Page 1

ELAFLEX PACIFIC PTY LTD · Unit 29 / 58 Box Road · Taren Point · NSW 2229 · Australia

Tel. +61 2 8058 9258 · info@elaflex.com.au · www.elaflex.com.au

INSTALLATION AND OPERATING MANUAL

ZVG 2 EURO UL

LPGas Nozzle with 'EURO' Connector

9 / 2018

Underwriters

Laboratory listed

Meets EN 13760 /

UN R 67 / ISO 19825

Picture shows

optional Scuguard

( Nozzle Talker ) EA 866

Page 2

Please read this manual carefully before installation or operation of the nozzle.

Be sure all instructions are understood. Correct installation, use and maintenance are essential.

In case of doubt or question please contact your service contractor or the manufacturer.

DESCRIPTION

The ZVG 2 EURO UL nozzle is designed for the LPGas vehicle refueling. Unlike the previously used LPGas nozzles with screw-on connectors, it is equipped with a 'EURO' coupling and optionally with an orange safe latching mechanism to increase user comfort as

per UL 125. It incorporates ease of use, operating safety and low gas release volume upon

uncoupling. The nozzle is designed to only allow gas to flow when it is correctly coupled.

APPROVALS / OPERATING CONDITIONS

ZVG 2 EURO UL is listed by Underwriters Laboratories for use with LPGas (Liquefied Petroleum Gas like propane, butane and their mixtures). It also meets the requirements of EN 13760,

UN R67 and ISO 19825.

Flowrate up to 50 litres/min. Rated service pressure 363 psi (25 bar), operation tempera ture range

-40° F (-40° C) to 131° F (70° C). Test pressure 544 psi (37.5 bar), burst pressure in excess of 1450

psi (100 bar). Each nozzle is factory tested before being labelled with the prescribed marking,

production date and unique serial number.

GENERAL INFORMATION ABOUT LPG / WARNINGS

• LPGas is liquefied under pressure when transported and stored. It is heavier than air.

Commercial LPGas is odourised before distribution to enable detection by its sulfurous smell.

It appears as white fog or cloud when exposed to the atmosphere. It has an evaporation factor

of 1/260: one liter of liquefied gas corresponds to 260 liters of inflammable gas.

A small gas release upon uncoupling is normal – but uncontrolled gas release to

the atmosphere must be avoided. If you suspect a leakage: stop refueling, use the

emergency button to shut o the dispenser, immediately evacuate the area and

inform station personnel.

• LPGas is extremely flammable, which is capable of igniting at concen tra tions between 2 and

10 % in air.

Open fires, smoking, sources of static electricity and the use of mobile phones

or other electric devices is prohibited in the area of gas transfer. Turn o vehicle

engine before refueling.

symbol icon

escaping gas

2

Page 3

• LPGas is extremely cold when released to the air (depressurized).

Local laws and code of practice regarding LPGas handling as well as instructions of vehicle,

dispenser and authorized personnel must be followed. Please also refer to the safety codes

NFPA 54 + 58 and NPGA 306.

INSTALLATION

The ZVG 2 EURO UL is delivered ready for use.

Nozzles should only be installed and tested by competent personnel. Applicable laws, regulations

and Codes of Practice have to be followed.

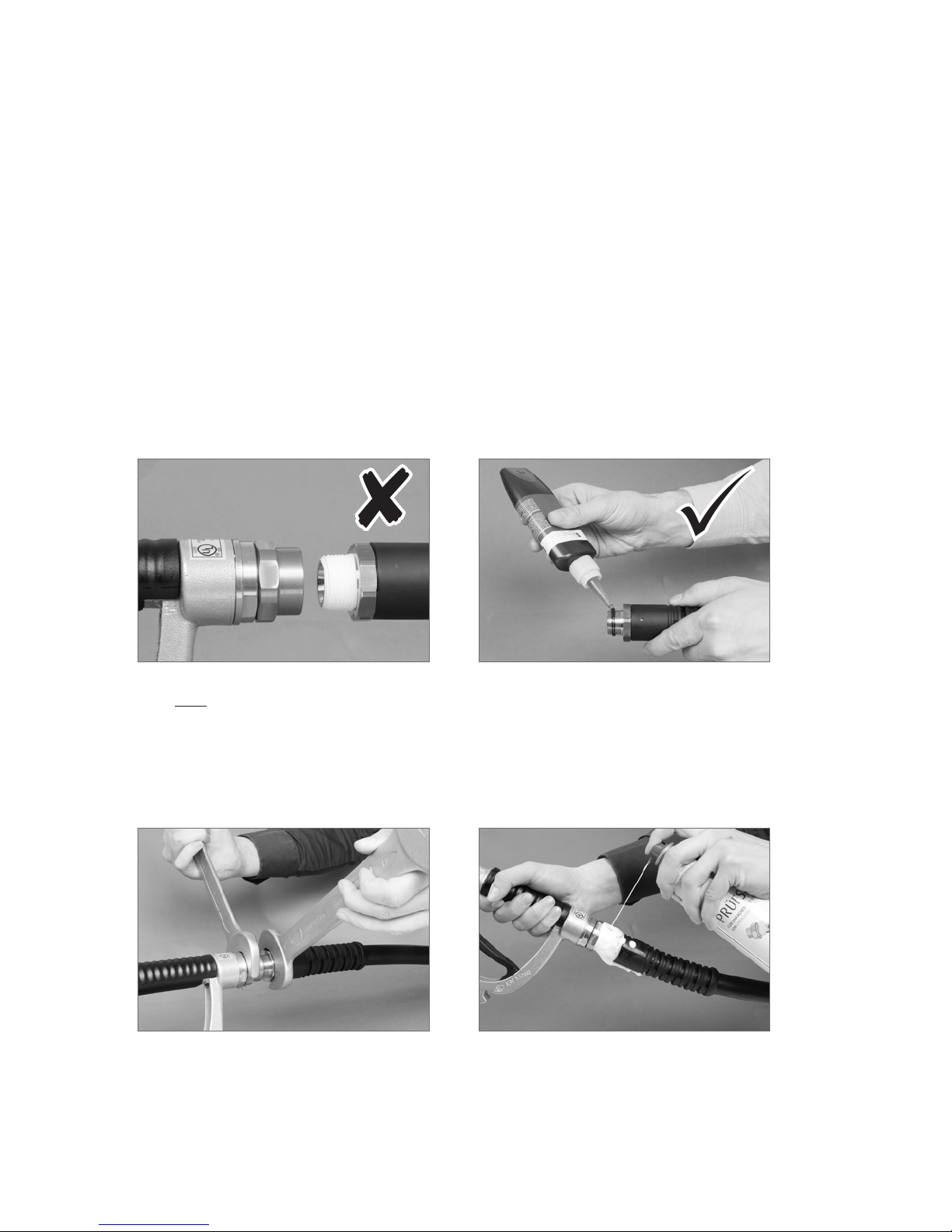

Do not use PTFE sealing tape for sealing threaded connections, as electrical conductivity may be

insucient and particles of the tape commonly become loose and could clog the nozzle strainer

or damage vehicle motor parts. Use suitable liquid seal (non permanent) instead.

Do n o t use PTFE tape Use liquid seal (non permanent)

After connecting to the hose assembly, an operational test shall be performed. It is essential to

examine that the nozzle, hose connector and swivel are tight under pressure and do not leak –

e. g. by external application of foaming agents.

Assemble with spanners Check tightness

3

Page 4

OPERATING INSTRUCTIONS

Please follow any additional

or deviating operating

instructions displayed

at the dispenser.

Ensure that all coupling parts,

seals and sealing surfaces of

nozzle and vehicle coupling are

clean and undamaged.

Switch o vehicle engine.

Take nozzle from dispenser. If

necessary activate the dispen-

ser. Align nozzle with vehicle si-

ded fill point as shown.

Remove nozzle and take it back

to its parking position on the

dispenser.

Push nozzle firmly onto the

vehicle fill point.

OFF

Fueling will now usually start.

If leakage is observed, release

lever to stop process.

Do not lean on / tilt the nozzle.

On completion of refueling

release lever to disconnect. If

latch is fitted, squeeze lever and

latch will automatically release.

During lever release a quantity

of liquid gas is discharged

from front of the nozzle.

If the vehicle is equipped with

an integrated EURO coupling

this will be a small amount.

If an adapter is used this will be

a considerably larger amount.

To avoid cold burns, keep

hands o the coupling area.

Pull nozzle lever as shown to

open the nozzle valve. If latch is

fitted, push latch up with forefinger and release lever.

4

Page 5

FILL POINT ADAPTORS

The use of fill point adaptors is not recommended by ELAFLEX PACIFIC PTY LTD.

If an adaptor is used, please note:

• During the release of the nozzle lever at the end of the fueling process, a quantity of liquid

gas remaining between vehicle fill point and nozzle is discharged. When using adaptors,

the released volume of gas is much greater compared to a direct connection with the

vehicle filling connector.

• Replace worn out adaptors (tears, breaks, cuts, damaged sealing surface).

MALFUNCTION

• If the lever cannot be pulled back

Check the correct seating of the nozzle to the vehicle coupling. A safety feature prevents

operation of the nozzle if the connection is misaligned. If you have any doubts or questions, please contact the station personnel.

Never force operation of the nozzle. If the connection process does not work smoothly,

disconnect and re-connect nozzle as indicated under chapter 'Operation'.

• Leakage ( escaping gas )

A small gas release upon uncoupling is normal. If uncontrolled and / or permanent gas

release to the atmosphere occurs, immediately stop fueling. If the leakage continues,

push emergency button of dispenser, leave area and inform station personnel.

If area is safe, check tight connection between vehicle connection and ZVG 2 EURO UL

nozzle and coupling. Check seals of vehicle connection and ZVG 2 EURO UL coupling.

If the problem persits notify the station personnel or the service contractor.

MAINTENANCE

The ZVG 2 EURO UL nozzle is a mechanical device that may become inoperative due to wear,

corrosion and ageing of components. Regular inspections and maintenance are essential for a

safe operation.

Daily visual inspections of the nozzle by trained personnel should be carried out to ensure

proper function. The nozzle coupling shall be clean and not show any signs of damage (e. g. dents,

sharp edges, blocked lever, swivel non rotating). Especially check the red coloured front seal

inside the coupling part of the nozzle to confirm there is no dirt or mechanical damage.

The nozzle condition shall be thoroughly checked during the annual pump maintenance by competent personnel. Applicable laws, regulations and Codes of Practice have to be followed.

Nozzles in unfit condition for use must be immediately replaced.

5

Page 6

CONDITIONS OF USE

Failure to comply with any warnings, instructions, procedures or any other common sense

procedures may result in injury, equipment damage, property damage or poor performance of

the equipment.

ELAFLEX PACIFIC PTY LTD accepts no liability for direct, indirect, incidental, special, or consequential damages resulting from failure to follow any warnings, instructions and procedures in

this manual, or any other common sense procedures generally applicable to equipment of this

type. The foregoing limitation extends to damages to person or property caused by the unit or

damages resulting from the inability to use the unit including loss of profits, loss of products, loss

of power supply, the cost of arranging an alternative power supply, and loss of time, whether

incurred by the user or their employees, the installer, the commissioner, a service technician, or

any third party.

The manufacturer reserves the right to change the specifications of its products or the information

in this manual without necessarily notifying its users.

Variations in installation and operating conditions may aect the unit‘s performance. ELAFLEX

PACIFIC PTY LTD has no control over each installation‘s unique operating environment. Hence, no

representations or warranties concerning the performance of the unit under the actual operating

conditions prevailing at the installation are made. A technical expert of your choosing should

validate all operating parameters for each application.

ELAFLEX PACIFIC PTY LTD has made every eort to explain all servicing procedures, warnings,

and safety precautions as clearly and completely as possible. However, due to the range of

operating environments, it is not possible to anticipate every issue that may arise. This manual

is intended to provide general guidance. For specific guidance and technical support, contact

your authorized supplier.

Only approved original parts shall be used and no unauthorized modifications to the hardware

shall be made. The use of non-approved parts or modifications will void all warranties and

approvals. The use of non-approved parts or modifications may also constitute a safety hazard.

Information in this manual shall not be deemed a warranty, representation, or guarantee. For

warranty provisions applicable to this unit, please refer to the warranty provided by the supplier.

Every eort has been made to ensure the accuracy of this document. However, it may contain

technical inaccuracies or typographical errors. ELAFLEX PACIFIC PTY LTD assumes no responsibility for and disclaims all liability of such inaccuracies, errors or omissions in this.

WARRANTY

ELAFLEX PACIFIC PTY LTD guarantee against defective materials and manufacturing for

18 months from date of supply. If the delivery date cannot be established, the factory date code

on the nozzle guard applies ( e. g. •18 = 1st quarter 2018 ).

Excluded are nozzles and parts subjected to wear and tear and damages caused by improper

use, for example the use with unsuitable fluids. Furthermore excluded are indirect damages and

costs, such as travelling related to exchange and repair work. We refuse any liability for consequential loss or damage resulting from the use of our nozzle.

6

Page 7

7

Page 8

8

Complete operating instructions see page 4 of this manual. Follow any additional or

deviating instructions displayed at dispenser.

STOP FUELING

START FUELING

Latching

Unlatching

Loading...

Loading...