e

5V and V

10V, R

SHUNT

e

0V. Propagation delay is measured at 0.4V movement of output.

INL

e

R

a

SHUNT

e

800 mA. ECL swing is defined by V

SR

b

e

6.5X.R

e

500X.50Xa22 pF snubber

L

INH

eb

0.8V and V

Test

Level

Propagation Delay, CMOS Swing 1.0 3.0 4.5 I ns

Due to Output Edge Direction 250 450 I ps

From ECL to CMOS Swings 250 450 I ps

Due to Repetition Rate 80 V ps

Slew Rate Symmetry 3 10 I %

CMOS Swing 190 500 I mV

ECL Swing (I

e

350 mA) 65 V mV

SR

Output Disable Delay Time 4.7 6.5 I ns

Output Enable Delay Time 6.0 8.5 I ns

Power-Down Delay Time 0.5 V ms

Power-On Delay Time 90 V ns

Comparator Delay Time Ð Switching ON 1.5 V ms

Switching Off 0.4 V ms

Units

I X

e

INL

Units

TDis 2.3inTDis 3.6in

3

EL1056AC/EL1056C

Monolithic High-Speed Pin Driver

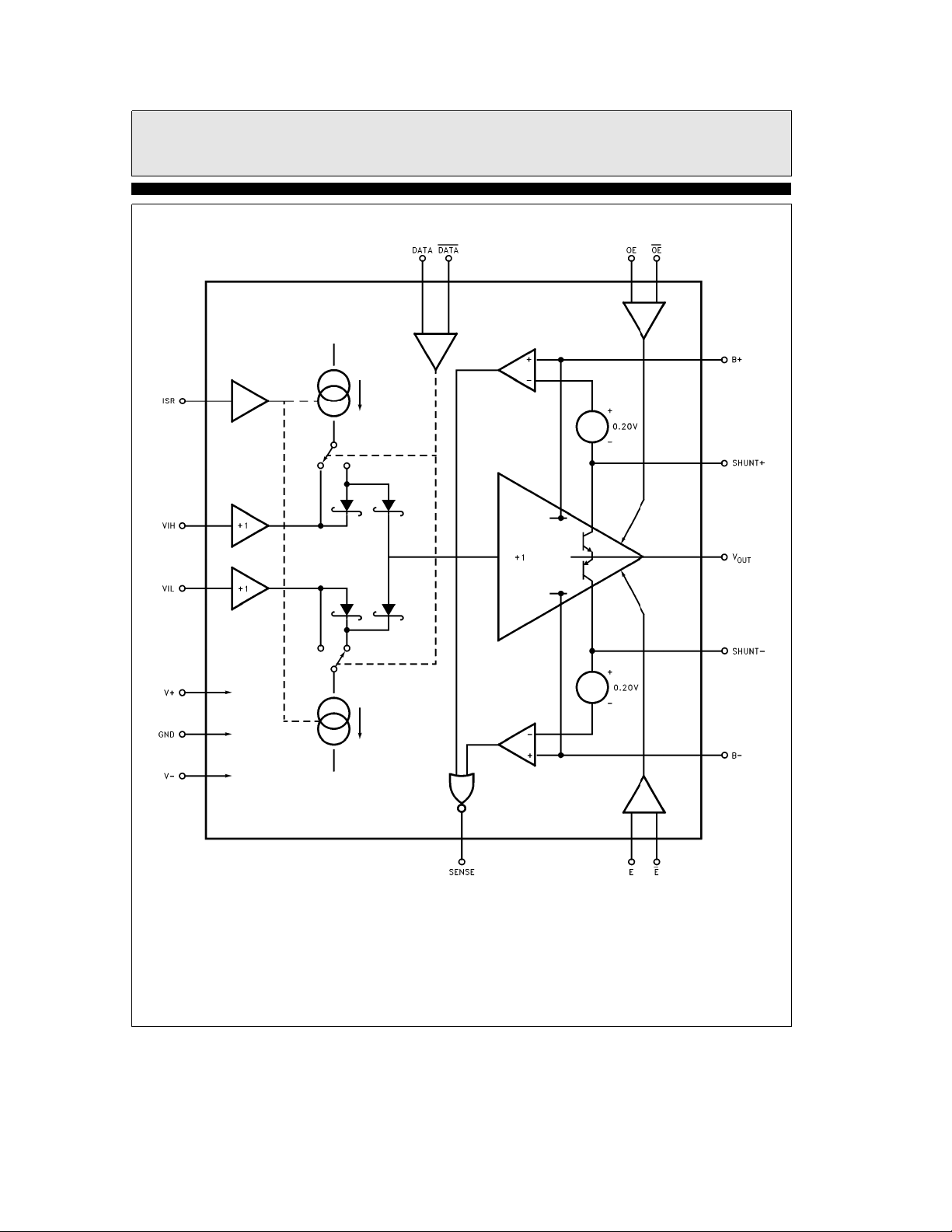

Block Diagram

1056– 5

4

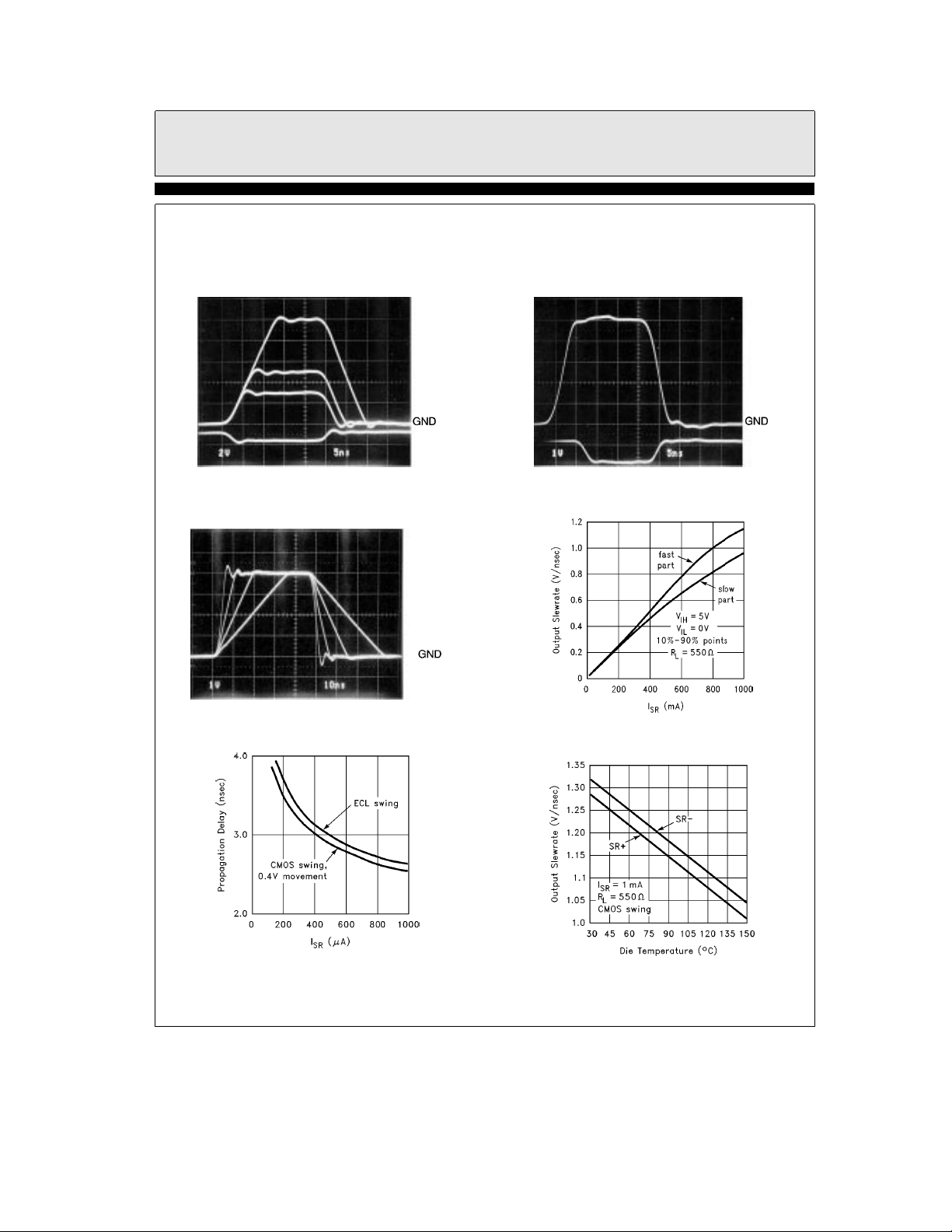

Typical Performance Curves

10V, CMOS, TTL, and ECL

Outputs into 550X Load

EL1056AC/EL1056C

Monolithic High-Speed Pin Driver

CMOS and ECL Outputs As Seen

at the End of an Unterminated

Cable, Backmatched at Driver

CMOS Output at I

SR

e

100 mA,

200 mA, 400 mA, and 1000 mA

Propagation Delay vs I

1056– 6

Output Slewrate vs I

(Two Samples)

1056– 8

SR

Output Slewrate vs

Die Temperature

SR

1056– 7

1056– 9

1056– 10

1056– 11

5

EL1056AC/EL1056C

Monolithic High-Speed Pin Driver

Typical Performance Curves

Propagation Delay Change

with Die Temperature

Output Edge Dispersion vs

Temperature

Ð Contd.

1056– 12

Change in Propagation Delay

with Power Supply Headroom

Edge Dispersion vs I

SR

1056– 13

Minimum Output Pulse Width

1056– 14

1056– 16

1056– 15

Output Offset vs I

SR

1056– 17

6

EL1056AC/EL1056C

Monolithic High-Speed Pin Driver

Typical Performance Curves

Tristate Turn-off Waveforms

Power-Down Disable Waveforms

Supply Current vs I

SR

Ð Contd.

1056– 18

1056– 20

Tristate Turn-on Waveforms

Power-Down Enable Waveforms

Total Supply Current vs

Supply Voltage

1056– 19

1056– 21

1056– 22

1056– 23

7

EL1056AC/EL1056C

Monolithic High-Speed Pin Driver

Typical Performance Curves

Mounted Thermal Resistance of

Package vs Airflow Speed

1056– 24

EL1056 Used in CMOS and TTL Systems

Ð Contd.

Package Power Dissipation

vs Ambient Temperature

1056– 25

Sense Comparator Delay

vs Overdrive

1056– 26

1056– 4

8

Monolithic High-Speed Pin Driver

Applications Information

Functional Description

The EL1056 is a fully integrated pin driver for

automatic test systems. Pin drivers are essentially pulse generators whose high and low levels can

be externally programmed and accurately switched in time, as well as incorporating an output

switch to disconnect the driver from a measurement bus. Additionally, the EL1056 has programmable slewrate.

Control Voltage Inputs

The analog level inputs are named V

V

, and the output replicates them as con-

INL

trolled by logic inputs. The analog inputs are

buffered and have bandwidths of 35 MHz and

slewrates of 25V/ms. For full slewrate, 4V of

headroom should be given to the inputs, that is

V

should be 4V less than Vaor Ba, and

INH

V

should be 4V more positive than Vbor

INL

b

B

. At lower slewrates (I

e

500 mA or less),

SR

3V of headroom will suffice. Insufficient headroom causes distorted output waveforms or delay

errors in output transitions. V

in voltage than V

, but the output will not fol-

INL

may be lower

INH

low the control logic correctly. Furthermore,

V

should be 200 mV more positive than V

INH

(the minimum output amplitude) for accurate

switching.

Logic Inputs

The logic inputs are all differential types, with

both NPN and PNP transistors connected to

each terminal. They are optimized for differential

ECL drive, which optimizes

atob

time matching. Larger logic levels can introduce

feedthrough glitches into the output waveform.

For CMOS input logic levels, an ECL output

waveform will show feedthrough when the

input risetime is shorter than 8 ns, differential or

single-ended. CMOS output swings show less aberration, and the EL1056 can toleratea4ns

single-ended risetime or 2 ns risetime for differential inputs. Attenuating CMOS or TTL inputs

to 1 Vp-p will eliminate all logic feedthrough as

shown in Figure 1.

and

INH

INL

edge delay

EL1056AC/EL1056C

1056– 2

Alternate Logic Interface

Figure 1

Slewrate Control

The slewrate is controlled by the ISRinput. This

is a current input and scales the output slewrate

by a nominal 1.25V/ns/mA. The slewrate maintains calibration and symmetry to at least as slow

as 0.2V/ns. The practical upper end of I

1 mA, and supply current increases with increasing I

.

SR

The I

control can be used to adjust individual

SR

pin drivers to a system standard, by adjusting

the value of its series resistor. Slewrate can also

be slowed to reduce output ringing and crosstalk.

With ECL output swings, there is not enough

voltage excursion to incur slewrate delays to 50%

logic threshold. The risetime, delays, and dispersions do not degrade with reasonably reduced

I

, and overshoot will reduce markedly. An I

SR

of 350 mA produces a very good ECL output, and

driver dissipation is also reduced.

1056– 3

SR

is

SR

9

EL1056AC/EL1056C

Monolithic High-Speed Pin Driver

Applications Information

The I

transistor whose base is biased a diode below

ground (see Figure 2). Thus, the I

like a low impedance for positive input currents,

and is biased close to ground. A protection diode

absorbs negative currents, and the input PNP

will not conduct. In power-down mode, the PNP

releases its current sink and the external circuit

must not present more than 6V to the disabled

I

SR

will occur within the driver. A signal diode or

zener can be used to clamp the I

tive input voltages if the voltage on the I

tor is potentially greater than 6V when the driver

is in power-down mode.

pin is connected to the emitter of a PNP

SR

input, or emitter-base damage to the NPN

Ð Contd.

input looks

SR

input for posi-

SR

SR

resis-

Output Stage–Tristate Mode

In tristate mode (OE low) the output transistors

have their emitter-base junctions reverse-biased

by a diode voltage. This turn-off voltage is in fact

provided by an internal buffer whose input is

connected to the output pin (see Figure 3). Transistors Q1 – Q4 form the output buffer in normal

mode. The tristate mode buffer Q5 –Q8 replicates

externally impressed voltages from the output

pin onto the internal schottky switch node. They

also turn off Q1 –Q4 by a reverse diode voltage

between bases and emitters, effectively bootstrapping the internal voltages, so that no transistor’s base-emitter junction is reverse-biased by

a damaging potential. Another benefit is that the

capacitance seen at the output in tristate mode is

reduced.

Because the tristate buffer’s input is connected to

the output terminal, the output is quite ‘‘alive’’

during tristate. For instance, the input bias current of the buffer is seen as the tristate ‘‘leakage’’,

and its variation with applied voltage becomes

tristate input impedance.

The tristate input current is like a current source,

and it can drag an output to unpredictable voltages. It is not a danger to connect a tristated output that has drifted to, say,

a device to be tested. The tristate output current

will simply comply with whatever voltage the

connected part normally establishes.

The tristate input impedance is also quite active

over frequency. The output can oscillate when

presented with resonant or inductive impedances.

To prevent this, a snubber should be connected

from output to ground, consisting of a resistor in

series with a small capacitor. The snubber can

also reduce the reflections of the coaxial line

when driven from the far end, since the line appears to have an open termination during tristate. Typical values for the resistor are 50X to

75X, and 12 pF to 22 pF for the series capacitor.

The effect of the snubber is to ‘‘de-Q’’ resonances

at the output.

b

6V to a logic pin of

Figure 2. ISRPin Circuitry

10

1056– 27

EL1056AC/EL1056C

Monolithic High-Speed Pin Driver

Applications Information

Ð Contd.

Figure 3. Output Stage Circuit in Tristate Mode

Output Stage–Normal Mode

Capacitive loads can cause the output stage to

ring. Little ringing occurs for loads less than

25 pF, but substantial ringing for more than

40 pF. Terminated transmission lines cause no

ringing, and actually suppress it as a snubber

does. A terminated line draws heavy DC current,

however, and greatly raises dissipation.

Driving a back-terminated line also causes little

ringing and does not cause DC dissipation. The

series matching resistor between the EL1056 output and a back-terminated line also serves to isolate the driver from capacitive loads and shortcircuits. The slewrate of the driver slows by

about 10% when driving a 50X back-matched

1056– 28

line, as seen at the end of the line. The snubber

can be on either side of the back-match resistor.

When placed on the line side it creates a highfrequency termination for the line when the

driver is tristated, but it slows the output smallsignal risetime by about 10% (although not slewrate). When placed on the driver side of the backmatch resistor, no speed reduction occurs in

normal mode but the cable is more poorly terminated in tristate.

The transient currents that occur when driving

capacitive or back-matched loads can be very

high, approaching 100 mA. The driver is capable

of outputting a peak of 140 mA, but long-term

11

EL1056AC/EL1056C

Monolithic High-Speed Pin Driver

Applications Information

load currents must be limited to 60 mA. Shortcircuits can rapidly destroy the EL1056, although

the part will survive for 20 ms periods. If there is

the possibility of output load fault the overcurrent sense circuitry should be used to signal

alarm to the controlling system, which should ultimately activate the tristate mode to relieve the

output stage. Driving large static currents also

raises internal dissipation and should be part of

the thermal budget.

Ð Contd.

The collectors of the output transistors are connected to the Shunt terminals, and the output

stage drivers’ collectors are connected to the B

and Bbterminals (see Figure 4). The Shunt

lines can have transient currents as high as

120 mA and are separated from the V

terminals to keep switching noise out of the control and logic circuitry. A bypass capacitor

should be connected to the B

nals.

a

a

and Bbtermi-

and V

a

b

Figure 4. Output Stage in Normal Mode

12

1056– 29

Applications Information

Ð Contd.

Overcurrent Protection

The sense comparators are available to alert the

test system’s controller that the driver is outputting excessive current. Shunt resistors are connected from B

When the internal comparators sense more than

a nominal 200 mV drop on the shunts, they cause

a 1.5 mA current to be sunk from the Sense terminal. The comparators are of ‘‘slow attack, fast

decay’’ design, so that transient load currents will

not trigger a sense output; only a sustained overcurrent will.

The sense resistors must not be inductive, and

the skin resistance of long, narrow connections

between Shunt and B

sient voltages that produce output overshoot

(but not ringing).

The Sense output is simply a switched current

source connected to V

face to CMOS, TTL, or ECL inputs. For CMOS

and TTL, it can be connected to a pull-up resistor

a

to

5V of 10K value. This establishes a logic

high value, and a clamp diode (internal to TTL)

establishes a low level of

should be available to provide a static logic high

level. An 820X pull-up resistor is wired to that

output. The logic low will be more negative than

is usual for ECL, but this will cause no problem.

In all cases, multiple Sense outputs may be connected together from many drivers to effect a

wired-or function.

A further protection scheme is to provide a series

resistor from B

resistor serves to limit the output fault current

by allowing B

heavy load. This also reduces the dissipation on

the output transistors for valid loads. Because

a

to Shuntaand Bbto Shuntb.

a

or Bbcan cause tran-

b

. It can be used to inter-

b

0.6V. For ECL, a gate

a

to Vaand Bbto Vb. The

a

and Bbvoltages to sag under

EL1056AC/EL1056C

Monolithic High-Speed Pin Driver

a

and Bbare separately bypassed, these volt-

B

ages will sustain under transient loads and dynamics will not be affected.

Output Accuracy

The accuracy of the output voltage depends on

several factors. The first is the gain error from

V

or V

INH

error is nominally

of a percent variation between parts. The second

is supply rejection. If the B

b

Shunt

by Elantec to test the part, there will be about

2.2 mV systematic shift in output offset per volt

of supply variation. The V

have much less influence on output error. Finally, there is a random V

data table.

Of course, the finite output impedance of the

EL1056 will cause additional output error when

the driver is loaded.

Power-Down

The EL1056 incorporates a power-down feature

that drastically reduces power consumption of an

unused driver and also drops the output leakage

current to nanoamperes (‘‘A’’ grade only). The

output is not a low capacitance in this mode,

however, and transients driven from the cable

can momentarily turn on the output transistors.

Power-down is intended to allow the switching of

accurate DC meters onto the bus without having

to relay out the driver’s leakage current. It takes

about 40 ms for the output leakage to sag to nanoamperes, but this is still much faster than relays or voltmeters.

Power-down is controlled by the E and E

ential inputs. There is no problem with logic amplitude or slewrate, and input resistor networks

are not needed.

to the output, unloaded. The gain

INL

voltages are different from those used

b

0.6%, and has a few tenths

a,Bb

, Shunta,or

a

and Vbsupplies

error as specified in the

OS

differ-

13

EL1056AC/EL1056C

Monolithic High-Speed Pin Driver

Power Down

Supply and Input Bypassing

The Va,Ba,Vb, and Bbleads should be bypassed very closely with 0.1 mF capacitors, preferably chip type. There should be a wide ground

plane between bypasses, and this can be the heatsink copper. It is wise to also have a 4.7 mF tantalum bypass capacitor within a couple of inches to

the driver.

The logic inputs are active device bases, and can

oscillate if presented with inductive lines. A local

resistor of 1000X or less to ground will suffice in

de-Q’ing any resonance. A 100 pF or larger capacitor can also serve as a bypass.

Ð Contd.

Thermal Considerations

The package of the EL1056 includes two fused

leads on each side which are connected to the internal die mounting metal. Heat generated in the

die flows through the mounting pad to the fused

leads, and then to the circuit-board copper,

achieving a thermal resistance to air around

40

/W. Characterization curves show the thermal

§

resistance versus airflow rate. Consult the

EL1056 Demonstration Board literature for a

suggested board pattern. Note that thicker layers

of copper than we used improves the thermal resistance further, to a limit of 22

nite heatsink’’ directly soldered to the fused

leads.

As a practical limit, the die temperature should

be kept to 125

to retain optimum timing accuracies.

C rather than the allowable 150§C

§

C/W for an ‘‘infi-

§

14

BLANK

15

EL1056AC/EL1056C

Monolithic High-Speed Pin Driver

EL1056AC/EL1056CMarch 1993 Rev A

General Disclaimer

Specifications contained in this data sheet are in effect as of the publication date shown. Elantec, Inc. reserves the right to make changes

in the circuitry or specifications contained herein at any time without notice. Elantec, Inc. assumes no responsibility for the use of any

circuits described herein and makes no representations that they are free from patent infringement.

WARNING Ð Life Support Policy

Elantec, Inc. products are not authorized for and should not be

used within Life Support Systems without the specific written

consent of Elantec, Inc. Life Support systems are equipment in-

Elantec, Inc.

1996 Tarob Court

Milpitas, CA 95035

Telephone: (408) 945-1323

(800) 333-6314

Fax: (408) 945-9305

European Office: 44-71-482-4596

tended to support or sustain life and whose failure to perform

when properly used in accordance with instructions provided can

be reasonably expected to result in significant personal injury or

death. Users contemplating application of Elantec, Inc. products

in Life Support Systems are requested to contact Elantec, Inc.

factory headquarters to establish suitable terms & conditions for

these applications. Elantec, Inc.’s warranty is limited to replacement of defective components and does not cover injury to persons or property or other consequential damages.

Printed in U.S.A.16

Loading...

Loading...