Page 1

TECHNISCHE ÄNDERUNGEN VORBEHALTEN · NACHDRUCK UND KOPIEN NUR MIT UNSEREM EINVERSTÄNDNIS · Specifications subject to change without notice · Copyright ELAFLEX

August 2015

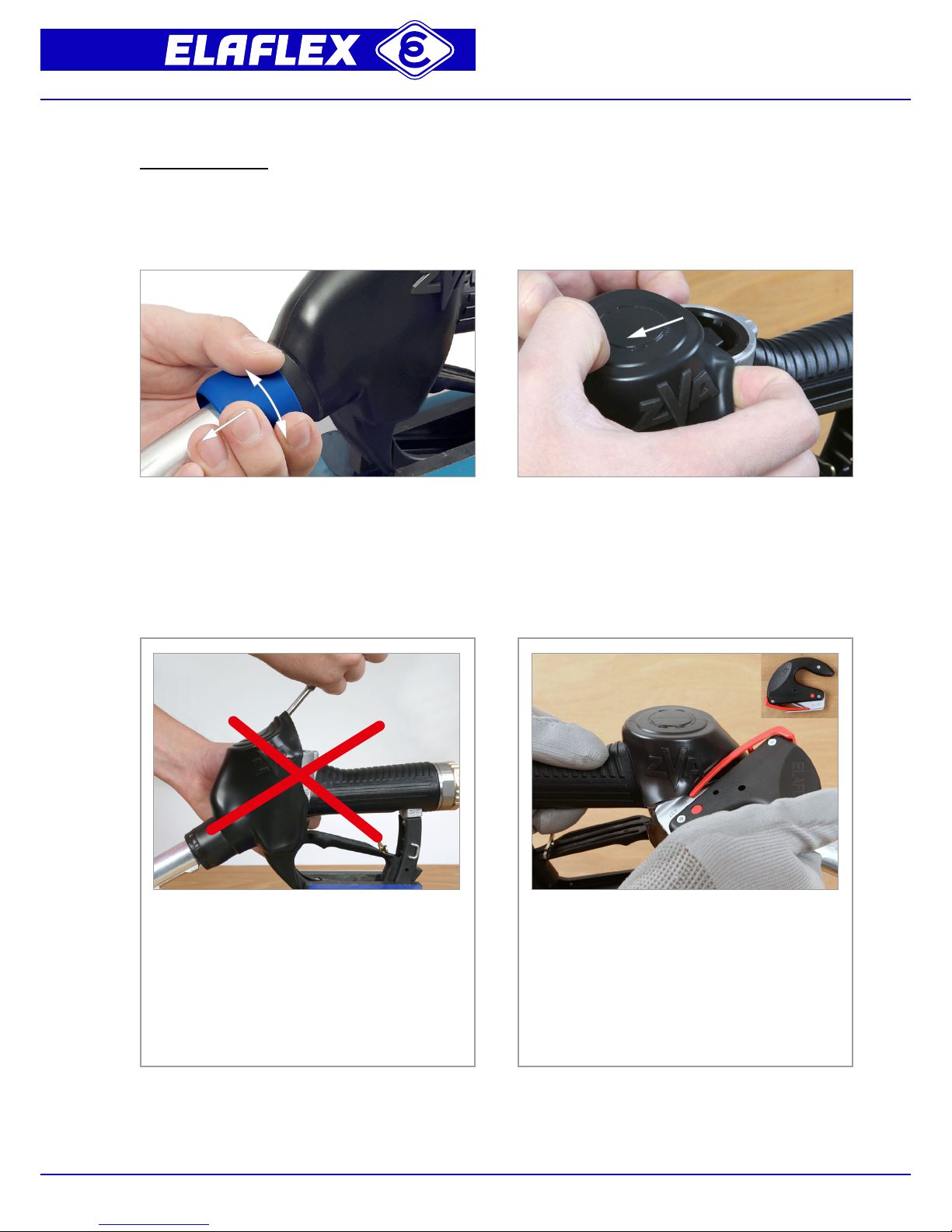

1) With a turning movement, pull off Product

Sleeve EK 043 ( or Splashguard EK 652 )

towards the spout tip.

Do not use tools ( e.g. screwdriver ) to

pull off the Scuffguard.

Tools might overscretch and permanently

deform the Scuffguard. In this case, the

Scuffguard does no longer fit onto the nozzle

body so that the Product Sleeve cannot be

assembled correctly.

To remove hardened scuffguards please use

our Safety-Cut-Off Tool EW-CUT.

For further information about the EW-CUT

please read at our manual 'Safety-Cut-Off

Tool'.

2) Put fingers below the Scuffguard EK 044 and

pull it towards the spout tip to remove.

ZVA Slimline 2 – Disassembling and

Assembling Scuffguard / Product Sleeve

DISASSEMBLING

Scuffguard

EK 044

Product Sleeve

EK 043

EW-CUT

These parts can by disassembled at room temperature, by hand. Using a vise ( smooth jaws, to protect the

plastic guard ) facilitates the procedure.

Page 2

c

c

b

b

a

a

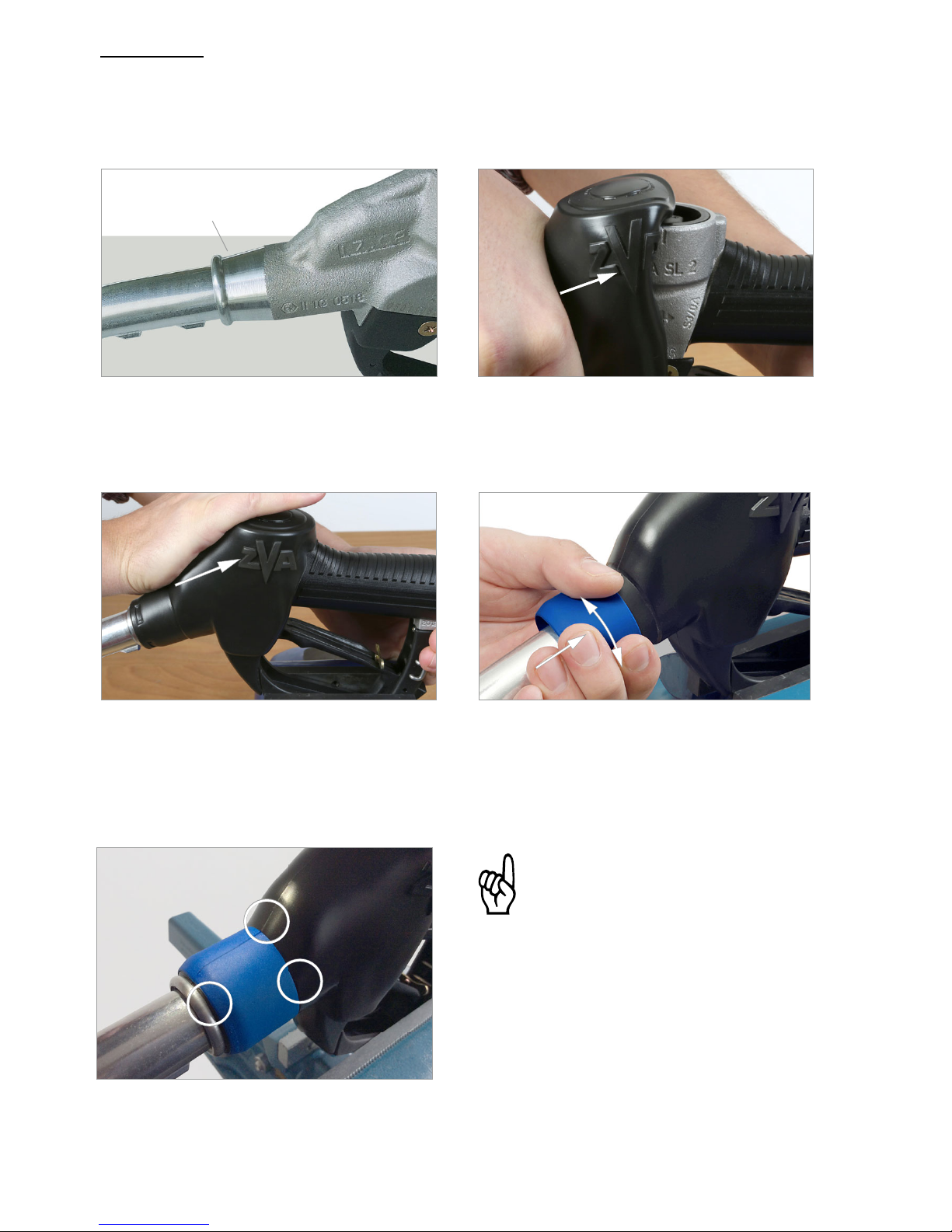

3) Push the Scuffguard further as shown in order

that the Product Sleeve can be fitted correctly.

2) Push the Scuffguard over the spout as shown.

Then put fingers slightly below the Scuffguard

to pull it onto the nozzle body.

4) Push Product Sleeve ( or Splashguard EK 652 )

onto the Scuffguard. While pushing the Product

Sleeve, turn it until it snaps in properly.

Pay attention to the correct position

of the Product Sleeve :

a) Correct position of the Scuffguard -

the nozzle body has to be visible.

b) The Product Sleeve has to snap onto the

Scuffguard: no gap between these two parts

allowed.

c) The parting line on the Product Sleeve has to

be in line with the parting line of the Scuffguard.

ASSEMBLING

The scuffguard can be mounted by hand, at room temperature. To facilitate assembling for large quantities or

at low ambient tempertures, it is admissable to warm up scuffguards, e. g. with warm air or water ( 45° C up to

max. 55° C ). Avoid higher temperatures.

1) Apply soap water to nozzle body in the area of

the Diesel Drip Catcher, e. g. with a sponge.

Diesel Drip Catcher

Loading...

Loading...